FLIR delivers world-class thermal cameras and test & measurement tools with the accuracy, reliability, and versatility you need to tackle your most challenging jobs. For more information please visit: www flir.ca/work/

APRIL 2020

Vol. 36, No. 2

Established 1985

www.mromagazine.com

Twitter: @mro_maintenance

Instagram: @mromagazine

LinkedIn: linkedin.com/company/mro-magazine

Mario Cywinski, Editor 226-931-4194 mcywinski@annexbusinessmedia.com

Contributors

Shawn Casemore, Javier Irazola, L. (Tex) Leugner, Douglas Martin, Joe Morgan, Doc Palmer, Peter Phillips, Brooke Smith

Michael King, Publisher 416-510-5107 mking@annexbusinessmedia.com

Mark Ryan, Media Designer

Barb Vowles, Account Co-ordinator 416-510-5103 bvowles@annexbusinessmedia.com

Beata Olechnowicz, Circulation Manager 416-510-5182 bolechnowicz@annexbusinessmedia.com

Tim Dimopoulos, Vice-President tdimopoulos@annexbusinessmedia.com

Scott Jamieson, COO sjamieson@annexbusinessmedia.com

Mike Fredericks, President & CEO

Machinery and Equipment MRO is published by Annex

Business Media, 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1; Tel. 416-442-5600, Fax 416-510-5140. Toll-free: 1-800-268-7742 in Canada, 1-800-387-0273 in the USA.

Printed in Canada

ISSN 0831-8603 (print); ISSN 1923-3698 (digital)

PUBLICATION MAIL AGREEMENT #40065710

CIRCULATION

E-mail: bolechnowicz@annexbusinessmedia.com

Tel: 416-510-5182 Fax: 416-510-6875 or 416-442-2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

Subscription rates.

Canada: 1 year $65, 2 years $103 United States: 1 year $143

Elsewhere: 1 year $164 Single copies $10 (Canada), $16.50 (U.S.), $21.50 (other). Add applicable taxes to all rates.

All prices in CAD funds

On occasion, our subscription list is made available to organizations whose products or services may be of interest to our readers. If you would prefer not to receive such information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Officer

Privacy@annexbusinessmedia.com, 800-668-2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2020 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

Since the last issue of MRO Magazine, the world has been turned upside down with the continuing spread of COVID-19. Every day, what we consider to be “normal” changes dramatically, and we have to adapt to new measures put in place by local, provincial, and federal governments.

This has included the closure of non-essential businesses and the suspension of production in some plants. Some businesses have employees working remotely (mainly from home); other businesses, unfortunately, have cut down on staff in order to remain viable.

While much of what has been reported over the last little while has been negative, let’s try to focus on the positive stories. To help fight the pandemic, many Canadian manufacturers have actually pivoted from their regular products by making medical supplies that are in dire need.

Canada Goose will use its Toronto and Winnipeg facilities to make scrubs for healthcare workers and gowns for patients. They plan to donate them locally. Nova Scotia-based Stanfield’s, which makes undergarments, will be producing 2,000 medical gowns daily per shift. Fiat Chrysler Automobiles is manufacturing protective masks for first responders and hospital and clinic workers across North America. Trusscore has started to make panels that hospitals can use to divide rooms. These panels have been delivered to hospitals in Guelph and Waterloo, Ont. Ford of Canada is also producing face shields for the medical community at its Windsor Site operations and will distribute them throughout Ontario, and across Canada. Many distilleries are also converting their operations to help produce hand sanitizer.

The list of companies making a difference as they continue to operate is growing larger by the day. Canadians, it seems, can come together in times of crisis.

Associations are also making a difference. Many have set up resources to assist their members, including web sites, webinars, workshops, Q&As, conference calls, and many other options. See Associations Helping Members During Pandemic, page 8.

While we wait to see what the next few months hold, in the meantime, from all of us here at MRO Magazine, stay healthy and stay safe.

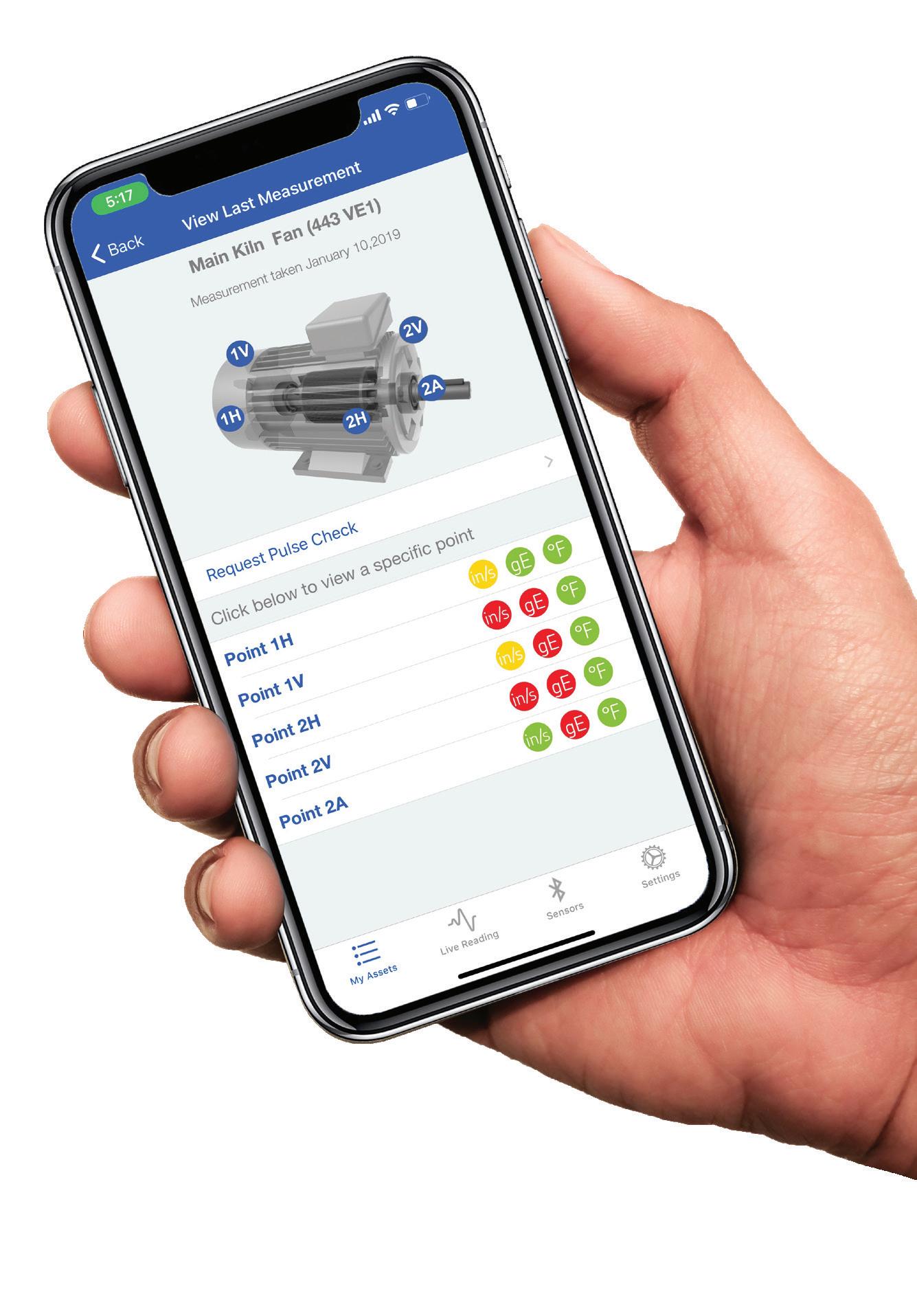

Gain operational insight like never before with SKF Pulse.

The SKF Pulse portable, Bluetooth™ sensor and free mobile app help you predict machinery issues before operations are impacted. Monitor vibration and temperature data on your rotating equipment, without the need for training or diagnostic expertise.

Tap into decades of SKF predictive maintenance and rotating machinery analysis expertise through SKF

Rotating Equipment Performance Centers, dedicated to improving your operation and finding solutions for every performance challenge.

SKF is your partner in moving toward a digital future. Visit skf.ca/skfpulse to see how SKF Pulse can improve your operation.

Contact your SKF authorized distributor for a quote today. You will be surprised how cost effective SKF Pulse is.

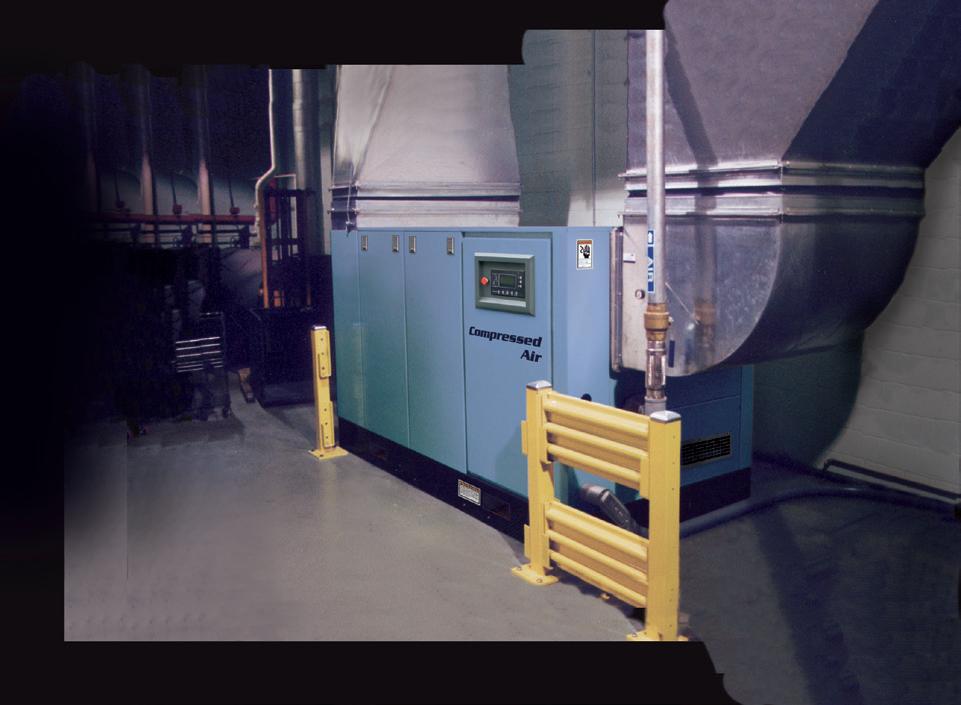

MRO spoke with Kaeser Compressors Canada Inc. about various compressed air systems topics.

Maintenance Scheduling / 12

Best Practice: Leave supervisors alone to create daily schedules.

Resource Sector / 16

Critical resilience: Hardening oil & gas and mining facilities.

Not Just New – Better / 22

Seeing sound with astounding accuracy is the future of leak detection in compressed air systems.

MRO Quiz / 14

Troubleshooting industrial pumps.

What’s Up Doug / 20

Lubrication selection based on speed.

Maintenance 101 / 24

Maintenance must win battles.

Editor’s Notebook / 3

Industry Newswatch / 6

COVID-19 Pandemic / 8

Mr. O / 30

CanWEA Hosts O&M Summit in GTA / 7

What’s New in Products / 28

Twitter: @mro_maintenance

Instagram: @mromagazine

LinkedIn: linkedin.com/company/ mro-magazine

Cover

caifas / Getty Images

Members of the PEMAC Asset Management Association of Canada met in Toronto recently.

The meeting focused on advancing the goals for the 2020-2024 Strategic Plan, reviewing a list of brainstormed initiatives provided by our staff and volunteer teams, prioritizing them, and figuring out how to marshal staff, volunteer and financial resources. PEMAC directors made recommendations and decisions that will further its plan.

The impacts of COVID-19 on PEMAC events and partner teaching institutions that offer face-to-face PEMAC courses were discussed.

The meeting took place on International Women’s Day, and Jean-Pierre Pascoli, Vice-President, acknowledged the role women play in PEMAC.

“In the typically male-dominated field of maintenance, reliability, and asset management, the PEMAC board is ex-

tremely proud that women play such critically important roles in our organization, including those of our president, executive director, and manager of education and professional development,” said Pascoli.

The Powe r Transmission Distributors Association (PTDA) released its 6th Edition of the Power Transmission Handbook and Workbook.

The book encompasses almost 400 pages and is a reference for power transmission/ motion control (PT/MC) fundamentals, written by industry experts. It offers charts, diagrams, drawings, and photos, covering the fundamentals of PT/MC products without brand-specific content.

Each chapter describes a product or technology and its various types and uses; maintenance and diagnostic tips; and basic application and selection criteria.

The Handbook is available as print – soft cover; e-book – Apple and Kindle; and individual chapters – file-protected PDF. MRO

For more, visit ptda.org/handbook.

“Susan Lubell, Cindy Snedden, and Nicolle Guillen, as well as the many other women in our team, have helped make PEMAC the strong Canadian leader in asset management we have become.” MRO

Wajax Corp. has acquired Calgary-based NorthPoint Technical Services ULC.

"We are extremely pleased to welcome NorthPoint and its team of dedicated professionals to Wajax,” said Mark Foote, President and CEO, Wajax. “The addition of NorthPoint gives our ERS platform strengthened national coverage, complementing the expanded footprint we acquired with Groupe Delom in 2018 and allowing us to better serve our customers. We continue to view ERS as a critical part of our growth strategy, as it is expected to enhance our EBITDA margins, requires a lower total working capital investment when compared to our distribution businesses, and further enhances our overall value proposition to new and existing customers.”

Formed in 2018, NorthPoint is a national electro-mechanical services provider. It specializes in repair of rotating industrial equipment, including motors, generators, gearboxes, switchgear, transformers, pumps, fans, and turbines.

“Partnering with Wajax provides our team with a significant opportunity to grow our volume nationally, leveraging Wajax’s extensive sales, marketing, and customer relationships,” said Paul Crawford, CEO, NorthPoint. “Combining with Wajax offers customers a national partner for all their ERS needs and sets us apart in the marketplace.”

NorthPoint has nine branches across Canada (Grand Prairie and Calgary, Alberta; Regina, Saskatchewan; Winnipeg, Manitoba; Kirkland Lake, Sudbury, and Sarnia, Ontario; Moncton, New Brunswick; and St. John’s, Newfoundland), employing approximately 177 people. MRO

Over 300 industry professionals took part in the CanWEA Operations and Maintenance (O&M) Summit in Mississauga, Ont., recently. Attendees listened to over 40 speakers, who discussed a variety of topics that focused on advancements in the wind energy space.

Topics covered during the Summit included cyber security, end of financed life, use of multiple technologies, advanced inspections, climate change, and the future of wind energy. Health and safety was top of mind throughout the Summit, and a special session on the development of robust health and safety programs was the highlight.

The Summit also allowed industry professionals to speak with 20 companies, as part of an exhibition, about any products they may need for their own operations.

“Team-1 Academy was delighted to exhibit at the CanWEA O&M Summit,” said Scott Connor, Chief of Training, Team-1 Academy. “With more than 300 attendees, the Summit provided an unmatched opportunity for us to share our wind energy safety training services with key decision-makers. It’s a must-attend for anyone in the O&M sector.”

Two awards were also presented for the O&M space at the awards breakfast. ENERCON won the Outstanding Achievement Award, for contributing to innovation in wind power facility O&M. Siemens Gamesa was given the Health and Safety Excellence Award for its progressive approach to its health and safety program. MRO

MRO reached out to several industry associations to find out how COVID-19 is impacting their industries and members, and how they're helping members cope.

Ann Arnott, CEO, PTDA, said, “PTDA’s members ensure companies manufacturing the equipment and resources to stem the spread COVID-19 stay up and running. As distributors and manufacturers of motors, bearings, conveyors and other power transmission/motion control components, our members keep industry moving. The biggest impact that we’ve heard from member companies is balancing the support and protection of their employees with meeting the needs of these essential manufacturers who are their customers. As the industry’s leading association, PTDA is providing members with key COVID-19 business-related information and also a forum to share and help one another in solving challenges.”

PTDA also has a web page dedicated to COVID-19 resources: www.ptda.org/ resources/covid-19-resources.aspx

JP Giroux, President, EMC, said, “We are monitoring industry needs and questions, and working on manufacturing alliances for solutions. All EMC staff and our online infrastructure are at manufacturers' disposal and in place should they require access to digital resources, virtual training, or other support during this time. Our Member Needs Help services is now available to all manufacturers and community partners to share practical tools and information developed by manufacturers and for manufacturers to use and implement.”

Robert Cattle, Executive Director, CTMA, said, “We are participating in conference calls/meetings set up by the provincial government, as well as conference calls with the Canadian Manufacturing Coalition, and giving them our input and advice as to what would help our members. We are also gathering and relaying all pertinent information to our members through weekly or biweekly electronic communications and providing resourc-

es and helpful information on our website, www.ctma.com

“CTMA staff are working from home, the Windsor Chapter tour of Dajcor Aluminum has been cancelled, the monitoring visits for the Career-Ready with CTMA program have shifted from in-person to either virtual or electronic communications, and we are assessing the need to reschedule our annual golf tournament.”

Jim Arner, Chair, Toronto Section, STLE said, “At our section level we followed the advice of the local government and our STLE parent. We had a planned tribology workshop in May, but we have postponed that until later this autumn. Other than the initial planning by our section, there was no significant impact on others.

“After all the work put into planning the special anniversary conference this year, the STLE is planning to reschedule it as soon as possible.”

Cindy Snedden, Executive Director, PEMAC, said, “PEMAC is a organization whose members are the professionals responsible for maintenance management, reliability management, and organization-level asset management of the civil and mechanical infrastructure that keeps things working. I have had the opportunity to hear from a few of them, and last week was about determining

what portion of each organization’s services are essential.

“When the answer is, ‘Yes, this service is essential’ (water and wastewater, food production, fuel delivery, healthcare facilities management), the challenge has been how to deliver services and keep frontline workers and their families safe. It was a particularly challenging todo, with kids coming home from school and alternate child care arrangements not in place. Desk workers were shifting to working from home, and plant staff were carefully working out safety measures that would make it possible to keep things running with minimum staff.

“When the answer is, ‘This service is not essential (right now),’ the challenge was whether and how to idle with minimum impact on both equipment and staff, hoping to bring teams back together to power up when the situation improves. Services we may have considered essential find themselves in this situation; airports being one example.

“It’s clear that we need a co-ordinated effort right now. What is also clear is that external circumstances are calling into question all former assumptions about the value that the organization that we serve produces. In some cases, it has been possible to pivot. We have members who work in distilleries who are retooling their production lines to produce sanitizer.” MRO

Fiat Chrysler Automobiles (FCA) will be manufacturing and donating protective face masks. It plans to produce over one million per month, with production capacity being installed and manufacturing beginning in the coming weeks with initial distribution to Canada, the United States, and Mexico.

The face masks will be donated to police, EMTs and firefighters, and hospital and health-care clinic workers.

“Protecting our first responders and health-care workers has never been more important,” said Mike Manley, CEO, FCA.

“In addition to the support we are giving to increase the production of ventilators, we canvassed our contacts across the

Canada Goose will use its manufacturing facilities to produce scrubs and patient gowns for front-line healthcare workers and patients.

Canada Goose will produce the gear at its manufacturing facilities in Toronto and Winnipeg. If the need arises to increase production, it can do so at other facilities. The company will have 50 employees per facility working on the gear and have a goal of producing 10,000 units. The gear will be donated locally at no cost.

“Across Canada, there are people risking their lives every day on the frontlines of COVID-19 in healthcare facilities, and they need help. Now is the time to put our manufacturing resources and capabilities to work for the greater good,” said Dani Reiss, President and CEO, Canada Goose. “Our employees are ready, willing and able to help, and that’s what we’re doing. It’s the Canadian thing to do.”

On March 17, the company set up the Canada Goose Employee Support fund for employees who are impacted by store and manufacturing closures but are not eligible for government assistance. In a letter to Canada Goose employees, Reiss announced he will forgo his salary for at least the next three months; it will be used for the Employee Support Fund. MRO

healthcare industry and it was very clear that there is an urgent and critical need for face masks. We’ve marshalled the resources of the FCA Group to focus immediately on installing production capacity for making masks and supporting those most in need on the front-line of this pandemic.”

FCA is developing a multifaceted global program through applying manufacturing, supply chain, and engineering expertise to support the global fight against COVID-19.

FCA is working with national, regional, and city authorities to make sure the donated face masks go to people and facilities with the most need. MRO

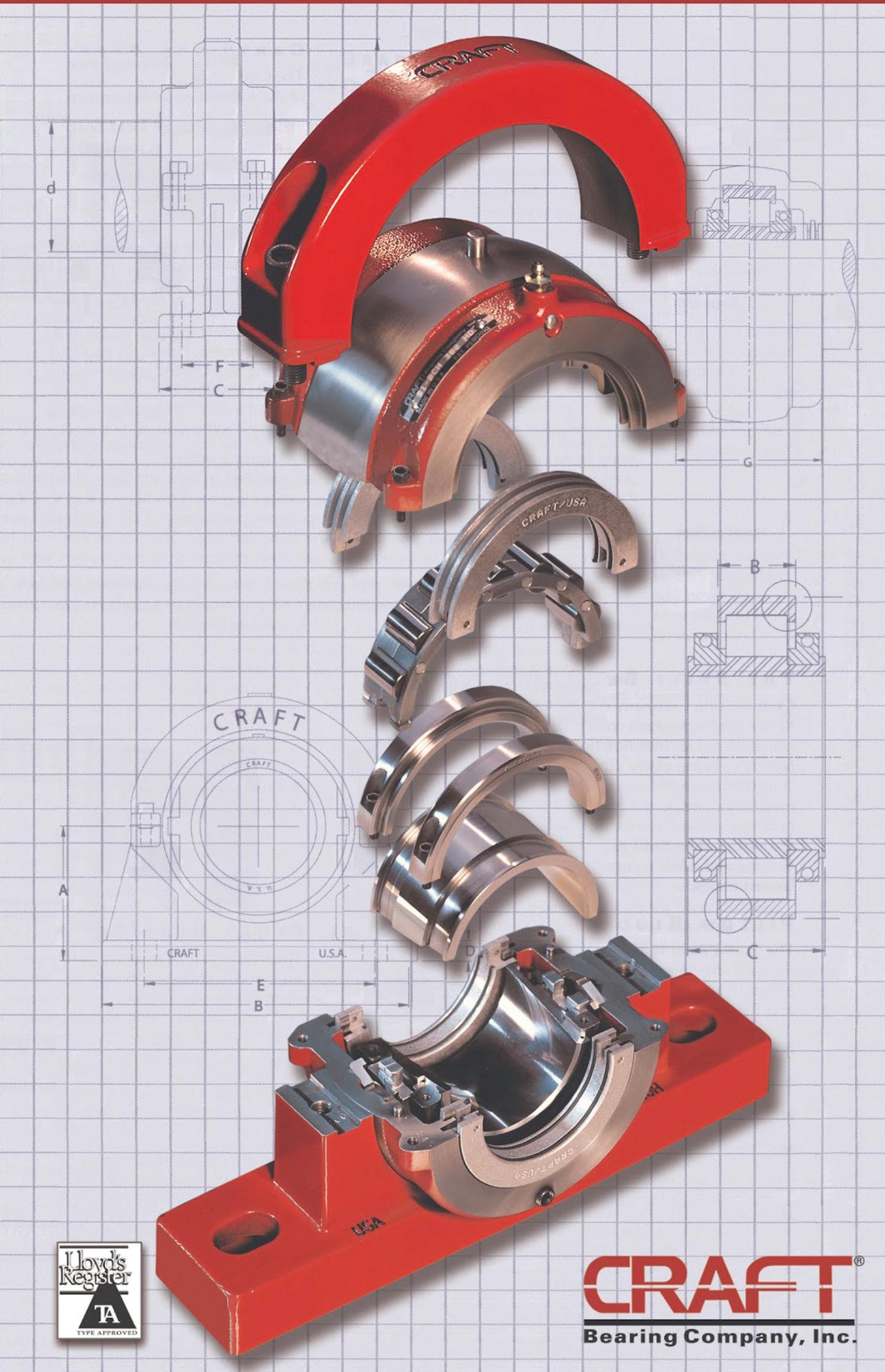

Global Bear Inc. is pleased to announce the opening of a branch in Langley, BC.

The 3000sq. ft. facility will be stocked with a broad range of all the products distributed by Global.

“The plan has always been to have coverage across Canada”. “That dream has now become a reality”, stated Harold Benz, founder and President of Global.

We look forward to servicing our Western Canadian customers from the new facility and welcome all inquiries for bearings, belts and power transmission products.

Our stock, featuring CRAFT and NKE bearings in Langley, will help distributors service the “end-user” markets in Alberta and British Columbia.

call

with your inquiries.

BY MARIO CYWINSKI

This month, MRO is looking at compressed air systems as its cover feature. As such, we reached out to Kaeser Compressors Canada Inc. to find out what customers think are the most important aspects of a compressed air system, how systems will change in the future, and if more technologically advanced machines are better than traditional ones.

MRO spoke with President and General Manager of Kaeser Compressors Canada, Harold Wagenknecht, about those compressed air systems topics, and how Kaeser products differ in the marketplace.

Kaeser Kompressoren recently celebrated its 100th anniversary, while Kaeser Compressors Canada Inc., celebrated its 25th anniversary. Founded by Carl Kaeser Sr., in 1919, the company has grown to operate in over 140 countries, employ over 6,700 people, and manufacture compressors and compressed air systems for the global market.

MRO: What do your customers say is the most important aspect of their compressed air system?

Wagenknecht: Surveys place reliability first, followed by energy efficiency, local service support, maintenance friendliness, and space requirements. Many customers like the low noise of newer compressed air systems (there are still quite a few "open/no sound cabinet" units installed). Low sound levels open the possibility to install the units in the work areas if needed.

MRO: What are the main advantages of having a more technologically advanced system, compared to a traditional system?

Wagenknecht: It is much more efficient, with better (and more consistent) air quality and more feedback (operational data) from the compressed air system (all components). Better projection of maintenance requirements based on that particular system and not based on a maintenance schedule

are developed to cover all systems of a particular HP.

MRO: How do you see compressed air systems changing in the near and long term?

Wagenknecht: Compressed air systems need to be designed correctly (if new), or analyzed. They need to be efficient, reliable, and durable; flexible to adjust to changing demands; and maintenance friendly.

MRO: What are some of the advancements in the space that you see coming in the future?

Wagenknecht: Connectivity and data acquisition of all components to customize operation and maintenance.

MRO: Break down some products that Kaeser offers.

Wagenknecht: Kaeser Compressors is more than just products. A big part of what Kaeser does is consulting (before, during, and after the sale) and after-sale service. Typical steps Kaeser and our distributors take are consulting with clients to perform a thorough and factbased analysis of their existing system using Air Demand Analysis (ADA), and developing a customized solution through Kaeser Energy Savings Software (KESS), which selects the most efficient compressed air system components based on the acquired ADA data. This solution predicts the energy consumption and savings, which are needed to receive financial incentives from various hydro companies (program depends on province). Depending on the customer's needs (based on the ADA), we select the following:

Compressors: Lubricated, oil-free and sizing.

Dryers: Refrigerated (integrated into compressors, stand alone, high pressure, high inlet temperature) for above freezing applications (90 per cent plus), desiccant dryers for applications in temperatures as low as -100°F (heated, non-heated, heat of compression). Membrane dryers with variable dew points typically used for point-of-use applications.

Filtration products: Pressure drop at rated operating conditions, separation efficiency, and ability to hold/carry large amounts of contaminants.

Drain products: Drains are the most overlooked, but a critical system com-

ponent as they "discharge" (oily) condensate and particulates out of the system. Reliability and energy efficiency are critical, as an open drain wastes a tremendous amount of energy, and a stuck drain contaminates the compressed air systems. They must be able to communicate.

Air system charging valve: Very important but 99 per cent overlooked. This valve makes sure that on Monday morning when the system is depressurized, the clean air treatment system (dryers, filtration) is not overrun. Why? The air at ambient pressure (compared to 100 psig) is about eight times the volume/velocity and it will "overrun" the dryer and filtration/drains.

Piping products: Kaeser sells an aluminum-based piping system, designed to offer leak-free and low pressure drop during operation. This is very important, as leaks still account for about 35 per cent of compressed air consumption.

SAM 4.0: Tying all these components together (especially multiple compressors), Sigma Air Manager (SAM) 4.0 "master controller" is selecting the most efficient compressor combination for the actual current demand. The software is "self-learning" and picks from over 4,000 different scenarios in milliseconds. It further annunciates and records maintenance, precautionary, and shutdown messages. It also records 12 months of continuous operating data (including energy usage), providing valuable system performance data.

MRO: What makes your products unique in the marketplace?

Wagenknecht: They are engineered for efficiency and reliability and durability.

One example of Kaeser’s features on compressors is the Electronic Thermal Management valve, which determines the exact discharge temperature of the compressor based on ambient temperature. All possible due to our Sigma Control 2

controller, which is an industrial computer, monitoring, logging (up to 12 months) and controlling compressors. Also, dryers, drains, and more can be connected to SAM 4.0 to be monitored for performance and maintenance needs. MRO

Mario Cywinski is the Editor of Machinery and Equipment MRO magazine, a member of the Automobile Journalists Association of Canada, and a judge for Canadian Truck King Challenge. He has over 11 years of editorial experience and over 16 years of automobile industry experience, as well as small business industry experience.

BY DOC PALMER

Several years ago, a maintenance manager gave me critical insight into daily scheduling. He asked, “Isn’t the daily schedule simply handing out the work orders?” Really, that’s about it!

We suffer from some kind of hypnosis when we hear the word schedule and imagine some complicated chart showing where everyone will be each hour for the entire next week. However, there is too much churn in the daily execution of maintenance to create such daily schedules a week ahead of time. Instead, leave the crew supervisors alone. Let them create daily schedules as the week unfolds. The first line supervisors should create the daily schedules, assign names, co-ordinate LOTO, and deal with new urgent work that cannot wait.

Many plants have weekly schedules

that consist of super-detailed daily schedules a week in advance. These plants reason that the schedule should dictate exact days and time slots to set expectations and give the best co-ordination. These schedules should allow the operators to have assets prepared on time for maintenance to work on time. Managers should be able to hold operations and maintenance accountable. Unfortunately, in real life, maintenance time estimates are not very accurate for individual work orders. Maintenance is simply not assembly line work. Often, a five-hour job takes eight hours, or a five-hour job takes only two hours. Most plants also have a significant amount of new urgent or emergency work. Operators continually call maintenance supervisors for help with issues that cannot wait. The resulting churn causes plants

that create daily schedules a week in advance to waste a considerable amount of time meeting each day to totally revise the schedules. This wasted time is in addition to the time spent creating such precise weekly schedules in the first place. If not careful, the management focus is on watching fancy computer screens showing where work orders are moving every day (on activities, not completions).

Other plants accept the churn and so do not create weekly schedules at all. Do not accept the churn as a reason not to create a weekly schedule. Crews need the weekly goal of work to serve as a focus or a sense of mission.

Instead, a better practice is to give the entire weekly schedule as a simple batch of work to the crew supervisor. Then leave the supervisor to create daily schedules as the week unfolds.

Tip: Improve productivity by not worrying about how supervisors create daily schedules. Focus instead on starting them each week with a full batch of work as a goal.

For example:

• On Friday, the supervisor takes the batch of work and figures out what to do on Monday. The supervisor then co-ordinates with operations to see if these jobs could get LOTO.

• Later on Friday, after this co-ordination, the supervisor posts the schedule for Monday.

• On Monday morning, the supervisor might reshuffle some of the work, depending on what happened over the weekend and if any craftspersons are absent.

• Throughout the day Monday, the supervisor monitors how jobs are going and redeploys persons to new reactive work as necessary.

• About midday, the supervisor starts figuring out what to try to do on Tuesday and then meets with operations to request LOTO.

The supervisor then posts the schedule and comes in the next day to reshuffle if necessary. The supervisor repeats this cycle throughout the week using the weekly schedule batch of work as a guide. The management focus at the end of the week should be how much work was completed on the weekly schedule (on completions, not just activity).

The approach of letting crews develop their own daily schedules from a batch of work accepts the churn of real life and improves productivity. The inferior approach of dictating precise daily schedules a week in advance tries to solve the churn, but does not solve the churn and does not improve productivity.

The other inferior approach of having no weekly schedule at all solves the churn but does not improve productivity.

Overly detailed weekly schedules that usurp supervisor authority to make daily assignments are also bound to create dissension. No one can assign particular jobs or craftspersons a week in advance because it is uncertain exactly when individual jobs will start or finish and, therefore, who is available when.

However, allowing supervisors to create the daily schedules as the week unfolds helps the supervisors assign individual names for particular work orders. Supervisors continually make the

best assignments possible as the week unfolds based on criteria that cannot be presupposed by any weekly scheduler. These criteria include things such as who works well together, who doesn’t work well together, which persons work better by themselves, which persons need to be paired up, who is the best pump person available now, and who needs pump experience, to name a few.

Finally, supervisors must be empowered to break the weekly schedule without seeking time-consuming approvals. The whole idea of productive maintenance is to work toward a goal of work for the week while understanding it is necessary to attack emergency and urgent work quickly. The idea of a simple batch of work as a goal encourages supervisors to try to meet the schedule, but readily admits that new urgent work must take precedence. A super-rigid schedule often discourages or slows response to take care of urgent work.

Tom Peters and Robert H. Waterman, Jr’s book, In Search of Excellence, supports proper management thinking about weekly versus daily scheduling. Their concept of “tight and loose” means that successful companies focus on what they care about (tight) and don’t worry about the rest (loose). The application for scheduling is to start each crew with a full batch of work for the week (tight) and to let the crew hand out work orders during the week any way they want (loose).

Best schedule practice is to recognize the churn of daily maintenance and to let supervisors create daily schedules as the week unfolds (but using a batch of work for the week as a goal). Understand the difference between weekly and daily scheduling to have great productivity. MRO

Doc Palmer, PE, MBA, CMRP, is the author of McGraw-Hill’s Maintenance Planning and Scheduling Handbook and, as managing partner of Richard Palmer and Associates, helps companies worldwide with planning and scheduling success. For more information, including currently scheduled public workshops, visit www.palmerplanning.com or email Doc at docpalmer@palmerplanning.com.

BY L. (TEX) LEUGNER

Depending on design and application, pumps are fitted with high-speed anti-friction or journal bearings, and lubrication systems used may be oil pump pressurized, self-contained oil in a bearing housing, or dry sump systems using oil mist lubrication. In all cases, pumps are subjected to contaminants, wear metals, direct water or condensation, temperature variations (both ambient and operational), and vibration caused by coupling misalignment, piping strain, foundation or base plate settling, or cavitation due to reduced net positive suction head.

1. What considerations do you believe are necessary when selecting pump lubricant?

Logic: The lubricant recommended will always be dependent on pump shaft speed, shaft diameter, bearing types, and method of lubrication. In addition, some newer pump manufacturers recommend PAO (polyalphaolefin) synthetic oil. Most pumps require mineral-based rust and oxidation (R&O) inhibited oil in viscosities ranging from ISO 32 for some centrifugal pumps, to as high as extreme pressure (EP) ISO 460 for some piston power pumps. Therefore, it is important to follow the manufacturer's recommendations regardless of the type of bearing lubrication system in use, and it is advisable to establish an oil analysis program for industrial pumps. The conditions monitored should include wear metals, contamination monitoring using ISO particle counts, viscosity, and acid number.

2. When selecting bearings either initially or for replacement, what considerations are important?

Logic: There is a direct relationship between the load rating and the nominal life of all bearings. Theoretically, doubling the load rating can allow for up to eight times the bearing life. There have been effective redesign modifications to highspeed angular contact bearings used in typical pump applications. These include hybrid bearings using ceramic balls, bearings with high temperature resistant plastic cages, and matched pairs of back-to-back angular contact ball bearings for high-speed applications, controlling both axial and radial loads. Bearing design, selection, and arrangement will depend on API or ANSI pump system design. Every pump bearing application is a complex system of interacting factors. (These factors are noted in Figure 1).

3. What must you consider when initial selection or replacement seals are made?

Logic: The correct specification and selection of seals, and sealing systems, will depend on pump design, application, speeds, and loads. Seal types include radial shaft, labyrinth, gas seal, or mechanical. Mechanical seals can be either single or double depending on the pump type, design, application, and bearing location. Radial shaft seals will incorporate a sealing lip made of a formulation of nitrile rubber.

Certain specifically produced seal lip materials have been developed to accommodate synthetic pump lubricants, or protect against chemically aggressive pump process fluids. Labyrinth seals, sometimes referred to as bearing isolators, feature a non-contacting internal path design that excludes process fluid and particle contaminants while retaining lubrication. They are of metal or plastic material and when installed correctly have a long service life.

Single mechanical seals are made up of a stationary member attached to the pump casing, and a rotating member attached to the shaft. The mating faces of the members perform the sealing. Double mechanical seals are used in applications where the pumped fluid may be toxic or flammable, and leakage to atmosphere cannot be tolerated under any circumstance. Typical applications for double mechanical seals are H2S, hydrofluoric acid alkylation, or sulfuric acid service. These seals consist of two mechanical seals, a primary and secondary (or backup). The backup or secondary seal uses a flush system with a low flash point fluid.

A relatively new application utilizes two gas seals in a double seal configuration using nitrogen or air as a buffer, maintained at a higher pressure than the pumped fluid, to prevent leakage of the processed fluid to atmosphere. (More information on this is available from API Standard 682).

The operating parameters to be considered when selecting radial sealing systems in pumps are:

• Shaft speed - The majority of standard small-bore radial

seals under eight-inch shaft diameter are rated up to 3600 feet per minute, while applications over eight-inch shaft diameter are rated to about 5000 fpm. To exceed these speeds requires special design considerations.

• Temperature - Every seal material has an optimum range, and upgrading the seal material to PTFE or fluoropolymer may be required for excessive thermal limits.

• Pressure - Pressure loading of the seals caused by excessive system conditions, or a fault such as a plugged vent, will mechanically load and distort the sealing contact profile. For example, most standard radial seals are designed for only about seven psi.

• Shaft surface finish - For optimum radial seal performance, consideration must be given to the fineness and type of shaft finish, direction and spiral of the finishing marks and leads, and a surface finish of at least 8-7 µin (micrometres per inch).

4. What operating conditions must the troubleshooter be aware of?

Logic: High pump temperatures, excessive noise, and vibration are conditions that must be investigated. High temperatures may be caused by a binding rotor, misaligned coupling, packing gland misaligned or adjusted too tightly, process fluid too viscous, “pump at run-out” on the performance curve, incorrect bearing lubricant viscosity, or faulty bearings. Excessive noise or vibration can indicate pump cavitation, low suction head, obstruction on the suction side, resonance of certain components, worn or loose bearings, air entrainment, and/or air leaks in the suction line.

5. What potential problems must you be aware of when using vibration analysis as a troubleshooting tool?

Logic: Fan blade and impeller problems, cavitation, flow turbulence, or surging can be detected using vibration analysis. Blade and impeller pass frequencies occur as each blade delivers its contribution to the pumping process. The blades create a frequency as the blade passes the outlet port and large blade pass frequencies with harmonics will be generated in pumps if the vane-to-diffuser gaps are unequal, if the impeller wear ring has seized on the shaft, or if welds fail.

High blade pass frequencies can also be caused by abrupt or sharp bends in piping or ducts, or by obstructions that disturb flow. Pump cavitation indicates voids in the pump inlet generating noise combined with high frequency energy superimposed with harmonics. Impeller vanes will erode as a result and vibrations generated by unbalance can also be generated. Whenever possible, pump inlets must be unrestricted, and even flooded, to reduce unwanted hydraulic and aerodynamic forces.

In conclusion, pumps will operate efficiently and relatively maintenance free if properly selected, carefully installed, and operated and maintained correctly. Oil analysis, vibration analysis, and acoustic ultrasound are invaluable in monitoring the operating condition of pumps. MRO

L. (Tex) Leugner, the author of Practical Handbook of Machinery Lubrication, is a 15-year veteran of the Royal Canadian Electrical Mechanical Engineers, where he served as a technical specialist. He was the founder and operations manager of Maintenance Technology International Inc. for 30 years. Tex holds an STLE lubricant specialist certification and is a millwright and heavy-duty mechanic. He can be reached at texleug@shaw.ca.

BY JOE MORGAN

When access to vital energy or natural resource supplies are threatened, the impact goes well beyond the oil field and mines, and potentially affects workers and communities. The oil & gas and mining industries have a complicated supply chain. It consists of exploration, extraction, transportation, refining, and distribution, which are dependent on one another and becoming more at risk from various threats.

Facility and site automation, AI, and Internet of Things (IoT) connectivity continue to grow, and so does the use of cloud services. This means, the entire production line of these operations is susceptible to cyber security-related threats that can impact the safety of worker and machine operation, and bring complete cessation of site and company workings.

The challenge of securing oil & gas and mining installations from a physical aspect is threefold: secure the property, the processes, and the safety of personnel. It may be a threefold process, but it doesn’t mean you have to triple your investment in security systems. With internet-protocol (IP)-based technology, it’s possible to achieve all three goals with one solution.

A typical installation would combine supervised checkpoints, camera surveillance, perimeter control, access control, fire protection, and alarms into an integrated security and surveillance system. It requires labour, and trips to remote areas to monitor pipelines and perimeter fences. Today’s network IP cameras are more powerful than earlier analogue cameras, allowing for processing of data to be done in the cameras. Known as "edge computing," this reduces the load on the network, as only relevant video is streamed from the camer-

as. Therefore, certain security decisions can be made in the field, rather than streaming all footage to a remote server to be analyzed.

Starting at the perimeter, network cameras can monitor and record activity, and video analytics can interpret and act on anything they detect in the captured video. For instance, if a camera detects an intruder, it can notify security staff, issue an alarm, or play a prerecorded message telling the intruder to leave the area. Analytics available include motion and audio detection; more advanced systems include camera tampering detection, people counting, virtual fences, thermal heat detection, and vehicle licence plate recognition.

Downtime is an anathema for the oil & gas and mining industries. As such, facilities must continuously monitor processes to forestall costly repairs and shutdowns. By integrating video surveillance and analytics into Supervisory Control and Data Acquisition (SCADA) sensors and mass communication systems, operators can remotely monitor production efficiency, and visually inspect and verify that functions and processes are running correctly. This enables personnel

to predict maintenance, which is key to safety, even in areas difficult to access, and provides remote assistance with planned maintenance.

Security cameras are well suited to the task of process security. A pan-tilt-zoom camera can shift from monitoring a fence line and zoom in to read a dial on a critical piece of equipment. Armed with thermal imaging technology and isothermal analytics, a thermal camera can detect subtle temperature

for example, self-igniting materials or equipment are about to combust. In an emergency, they can track heat signatures to ensure everyone evacuates safely. In case of harmful emissions or a chemical spill, they can identify safe exit routes that avoid the vented discharge or flow.

By combining network video with access control, and intelligent analytics, these sites can protect the health and safety of their workers, the public, and the surrounding environment. The technology can help management visually monitor policy adherence, and evaluate risks in real time, control access to restricted areas, and track and support rescue teams and confirm evacuations.

The more Industrial Internet of Things (IIoT) becomes critical to oil & gas and mining, the more vulnerabilities crop up, and the more pathways are created that can be used for unwanted incursions. According to a recent Forrester study, by 2018, nearly 60 per cent of relevant surveyed organizations had experienced a breach in their industrial control or SCADA systems. In a 2018 security survey by Ernst & Young, the survey identified that 54 per cent of mining extraction companies had experienced a “significant” cyber incident in the past 12 months.

variances that could indicate an overheating ball bearing, a blocked valve, or a leaky pipe. With their onboard intelligence and versatility, security cameras can be used to measure tank levels, monitor refinery flare stacks, and help operators avert wide-scale electrical outages by predicting transformer and switchgear failures at power substations.

Integrating network surveillance with production monitoring systems, critical infrastructures can inspect processes, and verify they are running correctly; visually assess reported failures; facilitate predictive maintenance and trend monitoring; and provide remote maintenance assistance via integration with network audio systems.

Oil & gas and mining sites can be dangerous, and safety is paramount. Surveillance cameras can help in mitigating risks. They can trigger alerts when they detect personnel entering dangerous or off-limit areas such as tunnels, railway tracks, and bridges. Thermal cameras can detect early-warning signs;

Mining extraction operations today include IIoT monitoring of tailings ponds, and dams or gas leaks, both on location and cyber, meaning, if a criminal penetrated a system, there could be a major threat. Employees are working underground or underwater where operations such as drilling, blasting, and welding are taking place; you wouldn’t want equipment to be compromised by a cyber attack, potentially bringing employees in harm’s way.

Security professionals must be able to harden all video cameras and IoT endpoints, and configure firewalls around various networks. Automation ensures that cyber security best practices are done correctly and at scale, saving hours of time spent manually performing hundreds of unfamiliar security tasks. Other best practices to automate include locking down exposed network connections, implementing security configurations, and monitoring devices 24/7 for health and cyber security.

A oil & gas and mining extraction site security plan needs to address all three areas of risk: traditional physical security, process security, and employee safety security, while ensuring all devices and systems are hardened against cyber attacks. Since a network surveillance system can handle multiple duties simultaneously, it's able to help facilities achieve superior intrusion detection, more reliable operations, and a safer, healthier environment for their workforce. It’s like getting three systems in one: triple the protection duty and triple the return on investment. MRO

Joe Morgan is the Segment Development Manager for Critical Infrastructure at Axis Communications, Inc. He is responsible for developing strategies and building channel relationships to expand Axis’ presence in markets specific to critical infrastructure in North America.

150 years ago, our founders set out to make the highest quality, best performing lubricants available. In doing so, they helped pioneer the use of anti-wear additives that significantly increased lubricant performance through the years. Today, that innovative tradition continues with our newest line of 100% synthetic, ultra high-performance lubricants. Engineered from the ground up, they provide a wide range of benefits including: extended lubrication intervals, multiple application capability, reduced friction, extended machinery life and reduced downtime. Products include...

HIGH-PERFORMANCE SYNTHETIC GEAR OILS

SYNTHETIC AIR COMPRESSOR FLUIDS

SYNTHETIC HYDRAULIC FLUIDS

HIGH-PERFORMANCE SYNTHETIC GREASES

NSF H1 REGISTERED FOOD GRADE LUBRICANTS

ECO-FRIENDLY SYNTHETIC LUBRICANTS

SYNTHETIC SPECIALTY LUBRICANTS

QUALITY INNOVATION PERFORMANCE FOR 150 YEARS

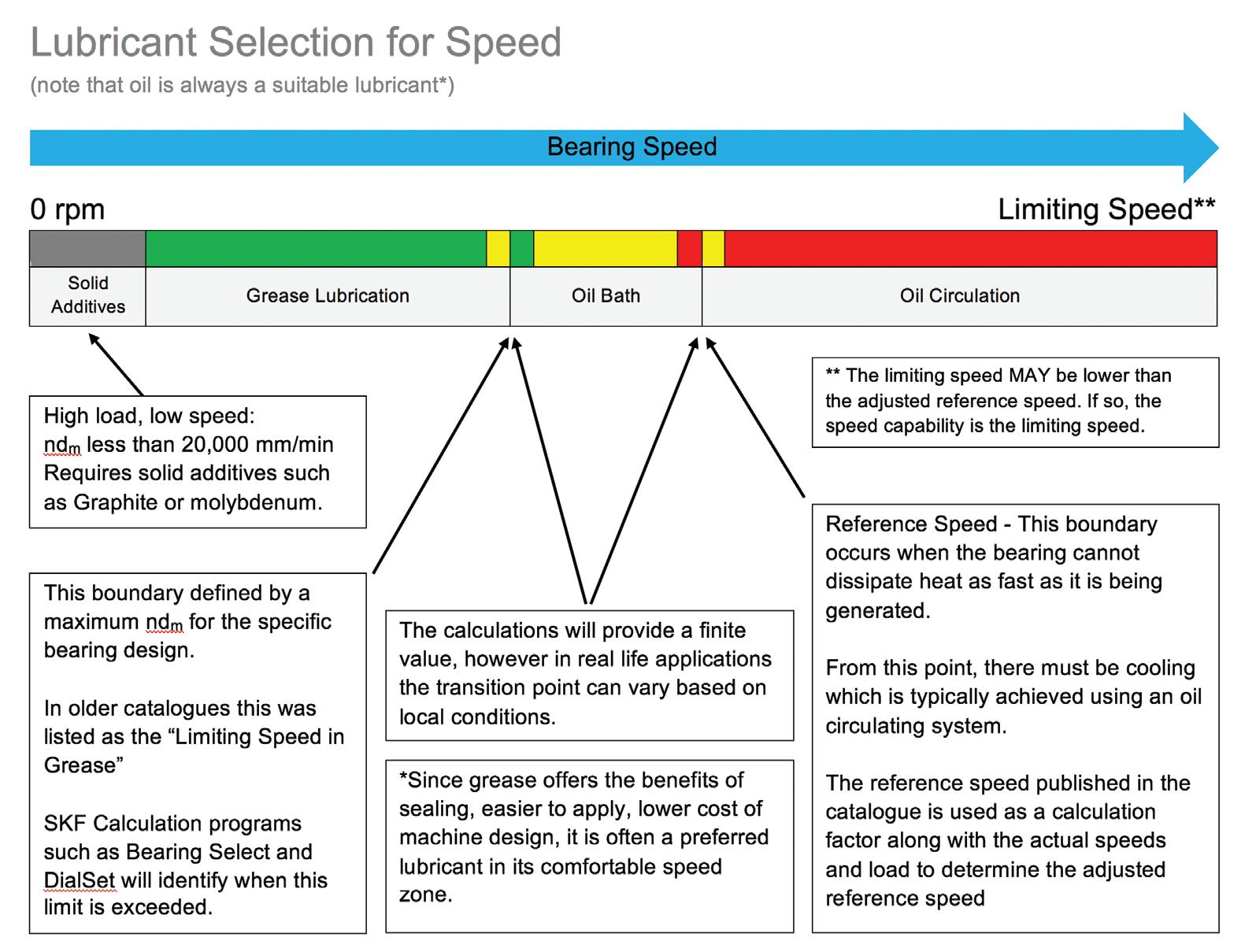

BY DOUGLAS MARTIN

If you look at an old bearing catalogue from the 1980s and earlier, you will see that bearing manufacturers published limiting speeds in grease, and in oil. These values were in the data tables that designers and users referenced as guidelines. In the text of general catalogues, a deeper explanation was given about heat generation, and the possible requirement for cooling in the realm above the limiting speed in grease, up to the limiting speed in oil. In many cases, these details were overlooked.

In the 1990s, the concept of a reference speed was introduced. Bearing manufacturers published a reference speed and a limiting speed. The reference speed relating heat generation to lubricant selection, and the limiting speed being the maximum speed the bearing can “mechanically” tolerate.

Unfortunately, the reference speed was a number to be used in a formula with the applied loads to the bearing to come up with an adjusted speed rating. Application engineers (like me) had to translate this “math formula” into something that the users could use or at least conceptualize. The answer was, the ref-

erence speed is about the speed at which the bearing generates heat as fast as it dissipates heat, and maintains a temperature of 70°C. Advice to customers

was that as they approach the reference speed, they need to consider switching to circulating oil to control the bearing temperature.

At the time, however, there were no automated programs to undertake the calculation. It was onerous to manually go through the calculations to come up with an “adjusted” limiting speed. In addition, when working with end users (as opposed to designers), the required inputs are often unknown. No longer do I ask a user “what the radial load applied to the bearing is,” as there is generally no way of knowing this, unless you are the designer of the machine.

With the advent of online calculation applications, we are now able to easily define the transition between the maximum speed for grease, where an oil bath should be used in the gap between grease lubrication, and oil circulation. The problem still arises in the estimation of the bearing load; however, this is overcome by estimating the loads based on whether the application is “heavily loaded” (more often slowly rotating bearings), “normally loaded” (most bearings), or “lightly loaded” (often higher speeds).

Of importance are bearing types, such as deep groove ball bearings, in which the limiting speed is lower than the reference speed. Be careful that you consider both speeds (but if you are using online calculators, there will be warnings).

The next speed level is low speed. At low speed, and high loads, oil is not able to create a complete film between the rolling contact surfaces. Below a surface speed (ndm of 20,000 mm/minute {rpm x mean diameter of bearing}), there will always be some requirement to protect from boundary lubrication, so the selection of grease should include a solid lubricant such as moly and graphite. Calcium sulphonate greases also provide similar protective properties.

Although a Kappa calculation may suggest all you need is a high base oil viscosity, the proper additive package for the low speeds and high loads is needed. A high viscosity base oil is recommended; however, the additive/soap properties are more important.

One recent issue that came up was with a full complement bearing. There was no reference speed published, but a limiting speed (of 4,500 rpm) was published. The customer was having issues, and upon investigation, there was a design consideration for full complement bearings in which the ndm should not exceed 20,000 mm/min. Therefore, for this bearing, the acceptable operating speed is 333 rpm. The reason is that the rollers contact one another, and the contact surfaces are moving in opposite directions, so

there is the opportunity for excessive wear. Seals also limit the speeds of bearings. Although the speed limit, in terms of a seal integrated into a bearing, is included in the bearing limiting speed, the design of the rotating equipment must also take into consideration the limiting speed of any external seals. MRO

Douglas Martin is a heavy-duty machinery engineer based in Vancouver. He specializes in the design of rotating equipment, failure analysis, and lubrication. Reach him by email at mro. whats.up.doug@gmail.com.

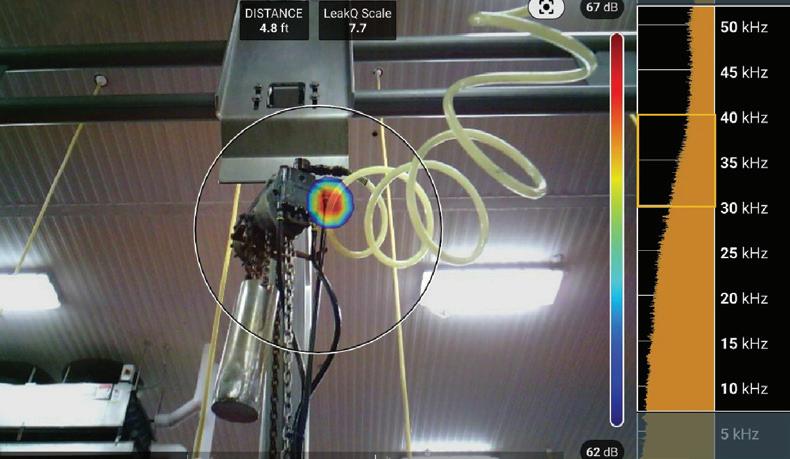

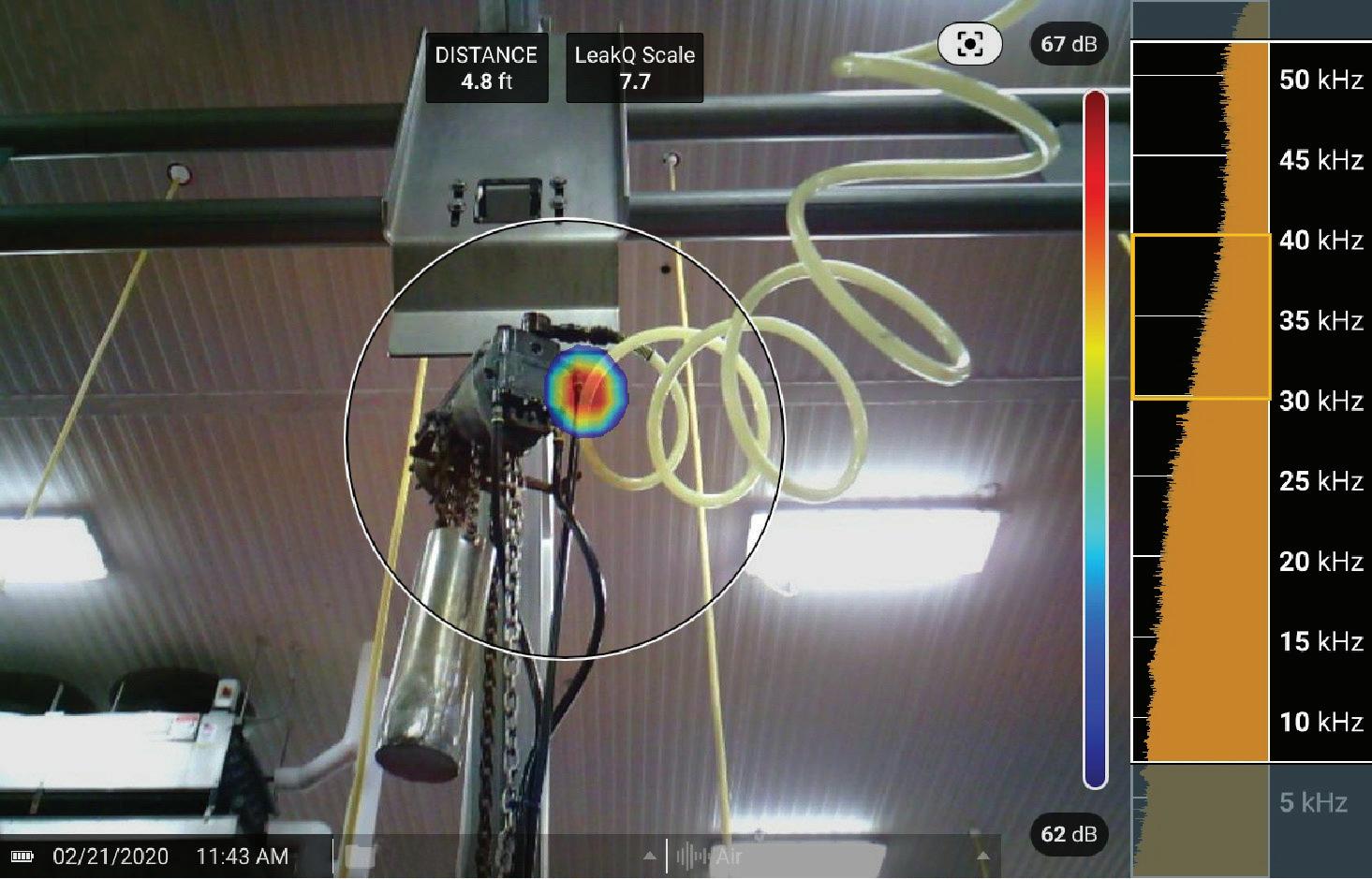

Seeing sound with astounding accuracy is the future of leak detection in compressed air systems. Acoustic imaging includes ground-breaking technology that uses an array of tiny supersensitive microphones to detect sounds both in the human hearing and ultrasonic ranges.

BY JAVIER IRAZOLA

Air leaks will occur, but today there is a more comprehensive method for finding them. The simplicity of the acoustic imager means anyone can use it. No more soapy water or hearing accessories necessary. Acoustic imagers are a practical and profitable method for facilities, allowing air leak detection to be added to regular preventive maintenance routines.

For production facilities that have started using the acoustic imager, early results validate energy savings. One customer saw a nearly 26 per cent recovery in compressed air capacity and close to $49,000 in annual electrical energy savings—based on their total installed capacity of air compressors equalling 330 horsepower.

Before using the sonic imager to inspect for air leaks, the plant ran four compressors close to full capacity. After a oneday inspection, they found and repaired more than 130 leaks. Now the facility can handle most of its compressed air needs with just three compressors. Since they were expanding the plant at the time, the fourth compressor will not go to waste and will save the company a capital expense.

In one day, you can scan your entire system to identify all the leaks in it. But then what? You might not have the resources on hand to repair all those leaks. The acoustic imager includes software that helps to identify where leaks are within the system, and allows for on-screen annotation, leak size estimation

(about how big is that leak?), and smooth report development.

• Asset tagging lets others know where the leak was found;

• On-screen annotation provides additional context and considerations for others; and,

• Leak analysis approximates the size of the leak to help you prioritize which leaks deserve attention first.

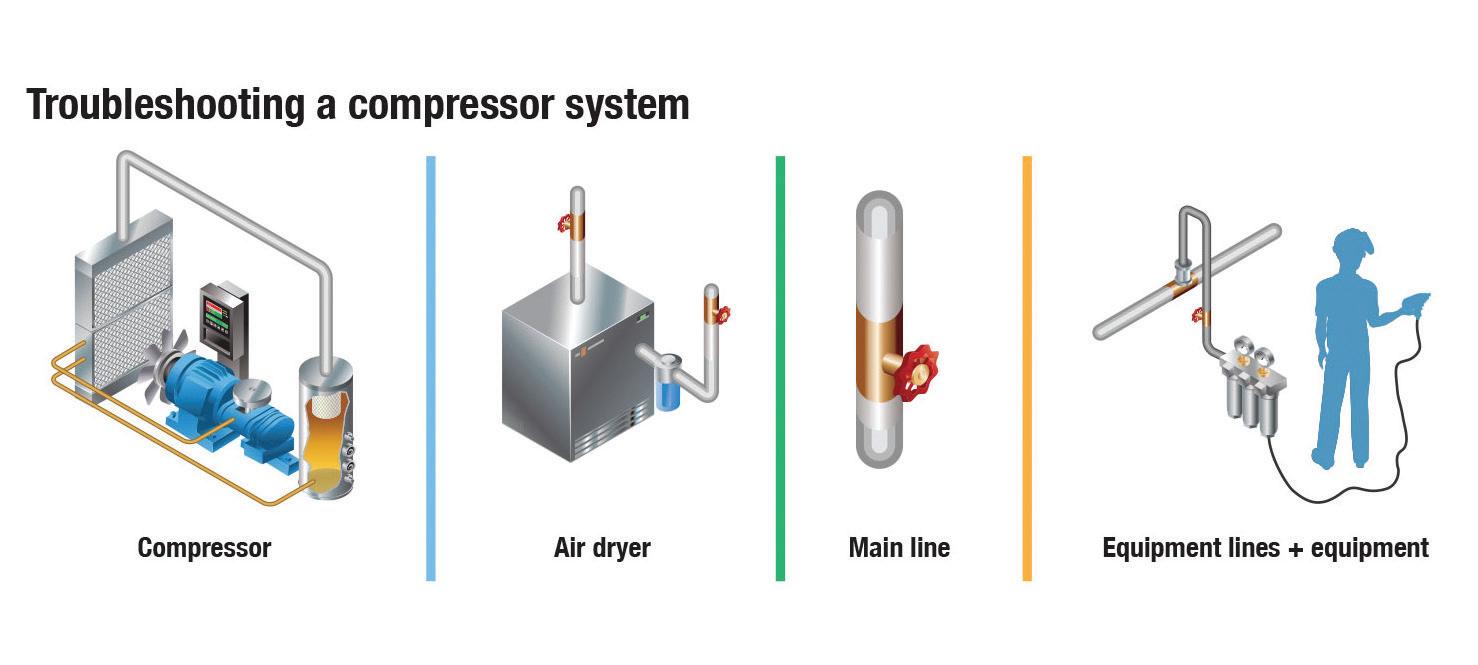

Before you can repair leaks, you must find them—and that can be difficult in even the quietest environments. Large manufacturing plants may have compressor systems that stretch from one end of the facility to the other, passing through and around other operating systems. From the compressor to the air dryer, main line to equipment lines, and equipment—leaks can be hidden anywhere.

The most common places to find air leaks are couplings, hoses, fittings, pipe joints, quick disconnects, condensate traps, and valves. That is a lot to inspect, and much of it is hard to reach. While maintenance team members do their best to fix leaks they find during normal maintenance routines, most facilities don’t have the resources to dedicate specifically to this task. Technicians might make more of an effort to identify where a leak is located if pneumatic tools were not working properly, but even then it is a trivial task.

Make the task of detecting air leaks easier, more comprehensive, and more accurate with these seven steps.

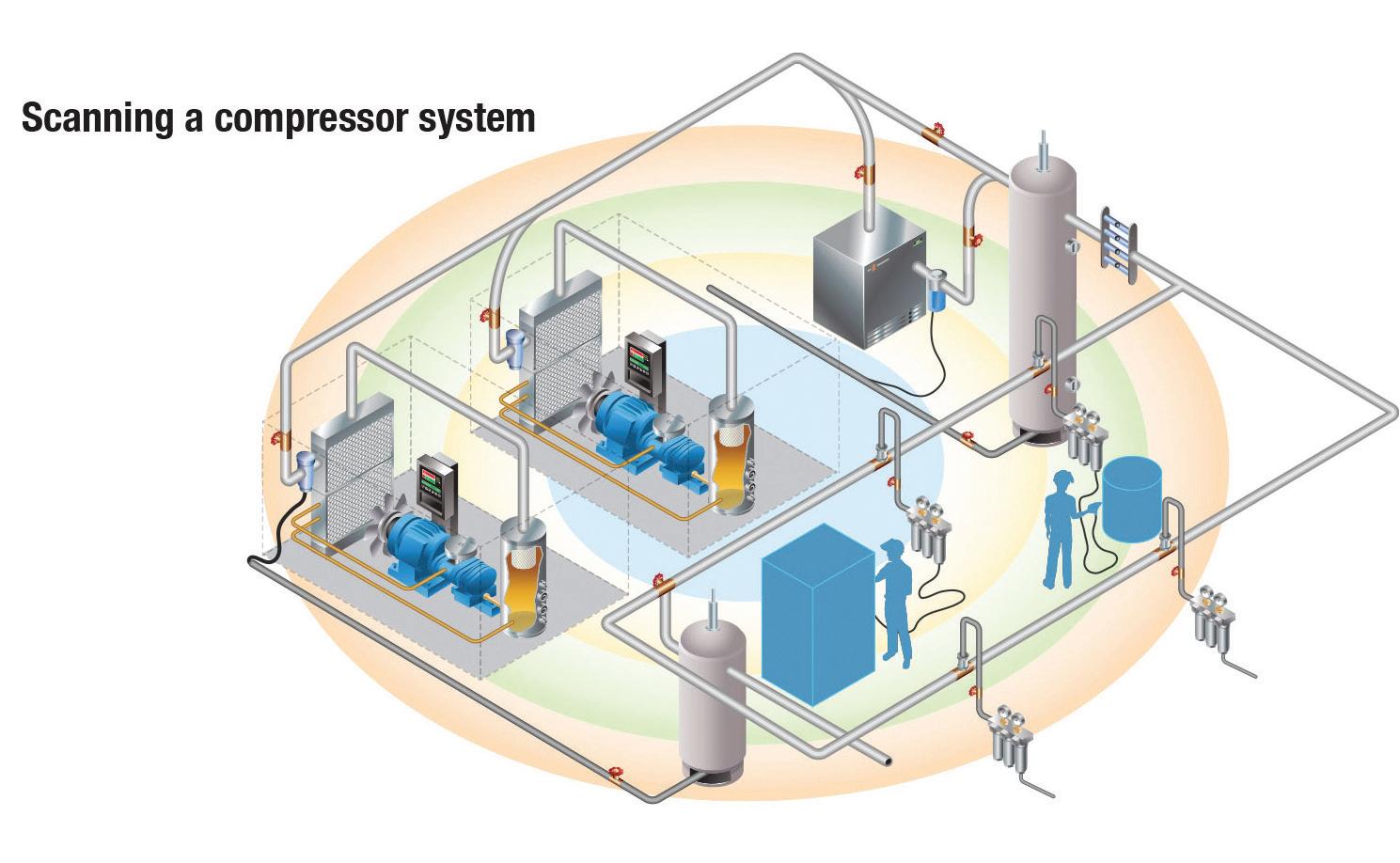

Step 1: Visualize the system; an acoustic imager can visually scan large areas from more than 10 metres away in heavy noise conditions. Scanning from a distance keeps technicians safe around running equipment, and makes finding leaks in hard-to-reach areas possible.

Step 2: Follow the path of the system scanning for leaks. An array of ultra-sensitive microphones expands the field of view so maintenance teams can quickly and accurately locate air, gas, and vacuum leaks in compressed air systems.

Step 3: Isolate the sound frequency of the leak to filter out loud background noise. You will see where the leaks are and be able to estimate their size, which is based on your distance from the leak and its decibel level.

Step 4: Capture and identify leaks for comprehensive reporting. This includes asset tagging and on-screen annotation.

Step 5: Create a comprehensive report, including leak images, asset tags, annotation, estimated leak size, and more—such as how much those leaks will cost if you don’t fix them.

Step 6: Use the report in your workflow management to ensure repairs are completed on high-priority leaks first and all leak repairs are documented.

Step 7: Confirm the repair using the acoustic imager.

Air leaks and the future

Part of the reason air leaks are a big issue is because they are hard to find. Even when found and fixed, new leaks keep popping up—a fact of life due to the wear and tear on equipment over time. Since it can be difficult to find air leaks, most facilities just accept them as a cost of doing business. While it may not be possible to eliminate all leaks, it is possible to substantially reduce their number. That is where an acoustic imager provides its greatest value, and where the future of leak detection is headed. MRO

Javier Irazola is Global Product Manager for the Industrial Imaging group at Fluke Corp. He is leading the launch of acoustic imaging solutions. He has eight years of previous experience in engineering and project management for utility projects in the USA and EU, and three years working for the product innovation department of Fluke Industrial Group.

BY PETER PHILLIPS

Recently, I wrote an article on getting back to maintenance basics. The article discussed maintenance fundamentals and how they affect equipment reliability.

The maintenance department will always have lots of priorities on the plate, but in order to deliver equipment reliability, some basic maintenance battles must be won.

These are not hard battles, they’re not even expensive. However, they take time and a great deal of commitment. These battles are key ingredients that can move the reliability needle in the right direction.

They fall into a few simple categories.

1. Spare part storage;

2. Area improvement boards;

3. Work order planning and scheduling;

4. Work order management;

5. Workshop organization, and;

6. Internal maintenance communication.

Spare part storage

Spare part storage is first for one reason: the time it takes to

implement a functional storeroom. If your storeroom is unorganized, filled with used parts, and looking for a needed part resembles a scavenger hunt, then there is a lot of work ahead. Unfortunately, 50 per cent of all storerooms fit in this category.

An organized and managed storeroom provides the parts needed to maintain the equipment. Technicians need to find the parts they need as quickly as possible; the industry benchmark is 90 seconds. The result is the reduction of overall downtime and equipment availability. A CMMS system tracks parts checking in and out of the storeroom and reorders inventory automatically.

Getting to this point is a labour-intensive undertaking. Spare parts management policies and procedures need to be developed, executed, and maintained. The actual reorganization needs to happen in the shortest time possible. Purging parts, cleaning, and reorganization need to happen quickly, so disruption for the technicians looking for parts is held to an absolute minimum. Assigning the appropriate resources is extremely important to get the organization completed. Storeroom projects often fail because of underestimating the labour and commitment it takes to make the finish line.

The other five categories can be done in any order, but all are equally important.

Area improvement boards (AIB) are developed to improve communications between maintenance and operations. The basic idea of AIBs is to create a sense of ownership between the two

parties for the area and equipment they are responsible to operate and maintain. The end result is better equipment reliability. Unfortunately, the AIB often fails. It starts out with good intentions, but the commitment to train the people on the AIB process, and the role each group plays, is often overlooked, and sustainable processes are not put in place. The AIB can be very complicated with too much information and it can quickly lose its lustre. Many companies have revisited the AIBs to simplify the process, and the goals they were designed to achieve. These modified AIBs give maintenance and production personnel the opportunity to discuss daily what needs to be done to keep the equipment reliable. Their primary purpose is to find and fix problems before they cause production downtime. Every day, the two parties meet, along with others (for example, the area engineer), to discuss repairs and improvements on the equipment. They decide the seriousness of the issue and when the repair needs to be completed. Management supports the process weekly with their attendance at the daily meeting, where the technician and operator present to them the plans for equipment maintenance and improvements. Attending the daily meeting is the highest priority on everyone’s list of responsibilities.

Work order planning and scheduling determine the success of maintenance activities, and their time execution. In recent years, companies have hired maintenance planners with the sole responsibility of preparing everything that will be needed

to complete a job start to finish. With the storeroom organized, work order kitting can be implemented, and all parts can be staged in advance. Weekly work schedules are prepared in consultation with the production department, and a work order schedule is displayed on the work order management board.

Work order management boards are used to organize and display the work assigned to technicians. There are mail slots for every technician, and the work orders are categorized into work needing downtime and work that can be completed when the equipment is running. They also have a project work order slot, and there is a place for opportunity work orders that can be done when a line goes down unexpectedly. Work order schedules are posted on the work order management board, so everyone is aware of today's and this week’s plan. There is a daily meeting held by the planner and supervisor with the technicians to discuss work assignments, work completed, and lessons learned.

Most commonly, companies talk about 5S projects for the maintenance shop. Historical poor housekeeping habits have become the norm in many maintenance shops: dirty floors and walls, benches covered with broken parts, and tools left lying around everywhere. Technicians' personal toolboxes and storage lockers are not near a professional standard. Clean and organized maintenance shops and tool rooms promote a sense of structure, pride, and responsibility, which spills over to the work done out in the plant. Industrial trades are a professional occupation and a 5S workshop improves that mentality.

Internal maintenance communication between shifts, and with maintenance management, is often handled through a simple whiteboard incorporated into the work order management area. Technicians and management post key equipment issues to help the next shift, and to identify major equipment priorities that can affect reliability.

These six categories must win maintenance battles. They do not cost a lot, but they do need commitment, and need a sense of urgency to get them implemented. Companies that have gone down this path and have a sustainable plan to keep them firmly in place, have seen a big increase in equipment reliability. They have won the battle with simple basic things that save thousands of dollars for maintenance, production, and quality every single day. MRO

Peter Phillips is the owner of Trailwalk Holdings Ltd., a Nova Scotia-based maintenance consulting and training company. Peter has over 40 years of industrial maintenance experience. He travels throughout North America working with maintenance departments and speaking at conferences. Reach him at 902-798-3601 or peter@trailwalk.ca.

MRO - DESIGN ENGINEERING - CANADIAN PLASTICS

This one-day tabletop show brings together Maintenance, reliability and asset managers, plant managers, engineering, plant operations and production managers, safety and purchasing managers, from the industries your company is trying to reach…

Automotive • Food Processing • Plastics • Chemical Processing • Mining

• Oil and Gas

• Utilities Aerospace • Custom Fabricators

Why You Should Exhibit.

MEET Face-to-face with buyers and develop new business opportunities.

CONNECT With clients and develop new leads for your business.

PROMOTE Your products and services to an engaged buying audience.

SHOWCASE Your newest product lines and innovations.

ENGAGE In an approachable, friendly atmostphere.

EXPERIENCE Easy and fast set-up and take-down table-top spaces.

PARKING Free on-site.

ENJOY CONVENIENT Location and hours.

Standard Booth

$1,395

• Includes draped table and company listing in all show participation correspondence.

Sponsorship

$3,995 (Includes 20 minute tech talk - workshop)

Limited sponsorship packages (only four available).

• Two skirted tables.

• Preferred table top location.

• Logo on all outbound marketing communications print, online and web site.

• Logo on all event signage.

Booth and Exhibiting inquiries contact: Mike King, Publisher • 416-510-5107 •

PACE Worldwide MT-200

MiniTweez is a thermal tweezer designed to rework tightly spaced microcomponents such as 0201s, 0402s, and 0603s. MT-200 features multi-axis tip alignment capability. Tip-Gap Adjustment Wheel allows operator to match the gap between the tips to the work, reducing grip stress and operator fatigue. MT-200 can also provide safe, rapid removal of much larger chips and components such as SOTs, D-PAKs, SOICs, and TSOPs.

Krohne Optiwave 6500C is a radar level transmitter for powders and dusty atmospheres. It offers continuous measurements in silos, hoppers, and containers.

The radar offers an 80 GHz (FMCW) bandwidth radar and a 70 millimetre lens antenna. It has a measuring range over 100 metres.

Other features include PEEK Lens antennae with concave and convex lenses for distances up to 100m and a large backlit LCD screen with a four-button keypad.

Designed for PACE’s AccuDrive power sources, MT-200 uses Blue-Series tip-heater cartridges that can be changed quickly, and heat up. MT-200 is available as a complete station with ADS200 AccuDrive power supply and Instant SetBack tool stand.

www.paceworldwide.com

SM Instruments BATCAM

2.0 is an ultrasonic and acoustic sound camera that helps identify a variety of undesirable industrial conditions.

With accuracy, the BATCAM 2.0 can measure car BSR (buzz, squeak, rattle), and offers visualization of air, gas leak, and electric arc location. It helps to prevent resource loss and disaster by gas leak, and electric arc diagnosis. It can diagnosis and evaluate noise in industrial sites. www.itm.com/smi-batcam-2-0

TE Connectivity (TE)

HTU31 humidity and temperature sensors are small and accurate.

HTU31’s keeps a linear response curve through humidity (0 to 100 per cent) and temperature (-40°C to 125°C), respectively. Its humidity die structure enables a response time of t63 per cent in five seconds. With condensation the response time is t63 per cent in 10 sec.

HTU31 provides a specific die and IP67 rated sealing with filter options that enable sustained performance, low hysteresis, and precise environment measurement. It is available in two versions: digital offers two I2C addresses, facilitating monitoring humidity and temperature in two locations using a single I2C bus line; it is also available in analogue. www.te.com/sensors

The Optiwave 6500C can be used for bulk storage in mining, minerals, chemicals, power, paper, and food and beverage industries.

www.krohne.com/en

FLIR Systems, Inc. MR277 building inspection system is its first moisture meter with infrared guided measurement (IGM) offering multispectral dynamic imaging technology.

FLIR Lepton thermal imaging sensor powers IGM. Inspectors can streamline diagnosis and documentation by using the built-in Bluetooth to connect to mobile devices running the FLIR Tools mobile app.

MR277 features a 50 per cent larger screen than previous FLIR moisture meter models. A dual-camera system powers FLIR MSX. MR277 can display and record MSX, thermal, and visual images, with storage for up to 15,000 images in the internal memory.

MR277 includes an MR02 removable pin probe in addition to the built-in pinless sensor. MR13 moisture hygrometer is also included.

www.flir.com/mr277

LK Metrology is now in the 3D articulating arm metrology systems space with the launch of a range of 24 portable measuring arms called Freedom.

It's available in a six-axis model and a seven-axis version. Both are available in two accuracy levels, and the four products come in six sizes with a reach of up to five metres.

The six-axis arms for tactile inspection are named FREEDOM classic and FREEDOM select, the former being the entry-level model and the latter the enhanced accuracy version with a calibration bar. The seven-axis arms, in two accuracy versions, are called FREEDOM classic scan and FREEDOM select scan. The touch probing accuracy of all FREEDOM arms is certified to ISO 10360-12 before delivery and may be supplied with a variety of aluminum and carbon fibre probe kits, styli, mounting rings, tripods, rolling stands, and carts.

A notable feature of the arms is the inclusion of absolute rather than incremental rotary encoders to feed back the angular position of every joint to the control software. www.lkmetrology.com

QED Environmental Systems, Inc.

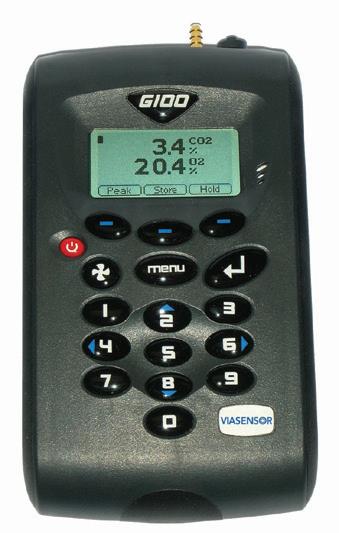

VIASENSOR

G100 series of gas analyzers measure CO2 levels and indoor air quality measurements.

VIASENSOR G100 and G110 monitoring systems come with accuracy, verification of CO2 levels, and large well-lit display. They feature stability with built-in moisture removal, and easy user calibration on the analyzer. There is data storage for 1,000 readings, download capabilities, long battery life, and quick manufacturing and service lead times. Available options include dual temperature, oxygen, and relative humidity capabilities.

Food and beverage operators can use VIASENSOR G150 model for background monitoring and indoor air quality applications to detect the presence of the gas and check for leaks. It detects CO2 ranging from 0 to 10,000 parts per million. www.qedenv.com

Continental introduces new beverage hose, Vintner Reserve 250 EPDM, to the North American market. It is designed

with improved chemical and temperature resistant capabilities for wine, beer, and beverage production.

Vintner 250 EPDM has a working pressure of 250 psi and a 4:1 safety factor. Features of the EPDM tube include higher chemical and temperature resilient, increased strength and hardness, and enhanced abrasion and ozone resistance.

Vintner 250 EPDM hose meets FDA and USDA regulations. It is certified to 3-A 18-02 Standard and monogrammed with certificate No. 3737.

www.continental.com

hawn Casemore has spent over two decades working in and supporting manufacturers. His career spans leadership roles in automotive, packaging, pharmaceuticals, electronics, and power generation and most recently, as the past-President of Excellence in Manufacturing Consortium.

Through his own experiences, as well as those of his clients, Shawn has learned why and how safety plays a critical role, not only in ensuring employee well-being, but also in supporting an engaged and high-performing workforce. MRO

Not sure about you, but if I had a nickel for every time someone in a plant had their safety glasses on top of their forehead, I’d be rich. That said, just because they may have forgotten to put their safety glasses back on doesn’t mean they don’t care about safety. There simply hasn’t been a recent trigger that has convinced them that their glasses are necessary protection.

The good news, however, is that you can make it a priority.

Typical approaches to safety are indirect. Employees are asked to read policies or listen to information about machine or personal safety, and then to take an action, such as wear personal protective equipment or operate equipment in a certain fashion. Often there is no “trigger” to influence them to take, and continue to take, safety precautions.

Consider, for example, our current situation amidst COVID-19. We’ve all been triggered by recent events to wash our hands feverishly, yet I predict that in a year’s time, our diligence around handwashing will have relaxed. It will take another significant reminder for most of us to maintain our handwashing diligence on a long-term basis.

Therefore, the question is, what kinds of triggers make safety an ongoing priority?

The answer? Continuously provide relevant examples that get people’s attention and trigger their desire to work safely. I’m not suggesting you need to put stricter policies or procedures in

place, but rather use powerful examples that suggest why safety is important.

Here is an example.

When I learned to ride a motorcycle, during training there were several graphic videos that influenced my awareness of safety while riding, at least in the early years. As time has gone on, however, I’ve become less aware of my safety, until, invariably, I have some sort of experience that re-triggers my awareness. Maybe it’s a car cutting me off, or the rear tire slipping in the rain. It takes a trigger to reinvigorate my safety awareness.

What are some of the most powerful triggers?

Personal stories by other employees who have had an incident. Videos that demonstrate what can happen when safety precautions aren’t taken. Recent publication of safety incidents that describe the incident, the outcome, and the safety impact.

It may seem that getting employees involved or even interested in safety is somewhat of a challenge, and it is. However, when you use relevant and powerful triggers, you can get people’s attention, and, more importantly, their buy-in for why safety is everyone’s responsibility. MRO

ShawnCasemore