Pacific BioEnergy reduces machine wear with ClassiCleaner

Pacific BioEnergy reduces machine wear with ClassiCleaner

AT PETERSON WE NEVER STOP DEVELOPING THE ULTIMATE INDUSTRY LEADING EQUIPMENT.

For over 35 years, we’ve built our business around building the most productive mobile chipping and grinding machines in the industry. Day after day, we partner with our customers by giving them the best tools for the job and exceptional support when they need us.

Visit us at www.petersoncorp.com today and see why Peterson is the industry leader for disc and drum chippers, horizontal grinders, blower trucks, screens and stacking conveyors.

Get the right sized product, sort it out, and stack it higher with Peterson!

Let us know how we can help grow your business!

Pacific

Surrey Biofuel Facility has set a new bar in waste management. The $68-million facility, located in Metro Vancouver, opened March 9, 2018, and is expected to produce roughly 120,000 gigajoules of RNG and 45,000 tonnes of compost annually.

Cellulose nanocrystals could be the future of concrete. Researchers have had their interests piqued by the small particles, produced from trees, that can drastically strengthen a product.

Local ownership breathed new life into Rentech’s Atikokan pellet plant. Under its new ownership, the Atikokan pellet plant is again fully operational and employs 25 experienced local employees to produce and deliver an Ontario Power Generation contract.

The official show guide for the Canadian Bioeconomy Conference and Exhibition coming to Prince George, B.C., from June 6–8, 2018.

“This ClassiCleaner was a

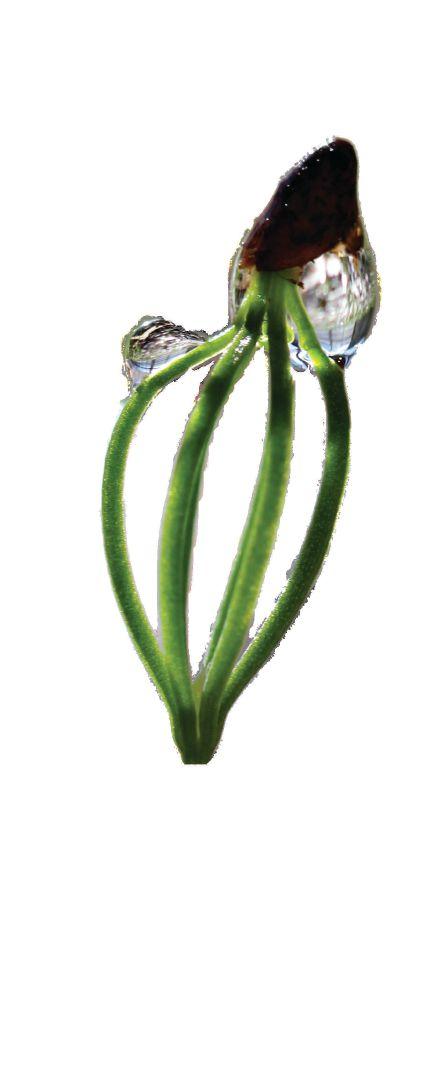

Pacific BioEnergy’s pellet plant in Prince George, B.C., has installed North America’s first ClassiCleaner — a multimillion-dollar installation that uses roller screening and air separation units to filter out contaminants. Vice-president of operations Shawn Bells says maintenance costs will be reduced by at least 10 per cent. Read the story on page 10.

’m a pretty average Canadian, I think. I work Monday to Friday, 9-5, in a medium-sized city, and every spring I pay what feels like a lot of taxes. I respect that the climate is changing, but I’m far from living plastic-free off the grid. I try to recycle when I can, and feel an appropriate stab of guilt when I throw things away.

Us average Canadians know we should probably be doing more, but we don’t want to compromise our lifestyle to do it. So one of two things needs to happen in order for things to change: either the government steps in to force change, or science and technology offer solutions.

Canadian Biomass contributor Lesley Allan. “The trucks are picking up waste, but they’re picking up waste that will ultimately fuel them on a daily basis.”

Lately the federal government has been doing its part. Both the national carbon tax and the clean fuel standard are set to make historic changes to carbon pollution produced in Canada. As I’ve mentioned before and as many readers are aware, this will have a big impact on the Canadian bioeconomy and should spur growth over the next few years.

Science and technology are also making significant and impressive strides right here in Canada. The latest is found in Surrey, B.C. The City of Surrey is now home to North America’s first integrated closed-loop organic waste management system. The Surrey Biofuel Facility turns curb-side organic waste into biofuel for the city’s fleet of natural gas vehicles.

It’s a terrific solution to waste collection and processing that involves little to no effort from the average citizen in Surrey.

“It’s really an amazing example of what a circular economy is,” Michael Leopold, general manager of Renewi Canada – the company that designed the facility – told

The state-of-the-art anaerobic digestion facility has two waste streams to effectively treat wet and dry waste separately. It also uses impressive technologies such as water scrubbing to remove CO2 and other impurities from the biogas, and an odour abatement system that includes several steps to remove ammonia. Read the full feature story on page 13.

Best of all (for Surrey taxpayers), the $68-million facility was built without any expense to ratepayers. Funding came from the federal government’s Public-Private Partnership program, the P3 Canada Fund.

It’s such an effortless solution for taxpayers. Life goes on uncompromised. Once a week, bleary-eyed Surrey citizens wake up early to drag out their trashcans to the curb for the umpteenth time. But perhaps now the weekly routine is carried out with a hint of pride, knowing their black bags are heading to a processing facility rather than a landfill, brought there by trucks fuelled by the very trash they’re collecting.

Congratulations to the City of Surrey for leading the way with this progressive facility. Let’s hope science continues to forge the path to a greener Canada. •

Volume 18 No. 3

Editor - Maria Church (226) 931-1396 mchurch@annexweb.com

Associate Editor - Tamar Atik (416) 510-5211 tatik@annexbusinessmedia.com

Contributors - Gordon Murray, Lesley Allan, Brier Dodge, Robynne Anderson.

Editorial Director/Group Publisher - Scott Jamieson (519) 429-3966 ext 244 sjamieson@annexbusinessmedia.com

Account Coordinator - Stephanie DeFields Ph: (519) 429-5196 sdefields@annexbusinessmedia.com

National Sales Manager - Ross Anderson Ph: (519) 429-5188 Fax: (519) 429-3094 randerson@annexbusinessmedia.com

Quebec Sales - Josée Crevier Ph: (514) 425-0025 Fax: (514) 425-0068 jcrevier@annexbusinessmedia.com

Western Sales Manager - Tim Shaddick tootall1@shaw.ca Ph: (604) 264-1158 Fax: (604) 264-1367

Media Designer - Alison Keba

Circulation Manager – Jay Doshi jdoshi@annexbusinessmedia.com Ph: (416) 442-5600 ext. 5124

COO - Ted Markle tmarkle@annexbusinessmedia.com

President/CEO Mike Fredericks

Canadian Biomass is published six times a year: February, April, June, August, October, and December. Published and printed by Annex Business Media.

Publication Mail Agreement # 40065710 Printed in Canada ISSN 2290-3097

Subscription Rates: Canada - 1 Yr $56.00; 2 Yr $100.00 Single Copy - $9.00 (Canadian prices do not include applicable taxes) USA – 1 Yr $91.60 US; Foreign – 1 Yr $104.00 US

CIRCULATION

mchana@annexbusinessmedia.com Tel: (416) 510-5109 Fax: (416) 510-6875 or (416) 442-2191 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Annex Privacy Officer Privacy@annexbusinessmedia.com Tel: 800-668-2374

Occasionally, Canadian Biomass magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above. No part of the editorial content of this publication may be reprinted without the publisher’s written permission ©2018 Annex Business Media, All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

www.canadianbiomassmagazine.ca

Modern wood heating is receiving a boost in northern Ontario. Biothermic has announced the addition of a second bulk wood pellet delivery truck to its fleet.

Garaged at the Thunder Bay, Ont., office, this brand new international truck is the first of its kind in the region. The truck is equipped with a self-contained silo, blower and on-board weighing system designed and built by Tropper of Austria.

Bulk wood pellet delivery is a key component to the successful development of larger wood pellet boiler systems. Trucks like Biothermic’s provide a direct link between pellet producers and pellet consumers. The new generation of pellet boilers are completely automated and will draw their fuel from a large bulk storage room or silos leading to handsfree heating with wood.

This truck will carry 14,000 kilograms (14 tonnes) at a

B.C.-based pellet producer Pinnacle Renewable Holdings Inc. has entered into a long-term, take-or-pay off-take contract with Ube Industries Ltd., a diversified Japanese conglomerate with annual revenues of approximately US$6 billion.

Under the terms of the contract, Pinnacle will supply 70,000 metric tons per annum of industrial wood pellets to Ube beginning in late 2019.

“Japan has made a strong commitment to decarbonization, and biomass is poised to become an increasingly important part of the country’s energy mix,” said Robert McCurdy, CEO of Pinnacle. “One third of our $421 million in contracted backlog in 2017 was with customers in Japan, and this new contract with Ube further builds on our strong sales momentum in this growing market.”

Pinnacle says demand for industrial wood pellets in Japan is accelerating, supported by the government’s Feedin Tariff system. There are more than 10 new biomass projects currently in late-stage development in Japan.

According to Hawkins Wright, a leading provider of market intelligence and analytical services to the international pulp, paper and biomass industries, the Japanese market represented three per cent of global demand for industrial wood pellets in 2016 and forecasts this market to increase to approximately 10 per cent of global demand in 2021 and 17 per cent in 2026.

time, which is enough fuel to heat two homes for one year. It will be able to access bulk pellets available in Thunder Bay, Atikokan and Hearst.

The truck’s on-board weighing system is accurate to within 10 kilograms, giving it the ability to accurately deliver small loads and large loads while assuring the client with accurate billing.

Pinnacle and West Fraser have begun the conversion of an existing particle board facility in Smithers, B.C., to a wood pellet production facility.

The project under the Smithers Pellet Limited Partnership will be co-owned by West Fraser Timber Co. (30 per cent) and Pinnacle (70 per cent).

Located in northwestern B.C. approximately halfway between Prince George and Prince Rupert, the Smithers facility is connected by direct rail to Pinnacle’s Westview Port Terminal in Prince Rupert.

The plant will have an annual capacity of 125,000 metric tonnes, with production expected to begin in the third quarter of 2018.

Both fibre supply and customer off-take agreements are in place under long-term agreements, the company reports.

“We are pleased to be partnering on the Smithers facility redevelopment with West Fraser. This project will contribute to the economic vitality and job growth of Smithers and other local communities,” Robert McCurdy, CEO of Pinnacle, said in a news release. “We are committed to the numerous communities throughout the Western Canadian fibre basket in which we operate, and we plan to continue to look for similar projects to support our future growth.”

Pinnacle currently operates six industrial wood pellet production facilities and a port terminal in B.C., and, in addition to the Smithers operation, has a new production facility under construction in Entwistle, Alta.

The Ontario government is contributing $8 million in funding for Comet Biorefining’s commercial-scale bio-based ingredient refinery in Sarnia, Ont.

The $79.8-million facility will be the first of its kind in the world. Comet Biorefining uses proprietary ingredient technology to convert of agricultural residues, including wheat straw, corn stover and wood products, into high purity ingredients. The ingredients are used in the food and beverage, animal nutrition

All aboard! Registration is now open for the annual WPAC AGM & Conference. Get the most up-to-date information on wood pellet certifications at this year’s event, Sept. 17–19, in Vancouver.

Our kick off reception takes us off land this year aboard the Magic Charm for a three-hour cruise through Indian Arm — a steep-sided glacial fjord formed during the last ice age.

This two-level yacht has a fully functional bar at the bow with an outdoor seating area perfect for networking and capturing stunning pictures. The second level is a sleek, modern lounge that opens onto a large, outdoor deck that offers the perfect area to mingle, enjoy a snack, and take in the breathtaking views.

Reserve your spot and save with our early bird pricing. Learn more at pellet.org/wpac-agm.

and biomaterials markets.

According to a government news release, the provincial funding through the Jobs and Prosperity Fund will help Comet:

• Grow the agri-based value chain and benefit local farmers by using residues from Ontario’s farming community

• Grow the emerging biochemical bioproduct ecosystem in Sarnia, while further establishing Ontario as a global player in the bioeconomy

• Help meet the growing world demand for biobased products.

Jeff Leal, Ontario’s minister of agriculture, food and rural affairs, said the provincial funds will help position Comet Biorefining to compete globally. “This will in turn help create and retain jobs, boost Sarnia’s local economy and support the competitiveness and further growth of Ontario’s agri-food sector,” he said.

CEO of Comet Biorefining Rich Troyer thanked

the Ontario Ministry of Agriculture, Food and Rural Affairs for their financial support and touted their leadership in making Canada a global front-runner for the manufacturing of bio-based products.

“Once completed, this facility will produce sustainable ingredients for customers across North American and provide a win for local farmers, a win for the environment, and a win for the Canadian bioeconomy as a whole,” he said.

The Ontario government spending $6.7 million on pilot programs that will help northern, rural and Indigenous communities transition from diesel and oil to new, efficient wood and pellet heating systems.

Four new programs are being launched through the Green Ontario Fund (GreenON), a non-profit provincial agency that doles out proceeds from Ontario’s carbon market.

Two Indigenous-led pilot programs will operate in Wiikwemikoong and Nishnawbe Aski Nation (NAN) territory and provide free installation of wood and pellet heating systems to replace diesel and oil or older, inefficient wood stoves. Two other municipally-led pilot programs will offer rebates to households in Wawa and Sioux Lookout.

“This project is a tremendous step forward in providing safer and healthier living conditions for our communities that rely on diesel power,” Deputy Grand Chief Derek Fox said in a news release. “Wood heat is an environmentally conscious alternative to fossil fuel and a sensible fuel choice for those living in the NAN Territory. The communities that have received the wood stoves will see a reduction of the health, safety and environmental impacts associated with diesel generation.”

Nathalie Des Rosiers, Ontario’s minister of natural resources and forestry, said the pilot projects will help support the province’s forest sector. “A strong local market for wood heating fuels will support a diverse forest product sector, spur innovation, and keep investment here in Ontario. By increasing the use of modern wood heating technologies in these communities, the pilots will reduce greenhouse gas emissions, create jobs and encourage development of Ontario’s abundant forest resources.”

The province is planning to invest up to $1.7 billion from its carbon market revenue into the Green Ontario Fund.

By Gord Murray, WPAC executive director

PAC participated on a wood pellet trade mission to Italy from Feb.19–23. This mission was organized by Ralph Spaans, secondary wood product specialist with the Ontario Ministry of Natural Resources and Forestry; Patrizia Giuliotti, trade commissioner for the Embassy of Canada to Italy; and myself. There were 16 participants including representatives of wood pellet producers from B.C., Ontario, New Brunswick, and Nova Scotia; Ontario First Nations; banking and finance; and certification/inspection companies.

The group began the tour in Milan on Feb. 19. Travelling by bus, we first visited the municipality of Bulciago, north of Milan, where we met with the wood pellet trading companies Woodtech and Agrifor. We next visited Savichem in Fontana Fredda. Savichem is a major distributor of stoves and fuels. Savichem imports ENplus wood pellets, mainly from Austria. Then we travelled to Ravenna, where we met with Italy’s largest wood pellet importer, Adriacoke. We toured Adriacoke’s wood pellet bagging facilities and learned that the company is planning to install its own pelletizer to process fines generated from the handling of bulk wood pellets. Next on the agenda was Sitta Group in San Giovanni al Natisone. Sitta Group is a major Italian manufacturer of baby furniture and accessories. The company began manufacturing wood pellets using sawdust from its manufacturing operations, then branched out to include wood pellet importing and distribution.

The group ended the tour with a two-day visit to the Progetto Fuoco (Project Fire) exhibition where participants met with numerous pellet buyers. Progetto Fuoco is a huge event held every second year in Verona. It features seven large exhibition halls with hundreds of pellet producers, traders, and manufacturers of stoves, boilers, pellet barbeques, pizza ovens, and every other kind of wood pellet appliance imaginable.

There were several key takeaways from the Italian mission:

• Italy experienced three warm winters in a row from 2014–2016, which temporarily slowed pellet demand in the country. For the past two winters, temperatures have normalized, enabling pellet demand to recover.

• Industr y participants were not able to give a precise figure for the size of Italian wood pellet market. Annual consumption is estimated to be between 2.5 and 3 million tonnes and is expected to double over the next five years. Presently about 90 per cent of wood pellets are imported.

• There is significant concern about the size of the wood pellet black market, which is estimated to be between 200,000 and 300,000 tonnes per year. Participants use the black market to avoid a punishing 22 per cent value-added tax on wood pellets.

• The 22 per cent value-added tax was imposed in 2014, decreasing the advantage of wood pellets over natural gas. Nevertheless, wood pellets continue to be cheaper than gas.

• Wood pellet demand has grown in other parts of Europe, making it more difficult for Italy to import wood pellets from countries that have grown their own domestic markets. This has led to increased interest in residential-quality pellets from Canada.

• Wood pellet traders realize that they must purchase pellets yearround in order to maintain reliable supply. Traders indicate that they are willing to set prices annually to match the practice of the large supermarket chains that sell wood pellets to end consumers.

• ENplus quality certification is essential. Supermarkets in particular, want certified wood pellets so as to avoid consumer quality claims. Italian consumers also prefer light-coloured

• The Italian wood pellet market is extremely fragmented. There are hundreds of brands available. Adriacoke, who is the largest distributor, handles only 140 thousand tonnes annually, which is only about five per cent market share.

pellets, which they associate with pellets imported from Austria.

• Although Italian traders purchase wood pellets in bulk and in bags, they prefer bagged product because logistics are easier and because bulk pellets result in significant quantities of fine dust that must be disposed of.

• There are around 3.1 million installed wood pellet stoves in Italy and 12,000 boilers, a ratio of nearly 200:1. Pellets are predominantly sold in 15-kilogram bags while bulk pellet sales are practically non-existent. Even many boilers used bagged wood pellets. Pellet stove sales are growing at a rate of 5-10 per cent annually. The average pellet stove uses less than one tonne of wood pellets each year, compared to about four tonnes per year in Canada.

• The Italian gover nment has introduced a program that enables taxpayers to recover 65 per cent of the cost of a pellet stove installation through their income tax returns.

• Inbound logistics: (1) bagged pellets are received by truck from Austria, Germa-

ny, France, Czech Republic, Croatia, Slovenia, Poland; (2) bagged pellets are received by train from Romania, Belarus, Ukraine, Netherlands, and Lithuania; (3) bagged pellets are received in shipping containers from Estonia, Latvia, Lithuania, Tunisia, U.S., and Canada; and (4) bulk pellets are received in ocean vessels from Portugal, Estonia, Latvia, Lithuania, Russia, U.S. and Canada.

• Ballpark per tonne wholesale pricing, ex works (transportation paid by buyer): (1) bagged pellets received by truck is 133 euros; (2) bagged pellets received by train is 144 euros; (3) bagged pellets received by container is 121 euros; and (4) bulk pellets received by ocean vessel is 91 euros.

• Canadian wood pellets are regarded to be of the highest quality, but expensive. Consequently many unscrupulous Italian distributors are branding pellets as “Canadian,” even if the pellets are imported from elsewhere. Our only protection is to use the CANplus pellet certification brand in addition to ENplus. No pellet producer outside Canada is

allowed to use the CANplus trademark.

• Air pollution from wood burning has become a political issue in Italy. The natural gas lobby has campaigned against wood pellets, saying the emissions from pellet stoves are the same as from the many old inefficient wood stoves that are still in service in Italy. Fortunately, Italy has passed a new “National Law for the Quality Classification of Biomass Heating Systems” which rates stoves on the basis of emissions performance for particulates, organic gases, nitrous oxides, and carbon monoxide. Pellet stoves have been found to be highly rated under the new law. Italy remains the best option for those wishing to export residential quality pellets to Europe. Winter temperatures have returned to normal after three consecutive warmer than normal years. Pellet demand in other European countries has depressed their exports to Italy. Pricing remains somewhat challenging. Nevertheless, Canadian exporters should consider shipping at least a portion of their production to Italy as a means of diversifying their global market risk. •

By Maria Church

BioEnergy’s 350,000-tonnes per year pellet plant in Prince George, B.C., consumes up to 1,200 tonnes of fibre a day, sourced from sawmill and forest residuals as well as low-quality whole logs. A new multi-million dollar installation from Dieffenbacher allows the industrial pellet plant to reduce machine wear and access more fibre sources than ever before.

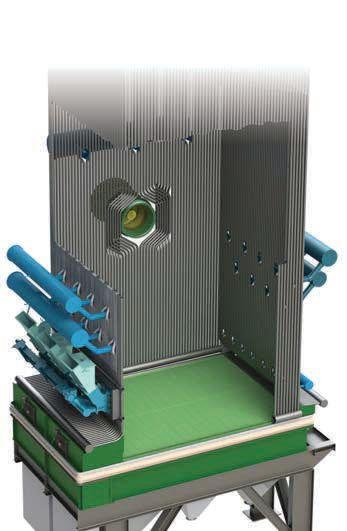

The installation, called a ClassiCleaner, uses a combination of roller screening and air separation units to filter out contaminants before fibre enters the hammer mills. It’s the first installation in North America, says Shawn Bells, Pacific BioEnergy’s (PacBio) vice-president of operations.

“It’s exciting technology,” Bells says during Canadian Biomass’ tour of the plant and new installation in April. He points to a bag filled with grain-sized rocks and flecks of wood throughout — the bag was collected from the ClassiCleaner’s smallest particle separation bins. After months in operation, Bells is more than pleased with the results.

“This ClassiCleaner was a strategic investment to allow us to open up access to higher-contaminated fibre streams. It gives us the ability now to run the plant on 100 per cent forest residuals,” he says.

PacBio has a non-replaceable forest licence in the Quesnel forest district, which allows them to harvest 700,000 cubic metres annually. In partnership with Tolko, the company has a biomass pre-processing facility in Quesnel where fibre is chipped with an 84-inch West Salem chipper.

In 2010 the pellet plant began increasing its consumption of forest residuals, local spruce, pine and fir. On average about 30 per cent of plant’s diet is sourced from brush piles, but that has increased to more than 40 per cent, Bells says. The plant also consumes low-quality pulp logs, and sawmill residuals — chips, sawdust and hog streams — from nearby mills. The variety of fibre consumed is a both a blessing and curse, Bells says. More sources amounts to a steadier fibre supply, but the plant’s equipment needs to handle a wide spectrum of particle sizes and contaminants.

PacBio trialled a vibratory air knife separator five years ago in an attempt to handle forest residuals and sawmill hog streams, both of which have high amounts of rock and other debris. The system

Pacific BioEnergy has installed North America’s first ClassiCleaner, a multi-million dollar installation from Dieffenbacher that uses roller screening and air separation units to filter out contaminants.

A different size of contamination is extracted in each section of the installation via a combination of scalping rolls, air knife separation, diamond roll beds and individual gravimetric separators.

didn’t meet their requirements, which forced the company to look for another solution.

Bells toured two ClassiCleaner installations in Europe — one in France, and another in Ireland. He was impressed with what he saw.

“Europe does an excellent job of recycling everything,” Bells says. But the pellet operation has unique demands.

The ClassiCleaner was commissioned in December after a 24-week project involving PacBio, Dieffenbacher and local firm, International Quest Engineering. One of their challenges was to install the system while the plant continued to operate 24-7.

The entire system is housed in three separate towers connected by a series of conveyors. A different size of contamination is extracted in each section, via a combination of scalping rolls, air knife separation, diamond roll beds and individual gravimetric separators.

A few weeks into operations, PacBio ran into challenges with the heavy particle separation unit. Dieffenbacher is re-engineering the scalping screens to reduce the amount

of wood in the reject material from the heavy particle separation unit. Bells says the support from Deiffenbacher has been exceptional. “They are committed to providing the best possible solution.

“Our setup is probably the most challenging Dieffenbacher has had to do for two reasons: One, the volume this facility processes is in excess of 50 ODT an hour, and two, the spectrum of particle size that it has to clean. We have to treat everything from 100 per cent forest residuals to 100 per cent sawdust. It has to do the full spectrum of everything,” he says.

Bells says the conservative estimate is that the ClassiCleaner will reduce their maintenance costs by 10 per cent. Wear parts that were once changed multiple times a week are now checked once a week and left in place. He says they can hear the difference in the downstream equipment when the ClassiCleaner is not running.

“Now that we know how many contaminants are actually in our feedstock material, we endeavour to run the ClassiCleaner with 100 per cent uptime,” Bells says.

It’s not only the reduction in maintenance costs they can look forward to, it’s also the ability to access other streams of fibre that they normally couldn’t run because of contaminants. That will mean more access to forest residuals and sawmill hog that have the highest amounts of rock and other debris. The plant will be able to reliably handle this material without subjecting its equipment to increased wear.

Fibre enters the plant in one of three infeed bins with variable frequency drives, designated for either forest residuals, sawdust or shavings.

The forest residuals and sawdust lines are first treated to the ClassiCleaner where contaminants are filtered out and the feedstock material is classified by particle size. The coarse material is fed into either the 800-hp Brunette BioSizer or the 500-hp LAMB Hog, which takes one to four-inch residuals and mulches it to a ½-inch minus. The smaller particulate bypasses the hogs and flows directly to the dryers with the shavings line that skips the ClassiCleaner.

The plant has two SolaGen dryers with 72-million BTU burners fuelled by wood dust, and supplemented by natural gas. Single ducts running from each of the dryers then split into two Allied Blower cyclones, each of which are close-coupled to either 400-hp Bliss hammer mills, or a 500-hp Andritz hammer mills.

From there paddle chain conveyors bring material to one of 10 Andritz pelletizers. Five of the older pelletizers have individual coolers underneath, while the five newer pelletizers installed in 2010 have a shared conveyor to bring the pellets to a large Law-Marot-Milpro (LMM) cooler. Vibrating screens extract the pellet fines, which are brought to dyers’ burners, and finished pellets are conveyed either into one of two storage silos or loaded directly into rail cars. The entire process from infeed to railcars is between 30 and 45 minutes.

PacBio’s history can be traced back to 1994, when partners John Swaan and Carrier Lumber established Pellet Flame. The company became the first in Canada to produce industrial wood pellets for the overseas bulk commercial market in 1998. Today 100 per cent of the plant’s production is shipped to utilities in Europe or Asia.

Last summer Sumitomo Corporation — the owner of several power generation plants in Japan — acquired a 48 per cent equity interest in PacBio. The new part owners mean greater access to the growing Japanese market, Bells says.

“The opportunity in the Japanese marketplace is huge,” Bells says. “We’re geographically advantaged to ship in that direction rather than to Europe. Long term the Asia Pacific marketplace is our focus.” Watch a video of the ClassiCleaner at www.canadianbiomassmagazine.ca/tag/video. •

By Lesley Allan

Anew state-of-the-art facility is calling British Columbia home as Renewi Canada and the City of Surrey open North America’s first integrated closedloop organic waste management system.

Used to produce renewable natural gas (RNG) and compost soil amenders, the Surrey Biofuel Facility (SBF) takes curbside organic waste and converts it into fuel for the city’s fleet of natural gas vehicles.

The $68-million facility, located in Metro Vancouver, opened March 9, 2018, and is expected to produce roughly 120,000 gigajoules of RNG and 45,000 tonnes of compost annually.

City-owned, the facility was designed by U.K.-based Renewi Plc., and will be operated by the waste management company’s North American subsidiary for 25 years while Surrey uses the biofuel by way of gas credits going into the Fortis

natural gas grid.

“It’s a very robust system and I think that’s why people will be interested in this kind of facility,” says William Selten, interim operations manager of the SBF.

Using the latest anaerobic digestion (AD) technology to convert waste into RNG, the process begins at the curb where trucks pick up organic waste, kitchen and yard, from residents and businesses. As trucks enter the facility negative air pressure prevents any odours from escaping the building and once within its walls waste will be treated exclusively in-vessel, only leaving the building once it is injected into the grid, or as a high-quality soil amender.

Inside the facility, waste is deposited in collection halls where it will be stored until ready to go into the AD for treatment. Once the process is complete raw biogas rises and is transported to

an adjacent gasholder. From there the gas is fed into a scrubber where it’s upgraded, dried and injected into the grid.

Fresh organic waste is also placed within specialized tunnels where it’s combined with digestate and inoculants then continuously monitored to ensure that no anaerobic spots develop.

Once the composting process is complete the material is filtered to remove contaminants and then stored until used within the community and eventually returned in the form of organic waste.

“It’s really an amazing example of what a circular economy is,” says Michael Leopold, general manager of Renewi Canada. “The trucks are picking up waste, but they’re picking up waste that will ultimately fuel them on a daily basis.”

Scott Brundett, process leader at SBF, says it’s this completely cyclical and

self-sustaining process that sets the SBF apart from other producers. “I think one thing that is a little different for us than some of the plants in Europe is that a lot of those [facilities] use the gas to produce electricity, so they’ll just burn the biogas directly in a generator,” he says. “Here, of course, electricity is much less expensive and [Surrey] wanted to fuel their waste trucks.”

In Canadian biofuel facilities, closedloop systems are not something that have been focused on, while the use of many biofuels remains similar to those in Europe.

“In Eastern Canada, there’s been anaerobic digestion technology for a while now in fermenters, but a lot of [companies] were doing it with hydroelectricity instead of gas, so they were generating a biomethane gas but were using it right on site to burn into generators that generate electricity,” says Leopold.

Between the ways biogases are used and the processes used for creating it, the SBF is already a unique advancement in green technology, however, according to Leopold there is another way the facility sets itself apart.

“We’re one of the only producers where we have all of these technologies under one roof,” he says. “It’s not like we’re doing anything original, in terms using a wet fermenter, but I don’t think anybody’s ever taken all these technologies and put them in the same building. It gives you a lot of flexibility.”

Used to produce renewable natural gas and compost soil amenders, the Surrey Biofuel Facility takes curb-side organic waste and converts it into fuel for the city’s fleet of natural gas vehicles. Photo courtesy of the City of Surrey.

ANAEROBIC

Anaerobic digestion uses bacteria to produce biogas from organic waste that’s been sealed inside specially constructed tunnels. A bacteria-rich percolate mixture, that includes liquids leached from organics during AD, as well as oils and fats, is sprayed on new material activating the biogas production process, which takes between 21 to 28 days. This process in not new, but SBF sets itself apart due to the variety and quality of material it is able to use.

“We’ve got a dry AD for dry waste but we also have wet AD for liquid waste streams, so there’s a combination of the two it’s not just one,” explains Selten.

“It’s a very flexible plant,” adds Brundett. “They are integrated, so all of the gas that is produced from the dry AD tunnels accumulates in the top of the liquid digester tank.”

Water scrubbing is an energy efficient and environmentally friendly way to upgrade biogas and produce biomethane, an RNG that is interchangeable with natural gas.

The process begins with raw biogas, a mixture of methane (CH4), carbon dioxide (CO2) and trace contaminants,

being compressed and fed into a scrubber where it’s showered with water, capturing the CH4 and flushing out CO2 and other impurities. Any methane not captured in the scrubber is removed in a flash tank, recovered and pumped into a stripper where the CO2 is released from the H2O.

Clean water is then circulated back into the scrubber, while the CO2 is recovered for use elsewhere in the facility and clean gas is dried then injected into the grid.

Fresh organic waste, combined with digestates and inoculants, is placed in specialized tunnels fitted with a spigot aeration system. Temperature, humidity and pressure levels within the tunnel are continuously monitored to ensure microorganisms are able to complete the composting process.

If oxygen levels drop, fresh air is injected up through the waste to increase them and ensure no anaerobic spots develop, while humidity levels are controlled by a leachate system that sprays water onto the composting material.

Under these precise conditions compost is produced in two to three weeks after which it’s moved to the refinement section where the material is separated into compost, inoculant materials and oversized fractions, which mainly consist of

plastics that can be converted into a solid recovered fuel in the future.

The facility’s odour abatement system uses a negative air pressure system to draw air into the facility when loading doors opened. The system runs through the entire building and contains 100 per cent of the composting odour.

“Our odour abatement system is stateof-the-art,” says Leopold. “We’re running the facility at 200,000 cubic metres of air flow an hour and all of that gets scrubbed.”

Ammonia, released during decomposition, is the primary source of odours associated with composting, so as air is expelled from the tunnels, it is channelled through an ammonia scrubber, where sulphuric acid reacts with ammonia to produce Ammonia Sulphate, which is recovered and used as fertilizer.

Next, the air is cooled and humidified by a counter-current water spray prior to being passed through a woody bio-filter where microorganisms are used to absorb any remaining odours. Finally, the air is sent up the vapour stack and is rapidly dispersed 70 metres above the ground.

Odour control at the SBF is monitored continuously using electronic nose technology.

With the ability to process 115,000 tonnes of organic waste a year, the 160,000 square foot SBF was designed to keep up with Surrey’s predicted growth over the next 25 years.

Currently the city is able to independently produce 65,000 tonnes of organic waste per year and expects be able to fully utilize the facility on its own by 2043, until that time organic waste will also be collected from commercial sectors and nearby municipalities.

The facility is only one of many initiatives the municipality has taken to meet diversion and carbon goals, and although it has only been open for a short time SBF has already taken Surrey beyond its initial goal.

“Our corporate admissions policy was released in 2010 and the provisions were that we, as a city, committed to reducing corporate carbon emissions by 20 per cent by the year 2020,” explains Robert Costanzo, general manager of corporate

Vancouver-based construction company Smith Bros. & Wilson Ltd. was the general contractor for the project.

Based out of the Netherlands and Germany, Waste Treatment Technologies (WTT) was the primary equipment supplier for the facility.

Greenlane Biogas, a world leader in biogas upgrading solutions with offices in Burnaby, B.C., supplied the biogas upgrading system.

Fortis BC provided the necessary equipment to connect the biofuel facility to the natural gas grid.

services with the City of Surrey. “Our current corporate carbon footprint is 16,000 metric tonnes a year and with the operation of this facility alone we have decreased carbon emissions by 49,000 tonnes a year which completely obliterated our corporate carbon footprint and enables us to utilize carbon credits in the open market and sell them for profit.”

The project was put together at no cost to Surrey ratepayers. Funding for the facility was made possible through the federal government’s Public-Private Partnership program (P3 Canada Fund), which sees private companies and the federal government collaborate to help bring new infrastructure to Canadian communities.

“Investing in innovative projects like the Surrey Biofuel Facility is vital to reducing our carbon footprint and establishing cleaner, more sustainable communities,” Ken Hardie, MP for Fleetwood–Port Kells, said in a release.

To learn more about the SBF, or to book a tour of the facility visit www.surreybiofuel.ca. •

By Brier Dodge

Inlabs across the world cellulose nanocrystals are being tested as an additive to all types of things — inks, bioplastics and construction products, to name a few.

“There aren’t a lot of things you can say are low cost, sustainable, improve the properties of something, and work out of the box,” says Jeffrey Youngblood, a professor of materials engineering at Purdue University. “That’s the unique thing about this whole line of research.”

Cellulose nanocrystals (CNCs) are a nanomaterial extracted from wood fibre. Researchers have had their interests piqued by the small particles, produced from trees, that can drastically strengthen a product. According to Natural Resources Canada, a small amount of CNC added to a material can increase the resistance to stress threefold.

So it makes sense that when mixed with cement, tests have shown a stronger concrete.

Youngblood first took an interest in CNC about a decade ago.

He was “trying to figure out what we could dump cellulose in” at school after a U.S. Forest Service researcher was preaching the benefits of CNCs when he had to mix up concrete to fix a fence post at home. When he was adding water to the sack of concrete he got at the local hardware store, a lightbulb went off.

He came back to the lab, and got working on tests, adding CNCs to cement to see what would happen.

“We could double three day strength,” Youngblood says. “That’s not anything to sneeze at.”

The nanoparticles are small, significantly smaller than the cement particles, Youngblood says. So when they mix with the cement particles, they’re small enough that they absorb to the

surface of the cement particles, strengthening the final product.

Cement is influenced by how well it cures, and cellulose nanocrystals and nano fibrillated cellulose (NFC) — a similar substance that has slightly longer particles — control the curing, preventing cracks and increasing the strength of concrete.

“What I was really excited about was the market size of concrete,” says Michael Goergen, the vice-president, innovation for the U.S. Endowment for Forestry and Communities Inc., who says 4.3 trillion tonnes of concrete are used worldwide each year.

“If you’re going to displace something, it’s got to be inexpensive, perform better, or people are going to look at it and say, ‘why am I going to change my processes?’”

Canada is one of the world leaders in manufacturing both cellulose nanocrystals and nano fibrillated cellulose, in part because of the availability of the raw materials: trees.

“People recognize we’re a world leader,” says Jean Hamel, vice-president, pulp, paper and bioproducts at FPInnovations, a Canada not-for-profit that works with partners like CelluForce, which produces CNC. “The patent space is pretty busy right now.”

Because of the nature of the research being done, not much more could be said about what FPInnovations is doing with CelluForce, beyond confirming they are “interested in concrete” when it comes to working with CNC.

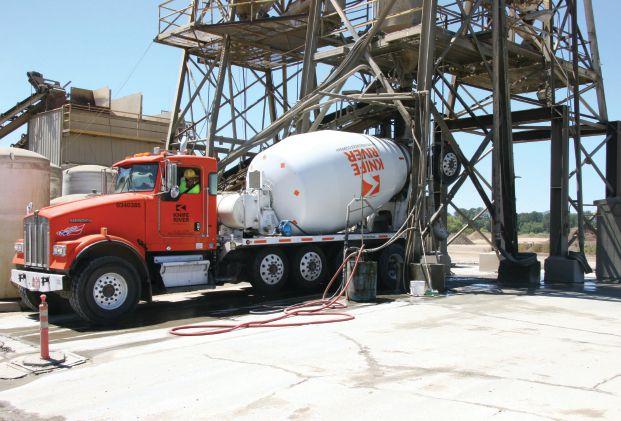

Cellulose nanocrystals (CNCs) are a nanomaterial extracted from wood fibre. According to Natural Resources Canada, a small amount of CNC added to a material can increase the resistance to stress threefold.

Gurminder Minhas, the Vancouver-based managing director of Performance BioFilaments Inc., says the Canadian company started their work into infusing concrete with nano fibrillated cellulose mid-2016, completed a second “much more extensive” study in November 2017, and are excited about the results.

The company uses the NFC instead of the CNC because the longer particles cost less.

“We don’t have as high of a surface area,” Minhas says. “But with that says, the ability for our material to hold water within the concrete is still quite high.”

Right now, mixtures being used in research at Purdue have shown a 25 per cent increase in strength, Youngblood says. An increase in strength means less concrete could be used to achieve the same result.

That’s exciting from an environmental standpoint because less concrete means fewer CO2 emissions, Goegen says.

At an estimated future cost of US$6 to $8 per pound, it’s a cost effective way for the construction companies to improve their environmental footprint he says — and potentially save money at the same time.

The CNC can also replace some of the plasticizers that sometimes go into concrete mixtures, and can cost up to US$32 per pound, increasing the economical argument for it’s use.

“If you’re reducing the amount of cement, as long as the nanocellulose is going to be cheaper, you’re going to get a win,” he says. “That’s the way I pitch it to (people). The environmental side of this, which is my personal passion, is a side benefit. I pitch it as look, this helps your material be positioned better, it’s more cost effective - you get all these additional wins.”

“There are certain jurisdictions that are saying you have to reduce your CO2 emissions,” Goegen says, such as state transportation department, which have a hard time finding ways to reduce what they’re producing. “You’ll see these demands on people, and (this is) a ready made solution that is really simple.”

He says four per cent of the world’s CO2 is from concrete production, so a reduction of 15 to 25 per cent in the volume of concrete needed, once mixed with CNC, could have a clear impact, even if it’s not used worldwide.

And future use of the materials in precast products, that are often trucked distances, could result in more CO2 savings.

“In the precast market, where a lot of these pieces are built, if you can use less concrete there’s a secondary savings of the weight of these pieces in transporting them around, typically in diesel trucks,” Minhas says.

There’s still work to be done in figuring out exactly what the right combination of additives for optimization is, Youngblood says. Researchers are still figuring out the intricacies of how CNCs work in concrete, and there are still unknowns, like how it’ll react with road salt or high sulphate ground water.

“Once we understand why, we can choose the nanocrystal and choose the right cement to optimize behaviour,” he says. Right now, there are an “infinite number” of combinations that

Cement is influenced by how well it cures, and cellulose nanocrystals and nano fibrillated cellulose — a similar substance that has slightly longer particles — control the curing, preventing cracks and increasing the strength of concrete.

Researchers are still figuring out the intricacies of how CNCs work in concrete, and there are still unknowns, like how it’ll react with road salt or high sulphate ground water.

could be tested.

Goergen estimates CNC infused concrete will be used in three years time in smaller projects by companies; he was involved in a July 2017 test pour that laid the foundation for a planned bridge this year in California.

County approval is the only thing left that has to happen for the precast bridge deck to be made and installed in Northern California, planned for this summer.

“We’ll make it ahead of time at a precast concrete facility, which is great because we can really fine tune the mix, and watch performance,” Goergen says. “Then once it’s finished, we’ll actually truck it down there and install it.”

Minhas says there are plans to conduct field trials in Canada potentially as early as this summer, though they won’t be as large scale as the precast bridge deck. And they’ll be working with a concrete manufacturer to develop products that would meet various quality and strength needs.

“The cool thing about nano cellulose… is it’s unlike almost every other material known to man,” Youngblood says. “This stuff works out of the box. You pour it in, and it works. Everything else is really optimization.” •

By Maria Church

Alittle over a year after news broke that U.S. pellet giant Rentech’s northern Ontario operations — Wawa and Atikokan — were struggling, the Atikokan wood pellet plant is once again fully operational under new, local ownership, and looking to expand.

BioPower Sustainable Energy Corp. purchased the Atikokan plant from Rentech in December 2017. BioPower is a subsidiary of True North Timber (TNT), a logging contractor based in Chapleau, Ont. Both TNT and BioPower are owned and operated by northern Ontario-born CEO Mark Guillemette.

“We had been looking for the right investment opportunity for several years, and this pellet plant was exactly the opportunity

we had in mind in northern Ontario. It is clean, innovative and a sustainable energy solution,” Guillemette says.

The Atikokan wood pellet plant complements TNT’s existing presence in sustainable woodland operations and allows the company to extend into new emerging markets, he says.

Originally a particle board processing mill, Rentech purchased the Atikokan facility in 2013. In the same year Rentech purchased a former strand processing mill in Wawa from Weyerhauser. Both mills were converted to pellet plants and secured long-term offtake contracts, but encountered delays in production due to equipment failures and issues with material handling equipment.

In February 2017 Rentech idled the Wawa mill, citing equipment and operational issues as well as an uncertain market for wood pellets. Atikokan remained open, but reduced its production to 45,000 tonnes per year, just enough to meet the company’s long-term contract with Ontario Power Generation’s (OPG) Atikokan generating facility, which is run 100 per cent on wood pellets.

Under its new ownership, the Atikokan pellet plant is again fully operational and employs 25 experienced local employees to produce and deliver the OPG contract, which is secure for the next seven years. BioPower will meet the production target of 45,000 metric tonnes of commercial

Mark Guillemette, owner of True North Timber purchased the Atikokan pellet plant in December under the subsidiary BioPower Sustainable Energy Corp. Photos by Deb Cain.

Under its new ownership, the Atikokan pellet plant is again fully operational and employs 25 experienced local employees.

grade pellets this year, and is looking to increase its customer base in order to produce even more. The plant’s current capability and configuration allows it to produce 110,000 tonnes per year.

Fibre for the mill continues to be supplied by Resolute Forest Products, which operates three sawmills and a pulp mill in northwestern Ontario. “Our premium quality pellets are produced from sustainably sourced raw materials from the world’s best managed and certified boreal forests,” Guillemette says.

BioPower’s pellets are sampled and tested by Biomass Energy Lab on a weekly, quarterly and annual basis.

While the mill itself is in excellent condition, BioPower is moving forward with some minor upgrades and capital improvements. One such upgrade is the installation of an automated bagging machine, which will allow the company to serve new customers and markets with residential wood pellets.

New business developments are underway to ship both residential and commercial pellets to customers worldwide, Guillemette says.

“Our management team is keen to make new connections and build our network of customers, suppliers and partners globally. We are also focused on expanding into the residential heating wood pellet market,” he says.

As a northern Ontarian himself, Guillemette says he is passionate about sustaining northern industries and

employment to help create prosperous communities. His father, Albert Guillemette, was the founder of TNT, which today produces over 400,000 metric tonnes annually and employs nearly 100 people.

“We are trusted and recognized for our experienced workforce, environmental

stewardship, efficient processes and customer-focused approach. By bringing our 20 plus years’ experience from TNT and working together, we believe we have a unique potential to bring new new opportunities regionally and globally,” Guillemette says.

“Our vision is: ‘We innovate to power a sustainable energy future,’” he says. •

A new powered conveyor belt tracker from Martin Engineering delivers immediate and continuous precision adjustment of hard-to-track reversing conveyors, helping operators reduce spillage and extend the life of belts and other system components. The robust unit has demonstrated greater durability and longer service life than previous designs, translating to a reduced cost of ownership. Versatile enough to run on 110V / 220V power or a plant’s existing compressed air, the Martin Tracker Reversing can even be specified with the company’s unique Roll Gen System, which uses the kinetic energy of the moving belt to produce a supply of electricity. www.martin-eng.com

KEITH Manufacturing Co. introduces the newest accessory for its Walking Floor self-unloading system for trailers. The Electric CleenSweep tarp system “sweeps” out the residual material as the trailer unloads.

It eliminates brooms and manual tarps, reducing the risk of injuries. A working sweep system is the best way to ensure drivers never climb into the trailer, which presents several safety concerns, including strains and falls. Payload cross contamination is minimized and the lightweight system takes up virtually no payload. It is also easy to install and operate, with the battery charging off the trailer’s power. www.keithwalkingfloor.com

Consisting of a fixed belt conveyor with a tripper car moving on rails located on the conveyor frame, this design from Cintasa Americas is a good option for

distributing material to various intermediate points between the conveyor pulleys. Material is distributed on either one or both sides of the conveyor by an electric or pneumatic by-pass to select the discharge side. Conveyor width, height, capacity and transport speed depends on the product and specific needs of each installation. In addition, a reversible conveyor can be installed on the tripper to distribute material at greater distances, creating more volume of stock. www.cintasa.com

Samson Materials Handling specializes in

the design and manufacture of bulk materials handling equipment for surface installation including truck reception, ship loading, stockpiling and unloading of dry bulk materials into ecological import hoppers. The handling of biomass-derived fuels can pose a challenge for plant engineers as the material characteristics can range from light and dry to heavy and cohesive. Samson equipment provides specific body and entry designs to fit the plant and material with flexible side seals to prevent spillage and waste and a buffer holding capacity to enable continuous high performance.

www.samson-mh.com

Since 1972 Action Equipment Company, Inc. manufactures heavy duty vibratory screening and processing equipment for the efficient handling of bulk materials in the wood products, biomass, and recycling industries. Action’s line of vibratory conveyors, hog in-feed conveyors, chipper infeed conveyors, and screeners are custom built to fit tonnage and space requirements. Options such as screens, in-line magnets, air knives, and/or metal detection are available. Screen options include perforated plate, wire mesh, patented flip-flow VIBRA-SNAP Screen, and TAPER-SLOT Screen. Action offers both unbalanced and

balanced units, the latter minimizes the vibration to a foundation, depending on the structural needs.

www.actionconveyors.com

ProcessBarron Bark/Biomass Drag Chain

Reclaim Conveyor design features hightorque and a low speed drive system for uninterrupted reliable operation. High amounts of torque and chain pull are required for hogged bark/biomass reclaimer applications for uninterrupted reliable operation. ProcessBarron uses a heavy-duty drag chain that is reverse barrel that was specifically designed for wood waste/biomass (bark, sand, dirt) applications where high erosion

protection and high stress requirements are necessary. Another design feature is the tail section and tail shaft assembly, which is designed with a radiused pan that lifts up material that has spilled onto the return pan and returns it to the carrying side (i.e. self cleaning). www.processbarron.com

The ASGCO Pro-Zone is a modular conveyor belt load-zone system designed to minimize and control dust often surrounding the receiving belt. A standard Pro-Zone system is comprised of our Slide-N-Roll bed combined with a set of aluminum or steel walls, internal seals, and a 20-degree pitched lid. Accessories consist of an optional

chute incorporated into the load zone lid, dust curtain(s), back plate, inspection door, canoe liners, and cross supports. ASGCO offers 4-ft (two supports) and 5-ft (three supports) lengths, as well as engineered customization. Less dust, product spillage, and belt wear means less maintenance and increased productivity! www.asgco.com

Warren & Baerg Manufacturing, Inc., is a manufacturer of cubing systems, grinding systems, and conveying systems for agricultural, biomass, industrial waste, and alternative fuel industries. The company’s conveyors come in standard widths of

24, 36, and 48 inches. Standard inclines are 30, 35, and 45 degrees. Warren & Baerg also customizes these conveyors to different widths, lengths and inclines at various degrees. The types of conveyors manufactured are drag chains, troughing, roller chains, slider beds, top feed and bottom feed. A current focus for the company is heavy duty mill quality top or bottom drag conveyors.

www.warrenbaerg.com

The Brunette SmartVIBE Vibrating Conveyor is a uniquely simple vibrating conveyor. Utilizing a patented torsion bar system, Brunette has eliminated all coil springs from the conveyor. The design optimizes low cost maintenance and maximum up-time efficiencies and is fully balanced. The conveyor maximizes

throughput with a secondary trough, and even adjust feeds speeds with the use of a VFD without having to stop for rebalancing. The Brunette SmartVIBE is suitable for many industries including sawmilling, biomass, recycling, pellet manufacturing, plywood, OSB, food processing and agro industries. Available in different widths and lengths complete with size specific screening options and metal detection. www.brunettemc.com

Wolf Material Handling Systems offers versatile Under-pile Reclaimer platforms that automatically reclaim and evenly meter all wood fuel products including: granular, chipped, hogged and even tub-

ground fuels. These robust and innovative designs include low profile offerings that can be incorporated into almost all new or retro-fit applications. Engineered with ease of maintenance in mind these systems are engineered to provide easy access to wear parts and include a slow speed chain design with VFD drives to further reduce wear. Other standard offerings include hardened chains and heavy-duty frame construction that allow “drive over” capability and provide years of service.

www.airoflex.com

performance, and the unique EDEM design claims the lowest horsepower requirement of any drive on the market. Power is provided by a premium efficiency, TEFC electric motor and standard V- belt drive. Each conveyor is custom designed and engineered to suit the customer’s exact requirements. All EDEM vibrating conveyors are available in both unbalanced and dynamically balanced configurations. EDEM patented Magnet Trap conveyors are used to remove smaller pieces of iron and steel (tramp metal) before they reach the metal detector. The system only shuts down to remove the larger pieces. The result is increased productivity and the elimination of damage caused by an attempt to alleviate shutdowns when the operator reduces the sensitivity of the metal detector.

www.edem.com

The Peterson TS4280 Tracked Stacking Conveyor is an innovative conveyor, which can often eliminate the need for a wheel loader. Fed by a large hopper, the generous 42-inch wide (107 cm) conveyor can easily keep up with horizontal grinders or screens. The 80-foot conveyor length can stack materials up to 35 feet high (1,100 cm). The TS4280 Tracked Stacking Conveyor is powered by a fuel efficient, 58-hp Kohler diesel engine. The engines are Tier IV compliant with no DPF for lower maintenance and operating costs. The TS4280

The heart of Optimil EDEM brand heavy duty vibrating conveyors for feeding, screening, fibre handling for sawmills, engineered wood, and pellet plans is a rugged coil spring/ eccentric shaft drive assembly. While simple in design these Optimil/EDEM coil springs are noted for outstanding

allows continual operation while conveying the material away from the feeding machine. This eliminates the need for double material handling with traditional wheel loaders, which can make a significant difference to the bottom line. TS4280 is easily repositioned with the powerful tracks to extend the pile or move to the next site. The machine can be setup in just minutes. The safe, simple hydraulic controls ease unloading, moving, setup, and tear down. The folding head section and optional folding tail, creates a compact travel position that reduces transportation length.

www.petersoncorp.com

There’s a saying that gets tossed around a lot here:

“It just runs.”

Our pellet mills and hammermills aren’t the prettiest. But they’re rock solid. And they run— year after year.

But “It just runs” isn’t just about our products.

It’s about our company, which literally spans centuries.

And it’s about our ongoing relationships with our customers—how we’ll always be there for you.

out just how CPM can run for you.

When it comes to fueling the future of your bu siness, our commitment covers your operation’s entire life cycle. From the first feedstock analysis in the field, through non-stop biofuel production. For Georgia Biomass, this meant building the world’s largest biomass plant, backed up by a new ANDRITZ dedicated service center in their own back yard. Find out how our world- class processing solutions and services can fuel your business at andritz.com/ft.

Built on over sixteen years of experience with wood Biomass boilers in North America, Fink Machine has the reputation of being in the fore front when it comes to design, supply, installation and most importantly ... Service!

Airex

Andritz

AscenTech Solutions

BC Biocarbon

beloTEQ

BID Group

Biomass Engineering Equipment

Brunette Machinery

CAW (Classen Apparatebau Wiesloch GmbH)

The City of Prince George

Clean Energy Consulting

CV Technology

Dansons

The DLA Piper (Canada)

LLP Forestry Law group

Eliza’s Village

Fink Machine

Frontline Machinery

GF Urecon

Great West Equipment

Hargassner

Integrity Welding

Isonor Inc.

KJM Sales

Laidig Systems

Petro-Canada Lubricants

Pezzolato

Pinnacle Renewable Energy

Prodesa

redIRIS

Sacré-Davey Engineering

Sinclar Forest Products

TSI

Turboden

Way-Tech Process Solutions

Wellons

WGL Technical

Wolftek

Woodland Equipment Co.

VETS Group

By Robynne Anderson — Member of the Bioenterprise board of directors and president of Emerging Ag.

anada has always been an agricultural powerhouse, but these days it’s not just about selling prairie wheat, P.E.I. potatoes and maple syrup to the world. Now we’re also building bio-cars from ag-based fibres, composites and foams. We’re creating naturally derived pharmaceuticals and functional foods that help fight disease. We’re cutting carbon emissions by finding valuable uses for agricultural wastes, and we’re boosting agricultural productivity in all kinds of ways.

commercialize innovations and grow successful businesses.

For example, Energrow enables farmers to process their own oilseeds on farm into fresh, high-quality meal and oil through one of the most reliable, efficient and user-friendly pressing systems on the market.

But innovation alone doesn’t guarantee commercial success. You also need business savvy, industry knowledge, and financial resources to navigate the path to market.

“… One of the biggest hurdles facing start-ups and established companies alike is financing growth…”

Recently, our prime minister issued a challenge to Canadian agriculture to grow our annual exports to $75 billion by 2025. This will only come through innovation and new technology. Bioenterprise is a great example of a federal-provincial-private partnership to accelerate that innovation.

Over the last 10 years, the organization’s clients (generally small start-ups) have launched more than 1,000 new products, services and technologies; created thousands of new jobs; and generated over $268 million in revenues. Bioenterprise has also worked closely with 30 companies in helping them secure more than $120 million in investment.

Agri-technology is a sector with huge potential, but it needs scientific and technical expertise, industry knowledge, business services and global connections, to help start-ups

capabilities and launch a highly targeted direct mail campaign engineered by one of Bioenterprise’s corporate partners.

At several points throughout the entrepreneurial journey, Enegrow turned to Bioenterprise for support. The agri-business accelerator helped source market data, established industry connections and provided all-important reality checks.

Today it is great to see the Ontario-based company has 15 dealers across North America and a customer base that Energrow expects to double in the coming year.

Of course, one of the biggest hurdles facing start-ups and established companies alike is financing growth — it’s especially challenging for agri-tech innovators in Canada. Seed funding and funding proposals, as well as connecting clients to investors, are a few ways Bioenterprise is working to address this gap for early-stage companies. But agri-tech is still just a blip on investors’ radars.

For one established Guelph, Ont., company, that seed financing helped them take their business to the next level. Rootham Gourmet Preserves turns Ontario produce into gourmet condiments, sold in local specialty markets and gift stores. Using a grant from Bioenterprise, they were able to expand processing

The results were immediate: Rootham gained more than two-dozen new clients in just two months. That boost to business allowed them to expand production, hire more staff and increase the hours of current employees. The grant also helped support product development with Longo’s, a chain of grocery stores across the Greater Toronto Area, leading to a significant contract. The company not only hit their target of doubling gross sales, but they did it in just one year instead of the projected two.

The fact is, Canada has no shortage of promising agri-tech ideas, technologies and products but the big stumbling block is the lack of growth or venture capital. There are few investment firms out there who understand the sector, and even fewer angel investors.

That’s why accelerators like Bioenterprise are needed. There are great inventors, farmers, and food innovators in Canada, we can help them get investment and market ready by providing strategic advice. It’s an area where Canada really excels, creating a co-funded public-private programme, such as Bioenterprise, to help those innovators grow.

Agri-food is a big sector in Canada that represents over 12 per cent of our employment and a big proportion of our trade — a growing proportion if we are to meet this new national target of $75 billion in exports. That goal, and the goal of healthy, diverse diets for Canadians, will be driven by innovation. So from super-clusters to agri-tech accelerators, it is a growing reality that the public and private sectors will be working together to reap the benefits. •