Dealing with Activists

Dealing with Activists

by KrIsty nudds

November 4 marks the seventh anniversary of the passing of proposition 2, a ballot referendum in the state of california initiated primarily by the humane society of the united states (hsus) and Farm sanctuary to prohibit the confinement of certain farm animals in a manner that does not allow them to turn around freely, lie down, stand up, and fully extend their limbs.

prop 2, officially known as the prevention of Farm animal cruelty act, requires that california farmers end the use of conventional “battery” cages for laying hens, as well as the use of crates for veal and sow gestation, by January 1, 2015.

The language of prop 2 was vague with respect to what housing standard was acceptable and the ambiguity of the law set off a complicated legal minefield that is still being navigated — with only two months until its implementation.

in a 2012 news release the association of california egg Farmers (aceF), a statewide trade association representing california’s egg farmers, said they were filing a lawsuit in an attempt “to gain a clear understanding of how to comply with proposition 2.”

earlier that same year the aceF had supported the congressional effort by the hsus and the united egg producers (uep) to establish national standards on egg laying hen enclosures, including dimensions and other key elements that are not found in proposition 2 (for more go to page 24).

While the so-called egg Bill was not passed, the aceF was able to get clarity on space requirements from the state — birds must have 116 square inches,

which can be satisfied with enriched or aviary systems. however, according to industry estimates, there will be a significant shortfall in the number of eggs produced that meet prop 2 standards. This shortfall can be filled by producers meeting the requirements in other states, as outlined in a 2010 assembly Bill (aB 1437) where the california legislature tried to level the playing field, requiring that all eggs consumed in the state meet prop 2 housing standards, regardless of where they were produced. earlier this year the state of missouri, along with five other states, filed a federal lawsuit claiming that attempts to regulate egg production outside of california violated the commerce clause of the constitution. it will be interesting to watch what unfolds in January and how california’s consumer egg needs will be met. Regardless of what happens, one thing is clear — prop 2 was a wake-up call for the egg industry in north america to start seriously addressing layer hen housing concerns and provided activist groups ammunition to pressure retailers into requiring housing standards from suppliers.

But left out of the discussion is what is truly best for the hen, not just what we have assumed is best. That’s why research such as that featured in our cover story (page 10) is so important. are we really improving welfare by placing hens in systems that may cause them undue injury and stress? ■

NOVEMBER 2014

Vol. 101, No. 9

Editor

Kristy Nudds – knudds@annexweb.com 519-428-3471 ext 266

Digital Editor – AgAnnex Lianne Appleby – lappleby@annexweb.com 226-971-2133

Publisher/Sales Manager

Marilyn White – mwhite@annexweb.com 519-400-2424

888-599-2228 ext 237 • fax: 888-404-1129

Account Coordinator

Mary Burnie – mburnie@annexweb.com 519-429-5175 • 888-599-2228 ext 234

Media Designer Gerry Wiebe

Group Publisher

Diane Kleer – dkleer@annexweb.com

President Mike Fredericks – mfredericks@annexweb.com

Mailing Address

P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

Publication Mail Agreement #40065710

REtuRN uNDELiVERABLE CANADiAN ADDRESSES tO CiRCuLAtiON DEPt., P.O. BOx 530, SiMCOE, ON N3Y 4N5. email: subscribe@canadianpoultrymag.com.

Printed in Canada iSSN 1703-2911

Circulation email: subscribe@canadianpoultrymag.com Tel: 866-790-6070 ext 201 Fax: 877-624-1940

Mail: P.O. Box 530, Simcoe, ON N3Y 4N5

Subscription Rates

Canada – 1 Year $30.00 per year (with GSt $31.50, with HSt/QSt $33.90)

GSt – #867172652Rt0001

uSA – 1 Year $ 66.00 uSD Foreign – $75.00 per year

Occasionally, Canadian Poultry Magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2014 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Got Lubing? Contact your local Lubing Distributor for more detailed information about our innovative products or vist our website at www.lubingusa.com.

Scan code to see What’s New at Lubing.

Glass-Pac Canada

St. Jacobs, Ontario

Tel: (519) 664.3811

Fax: (519) 664.3003

Carstairs, Alberta

Tel: (403) 337-3767

Fax: (403) 337-3590

J. Dean Williamson Ltd.

London, Ontario

Tel: (519) 657.5231

Fax: (519) 657.4092

With more than 60 years of experience developing innovative products for poultry producers worldwide, Lubing has established a reputation of leadership by introducing new, cutting-edge technologies to the poultry industry.

Our innovative products are produced with the most modern manufacturing capabilities giving our customers a profitable advantage in productivity.

Curve Conveyors

Handle up to 60° angles

Belt Conveyors

Lengths up to 2,000 ft.

Transfer Tables

Rugged Construction - Built to last

Dirty Egg Returns

Superior design - Reliable performance

Nipple Drinking

Ideal water flow from pullets to layers

Les Equipments Avipor

Cowansville, Quebec

Tel: (450) 263.6222

Fax: (450) 263.9021

Specht-Canada Inc.

Stony Plain, Alberta

Tel: (780) 963.4795

Fax: (780) 963.5034

The president’s council of advisors on science and Technology (pcasT) released a report to the president, c ombating a ntibiotic Resistance, in mid-september. The report was released simultaneously with a national strategy on combating antibiotic Resistant Bacteria as well as with a presidential executive order, emphasizing to the u.s. the importance of addressing the “growing challenge” of antibiotic resistance.

on the official White house website, pcasT members christopher chyba and eric Lander said “the evolution of antibiotic resistance in bacteria is occurring at an alarming rate and is outpacing the development of new countermeasures.” They point to a centers for disease control and prevention (cdc) report

that says the annual domestic impact of antibiotic-resistant infections to the u s. economy is estimated at $20 billion in direct health care costs, with additional costs to society for lost productivity as high as $35 billion per year and 8 million additional days in hospitals.

“The safety of many modern medical procedures — including cancer chemotherapy, complex surgery, dialysis for renal disease, and organ transplantation — relies on effective antibiotics. These interventions become significantly more dangerous as bacterial resistance rises. The World health organization recently warned that we risk entering a “postantibiotic” era unless we act now,” they said.

pcasT recommends measures to strengthen antibiotic stewardship, boost surveillance,

and facilitate the development of new drugs, diagnostics, and vaccines as strategies to combat antibiotic resistance.

“optimizing the use of our current antibiotics in human healthcare and animal agriculture will extend the longevity of these life-saving medicines and maximize their benefits,” they said.

They go on to write that increased surveillance for antibiotic-resistant bacteria will enable more effective responses to resistant strains, support earlier identification of outbreaks, and limit the spread of resistant organisms. improved surveillance will help address fundamental questions of where resistant infections originate, practices that contribute to emergence, and how resistant microbes are being transmitted. visit: www.whitehouse.gov

the Food donation Tax credit for Farmers — the only one of its kind in canada, according to the ontario government — is giving farmers

a tax credit valued at 25 per cent of the fair market value of the agricultural products they donate to community food programs, including food banks and student nutrition programs.

The tax credit is a part of the ontario government’s local food strategy and Local Food act, 2013 to promote the good

things that are grown and harvested across the province.

The provincial government says the new tax credit will help farmers donate more fresh food to their local food banks, in an effort to support the farmers themselves, plus drive local economic growth, and benefit families in communities across the province.

Chicken Farmers of ontario (cFo) has given final approval to its new specialty Breeds chicken program. The program was designed to support the increasing ontario consumer demand for alternative breeds of chicken, and cFo says it will “create exciting opportunities for the specialty chicken value chain,” which includes hatcheries, farmers, distributors and retailers of specialty breeds of chicken.

cFo’s specialty Breeds chicken program was developed to bring ontario into alignment with the national chicken Farmers of canada specialty breeds policy. The new program specifies that two common breeds of specialty chicken will now be included under this program: Frey’s special dual purpose chickens and silkie chicken. These breeds are processed with “head and feet on” and are popular with many of ontario’s growing ethnocultural consumer communities.

cFo chair henry Zantingh said in a release that the program will “provide a significant growth opportunity for the ontario chicken industry” and meet the growing demand for different types of chicken

from ontario’s changing demographics.

although silkies and Frey’s special dual purpose chicken breeds have been available for sale in ontario for some time,cFo president and ceo Rob dougans noted that the market for these products has been underdeveloped.

farmer-led research to find new feed wheat varieties will receive $400,000 as part of a commitment to innovation under growing Forward 2. The focus of this four-year project is to develop new feed wheat varieties that have characteristics such as high yield, flood tolerance, fusarium resistance and tolerance for manitoba soils with high salinity. it will

nOVember 2014

november 12, 2014

5th Annual Health Forum delta guelph hotel and conference centre, guelph, ont. Theme of the conference is “agriculture’s efforts to combat antimicrobial Resistance.” To register, call (877) 424-1300 or email: ag.info.omafra@ ontario.ca

november 19-21, 2014 Agricultural Excellence Conference Fort garry hotel, Winnipeg, man. For more information, visit: www.fmc-gac.com

deCember 2014

december 10, 2014

Prairie Livestock Expo (formerly Hog and Poultry Days) victoria inn hotel & convention centre, Winnipeg, man. For more information, visit: www.prairielivestockexpo. ca or email: info@ prairielivestockexpo.ca

January 2015

use traditional plant breeding techniques, so any resulting varieties will not be considered genetically modified and could be used in all livestock operations. The research will be led by the Western Feed grain development (WFgd) co-op, which was established in 2005 to find new wheat varieties suitable for livestock feed and the ethanol industry. WFgd and its farmer-members are also contributing $1.8 million toward this research.

January 27-29, 2015 International Production and Processing Expo (IPPE)

World congress center, atlanta, georgia. For more information, visit:www.ippexpo.com

January 29-31, 2015

Pacific Agriculture Show Tradex exhibition centre (abbotsford airport), abbotsford, B.c. For more information, visit: www.agricultureshow.net

ajoint project by cobb europe and the Roslin institute in scotland has been awarded a grant of almost £650,000 from innovate uK, for genome biobanking to optimize valuable broiler genetic stocks.

The award will fund cryopreservation and cutting-edge sequencing technologies to address food security and production efficiency. new stem

cell preservation technology will be used to enable biobank ing of pure lines to ensure these current genetic resources are available in the future.

The work will also further mine the genome of poultry resources to under stand the genetic drivers of key economic traits and exploit existing genetic variation to drive significant improvements in commercial performance.

The e gg Farmers of canada (eFc) is the 2014 recipient of the crystal egg award for outstanding commitment to corporate and social responsibility by the international egg commission (iec).

The iec, currently celebrating its 50th anniversary, made the announcement at its annual gala where hundreds of delegates from across the world gathered to share best practices, discuss global trends and emerging opportunities in the international egg industry.

e F c is working with

many national organiza tions, such as Breakfast of canada and Food Banks canada to promote healthy living at home and in the classroom. They also sponsor events such as the Forum for young canadians, who wel comes students from across the country in the nation’s capital and teach them the roots of canadian politics.

eFc is also the nutritional p c anadian Breast Foundation ci cure, held october 5th.

There are many things to consider when creating quality space for your flock, such as proper ventilation, a fresh and even supply of feed and water, quality litter, perch space, and nest placement... just to name a few. We focus on providing quality space for your flock so they can thrive and have a healthy and highly productive life.

By Karen Dallimore

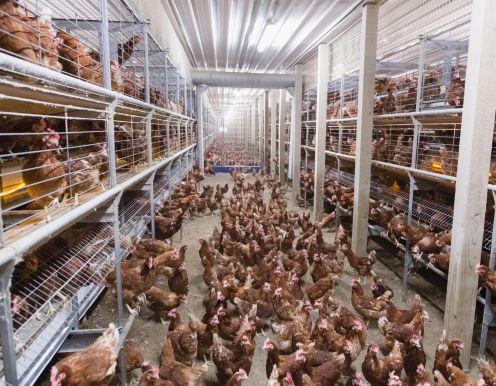

The public wants to know that birds are being well kept and the poultry industry wants the same, but what does the bird want?

That’s what dr. alexandra harlander wants to know. she is leading a series of poultry behavioural studies at the university of guelph’s arkell poultry Research center where the birds are having their say.

poultry producers are under public pressure to provide the best possible environment for chickens, and single- or multi-tier aviary systems may provide commercial options. in these systems, birds can walk and flap and fly – performing species-specific behaviour – but they also seem to have increased risk of bone fractures, particularly keel bone fractures, with 80 percent of birds sustaining injuries while navigating the cages.

Msc. student stephanie leBlanc is looking at how typical production diseases affect the balancing ability of laying hens. for example, does physical impairment have any impact on the incidence of falls and subsequent keel bone fractures in aviary systems?

until now, there has been no science behind the locomotor skills of the birds on the ground or in the air, nor has there been any study of the laying hens’ preference for flying or walking. are pullets and hens of different strains better able to adapt to different heights, angles and arrangements of perches and tiers? are some genetic lines better able to adapt to alternative housing systems?

harlander and her research students are investigating the set up of aviary systems, including perches, nest boxes, feeders, drinkers and litter, and the behaviour of birds in them with the intention of providing recommendations for these aviary systems in commercial settings.

one of three current projects involves testing the optimum ramp incline that hens can master across ages and strains. a steeper ramp means less room used but are the hens more likely to fly up and risk injury? chantal LeBlanc, a master’s student at

the university of guelph, is testing ramp inclines of 20, 50 and 70 degrees leading to two different platform heights similar to those found in commercial aviaries. “nobody has tested that before,” said LeBlanc. she is also comparing two different surface materials on the ramp –sandpaper versus more commonly used wire mesh.

starting at just one week old the birds have been tested weekly through 8 weeks of age, bi-weekly from 8 weeks to 20 weeks old, then will be tested further at 25 and 30 weeks of age. LeBlanc places birds from the same home pen — the hen’s friends — in a ‘social attraction’ cage at the top of the ramp, as well as offering food rewards (the birds love raisins) to entice them up the ramp. The hen is first placed on the platform so she sees the reward, then she is released at the bottom of the ramp and allowed to climb. LeBlanc is measuring their behaviour – how do they go up the ramps? Will she fly? Will she walk? at what point do they change from walking up to flying up?

at the bottom of the ramp is a force plate that measures how much they anticipate the climb by the ground-reaction force exerted on the plate – the hypothesis is that the greater the ramp incline, the greater the ground reaction force: it’s more effort.

in another research study, master’s student stephanie LeBlanc is looking at how typical production diseases affect the balancing ability of laying hens. does physical impairment have any impact on the incidence of falls and subsequent keel bone fractures in aviary systems?

LeBlanc tested birds on a motorized moving perch system that sways back and forth. The birds were 69 weeks old and had some typical damage such as footpad dermatitis, poor

the decrease in production of settable eggs

wing feather coverage or keel bone fractures. This study is looking at how that damage affected their balancing ability on the moving perch. The research is very realistic, using birds that industry actually deals with every day.

The birds were also subjected to different treatments – rubber chickens, for example, were placed on each side of a bird to allow 15 cm of perch: how does this affect her ability to balance? There can be other birds next to a bird on the perch when she’s trying to take off or land – how does this impact the bird’s balance? “she isn’t able to flap,” said LeBlanc, which could increase the probability of injury. she also put a cotton mask on some birds to mimic low lighting conditions to see how that impacted the birds, adding to much-needed baseline research data for aviary systems.

in another section of the poultry research centre in arkell, master’s candidate madison Kozak is using time loggers to compare the day-to-day behaviour of four different common industry breeds – two Lohman, brown & white, dekalb white and hyline white hens in aviaries. “no one has ever made a time budget for a chicken,” said Kozak. how much time do they spend on the ground? how much time do they spend on a platform or perch?

her research is also going back to the basics to look at the locomotor patterns of the chickens, trying to see how they navigate the aviary systems, trying to distinguish between what we think they want and what they choose. “it’s very basic but necessary,” said Kozak.

aviaries are becoming increasingly popular, said Kozak, as an option that allows birds to fly, move, run and jump. aviary systems are supposed to improve hen welfare but a lot of birds

are having a hard time navigating them. she has designed an experimental aviary system with a ramp and a ladder, two platforms and a higher perch with two different thicknesses with a spring on it so when they step on it, it’s more like a branch. The wooden features in the pens mimic those made of steel in commercial aviaries. in the industry there will be a higher stocking density.

“We’re getting a time budget,” explained Kozak, who will be measuring the time spent on each behaviour for two hours per day using non-intrusive data loggers attached to the hen’s back. some birds are fitted with a real data logger; some just have dummy data loggers of the same weight to see if having the apparatus attached to their backs affects their behaviour. The data loggers measure the height of where the bird is in the aviary and an accelerometer is used to measure the speed of the bird and the distance they’ve gone in any direction. Kozak will calibrate this data with videos to evaluate the accuracy of the data logger information for use in further research. “There’s a ton of data that will be easier to analyze with the data logger than with videos,” said Kozak.

how much time to they spend in the ground or in the air? do they actually use all of the areas of the cage? maybe they only need one platform? do they prefer the ramp or the ladder or do they care? do they prefer to walk or fly, up and down?

she is already seeing that the ladders used by the white birds have a lot of feces on them, which indicates a lot of use compared to the brown birds. maybe certain breeds are better suited for aviaries?

Kozak also placed brooder boxes in the aviaries for the first eight weeks to simulate the darkness the young

birds would experience when hiding in the feathers of a hen. is it possible these birds will be better adjusted hens later, expressing less feather pecking than those reared without the darkness? Brooder boxes are easy and cheap to construct.

all three studies will combine to help define the right aviary design, one that prevents injuries, and provide suggestions for how birds could be raised for the aviary systems. “We can’t think like a bird,” said Kozak, but we will soon know more about what a bird thinks. Results are expected starting this fall.

Leading this research is dr. alexandra harlander, an assistant professor in animal science at the university of guelph, who has recently been gifted $500,000 by Burnbrae Farms, canada’s largest egg producer, to establish a professorship in

the department of animal and poultry science. harlander received her veterinary degree in vienna, continuing her poultry research at the university of hohanheim in germany and the university of Bern in switzerland before choosing to come to canada, lured by the positive research atmosphere here. she currently advises five research projects involving the welfare and behaviour of poultry. “i’m very grateful to all my students,” said harlander. “it’s hard to convince students that chickens are exciting…they are great and they are funny. you can train chickens – they’re very clever. i’d like to raise the excitement level just a bit.” ■

BY KAReN DALLImORe

What would you do if mercy for animals released a video taken in your barn? how would you react? you can guarantee the video would be hard to watch —that’s the whole point: to generate an emotional response from viewers.

There are resources available to help you prepare for such an event, people that can work with you to reduce the chances of your farm being on the evening news and to deal with the fallout after the fact.

Lisa mcLean is with The ag & Food exchange, a national specialized service designed to help farm and food businesses manage special interest group pressure. While she can’t make the activists go away and she doesn’t condone poor animal welfare practices, she is part of a team that can help to prepare for an activist-related incident, giving you the resources to make more effective decisions.

That team, known as “aFX,” monitors trends, watches for pressure points, and provides guidance on dealing with sensitive issues impacting agriculture and food in canada.

“animal rights doesn’t mean animal welfare,” mcLean told delegates at the 2014 Farm & Food care annual general meeting, “They don’t want us to use, eat or own animals at all. That makes farmers a prime target.”

activists now come dressed in suits, not just Birkenstocks. They hold postermaking parties and organize carpooling

activists hold poster-making parties and organize carpooling to protests, finding strength in a sense of community. campaigns have widened to include lobbying retailers, government and large food business customers

to protests, finding strength in a sense of community. a few are willing to break the law. activist coalitions are widening their campaigns — they support each other, staging protests and publicity stunts. Their lobbying targets retailers, government and large food business customers.

Take Toronto pig save, for example. it started as one woman standing with a sign outside Quality meat packers in Toronto, said mcLean. Their mission statement on

their website now reads, “to build a democratic, mass-based, grassroots movement to bear witness of animal suffering, end the animal emergency, and create a world of animal equality and animal sanctuaries. We use a love-based approach…” The group now holds weekly vigils “to bear witness of chickens, cows & pigs being sent to slaughter.”

The “save” movement has grown internationally to include Toronto cow

and chicken save, golden horseshoe Farm animal save, Waterloo Wellington animal save, Windsor pig save, Brampton and London chicken save, montreal, manitoba and Brandon pig save as well as chapters in the u.s., australia and Brazil. notices such as this one on their Facebook page alert over 3,600 followers of upcoming strategy: “The World day for Farmed animals on Thursday, october 2 will be held at maple Leaf poultry at 100 ethel street in Toronto (a change in location from Brampton’s maple Lodge “Farms”) due to logistics and also the hope of getting more people out and more media attention.”

one familiar tactic of animal rights activists is the use of undercover videos. some have exposed employee indiscretions while others depict housing systems and production methods that can easily be misunderstood by the non-farming public, leaving farmers to be judged by the general public jury. The undercover employee

behind the camera is typically your best employee, said mcLean, discreetly working for a few weeks to gather enough video to edit and direct into a campaign of public shaming of animal production.

a video doesn’t just affect the farm; it chips away at the integrity and trust surrounding that industry sector as well as the rest of agriculture. “activism is a business threat,” said mcLean, and once a video is aired, it’s not over; the video will re-surface again and again, along with public pressure campaigns against that sector.

aFX is a service that can help farmers deal with activists. They monitor pressure points and issues; provide guidelines, produce reports and resources, and help clients to prepare for and deal with actions against them. “When emotions are high and you don’t know what to do,” said mcLean, “we’ll walk you through it.”

There are different levels of service, ranging from membership that gives you access

to weekly activist activity and background information so you know what to expect. aFX won’t speak on your behalf but they will co-ordinate with your public relations or issues management team, or provide guidance and monitoring about upcoming actions. services start at $2,500 annually.

What can you do on your own farm? “Keep doing the right thing and telling people about it,” says mcLean. “have, use and enforce an animal care code of conduct. make sure it outlines your expectations to employees and have employees sign it,” as well, ensure all employees receive training in proper handling of animals and familiarize them with company policies. as she says, “mean what you say and do the right thing, because it is the right thing to do.“ one thing is for sure: you can’t just park a tractor across the end of your laneway and make it all go away. For more information on aFX, email info@agandfoodexchange.ca ■

BY KAReN DALLImORe

Remember the rotary dial telephone? manually filling out forms will soon be a similar distant memory, when farmers will all be using a new tool called Feather central instead of a pen.

developed in ontario by Bio, specializing in data transfer, in partnership with iT specialist Farms.com, Feather central allows farmers to trace their birds from the hatchery to the processor electronically, replacing the manual forms currently in use.

The chicken Farmers of ontario (cFo) spearheaded the project that enables farmers to record their data on-line, reducing the paper burden and allowing the information to be transferred quickly and easily. cFo administers the program for ontario Broiler farmers.

There are two components to Feather central. The first is traceability, linking the hatchery through to the processor, collecting the same data that is currently recorded with pen and paper. “it’s the same information,” said Betty Jo almond, sales and service manager at Bio, “just in real time now.”

a second component services on farm food safety programs, allowing the daily, weekly, monthly or quarterly collection of data such as temperature and light settings in the barn, or cleaning and disinfecting records, for example.

What Bio will do is provide customer

feather central allows farmers to trace their birds from the hatchery to the processor electronically, replacing the manual forms currently in use.

support, beginning by helping to set up your farm under the program, barn location(s), number of barns and number of floors. as a crop is set at each location an order of activities can be customized. The farmer already does the checks but now data can be recorded right away, in sequence, without going back to the office. The accumulated data may be used to compare flocks or track crops by barn and floor, providing a history for future planning.

documents such as certificates or visitor log-ins can be uploaded as well, and specific personnel — managers and barn

workers — can be given access to particular data. “a manager can look at all the barns,” said almond, “while laborers may only see their own barn.”

To use Feather central you will need a hardware device that can access the internet. at this time if you want to download Feather central as an app you will need an apple product, said almond - an iphone, ipod or ipad. she explained that you don’t need to be connected to the internet in the barn to use the app — each day the information can be uploaded by hitting the “synchronize” button when you get back to the house.

For data security Feather central uses the same systems as on-line banking. The information is secure, backed up and readily available, and through the feathercentral.com website, accessible from anywhere in the world. going on vacation? you can still monitor your data, even from pool-side, said almond.

™ Use Grand Valley Power Pac Layer premix to maximize your flocks potential.

Power Pac premix has been formulated to develop a structurally sound laying hen to maximize egg quality and the total number of eggs laid per hen per cycle.

Call us today at 1-877-625-4400 and speak to one of our Poultry Specialists and find out how you can add to your bottom line. www.grandvalley.com

Bio sees all turkey, broiler, pullett and egg farmers as potential users for Feather central as a tool for data collection, and hopes to attract the interest of provincial organizations for the traceability application. The data collection component costs $25 per month for one barn, for a total of $300 per year, and an additional $50 per year for each additional barn. on the traceability side, the price will depend on what services are required in each province. ■

For more information on Feather Central, call 877-816-9425 or email info@feathercentral.com.

the canadian livestock transport training and certification program is providing consistent information for livestock haulers

BY LeSLIe BALLeNTINe

While most people will never see the inside of a barn, many do see livestock and poultry as they pass by on our roadways. Whether in rural or urban areas, livestock transport is highly visible. Transport accidents involving animals nearly always get reported in the media, and public complaints to enforcement authorities are a repeated occurrence. all too often the subject is heightened by concerned citizens who have limited understanding of acceptable and necessary industry practices. But sometimes their concerns are warranted. in a day and age when many canadians are showing growing interest in food production practices, animal transport is also one of growing contention. it’s rumoured that the federal agriculture minister receives more correspondence on animal welfare in general, and livestock transport in particular, than any other topic. it is known however that issues related to transport are also placing a burden on government regulators, enforcement agencies, and on the supply chain from producer to processor. it is for these reasons that the canadian Livestock Transport (cLT) training and certification program was invented. Begun as a pilot project in 2007 through alberta

clt has established itself as a credible program recognized by processing plants and industry groups in both canada and the U.s.

Farm animal care (aFac) in association with its sister animal care associations in saskatchewan, manitoba and ontario, cLT has since been expanded and updated. Rolled out as a national program in late 2013 under the auspices of the canadian animal health coalition the cLT program began actively offering a poultry transport training and certification program this past spring. Joining the three cLT programs offered for cattle and sheep, hogs, and

horses, the poultry program covers layers, broilers and turkeys.

To become certified, each trainee must attend a course delivered by a cLT certified instructor and pass a competency exam presented at the end of the training.

stéphane Beaudoin is a private animal welfare consultant and a certified cLT program instructor based in Quebec. since first offering the poultry course this past april he says he has had 300 drivers,

catchers and plant personnel sign up. Beaudoin is providing the 4-hour classroom training courses and examinations in locations across Quebec, and the feed-back has been extremely positive, he says.

“attendees at every session i’ve held so far all tell me that for the very first time the entire transport chain is getting consistent information.” They appreciate the factual, unbiased information that cLT gives them, he says. and they feel it is information that is needed by all the players in the sector.

While incorporating the recommendations contained in the codes of practice, cLT goes further by providing practical and effective best practices. By using a classroom setting, Beaudoin says, participants are also able to learn from each other’s reallife experiences and ideas.

“many will share their own experiences about how challenging it is at times to ensure birds are transported properly under less-than-ideal situations. sharing with others also helps trainees better realize that animal welfare is the responsibility of all the players within the sector.”

Livestock transport specialist Jennifer Woods runs J. Woods Livestock services out of Blackie, alberta. she was among the original group that created the pilot program and she continues to help guide the growth and evolution of cLT. The animals benefit the most from the driver training, she says. But there are also significant economic paybacks. “We in the industry have always known that poultry are more vulnerable to morbidity and mortality and that in sheer numbers alone those transport losses exceed losses in other livestock sectors.” over the years, the poultry industry has made progress in reducing transport losses and a part of that has been achieved by following effective procedures and changing our practices, she says. chickens and turkeys make up the vast majority (roughly 87%) of all farm animals raised in canada each year.

The canadian Food inspection agency and the canadian meat council recommend it, but cLT continues to be a voluntary training program. now that it is available, however, the L’association des abattoirs avicoles du Québec (aaaQ), and

the ontario poultry services association have directed their members to obtain cLT poultry certification.

daniel dufour, secrétaire general of aaaQ says his member companies, which make up 100 per cent of the commercial processors in Quebec, have asked for cLT certification as a part of a collective approach to continuous improvement. “The companies, the drivers and catching companies all want to do it,” he says. dufour estimates that about 50 pe rcent of those taking the certification are drivers and catching crew supervisors while the remainder are procurement and plant management personnel. They all like cLT, he explains, because it requires re-certification every three years, so not only does it teach new information but it also provides a refresher.

“cLT also provides proof that we in Quebec follow good practices,” he says. cLT will be a minimum requirement for drivers, old and new, who haul for Quebec poultry plants. discussions are also underway to eventually involve producers and to follow-up with further education and hands-on workshops. “The time is now,” dufour says and cLT is the first step in a team approach.

Transport issues also create a black eye for the industry. most recent are the court cases involving maple Lodge Farms in ontario and Lilydale Farms in B.c.

The canadian Food inspection agency laid charges against maple Lodge Farms under the health of animals act for failing to transport chickens humanely after some 2,000 birds died from cold exposure on two trips to slaughter in the winter of 2008-2009. in passing sentence, ontario superior court Justice nancy Kastner said “lack of adequate training, personnel, or equipment” contributed to the high mortality rate of the transported birds.

Lilydale is, at the time of writing, facing four similar charges laid by the cFia. The charges stem from exposing chickens to freezing temperatures while transporting them from chilliwack to its slaughterhouse in port coquitlam on January 18, 2012.

These two cases alone have involved thousands of birds, significant investigation man-hours, lengthy court proceedings

and negative publicity for the agriculture and food industry, says Wood. “had these companies been able at the time to train their drivers under cLT these charges might not have happened.” That is because transport in extreme temperatures is one of the training components contained in cLT. each of the four species modules encompasses all aspects of transportation including pre-loading, loading, time in transit and arrival at the destination. Topics include animal welfare, regulations, handling and behaviour, environmental considerations, equipment and emergency response. Woods explains that each module has been developed based on the specific needs of each of the individual species groups.

When asked who benefits from cLT, Woods says “just about everyone.” her list includes the producers who depend on competent transporters: Whether it’s moving birds from barn to barn or barn to plant.

governments, which are under pressure to enact new regulations, increase enforcement and to step up court prosecutions for offenders, benefit from the higher compliance that comes from properly trained transporters and handlers.

processors, who use properly trained personnel can avoid costly mistakes and as added value can include cLT certification to their social responsibility portfolios. and while canadian retailers aren’t yet demanding proof of transportation competency to go along with their animal welfare assurance policies, signals on the horizon say it won’t be far off. Woods adds that certificate of competency will also become part of international trade agreements as we move forward.

Beaudoin says he is teaching more than just drivers. Training is beneficial, and in some instances required, for dispatchers, handlers (at farms and sales yards) plant crews, loading crews and

Wood’s says cLT has established itself as a credible program recognized by processing plants and industry groups in both canada and the u.s. she says that transportation is a vital part of livestock and poultry production that requires special skills and knowledge. it takes professionals she says, and cLT is a part of that. ■

Egg Farmers of Canada is committed to supporting research and development for the egg farming industry.

Find out more at eggfarmers.ca.

Les Producteurs d’œufs du Canada sont engagés à appuyer la recherche et le développement pour l’industrie de la production d’œufs.

Pour en savoir plus, visitez producteursdoeufs.ca.

the legislative push in the U.s. for enriched cages is over for now, but the phase-out of battery cages in the U.s. and around the world is growing

BY TReeNA HeIN

Nearly two years ago, Canadian Poultry reported to you about the quest to enact historic national u s. legislation relating to mandatory enriched cages for layer hens. That quest is over for now, but the move to larger, enriched cages and other welfare-related changes is inevitable in that country, according to some major industry players.

The so-called “egg Bill” (The egg products inspection act amendments of 2012) would have required enriched colony housing systems to be phased in at every commercial egg production facility in the u s., over the 15 to 18 years after it was passed. phase-in schedules would have been more rapid in california, consistent with an initiative there already approved by that state’s voters (proposition 2, see sidebar).

The bill had formed out of lobbying efforts that were put forward over the previous few years by the humane society of the united states (hsus), and was strongly supported by uep (the united egg producers), a group which represents those who produce almost all u.s. eggs. it was also supported by hundreds of family farmers, other animal welfare groups such as the american society for the prevention of cruelty to animals (hsus), major consumer groups like consumer Federation of america

the so-called “Egg Bill” would have required enriched colony housing systems to be phased in at every commercial egg production facility in the U.s. over a 15- to 18-year period

and national consumers League, and scientific groups such as the american veterinary medical association and the association of avian veterinarians. dozens of media outlets - including heavy hitters the chicago Tribune, new york Times and usa Today — were also in support.

Before we get into what happened and why, let’s review the bill. The cage systems proposed within it would have seen each egg‐laying hen have nearly double the amount of space (the majority of u.s. hens are currently mandated to have at least 67 square inches of space,

but up to 50 million of them have just 48 square inches). The proposed legislation set a minimum of 124 square inches of space for white hens and 144 for brown. The bill also called for eventual environmental enrichments to be provided for all birds, including perches, nesting boxes and scratching areas that allow hens to express natural behaviors. and that wasn’t all. There were requirements in the bill for labeling to inform consumers about production method. Feed-withdrawal or water‐withdrawal molting to extend the laying cycle would have been prohibited (a practice

already prohibited under the uep’s ‘certified’ program). in addition, the bill included standards for euthanasia of egg‐laying hens that have been approved by the american veterinary medical association, limits on ammonia levels in henhouses, and the prohibition of the transport and sale of eggs and egg products nationwide that don’t meet these requirements.

The hsus had already been successful in 2008 in having phased-in roomier layer housing mandated in california. in 2010, a follow-up law was passed that applied the same provisions to out-of-state farmers who sell their eggs in california. (in 2013, missouri’s attorney general filed a lawsuit to fight that law.) hsus was also making progress in other states with respect to getting more humane and natural hen and swine housing in place.

uep threw its support behind a national legislative effort for several reasons. as uep president chad gregory told Canadian Poultry in 2012, “We at the uep felt it was time to do the right thing — that enriched cages are a more humane way to produce eggs, and that fighting this state-by-state or nationally was not the course of action that was best for our industry.” For a commodity that’s often shipped from state to state, uniform federal legislation would prevent egg producers from having to deal with contradictory and competing state legislation that was

In2009, Michigan passed a law which, among other things, phases out battery cages for laying hens and gestation crates for breeding sows by 2019. In 2010, Ohio (the second-largest eggproducing state in the U.S.) declared a moratorium on permits for new battery cage facilities.

In February 2014, the government of Australia passed a law to ban battery cages in egg production and gestational crates for sows and beak trimming of chickens. This follows the action of the government of Tasmania late in 2013 to phase out gestational stalls and new battery cage facilities. Battery cages are being phased out in New Zealand, and have already been banned in Switzerland, Austria and Sweden.

In 2010, global food manufacturing giant Unilever stated it would switch all of the 350 million eggs it uses for Hellmann’s mayonnaise to those produced in cage-free facilities. The HSUS says other companies converting to cage-free eggs include Marriott International, Burger King, Compass Group, Aramark, and Sodexo.

Cobb geneticists have recognized the importance of efficiency in converting feed into meat for more than 30 years. Cobb broilers have always been known for their high meat yield, efficient feed conversion and excellent growth rate. This assists the customer’s goal of achieving a targeted weight with competitive advantages of lower cost. At Cobb we invest 12-14% of our annual sales revenue in research and development. This investment enables Cobb to continue leading the way in delivering consistent continuous genetic progress year over year.

sure to spring up instead. gregory explained at the time that “a growing patchwork of inconsistent state laws will restrict interstate movement of eggs, distort competition and put many farmers out of business. This is a very serious situation.” some farm groups fought the bill, concerned it would set a precedent for how all farm animals are managed. There were also concerns among egg farmers about the costs of transitioning to enriched cages. gregory cited studies showing that enriched colony cages can be better for production than conventional cages. he countered worries over the cost of eggs going up with citing studies indicating enriched cages only add a modest operating cost increase over the current system, and since the changes would be phased in over the next 15 to 18 years — many during the normal course of replacing aged equipment.

By last year, the egg Bill was known as The egg products inspection act of 2013. however, over the course of legislative negotiations as the Farm Bill (which it was part of) progressed, it was excluded. hsus president Wayne pacelle stated in a blog post in early 2014 that the act was killed “because of the dysfunction of congress, the blocking maneuvers of a small number of lawmakers, and bullying and lobbying by other sectors of animal agriculture.”

at this time, gregory explains that uep and hsus have agreed not to extend any formal connection that existed during the bill’s consideration. “uep remains committed to facilitating discussions that are needed to provide stability in the egg industry and to secure uniformity in egg production standards,” said gregory. he said the organization now is focused on preparing its members, their customers and us consumers for potential changes in the egg market when new laws governing egg production, enacted after the passage of proposition 2, taking effect in california in January 2015.

he adds, “our members provided tremendous leadership in working to pass the egg Bill and establish uniform national standards for hen housing. enriched housing for egg-laying hens represents an important step forward for the egg farming community, and we applaud the voluntary efforts of many of

Weasked the Egg Farmers of Canada (EFC) for its thoughts on the UEP’s efforts over the last few years to move its producers towards larger, enriched cages. Specifically, we asked if EFC applauds this direction, whether it see UEP’s plans as a reasonable goal, and what it sees as the major challenges to having all egg production in enriched, larger cages or cage-free enriched facilities.

Alison Evans, EFC manager of corporate and public affairs, says “We continue to support ongoing research and assessment of all types of housing and the industry responds to changing consumer demand. Currently, EFC invests in the work of several Canadian researchers.”

She adds that “Furnished housing is increasingly being considered in many jurisdictions as an alternative to conventional cages. This is due, in large part, to the fact that the amenities typically included— perch, enclosed nesting areas, dustbath or scratchpad—provide opportunities for birds to express a greater variety of behaviour patterns. Whether it is at the farm (micro level) or macro (provincial or industry-wide level), any transition must be well-planned and orderly, taking into account all levels of the supply chain and customers, operations, costs and other implications.”

When asked if EFC has a goal for phasing out cages for layers in Canada, Evans says “There are many important reasons to house birds in cages—ranging from disease management to food safety to mitigation of aggressive behaviours…The EFC Code of Practice recommends reduced density as farmers purchase new cage housing and all egg producers must meet the density targets to pass the EFC ‘Animal Care Program,’ which is based on the Code of Practice.” She adds that some provinces are implementing policies that help farmers make decisions about retooling or installing new housing systems.

When asked the estimated percentage of cage-free operations in Canada, Evans says cages are currently the most widely-used housing system, though other systems are being adopted, including free-run indoor systems and free-range systems with access to the outdoors, weather permitting. “There are plusses and minuses to all housing types,” she notes, “and trade-offs must be carefully analyzed and assessed.”

Almost all the housing for layers that Big Dutchman has been selling since 2010 in all of U.S. and Canada are cage-free and enriched/enrichable systems, says cage-free systems manager Bill Snow. “There have been a couple conventional cage systems sold, but only a few,” he notes. “Mostly cage-free is what we are seeing in California. “The return-on- investment is usually seven years, but I am sure this varies.”

our farmer-members to incorporate this housing into their farm operations.” gregory said uep is dedicated to partnering with its members, allied industry and other stakeholders to identify workable, long-term solutions that maintain the viability of the egg industry. ■

BY LYNe ROBICHAUD, eGG FARmeRS OF CANADA

As part of its commitment toward building a sustainable egg industry, egg Farmers of canada (eFc) puts a lot of weight behind research and development. By investing in research conducted at universities across the country, eFc, on behalf of egg farmers, address issues of great importance to the industry and consumers alike.

With a focus on egg production, poultry science, animal and human nutrition, and environmental technologies and techniques, egg Farmers of canada funds research in areas that will shape the future of egg farming in canada. To this end, we have launched a research chair program focused on the egg industry.

“supporting proactive discovery is such an important part of our research efforts and working with maurice and Tina makes it possible for us to shape the future of egg farming,” explains peter clarke, chairman of egg Farmers of canada. “our chairholders are thought leaders in their fields, who were selected for their commitment to research excellence. We are very proud to be working with them.”

eFc is dedicated to looking forward and nurturing the next generation of researchers and industry experts. “our philosophy towards research is simple: in order to be at the forefront of social change we must drive innovation by investing in tomorrow’s industry experts,” adds peter clarke.

dr. tina Widowski’s work focuses on hen welfare and health, and best practices for the management of housing systems.

Dr. Maurice Doyon, Egg Industry Economic Research Chair at Université Laval in Quebec City

dr. doyon’s research focuses on the economic implications of the canadian egg industry and supply management. dr. doyon and his team are developing a variety of projects on the economics of egg production that promote growth and innovation in the sector.

Their projects include the development of a quota trading system between farmers, an examination of the implications of international trade on the system

of supply management, an evaluation of consumers’ willingness to pay for specialty eggs and the development of a model of egg producers’ behaviour in situations of economic risk.

Dr. Tina Widowski, Poultry Welfare Research Chair at the University of Guelph

dr. Widowski’s work focuses on hen welfare and health, and best practices for the management of housing systems. The first project she will complete in this area examines the ways in which different pullet rearing systems affect hens’ behaviour, bone health and egg production.

The “Raised by a Canadian Farmer” brand will tell shoppers, right on the package, that their chicken meets the highest standards of care, quality and freshness, and that it was raised in Canada by dedicated farmers like you.

Learn more about the brand and other ways Chicken Farmers of Canada is giving Canadians “The Inside Coop” on Canada’s #1 meat at chickenfarmers.ca and chickenfarmers.ca/blog .

dr. Widowski’s research team is developing projects on the development of flight and locomotion in different breeds of laying hens in aviary systems, the causes and prevention of feather pecking and the effects of ammonia outputs from manure in alternative housing systems.

lOOKiNg AhEAd

egg Farmers of canada are dedicated to making sure we invest in innovative technology and practices for years to come, assuring the sustainability of the canadian egg industry.

dr. Maurice doyon is EFC’s Egg industry Economic Chair and he and his team are developing a variety of projects on the economics of egg production that promote growth and innovation in the sector

“We look forward to continuing our work with our research chairs, as well as our broader network of researchers across the country,” says clarke. “it is important to work together to mobilizing this new knowledge for the benefit of our farms, farmers and stakeholders in canada and with partners around the world.” ■

For more information about our research programs, please visit eggfarmers.ca.

Award applications for the 2015 Canadian Poultry Sustainability Award will be available at www.cpsustainability.com from April 1, 2015 to July 31, 2015. The award winner will be announced at the Canadian Poultry Sustainability Symposium in October 2015.

BY TReeNA HeIN

When a W5 Tv show story broke in october 2013 about alleged inhumane practices on two poultry farms in alberta, it elicited a strong reaction from those inside and outside the poultry industry. The cTv current affairs documentary program depicted “undercover” video footage taken by mercy for animals canada at Ku-Ku Farms (layers) in morinville and creekside grove Farms (pullets) in spruce grove. The footage shows housing and euthanasia methods not compliant with industry recommendations or standards.

amin valji, owner of the farms, was a board member at the egg Farmers of alberta (eFa) at the time. he completed his second consecutive three-year term in February 2014, and following eFa regulations, was required to step down for a period of at least a year. he is eligible to run for election again in 2015.

eFa stated to Canadian Poultry after the video release that it had been “working closely with mr. valji, who is deeply concerned about what happened on his farm.” Both eFa and egg Farmers of canada (eFc) inspected the farms, and mr. valji immediately reinforced training with all farm staff with the help of poultry veterinarians, and enhanced compliance measures. eFa stated that “Working through a situation like the one he’s currently facing provides mr. valji with unique insight and experience, which will be a valuable lesson to be shared with

susan gal, Egg farmers of alberta general manager, says as a result of the W5 video Efc made a key change to the animal care Program, and Ku-Ku farms was the first in the country to implement this change

the eFa Board, his fellow producers and the canadian egg industry.” now that it’s about a year later, canadian poultry asks about the lesson learned, what’s been happening on the valji farms, layer farms across alberta, and beyond as well.

now that it has been one year since the W5 video’s release, Canadian Poultry asks the eFa and mr. valji about the lessons learned, what’s been happening on his farms, and layer farms across alberta and beyond as well.

in addition to immediately reinforcing

and reviewing training with all farm staff with the help of poultry veterinarians, mr. valji developed and implemented standard operating procedures and an employee code of conduct, which are regularly updated and are now part of mandatory employee training. an onfarm inspection plan was also developed and implemented specifically for the farm’s pullet facility.

at the national level, eFc made expedited updates and additions to the country-wide animal care program, with

Providing a wealth of background knowledge on poultry anatomy, physiology, and immunology, this comprehensive reference explores poultry diseases that are directly related to or influenced by the gastrointestinal tract.

Filled with useful images, this informative record discusses the impact of human pathogens harbored by poultry and offers alternatives to antibiotics in the treatment of intestinal disorders in poultry.

The fog generated by a PulsFOG will cover all hard to reach areas. Assortment of PulsFOG models to choose from.

the valji farm subjected to all of them before they were rolled-out across canada. “[a] key change to the animal care program was the addition of three new on-farm policies, which this farm became the first in canada to adopt: the Farm Welfare policy, the employee code of conduct and the visitor policy,” explains eFa general manager susan gal. “These additions help ensure that everyone on farm is made aware of animal care policies and best practices, receives proper animal handling training as required, and is familiarized with the accountability of their actions.”

valji established a new employee animal care audit, which is completed on a quarterly basis, ensuring that the Farm Welfare policy, the employee code of conduct and animal care program standards are being upheld by all employees. in terms of inspections of the valji operations, gal says multiple ones (including some that were unannounced) have been completed by numerous groups. “inspections were performed by eFa, eFc, and the alberta society for the prevention of cruelty to animals, in addition to a complete animal care audit by guelph Food Technologies,” she notes. “The farm passed every audit, which was a requirement for the province’s graders to begin accepting their eggs once again.”

We asked mr. valji what he has learned through having inhumane practices used by employees on his farms exposed in the 2013 W5 investigation and what occurred afterwards. “Through this experience, we realize that public perception is established immediately after video footage is depicted, whether or not it is accurate, or taken out of context,” he says. “during the entire experience, it was very important to us that we remain transparent at all times. We facilitated all inspections that were requested, and remained open to all the feedback and recommendations that were shared with us. although it was a difficult situation, we kept our focus on implementing changes that would be positive for our farm and the canadian egg industry.”

one of the key things that valji identifies as having learned from this incident is the fact that as a farming operation becomes larger and the number of employees increases,

the need for structured training programs and documentation is essential. “my father began a small family-run poultry farm over 30 years ago and, over time, we have slowly grown our farm into the larger-scale operation that we are proud to have today,” he explains. “With the additional employees we require, ensuring that every employee is following the established standards and the training they were provided has definitely become more of a challenge.”

valji adds that the various policies, procedures, audits and training programs that they have implemented since the incident have helped them ensure that all employees are trained consistently and provide the expected standards of care. “While the measures we have taken required a significant commitment and much effort, they provide us with the reassurance that we are doing everything we can to maintain the highest standard of care possible for our flock,” he says.

during eFa’s regional producer meetings in January 2014, mr. valji shared his experience with his fellow egg farmers. eFa has also shared his story and insights as part of a ‘lessons learned’ document, which has been shared with egg Boards across the country, as well as with many other producer groups. “his experience served as a reminder of the importance of ensuring that everyone on farm is keenly aware of the animal care program requirements,” says gal, “and that anyone working directly with the birds has received up-to-date training on the best practices for hen handling.”

she notes that eFc continually works closely with the provincial egg Boards to update and enhance the provincial onfarm programs, and that was no different over the past year. “each update, addition and enhancement to the animal care program that was first implemented on the farm in question, as well as further changes that are planned, was already either scheduled or in the works,” gal says. several updates took effect in august 2014 (changes to the animal care program scoring framework, and the introduction of Farm Welfare policy, visitor policy and employee code of conduct), with several more updates ready to take effect in January 2015

(introduction of the Routine inspection policy, introduction of the handling, catch and Loading policy, and introduction of the euthanasia plan).

“as of april 2014, adherence to the animal care program a mandatory requirement for all alberta egg famers, as a requirement for being licensed to produce eggs,

and measures are taken immediately to address departures from accepted industry practices,” gal says.

“The canadian egg industry remains committed to continuous improvement,” she notes, “especially with regards to our national on-farm programs for animal care and food safety. ■

Managing the breed, not just the bird is key for maximizing performance

BY SHAwN CONLeY

it’s an easy mistake to make. For the most part, they look the same, sound the same, walk the same, and behave pretty much the same. There are just a few breeds of chicken and turkey, and within those, just a few widely used strains. Because they seem so similar, a lot of growers tend to raise the breeds the same way, resulting in inconsistent performance, or one or both breeds performing poorly on a regular basis in a particular operation. The question is, why does one bird perform poorly compared to the other for one grower, but for another grower, the same bird outperforms its counterpart? Well, there are a few answers…

all of the breeder companies are working toward the perfect bird, and each breed has its strengths. But to truly find out what bird is best in any operation, they need to be raised in their ideal conditions, which can be significantly different – or maybe not necessarily so different, but small differences can significantly affect the end results. The first example is one that is outside of the control of the producer, but can actually affect flock performance as much as any other factor, hatchery temperature and humidity profiles. as you all know, especially in the day of mixed breed hatcheries, following the same

turkeys are a great example of how breeds or strains within a breed can perform much differently when fed a diet not forumulated for that particular bird. leg, crop, feathering and other issues can also result

profiles for different breeds can result in a much different chick / poult, or big differences in percent hatched of set eggs. For those who are not well-versed in incubation and hatching, it may be surprising to find that the eggs are ventilated to release heat, rather than having to provide heat throughout the process to keep them warm. This heat removal process is affected by egg size and shell

thickness, so a strain with larger eggs or a breed with thicker shells may have a lower ambient temperature requirement to maintain the proper internal temperature. a degree or two either way can dehydrate the poults, or alter their development, which can cause leg issues or high early mortality at the farm. The profiles should even vary between eggs early in a flock to eggs late in a flock.

Meller offers a wide variety of Poultry equipment to meet today’s standards and needs. The Meller Aviary meets all EU standards as well as providing an exceptional living space where the welfare and production of the flock are able to flourish. Starting from day old chicks to 19 week layers Meller has it all.

POULTRY EQUIPMENT INC.

826 Nanticoke Creek Parkway, Jarvis, Ontario, Canada, N0A 1J0, Ph: 519-587-2667

Call for more information or check out www.meller.ca • Email: meller@optionsdsl.ca

Official Dealer for all Jansen Poultry Equipment products in Ontario and Manitoba

The primary breeding companies have commercial management guides, and within the guides you’ll find several tables and graphs illustrating their best recommendations for optimum performance. one of these will be a temperature profile table. some of the companies have gone to as much effort to provide them along with humidity ranges so temperatures can be adjusted if there are big shifts in humidity. one example of a difference in temperature is in the general broiler guides where we see recommendations when humidity is 50 – 60% of 75 – 79°F for cobb, 73 – 76.5°F for Ross. The same types of differences can also be seen in turkeys. it is easy to see how large swings in temperature can affect performance in the summer with decreased weights. it has been shown in trials that small early differences from standard temperatures cause lost weight and disease that is difficult to compensate for later in the flock.

Turkeys are a great example where breeds or strains within a breed can perform much differently when fed a diet not formulated for that particular bird. Feeding a diet formulated for a

different breed can actually result in weight shortfalls as much as a kilogram. Leg, crop, feathering, and other issues can also result from formulations that are not tailored to the strain. These types of performance problems can arise from imbalances in amino acids and other nutrients, like the balance of calcium and phosphorous. There are strains of turkey that grow better than others when fed a veggie diet, and some are more suited for an antibiotic free program. There are even seasonal differences, with some strains being particularly strong performers in the cooler months when low ventilation rates can cause respiratory problems or poor litter conditions, which normally would lead to higher condemn rates in other strains.

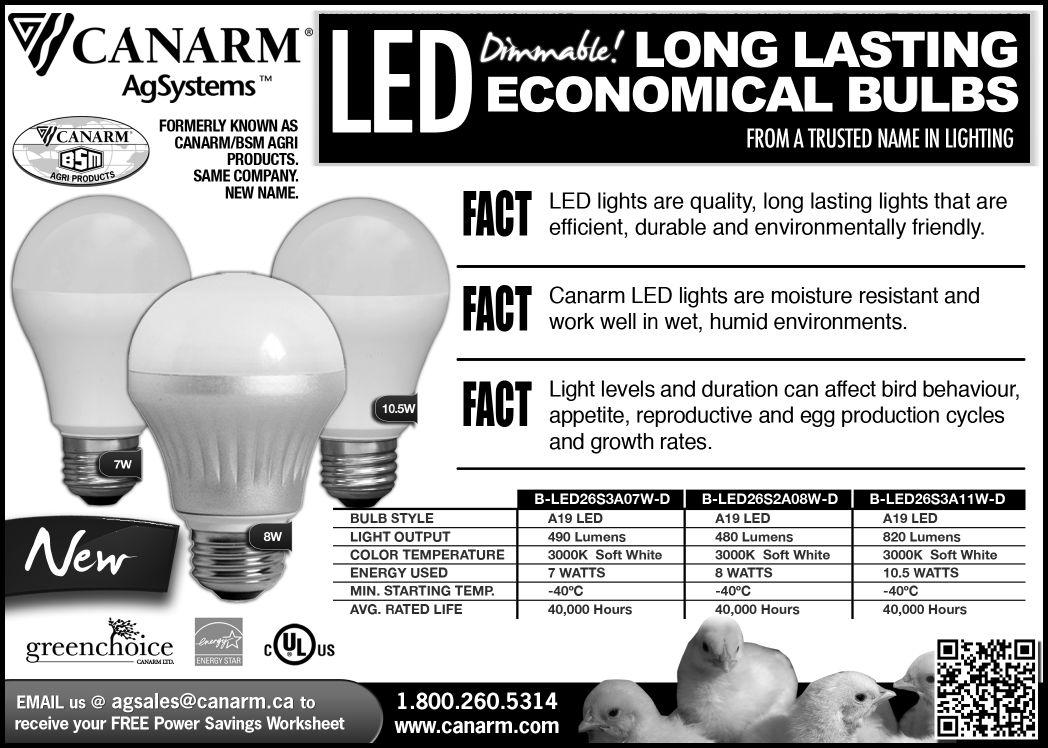

When it comes to lighting, there are many variables, and with some aspects, not enough research has been done to establish rock-solid standards. There are still some questions, but there are some things we do know. When it comes to colour, in general breeding birds respond to red and yellow tones best, around 3000K, while commercial birds are more flexible. There has been little data showing much performance affect changing wavelengths for lighting meat birds. colour for the most part, though, is pretty universal for breeds and strains. The real differences come in when we talk about dark periods and light intensity.

Ross recommends a first week light intensity of 40-50 lux, reduced to 5-10 thereafter, while cobb is at 25 lux first week, and 5-10 following. When it comes to turkeys, hybrid, for example recommends 80-100 lux in brood, with a reduction to as little as 60 lux after that. dark periods are somewhat controversial because everyone has their own ideas about “midnight snacks”, or giving birds the equivalent of a full night of sleep a people would take. Ross and cobb, however, have recommendations, and they vary a little. Ross advises one hour of dark in brood, 4 hours after that, and never more than six hours. cobb is also at one hour in brood, and anywhere from six to twelve hours (in the case of birds with an adg greater than 60 grams). These are pretty dramatic differences. in summary, it is clear that managing to the specifications of the breed and strain of bird you have is one of the big keys to maximizing performance. From the hatchery and barn temperature and humidity profiles to the nutritional requirements and lighting recommendations, each factor can affect mortality, morbidity, feed conversion, and condemnation to a great extent. it’s a great idea to make use of the management guides, nutritional information, and other technical support that breeding companies provide on their websites and through their representatives. ■

by LesLIe baLLentIne

iconfess i’m not much of a label reader. according to statistics canada, i am in the minority among the 60 per cent of canadians who report they do read food labels for nutritional content alone. add to that “best before” dates, ingredients, allergy information, production methods, country of origin, marketing claims, sKus and QR codes, weights and volumes, cooking instructions, company contact information, all in both official languages, and i find it pretty amazing that we can cram all this information onto a food package.

so when i hear calls for even more mandatory food labels i shake my head. it isn’t that i disagree with imparting information. i am consistent in my opinion that people deserve to make informed choices. (Whether we do or not is another matter.) in fact, i have long said that labelling may be a sometimes solution to some of our controversial food issues.

Take genetically modified foods as an example. There is an escalating battle over biotechnology labelling in food. ironically, there is no such public debate surrounding biotech medicines which we also ingest and can be just as lifesaving or life improving as the food we eat.

according to industry estimates, in the nearly two decades since genetically modified seeds were made commercially available these crops have become the norm in the typical north american diet. used to make ingredients in about 80 per cent of packaged food, today, more than 90 per cent of corn, canola, soybean and sugar beet crops in the u s. are genetically modified. These same gm crops are also grown in canada and used for food, consumer goods and animal feed. so labelling foods containing gm ingredients would arguably encompass most of the processed foods and animal products we eat.

science says isn’t necessary. after all they argue we don’t label foods for pesticides, fertilizers or these other “conventional” food-production technologies.

in canada, the voluntary labelling of novel foods derived from genetic modification is allowed, on the condition that the claim is not misleading or deceptive and the claim itself is factual. government regulators cannot require products be labelled if there is no material difference between them and food produced by conventional methods. instead manufacturers and retailers can opt to label (and charge a premium) for foods that can be assured to not come from gm crops and animals. Those consumers who want to avoid gms have the option to do so: there are a range of organic and non-gmo certified products on the market.

“non-gmo” is one of the fastest-growing label trends on u.s. food packages, with sales of such items growing 28 per cent last year to about $3 billion, according to market-research firm nielsen. a company press release reports that in a 2014 poll of nearly 1,200 u.s. consumers for the Wall street Journal, nielsen found that 61 per cent of consumers had heard of gmos and nearly half of those people said they avoid eating them. The biggest reason given was because it “doesn’t sound like something i should eat.”

Food marketers could change that.

Better understanding could begin by giving the technology a non-threatening name

gm ingredients are the new “conventional”.

Retailers and food producers such as Whole Foods, Ben and Jerry’s, and organic anything, are often those who are pushing for such labelling — no doubt to better position themselves in the gmo-free marketplace, where gmo has become a pejorative and has gained a reputation as something to fear.

as globe and mail business columnist Todd hirsch recently opined about gm labelling, “[i]f consumers can be convinced they should be nervous or fearful of something, it’s an easy step to sell them things they don’t need.” Labelling is something many large food companies oppose as an unnecessary cost and that from a human health and safety perspective,

most of the foodstuffs we consume directly isn’t gm, but the crops are used to produce common ingredients like corn syrup, soy lecithin and sugar — plus the feed consumed by our livestock.

Just as we have bred poultry to grow faster and more efficiently, gm applications could also be used to replace or enhance these traditional selective breeding methods. genetic modification also has purpose in reducing the environmental footprint of food animal production and improving animal health and welfare, attributes that consumers would support.

here’s the point: of course we are likely never all going to agree on labelling just as we can’t agree on whether we call them gms, gmos, ge, giFs, and so on. social acceptance, and the farm and food community, might be better served by branding the positive attributes of gm foods. polls show most everyone is aware of gmo’s. awareness and understanding of gmos are two different things. Better understanding could begin by giving the technology a non-threatening name. “genetically improved Foods” or “genetically enhanced” would be a start. ■

• Patented Egg Saver System paired with Farmer Automatic Pro-Soft Elevator for industry leading egg collection performance

• Rugged and proven systems installed globally

• Solid galvanized partitions for greater bird comfort

• Durable V-link chain feeding system for long life and even feed distribution

• Easy open full width plastic cage doors designed for greater bird comfort

• Optional PA/polyamide-coated floors improve hygiene, comfort and egg quality

“We chose the Farmer Automatic classic system for its excellent reputation and the ability to optimize our bird population while maintaining excellent egg production.” – Jim VanHemert, ON.

www.farmerautomatic-inc.com

For sales and product inquiries please contact:

ONTARIO: Clark Ag Systems

Caledonia, Ontario

1.800.263.6410 sales@clarkagsystems.com

BC & ALBERTA: Martin Kaiser Westaskawin, Alberta

1.780.361.5994

mkaiser@kaiseragsolutions.ca

QUEBEC: Mario Godbout Montreal, Quebec 1.514.803.5431 mgodbout@gmail.com

SK, MB & MARITIMES Farmer Automatic of Canada 1.844.440.3276 sales@farmerautomaticcanada.com