MARCH/APRIL 2011

MARCH/APRIL 2011

Wisconsin dairy using combined plug flow and mixed digester

Wisconsin dairy using combined plug flow and mixed digester to produce electricity, bedding

B.C. dairy installs digester for 50-cow dairy operation

Texas dairy farmers find white knight in EM Biogas

Cover: Pagel’s Ponderosa Dairy’s anaerobic digester is designed by GHD Inc. and combines plug flow and mixed digester technology in the 3.2 million gallon vessel. Photo by Margaret Land

Volume 9 • No. 2

Published by:

Annex Publishing & Printing Inc. P.O. Box 530 Simcoe, Ontario N3Y 4N5

Editor

Margaret Land • (519) 429-5190, (888) 599-2228, ext 269 mland@annexweb.com

Contributing Editors

Nigel Key, Tony Kryzanowski, David Schmidt, Stacy Sneeringer

Advertising Manager

Sharon Kauk • (519) 429-5189, (888) 599-2228, ext 242 skauk@annexweb.com

Sales Assistant

Mary Burnie • (519) 429-5175, (888) 599-2228, ext 234 mburnie@annexweb.com

Production Artist

Kate Patchell

VP Production/Group Publisher Diane Kleer dkleer@annexweb.com

President Mike Fredericks mfredericks@annexweb.com

Publication Mail Agreement #40065710

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO CIRCULATION DEPARTMENT, P.O. BOX 530, SIMCOE, ON N3Y 4N5

e-mail: mweiler@annexweb.com

Printed in Canada

Circulation

e-mail: mweiler@annexweb.com

Tel: 866-790-6070 ext. 211

Fax: 877-624-1940

Mail: P.O. Box 530 Simcoe, ON N3Y 4N5

Subscription Rates

Canadian Subscriptions

$35.24 Cdn, one year (with GST $37.00, with HST/QST $39.82)

U.S. Subscriptions:

$47.00 USD, one year

Occasionally, Manure Manager will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher's written permission. ©2011 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher's approval. Such approval does not imply any endorsement of the products or services advertisted. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Website: www.manuremanager.com

By Margaret Land

Ilove meat. Give me a medium well-done rib steak with a bit of barbecue sauce and a splash of salt, pair it with a baked potato, sour cream and French-cut green beans, and I am in heaven. I’m also fond of ribs, bacon, fried chicken, sausage, juicy hamburgers and the list goes on.

So, I was a bit dismayed when I read about the latest research coming out of the Netherlands. According to a report from Wageningen University and Research Centre, scientists, industry and government officials have “joined forces to investigate whether the rearing of insects could contribute to more sustainable protein production” compared to the raising of beef and pork. As a result, the obviously deranged group has discovered that insects produce much smaller quantities of greenhouse gases per kilogram of meat than cattle and hogs. Therefore “the study indicates that proteins originating from insects, in principle, form an environmentally friendly alternative to proteins from meat originating from conventional livestock.”

What will scientists think up next?

Do they actually think they can convince people to stop eating pork chops with applesauce, foot-long hotdogs and filet mignon in favor of cricket crunchies, spider sauce and cockroach canapés because of the resulting reduction in greenhouse gas emissions? Have they lost their minds? Or just their taste buds?

Don’t get me wrong, I’m all for helping the planet. We plant trees on our small acreage, recycle when we can, pick up litter, use phosphate-free shampoo when camping, compost our manure. But it will be a cold day in Fiji when I can be convinced to chew on a grasshopper leg rather than a T-bone. I mean, I’ve heard of cricket ranches for raising feed for lizards and snakes, but this is ridiculous.

I think the icing on the cake – or the cupcake, in this case – was the photo that accompanied the research report. It was a photograph of a lovely chocolate cupcake, perched in gold foil, and topped by a greenish glazed grasshopper. I actually gasped in disgust when I saw it. This was the food alternative they were promoting? Blahh!

Yes, greenhouse gas emissions are a serious issue. Yes, there is more we can do to help reduce them. But no way should that involve eating insects. You can keep your mealworm meatball – I’d rather become a vegetarian.

By Margaret Land

John Pagel grew up in Wisconsin’s Kewaunee County and has lived in the same house on his family’s farm operation his entire life.

“And I still want my neighbors to wave at me with all their fingers,” he explains.

That was one of the main reasons Pagel’s Ponderosa, a 4,600-cow dairy facility located near Green Bay, Wis. – not far from the shores of Lake Michigan – decided to install an anaerobic digester in 2008.

“We looked hard at putting a digester in … the main reason being for public acceptance,” recalls Pagel. “There had been times in the state of Wisconsin and other parts of the country that large-scale agriculture was not always welcomed. We were trying to do what we could to improve that situation.

“At the time we put it in, it was a $3.2 million investment and we received about 10 percent with government grants for new technologies,” he says, adding the farm is hoping for a seven- to 10-year payback on the project.

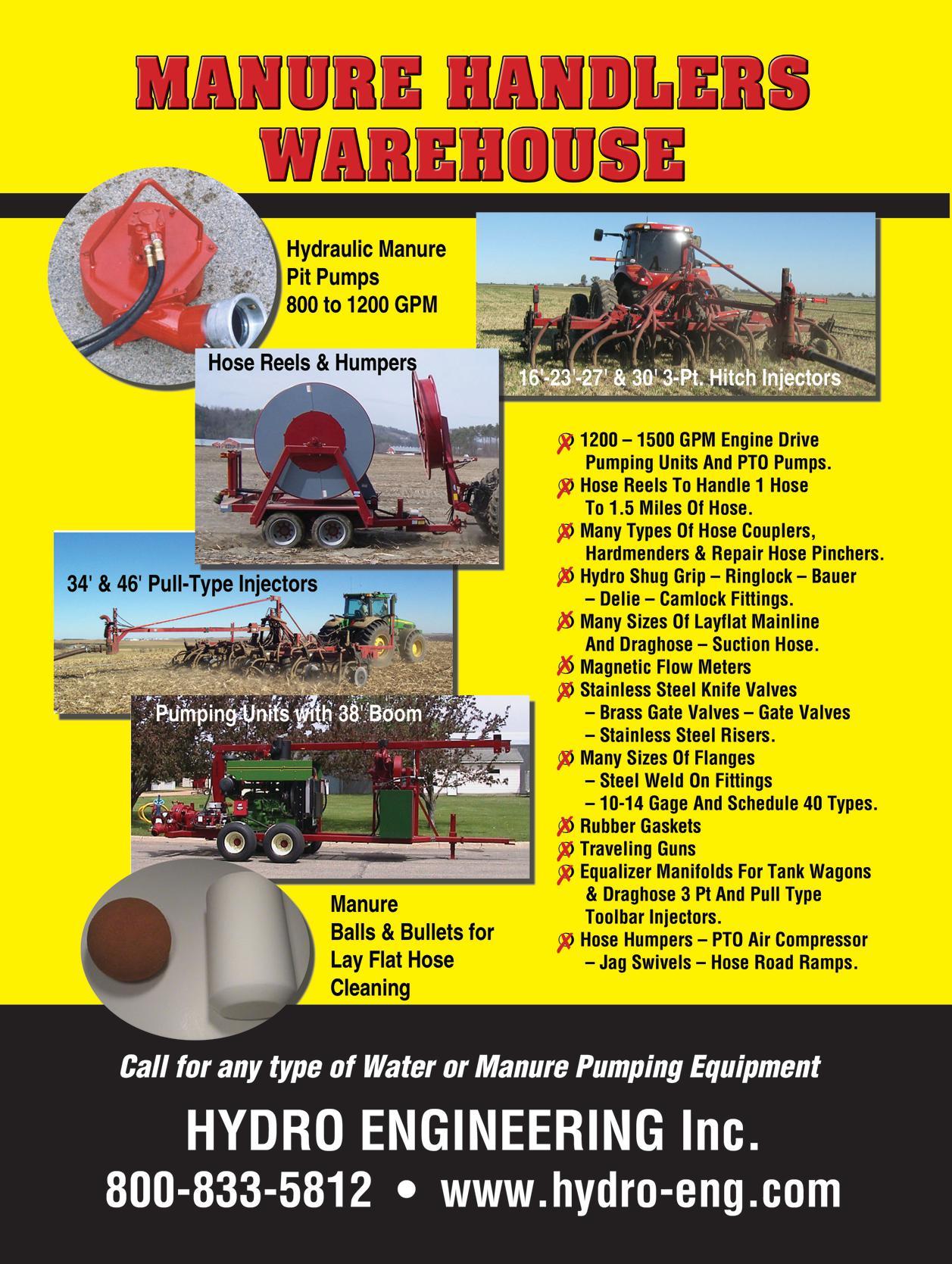

The Pagels’ GHD Inc.-designed combined plug flow and mix digester not only helps with the neighbors, but it also helps with odor reduction plus supplies bedding to the dairy and 800 kilowatts of renewable energy to the surrounding area.

The anaerobic digester

Pagel’s Ponderosa features six free stall barns with a combined 500,000 square feet of living space for the farm’s dairy herd. Manure from the facility’s two newest free stall barns, which are tunnel ventilated and contain 1,750 cows each, is scraped several times a day via skid steer into a

Pagel’s Ponderosa Dairy is a 4,600-cow dairy facility located in Kewaunee County near Green Bay, Wis. – not far from the shores of Lake Michigan. Photo by Margaret Land

flume system. From there, the manure is stored in two reception pits and comingled to create a consistent recipe before entering the farm’s anaerobic digester.

“Basically, it’s a big cow stomach,” says Melissa Van Ornum, marketing manager with GHD Anaerobic Digesters of Chilton, Wis. “When (cows) take in the feed, it goes into the stomach and the bacteria in the stomach break down the long chains of proteins, carbs and such, into smaller chains. They release energy when they do that and that’s the energy the animal uses (to produce milk). But because the cow only holds that feed for maybe half a day or three quarters of a day, there’s still a lot of energy in the waste. So we put it into our concrete stomach and hold the waste for 22 days.”

The Pagels’ 16-foot-deep digester is 144 feet wide and 200 feet long. Like a traditional plug-flow digester, new manure enters from the reception pit, displacing manure in the digester and forcing digestate out the other end.

“Where we’re unique is we’ve combined the two traditional types into one,” says Van Ornum. “We have the plug flow

shape so the new is pushing the old forward. But at the same time, we take some of the biogas off the top and inject it in the bottom. That causes a lifting and a mixing motion.”

With this design, the GHD digester is able to take in manure with less than one percent solids, something that would be impossible with a traditional plug flow digester, which is limited to manure with 11 percent solids or greater, explains Van Ornum.

“We’re sweeping that floor when we’re mixing,” she says. “You don’t have the buildup. At all of our sites, we’re taking not just the manure but also the parlor water. Often, we’re seeing waste with six to eight percent solids going into our digester and we can handle that, no problem.”

In the digester, biogas is collected in the 2.5-foot headspace at the top of the vessel, which is covered in spancrete and foam insulation plus a UV coating to protect it from the sun. The collected gas, which is made up of 60 percent methane and 40 percent CO2, is used to power the Pagel’s 3516 CAT engine, which generates 800 kilowatts of power.

“We sell 100 percent of the power we

make and we buy 100 percent of what we use,” says Pagel. “At 800 kilowatts, we’re making about 25 percent more than what we’re using on the farm itself.”

The dairy plans to add a second engine and provide an additional 500 to 600 kilowatts of power, “if we have enough methane gas,” says Pagel.

Installation of the anaerobic digester came with a steep learning curve for the Pagel family.

“We were digester virgins when we put this thing in,” says Pagel. “We knew absolutely nothing about them. We’ve learned a lot since.”

Among the learning opportunities with the operation have been issues with buildup in the digester pipes that can flake off and cause blockages.

“It’s a scale-type material,” explains Pagel. “We’ve blocked the pipes more than once. If you want to talk to anyone, talk to my son about how much fun it is to get it out. We have cleanouts installed and we need to put in more.”

When the digestate leaves the GHD digester, it is piped into the Pagels’ digester building where it is fed into a top holding tank before being fed through the farm’s three screw press separators. A safety system has been installed into the separator system to prevent possible spills.

“Once we had the tank overflow and we were close to having a spill,” explains Pagel, adding that the safety system shuts down all the pumps if there is an overflow.

The resulting separated biosolids, which are about 30 to 35 percent solids,

The Pagels’ anaerobic digester is designed by GHD Inc. and combines plug flow and mixed digester technology in the 3.2 million gallon vessel. Photo by Margaret Land

are recycled back into the Pagels’ free stall buildings as bedding for the dairy cows. The free stalls are leveled and bedded three times per week.

“We really like the digester and we really like the bedding it provides,” says Pagel. “We use it for bedding on our facility plus five other farms we sell to. We make about 40 percent more bedding than what we use.”

The farm also makes it available to area neighbors for use in their gardens and landscaping projects.

“We have more than 100 people who come and get that material and they just love it,” says Pagel. “We’ve had people come back and give us vegetables out of their gardens because the harvest has been so much higher.”

Pagel’s Ponderosa bedded on sand starting in 1985 and switched over to biosolids with the construction of the digester.

“We love the bedding. We really like the solids for cow comfort. The cow is a little bit cleaner because it keeps the manure drier inside the alley. It’s a nice soft pillow for the cow to lie on. The cows love the material.”

The liquid resulting from the screw presses is pumped out to the operation’s lagoon system, which consists of four lagoons in sequence.

“They all flow from one to the next one to the next one to try to have some kind of separation-type system so that we can have liquids with the least amount of nutrients in them for irrigating on land close by,” says Pagel.

In total, Pagel’s Ponderosa crops about 8,000 acres. The family is also involved in a second dairy operation near Casco, Wis. – Dairy Dreams – which milks about 2,800 cows and is managed by Dr. Don Niles. That operation installed an anaerobic digester in August 2010. The Pagels also operate a heifer facility with about 1,100 head and keep about 2,100 calves and heifers at the Ponderosa Calf Ranch.

Pagel’s Ponderosa is not only an operating dairy – the largest single family-owned operation in Wisconsin – it’s also a tourist destination and educational facility. The farm hosts school tours on a regular basis and also welcomes other visitors. A special observation area has been constructed so people can watch the

dairy’s cows being milked on the farm’s 72-cow rotary milking parlor and a large conference room has been constructed on the second floor to accommodate groups.

In 2010, the farm welcomed 8,000 to 10,000 visitors.

“I believe that it’s our responsibility to educate the people who are non-farm people as to what’s going on [at] the farm,” says Pagel. “I don’t think we’ve done a good enough job of it in the past. And you can see that because of some of the articles that you read in the paper every once in a while. There’s always that false information that large farms are bad, that they don’t take care of their animals and that they’re not good for the environment.

“We also believe that though this is a large farm, it’s also a family farm. We have four children and all four children are involved in the farm along with two of their spouses. It’s important to us to try to educate the public.”

The Pagels host school tours on a regular basis and also welcome other visitors. An observation area has been provided so people can watch the dairy’s cows being milked on the farm’s 72-cow rotary milking parlor.

Photo by Margaret Land

By David Schmidt

When you decide to build a retail food market next to a dairy barn, encourage the general public into that barn and dare to call yourself eco-friendly, you’d better be prepared to do something to eliminate the “warts” on the farm. In the dairy business, that means finding an ecofriendly and odor-free way to manage the manure.

That was the situation facing Bill Vanderkooi of Abbotsford, B.C. When Bill’s dad retired about two years ago, his four sons split up the family assets, which then included three dairy farms in B.C. and Saskatchewan, milking a total 850 cows, as well as a number of small agri-businesses. Each of his brothers took over one farm, Bill receiving an 80-acre parcel next to the original farm along with 50 cows and quota. He also kept most of the agri-businesses.

While some might think he was short-changed, Vanderkooi did not. A dairy nutritionist by training with a keen sense of animal welfare and behavior, he had some big ideas about how to make a silk purse out of a sow’s ear, or in his case, an agri-tourism destination offering “healthier” products out of a working dairy farm.

He was able to consider this option due to his location on a 1.2-mile (twokilometer) highway linking Abbotsford and the 401 Freeway with a busy border crossing. Add Costco and other major retailers across the road and you get countless daily drive-bys of both locals and tourists - plus a steady source for complaints about manure and odor.

Key to the entire project is the plugflow anaerobic digester, which allows Vanderkooi to bill his Bakerview EcoDairy as a “sustainable” operation. He calls the digester the “cornerstone” of green technology on the farm, saying it “allows (a farmer) to milk more cows on less acres which is necessary for sustainability.”

Bill Vanderkooi of Abbotsford, B.C., has taken an 80-acre parcel with 50 cows and made it into a “sustainable” operation, complete with a plug-flow anaerobic digester.

To date, most digesters have had a large footprint and a large appetite, making them viable only on dairies or feedlots with large herds. Smaller dairies would have to either grow corn or other feedstock specifically for the anaerobic digester or bring extra manure and/or other feedstock onto the farm.

Designed by Avatar Energy of Vermont, the Bakerview digester is a modular system intended to break-even on farms as small as 150- to 200cow dairy. Although Avatar has been running a pilot plant in Vermont for several years, this was the company’s first installation on a commercial dairy. The company is now installing the system on several American dairies and

expects to have another commercial system online this spring in Vermont.

Like most dairies, manure flows into a holding tank. Bakerview’s tank has only a three-day capacity instead of the six-months’ storage capacity a standard Environmental Farm Plan calls for. From the holding tank, the manure is preheated using heat from the digester, then pushed into the digester with a piston.

The actual digester consists of one or more fiberglass barrels. Each is eight feet in diameter and 20 to 40 feet long. The Bakerview system is 60 feet long (a 20-foot and a 40-foot barrel bolted together). Two 40-foot barrels will process the waste from 100 cows.

Sam Wampler of Avatar Energy says the barrels are made of fiberglass instead of stainless steel, as fiberglass is impervious to acids in the manure, which thereby gives them a lifespan of several decades. There are no moving parts within the barrels so breakdown is minimized. Instead, the system relies on the pressure from the piston to push manure through the barrel.

On its 21-day journey through the barrel, the manure heats up, releasing a biogas that creates a low-pressure (three to five psi) gas bubble at the top of the barrel and sterilizing the liquid/ solid residue.

“We have a 99.97 percent kill rate for pathogens,” Wampler claims.

The biogas flows through a series of valves along the top of the barrel. It is used to run a generator, which provides power for the farm. In Bakerview’s case, the biogas fuels a 20-kilowatt generator that can provide about 12 to 15 kilowatts per hour, enough to power at least six houses.

Avatar expects most systems will

generate enough power to run an entire farm. That is not the case at Bakerview, both because of the very small herd size and because of the higher electrical demand created by the presentation centre and on-farm market.

Once it exits the barrel, the digestate is processed through a separator to divide it into liquid and solid fractions. The now-sterilized solids can be reused as bedding, sold as compost or applied on the fields as a soil amendment.

The liquid effluent is sent through a trickle biofilter, which converts the ammonia into an odorless nitrate and isolates up to 70 percent of the phosphorus. Again, the liquid can be used on farm, or sold to plant growers as a nutrient-rich liquid fertilizer.

“This is a complete dairy manure management system,” Wampler says. “You get electricity to run the farm, bedding and a better fertilizer.”

For Vanderkooi, the system’s ability to remove phosphorus is one of its strengths, noting many Fraser Valley

farmers have excess phosphorus in their fields and feed, potentially causing eutrophication of nearby water sources and/or health problems in the herd.

Avatar gave Bakerview “a great deal” on the system.

Wampler notes the company expects to get great benefits from the Bakerview project and EcoDairy demonstration site. They are not alone. B.C. Hydro, the Environmental Farm Plan program and the B.C. Bioenergy Network also contributed to the project for the same reason.

It is already starting to see results.

“We have only been here a few days installing the system and we are already getting a steady stream of farmers to look,” Wampler says.

The Bakerview EcoDairy is the first demonstration dairy of its kind in Canada. The EcoDairy site includes the upscale Nutrifoods Market and the head office of the Nutriva Group, and Vanderkooi’s collection of

e: bjansen@cornellpump.com p: (503)653-0330 w: cornellpump.com

The white unit on the side is the solid/liquid separator and biofilter for the Bakerview EcoDairy anaerobic digester. When the system is complete it will sit on the lower of the two steel frames and be top fed from the barrel.

agribusinesses, consisting of Bradner Milk Transport, Dairysmart Nutrition Group, Diverse Byproducts, Fraser Analytical Services and Nutrifood Solutions.

Although Vanderkooi owns the land, cows and quota, the EcoDairy presentation centre is owned by the Dairy Innovation Association, a non-profit group consisting of 10 agribusiness members, including J & D Farmers Dairy Service (DeLaval), Avalon Dairy (which processes Nutriva’s Vitala milk and yogurt) and Artex Barn Solutions (Comfort Zone).

With each member paying $20,000 to $80,000 dollars to participate, Vanderkooi was able to raise more than $400,000 for the project. The barn features members’ products, including a DeLaval robotic milker, Comfort Zone stalls and SunNorth’s natural ventilation system. It is run by four full-time staff and augmented by local volunteers, with ongoing operations funded from tour fees.

“Agri-tourism is not a moneymaker,” Vanderkooi explains. “I just want to recoup my investment.”

The barn is covered in storyboards and attached to a presentation centre with a theatre and meeting space. In most other respects, the barn is simply a small version of the freestall barns on most dairy farms. It does, however, have several rare features, aimed at appealing to untrained guests, reducing labor and reinforcing the farm’s ecofriendly label.

The robotic milker has a viewing area on one side. A conveyor used to deliver bedding straddles the double row of comfort stalls. An angled blade pushes sawdust off the conveyor into the head end of the stalls. The bedding is then distributed further by the cows’ activities. The system ensures a steady supply of fresh, clean bedding with minimal labor input. There are stall dividers along the feed bunk to minimize fighting for feed and the feed lane is elevated so the cows’ feet do not touch the automatic alley scrapers, which are run more often than in a conventional barn. The alleys are also cantilevered so urine runs into a drainage channel in the centre, thereby

keeping both the barn and the cattle in pristine condition.

Everything is monitored constantly – by anyone! Five cameras mounted in the barn and on the robotic milker are linked to the EcoDairy website (www. ecodairy.ca) so anyone can watch online at any time. The most common question visitors ask is whether cows have access to pasture. The answer is no, with staff carefully explaining the barn is designed to provide a safe, healthy environment for the cows. They stress the room provided for individual cow movement and the “perfect blend of nutrients” the diet provides.

In addition to the usual mix of grain, corn silage and hay, Vanderkooi’s total mix ration (TMR) includes whole flax seed and tuna oil. This results in higher CLA and Omega 3s in the milk, allowing him to market it as branded Vitala milk and yogurt.

There are no moving parts within the Avatar anaerobic digester so breakdown is minimized. Instead, the system relies on the pressure from the piston to push manure through the barrel. Photo by David Schmidt

Located about 50 miles southwest of Fort Worth, the Huckabay Ridge facility is in the heart of the Texas dairy community, consisting of eight digester tanks, each with a capacity of 916,000 gallons capable of converting manure and organics into methane-rich biogas. Contributed photo

By Tony Kryzanowski

Dairy farmers in the Bosque River Watershed in Texas currently shipping their manure to the massive Huckabay Ridge anaerobic digester facility are breathing easier now that the facility has been purchased by EM Biogas, a subsidiary of Houston-based, Element Markets, from bankrupt Environmental Power Corporation (EPC).

EPC’s Huckabay Ridge facility went into receivership in July 2010. EM Biogas purchased the facility in November from EPC for $3.3 million. According to chief marketing officer Randy Lack, the company intends to convert the facility into a commercial as well as a technological success. The facility is the largest anaerobic digester in the U.S.

“It (Huckabay Ridge) is one of the beacons in the anaerobic digestion

space, which is a space we believe in,” says Lack. “It has excellent anaerobic digesters and a nice setup.”

He adds that with the project in its current state, EM Biogas will be making significant capital investment into it, “just because there are some things that we think either need upgrading, improving, or revamping in some way. It certainly needs additional capital investment, but it is a good technology project.” A major focus of capital investment is to ensure that there is a steady stream of marketready gas from the facility and that the volume increases over time, while simultaneously increasing the benefits of the facility to the nearby Stephenville area.

“I think the burden on us, from a technological perspective is to really optimize process, meaning manure

feedstock management, conversion to methane, and really focusing on the anaerobic digestion process to increase methane and ensure that we are taking the right kinds of feedstocks,” says Lack. “So it is more chemistry than process engineering.”

Located about 50 miles southwest of Fort Worth, the Huckabay Ridge facility is right in the heart of the dairy community in Texas and consists of eight digester tanks, each with a capacity of 916,000 gallons capable of converting manure and organics into methane-rich biogas. The facility also serves as a gas treating plant, which upgrades the biogas to pipeline quality. It was originally built in 2006 and achieved full production in 2008. The digesters continued to operate through the bankruptcy and ownership transition. In the past, the facility also

produced a nutrient-rich byproduct that was used as organic fertilizer in crop production.

Better manure management among the 51 dairy farms located in the Upper North Bosque River Watershed has been ongoing for nearly two decades and today is tightly controlled by a new waste permitting system run by the Texas Commission on Environmental Quality. The North Bosque River flows into Lake Waco, which serves as a water supply reservoir for more than 200,000 people in the city of Waco and surrounding area. The area witnessed significant growth from new dairy owners moving in from California and Arizona because of cheaper land prices, with the number of cows increasing by about 50,000 cows in the late 1980s to more than 80,000 cows today, an increase of almost 50 percent.

Lack says there is no doubt that the large anaerobic digester offers a significant benefit to local dairy farmers and to the community.

“The benefit of being able to take the manure into our project is valuable to the local dairy community, as it offers a viable alternative to land application or stacking the manure on their own land,” says Lack

Besides processing manure from dairy farms within a 20-mile radius of the facility, the digestion process also accepts grease-trap wastes from Dallas-Fort Worth restaurants to supplement the gas production process. In the past, the facility was paid to receive and dispose of the waste material.

“All of the inputs to the facility are an important part of the economics but the largest portion currently of the projected revenues is associated with renewable natural gas sales,” says Lack. Element Markets believes that EM Biogas will succeed where EPC faltered because of the Element Markets business strategy, which is not only to operate alternative energy assets, but to supplement the company’s income stream with profitable carbon credit offset trading and technology investments. To Element Markets, the combination of physical energy assets like Huckabay Ridge with the company’s deep trading and technology experience allows it to maximize profits. In other words, Element Markets is engaged in a number of renewables markets to establish a stronger business foundation. Purchase of the

Huckabay Ridge facility makes EM Biogas one of the largest biomethane suppliers in North America. In addition to biogas, Element Markets has invested in wind and solar energy projects. It recently sold its wind assets to really focus on biogas production and marketing.

“There’s been a lot of technological successes within the anaerobic digestion world but, as far as the energy business is concerned, there has been a lack really of commercial success,” says Lack. “Given the experience that Element Markets has

in understanding the energy business, plus our expertise in environmental commodities and operations, we felt like it was a project that fit us very well.”

One niche market the company is hoping to capitalize on is the premium the company says it can earn on its biogas versus fossil-fuel-based natural gas because of its green source. Lack says it is possible to earn a premium on this gas, but was reluctant to disclose how much that premium is, for business reasons. While the facility itself does not generate renewable energy credits (RECs) directly, because the facility

The facility also serves as a gas treating plant, which upgrades the biogas to pipeline quality. The digesters continued to operate through the bankruptcy and ownership transition.

federal level for 20 percent renewables by 2020. For example, any driver traveling through Central or West Texas alone would be hard pressed not to see a wind farm. The driving force for growth in renewables, and why Lack feels confident about the future growth potential of the industry, is state and federal legislation requiring that a certain percentage of power be generated from renewable sources by specified target dates.

In terms of the Huckabay Ridge facility, because Element Markets was aware of the technology being employed, they felt that the project represented good value. They understood that even though they would be able to earn a premium on the biogas, prices would still be dictated largely by the current very low prices being paid for fossil-fuel-based natural gas. The whipsaw nature of prices for natural gas over the past five years is something that has caught everyone by surprise.

does not generate electrical power, the RECs, a tradable and salable commodity, are generated for those who purchase the gas and produce green products like power from this renewable resource. So that is one marketing approach available to the company.

The company is currently conducting an inventory of the full value of the facility, including its benefit to the environment in terms of offseting greenhouse gases.

“We don’t have a good number on that yet, but what I can tell you is

that it is significant,” says Lack. “If you look at the amount of waste that was put into a lagoon or into landfills that is now coming to our site, allowing us to prevent the degradation of methane released from those facilities, we believe it is a very significant reduction in greenhouse gases.”

He says there is no doubt that the “green” energy industry has grown exponentially over the past decade and is much larger than most people realize – probably 10 to 12 percent of the total energy produced in the U.S. – with proposals floated at the

“The shock about the whole natural gas industry was simply the volatility,” says Lack. “I think most people were surprised at how far it went up and most people were surprised by how far it came down. Shale gas will provide a good source of natural gas for a long time to come but what it doesn’t provide is the environmental incentive that renewable gas does. A project like Huckabay Ridge has the benefit of providing natural gas, renewable power, and being greenhouse gas neutral or reducing greenhouse gases.” The key, he adds, is to market the biogas properly and, given the company’s knowledge of both the energy and the environmental commodity markets, he feels it will succeed.

Once EM Biogas has the Huckabay Ridge facility operating to its satisfaction, it has not ruled out replicating the technology elsewhere, but it is focused on optimizing that site, which is capable of holding seven million gallons of waste at a time. Lack emphasizes that Element Markets is always looking for growth opportunities and this is a green energy space that the company is very passionate about.

By Nigel Key and Stacy Sneeringer

What is the issue?

Methane digester systems capture methane from lagoon or pit manure storage facilities and use it as a fuel to generate electricity or heat. In addition to providing a renewable source of energy, digesters can reduce greenhouse gas emissions, odors from manure, and potential contamination of surface water. Methane digesters have not been widely adopted in the United States mainly because the costs of constructing and maintaining these systems have exceeded the value of the benefits provided to the operator. Policies to reduce greenhouse gas emissions could create new opportunities for livestock producers to earn revenue from burning methane from manure, making such biogas recovery facilities profitable for many livestock producers. However, there is likely to be wide variation in the scale, location and characteristics of livestock operations that would benefit, so these policies could have long-run structural implications for the U.S. livestock sector. In this report we estimate the number and type of hog and dairy operations that would find it profitable to adopt a digester at any given carbon price. We also estimate the relationship between the price of carbon (CO 2) and the amount of emissions reduced by digesters on these operations.

What are the major findings?

The extent to which livestock operations can reduce greenhouse gas emissions from manure management depends in part on the number of livestock operations that adopt methane digesters, which in turn depends on digester profitability from energy savings, energy sales, and/or sales of emission reductions in a carbon offset market. An offset market allows livestock producers who reduce methane emissions to sell these reductions or “carbon offsets” to other greenhouse gas emitters who might face emissions caps.

Factors that influence digester

Methane digesters have not been widely adopted in the United States mainly because the costs of constructing and maintaining these systems have exceeded the value of the benefits provided to the operator.

profitability, and that determine the characteristics and locations of the livestock operations that could benefit from the introduction of a carbon offset market, include:

• operation size – costs of constructing and operating a digester decline on a per-head basis, making digesters more profitable on larger operations

• the selling price of surplus electricity – a higher price makes digesters more valuable for operations that can generate more electricity than they use on farm

• farm electricity expenditures, which depend on electricity prices and on farm use – higher expenditures make digestergenerated electricity more valuable, especially if the operation cannot sell electricity or if the selling price of electricity is below the retail price

• participation in cost-share and other incentive programs – this can defray the cost of building digesters

• the farm’s initial level of methane emissions – this determines the maximum quantity of carbon emissions reductions that can be sold

• carbon price – a higher carbon price makes digesters more profitable for operations that can sell carbon offsets.

Larger operations would be more likely to adopt a digester, and likely would earn substantially higher profits on average than smaller operations. Hence, introduction of a carbon market in a region could enhance existing economies of scale in production and result in further concentration of production on the largest operations. However, smaller livestock operations may be able to achieve a more efficient digester scale by supplementing manure with food

JUNE 8-10, 2011

Iowa State Fairgrounds

Des Moines, Iowa USA

Pre-Register Now

• Business Seminars

• Opportunity for Industry Networking

• Enjoy the Hospitality Tents and Social Events

• Thursday Evening MusicFest

• Junior National Swine Show Trade Show

Wednesday, June 8th – 8 a.m. to 5 p.m.

Thursday, June 9th – 8 a.m. to 5 p.m.

Friday, June 10th – 8 a.m. to 1 p.m.

For more information and to pre-register, visit

Larger operations would be more likely to adopt a digester, and likely would earn substantially higher profits, on average, than smaller operations.

waste products or by sharing a digester with other small operations. In addition, if the adoption of methane digesters by smaller operations is a policy goal, several tools exist – such as cost-share subsidies or tax incentives – that could be used to encourage their adoption by small farms. Additional revenues from the sale of carbon emissions reductions (offsets) could substantially increase the number of operations that would adopt a biogas recovery system. Findings in this study indicate that a carbon price of $13 per metric ton of carbon dioxide equivalent emissions (an initial price estimated under one scenario for a nationwide cap-and-trade

• induce dairy and hog operations to supply offsets equivalent to about 22 million tons of carbon dioxide annually, amounting to about 62 percent of the current greenhouse gas emissions from manure management in these industries, or about five percent of total greenhouse gas emissions from the U.S. agricultural sector

• allow dairy and hog operators as a group to earn up to $1.8 billion in additional profits over 15 years from installing methane digesters. Currently, the price of electricity and onfarm electricity expenditures are key determinants of digester profitability. However, when carbon prices are above $4 per metric ton of CO2 equivalent emissions, carbon offset sales become a larger source of digester revenue than electricity generation. At a price of $13 per metric ton of CO2 equivalent emissions, revenues from emission reduction sales (offsets) contribute 66 percent of gross digester revenues for all dairy and hog operations, electricity sales contribute eight percent, and cost savings from avoided energy expenses contribute the remaining 26 percent.

11-MC-0100.WheresMilk_MM.pdf 1 2/18/11 9:20 AM

At higher carbon prices, the distribution of profits from digesters reflects

the location of large-scale operations and the prevalence of lagoons. Among states with the greatest number of dairies, the study finds that California, New York, Wisconsin, and Texas each have at least 100 such operations that would find it profitable to adopt a digester at a carbon price of $13 per metric ton of CO2 equivalent emissions. At the same price, North Carolina, Illinois, Indiana, Missouri and Oklahoma each have at least 100 hog farm operators who would find a methane digester profitable.

How was the study conducted?

We used a model of digester profitability to estimate how farm size, manure management methods, electricity prices and carbon prices affect producers’ decisions to adopt biogas recovery systems. Hog and dairy producers are assumed to adopt a digester if the present value of the discounted stream of profits (the net present value) is positive. Profits derive from electricity generation and carbon emission reductions sales less the digester construction and maintenance costs. Using case study information, we parameterized the model. Electricity price data are drawn from the U.S. Department of Energy, and methane emissions are estimated using State-level Intergovernmental Panel on Climate Change emission coefficients. By computing the present value of digester profits for every farm in nationally representative samples of dairy and hog operations (USDA’s Agricultural Resource Management Survey or ARMS), we used the model to provide an estimate of the number, size, and location of farms that would find it profitable to adopt a digester at any given carbon price. ARMS is conducted by USDA’s National Agricultural Statistics Service (NASS) in conjunction with the Economic Research Service. By predicting which operations would earn profits from digester adoption and then summing the reduction in tons of carbon dioxide equivalent emissions, it is possible to estimate the relationship between the price of carbon and the amount of emissions reduced by methane digesters on dairy and hog operations. We used the model to estimate how the present value of farm revenues changes with the carbon price and to simulate the effect of surplus electricity prices and government cost-share policies on the potential supply of carbon emissions reductions.

The full report can be viewed at www.ers.usda.gov/Publications/ ERR111/.

Nigel Key and Stacy Sneeringer are researchers with the U.S. Department of Agriculture’s Economic Research Service.

Recently, the American Society of Agricultural and Biological Engineers (ASABE) announced the winners of the 2011 AE50 awards, sponsored by ASABE’s Resource magazine.

The winners of this annual award represent “the best and the brightest” products aimed at agricultural, food and biological systems services.

The inventions and designs chosen were selected from numerous entries submitted to the AE50 competition. The judges who chose the winners represent all facets of the agricultural, food, biological and related systems engineering professions. The expert panel picked the best products first introduced into the marketplace during 2010. These products are expected to save producers time, costs, and labor while improving user safety.

The winners servicing the manurehandling sector included:

The XPulse Twin Piston Pump is a positivedisplacement pump transferring livestock manure slurry between 76 and 587 L (20 and 155 gal) per minute. The dual pumping chambers in sequence provide a nonpulsing flow, ideal for feeding downstream processing equipment, while using 25 percent less power than conventional transfer equipment. The XPulse uses existing pumping-tube technology. The compact footprint and controllable flow rate make this pump easy to retrofit into existing systems as well as new construction. The flapper doors with a rubber and urethane-sealing surface, combined with an air relief, allow the pump to self-prime. The top-down assembly of the pump enables all working components to be removed from the top using standard tools. The openness of the base enables passage

of solids found in manure; additionally, the placement of the access doors allows easy cleaning of unwanted material.

The Xpress cascading roller press system squeezes liquid from the solid reject of a de-waterer, processing raw scraped manure or digester effluent to produce a material suitable for bedding or compost. The modular design increases the serviceability and performance of the system by providing drier fibers, and it can be tailor-fit to any size dairy operation. The equipment package can include a 1.8, 1.2, and 0.6 m (6, 4, and 2 ft) wide roller press system with primary or secondary screens. The virgin gum rubber and perforated stainless steel rollers squeeze material to produce a dry fiber with minimal power. The frame design allows individual removal of the rollers from the front and side access to the inside of the roller and the upgraded heavy-duty bearings. The air pressure suspension system limits mechanical shock loads while allowing adjustment of each squeezing step.

The Digi-Star Nutrient Tracker™system is an application management tool and documentation system for manure or fertilizer spreading operations. The Nutrient Tracker™System allows operators to see the application rate while spreading and automatically collects information for the time, date, field names, and amount of

material applied with GPS verification data. The system then records the data to internal memory and makes it available for downloading to a USB drive at the end of the day, week, or month. The Nutrient Tracker includes scales on the spreader, the NT460 data-collecting indicator with GPS interface, and PC software. The proprietary PC software combines the data with downloaded Google satellite images of operator’s fields to show exactly where, when, and how much of the nutrients were applied. The N application information helps producers comply with EPA and DNR CAFO regulations and also aids in reducing the amount of commercial fertilizers needed to grow a successful crop.

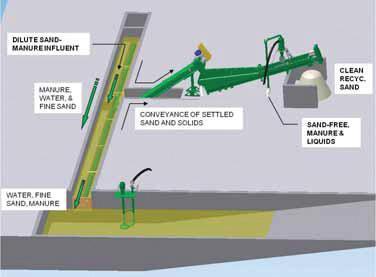

The McLanahan Self-Cleaning Sand Lane (SCSL) is an equipment system for processing flushed or otherwise diluted sand-laden dairy manure. Sand is the preferred bedding on dairy farms, as it maintains a comfortable and healthy resting environment for cows due to its cushioning capabilities and its inability to sustain mastitis-causing organisms. Conventional methods of handling diluted sand-laden manure are labor and machinery intensive while producing a poor quality (high organic matter content) sand product. Due to the difficulties associated with managing traditional systems, the quantity of sand recovered is poor, resulting in manure storage ponds and treatment systems failing as sand accumulates. The McLanahan SCSL is an automated, quarry-duty system for separating sand from highly dilute manure at flow rates in excess of 22,700 L (6,000 gal) per minute. The automated nature of the system allows for high recovery of sand both in terms of quality and quantity. Recycled sand is reused with lactating cows in less than one week.

North and South Carolina have seen a steady increase in swine production over the last 15 years. In North Carolina alone, swine production generates approximately a quarter of the state’s gross farm receipts. The presence of so many large-scale pig farms leads to the problem of proper animal waste disposal.

The most common practice in the Carolinas is storing animal waste in anaerobic lagoons. They are primarily used to concentrate and passively treat urine and feces but because of the widespread use of this practice, the environmental impact could be quite severe. Conflicting reports implicate lagoon sites to be responsible for high emission rates of nitrogen gas and volatized ammonia.

A team of Agricultural Research Service (ARS) scientists from the U.S. Department of Agriculture (USDA) examined a series of commercial, anaerobic, swine wastewater lagoons in North and South Carolina for genes involved in the nitrogen cycling process. Nitrification and denitrification are the parts of the process responsible for turning ammonia into nitrogen gas. After analyzing eight lagoons and measuring the abundance of four nitrogen cycling genes, researchers concluded that the denitrifying and nitrifying organisms were not active despite there being a thriving amount. Acidification and eutrophication of the surrounding ecosystem could be the result of prolonged exposure to volatilized ammonia.

“These anaerobic lagoons have relatively consistent levels of nitrogen-cycling genes throughout their water column,” says Thomas F. Ducey, one of the authors of the study. “While they are similar to natural ecosystems, they are not as high as some wastewater treatment systems. Moreover,

these gene levels did not translate into the high denitrification enzyme activity that is typical of wastewater treatment systems.”

Research is continuing to help agricultural and scientific communities further understand the microbial ecology and nutrient cycling in anaerobic lagoons. The full study can be found in the March/April 2011 issue of the Journal of Environmental Quality. The abstract can be viewed at www.agronomy.org/publications/ jeq/abstracts/40/2/610.

Manitoba pig producers provided manure management funding

Manitoba pig producers will soon have access to more than $26 million to help them improve manure management and to reduce the risk of water contamination.

The goal of the Manure Management Financial Assistance Program (MMFAP) – announced Feb. 24 – is to help pig producers build and repair manure storage structures that eliminate the need for winter application. Also, by encouraging the adoption of manure treatment systems, producers are in a better position to reduce soil phosphorus on their land. This program will help reduce the risk of water contamination.

The program is supported by a three-year investment by the federal and provincial governments (cost-shared 6040). The Government of Canada will make almost $16 million available through the Agricultural Flexibility fund to finance the acquisition of manure treatment systems. The Province of Manitoba will provide more than $10 million for the building and repair of manure storage structures.

“This funding will assist producers with the cost of building or repairing manure storage structures and adopting manure treatment systems that will help them protect our water,” said Manitoba Agriculture, Food and Rural Initiatives Minister Stan Struthers. “We recognize that we all share responsibility for protecting our water and we also recognize the challenges this industry has faced with the rising dollar and unstable prices.”

Livestock effluents have always been used as fertilizer on crop fields. But there is concern untreated manure can transmit diseases to humans and animals. To deal with this issue, scientists with Cemagref, a French research firm, are investigating the use of heat exchangers for thermal

treatment of the slurry, a well-known technique that they are trying to make more energy efficient.

The higher the temperature, the more effectively the micro-organisms are destroyed, so an easy solution would be to set up sterilization programs, e.g., treatment at more than 120 C for at least 30 minutes. But the cost of such treatments would be much too high for most farmers. The initial goal of the research is therefore to create treatments that are less costly, but sufficient to meet sanitation targets. The slurry is heated to temperatures between 55 C and 96 C and maintained at a high temperature before cooling and storage. To determine treatment effectiveness, the researchers selected a set of seven bacterial and viral indicators, representing various levels of thermoresistance.

The results showed that heating to 60 C for 10 minutes is sufficient to make the slurry acceptable for spreading purposes. But none of the treatments up to 55 C for three days or 70 C for one hour (protocols based on those required for composting) were sufficient to destroy the most resistant pathogens. Heating to 96 C for 10 minutes is required to destroy some of them and temperatures over 100 C would appear necessary to completely remove pathogens from the slurry.

These results prompted the researchers to look for less costly solutions, including the use of a second heat exchanger to recycle the calories from the hot slurry as it cools. This technique recovers between 55 and 70 percent of the energy used to heat the slurry.

Researchers also plan to investigate ways of eliminating progressive clogging of the system, which reduces heat exchange, ultimately increasing the cost of the process. It will be necessary to determine the best treatment strategies for the future development of the process and the best cleaning

techniques, whether mechanical or chemical. They are also investigating ways to couple the process with a methanization system to produce biogas as an energy source.

The Western United Dairymen board of directors recently voted to endorse a program to significantly reduce regulatory costs for member dairies by administering a representative groundwater monitoring program.

A dairy’s membership in good standing in Central Valley Dairy Representative Monitoring Program (CVDRMP) can substitute as a lowercost alternative for the current regulatory requirement for each dairy to install monitoring wells.

WUD director Tom Barcellos serves as CVDRMP chairman. In a recent Ag Alert article, Barcellos explained that in 2007 the state adopted comprehensive new water quality regulations for Central Valley dairies requiring the installation of wells exclusively for monitoring first-encountered groundwater. It was estimated that the costs of the regulation could be $40,000 per dairy to drill the wells, plus the ongoing costs to cover sampling and reporting.

“Our coalition offers a better alternative,” said Barcellos. “A scientifically guided program will locate wells strategically on a representative set of dairies, instead of all dairies. Our program will be smaller, smarter and more efficient. It will generate the results to meet the regulatory compliance needs of our monitoring coalition members, but it will cost significantly less because fewer dairies will need to be monitored and because we will pool resources and pass the savings along to coalition members.”

More information on the coalition is available at www.dairycares.com/ CVDRMP/.

JCB recently introduced the newly designed 3230 Fastrac Xtra.

First launched to the European market in June 2010, this new model retains the performance and features of the previous model plus incorporates a host of new features.

The 3230 Xtra comes standard with the 24-speed P-TRONIC powershift transmission already offered in the Fastrac 7000 Series. With this transmission, operators can move the joystick for clutch-less gear and range changes between the six gears in each of the four ranges.

The P-TRONIC Transmission also offers the same flexibility and automation as the 7000 Series. In drive mode, the tractor shifts like an automatic car for operation on the road. Similarly, a cruise control option allows the operator to set and resume a forward speed. Autoshift mode is also available, enabling the tractor to automatically shift gears in the field based on the engine load and within parameters pre-set by the operator.

The JCB Fastrac 3230 Xtra also features Xtra-Drive as standard. This new feature makes it possible to drive the machine by just using the brake pedal. When the operator is hitching the 3230 Xtra up to implements, the tractor’s clutch pedal overrides XtraDrive to retain inching capabilities.

JCB has increased the 3230 Xtra’s engine torque by up to 22 percent, giving the machine more pulling power in heavy field-work applications. A user-selectable power boost feature is controlled by an illuminated button on the armrest,

allowing operators to choose between power and economy modes. When active, the power boost feature boosts the 3230 Xtra up to 270 horsepower in the top two gears for greater acceleration at higher road speeds and more power when climbing hills.

The JCB 3230 Xtra features variable flow hydraulics with colorcoded spool controls mounted on the armrest for ease of operation. This load-sensing system provides flow rates of up to 37 GPM with 26 GPM per slice for the most demanding implements – an increase of more than 25 percent over the previous model.

The load-sensing power beyond option is available for implements with their own valve block. With this option, the implement demands oil from the tractor only when required.

A priority flow option is also available to replace the flow divider option on previous machines. This provides constant oil flow through the green spool valve independent of any other hydraulic functions. www.jcbna.com

BiOWiSH Technologies recently introduced BiOWiSH™ Odor, an allnatural product that is reported to reduce the strength of effluent by up to 80 percent and cut sludge production by more than 50 percent.

According to the company, BiOWiSH Odor degrades organic wastes – including fats, proteins, carbohydrates, and cellulose – into safe

and smell-free compounds such as carbon dioxide, nitrogen gas and water. It is reportedly suitable for all manure treatment systems and eliminates odorcausing compounds at their source instead of masking them.

Commercial use in Asia, Australia and North America has proven that BiOWiSH Odor lowers total nitrogen, phosphorus and potassium by up to 40 percent, as well as reduces biological oxygen demand and total suspended solids by up to 80 percent, the company reports.

Delivered in freeze-dried powder form that is activated in water before applying to the solid waste or wastewater, BiOWiSH Odor is available in 2.2-, 11- and 22-pound bags. www.biowishtechnologies.com

A new, all-steel radial flotation tire from Alliance Tire –the Alliance 390 All-Steel AgriTransport Flotation Radial – is the first flotation radial to receive Department of Transportation (DOT) certification for highway use at 50 m.p.h. It’s also the first all-steel flotation radial in the industry and the first to carry nearly 11,000 pounds of load at 50 m.p.h., according to Michael Aguon, national Alliance product manager of Alliance Tire Americas,

“The new, all-steel 390 provides performance, speed and versatility that will allow farmers to lower operating costs and improve their productivity,” says Aguon. “This is a world-class innovation, the next generation of flotation tire from the company that introduced the first radial flotation tires to the world market.”

The steel belts in the new 390

deliver resistance to cuts and punctures and ensure a broad, flat footprint for improved traction and flotation, Aguon adds. A rugged tread compound improves wear resistance to maximize service life and return on investment. Extensive on-farm testing in the U.S. and abroad shows longer service life and higher load-speed performance than competitors’ nylon-construction radial flotation tires, Aguon says, with no downtime.

The all-steel 390 is currently available in the popular 600/50R 22.5 size, widely used on manure tanks and wagons, grain carts and agricultural trucks. Aguon says other sizes are in development and will be available soon. www.atgtire.com

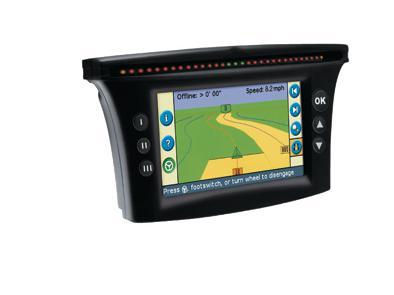

Crop producers using precision guidance systems in their farming operations now can experience faster system startups and less downtime with the new StarFire™ 3000 Global Navigation Satellite System (GNSS) receiver from John Deere Ag Management Solutions (AMS). This next-generation technology is a direct replacement for the popular StarFire iTC.

The StarFire 3000 is compatible with the StarFire 450 RTK and 900 RTK radios as well as GPS and GLONASS satellite signals. It incorporates a number of technical innovations that contribute to greater efficiency in the field:

• Reduced startup time and downtime. StarFire 3000 significantly reduces the time needed to acquire a signal when starting equipment for the day. If that signal is lost, the receiver can reacquire it quickly.

• Terrain compensation

response. The receiver detects changes in roll, pitch and yaw of the vehicle and adjusts its position relative to the ground.

• Better shade performance. Receiver performance is improved in shaded conditions because StarFire 3000 automatically tracks weak satellite signals and acquires new ones.

• Over-the-air activation. Receiver upgrades with activations and subscription renewals can be handled

over the air, which eliminates the need to manually type in activation codes.

• Diagnostic display. LED lights on the front of the unit notify the operator about receiver status and can help quickly diagnose problems that may arise.

• John Deere reliability. The StarFire network remains the first and only system developed exclusively for agriculture and backed by the John Deere name. www.JohnDeere.com

Kyte Centrifuge supplies reconditioned or new centrifuges for manure dewatering and fine particle separation. Benefits include: uses no screens / filters, separates particles to less than 50 microns in size, and reduces phosphorus, nitrogen and potassium in wastewater.

Mailed six times per year. Subscriptions are free to farm owners, partners and managers of large livestock or poultry operations in Canada and the USA. free subscriptions must be renewed annually. Great rates are available to other interested readers.

For best service, subscribe or renew online at www.manuremanager.com. If you are renewing, please quote the seven digit customer number found on your mailing label.

Telephone 866-790-6070 • fax 877-624-1940 e-mail mweiler@annexweb.com www.manuremanager.com

The U.S. pork industry’s newest technologies, outstanding breeding stock and educational seminars are just a few reasons to attend the 2011 World Pork Expo. Plans are well underway for this year’s event, scheduled for June 8 to 10 at the Iowa State Fairgrounds in Des Moines, Iowa.

“Not only is World Pork Expo a must-see for swine-industry enthusiasts, but it also is one of the premier events in Iowa,” says Doug Fricke, World Pork Expo show manager. “Hotels rooms already are going fast, so making travel plans early means you won’t miss out on the chance to stay at one of the official World Pork Expo hotels.”

Each year, nearly 20,000 producers and industry professionals attend expo, the world's largest pork-specific trade show. Attendees will find business seminars on profitability, animal health and current issues. They can see the newest products, services and technologies offered by more than

450 commercial exhibitors. They will have the opportunity to watch junior showmen and swine breeders exhibit some of the best market hogs and breeding animals available, as they compete for top prizes. And throughout the event, they can feast on great food and enjoy family entertainment.

The expo trade show is open from 8 a.m. to 5 p.m. on June 8 and June 9, as well as from 8 a.m. to 1 p.m. on June 10. The breeding stock sales will continue on June 11 from 8 a.m. until they’re completed (at approximately noon).

Once again, MusicFest will be the social highlight of World Pork Expo. From 3:30 p.m. to 8 p.m. on June 9, expo attendees can enjoy roasted pork and refreshments while listening to music performed by live bands.

Several pre-expo tours are planned so that producers from throughout the world can experience Midwestern agriculture – and hospitality – at its finest. By popular demand, the June 6 and 7 tour will feature a stop at

Cinnamon Ridge Farms in eastern Iowa.

To receive a $10 World Pork Expo early registration discount and free expo alerts via e-mail, go to www.worldpork. org and click on the Register Now tab. The website also has the latest details about room availability at the official expo hotels in its Producer section. Additional information is available when you connect with World Pork Expo on Facebook and follow World Pork Expo on Twitter (hashtag: @NPPCWPX).

World Pork Expo, the world’s largest pork-specific trade show, is brought to the entire swine industry by the National Pork Producers Council (NPPC). For more information, visit NPPC’s website at www.nppc.org.

Trimble’s EZ-Guide 250 and EZ-Guide 500 lightbars can now provide record-keeping, tracking and feature mapping of your liquid and dry manure applications. Combine this new technology with Trimble’s proven guidance capability in order to more easily fulfill EPA and DNR manure handling record-keeping requirements. Increase efficiency by using colorful on-screen maps to eliminate gaps or overlaps, and avoid restricted application zones or tile lines. To find a Trimble dealer, visit www.trimble.com/agriculture or call 800-865-7438. Trimble Agriculture. The