For over half a century, Doda has provided Organic Waste Solutions by manufacturing a broad variety of products for agricultural use with strict adherence to cost/benefit advantages. BG80

For over half a century, Doda has provided Organic Waste Solutions by manufacturing a broad variety of products for agricultural use with strict adherence to cost/benefit advantages. BG80

Volume 11 • No. 3

Published by:

Annex Publishing & Printing Inc. P.O. Box 530 Simcoe, Ontario N3Y 4N5

Editor

Margaret Land • (519) 429-5190, (888) 599-2228, ext 269 mland@annexweb.com

Contributing Editors

Karen Dallimore, Tony Kryzanowski, Diane Mettler

Advertising Manager

Sharon Kauk • (519) 429-5189, (888) 599-2228, ext 242 skauk@annexweb.com

Sales Assistant

Mary Burnie • (519) 429-5175, (888) 599-2228, ext 234 mburnie@annexweb.com

Media Designer Chris Springle

VP Production/Group Publisher Diane Kleer dkleer@annexweb.com

President Mike Fredericks mfredericks@annexweb.com

Publication Mail Agreement #40065710

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO CIRCULATION DEPARTMENT, P.O. BOX 530, SIMCOE, ON N3Y 4N5

e-mail: subscribe@manuremanager.com

Printed in Canada

Circulation

e-mail: subscribe@manuremanager.com

Tel: 866-790-6070 ext. 211

Fax: 877-624-1940

Mail: P.O. Box 530 Simcoe, ON N3Y 4N5

Subscription Rates

Canadian Subscriptions

$35.24 Cdn, one year (with GST $37.00, with HST/QST $39.82)

U.S. Subscriptions:

$47.00 USD, one year

Occasionally, Manure Manager will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher's written permission. ©2013 Annex Publishing and Printing Inc.. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher's approval. Such approval does not imply any endorsement of the products or services advertisted. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Website: www.manuremanager.com

By Margaret Land

I’m a news junkie. I admit it, which I believe is the first of 12 steps toward rehabilitation, although I’m not expecting to beat the addiction any time soon. I blame my father, from whom I caught the habit. For most of my childhood, he was either away working or sitting with his head in the newspaper. I followed his example.

Of course, these days, my face is glued to a computer monitor rather than hidden behind newsprint. I’ve been known to check news headlines and Twitter feed half a dozen times a day, following stories through the tiniest of developments. Usually half the information provided is not even verified, a weakness in the news cycle’s current need to provide information up to the second. It used to be you got the hot news update the next day or during the next newscast or in the next hour. Now, it’s with the next Tweet.

Recently, I was feeding my addiction by following the latest Twitter feed describing the tragic explosion at the West, Texas, fertilizer plant. I started out searching Twitter for manure-related posts but instead found I was continually being fed updates on the explosion. That was when I realized the people Tweeting the news weren’t calling the location a fertilizer plant; they were calling it a manure plant.

First of all, the only manure plant I’ve ever heard of is found within most human beings and animals. It’s called the alimentary canal, namely the final step in the system –excretion. I think I’ve also heard of the odd swine farm, dog or baby jokingly referred to as one as well.

I understand for some people the terms fertilizer and manure may appear to be interchangeable. But those of us with an education in agriculture know the difference.

At first I was amused by the mix-up. But then the Twitter posts became somewhat irrational. People were worrying about how explosive the bags of manure compost in their car trunks were or whether their flower gardens could just spontaneously combust. I decided something had to be done. So I started sending Tweets to the people spreading the false information, explaining it was a fertilizer plant that had exploded, not a manure plant, and that there actually was a difference between the two words.

Most people appreciated the information and quickly corrected their Tweets. But there’s always one in the bunch who quickly makes you realize maybe you should have just left the topic alone. I wish I could post the response I received from him – all of it in capitals – but unfortunately, due to the language used, I can’t. Let’s just say he wasn’t very happy with me and thought I was attempting to infringe on his freedom of speech.

I realized I was fighting a losing battle. Most people didn’t care whether it was a fertilizer plant or a manure plant – they were going to call it whatever they wanted to. It didn’t matter whether the information was wrong or right – it was more exciting to believe that the location was a manure plant.

So I dropped my feeble information campaign and ruminated on what was more important – the loss of life. I extend my deepest condolences to the family and friends of the 15 people killed and the numerous others injured in this terrible tragedy.

By Tony Kryzanowski

Wayne Dahl family farm seeks balance between stewardship and profitability

For Dawson, Minn., hog farmers, Wayne and Laura Dahl, good just isn’t good enough. If they can try something new to improve the air quality in their hog barns, benefit the environment, or improve the way they handle their manure, they don’t just talk about it. They do their homework and then implement what’s feasible and proven beneficial.

Wayne grew up on a mixed farm that raised hogs so purchasing his own farm with his new bride, Laura, back in 1977 in Lac Qui Parle County near the South Dakota border wasn’t like an episode of that old TV show, Green Acres – although all the work that Wayne and Laura have done on their property while raising five children has created plenty of green acres.

Today, the farm operates as a contract nursery-to-finishing hog business owned by Wayne and Laura, as well as a corn and soybean crop operation managed by Wayne and his brother, David. They farm a total of about 1,800 acres. Wayne and Laura’s youngest son, Jordan, helps manage the hog operation with the intent that he will take over at some point.

Wayne Dahl Family Farm raises hogs on contract for Mill Farms, which actually

owns the hogs. The operation consists of four 1,100-head finishing barns and a 4,400head nursery. The barns are equipped with slatted floors and eight-foot-deep manure collection pits, which have enough capacity to store a year’s worth of manure. The farm generates about two million gallons of liquid manure annually. The pits are emptied each fall.

The Dahls work with a professional agronomy firm called Anez Consulting Inc. to help them establish the liquid manure application rate for each field, based on nutrient testing of the manure pits and soil testing in the fields.

After their agronomist establishes the application rates, Wayne hires his nephew, Brent Dahl, as a contract manure applicator to land apply the manure using the injection method. Brent’s custom manure applicator

Laura and Wayne Dahl (top centre), surrounded by other family members, received an Environmental Stewardship Award from the US National Pork Board. (Photo provided by National Pork Board)

It

is not only about

It is more than that.

It is the certainty to get a fast and effective management of manure contained in your lagoon or in your concrete pit. The Articulated Agi-Pompe stands out with its propeller giving a constant agitation up to 21 500 US gpm in loading mode as well as in agitation mode. Equipped with an articulated housing, the agitation nozzle combined with the 40° vertical rotation of the housing allows to significantly reduce main storage homogenization time. GEA Farm Technologies never stops offering unbeatable products.

Articulated Agi-Pompe

GEA Farm Equipment | Houle

GEA Farm Technologies Canada Inc.

Tel. 1.800.563.4685 / Fax. 1.819.477.0486

www.gea.com / www.geahoule.com

engineering for a better world

unit is equipped with GPS and flow meters so that he can apply the recommended amount per acre as required.

Prior to injection, an agitation pump stirs the pits so that the nutrient content in the liquid manure is balanced once it reaches the field. The agitated manure is pumped into a semi-trailer tanker and trucked to the application site, where it is transferred to one of two field applicator tanks, which have a total hauling capacity of about 10,000 gallons. The manure is then applied below ground into a furrow created by a coulter disk on the manure application drawbar. The manure can be applied anywhere from two to six inches into the soil. Covering disks located behind the application nozzles on the drawbar cover the furrow.

“It takes us about three days to dispose of the manure and we try to do it when the temperature is below 50 degrees to minimize the amount of nitrogen that we lose to the atmosphere,” says Wayne.

Jared Anez, co-owner of Anez Consulting, says given the cost of commercial nitrogen, farmers should do everything possible to save the nitrogen that is in the organic fertilizer, and injection is one way of doing that. Also, with liquid manure injection, they are able to reduce the size of setbacks, so more land is

fertilized. Once the Dahls have planted their crops and the corn is six inches tall, Anez Consulting will conduct 12-inch-depth samples to see if more nitrogen is needed. They also conduct cornstalk nitrate testing at the end of the season to evaluate how well the application strategy worked.

In two of its barn manure pits, the farm is testing a product called More Than Manure, which is a product that helps stabilize the nitrogen in the organic fertilizer. It is also an odor control product.

Wayne Dahl Family Farm has evaluated how much financial benefit they gain from using the hog manure as organic fertilizer. The hog manure is lab tested and what they receive is a dollar value on 1,000 gallons based on its nutrient content. The nutrient content does depend on whether the liquid manure is tested from the nursery barn or from the finisher barns.

“For 1,000 gallons of liquid manure from a finisher barn last year, the average cost of an equivalent amount of commercial fertilizer would have been about $48,” says Wayne. “That’s based on getting 75 percent availability of the nutrients within the liquid manure.”

Because the nutrients within the nursery barn manure are weaker, 1,000 gallons from that barn would equate to about $34 in commercial fertilizer. They apply between 3,000 and 3,500 gallons per acre of finisher barn manure and about 6,000 gallons of nursery barn manure, “and that was costing us about $50 per acre to have that applied,” says Wayne. “So the savings are substantial.”

Because phosphorus builds up in cropland, it is a concern when applying fertilizer. Wayne Dahl Family Farm uses a feed additive called phytase, which reduces the amount of phosphorus in the manure. The benefit is that by reducing phosphorus, the manure application rates can be increased by 20 percent without phosphorus building up in the soil.

“A lot of farmers are really sharp and a lot of times they just need to have peace of mind that they are headed in the right direction,” says Anez. “They need someone like us to bring in some new ideas to the table that are being tried in other areas so that they can implement the best ideas on their farm earlier. This helps them to continue to be profitable and stay on the

cutting edge.”

The farm’s manure management method has come a long way since 1977, when Wayne and Laura were basically starting from scratch to establish a hog operation. They started with building a 26 by 90 foot farrowing and nursery barn with a manure scraper system that collected the manure into an enclosed pit next to the barn to complement the existing 20 by 30 foot older, breeding and gestating hog house. They also built a 32 by 132 foot, partial slat floor, finishing barn, which they also used partially for breeding and gestating. It was equipped with a below-ground storage pit. In those days, the manure volume was smaller but because of the limited storage capacity, the hog manure would sometimes be pumped out and broadcast on fields in winter as well as in the fall.

The major investment into current operations started in 2003, when the Dahls successfully negotiated a custom hog nursery-to-finishing contract, which allowed them to arrange for the financing to construct their first large finishing barn. That was when they also started working with Anez Consulting to help them acquire the necessary regulatory permitting.

“When we compare what we did then to what we do now in terms of manure management, it’s almost entirely different,”

says Wayne. “The big difference now is that we inject everything, we have flow meters which give us the exact gallons per acre that we want, and it’s GPS controlled. So it’s applied as well as any commercial fertilizer could be.”

Making a substantial investment into raising hogs on contract is only one of several changes that have occurred on the farm since 1977. The farm has also been enrolled in the United States Department of Agriculture Conservation Stewardship Program (CSP) for the past three years, where they are compensated to follow specific guidelines to protect the environment and enhance wildlife habitat in their farm operation.

“We appreciate programs like CSP to point out good, sound environmental practices,” says Wayne

One of the obvious environmental enhancements they have made on the property itself was to installed grass buffers on both sides of a drainage ditch, which helps to improve water quality. They have also planted native grasses on what once was cropland and new trees for windbreaks, which creates better habitat for wildlife. The farmstead is also teeming with birdhouses.

In addition to environmental enhancement and manure management protocols, the CSP includes a crop pest control management component so that action is taken to control pests based on financial thresholds rather than a simple occurrences of the pest. The farm’s manure management method follows CSP recommendations.

“The CSP awards points for following their manure management protocols and eventually once we accumulate a certain number of points, we are financially rewarded for it,” says Wayne.

Furthermore, in the barns, they have installed a technology called electrostatic particulate ionization (EPI), which reduces the amount of dust particles in the air and helps to reduce odor. Wayne says this creates a healthier environment for both the hogs and the workers. It was provided by a company called Baumgartner Environics located in Olivia, Minn.

“It’s great for improving the work environment because they claim that it takes 75 percent of the dust out of the air and I believe them,” says Wayne. “It also takes out odor gases like hydrogen sulfide and ammonia, traps micro-organisms, and kills bacteria.”

The EPI system complements the pit ventilation system that vents the gases produced from the manure pits installed in the barns.

The farm also uses a biological-based pit additive manufactured by a company called Eco-Cure to help reduce odor from their manure pits. Wayne says that claims made by the product manufacturer and how it is applied made sense to him. Also, it was reasonably priced.

“The bacteria supposedly digests some of the organisms that create the gas from the manure, so it lowers the gas level in the barn,” says Wayne. “Now, since we started using the product, the odor seems to be even less than it was.”

The Dahls received a 2012 Pork Industry Environmental Stewards Award from the National Pork Board, given to pork producers who demonstrate a commitment to safeguarding the environment and their local communities.

To view a video highlighting Wayne Dahl Family Farm's many environmental stewardship accomplishments, visit www. youtube.com/watch?v=9LhERzKkDmI.

For more on sustainability, visit www.manuremanager.com

The PUMPELLER Hybrid Turbine revolutionizes manure pump performance. Incredible intake suction pulls solids into the cutter knives, reducing the toughest crust to nothing in just seconds. The turbine combines the high-volume mixing of a propeller agitator with the power and reach of a lagoon pump, the resulting hybrid design radically outperforms both.

Jamesway’s ULTRA-TRAC steering and powerful industrial brakes keep you in control and on the road.

Steering operates at road speed

Jamesway’s steering system operates completely automatically at any tractor speed.

Fully automatic, no operator input is required

Extremely simple construction, easy-to-maintain

Minimizes “jackknife” force during cornering

Reduces tire wear

Reduces strain on axles

Reduces road and field damage

By Diane Mettler

Necessity is often the mother of invention – that goes double for farmers.

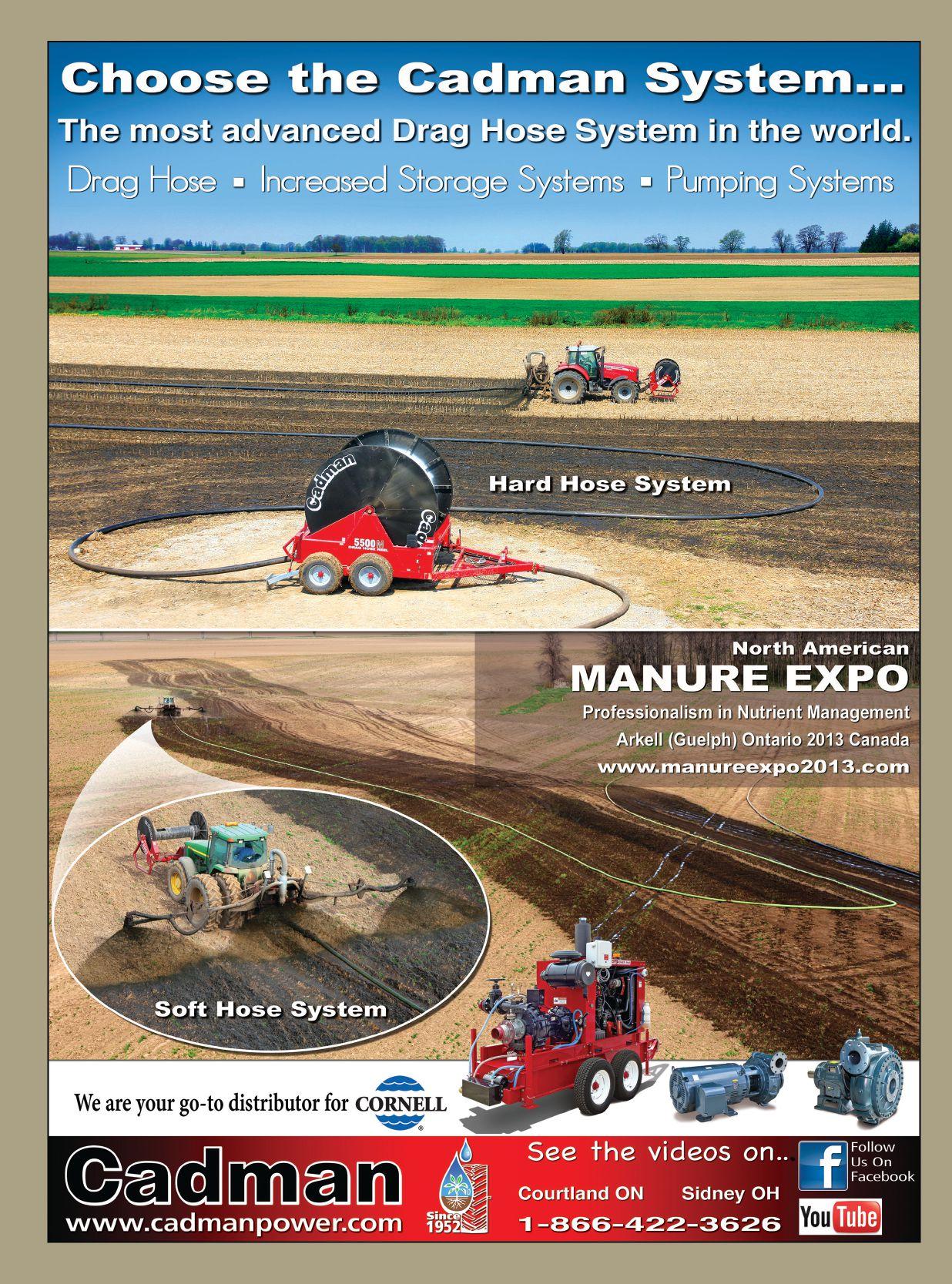

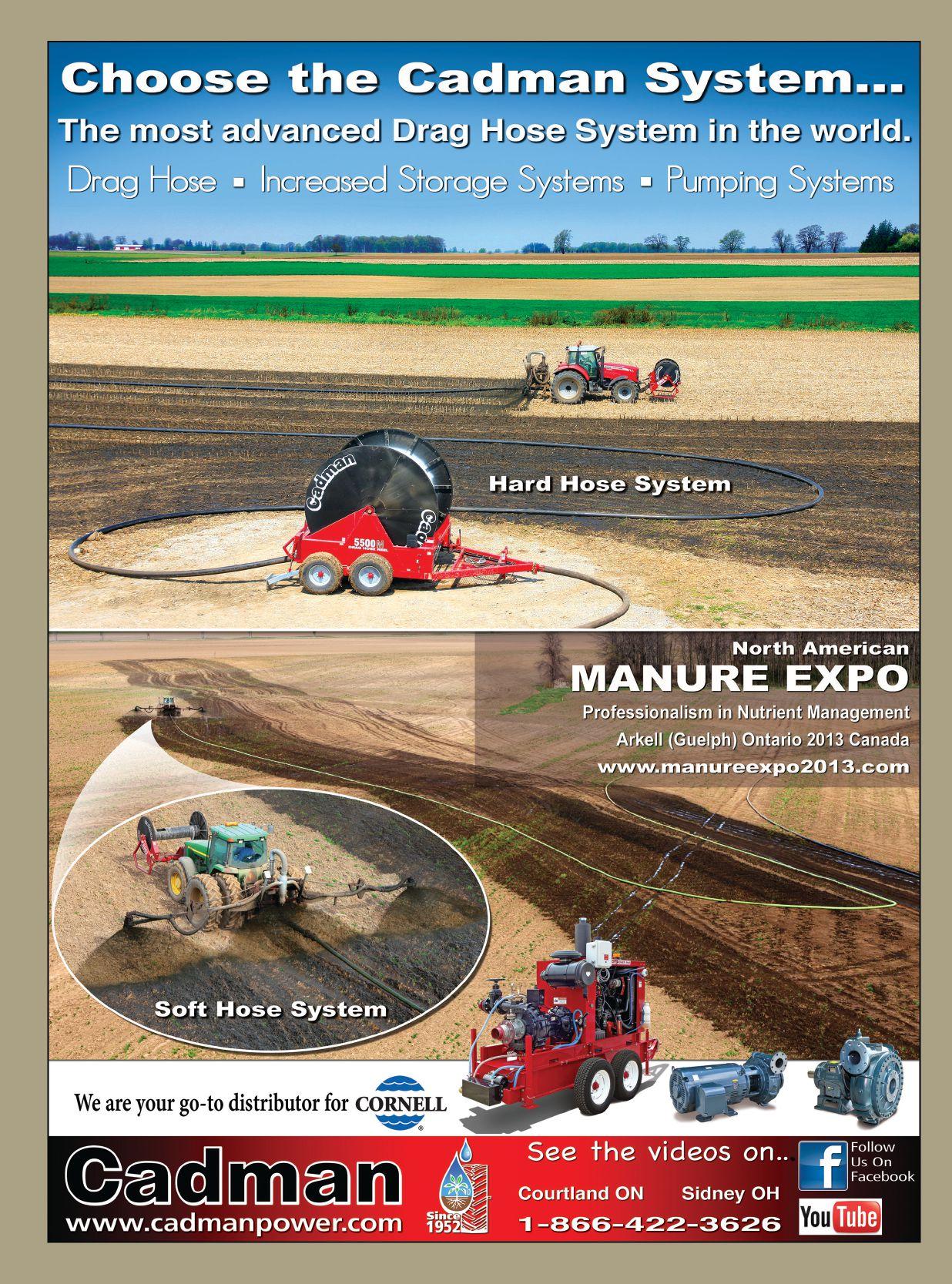

Cadman, with the help of innovative farmers in need, has developed a drag hose system that works as well today as it did 20 years ago.

In the 1990s, new Ontario, Canada, environmental regulations banned farmers from using their irrigation systems to spread manure through a sprinkler gun. Farmers had gotten used to the efficient system and didn’t want to go back to tankers, which, among other things, were more time consuming when it came to spreading large daily volumes of manure.

To meet these new environmental standards, an innovative farmer named Doug McLeod of Stratford, Ont., decided

to take matters into his own hands. He built a manure-spreading prototype boom to see if he could still utilize his Cadman water irrigation equipment and continue the efficiencies gained over tankers for large single-day manure spreading setups.

McLeod pieced together a crude two-nozzle boom and hooked it up to his Cadman irrigation system. After working out some of the bugs, he approached Cadman – which had quietly been designing a complete line of manure handling equipment in response to the same new government regulations – to help build a more sophisticated version of his prototype. The company took on the challenge and McLeod was the first farmer to have a commercial boom.

It didn’t take long for other farmers working in conditions that are optimal for dragline setups to begin investing in the new Cadman booms to work in conjunction with their irrigation systems.

The setup took about an hour and half (and still does), and for larger fields with large daily manure volumes, it saved a lot of time driving back and forth with a tanker. A big manure reel could be parked in the field and never moved while hooked up directly to a manure pit as much as a mile and a half away.

“Spreading the same large daily manure volumes with tankers necessitated numerous trips back and forth between the field and pit, which ate up a lot of time,

Necessity is often the mother of invention and farmers are excellent inventors. One of the first farmers to experiment with using his irrigation equipment for spreading manure also built a prototype boom to aid in application. Photo by Paul Sontrop

fuel, caused a lot of compaction in the field as well as exposure to annoying and sometimes dangerous highway traffic issues,” says Craig Cadman, of Cadman Power Equipment.

In early 2000, with the help of motivated farmers like McLeod, Cadman continued to modify their manure handling systems. The line of booms was improved and expanded to work with the company’s already extensive line of hose reels, hose caddies, power units and variety of hoses.

Also, over the years more models of reels and caddies were developed by Cadman to accommodate specific manure applications – including a range of hard hose reels specifically engineered to handle the more strenuous conditions of manure spreading.

In short, drag hose reels didn’t need the bells and whistles of irrigation reels. What was needed was something more rugged and unique to manure handling. Manure reels were beefed up with a bigger drum, heavier frame and wheels to accommodate the larger and heavier drag hoses.

“Also, portable diesel engine driven power units were modified and coupled to pumps designed specifically for manure pumping from suppliers like Cornell and Doda,” says Cadman.

The hard drag hoses continued to evolve during the early 2000s. First, Cadman switched to larger diameter hoses to handle the demands of manure versus water. Next, the company realized it needed a tougher hose composition to better handle dragging over frozen soils, stony ground and rough stubble. Working directly with their hose supplier, Cadman engineers incorporated a companydeveloped resin formula. Over time, that formula was perfected for superior longevity and ruggedness.

There are basically two types of drag hoses out there on the market today – polyurethane soft hose and polyethylene hard hose. Though both soft and hard hose systems offer comparable levels of tensile strength and burst pressure, there are important differences: Because hard hoses are round and solid, they won’t twist in the field like soft hoses.

• Hard hose comes in continuous lengths of up to 2,000 feet. (Soft hoses are limited to 1,320 feet.)

• Farmers replace hard hose less frequently. Many customers

Drag hose reels don’t need the bells and whistles of irrigation reels. Manure reels were beefed up with a bigger drum, heavier frame and wheels to accommodate the larger and heavier drag hoses. Photo by Paul Sontrop

have pumped up to 250 million gallons over a period of 13 to 15 years before needing a replacement,” says Cadman.

• Hard hoses remain rounded even when empty and thereforedon’t require pressurization to maneuver, as soft hoses do. This saves on fuel compared to soft hose where the pumps have to maintain a higher pressure in the system.

• Because of its rigid composition, hard hoses slide easily across the field. A hard hose system “uses up to 30 percent less horsepower and less fuel than a soft hose system,” says Cadman.

• Hard hose systems can spread more acres per setup than soft hose. Cadman even builds a machine that will do a quarter section (160 acres) in one setup.

With so many benefits to hard hose, why do farmers still choose soft hose systems? “It all gets down to cash flow and upfront investment differences,” says Cadman.

“Some of our customers want a drag hose system with as little upfront cost as possible and therefore prefer a soft hose system. It may also be for the simple reason that they are used to a soft hose system. Others who are more committed to long-term use, or are in a better cash position, opt for the hard hose system and are willing to lay down the larger upfront costs associated with it in exchange for long-term savings and better performance.”

So what are those cost differences between a soft and hard hose system?

About $45,000 to $95,000 USD for the hard hose reels (includes the hard hose).

“With those numbers, it is understandable that most drag hose customers still opt for the soft hose systems,” says Cadman. “However, livestock farmers, and particularly custom operators, report that the hard hose drag reel system definitely produces the highest rate of return on investment over the long haul.”

This is hardly the end of the story. New advancements in this system and others continue. Cadman engineers (and a few farmers) are at work, creating that next advancement to help make manure spreading that much more efficient and affordable.

For more on equipment, visit www.manuremanager.com

Hard drag hoses have continued to evolve, developing larger diameter hoses and tougher hose composition to handle dragging over frozen soils, stony ground and rough stubble.

by Karen Dallimore

Does precision agriculture have a place in manure management?

By Karen Dallimore

With a show of hands, about half of those listening to the presentation in Jake Kraayenbrink’s back 40 near Moorefield, Ont., confessed to having a smartphone of some sort.

That means that half of the crowd at a recent Ontario manure management demonstration would instantly be able to pinpoint their location at that particular moment, in that particular field, using the GPS feature on their smartphone. It also means that they may be only a step away from utilizing precision agriculture to manage their manure.

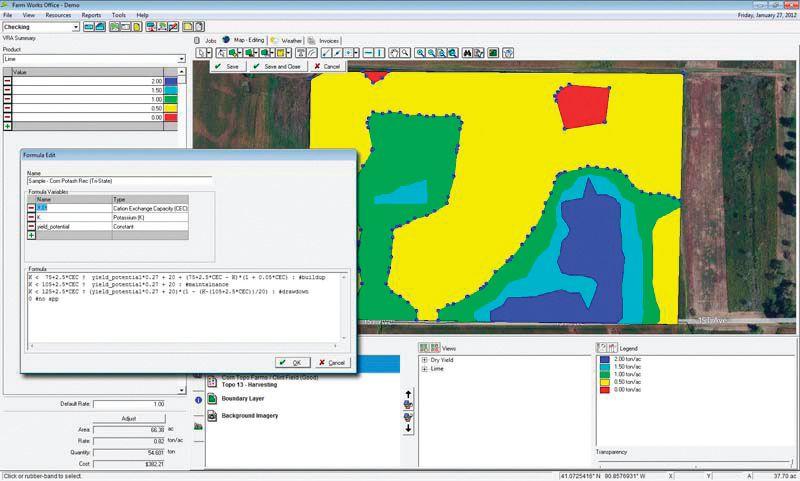

What exactly is precision agriculture? Basically, it’s farming by the inch instead of the acre. It’s using a GPS (global positioning system) and imag-

ery – satellite and sensor data – with computer software to map and manage field data, generating distinct records for every field of the farm with the goal of better managing resources.

The most common tool to achieve this is GPS technology, used on field equipment to accurately steer and control applications based on the position of the equipment in the field. Every operation done by a piece of equipment can be mapped and data is managed by software specifically developed as a business management tool.

“It’s pretty cool technology,” Larry Prong, a GPS specialist with Premier Equipment in Elmira, Ont., told farmers. “It’s starting to become the norm to sell GPS equipment with new tractors.”

Precision agriculture components typically include a GPS receiver, in-cab computer display, machine controls for guidance, commonly known as autosteer systems, and machine controls for application such as spray controllers, rate controllers for dry box spreaders, or flow meters for manure tankers. Other components may include field scouting devices and desktop GIS (geographic

information system) for data management.

But does precision agriculture technology have an application in manure management?

“Yes,” said Prong. “That’s the purpose of precision agriculture: getting more exact with our field operations and gaining the efficiencies through that.”

Using precision agriculture technology tools can increase manure placement accuracy and application rates, but then the data can be sent back to the office to map your fields and help to keep good records too.

When it comes to manure application, the placement accuracy you’re looking for is probably six to eight inches, explained Prong. That’s good enough to make sure you don’t have any big skips as you move up and down the field, but at the same time you’re not getting a lot of overlap either.

One good example of where GPS accuracy would come into play in nutrient management would be side-dressing liquid manure into standing corn: it’s tricky and there is not a lot of room for error. Corn planted with high accuracy guidance will have bullet-straight rows

A screen shot from Farm Works software. Farm Works software has just released the Connected Farm app that runs on iPhones and Android smartphones, allowing field scouting with a GPS-enabled smartphone.

Photo courtesy of Larry Prong

but, more importantly, you can go back exactly into same wheel track within one inch six or eight weeks later.

Some people may say: “It’s just manure, why do we have to record all that data?”

As your commercial fertilizer costs go up, manure becomes liquid gold, said Prong. There’s a tremendous value to what you’re putting on the land. If you’re going to take the time to work with an agronomist for your fields and you’re expecting a certain yield from your ground, it’s just another piece of the puzzle that the tools of precision agriculture are going to record and track for you.

Another side of the coin is, unfortunately, the fact that manure is also regarded as a hazardous material. We need to know where it’s going down as well as setbacks from wellheads and waterways, said Prong. Every time you use a GPS system it provides an audit trail: this is how much I put down and this is where I put it down.

One of the key pieces of information is the amount of manure you’re putting down, which involves not only measuring amounts but also measuring application rates. This is where a rate controller can be useful.

For solid manure, a rate controller gives you the ability to measure load size under a dry spreader box, measuring change in weight to calculate the application rate. A hydraulic gate valve can then help regulate the amounts going on the field.

With liquid manure, that measurement requires the use of a flow meter. Putting a flow meter on a tanker will measure liquid manure application in gallons per minute. Prong says a flow meter is a common feature on machines nowadays.

“That’s important in injected manure where you can’t see what’s going in the ground,” said Prong. “It’s amazing how a change in ground speed can spike your application rates.”

For example, at four miles per hour

with a 2,500-gallon per acre target flow, you will be applying 300 gallons per minute. Keeping the same flow but dropping to three miles per hour, that application rate is now 3,300 gallons per acre. That’s a 30 percent increase in application rate just by slowing down, and that decrease in speed can be caused by something as simple as going up a hill.

Premier Equipment has developed a creative solution that integrates an application rate control system with the IVT trans-

mission of many John Deere tractors. As Prong explained, their rate controller actively adjusts the transmission of the tractor to maintain a consistent ground speed, which is highly critical in a dragline scenario for maintaining a consistent application rate.

In precision agriculture, as you start to use the technology you begin to create maps of your fields, allowing you to define and record not only where you’re putting down manure but also how much you’re putting down.

“That’s a plus for nutrient management,” said Prong. When you need to calculate how much commercial fertilizer to use above and beyond just manure, you’ll have accurate data.

Whether you have a GPS in your tractor or in the phone on your belt, or maybe you take a GPS unit out on the four-wheeler to chart your fields, you’ll still need some software to process the data.

Basically, software just helps to organize your data. The detailed records you bring in from the field will need to be stored and accessible since you will need to go back and analyze that information over time, both in the short term and over several years.

A number of office software products are available to do this and more programs are still in the development stage. Farm Works software has just officially released the Connected Farm app that runs on iPhones and Android smartphones. This allows you to do field scouting with a GPS enabled smartphone.

Data can be transferred from the tractor using a memory stick, but with wireless technology, that transfer can be done while you’re still out in the field. As soon as you’re done putting manure down you can send the details in to your office desktop computer wirelessly and software will automatically recognize it and file it for you, including the geographical locations in the field.

“Quite a few people haven’t gotten there yet – they’re physically moving their data from the tractor to the desktop, but I think this is the next step in precision agriculture,” said Prong. Looking to the future, he predicts that the next advancements will be in wireless transmission and software improvements.

For more on equipment, visit www.manuremanager.com

By Diane Mettler

Oklahoma’s Trail’s End Sow Farm #2 isn’t one of those farms that one day decided they should start making sustainable changes. Since the farm started up in 1998, the owners and employees have focused on sustainable solutions while maintaining a solid bottom line.

It was one of four farms chosen to receive the 2012 Pork Industry Environmental Steward award, which recognizes producers that demonstrate a commitment to safeguarding the environment. Judges, representing both pork producers and environmental organizations, selected winners.

Swine operations, like Trail’s End, are evaluated on their manure management systems, water and soil conservation practices, odor-control strategies, farm aesthetics, neighbor relations, wildlife habitat promotion, innovative ideas used to protect the environment and an essay on the meaning of environmental stewardship

The layout Trail’s End is located in the Ames, Okla., area, near the Cimarron River. It’s part of The HANOR Family of Companies (HANOR), and is surrounded by 560 acres – primarily fields of cereal rye, winter wheat, Pearl millet, triticale and crabgrass.

The farm was built on an elevated

pad for 10,000 sows and includes eight gestation barns and four farrowing barns. Bill Barnes, who oversees environmental operations at the farm, says, “The farm is basically divided up into four 2,500-sow quadrants, so on each quadrant there are two gestation barns and a farrowing barn.”

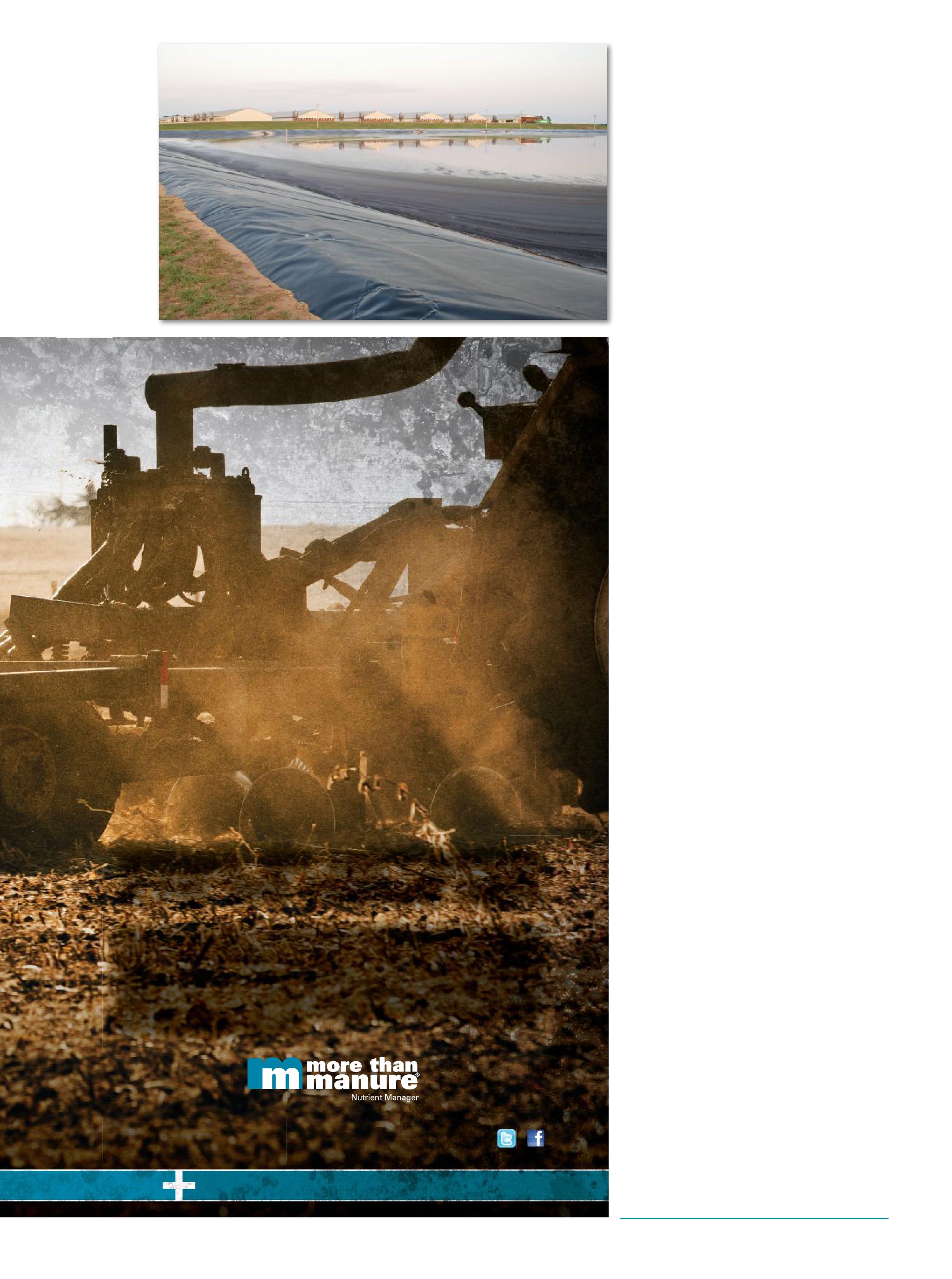

Included on the farm are two large lagoons – one on the east side of the farm, one on the west side. Because of the area’s soil type, and to avoid any seepage into the groundwater, both lagoons have a 30-mil high-density polyethylene liner (HDPE).

The State of Oklahoma requires monitoring wells at each lagoon.

“It’s a state requirement that ensures ground water quality,” says Barnes. “We

Since Oklahoma’s Trail’s End Sow Farm #2 started up in 1998, the owners and employees have focused on sustainable solutions while maintaining a solid bottom line. Photo courtesy of Pork Checkoff

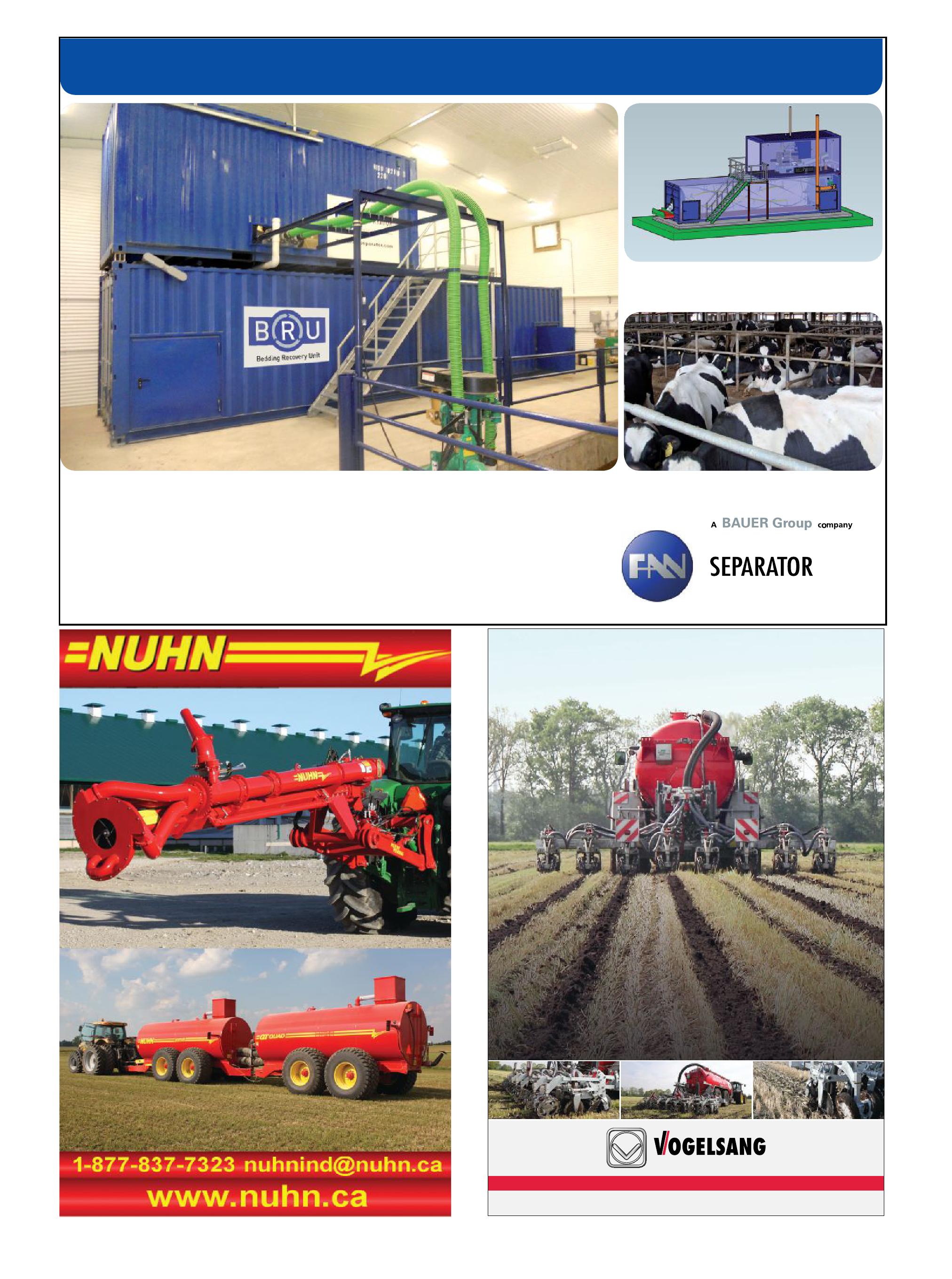

FAN Bedding Recovery Unit – increase of cow comfort and health –increase of milk production – reduction of costs for manure management

• Produces bedding for up to 2,000 cows

• New and improved chainless drive system

• Low energy consumption

• User friendly touch-screen control panel

Office: Michigan City Tel. +1 800 451-8001

j.dewitt@bauer-at.com

t.burns@bauer-at.com

r.hultgren@bauer-at.com

b.coughlin@bauer-at.com

have one monitoring well up gradient and two monitoring wells down gradient. The wells were placed by a hydrologist in the direction that the groundwater flows.”

Moving the manure from barns to lagoon is simple and economical. All the gestation barns have slated floors with 18inch concrete pits underneath. The barns are washed on a regular basis, to keep odors down and for general hygiene. When the pits are full, which is about once a week, a gravity flow system of underground pipes takes manure to the lagoons.

The farm also uses an agricultural engineer to help determine water needs for the animals and for barn cleaning.

“This helps us create a water budget so we can target monthly water usage for minimizing wastage” says Barnes.

The lagoons were designed to anaerobically digest the manure into the component nutrients, says Barnes. The crops dictate when they pump those nutrients onto the field.

“When the forage is actively growing is the best time to add nutrients,” he adds.

“We will pump primarily in the spring and fall, and may also do some in the summer. It’s based on the crop and the crop needs. We observe the crops and we also work to pump at agronomic rates so that we don’t over-apply.”

Trail’s End initially hired a third-party agricultural engineer to set up the system, which was based on the number of animals and output.

“We do sampling to determine the nutrient level in the effluent and soil sampling to determine soil nutrient level. Based on those readings, we establish yearly goals for nutrient levels that we apply,” explains Barnes.

At the time of pumping, the solids have pretty much settled and the liquid is pumped as far as half a mile and applied on 270 acres through a center pivot irrigation system. The system is working so well that Trail’s End rarely buys commercial fertilizer.

One of the things that make Trail’s End unique is that they are able to grow forage crops year round. Barnes says there are only

More Than Manure® (MTM®) Nutrient Manager is the first and only manure manager proven to reduce nitrogen loss and phosphorus lock-up in manure. That means improved nutrient efficiency for your crops, and better results in the bin. When pre-treated in a pit or lagoon, MTM can also reduce solids and ammonia levels, which will make your pit or lagoon almost, well…pleasant. To get your free starter pack and to learn more, visit us at sfp.com.

Both of Trail’s Ends’ two lagoons have a 30-mil high-density polyethylene liner (HDPE) to avoid any seepage into the groundwater, Monitoring wells are also located at each lagoon. Photo courtesy of Pork Checkoff

two to three weeks in the fall that the farm won’t have active roots in the soil absorbing nutrients.

Bill describes the cycle: “Our growing year begins in the fall when we plant rye. We plant around the first of September, and the rye comes up, and then that will either be grazed through the winter and spring with cattle, or, sometimes we’ll make hay out of the rye. Occasionally in late spring and early summer, the fields are overseeded with crab grass [and] that does a good job reseeding itself every year. So, in late spring and early summer, as the rye is taken off, the crabgrass starts growing. So, there will be a couple of weeks we’ll have crabgrass and late spring and early summer, that is overseeded (with pearl millet), which will either be grazed or taken off as forage through the summer, and then that takes us back to late summer and early fall when the rye is again sown.”

Trail’s End and other local farms use no-till methods to keep the soil intact. If the soil were to be tilled it would blow away, increasing the probabilities of wind erosion.

The crops were chosen not just because of soil and nutrients, but also based on the weather patterns. The area experiences hot summers, but relatively cool winters, with very few really cold days.

“The crabgrass just loves hot weather,” says Barnes. “And because we’ve got irrigation with our center pivots, we can apply either water or effluent with those pivots. We have a separate effluent line and water line, so if we switch from one to the other, there’s no danger of getting effluent in our water line, which could possibly contaminate groundwater.”

Trail’s End isn’t near any populated centers, but even if it were, odor wouldn’t be a big concern. Barnes says the lagoons naturally turn over in the spring and fall, just like a farm pond will, causing a little odor.

sfp.com | 888.446.GROW

These particular lagoons were designed in the late 1990s to accumulate sludge over a 20- or 30-year period. There may come a time for dredging in the future, which would cause some odor, but the farm hasn’t reached that point. The sludge would create a really good source of organic material for local farms.

“It’s a well-designed system,” says Barnes. “It was based on output of the animals, and so it was engineered to handle the digestion of the nutrients of the manure. It’s handled the manure really well.”

When asked why he thinks Trail’s End stood out as an environmental steward, Barnes is at a loss. “We didn’t do anything out of the ordinary. We just described what we do and our philosophy as far as protecting the environment.”

He adds, “There are members of our management team that are Oklahoma natives and have an agricultural background, so they realize the importance of maintaining our environment. It’s important to us. For example, when we built this we didn’t clear any more land than what was necessary to operate the pivots. It was rolling hills that were covered with black jack oak trees.”

Because of Trail’s End’s early decisions, it’s not just cows that enjoy the environmental benefits. In the morning and evening you’ll find whitetail deer grazing. And if you look closer, you’ll also find turkeys, coyotes and pheasants. The farm even sponsors the Grand National Quail Hunt.

Currently there are 35 full-time employees at Trail’s End Sow Farm #2. Although all employees are environmentally minded and trained, those who are responsible for handling effluent, as well as those who oversee the farm operations, are required by the state to have an initial nine-hour environmental training course. To stay current, every three years they are also required to have three additional hours of training.

Trail’s End hires an engineer to come out to the farm to do the training.

“They cover state regulations – what we do and why we do it,” says Barnes. “We also go over our best management practices, which are in our pollution prevention plan required of LMFOs/ CAFOs in Oklahoma. They also include odor management, carcass disposal, pest control, etc.”

The owners of Trail’s End like the farm looking good from every angle. “Our owners are very particular about how our property looks, the same way they are with their own homes,” says Barnes. “And not just the sow farms, but all the surrounding property. We grow Bermuda grass around the barn sites because of the sandy soil, mow the barn ditches, and weed eat around the fence lines.”

This not only gives a good impression to the public, but it helps eliminate pests, particularly rodents that like to live in taller grass.

Trail’s End has also invested in a BIOvator, which is used for composting piglet mortalities. The large, stainless steel cylinder rotates slowly, and with the addition of fine wood chips, the mortalities are composted in about two weeks.

The compost is used in trouble spots where the soil is especially light and in danger of blowing away.

“We’re actually building up the soil organic matter and keeping the land in place,” says Barnes.

He is proud of the farm and its environmental steward award.

“We are employing the natural nutrient cycles to recycle the nutrients. It’s a beautiful example of recycling. In the case of the ground that our crops are on, we’re actually increasing the productivity of the soil of what it would be if it was just natural.”

To view a video highlighting Trail's End Farm's many environmental stewardship accomplishments, visit www.youtube.com/watch?v=6_XdDfaHYJw.

For more on sustainability, visit www.manuremanager.com

was built on an elevated pad for 10,000 sows and includes eight gestation barns and four farrowing barns.

By Karen Dallimore

It wasn’t too long ago that manure was just a waste that nobody wanted. For more than a decade, Dennis Nuhn, president of Nuhn Industries Ltd., has watched manure become more appreciated.

“Manure injection and manure in general – it’s come a long way in the last 10 years,” Nuhn told the crowd that had gathered at Jake Kraayenbrink’s farm near Moorefield, Ont., for a manure demonstration day late last summer.

Making the best use of manure means making the best use of a natural resource. Manure is becoming more recognized as a natural fertilizer that adds micronutrients and contributes to the biological control of diseases in the soil.

Nuhn has been involved in manure injection research for more than a decade. Thirteen years ago, he was lucky to be part of a multiyear project doing manure injection with Bonnie Ball and Agriculture and Agri-Food Canada. As Nuhn described, they used water colored with Freshie dye and dug it up to see where it all went.

“It really was a fun time,” Nuhn recalls. “Injection was a hard sell at that time because nobody really appreciated the value of manure so it never really caught on.”

Computerized spreading with GPS was just coming in at the time, which meant a much more accurate spread.

“All of the lines and the differences between the plots were well defined,” said Nuhn. “It wasn’t so grey as it always was.”

But the biggest change in acceptance for injection though was three or four years ago when fertilizer did the “big spike,” said Nuhn: “Suddenly manure didn’t just smell anymore and everybody started looking to get more value out of it.

“Probably the simplest and easiest way to get more value from your manure is to inject it,” Nuhn told about 135 observers at the demo day.

The 12,000-gallon Quad that Nuhn had brought to the demonstration was fitted with a Dietrich injector.

“The farmer who wants to get more bang for his buck and wants the best application possible will probably go to the Dietrich or something that puts it in the ground,” Nuhn told the audience. “There’s another attachment that Bill (Dietrich) has come out with called closures – which is a double disc that covers the crack up.”

The trouble with injectors is that no one injector is good for every application, said Nuhn. In Iowa, Nuhn sells a lot of double disc injectors that put manure on the ground and throw dirt on top of it. The custom haulers like it – it’s fast and easy and can go through anything – but with injection each application is a little different.

Another issue with manure was when regulations came in that said you couldn’t spread it around the barn forever. Farmers needed more efficient tools to take large volumes five miles down the road.

That’s where the capacity of the Nuhn Quad came in. The Quad

is an integrated system, not just two tanks in line. It was a hard sell in the beginning because it was different, said Nuhn, but the train concept is growing in popularity as custom haulers get bigger and drivers realize the handling advantage of having two tanks versus one larger tank.

With in-tank mixing, the Quad provides a consistent spread too. “What I say is if you spread manure, the key is you want to get the right amount and put it on properly,” said Nuhn “If the first half is different from the last half you’re not going to get the results you want.”

A triple Quad experimental unit is now in the works in Iowa. Nuhn likes the train concept but while Nuhn’s standard double Quad is very maneuverable, able to turn in tight spaces and easy to back up, he admits this one is harder to back up and its use may be limited to larger, flat acreage.

Joseph Gallo Farms receives CA’s highest environmental honor

Joseph Gallo Farms, maker of Joseph Farms Cheese, was recently awarded the Governor’s Environmental and Economic Leadership Award for its sustainable farming and cheese making.

The award, known as the GEELA, is California’s highest and most prestigious environmental honor. It recognizes individuals, organizations and businesses for their exceptional leadership in voluntary achievements that help conserve California’s resources, protect and enhance the environment and build public-private partnerships.

“We are honored and pleased that the Governor has recognized our commitment to sustainable practices,” said Mike Gallo, CEO of Joseph Gallo Farms.

“Sustainability is something my family and I are very passionate about. This award is a testament to the amazing support we receive from our family of customers and employees, and it inspires us to continually improve.”

Joseph Gallo Farms began in 1946 as a small family farm and is today a model of sustainable agriculture, pioneering practices that have become industry standards for large-scale dairying and cheese making. The farm’s biogas digester turns methane into power to run the cheese-making operation, and it reclaims and reuses 100 percent of the effluent in a closed system.

The third-generation family farm has pioneered investments in renewable energy, which have played a crucial role in

allowing the family to reduce dependence on fossil fuel, better preserve the natural environment and maximize economic health. Joseph Gallo Farms was able to create hundreds of new jobs during the recession, Gallo noted.

“We designed our operation to maximize efficiency and sustainability, and we are proud that our practices have a positive impact on our community and the natural environment,” he added.

The Governor’s Award joins a long list of awards for Joseph Gallo Farms’ environmentally sustainable practices, including three California EPA awards for waste reduction; a U.S. EPA award for outstanding leadership in protecting the environment; and awards from the U.S. Fish and Wildlife Service and other environmental agencies for the development of agriculture conservation easements and wetlands preservation and restoration.

Agriculture Secretary Tom Vilsack recently renewed an agreement with U.S. dairy producers to accelerate the adoption of innovative waste-toenergy projects and energy efficiency improvements on U.S. dairy farms, both of which help producers diversify revenues and reduce utility expenses on their operations.

The pact extends a Memorandum of Understanding signed in Copenhagen, Denmark, in 2009.

“Through this renewed commitment, USDA and the Innovation Center for U.S. Dairy will continue research that helps dairy farmers improve the sustainability of their operations,” Vilsack said. “This vital research also will support the dairy industry as it works to reach its longterm goal of reducing greenhouse gas emissions by 25 percent by 2020.”

The secretary signed the agreement at the White House and was joined by representatives of the Innovation Center

for U.S. Dairy and Dairy Management, including Thomas P. Gallagher, CEO of the center.

One objective of the MOU is to increase the construction of anaerobic digesters and explore innovative ways to use products previously considered waste streams from dairy production, processing and handling.

“We have a long and strong relationship with USDA and Secretary Vilsack, and dairy farmers and the dairy industry are very happy that USDA is entering into the next MOU with the Innovation Center,” said Gallagher. “We are all interested in sustainable agriculture and producing good food responsibly, while bolstering an important rural economy, and this new MOU lays out the road map for more improvements. That’s good for dairy, good for the economy and good for consumers.”

Since signing the MOU, USDA has made nearly 180 awards that helped finance the development, construction, and biogas production of anaerobic digester systems with Rural Development programs, such as the Rural Energy for America Program (REAP), Bioenergy Program for Advanced Biofuels, Business and Industry Guaranteed Loan Program, Value Added Producer Grants, among others. These systems capture methane and produce renewable energy for on-farm use and sale onto the electric grid. Additionally, during this period, USDA awarded approximately 140 REAP loans and grants to help dairy farmers develop other types of renewable energy and energy efficiency systems at their operations.

Also, USDA’s Natural Resources Conservation Service (NRCS) has provided $257 million in funding since 2009 that has helped more than 6,000 dairy farmers plan and implement conservation practices to improve sustainability. NRCS support for the dairy industry has resulted in 354 on-farm and in-plant energy audits as well as 18

conservation innovation grants for dairyrelated projects during the past three years.

Anaerobic digester technology is a proven method of capturing methane from waste products, such as manure, and converting it into heat and electricity. The technology utilizes generators that are fueled by the captured methane. Dairy operations with anaerobic digesters routinely generate enough electricity to power hundreds of homes per year.

Hydro Dynamics, Inc. partnered with Three-Es of Milan, Italy, to exhibit the ShockWave Power Reactor (SPR) at the BioGas World Trade Fair in Berlin, Germany.

The event ran from April 23 to 25, 2013. In tests, the SPR has been shown to increase the yield of biogas by 20 percent or more along with a 20 percent reduction in time and energy use. A commercial trial has been ongoing for more than 60 days with similar results.

“Biogas represents an exciting new dimension to the SPR biofuel portfolio,”

said Doug Mancosky, vice-president of research and development with HDI. “We’re extremely excited about the work Three-Es is doing in the European market.”

Digi-Star recently participated as a sponsor in the 12th Annual Dairy Challenge held April 4 to 6, 2013.

Thirty-seven university dairy programs from across the U.S. and Canada – 223 students in total – were represented at the competition. DigiStar supported the event by placing TMR Tracker, EZ4600 Indicators and cab controls on three of the four host dairies.

The Dairy Challenge allows students to put textbook knowledge to work in a real world environment and consult for a dairy.

“It was exciting to see and hear the students work together as teams identifying positive management practices and areas that needed improvement,” said Carol Coulombe, software sales manager with Digi-Star.

The students also had several

opportunities to interact and network with industry professionals throughout the event.

Digi-Star congratulates the four winning teams from California Polytechnic State University, South Dakota State University, University of Vermont and University of Wisconsin-River Falls.

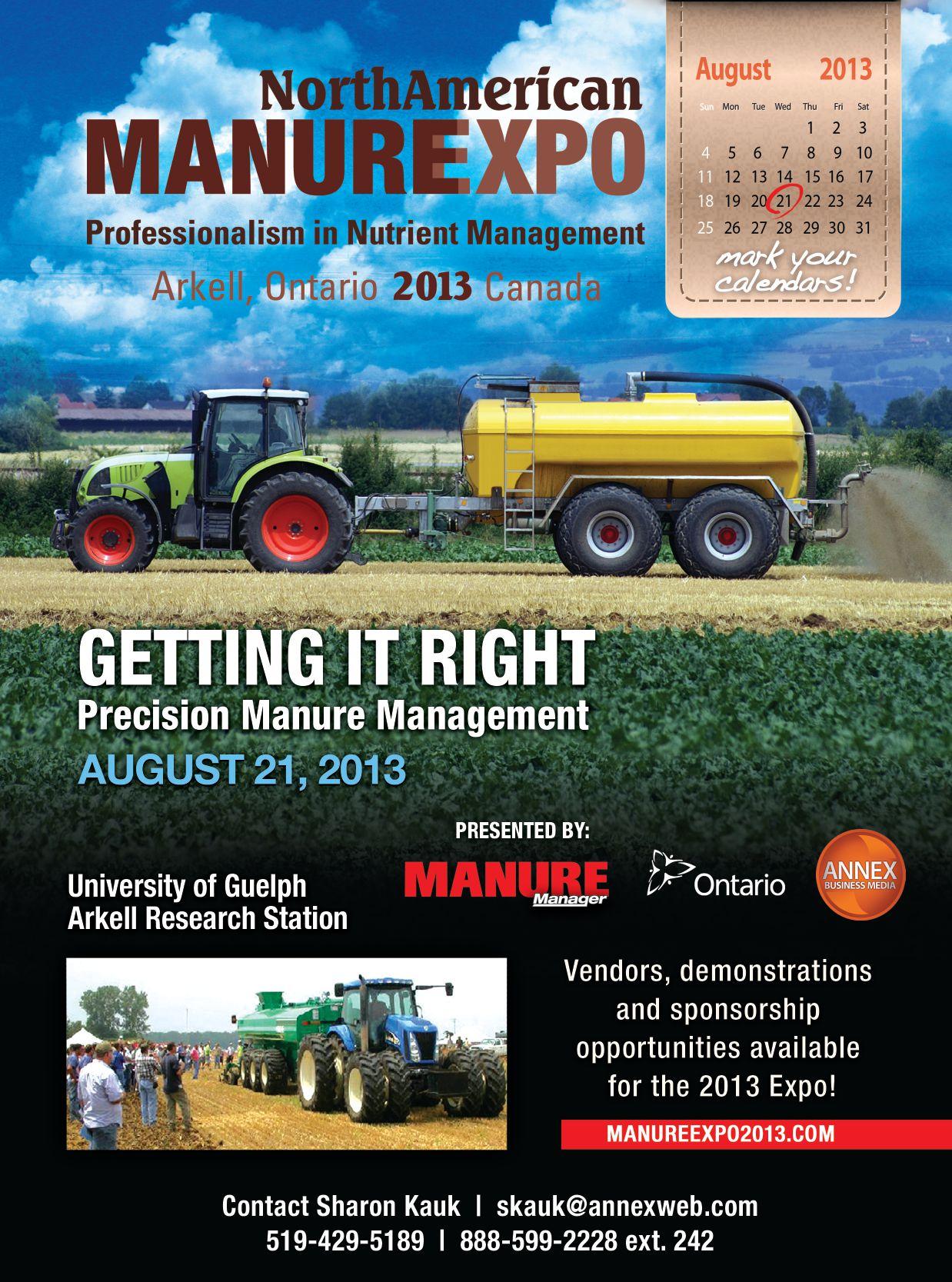

The world’s largest pork-specific trade show – the 2013 World Pork Expo –is marking its 25th anniversary this summer.

It is scheduled for Wednesday, June 5, through Friday, June 7, at the Iowa State Fairgrounds in Des Moines, Iowa.

“World Pork Expo always showcases the latest innovations and information, making it the place to be for porkindustry enthusiasts each June,” says Doug Fricke, director of trade show

marketing, NPPC. “This is one year you won’t want to miss as the industry celebrates the Expo’s 25th anniversary. Now’s the time to start your travel plans as official World Pork Expo hotels fill up quickly.”

In 2012, nearly 20,000 pork producers and industry professionals from 38 countries attended Expo, and the organizers expect a similar showing this year.

Attendees will find the latest porkproduction technologies, products and services on display by more than 400 U.S. and international commercial exhibitors. The trade show is open from 8 a.m. to 5 p.m. June 5 and June 6, and from 8 a.m. to 1 p.m on June 7. This year’s Expo will debut an additional trade-show location — the Agriculture Building, which is located next to the main entry gate and the Big Grill.

High on the list of must-see events are the free business seminars, which take place throughout the day on both Wednesday and Thursday. Seminar topics are designed to provide solutions for on-farm production needs, including marketing options, herd-health protocols, feeding strategies and current issues.

Several pre-Expo tours are being planned to enable producers from other countries to experience Midwestern agriculture — and hospitality — at its finest before the exposition begins.

Online registration is available at www.worldpork.org.

Ohio State University scientist Yebo Li, who works to develop new sustainable bioproduct and bioenergy sources, was recently awarded the Ohio Agricultural Research and Development Center’s (OARDC) Junior Faculty Research Award.

The award honors outstanding achievements by an OARDC faculty member at the rank of assistant or associate professor.

Li, is an associate professor in Department of Food, Agricultural and

Biological Engineering and leads OARDC’s Wooster-based Bioproducts and Bioenergy Research Laboratory, which focuses on biomass, biofuels, biopolymers, anaerobic digestion and algae-based biofuels.

“The results of his work have led to industries seeking him out as a collaborator and to license the discoveries and technologies coming out of his lab,” one of Li’s nominators wrote.

Li has teamed with Clevelandbased Quasar Energy Group to develop patent-pending technology for an integrated anaerobic digestion system, called iADs. The new system costeffectively produces clean energy from solid and liquid organic wastes.

Since joining OARDC in 2007, Li has received nearly $12 million in grant funding as principal investigator or co-principal investigator; has published 36 papers in peer-reviewed scientific journals, 47 papers in proceedings and scholarly presentations, and seven fact sheets and technical bulletins; and has advised or is advising eight PhD students and eight master’s degree students.

His previous honors include the 2012 American Society of Agricultural and Biological Engineers’ Rain Bird Engineering Concept of the Year Award, Ohio State’s 2011 Early Career Innovator of the Year Award, and the 2010 Lumley Research Award from Ohio State’s College of Engineering.

The Washington State Department of Agriculture (WSDA) has cited a dairy operation in Lynden, Wash., for two violations of the state’s Water Pollution Control Act, including improperly applying manure onto a field and allowing polluted water to enter tributaries that lead to a creek identified as salmon habitat. Together, the violations carry a fine of $17,000.

Washington’s Dairy Nutrient Management Act requires dairies to develop plans to manage the manure produced by their cows.

Inspectors with WSDA's Dairy Nutrient Management Program visit all of the state’s dairies approximately once every 22 months to examine how dairy owners manage manure and clean water on their property. Inspectors also review soil tests, manure nutrient analysis results, manure application and movement off farm, and irrigation records.

The fined dairy’s inspection began in

November 2012 after a complaint was made that a worker was improperly applying manure to a field in the rain. A WSDA inspector visited the dairy twice over the next few days and found that material from the dairy’s manure digester had been applied to a field saturated with water. The inspector also found standing water in some areas of the field and evidence that water with digestate in it had flowed into a nearby ditch. This violation included a $9,000 fine.

In addition, the inspector found a leaking valve in a waste water system. An analysis determined this polluted water contained fecal matter at rates in excess of state regulations, and it had leaked into ditches that ultimately led to Bertrand Creek, identified as both a salmon habitat and a human recreation area. This violation included an $8,000 fine.

The dairy has been co-operative in addressing issues raised through these inspections.

One of Wisconsin’s small dairy farms moved one step closer to becoming a green-energy pioneer.

The Titan 55 was lowered into its new home at Allen Farms, northwest of Oshkosh, Wis., last fall. It took more than a month for the small-scale, plug-andplay containerized digester to travel from a manufacturing plant in Poland by ship, and across America’s heartland before reaching Oshkosh.

The Titan 55 is BIOFerm Energy Systems’ smallest anaerobic digester and is specifically designed for operations that have a limited organic waste stream, making it ideal for farms the size of Dave Allen’s. The biodigester will process manure produced by the farm’s 135 dairy cows to make biogas. Part of Titan 55’s appeal is its smaller, more manageable size. It was designed with farmers specifically in mind, to help them process waste such as manure, bedding and spoiled silage while at the same time adding value to the farm.

University of Wisconsin – Oshkosh faculty and students are serving as field advisors and researchers to assist Allen Farms.

Titan 55 is the second biodigester to come from BIOFerm’s partnership with the University of Wisconsin – Oshkosh (UWO) and the UW Oshkosh Foundation. For

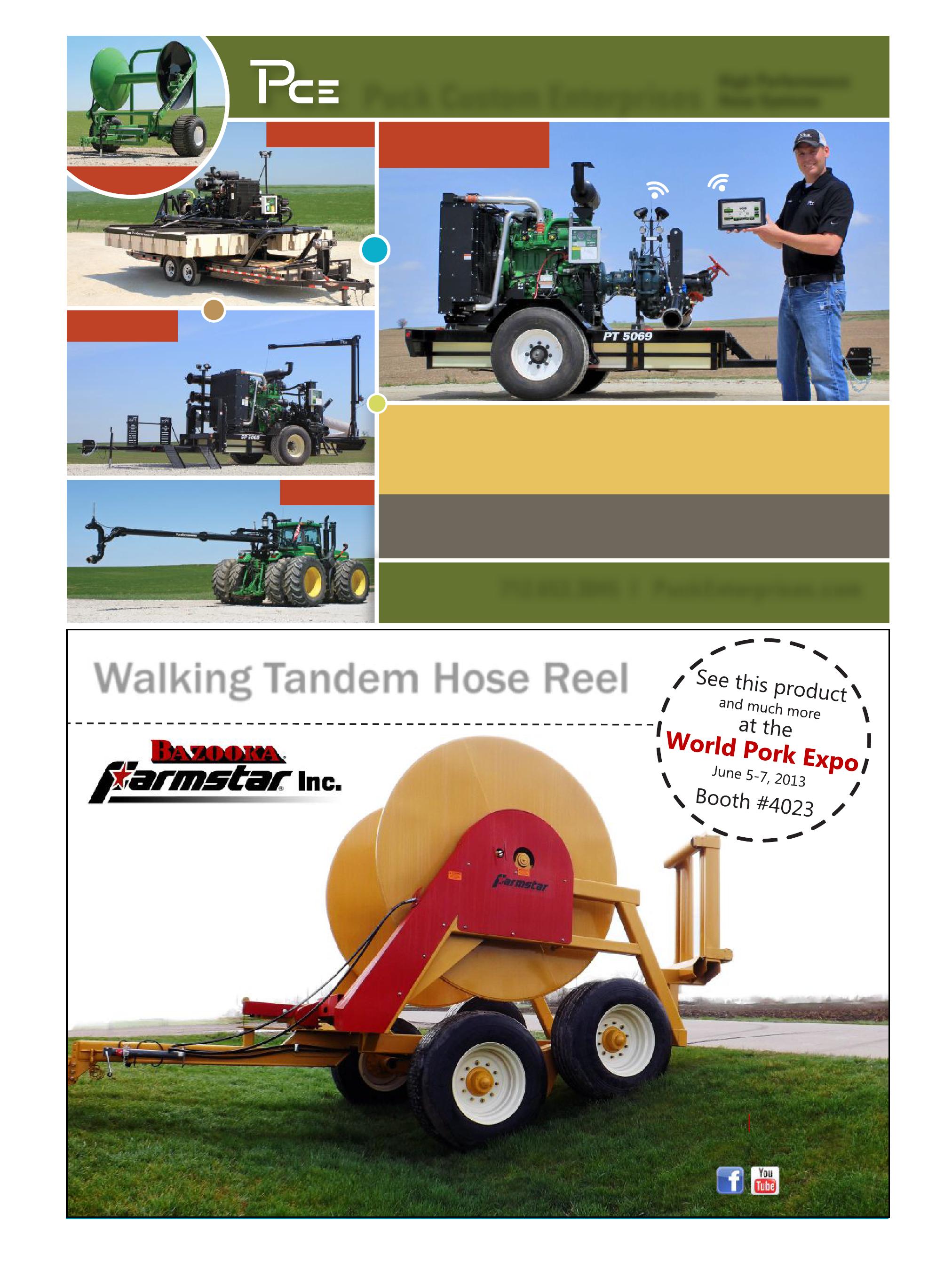

Bazooka Farmstar has re-engineered the Coulter Till toolbar for 2013. The 13 wave Coulter blades create minimal ground disturbance and evenly distributes anywhere from 3,000-12,000 gallons of manure per acre in all type of ground from hay fields to chopped corn stubble. Pull-type toolbars are available in 24” or 30” row spacing and can easily maneuver around corners without leaving the ground. The Coulter Till rolls more easily through the ground than a traditional shank, so it requires less horsepower to pull it, which leads to decreased fuel consumption and cost savings. The 2013 Coulter Till toolbar will be featured at booth #4023 during the 2013 World Pork Expo, scheduled for June 5-7 in Des Moines, Iowa. www.bazookafarmstar.com

From the feedlot to the pasture, the Case IH Farmall C tractors delivers the power and performance utility tractor owners expect, all in a superior interior environment. Three new utility powerhouses meet the demand for rugged, comfortable and easy-to-operate equipment to get day-to-day jobs done:

• Farmall 85C with 75 PTO HP

• Farmall 95C with 85 PTO HP

• Farmall 105C with 95 PTO HP

The new Farmall C models use Tier 4A-compliant Case IH FPT 4-cylinder 3.4-L turbocharged and intercooled engines. Precise electronic metering of fuel delivered with electronic high-pressure common-rail fuel injection provides a more efficient combustion process. Glow plugs warm the engine prior to a cold-weather start, eliminating the need to use ether for more reliable starting in freezing temperatures.

Proven 12-speed forward, 12-speed reverse transmissions are designed with operator productivity in mind. The three Farmall C units use a synchronized, mechanical shuttle, wet- or dry-clutch transmission. If the application demands it, upgraded transmission options are available.

The newly designed Farmall cab includes:

• Easy-to-read instrument cluster tilts with the steering column

• Integrated position for loader joystick

• Remote valves in a more accessible position

The optional high-visibility roof panel, visibility to the loader and other attachments is unmatched among tractors in this class. The optional instructor seat comfortably allows two adults to be in the cab together. The driver’s seat can be upgraded to air suspension with a 15-degree swivel to make repetitive tasks less monotonous.

The new climate control system includes an improved HVAC system in the flat-deck floor and has 10 adjustable vents. For operators who prefer a wide-open platform with zero obstructions, the Farmall C models are also available in ROPS configurations.

Owners can choose between standard factory-installed regular or heavy-duty loaders with either non-self-leveling or mechanical self-leveling 72- or 84-inch Skid Steer style buckets. A standard grille guard is included for added protection. The Farmall C is also available in ROPS/ cab and 4WD/2WD configurations. Tackle loads with the standard 12.5-gpm hydraulic pump. If more flow is needed,

upgrade to 16.9 gpm. Up to two rear remotes offer quick connections for a variety of functions requiring hydraulics. www.caseih.com

Gehl/Mustang recently introduced the Gehl/ Mustang R Series radiallift skid loaders. The new line includes three models for Gehl – the R190, the R220 and the R260 – plus three models for Mustang –the 1900R, the 2200R and the 2600R.

The R Series offers a newly designed operator station with an integrated digital display, improved visibility all-around, pressurized cabs, Tier IV engines and a hydraulic system.

The R Series radial-lift skid loaders fall into the large-frame category. When equipped with optional counterweights, the rated operating capacities range from 2,110 lb. (957 kg) on the R190/1900R to 2,780 lb. (1261 kg) on the R260/2600R. Lift heights reach up to 120.5 in. (3061 mm) on the R190/1900R and 123 in. (3124 mm) on the R220/2200R and R260/2600R.

These large-frame loaders come equipped with emissions compliant Tier IV Yanmar engines that incorporate DPF (diesel particulate filter) technology. This engine technology does not require fuel after-treatments, such as urea. Maximum torque ratings range from 173 ft.-lb. (235 Nm) on the R190/1900R to 206 ft.-lb. (279.3 Nm) on the R260/2600R.

The R Series skid loaders come equipped with auxiliary hydraulics that can achieve flow rates from 31.5 gpm (119 l/min.) on the R190/1900R to 35 gpm (132.5 l/min.) on the R220/2200R and R260/2600R with the high-flow configuration.

The operator’s compartment features a side-folding restraint bar and armrests with multiple adjustments. Joystick and

hand/foot control towers are adjustable and mechanical or air-ride suspension seat options are available. A cab-forward design and lowered rear towers provides visibility to the bucket edge and rear of the machine. A pressurized sealed cab enclosure, with sound reduction material and a rear-mounted air filter, is also available.

The R Series can be customized with one of three control options: T-bar, joystick, and hand/foot. Auxiliary hydraulic controls are located on the joystick in all configurations for easy access. A customizable digital display provides coolant, fuel, battery, environmental, engine regeneration information and other features in real time.

The R Series skid loaders also include other features such as the manual Quicka-Tach™ or hydraulic Power-a-Tach™ attachment systems, HydraGlide™ ride control and the Hydraloc™ safety system. www.gehl.com/www.mustangmfg.com

Vogelsang USA, Inc., a manufacturer of pumps, grinders and related equipment for the municipal, industrial and agricultural markets, recently announced the appointment of Scott Holtz as the company’s national sales manager.

In his new position, Holtz will be responsible for managing all sales functions for the company in North America. He will also oversee the development of short- and long-term sales strategies and develop and implement the annual sales plan. Holtz will support the sales team in meeting corporate sales objectives and assist in cultivating and maintaining relationships with Vogelsang USA’s customers.

Holtz has been in the positive displacement pump business for 30 years and has vast cross-company experience in management positions with Roper, Monflo, APV and Robbins & Meyers, Moyno.

“Scott has been an integral part of the positive displacement market for the past 30 years,” said Russ Boring, president of Vogelsang USA Inc. “His track record of success within the industry, his relationships with clients and respect earned from the community make him a perfect fit to lead the sales function.

“I am delighted to have been offered the role of national sales manager,” said Holtz. “I am excited about the new responsibilities and challenges that lie ahead.

“Building client relationships, improving

customer service and support and the promotion of Vogelsang’s new and exciting products are my primary focus areas,” he added. “The role will enable me to be very hands-on and I intend to provide leadership through the active coaching and development of the sales team, both in the field and our internal sales function”

New Holland has introduced its next generation of utility tractors, the T4 Series. This tractor produces between 84 to 106

horsepower using a four-cylinder engine with Common Rail technology and a cooled exhaust gas recirculation system to meet Tier 4A compliance.

T4 models are fitted with a 207 in.3 (3.4 l), Common Rail F5C engine. These engines benefit from Cooled Exhaust Gas Recirculation (CEGR) technology for Tier 4A compliance.

F5C engines deliver between 84 and 106 engine horsepower. Productivity in demanding conditions is enhanced with a 35 percent torque rise. Sustained maximum power is available from 1900 to 2300 rpm to deliver flexibility in the majority of tasks.

Up to two rear remotes and two midmount hydraulic remote valves can be installed at the factory. An additional third rear remote can be installed by any New Holland dealer.

The T4 Series offers extensive transmission choices, meaning producers can tailor the tractor to suit their individual needs. Choose from a 2WD, ROPS, mechanical shuttle version for basic PTO horsepower all the way up to a 4WD, cab, electrohydraulic shuttle model for deluxe comfort and all weather versatility. On ROPS models, operators will benefit from the same operating environment and ergonomic layout as cab models.

Both cab and ROPS models are available with two mechanical transmission options: the 12x12 Synchro Command shuttle and 20x12 Synchro Command shuttle with a creeper. The left hand column-mounted shuttle enables operators to change directions without having to remove their hand from the steering wheel.

www.agriculture.newholland.com

Soucy International Inc. recently announced the launch of a new product in its line of Soucy Track agricultural track systems: the S-Tech 800.

Designed for high-power tractors, this track system is the culmination of many years of research and development.

“With this system, we’ve raised the bar, bringing every single detail that matters to farmers to a new level of evolution,” said André Todd, general manager of Soucy International Inc. “No compromises were made in the creation of this system. Whenever a decision had to be made, we opted for performance and durability.”

The S-Tech 800 features a completely revamped design with independent

lateral tandems on the support wheels. These tandems enable the wheels to follow ground contours while providing comfort and better load distribution, which increases traction, flotation and the system’s lifespan.

“It’s a brand new platform with a central geometry developed using castings,” said Steve Fréchette, S-Tech 800 project manager. “It does an excellent job of preventing the accumulation of debris and offers the durability and flexibility demanded by farmers.”

Soucy Track has also developed a new adaptation system that “does not require any modifications to the tractor and respects its transmission ratios, ensuring the longevity of the track system and the tractor,” added Fréchette.

The S-Tech 800 also features a new rubber track, whose design and exclusive materials add to the comfort, traction and endurance of the system.

The S-Tech 800 is currently available for John Deere 8030 and 8R series tractors. It will also soon be available for Case, New Holland and Fendt tractors. www.soucy-track.com

Kifco offers a full line of traveling irrigation systems, pto pumps, slurry pumps & primary pump packages

With outstanding service & support through the largest network of authorized dealers, there’s only one name you can trust

Boerger, LLC has hired a new biogas and agriculture sales manager for North America – Steven Widdicombe. Widdicome has completed training in Germany, is very familiar with Boerger’s technology on farms and at anaerobic digestion plants and will be a knowledgeable source for consulting engineers, OEMs and end users.

Widdicombe is based at Boerger’s North American head office in Chanhassen, Minn. He can be reached at 612-435-7353 or at swi@boerger.com. For even more product news, visit www.manuremanager.com

Over a 2 year period starting in 2005, a Midwestern hog farmer used BioDigest and tripled the nitrogen retained in his manure slurry. He then switched to a different product and started losing nitrogen. In 2011, he returned to BioDigest, and his nitrogen levels are again on the rise.

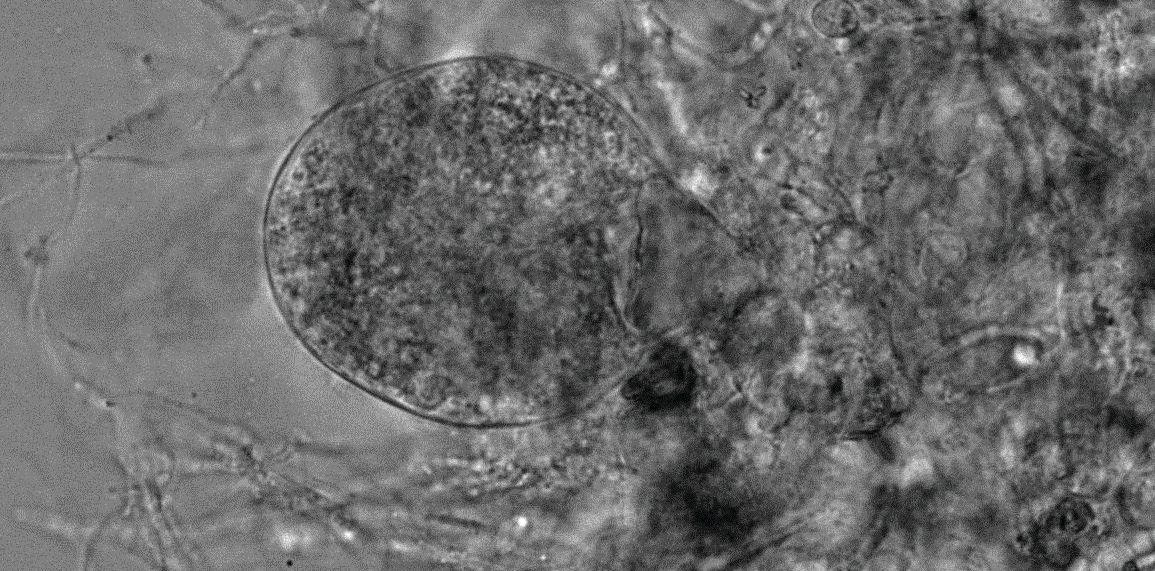

Stepping into unexplored territory in efforts to use corn stalks, grass and other non-food plants to make biofuels, scientists recently described the discovery of a potential treasure-trove of candidate enzymes in fungi thriving in the feces and intestinal tracts of horses.

They reported on these enzymes – the key to economical production of biofuels from non-food plant material – at the 245th National Meeting & Exposition of the American Chemical Society (ACS) held recently in New Orleans, La.

Dr. Michelle A. O’Malley explained that cellulose is the raw material for making biofuels from non-food plant materials. Cellulose, however, is sealed away inside a tough network of lignin within the cell walls of plants. To produce biofuels from these materials, lignin must be removed through an expensive pretreatment process. Then, a collection of enzymes breaks cellulose down into sugars. Finally, in a process much like production of beer or wine, those sugars become food for microbes to ferment into alcohol for fuel, ingredients for plastics and other materials.

“Nature has made it very difficult and expensive to access the cellulose in plants,” said O’Malley. “Additionally, we need to find the best enzyme mixture to convert that cellulose into sugar.

“We have discovered a fungus from

the digestive tract of a horse that addresses both issues – it thrives on lignin-rich plants and converts these materials into sugars for the animal. It is a potential treasure trove of enzymes for solving this problem and reducing the cost of biofuels.”

The digestive tracts of large herbivores such as cows and horses, which can digest lignin-rich grasses, have been a welltrodden path for scientists seeking such enzymes. But in the past, their focus has been mainly on enzymes in bacteria, rather than fungi, which include yeasts and molds. The goal: Take the genes that produce such enzymes from gut fungi and genetically engineer them into yeasts. Yeasts already are used in time-tested processes on an industrial scale to produce huge quantities of antibiotics, foods and other products. That proven production technology would mean clear sailing for commercial production of biofuels.

O’Malley explained that several genes from gut fungi are unique compared to bacteria, since the fungi grow invasively into plant material. Also, they secrete powerful enzyme complexes that work together to break down cellulose. Until now, however, fungi have largely been ignored in the search for new biofuel enzymes – and for good reason.

“There was relatively little scientific knowledge about fungi in the digestive tracts of these large animals,” O’Malley explained. “They are there, but in very low numbers, making it difficult to study. The low concentrations also fostered a misconception that fungi must be unimportant in digestion of cellulose. And it is extremely difficult to isolate and grow these fungi to study their enzymes.”

O’Malley’s research group at the University of California, Santa Barbara, collaborated with researchers at the Broad Institute of the Massachusetts Institute of Technology and Harvard University. They worked with a gut fungus isolated from horse feces and identified all the genetic material that the fungus uses to manufacture enzymes and other proteins. This collection of protein-encoding material – the fungus’s so-called “transcriptome” – led to the identification of literally hundreds of enzymes capable of breaking through that tough lignin in plant cell walls and the cellulose within. The team now is shifting through that bounty to identify the most active enzyme and working on methods for transferring the genetic machinery for its production into the yeast currently used in industrial processes.

The difference between this Fendt and other tractors is the location of the manure.

Sure, other brands will tell you they have a continuously variable transmission. So ask them why their supposedly continuously variable transmission needs a clutch and see what a load they’ll give you. And don’t even bother asking about features like our stability control or reverse station operation unless you’re wearing tall boots.

And if that’s not enough, we also back it up with our Fendt Gold Star Customer Care program that gives you 3-years or 3,000 hours of comprehensive warranty with included routine maintenance - the best in the industry.

In the hauling business, you need a tractor that’s capable and dependable.

That’s why the best run operations run Fendt.