Winds of change

A.W. Leil looks to lift Atlantic Canada’s wind sector to the next level p.10

INSIDE

Safety and belonging on the jobsite p. 16

The latest rough terrain cranes p. 26

BY JACK BURTON

Opportunity knocks FROM THE EDITOR

It’s that time of year – you can leave your jacket at home, fire up the grill, and enjoy a couple more hours of daylight. For this sector, the warm weather brings a time of opportunity – and I’m not just talking about construction season heading into full swing.

As editor of this publication, it’s my job to connect the many parts and people of Canada’s heavy lifting industry, whether through the latest news, sharing your stories in company and personal profiles, or deep dives into the latest changes we’re facing.

No matter the coverage I’m putting together, it’s all united by the goal of celebrating this industry across the country and recognizing the achievements of those within it.

On that front, I’m excited to announce the time of year has come for your hard work to get the celebration it deserves through some of Crane & Hoist Canada’s industry recognition programs, now open for submissions.

Cover-star cranes

Our annual photo contest presents a number of opportunities: showcasing the cool projects your company has been working on, flexing your creative muscle, and highlighting the diverse lifts being done nationwide. Most excitingly, it’s an opportunity to get on the cover of Crane & Hoist Canada

Entries for our annual photo contest, presented in collaboration with the Canadian Crane Rental Association, are now open – send over your submissions, along with the type of crane, where and when the picture was taken and a few words about the project depicted to jburton@annexbusinessmedia.com by August 1!

While the issue will feature dedicated space highlighting the standouts, I have a few tips to share for those of you gunning for that cover-star spot:

• Quality matters: photos must be high-resolution to make it onto our cover – while we love the perspective that an iPhone photo provides, the resolution is too low to be printed on our cover.

• Keep it current: if this year has taught us anything, it’s that things move fast.

Our photo contest is a way to provide a visual update of your latest and greatest lifts and equipment, so make sure all photos are taken after January 1, 2024!

• Portrait is preferred: pictures can be cropped to fit on our cover, but a wide photo with a lot going on can be difficult to edit while still showing everything.

• It’s all in the details: though we need to know the crane model and where and when the picture was taken, providing some additional context on the lift and its unique aspects will help you stand out.

On top of making the cover for our September/October 2025 issue, the winner will also receive membership to the Canadian Crane Rental Association. Submit today!

Top 10 Under 40

Now entering its sixth year, our ever-popular Top 10 Under 40 program is the perfect way to recognize the rising stars from across Canada’s crane and heavy lifting industry –and it’s now open for nominations!

Our 2025 Top 10 Under 40 will profile the best of who’s next across the industry in our November/December 2025 issue, and as it prepares to turn six, the program remains far from showing its age. In fact, if you ask me, it’s more vital than ever.

Labour shortages are a regular discussion among the trades, but one of the primary struggles faced by the crane and heavy lifting sector is showing those entering the workforce the possibilities and unique paths that exist in this industry. Show them what’s possible by sharing the journeys and experiences of your own young superstars!

The influx of Canadian pride demanded by the current moment also highlights the importance of programs like this. Despite the uncertainty that may be out there, now more than ever we should celebrate our homegrown talent and show what we, as an industry and a country, are capable of.

Applications are now live onour webiste. Nominate a rising star from the industry before Wednesday, September 17!

Jack Burton jburton@annexbusinessmedia.com

16, ISSUE 3 | MAY/JUNE 2025

Reader Service

Print and digital subscription inquiries or changes, please contact customer service

Angelita Potal

Tel: (416) 510-5113

Fax: (416) 510-6875

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR | JACK BURTON jburton@annexbusinessmedia.com

NATIONAL ACCOUNT MANAGER | LAURA GOODWIN lgoodwin@annexbusinessmedia.com • 289-928-8543

MEDIA DESIGNER | BROOKE SHAW bshaw@annexbusinessmedia.com

ACCOUNT COORDINATOR | BARB COMER bcomer@annexbusinessmedia.com

AUDIENCE DEVELOPMENT MANAGER | URSZULA GRZYB ugrzyb@annexbusinessmedia.com • 416-510-5180

GROUP PUBLISHER | DANIELLE LABRIE dlabrie@annexbusinessmedia.com

CEO | SCOTT JAMIESON sjamieson@annexbusinessmedia.com

PUBLISHED BY ANNEX BUSINESS MEDIA 105 Donly Drive South, Simcoe, ON N3Y 4N5

Crane & Hoist Canada is published six times a year by Annex Business Media. Reference to named products or technologies does not imply endorsement by the publisher.

Subscription rates (six issues) Canada: $37.74 + tax per year USA: $48.96 CAD • Foreign: $63.24 CAD Send cheque or VISA/Mastercard number to Subscription Department, Crane & Hoist Canada, 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1. Fax orders to 416-510-6875. Or subscribe online at www.craneandhoistcanada.com

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO: Crane & Hoist Canada. CIRCULATION DEPT. 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

PRINTED IN CANADA ISSN 1923-788X Publications Mail Agreement #PM40065710

Annex Privacy Officer

The contents of Crane & Hoist Canada are copyright ©2025 by Annex Business Media and may not be reproduced in whole or part without written consent. Annex Business Media disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication.

Next Advertising Deadline: June 27, 2025 Don’t miss the opportunity to be part of this exciting industry publication. For more information, or to reserve space in the next issue, call Laura Goodwin at our Advertising Department Tel: +1-289-928-8543 lgoodwin@annexbusinessmedia.com

Next Editorial Deadline: July 1, 2025. For writers’ guidelines and submission requirements get in touch with the editor, Jack Burton, at jburton@annexbusinessmedia.com

Privacy@annexbusinessmedia.com Tel: 800-668-2374 MEMBER OF: MEDIA PARTNER:

The versatile and powerful GRT8100-1 takes Grove’s 100 ton rough-terrain crane to the next level. The crane integrates the wide cab and carrier of the GRT8120 with the superstructure of the GRT8100 to bring you improved operation, easier serviceability, and added jobsite flexibility with the MAXbase outrigger system.

New and used Manitowoc and Grove Sales, Rentals, Parts and Service.

AUTHORIZED DISTRIBUTOR

Sarens performs lifting for Edmonton carbon capture facility

Sarens, on behalf of PCL Construction, is providing the lifting for Heidelberg’s Carbon Capture, Usage and Storage (CCUS) silos in Edmonton.

Expected to be complete by the end of 2026, Sarens began working on the project four months ago. When finished, the project will reduce the plant’s emissions by 95 per cent and introduce more than 1,900 full-time employment opportunities to the region.

Sarens’ role in the project has included lifting loads of up to 7,000 pounds consisting of material forms, rebar and concrete at heights in excess of 215 feet. To perform these tasks, Sarens has deployed a GROVE GMK 5150 with swingaway jibs, a Liebherr LTM 1070, and a Hoeflon C10 spider crane to the project site.

“We are proud to be able to participate directly in a project of this significance, which will not only contribute economically and socially to the development of Alberta and our country, but will also have a very positive impact on the construction sector, one of the major drivers of our economy,” said Jeff Chernish, Sarens’ country manager for Canada.

The project began with a 2019 feasibility study, with a Memorandum of Understanding signed between Heidelberg and the Government of Canada in 2023 to provide the project with up to $275 million as part of the federal Roadmap to Net-Zero Carbon Concrete 2050 strategy.

Alberta’s

J.D.A.

Ventures

purchases Liebherr mobile crane duo at bauma

The company purchased a Liebherr LTM 1400-6.1 and an LTM 1160-5.2 for its fleet, with the machines to be used for wind energy and oil and gas projects in northwest Alberta and northeast British Columbia.

Upon its arrival, the 400-tonne LTM 1400-6.1 will stand as the most powerful crane in J.D.A.’s fleet. The six-axle crane features a 70-metre telescopic boom, modern Y-guying system and optimized set-up.

The new LTM 1160-5.2 will be the fourth addition of this model to J.D.A.’s fleet, with the company primarily using this machine for taxi crane applications.

crane index has been released for the first quarter of 2025, with Toronto leading in both overall crane counts and greatest increase in cranes among the 14 cities covered by the report.

RLB’s report showed Toronto to currently have 106 active tower cranes on jobsites in the downtown core, with this number increasing by 28 per cent at 23 cranes between August 2024 and February 2025.

Ventures added a a Liebherr LTM 1400-6.1 and an LTM 1160-5.2 following their trip to

(PHOTO: LIEBHERR)

in Munich this April.

Alberta’s J.D.A. Ventures Ltd. has ordered two new Liebherr mobile cranes following its attendance at bauma 2025 in Munich, Germany.

Founded in 1986, J.D.A.’s fleet is currently comprised of twelve cranes and around 300 other pieces of equipment. The company has two primary locations in Alberta including Grande Prairie and Whitecourt, along with a satellite brand in Fox Creek. J.D.A. also has a branch in Fort Saint John, B.C.

Toronto leads North American tower crane growth for Q1 2025

Rider Levett Bucknall (RLB)’s biannual tower

Alongside New York, Toronto was one of only two cities to see its crane count grow since the previous report. Trends showed an overall slowdown across North American cities, with seven reporting decreases of 20 per cent or more and five seeing no movement in either direction.

Calgary, the other Canadian city covered by the report, did not see any movement in its crane count; remaining at a count of 24.

RLB shared that these downward trends reflect an overall hesitation across the market to move forward with any major construction projects, stemming from economic uncertainty.

To help build Heidelberg’s carbon capture silos, Sarens is lifting loads of up to 7,000 pounds consisting of material forms, rebar and concrete at heights in excess of 215 feet.

PHOTO CREDIT: SARENS

J.D.A

bauma

NEW A CLASS OF ITS OWN –REDEFINED.

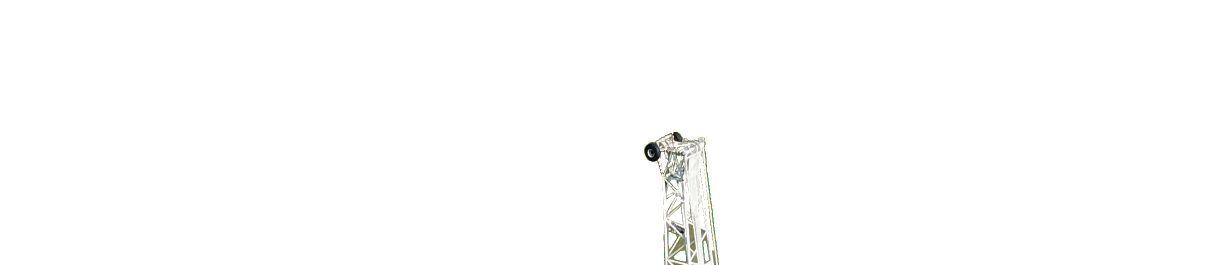

Engineered for the toughest lifting challenges, the CC 78.1250-1 sets new industry standards.

It delivers up to 154.3 US tons at a staggering 736.5-foot hook height – and up to 1,375 US tons rated capacity. With this performance, it dominates heavy-lift applications, including infrastructure, the petrochemical industry, and the expanding wind power sector.

Its redesigned superstructure, carbody and crawler frames ensure maximum stability, while adjustable crawler shoe widths and an optional PC kit provide unmatched adaptability on any terrain.

Precision, power, and efficiency – redefined.

Around the world

The CCRA shares updates from the ICSA’s User’s Meeting during bauma this past April.

As the global construction industry gathered in Germany for the 2025 installment of bauma, heavy lifting leaders from across the world came together for the International Crane Stakeholders Assembly (ICSA)’s User’s Meeting on April 9, 2025, at the Westin Grand Munich.

The meeting was attended by representatives from the Association of Equipment Manufacturers (AEM), the Crane Industry Council of Australia (CICA), the Canadian Crane Rental Association (CCRA), the European Association of Abnormal Road Transport and Mobile Cranes (ESTA), the European Federation of Material Handling (FEM), Specialized Carriers & Rigging Association (SC&RA) and the Japan Crane Association (JCA).

The CCRA was represented by its executive director Claire Bélanger-Parker, Clinton Connell, executive director of BC Crane Safety and Paul Walchuk, Vice-President of Kova Engineering. The CCRA played a significant role in several agenda items and industry issues discussed at the meeting:

CSA-Z150 (Mobile Crane) / CSA-Z248 (Tower Crane): One of the key discussions the CCRA was involved in pertained to the current updates to the CSA standards and the future development of a new standard for rotating telehandlers.

The recent CSA Group report highlights the urgent need for updated and specific standards to address the growing use of rotating telehandlers in Canada, ensuring the safety of operators and worksites. The development of new Canadian standards, potentially drawing upon established international best practices, appears to be the most effective path forward.

High-level crane operator recruitment survey: Produced by BC Crane Safety, the survey link will be shared with CCRA Members and ICSA Members so that each region can consider distributing the survey to their own members to both increase the sample size and be able to review the results from their own respective jurisdictions.

The high-level crane operator recruitment survey is to address the challenges faced in recruiting skilled crane operators. The survey aims to gather data on the current recruitment landscape, identify gaps and propose solutions to attract and retain talent in the crane industry. The results of this survey will be shared with CCRA and ICSA members.

Below-the-hook personnel lifting systems and lifting platforms: Another important topic discussed by CCRA was the use of below-the-hook personnel lifting systems and lift platforms. These tools are essential for safe and efficient lifting operations.

The CCRA emphasized the need for proper training and certification for operators using these systems and platforms, along with international design and inspection standards to prevent accidents and ensure compliance with safety regulations.

Bridge formula research: The CCRA provided an update on its ongoing bridge formula research project and provided an update on the CSA Group review of the CSA-S6 Bridge Safety Standards, to which the CCRA is recommending active representation.

World Skills Competition: ICSA members agreed to facilitate

The International Crane Stakeholders Assembly’s User’s Meeting took place in Munich as over 600,000 from the global construction industry gathered for bauma 2025.

the introduction of rigging and crane operation into the World Skills Competition. British Columbia already includes a crane operator component in its competition, and this year marks the second participation of BC Crane Safety.

The Skills Canada Competition, held in Regina, Sask., will see the CCRA collaborate with Skills Canada’s business director to further advance this initiative. Skills Canada requires a minimum of six provincial competitions to integrate it into the national level, which can then progress to a worldwide competition.

The CCRA aims to encourage provincial skills competitions, ultimately enabling Canada to compete internationally alongside the European Union, Australia and the USA.

ICSA Position Papers Update: The SC&RA has proposed a guideline for tower cranes in windy conditions, on which the CCRA and the CICA will collaborate.

Safety Pictograms: FEM is preparing a guide on safety pictograms without text to be presented at the CONEXPO 2026 ICSA Meeting. Safety hazard identification is regulated by ANSI Z535 standards, which aim to improve hazard identification for workers and property, known as Hazardous Communication (HazCom). These standards guide the design and application of HazCom across North America and globally, integrating with ISO 3864 for international compliance. In the future, if approved, this important initiative may lead to the replacement of multiple stickers in multiple languages currently appearing on the sides of mobile cranes.

Together with these organizations, the active participation of the CCRA underscores its commitment to advancing the crane industry through the development of standards, addressing recruitment challenges, and promoting safe lifting practices.

• Rough Terrain Cranes: 35–120T capacity

• Telescopic Boom Crawler Cranes: 90T & 160T capacity

• Lattice Boom Crawler Cranes: 100–400T capacity

• All Terrain Crane designed for North America coming soon PRODUCT LINEUP INCLUDES

• Technologically advanced, user-friendly designs

• Reliable product support from North West Crane & SANY North American service team KEY FEATURES

Winds of change

A.W. Leil takes next step in meeting Atlantic Canada’s demand for wind energy projects.

By Jack Burton

Over 15 years ago, Allison Leil, founder and then-president of Nova Scotia-based A.W. Leil Cranes & Equipment took a chance that, even decades later, continues to pay dividends for the company.

Leil brought two brand-new crawler cranes into his company’s fleet, one 400 tonne-capacity (440 USt) machine and the other at 600 tonnes (660 USt). Despite the positive impact it has since brought, the purchase inspired a cocked eyebrow or two, not only for being an unusually large investment in these cranes for the time, but also due to the relatively smaller operational size of A.W. Leil, said current president Ryan Long.

The purchase was made due to Leil’s belief in the growing impact of the wind energy sector on the area’s construction and infrastructure projects. These debut

entries into A.W. Leil’s wind energy fleet allowed the company to get a foothold on the area’s sector just as it was beginning to take off, and while the 400-tonne model was recently sold, both cranes remain in operation today.

“It’s a big, big part of our business,” said Long. “Because Mr. Leil had the foresight to do that, they had great success and put up the majority of wind turbines through Atlantic Canada in the early days, but both of those cranes are still used on a regular basis, and what we’re finding is those cranes still have a great spot to maintain the 500 turbines that are standing in Atlantic Canada now.”

As A.W. Leil’s wind fleet continues to perform maintenance duties across much of the influx of turbines that arrived to the Atlantic provinces in the first two decades of the millennium, new demands are emer-

A.W. Leil’s role in Atlantic Canada’s wind energy sector began with its 2009 purchase of two crawler cranes, with turbine construction and maintenance growing into a key aspect of the company in the decades since.

ging from the increased urgency of Canada’s carbon goals and renewable energy’s role in achieving them – demands for bigger turbines, and more importantly, bigger cranes to put them together.

Eager to meet this demand head-on – and taking a page or two out of A.W. Leil’s playbook of the past – Long has made a major purchase to his company’s fleet to keep them competitive in meeting the need for these larger projects.

Meet the new boss

The newest addition to A.W. Leil’s fleet is the Liebherr LG 1750-SX; a 750-tonne (850 USt) lattice boom mobile crane. While Long mentions that other fleets in Ontario and Alberta also count the LG-1750 among their ranks, this latest purchase brings the first model of this crane to Canada’s east coast.

A.W. Leil recently received their delivery for the massive crane, which due to its size was transported to them across a total of 72 tractor trailers.

The LG1750-SX combines a traditional lattice boom with a rubber-tired eight-axle carrier, and travels at a width of three metres between turbines versus the standard 10 to 12 metre width of crawler cranes traditionally used on wind energy projects.

“This new crane takes the upper works of a crawler crane, and mounts that on a rubber-tired truck crane chassis,” Long explained. “Now, when we move between turbines, we’re actually three meters wide – it’s a big, big savings to customers and to developers, and it also lessens the footprint of the project. We feel that having this unique offering is going to make a big difference to prospective clients.”

The model is also equipped with its optional super lift ballast and derrick systems, along with its three enhanced boom stability additions, the SX, SX-2, and SX-3 systems, which allows for longer and safer boom reach. Combined, A.W. Leil’s LG-1750-SX

has the capacity of operating at a maximum tip height of 172 metres in the air.

“I don’t know if I’d ever want to see that high up in the air, but that is what it’s capable of – its lifting capacities are much greater than our 600-tonne crawler,” said Long.

While Long and his company are among a select few in the country to count this

LEFT: The LG 1750’s SX, SX-2, and SX-3 systems – the only model in Canada to feature all three – allows the machine to reach a maximum operating tip height of 172 metres in the air.

crane’s power among their fleets, he mentioned that their machine is singular across the country in being the only one to feature both the SX-2 and SX-3 systems, and therefore boasts the highest lifting capacity at maximum tip heights among all other Canadian models.

It’s a massive purchase – especially relative to the size of A.W. Leil’s roughly 70-person operation – but as the wind energy sector on Canada’s east coast prepares to kick things into the next gear, Long believes it is time to start writing the next chapter to his company’s purchase of those crawler cranes decades ago.

“If you don’t have it, clients can’t build to suit it,” said Long. “Our ownership believes in us and decided to go along with this investment because of that same foresight that Mr. Leil had back when he

A weeklong training session for the new LG 1750-SX was held for 10 of A.W. Leil’s operators, with further sessions set to take place this summer.

purchased that 600-tonne crawler crane. Knowing that we have this crane, developers can now plan and think about projects in a certain way they previously couldn’t.”

Local impact

While their latest crane ensures that A.W. Leil will play a role in whatever comes next for the area’s wind energy sector, it also ensures that any work required on these massive structures after they go up remains not just Canadian, but local.

“It’s one thing to hire a multinational to come in and build your project, but that’s a 20-year lifespan turbine in the air. It’s going to need maintenance, and if the multinational has left, you’ve got nobody,” said Long.

The LG-1750-SX will allow A.W. Leil to perform wind turbine work at a scale not previously seen in the area, but it’s far from a new beginning for the company – rather, the path forward it will help them chart will allow the company to continue to grow alongside the sector and the connections they have cultivated within it over the last several decades.

“Being the first on the block with this machine, we hope this will give us a rolling head start,” said Long. “We have a lot of long-term partners who were there in the early days and are still here now, and that’s where a lot of our confidence comes from: knowing we have great customers and connections, and that they have confidence in us as well.”

RIGHT: A.W. Leil’s newly-purchased Liebherr LG 1750-SX is both the company and Atlantic Canada’s next step toward tackling bigger wind projects in the region’s burgeoning energy sector.

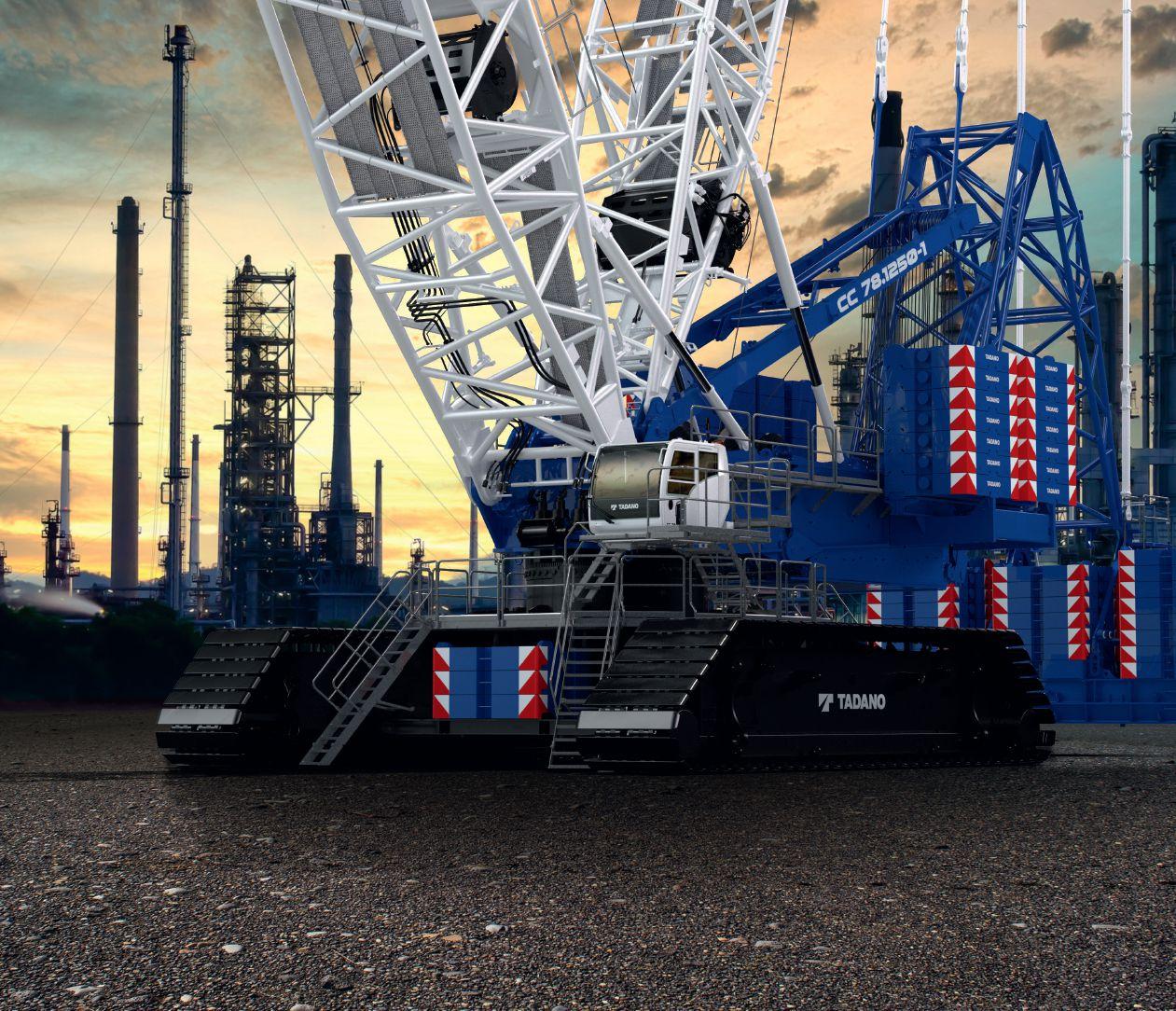

3D LIFT PLAN APP

- Use any device with apps

- Brand new user interface with, integrated access to other apps

- Intuitive controls layout for easy use

JOBSITE

DESIGNER

- 1-Click scaled building creation

- Import CAD object capability

- Draw custom shapes

SKETCH PAD

- Bring in a scaled jobsite with touch of button - Superior annotation tools - Great for field sales teams

RIGGING DESIGNER

- Point, click, drag, and drop rigging components

-Create save simple or complex rigging for any lift equipment

The big easy

Following the successful delivery of the crane to the east coast, A.W. Leil held a weeklong training session on the machine for a team of 10 operators ranging from energy sector veterans to a first-year apprentice from the local International Union of Operation Engineers chapter.

“He expected to be sweeping the shop floor and doing other ‘new guy’ type tasks, and now he’s going to be spending the summer alongside this world-class crane,” said Long.

Training involved a Liebherr representative taking the team through the ins and outs of the machine, and will continue in the coming months through ongoing sessions centered around repair and troubleshooting measures.

Long remarked that beyond its massive size, the A.W. Leil team was most impressed with the transportation efficiency of the machine. The crew found the machine’s processes to be much more efficient when it comes to set-up and travel between tur-

bines, he said.

“[Liebherr] took a lot of user-friendliness into account when designing the machine, and the guys were remarking last week about some of the improvements over the 600-tonne that we have now,” said Long. “They’re just finding it easier on their bodies, and they like how it can move itself to the next site partially assembled.”

A.W. Leil’s set-up process for the LG1750-SX involves two 200-tonne mobile cranes for assembly and installation of the boom and counterweight; a process that takes roughly four to five days. Travel to additional turbines after the first on a wind energy site only requires a partial disassembly, removing counterweights prior to transportation while leaving the outriggers and a portion of the short boom untouched.

Breezing forward

Even with their fleet’s new headliner star, wind still remains just one aspect of A.W. Leil’s heavy lifting jobs across Atlantic

BELOW: The reach of renewable energy’s impact on the crane industry travels beyond Atlantic Canada, with Long believing wind, solar, and eventually hydrogen to be well on their way to playing major roles for lifting operations across Canada.

Canada: while Long makes it clear that his company is just as committed to turbine assembly as it is to the daily grind of taxi crane work, he highlights that Canada’s renewable energy sector is only set to grow in the coming decades, and with it, the role it plays in A.W. Leil’s contracts.

“I certainly track the Atlantic Canada projects a lot more closely than others –there are, give or take, 500 turbines standing in Atlantic Canada right now, and my tracking sheet shows over 1,200 that are proposed,” Long shared. “It sounds outlandish to even say that number! But, if a third of those happen, we’ll be thrilled.”

A.W. Leil’s positioning on the East Coast may give them a certain home-field advantage when it comes to these projects, but Long clarifies that the renewable energy sector is well on its way to bring big impacts to the crane and heavy lifting industries of provinces across Canada.

“I think it’s sort of the next era for crane requirements,” said Long. “I don’t think we’ll be building many new refineries, or certainly not coal-fired plants in the next while, so I think wind, solar and then eventually hydrogen could be the game changers.”

Mi-Jack Canada is your authorized Manitowoc® and Grove® Distributor in Alberta & Saskatchewan.

New and used sales, rental purchase options, unsurpassed customer support, and factory-trained service technicians. As part of the Lanco Equipment Group, Mi-Jack Canada is part of the world’s largest Manitowoc dealer group, and North America’s largest parts inventory, all on-hand and ready to ship.

New and used Manitowoc and Grove Sales, Rentals, Parts and Service. Serving Alberta and Saskatchewan.

Safety and belonging on the jobsite

Panel discussion covered mentorship, unconscious bias and women’s PPE as part of Women in Construction 2025.

By Crane & Hoist Staff

On March 3, leaders from across Canada’s construction industry gathered online for Annex Business Media’s fifth annual Women in Construction virtual event, tackling topics such as inclusivity in training and the transition from the jobsite to the board room.

As part of the afternoon’s events, BC Crane Safety’s field OHS advisor Jen Mutas led a panel exploring the intersecting issues of safety and belonging on the modern construction jobsite, discussing the impact an inclusive work environment can have in protecting your workforce.

Mutas was joined by Dianne Finnigan, CEO of women’s PPE company the Dirty

Jen Mutas, field

Seahorse and Andrea Martin, a district sales manager for construction and industrial safety supplies provider White Cap with a background in fall protection, to share their experiences protecting the safety of women in construction by creating a sense of belonging.

MUTAS: Could you each share a little bit of information about your role and organization, along with why you chose health and safety as a career path?

FINNIGAN: I am the CEO and founder of the Dirty Seahorse. The company came about after my daughter’s experience in masonry school at Conestoga College. When we went to go get her workwear, we

“It’s 2025: we, as females, should be able to walk onto a job site and not be looked at as just our gender,” said White Cap’s Andrea Martin. (PHOTO: WHITE CAP)

soon discovered there wasn’t any available for her, and if we did find it, it didn’t fit her properly.

After we discovered this, we started what I thought was a one-off, but it turned out to be way more than that. I knew workwear to be a huge problem for women in skilled trades, and it astounded me that nobody had tried to address this problem for women, so I took it upon myself.

I did nine months of market research, and we soon discovered that this was in multiple trades across multiple industries. I decided to go back to school for a year, and I learned how to sew, do patternmaking and garment construction.

We did the prototypes here in Canada and involved women in skilled trades –

After her daughter struggled finding properly-fitting workwear, Dianne Finnigan returned to school and taught herself sewing and garment construction to help launch the Dirty Seahorse. (PHOTO: THE DIRTY SEAHORSE)

OHS advisor at BC Crane Safety and moderator for Women in Construction’s Safety and Belonging in the Workplace panel, shared that inclusivity doesn’t just come from policies, but participation. (PHOTO: BC CRANE SAFETY)

WOMEN IN CONSTRUCTION

“Looking at the workwear aspect of belonging, it should be like you’re wearing your favorite dress: it makes you feel great and in turn, it makes you feel confident. From workwear to work environment, you should feel the same if you belong.”

- Dianne Finnigan

they are the backbone of this company, so we involved them every step of the way. They chose the features they wanted and needed, and we also sent it out to apprentices who tested it in the field.

MARTIN: I am currently a district sales manager for White Cap Canada, a construction and industrial distributor based in Ontario. I started my career 20 years ago in glove manufacturing, and I’ve mostly focused on the safety world, mainly in the world of fall protection. No pun intended, but I literally fell into it. I love puzzles, and I found the world of fall protection and rescue was all about putting all those perfect puzzle pieces together; it’s very solution-based. That’s really been my focus for around the past 18 years.

MUTAS : I want to really get an understanding about what belonging looks like to you – or, more importantly, feels like – and how you see safety and belonging supporting one another.

MARTIN: When I look at it, belonging simply means a sense of fitting in or feeling like you’re an important member of a group. Many have experienced a sense of not belonging at some point, whether it was a bully in school or even in the workplace. Without a sense of belonging, not only can your mental health be affected, but if you’re not focused on the task at hand, this can become a safety issue. It puts people into jeopardy when we’re focusing on something, whether it’s a bully or sexual harassment. Our focus, and our biggest concern, is getting hurt on the job. We want everybody to go home safe.

Recently, I read an article that articulated the meaning of belonging to a T for me. Tracey Paulo-Brown, the director of talent, attraction and diversity at Rexall, broke down belonging in this way: she said that diversity is being invited to the party, inclusion is being invited to the dance, and equity and belonging are about dancing as if no one is watching and judging.

FINNIGAN : You’re absolutely right about the belonging and mental health part, because if you get into a toxic situation or toxic work environment, it does affect your mental health and

you become paranoid. You’re constantly looking over your shoulder for what’s coming next.

It’s about feeling secure. Looking at the workwear aspect of belonging, it should be like you’re wearing your favorite dress: it makes you feel great and in turn, it makes you feel confident. From workwear to work environment, you should feel the same if you belong.

MUTAS : Are there any initiatives that you’ve been a part of or seen from other companies that look to increase safety through cultivating this belonging?

FINNIGAN: One of our pillars for the Dirty Seahorse is that we make it our mission to advocate on behalf of women in skilled trades. We educate employers and women working in the trades with proper fitting workwear, and we also advocate to the federal and the provincial governments.

We had the privilege of being invited to Parliament Hill, and we actually got to sit down with three members of Parliament that sit on the Standing Committee Status on Women and explain to them all the problems associated with women’s workwear.

MARTIN: Mentorship has always been huge for me. I wouldn’t be in the world that I am, under the fall protection side, if it wasn’t for a male advocate who believed in me: he didn’t discount me as a female and he answered all my questions. Mentorship, allyship and advocacy in the workplace have always been very, very important initiatives.

At White Cap, we have a ‘Build Her’ community committee, so we focus on a lot of internal female employees and mentor-mentee events. When I worked at 3M, we had a Women’s Leadership Forum. The focus within these groups is to build that sense of confidence, mentorship, empowerment and growth. As we’re bringing in new or younger women, we want to help them grow that self-confidence right from the beginning.

It’s 2025: we, as females, should be able to walk onto a job site and not be looked at as just our gender. It should be like, ‘Okay, this person’s walking onto the job site. I don’t care if their name’s Jen, Dianne or Andrea. They have the skills, just go and just do your thing.’

- Andrea Martin

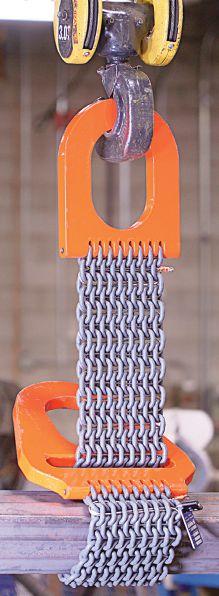

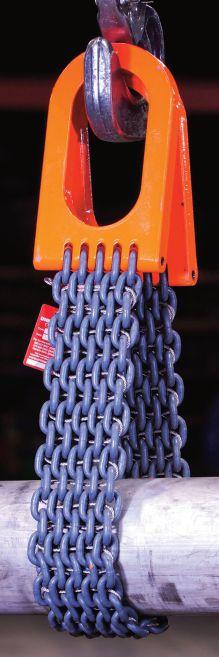

Chain Mesh Slings

MUTAS: I think we all understand that companies can implement the policies and procedures regarding this topic from the top down, but it isn’t complete until you get at least a majority buy-in. That comes from conversations when you’re together.

In noticing things that aren’t right, you should make everybody feel confident enough that if they do have an issue, they can go to their superiors and say: ‘This is my experience, it’s not good and we need to do something to make sure it doesn’t happen again.’

Andrea, what has the push towards safety and belonging on the jobsite looked like across your experiences? Has the approach been proactive or reactive for the companies that you’ve been involved with?

MARTIN: In the companies that I’ve been a part of, it’s always been proactive. When I’m out on jobsites, though, I can see some pushback. Sometimes guys would be like, ‘We get it, girls are joining. What else do you want us to know?’ While it is a constant conversation, that’s because it’s a conversation worth continuing.

It’s 2025: we, as females, should be able to walk onto a jobsite and not be looked at as just our gender. It should be like, ‘Okay, this person’s walking onto the job site. I don’t care if their name’s Jen, Dianne or Andrea. They have the skills, just go and just do your thing.’

MUTAS: What are some obstacles or oversights you’ve experienced in creating that sense of belonging, and how can they be avoided?

MARTIN: As a female, sometimes we feel like we have to know everything, because we need to have the answer right there, right then to shut down anyone else’s unconscious biases. We have to remove the unconscious bias that sees a female walking onto a construction site and assumes her gender does not allow her to compute the information she’s been trained on.

Figure 1: An example of ill-fitting versus proper-fitting women’s PPE. (Photo credit: The Dirty Seahorse)

A LONG WAY TOGETHER

AIROMAX AM 27

No matter how challenging your needs, AIROMAX AM 27 is your best ally for mobile cranes in industrial applications. The tire is particularly suitable for road usage. Thanks to its All Steel casing and the special tread design, AIROMAX AM 27 provides extraordinary traction along with high load capacity.

AIROMAX AM 27 is BKT’s response to withstand the toughest conditions in the construction industry.

WOMEN IN CONSTRUCTION

I’ve also seen a lack of accountability where bullying or sexually harassing comments are made, and I see it still to this day. It’s not acceptable in this day and age. There are workplace harassment laws and training you’re going through, but they can’t just be buzzwords – they have to be followed.

FINNIGAN: We see a lot of it. Women will come to us, and they’ll share their stories and their experiences with us. Like you both said, this harassment can look like a number of things, and create a number of different types of issues.

MUTAS: Something that seems so far-fetched, but unfortunately is a reality, is the power of knowing your company’s health and safety manual and policies around this topic. It’s pretty satisfying to be able to slide that piece of paper across the table to a supervisor or owner and say, ‘This is actually your rule. It’s not mine, I’m just trying to follow it.’

With women’s PPE, could you explain how moving away from a ‘one-size-fits-all approach’ can help women feel a greater sense of belonging in the workplace?

MARTIN: As Dianne said before: clothing that fits is a confidence booster. When that clothing fits? One, you feel confident. Two, you feel safe, which adds to the confidence. I think it’s so important that we’re looking at women’s workwear.

At White Cap, we’re in the process of putting together a whole women’s workwear component. We have a lot of women in the field, and we deal with a lot of women on a daily basis. We don’t want women to be out there looking like they just put on their dad’s outfits.

MUTAS : I hate that it’s still a topic of conversation, but it is important to talk about, because like a lot of the things we’ve discussed today, it’s not quite fixed yet.

When I was up in the oil patch, I was given a very large piece of men’s PPE. The tool crib guy said, ‘You’re lucky you got some meat on your bones, you’ll be able to fill this out pretty good.’ Bless him – I believe he thought that was a compliment – but it was the furthest thing from it.

Joe Dias Eastern Zone Manager

Directeur Régional, Est du Canada

BKT Tires (Canada) Inc.

Cell: 514-792-9220

Web: www.bkt-tires.com

FINNIGAN : This is Isabella [see Figure 1, page 19], and I met her at the Toronto Airport. She shared that her company provided her with XXXL men’s workwear. I ended up giving her a pair of our overalls to try on at the airport, which she did. She was ecstatic; she couldn’t believe the fact that they actually fit her in all the right proportions.

Along with the proper protection it provided, it also let her focus on safety on the jobsite. Now that she had something that fit, her focus is on the job, not on adjusting her workwear across an eight to 10 hour shift.

We’re working our tails off, and we come to this place that’s supposed to provide us with personal protective equipment. I’m supposed to be protected when I put this on. Meanwhile, I’m swimming in it.

I feel like if we show up in clothing that’s that doesn’t fit us properly, it also might support the narrative that we don’t belong there. The talk around the site would be how you’re probably wearing your dad’s or husband’s coveralls, and we don’t need that.

This discussion has been edited and condensed. To view the full panel and other sessions from the Women in Construction virtual event, please visit women-in-construction.ca.

KNOWING THE ROPES BY JUSTIN BROWN

Training scripture

Training should never be aligned with profit and loss, and a robust in-house program is essential.

If a company is selling safety-related products, particularly those with limited alternative paths to obtain use and inspection knowledge, it has a responsibility to support its customers with training. Providing guidance and hands-on education ensures that customers are not only using products correctly, but are also prioritizing safety in their operations.

Yet, training is a subject that often gets misconstrued. The first and often overlooked truth about training is that it must be separated from revenue. There are exceptions but generally, companies that are engaged in the lifting and rigging business should not look at training as an expense or opportunity to make money. It’s beyond that.

Do we charge for training courses? Yes, but these fees are designed to sustain the program; our priority is sharing knowledge and promoting safe lifting practices. Training allows us to contribute to the industry and build deeper relationships with our customers, aligning with our overall mission of safety and expertise. If that positively impacts the bottom line as a by-product, so be it.

The second crucial fact about training is that a business has to take ownership before pivoting outwards to take its community with it, and that’s really the crux of this article.

Having a dedicated facility on site is hugely beneficial. A training centre provides tools, space and resources for developing skilled employees. Hands-on workshops and real-world scenarios help workers identify safety hazards,

A dedicated training facility – such as Unirope’s new Mississauga, Ont. training centre – “fosters a mindset centered around learning and improvement,” says Justin Brown.

(PHOTO: BRIDGER HOWES)

leading to fewer mistakes, less downtime and a stronger reputation for quality results.

Our new training centre, for example, has been a fantastic addition to our operations and is ready to accommodate the diverse needs of our clients.

We have excellent flexibility in scheduling, tailoring courses to fit the unique timelines and demands of our customers.

This ensures that they can access high-quality training on

Opening a training centre

their terms, and our team can dedicate the time and attention needed for personalized, impactful learning experiences.

A dedicated training facility fosters a mindset centered around learning and improvement. It sends a clear message to employees and customers that safety, skill and professional development are priorities. Regular exposure to this commitment to education fosters a culture of account-

ability, encouraging adherence to the highest standards and awareness of best practices.

Targeted, practical content

Having a structured, in-house training program is invaluable. A ‘training bible’ standardizes knowledge, ensures safety protocols are followed, and provides a resource for new and experienced staff alike. It also fosters a culture of accountability and professionalism. At my company, we’ve found that this approach significantly enhances operational quality and safety.

While an organizational training program is crucial, quality over quantity is essential too. Rather than overwhelming participants and staff with endless material, our approach is to provide targeted, practical content tailored to their needs. The industry evolves constantly, with advancements in technology, changes in regulations and new safety challenges.

Continuing professional development helps even seasoned professionals refine their skills,

While the decision to develop such facilities depends on resources and demand, companies dealing in safety-critical products should see it as a vital part of their commitment to customer support and industry standards.

Start by identifying specific needs and objectives. Conduct an internal audit to pinpoint skill gaps or areas where safety could improve. Partnering with a reputable training provider is a great next step, especially if they offer customized solutions.

Remember, a training centre is just a dedicated space. The cornerstones will always be the programs and the instructors. To elaborate, effective training starts with thoughtfully designed programs tailored to address real-world challenges and customer needs.

And then there’s the instructors. Trainers should bring extensive industry knowledge and hands-on experience to the table, ensuring that every course is relevant, practical and impactful. This personalized approach, combined with a strong focus on quality and engagement, sets effective training apart from simply setting up a room with basic equipment.

Commit to consistency. Training shouldn’t be a one-off event, but an ongoing process.

stay updated and adapt to changes.

It is a good idea to take it a step further and develop inhouse training materials. Our flagship course, ‘Prevention of Rigger Mortis,’ and other modules are designed for hands-on learning, with a focus on safety, compliance and real-world application.

This course was developed in response to a clear industry need for practical, tailored training in rigging safety. Its name is a playful nod to serious workplace risks, emphasizing the importance of awareness and proper rigging inspection and practices.

The course combines foundational rigging concepts with hands-on workshops, ensuring participants leave with action-

“Generally, companies that are engaged in the lifting and rigging business should not look at training as an expense or opportunity to make money. It’s beyond that.”

able skills they can apply immediately in the field. The course was originally developed by Mike Riggs at Slingmax Rigging Solutions and has since been enhanced by our team.

Individuals are inescapably central to training strategy and development; it must be a collaborative effort. Our rigging consultants, who work directly with customers in the field, lead most of our sessions. Our spe-

cialized Wire Rope program is conducted by either Knut Buschmann, our head of engineered product development, or me. Scott Fleming, director and sales / rigging training manager, oversees everything, ensuring our courses are tailored to industry needs and remain relevant and impactful.

We can’t talk about training without acknowledging the importance of third parties,

which have a role to play in providing content and certifying industry materials. Third parties serve as trusted sources of certification, lending credibility and assuring compliance with industry standards. They can also bring in specialized content where necessary. The National Commission for the Certification of Crane Operators (NCCCO) and the Lifting Equipment Engineers Association (LEEA) especially uphold the highest standards in lifting and rigging education to enhance our offerings.

Justin Brown is the president of Unirope Limited, a Canadian company focused on the training, testing, and distribution of wire rope and rigging products. Brown holds active memberships with the AWRF and OIPEEC.

Lifting careers, building futures

Global Lifting Awareness Day 2025 looks to elevate the industry’s next generation this June.

By Jack Burton

June 12 marks 2025’s Global Lifting Awareness Day (GLAD), with the Lifting Equipment Engineers Association (LEEA) centering this year’s installment on the growing issues surrounding the labour pipeline and skills shortages through its theme of ‘Lifting careers, building futures.’

As part of its focus on these issues, GLAD is promoting practical tools for attracting new talent, along with strategies for inspiring the next generation of lifting professionals through initiatives such as a global survey for members of the lifting industry and a webinar presentation on the day featuring Ross Moloney, CEO of LEEA.

In anticipation of this year’s GLAD, we caught up with Moloney to discuss the inspirations and goals behind this year’s theme, and how LEEA is approaching the day as a springboard to solutions for the sector’s struggles and shortages surrounding the global workforce.

CRANE & HOIST CANADA: What inspired this year’s theme for GLAD, ‘Lifting careers, building futures?’

MOLONEY: Well, there’s sort of two main reasons for it. The first is, when you represent an industry as diverse as ours, let alone as global as ours, trying to find an industry theme is quite a difficult thing.

For instance, I run a global organization headquartered in the UK, but I’ve got more members outside of the UK, so you’re always really cognizant of focusing on big picture, global issues and not just wanting to be a national trade association.

Wherever I go in the world, I speak to a lot of managing directors and owners. When I’m trying to get to know them a bit better, I will say to them, what is it that keeps you up at night? Universally, there’s worry about where the next generation or workforce is going to come from.

But it’s also really worrying that that we

For LEEA CEO Ross Moloney, GLAD 2025 isn’t just about industry awareness, but also shining a light on the struggles and solutions to labour and skills shortages in the global lifting industry. The 2025 installment of Global Lifting Awareness Day includes initiatives such as a global survey on lifting’s labour issues and a webinar discussing the topic on June 12. (PHOTO: LEEA)

can’t recruit new entrants in an engineering sector that pays well and takes you literally around the world. We were talking about that here at LEEA and asked ourselves, are we going to just sit and worry about it, or are we going to try and do something about it?

We’re talking about how we might be able to engage with young people, and we’re talking about how we might be able to catch them before they go on a career trajectory, as well as how we might be able to support them in some sort of transition.

But that only tells half the story, because that’s very much about glamourizing an industry which sometimes isn’t always glamourous. The other side looks at how we can work with our members to broaden where they go looking when they are starting to recruit.

I was in Scottish Parliament last week talking to members, and it’s amazing how recruitment in lifting seems to be through family and friends. So, we’re actively going to be pushing messages this year about looking to other pools of talent.

To answer your question, how did we get to it? We’re a trade association, and we’re here to listen to our members, and their number one challenge is, ‘Where’s the next generation going to come from?’

CHC: Given your role as the CEO of LEEA, what is your firsthand perspective on these labour trends and their direction into the near future and beyond?

MOLONEY: In terms of recruitment, wherever you are in the world, all roles from operator, inspectors to examiners, are at an absolute premium. There are real gaps in employment for operators of equipment.

From my perspective, something I noticed that other people might not be overly interested in, but I think is an important part of the industry moving forward, is there is a real shift away from this generation of experts that worked in standardization and the harmonization of standards.

A lot of these experts are reaching the end of their working careers, so LEEA’s focused

“GLAD is an awareness day where we speak outside of our echo chamber, where we speak to people who have never thought about lifting and remind them that what we do is foundational to everything that happens.”

– Ross Moloney, CEO of LEEA

Those stakeholders are policy makers, the firms in our marketplace, and trade associations. Looking at what’s different the day after might be a bit soon to see that change, but in terms of the impact of it, if nothing’s changed in six months or a year? Then frankly, we’ve wasted everybody’s time. What LEEA expects to get out of this piece of analysis is a clear direction on the product, services and solutions that the association must be delivering.

on filling that gap. We’re becoming a bit worried about the quality of harmonization and standardization work.

Standardization matters because it’s an important way to assure safety across the globe, and the harmonization of those standards matters because it shortens down supply chains – people can trust the product that comes to them from wherever it is.

When harmonization happens at LEEA, we feel like we’re stepping into the breach a bit, because employers are under so much pressure that devoting time pro bono to standardization work is problematic, and the sort of people that are a real value to that consultation process are probably the ones that you can least do without in your workplace.

It’s a difficult thing to navigate, because what we’re saying is we need more of their time, but their employers are saying that there’s less of their time available. That’s something I’ve really noticed at LEEA, is making sure that there is expertise that is influencing and investing in the future of the industry.

CHC: Could you talk about the webinar and industry report component of this year’s GLAD? How do each of them serve to further GLAD 2025’s messaging?

MOLONEY: Something we were keen to do this year is to create an evidence-based argument for these issues and any potential solutions. Everybody has an opinion, but what we’re trying to do in this survey is to create an evidence base so that the recommendations that we make to others come from somewhere that can be trusted.

We are not here to make or win arguments – we’re here to identify what the industry says. The survey has deliberately been created so that it’s not burdensome: filling it in will take 15 minutes of somebody’s time to complete, and we’re aiming for between 500 and 1,000 respondents. In the week since we’ve

launched it, we’ve hit 200 responses, so it feels as if we’re going to get a really critical amount of info to help us be confident in our conclusions.

We’re going to be launching a webinar where we talk about what the industry has identified, and there’s several reasons that we’re doing that. The first is, GLAD is an awareness day where we speak outside of our echo chamber, where we speak to people who have never thought about lifting and remind them that what we do is foundational to everything that happens.

I was with a member of LEEA last week who reminded me that nothing happens unless it’s welded, bolted or lifted. That’s something that the world in general would do well to remember, that if it’s not welded well or bolted well or lifted, it won’t happen.

The second part is reminding members of the things that they probably already know, but giving them the confidence to act on that information. That will help them with their own plans, whether it be recruitment, training or any other plans for their business where there are gaps or opportunities.

The third point is that we’ll be inviting stakeholders from across the world. Whether it be the Ministry of Manpower in Singapore, departments here in the UK or colleagues we work with globally, we will deliberately be showing them evidence of what’s needed in our industry.

CHC: Could you go in depth about this report: what are some of the data points you’re looking for insights on, and how is this research is being conducted?

MOLONEY: To me, there’s no point doing research if it doesn’t result in some sort of change. When we were putting together the survey, it was all about how we can we identify what good change looks like – this one has deliberately been framed as a tool that will help stakeholders.

So, what’s the point of the survey? To make the industry safer, and how we make the industry safer will be informed by the gaps and the shortages that we identify. Effectively, it’s an audit.

CHC: To leave us off, do you have any key insights or advice for readers whose organizations might be struggling with these labour shortages?

MOLONEY: I really believe in upskilling your current workforce. It can be quite easy when you’re in a leadership position to think that the grass is greener, and you can just go to market to recruit. However, it mirrors the question of, is it easier to find a new client or to keep a current client?

Upskilling a current workforce really should be where people start; it really makes sense. Upskilling is something that sometimes sounds hard to do, but there are associations – obviously, I’ll say LEEA is one of them – that have training packages in place that will help upskill your current workforce; it doesn’t have to be expensive.

My other piece of advice goes back to that quote about the definition of insanity as doing the same thing over and over and expecting a different result. We all know how we recruit, yet we all talk about how hard recruitment is. I think now might be the opportune time to think about how we’ve been doing recruitment, and where are we doing recruitment.

It’s not always about finding somebody that’s 18 – I don’t think I knew what I wanted to be when I was 18, and I’m not sure many people do.

When we talk about pathways into the industry, sometimes it should be a crossover pathway.

Two things that I hope to push out of this is answering how we can better support companies to upskill their current workforce, but also how can we encourage our workforce and employers to think differently about how, and who, they recruit.

Diamonds in the rough

Tackle

tasks in the toughest environments with our rough terrain crane roundup.

By Crane & Hoist Staff

Canada’s diverse landscapes are a cornerstone of its national identity, but accommodating the vast array of environments found between the Atlantic and Pacific coasts can also present an obstacle to building the projects and infrastructure needed across its provinces. One solution? Rough terrain cranes.

From helping install the heavy equipment needed on the oil sands of Alberta to moving materials through the dense forests of Quebec, the adaptability of these cranes is essential to conquering the diverse range of the country’s industries and terrains when it comes to bringing productivity to your project.

Designed to withstand the challenges brought on by harsh environmental conditions and uneven, off-road sites, rough terrain cranes bring safety and efficiency to even the most rugged jobsites and projects.

The last year has seen a number of updates and changes to the lifting equipment world’s rough terrain offerings, with the introduction of North America’s first fully-electric rough terrain model and newlylaunched updates to rough terrain lineups. Check out our showcase of these latest offerings below.

Tadano EVOLT

Tadano launched the first fully-electric RT crane in the North American market with its new 100-ton capacity EVOLT eGR-1000XLL-1 , re-

vealed in late 2024.

A zero-emissions upgrade to Tadano’s GR-1000XLL-4, the new eGR comes with an onboard battery pack that can power up to seven hours of lifting, or up to five hours of lifting when combined with up to 8.85 miles of jobsite travel.

The crane features a main boom length ranging from 12.8 to 51 metres, with boom extension available between 10.1 and 17.7 metres. The eGR-1000XLL1’s maximum tip height sits at 68.3 metres, with the machine able to reach a maximum radius of 57.91 metres.

The eGR-1000XLL-1’s

high-performance lithium-ion battery eliminates fuel use, leading to annual CO2 emission reductions of up to 22,000 kilograms. The crane can be charged on a 480 VAC grid power or a CCS1 rapid charging system, with a charge time of 4.5 to 5.5 hours on a normal system and two to three hours when using a rapid charging system.

The crane’s battery power source also leads to significant reductions in operating noise when compared to traditional diesel-powered machines, with this quieter performance optimal for work in urban environments and areas with noise regulations.

A number of software solutions come packaged with the crane to drive operational efficiency and safety. This includes Tadano’s Lift Visualizer program, which uses a camera to allow operators to monitor suspended loads from above. The crane also uses a number of programs for monitoring and diagnostics, such as Tadano’s EVOLT App, the AML Control System and the HELLO-NET telematics system.

Terex TRT series

Terex expanded its TRT series

with the addition of three new models to the line over 2024: the TRT 60, TRT 80L and TRT 100.

The TRT 60 features a five-section, 42.5 metre-long main boom, and is rated at a 2.3-metre radius with a maximum capacity of 60 tonnes. When fully extended, the main boom can handle up to eight tonnes at a radius of up to nine metres. Maximum tip height can be increased to 60 metres with an eight to 15-metre bifold swingaway extension.

Both the TRT 60 and TRT 100 are the first two Terex RT models to include the IdeaLift

Designed to withstand the challenges brought on by harsh environmental conditions and uneven, off-road sites, rough terrain cranes bring safety and efficiency to even the most rugged jobsites and projects.

The Tadano EVOLT eGR1000XLL-1 is North America’s first fully-electric RT crane.

(PHOTO CREDIT: TADANO)

The Terex TRT 80L is one of three new additions to Terex’s rough terrain line from 2024.

(PHOTO: TEREX)

variable asymmetric outrigger platform for set-up and monitoring. Through IdeaLift, the crane automatically selects the ideal lifting capacity based on the deployed outrigger setup.

The machine, alongside the TRT 80L and TRT 100, all feature the wider-sized S-Pace cab to accommodate operators, along with Terex Operating System (TEOS) controls, a 10-inch full-colour touchscreen display and Terex’s T-Link telematics system.

Despite the larger cab, the crane retains an overall width of three metres for efficient transport. All machines are powered by a Cummins Stage V diesel, with a Cummins Stage III/Tier 3 engine also available in certain markets.

The TRT 80L is an upgrade of the line’s 80-tonne capacity TRT 80 model that extends its boom from the previous model’s 42 metres to 47 metres. The five-section main boom comes with three extension modes, along with a self-remove and install counterweight system. Tip height can be increased to 66 metres with a nine to 17-metre bi-fold swingaway extension.

When fully equipped with hook blocks, rigging and the bi-fold extension, the TRT 80L has an overall weight of 52.5 tonnes; dropping to 42.5 tonnes with the removal of counterweight and extension.

Terex’s 100-tonne TRT 100 features a 47-metre, five-section main boom with three telescopic modes, with a capacity of 8.9 tonnes when the boom is fully extended to its 12-metre radius. As with the other models, a bi-fold swingaway jib is available to extend the boom’s maximum tip height to 66 metres.

The machine’s 10-tonne counterweight can be self-installed, and when removed can reduce the TRT 100’s trans-

port weight to 43.25 tonnes. When stowed for transport, the machine has a width of 3.17 metres, a length of 14.1 metres and a height of just under 4 metres.

Grove GRT7 series

Manitowoc’s GROVE brand launched two additions to its GRT line-up of rough terrain cranes toward the end of 2024, the GRT765 and GRT780, with both models upgrading previous RT cranes from the company.

The new GROVE Connect telematics and fleet management system, launched in 2022, makes its debut on both of these machines.

Other updates featured across both models include a winch/hoist with a single pull of 7,800kg, GROVE’s MAXbase variable outrigger system and a 12-inch touchscreen CCS display.

The models also feature a number of operator quality of life improvements over their predecessors, including a slightly wider cab with up to 20 degrees of tilt, along with an all-around three-camera visibility system. Both models stand at a width of three metres.

The GRT765 updates the RT765E-2, extending the previous model’s 33-metre main boom out to 38.5 metres.

The length of the four-section boom can be extended to 58.5 metres through a 10.1 to 17.1 metre bi-fold swingaway jib.

The machine has a capacity of 65 tonnes at a 10-foot radius and 58 tonnes at a three-metre radius, with a full boom length radius of 33 metres that can handle up to 656 kilograms.

The total weight of the GRT765 is 42.4 tonnes, including a 6.9-tonne counterweight, with an overall width of three metres. An optional hydraulic counterweight removal sys-

The GRT780 is one of two new updates to GROVE’s rough terrain line from last year, replacing the RT770E and GRT880 models.

tem is also available.

The GRT780 was launched as a replacement for GROVE’s RT770E and GRT880 models.

The updated crane features a five-section full power boom with a length of 47.3 metres and a maximum tip height of 67 metres, with a maximum load capacity of 80 tonnes.

When at full boom, the GRT780 has a maximum capacity of 8.1 tonnes at a radius of

up to 15 metres, with the machine’s full boom having a capacity of 567kg when at its maximum radius of 39 metres.

The GRT780 has a total weight of 45.1 tonnes when equipped with its standard eight-tonne counterweight. Users can increase counterweights up to 9.3 tonnes for added stability, which in turn brings the total machine weight up to 46.5 tonnes.

The CCRA has partnered with ICBA Benefits to introduce an exclusive, members-only group health, dental, and retirement plan. CCRA members can now enjoy highly competitive rates, exceptional service, and the dedicated support of ICBA’s local team. This plan is designed to benefit your workers, their families, and your bottom line.

DICA launches new crane pad, expanded sizes

DICA has announced its new EcoMax crane pad, which features a combination of steel and composite materials, offering DICA’s standard level of performance and durability at a lower cost.

The EcoMax combines the benefits of both of its materials to maximize load distribution, leveraging the stiffness and strength of steel with the durability and longevity of composite materials.

The debut EcoMax model is sized at 24 square feet, with a maximum capacity of 160,000 lbs. The pad is also rated for a “bridge rating” capacity, for scenarios where the ends of the pad are supported by the ground with a gap beneath the center.

The pad is designed to allow its single, rigid body to move uniformly. The design also features a center plate built into the pad, which creates a designated operating area to assist operators with outrigger float placement and makes it easier to optimize load distribution through the placement of the float.

Additional features include built-in lifting lugs, along with a non-slip coating finish on the pad’s steel components for improved friction.

DICA has also expanded its award-winning LevelRight line-up of outrigger pads, with the series now available in four sizes including 12 inches, 24 inches, 30 inches and 35 inches.

All LevelRight pads support rated capacity up to 350,000 lbs. and are adjustable in angles of up to 10 degree in multiple planes. Features such as a built-in bubble level ensure precise adjustment for safe and level set-ups on uneven terrain.

Pads are made from DICA’s durable SafetyTech material, which includes added texturing for enhanced grip. The new expanded sizes added to the line are able to accommodate larger outrigger floats and other specialized equipment requirements.

LevelRight pads can also be used as a base for DICA’s ProStack cribbing blocks in set-ups that require extra height while keeping equipment level.

“An out-of-level setup not only increases the risk of tipping but also leads to operational inefficiencies and accelerated equipment wear. The expanded LevelRight lineup provides crane operations with a fast and reliable solution to stabilize outriggers on unlevel terrain –eliminating the need for time-consuming site modifications like digging, wedging, or shoveling,” said Kris Koberg, CEO of DICA.

Tadano unveils 1-tonne

capacity boom lift for North American market

Tadano launched its AS-63HD boom lift mobile elevating work platform for the Canadian and U.S. markets at bauma this past April.

The AS-63HD has a 1-tonne maximum platform capacity; the first of its kind in North America. Designed for high-reach applications, the lift can reach a maximum height of 19.1 metres and has a maximum horizontal outreach of 11.4 metres.

The model features a mast inspired by rigid cranes, which combines with the four-section synchronized boom to ensure near-zero platform deflection and stability.

Efficiency and operator experience are prioritized through automatic 4-motion controls, 360-degree continuous platform rotation, and a set-up process that can be performed without outriggers or stabilizers.

At 4.2m x 1.94m x 1.1m, the AS-63HD’s platform can support up to 10 occupants, or smaller groups working with heavy tools. The platform also features a 120V AC outlet, with optional generator installation packages also available.

“We believe the AS-63HD is a disruptive product – one that can do work that a traditional boom or scissor lift cannot do alone,” said Erik Elzinga, Tadano America’s vice president of AWP business development for Pan-America operations. “With its 1-tonne capacity and massive platform, it allows contractors to move workers and heavy materials simultaneously, reducing the need for multiple machines on-site.”

The new AS-63HD boom lift mobile elevating work platform from Tadano. (PHOTO CREDIT: TADANO)

Manitowoc reveals new GROVE GHC200 telecrawler

Manitowoc has revealed its new GROVE GHC200 telescopic crawler crane, featuring a maximum capacity of 160 tonnes and a six section, 56.4-metre pinned boom.

Greater overlaps between each boom section can be achieved by pinning each segment at 90 per cent of its full extension, which allows for improved capacity and rigidity. Extensions of up to 21.6 metres can be added to the boom, increasing its maximum tip height to 81 metres.

The GROVE GHC200 telecrawler from Manitowoc.

For more efficient transportation, the GHC200 can be transported across six to seven loads. The crane also includes load charts for working up to four degrees off level.

“As jobs get more challenging, higher load charts are needed to accomplish them. We are excited to bring the GHC200 to the market because it will increase the ability of companies to compete for and win jobs that require higher lifting capacities,” said GROVE’s product manager JJ Grace. “It is an ideal crane for general construction and renewable energy, for example, because of its strength and increased pick & carry capabilities.”

Liebherr upgrades 120-tonne LTM model

Liebherr’s LTM 1120-4.2 all-terrain crane. (PHOTO CREDIT: LIEBHERR)

Liebherr officially launched its LTM 1120-4.2 all-terrain crane at bauma 2025 in Munich this April.

The model is an updated version of its LTM 1120-4.1 AT crane and will feature Liebherr’s proprietary Liccon3 control system. The system offers faster data processing and expanded memory compared to its predecessors, with fully-integrated telematics and fleet management features.

The suite of Liccon3’s features, which also features a central lubrication system and digital tire pressure monitor, can be controlled by operators through a new touchscreen display.

Similar to its predecessor, the LTM 1120-4.2 is a four-axle crane with a seven-section, 66-metre main boom and 10.8- to 19-metre bi-fold swingaway extension. Along with the upgraded Liccon3 system, the new model also features enhanced driver assistance systems, a newly-designed cab and TraXon DynamicPerform clutch system.

MARKETPLACE

CRANE

SAFETY CORNER

BY ALBERT WANG

Navigating the terrain

Safe and efficient operations for rough terrain cranes and telehandlers.

Rough terrain (RT) cranes and telehandlers are the workhorses of off-road construction, designed to tackle the toughest jobs in challenging environments where traditional equipment might falter, such as steep slopes and unstable ground. However, their effectiveness hinges on proper setup, operation and maintenance.

ACCESS AND EGRESS:

The step to safety

Getting in and out of equipment can be as hazardous as operating in off-road environments. Uneven terrain, mud and debris can turn a simple step into a slip-and-fall incident. For RT cranes and telehandlers, operators must ensure that steps, handrails and platforms are free of obstructions and slip hazards.

Always maintain three points of contact when climbing in or out of the equipment. If the manufacturer’s design doesn’t account for extreme conditions, consider adding non-slip surfaces or additional handholds. Proper access and egress practices not only prevent injuries but also set the tone for a safety-focused workday.

SETUP:

Stability is key

Operating on uneven ground or steep slopes is one of the most challenging aspects of equipment operation in construction. RT cranes and telehandlers are designed for such conditions, but their stability depends on proper setup and adherence to manufacturer guidelines. Before positioning the equipment, conduct a thorough hazard assessment along all points of travel and your different work areas. Identify slope-related risks and develop a lift plan that includes control measures. Use inclinometers or built-in slope indicators to ensure the machine is within the manufacturer’s recommended limits.

Always keep the load downhill when operating on slopes and avoid sudden movements. Telehandlers carry the load low and close to the machine to maintain stability. Remember, even the most robust

equipment has its limits – knowing when to stop is just as important as knowing how to proceed.

GROUND CONDITIONS:

The foundation of safe operations

Understanding and evaluating ground conditions is critical for the safe operation of RT cranes and telehandlers. As part of the hazard assessment mentioned in the previous section, operators should perform a site assessment to identify potential hazards such as soft soils, uneven terrain or underground voids that could compromise the equipment’s stability. Soil stability, moisture content and surface uniformity all influence the equipment’s performance. Loose or wet soil can cause the crane to sink or tilt, jeopardizing both the machine and the crew.

BC Crane Safety emphasizes the importance of accurate, up-to-date information about the slope and ground conditions. This data is essential for establishing construction requirements for the supporting surface. A geotechnical report may be required for operation in certain work areas. Consult your supervisor if you have concerns over soil conditions before starting the work.

In winter conditions, frost and ice can further complicate operations. Clear snow and ice from the work area and consider using sand or salt to improve traction. Always monitor ground conditions throughout the day, as they can change rapidly, especially in variable weather.

LEVELLING THE CRANE:

A critical step

Proper levelling is crucial for preventing tip-overs during crane operations. Mobile cranes and boom trucks use outriggers or other stabilizing equipment for levelling. Always follow manufacturer specifications for levelling the crane or telehandler to ensure compliance and safety.

Outriggers should be fully extended beams and placed onto the pads on stable, level ground. If the terrain is uneven, use cribbing or mats to create a stable foundation.

Telehandlers should be equipped with

appropriate tires for the terrain: pneumatic tires for softer ground, and solid tires for rocky or abrasive surfaces.

The cranes and telehandlers’ stability and rated capacity depend on these conditions. Always consult the manufacturer’s specifications for adequate support and degree of level.

PREVENTIVE MAINTENANCE:

The unsung hero

While this article focuses on operational considerations, it’s impossible to overlook the importance of preventive maintenance. RT cranes and telehandlers are subjected to harsh conditions, and regular maintenance is crucial to keep them running safely and efficiently.

Inspect hydraulic systems, brakes and tires before each shift. Check for wear and tear on outriggers and stabilizers, and ensure all safety systems, such as load limit indicators and alarms, are functioning correctly. A well-maintained machine is not only safer but also more productive.

REGULATORY COMPLIANCE:

The framework for safe operations

You must follow the local regulatory requirements for safety devices on RT cranes and telehandlers.