Powered by manure

A Pennsylvania dairy embraces digesters to advance its operation. | 14

Preparing for an inspection

Simple compliance checks to keep your operation inspection ready. | 20

Composting or stockpiling

What’s the big difference? | 26

Powered by manure

A Pennsylvania dairy embraces digesters to advance its operation. | 14

Preparing for an inspection

Simple compliance checks to keep your operation inspection ready. | 20

Composting or stockpiling

What’s the big difference? | 26

EuroTier features the latest manure management innovations European trade show focuses on benefits of manure processing.

Karlheinz Rieke, CEO of Karl Farming exhibited a wide range of high-tech composters during EuroTier. Photo courtesy of Chris McCullough. For more see page 10.

Finding

Preparing for an inspection

Simple compliance

BY TREENA HEIN

BY HALEY BANWART

Composting or Stockpiling?

A look at the differences between the two storage options.

BY DANIEL ANDERSEN

With the New Year in full effect, so too is the conference and trade show season. All across North America (and the world), industry folk have been braving the winter temperatures to take in the latest educational sessions, network with a few likeminded individuals or maybe just collect a few free pens. Regardless of the motives, trade show season is full of opportunity.

In the initial 2019 issue of Manure Manager, our cover story gets in on the action of the season, taking you to the floor of the world’s leading event for animal production – EuroTier. Innovations from around the world were put on display by hundreds of exhibitors, showcasing the latest in manure management processes and equipment. For all the details, check out the feature on page 10.

“I often hear the comment from journalists that new concepts shown at EuroTier are a good indicator as to what will come to North America later,” said Malene Conlong, the event organizer’s communications manager. “A good example of this is group housing for sows, which began in Europe and is now being adopted in

manager, Dr. Karl Schlösser.

Along with covering nearly every aspect of livestock production, EuroTier also showcased another side of manure innovation, playing host to EnergyDecentral, the leading trade fair for bioenergy and decentralized energy concepts.

EnergyDecentral was hosted by the German Biogas Association. With 4,700 members, the German Biogas Association is Europe’s strongest organization in biogas. Germany itself tends to be leading the way when it comes to biogas technology and production. With the help of strong initiatives from the government, Germany has approximately 9,500 biogas plants in operation throughout the country and overseas demand for German biogas technology remains strong.

So, perhaps Conlong is correct in saying that many concepts displayed at EuroTier are a good indicator as to what will be coming to North America in the future.

Germany has approximately 9,500 biogas plants in operation.

the U.S. as swine farm operators react to changing consumer demands on animal welfare.”

EuroTier is held in Germany every two years. The theme for this year’s event was digital animal farming –management support, animal health, food safety.

“New concepts around digitization can bring added value to agriculture, help integrate agriculture into a dynamic rural area, and highlight its role as an indispensable part of society,” explained EuroTier’s project

And while German may be leading the charge when it comes to biogas production, North American farms are certainly heading towards more innovative ways of utilizing manure. For instance, Reinford Farms in Pennsylvania, who have been creating their own energy since installing an anaerobic digester on the 720-head dairy operation in 2008. The farming operation uses approximately 48 tons of manure in their digester per day and currently there are no fossil fuels used on farm for heating or electricity.

Check out page 14 for the profile of Reinford Farms, who have found their own success with biogas production right here at home.•

M2H 3R1 Occasionally, Manure

will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above. Annex Privacy Officer privacy@annexbusinessmedia.com Tel: 800-668-2374 No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2019 Annex Publishing and Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertisted. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

The National Waste and Recycling Association recently recognized industry innovators at the annual Executive Leadership Roundtable. Awards were given to companies that have made substantial contributions to American recycling. The 2018 Organics Recycler of the Year Award went to Vanguard Renewables. Vanguard’s Farm Powered organics recycling and anaerobic digester program vertically integrates the organics feedstock chain

and farms to solve food waste challenges and generate energy. By the close of 2018, Vanguard’s Farm Powered operating portfolio of anaerobic digesters will represent the largest organics recycling destination in Massachusetts with more than 190,000 tons per year of combined on-farm and off-farm organics being processed. Vanguard’s program of single stream and co-digestion facilities in development reaches across eight states.

The Government of Canada plans to invest up to $1.5 million in the Canadian Pork Council (CPC) to adopt a virus detection system to support animal health. Funded under the Canadian Agricultural Partnership’s AgriAssurance Program, the virus detection system will enable the CPC to provide consistent information on the health status of the hog population

across the country, track early disease warning signs, and rapidly identify new and emerging diseases in the sector before they spread. This complements a previous investment of more than $94,000 to the University of Montréal (UdeM) to develop an advanced disease surveillance tool to enable faster threat detection across Canada. With funding under Growing Forward

2’s AgriMarketing Program (Assurance Systems stream), the surveillance model developed by the UdeM’s Diagnostic Services will enable the hog sector to better understand the frequency of diseases, emerging strains, and the movement of endemic diseases in Canada.

“Canadian pork producers welcome this investment in research and development from

the Government of Canada in the area of swine health. This project will provide comprehensive tests to laboratories and will help veterinarians and producers manage the Canadian hog herd. Furthermore, using the data obtained through this project to inform disease surveillance activities will greatly benefit the industry and help prepare for disease mitigation,” said Rick Bergmann, CPC chair.

Source: The American Biogas Council

Biogas generally contains

55-75% 24-44%

American biogas systems

2,100

247 1,241

860

10,000 sites in the U.S. are producing biogas anaerobic digesters on farms wastewater treatment plants are using an anaerobic digester currently use the biogas they produce standalone (non-agriculture or wastewater) anaerobic digesters

landfill gas projects

38 645

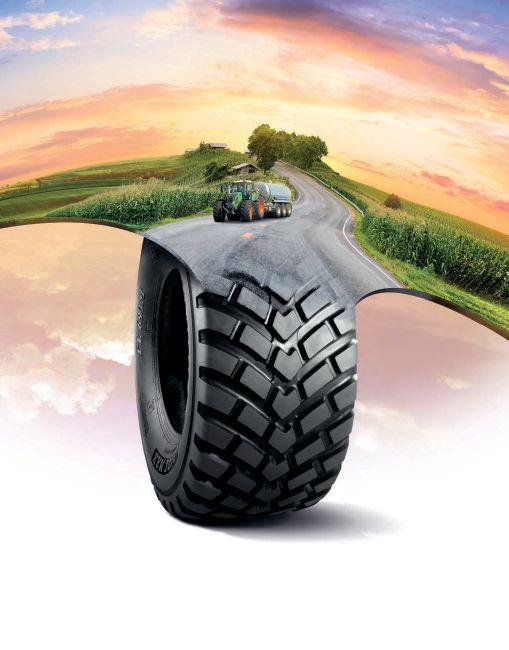

To meet the demand for premium tires, in 2019, Nokian Heavy Tyres plans to build a new research and development (R&D) center in Nokia, Finland. The modern R&D center will accelerate the testing phase of new tire models.

The center has a 3,500-square meter capacity and is part of a substantial production capacity increase for the company. A year ago, Nokian Heavy Tyres Ltd., part of the Nokian Tyres group, reacted to the growing demand for tires with an ongoing three-year, R&D and production investment of approximately 70 million euros and a 50 percent production capacity growth target.

The new modern testing machinery of the R&D Center and increasingly specific data collection will ensure Nokian Heavy Tyres leads the upcoming revolution of heavy work. In the new R&D center all indoor testing will be in the same facility and close to production lines.

“The center will be filled with modern machinery”, says Nokian Heavy Tyres development manager, Matti Kaunisto. “We can triple the number of tires tested and test more variables to serve our OEM clients with the highest standards.”

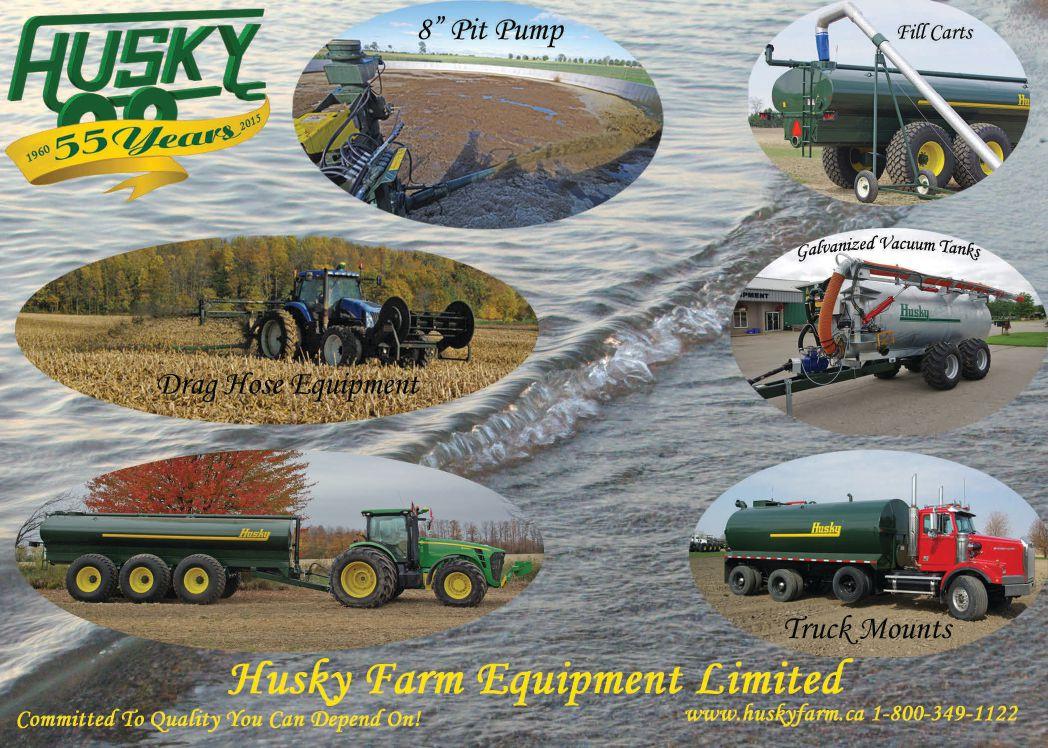

Puck Custom Enterprises (PCE) has partnered up with two international organizations to bring its manure application and agitation equipment to Serbia. This move marks a step forward for the country’s manure practices, as well as another regional achievement for Iowa-based PCE, which has an international headquarters in Osijek, Croatia. The dragline system and agitation equipment was co-funded by the Demo Environment Programme, a project of the Swedish Agency for Economic and Regional Growth. This organization focuses on bringing clean, innovative technology with advantages over existing solutions to new areas.

The Demo Environment Programme provided a grant to Almex –Veterinarska Služba, a Serbian farming operation, to support the introduction and demonstration of a new PCE dragline system for manure application and management. When it was looking for solutions for excessive generation of manure on its pig and cow farms, along with resources on how to apply the quantities effectively, Almex turned to the University of Belgrade’s Cleaner Production Centre within the Faculty of Technology and Metallurgy. This program, looking for technology that complied with European

GEA, one of the world’s largest suppliers of process technology, recently achieved a significant milestone in its company history by manufacturing its 10,000 liquid manure spreader tank.

With a stainless-steel reservoir capacity of 10,500 gallons, the EL48-8D 8800 is the biggest single reservoir model available on the market. The unit was sold by GEA dealer, Automated Waste Systems (AWS), LLC and delivered to PK Winter Farms Inc. in Sheldon, Iowa.

“I have been farming for 35 years and we have been working with AWS for the past seven to eight years as we have been hauling our own liquid manure,” says Paul Winter from PK Winter Farms.

Union standards and presented the opportunity for financial savings, connected the company to PCE International. This cooperation resulted in the first implementation of an advanced dragline system and agitation boat in Serbia.

With Almex implementing PCE products and new processes into its operations, including an applicator that injects liquid manure directly into the ground, soil quality is beginning to improve. PCE’s agitation boat is also helping the farm with fertilizer, allowing the lagoon to maintain a homogenous mix of nutrients that helps crops thrive.

“We are excited to work with these organizations to bring this technology to Serbia for the first time,” says Jeremy Puck, general manager of PCE. “This partnership is revolutionary for manure management and agriculture as a whole in eastern Europe.”

“I am very proud to be part of an organization that has made such

an impact on the liquid manure spreader industry as we have with our line of spreaders,” says Randy Gorter, head of manure management sales, GEA North America. “We started building liquid manure spreaders in 1990. We introduced our steerable line of spreaders in 1992, and here we are now, 28 years later, delivering number 10,000.”

Founded in 1957 in Wickham, Que., J. Houle & Fils Inc. was acquired in April 2007 by WestfaliaSurge GmbH, an international leading manufacturer of milking equipment and a member of the GEA Group. Since 2015, the manure management product line is part of GEA’s Milking and Dairy Farming product group and it is currently distributed in 22 countries through a large network of distributors.

Cadman Power exhibits its Continuous Manure Applicator. (L to R) Scott Black, sales representative and Craig Cadman, VP of operations.

Using manure more efficiently and saving on input costs were two of the key areas focused on at the international EuroTier trade show held in Germany in late 2018.

Defined as the world’s leading trade fair for animal production, EuroTier is held every second year and is organized by the German Agricultural Society, DLG.

This year approximately 155,000 visitors from 130 countries attended the show to view the latest innovations from 2,526 exhibitors.

If farming is to be sustainable in the future there is no doubt the industry needs to embrace new technology by the horns and put it into practice. And while much of the technology at the event centred on robotic feeding, housing comfort and feed supplements, many companies also introduced new techniques in dealing with manure.

Whether it was by separation, composting or burning, visitors to EuroTier saw firsthand how they could make more use of the readily available natural resource on their farms, and even a few options to make money from it.

Composting is one of the oldest and most widespread methods of utilizing manure across the world. Germany-based company,

Karl Farming exhibited its range of high-tech composters that are already being used to reduce food waste in Canada. However, at EuroTier, Karl Farming CEO Karlheinz Rieke explained how his system is now set up to compost livestock waste.

“We have four sizes of composters on the market – eight, 40, 60, and 100-cubic metres, but there is a new one being finalized with capacity of 200-cubic metres,” he said. “The 100-cubic metres model can take in 12-tons of pig, poultry or cattle manure each day and also produce the same quantity per day after eight to 11 days in the composter. Advantages with this process include no smell, no bad bacteria and a very valuable byproduct fertilizer with 80 percent dry matter.”

These composters are very popular in China and Japan and are becoming more popular on North American farms.

“Our Greendragon TC range is a vertical fermenter that makes use of oxygen from the manure to make a premium fertilizer. During the process the manure is homogenized and all harmful bacteria are killed by the high temperature.”

On the Bauer stand, its latest S300 separator was in working mode. The Bauer S300 is a new

EuroTier, the world’s leading trade show for animal production, provides an overview of the latest and greatest in manure management and processing.

BY CHRIS MCCULLOUGH

Since 1960, Vaughan Chopper Pumps have delivered GUARANTEED PERFORMANCE in the toughest applications. See why the original chopper pump is still unmatched.

• Expedite pumps and parts delivery

• Written performance guarantee

• Superior life cycle costs

• Hardened wear components

• Eliminates use of comminutors prior to pumping

• 6 individual chopping features

• Vaughan’s unique, cartridge-style flushless mechanical seal

• Free trial program available

• Ask about our on-site chopper pump demonstration

Experience ease of maintenance with Vaughan Chopper Pumps.

LEFT

A series of decanter lines were introduced by GEA technologies at the event.

design of press-screw separator, which is able to produce material with a higher dry matter content than its predecessor of up to 32 percent. It can process waste at a rate of up to 16m 3 per hour and, according to the company, has low operating costs. The end product can be used as a material for bedding livestock.

Separators proved popular at the show as over on the Rotecna stand there was a Techapur solid liquid model that also improved the fertilizer value of slurry. This model is made from stainless steel, and performs the three basic operations of filtering pressing and scraping in a single unit.

It has a large filtering surface for treatment of up to 20m 3 per hour and a power consumption of less than 0.75Kw per hour. This one can separate up to 40 percent of total solids and reduces up to 20 percent of the liquid volume.

“Advantages with this process include no smell, no bad bacteria and a very valuable byproduct fertilizer with 80 percent dry matter.”

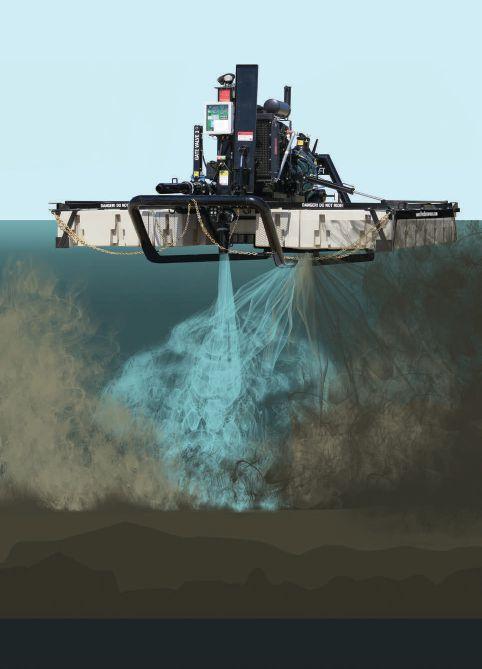

Turning towards manure handling machinery, Cadman Power, based in Courtland Ont., exhibited its massive Continuous Manure Applicator (CMA).

This machine holds 800-metres of 5.5 inch hose and pumps slurry with a Cornell pump powered by a John Deere 375-horsepower engine. It is designed to be a one-man operation and can apply slurry to growing crops up to one-metre in height.

A tractor pulls the injector with the patented CMA swivel arm, which in turn pulls the hose away from the CMA and incorporates in 30’ or 40’ width rows. When the tractor gets to

the opposite end of the field (up to 0.5 miles), the tractor turns 180-degrees and comes back down the field, incorporating another 30’ and 40’ strip. When the tractor turns, the swing arm turns to the side of the toolbar, which keeps the hose in the same row it was pulled out on.

While the operator is completing his return trip, the remote control automatically moves the CMA forward another 60’ or 80’ in order to start another pass. The empty weight of the unit is 32 tons.

Craig Cadman, vice president of operations and Scott Black, sales representative, were present on the stand and were happy to report the unit on exhibit had been sold to a farm in Germany.

A series of decanter lines were introduced by GEA technologies, which treat manure to enable the utilization of the associated nutrient surpluses. Through continuous removal of solids and the high dewatering performance, the clarified manure is largely free of phosphate and can thus be spread on land without causing any environmental problems. Most of the phosphor is in the solid phase and can easily be transported to nutrient-deficient areas.

The GEA manure decanter separates 70 to 90 percent of the phosphate and 30 to 35 percent of the nitrogen compounds and dewaters the solid particles to a compost-like crumbly consistency. This material can later be processed into fertilizer after being dried or composted.

GEA also introduced its new slurry pump that suits all pits as it can adjust to varying lengths. The Super Slider Pump is a new eightinch, adjustable-length, highly-versatile manure pump, specifically designed for use by dairy, pig and beef farmers with multiple pits.

It is available in two depth ranges – eight to 12 feet (2.44m to 3.66m) and 10 to 16 feet (3.05m to 4.88m). The sliding feature of the pump frame means that one pump can replace two or three other pumps, thereby reducing costs and increasing efficiency.

The Super Slider Pump is equipped with GEA’s exclusive dual nozzle design, enabling better and safer manure pit management. The pump is available in 540 and 1,000 rpm (revolutions per minute) versions and is currently available in the extended tilting threepoint hitch, new tilting two-point hitch and trailer mounting configurations.

Belgian machinery manufacturer Joskin celebrated its 50th anniversary at the event and exhibited a wide range of manure application machinery from small tankers through to the giant manure injection applicators.

Eurotier will have the latest manure management innovations on display again at its next event, taking place in Hanover, Germany in November 2020. •

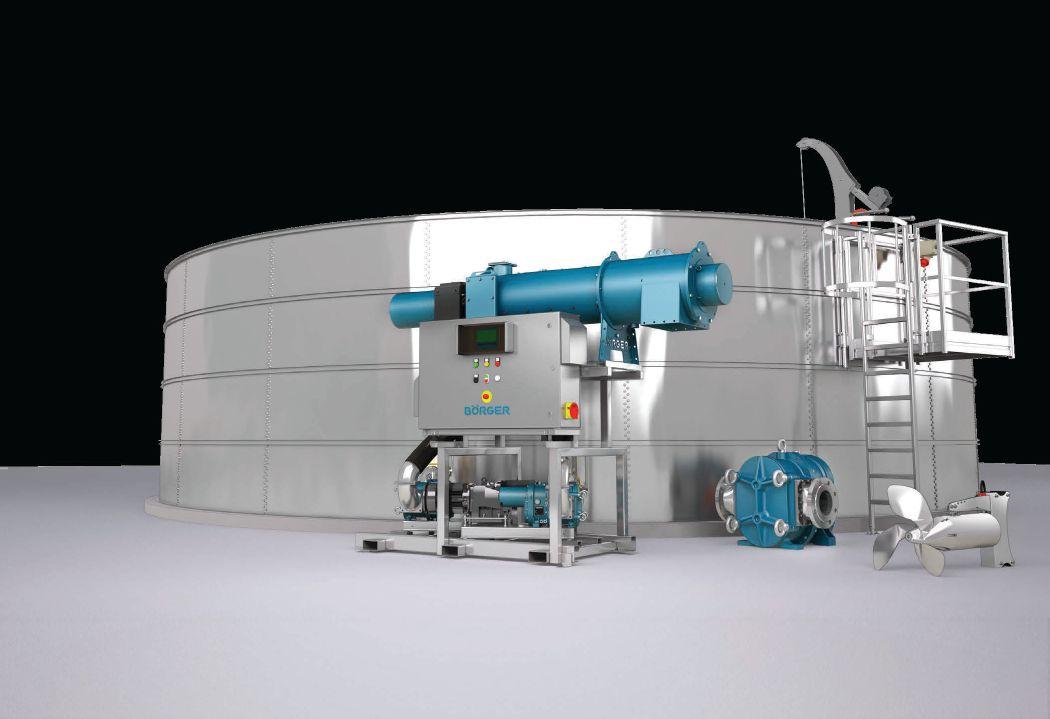

Manure is powering this Pennsylvania farm into the future.

BY TREENA HEIN

The story of how Reinford Farms in Mifflinton, Pennsylvania ended up where it is now – with sources of income and savings stemming from their digester – is both surprising and inspiring.

Reinford Farms was started in 1990 by Steve and Regina Reinford and now has 20 full-time employees, including their three adult sons – Chad, Brett and Drew. It was when Brett was in college that he first became familiar with digesters, and it got him thinking that one on the farm would be a great way to help the planet, reduce odor and better manage manure from their 720-head dairy farm.

“Actually, the biggest reason we built a digester was for the odor-reducing capabilities,” Brett explains. “It doesn’t reduce all the odor, but it certainly helps. We are simply trying to be a better neighbor to our neighbors. We feel public relations is one of the keys to operating a successful farm.”

The family started investigating their options and were excited to find out that Pennsylvania had

ABOVE

several grant programs for biogas projects. Reinford Farms hired Martin Construction to assist in applying for grant funding and to design the digester. Construction began in 2007 and was finished in 2008. The project cost $1.1 million at the time, but state and federal grants covered 60 percent of costs.

The system not only produces electricity to the farm, but sells it to the grid. Waste heat is used to operate a grain dryer, keep several farm buildings and their home. It also produces all the hot water needed for the dairy operation and the farm house. Digester solids are used as cattle bedding. The savings from not having to purchase electricity, heat and bedding alone add up to over $150,000 USD a year, and the profits from electricity are a bonus.

Another revenue stream comes from tipping fees for biodegradable food waste, which the Reinfords started accepting into their digester in 2008.

In mid-2017, in order to expand the amount of food waste they could use, the family purchased

Reinford Farms hired Martin Construction to assist in applying for grant funding and to design the digester. Construction began in 2007 and was finished in 2008.

+ Solid Liquid Separation

+ With Structure

+ Without Chemicals POWERFEED

+ Feeding and Transfer of Organic Waste

+ Closed Loop System

+ Process Control

+ Energy Efficient

In mid-2017, in order to expand the amount of food waste they could use, the family purchased and installed a food waste depackager.

and installed a food waste depackager. This machine separates clear plastic wrapping, produce trays and other packaging from grocery store food waste, and then converts the food into a slurry, which is easily digested by the bacteria in the digester. The farm charges less than supermarkets would have to pay to the local landfill to accept the waste, so it’s a win-win situation for everyone.

“If the liquid food waste sources dry up, we are now able to pursue the packaged food waste to continue to provide feedstock of our digester,” Brett explains. “Recycling food waste has given our farm a different story, which has opened up opportunity for us to have access to customers at a different level. Food waste and what to do with it is has been a big topic in recent years. People are excited when finding that farmers can offer a sustainable solution to the problem.” As reinforcement of this notion,

Reinford Farms won a Sustainability Award from the Innovation Center for U.S. Dairy in 2018.

The Reinfords are now planning to add another generator to the original 140-kw generator, a 500-kw unit, as well as a second digester.

“The second digester will be a lot bigger than our first,” Brett says. “We’ve run into some setbacks regarding funding but hope to work through it so we can start construction in early 2019. The reason for a bigger size is that we expect our cow numbers and food waste business to continue to grow and wanted to make sure we had the capacity. Our current digester was sized for 800 cows and no food waste. It’s currently over capacity and we have a very short detention time of the manure and food waste. We are losing some of the energy value of the feedstock because it’s being pushed through the digester too quickly. Installing our new digester will allow us to expand our cow numbers and food waste capacity.”

According to Brett, the gas scrubber in the first digester doesn’t work very well, but the new digester will have a scrubber that will properly clean gas from both digesters.

“This will hopefully allow us to get more life out of our generator engines,” he notes. “We expect both digesters to be running at full capacity (640 kHw), which should provide enough power for 400 to 500 houses.”

Prior to installing the digester, however, Brett notes that manure management was much simpler. Previoulsy, all the manure at Reinford Farms had been scraped into a pit and land applied, but the slurry was very thick and sometimes challenging to pump.

“When we installed the digester, we added a manure separator so we could bed the cows with the solids,” Brett reports. “Removing a lot of the solids helped the digester to break down the manure better. Our manure is now more viscos and we’ve installed pipes under that ground that we use to spread manure more efficiently. Also, there are a lot more pumps and mixers on the market now, so the manure management takes a lot more attention to ensure it is working properly.”

When asked whether he can imagine his family’s farm without the digester, Brett says that would be tough to do.

“It’s been so incorporated into our farm that when it is not working properly, the rest of the farm knows it immediately,” he says. “From the hot water to the financials, it’s all tied into the digester, so it’s critical that we successfully operate it and continue to look for ways to use its potential to bring additional value to the farm.

I cannot imagine farming without a digester, but at the same time, we caution that they are not for everyone.”

On that note, Brett offers insights from the lessons he and his family has learned along the way. First, he advises planning ahead carefully. Where a digester is located on your farm determines how you can best utilize the value it can provide, he notes. He advises thinking ten or more years down the road to ensure that you can manage the space around the digester.

“Who knows, like us, your farm might grow and you’ll need more space to add an additional digester,” he says.

Brett also cautions that while their acceptance of food waste has been going on for over ten years, since installing the depackager in 2017, the challenges have become greater, not easier. He says managing the supply, or lack thereof, is still something they are

Lastly, Brett advises anyone who wants to get a digester to first figure out

“If you build a digester and expect it to simply make money, you’ll probably be disappointed,” he says. “It takes time and energy to manage a digester. Make sure it aligns with your strategic goals

Approximately 20 tons of food waste enters the Reinford digester per day. And, about 48 tons of manure from 720 cows is used in the digester per day.

There are no fossil fuels used on farm for heating or electricity. Products created via digestion:

• Electricity

• Heat for the house and farm buildings, hot water and for drying corn

• Dried digester remains are used for cattle bedding on farm

• Liquid manure (kept in long term storage and land applied)

Biogas generation: Now 68 scfm, future: 130+ scfm

Energy: The farm is operating a 140 kW genset and in the process of upgrading to an additional 500 kW by end of 2019.

The new box-style robot from GEA, the DairyRobot R9500, is engineered to enhance the milking process and increase on-farm efficiency.

The DairyMilk M6850 sensor is the industry’s first SCC monitor that continuously analyzes milk flow from each individual quarter throughout the entire milking process. It collects reliable data in real time, without chemical reagents, to help detect mastitis early. This early detection helps minimize treatment time and protect the health of the herd. Both entrance and exit doors are designed so cows can be milked

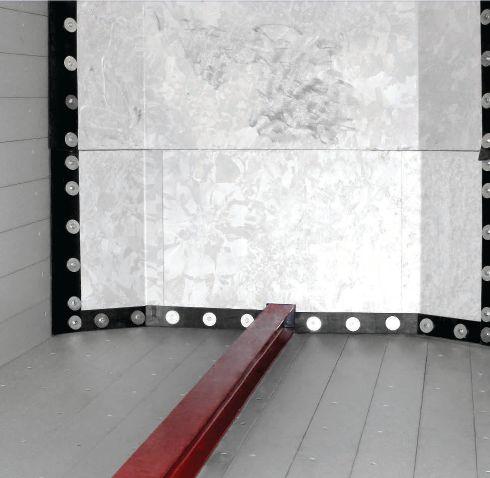

The new KUHN Knight PXL 100 Series ProSpread apron box spreaders are high-capacity, commercial spreaders that provide producers with a reliable, heavy-duty machine designed for high usage. The PXL 100 Series spreaders, with heaped capacities ranging from 865 to 1,230 ft 3, are KUHN’s largest box spreaders to date, and have been designed for agricultural and commercial applications that process a wide array of semi-solid and solid materials.

All three PXL models are available as trailer models, while the PXL 185 and 1100 are also available as truck-mounted models. With three discharge options, horizontal beaters, VertiSpread vertical beaters or an AccuSpread spinner discharge, these spreaders will efficiently spread a broad range of materials giving you the ultimate versatility to match your operation’s needs. Kuhn.com

quietly and comfortably without disturbance from the next cow in line. The feed trough has been engineered to optimize feed intake and increase ingredient options. A trough bowl cover slides up during cow exit to keep cows moving at the end of milking, allowing the next cow to enter as soon as possible. An unobstructed view of the udder provides easy access to

safely care for cows during dry-off, treatment or to manually attach the unit for a special needs cow. The new G5 time-of-flight camera on the R9500 provides precise teat detection for fast teat cup attachments. Then, every step in the milking process is performed in a single attachment with GEA’s in-liner technology. Gea.com

The new, all-steel Alliance Agriflex+ 389 flotation radial is the world’s first VF (very high flexion) flotation tire, purpose-built for manure handlers. 30% less inflation pressure means significantly less soil compaction. That’s thanks to extra-flexible sidewalls that help create a 25% larger footprint. Then there’s the tread—stable on the road, sure-footed in the field, with non-directional bars for traction and a dense center rib for long life…so you’ll haul more and compact less.

More livestock operations are being subjected to government inspections with little or no notice. It’s better to be prepared.

BY HALEY BANWART

Livestock farmers are subject to inspections by the Environmental Protection Agency (EPA) and the Department of Natural Resources (DNR). And, because these assessments usually occur with little or no notice to the farmer, it is essential to be prepared for your livestock farm to be inspected at any time. Follow these simple compliance checks to ensure your farm is in accordance with the environmental rules and regulations, and to learn how to best respond to potential DNR or EPA inquiries.

ABOVE

1. Collect background information and take corrective action

The EPA is not legally required to notify farmers before assessing livestock farms. However, if you are contacted prior to inspection, collect as much information as possible about the investigation. Consider presenting the following questions to the inspection agent:

• What prompted the inspection?

• What areas of the farm will be inspected?

• How much time will the

Do not give an inspector unaccompanied access to your property. Instead, select a point of contact to be present while the agent is assessing the farm.

inspection take?

• How many inspectors will be assessing the farm?

• Does the inspector intend to interview farm employees?

• Does the inspector intend to collect samples?

After gathering this information, complete a self assessment of your farm as a compliance check and take corrective actions to fix any issues. Consider your farm’s proximity to water sources, potential for manure discharge or other areas of improvement of your management practices.

2. Review your records and identify confidential information

Confined animal feeding operations (CAFO) are required to keep detailed records. Whether or not your farm meets the definition of a CAFO, you should maintain monthly records to verify your animal inventory, document manure storage levels and track manure application dates, acres applied and nutrient testing results.

3. Designate a point of contact and develop an inspection plan

Do not give an inspector unaccompanied access to your property. Instead, select a point of contact to be present while the agent is assessing the farm. Designate either a family member or an employee who is most familiar with your farm’s environmental compliance and management practices, and develop an action plan so all members of the farm know who to notify, as well as, under what conditions the inspector should be granted access to documents and property. All parties involved should be courteous, truthful and answer only the questions asked of them.

“If you don’t know an answer, assure the inspector you will follow-up in a timely fashion.”

Of course, there are other farm records that you are entitled to identify as confidential information, such as legal correspondence or environmental audits. Prior to inspection, determine which records will remain off-limits and which records may be made available to the inspector but claimed as confidential business information (CBI). You should also consider what areas of the farm may be off limits due to safety or biosecurity requirements.

4. Consider legal counsel or an environmental consultant

While most farms do not have legal counsel on-site during an inspection, it may be wise to request assistance from an attorney or your environmental consultant if the inspection is unannounced or not routine, if a state enforcement action is threatened or pending, or if there are indications of a criminal investigation.

1. Accompany the inspector and cooperate with requests for information

After notifying all family members or employees that an enforcement official will be evaluating the farm’s environmental compliance, direct the point of contact to accompany the inspector at all times. If the inspector takes notes, photos or samples, so

should the point person. If the inspector requests a copy of certain records, be sure the point of contact also makes a copy and obtains receipts for any samples or original documents that will leave the farm. Following these steps will allow you to know exactly what information the inspector has collected and will serve as evidence against any disputes or discrepancies in the future.

During the EPA or DNR inspection, it is also important to cooperate, but not speculate. Although it may seem natural to put up your defenses, remember that federal law prohibits knowingly and willfully falsifying or concealing material facts or making fraudulent statements of material facts. Answer the agent’s questions truthfully while not volunteering information beyond what was asked of you. If you don’t know an answer, assure the inspector you will follow-up in a timely fashion.

2. Claim confidentiality and determine if employee interviews will be conducted

If applicable, claim any records the inspector requests as confidential business information (CBI) to protect trade secrets or other private business matters. Failure to claim CBI may waive your farm’s claim and subject the records to public scrutiny.

In the event the inspector wishes to formally interview specific individuals other than the point of contact, notify legal counsel immediately. A request for interviews may signal the EPA or DNR is building a record against your farm.

3. Request an exit interview

Rather than waiting to receive the inspectors final report, request an exit interview to learn as much as possible about the investigator’s

findings. This step will allow you to ensure the agent’s conclusions are not based on inadequate information or a misunderstanding, and it will help you determine how to handle any potential disputes.

1. Organize notes and obtain the inspection report

Following the inspection, ask the point of contact to summarize the inspection and exit interview in written form. Compare these notes to the EPA or DNR report to identify any errors. All owners or management not present at the time of the inspection should be informed about what information was collected. If potential violations were noted, contact legal counsel to determine how to proceed.

2. Respond to the DNR or EPA requests and conclusions

If additional information was requested at the time of the inspection, provide it to the inspector as soon as possible. You may wish to consult with legal counsel to help prepare this information and communicate with the environmental organization on your behalf.

The EPA responds to non-compliance in a number of ways including: A letter notifying the farm of violations, administrative compliance order, administrative compliance order plus an administrative penalty, civil judicial enforcement action (penalties and/or injunctive relief) or criminal enforcement. Any of these noncompliance notices require immediate attention.

3. Correct all violations

Once you are aware of what violations have been issued to your farm, correct them as quickly as possible. Your cooperation will demonstrate a cooperative attitude and will reduce any “per day” penalties.

For more information about preparing for a DNR or EPA inspection, visit: supportfarmers.com/InspectionInfo or call 1-800932-2436. •

Haley Banwart is an assistant field specialist at the Coalition to Support Iowa’s Farmers. She can be contacted at hbanwart@supportfarmers.com.

Section 308 of the Clean Water Act provides EPA with the authority to enter any premises in which an effluent source is located. This broad authority allows EPA to inspect operations where discharges from point sources such as concentrated animal feeding operations are suspected or located.

It also allows EPA to review and copy records and collect discharge samples or other information from effluent sources, as required. Under United States Code, Title 18, section 1001, it is a crime to lie to, or conceal information from, a federal official.

EPA’s biosecurity protocol requires that, among other procedures, the inspector should:

• Inform the operator where the inspector plans to go onsite and determine appropriate biosecurity procedures.

• Enter animal housing buildings only if necessary.

• Consider using the facility’s biosecurity procedures if more stringent than the EPA’s, as appropriate.

Source: United States Environmental Protection Agency

What is stockpiling? If you look up stockpile, you’ll find that it means a passive management of solid manure where the material is placed into a storage where it remains until it is either land applied or moved. In either case, the important points to stockpiling are that this is a passive management system, once the manure is stacked it is left alone and not disturbed, and, as a result the pile will become anaerobic.

It is only passive in the fact that we, the farmer or manager, won’t perform regular activities to alter the pile, but within the pile microbial activity will still be occurring. Despite this, stockpiling is essentially a storage technique.

In contrast, composting is an active management and treatment technique that encourages aerobic conditions to accelerate the breakdown of organic matter within the manure. This produces higher temperatures within the pile that encourages faster microbial activity and can also reduce the viability of pathogens, bacteria and seeds within the composted material. The important points here are that composting is an active management process for treatment of the manure and the process is aerobic.

The difference in aerobic and anaerobic may seem small, but there are some important distinctions between the two that result in vast differences.

In anaerobic conditions, breakdown of organic matter releases only very small amounts of energy and makes compounds like methane, carbon dioxide, ammonia, hydrogen sulfide, and many partially degraded organics (volatile fatty acids, alcohols, phenols). This means that while the pile may heat up a little, since there is little energy released, temperature increases tend to be small and breakdown tends to be slow. Also, the compounds we make tend to be ones that we can smell.

Aerobic reactions tend to release larger amounts of energy; these exothermic reactions will cause the pile to warm up and accelerate biological activity and growth. In this situation we will still make carbon dioxide and ammonia but won’t make those other compounds.

What these differences mean to us is that we will have different amounts of break down occurring. The amount of difference this makes is

very dependent on the initial manure properties, with manures with high amounts of carbon in them (such as bedded manures) typically exhibiting a bigger difference. For example, studies of composting bedded cattle manure have suggested that a mass loss of 40 to 70 percent (water plus dry matter) can be achieved, while cattle manures from earthen feedlots typically range in the 15 to 25 percent range.

More recently additional topics related to manure stockpiling have come to the forefront. While poultry manures tend to have sufficient potassium in them to support crop production, certain management approaches can leave their potassium content lower than expected. Potassium is very water soluble and stockpiles exposed to the elements, such as rainfall, can have the potassium within them leached into the soil below. While this poses minimal risk for water quality, it is an important consideration for using stockpiled manure as a fertilizer source.

Good stockpiling shaping, taller rather than wider, and with sloped surface to encourage rainwater shedding rather than water moving through the pile can help maintain potassium content. Additionally, stacking sheds can help keep rainwater off the manure and help hold potassium in the manure. Similar results have been found for nitrogen, with covered or roofed stockpiles only losing five to 15 percent of the nitrogen in the pile, while outside piles losing 15 to 25 percent of their nitrogen.

These nitrogen losses also have implications for crop production. In general, most of the nitrogen lost is from the ammonium fraction, which is first year plant available. Manures that have been stockpiled in ways that have minimized nitrogen loss from the pile (covered or roofed stockpiles) tend to result in a greater fraction of the excreted nitrogen making it both to the field and ultimately into the crop through uptake and utilization.

In summary, stockpiling remains a viable manure management strategy to help get the most fertilizer value from solid manures. However, opportunities to improve management do exist with covered and roofed storages potentially providing mechanisms to help hold onto nitrogen within the manure and minimize potassium loss during storage.•

GEA’s STR Series Manure Semi-Tanker streamlines manure transportation for faster, farther hauling. From farm to field, this first-class manure hauling system saves time, fuel and equipment wear and tear. The STR Series SemiTanker can also haul and apply slurry directly on hard soils after harvesting, giving you flexibility in hauling times.

The GEA STR Series Semi-Tanks meets all traffic safety regulations for vehicle weight and width for increased safety for you and everyone on the roads.

Don’t let distance slow you down. Hit the road with GEA’s STR Series Manure Semi-Tanker