Affordable HMIs for any budget

C-more micro HMIs are perfect for small systems and costconscious applications. With free programming software and a starting price of $98.00, these micro HMIs can provide the visibility and cost savings your project needs.

• NEW! Reduced price 3-inch non-touch and touch screen HMIs

• 3-inch EA3 models have 12 selectable background colors while 4-inch and 6-inch models provide 32K color TFT displays

• Serial communications on all panels, with USB and Ethernet options available

• FREE C-more micro HMI programming software with simulator (EA-MG-PGMSW)

C-more HMIs provide the advanced functionality needed in more complex applications including animations, logic, math, alarming, remote accessibility (web server and mobile app) and a myriad of supported communication protocols.

• NEW! 10-inch widescreen and reduced price 15-inch base model available

• 10-touch screen models offered with 7 different screen sizes supporting 64K colors

• Serial communication, USB programming, and SD card slot for data logging/program backup on all panels; Ethernet, HDMI video, and audio output options available

• C-more HMI programming software (EA9-PGMSW) $99.00

NOTABLE TWEETS

@splicemachine

“With all of the advancements in #machinelearning, the time’s right for preventive maintenance to become #predictive.”

Read what our CEO @mzweben said in @AutomationMag on how preventative maintenance gets an upgrade with #OLPP. bit.ly/2EDpyPT

@MFGTalkRadio

The #manufacturing industry shouldn’t fear #automation and #robotics. These technologies have so much to offer the industry.

@HeimatecInc

#IMTS2018 will be here before we know it, and it’s only going to be an even larger event than ever before. It’s predicted that @IMTSchicago will feature 44% more exhibition space than #IMTS2016 via @ AutomationMag: bit.ly/2vv72G5.

Technology investment is key for business innovation

In a quest to measure business and government readiness for Industry 4.0, the Deloitte Global survey polled roughly 1,600 C-level executives across 19 countries in the second half of last year. One of its most notable findings is the strong correlation between how executives approach technology and how well prepared they believe they are for Industry 4.0, and as such, the business case they make for new technologies.

Respondents who view implementing new technologies as the key competitive differentiator feel they are more prepared across a range of areas than those who say technology is simply one of many priorities, according to the findings.

“The concept of digitizing everything is becoming a reality. Automation, artificial intelligence, IoT, machine learning and other advanced technologies can quickly capture and analyze a wealth of data that gives us previously unimaginable amounts and types of information to work from,” wrote Brian Householder, president and chief operating officer of Hitachi Vantara, in a report that analyzes the survey results. “Our challenge becomes moving to the next phase – changing how we think, train and work using data – to create value from the findings obtained through advanced technologies.”

Deloitte found that “close to a third of respondents from the Americas consider technology a key competitive differentiator, compared with 12 per cent in APAC and 18 per cent in EMEA. This focus on technology breeds a degree of confidence: More

respondents from North America believe that they have a strong business case for their technology solutions (14 per cent), with APAC respondents being the most doubtful (5 per cent), and Latin America and EMEA coming in at 9 per cent.”

Disruptive technologies will enable organizations to develop and support new business models, advanced product innovation and holistic customer servitization.

“In this way, Industry 4.0 also enables organizations to take advantage of network-based, data-driven, autonomous and cognitive digital and physical technologies to create truly innovative business solutions — rather than simply using technology to pursue the same old ways of doing business,” noted the authors of the Deloitte survey report.

As I write this editorial, I’m halfway through my week at Hannover Messe in Germany. This year more than 5,000 exhibitors from 75 different nations are presenting the technologies of tomorrow’s factories, discussing the impact of connectivity, artificial intelligence, the Digital Twin, robotics and self-learning machines on the industrial automation world. After chatting with a number of automation experts at the action-packed trade fair, one thing is certain: Today’s manufacturers must embrace these transformative technologies to ensure they remain cost-effective, agile and competitive on the global stage. | MA

EDITORIAL ADVISORY BOARD

AL DIGGINS, Chairman of the Board, Treasurer and General Manager, Excellence in Manufacturing Consortium

DAVID GREEN, Technology and Business-to-Business Consultant

KARIN LINDNER, Founder and owner of Karico Performance Solutions

DON MCCRUDDEN, Vice-President, Business Development, Festo

DAVID MCPHAIL, President and CEO, Memex Automation

NIGEL SOUTHWAY, Business Productivity Consultant and Author on Lean Thinking

BILL VALEDIS, Vice-President, Precision Training, Products and Services Inc.

Your resource for Canada’s industrial automation news

EDITOR

Alyssa Dalton adalton@annexbusinessmedia.com

PUBLISHER

Klaus B. Pirker kpirker@annexbusinessmedia.com

VICE PRESIDENT & EXECUTIVE PUBLISHER

Tim Dimopoulos tdimopoulos@annexbusinessmedia.com

ART DIRECTOR

Graham Jeffrey gjeffrey@annexbusinessmedia.com

ACCOUNT CO-ORDINATOR

Debbie Smith dsmith@annexbusinessmedia.com

CIRCULATION MANAGER

Urszula Grzyb ugrzyb@annexbusinessmedia.com

Tel: 416-442-5600 ext. 3537

COO

Ted Markle tmarkle@annexbusinessmedia.com

PRESIDENT & CEO Mike Fredericks

CONTRIBUTING WRITERS

Anthony Borges, Paul Hogendoorn, Doug Macdonald, Dave Mannila, Jennifer Rideout, Rittal North America, Tony Winter, WSPS

Manufacturing Automation is published seven times a year by:

Annex Business Media

111 Gordon Baker Rd., Suite 400, Toronto, ON, M2H 3R1 Tel: 416-442-5600 Fax: 416-442-2191

Printed in Canada ISSN 1480-2996

Publication Mail Agreement #40065710

CIRCULATION

email: lmalicdem@annexbusinessmedia.com

Tel: 416-510-5187

Fax: 416-510-6875

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON, M2H 3R1

SUBSCRIPTION RATES

Canada — $42 per year

United States — $74 (US) per year and Foreign — $84.50 (US) per year

Students — $20 per year

ANNEX PRIVACY OFFICER

email: privacy@annexbusinessmedia.com

Tel: 800-668-2374

Occasionally, Manufacturing Automation will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

The contents of Manufacturing Automation are copyright © 2018 by Annex Publishing & Printing Inc. and may not be reproduced in whole or part without written consent. Annex Publishing & Printing Inc. disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication.

We acknowledge the [financial] support of the Government of Canada.

BREWERY INVESTMENTS

Sleeman brings production back from U.S., creates new jobs in Guelph

One of Canada’s largest brewing operations will invest in equipment upgrades and new beer tanks and expand its packaging capabilities at its Guelph, Ont., location.

With an investment of $422,000 from the Southwestern Ontario Development Fund, Sleeman Breweries Ltd. will commit more than $6.6 million to the project, enabling it to brew and package beer that is currently produced by a contractor in the U.S. It will also be able to implement new can packaging technology and produce 710 ml aluminum cans of select brands for the Canadian market.

The project, which will create 15 new jobs and help retain 412 existing positions, is expected to be completed by December 2020.

“Our company’s history in Ontario dates back to 1834 and we have always been proud to offer premium quality products to our customers. This funding will support our capacity to create jobs as well as drive exports and innovation on our brands to ensure continued growth and a vibrant, sustainable future for years to come,” said John Sleeman, founder and chairman of Sleeman Breweries.

Steam Whistle’s $22.8-million expansion to create 100 new jobs

The Ontario government is partnering with Steam Whistle

Brewery to invest in new equipment to expand its product line, creating 100 new jobs and retaining 143 positions in Toronto.

Founded in 2000, Steam Whistle Brewery is one of the country’s largest independent craft brewer. The company currently produces a single brand pilsner in a national historic site in downtown Toronto. With a grant of up to $1,330,860 million

Steam Whistle expects the $22.8-million expansion to create 100 new jobs.

AUTOMATION UPFRONT

from Ontario’s Jobs and Prosperity Fund, Steam Whistle Brewery will purchase new equipment and invest in a new facility in Etobicoke, Ont., that will help the company expand its product line to include a new ale brand and a non-alcoholic offering.

“This investment will not only help Steam Whistle increase production and efficiency, but enable us to build our capacity to enter new markets. The craft brewing sector in Ontario has seen tremendous growth. We want to continue to lead the sector and remain competitive through our innovative brewing techniques and our novel approaches to producing great tasting, quality products,” said Cam Heaps, cofounder and CEO, Steam Whistle Brewery.

The company anticipates the project to cost a total of $22.8 million, and to be completed by January 2024.

DISRUPTION

Report: Automation to impact 50% of Canadian jobs in the next 10 years

A new RBC research paper, Humans Wanted – How Canadian youth can thrive in the age of disruption, predicts that 50 per cent of Canadian jobs will be disrupted by automation in the next decade.

As a result of this disruption, the report believes Canada’s Gen Mobile – young people who are currently transitioning from education to employment – are unprepared for the rapidly changing workplace. With 4 million Canadian youth entering the workforce over the next decade and the shift from a jobs economy to a skills economy, the research indicates young people will need a portfolio of “human skills” to

remain competitive and resilient in the labour market.

“Canada is at a historic crossroads – we have the largest generation of young people coming into the workforce at the very same time technology is starting to impact most jobs in the country,” said Dave McKay, president and CEO, RBC. “Canada is on the brink of a skills revolution and we have a responsibility to prepare young people for the opportunities and ambiguities of the future.”

Key findings of the report:

• Canada’s economy is on target to add 2.4 million jobs over the next four years, virtually all of which will require a different mix of skills.

• A growing demand for “human skills” will grow across all job sectors and include: critical thinking, co-ordination, social perceptiveness, active listening and complex problem solving.

• Rather than a nation of coders, digital literacy – the ability to understand digital items, digital technologies or the Internet fluently – will be necessary for all new jobs.

• Canada’s education system, training programs and labour market initiatives are inadequately designed to help Canadian youth navigate the new skills economy, resulting in roughly half a million 15-29 year olds who are unemployed

and another quarter of a million who are working parttime involuntarily.

• Canadian employers are generally not prepared to recruit and develop the skills needed to ensure their organizations remain competitive in the digital economy.

ADDITIVE MANUFACTURING

Siemens 3D prints replacement parts for industrial steam turbine

Siemens says it has reached an additive manufacturing (AM) milestone in the power generation industry with its first replacement parts 3D-printed from metal for an industrial steam turbine.

Last year, Siemens finished its first full-load engine tests for gas turbine blades completely produced using AM technology.

The RBC report finds Canada’s economy will add 2.4 million jobs over the next four years, most of which will require a different mix of skills.

The rings will be installed on an industrial steam turbine in India. PHOTO:

Now after years of research, development and testing, the company has extended its use of AM in energy applications by producing a steam turbine replacement part with AM, reducing lead time by as much as 40 per cent, it says.

The 3D-printed parts are two oil sealing rings used in keeping oil separated from steam inside the steam turbine using pressurized air. The rings are being installed as replacement parts on the SST-300 industrial steam turbine operating at the JSW Steel Ltd. plant in Salem, India.

Siemens engineered, designed and developed the parts as part of a collaborative project between Siemens experts in Germany and India, as well as in Sweden, where the company operates a primary additive manufacturing centre.

Siemens describes AM as a process that builds parts layer by layer from sliced CAD models to form solid objects, resulting in

“highly precise solutions to be formed from powdered high-performance materials.”

ENERGY EFFICIENCY

BASF Canada reduces carbon footprint with Bullfrog Power

BASF has chosen to power its Canadian corporate headquarters and production facilities across the country with green electricity from Bullfrog Power, a move that is predicted to reduce the company’s CO2 emissions footprint by approximately 1,520 tonnes annually.

The agreement means that 100 per cent renewable electricity is put onto the grid to match the amount of conventional electricity being used at BASF’s Canadian corporate headquarters and its Bullfrog-powered production facilities, which include plants

in Windsor, Cornwall and Etobicoke, Ont.; Blackie and Nisku, Alta.; Saint Leonard, Que.; and Saskatoon, Sask. Across Canada, Bullfrog’s green electricity comes from a blend of wind and hydro power sourced from new Canadian renewable energy facilities.

“Through the partnership

with Bullfrog Power, BASF is reducing its environmental impact and supporting an innovative approach to growing Canada’s renewable energy industry,” said Marcelo Lu, BASF Canada president. “BASF wants to contribute to a world that provides a viable future with enhanced quality of

Innovative Automation Solutions

SENSORS: Inductive and Capacitive Proximity Sensors • Photoelectric Sensors • Level Sensors • Ultrasonic Sensors • Magnetic Sensors • Limit Switches • Safety Interlocks

Whether it’s our industry leading range of solid state relays and contactors, or our vast range of sensors, motor controls, energy meters and voltage/current monitors, CARLO GAVAZZI has the solution for your application needs.

Contact us today, and one of our field sales representatives will show you why we are one of the fastest growing automation companies worldwide. We’ll even provide a free evaluation sample to qualified OEMs.

L to R: Sean Drygas, vice president, finance and corporate development, Bullfrog Power, and Marcelo Lu, president of BASF Canada.

life for everyone. Partnering with Bullfrog Power means BASF is helping to support community renewable energy projects across Canada.”

Headquartered in Mississauga, Ont., BASF Canada has approximately 700 employees at 11 production facilities and offices across the country.

EDUCATION

Coding and robotics classes coming to Saskatchewan

The Government of Saskatchewan has announced new coding and robotics opportunities for middle years and high school students in the province. These elective courses will be available to all high schools, while Grades 7-9 teachers can also introduce students to coding and robotics.

“Our government is following

through on our commitment to develop Saskatchewan students’ computer coding skills that will help prepare them for emerging careers in science, mathematics, engineering and technology,” said Deputy Premier and Education Minister Gordon Wyant. “[This] announcement will build upon local successes we have seen across the province in coding and robotics education.”

“Saskatchewan’s rapidly growing tech sector relies on a diverse and highly educated workforce that can be achieved only through continued and innovative support at every level of education,” SaskTech spokesperson Dr. Aaron Genest said. “We are thrilled to see the Government of Saskatchewan demonstrate a commitment to position Saskatchewan’s children as leaders in an increasingly technical world. We thank the government for understanding

that robotics and coding skills are best introduced early to ensure all students benefit.”

PACKAGING

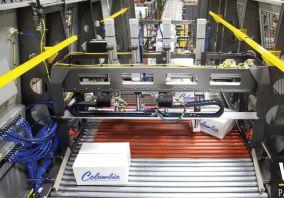

Nestlé aims for 100% recyclable, reusable packaging by 2025

Nestlé has announced its goal of making 100 per cent of its packaging recyclable or reusable by 2025, saying its vision is that none of its packaging – including plastics – ends up in landfill or as litter.

The company intends to focus on three areas: eliminate non-recyclable plastics; encourage the use of plastics that allow better recycling rates; and eliminate or change complex combinations of packaging materials.

The company says it plans to work with value chain partners and industry associations to explore different packaging solutions to reduce plastic usage, facilitate recycling and develop new approaches to eliminate plastic waste. As well, it intends to label plastic product packaging with recycling information to help consumers dispose of it correctly.

INTERNATIONAL

THE NETHERLANDS

c3controls opens its European operation

c3controls, a manufacturer of industrial control products based in Beaver, Penn., has opened an

operation in the Netherlands to serve the European market. c3controls Europe will serve both western and eastern Europe with its full line of over 15 million product configurations, in categories including power and actuation, control logic, human machine interface, and wiring and cable duct.

By controlling the key aspects of product development and manufacturing from tool and die fabrication and up, c3 says it builds the majority of its products from components designed and made in-house.

DEAL MAKERS

Schneider Electric signs with Calgary’s Leading Edge Sales

Energy management automation solution provider Schneider Electric Canada has signed Leading Edge Sales (LES), a Calgary, Alberta-based sales representative, to identify, develop and secure opportunities for the protection, control, and automation of power systems in Western Canada.

“This partnership reinforces Schneider Electric’s commitment to providing solutions for protection, control and automation of power systems in Canada, and brings more support to our customers,” said Emily Heitman, Vice President of Energy, Canada & U.S., Schneider Electric.

“We look forward to promoting these products to a wider user base in western Canada,” said Jeffrey Pooranalingam, LES partner. | MA

Nestlé aims for 100 per cent recyclable or reusable packaging by 2025. PHOTO:

MOVERS AND SHAKERS

Shimco, a manufacturer of precision parts and gapmanagement solutions, has announced Katie Chiasson, a third-year Mathematics and Statistics student in the Faculty of Science at McMaster University, as the 2017 recipient of its annual scholarship. Awarded annually to a student in the Faculty of Science or Engineering at McMaster University since 2015, the Shimco Scholarship recognizes a student demonstrating outstanding academic achievement.

Doug LoFranco has been named the president and CEO of the AIS Technologies Group, which comprises

the Radix Inc. and the Active Industrial Solutions companies: Automation, Gauge & Fixture, and Specialty Machining divisions. Most recently serving as president of M&R Automation Canada, LoFranco’s executive management experience in the industrial automation space includes VP and general manager of ABB Robotics Canada, and VP and general manager of Wheelabrator Group Canada.

Global enterprise applications company IFS is welcoming Darren Roos as its CEO. The appointment aligns with the retirement of Alastair Sorbie at the end of the first quarter. Most recently Roos was president of Cloud ERP business at SAP and, prior

to that, grew international operations at Software AG, which enabled the company to triple in size during his tenure.

Yaskawa Motoman is welcoming David Troeter as its new vice-president of customer satisfaction, where he will be responsible for the overall performance of Yaskawa Motoman’s Customer Satisfaction Group (CSG) including field service, technical support, training, spare parts, robot refurbishment and repair, retrofits and aftermarket support sales for the Americas. Troeter was most recently director of customer support services for Stiles Machinery in Grand Rapids, Mich., a provider of advanced manufacturing solutions.

OPTIONS. MORE FEATURES.

mounting

Mahr has promoted Don Foisy to director of operations, where he will oversee the engineering, manufacturing, planning and facilities departments. With seven years of experience at Mahr, his “strong managerial skills and mechanical engineering expertise will help to further enhance the company’s commitment to high quality,” said Mahr.

Winters Instruments has promoted Kelly Lessard to EVP Winters Canada and Europe, Middle East and Africa (EMEA). The company says Lessard has demonstrated “strong leadership skills and created numerous sales management tools which have enabled all divisions to further their growth.” | MA

BY PAUL HOGENDOORN

‘Change management’ is an oxymoron INDUSTRY

Paul Hogendoorn co-founded FreePoint Technologies. “Measure. Analyze. Share. Don’t forget to share.” He can be contacted at paul.hogendoorn@getfreepoint.com or www.getfreepoint.com.

As I write this column, I sit quietly in my favourite chair, expecting the phone to ring and announce the arrival of my fifth grandchild. And as I wait and write, I reflect on how life has changed since my first grandchild arrived in my life, somewhat unexpectedly, 12 years ago.

I have come to conclude that the term change management is an oxymoron. You can’t manage change; change simply happens or it is caused to happen. Managing change means restricting change. Causing it to happen means leading change or perhaps, change leadership . Sometimes it is welcome and expected, sometimes unwelcome and unexpected, and sometimes it is simply needed.

I think our manufacturing companies need to change and the ideas behind Industry 4.0 need to change too. Industry 4.0 seems to be led by people believing that automation and machines talking to machines are the way for the future, but what good is the future of our factories if there is no future for our people? Henry Ford is rightfully credited with lowering the cost of an automobile by changing the way cars were built but at the same time, he was the catalyst for an even bigger change by changing the standard of living for the people he employed, creating a market for the products he made. It wasn’t a matter of change management — it was change leadership. And that’s what we need now in our factories — not change management but change leadership.

A problem I’ve always had with the concept of continuous improvement (CI) is that it not only settled for incremental change, it usually restricts and limits a company’s ability to even ponder significant changes, not to mention paradigm changes. These CI efforts are managed by managers. There’s nothing wrong with consistent incremental change, but at some point you have to be able to at least consider a complete paradigm change. Industry 4.0 purports to be this type of change, but from what I’ve seen and experienced, this movement is now being managed by large organizations and

associations more than it is being led by people causing – or even simply allowing – significant change to happen.

What good is the future of our factories if there is no future for our people?

Allowing change to happen means allowing people – and ideas – to fail. If we manage the process by setting the rules and parameters so tightly to avoid failure, we are limiting the opportunity for success and growth within our companies, industry and people. A lot of time and energy is often spent trying to prove how we were right about something that went wrong – or why we weren’t to blame for something that did – which creates two classes of change managers: those who never make a decision unless risk is totally eliminated, and those who are ready to offer an opposing view to any decision that eventually gets made. Change is difficult, but change is necessary, and that’s why our companies need to embrace and support change leaders.

This is an interesting time to grow the change leadership in our organizations. The Industry 4.0 discussion and the arrival of Industrial Internet of Things (IIoT) devices and technologies, the new attitudes and ideals of a

younger workforce, and the challenges of attracting and retaining workers are all great opportunities to encourage thought leaders and bold decisions. And of course, the importance of manufacturing jobs to our middle class, our communities and our society in general. Our factories produce more than the products they make — they create jobs for people, which in turn creates a sense of belonging, meaning and purpose. Change to our factory floors is eminent and inevitable, and in these times in particular, very necessary. If you have the right outcomes in mind, you can lead change in that direction. Or, you can simply react to it when it happens, but you really can’t manage it or avoid it.

When my first grandchild was born, I recall thinking, “how she got here no longer matters; she is here and that’s all that matters.” It has been 12 years of change – of growth – for her as well as for me since then. And, just when I start to think I am settled in and getting used to everything as it is, things will change again... perhaps as soon as with the next phone call. | MA

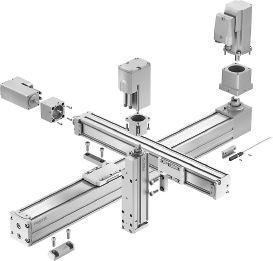

Single Source Motion Control Solutions

Complete motion control solutions - from Mechatronics, Conveyance, Assembly Handling, and Tightening Systems, to Linear and Electrical Drives and Controls Technology

Rely on Bosch Rexroth, the world leader in drive and motion control technologies that power today’s most advanced manufacturing systems.

Our automation solutions drive your manufacturing performance with fast throughput, precision, repeatable efficient motion control with maximum uptime. We’re set to help you achieve this with the industry’s most advanced conveyor technologies, electric drives and controls, linear motion components and systems, as well as production tools and tightening systems. All equipped for fast changeovers, and ready for Industry 4.0.

Smarter, more productive automation starts with the right technology. Make your move to Rexroth’s motion control solutions today. We Move. You Win!

Order your free Factory Automation Resource Kit: www.boschrexroth.ca/factoryautokit For expert advice call 1-855-REXROTH (739-7684) or email us at info@boschrexroth.ca

BY WSPS

Focus on the noise: Preventing hearing loss in the workplace

Results from a Statistics Canada health study, the Hearing loss of Canadians, 2012 and 2013, offer disturbing findings regarding adult hearing loss. Could you or your co-workers be among the one in five adults aged 19 to 79 who have mild hearing loss or more in at least one ear?

Here’s another: most people with measured hearing loss were unaware they had any hearing problems. Chances are, with time and continued exposure, the problem will get worse.

Protect the hearing of everyone in your workplace, including yourself, by leveraging the below tips. WSPS occupational hygiene specialist Warren Clements offers eight suggestions. But first, here are a few facts about noise exposure and hearing.

Forty-two per cent of Canadians aged 16 to 79 have worked or currently work in an environment where communicating to someone an arm’s length away requires speaking in a raised voice.

“That’s a noisy work environment,” says Clements

Among these individuals, 22 per cent said they always use hearing protection while 39 per cent said they never do. The remaining percentage said they sometimes, often, or rarely, use hearing protection.

Noise exposure cuts across all industries. Furthermore, says Clements, all noise sources count, whether you’re at work, home or play. If you’re working with tools around the house, cutting wood with a chainsaw, or hunting with firearms, they too could contribute to your overall noise exposure.

Because hearing loss is a gradual process, continues Clements, ma ny people may not realize their hearing is at risk until it’s too late. The resulting hearing loss can have severe emotional and social consequences, including social isolation, depression, limited mobility, and reduced income and employment opportunities.

It can even put people at greater risk of injury if they can’t hear back-up alarms and other warning sounds.

Here are eight ways to get started with a noise control program:

• Set up a noise control display;

• Schedule hearing loss prevention training and education, including hazards of noise exposure, audiometric testing, and proper use of hearing protection on and off the job;

• Invite senior management on a noise-related inspection and discuss noise control options after;

• Make a public commitment to maintaining your hearing, at work and at home. Invite others to join you;

• Conduct an informal employee survey;

• If your workplace has a hearing loss prevention program in place, also promote some aspect of the program;

• Mark achievements to date;

• Update your noise exposure assessment. If you have not had a formal exposure assessment, start with an informal JHSC-partnered employee survey; and

• Announce program updates and new initiatives.

How will you know if your workplace

1 IN 5

According to a Statistics Canada study, one in five adults aged 19 to 79 have mild hearing loss or more in at least one ear.

needs a noise control program? Ask yourself and a sampling of employees the following questions.

• Do I need to raise my voice while I’m in the workplace?

• Do I have ringing in my ears?

• On my way home from work, do I need to increase the volume of my radio or digital music player higher than what it was on my way to work?

• When I’m in a noisy environment with competing noises – like at a restaurant or a social gathering –is it difficult to hear other people?

If you and the people you survey answer yes to these questions, look into conducting a more formal assessment.

Noise apps: What you need to know

Measuring noise levels with an app on your smartphone or tablet: What could be simpler? But are the measurements accurate? Could these apps be too good to be true?

“How useful the apps are depends in part on what you’re using them for,” says Clements. “Recording nuisance noise – a too-loud house party next door, or a sound system blasting from

the apartment above you – may help back up your complaint to a by-law officer or building manager, but as for assessing noise levels at work, a higher level of accuracy is required.”

Understanding the decibels

According to a study done by Journal of Occupational and Environmental Hygiene, in certain situations smartphones, using an effective application and equipped with an external calibrated microphone can collect measurements just as accurately as a Type 2 sound level meter – a device typically used by trained professionals to take noise level readings.

Measurements must be accurate, especially if the noise level may be close to the province/territory’s maximum time-weighted noise exposure limit. Decibels are based on a logarithmic scale, not a linear scale. For a linear scale, like length, four metres are twice as long as two metres. For a logarithmic scale like decibels, twice as loud as 85 dBA is not 170 dBA. Using

Hearing loss can result in a range of emotional and social consequences, including depression and reduced income and employment opportunities.

a 3dB exchange rate, it’s 88 dBA.

We are exposed to noise at work and at home, noise is everywhere. Up to 90 per cent of most production type workplaces, even warehousing, could have noise levels above the maximum allowable limit, estimated one WSPS occupational hygienist recently.

“Using a smartphone app and an external microphone will give you data,” says Clements. “But the data might be misleading if you are not using a

Modular Embedded PCs

calibrated, external microphone. How can you make sound decisions if you don’t have the right information?”

Clements offers an alternative that doesn’t involve any technology. “If you’re a metre away and have to raise your voice to a very loud level to make yourself heard, this tells me the noise level may be around 85 db,” he says. “But this too is a rough, subjective guideline. Use it only as an indicator that further testing may be required.” | MA

www.advantech.com

Modular Platform Design Features a stackable design that is available in a universal, custom, or design-specific solution. Wide Range Power Input 10~36V power input ensures normal operation in unstable power environments.

Multiple I/O Expansion Modules

Various I/O expansion modules support most popular protocols offering more than 100 combinations to support vertical application scenarios.

Versatile Mounting

GOING DIGITAL

BY JENNIFER RIDEOUT

Securing your industrial control system

Every year the cybersecurity experts at Cisco release the Cisco Annual Cybersecurity Report, an industry tome that discusses security trends and emerging threats. In the 2018 report, the role of the Internet of Things (IoT) and its effect on cybersecurity was analyzed, particularly as it pertained to operational technology and networks.

The report surveyed security professionals within the manufacturing industry to determine how prevalent attacks on operational technology (OT) equipment and networks have become. The results proved what many have already warned manufacturers about: The attacks are coming and you need to be prepared.

Here is a snapshot of the report findings:

• Thirty-one per cent of security professionals said their organizations have already experienced cyber-attacks on OT infrastructure.

• Thirty-eight per cent said they expect attacks to extend from IT to OT in the next year.

• Sixty-nine per cent of organizations surveyed believe OT is a viable attack vector in 2018.

So how can the nearly 70 per cent of manufacturers protect their OT infrastructure from the WannaCrys and Nyetyas of the future? The good news is some are already investing in improvements to their cybersecurity architecture. Industrial zone cybersecurity strategies and industrial firewalls to protect the overall network were in use by 50 per cent or more of respondents. It’s a great start, but more can be done. Specifically, more can be done to secure the industrial control systems (ICS) that operate within the OT network.

How can you secure your ICS?

Cybersecurity requires several layers of defence to protect equipment from the various vulnerabilities that hackers can exploit. Think of it as a soccer team. It’s not enough to have a keeper — you need defenders and midfielders to contain attacking players. In this analogy, your keeper is an industrial firewall and your fielders are ICS solutions.

To secure your ICS, ask prospective vendors the following questions to determine whether they can implement a successful security solution.

• How do you detect and protect against an ICS security threat?

Monitoring, defending and remediating against risks and threats throughout your network prevents downtime and loss of control, even against physical anomalies, such as squirrels, jellyfish or birds.

• How do you participate in ICS standards creation, research and industry training?

Adhering to ICS standards with up-todate products, policies and procedures ensures you won’t implement an inefficient security solution that doesn’t drive compliance.

• How do you secure each boundary level of an ICS network?

Applying a strategy to secure every level of your ICS network prevents disjointed solutions and insufficient levels of security.

• How are your industrial hardware manufacturers supported?

Employing compatible, supportable and flexible hardware from a vendor with design and support expertise is vital to avoid unnecessary network traffic and implementation issues from a poorly designed system.

• How does your security help drive broader business outcomes?

Maintaining the same standards of availability while securing your ICS is critical to achieve the increased connectivity required for an IoT network and drive the digital transformation of your architecture.

• How does your solution integrate with other IT and OT products and services you offer? Integrating IT and OT security products and services decreases the likelihood of

introducing vulnerabilities and gaps into your system.

• What types of visibility does your solution offer into an ICS?

Gaining full visibility into every zone and segment of your ICS enables you to defend against risks and threats that go undetected through different layers.

• Can you describe the full range of security provided by your solutions at the IT and operations interconnect?

Establishing network requirements and management processes through IT and OT convergence preserves the existing availability standards and improves your security.

• What authentication and authorization protocols do you implement for network access?

Utilizing a comprehensive set of authorization policies and protocols lowers your risk by keeping out unknown or unwanted entities without impacting operations.

• How do you know that your security solution will successfully integrate with my network architecture?

Implementing a solution that integrates seamlessly with your existing systems helps you avoid introducing unknowns and unintended consequences, or creating new vulnerabilities.

W hen looking to secure and maintain your ICS, remember that every vendor has strengths and weaknesses. The answers to the above questions will help you identify potential weaknesses and make an informed decision around the services and features required to secure your ICS. | MA

Jennifer Rideout is the manufacturing marketing manager for Cisco Canada. She is responsible for developing go-to-market strategies for the manufacturing sector in Canada, including channel alignment and content development. She can be contacted at jerideou@cisco.com.

Download your free pressure calibration application note at fluke.com/729calibrator

Simplify pressure calibration

Let the new Fluke 729 Automatic Pressure Calibrator change the way you calibrate.

• Fast, easy setup with automatic pressure regulation

• Automatic, no-hassle calibration and documentation

• Built-in HART communication

• No hand pumps or manual adjustments required

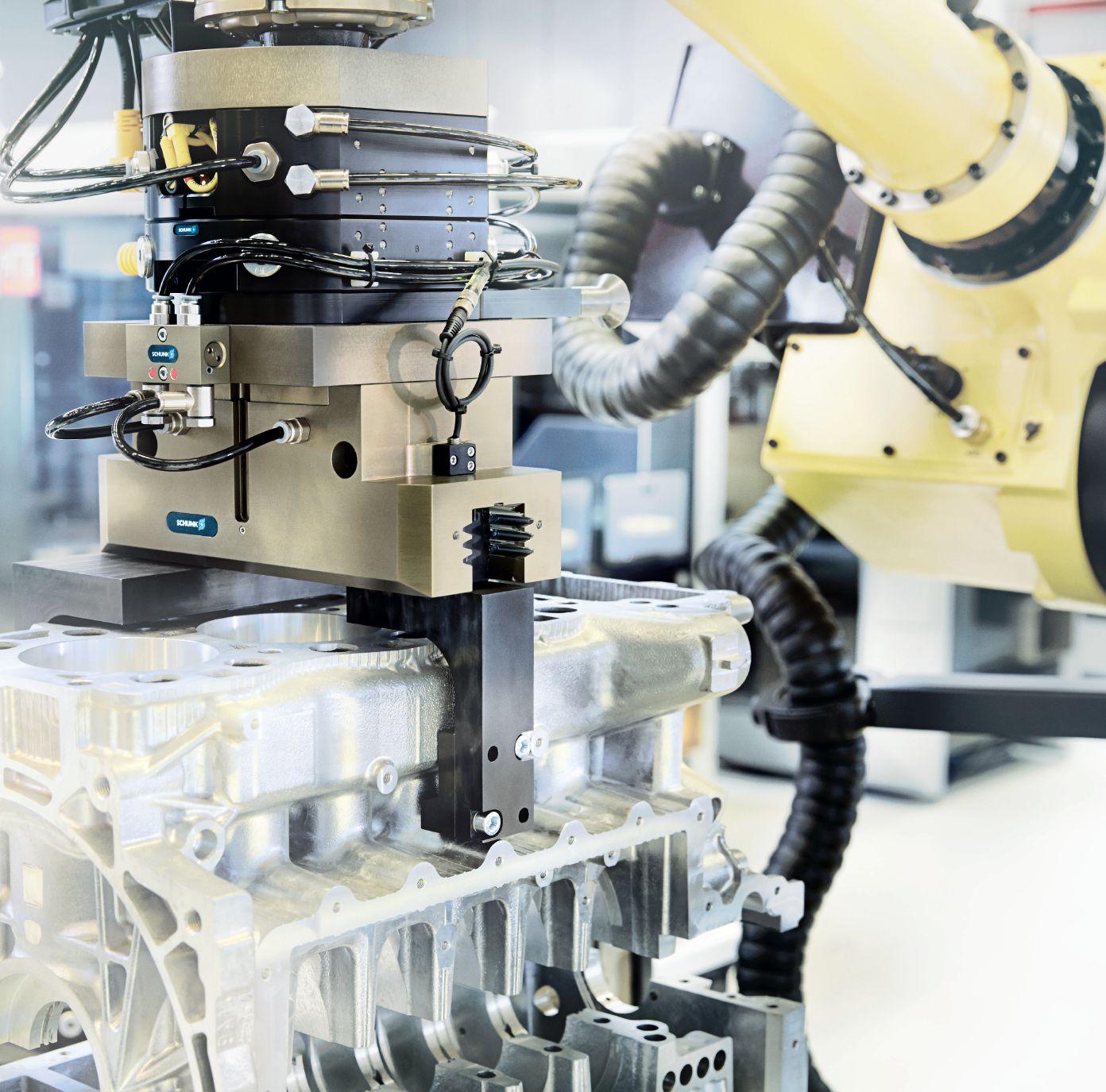

We speak to Eric Logan, U.S. Advisory Managing Director at KPMG LLP, for his thoughts on industrial robotics and the evolving manufacturing environment.

• The current industrial robotics landscape

The industry has been preparing for the increased use of automation for quite a while. In fact, KPMG’s own research indicates that robotics is expected to grow by 23 per cent over the next three years, meaning the ability to deploy in an efficient and effective way is going to be critical. If you look at the robotics industry, historically, the bulk of the impact has been in areas that weren’t specifically manufacturing related or designed for new robotic systems. However, as the demand for automation increases, the industry is shifting. In the past, we saw manufacturers invest in robotics simply for discrete tasks — using a robotic arm to move an item from one line to another. Today, for Industry 4.0, robotics is one link in the chain. Now, we’re seeing a lot more cobots and automation that is real-time data driven. In Industry 4.0, different components are interconnected within the manufacturing environment where one doesn’t really exist without the other. Yet the true potential exists when these components are also connected to key activities outside the manufacturing environment. We tell clients that confining any of these discrete elements to ‘the four walls of the manufacturing floor’ means losing a good deal of the potential benefits of Industry 4.0.

The fact is today’s robots don’t exist in a vacuum. They are consistently fed with an immense amount of information that enables them to complete multiple tasks. For example, in a storage facility, a robot can determine what item to pick based off of the schedule in the facility. The robot can make ‘decisions’ based on the data it’s fed versus performing the same discrete task over and over.

• Some barriers that hold manufacturers back from adopting the smart factory

We have a number of clients who ask us how they can implement Industry 4.0. We tell them all the same thing: first, take a step back and evaluate your strategy. The type of technology an organization implements must be integrated with the business model, the organization and the output, and there must ultimately be buy-in from the individuals

there. Having this kind of ecosystem view also takes into account an organization’s mechanisms for communication and network infrastructure, like a methodology that pulls big data into a Cloud application that feeds AI information to the machines. Because of all the necessary infrastructure that is part of the connected factory, implementing Industry 4.0 means that manufacturers must take a topdown holistic approach as opposed to a project-specific approach.

In my view, this is where a lot of organizations fail. They don’t look at integrating technology holistically, but rather as one-off opportunities. Industry 4.0 should be seen as a system of opportunities that work together to deliver a specific return, and that return is not always just an economic return. It should be a specific return – or set of returns – that is driven by the organization’s strategy.

Two challenges manufacturers need to overcome to have a betterconnected environment are data analysis and data security. The key is ensuring you have the correct data storage methodology, the right data analysis tools, and that you’re using the data appropriately.

The collection piece isn’t as hard today; the real challenge is determining what data is important and how you analyze it to make it useful and help increase manufacturing output. There is so much data today that manufacturers are overwhelmed with the amount they’re able to collect. There are organizations that have opened separate

centres just to hold the data they’ve collected without having an understanding of how to appropriately use it. And of course, when using Cloud technology that crosses the boundaries of the manufacturing floor, cybersecurity becomes a significant concern.

• The rise of industrial robotics

Robots are definitely driving manufacturing efficiency; in some cases, they are working with humans and in other cases, they are working beside humans. In many cases, people implement automation to define greater repeatability and reliability — as opposed to having humans perform the same task. A bunch of new jobs have opened up thanks to robotics. People doing data and analytics and process automation will have new opportunities because this is a growth industry.

There has to be intent behind how you roadmap for Industry 4.0 and how you integrate it into your business. Robots today are much more driven at the interface by some type of artificial intelligence. The reality is today’s technologies extend beyond the four walls – it’s about connectivity in an interactive hub. We’re seeing a huge revolution of automation and it’s reaching all areas of the manufacturing operation –including the front office, back office and supply chain. It’s not just about putting a robot on the floor. It’s important to think through the whole organizational structure and how it could be impacted. | MA

THE TECHNOLOGY WAVE

Latest survey results show strong commitment from Canadian manufacturers to invest in near-term technology and machine upgrades

BY ALYSSA DALTON

This year marks the return of the annual Canadian Manufacturing Study after a year’s hiatus in 2017, and based on our results, the Canadian manufacturing landscape has ticked up ever so slightly since our findings in October 2016, a trend that is consistent with the past several editions of the study.

Conducted by Manufacturing AUTOMATION in conjunction with the Excellence in Manufacturing Consortium (EMC), the survey is designed to provide insight into Canadian manufacturers and their strategies, preferred technologies and near-term spending plans, while offering company snapshots and year-toyear comparisons of industrial performance.

One of the most promising findings is that more than three-quarters of the 561 respondents say they have plans to invest in new equipment, machinery or technology upgrades within the next three years, signalling strong commitment from Canadian manufacturers across the board to replace, upgrade or retrofit aged assets and legacy systems. This is up from the 59 per cent of respondents who, in 2016, said they intended to pursue a production upgrade.

WHAT OUR RESPONDENTS SHARED WITH US

“The only way to compete is to automate the automation. It is harder to find staff and so we must leverage the ones we have. Smarter not harder is the catch word for the future... Let technology and vision be our advantage.”

A new question we asked respondents this year is why they believe facility and operation upgrades are important, and we received a number of comments. One respondent wrote, “[It is the] only way to remain competitive –overhead and expenses continue to increase yet the marketplace will not accept [cost] increases, therefore we need to manufacture and sell more aggressively.”

Another comment simply read, “If you don’t stay current, you are not competitive.” Very well said, my friend.

SURVEY HIGHLIGHTS:

• Nearly 65 per cent of respondents – up almost 10 per cent than our 2016 findings – ranked the availability of skilled labour and the skills gap as the top barrier to their company’s future competitiveness. Labour costs and the value of the Canadian dollar followed at 49.16 per cent and 43.41 per cent respectively, as other challenges they are facing. It’s worth noting close to 40 per cent cite investing in new equipment and technology upgrades as another common hurdle.

• A whooping 81.55 per cent of respondents say they plan to undergo a near-term

“Technology changes so fast and if you don’t keep up, you become obsolete.”

production-related investment – consisting of new equipment, machinery or technology upgrades – over the next three years. Engineering/R&D and training and education both came in around the mid40 per cent mark as the second and third most popular areas for near-term capital investment. Surprising, investing in cybersecurity strategies came in last at around 11 per cent.

• Automation software came in as the top new production purchase (nearly 40 per cent) most respondents are targeting. Following closely behind are production control, CNC machining/milling and material handling. — the same top four production activities respondents chose in 2016.

• Fifty-two per cent of respondents say they do not use robotics in their manufacturing operations, down a bit from 2016’s 60 per cent. It’s interesting that 32.66 per cent ranked their use of robotics from somewhat important to critical, an eight per cent jump up from the 2016 survey.

• Fifty-eight per cent say they have experienced increased demand from customers, up from 2016’s findings of 54.67 per cent.

• Like previous years, our home country is once again the top region Canadian manufacturer plan to expand into, followed by the United States, Europe and Asia. Roughly 14 per cent say they have no current plans for future expansion at this time. | MA

Are these findings in line with what you see in your facility? Continue the conversation and share your thoughts with our editor at adalton@annexbusinessmedia.com.

“The greatest challenge we face is not in acquiring new technology but having the knowledge and skill set (labour) to execute the technology. Funding is available for hardware and some software but not for the labour component.”

“Change is inevitable. Products and use evolve so must we evolve to ensure and continue our long-term sustainability. We invested from day one and it is naive to think that you have just that initial investment we need to protect what we’ve already invested and keep moving forward.”

“Innovation is key to succeed in the future. More precise data means better decisions to be taken. Productivity must increase and we don’t have choice to modernize our equipment, since it has become harder to find good employees, and even just find employees!”

COMPANY SNAPSHOT

(Note: respondents were able to select more than one industry as their primary industry.) What is the primary sector you serve?

STRATEGIES FOR GROWTH

What is your best estimate at a dollar amount for how much manufacturing technology, software and related capital equipment and services your firm will purchase over the next three years?

A total of 561 completedrespondents the survey over a six-week period in February/March.

OPTIMIZING OPERATIONS

How touchscreens can motivate assembly line workers to do quality work

BY ANTHONY BORGES

When UTC Aerospace required a solution to manage assembly line workers with no previous manufacturing experience, it decided to try something new that set a precedent for its future manufacturing operations management (MOM) strategy. Using manufacturing software from PINpoint Information Systems that features

situational awareness graphics on plant floor touchscreens, the manufacturer was able to train an unskilled workforce to build safety critical electronics without defects, which actually helped ramp up production within days, said UTC Aerospace. With the software monitoring and controlling the hundreds of process steps needed to build the products, problems and defects could not go unchecked so error-proofing was maximized.

How do touchscreens motivate assembly line workers to do quality work on time? All manufacturing stakeholders become accountable for the quality of the product, and the efficiency or timing in which it is assembled when individuals report to their own workstation touchscreens. The information created through an individual’s interactions with the touchscreens is also broadcasted to large plant floor displays for all team members to see, critique and act on. This manufacturing methodology emphasizes every line worker’s and supervisor’s own responsibility to contribute positively to the overall goal of manufacturing products of high quality in an efficient way, with the least amount of waste produced.

A ssembly line workers and

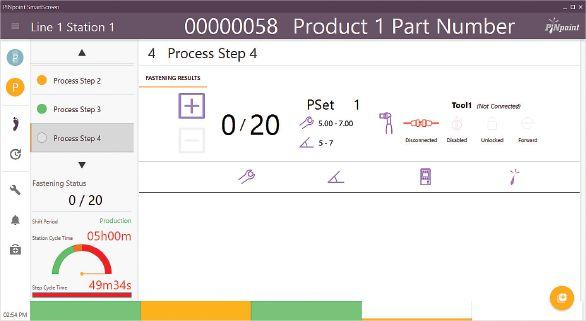

area supervisors become fully accountable for the finished product the moment they log into the user interface software with their own unique login and password. Figure 1 is an example of the SmartScreen user interface with various situational awareness graphics reporting the details and real-time performance of the individual line worker/ workstation. The information includes the scheduled production time, the real-time status of the Goal Planned Actual (GPA), and Overall Equipment Effectiveness (OEE) which helps ensure the line worker is made aware and of their progress within the cycle time.

S ince each manufacturing stakeholder is identified by her/ his own credentials, they must

Figure 1: Assembly line touchscreen user interface featuring situational awareness graphics.

Figure 2: Fastening

visualization.

The touchscreen user interface and software help foster a teambased approach that instills a new culture, and closed-loop accountability in the factory where all manufacturing stakeholders are made accountable for what they contribute.

succumb to the first level of assembly line error-proofing. The software behind the user interface touchscreen identifies the worker and then confirms – before any work can start or tools are enabled – whether that person is actually qualified to do the work. The software, PINpoint describes, ensures quality by authenticating that the person has received the proper training to perform the process steps and that they are aware of the latest quality alerts and safety requirements unique to their workstation or process.

At the heart of the user interface software is a manufacturing execution system (MES) and multi-dimensional database containing all the information required to build the product, along with the record of the line worker’s credentials, their training and up-to-the-second historical assembly line performance data.

Once the line worker is verified, the user interface presents the relevant work instructions so they can begin performing the steps to build the product. In the case of the common fastening operation, the user interface displays the tolerances required for the fastening operation. Figure 2 shows a SmartScreen example where the line worker has progressed to Process Step 4 requiring them to perform 20 fastening operations within the parameter set (PSet) of 5.00 – 7.00Nm at an angle of 5 - 7°.

PINpoint believes the worker is motivated to perform each process step carefully and quickly since they are made aware of the cycle time remaining to complete

the operation by way of the cycle time gauge shown at the bottom left side of the main screen. Along the bottom of the screen are coloured bars that can also be configured to visually indicate and further re-enforce how they are progressing.

Once the worker begins performing the fastening operation, the touchscreen displays their Fastening Results step by step with textual data and graphics that shows the worker’s progress. Not only does the touchscreen help guide the worker in each fastening operation, the system monitors their performance and can halt their progress and even turn off their tools should any operation be performed outside the set parameters.

The touchscreen user interface and software not only motivate line workers, they help foster a team-based approach to manufacturing execution that instills a new culture, and closed-loop accountability in the factory where all manufacturing stakeholders are made accountable for what they contribute, describes PINpoint. The data generated by the line workers’ activities and the data recorded from the machines also becomes indispensable as business and manufacturing intelligence reports become increasingly essential for optimizing manufacturing operations. | MA

Anthony Borges, marketing manager at PINpoint Information Systems, offers over 14 years of manufacturing optimization knowledge, with an aptitude for solving problems which increase business and manufacturing efficiency. Headquartered in Burlington, Ont., PINpoint services industry internationally from its offices in Canada, the United States and China.

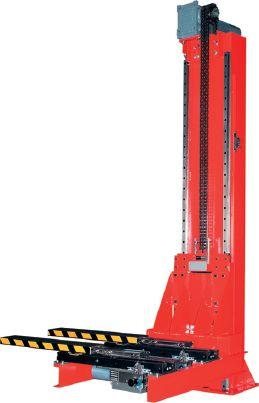

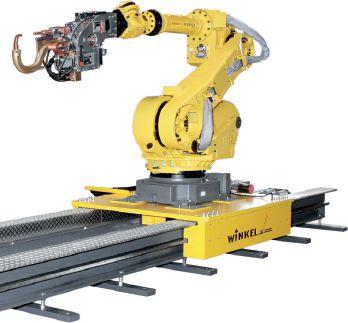

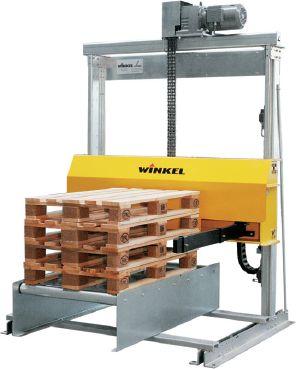

linear from 0.1 – 100 t No. 1 in Heavy Load Handling economical and innovative robust, value for money, from stock

Pallet stacker

Robot tracks

THE INDUSTRY 4.0 PHILOSOPHY

The key is to move forward or face the risk of being left behind

The Industry 4.0 concept is the result of a question initially posed by the German government to its manufacturing leaders: What’s the next stage of evolution for manufacturing? What would our roadmap for the future of the industry and manufacturing look like? Those questions have evolved into a global movement known as Industry 4.0, which strives to make production operations more efficient, cost-effective and flexible while delivering a better-made product to the customer in less time. Rather than aiming to optimize individual engineering, production or logistics stages, Industry 4.0 demands us to re-examine and improve the way these stages inter-relate.

In essence, Industry 4.0 is about data, software and interfaces and the ability to use those elements to model and simulate the final product in a virtual environment to optimize the design and eliminate errors prior to the actual manufacturing process. A seamless value chain can make it possible to slash engineering and production costs by up to 50 per cent. Some manufacturers have also been able to shorten design times by up to 60 per cent by reducing delays caused by repetitive rework involved in design changes.

The four Industrial Revolutions

First, let’s consider what brought us to this 4.0 stage in industrial manufacturing automation. The First Industrial Revolution marked the transition from making things using human and animal power to making them with machines by harnessing

14%

Just 14 per cent of executives polled across 19 countries are “highly confident” their organizations are ready to fully harness the changes associated with Industry 4.0, according to the 2017 Deloitte Global survey.

$900B

Businesses are committing more than US$900 billion a year toward their digital transformation strategy, according to a PwC 2016 survey.

Industry 4.0 companies are completely digitizing their physical assets and integrating themselves into digital ecosystems that include partners along the value chain, from suppliers to customers.

water and steam power. The ability to use electricity in the mass production of goods made the Second Industrial Revolution possible; the Third came as the result of the use of computers to automate production processes. The name Industry 4.0 represents the Fourth Industrial Revolution, marked by the continuing digitization of the manufacturing world – through the use of cyber-physical systems and the Internet of Things (IoT) – in order to maximize flexibility, resource usage and efficiency.

Introducing IIoT

A cyber-physical system is a group of elements – such as machinery, tools and workstations – that communicate with each other in a coordinated way. This is possible because modern electrical, electromechanical and hydraulic systems, and system components have their own intelligent elements (controls, sensors and actuators) and communication interfaces that allow the exchange of data between the individual systems and components through the Industrial Internet of Things (IIoT).

Cyber-physical systems and the IIoT are critical elements of smart factories — production environments in which all the elements involved in the production process (engineering, machinery, logistics chains, etc.) communicate with each other to maximize

production flexibility and prevent wasted resources, such as costs, worker effort, equipment capacity, mis-machined parts, and incorrectly assembled systems.

Although tools to provide Overall Equipment Effectiveness (OEE) information to factory management have been around for decades, they tend to focus on finding root causes for problems that have already happened rather than on providing predictions that managers can use to prevent future problems. The IIoT, the smart factory and Industry 4.0 concepts go well beyond real-time condition monitoring and fault diagnosis to a single, interconnected data path from design to revisions to production.

The ultimate goal is that by linking these aspects in one value-added chain, manufacturing is accelerated because costly waste and production delays are removed.

The era of total digitization

The Industry 4.0 revolution goes well beyond concepts like the Industrial Internet and the digital factory. Industry 4.0 companies are completely digitizing their physical assets and integrating themselves into digital ecosystems that include partners along the value chain, from suppliers to customers.

The PwC 2016 Global Industry 4.0

survey reveals more and more industrial companies worldwide are making digital transformation the focus of their business strategy. Globally, these companies plan to double their average level of digitization within five years, from 33 to 72 per cent and are investing more than US$900 billion annually to do it. The message from this study is clear — the time for talk is over, and the time for action and investment is now.

No one factor is driving the Industry 4.0 revolution, but the unstoppable need for profitable growth is powerful. Customers are demanding more while insisting on lower prices. Digital technologies offer a means to meet these demands, as well as a route to new and potentially lucrative products and services. At the same time, industry heavyweights have already begun their digital transformation, adding pressure on other industry players to keep pace. The connected technologies of Industry 4.0 offer today’s manufacturers the opportunity to achieve sustained success in the years to come. | MA

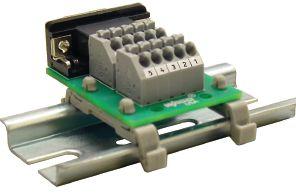

Evolving electronic enclosure design and production

Producing customized industrial control panels and enclosures has traditionally been a highly labour-intensive process. In the past, electronics enclosures typically started with very large, welded, fixed-form metal boxes, and the manufacturer would mount all of the components to the walls or the mounting panels. The problem with this approach comes when the standard size isn’t quite big enough to accommodate all the electronics, power distribution and climate control hardware that must go inside. At that point, the only option is to create a custom box, which adds significant cost and engineering complexity to the design. Even after factory computer networks became common, many operations associated with building custom enclosures still had to be performed manually, including engineering; layout; punching and drilling the back panels and enclosures; cutting to length, stripping, crimping, and labeling the wires; installing the components; and wiring the panels. Revisions were common during the build cycle, which meant all documentation had to be updated to reflect the changes manually, leading to costly and time-consuming rework.

One example of the Industry 4.0 philosophy in action is the sister companies at Friedhelm Loh who say they strive to simplify the control panel and enclosure design and manufacturing process by forging every link of the value chain from the enterprise resource planning (ERP) connection for managing costs and bill of materials, through EPLAN, for designing the mechanical, electrical, pneumatic, and hydraulic systems, then on to building and placing the physical control panel components into a modular Rittal enclosure. Meanwhile Rittal Automation Systems’ automated panel cutting and wiring machines cut holes to accommodate accessories, drill and tap mounting holes and run the wires without any human intervention, using the files created in the software during the design process.

“Although the greatest benefits come when EPLAN’s CAE Environment, Rittal’s modular enclosures, and Rittal Automation Systems’ Perforex CNC machines are used together, they can be used separately as well. The beauty of this approach is that it offers the flexibility of an open value chain; these tools can automate the design-to-build process even for enclosure projects for customers who choose enclosures manufactured by some of our competitors,” explains Rittal. | MA

The open remote I/O system o ers maximum flexibility for the adaptation of existing system environments with head modules for PROFINET/PROFIsafe, Ethernet/IP and CIP Safety. A simple substitution of the head module allows the communication within di erent networks. Wide ranges of safe and standard I/O modules are available.

to watch our PSSuniversal 2 video. Online information at www.pilz.ca

Automation Safety Canada L.P., www.pilz.ca

This article has been reproduced with permission from Rittal North America LLC.

EFFECTIVE DATA ANALYSIS

You’re collecting data, now put it to work

BY DAVE MANNILA

Your production lines are likely collecting data like never before, but are you obtaining timely and actionable insight from this data? Insight to reduce production costs per unit by boosting first time yield? Insight to reduce warranty claims and recalls? Insight to improve quality with fewer in-process test stations?

Industry 3.0 computerized manufacturing and gave us the tools to collect a variety of data from across the plant floor. It did not, however, provide the most effective means to make timely use of this data to improve these performance measures.

With Industry 4.0 – or Manufacturing 4.0 – data collection has become even more pervasive and granular. More is not necessarily better. Data that doesn’t work for you every day, on every shift and through every cycle of a production process or test isn’t worth much.

The good news is effective data analysis is also a hallmark of Manufacturing 4.0. The Big Data management, analysis and visualization tools that unlock your data’s full potential and make it accessible to the non-engineer are widely available today. Here is what these tools allow you to do.

First, collect and organize Every cycle of a production process or in-process test generates data.

This includes SPC and scalar data that is great for monitoring and tracking the health of production line at a high level. What’s more important is the digital process signature generated by each process or test cycle — these provide much more granular insight to trace the root cause when a problem occurs. And let’s not forget the images and related datasets generated by machine vision systems used for quality inspection.

All this data must be collected into a single central database. It can’t be left to languish in silos trapped on the plant floor. We can do this by equipping process and test stations with appropriate digital sensors, connected over a robust network architecture.

O nce collected, this data must be organized in the right way — by the serial number of the individual part or assembly. This serialized dataset, called a birth history record, paints a picture of what happened to that part or assembly through every stage of production and testing in millisecond increments.

The next step: Analyze Many systems capture and store

digital process signatures as flat image files. These systems lack on-demand visualization tools. Data must be exported into spreadsheets, in which each test or part has its own tab with its signature’s waveform image. There is no way to overlay and correlate these images. Making any sense of this pile is time-consuming and frustrating, and these files are not easily correlated with other related data, such as scalars or machine vision images.

Modern analytics tools convert data into histograms that can be correlated with other data types associated with that serial number or type of part to illustrate the profile of a good unit and the range of acceptable deviation. This makes it easy to create and visualize a baseline against which to compare all units.

Then act with surgical precision

With this approach, process variations or anomalies can be spotted before they lead to scrap and rework, and be further analyzed to reveal relationships that might explain the problem. Anomalies can be quickly searched for

within a large group of units and only those that match the anomaly need to be quarantined or recalled. This is particularly valuable if the product has already shipped. Instead of a mass recall that impacts a large number of customers and tarnishes your reputation, you can engage in a targeted and limited recall of the specific serial numbers, as the data indicates the flaw.

S ay a final assembly, like a hydraulic system or a fuel pump, is leaking. The first step is to pull all the data for that problem unit. See if there is anything off about the unit’s original test signatures, even within the range of standard deviation. Then, look at the data from all the other processes upstream that touched the unit. Sometimes a problem just doesn’t show up at a test station.

For example, maybe a pressing operation was flawed and this can show up in the force versus distance signature for that process. The part may still pass its final leak test, but will eventually leak like a sieve at the location of the poorly pressed components when subjected to normal use over time.

You can play ‘what if?’ at any time

Once you have optimized the function and performance of your production and test stations through this process of data collection and analysis, you don’t have to reinvent the wheel. With the root cause of a production or quality issue identified, the comparable process, test or machine on other lines or at other plants can be adjusted before they can suffer the same problem. Process signatures from a new production line can be matched against an existing production line to give a strong indication of conformance.

Take your leak test, for example. With any test, there is always that point where running the test longer will not yield further improvement — or in the case of a leak, take more time to fill or stabilize the part. In the old days, quality engineers had no choice but to rely on archaic methods of trial and error, wading through piles of spreadsheets with manual calculations to find the ideal test limits. They don’t have to anymore.

Today’s data analytics tools can automatically calculate statistically based limits. Hundreds or even thousands of datasets can be tested and reviewed offline to explore the impact of different test parameter and limit settings. On a high-volume production line, shaving a couple seconds off each test cycle can be enough to reduce the number of test stations that are needed to keep up with production.

With all that data at your fingertips, you don’t have to wait until you know you have a problem or a new requirement to implement before taking action. You can run a simulation or data model at any time on your archive of data, just to see what the outcome might be. Play with the numbers, run them again, and compare the results. In just minutes or hours, algorithms can achieve reams of spreadsheets, which once took days or weeks to accomplish.

The end goal is to find out how

you can make those little tweaks that can add up to a big impact on quality, efficiency and yield. Best of all, this can be done offline so it doesn’t disrupt or interfere with the line operation, the test stations or with anyone doing their job.

Rapid ROI and big savings Data makes all the difference when it comes to continuous

improvement in manufacturing. Visibility into the process –what’s working and where the problems lie – is a powerful tool for reducing cycle time, controlling costs and improving productivity across the plant. The more data you have, the better the insight you can achieve. With today’s off-the-shelf data analysis and visualization tools, a modest investment can generate a

return on investment in a matter of months and yield millions in annual savings. | MA

As a senior product manager at Sciemetric Instruments, Dave Mannila has broad responsibility for new product concept, definition and development, as well as maintaining Sciemetric’s overall product roadmap. He has more than 20 years of hands-on experience working with manufacturers to develop products that make them more efficient, profitable and respected in the marketplace.

Servo Mount Gearheads Low Backlash For Life!

HPN Harmonic Planetary® value series provides a low cost solution without the need to compromise on quality or performance. This new value series of planetary gears carry the reputation for quality and reliability for which Harmonic Drive® products are known throughout the world.

• Helical Gearing

• Available in 5 frame sizes

• Peak Torque: 9Nm to 752Nm

• Ratios: 3:1 to 31:1, new two-stage ratios available soon

• Quick Connect® mounting system

• High Efficiency

• Backlash: <5 arc-min (single stage), <7 arc-min (two stage)

• Fast Delivery

• Shaft output available with key and centertapped hole or with center-tapped hole

INNOVATE WITH PLM TIME TO

How is your legacy system limiting you?

BY DOUG MACDONALD

Product lifecycle management (PLM) systems were conceived to synchronize and standardize product development processes and have been around for more than 20 years. Initially defined by CAD and CAD data management, legacy PLM has not progressed much further in its ability to handle the current level of product complexity of say, an autonomous vehicle. In fact, in the development of smart, connected products, teams need PLM more than ever and have become disillusioned by the limitations of their current PLM systems. To move forward, here are some reasons PLM initiatives get stuck and how this can hold teams back from innovating.

Why do we need to change?

We live in a world in which product complexity is increasing exponentially and shows no signs of letting up. Across all major industries, manufacturers need to manage products that are not only systems, but often systems of systems. Think of any car built in the last few years. They have product designs that require a mix of hardware, software, electronics and/ or firmware. Managing these systems of systems is a challenge that can’t be met using the simple tools of the past.

A recent Gatepoint Research PLM Benchmark survey found that there is a major disconnect between current PLM implementations and their promised value. Much of this is due to the architecture of legacy PLM and the ‘closed’ approach of their vendors. But a new approach is coming to the fore; the Product Innovation Platform — an innovation-enabling business platform that supports all product related disciplines and users.

But isn’t it easier to just do nothing?

Before you can even get started with implementing a Product Innovation Platform, there are some initial hurdles and misconceptions that need to be overcome — beginning with

your company’s legacy. Consider this mentality: “we’ve managed this way for so long, why change?” Is the risk of changing greater than the risk of simply doing nothing? For those who say, “It’s too big a job to change the entire PLM system,” the advice is to think big and start small. Your best bet is to start with one reasonably sized project, tackle that first and then decide whether you should undertake a full “rip and replace” approach or continue with an incremental approach that allows you to work with your legacy systems.

Many legacy systems are made up of disparate products that have been stitched together through years of acquisitions, resulting in silos within the PLM system architecture that make collaboration challenging.

What are the challenges we can expect?

• Inflexibility

While an out-of-the box solution seems attractive, and easier and faster to implement, it is more likely that a generic solution simply cannot meet the unique PLM requirements of a given company. Yes, they may be easier to initially roll out but because they don’t truly meet a company’s specific need, they are left with a minimally functional PLM system.

Traditional PLM systems are difficult to customize due to hard-coded business logic and data models that are used to define workflows, approvals, item types, etc. This means extensive reprogramming is required in order to customize, change or add new features to meet evolving business needs. This process can take months or even years to complete and can put the entire implementation at risk.

• Inability to scale to meet the needs of a large number of users Implementing PLM systems often means settling for less than what was hoped for. Companies often fall victim to the 10-10-100

formula: 10 per cent of the desired functionality is achieved, 10 per cent of the expected users are connected to the system, but 100 per cent of the planned budget is spent.

• Fragmented PLM systems

Many legacy PLM systems are actually made up of a mashed-up collection of disparate products that have been stitched together through years of acquisitions. This results in silos within the PLM system architecture that make collaboration challenging. Even though many PLM systems claim full functionality across disciplines, the individual pieces of software often don’t work well together and make communication and collaboration challenging. These siloed systems can make the creation of a comprehensive bill of materials (BOM) or an engineering change order (ECO), spanning multiple disciplines, impossible due to the multiple systems involved.

•

Legacy is legacy

Just because the product has a new name, it doesn’t mean it’s not a legacy system. Legacy is an approach, not a name. You can’t expect yesterday’s systems to address today’s and tomorrow’s problems.

What’s the way forward?