MARCH/APRIL 2010

MARCH/APRIL 2010

Partnership with biogas firm relieves dairy of digester management

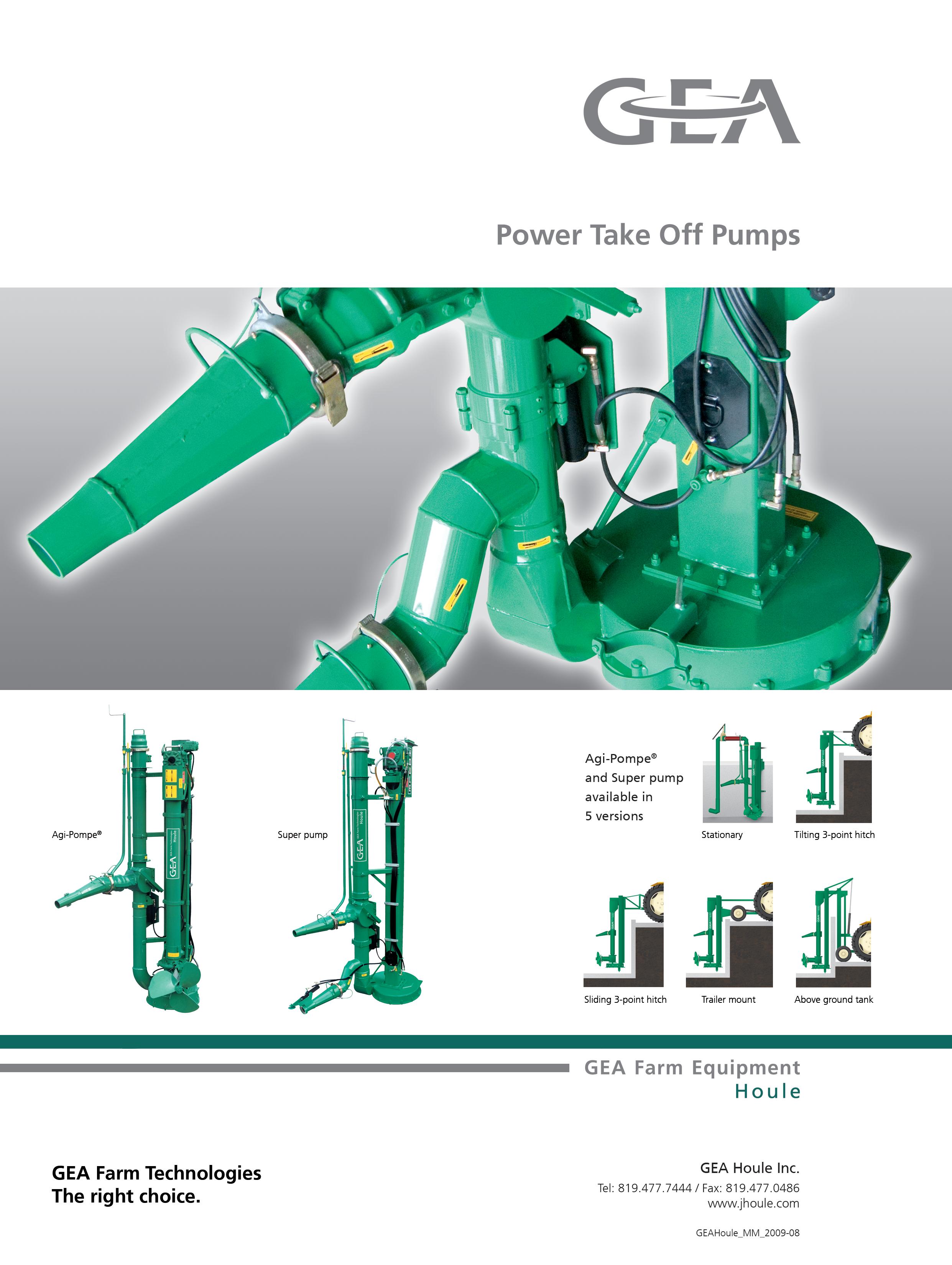

INJECTION EQUIP M ENT, L A GOON A GIT A TION

March/April 2010

Volume 8 • No. 2

Published by:

Annex Publishing & Printing Inc. P.O. Box 530 Simcoe, Ontario N3Y 4N5

Editor

Margaret Land • (519) 429-5190, (888) 599-2228, ext 269 mland@annexweb.com

Contributing Editors Tony Kryzanowski, Diane Mettler, Tracy Schlater

Advertising Manager

Sharon Kauk • (519) 429-5189, (888) 599-2228, ext 242 skauk@annexweb.com

Sales Assistant

Mary Burnie • (519) 429-5175, (888) 599-2228, ext 234 mburnie@annexweb.com

Production Manager Angela Simon

VP Production/Group Publisher Diane Kleer dkleer@annexweb.com

President Mike Fredericks mfredericks@annexweb.com

Publication Mail Agreement #40065710

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO CIRCULATION DEPARTMENT, P.O. BOX 530, SIMCOE, ON N3Y 4N5

e-mail: mweiler@annexweb.com

Printed in Canada

Circulation

e-mail: mweiler@annexweb.com

Tel: 866-790-6070 ext. 211 Fax: 877-624-1940

Mail: P.O. Box 530 Simcoe, ON N3Y 4N5

Subscription Rates

Canadian Subscriptions (GST included)

$37 Cdn, one year - $65 Cdn, two years

U.S. Subscriptions: $37 US, one year - $64 US, two years

International Subscriptions $70 US, one year

From time to time, we at Manure Manager make our subscription list available to reputable companies and organizations whose products and services we believe maybe of interest to you. If you do not want your name to be made available, contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher's written permission. ©2010 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher's approval. Such approval does not imply any endorsement of the products or services advertisted. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Website: www.manuremanager.com

By Margaret Land

Nothing says spring quite like overly exuberant singing birds, slippery snow remnants, falling in the mud, flapping around with a soaking wet sock (caused by a hole in the boot) or hopping around on one foot after having your footwear completely sucked off by the mud.

I recently experienced all of these wonderful springtime rituals during an anaerobic digester technology tour, held during the second annual Canadian Farm and Food Biogas Conference in southern Ontario, Canada.

There’s nothing I enjoy more than a good farm tour filled with high-tech innovations, intelligent conversation, shiny new equipment, and good-natured jokes and ribbing with farmers and equipment manufacturers. I like viewing the operations, getting the information straight from the owner, hearing all the nitty-gritty details –both good and bad – plus getting the “unofficial” input from others in the group.

What I don’t enjoy is mud.

I spent my teenage years on a farm operation with rather “heavy” soil and have experienced my fair share of boot sucking, mud flinging and having to scrape clay balls from boots and shoes. The joke on our farm was you always came back a bit heavier than when you left to do chores.

I might be used to the routine but that doesn’t mean I have to enjoy it. Following almost every farm stop we made during that early March technology tour, the participants had to search out the nearest patch of clean snow to clean off their boots. We all scratched and kicked snow and ice like a group of laying hens in search of grubs. And our bus tires had to be the best tested around as we kicked the loose mud clods off against the rubber sidewalls.

It became really interesting during the final stop at a dairy operation that was in the midst of building two anaerobic digesters. Tour participants were handed plastic booties for added biosecurity and boot protection. Soon, we were all slipping and sliding on the melting snow and ice. I almost fell about half a dozen times and was only saved by a strong arm or shoulder that just happened to be standing nearby. A fair share of nearby participants also had snow kicked over their pant legs as my feet scrambled for traction. After viewing the eight-foot drop into the digester foundation, I soon had those booties off. I’d rather brave the mud than have to cling to a crane chain to get out of that hole.

In all, the experience was an educational one. We all learned a great deal about anaerobic digesters, manure management and electrical generation plus had a great laugh as we slipped and slid our way around rural Ontario. Keep your eyes open for articles about the tour and the Canadian Farm and Food Biogas Conference in upcoming issues of Manure Manager

I look forward to next year’s tour, although I might have to invest in steel cleats for my boots.

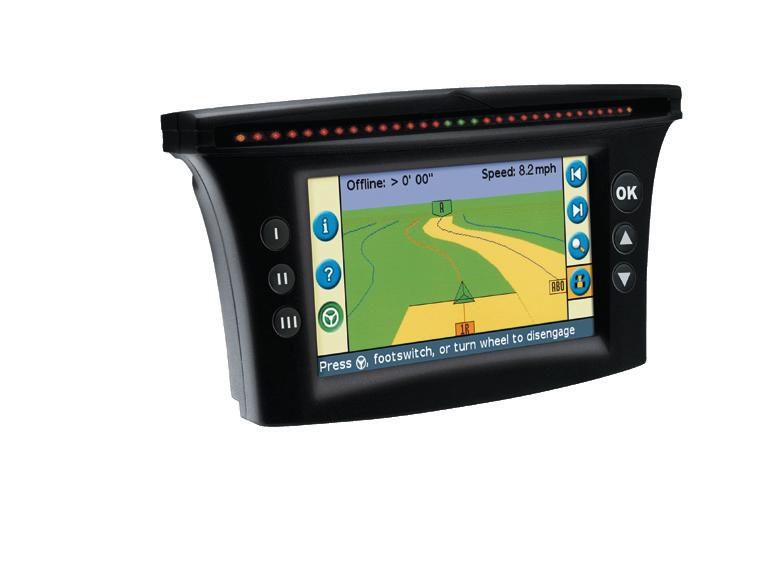

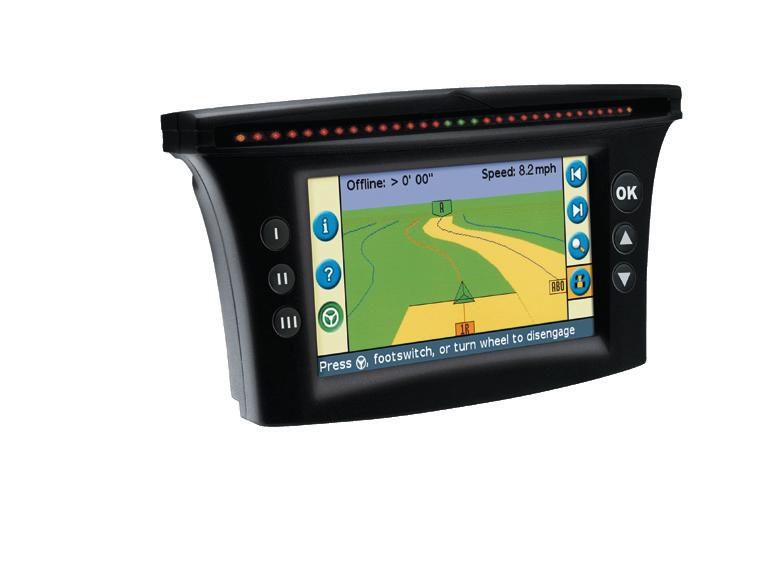

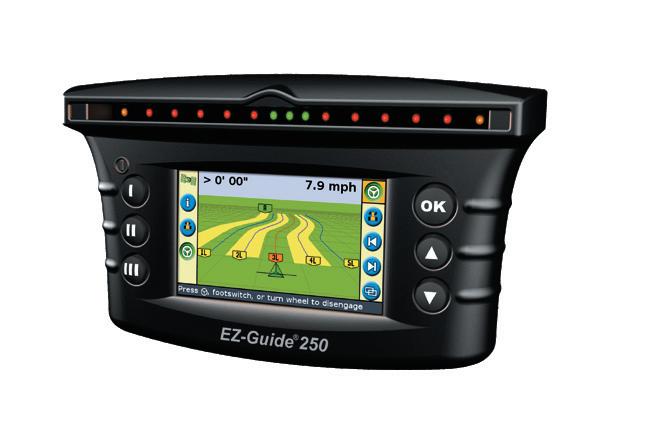

Trimble’s EZ-Guide 250 and EZ-Guide 500 lightbars can now provide record-keeping, tracking and feature mapping of your liquid and dry manure applications. Combine this new technology with Trimble’s proven guidance capability in order to more easily fulfill EPA and DNR manure handling record-keeping requirements. Increase efficiency by using colorful on-screen maps to eliminate gaps or overlaps, and avoid restricted application zones or tile lines. To find a Trimble dealer, visit www.trimble.com/agriculture or call 800-865-7438. Trimble

By Tony Kryzanowski

Not only does Crave Brothers Dairy Farm in Wisconsin have contented cows, it also has contented cow owners – four of them in fact, all responsible for various aspects of the 1,100-head dairy, 1,700-acre farm, and cheese factory.

That’s because of the minimal risk they have taken on in a partnership with Clear Horizons LLC, a biogas-to-energy company headquartered in Milwaukee, Wisconsin. Clear Horizons has provided a turnkey solution to convert its manure into biogas for power generation, solids into compost for bedding, and a steady stream of nutrient-rich manure liquids that the dairy uses for crop irrigation.

The dairy generates about 60,000 gallons of manure per day, and that includes whey from its cheese factory.

“The biggest motivation for us to adopt anaerobic digestion was to be able to separate our manure, have less smell, and be able to apply the liquid manure to the land, which is more suitable for crop needs than raw manure,” says Tom Crave. He looks after the dairy farm’s crop operations. “We thought about it for about three years because it is a big investment. Over that three-year period, we were able to work with this company where they actually own the digester. So it was a

decision made easier because we didn’t have to invest in it.”

With the manure stream and odor situation under control, Charles, Thomas, Mark and George Crave can concentrate on their other ventures, producing milk and making a variety of cheese products for both the domestic and international markets. About 80 percent of the milk the dairy produces goes into cheese production.

All the dairy is providing Clear Horizons is a steady stream of manure and a plot of land, while the bioenergy company has invested $3 to $4 million in the collection, anaerobic digestion, and compost storage infrastructure. The Crave Brothers installation, located about an hour west of Milwaukee in Waterloo, features two anaerobic digesters and is Clear Horizons’ first installation. This year, the company is constructing an even larger project in Wisconsin called the Dane County Community Digester, which will involve biogas-to-energy production from processing manure provided by three separate dairy farms.

“We got our start here in Wisconsin about four or five years ago, investigating some of the systems that were in Wisconsin at the time and investigating digester systems in Europe,” says Karl Crave, project manager for Clear Horizons, which monitors biogas and compost production at the Crave Brothers Dairy. “We found a need in the market for a little more professionally engineered, professionally built, and better trained operators of these biogas systems, as well as taking a more holistic approach to the project.”

He says the company discovered that using anaerobic digesters to produce biogas for power generation was often just a sideline project for farms and not necessarily a priority, and financially, that hurt them over the long term. Clear Horizons saw a need for a new approach.

“We complete every aspect of the project from the initial feasibility study up front to engineering, through construction, and then we operate and maintain the plant for the farm as well,” he says. “So, it sort of allows the farm to concentrate on what they are good at and what they can get a good return on, which is milking cows and running their farm, and it allows us to do what we feel we are good at, which is operating biogas plants.”

Clear Horizons also offers projects where the farm owns some equity in the biogas enterprise, as well as situations where there is a third party investor. The company can also apply its biogas generation technology to more industrial environments where organic waste is being generated, such as in the food processing industry.

The Crave dairy consists of two sets of buildings – one set of three buildings for milking cows and a second set for heifers and dry cows. The manure in the milking barns falls through a slatted floor and gravity flows through

The Crave Brothers biogas installation was the first one for Clear Horizons although the company is currently constructing an even larger project in Dane County, Wisconsin, which will be fed manure provided by three separate dairy farms. Contributed photo

an underground pipe to a reception pit. Manure accumulated in the heifer and dry cow buildings is scraped into another reception pit. Manure accumulated in the reception pits is pumped into one of the two 720,000 gallon digesters as needed. There are mechanical mixers within the digesters and manure is added to the tanks every couple of hours at a set rate. The organic mix flowing into the digesters is a mixture of manure and other organic feedstocks such as whey and bedding pack. Excess heat from the engine that burns the biogas and powers the electrical generator heats the mixture inside the oxygen-free environment of the digesters to about 100 degrees Fahrenheit. That encourages the natural microbes within the digester to break down the organics, thus creating biogas. The biogas is about 60 percent methane, rises, and collects in the flexible roof of each digester. The gas is processed through a chiller to remove the water vapor before it is burned in the GE Jenbacher 633-kilowatt generator. It takes about 21 days on average to digest the manure into gas, liquid, and solid byproducts. The nutrient-rich liquid stream gravity flows from the digesters into a 10-million gallon lagoon. The solid stream is processed through a Vincent screw press to reduce its moisture content and is then placed into covered storage where it is available for bedding on the dairy farm or to Clear Horizons as a marketable product.

“It really is very similar equipment to other digester systems,” says Karl Crave. “It’s nothing secret or proprietary. We just try to build a total system that works best for each individual farm.”

Heat from the engine exhaust is also used to heat farm buildings and also to heat hot water for farm use.

“A lot of buildings have in-floor heat now,” says Crave, “so this is a great use for that heat, especially during the winter in Wisconsin.”

Clear Horizons is also responsible for providing the electrical tie-in equipment to the local power grid and markets the power it generates at what is called the power retailer’s biogas buy-back rate. Unfortunately, Clear Horizons is not in a competitive market for its power and sells it to whoever is the local power provider at whatever their buy-back rate is. That situation could change soon.

“There is legislation introduced in Wisconsin that would allow the Public Service Commission, which oversees the utilities, to set a specific rate to even the playing field for all utilities and all biogas

➤ Manure Pits,Channels & Covers

➤ Suspended Slabs - up to 40’ clearspan

➤ Hog & Cattle Slats - up to 25’ clearspan

➤ Weeping Walls - manure separation

➤ Milking Parlors

➤ Strainer Boxes

➤ Commodity Storage

➤ Bridges

➤ Bunker Silos (8 types)

➤ Syloguard Concrete repair

➤ Retaining Walls

➤ L & T Walls up to 16’ high

• Built to engineers’ specifications

• All sections are high strength, pre-stressed,reinforcedconcrete for longer life

• Quick & easy to build

• Air-tight seals and protectant using Syloguard products

producers,” says Karl. “We’re absolutely in favor of that because right now it is a very unfair system. The majority of the utilities in Wisconsin are very hesitant to pay a reasonable rate for biogas-generated power because it is more costly than their other energy sources, which is mainly coal.”

Right now, about 50 percent of Clear Horizons’ revenue from the Crave dairy project comes from power sales and 50 percent from secondary markets related to the compost. Karl says having those secondary markets is crucial for the operation to turn a profit because if the biogas-to-energy company depended solely on the sale of power, it would require about 15 to 20 cents per kilowatt hour, while the average rate in Wisconsin is only five to six cents per kilowatt hour.

Marketing all the compost produced in a timely fashion has been a challenge because Clear Horizons is producing and stockpiling compost every day while the market for compost tends to be seasonal, such as when landscapers are busy. So the company has developed some of its own compost-based retail products, such as EnerGro, which is a growing medium for potting mixes to complement its bulk compost sales to wholesalers. Clear Horizons also sells the compost as bedding to other dairy farms. About half the compost produced at the Crave Dairy is used by the dairy as bedding with the remainder sold in various forms and ways by Clear Horizons.

Crave Brothers Dairy hires a custom manure applicator that uses a drag hose system to apply the accumulated liquid in its lagoon to its cropland.

“We hire a custom applicator that has pumps and hoses, a tractor with GPS, a flow meter and mapping system all on the tractor,” says Tom Crave. “We have a nutrient management plan, which is part of our permit for large farms, and every field is identified and has a plan. In fact, it is a five-year plan according to what we are going to plant.”

He says the owners aren’t terribly concerned that they have relinquished a lot of control of their manure management to an outside company because of the many benefits they derive from the partnership.

“No, we don’t have any concerns about that at this time,” says Tom, “because we are still able to use the compost for bedding and we get the liquid to put on our land, so it’s a win-win for both of us. We are happy and I think they are happy also.”

Puck Custom Enterprises of Iowa has been working with a new system. They place the sensors in the barn, across from the agitator, when they are pumping out. Contributed photo

By Diane Mettler

New technology helps keep both hogs and humans safe

Each year swine loss occurs due to hydrogen sulfide poisoning during pumpout, and there have been human fatalities as well. Now a new technology, SwineSafe™, may make those deaths a thing of the past.

Three years ago, Ross Muhlbauer’s father lost 300 hogs from hydrogen sulfide (H2S) poisoning during a pumpout from his deep pit swine finisher. He’d used the same procedures he used for years, which had never resulted in mortalities. But now, within minutes, he’d lost approximately $45,000 in hogs.

After the loss, Muhlbauer’s son, Ross, was determined to find a solution. Ross was a student at Iowa State University, and a research assistant to Dr. Robert Burns in the Ag Waste Management Lab. After the H2S poisoning, Ross began his own research.

“At Iowa State we started looking at other industries that had similar problems with hydrogen sulfide, and one was the oil field industry,” says Ross. “We took some technology from that industry and started using it to monitor H2S in swine housing during pumpouts.”

After extensive research, developing and testing hydrogen sulfide detection system for use in a swine house. It worked and a paper was published on the findings.1

From there Ross took the detection units and turned them into what he calls “more of a management system,” where H2S levels could not only be detected, but alarms would sound if a H2S burst occurred. His innovative system became the SwineSafe™ Mobile (patent pending), which is available now, and the SwineSafe™ Wireless that will be available this spring through his company, Manure Safety Solutions, LLC.

“It allows swine industry workers to monitor H2S levels in swine facilities during pumpouts by using a multi-point monitoring scheme,” says Ross. “The system has alarms to notify manure applicators that dangerous levels of H2S exist in the facility so they can stop agitation and/or apply additional ventilation — without entering the facility.”

He adds, “It also has the option to integrate with the facility’s existing ventilation system and automatically add additional ventilation via fans or curtain drop in the event of deadly H2S gas release during pumpouts.

Jeremy Puck, manager of Puck Custom Enterprises, has been working with the new system. The company employs 14 and pumped 170 million gallons last year. Puck is pleased with the results. “We used the monitor this fall and also last spring some when the first prototype came out,” says Puck. “When we’re pumping someone’s barn, we place the sensors in the barn, across from the agitator, and it successfully monitors the hydrogen sulfide levels.”

He adds that the system sets up in about 10 minutes. Once the sensors are in the barn, his crew run the cords out to a monitor outside, where they can easily read the parts per million (PPM) of H2S inside the barn during the pumpout.

So far Puck’s crews haven’t reached any dangerously high levels of H2S, but the system has confirmed what they always suspected — levels will rise if the gun is exposed during agitation.

Each year swine loss occurs due to hydrogen sulfide poisoning during pumpout. A new technology, SwineSafe™, may make those deaths a thing of the past. Contributed photo

During the pumpout Puck says they were running around five to 10 parts per million of H2S in the air. But if there had been an H2S burst, and the H2S levels rose to more than 20 ppm, an alarm would have been set off.

“There’s both a siren and strobe light. We use the strobe light, because there’s always a person on site that’s running the pump that can see it,” says Puck. “He can shut down the agitation, turn more fans on in the barn, or he could drop a curtain.”

He adds that the learning curve is almost non-existent. “Just place your sensors where you think they should be, across from the agitator. That’s about the only learning curve there is to it.”

The monitor has an easy-to-read digital display and runs off a 12-volt battery, with a battery life of approximately 30 hours. “It can charge like a cell phone — off the cigarette lighter plugs in the truck,” says Puck. It comes standard with a A/C power wall charger.

Manure Safety Solutions, LLC hopes to release the SwineSafe™ Wireless later this spring. Contributed photo

Puck says that for companies like his, there’s always a gray area as to whose liability it is if any hogs are killed due to HS2 poisoning.

“This system is protection for ourselves and protection for the grower. Because nobody wins either way if the pigs die,” says Puck. “You gain a certain peace of mind monitoring — knowing that you have equipment that is accurately telling us what’s going on. Otherwise, we’re just modifying ventilation, or following protocols given us by different growers.”

Puck is also hoping that the SwineSafe™ products will lower his

The detection units not only detect H2S levels but also have alarms and strobe lights that activate if an H2S burst occurs. Contributed photo

insurance premiums. “We’re talking to the insurance companies now. It makes sense that eliminating our risk with more monitoring equipment would bring our insurance premiums down, but we haven’t gotten a definite yes or no yet.”

Although SwineSafe™ was developed to keep swine from HS2 poisoning, it will help save human lives as well. From 1983 to 1990, H2S poisoning was responsible for the deaths of 24 swine workers in the Midwest and at least 15 more deaths since 1994.

Puck Custom Enterprises has always

worked to ensure human life is never at risk by never allowing anyone in the barn once pumping has started. But the company doesn’t always control all the variables.

“We do a lot of sow barns where we usually work around people’s schedules,” says Puck. “Normally they work from 5 a.m. to 3 p.m. and we start pumping after they leave until morning. With a monitor, when they returned they could see if the air was clean before they came in.”

The SwineSafe™ Wireless will be

available this spring and manure applicators will be able to purchase the control unit and add up to 32 wireless H2S sensors to their network at one site, or an unlimited number at multiple sites says Ross. “Applicators could use the same three to four sensors at every facility or each facility could have their own. And with the control unit, the applicator could read the signal from the sensors inside the swine facility. Like the mobile model, this data can then be used for alarms to alert applicators of dangerous H2S concentrations in house

and/or to automatically apply more ventilation.”

Puck says he’s looking forward to the next evolution of the technology — H2S detection units that tie in directly into the barn’s ventilation system. Although the SwineSafe™ units are capable of ventilation management now, a certain amount of producer co-operation will be required to integrate fully with a facility’s ventilation management system. “That way, if there’s a burst, the ventilation would come on and pull that air out. It would be ideal for something like a farrowing barn. They are very bio-secure and we have no way to enter that barn or touch any of the controls. So we couldn’t adjust anything after the workers left.”

Another option that will soon be available is data logging. “This will allow you to log the H2S levels of your entire pump out event,” says Ross. “After it’s over, you can go back and retrieve that data and look at exactly where the H2S levels were during your whole pump out.”

Right now though, Puck is going to be strongly suggesting that his customers invest in the detection units — whether it’s the mobile or the wireless.

“It’s not an expensive investment when you look at the cost of your pigs, especially on the farrowing side,” Puck says. “Farmers put a lot of money into those sows, and for those with finishing barns, their margins right now are so slim, they can’t afford those losses.”

Both Ross and Puck understand that industry won’t embrace the technology until there are more proven tests. With that in mind, Ross will demo SwineSafe™ products at a number of farms this spring.

Puck Customer Enterprises will also be using the SwineSafe™ Wireless. “We expect to have a lot more information and data after we get through this next season,” says Puck.

Ross says, until then, he’s excited about this new line of products. “We believe they will significantly increase the safety and efficiency of our customers’ operations — be they swine producers or custom manure applicators.”

(1) R.V. Muhlbauer, R.J. Swestka, R.T. Burns, H. Xin, S. Hoff, H. Li. Development and Testing of a Hydrogen Sulfide Detection System for use in Swine Housing. 2008. Proceedings: 2008 ASABE Annual International Meeting. June 29July 2, 2008.

By Tony Kryzanowski

As environmental regulations were toughened up over the past 15 years on intensive livestock operations, some took a negative view concerning the impact that these more stringent manure handling and application requirements would have on their bottom line. However, some recognized that by doing the right thing for themselves, this was also a new business opportunity to expand farm income.

That’s what happened to Scott and Michelle Hislop. They own and operate their 144-year-old business called Hislop Farms and Choice Connection near Mapleton, Minnesota, about an hour and a half south of Minneapolis.

As they were developing their knowledge about manure spreading on their own farm, they reckoned it was probable that a lot more farmers in the area were in the market for a custom manure application service as well. Although there are a few dairy farms in the Mapleton area, the majority are hog producers. The main cash and feed crops are corn and soybeans.

In 2000, one of the Hislop companies, Choice Connection, launched a manure application business. This was also about the time when Agronomy Department Manager, Dave Malakowsky, joined the company. He has a degree in agronomy and mechanical agriculture from the University of Minnesota – Waseca. He’s seen the business evolve from an old 5,500-gallon slurry wagon and a handful of customers to a high-tech, Ag-Chem 9205 Terragator manure applicator. The company currently spreads about 20 million gallons of manure annually. Its customer mix is about 75 percent hog producers and 25 percent dairy.

One reason why customers call on Choice Connection is its ability to

Minnesota-based Choice Connection is attracting business by transporting liquid manure for application in fields that have never had manure applied to them, as a hedge against commercial fertilizer use. Contributed photos

move large volumes of liquid manure over longer distances to cropland where application of organic fertilizer is needed.

“The value of precisely applying the fertilizer nutrients of manure keeps increasing every year,” says Malakowsky. “Like everybody else in the country, if you are a hog or dairy producer, you have manure and we’re trying to place it in fields where they will realize the most benefit. Instead of buying commercial NPK, we are helping them realize what they have and that they are actually saving money in the long run.”

Typically, they will haul the liquid manure about four to nine miles for application, but over the past year they have gone as far as 27 miles. Its customers’ desire to transport large volumes further distances was the main reason why Choice Connection opted to develop its business around transporting the manure using tanker trucks, using a field site holding tank and field applying using a rubbed tired, purpose-built manure application unit. A drag hose system, which limits where the manure can be economically applied by the length of hose and number of booster pumps attached to it, simply did not offer that option.

An important part of Choice Connection’s business plan is not only to operate profitably, but also to work safely, which includes an understanding of biosecurity requirements when spreading manure for hog producers. While many of their customers are owner-operator farms, they are raising hogs on contract for various corporations.

The owners of Choice Connection custom manure applicators started out solely as hog and crop producers, but saw a business opportunity as application demands become more stringent.

Choice Connection is able to pull a 31- foot tool bar behind its Terragator 9205 custom manure applicator.

“The main thing is that we are coming there clean,” says Malakowsky. “We use a sanitizer on our equipment. We definitely wash our semi-tankers when we go from one farm operation to the next and get them as clean as we can, using four different area truck washes.”

Choice Connection has three Houle lagoon agitation pumps in its fleet, and a Balzer pump to transfer the manure from the pit to semi-tanker trucks. The company is extremely careful to ensure there is no leakage from its pumps, either during agitation or during the manure transfer process. The tankers also have sensor indicators showing when the tanks are coming close to being filled for safety and also to comply with highway load weight restrictions.

One procedure Choice Connection uses for biosecurity and to operate efficiently regarding their Terragator is using a 17,500-gallon Balzer holding tank in the field.

“We’re not cleaning the Terragator or tank as much because they are never coming into the yard where the manure is coming from,” says Malakowsky.

From an efficiency standpoint, Choice Connection is able to operate as many as four semi-tanker trucks each with about 7,000-gallon tanks from the manure source to the holding tank, while the single Terragator goes about its business transferring the liquid manure from the holding tank to its tank, and then carefully following the application program set out in the farmer’s nutrient management plan for each field.

Because the manure is being transported on public roads and the transfer process from tanker to holding tank is often taking place near field entrances, making sure that everyone gets home safely during the haul and application procedure is important. During the busy season, workers spend a lot of time working beside roads where sometimes there is a fair amount of traffic.

“We try to have beacon lights on our trucks and our semi drivers wear safety vests when they are on the highways,” says Malakowsky. The truck drivers are also careful to avoid spillage as the manure is transferred from the semi to the holding tank. Overall, the service provided to customers does require a lot of co-ordination.

After starting out on a smaller scale, Choice Connections made its first investment into a purpose-built custom application unit in 2004, selecting a fourwheel 3104 Ag-Chem Terragator with a 4,000-gallon tank.

“The Ag-Chem unit was a little higher price than just a regular manure tanker,” says Malakowsky, “but we decided to take on a lot more gallons. We had the equipment and thought we might as well just do it – go ahead and do some custom work and farm besides.” By 2006, they had increased from about six million gallons annually with their old tanker units to 20 million gallons with the new Ag-Chem unit, and the use of a second rental unit.

“That was kind of my goal, just to see how much business was out there,” says Malakowsky. “So I booked that much and we rented another Ag-Chem unit, and we did 19 million gallons that year. We learned a lot.” One of the most important lessons they learned is that there was more value hauling fewer gallons over longer distances, especially to fields that had never had manure applied before, which explains the company’s focus at the present time.

Because of the number of hours

accumulated on the Ag-Chem Terragator 3104, Choice Connection traded that in for a 9205 Terragator in 2008.

“That was really a step up,” says Malakowsky. “It was 500 horsepower versus 300 horsepower, a bigger tank by 1,000 gallons and with auto steer.” It also provided the company with field mapping in the cab so that they could apply variable rates of manure in different parts of the field. Malakowsky sets the actual application rate with the customer based on pit nutrient content analysis and field requirements long before they arrive on site.

The five-wheel 9205 Terragator allows Choice Connection to pull a 31foot toolbar with injector tubes placed a foot apart. It is essentially a John Deere 2410 chisel plow that they converted into a manure applicator. A Vogelsang distributor is connected to the Ag-Chem Terragator computer control system and controls the flow rate through the injectors. The Terragator also comes equipped with a superloader system that transfers a load of manure from the holding tank to the manure applicator tank in about two minutes, which is a major time saver for the company. During the application process, the Terragator is operating at between 7.5 and 8 miles per hour, which again is significantly faster than smaller Ag-Chem units. The software in the cab adjusts the application rate according to the speed of the unit. GPS co-ordinates displayed on a screen in the cab also show the operator exactly where he is located on the field.

Choice Connection has been able to bridge the income gap somewhat between the busy spring and fall application seasons by applying manure to alfalfa crops mainly for dairy operators. To serve these customers, the company has purchased a 21-foot wide Venius toolbar, which is manufactured in Europe. Malakowsky describes the toolbar as not an aerator but more like a disc opener, where the company will come in after the first and third cutting and apply between 3,000 to 4,000 gallons of manure per acre, placing the manure directly into the soil groove so the manure does not touch the alfalfa plant or damage it. Timing is everything in this instance, as the manure must be applied within seven days of the alfalfa being cut.

“The alfalfa is gaining all those nutrients against the next cutting,” says Malakowsky. “It really helps the alfalfa and our customers gain extra tonnage throughout the year.”

This toolbar is also used on pasture and after pea crops have been harvested.

April 27-28, 2010

AgSTAR National Conference 2010 Hotel Sierra/KI Convention Center, Green Bay, Wisconsin. Visit: www.epa.gov/agstar/

June 2010 (Date yet to be determined) Farm Pilot Project Coordination Inc. Midwest Summit. Details still to be determined.

Visit: www.fppcinc.org

June 9-11, 2010

2010 World Pork Expo, Iowa State Fairgrounds, Des Moines, Iowa.

Visit: www.worldpork.org

July 15, 2010

2010 Great Lakes Manure Handling Expo, Penn State’s Ag Progress Days Site, State College, Pennsylvania.

Visit: http://das.psu.edu/manure-expo

August 2010 (Date yet to be determined) Farm Pilot Project Coordination Inc. Annual Summit, St. Petersburg, Florida. Details still to be determined.

Visit: www.fppcinc.org

September 13-16, 2010

International Symposium on Air Quality and Manure Management for Agriculture, Doubtletree Hotel, Dallas, Texas. Visit: www.asabe.org/meetings/ airwaste2010/index.htm

September 22-24, 2010

NOSE 2010, Palazzo degli Affari, Florence, Italy.

Visit: www.aidic.it/nose2010

September 28-October 2, 2010

2010 World Dairy Expo, Alliant Energy Center of Dane County, Madison, Wisconsin.

Visit: www.worlddairyexpo.com

October 3-8, 2010

Greenhouse Gases and Animal Agriculture Conference, Banff Park Lodge, Banff, Alberta, Canada. Visit: www.ggaa2010.org

Despite a recent Missouri jury returning a collective $11 million verdict against Premium Standard Farms, Inc. and ContiGroup Companies, Premium Standard plans to appeal the decision.

“We are obviously disappointed in (the) verdict; however, we believe that there are substantial grounds for reversal on appeal,” the company stated in a press release issued not long after the court decision was announced.

“The court gave the jury the impossible task of sorting through claims by 15 different individuals from seven different families in different locations with each claim raising a set of distinctive issues. While the jury tried its best, it was inevitable that this ‘gang trial’ would result in a ‘gang verdict.’ We will ask the appellate court to require that each family’s claim against a specific farm be litigated separately. That is the only way the parties can be assured of a fair trial.”

The $11 million verdict, delivered March 4, 2010, represents one of the largest jury awards against a hog farm in an odor nuisance case. It covered 11 years of damages.

During the case, the plaintiffs alleged that “relentless and extreme odors” from the defendants’ finishing farm created an unreasonable nuisance. Family members testified at trial that the smell was intense enough to prevent them from venturing outdoors on many days.

Nearly five weeks of evidence was heard centering on the defendants’ land application of liquid hog manure, maintenance of wastewater lagoons, and other farming activities at the state permitted farm in Gentry County.

“The jury recognized that the pumping is merely a disguised form of waste disposal – with the farms releasing far more effluent than the land can possibly absorb,” said lawyer Charles F. Speer of Speer Law Firm, one of three firms who argued the case on behalf of the plaintiffs, in a press release.

“(The) defendants claimed their operations complied with state environmental regulations – however, this trial showed that PSF produced industrial-scale pollution with complete lack of regard for the extreme toxicity its operation caused for its neighbors, day in and day out,” stated lead trial counsel Richard H. Middleton, Jr. of The Middleton

Firm in a press release.

In light of the decision and “the continuing hostile environment toward live hog operations,” Premium Standard Farms officials said the company is seriously considering whether to make any future investments in Missouri.

“It threatens the viability of the Missouri farm economy when a farm that has been granted a permit to operate by

the state and is in compliance with the permit and state and federal regulations can be held liable for such damages,” the company stated in a press release.

“If it is indeed the law in Missouri that a permitted farm in compliance with its permit can be subject to such damages then, to preserve its agribusiness sector, the legislature should move swiftly to correct this aberration.”

J&D Manufacturing has hired Jeff Sebold as an outside sales representative for the state of Wisconsin. Jeff has been selling and servicing feed and manure handling equipment in the Midwest for more than 20 years, most recently with Jamesway Farm Equipment. He is eager to expand his knowledge in ventilation and cow comfort products and applications.

www.jdmfg.com

Parkson Corporation and Vapex Environmental Technologies recently announced a partnership in bringing Vapex’s odor control technology to the North American market.

The O-Mega hydroxyl ion fogging technology eliminates odors and reduces pH corrosion found throughout wastewater systems. Instead of more traditional technologies that use a considerable amount of energy to extract and scrub the odors, the O-Mega oxidizes the odorous space itself, eradicating the odors without the expense of moving high volumes of air. The O-Mega has been proven throughout the collection system.

The two companies will also offer the Sentinel scrubber control system. For scrubber systems, the Sentinel monitors the internal gas passing through the scrubber and reduces scrubber chemicals by up to 60 percent. The system saves plants money and introduces a lowmaintenance control system with continuous monitoring of the scrubber.

Parkson and Vapex will work together to bring these two products to the North American market. Specifically, Parkson will sell into collection systems in Canada, Mexico and the northern parts of the U.S.

Vapex will continue to sell its products directly into collection systems in the southern parts of the U.S. Parkson will also work with Vapex to develop new, customized applications for specific odor-control solutions, creating efficient methods to treat offensive odors.

www.parkson.com

www.vapex.com

Contrary to popular belief, some diseasecausing bacteria may actually survive the composting process.

Researchers from Agriculture and Agri-Food Canada report in the February 2010 issue of the journal Applied and Environmental Microbiology that campylobacter bacteria in cattle manure can survive composting and persist for long periods in the final product.

Campylobacter bacteria are the most common cause of gastroenteritis in the developed world. They are frequently shed by beef cattle in manure and although the impact on human health is undetermined, there appears to be a link in areas such as Alberta, Canada, where cases of human campylobacteriosis are extremely common and the cattle density is high.

In the study, researchers examined the persistence of naturally occurring campylobacter bacteria in compost derived from manure of beef cattle that were administered antibiotics (AS700) and a control group that were not. Bacterial populations were the same in both groups, however, the temperature of the AS700 compost was more viable and not as high as that of the control group. Water content, total carbon, total nitrogen and electrical conductivity varied significantly between groups. Results showed that no reductions in the quantities of Campylobacter jejuni DNA were observed throughout the 10 month composting period. Further, testing suggests that campylobacter DNA examined from compost was extracted from viable cells.

treatment projects announced in California ProTech General Contracting Services, in partnership with the California Department of Food and Agriculture (CDFA) and three select dairy farms from the Merced Irrigation District (MID), recently signed a Memorandum of Understanding (MOU) to launch a pilot project with a new manure management system.

The public signing at the World Ag Expo confirmed the public-private partnership between MID, Gallo Farms, Hillcrest Dairy Farms, and Lima Farms (all in that district’s service territory), and the CDFA.

The dairy farms participating in the Dairy Waste Treatment Project are all located in Central California and have between 1000 and 5000 head of cows producing an average of 120 pounds of waste per day, including 16 pounds of solids and the balance as liquid. Each farm site is committed to providing a maximum of two acres per site for the footprint of the treatment plant’s technical components, including an anaerobic digester, aerobic digester, and highgrowth algae ponds.

According to ProTech, the economics of the dairy farm projects indicate a payback for stakeholders in no more than seven years with a minimum internal rate of return of 20 percent over the 20-year economic life of the projects.

It’s hoped the Dairy Waste Treatment Project will improve air quality and water quality, generate 3.5 megawatts of clean renewable power per year at the three sites from animal and farm waste, and produce approximately 900 tons of algae and approximately 32,000 tons of high-grade organic, weed-free fertilizer with significant bio-available nitrogen. In addition, the projects are expected to enable the dairies to hire staff for green tech positions and empower farmers to improve upon existing nutrient management plans.

Supplier of engineered and innovated patented solid/liquid separation equipment.

• Save water by mechanical separation

• Produce organic bedding material

• Increase the ef ciency of your digester

• Complete system solutions

America – Europe – Asia

Contact in USA: m.stewart@few-separator.com

Tel.: +1 (604) 932 7931

Germany: FEW Separator GmbH, Osthofenstr. 67, D-59494 Soest, Germany, Tel.: +49 - 2921 - 34 44 737 www.few-separator.com · info@few-separator.com www.food-energy-water.com

Innovative projects require innovative products, like Firestone Geomembranes. From anaerobic digesters, which convert animal waste into an alternative energy source, to constructed wetlands that provide environmentally sound water treatment – Firestone is proud to be a part of the solution. Our geomembrane products’ durability and elasticity even in exposed applications, combined with our expertise, help ensure the success of even the most demanding projects.

SUCCESSFUL APPLICATIONS INCLUDE:

{ Eco Friendly Solutions }

DariTech, Inc. of Lynden, Washington recently introduced its new Sand Recovery System (SRSystem), including the Sand Cannon and One-Shot sand separators. The SRSystem is based on the company’s sand separators and offers a split dewatering flight, sand scoop and fixed flight augers.

under control. With the ability to separate fine sand, dairies will be able to bed their cows on any sand they choose. The high level of filtration during the manure solids separation step will help keep lagoons cleaner and easier to manage.

Sand laden manure is either scraped or flushed out of the barns. In the case of scrape manure, it is lifted into the base of the Sand Cannon. A special hybrid DT-360 recycles dilution water for the sand laden manure, at the same time stacking sandfree solids for removal. The sand is washed as it’s carried to the end of the flighted drum, to be stacked and ready for re-use.

With sand bedded dairies everywhere looking for affordable methods of reusing their bedding, the lower initial costs and horsepower demand of the SRSystem can help keep capital and operating budgets

In flush or flume operations, sand is directed to the entry of the One-Shot, which lifts, washes and stacks the sand all in one step.

10-MC-0138.SndSltns_MM:10-MC-0138.SndSltns_MM 3/10/10 8:33 AM Page 1

www.daritech.com

■ Complete Sand-Laden Manure Conveyance & Manure Processing Systems

■ Stall Fillers – Truck Or Trailer Mounted McLanahan’s Team Of Dair y Industr y Professionals Can Provide You With Practical, Profitable And Reliable Sand Solutions.

New for 2010, Leon’s Mfg. Company is now offering the Leon QV400 quick on and quick off four-wheel drive dozer blade series. The blade will fit Versatile four-wheel drive tractor models 305, 340, 375, and 400.

Complete QV400 dozer blade packages include:

• high lift 45-inch lift height capability

• quick on and quick off push assembly

• 27 degree left and right hydraulic angle positioning to avoid contact with working terrain

• ripple formed blades for clean roll off and roll break

• high tractor under-frame clearance

• replaceable heat treated cutting edges

• blade widths ranging from 12 to 20 feet with side extensions available

• mounting kit

• chromium carbide skid shoes www.leonsmfg.com

200 Wall Street Hollidaysburg, PA 16648

Email: agdivision@mclanahan com 814-695-9807

sandmanuresolutions.com Safety covers required but not shown

McLanahan Corporation officially launched its redesigned website in January 2010. McLanahan Corporation is celebrating its 175th Year Anniversary and the design of a new website is just one of the many ways this family-owned business has decided to commemorate this special occasion. Showcasing all six divisions, the new site was designed to offer customers information regarding equipment and services; more detailed pictures; videos of field footage; and updated news and events on related industries as well as trade shows

and expos. McLanahan is a unique corporation due to its diversified lines of equipment and different industries that they are able to service. This is why the site has a distinct new look so customers are able to view the wealth of information available, but are still able to navigate through the site very easily.

McLanahan has also designed new brochures for several pieces of equipment & services. These brochures are all attached to the website where customers can get the most up to date information regarding products and view pictures of our most recent jobs. Videos of our new Plate & Frame Filter Press, DDC Sizers, Separators™, and many more pieces of equipment are available to view of the new site. Each division provides a list of contact names, numbers, and emails so customers always have quick and easy access to our qualified staff. www.mclanahan.com

Digi-Star LLC has introduced Nutrient Tracker™, a new application management and documentation system for manure or fertilizer spreading operations.

It is the first to be specifically developed as an interface with manure spreaders, offering significant benefits for recordkeeping and documentation in the field, along with report generation and management features in the office.

Manufacturers of spreaders today are now offering the option of adding scales and indicators. Now with DigiStar’s new Nutrient Tracker system, operators can see the application rate while spreading and automatically collect the information on time, date, field names, and amount applied with GPS verification data. The Nutrient Tracker proprietary PC software combines the data with downloaded satellite images of your fields to show exactly where, when and how much of the nutrients were applied.

The NT460 uniquely designed indicator can be cab-mounted, and allow the operator to record data regarding farm and field name, load numbers,

load weights, application rates and accumulated totals. Keys with symbols facilitate entering or modifying field data. The system is user-friendly and provides easy training for operators. Its unique START•STOP feature (patent pending) records application amounts, time, date, field names, and GPS coordinate data for each load. The operator simply pushes START when he begins to unload, and STOP when completed. The system does the rest.

Actual field information is easily transferred to a portable USB flash drive from the full-featured NT460 indicator

to the PC. The included Nutrient Tracker software helps to capture the information and generate reports in PDF or Excel formats. GPS field data of application rates is overlaid on satellite images of the producer’s fields to provide a visual document of where material was applied.

Strong interest for the Nutrient Tracker has been demonstrated during our testing period last fall as customers see the benefit of the “live” application rate information to ensure consistent field coverage. There is no more guessing on how much is being applied or if you are going too fast or too slow

the scale gives the operator the feedback he has been looking for. There is also an audible and visual alarm that can be set to remind the operator that he is outside of the tolerance set for a target application rate.

Customers have also enjoyed having report documentation from the Nutrient Tracker software to support and document their Nutrient Management Plan. For today’s progressive managers it is important to provide evidence to the USDA-NRCS’s Animal Waste Management regulations and comply with EPA and DNR CAFO recommendations for application restrictions. Today’s fertilizer costs also give more value to the nutrients spread and the need to know how much was applied to a field and exactly where it went.

The Nutrient Tracker system is marketed through progressive manure handling equipment manufacturers and their dealers.

www.digi-star.com

McLanahan Corporation has developed the 44 Super Magnum Sand Pump engineered and built specifically to meet the pumping needs of sand bedded dairies. It is a vertical shaft, centrifugal pump designed to withstand the rigorous demands of pumping sand and manure with minimal wear on the wet end components. The pump received a 2010 AE50 award for agricultural engineering innovations and was chosen as one of the Top 10 New Products at the 2010 World Ag Expo.

The 44 Super Magnum Sand Pump utilizes replaceable, rubber linings to protect the split casings and a rubber lined impeller to dramatically extend wear life in abrasive environments as compared to conventional manure pumps of steel construction. The shafts and bearings operate in an oil bath and are separated

from the sand and manure by a heavyduty mechanical seal.

The pump uses technology that has been proven in the mining and wastewater industries and has been adapted to fit the needs of the dairy and agriculture markets. Each pump is sized according to the application’s needs and conditions.

www.sandmanuresolutions.com

Kenworth is now accepting orders for its new Kenworth T440 model with production scheduled to begin during the second quarter.

The T440 has a gross vehicle weight (GVW) ranging from a heavy Class 7 vehicle at 33,000 lbs. up to a light Class 8 truck at 68,000 lbs. The 2010 PACCAR PX-8 engine, rated to 350 hp and 1,000 lb-ft of torque, is standard equipment. The optional 9-liter, 2010 Cummins ISL engine is rated to 380 hp and 1,300 lb-ft of torque. Emergency fire truck ratings are available on both engines. The T440 offers 6-, 9-, 10-, 11-, and 13-speed manual and 5- and 6-speed automatic transmissions; and 12,000 to 22,000 lb. rated front axles, 21,000 to 30,000 lb. rated single rear axles, and 40,000 to 46,000 lb. rated tandem rear axles.

“(The) Kenworth T440 is available in tractor and truck configurations for numerous vocational, regional haul, pickup and delivery, and municipal applications,” said Jason Skoog, Kenworth director of marketing planning and research. “The T440 provides a quality product for vocational and municipal customers who require a heavy front axle for dump, mixers and fire trucks.”

The T440’s styling features an aerodynamic sloped hood, which gives the driver enhanced forward visibility. A tapered channel bumper, Kenworth signature grille, and forward lighting with Halogen projector headlamps are standard equipment. An aluminum or three-piece aerodynamic bumper and high intensity discharge (HID) lighting are available as options.

The Kenworth T440 offers the same multiplexed dash installed in Kenworth’s Class 8 product line with a large panel for convenient installation of body controls and gauges. The Kenworth Driver Information Center is standard in the T440. Also available are factory installation of a power take-off (PTO) and one lift axle.

www.kenworth.com

Designed for custom haulers and large operators, Jamesway’s Ultra-Pump™ has the reach and the power to handle the big jobs. The Commercial Series lagoon pump can be equipped with a Super-1000 impeller kit for use in the largest lagoons. The reach of the agitation cannon allows the Super-1000 version of the Ultra-Pump™ to agitate a 200-foot by 400-foot lagoon from a single location. Recommended tractor sizes are 225 HP for the standard model or 240 HP for the model with gearbox and propeller. The T1 steel construction of the impeller kit resists wear, and the eight-inch discharge runs through a massive full-flow control valve.

As with all models of Ultra-Pump™ lagoon pumps, purchasers can choose a bi-pod fill pipe, a load cart fill pipe, or the Power-Boom™ fill pipe.

Jamesway Transfer Kits use all bolted connections so the transfer arm may be mounted on the left or right. Bolt-on accessories include high-mount spread nozzle, low-mount spread nozzle or hose connection kit for long distance transfer. The kit may be configured with the input from the top, bottom or side to accommodate a wide range of retrofit applications, and the controls may be rear mounted or cab mounted. The hydraulic drive motor is mounted to the proven oil bath bearing chamber found on all Jamesway pump kits. www.JameswayFarmEq.com

Introducing the new and improved Crisafulli trailer-mounted Slurry Pump, used in ponds and lagoons to agitate, mix and pump viscous, solidified manure sludges. This pump’s new design from Crisafulli helps to reduce maintenance costs by eliminating the gearbox used in competitive designs. Crisafulli’s redesigned, hydraulically adjustable aeration nozzle – coupled with a hydraulically actuated slurry gate – combine to break up and distribute nutrients evenly and to clear overgrown areas in the lagoon. The Crisafulli nozzle adjusts to 74 degrees of vertical movement, 320 degrees of rotation, and can discharge up to 105 feet away from the pump, effectively breaking through the lagoons’ manure crust.

Using this agitation tool is simple and easy. All producers need to do is back their Crisafulli slurry trailer pump into the lagoon and engage their tractor’s PTO or connect their power

unit. The hydraulic axle lowers the pump through the solids to the bottom. Open the slurry gate to agitate and mix, drawing solids and liquids in, blending and injecting through the gate into unmixed material.

The pump will draw, agitate and blend even heavily crusted ponds, mixing from top to bottom, while the nozzle breaks through the lagoon’s crust. Close the slurry gate to pump the slurry away at high volume. Crisafulli Slurry Pumps slurry and clean ponds as large as 200 feet by 200 feet by eight feet in as little as six to eight hours.

Both four-inch and 16-inch discharge sizes are available.

Other Crisafulli solutions for manure mixing and pumping include floating pumps for lagoons and vertical pumps for stationary installation in sumps.

www.crisafulli.com

Jamesway Farm Equipment recently introduced the NutriJector High Speed Injection System. The unique knife causes subsoil mixing to produce a high capacity injection zone while leaving the surface minimally disturbed. The Nutri-Jector system uses a triple toolbar with a coulter opener on the first toolbar while the injector knives are mounted in a staggered pattern on the second and third toolbars to allow for easy trash passage. A double disc closer behind each knife may be adjusted to leave the soil flat and ready for planting, or may be set as “hillers” to prevent leaching in certain soil types.

While most injection systems operate at approximately three miles-per-hour, the Jamesway Nutri-Jector can operate at up to seven miles-per-hour, allowing far greater acreage coverage per day. The cost per acre for consumable wear parts is reduced as are fuel costs with the much lower horsepower demand than traditional chisels.

While most injection systems require frequent adjustments, the new Level-Lift mounting system always keeps the injection knives at the correct pitch angle at any height. The Level-Lift system automatically floats to follow uneven terrain so even inexperienced operators can consistently produce excellent results and the tremendous transport clearance makes it easy to get into the field.

The on-board spreading kit lets operators switch between injection and spreading at any time and the Quick-Attach toolbar mounting on the Level-Lift system makes it fast and easy to detach or re-attach the injection system. The distributor is mounted on the toolbar so there is only a single hose connection to the tanker and access to the distributor is safely at ground level. www.JameswayFarmEq.com

By Tracy Schlater

On every farm and ranch across the world, manure happens. It’s one of the few constants in raising livestock. There’s more to managing manure than just the odor. Manure is the cause of thousands of injuries and deaths across the country. According to the National Institute for Occupational Health and Safety, between 1995 and 2002, an estimated 907 youth died on farms in the United States, and about 5,800 youth were injured while performing work on farms in 2006.

Any amount of manure in a confined space can release various gasses. Hydrogen sulfide is an extremely toxic gas that can cause headaches, nausea, and dizziness. It smells like rotten eggs, but eventually the gas paralyzes your sense of smell, which makes some believe there isn’t an immediate danger.

According to the National Ag Safety Database, manure also releases other gasses including ammonia, carbon dioxide, and methane all of which cause asphyxiation. The main hazard of methane is its flammable nature. Without proper ventilation, manure pits and lagoons are at risk of explosion.

Gasses are only one of the many hazards. Slurry is thicker than water, making it extremely difficult for someone to pull themselves out if they fall into a pit or lagoon. Children may be at a higher risk for these hazards due to their natural curiosity, lack of understanding about these potential dangers, and limited physical strength.

Amanda Vittetoe, from a pork producing family in southeastern Iowa, fell into a manure pit while helping unload pigs from a trailer.

“The manure was more than eight feet deep,” said Vittetoe to National Hog Farmer magazine. “It’s a completely different consistency than water. There was no coming up for a breath (of air). I didn’t have time to think. I was just trying to survive.”

Luckily, the truck driver delivering the pigs heard her fall and helped pull Vittetoe from the pit with the help of her mother. Vittetoe stresses the importance of taking your time, getting plenty of rest, and checking your work area for potential hazards.

In addition to gas and drowning incidents, a number of other accidents and injuries are possible while dealing with manure. Jennifer Hale of Okeana, Ohio, was helping her son clean his steer pen when the pitch fork he was using went through her rubber boot, piercing her big toe, breaking the bone, and exiting the other side of her toe.

“I was thinking of how dirty a manure covered pitchfork was and what it was going to do to my toe,” said Hale. “The doctors at the hospital were concerned with infection getting into the bone.”

Like Hale’s injury, nearly all manure related accidents are preventable. Keep these safety tips in mind while working around manure.

• Education – Know and understand the dangers of working with manure. Teach these hazards to family members, employees, and visitors.

• Signs – Post “warning” or “danger” signs in enclosed areas where toxic gases may build up. The visual

may be just enough to remind people of the potential hazards.

• Minimal agitation – According to the Iowa’s Center for Agricultural Safety and Health (I-CASH), hydrogen sulfide is released faster when the manure is agitated. Keep agitation while pumping to a minimum and use all ventilation possible. Even if the area is ventilated, it is possible to have toxic levels of gas. Keep all people and animals out of the building while pumping is occurring.

• Stay out – There is no safe way to go into a pit or lagoon. If you don’t have to go in, just stay out. If you must go into a pit for repair, empty it, fill it one-third full of water, empty again, and leave for 24 hours. You must wear a Self Contained Breathing Apparatus (SCBA), which requires training and certification to use and does not adequately fit children. Always use a harness and have two people outside ready to pull you out.

• Monitor – Equipment is now available to determine the level of gases present. Purchase and use monitors to know when the gasses reach dangerous levels.

• Protection – Manure pits and lagoons should be covered. Ensure they fit securely and are in good condition. Take it one step further by building a fence around the pit to keep people away from the potential dangers.

Probably the toughest safety precaution in manure related accidents is not to go into the pit to help if someone is in trouble. If the person becomes asphyxiated, the gas levels are too high. More than likely the rescuer will not have enough time to save the person, and they will become a victim as well.

Likewise, if the pit is full and someone falls in, do not attempt to save him or her. Even before setting foot inside a manure pit or lagoon, a person should be harnessed with enough force at the top to pull them out. Trying to save someone under the heavy weight of slurry is nearly impossible.

Instead, call 911 immediately. The responders will have the knowledge, equipment, and manpower to help a drowning victim while minimizing the risk to the rescuer.

How can kids help? Get them involved. Make sure they’re aware of the dangers. Encourage them to tell you if they smell rotten eggs or see any potential hazards. Ask them to be safety stewards by reminding others – including parents – of necessary safety precautions.

It’s crucial to be aware of the dangers when working around manure. Implementing a few safety precautions can mean the difference between life and death.

Tracy Schlater is the marketing director for Farm Safety 4 Just Kids. Farm Safety 4 Just Kids strives to keep rural kids safe and healthy by creating farm safety material for youth and sponsoring programs put on by our chapter network across the United States and Canada. www.fs4jk.org.