Canadian bio-digester report

Making digesters profitable for farmers a multi-pronged approach

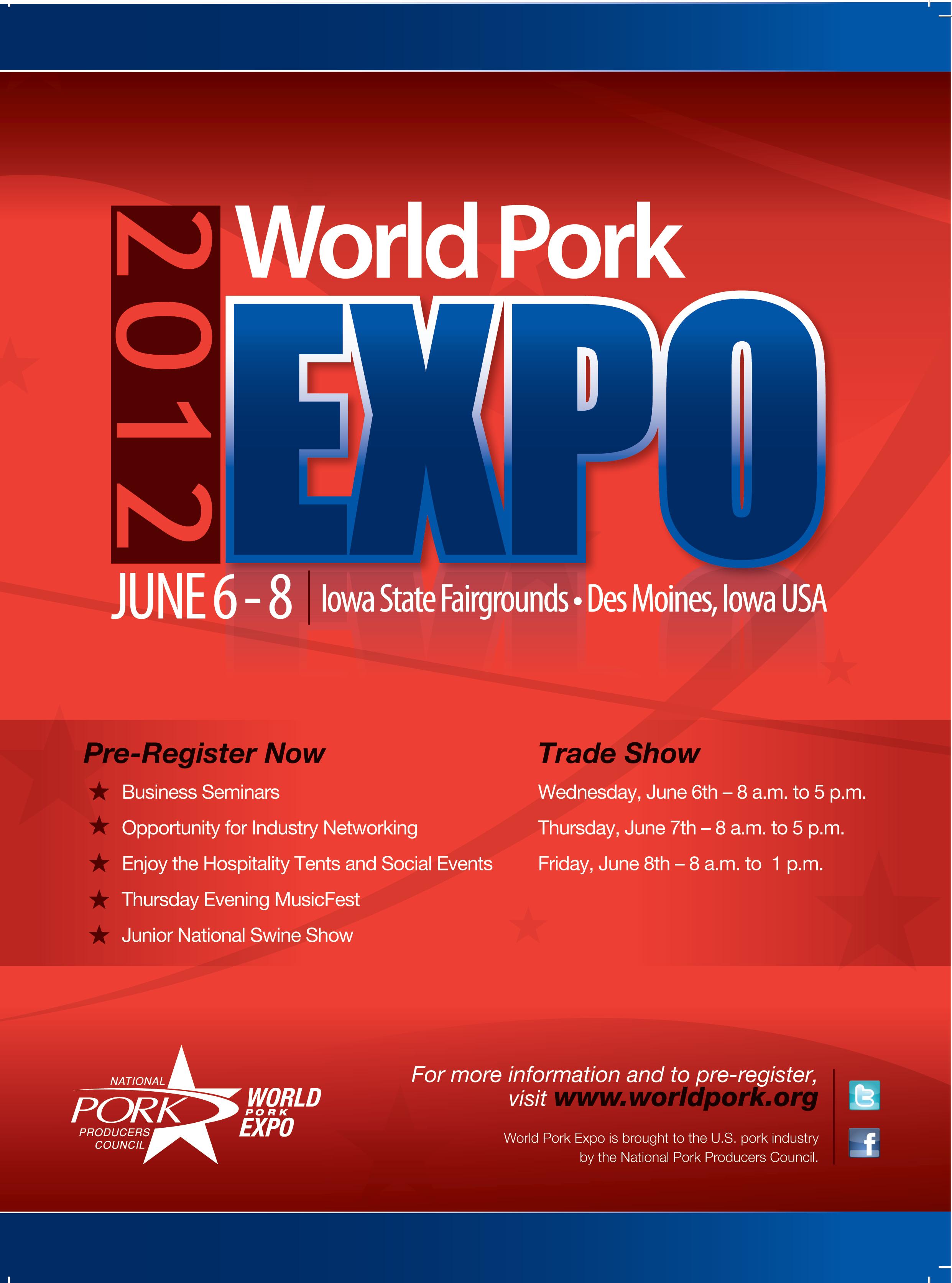

OMG, Google invests in North Carolina biogas-to-energy project on hog farm, FYI Hog facility Loyd Ray Farms constructs a digester with the help of Duke University and Duke Energy, with Google purchasing a portion of the carbon credits generated over the next five years.

18

Compost from cattle manure finds home in Alberta potato production

The Kasko Cattle Company is an example of feedlots and specialty crop production working together to benefit from manure.

Cover: The anaerobic digester installation located at Delft Blue’s veal farm near Cambridge, Ont. Farm-based biogas facilities are slowly increasing in number across Canada with the majority located in the province of Ontario. Photo by Margaret Land

March/April 2012

Volume 10 • No. 2

Published by:

Annex Publishing & Printing Inc. P.O. Box 530 Simcoe, Ontario N3Y 4N5

Editor

Margaret Land • (519) 429-5190, (888) 599-2228, ext 269 mland@annexweb.com

Contributing Editors

Mauricio Espinoza, Treena Hein, Tony Kryzanowski

Advertising Manager

Sharon Kauk • (519) 429-5189, (888) 599-2228, ext 242 skauk@annexweb.com

Sales Assistant Mary Burnie • (519) 429-5175, (888) 599-2228, ext 234 mburnie@annexweb.com

Production Artist Emily Sun

VP Production/Group Publisher Diane Kleer dkleer@annexweb.com

President Mike Fredericks mfredericks@annexweb.com

Publication Mail Agreement #40065710

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO CIRCULATION DEPARTMENT, P.O. BOX 530, SIMCOE, ON N3Y 4N5

e-mail: subscribe@manuremanager.com

Printed in Canada

Circulation

e-mail: subscribe@manuremanager.com

Tel: 866-790-6070 ext. 211

Fax: 877-624-1940

Mail: P.O. Box 530

Simcoe, ON N3Y 4N5

Subscription Rates

Canadian Subscriptions

$35.24 Cdn, one year (with GST $37.00, with HST/QST $39.82)

U.S. Subscriptions: $47.00 USD, one year

Occasionally, Manure Manager will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher's written permission. ©2012 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher's approval. Such approval does not imply any endorsement of the products or services advertisted. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

www.manuremanager.com

By Margaret Land

Jennifer Green, executive coordinator of the Agri-Energy Producers Association of Ontario (APAO), has a vision for the biogas sector in her province.

“The [APAO] is not interested in seeing another 10 or 20 projects come down the pipe,” she stated during the recent Canadian Farm and Food Biogas Conference held in London, Ont. “I think there needs to be some reasonable, gradual growth in the sector but, ultimately, we would like to see hundreds of these [biogas] projects be able to be up and operational so we can call our industry an industry.”

In 2003, a small dairy operation in Eastern Ontario – Fepro Farms – constructed an anaerobic digester that initially supplied 50 kilowatts of energy. A few years later, it became the first farm in the province to connect its system to the electrical grid.

While the on-farm biogas sector has changed in Ontario and across Canada since those early days, it still remains a small industry with a handful of farm-based anaerobic digesters in operation from coast to coast (see Manure Manager’s cover feature starting on page 6). Some of the limiting factors for the industry include smaller animal unit numbers (in comparison to U.S. operations), limited understanding of the technology by policy makers, restrictive laws, and expensive approval processes.

“Where we see other sectors that have a very mature base and a lot of experience, we’re just at the cutting edge,” said Green, adding that “for a very young industry, biogas has achieved some major milestones in less than five years.”

Those include the creation of a feed-in tariff (FIT) program in 2009 within Ontario, which has a mandate to receive 12 percent of its power from renewable sources by 2025. Under the FIT program, on-farm biogas systems that generate 100 kW or less receive 19.5 cents per kWh while projects that generate between 100 kW and 250 MW receive 18.5 cents per kWh – both under a 20-year contract, with bonuses for production during peak demand. The lead time for review and approval of a FIT biogas contract is three years and the program is currently undergoing review.

“As a snapshot of Ontario’s agriculture biogas industry, projects are typically between 250 and 500 kWh and the inputs are primarily from the animals they have there on the farm,” explained Green. “They augment that with off-farm materials. These farms are also using the digestate … as fertilizer for the land and to potentially replace their bedding materials for their animals.”

She admits that most early adopters of the technology have been larger-scale farm operations.

“We do recognize that the small to medium-sized farms are not necessarily being captured in these developments,” said Green. “We want to see that opportunity for energy production happen in a similar fashion across the board, independent of what size you are.”

While Ontario currently hosts most of the current on-farm biogas projects in Canada, other provinces do have projects, including a biomethane system in British Columbia that injects scrubbed gas into the pipeline of one of the province’s natural gas providers. It’s an idea that Ontario energy providers are also investigating. Last year, gas utilities in the province submitted joint applications to the Ontario Energy Board to explore biomethane opportunities. The APAO is also investigating the industry’s potential and is producing an information guide for interested farmers.

“The biogas sector has emerged here in Ontario,” said Green. “It has the potential to grow and see very good things happen.”

By Treena Hein

Making digesters profitable for farmers a multi-pronged approach

The number of manure biodigesters – and other types as well – is still slowly increasing across Canada these days. This is due to further government support and updated regulations that allow farms to accept off-farm materials, which greatly boost gas production.

Of all provinces, Ontario still leads the way in number of on-farm digesters with manure as the primary feedstock to generate methane, with about 20 operational or being commissioned. They are mostly located on dairy farms, with three at greenhouses, a few on beef farms and one on a veal farm; one dairy farm digester also uses some hog manure. There are several reasons why Ontario has the most digesters, mostly because that provincial government has been involved longer than others in supporting digesters. In 2006, Ontario offered a Renewable Energy Standard

Offer Program, which was replaced by the Feed-In-Tariff (FIT) program in 2009; it is now under review. St. Eugene, Ont., dairy farmers George and Linda Heinzle signed a Standard Offer contract for $0.12 per kWh shortly after their digester became operational in mid-2007. Manure from the farm’s 300 cattle and a weekly input of 110 tonnes of off-farm material now produces enough methane to generate 360 kW per week – sufficient, Linda says, to power 300 homes.

The Heinzles and other farmers received funding to build or expand their digesters through an Ontario Ministry of Agriculture, Food and Rural Affairs (OMAFRA) program that ran from 2007 to 2010; this funding availability is another reason digester numbers are highest in Ontario.

“There was very strong interest,” says Chris Duke, a program analyst with OMAFRA’s Environmental Management Branch. “The program funded up to 70 percent, or $35,000, for digester feasibility studies (46 studies were funded out of about 90 applications), and up to 40 percent, or $400,000, for new or

expanding biogas systems construction (27 projects were funded). Of these, 25 have been or are being commissioned (17 with manure as the primary feedstock) and two are still in development. One is solely thermal; that is, it produces methane to burn, which offsets the natural gas used at the site to make animal feed. Duke says five other digesters that don’t involve OMAFRA funding are being constructed; most are using dairy and beef manure along with food industry byproducts.

Standard energy purchase offers are also now available in provinces like Nova Scotia, New Brunswick and British Columbia. B.C. has also provided $1.5 million to assist the development of B.C.’s first anaerobic digestion facility, Fraser Valley Biogas in Abbotsford. (The other digester project in the province is a demo unit at a dairy farm.)

“B.C.’s Clean Energy Act sets a target to ensure our electricity supply is 93 percent renewable,” notes Sue Bonnyman, director of generation and regulation electricity policy at B.C.’s Ministry of Energy and Mines. “However,

The digester of dairy producers George and Linda Heinzle located near St. Eugene, Ont. Photo courtesy of George and Linda Heinzle

the current low electricity prices, due to B.C.’s very fine hydroelectric system, create challenges for a number of new or renewable technologies.”

These low electricity rates are one reason the province has made it possible for Fraser Valley Biogas to sell cleanedup biogas to gas company Fortis. The Fraser Valley Biogas digester is a PlanET Biogas system that began operation in August 2010; it uses liquid dairy cattle manure and solid chicken manure from four nearby farms (both directly from barn cleanout or, in the case of the dairy manure, sometimes from a storage lagoon) as well as food industry byproducts. PlanET Biogas has nine other digester projects across Canada in various stages of construction (six are operational), and most use dairy manure as the primary feedstock.

Before digester biogas is injected into the natural gas network, it must be scrubbed, and the cleaned product is known as “biomethane.” However, “the gas-scrubbing equipment required is costly, and thus only makes sense at larger-sized projects of at least 1 MW, generated using a combination of manure and off-farm materials,” notes PlanET Biogas application manager Matt Lensink.

(He says how many tonnes per day of dry matter or wet matter manure is used depends on the type of manure and the type and amount of off-farm materials.)

The Fraser Valley Biogas digester is designed to produce 800 m3 per hour of biomethane, in comparison to 125 m3 per hour in the typical on-farm digester in Ontario. So, not only must a biomethaneselling digester be very large, but also it must be located near a natural gas pipeline.

All other digesters in Canada that are currently injecting biomethane into the natural gas network are at municipal sewage plants, landfills or food processing companies. Electrigaz Technologies Inc. president Eric Camirand notes that in Quebec, the Ministry of Environment now subsidizes municipal biogas plants up to 66 percent of capital costs, with the focus on injection of biomethane.

“Like B.C., we already have a lot of green electricity being produced in Quebec with hydroelectric dams, so creating and using biogas directly to offset the use of gas from fossil fuel sources instead of for electricity production is favored,” he says, adding, “[the] interest in using biogas directly is increasing in Ontario as well.”

The city of Hamilton, Ont., is already doing this with its sewage sludge anaerobic digester. Electrigaz has done several studies for gas companies such as Union and Enbridge on scrubbing biogas and injectiing biomethane into their networks.

“Gas utilities are now requesting the right from their respective utilities

commissions to acquire and distribute this renewable natural gas, as electrical utilities have done for renewably generated electricity in Ontario,” says Camirand.

Besides decent tariff offers and funding availability, the other most significant factor in the spread of digesters in Canada is the allowance for streaming of off-farm food sector resources (mostly fats and oils from restaurants) into digesters, which boosts electricity output considerably. The Heinzles’ digester uses manure from the farm’s 300 cattle and a weekly input of 110 tonnes of greasetrap and floatation material from local water treatment plants (with a little food processing byproduct) to produce 360 kW. Linda says that without the offfarm material, energy production drops by about 90 percent. Allowing off-farm materials into digesters was a regulatory hurdle that has been sorted out in most provinces, and recently Ontario lifted annual volume restrictions. Off-farm material was legally considered a waste product and in the past, for farms to accept it, used to require that farms be designated waste disposal sites.

The Klaesi families (FEPRO Farms), who share a digester between their dairy farms near Cobden, Ont. (two hours’ drive northwest of Ottawa), received official approval to accept off-farm food wastes in 2008. Operation of this digester is on hold due to a dairy barn fire in early December 2011. Over the last three years, the system fed electricity

into the grid continually and drew from the grid during milking, so that the farm was billed only for net power used. The generator also provided supplemental winter heat to buildings.

“Co-substrates are definitely needed for manure digesters to be economically viable, and are a necessity with hog manure in some systems,” notes CH-Four

Biogas Inc. systems analyst Claire Allen. The company has created a software program to analyze what amount of a given substrate such as source-separated organics or fat/oil/grease is advisable to add to what’s already present in a digester.

“When clients gain access to a new substrate or want to check how much

Prince Edward Island One, uses potato byproducts

New Brunswick One, dairy manure

Quebec Two, hog manure; thermal only

Ontario 27 operational, or being commissioned; Five under construction (about 26 use or will use primarily manure; 17 of these are operational)

Cavendish Farms; Electrigaz system; built in 2009; 12 MW thermal energy plant uses potato processing byproducts to process (boil and fry) potatoes

Grand Falls, 600 kW; commissioned 2011; Laforge Bio-Environmental; dairy manure plus food processing byproducts

St-Edwidge-de-Clifton (2001) and St-Odilon-deCranbourne (2004). Bio-terre Systems Inc.

Range from 100 kW to 1.6 MW

Feedstock is mostly dairy manure, three greenhouses (composted material, some manure and other industry byproducts) and two beef operations, one thermal digester at an animal feed plant

Many consulting, design, construction and operational support companies are involved in these projects, 25 biogas related companies in Ontario, several also outside the provinces.

(Note: Several municipalities collecting gas from landfills and water treatment facilities and generating electricity; a digester in the city of Hamilton’s sewage treatment plant produces and feeds biogas into the province’s natural gas pipeline network.)

to add, they can consult with us,” says Allen. “The program analyzes how the interaction will go and whether digestion will still be stable. For example, if proteins are too high, you will have inhibition of bacterial activity from ammonia. Inhibitions will also occur with too much salt or sulphur.”

CH-Four has nine systems running in Canada, one in New York state and three more being constructed in Canada. All CH-Four systems are combined heat & power (CHP); they have one under construction in Canada that will use hog manure (sludge from pits under the hog pens that is washed into anaerobic lagoons) as the primary feedstock.

“Pig manure has less solids content, and this negatively impacts gas production, so the energy that comes from other substrates is critical,” Allen notes. “Hog manure also has more disinfectants and more antibiotics than dairy manure, and this also affects bacterial activity.

Manitoba

At least six, two on-farm (one operational), two food industry and one municipal (Winnipeg; sewage)

Sweetridge Dairy in Winkler; electricity produced primarily for on-farm use; completed November 2011; 200 cows; PlanET-Biogas system; mesophilic; CHP (55 kW)

Cook Feeders in Teulon; Bio-Terre system; hog manure; low-temperature CHP (62 kW electricity, 31 kW heat energy)

Three potato processing plants have anaerobic digesters: McCain Foods (Portage la Prairie and Carberry plants; at least one is offsetting natural gas use), and Simplot (Portage la Prairie; offsets natural gas use).

Saskatchewan One, currently nonoperational Pig manure, Cudworth Pork; built in 2003. Kriegfischer technology; non-operational due to several issues

Six built (four operational)

Alberta

(One under construction and eight proposed)

British Columbia 2, both on-farm

Highmark Renewables system in Vegreville; 999 kW to grid. Two vertical wet digesters; uses cattle manure and food processing byproducts; will be adding another two larger digesters as part of ethanol project GP Hairy Hill Intergrated Biorefinery (expansion of Highmark project) 1.2 MW of electricity to grid; part of an ethanol complex and feedlot complex

Cargill Meat Solutions – internal use for natural gas offsetting to fire two boilers; uses beef renderings Lamb Weston – offsetting natural gas to fire a boiler; uses potato byproducts

An ADI ‘UEM’ 5.5 MW anaerobic hybrid digester will be built in the spring at the Millar Western pulp mill in Whitecourt; will use pulp mill sludge

Bakerview Eco Dairy in the Fraser Valley, demo unit piloting Avatar Technology

Fraser Valley Biogas in Abbotsford; PlanET Biogas system; dairy manure from several manure plus offfarm materials; sells electricity as well as biomethane

“In a hog manure digester, we put dairy manure in at the start to provide good bacterial activity. Dairy manure has more of an optimum solids content, so a plug-flow digester system can be used, but hog manure digesters must be of the type sold by CH-Four. “All our systems are continuous flow, mixed automatically for 15 minutes every hour,” says Allen. “This also ensures that the temperature in the digester is maintained. We also install digesters partially in-ground to help them retain heat, and never attempt startup in the winter.”

Bio-Terre Systems Inc. has installed three systems in Canada so far, all that use solely hog manure with the biogas used to produce heat only. Two are in Quebec, on farms in St-Edwidgede-Clifton (2001) and St-Odilon-deCranbourne (2004), and the other is at Cook Feeders in Teulon, Man. (2004). Bio-Terre specializes in lowtemperature digestion that is well-suited for highly diluted hog and dairy cattle manure.

“With higher temperature systems, because there is so much liquid to heat with highly diluted manure, there is more energy needed to make anaerobic digestion work than is being produced,” says Bio-Terre chief operations officer Elise Villeneuve. “Only a lowertemperature system is able to achieve a positive energy balance.” Bio-Terre’s technology uses sequential batch operation with a seven-day cycle and gives a methane yield similar to highertemperature digesters.

“We create an environment where

we can keep the untreated solids in and discharge what has already been treated,” Villeneuve says. “Our psychrophilic anaerobic digestion relies on robust, but slower-acting, bacteria that work at temperatures between 5 and 28 C, with an optimum between 20 and 25 C.” Mesophilic (mid-temperature) and thermophilic (high-temperature) digester processes operate at about 35 C and 55 C, respectively. Bio-Terre also has two digesters finished in the U.S. and a third being built, all on dairy farms; the company has partnered with Revolution Energy Solutions to have electricity production at each of these sites and at all future digester installations.

Multiple income streams needed “Energy recovery alone is rarely enough to cover capital and operation costs of digesters,” Villeneuve says. “Financially viable projects require a combination of tipping fees, energy recovery with a good tariff and fertilizer revenue. The perceived value of digestate is currently low (it’s often not worth anything), but we hope that it will increase.”

The value of digestate depends on many factors such as chemical fertilizer costs (if they go up, manure and other sources of organic fertilizer gain value), what’s in the digestate, and transportation costs. The Heinzles use all of their digestate in two ways. They store the liquid from the digester in a pit lagoon for spreading on the farm’s fields three times a year, which offsets their fertilizer costs by about 80 percent.

“It’s extremely good fertilizer that’s very bio-available to the plant,” says Linda. They also use the solids from the digester tank as cattle bedding (placed in the barn for cows to lie on during the colder months).

“The farms in Ontario that are doing this are able to produce quite a bit of solids,” notes Duke. “They use about half of it or all of it, and a few places are selling the fibers for bedding. The fibers are about 70 percent moisture content… cattle like it…and farmers are very pleased.”

The Heinzles also receive income from taking off-farm materials into their digester. “We are accepting materials that would have gone to the landfill at up to $90 per tonne, but we keep the rates private,” Heinzle explains. “It’s a lot less than landfills charge, and the price depends on the quality.”

Like Bio-Terre, Highmark Renewable (IMUS digesters) is also focusing on large livestock operations. Growing

Power Hairy Hill (GPHH) near Vegreville, Alta., operates an IMUS digester that was commissioned in 2005, designed to process approximately 15 percent of the manure from a 36,000-head feedlot (nearly 100 tonnes of open-pen manure, with a moisture content between 50 and 75 percent). The digester is a 2.5 MW cogeneration facility fueled by polished biogas (partially scrubbed biogas).

Trevor Nickel, Highmark’s assistant general manager, says the moisture and hydrogen sulfide in raw biogas can increase maintenance costs of generators

and shorten their lives. The Highmark design is also unique in its mechanical separation system, which removes debris from the active digester without the need to shut it down.

Nickel says debris accumulation is the cause of failure for all other types of feedlot digesters. Debris can include rocks, stones, gravel, sand and even things like horseshoes and tractor parts. Nickel notes that with most dairy operations, debris accumulation takes a relatively long time, but if the dairy or feedlot manure is sandy, sand and

By Tony Kryzanowski

In a world where a “like” or “dislike” thumb pointing up or down has immense control over public opinion, an endorsement by Google relating to the carbon credits generated by a project that uses biogas from hog manure to create electricity speaks volumes.

That’s the case with the $1.2 million green energy installation featuring anaerobic digestion of hog manure at Loyd Ray Farms in Yadkinville, N.C., about 25 miles west of Winston-Salem. Conceived and financed by Duke University and Duke Energy, Google helped pay for part of the university’s contribution toward the project in exchange for a portion of the carbon credits generated over the next five years, aimed at offsetting its own emissions.

“Google’s involvement adds a lot of visibility to the project because when they do something, everybody looks,” says Marc Deshusses, a professor of civil and environmental engineering at Duke University. He’s responsible for conducting a technical evaluation of the project, from overall performance to environmental impact. “The company is also very thorough in its search for highquality carbon credits. Projects go through a rigorous evaluation process.”

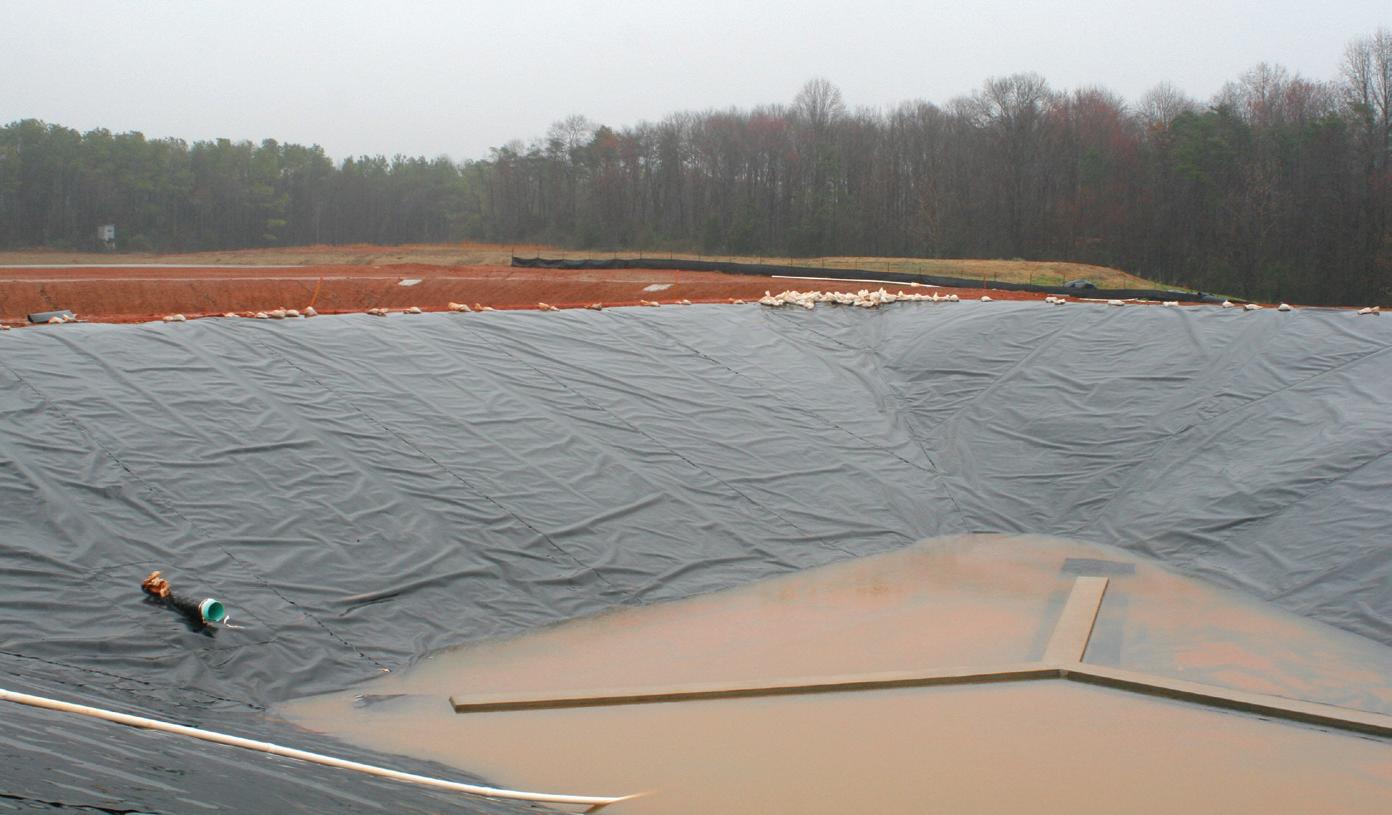

Rather than liquid manure generated by the 8,640 hogs on Loyd Ray Farms being flushed into a storage lagoon and then land applied for disposal and fertilizer, about 196,000 gallons are processed weekly through the

two-million-gallon anaerobic digester designed by environmental engineering firm Cavanaugh & Associates. The methane and carbon dioxide generated by the digester is diverted as fuel to a 65-kilowatt micro turbine-generator, which produces enough power on a 24/7 basis for five of the nine hog barns on the farm in addition to the environmental management system itself. The power generated by the project is the equivalent of the amount of power consumed annually by 35 homes. The liquid byproduct is collected in the existing 10.5 million gallon storage lagoon covering 4.8 acres, with a portion recycled through the hog operation as wash water and the remainder eventually land applied as organic fertilizer as well as used to irrigate cash crops. The plan is to clean out the solid sludge built up in the digester once a year and inject it as fertilizer.

The hog manure to biogas project broke ground in September 2010 and has been in operation since May 2011. Duke University and Duke Energy will share in the operating and maintenance cost of the project for 10 years.

Loyd Ray Farms owner Loyd Bryant says the farm benefits many ways. First, the power supplied by the micro turbine-generator has cut the farm’s power bill by $300 to $400 per month. Second, the reduced nitrogen content in the treated wastewater versus raw manure will allow the farm to use it as

fertilizer on cash crops such as corn, wheat and beans instead of just hay on the farm’s 154 acres. State regulations do not allow application of raw manure on any crop other than hay at the present time because of its high nitrogen content. Third, Bryant anticipates that the improved air quality in the hog barns will result in lower mortality rates, more efficient conversion of feed by the hogs, and best of all, fatter hogs headed to market. The odor emanating from the storage lagoon has also been reduced, and Bryant says looking after the system has had minimal impact on his daily routine. Deshusses says that because the system meets stringent environmental performance standards, Bryant could one day expand his hog farm. The standards include the substantial elimination of odors, pathogens, nutrients, ammonia, and heavy metals as well as the total elimination of discharge of waste to surface and groundwater. Under state law, no farm can expand unless it installs a waste management system that meets these standards.

“This system has the potential for reducing the environmental footprint of hog farming, while creating new revenue streams for the farmers,” he says, “but I think we are really at the beginning of an exciting path.”

When asked if the system is something he could recommend to other hog farmers, Bryant says it is unlikely that

The biogas generated by anaerobic digestion of hog manure on the Loyd Ray Farms operation is collected under this flexible dome. Contributed photo

farmers would be prepared to invest into the system on their own, but there would likely be interest if there were some form of state or federal assistance with the installation cost.

In addition to the project benefiting the farm financially, it also delivers a number of environmental and energy dividends. While meeting stringent environmental performance standards, it also reduces carbon emissions by about 5,000 metric tons per year by destroying methane that would otherwise be emitted from the lagoon. Methane gas is 21 times more potent as a greenhouse gas than carbon dioxide. The system also is expected to produce about 500 megawatt-hours of electricity each year.

Besides the global profile that Google’s involvement brings to the project and to Duke University, the university will also be able to use a portion of the carbon credits generated by the project toward its goal of becoming carbon neutral by 2024. Additionally, the project will act as a classroom extension, where some students will study the project’s design and its performance as part of their studies.

The Loyd Ray Farms project is a prototype. With the experience of this construction project under their belt, Deshusses adds that those involved in its construction believe that the cost to duplicate this installation on other farms could be between 20 to 50 percent lower. The goal now is to monitor the performance of the entire system and to present the information to other hog farms for their consideration. North Carolina is the second largest hog producer in the United States, with about 2100 permitted farms raising about 9.4 million animals per year.

“This system is serial number one, and the intent is that there will be other systems because we believe that it is a good system,” says Deshusses. “This is a full-scale system on a medium to large hog farm. We are hoping that the system will fulfill all its promises, that we can present it as an economically viable option for farmers, and that there will be more of the same.”

What’s significant about the Loyd Ray Farms installation is that it is being offered as an “open source” design, meaning that it isn’t patented. Replicating the concept is available to anyone willing to spend the money on their own farm or to businesspeople interested in taking the concept and offering its installation as a service to hog farms. In addition to an open design, the concept was developed

with the intent of using easily accessible, off-the-shelf components. Deshusses says the only item in the design that farmers may find unfamiliar is the power generator. Otherwise, the remaining components consist of pumps, valves and storage systems familiar to hog farmers that also aren’t necessarily specialized technology. In other words, the farmer can choose whatever pump brand he wants, as long as it meets the specifications outlined in the system design.

“There have been a number of creative and innovative solutions for handling hog manure, with some of them including composting,” says Deshusses. “They need sophisticated equipment that farmers are not likely to adopt because it just is not familiar to them,”

The liquid manure is collected in the conventional way in each hog barn, in storage pits below floor slats. The pits not only collect waste from the hogs but also any wash and fresh water used on a daily basis in the hog operation. Each storage pit is equipped with an overflow valve much like the overflow valve on a bathtub, meaning that there is constant gravity flow

of some raw liquid manure through pipes from each barn connected to a central collection point, which in turn uses gravity flow to supply the anaerobic digester. Once a day, Bryant opens the valve on two of the nine barns to send a large volume of liquid manure into the digester, replenishing the water for the pits from an aeration basin, which stores some of the treated water discharged from the digester. Gas produced through biological digestion rises to the top, collects in a flexible dome, and is connected for use as fuel in the micro turbine. It consists of about 60 percent methane and 40 percent carbon dioxide. The liquid byproduct flows into the 1.1 million gallon aeration basin located next to the digester as raw manure is added to the digester, where the remaining nutrients in the water undergo further chemical transformation of the ammonia into nitrite and nitrate in the open-air environment. A portion of this water is recycled through the hog operation as wash water. The remainder is stored in the old storage lagoon and eventually used to irrigate farmland as organic fertilizer.

Perdue AgriBusiness, Inc., in partnership with Fibrowatt LLC, is submitting a proposal to the state of Maryland in response to the state’s Clean Bay Power Request for Proposal.

The Fibrowatt/Perdue AgriBusiness proposal calls for a combined heat and power biomass boiler operation to be located at the Perdue AgriBusiness Zion Church Road complex near Salisbury, Md. The proposed facility will provide 10 megawatts of electricity to the state as well as up to 70,000 pounds per hour of steam to the Perdue AgriBusiness complex. The renewable fuel source will be a combination of poultry litter, layer hen manure, wood chips and other locally sourced biomass.

Perdue AgriBusiness currently uses fossil fuel to generate steam, which provides heat during various steps of soybean processing and poultry feed manufacturing. For the past two years, a team has conducted a thorough review of available technologies to convert poultry litter to energy, meeting with more than 45 companies and evaluating five technology categories in the course of its review.

“Our conclusion at this point is that the only commercially viable technology is combustion,” said Dick Willey, Perdue AgriBusiness president. ”The other technologies, while promising to varying degrees, represent a significant risk of project failure compared to combustion.”

Perdue AgriBusiness has experience providing alternatives for land application of poultry litter and alternative energy projects. In 2001, the company established a subsidiary – Perdue AgriRecycle, LLC – which converts poultry litter to a pasteurized, pelletized organic fertilizer. This provides poultry growers with an important management alternative for their

“It’s all designed to function with a minimum of moving parts,” says Deshusses. “So for any volume that enters the digester, a similar volume will overflow from the digester into the aeration basin, which is essentially a partial nitrification of the ammonia. And then that water is used to flush the barns.” Some water from the aeration basin can also be pumped back for reprocessing through the digester in the event that there is sludge built up in the basin. There are also some pumps connected to the digester to promote mixing of the solid material.

The system is built with flexibility in mind so that if the micro turbinegenerator needs to be shut down for a short time for service, the digester gas will simply accumulate under the flexible dome.

In additional to financial support from Google and Duke Energy, the university also received $500,000 from the U.S. Department of Agriculture and the North Carolina Department of Environment and Natural Resources Lagoon Conversion Program to construct the project.

litter. Since its establishment, Perdue AgriRecycle has shipped approximately 12 million pounds of nitrogen and 7.5 million pounds of phosphorus out of the Chesapeake Bay watershed. Through Perdue AgriRecycle, Perdue AgriBusiness is the largest buyer of poultry litter in Maryland.

Fibrowatt also brings extensive experience in the combustion of poultry litter to the project. The company’s management team has been developing and operating poultry-litter-fueled power plants for a total of 21 years. Fibrowatt operates three poultry-powered plants (13 megawatts, 14 megawatts, and 39 megawatts) in the U.K. plus a 55-megawatt power plant in Benson, Minn., that combusts more than 700,000 tons of litter and biomass annually.

“We are excited about this project because it supports agriculture and the environment,” said Willey. “It supports both animal agriculture and crop production in Maryland by providing poultry growers an additional management alternative for their poultry litter while keeping litter, a great fertilizer and soil amendment, available to crop producers for appropriate application.

“Environmentally, this project will remove a significant amount of poultry litter from land application, thereby eliminating the risk of any portion of the nitrogen or phosphorus in this litter or manure from finding its way into the Chesapeake Bay watershed,” Willey said.

“This proposed project will continue our successful legacy of developing, financing, constructing and operating power projects that combust poultry litter,” said Jim Potter, president and chief operating officer of Homeland Renewable Energy Inc., the parent company of Fibrowatt.

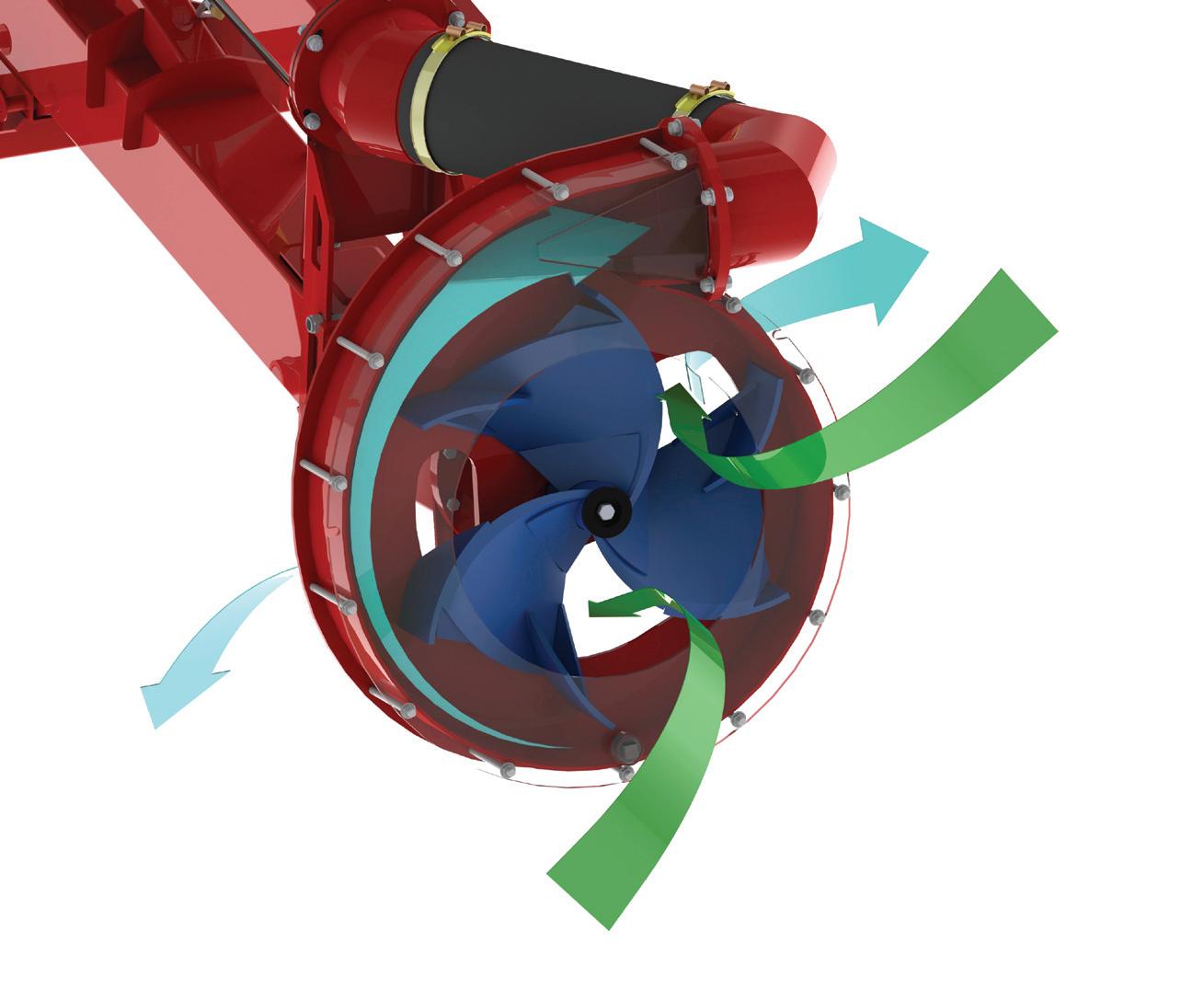

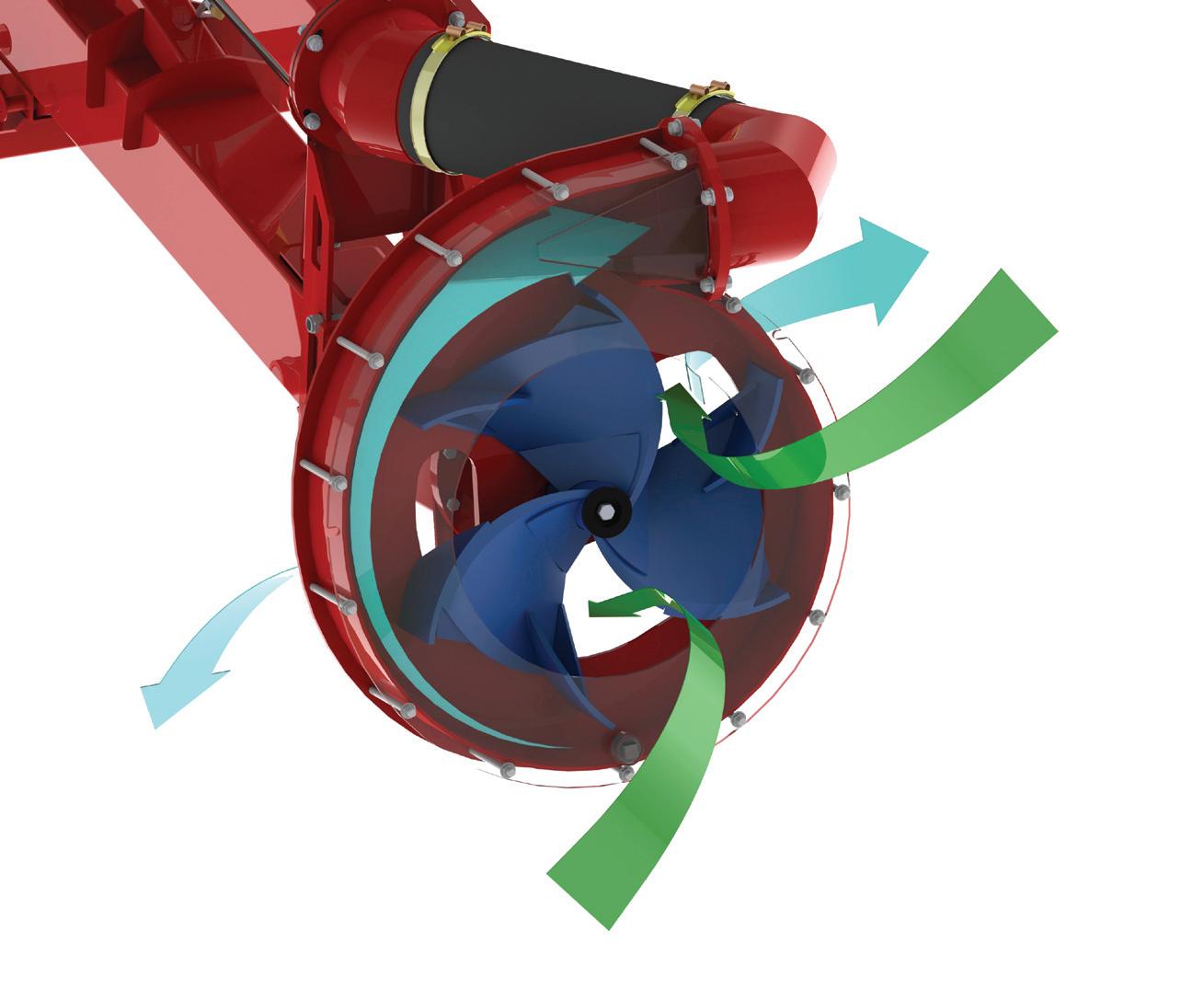

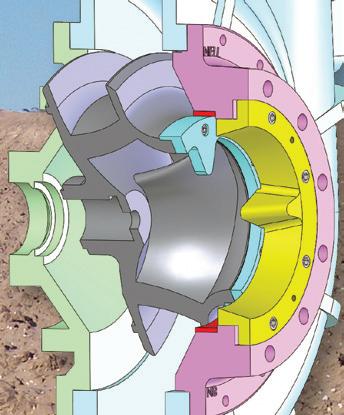

The PUMPELLER Hybrid Turbine revolutionizes manure pump performance. Incredible intake suction pulls solids into the cutter knives, reducing the toughest crust to nothing in just seconds. The turbine combines the high-volume mixing of a propeller agitator with the power and reach of a lagoon pump, the resulting hybrid design radically outperforms both.

By Tony Kryzanowski

Southern Alberta is cattle country but it is also home to a significant agricultural industry where specialty crops are grown. The Kasko Cattle Company, located near the town of Taber, is one example of both industries working together to benefit from the manure generated by the feedlot’s cattle.

The 10-quarter sections of land surrounding the feedlot are owned by feedlot proprietor Ryan Kasko plus Harold Perry and Chris Perry. The feedlot raises about 14,000 head of cattle annually. While Ryan owns and operates the feedlot, the Perry family, which includes Harold and Chris’ father, Gerald, has expertise in producing crops such as potatoes, sunflowers and peas on 4,600 owned and rented acres close to the town of Chin, about 40 kilometers from the feedlot. They have a contract to produce 13,500 tonnes of potatoes for Frito Lay and 8,500 tonnes of potatoes for McCain Foods on about 1,300 acres that are under irrigation for that purpose. They also grow peas for Lucerne as well as some

sunflowers, hay and oats. The area around Chin has a hot, dry climate requiring irrigation, with plenty of frost-free days.

The Perrys have used cattle manure compost as fertilizer in their potato growing operation on their own land for the past decade because of the nutrient and microbial benefits they’ve realized from using it. Harold says they observed with growing potatoes on virgin potato growing soil versus soil that had been under cultivation previously in a fouryear potato crop rotation that there was a dropoff in potato production on soil where potatoes had been grown in the past. They discovered that by using compost on the potato rotation land, it not only provided organic fertilizer to the crop but also worked as an excellent soil amendment, adding many micronutrient and biological unknowns to the overall quality of potato growing land that really made a difference in commercial potato production.

“We wanted to try compost because that is the natural way that things work,”

says Perry. “When the buffalo were here, they ate and manured the grass at the same time, and that’s how the natural cycle worked. Fertilizer prices have also helped because compost makes sense if you go strictly by dollars. The cost of putting the amount of nutrients you put on your soil using compost is less than if you were to purchase that at a fertilizer dealership.”

Not all the land on which they grow potatoes is fertilized with compost – only the land they own. Because potatoes must be grown on a four-year land rotation, it is essential that the Perrys participate in a land exchange program with other farmers to meet their production obligations. They exchange use of some of their farmland with other farmers to maintain that four-year potato crop rotation. Because they have no control over other people’s land, raw manure from area feedlots, including some from Kasko Cattle Company is typically applied on land owned by other farmers where the Perrys grow potatoes as part of the

A Sittler compost turner is an essential piece of equipment in Harold Perry's composting operation. Contributed photo

ThermoEnergy’s Thermo ARP™ high-efficiency ammonia recovery system is an unbeatable option for operators of anaerobic digesters who want to both comply with nitrogen regulations and recover ammonia as a valuable product. Thermo ARP recycles the ammonia in digester wastewater into ammonium sulfate or ammonium nitrate for the production of valuable fertilizers and industrial products. Thermo ARP is energy efficient, extremely robust, and compact – suitable for even rugged field conditions.

For more information email info@thermoenergy.com or visit our website at www.thermoenergy.com .

To spread compost fertilizer on land destined for growing potatoes, the Perrys use a Bunning spreader with vertical beaters. Contributed photo

exchange program.

Until last year, the Perrys purchased the compost fertilizer used on their land from a commercial supplier. Because of compost quality issues, they invested in land surrounding the Taber area feedlot with Ryan Kasko partly to acquire their own supply of raw cattle manure to manufacture their own compost. While they were getting good service from their commercial compost provider, compost quality from cattle manure gathered from feedlots in southern Alberta generally has suffered recently because of considerable rain and snow in the area. A lot more clay is being mixed in with the manure simply because the ground cover in area feedlot corrals has been a lot wetter, resulting in more dirt and clay in the manure gathered to make compost. The Perrys were concerned about adding clay to their potato cropland and decided to try their hand at compost production themselves. The Taber feedlot and surrounding land happened to come up for sale near their potato growing operations, so all the pieces conveniently fell into place. Having their own raw manure source gave them

more control over converting the manure to compost. For example, when the quality of the manure delivered is questionable, Harold can take action to improve its quality or set it aside completely, which he couldn’t do when they purchased compost from a supplier. He now has more control over the final quality of compost used on their potato fields, no matter what kind of weather the area experiences.

Harold, who is in charge of the composting operation, has an agriculture technology diploma from Lethbridge College and has a passion for improving soil quality. His brother, Chris, has an agriculture degree from Washington State University.

“If I have a goal, it’s to have healthier soils, for healthier crops, for a healthier population,” says Harold.

In addition to the micronutrient and biological value that compost provides to soil, he says that there are also financial advantages to transporting compost versus raw manure.

“Good compost has about 60 percent of the weight of raw manure,” says Perry.

“So if you get too far away from the feedlot, then the trucking just kills you.”

The Perrys pay Kasko for the cattle manure, and Kasko in turn hires a custom contractor to deliver the raw manure to a location with good drainage control located next to the feedlot. The custom manure hauler creates the windrows needed to produce compost. According to Kasko, the feedlot delivered 9,000 tonnes of manure to the site last year. Overall, he estimates that the feedlot generates about 15,000 tonnes of manure annually. The remaining 6,000 tonnes of raw manure was land applied in the vicinity of the feedlot.

He adds that composting the manure prior to application is a rather specialized requirement of farmers like the Perry potato growing operation and without that demand, the raw manure would likely continue to be land applied as has traditionally been the case. However, he agrees with Perry that because of the weight factor, converting the manure to compost could make sense should there be more manure generated by feedlots than area land can support and it needs to be transported longer distances.

Last year, the custom manure contractor created the windrows by using conventional manure spreader trucks, which moved more slowly than they typically would in a field to deposit the manure. The manure was processed through spreader beaters as it was put in the windrows, which mixed more air into the piles. Perry says this helped the composting process. Delivery of the manure resulted in four windrows measuring a distance of about half a kilometer each.

Once the windrows were created, Perry began monitoring the conversion process and using his new compost turning equipment as needed. He acknowledges being a bit anxious about delving into compost production because of the science required to ensure that the biological organisms have a healthy environment to carry out the conversion process, but adds that learning to compost has also been an enjoyable experience. To prepare himself, he took a composting course offered by Midwest BioSystems. He manufactured about 7,500 tonnes last year, with the process taking from July to mid-October. The compost was land applied in October, worked in, and then the potato hills were created for next year’s planting.

To turn the compost, Perry purchased a 14-foot-wide, pull-type, Sittler compost turner, which retails for about $45,000 Cdn. He was able to recoup about half the cost by applying to a government program called the Growing Forward Manure Management Program. He checked the heat and moisture content in the composting windrows regularly to ensure that the organisms were working in an optimum environment. He also purchased a Sittler water wagon that can be towed along with the compost turner so that moisture can be applied to the windrows as needed. Perry says he turned the compost six or seven times with the main determining factor being when the temperature in the compost heap reached 160 F. At the beginning, the turning was done every four or five days because of the strong biological activity underway. Ideally, the conversion process should take 10 weeks, but Perry says he prefers to wait 16 to 20 weeks.

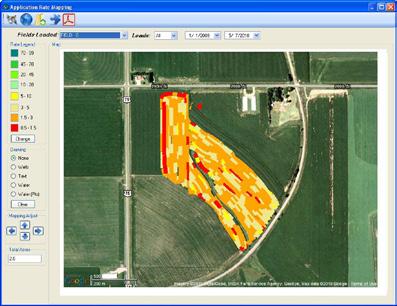

As part of the Perrys’ adventure into composting, they hired an agriculture consultant from Sunrise Ag in Taber to soil sample and develop topography maps to help determine how much compost should be applied in various points on their cropland. The consultant developed maps showing six zones where the compost should be applied to a lesser or greater extent to achieve ideal growing potential. The Perrys plan to use the maps to place their compost more precisely this coming year. To spread the compost, Perry has purchased a Bunning compost spreader with vertical beaters, which he pulls using a John Deere 8430 tractor equipped with hydrostatic drive. Perry recommends a tractor in the 180- to 200-horsepower range. The tractor moves at about 16 kilometers per hour, and the spreader broadcasts the compost over a width of about 40 feet. This results in an application rate of about four tonnes per acre. Increasing or decreasing tractor speed based upon the zone mapping displayed in the cab will increase or decrease the application rate.

Composting is just one way that the Perrys are making better use of cattle manure. Harold and Chris are planning to build an anaerobic digester on their farm that will process cattle manure, rotting potatoes and possibly green bin waste from the nearby town of Coaldale to produce methane gas. The gas will be used to power an engine to generate 640 kilowatts of electricity. The plan is to put about 55 tonnes of biological material into the digester per day, which will create 35 tonnes of digested material that is similar to compost annually, which the Perrys will also spread on their land. Construction is slated to begin in 2012.

Manure Systems Inc. of Abbotsford, B.C., received a Top 10 Product Innovation Award at the 2011 World Dairy Expo for its Trident Nutrient Technology (TNT) recovery system.

The TNT recovery system is a manure management process designed to enable dairy farmers to extract the nutrients on a daily basis from their animal manure. Once nutrients from the manure are captured they are concentrated for processing into fertilizer that can be easily stored for on-farm use or sold.

“Many people think it is easy for farmers to use the manure they produce for spreading on the fields,” explains Kerry Doyle, president of Manure Systems Inc and manufacturer of the TNT system. “It’s not that simple. The excess nutrients in manure are now recognized as a major environmental problem. Our soils are simply getting too much nutrient, potentially polluting the land we live on and the water we use and drink.

“We’ve been determined to solve this problem for years,” says Doyle. “Shortly after I co-invented and developed the first rotary screen manure separator … I began experimenting with additional equipment that could be bolted on to solve other problems.”

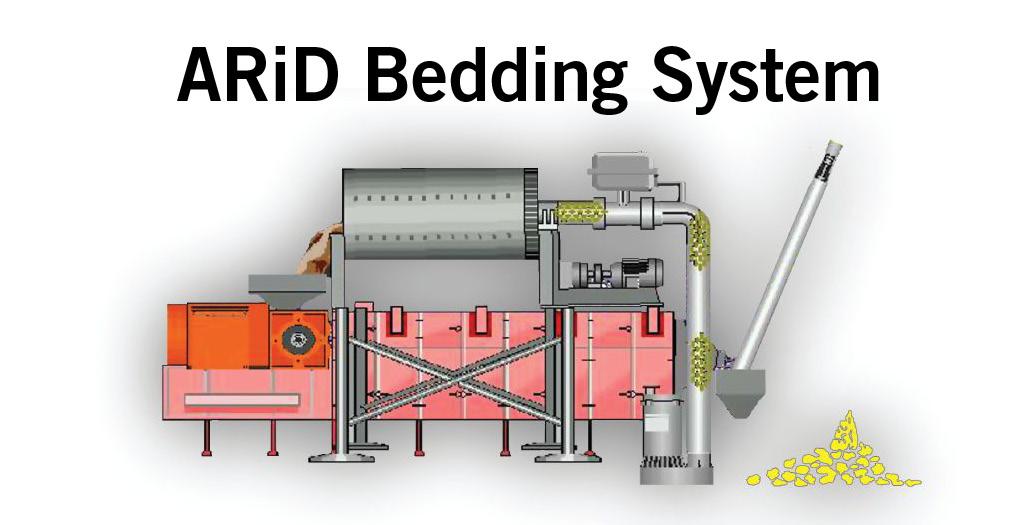

One of those units is the ARiD bedding system, which allows farmers to use the Trident separator in series with a special “high-solids press” that allows farmers to create bedding out of the heavy fibers that remain after the manure is scrubbed clean.

“The ARiD Bedding System saves farmers money and recycles manure material into something valuable,” says Doyle. “But, the separator and the bedding system still leave the problem of the excessive nutrients left concentrated in the unused liquid part of the manure. This remaining effluent still has to be dealt with. A process is needed to pull the nutrients out of the liquid fraction.”

That is what Manure Systems Inc., along with its technology partners, developed with the TNT system.

The remaining clarified and nutrient-depleted effluent is ready for use as a high-quality flush liquid or applied to the land with irrigation equipment.

The TNT system is a fully automated system, a combination of proven mechanical and chemical technologies. Its plug-and-play configuration makes it suitable for new or existing dairies and provides a manure management solution that helps dairymen meet their nutrient management plan and maximize their profit potential. The system can be delivered anywhere in the world and is supported by a global dealer network.

Manure spread on snow-covered or frozen ground before a rain or snowmelt can wash into streams and lakes. Photo courtesy of the Wisconsin Department of Natural Resources

Farmers can now go online for the latest forecast showing the risk that runoff from manure spread on their fields could pose to lakes, rivers or groundwater, state agricultural and natural resource officials say.

Wisconsin’s runoff risk advisory forecast shows what parts of the state are at high risk over the next three to 10 days for runoff based on rainfall, snowmelt, soil conditions, temperatures and weather forecasts. The forecasts are updated three times a day by the National Weather Service.

“With our new runoff risk advisory forecast, farmers don’t have to guess how risky it is to spread manure,” says Jim VandenBrook, water quality section chief for the Wisconsin Department of Agriculture, Trade and Consumer Protection.

The forecast is part of the Wisconsin Manure Management Advisory System that state and federal agricultural and natural resource agencies and the University of Wisconsin have put in place to help Wisconsin farmers know when conditions are right to spread manure on their land. The advisory available on the web at http://www.manureadvisorysystem.wi.gov and also can be easily reached by searching online for “manure advisory system.”

“By checking the forecast, farmers will know when conditions are right to spread manure so that it stays on the fields and fertilizes the soil instead of risking pollution of streams and groundwater,” VandenBrook says.

Public service announcements promoting the runoff risk advisory are being sent to radio stations across the state this week, and will be aired on agricultural programming on several stations starting next week, according to Tom Bauman,

Department of Natural Resources agricultural runoff coordinator.

“We think this is a valuable tool to help farmers protect their bottom line and Wisconsin waters,” Bauman says. “This ensures that runoff warnings are based on the latest information about conditions on the ground, not what the calendar says they might be.”

The risk advisory also contains recommendations if farmers cannot avoid spreading manure on days when the risk of runoff is high, and links to a DNR video showing precautions farmers can take if they must spread, including finding lower-risk fields, and how to respond if a manure spill or runoff does occur.

The runoff risk advisory joins the nutrient application restriction maps featured on the Wisconsin Manure Management Advisory System for several years. The restriction maps help farmers develop nutrient management plans that guide where, when and how much manure can be spread. Following such plans can avoid long-term phosphorus buildup in soils, reduce the chances of nitrogen leaching into groundwater, and cut the risk of winter spreading on fields where it should be avoided, VandenBrook says.

The mapping website is a joint project of the Wisconsin Department of Agriculture, Trade and Consumer Protection; Wisconsin Department of Natural Resources; National Oceanic and Atmospheric Administration-National Weather Service River Forecasting Center; U.S. Department of Agriculture-Natural Resources Conservation Service; University of WisconsinMadison College of Agricultural and Life Sciences and Soil Science Department; Discovery Farms; UW-Platteville and its Pioneer Farm; and U.S. Geological Survey.

To better manage its growth, CLAAS is investing in its North American operations by increasing resources and capacity. To support this growth, CLAAS is expanding its senior management team while also adding new talent in key areas.

“CLAAS has experienced tremendous growth over the last couple of years and similar growth is projected well into the future,” says Leif Magnusson, president of CLAAS of America and regional director of the Americas. “To ensure the company is structured to provide the greatest possible support for our dealers and innovative new products for the growers of North America, we’ve expanded and restructured our senior management team.”

Mark Oehmke has joined CLAAS of America as vice president of sales. Most recently the director of sales, marketing and dealer development at Terex Roadbuilding, Oehmke was at one time the senior sales director for Case New Holland’s construction, agricultural and government accounts. He was also the VP and GM of the Michigan CAT power systems division as well as the regional engine and parts sales manager for Caterpillar Inc.

Bob Armstrong has been promoted to vice president of product and marketing for CLAAS of America. He has been with the company for 22 years.

Holger Krumel, recently named executive VP of finance and CFO for CLAAS North America Holding Inc., will be responsible for financial business development, human resources and information technology services in North America.

In addition to the new senior management team, CLAAS has restructured its service organization to improve the support of its North American dealer network and the many growers who purchase its equipment. www.claasofamerica.com

Bio-Methatech recently signed a contract to build – in spring 2012 – a biogas system on Riverview Farm, located in Franklin, Vt.

The owners have a herd of 450 dairy cows and intend to produce electricity that will be sold to the public electricity network. Heat produced by the co-generator will be recovered to maintain the temperature of the digester as well as to heat the buildings. To produce the biogas, animal waste, farm waste and other organic waste will be treated in an anaerobic digester. The project has a capacity of 180 kW.

After pressing, the digested residues in the process will also provide bedding for the animals.

In practice, biomethanization is a natural biochemical process of recovery from the fermentation of organic wastes, which produces green energy: biogas. During this process the methane emissions in the atmosphere are reduced. The gas is produced in

a sealed tank called a digester. The biogas is composed of 60 to 70 percent methane and this energy is captured and burned in a co-generator to produce electricity and heat.

Biomethanization provides a renewable source of energy, a positive energy balance, a reduction in greenhouse gas emissions in the atmosphere, the production of clean and quality bedding and a respectful cycle of organic waste

Following the digestion of the manure and other compostable materials, the residues have no odor. This allows for harmonious coexistence with the community during the periods of manure spreading. www.bio-methatech.com

Bernardin Lochmueller & Associates (BLA), a company specializing in sustainable infrastructure design, recently received a method patent for its Eco-Treatment constructed wetland system to treat wastewater from animal confinement operations.

Constructed wetlands, whether used as a stand-alone system or in combination with land application or other treatment alternatives, can offer a cost-effective solution to assist CAFOs in meeting the zero discharge requirement, according to BLA. Using plants and a variety of filter media, the system provides a natural approach to reducing or eliminating nutrients and other chemicals from manure and wastes. The system can be fine-tuned to provide effluent with nutrient loads that match the needs of specific crops.

To date, BLA’s water resources team – led by Mark Harrison, PE, LEED AP – has designed more than 80 constructed wetland systems for the treatment of animal waste, site and municipal sewage, and combined sewer overflows (CSOs).

“Constructed wetlands offer a variety of benefits,” says Harrison. “Because nature does the work, it reduces the energy used, be that energy needed to transport manure or run a mechanical treatment system, not to mention cutting the cost of additional chemicals to treat waste. In some instances, we’ve even designed wetlands to provide habitat for wildlife or walking trails. It’s just an all-around great solution.” www.blainc.com

In the first-ever Dairy Herd Innovation Awards, Livestock Water Recycling, Inc. (LWR) earned a place in the top 10 for its manure treatment system.

The LWR system takes effluent directly from the barn and flows it through a system where solids are sequentially removed. The system treats and processes the manure, resulting in clean potable water, dry solids and concentrated liquid nutrients.

The Top 10 award was presented at the World Dairy Expo,

which took place Oct. 4 to 8, 2011, in Madison, Wis. The LWR system also won the World Ag Expo Top 10 Award and the Emerald Award in 2010.

LWR is currently installing a new system at a dairy operation near Chilliwack, B.C.

GHD, Inc., a U.S. anaerobic digester designer, recently announced it now exports its technology to Asia, Europe and South America. To prepare for this international expansion, GHD, Inc. also announced the company has changed its name to DVO, Inc.

Farmers in South Korea, Serbia, Chile and Canada have contracted with DVO to use the same technology available to American farmers.

In addition to DVO’s international expansion, DVO will soon announce its first municipal customer in the U.S., as well as the first farm-practical nutrient recovery system. Patents are pending on DVO’s new technology, which turns digester byproducts into valuable fertilizers, using methods that make economic sense for farmers.

“In general, anaerobic digesters take waste and turn it into biogas, fertilizer, animal bedding and more, depending on farm and community needs,” said Stephen Dvorak, DVO’s president. “What puts DVO ahead of our competition is that our technology has superior energy production and pathogen kill, an especially robust design and will process a wide range of wastes.”

DVO’s design means farmers can stay focused on farming. According to the American Biogas Council and U.S. Environmental Protection Agency, currently less than 200 farm-based digesters are operational; however, U.S. farming will support at least 8,500 more, plus thousands of additional non-farm systems.

With these changes, DVO customers will experience no

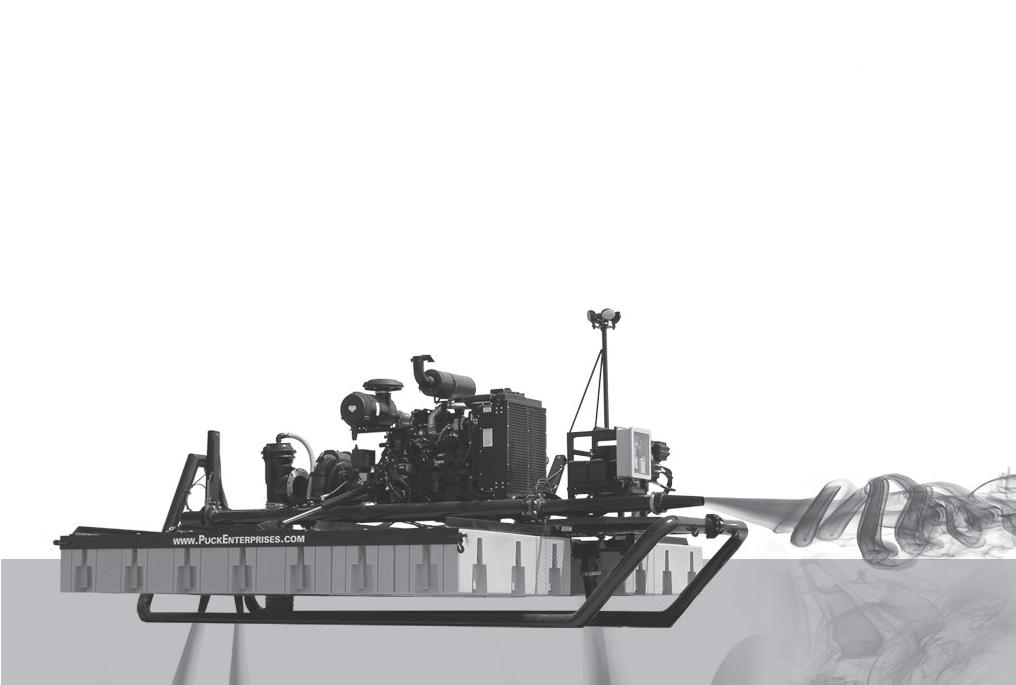

www.PuckEnterprises.com [o] 712.653.3045

Built by Manure Applicators in Iowa

change in products and services, but all should watch for new activity in 2012 and beyond. For more information about DVO, biogas and anaerobic digesters, visit the new website at www. DVOinc.net.

The Wisconsin Farm Bureau Federation is pleased with the recent passage of Senate Bill 410 by both houses of the Wisconsin Legislature.

SB 410 helps improve the efficiency of applying manure. Specifically, it allows vehicles or vehicle combinations transporting manure to or from a farm to exceed weight limits by not more than 15 percent from Sept. 1 to Dec. 31 annually. This exemption is similar to the agricultural crop exemption that allows vehicles to exceed weight limits by not more than 15 percent for harvesting purposes during the same time frame.

“During the fall of 2011 there was increased enforcement of road weight limits in certain parts of the state,” explained Paul Zimmerman, WFBF’s executive director of governmental relations. “Several farmers and custom manure haulers were cited for being overweight when transporting manure from the farm to the fields for application.

“The Wisconsin Farm Bureau understands that there are still issues to be resolved regarding road weight limits and modern farm equipment, but this legislation is a step in the right direction,” Zimmerman added. “The farm bureau is committed to working with local highway departments and the Wisconsin Department of Transportation to resolve such issues regarding farm equipment.”

SB 410 passed both the State Senate and State Assembly on voice votes in late February.

tation Bo B ats i mix wiith 3 d ressureoutflowsandareremotely Lagoon Agitation Boats

PCE Agitation Boats mix with 3 downward, high pressure outflows, and are remotely controlled from shore. Easily access all areas of any size of lagoon. Call for details, and ask about PCE pumping systems to quickly take all this rich nutrient to the field.

Challenge Technology, an Americanbased company, has developed the Methane Potential Analyzer (MPA-200), to provide for the measurement of biogas in anaerobic reaction in laboratory testing.

The MPA-200 will allow the user to monitor and analyze the production of biogas in bench scale reactors, thereby optimizing gas production and allowing for evaluation of environmental and concentration adjustments.

This MPA-200 base system utilizes eight standard 500 mL glass reactors set on a magnetic stirring base, incorporating magnets and stirring bars with Spin Rings. The MPA-200 is expandable to 16 reactors. The system comes complete with computer and preinstalled software for detailed data collection and graphing for precise analysis of methane potential. The unit is durable, with easy setup and operation and quick cleanup. The system is factory calibrated and requires no user calibration.

With 10 times the resolution of other systems currently on the market (.12mL vs. 13mL), the MPA-200 is capable of producing tests of enhanced quality. An inline CO2 stripper is available for methane CO2 ratio evaluation. www.challenge-sys.com

ThermoEnergy Corp. recently announced it has successfully completed field and laboratory tests to prove its Thermo ARP™ (Ammonia Recovery Process) system can efficiently recycle the wastewater from agricultural anaerobic digester biogas plants into valuable fertilizers and chemicals. The tests were conducted on behalf of major biogas developers in the U.S.

“[ThermoEnergy] believes the agricultural biogas industry will be a significant growth market for the company, both in the U.S. and internationally," said Cary Bullock, ThermoEnergy’s chairman and CEO. "Our Thermo ARP System has the potential to increase the profitability of agricultural biogas production by recycling

environmentally problematic wastewater streams into high-value products. This provides numerous benefits to the biogas industry, the economy, and our environment.”

The EPA AgSTAR program estimates there are approximately 170 anaerobic digesters currently in operation and more than 8,000 diary and swine operations in the U.S. with the potential to support biogas recovery systems. There are also a significant number of biogas operations throughout Europe, where high-fuel prices and stricter carbon regulations have made these projects more competitive. The processing of manure into biogas through anaerobic digesters produces fuel for electricity generation and considerably reduces methane emissions from cattle manure. Methane is a greenhouse gas with 20 times the potency of CO2.

“The recycling process makes agricultural biogas more economically attractive, which in turn increases renewable fuel production for distributed electricity generation,” said Bullock. “Additionally, our services reduce the dependence on fossil fuels, create alternative energy jobs, and reduce harmful methane emissions that contribute to global warming.”

Jamesway Farm Equipment recently introduced a new design of lagoon pump at the Jamesway dealer meeting held in late February.

The patented hybrid turbine takes less time and fuel to agitate lagoons without the need for any gearbox.

“The output of the hybrid turbine does two jobs,” explains Ralph Fanning,

sales manager for Jamesway. “First, the turbine core pushes manure into the impeller blades, in effect supercharging the pump capacity, which is very noticeable in thicker material. Secondly, the rest of the turbine output is vented right through the pump housing to move processed manure away from the pump. The huge throughput of the turbine produces incredible intake suction that pulls solids into the cutter knives, chopping up the largest rafts of solids in mere seconds. It’s a lot like passing through a jet engine…not much survives the trip.”

The Pumpeller Hybrid lagoon pump uses the Ultra-Pump chassis, with trailer models up to 62 feet long and three-pointhitch mount models up to 25 feet long. www.JameswayFarmEq.com

Pit foaming is a source of major frustration as well as a fire or explosion hazard on swine operations. Now, Manure Master FoamAway may be part of the solution. The product is designed to stop or reduce pit foaming in its tracks. The product is a dry granule (not a de-foamer) that is applied at five pounds per 100,000 gallons of manure. It is reported to shut down methane production and foam initiation within two days.

For more information, visit ManureMaster.com or call 888-875-2425, ext.105.

JCB has upgraded its 1CX product – the smallest member of its backhoe loader family – with a new appearance, longer loader arms, an extending dipper option, servo controls and a power management system.

The 1CX has been updated with the latest JCB corporate styling, including a revised cab roof trim, improved working

lights and sturdy electrical switchgear. The new optional loader arms are four inches longer to provide easier loading.

At the rear, an extending dipper option adds up to 20 inches to the digging envelope, taking the maximum dig depth to 10 feet.

The Power Management System (PMS) reduces engine lug down as the machine starts to dig and increases power when driving into a pile with the front bucket.

Optional Servo controls for the backhoe provide the operator with greater control and less effort, and no need to lean forward when working the rear excavator. The control lever post has been removed, creating more space for the operator, particularly around the feet. Customers can choose between either SAE or ISO control pattern by using the optional changeover switch to suit the individual operator and ensure rapid driver acceptance.

Inside the cab, the 1CX offers 2 inches of additional legroom, making it easier to spin the seat for backhoe operation. Auxiliary functions can now be controlled by optional proportional switches in the servo levers, rather than by the foot pedal. The cab also is equipped with laser-etched image switches as used on the larger 3CX and 4CX models. www.jcb.com

MTS Environmental Inc.’s Ammonia Control 250, a manure treatment product, has been awarded approval by the Canadian Food Inspection Agency (CFIA) after three and half years of testing.

The product has been registered for administration to all types of pigs through the feed and, according to the company, has been shown to reduce ammonia in the air of swine barns by an average of 54 percent.

“Lower ammonia levels will typically improve pig performance and make a much more pleasant environment for workers,” said Hiram Thompson, general manager of MTS Environmental.

Ammonia Control 250 is available from all feed suppliers in Canada.

MTS Environmental provides natural solutions to agriculture, municipal, residential, recreational, and industrial organic waste and water environmental issues. Products developed by MTS Environmental work to restore a natural balance of microbial life, activating the natural biodigestion system to eliminate the cause as well as the symptoms. www.mtsenvironmental.ca

The Valtra T133 Dual Fuel is the first tractor to combine the use of biogas with SCR technology. The new tractor is a continuation of Valtra’s biogas project; the first test tractor – a four-cylinder N111 HiTech – was presented in the summer of 2010. The biogas N111 was a success in testing and Valtra wants to develop this technology further and adapt it for use in other tractor models.

The T133 Dual Fuel runs on both biogas and diesel. In biogas mode, approximately 83 percent of power is produced by biogas and 17 percent by diesel or biodiesel. A small amount of diesel is required to ignite the biogas in the cylinders. In diesel mode, the engine operates like a traditional diesel engine. Natural gas for vehicles can also be used as a fuel. The dual fuel engine is not only more flexible than engines powered by gas alone, it is also significantly more efficient.

All tractors in the size class must be equipped with an SCR system or similar technology to clean the exhaust emissions. The SCR system sprays AdBlue into the exhaust gases, reducing emissions to the level required by the latest Tier 3b standard. Valtra is developing combined Dual Fuel and SCR technologies to comply with even stricter standards in the future.

Valtra’s T133 and N111 biogas tractors are similar to standard tractors in terms of characteristics, equipment and performance. The fuel cost of biogas tractors is approximately 10 to 40 percent lower than that of standard tractors. When driven on biodiesel and biogas, Valtra Dual Fuel tractors are powered entirely by renewable energy sources.

The storage containers for the gas are positioned in a safe location within the tractor frame. The containers can hold 170 litres of gas at 200 bars of pressure. This amount corresponds to approximately 30 litres of diesel and is sufficient for three to five hours of work.

Additional storage tanks can be fitted to the system if needed. The tractors can also carry 165 litres of diesel and 27 litres of AdBlue, as on standard tractors.

www.valtra.us

The Cat D3K2, D4K2, D5K2 track-type tractors feature Stable Blade technology that complements operator blade control input. The feature remains activated unless cancelled by the operator. According to Cat, using Eco Mode can improve fuel economy up to 25 percent. The mode has two settings – Forward/Reverse or Reverse Only – that are selected via the rotary throttle. Once set, Eco Mode automatically controls engine speed.

With the Cat C4.4 ACERT engine – which meets Stage IIIB/Tier 4 Interim emissions requirements – the K2 models feature hydrostatic drive with traction control, reducing track slip at maximum load. Traction control is an operatoractivated system that reduces track slippage under heavy load by sensing and controlling track speed, resulting in fewer situations where operator must lift the blade to prevent track slip.

New in-cab amenities include ventilated seat plus heated control handles and Power Pitch allows the operator to control blade pitch fore/aft.

K2 models blend new features with the basic design of their K family predecessors, including single-lever travel/steering control, an operator station with standard air conditioning when cab-equipped, single-lever blade control, plus a Cat Sealedand-Lubricated Track (SALT) or Cat SystemOne undercarriage. Undercarriage configurations include XL (Extra Long) and LGP (Low Ground Pressure) versions, with an LGP version that features 30-inch track shoes.

Net power ratings have increased by more than eight percent from 55 to 59 kW (74 to 80 hp) for the D3K2, and from

62 to 69 (84 to 92 net hp) for the D4K2. The D5K2 gets a power boost from 71 to 78 kW (96 to 104 hp). The C4.4 ACERT engine features air-to-air charge-air after cooling, an electric fuel priming pump, and a passive regeneration system for emissions reduction.

www.cat.com

Manitou America Inc. recently announced the completion of its combination efforts with Manitou Forklifts Canada, combining sales, service and marketing support teams from both companies into one organization.

The new support structure under Manitou Americas will provide the Manitou Canada market with:

• dedicated field sales and support service

• a dedicated dealer service and sales call center, located in North America

• better parts availability from a North American warehouse, and

• machine manufacturing and inventory in North America for more responsive deliveries.

By combining the industry knowledge of Manitou Forklifts Canada and Manitou Americas’ sales, marketing and after-sales support teams, the Canadian market will receive an expanded level of local support. Two field support and service teams – specializing in sales, service and training – will support Eastern and Western Canada with dedicated dealer development and service.

In addition to the increased level of support for sales and service, Manitou Americas also hopes to provide enhanced technological support for the Manitou brand and its dealer network. A webbased Manitou dealer information center will provide detailed business information to authorized Manitou dealers, increasing the level of support dealers can provide to equipment owners.

Manitou Americas also hopes to provide the right products for the Canadian market. The product offering will include semi-industrial forklifts, rough terrain masted forklifts, agricultural and multipurpose telescopic handlers, construction telescopic handlers, heavy capacity telescopic handlers, rotating telescopic handlers and truck-mounted forklifts. www.manitou-group.com

Challenger recently introduced the MT500D Series high horsepower wheeled row crop tractors to North America.

The MT500D Series tractors range from 170 to 225 engine horsepower (140 to 180 PTO HP) and are packaged with features to help producers handle the most challenging jobs. Optional factory-installed auto-steering and telemetry technologies are also available on these models to help improve productivity and operational efficiency for any size farming operation.

The Challenger MT500D Series is powered by Tier 4-interim emissions-compliant AGCO POWER diesel engines with e3™ selective catalytic reduction (SCR) clean-air technology for improved emissions, minimal maintenance and fuel efficiency.

The MT500D Series can be outfitted with System 150 autosteering technology and the AGCOMMAND™ telemetry system, which provides real-time tractor-performance information to help producers monitor and increase tractor performance, productivity and efficiency.

Shifting on the MT500D Series is made possible by a TechStar continuously variable transmission (CVT), which delivers clutch-less, step-less shifting, and limited moving parts for long life. Power Management (PM) continuously monitors the load on the engine, adjusting the engine and transmission to deliver power and fuel efficiency. An AutoPower VI (partialpowershift) transmission is also available.

In addition, these tractors feature redesigned cabs that offer a wide-angle view and superior operator comfort.

The MT500D Series are powered by 6.6L or 7.4L AGCO POWER six-cylinder engines with Generation 2 e3 SCR technology that incorporates emissions components to meet Tier 4-interim emissions requirements. The catalytic converter and diesel oxidation catalyst work with the tractor’s engine to maximize efficiency and simplify maintenance.

The MT500D Series comes with larger 114-gallon capacity diesel fuel and 11-gallon DEF tanks to allow longer periods of work between refueling. www.challenger-ag.com

John Deere is expanding its lineup of 6R Series tractors with three new models – the 6105R with 105 engine horsepower; 6115R with 115 engine horsepower; and the 6125R with 125 engine horsepower.

According to Scott Hessel, product marketing manager with John Deere, the new 6R Series

tractors are designed to be a do-it-all utility tractor with the versatility, power and comfort never before seen in a tractor in this horsepower range.

“We’ve made the cab 20 percent larger and added the GreenStar 3 Command Center with touch screen display,” says Hessel. “We’ve also included Triple Link and Adaptive Hydraulic Cab suspension to make the new 6R models the most comfortable and easy-to-operate tractors in their class. In addition, we’ve increased the hydraulic lift capacity by 20 percent and added new 50K (31 mph) transmission options that give this spacious utility tractor the functions of a much larger machine.”

All three 6R models come standard with John Deere 4.5L PowerTech PVX Interim Tier 4 diesel engines with Intelligent Power Management that provides an additional 20 hp during transport and non-stationary PTO applications. Transmission options include a 24-speed AutoQuad Plus ECO Transmission (standard), 16-speed PowerQuad Plus (optional) and IVT Transmissions (optional). IVT and AutoQuad Plus configurations are available with up to 50K (31 mph) transport speed.