Minnesota dairy expanding

Skyview Dairy is going through some significant expansions as the owners recognize the commercial value of manure as a commodity. 10

Applying with style

Two award-winning farmers talk about their different manure application styles. 16

ISU Farm defeats swine odor through aeration

As an informal odor control experiment, ISU Farm management and researchers added a submersible aeration system to the slurry separation process chain. 18

What’s feedlot manure worth as fertilizer?

Can manure be turned to gold?

Researchers Exploring ways to convert manure gas into fertilizer

Ohio State University and University of Minnesota researchers are studying the feasibility of capturing and recycling ammonia emissions from manure in poultry and swine operations.

Great Lakes Manure Handling Expo a success

Hundreds of livestock and crop farmers took part in the educational sessions and field demonstrations at the 2008 Great Lakes Manure Handling Expo.

Innovations

Guest column: Cover crops: Manure’s best friend

Natalie Rector is a nutrient management educator with Michigan State University Extension. Dr. Dale Mutch is a Michigan State University Extension specialist in field crops IPM and cover crops.

Cover: Loren Keppy of Durant, Iowa, inspects one of his manure tankers.

Published by:

Annex Publishing & Printing Inc. P.O. Box 530 Simcoe, Ontario N3Y 4N5 (800) 265-2827 or (519) 429-3966

Fax: (519) 429-3094

Editor

Margaret Land • (519) 429-5190, (888) 599-2228, ext 269 mland@annexweb.com

Contributing Editors

Candace Pollock, Dr. Dale Mutch, David Ostdiek, Diane Mettler, Natalie Rector, Tony Kryzanowski

Advertising Manager

Laura Cofell • (519) 429-5188, (888) 599-2228, ext 275 lcofell@annexweb.com

Production Manager Angela Simon

Circulation Supervisor Marie Weiler mweiler@annexweb.com

Vice-President/Group Publisher

Diane Kleer • (519) 429-5177 dkleer@annexweb.com

Website: www.manuremanager.com

US Subscriptions:

$37 US one year

$64 US two years

International Subscriptions

$70 US one year

Canadian Subscriptions (GST included)

$37 Cdn one year

$64 Cdn two years

Canadian Publications Agreement #40065710

Return undeliverable addresses to:

Annex Publishing & Printing Inc. P.O. Box 530, Simcoe, ON N3Y 4N5

Reproduction prohibited without permission of the publisher.

Printed in Canada

Setember/October 2008

Volume 6 • No. 5

If the latest newspaper headlines are anything to go by, the state of Missouri is now closed to any new livestock production facilities.

In late August, an associate circuit judge in Missouri’s Cole County Circuit Court made a decision that has left that state’s livestock producers fuming and the Missouri Department of Natural Resources considering an appeal.

The issue? A hog producer in central Missouri wanted to expand his existing operation and house 4,500 pigs on property he owns about two miles from the Village of Arrow Rock (population 79), a national historic landmark along the banks of the Missouri River. The property’s neighbors and surrounding community weren’t enamored with the idea, fearing the operation would discourage tourists from visiting the site. Despite this opposition, Missouri’s Department of Natural Resources approved the operation’s construction permit, which met all of the legal requirements. As a result, several community organizations filed a lawsuit against the DNR, arguing the department was obligated to protect state parks, such as Arrow Rock.

It would appear the judge agreed with them. In the resulting decision, the judge ruled that no CAFO, including the farmer’s proposed operation, be allowed within a 15-mile radius of the village and other nearby historical sites. As well, the judge ruled that “no CAFO can transport, spread or otherwise deposit or dispose of any waste from its operation” within that same buffer zone.

“It basically knocks out CAFOs in the state of Missouri,” state DNR director Doyle Childers is quoted as saying in the Joplin Globe newspaper,

He added that even though the judge’s decision only involved Cole

By Margaret Land

County, the DNR is mandated to treat all counties the same – no permits in Cole County means not permits in all of Missouri.

As of press time, there was still confusion over what this decision actually means to Missouri livestock producers, manure handling and applicator companies operating in the state and even the individual livestock farmer who had applied for the original permit – after all, his existing hog operation is within that new, court-imposed 15-mile zone, along with nine other CAFOs and a research facility.

The Missouri Department of Agriculture’s position is that it’s “business as usual” for state farmers. “Although this narrow ruling raised eyebrows and got our attention, we advise farmers that it is business as usual for Missouri agriculture and have encouraged the Missouri Department of Natural Resources to take action with an appeal,” stated MDA director Don Steen in his monthly director’s column.

In a press release, the MDA suggests that farmers not named in the lawsuit “continue to conduct business in their usual manner.”

I suggest it’s pretty hard to stay in the livestock business if you can’t transport or spread manure. It’s also difficult to plan for the future if there’s uncertainty over whether you can obtain a permit from the local regulating body, in this case, the Missouri DNR.

As one producer so eloquently put it in a Marshall Democrat-News article, “If you can’t spread your manure, then you can’t have hogs. We’re basically out of business.”

Hopefully, the Missouri DNR will soon have its legal team ready to appeal this verdict, the sooner the better.

By Tony Kryzanowski

As dairy businesses contemplate expansion, many now realize they have the means to combat the rising cost of power and commercial fertilizer as part of their growth, given the high volume of manure generated as a waste product from their day-to-day operations.

As a result, they are installing the tools they need to capture maximum value from this by-product.

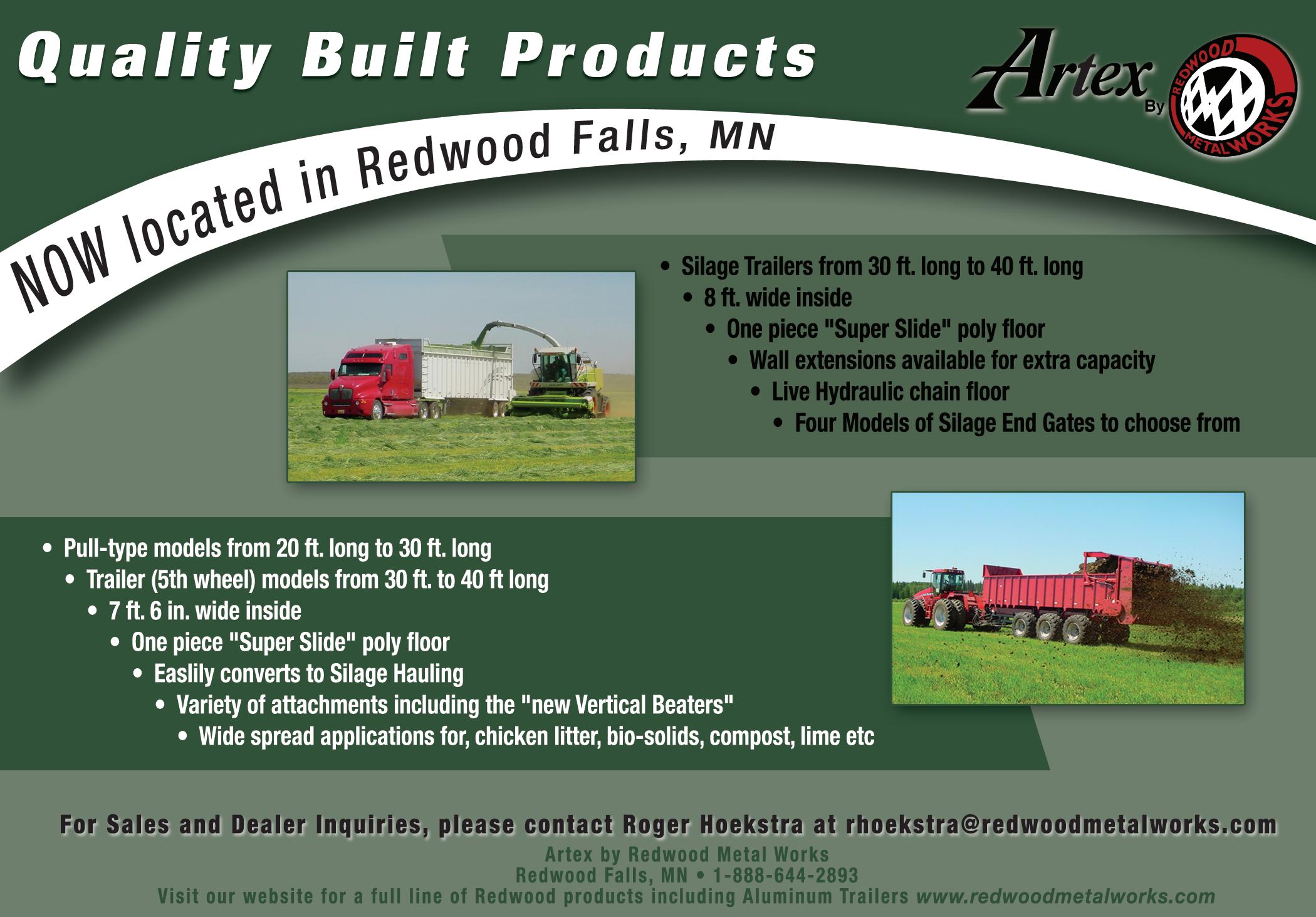

Minnesota-based Skyview Dairy is just one example of a dairy operation going through a number of significant expansions. Tapping into the full potential of their manure resource is one important new aspect of their overall business plan. They recognize the commercial value of manure as a commodity to produce compost, as a fertilizer alternative for their own use, and as a product capable of being sold to neighboring farms.

“If you asked any farmer 10 to 15 years ago about manure, they’d treat it like a waste,” says Skyview Dairy co-owner and assistant dairy manager, Garrett Luthens. “Today, it’s a commodity that people want to buy.”

He adds that as the price for commercial fertilizer rises, based on nitrogen and ammonia applied per acre, so has the price for manure because of its ability to provide those same nutrients, but from an organic source.

Located 60 miles west of Minneapolis-St. Paul, the Skyview Dairy is in the process of adding about 600 milk cows to its existing herd, bringing the total number of milk cows up to 1600. The dairy was established in 1969 by Garrett’s father, Daryl Luthens. He started out with only 11 cows. Today, Daryl has four sons who are partners

The City of Hutchinson will bring out its compost turner about twice a year to process the manure supplied as the raw material by Skyview Dairy so that it converts to compost evenly.

with him in the business. Shane is the general dairy manager, Brandon is the financial officer and treasurer, Justin is the crop manager and oversees the heifer operation, and Garrett is the assistant dairy manager. Given his nearly 40 years of experience, Daryl continues to offer advice on dairy operations and on expansion projects.

A number of building construction projects have occurred at the dairy, particularly since about 2002. Since then, Skyview Dairy has constructed three barns and one parlor positioned in an ‘H’ configuration to efficiently manage milk production and manure collection.

To provide for its feed needs, Skyview Dairy seeds 2,500 acres of alfalfa and corn. Any surplus feed left after each season is sold as a cash crop.

As part of its expansion plans, the dairy expects to make a decision on what style of manure anaerobic digester would best fit its operation within the next two years. At present, it generates between 10 and 11 million gallons of manure annually, which will increase significantly once the current expansion is complete.

Skyview Dairy has already made the transition to using solid waste from separated dry manure for bedding. By using the dry manure solids as bedding the dairy saves about $80,000 annually on the purchase of sawdust. Manure digestion will produce a higher quality bedding product that is reduced in bacteria count. Right now, each barn stall is equipped with a mattress layer, followed by a layer of a lime product that is replenished every couple of days, and then a layer of dry manure solid bedding. The lime product helps to eradicate bacteria on the mattresses and in the manure bedding.

When the dairy made the transition to dry manure bedding, the milk cows began producing milk with an elevated somatic cell count but that has since tapered off. Managing the somatic cell count continues to require management, which is why the dairy owners are looking forward to the day when the manure is processed through a digester and the solids will have a reduced amount of bacteria.

Conversion of a portion of its manure to compost is something that Skyview Dairy is already doing. In summer, surplus separated solids are applied to alfalfa crops after being stockpiled for about a month. However, during the winter months, whatever manure is not used for bedding is stockpiled and converted

Skyview Dairy uses the hand squeeze test to determine if the separated manure solids are dry enough to recycle as bedding.

into compost through a partnership that the dairy has established with the City of Hutchinson, located about two miles away. The dairy stockpiles about 10,000 yards of manure at a time, which is allowed to sit for about a year. During that time, the city brings out a mechanical compost turner a few times to ensure that the manure pile is successfully making the conversion to compost. After about a year, Skyview Dairy delivers the manufactured compost to the city where it is bagged and sold, primarily to nurseries, as an organic fertilizer.

“This relationship with the city is a good one for us because it helps us to maintain good relations with them, being as they are so close by,” says Luthens.

With the encroachment of development all around them, he says the dairy is spending more and more time on public relations and is keenly aware of how its operations may impact upon neighbors. As a testament to their efforts, a neighbor living only 300 yards away from a dairy barn spoke out in favor of their expansion plans because of how well the dairy has been able to manage any offensive odors from dairy or manure spreading activities.

The City of Hutchinson composting program started about seven years ago. Skyview Dairy became involved in the program right from the start. Initially, the manure was being mixed with other biodegradable material collected by the city. Now, the city makes and markets a compost product strictly from the dairy compost and, in turn, the dairy is compensated at a fixed rate per yard of compost.

The manure management process at the dairy starts with a manure management plan submitted to state authorities. The plan directs when the manure will be applied to cropland, how it will be managed and where it will be applied.

The dry manure bedding is scrapped daily into a central gutter that transports the manure to a FAN separator for recycling.

Every day, a skid steer places fresh separated dry manure solids as bedding material in barn stalls. The practice of using dry manure solids saves Skyview Dairy about $80,000 in sawdust costs.

As far as day-to-day operations, Skyview Dairy has established what can best be described as just-in-time bedding production. Starting early in the morning, the dairy starts to process raw manure through a FAN separator, using a squeeze test to determine if the separator is producing manure that is dry enough to use for bedding.

“If you squeeze as hard as you can and no water comes out, it’s dry enough,” says Luthens.

A blower conveys the dried solids over to a storage building, and this process drops the moisture content a few points more. Bedding is changed in the three barns every day and Skyview Dairy has contracted this process out.

Usually by morning, the cows themselves have done a good job of cleaning out their stalls and have pushed a lot of the bedding away into the alleyway so that there is actually very little manure

left on the mattresses. A hired hand uses a fork to clean off any manure left on the mats while the cows are being milked. At the same time, two skid steers work simultaneously to push the manure into a central gutter and also to set down new bedding material. The central gutter is equipped with a chain conveyance system that transports the raw manure to a centralized pit, where the manure is agitated using a Houle agitator and two Patz agitator pumps. This manure is eventually separated to either become bedding or is stockpiled. Luthens estimates that about 55 percent of the manure is recycled daily into bedding while the rest is stockpiled. Once enough bedding material has been manufactured, the settings are adjusted on the FAN separator so that it produces a wetter product that is collected and stockpiled for application on alfalfa crops. This reduces wear and tear on the separator. The extra manure solids are collected and removed to the stockpile daily as the dairy management has found the solids tend to heat up quickly if left standing for more than a day.

The liquids accumulated from the separation process are collected in a reception pit. After four to six hours of constant separation, the pit is full and the liquid is transported using a Patz separation pump to one of two lagoons.

The nutrients in the liquid stream also help the dairy cut its commercial fertilizer costs. Skyview Dairy injects the liquid waste collected in its lagoons as organic fertilizer on its cropland. The dairy uses a Hydro-Engineering drag hose system to inject the liquid manure. Luthens estimates that the dairy only purchases about half as much commercial fertilizer as it would normally need by applying the manure effluent and solids as organic fertilizer.

In future, installation of a digester will also provide the dairy with an opportunity to use the methane gas generated by the digester as fuel in power generation, providing the dairy with its power needs. Any surplus power production will be sold through a local utility. Like the composting operation, power generation saves the dairy money and has the potential to provide another income stream to the dairy business.

The combination of all these initiatives generates more income to support all five dairy owners, and for many modern dairy operations, milk is no longer their only income stream. That’s because the value of the manure byproduct is finally being recognized.

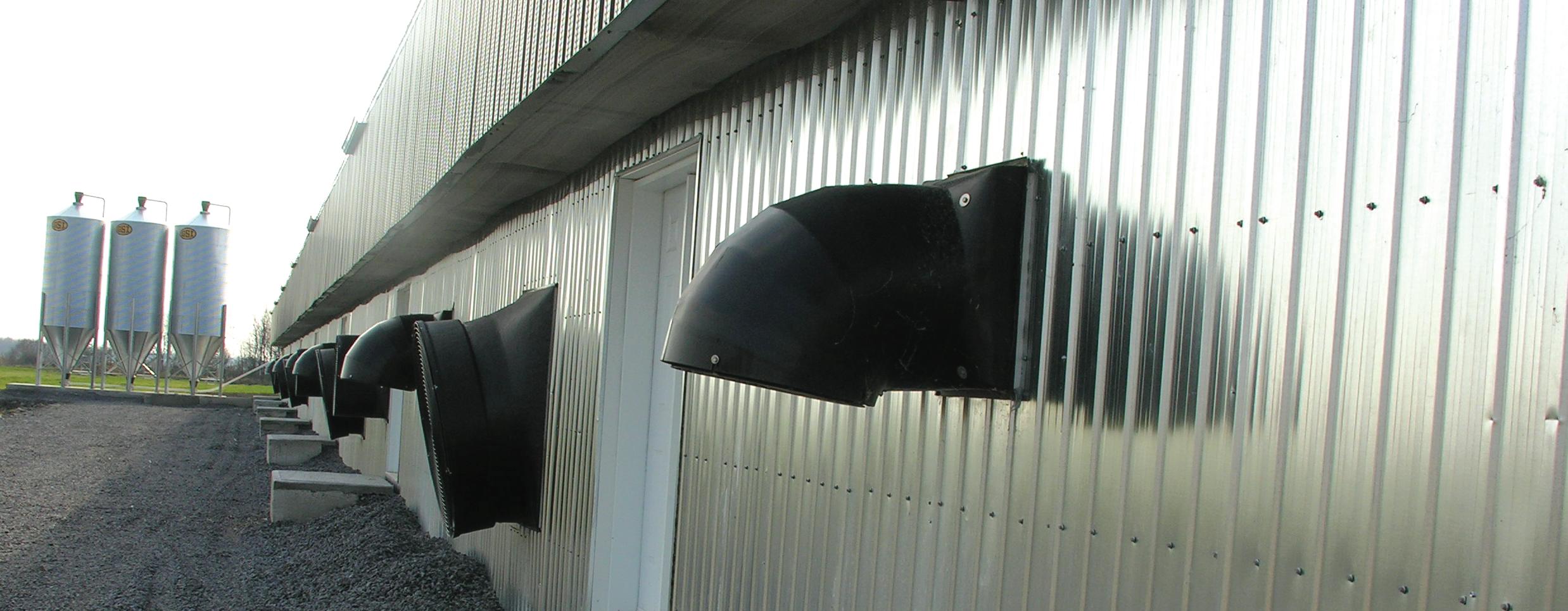

Planting just three rows of trees around a poultry farm can cut nuisance emissions of dust, ammonia, and odors from poultry houses and aid in reducing neighbor complaints, according to scientists from the University of Delaware.

Some of the emissions were cut by almost half, according to Dr. George W. Malone and his colleagues who presented their information at the 236th National Meeting of the American Chemical Society (ACS). Trees also provide farms with the added benefit of reducing energy consumption, he noted.

Dr. Malone, who is an extension poultry specialist with the University of Delaware, points out that trees have been used in the past as aesthetic barriers. His research on giving trees a new role in the poultry industry began in 2000, when residents near farms on the Delmarva Peninsula in Delaware, Maryland and Virginia complained about dust and odors from poultry houses that had recently switched to new ventilation systems.

In the report, Dr. Malone’s team suggested that planting vegetation could reduce ammonia and particulates that may degrade surrounding air and water quality.

“We were aware of the concerns locally,” said Dr. Malone. “We looked at what we could do to address them and the whole area of air quality as it relates to the emission of ammonia from poultry houses.”

In response, they proposed planting trees to serve as a vegetative filter that could capture emissions from these family farms, which individually can house an average of 75,000 chickens. In a six-year study, Dr. Malone and his team found that a three-row plot of trees of various species and sizes reduced total dust by 56 percent, ammonia 53 percent, and odor 18 percent. The approach is being adopted around the Delmarva.

The research showed that as vegetative “filters,” not all trees are created equal.

“We’ve certainly been on a learning curve since 2001 about the different

plant materials suitable for this practice. We typically recommend the first row nearest the fans to be either a deciduous tree or a tree with a waxy leaf surface and the other two rows be an evergreen,” Dr. Malone said. “It’s very important to realize there are a number of criteria that you use in tree selection and planting design. What works for our soil types and climate on the Delmarva Peninsula may not be suitable for other locations.”

Certain species of trees can grow eight to 10 feet per year, Dr. Malone said, which allows for a quick start in creating a buffer. “One initial concern was that it takes years for trees to grow to become effective in filtering out poultry house emissions, but that’s not necessarily the case.”

Trees reduce poultry house emissions by capturing dust, ammonia and odors in their leaves. They also aid in dispersion of emissions, which reduces the impact on neighbors.

Another factor intensifying the need for environmentally friendly agricultural practices has been the rapid growth of residential development in poultryproducing areas. “Planting trees demonstrates that the poultry grower is being proactive to address potential concerns of neighbors, gives the poultry farm a landscape appearance and increases property values. Adding the vegetative buffers also helps to reduce noise associated with farm operations,” he said.

Today, about 35 percent of Delmarva Peninsula’s 2,000 farms have developed vegetative buffers, making this region the first in the country to adopt a widespread comprehensive vegetative buffer program, Dr. Malone said.

The living filter system also has other benefits, Dr. Malone noted. For instance, it conserves energy by increasing shade and cooling in the summer and acts as a buffer to reduce heating costs in the winter.

Not only do trees enhance air quality, they also improve the water quality around poultry farms because they can filter pollutants from soil and groundwater.

By Diane Mettler

Loren Keppy uses a three-bay compost pile to manage his operation’s mortalities, which are mixed with materials he gets from a nearby horse farm and the shavings from a local logging mill.

Iowa’s Kelly Farms and Minnesota’s M&J Farms both received the 2007 Port Industry Environmental Steward Award. They are both contract pig farms, and both are proactive when it comes to manure management. But when it comes to manure application, their individuality shines through.

Loren Keppy’s farm differs quite a bit from Haupert’s. Loren and his father farm a little over 900 acres near Durant, Iowa.

In 1995, Loren built two 1,000-head barns – each approximately 200-feet long by roughly 50-feet wide – for his 2,000 head feed-to-finish operation. He has a pull plug system and under each barn are eight pits, each two feet deep.

“I pull them once a month,” says Loren. “And then we add some fresh water and add Pit Remedy (for odor control). The additive seems to be working well. It helps with odor and it breaks down the solids a little more quickly.”

The additive also helps the manure flow more easily to an earthen basin, which is roughly 150-feet by x180-feet and holds well over 750,000 gallons.

Loren says they pump from the basin once a year in the fall.

“Usually we wait until the soil temperature gets below 55 degrees (Fahrenheit). And we treat (the manure) just like a regular anhydrous fertilizer. We don’t want to lose any of it, and usually the fall is when the time allows.”

Instead of driving tankers down the road, and dealing with traffic, broken hitches and other issues, Loren typically lays a hose from the basin to the field. “Then we’ll put two Houle chopper pumps in the basin, one to agitate and one to pump. The manure is sent directly to the fields and that saves on time and fuel and machinery.”

Manure application on Keppy’s farm is dependent on the crop rotation and the operation’s manure management plan.

Normally, Loren runs the hose out less than mile from the pit and the application will depend on the crop rotation and the manure management plan. Loren uses Kappler Farm Inc., a custom applicator, and they are able to pump between 20,000 to 30,000 gallons per hour and finish the job in about two days.

It’s an ideal process for the Keppy farm. Kappler brings tanks out to the fields, which are constantly being filled from the basin. “We have a load stand in the fields and we just drive under it and load it,” Loren says. “We’ve done it this way for three or four years now. It seems to work the best of everything we’ve tried. It preserves our nutrients and gets the job done quickly, safely and efficiently.”

The farm has experienced multiple benefits from spreading manure, including saving money. “With the price of commercial fertilizer, it makes this an invaluable asset to our farm,” Loren says. “We’re typically saving around $50 an acre. That was last year’s prices; who knows what it’s going to be this next year.”

Keeping odor down is always an issue. Keppy’s farm is only a mile and a half from the town of Durant and about threequarters of a mile from Interstate 80, and neighbors are within a half mile. Despite the close neighbors, he hasn’t had any complaints about odor.

One of the ways the operation has been able to reduce odors is by covering the manure basin with oat straw. “It not only reduces the odors,” he says, “it also preserves the nutrients. Unfortunately, the company that did it has gone out of business. It’s not very easy to find somebody that does that. There’s special equipment to blow big round bales on that.

“There are times when there are odors but we try to keep them down to as little as possible,” he says. “We try to take every step we can.” That includes everything from cleaning up spills to washing down fans regularly.

Another step they take to combat odors is composting. “It keeps any mortality odors down to practically zero,” says Loren.

The farm has a three-bay compost, approximately 36-feet by 12-feet. Loren mixes the mortalities with materials he gets from a nearby horse farm and the shavings from a local logging mill.

“You have to keep the sawdust moist enough to create heat,” he says. “But once you pile it, it really fires.” Within three months, there are no signs of the mortalities and the compost is then used as fertilizer in the fall on the fields, Loren says.

Keppy raises corn and soybeans and, like Haupert, sees better results using the pig manure versus commercial fertilizers.

Manure from the Keppy barns flows to an earthen basin, which is roughly 150-feet by x180-feet and holds well over 750,000 gallons.

“You can tell exactly the line where you stop using manure as fertilizer compared to commercial fertilizer. I think it has to do with all the micronutrients you’re getting in the manure that you just can’t go out and purchase easily.”

Loren says he wouldn’t do anything differently. Although he admits the pull plug system is more labor intensive, he enjoys the better air quality that comes with it.

Mike Haupert, owner of M&J Farms, has been a contract finisher for Christensens Farms for five years. Before that, he worked with his cousin, Jeff Boz, on his nearby 3,000-acre farm.

Mike has a nine-acre site and a large barn – 51-feet x 477feet – to house his 3,120 head. “It’s basically three rooms that hold approximately 1,000 pigs apiece,” says Mike.

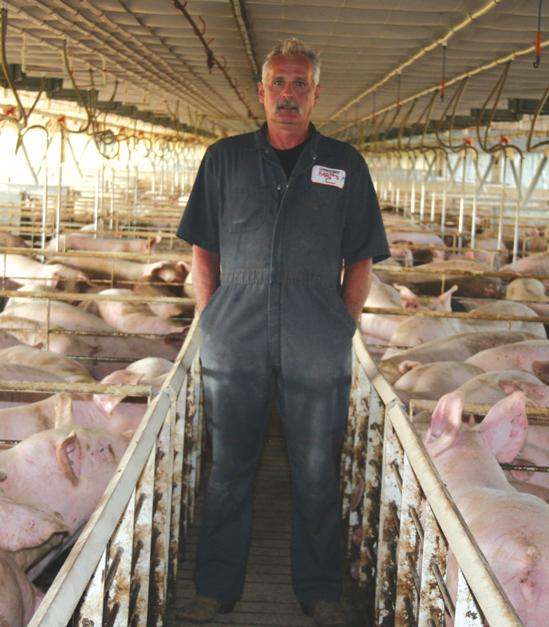

Mike Haupert, owner of M&J Farms, has been a contract finisher for Christensens Farms for five years.

The barn is comprised of three rooms with each holding approximately 1,000 pigs each.

Mike Haupert operates on a nine-acre site with a 51-feet by 477-feet barn, which houses 3,120 finishing hogs.

Odor hasn’t been an issue at M&J Farms, in part because additives are used in the pigs’ feed to keep odors down.

When Mike had the barn built five years ago, there were a number of county ordinances he had to meet, including: being 300 feet from a creek; a half a mile from neighbors; a mile from town, among others. “It was actually kind of hard to find a site that met all the requirements when you started looking,” recalls Mike.

There’s an eight-foot pit running underneath the entire length of the barn. When it’s time to apply — normally once a year — four agitators are placed throughout the pit. Once the manure is agitated, it’s pumped straight from the pit to the fields.

How much to spread and where, Mike says, he leaves up to an expert. “My cousin has an agronomist and we go by everything he recommends. We give him the manure and soil samples and he puts it all together and that’s what we put on.”

Mike uses Scotts’ Liquid Handling out of Tracy, Minn., to do the application. The company has been applying at M&J Farms since Mike started up his operation. “I think last year he pumped about 1,200,000 gallons,” says Mike.

When it’s time to spread Ron [owner of Scott’s Liquid Handling] takes a TerraGator out to the field. “Then Ron loads the semis in my yard and he hauls them out to the field,” says Mike. “He pumps the contents of the semis into a large tank out there. And then the TerraGator just pumps out of the tank. It works pretty slick.”

Mike’s manure plan requires that he apply on 700 acres, and he’s currently applying on around 900 acres on his cousin’s farm just to be safe. All of the acreage falls within one to two miles of Mike’s farm.

Once the manure is applied, Mike goes out and reworks the field — again just to be safe. “We wait about two days, and then we chisel plow the whole field again. And that’s just to make sure that we don’t lose any of the nutrients.”

Crops have improved since they’ve moved from synthetic fertilizers to spreading hog manure, says Mike. “The first year, the corn crop will be between 8 and 10 percent better (using) hog manure than it is (using) commercial fertilizer,” says Mike. “The next year, we rotate the crop with beans, and the beans will be about five percent better than ground that just had commercial fertilizer.”

Mike says the manure from his barn is high in nutrients based on the samples Ron takes. He attributes that to the fact that he doesn’t use much water in his barn for washing. “I’ve got a big pressure washer, so evidentially I don’t use as much water as a lot of other people,” says Mike. “So the manure is pretty high for nutrients.”

Besides being great fertilizer, the situation is also saving Mike’s cousin some money. “I sell it to my cousin for 75 percent of commercial value. That’s kind of a going rate within a mile or two.”

Mike says odor hasn’t been an issue at the farm, in part because Christensens Farms puts some additives in the pigs’ feed to keep odors down. But Mike also does his part as well. He’s planted a number of trees and kept areas wild to buffer the smell. “I think that trees helps a lot because it forces the air up. So it gets up in the atmosphere and dissipates.”

When asked if he would change anything about the system in place on the farm today, Mike says he wouldn’t change a thing. “If I could, I’d expand,” he admits with a laugh.

TAs an informal odor control experiment, ISU Farm management and researchers added a submersible aeration system to the slurry separation process chain.

he large-scale hog farms of today have brought a proportionate increase in environmental issues for this multi-billion dollar segment of the agricultural economy. With some swine operations having hundreds, even thousands, of confined animals in various stages before market, their waste management has become a catalyst for controversy and led some regulators to limit or cease issuing permits for construction of new or expanded hog farms. Some experts even foresee the U.S. Environmental Protection Agency adopting additional regulations affecting established manure management practices.

Researchers at the 610-acre Illinois State University (ISU) Farm near Lexington, Illinois, have been addressing the issue of manure and odor management with a number of demonstration

initiatives at the facility’s 200-sow farrowto-finish unit. The program has focused on polymer-assisted separation of manure solids from the much larger percentage of liquid in manure. Other elements include producing marketable compost from the separated manure solids and using the separated effluent for land application at controlled rates and nutrient compositions on a cornfield.

separation results in removal of up to 98 percent of the solids.

Most recently, the ISU Farm has been experimenting with odor control of the separated effluent in light of complaints from neighboring property owners about objectionable smells.

The operation’s existing manure management program involves a solid-liquid separation system utilizing a polyacylamide flocculent in conjunction with passing the raw slurry through a belt thickener and gravity screen separator. The two-step

The Illinois State University Farm’s program strives to objectively analyze combined solid/liquid separation in tandem with solids composting to control odor and phosphorous contamination as well as to develop instruction materials and to host field days to demonstrate manure management practices for farmers, academics, consultants and government agency educators.

The farm’s composting program converts manure solids into 200 to 400 net cubic tons of compost a year at a 15-acre site. Leaves, yard waste and cattle bedding are added to produce a value-added product sold to homeowners and organic farms, explained Russ Derango, ISU Farm manager.

“In addition to keeping the odor down in the solids, we produce a value-added product that can supplement farm income,” he added.

The cost for composting the manure solids has ranged from $10 to $20 per ton of finished compost. As a comparison,

Researchers at the 610-acre Illinois State University (ISU) Farm have been addressing manure and odor management issues with a number of demonstration initiatives at the facility’s 200-sow farrow-to-finish unit.

the farm can separate processed liquid manure for less than one cent a gallon.

Other research on the farm, which is located in the heart of the U.S. cornbelt, includes the use of raw and separated manure on crops.

Past farm research has shown that applying enough raw slurry to cornfields to achieve yields of 180 bushels/acre reflects a 95-pound over-application of phosphorous. By separating the liquid and solid fractions of the manure and applying the effluent alone, researchers have shown that phosphorous is reduced to a 32-pound acre deficient, making it a non-issue. The N:P ratio shifts from 4:1 for unprocessed raw slurry to a range between 15 to 20:1 in separated effluent. The corn plant requires a 15 to 16:1 N:P ratio.

Dr. Paul Walker, a professor of animal science at ISU, says the ISU Farm can separate processed liquid manure for less than one cent per gallon and the liquid is so clean that clogging does not occur along the center pivot system.

A single nozzle aerator, driven by a 10-horsepower Flygt submersible N-pump, was installed in the farm’s 900,000-gallon Slurrystore to help convert the anaerobic process within the tank into an aerobic environment.

Over the past two years, swine on the farm have produced two million gallons of raw slurry, resulting in 1.8 million gallons of effluent and 200,000 gallons of solids. While the liquid is stored in an above ground storage tank before being used for weekly gutter flushing or applied as irrigation water to crops, the separated solids are condensed into 10 to 12 percent dry matter and combined with landscape waste to produce 200 to 400 tons of marketable compost (see sidebar).

As an informal odor control experiment, ISU Farm management and researchers recently added a submersible aeration system to the slurry separation process chain. A single nozzle aerator, driven by a 10-horsepower Flygt submersible N-pump, was installed in the farm’s 900,000-gallon Slurrystore to help convert the anaerobic process within the tank into an aerobic environment. A Flygt specialist in agriculture arranged for loan of the system.

“A submersible aerator works much better than a surface mixer, which only stirs the liquid and pulls some oxygen off the top but not in significant enough amounts to create the desired aerobic results,” explains Ron Skinner, agricultural market manager for Flygt. “The aeration system used at the farm employs a Venturi effect ejector that pulls air deep into the tank to more fully oxygenate it. That reduces the odor along with the amount of nitrogen as a result of the transfer.”

According to farm management, the additional aeration almost immediately improved the separated liquid, which always retained a certain degree of objectionable odor during prior irrigation use despite being a nearly clear fluid following the separation process.

“Although we didn’t conduct a really scientific trial of the aerated liquid, the addition of aeration within the storage tank delivered an immediate odor reduction in the separated liquid,” said Dr. Paul Walker,

a professor of animal science at ISU. “The field hands noticed it when working on the irrigation system and, equally important, so did the neighboring farmer.

“It clearly passed the sniff test,” Dr. Walker concluded.

A 40-acre cornfield – with 180/bushel yield as the production goal – received the aerated effluent through a center pivot and newly installed underground irrigation system.

Dr. Walker anticipates that public opposition to hog farm odor emissions will result in the U.S. Environmental Protection Agency (EPA) encouraging — through regu-

lation — changes in the customary storage and land application practices. It’s hoped that research conducted at the ISU Farm, including the informal aeration demonstration, can help benefit manure management programs at both large and small swine operations.

“The aeration experiment was less scientific than a practical attempt to overcome the significant odor off the center pivot that was reaching a downwind neighboring farm,” said Russ Derango, ISU Farm manager. “We tried to show here that a swine operation can be a good neighbor.”

By David Ostdiek

Well, probably not gold, but manure is a potential source of extra income for feedlot owners. And right now, there’s a lot of interest in selling feedlot manure to farmers or homeowners as fertilizer, according to Dr. Judson Vasconcelos, a University of Nebraska – Lincoln feedlot nutrition and management specialist based at the university’s Panhandle Research and Extension Center.

Commercial fertilizer is more expensive than ever. Gary Hergert, extension soils specialist at the Panhandle Center, noted at a recent field day that nitrogen prices have more than doubled in the past two years, while phosphate prices have more than tripled. One factor behind fertilizer prices is increased demand, due partly to the growth in corn acreage for ethanol.

Feedlot operations produce a lot of manure – one ton per head per year is the standard rule of thumb, Dr. Vasconcelos says. But how does one put a price on it? One way is to compare it to commercial fertilizer.

Commercial fertilizer lists the types and amount of various nutrients on the label. Two of the most important are nitrogen (N) and phosphorus (P). But manure’s nutrient content can vary from one feedlot to the next, and Dr. Vasconcelos says several factors must be considered when comparing it to commercial fertilizer

First of all, manure is not a balanced fertilizer. Meeting a crop’s need for one nutrient might result in exceeding it for another nutrient. Also, feedlot manure also usually has lower nutrient concentrations than commercial fertilizer, resulting in higher handling and application cost. Feedlot manure also can be a source of weed seeds if it is not composted, Dr. Vasconcelos says.

But manure also has some advantages. In some areas manure is readily available, and feedlots need to remove it regularly. Another advantage is that manure is an organic fertilizer, so not all of its nutrients will be immediately available

for crop uptake. In other words, it is a slowrelease fertilizer.

Dr. Vasconcelos says it is not easy to use manure easily as a source of both nitrogen and phosphorus.

Historically, he said, manure management programs have been based on crop N requirements. But often when manure is applied, the ratio of nitrogen to phosphorus changes, because some nitrogen is lost as ammonia to volatilization during handling, spreading and composting. The result – applying manure based on nitrogen content will result in excess phosphorus, which can cause water contamination.

The bottom line is that University of Nebraska – Lincoln researchers highly recommend that producers estimate manure land requirements based on phosphorus, Dr. Vasconcelos says, adding it is important to know each field’s phosphorus index, which predicts the potential for contamination. The index is based on soil phosphorus levels, potential for runoff and erosion, and proximity to water, among other factors.

“So soil testing is important to determine the nutrients that are really needed for profitable crop production, so we don’t add too much nutrients,” he says.

On the economic side, establishing a price for manure involves a process known as manure replacement value, which bases manure’s value on the cost of using it to replace N and P from commercial fertilizer. Dr. Vasconcelos says Extension educator Tom Holman has performed some calculations using assumptions and averages to suggest values.

Manure’s actual nitrogen and phosphorus content can be determined only by laboratory analysis. But for calculation purposes, Dr. Vasconcelos assumes an average content of 15 to 25 pounds of N (at 70 cents a pound) and 15 to 25 pounds of P (at $1.00 per pound) in a ton of manure. University of Nebraska – Lincoln researchers estimate that about 50 percent of the nitrogen in manure can be used the first year.

These assumptions produce an estimated value of $34 per ton. But remember that not all of manure’s nutrients are

immediately available for crop uptake. So an acceptable manure application rate can be calculated based on the phosphorus content and the assumption that the crop will use 90 percent of that phosphorus during the first year. Dr. Vasconcelos and Holman estimate a manure value of about $25 per ton.

“We don’t really have a magical number to recommend, but these calculations could give us an idea of how much we might charge,” Dr. Vasconcelos explains. “We do think that producers can make some money from manure produced in feedlots through composting or just selling as a fertilizer.”

Historically, area feedlots have charged about $12 to $20 per ton at the feedlot, which is probably a good estimate, considering the nutrients actually used where the manure is spread.

Dr. Vasconcelos also points out that the nutrient profile of manure can vary based on the feedlot diet, so for instance manure produced in one feedlot might not be the same as another where more distillers grains are fed.

The University of Nebraska specialist says the actual price of manure should be negotiated between feedlots and buyers. Manure with higher nutrient content has potential for higher value.

Cost of transportation and distribution are critical, but that information is limited, so Dr. Vasconcelos says it was not considered. Data from a 2008 Nebraska survey indicate a charge of $50 to $75 per hour for loading, and $50 to $150 per hour for hauling and spreading.

For the farmer buying the manure, one key to maximizing its value is avoiding nutrient loss. Immediately incorporating manure at application will result in about 25 percent more available N due to reduced loss of ammonia. But Dr. Vasconcelos acknowledges that is not always feasible to incorporate right away.

David Ostdiek is a communications specialist with the University of Nebraska – Lincoln’s Panhandle Research and Extension Center.

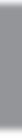

By Candace Pollock

Many farmers are looking to manure application for their fertility needs as a way of combating high commercial fertilizer costs. Now new strides in technology may soon make it possible to capture and recycle gas emissions from livestock waste as an additional source of natural fertilizer, while at the same time improving the environment.

The grant supports four main objectives:

•

Ohio State University air quality and bio-energy researchers, along with researchers from the University of Minnesota, have received a $599,836 U.S. Department of Agriculture National Research Initiative grant to study the feasibility of capturing and recycling ammonia emissions from manure in poultry and swine operations using a new type of wet scrubber (pollution control) technology, and then reapplying the fertilizer on the farm.

“Large amounts of ammonia emissions from animal feeding operations have caused significant environmental and health concerns,” says project director Lingying Zhao, an OSU Extension specialist in agricultural air quality and bioenvironmental control. “The Environmental Protection Agency estimates in 2002 that 2.4 million tons of ammonia were emitted into the air. Meanwhile, soaring natural gas prices have raised questions about the future availability and affordability of nitrogen fertilizer for farming. This project is intended to offer animal producers an innovative tool to reduce air emission impact on the environment while generating an alternative product to commercial nitrogen fertilizer.”

to develop a wet scrubber for trapping ammonia emissions from typical animal manure storage such as deep pits, manure composting facilities or covered manure storage facilities; to evaluate the performance, maintenance and costs of wet scrubbers on commercial farms to assess their practicality and economic feasibility; to explore processes to convert the ammonia captured in the wet scrubber into nitrogen fertilizer; and to educate producers and livestock and poultry professionals on the technology.

Zhao, who also holds an Ohio Agricultural Research and Development Center appointment, says the wet scrubber technology is not new, but the type being used for the purposes of the research is.

Most effective wet scrubbers used to remove gaseous pollutants are known as packed towers, in which air pollutant vapors are absorbed by liquids over the surface of packing material.

“Packed towers, however, cause significant pressure drop and energy consumption and don’t operate well with agricultural ventilation fans, which normally move large amounts of air at lower pressures,” says Zhao. “They are used in Europe for smaller farm operations, but when you are talking about large animal facilities with many fans, the cost to install the packed-type wet scrubber does not make the technology feasible.”

Zhao and her colleagues have been focusing on a spray-type of wet scrubber that operates by capturing gas in water/ acid liquid droplets normally sprayed in the device. The ammonia gas is transferred to the liquid via air being passed through, and then recycled. Such wet scrubbers are generally used to collect dust particles and not gaseous pollutants, and are of lower efficiency than packed towers.

Researchers are working to improve on the technology and optimize the design to increase the scrubber’s efficiency. They developed a prototype of the scrubber in the lab, collecting 70 to 90 percent of ammonia emissions depending on the operating conditions, and are now interested in testing the prototype in the field.

“From our results in the lab, we see the potential the scrubber has on an animal farming operation,” says Zhao. “Scrubber technology is complex. What we want to do is create a small-scale scrubber applicable to a farm. If a composting facility generates approximately 100 tons of ammonia annually, and the scrubber is efficient, even at only 70 percent collection efficiency, 70 tons of ammonia can be collected and recycled for use on the farm.”

The three-year grant is part of USDA’s Cooperative State Research, Education, and Extension Service air quality competitive grants program. The USDA has awarded $5 million to 11 universities to conduct air quality projects aimed at developing and evaluating emission control technologies.

Hundreds of livestock and crop farmers descended on rural central Ohio in early July to take part in the Great Lakes Manure Handling Expo.

The event was held at the Molly Caren Agricultural Center in London, Ohio, and was spearheaded by five land-grant universities – Ohio State University (OSU Extension and the Ohio Agricultural Research and Development Center), Michigan State University, Purdue University, Penn State University and Cornell University. Other organizers included Ohio Composting and Manure Management, and the Midwest Professional Nutrient Applicators Association.

The theme of the expo was The Economics of Recycling and included commercial field demonstrations, educational demonstrations, educational sessions, and commercial vendor displays.

application and the bottom line, safety precautions in manure application and storage, and case studies from farmers who shared their stories about manure management.

Educational demonstrations held during the event included solid manure application rates, liquid manure applications rates, preferential flow, calibration of manure application equipment, stockpiling best management practices, compaction, slurry seeding and equipment safety.

Session topics included calculating the value of manure nutrients, the benefits of proper equipment calibration, the importance of accurate recordkeeping, how communication among applicator, producer and regulatory agency can improve

Expo participants also had an opportunity to view the latest manure management equipment in action, including both solid and liquid manure spreaders, and chat with more than 50 different equipment and service providers who exhibited during the one-day event.

Planning is already underway for next year’s manure handling event, the Upper Midwest Manure Handling Expo, set for July 22, 2009 at the Central Iowa Expo Center near Boone, Iowa. Be sure to visit http://www.abe.iastate.edu/wastemgmt for regular updates as they become available.

Top: Expo participants had an opportunity to chat with more than 50 different equipment and service providers who exhibited during the 2008 Great Lakes Manure Handling Expo. Left: Hundreds of livestock and crop farmers took part in the 2008 Great Lakes Manure Handling Expo, held near London, Ohio in early July. Middle: Natalie Rector, a nutrient management educator with Michigan State University Extension, works with some volunteers to determine the application rate and calibration of a solid manure spreader during the 2008 Great Lakes Manure Handling Expo. Right: A small crowd gathers to learn about solid manure spreader calibration during the 2008 Great Lakes Manure Handling Expo. Bottom: Kevin Elder, executive director of the Ohio Department of Agriculture’s Livestock Environmental Permitting Program, explains the five W’s of manure application records during the 2008 Great Lakes Manure Handling Expo.

September 30-October 4, 2008: World Dairy Expo, Alliant Energy Center of Dane County, Madison, Wisconsin. Visit www.world-dairy-expo.com.

October 6-8, 2008: 8th Annual BioCycle Conference on Renewable Energy From Organics Recycling, Madison Marriott West, Madison, Wisconsin. Visit www. jgpress.com/conferences1/conferences1. html

October 14-16, 2008: Professional Dairy Producers of Wisconsin (PDPW) Nutrient Innovation & Technology Tours, across Wisconsin. Visit www.pdpw.org

October 14-16, 2008: Energy From Biomass and Waste Conference, David L. Lawrence Convention Center, Pittsburgh, Pennsylvania. Visit www.ebw-expo.com

October 21-23, 2008: 2008 National Poultry Waste Management Symposium, West Des Moines Marriott, West Des Moines, Iowa. Visit www.ces.ncsu.edu/ depts/poulsci/poultry_waste_symposium. html

October 21-24, 2008: Professional Dairy Managers of Pennsylvania 2008 Dairy Tour to Colorado, across Colorado. Visit www.pdmp.org/cDT_itinerary.htm.

October 31-November 8, 2008: Farmfair International, Northlands AgriCom & Northlands Sportex, Edmonton, Alberta. Visit www.farmfairinternational.com

November 8-21, 2008: North American International Livestock Expo, Kentucky Exposition Center, Louisville, Kentucky. Visit www.livestockexpo.org

November 12-13, 2008: Cornell University Fall Dairy Conference, Holiday Inn, Liverpool, New York. Visit www.ansci. cornell.edu/prodairy/health/conference/ index.html

November 11-13, 2008: Wichita Farm and Ranch Show, Kansas Coliseum, Valley Centre, Kansas. Visit www.tradexpos. com.

November 14, 2008: Energy Generation Using Anaerobic Treatment of Livestock Waste, Da Vinci Building, University of California, Davis, California. Visit www.extension.ucdavis.edu/engineering.

November 24-29, 2008: Canadian Western Agribition, IPSCO Place, Regina, Saskatchewan. Visit www.agribition.com.

December 2-5, 2008: Amarillo Farm and Ranch Show, Amarillo Civic Center, Amarillo, Texas. Visit http://www.farmshows. com.

The Ag Carbon Markets Working Group (ACMWG) recently launched a new website aimed at helping farmers understand the potential financial benefits of climate legislation currently pending before Congress.

Under the Lieberman Warner Climate Security Act, which is now before the Senate, U.S. agricultural producers could receive billions of dollars annually from offset markets or choose to participate in a U.S. Department of Agriculture carbon conservation program funded by the climate market. These new markets are not assured as the final bill has not passed the Senate floor, and the House has yet to announce their own version of a climate bill.

“Our website will help farmers better understand the value of agriculture offsets like methane capture and soil carbon sequestration,” said Laura Sands, coordinator of the Ag Carbon Markets Working Group. “(It) is a resource driven site that hopes to pull all of the material about ag offsets into one location to make it as easy as possible for interested parties to learn more.”

Current estimates of U.S. greenhouse gas markets indicate that U.S. farms have the potential to mitigate as much as 40 percent of the nation’s total climate impact with practices such as soil carbon sequestration or methane capture. www.agcarbonmarkets.com

American Alternative Energy Systems Corp. (AAESC), a company involved in renewable energy systems, recently concluded an agreement to grant Canadian rights to its anaerobic digester system to Canadian Alternative Renewable Energy Systems Inc. (CARES).

American Alternative Energy Systems will receive $1 million for the initial rights and three percent of all sales generated by the anaerobic digester system. Plans were to have systems in operation at selective sites throughout Canada by May 1, 2008.

The digester market is small in Canada with an estimated 10 digesters compared to roughly 100 in the U.S. and 2,400 in Europe. AAESC’s goal is to become Canada’s market leader in digesters. www.arenergysystems.com

The soil fertility web site at Iowa State University Extension has a new look. The Iowa State University Agronomy Extension Soil Fertility web site has undergone a recent redesign. Part of the web site’s overhaul includes implementation of a new section located on the home page called Current Topic. In this section, extension staff will contribute timely articles on current soil fertility and nutrient management issues in Iowa crop production. The most recent article will be posted on the home page, as well as links to the past three articles. To read the full article (PDF format), simply click on the Read on link. To read one of the Recent Current Topic articles, click on one of the three listed article links. The Past Current Topics section has a link leading to a listing of all Current Topic articles. Visitors are urged to check back often to find new articles and to look for other information related to soil fertility

and nutrient management.

www.agronext.iastate.edu/soilfertility

Puget Sound Energy officials recently announced they had reached a memorandum of understanding with Farm Power Northwest, LLC, of Skagit County to develop a dairy digester facility to produce electric power from manure.

PSE, in conjunction with Farm Power founders Kevin and Daryl Maas of Mount Vernon, signed the agreement as a first step toward the generation of up to 1.5 megawatts (MW) of electric power – enough to meet the needs of 1,000 households. Under the agreement, PSE will purchase electricity generated by Farm Power as well as the associated renewable energy credits resulting from the renewable energy source.

At present, Farm Power has manure commitments from four dairy farmers west of Mount Vernon and is permitting a site located near them. The manure will be used in the generation of power by warming it in the digester to spur microbes to produce methane gas. The methane then fuels electrical generators, with the excess heat being used to warm additional manure and continue the electrical generation cycle.

In addition to the expected 1.5 MW of electricity, byproducts will include sanitary bedding for use with dairy cattle and a more environmentally compatible liquid fertilizer to be stored in the farms’ holding lagoons. Compared with unprocessed manure, the nitrogen in this liquid is easier for plants to absorb and is less likely to mix with rain runoff. www.FarmPower.com

Lincoln Burton, state conservationist for the USDA Natural Resources Conservation Service (NRCS) in California, recently announced statewide distribution of conservation cost share contracts has been completed for fiscal year 2008.

According to Burton, 1,078 farmers and ranchers are receiving contracts totaling nearly $39 million under the Environmental Quality Incentives Program (EQIP). “Agricultural producers work hard to find the best ways to be economically and environmentally sustainable,” says Burton. “EQIP helps us combine the vital work of conservation planning for the landscape with an economic assistance tool to implement needed improvements

on a scheduled timetable.”

Some of the most popular conservation improvements funded this year include air quality improvements (e.g. cleaner engines and dust control on farm roads), and nutrient planning and management on dairies. An NRCS spokesperson said $5.7 million was awarded for manure management, with the vast majority going to dairy projects. This includes manure transfer lines, waste storage facilities including liners and covers, and separators. Additionally, technical assistance helps farmers put together a plan for how to separate, store and

apply the liquid and solid portions of the manure to be profitably used as fertilizer on cropland. Funding overall in California decreased 19 percent due to the expiration of key programs in the 2002 farm bill that had funded the Klamath Basin and other ground and surface water projects. Consequently, EQIP funding was lower in almost every county in California.

XACT Systems proudly introduces the high efficiency Centrisys Dewatering System to the agricultural market.

The XACT Systems Centrisys Dewatering System is an industrial centrifuge manufactured since 1987 with units operating around the world in municipal, food processing and industrial applications. Now, dairymen can access this same high performance dewatering technology to separate solid manure from the liquid.

Recent tests on a large dairy showed the XACT Systems Centrisys Dewatering System removed an average 77 percent of solids from the liquids (documented by certified laboratory) and an average of 62 percent of the phosphorus from the liquids. This percentage of solids removed is well above industry norms.

By removing the majority of the suspended solids, dairymen may never again need to use a dragline to clean out settling ponds, providing substantial savings. Farmers may even be able to virtually eliminate settling ponds.

The small amount of solids remaining in the liquid should break down quickly in the wastewater lagoons. Much of the odor coming from these lagoons comes from the large volume of decaying solids. Reduced solids in these lagoons should mean reduced odor, happier neighbors, state, county and air quality regulatory people.

The XACT dewatering system will have a huge impact on large farms, particularly dairies experiencing phos-

phorus problem. With XACT Systems Centrisys Dewaterer’s ability to remove phosphorous, more liquid manure can be applied per acre without adding more phosphorous to the soil, even close to the barn where one usually finds the greatest amount of phosphorous build up in the soil.

With escalating energy costs, being able to land apply twice as many gallons, or more, of liquid manure per acre is a huge savings since the manure does not have to be pumped or trucked miles away from the dairy to be land applied. This savings will grow annually as energy costs increase.

www.xactsystemscomposting.com

StormFisher Biogas announced recently it has formed a strategic partnership with Denham Capital Management, a Bostonbased private equity firm, to develop a $350 million portfolio of biogas projects. The partnership is projected to bring about a reduction of greenhouse gases equivalent to removing approximately 26,000 average-sized cars from the road.

StormFisher’s president, Bas van Berkel, said the firm will seek biogas projects – at any stage of development – across North America, and will consider acquisitions as well.

StormFisher intends to develop a portfolio of about 30 biogas projects across North America over the next five years. Power projects are expected to be between two and five megawatts in size, while natural gas projects are expected to deliver between 150,000 and 350,000 MMBtu per year of pipeline quality natural gas. StormFisher’s first three development projects, which are all located in Ontario, Canada, will break ground in late 2008 and be operational by Fall 2009. www.stormfisher.com

With warm weather, barn managers are

dealing with another pesky fly season. There are many methods of fly control on the market, but the best way to keep the flies under control is to break the breeding cycle. To make flyspray systems more economical, www.flyspray. com was launched, an Internet sales site and call center for designing and technical support for installation of flyspray systems.

This company allows consumers to save money on Automagic flyspray systems and refills by making the installation and refill process a do-it-yourself procedure. With a quick consultation over the phone, staff will design a custom flyspray system and guide customers through the installation process. With this detailed information, the system can be installed in as little as one hour. Only a few tools are needed for installation. www.flyspray.com

Green Lubrication Solutions™ (GLS) is joining the nation’s growing number of companies offering products formulated for minimal impact on the environment.

The company is the exclusive western U.S. distributor of a unique line of lubrication and engine enhancement products – MotorSilk™ and LubriSilk™ – that provide an easy-to-implement option for those looking to “go green” and use less oil.

MotorSilk and LubriSilk can treat farm vehicles, equipment, and related machinery using a patented lubrication technology invented at the U.S. Department of Energy labs (originally formulated as an extreme conditions lubricant suitable for the rigors of the NASA space program). These products increase energy efficiency in engines, reduce emissions, save gas and lubrication oil use, and can even be used to obtain carbon credits. They are also fully biodegradable and non-toxic.

Unlike typical oil additives and lubricants, these GLS products require only one treatment to provide long-term engine benefits. They bond to engine

➤ Manure Pits,Channels & Covers

➤ Suspended Slabs - up to 40’ clearspan

➤ Hog & Cattle Slats - up to 25’ clearspan

➤ Weeping Walls - manure separation

➤ Milking Parlors

➤ Strainer Boxes

➤ Commodity Storage

➤ Bridges

➤ Bunker Silos (8 types)

➤ Syloguard Concrete repair

➤ Retaining Walls

➤ L & T Walls up to 16’ high

• Built to engineers’ specifications

• All sections are high strength, pre-stressed,reinforcedconcrete for longer life

• Quick & easy to build

• Air-tight seals and protectant using Syloguard products

metal surfaces to greatly decrease friction, increase power and gas mileage, and cut down on wear, which all combine into long-term maintenance cost savings. For farms with multiple vehicles, the long-term aggregate savings can be enormous.

www.greenls.com

Kenworth Truck Company recently expanded into the Class 5 market with the introduction of the Kenworth T170 model.

The Kenworth T170 is a straight truck in a 4 x 2 configuration with a gross vehicle weight rating (GVWR) up to 19,500 lbs. Standard features include the PACCAR PX-6 engine rated at 200 hp and 520 ft-lb of torque, 8,000 lb. front axle and 11,500 lb. rear axle, hydraulic brakes, low-frame height chassis with 19.5-inch wheels and tires, power door locks, passenger-side electric windows (optional on drivers side),

and Kenworth DayLite doors with right-hand peeper window. Customers can choose a manual or automatic transmission.

The T170 incorporates a single-piece, painted steel bumper, located forward of the hood to help reduce impact damage, and new Metton quarter fenders for additional durability and impact resistance. The new sheet-molded composite (SMC) hood offers superior access to the engine compartment with 90-degree hood tilt for ease of service. New halogen projector low beam headlamps provide up to 30 percent more light down the road and three times longer life than sealed beam headlamps. The Kenworth T170 also comes with a steel battery box and ABS cover, heat-treated frame rail, and a 35gallon, steel rectangular fuel tank.

Inside, the Kenworth T170s ergonomically friendly dash features a wrap-around instrument panel with large,

easy-to-read, gauges. Key options include a telescoping and tilting steering wheel, workstation with two 12-volt power ports for laptops or printers, optional corner windows to aid in backing and negotiating tight spots, and an electronic shift module.

www.kenworth.com

BioEnergy Solutions of Bakersfield, Calif., has launched the state’s first biogasto-pipeline injection project in Fresno County, located in central California. The project is using renewable natural gas derived from animal waste at a PG&E site.

David Albers, president of BioEnergy Solutions, says the project, located in the town of Riverdale, uses manure from 5,000 milk-producing cows and calves at Vintage Dairy. The biogas is upgraded, or “scrubbed” to remove corrosive materials to meet PG&E’s environmental standards for power plants and then delivered to PG&E through the utility’s pipeline.

But transporting and marketing methane through pipelines requires that it meet safety and quality standards. Since virtually all biogas contains significant amounts and varieties of impurities that must be removed before pipelines will transport it and customers will accept it.

That’s where SpectraSensors gas moisture analyzer comes in.

“We are using these moisture analyzers to monitor moisture in the methane,” explains Albers. “And of course, we’re checking for hydrogen sulfide content and carbon dioxide content.”

The SpectraSensors TDL-based gas analyzer uses laser (light) absorption spectroscopy to identify and measure one or more gases in a flow of mixed gases. As the laser light passes through the gas sample in the cell, the presence of any target gas is detected and its concentration measured. Typically, this type of analyzer is “tuned” to monitor a target gas (e.g. H20, CO2, H2S) by monitoring the absorption of light at wavelengths specific to the target gas.

The SpectraSensors gas moisture analyzer line is designed to provide extremely fast and accurate readings without expensive labor and replacement costs.

www.spectrasensors.com

The Goodyear Tire & Rubber Company recently introduced a new Kelly Armorsteel KRH regional tire for pickup and delivery trucks. Available through Kelly dealers and truck stops, the new rib tire was developed for uniform and long-lasting wear in regional applications. Available in 11R22.5 and 11R 24.5 sizes in an H load rating, the tire has an enhanced belt package for multiple retreads.

Bruce Woodruff, marketing manager for regional and light-truck commercial tires, said the Armorsteel KRH tread pattern provides superb traction on wet and dry roads, as circumferential grooves and lateral blading help displace water from under the tire, allowing for confident driving in wet conditions.

Special tread compounding helps the tire resist “tread scrubbing and curbing in tight turns,” said Woodruff.

www.kellytires.com

General Environmental Science Corp., a world leader in the manufacturing of environmentally beneficial bacteria, is now marketing direct to hog farms nationwide, providing producers with easier access to manure management technologies.

For 35 years, GES Corp. has been a world leader in the bacterial treatment of wastewater. The company is now marketing its LLMO S-1 live bacteria formula – a broad-based product used to hydrolyze a wide variety of organic solids – to small- and medium-size hog farms nationally, at a factory-direct price with freight paid. LLMO S-1 can help reduce odors and liquefy hog manure pits to make pumping substantially easier.

For more information, contact Frank Young, national sales manager, at 800-234-9686.

www.generalenvironmentalscience.com

Bobcat recently introduced the S70, the smallest model in the company’s line of skid-steer loaders. It replaces the model 463.

The S70 is 71.4 inches high, 35.4 inches wide and 75.5 inches long without an attachment, making it useful for work in tight jobsites. The S70 can fit in many areas where other equipment cannot, such as the confined space of barns.

The S70 has a rated operating capacity of 700 pounds and is powered by a 23.5-horsepower diesel engine that powers a fully hydrostatic, four-wheel drive system with a travel speed of 6.1 miles per hour and an operating weight of 2,845 pounds.

The S70 incorporates new features, including an updated engine mount, hydrostatic pump centering and belt drive system. The new engine mount reduces vibration in the machine for greater operator comfort. The new hydrostatic pump centering is based on a similar setup in Bobcat mini track loaders and uses a tension spring instead of a torsion spring.

The new belt tensioner features a simpler design that uses technology from larger Bobcat loaders. A micro, serpentine-style V belt is used in the new belt tensioner system.

The S70 has a transversely mounted engine and a tip-up cab for easier access when the machine needs to be serviced. The center-mounted, maintenance-free chaincase allows the S70 to travel through deep mud and other areas more easily because of its keel-shaped belly pan. The axle housings are fixed and welded to the chaincase, eliminating maintenance related to tightening bolts or other chain adjustments.

The S70 includes the Bob-Tach™ attachment system and a 14-pin attachment control kit. Bobcat provides 35 attachments that can be used on the S70. These attachments assist customers in a number of markets, from buildings and grounds to construction and landscaping, in performing a variety of labor-saving tasks. www.bobcat.com

Tier III certified engine power is now available on the Case 410, 420, 430, 435, 440, 445, 450 and 465 skids steers, meaning increased in horsepower across the board. The net horsepower for the line now ranges from 57 to 83 (42 to 62 kW).

The 410 Series 3 is powered by an ISM 2.2-liter turbocharged engine. The 420, 430, 435 and 445 Series 3 machines boast Case 3.2-liter turbocharged engines. And the 440, 450, and 465 Series 3 skid steer loaders are powered by a 4.5-liter turbocharged Case engine. In addition to Tier III certification, these new engines provide improved torque.

On the interior, a suspension seat comes standard, while a new cushioned lap bar with armrest and new ergonomically designed control handles provides more comfort and space when operating the machines. The parking brake has been relocated to the handle and the foot throttle is now standard on all models, allowing operators to easily control RPMs.

On the exterior, industry-exclusive side lighting provides full visibility to the sides during nighttime operation. A standard overhead window with more punch-outs than previous models provides outstanding visibility to the loader arms when the bucket is in the raised position. The loader tower profile has also been redesigned to provide better visibility while operating.

The new Case 400 Series 3 skid steers feature improved oil and fuel filter access, a wide-fin side-by-side radiator and oil cooler, a no-maintenance fan belt (420, 430, 435 and 445 Series 3 models) and an automatic belt tensioner (440, 450 and 465 Series 3). Battery-disconnect and remote-jumpstart terminals are standard on all models, with the exception of the 410 and 420.

All Case 400 Series 3 skid steer models are built to start

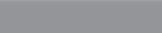

Tired of wasting time and energy running back and forth from the slurry tank to the agitation pump?

Would you like to control the agitation pump from the comfort of your tractor cab and not have to get out in the elements to make those extra trips?

Now you can with REMOTE LOAD! Control your agitation pump with a convenient hand held remote. Just pull your tank under the load stand, push a button and ll. When full, push another button and head back to the eld. It’s that simple!

Instead of hiring someone to turn your agitation pump on and off, Get REMOTE LOAD!

It works 24/7 and never takes a break.

in colder temperatures. A larger, 1125 CCA battery (32 percent more powerful than previous models) and glow plugs on the 410, or a grid heater on all other models, are standard. The massive, heavy-duty radiator and air cooler are sized for high-flow auxiliary hydraulics as well as operation in extreme temperatures with 10 fins per inch, four rows deep. www.caseih.com

Caterpillar introduces the completely redesigned 906H and 908H compact wheel loaders.

A key feature of the new machines is a universal coupler that accommodates most Cat® skid steer and multi terrain loader work tools. The coupler extends the versatility of the compact loaders and makes it easy to integrate them into a fleet of Cat machines.

A Cat C3.4 engine with ACERT® technology powers both wheel loaders. The engine in the 906H is rated at 70 net horsepower (52 kW), while the 908H version delivers 80 net horsepower (59 kW). The C3.4 meets EPA Tier 3 emissions regulations.

Other features include an oscillating chassis, standard differential locks in both axles, Z-bar linkage, and an enhanced hydraulic system. This increases the 906H’s lift capacity (with forks) by 15 percent over the model it replaces. The rated operating load for the bucket on the 906H has been increased by seven percent.

Both models can be equipped with a variety of options, including high-speed (increases top travel speed to 22 mph), a ride control system, and a 33-gpm, high-flow hydraulics system.

Operators can work comfortably and productively in the 906H and 908H whether the machine is equipped with a canopy or cab. A 906H with cab is 8 feet, 1 inch (2465 mm) tall, so the machine can work in more areas, including tight spaces and indoor environments. Both models offer spacious operator stations, excellent visibility, and low-effort, intuitive joystick controls to reduce fatigue. An easy-to-read digital display cluster keeps the operator informed about system conditions.

Maintenance points are grouped together and accessible from the ground. These include a swing-out hydraulic oil cooler, vertical spin-off fluid filters, S O S valves and pressure taps, and an Electronic Technician port. www.cat.com

JCB recently reworked its Series II skid steers and track loaders, which feature better operator comfort, performance and controllability. The new and improved Series II also includes an all-new 1800-pound class skid steer loader, the 180. Other models include the JCB 160, JCB 170, JCB 180T, JCB 190, JCB 190T, JCB1110 and the JCB 1110T.

The Series II features:

• 50, 60, 84.5 and 92.5hp gross engine power models

• A low-slung loader arm

• An endurance-tested steel structure

• An industry standard quickhitch

• A single chain case for easy maintenance (JCB 160, 170 and 180)

• Hydrostatic transmission

• Creep speed option

• Two speed models (JCB 190, 1110)

• ROPS and FOPS certified cab

• Easy access to all components

• Excellent all-round visibility

• Grouped filters and services

• A lifetime warranty

A wide range of tire options is available for the Series II, including standard pneumatic and extra-high flotation tires for low ground bearing pressure. www.jcb.com

John Deere recently introduced two new additions to the company’s skid steer family – the 313 and 315. Both feature the same design as the rest of the line and continue the 300 Series commitment to stability, visibility and serviceability.

A key feature of the 313 and 315 is the radial lift boom, a design that is preferred by customers who work in enclosed areas for super compactness. The bucket rests close to the machine when in the down position and swings forward for great

reach in the four to five-foot range. Cushioned bucket and lift cylinders provide smooth deceleration at the end of the boom lower position, also cushioning the bucket when curling and dumping a load. This feature provides less noise and reduced material spillage in any operation.

A 60:40 weight distribution provides a balance of power and maneuverability, while the 360-degree visibility offers uninterrupted views to the sides, both above and below the lift arms, so the operator can see the tires and ground around the machine with the boom in the rest position. The low-sloped rear hood provides good rear visibility, even on a radial lift-style machine.

The operator station is designed for optimum comfort, visibility and functionality. A wide opening makes it easy to enter and exit. Standard features include a high-back ergonomic and adjustable seat with armrests. The standard monitor includes an anti-theft system and backlit gauges, switches and LED warning lights. Also included are a digital hour meter, glove-friendly rocker switches and a large LCD panel for easy viewing.

Several design features keep costs low by ensuring fast and easy machine service. The oil cooler swings out with the hinged rear door for full, easy inspection or cleaning. Engine oil changes are simplified with extended, 500-hour oil change intervals. Both models are equipped with visual hydraulic fluid level checks, resulting in fast, easy and no-mess daily checks. www.deere.com

Kanga Loaders’ Series 2 loader – known as the Kanga Kid – has an overall track width of 32.3 inches, height of 47.6 inches and an overall length – including a four-in-one bucket – of 84.5 inches. This design allows access to animal pens for very quick cleaning.

The “Kid” is powered by a 16 hp (11.5kW) Honda V twin. Attachments such as the four-in-one bucket, manure bucket, mulch bucket, grapple bucket, trencher, and auger power head are simple and quick to install in just a few seconds. Many other attachments are available.

A self-leveling system maintains the attachment angle in all lift positions. Additionally, the bucket rollback keeps a full bucket from heavy spillage during transportation. Self-leveling helps maintain the exceptional balance of all Kanga units.

All “Kids” have a back brace system for greater operator safety. The non-slip perforated platform, safety release hydraulic valve, rupture-proof fuel tank, isolation from the hot engine, and soft touch controls make all Kanga equipment operator-friendly and safe.

“From the world’s smallest, to the most powerful, Kanga Power ain’t no toy!” www.kanga-loader.com

Manitou’s MLT series of multi-purpose telehandlers is specially designed to meet the requirements of agriculture. The broadest and most versatile range for agriculture, the MLT telescopic trucks will handle 5,000 to 8,000 pound loads at heights from

16’ 2” to 29’ 5”. With a wide range of machines in the market, Manitou offers day-to-day productivity and comfort for all kinds of agricultural handling work. The MLT series includes the MLT 523, MLT 735 and MLT 940.

MLT 523

• Lift capacity of 5,000 lb.

• Lift height of 16 ft. 2 in.