Control Motion AND Cost

SureServo® Servo Systems

Complete systems (motor, drive, & cable set) starting at $971.00

The fully digital SureServo family of brushless servo systems offers a rich set of features to cover a broad range of applications. Choose from eight standard permanent magnet servo motors that operate in combination with one of three standard servo drives.

• Precise control of position, velocity and/or torque

• Eight standard systems from 100W to 3kW

• Use with PLCs or any other host controller

• Drives feature on-board indexer and adaptive tuning modes

• Free setup software - download at: www.SureServo.com/downloads

• 30-day money-back guarantee

• Two year warranty

®

Add a precision planetary gearbox to increase available torque or for inertia balancing:

• Inline, right-angle, or hub style

• Best-in-class backlash

• Six gear ratios: 5:1, 10:1, 15:1, 25:1, 36:1, and 50:1

• All hardware included for mounting to SureServo motor

• Maintenance free with 5-year warranty Servo gearbox selector: www.go2adc.com/gearselect

Orders over $49 get FAST FREE SHIPPING

Jack Warner

Mary Del Ciancio

Assessing

BY ALYSSA DALTON

NOTABLE TWEETS

@IQMSERP

@LNSResearch,

@arc_advisory, and EY Americas Technology

Solutions share great perspectives in @AutomationMag article, “Top 5 in 2018”

@GeneralToolCo Safety is top priority in #manufacturing!

http://bit.

ly/2nqNYCx via @Auto-

Increasing robot density illustrates automation growth potential

There’s no doubt about it — industrial automation is on the rise around the world. According to the International Federation of Robotics (IFR), 74 robot units per 10,000 employees is the 2016 average of global robot density in manufacturing industries, up from 66 units in 2015.

@SymetriMFG

Time to #upskill! Find out more on how #automation leads to opportunities for this in the #mfg industry: autode.

sk/2rDGvEF

@VERASystem Intelligent Automation delivers #flexible #manufacturing processes that react in real time to changes on the shop floor. The factory of the future will be realized with intelligent automation: https://goo.gl/ jv72vz

The Republic of Korea has by far the highest robot density in the global manufacturing industry, a position it’s held since 2010. At 631 units, its robot density exceeds the global average by more than eight times. The high growth rate, the IFR explains, is the result of continued installations of a high volume of robots in the electrical, electronics and automotive industries.

Singapore takes second place with a density of 488 robots per 10,000 employees in 2016. About 90 per cent of robots are installed in the electronics industry in Singapore, finds the IFR. Meanwhile, Germany and Japan rank third and fourth in the world with 309 and 303 robot units, respectively. The IFR predicts that between 2018 and 2020, the annual supply in Germany will grow by at least 5 per cent a year due to increasing demand for industrial and automotive robots.

Rounding out the top five countries with the highest robot density in 2016 is Sweden at 223 units.

“Robot density is an excellent standard for comparison in order to take into account the differences in the automation degree of the manufacturing industry in various countries,” said Junji Tsuda, IFR president.

While robot density in Canada has grown steadily over the years, we land in 13th place at 145 units in 2016, largely driven by installations in the automotive industry.

Comparatively, robot density south of the border rose to 189 robots, placing the United States in seventh position.

One country to keep an eye on is China in its pursuit to become one of the world’s 10 most automated countries by 2020. Currently in 23rd place in terms of robot density, China has displayed the most dynamic development of robot density worldwide, says the IFR. Due to its significant growth of robot installations, its density rate rose from 25 units in 2013 to 68 units in 2016.

“The speed with which automation technologies are emerging, and the extent to which they could disrupt the world of work, may appear daunting but is not unprecedented,” states a 2017 McKinsey Global Institute report. “Technological change has reshaped the workplace continually over the past two centuries since the Industrial Revolution, and even earlier. Nonetheless, the latest technological developments will touch every job in every sector and in every country.”

But how exactly – and to what degree – will automation transform the workplace, a widening range of industries, and the global economy? Only time will tell. | MA

Your resource for Canada’s industrial automation news

EDITOR

Alyssa Dalton adalton@annexbusinessmedia.com

PUBLISHER

Klaus B. Pirker kpirker@annexbusinessmedia.com

VICE PRESIDENT & EXECUTIVE PUBLISHER

Tim Dimopoulos tdimopoulos@annexbusinessmedia.com

ART DIRECTOR

Graham Jeffrey gjeffrey@annexbusinessmedia.com

ACCOUNT CO-ORDINATOR

Debbie Smith dsmith@annexbusinessmedia.com

CIRCULATION MANAGER

Urszula Grzyb ugrzyb@annexbusinessmedia.com Tel: 416-442-5600 ext. 3537

COO

Ted Markle tmarkle@annexbusinessmedia.com

PRESIDENT & CEO

Mike Fredericks

CONTRIBUTING WRITERS

Mary Del Ciancio, Derek Eversdyke, John Graff, Paul Hogendoorn, Jennifer Rideout, Jack Warner, Jonathan Wilkins

Manufacturing Automation is published seven times a year by:

Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON, M2H 3R1 Tel: 416-442-5600 Fax: 416-442-2191

Printed in Canada ISSN 1480-2996

Publication Mail Agreement #40065710

CIRCULATION

email: lmalicdem@annexbusinessmedia.com Tel: 416-510-5187 Fax: 416-510-6875

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON, M2H 3R1

SUBSCRIPTION RATES

Canada — $42 per year

United States — $74 (US) per year and Foreign — $84.50 (US) per year

Students — $20 per year

ANNEX PRIVACY OFFICER

email: privacy@annexbusinessmedia.com

Tel: 800-668-2374

Occasionally, Manufacturing Automation will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

EDITORIAL ADVISORY BOARD

AL DIGGINS, Chair of the Board, Treasurer and General Manager, Excellence in Manufacturing Consortium, and Chairman and CEO, Canadian Manufacturing Network

DAVID GREEN, Technology and Business-to-Business Consultant

KARIN LINDNER, founder and owner of Karico Performance Solutions

DON MCCRUDDEN, Vice-President, Business Development, Festo

DAVID MCPHAIL, President and CEO, Memex Automation

NIGEL SOUTHWAY, Business Productivity Consultant and Author on Lean Thinking

BILL VALEDIS, Vice-President, Precision Training, Products and Services Inc.

The contents of Manufacturing Automation are copyright © 2018 by Annex Publishing & Printing Inc. and may not be reproduced in whole or part without written consent. Annex Publishing & Printing Inc. disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication.

We acknowledge the [financial] support of the Government of Canada.

AUTOMATION UPFRONT

INVESTMENT

ArcelorMittal commits $70 million to modernize Quebec steel mills

Steel producer ArcelorMittal Long Products Canada is committing $70 million to upgrade two adjacent operations in Contrecoeur, Que., where it produces wire rod and industrial steel.

The company plans to replace two reheating furnaces at the two facilities, boosting its overall rolling capacity by 100,000 tonnes, it says. Meanwhile, the dust collector at the ContrecoeurWest steelworks mill will also be replaced. The three initiatives are expected to improve energy use while reducing emissions at the complex and earn the company a rebate of roughly $25 million from Quebec government initiatives.

The upgrades are expected to be complete by 2020.

Linamar receives up to $100 million for advanced manufacturing development

The federal and Ontario governments have announced up to $100 million worth of combined grants to help automotive parts maker Linamar develop advanced manufacturing technologies.

The funding will help create 1,500 new Canadian jobs and maintain more than 8,000 by supporting advanced manufacturing processes – including artificial intelligence (AI) and 3D printing – and cleaner automotive technologies, says Linamar. The manufacturer will also open a new innovation centre in Guelph, Ont., focusing on technologies such as AI, machine learning and collaborative robotics.

“Innovation is the single most important thing we can do in terms of product design, process design and material development to solve global problems and

create opportunities for us all to succeed. To have our government support us in that endeavour is fantastic, further cementing the fact that Canada is a great place for advanced manufacturing to thrive,” said Linda Hasenfratz, Linamar CEO.

This is the first project announced under the Strategic Innovation Fund, a new program designed to attract and support

business investments across all sectors of the economy. The feds will provide a grant of $49 million

to the company and Ontario will provide a conditional grant of up to $50 million.

Funding plans: The Linamar investment will help create 1,500 new jobs and an innovation centre focused on cobots, machine learning, AI and more.

CLOSURE

Campbell to close Toronto soup factory; 380 jobs affected

Campbell Soup Company says it plans to close its manufacturing facility in Toronto, Ont., to improve the operational efficiency of its North American thermal supply chain network, as it moves its Canadian headquarters and commercial operations to a new location in the Greater Toronto Area.

The company cites significant productivity improvements and volume declines of canned soup in North America as two factors that have resulted in excess capacity in Campbell’s North American thermal supply chain network.

Campbell employs nearly 600 people in Toronto including its headquarters, commercial operations and manufacturing

functions. Approximately 380 manufacturing and manufacturing-related roles will be impacted. Opened in 1931, Toronto is the oldest plant in the Campbell thermal network.

“Due to its size and age, the Toronto plant cannot be retrofit in a way that is competitively viable,” according to a company statement. Campbell plans to operate the Toronto facility for up to 18 months and will close it in phases, transitioning its production to three U.S. thermal plants in Maxton, N.C.; Napoleon, Ohio; and Paris, Texas.

Canadian soup and broth production will be consolidated into the company’s existing U.S. manufacturing network.

“The decision to stop producing soup and broth in Canada was a difficult one. After a thorough review, we decided this was the best course of action for our business. We are operating in an

increasingly challenging environment as our industry’s consumer and retail landscapes continue to change dramatically. This decision in no way reflects on the talent or dedication of our team at our Toronto facility, and we are committed to assisting them through this difficult transition,” said Mark Alexander, president, Americas Simple Meals and Beverages.

mobile network and a super computer, the AI research park will focus on developing areas such as high-speed Big Data, Cloud computing and services, biometric identification and deep learning, Xinhua reports.

EDUCATION

A new workforce development training program for Humber College students

Hollow Bore Absolute Encoder

The company plans to relocate the Canadian headquarters in the next several months, noting that site selection is currently underway for a new location in the Greater Toronto Area, which will feature a new food innovation centre.

The decision to stop manufacturing in Toronto is part of a previously announced cost savings initiative. As of Oct. 29, 2017, Campbell has generated $345 million in annual ongoing cost savings from this multi-year initiative, and is investing a portion of the savings back into the business.

ARTIFICIAL INTELLIGENCE

China is reportedly building a $2.6-billion AI research park

China is planning to build a 13.8 billion yuan (C$2.6 billion) artificial intelligence (AI) development park, according to Xinhua news agency, which is expected to attract about 400 enterprises. Along with a fifth generation

Humber College and Festo Didactic are entering into a five-year partnership agreement designed to address the skills gap between industry needs and educational programming.

The agreement, in which Humber will become the exclusive post-secondary partner for the delivery of Festo’s proprietary training courses in the Greater Toronto Area, also includes the installation of the first Cyber Physical Factory in English Canada. The factory, to be housed in the Barrett Centre for Technology Innovation, is an expandable model enabling companies to research and engage in industrial simulations using technology to support production, logistics and quality assurance.

“Festo’s collaboration will strengthen Humber’s track record of providing leading advanced manufacturing and mechatronics education to our students and the community,” said Dr. Chris Whitaker, president of Humber

Festo and Humber College: As part of a new deal, Festo will install its Cyber Physical Factory at Humber’s Barrett Centre for Technology Innovation.

College. “This partnership brings the future of Learning Systems education to Humber, and shows the importance of industry partners working with students on emerging technologies.”

In addition to training, professional development and certification initiatives, the partnership will focus on fostering innovation and education through a science, technology, engineering and mathematics (STEM) outreach program to engage Ontario youth.

“Festo Didactic values Humber’s vision for the future of technology and innovation, and we’re excited to partner with the college to provide the opportunity for students to learn the skills and gain practical experience that today’s employers demand,” said Thomas Lichtenberger, Festo Didactic CEO.

The agreement will also provide students with internship opportunities in automation and manufacturing at Festo’s

headquarters in Germany, as well as employment pathways to positions at Festo’s Customer Interaction Center in Toronto.

Sask Polytech receives $157,000 from automation companies

An $82,133 donation from Mitutoyo Canada and a $75,000 donation from Sandvik Coromant Canada will help secure new equipment and student awards at Saskatchewan Polytechnic.

“These two gifts directly impact the heart of Sask Polytech’s mission to educate students and provide skilled and successful graduates,” said Dr. Anne Neufeld, provost and vice-president, Academic, Saskatchewan Polytechnic.

In recognition of the partnership, the Mitutoyo Canada Metrology Lab will be established in the Innovative Manufacturing program area at the school’s

Regina campus. It will provide an opportunity for students to learn on industry-standard equipment.

The Innovative Manufacturing program, which opened in September 2017, is a two-year diploma program designed to provide students with manufacturing knowledge that ranges from mechanical and CAD/CAM

engineering technologies, welding and machining disciplines to project management, industrial design and quality control/quality assurance strategies.

Meanwhile, the Sandvik Coromant donation will provide support directly to students in the Innovative Manufacturing and Machining programs at the

Innovative Automation Solutions

SENSORS: Inductive and Capacitive Proximity Sensors • Photoelectric Sensors • Level Sensors • Ultrasonic Sensors • Magnetic Sensors • Limit Switches • Safety Interlocks

Whether it’s our industry leading range of solid state relays and contactors, or our vast range of sensors, motor controls, energy meters and voltage/current monitors, CARLO GAVAZZI has the solution for your application needs.

Contact us today, and one of our field sales representatives will show you why we are one of the fastest growing automation companies worldwide. We’ll even provide a free evaluation sample to qualified OEMs.

Curriculum commitment: The combined $157,000 donation from Mitutoyo Canada and Sandvik Coromant will help secure new equipment and student awards at Saskatchewan Polytechnic.

AUTOMATION UPFRONT

Regina and Saskatoon campuses through student awards and enhanced training opportunities for faculty and alumni. As well, the donation of carbide tooling will help ensure programs have the resources required to efficiently operate the program labs, says the company.

“Education and training is imperative for increased competency in modern manufacturing,” added Randy Bossie, Sandvik Coromant Canada general manager.

TECHNOLOGY

Open Mind, Heidenhain team up for virtual machining

Open Mind Technologies has partnered with Heidenhain TNC controls for the first use of its

new NC code-based simulation solution hyperMILL Virtual Machining. The Connected Machining module allows networked Heidenhain TNC controls to be run from remote locations. The solution is available with the hyperMILL 2018.1 release.

“We are thrilled to begin rollout of this unique new virtual machining feature in conjunction with the powerful Heidenhain TNC 640 control,” said Alan Levine, Open Mind managing director, North America. “Open Mind’s bi-directional virtual software will allow the user to start or stop the machine tool, review or override some settings, run simulations, synchronize the machine simulation to the actual machine position and modify the Heidenhain control from anywhere our software is networked.”

Heidenhain’s workshop-oriented TNC 640 mill-turn contouring control focuses on HSC and 5-axis machining on machines with up to 18 axes. Guiding basic to advanced machining, the TNC 640 pairs well with Open Mind’s virtual software by connecting with Heidenhain’s DNC software and TNC Remo SDK options.

INTERNATIONAL

POLAND

RTP Company expands with new plant

RTP Company has expanded its operations into Poland with an 86,000-square-foot facility, which will support RTP’s custom compounded thermoplastics to customers in Europe. Expected to open this summer, the facility will have a wide dock area and a high clearance ceiling, says RTP, as well as a laboratory with controlled temperature and humidity, and space for up to six production lines.

DEAL MAKERS

Fives buys Konecranes Machine Tool Service Fives Machining Systems, a global machine tool and manufacturing

solutions provider, has acquired Konecranes Machine Tool Service (MTS) division.

Konecranes MTS division brings nearly four decades of experience providing preventive maintenance, rebuild, remanufacture, retrofit and repair services, as well as onsite support for machine tools.

According to the parties, the acquisition will provide customers with a greater depth of productivity solutions and services for a wider range of products and industries.

Fives Machining Systems Global Services and Konecranes MTS division are now combined in a new comprehensive aftermarket division.

“Our mission is to be the primary service and solutions provider for productivity enhancements and service support, to aerospace and industrial manufacturers, for the full range of machine tools in their facilities,” said Steve Thiry, Fives president and CEO. “For our customers, this means a broader range of machines that can serviced by some of the most talented machine tool specialists, control engineers, alignment/ calibration experts in the industry. Customers will no longer need to rely on multiple service providers eliminating potential

downtime due to scheduling and coordination conflicts.”

Luff Industries achieves SKF Equipped status

Manufacturer of conveyor components Luff Industries is the first North American original equipment manufacturer (OEM) to achieve SKF Equipped status.

SKF Canada describes the Equipped program as placing “strict quality standards on the design, manufacture and assembly of rotating equipment to achieve the highest performance.”

From this point forward, Calgary, Alberta-based Luff Industries will be able to label its conveyor components as SKF Equipped.

In order to achieve SKF Equipped status, Luff had to show it meets strict quality standards on the design, manufacture and assembly procedures of rotating equipment.

MOVERS & SHAKERS

Excellence in Manufacturing Consortium (EMC), a notfor-profit consortium serving and supporting Canada’s manufacturing industry, has announced several changes to its board of directors and daily operations. Jim McCoubrey, chair of the board, will be transitioning to director, board of directors. Al Diggins, president and general manager, will be transitioning into the role of chair of the board, treasurer and general manager. Shawn Casemore, board of directors, will transition into the role of president.

Tobias Kuehnle (left) has been named managing director of Trumpf Canada, succeeding Stefan Fickenscher, who became sales director of the Machine Tool division in the United States at Trumpf Inc., on January 1.

Kuehnle joined Trumpf GmbH + Co KG more than a decade ago in 2006. He began his career in the service department, holding three additional positions before becoming the head of Spare Parts in 2014. In 2015, Kuehnle became the head of Global Services Sales and in July 2017, he took on the role as head of Product Management and Sales Support Services. In his new role,

he will be responsible for the day-to-day operations of Trumpf Canada, including machine tool and laser sales, TruServices and technical service in the Mississauga, Ont., location.

Steven Travis has joined Klauber Machine & Gear in the role of plant manager, where he will manage the Pacific, Mo., manufacturing facility. His

responsibilities include servicing customers, developing internal teams, optimizing processes and production, and ensuring a safe work environment, says the company. His sales territory will cover North America. Klauber Machine & Gear, a business unit of Trident Motion Technologies (TMT), manufactures a range of fractional horsepower gearmotors. | MA

Digitalized Pneumatics

INDUSTRY WATCH

BY PAUL HOGENDOORN

Paul Hogendoorn (paulh@getfreepoint.com) is co-founder of

Technologies, “Measure. Analyze. Share.” (Don’t forget to share!) Visit www.getfreepoint.com for

Making things happen and getting things done

Five years ago, I started a new company with a couple of colleagues. We put a big whiteboard in the office, and across the top of it, we wrote: In a start-up company, everyone has to make things happen or get things done.

Five years later, the company is far beyond that stage, but the message is still on the whiteboard. It is still as true today as it was when it was first written. In fact, I think this message is valid today for every manufacturing company: Big or small, well-established or just getting started. Let me explain.

First of all, there is a subtle inference: Everyone should make good things happen, and get the right things done. One thing I recognize in myself, and in many people and organizations, is the need to be busy, and the desire to be doing exciting things. It’s not difficult keeping yourself busy doing things you want to do or that make you feel important and useful, but you might not actually be getting anything of real value done. A simple request to one service provider resulted in six emails bouncing back and forth over a week, which eventually led to a letter of engagement that needed to be signed before the initial question could be answered. The same question to an alternate service provider resulted in a short telephone conversation and an answer a day later. One got things done, while the other did a lot of work and just got busy.

When a candidate for employment makes it to the second interview stage, I often ask a simple thing of them post-interview: If they were offered the job, what are the first two or three things that should be done? At this point, I’m not looking for elaborate plans or asking them to do a lot of work, I’m looking for an indication that they are good listeners, grasp the general nature of the role and, most importantly, can set their focus on getting things done. Some folks will say they have to plan or do more research, and some won’t even respond. Planning and research are good, but certainly there must also be a few small things that are easy to identify and get done.

A journey of 1,000 miles still starts with

a first step. If someone is unable – or unwilling – to identify the first step or two, they likely aren’t a fit for us.

Because of this intense and relentless focus on delivery, many manufacturers spend little — if any time at all — on trying to make good things happen.

T he manufacturing world gets things done. Every day there are products that have to be built and sent to the shipping door. The right amount has to be there, in the right quantity, in the right order, for the right price, and of the right quality. No exceptions, day in and day out, manufacturers have to get things done. But because of this intense and relentless focus on delivery, many manufacturers spend little – if any time at all – on trying to make good things happen. Many have Lean and continuous improvement activities ongoing but I’d argue that this is primarily still a focus on getting things done, and not a focus on making good things happen. These activities have become a matter of making things and processes a little bit better; they seldom result in making something significantly better happen.

As an example, many automotive manufacturing suppliers will aim for 2 or 3 per cent productivity gains. When we suggest that a 15 to 30 per cent gain is possible on some processes, it’s because we are proposing an approach that involves changes to the way they are measuring, reporting or communicating information.

The cost is not the issue, it’s the fact that “we don’t do those things those

ways,” or “that’s not how we do it here.” Even though the person or team is tasked to make improvements, they really aren’t commissioned to ‘make things happen.’

Few manufacturers have any bandwidth for this kind of thinking because they are too occupied just trying to get things done. As a result, they continually settle for small incremental improvements, striving to keep up with their customer’s current expectations, or slightly ahead of their competitors — completely missing the opportunity to make significant improvement. And sometimes it’s even their customers who are the roadblock; they mandate small cost reductions over time but any savings achieved has to be returned to them. This kind of arrangement forces the supplier to simply aim to achieve the 2 or 3 per cent target – just get it “done” and make them happy – without any motivation to really think outside of the box and try to make something far better begin to happen. The terms of their deals actually get in the way. As I visit manufacturing plants all over North America, I remain convinced that our companies can remain competitive and our industry can be sustainable. The most successful companies I see are the ones that continually make good things happen, while getting the right things done. | MA

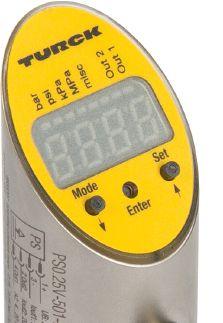

Full Range Of Pressure Sensors

• Ideal in pneumatic, hydraulic and many other applications

• Product for the OEM and end user

• With or without local display option

• Analog, discrete and I/O Link outputs

• Optional accessories available for mounting in challenging applications

GOING DIGITAL

BY JENNIFER RIDEOUT

The incorruptible power of blockchain

“The blockchain is an incorruptible digital ledger of economic transactions that can be programmed to record not just financial transactions but virtually everything of value.”

This is how blockchain technology is defined by Don and Alex Tapscott, authors of the 2016 book, Blockchain Revolution. It’s an accurate definition, but not necessarily one that is easily understood. So… just what is blockchain technology, anyway?

A blockchain is a continuously growing list of records or transactions between peers that are linked together sequentially in ‘blocks.’ Each block in the link (or chain) contains a cryptographic hash for the previous block, a timestamp and transaction data. Blocks include a record of every transaction that occurred on the network during that period, and every transaction is validated to guarantee accuracy.

Blockchain data is secured using cryptography. It is also stored across the blockchain network in a decentralized system, meaning that every node on the network stores the entire chain. This means the data being recorded is transparent to all nodes on the chain — albeit encrypted so only the persons involved in a given transaction can access their digital assets. What makes blockchain technology appealing is that it guarantees trust in peer-to-peer transactions, limiting the need for intermediaries like banks, car dealerships or retailers.

To put into context how secure blockchains are, consider that provider Ethereum has 25,000 nodes across the world on its network. In order for a hacker to steal or modify data on the chain, they would need to find a way to do so on every node at the same time. They would then need to repeat this for every subsequent block in the chain, forever. Therefore, data contained within a blockchain is considered incorruptible.

Put another way, let’s say you created a blockchain network (or leveraged an existing one) to track products across your supply chain. Because of the incorruptible nature of the data being recorded, you would never need to worry that shipment times, environmental conditions, or a slew of other recordable data points were modified or inaccurate.

But isn’t blockchain just bitcoin?

No. Blockchain is a network framework that enables secure digital transactions between peers while bitcoin is a digital currency.

Although bitcoin is transacted through blockchains, blockchains can transact far more than just bitcoins.

Why

should I care about blockchain?

First, blockchain presents incredible opportunities for data security. As mentioned above, the only way to falsify data is to falsify it on every node in the chain and in every block created since the initial validation. How would you like to have data that you absolutely know you can trust?

S econd, when leveraged appropriately, blockchain technology can save organizations a lot of time and money. ‘Smart contracts’ are possible with blockchain technology, which can automate actions and transactions between parties. For example, a smart contract can be created that only allows payment, or acceptance of delivery, if products are kept at a certain temperature during travel. If environmental sensors detect that the temperature went outside the acceptable range, the contract is not completed.

Last, although blockchain is seen by many as impacting only the financial industry, the technology is gaining ground in virtually every sector. In fact, the possibilities are nearly endless: Blockchain in the real estate industry can help record, track and transfer land titles, property deeds and more, and ensure every document is accurate.

Blockchain technology could mean healthcare providers finally have a way to share data across hospitals, doctors, patients and other parties without compromising data security or integrity.

For those who donate to charity, blockchain technology makes it possible to see

exactly where your donations go, and how those funds were used. It also makes it impossible for organizations to misrepresent how many donations they received and how they were spent.

And for retailers, blockchain can provide an irrefutable product history that verifies where, when, how and by whom their products were made. There is already work being done in this area by international coffee providers.

How will blockchain affect manufacturers?

In the near term, the biggest impact of blockchain for manufacturers is in the supply chain. I’ve provided some examples already, but the data accuracy and automation that smart contracts offer make it ideal for use across production and distribution. The ability, for example, to guarantee product quality can improve brand loyalty and make manufacturers more desirable to customers and consumers alike.

Blockchain also goes hand-in-hand with another network-based technology — the Industrial Internet of Things (IIoT). Manufacturers should know that the more data being captured across their supply chain, the better results they will receive from blockchain technology. For example, the smart contract scenario outlined above is only possible if environmental sensors are deployed in delivery trucks and send data to the network to report on conditions.

Like other technologies before, we are still discovering how blockchain will impact organizations. But as the use and use cases of blockchain expand, it will become increasingly difficult for manufacturers to ignore the possibilities of this new technology. | MA

Jennifer Rideout is the manufacturing marketing manager for Cisco Canada. She is responsible for developing go-to-market strategies for the manufacturing sector in Canada, including channel alignment and content development. She can be contacted at jerideou@cisco.com.

BY DEREK EVERSDYKE

Derek Eversdyke, Director of Facility Safety Products at Clarion Safety Systems, collaborates with safety professionals on best practice product safety label and facility sign systems. Visit www.clarionsafety.com for more information.

Machinery safety labels: Three tools for effective warnings

If your company manufactures machinery that has potential hazards associated with its transportation, installation, use, maintenance, decommissioning and/or disposal, you likely have a very strong need to create effective product safety labels. This task must be done right: Product safety labels play an integral role in your company’s product safety and liability prevention efforts. And that means that people’s lives and your company’s financial well-being are on the line. There are two factors to keep in mind when it comes to effective safety labels:

1. If properly designed, they can dramatically reduce accidents. This not only improves a product’s overall safety record but adds to a company’s bottom line by reducing product liability litigation and insurance costs.

2. If poorly designed, needed safety communication does not take place and this can lead to accidents that cause injuries. With these accidents, companies face high costs settling or fighting lawsuits because their products lacked “adequate warnings.”

With the rise in product liability litigation based on “failure to warn” over the past several decades, product safety labels have become a leading focal point in lawsuits faced by capital equipment manufacturers. Here are three best practice tools for product safety label design to help create or improve your safety label strategy in order to better protect your product users from harm and your company from litigation-related losses.

Tool #1:

The standards

As a manufacturer, your legal obligation is to meet or exceed the most recent versions of standards related to your product at the time it’s sold into the marketplace. Warning label standards are the first place to turn to when it comes to

defining your product safety labels. Presently, Canada does not have a warning label standard. Since Canada imports machinery from the U.S. and the EU, it is quite common to see either ANSI Z535-style labels or ISO 3864-style labels on products. Under Canadian law, neither is more correct. However, Quebec has specific requirements for French language translations, and many CSA standards prescribe specific hazard warning labels that do not conform to either ANSI or ISO styles.

Following the design principles in ANSI Z535.4 or ISO 3864-2 offers a starting place for both the content and format choices you have to make for your products’ safety labels, bearing in mind the language requirements of your jurisdiction.

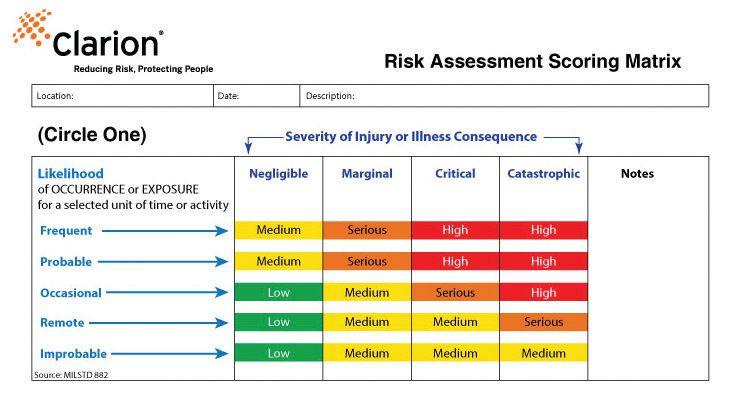

Tool #2: Risk assessment

From an engineering perspective, your job is to identify potential hazards and then determine if they need to be designed out, guarded or warned about. From a legal perspective, your job is to define what hazards are reasonably foreseeable and reasonable ways to mitigate risks associated with hazards that cannot be designed out. This is where risk assessment comes into play.

In today’s world, a product is expected to be designed with safety in mind. The risk assessment process helps you to accomplish this task. At its most basic level, risk assessment involves considering the probability and severity of outcomes that can result from potentially hazardous situations. After identifying the potential hazards related to your product at

every point in its lifecycle, you then consider various strategies to eliminate or reduce the risk of people interacting with these hazards. The best practice risk assessment standards that exist today (i.e. ANSI Z10, ANSI B11, CSA Z432, CSA Z1002, ISO 12100, ISO 31000, ISO 31010) offer a process to quantify and reduce risks. Using these standards as the basis for a formalized risk assessment process will not only help you to develop better safety labels and a safer product, but will also provide you with documentation that you can use to show the world you are a safety-conscious company that uses the latest standards-based technology to reduce risks. This will be highly important should you be involved in product liability litigation down the road.

Tool #3: Global warnings that use symbols

A large number of machinery manufacturers sell their products around the globe and when this is the case, compliance with global standards is a requirement. The ANSI Z535.4 and ISO 3864-2 product safety label standards, and the EU machinery directive, place an emphasis on using well-designed symbols on machinery safety labels so information can be conveyed across language barriers. The EU Machinery Directive 2006/42/EC requires that all information for use be provided in the official languages of the country of use. Information for use includes hazard warning signs and labels that bear messages in text. Adding symbols also increases your labels’ noticeability. The use of symbols to convey safety is becoming

A typical Clarion machine safety label that uses an internationally formatted graphical symbol and a format that meets both ANSI Z535.4 and ISO 3864-2 design principles. (Design ©Clarion Safety Systems. All rights reserved.)

The ANSI Z535.4 and ISO 3864-2 product safety label standards.

commonplace worldwide and not taking advantage of this new visual language risks making your safety labels obsolete and non-compliant with local, regional and international codes. In ISO 3864-2’s latest (2016) update, a major change in ISO label formats was made: A new “wordless” format that conveys risk severity was added to the standard. This new label format uses what ISO calls a “hazard severity panel” but no signal word. It communicates the level of risk through colour-coding of the hazard severity panel, eliminating the use of words — thus making translations unnecessary. It should be noted that sometimes symbols alone cannot convey complex safety messages. In these cases, text is often still used. When shipping to non-English speaking countries, the trend today is to translate the text into the language of the country in which the machine is sold. Digital print technology makes this solution much more cost effective and efficient than in the past.

Concluding thoughts

The safety labels that appear on your products are one of its most visible components. If they don’t meet current standards, if they aren’t

designed as the result of a risk assessment, and if they don’t incorporate well-designed graphical symbols, your company risks litigation and non-conformance with market requirements. Most importantly, you may be putting those who interact with your machinery at risk of harm. Making sure your product safety labels are up-to-date is an important task for every engineer responsible for a machine’s design. | MA

An example of a risk assessment scoring matrix (based on MIL STD 882 as defined in ANSI B11/ISO 12100 Safety of Machinery – Risk Assessment Annex D).

This article originally appeared as a guest blog on Machinery Safety 101, machinerysafety101.com.

Whistler Water plant manager Daniel Marcoux shares

his thoughts on the importance of

quality control in manufacturing.

MA: Please describe the plant operation.

DM: We own a 12-acre property north of Whistler, B.C., and on that land, we have two wells where we pump water from an aquifer. [Our products] are bottled under the Whistler Water and Polaris brands, and we also do private label products for a variety of different customers.

The plant is divided into two sections, one is for our water business and the other is for carbonated products for private-label customers. We also produce alcohol-based products like ciders, either in glass or PET bottles. [Across the plant], we have three production lines. The most automated line runs four bottle sizes: 350 ml, 500 ml, 1.0 L, 1.5 L. Here we blow our own bottles and fill them with our glacier-fed water. This line runs with four operators, and at 420 bottles a minute, it starts, stops, slows down, and speeds up automatically. After the bottles get blown, they go into a pressurized cleanroom for filling, which ensures no outside components can get in and affect the quality of our water. We also alternate and sterilize the water just before we fill the bottles in case there are any micro-organisms in that went through the system. [Upon leaving] the cleanroom, the bottles are capped with sanitized caps and go through machines for their various labelling and packaging [requirements].

The other two bottling lines are [comprised] of older equipment and involve more manual processes. The carbonation line in particular is a lot more complex because of the different batching processes for our customers — you have to add the right ingredients, colours and flavours based on the formulation process.

Another bottling line is for 4 L gallon jugs and uses premade 4 L PET and 4 L HDPE varieties. Again, these products are for our own brand as well as private label.

MA: How large is the facility?

DM: The factory is about 70,000 square feet and the warehouse is about 20,000 square feet, and those operations are staffed by 35 employees. Our manufacturing [operation] runs Monday to Thursday on 10hour shifts. Along with our sales and marketing teams, we total around 45 employees.

The plant itself has been in operation for more than two decades but has been under about four different owners since it started — our newest owner took over in 2016. Over the years, the brand and [corporate vision] hasn’t changed, just the ownership.

MA: Maintaining a high quality standard is imperative for all manufacturers. How does Whistler Water tackle this?

DM: We maintain a very complex quality program for water and follow three different quality assurance programs: the National Sanitation Foundation [NSF]; the International Bottled Water Association [IBWA]; and the Canadian Bottled Water Association [CBWA]. Recently for the seventh consecutive year, [we] were awarded Excellence in Manufacturing from the CBWA. To receive the award, the [bottler member] must obtain 97 per cent or better with all critical areas in full compliance based on a third-party audit that is conducted every year. We’re very transparent with the results – all our audit reports can be found on our website. Receiving this certificate of excellence means our customers and

consumers can feel comfortable in the quality of the water they receive from us. While most of our sales is concentrated in British Columbia and Alberta as well as the United States, we also export to China, Japan and Australia, among others...By following [international] standards, it also [allows for] new potential business opportunities.

As a secondary measure, we send 50 samples of our water a year, so roughly once a week, to a third-party lab to be analyzed, which helps maintain a high quality standard.

On the safety side, we have implemented a 5S Health and Safety Program. It is very important [to us] that we ensure the safety of all our employees.

We also strongly believe in [practicing] sustainable principles and are currently developing a zero-waste program. We anticipate that by sometime next year, we will be able to say we run a zero-waste operation.

MA: With all these different programs in place, how do you ensure success?

DM: I would say it is through communication and employee involvement. We have regular meetings with our staff to help keep them informed about our programs. Let’s say you were an auditor and came onsite, not only would you want to see the documentation for all our training and quality programs to make sure we are doing what we say we are, but it’s really about talking to the employees on the floor to see if they are being regularly trained and kept aware of program developments.

It’s a lot of work to meet the qualifications for these yearly [programs] but I’m very proud of what we achieve. | MA

COGNITIVE TECHNOLOGY

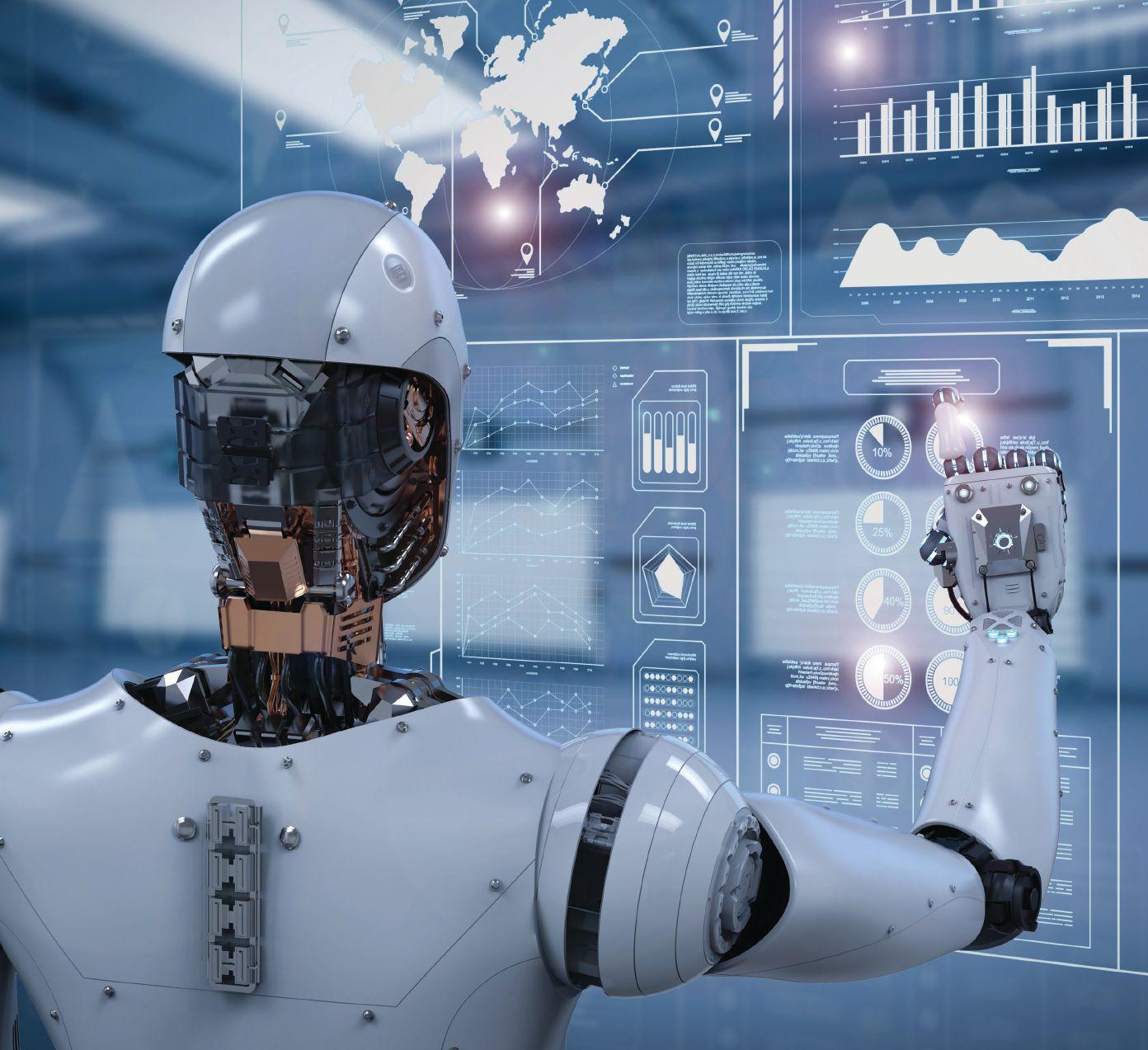

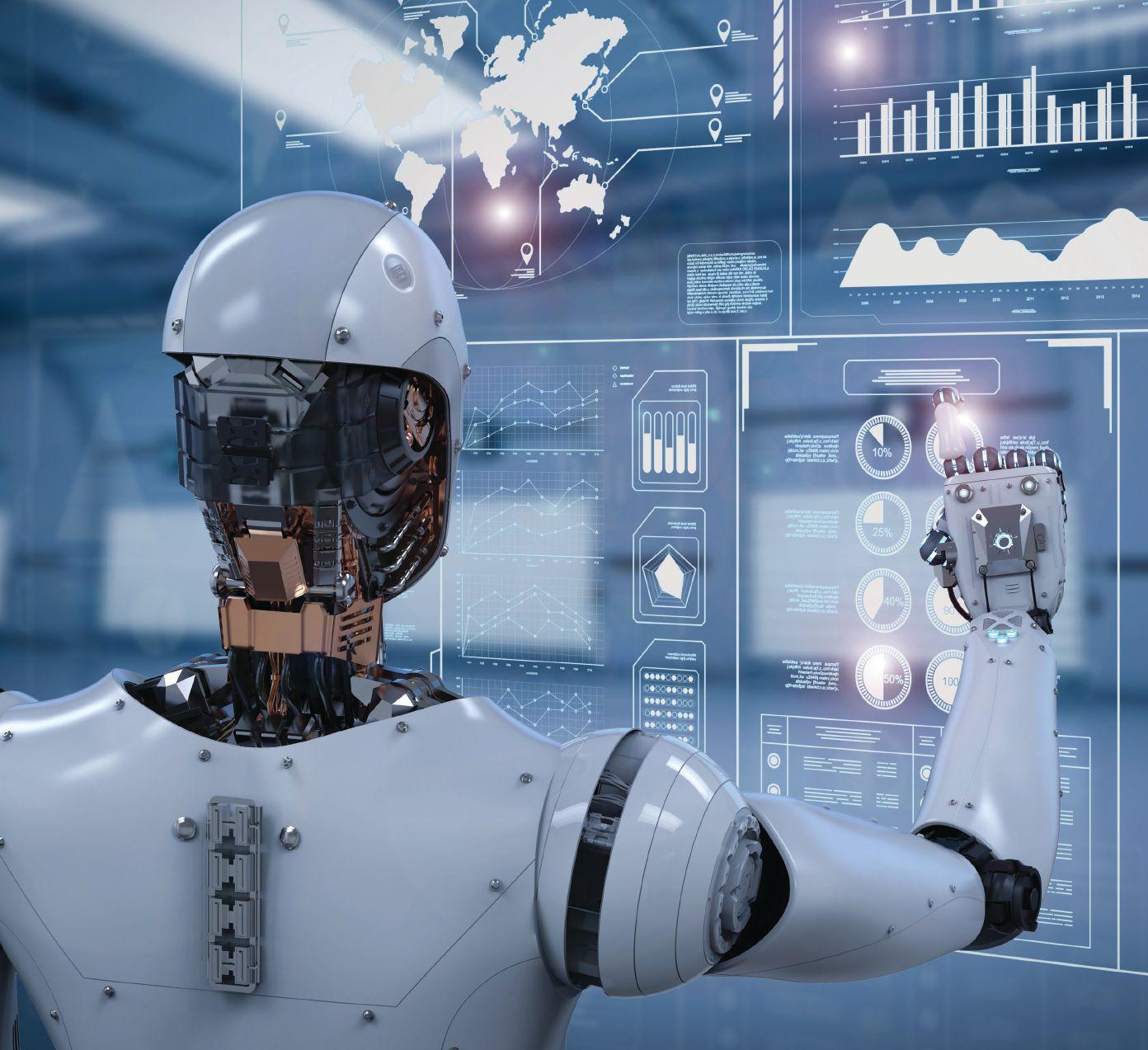

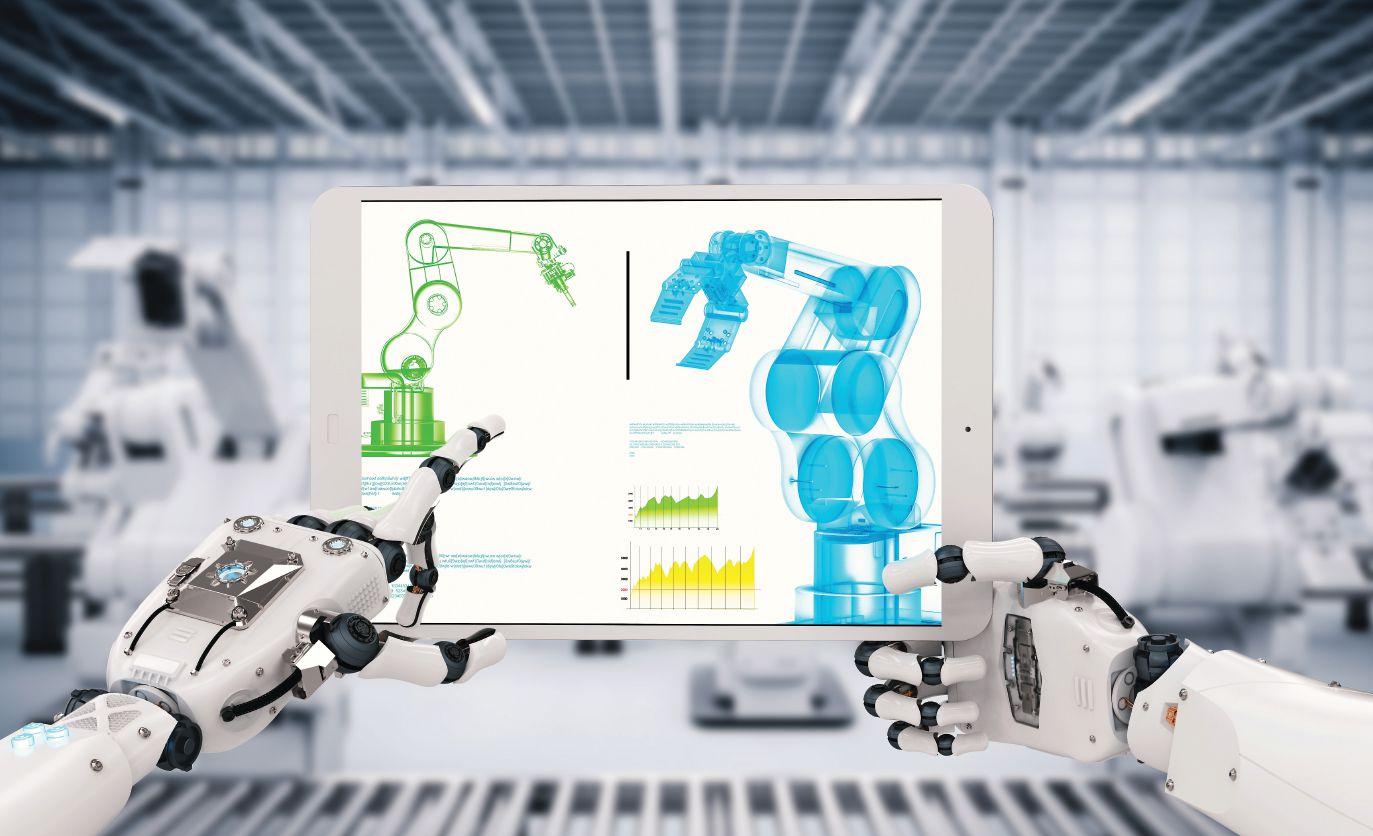

How artificial intelligence and machine learning are reshaping the manufacturing sector

BY JACK WARNER

The world is rapidly moving toward Industry 4.0 or the Fourth Industrial Revolution, where artificial intelligence (AI) and machine learning-based systems are not only changing the ways we interact with information and computers but also revolutionizing the manufacturing sector.

According to an Infosys report on AI, in manufacturing and high-tech sectors specifically, use of machine learning is higher (79 per cent) as is the institutionalization of enterprise knowledge

using AI (66 per cent) and cognitive AI-led processes/tasks (60 per cent). Most companies want to automate manufacturing to increase productivity (66 per cent), minimize manual errors (61 per cent), reduce costs (59 per cent) and refocus people’s efforts on non-repetitive tasks that benefit from human intervention (50 per cent).

The increasing demand for customized products at reasonable rates is the principal driving force behind the need to use various aspects of AI and machine learning in the manufacturing process. Here is how these disruptive

technologies are affecting manufacturing now and in coming years.

1. Predictive maintenance for reducing O&M costs

E ven today, most manufacturing plants have a fixed schedule for preventive maintenance. However, as it takes place regardless of the operating conditions, this type of preventive maintenance often leads to unexpected equipment downtime, wasted labour and production losses. With the help of cognitive AI technology, smart sensors, and an interconnected network of machines, plant engineers will be able to monitor devices on the floor. The constant monitoring will, in turn, allow floor managers to generate predictive analytics.

For years, Digital Twin technology has been restricted to high-end

A 2017 Infosys report finds that 76 per cent of senior business decision makers polled believe AI is fundamental to the success of their organization’s strategy.

applications such as running spacecraft simulations at NASA. However, the rapid rise of AI and allied technologies are bringing this technology to the manufacturing sector. It can analyze the data collected from a complex array of sensors. It can be used to track anomalies and diagnose failure situations. Gartner predicts that by 2021, half of large industrial companies will use Digital Twins, resulting in those organizations gaining a 10 per cent improvement in effectiveness.

Companies around the globe are trying to reduce equipment downtime through the use of various AI technologies. GE built its first-ever Brilliant Factory in Pune, India, powered by Predix, an Industrial Internet of Things (IIoT) platform. The platform uses sensors for monitoring each step of the manufacturing process to prevent downtime. The company claims the technology improved equipment effectiveness at the plant by 18 per cent.

2. Improved supply chain management

In recent years, several companies have started using AI and machine learning to optimize global supply chain management. The modern supply chains generate massive amounts

of data. AI not only helps to analyze this data but also organize it into useful bits and pieces. With the help of AI, it becomes easier to adapt to changing market scenarios.

In fact, several different tech companies have developed customized AI-based supply chain management solutions as software as a service (SaaS). For example, IBM’s Watson Supply Chain system uses cognitive AI technology to monitor supply chain process. It collects and analyzes data from different sources including social media, news feeds, weather forecasts and historical data. TransVoyant can also collect and analyze nearly one trillion events from sensors, satellites, radar, video cameras and smartphones daily.

In the end, the use of AI and machine learning boils down to creating a cohesive and self-sustaining ecosystem that facilitates seamless exchange of information, enhancing the performance across all areas of a supply chain including warehousing, transportation, customer feedback, production and packaging.

3. Seamless quality control

AI or machine learning-based quality assurance has become the new research frontier in the manufacturing

10%

Research firm Gartner predicts that by 2021, 50 per cent of large industrial companies will be using Digital Twins, enabling them to gain a 10 per cent improvement in effectiveness.

sector. Until now, most manufacturing companies have used a network of computers and sensors to remove low-quality products from the assembly line. However, AI and machine-learning based system will provide a seamless quality control over the entire manufacturing process. Rather than relying on in-process manual inspections, manufacturers can use computers and sensors to discover defects with striking efficiency and accuracy. It will enable companies to improve the features of low-quality products instead of discarding them. It helps reduce expensive production delays that continue to pile up in conventional quality control systems. As a result, the demand for human labour in quality control is more likely to dwindle in the future.

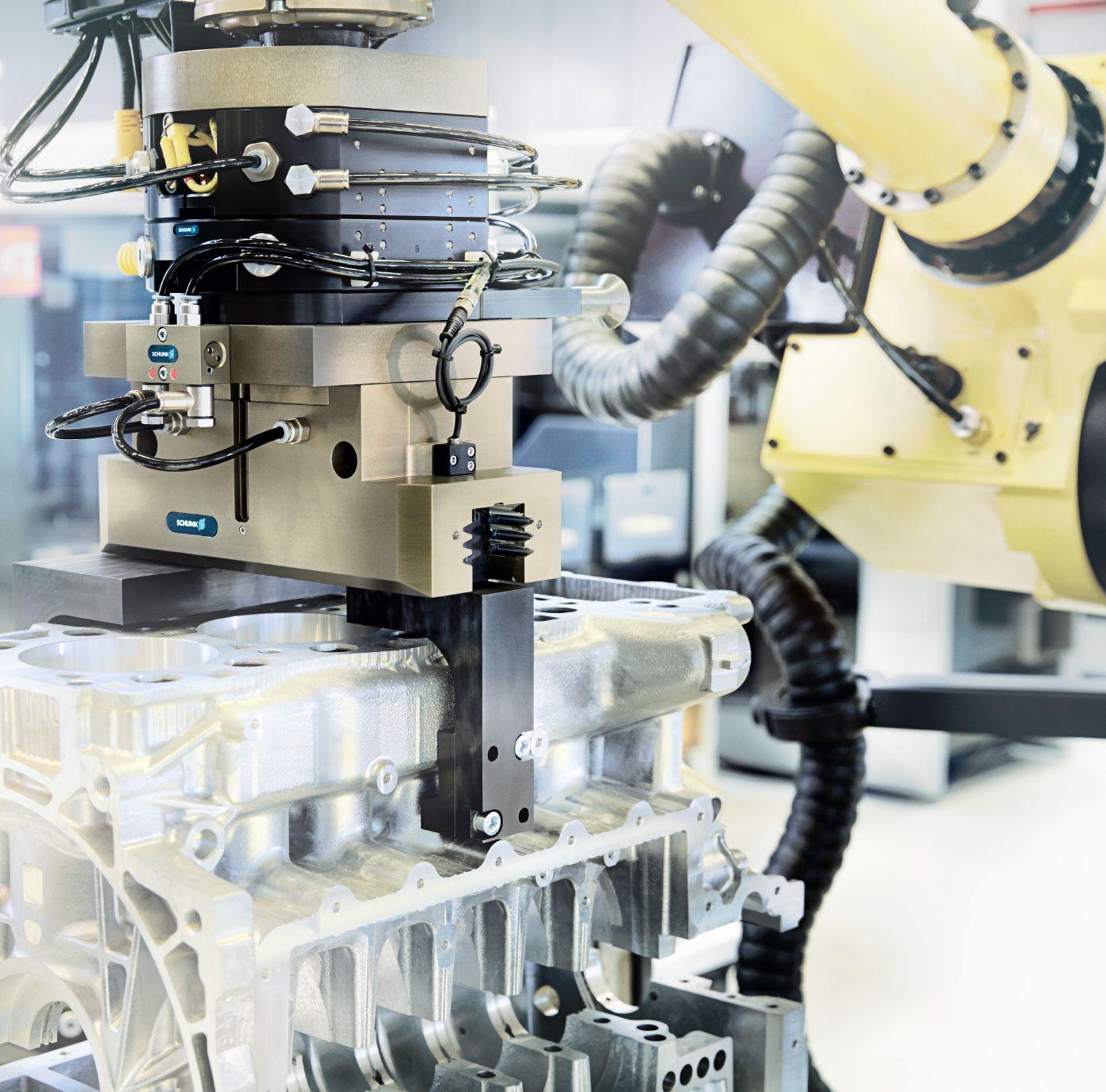

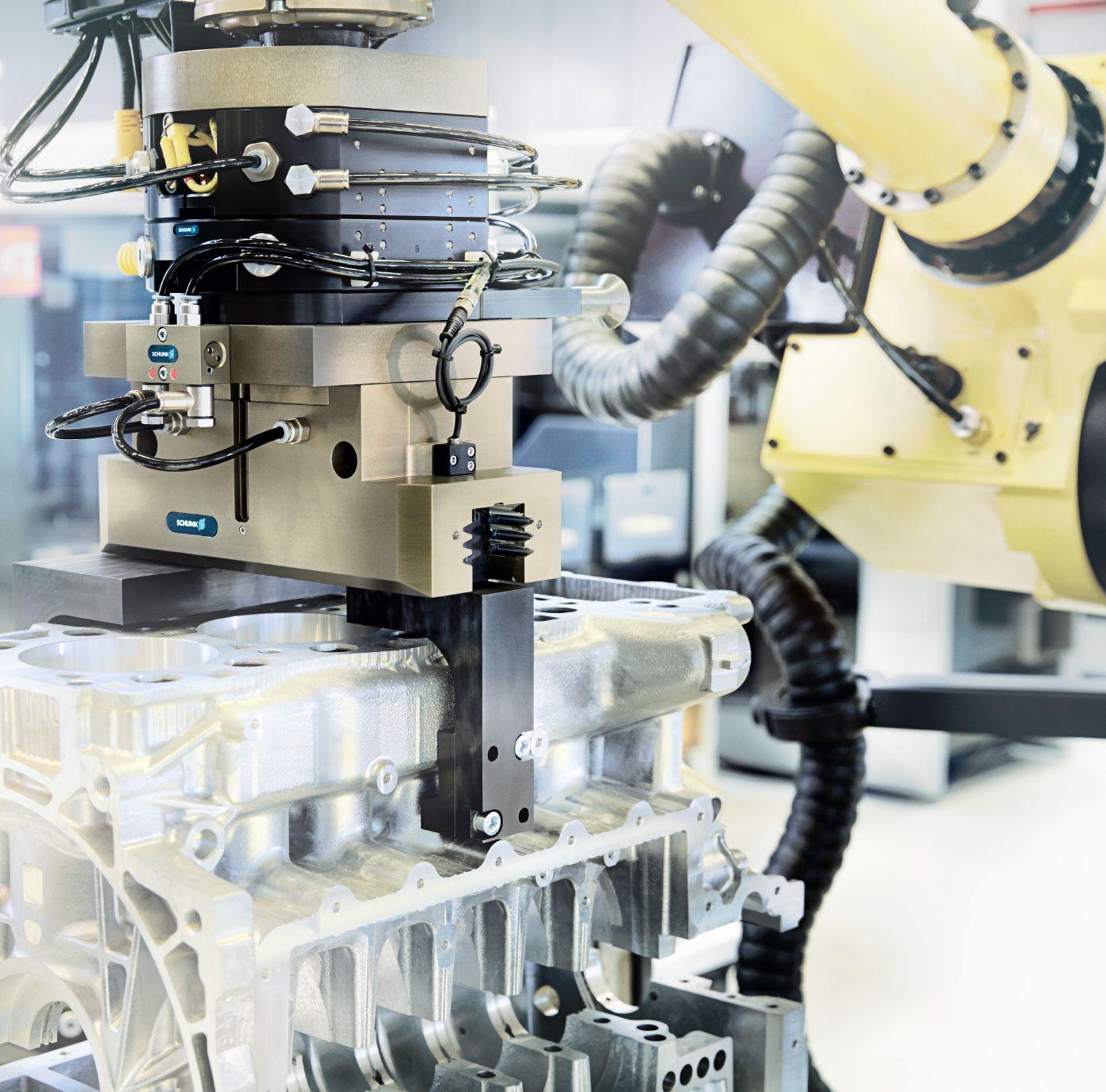

4. Improved human-robot collaboration

With the rise of AI and machine learning, we are moving beyond the pinnacle of dumb robots engaged in repetitive manufacturing tasks is coming to an end. In the future, humans and robots will need to work together to create agile manufacturing processes. Working with the ‘heavy-duty dumb robot’ is still considered a risk factor in

most manufacturing industries. However, working with next-generation smart robots will be much safer and manageable for the human workforce. Chinese-owned German manufacturing company KUKA says it has developed the world’s first series-produced and HRC-compatible smart robot called LBR iiwa, describing it as being able to work directly with its human colleagues without compromising their safety. Such robots have virtually endless applications in the coming years. They can help improve efficiency and flexibility in factories as you can reassign any task to them. They will also be able to recognize patterns and learn to modify their responses accordingly.

5. Consumer-centric production

Today, manufacturers need to focus on consumer-centric production as the demand for highly customized products is on the rise. This is where AI and machine learning come in. These technologies

Digital Twin

IBM defines the Digital Twin as a virtual replica of a process, product or service across its lifecycle which uses real-time data to enable understanding, learning and reasoning.

With the help of cognitive artificial intelligence technology, smart sensors, and an interconnected network of machines, plant engineers will be able to monitor devices on the floor. The constant monitoring will, in turn, allow floor managers to generate predictive analytics.

will allow companies to build smart manufacturing processes that can adapt to the ever-changing consumer demand. However, it will require a comprehensive network that connects consumers directly with manufacturers. One of the best ways to make this happen is to connect IoT with IIoT. For example, companies can collect data from smart homes to understand the latest consumer trends. These technologies will usher in a new level of communication in the modern manufacturing industry.

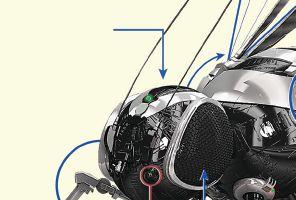

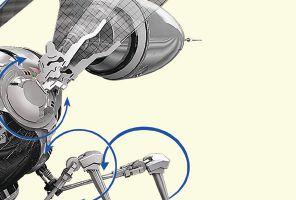

Bring Your Machine To Life With Custom Software

Aerotech can partner with you to design a custom automation solution for your specific application to make your machines easy to use.

In our concept machine at right, Aerotech could design and manufacture a wireless joystick interface or an app for your phone to control the flight, walking, and stinging actions.

Aerotech’s standard software is flexible enough to program in nearly any language. If you need a special interface (operator interface or programmatic interface), Aerotech can design and develop this with you using an Agile process. Contact us today to get started.

Contact our Control Systems Group at 412-967-6839 or sales@aerotech.com to discuss your application today, or see go.aerotech.com/csg105

AI and machine learning are the backbones of Industry 4.0. The deployment of these cutting-edge technologies has already helped automate core manufacturing processes and will continue to cause massive disruption in various industrial sectors around the world. | MA

Jack Warner is a tech enthusiast who loves to explore the world of machines and automation. He currently writes for Power Jack Motion (www.powerjackmotion.com).

IMPROVEMENT

THROUGH ENGAGEMENT

Manufacturer boosts machine uptime and productivity through employee involvement

BY MARY DEL CIANCIO

Successful manufacturers understand that in order to make productivity improvements, they need a clear picture of what is happening on the plant floor. Massiv Die-Form is no exception. The Brampton, Ontario-based company, a division of Magna International, knows how important plant productivity and shop floor transparency are when it comes to fulfilling orders and meeting the demands of its customers, such as automotive manufacturers like Volkswagen, Audi, BMW, Mercedes, Chrysler, Ford, Toyota, Honda and General Motors. With 24/7 operations, it’s critical that the producer of doors, hoods, body sides, hot stamp tooling and more keeps track of what’s happening on the shop floor, so that it can prevent costly downtime and determine opportunities for improvement.

This need for transparency and increased productivity was behind the company’s recent technology update in its hot stamp machine shop: the implementation of machine monitoring equipment and the development of custom software to enable interactive scheduling. The results of the implementation were increased productivity and decreased downtime, but that comes as no surprise to machine shop manager Jason Sultana. He ensured the project’s success by consulting with the machine operators every step of the way, so that the technology – and how they interacted with it – met their exact needs.

Operator input is key

Massiv Die -Form began tracking machine downtime in its hot stamp machine shop, which produces the tooling to manufacture automotive parts, about eight years ago with some success. However, as a specialist in hot stamp die manufacturing, an approach to

forming lightweight, ultra high strength steels, the machine shop felt pressure to increase its efficiencies further, and decided to transition from the manual scheduling process it had been using – an old-fashioned whiteboard that detailed the machines and jobs – to a digital scheduling process. The problem was that the machine tracking software it was using at the time could not integrate with any scheduling software. That prompted Sultana to seek out a new, more flexible solution.

In the hunt for new technology, however, one thing was very clear: the system wasn’t going to work if it didn’t engage plant floor operators.

“Systems like this can be, for machinists on the floor, looked at almost like Big Brother — like someone is always watching them,” explains Sultana. “It’s always hard to get the buy-in from the guys on the shop floor.”

That’s what made FreePoint Technologies a good fit. The London, Ontario-based provider of machine monitoring products has a focus on engaging the operator and capturing the knowledge on the plant floor. Its technology, ShiftWorx, is an analytics and information sharing platform that tracks machine downtime so that manufacturers can measure, analyze and share information in real time. However, before ShiftWorx was even implemented on the plant floor, FreePoint consulted with Massiv’s machine shop operators to determine what they wanted out of a machine monitoring system.

“We got the operators’ input before we got any management input,” explains Paul Hogendoorn, FreePoint president. “The wishlist was built by the operators and what they wanted the system to do for them.”

This approach was important in order to ensure success, says Sultana.

“ When we switched to FreePoint, we made the transition about the employees and about what they wanted to see, and made them understand that it wasn’t there to track their performance, but it’s there to help us as management make their job easier, and make their lives easier while they’re at work.”

The same approach was taken when determining the must-have features for the company’s custom-made scheduling system. Sultana, along with the FreePoint team, spent hours talking to machine operators to determine what they wanted to see, so they could make the system work for them.

“We had a lot of input into how we wanted it built,” says Van Goe, day shift lead hand in the company’s machine shop. “Jason asked us what we wanted it to look like. He let everybody [provide] input into what needed to be added and what was missing. From the ground up, we had a say in what we wanted it to be.”

The result? Massiv’s machine shop got a flexible solution that enables operators to easily communicate downtime issues back to management, emphasizing the importance of operator expertise when analyzing machine performance. In addition, they also got an

ShiftWorx is installed on almost every machine in Massiv Die-Form’s hot stamp machine shop. L to R: Jason Sultana and Van Goe.

interactive scheduling system that simplifies the scheduling process, while adding increased efficiencies.

A flexible solution

ShiftWorx is installed on almost every machine in Massiv Die-Form’s hot stamp machine shop — including vertical mills, horizontal mills, five-axis machines, boring mills and gun drills — to record downtime information. It features a little black box, which connects easily and non-invasively with any type of machine to pull data from that piece of equipment, regardless of its age or manufacturing process. In fact, it can be installed in an hour without any modifications to the machine.

Once installed, ShiftWorx can monitor start times, cycle times, stop times, down times, parts per second time and more, and has a screen at each workstation with a running bar graph so that operators can easily see this information in a way that’s meaningful and relevant to them. If the machine stops, the operator is prompted to input a reason for downtime, a task designed to engage the operators and take data collection to the next level.

“Data from the machine is information, but information from the operator is knowledge,” says Hogendoorn. “Our operator engagement modules are designed to really bring the operator’s knowledge into the database and to engage the operator by really letting them know that their knowledge matters.”

With this data, Massiv can now focus on the work that adds value, and find the actionable information that can make an immediate difference. ShiftWorx also enables the information to be shared to all team members in real time.

As this solution is web-based, Sultana can view these details in real time on his computer — or any computer or mobile device by logging in — and see how the machines are running, their percentage of efficiency, whether there has been a maintenance breakdown, and if there’s something holding these machines up. In addition, Sultana can receive daily, weekly or monthly reports on how efficient the machine shop has been and the main reasons for downtime. Armed with this valuable information, he can target certain machines or processes to try and improve the efficiency of the shop.

Next-level scheduling

The second part of the implementation was a scheduling system that would allow team members to easily schedule jobs in the machine shop. It was developed with FreePoint, and customized to Massiv Die-Form’s needs.

The new scheduling system allows the team to schedule jobs on machinery as far in advance as they need to (compared to the 36hour forecast of the company’s former manual scheduling system). The jobs and machines are listed on the new system — a “smart board” — and operators can simply drag and drop the job to the machine that has capacity for it. When changes are made and jobs are moved around, the system can recalculate completion times, making this process much faster and smoother than the previous manual calculation.

Data derived from the scheduling system tells Sultana how accurately they’re planning and how far in advance they are able to forecast the machine shop. It also tells them whether they need additional equipment or workers, depending on the workload and

downtime and uptime of each machine. The scheduling system allows users to keep a history of the data they have collected, and enables them to see trends.

“It provided a lot of clarity for me, and I think it made, for the lead hands on the shop floor, it easier to manage their time and the time of the guys on the machines,” Sultana explains.

Gauging success

Since adopting ShiftWorx and incorporating the custom-made scheduling system, Sultana says he has seen an increase in uptime and efficiency on the shop floor and, thanks to the ease of scheduling, the team is much more efficient in how they organize and plan the machine shop. The company is so happy with the results, that management is looking into incorporating ShiftWorx, and eventually the scheduling system, into different areas of the plant. In fact, ShiftWorx has just been installed on some of the die presses in Massiv’s press shop so that similar actionable data can be pulled from that machinery. Next, the company is planning to target the assembly area to provide more clarity on its overall productivity.

“I think that would be the best gauge of success,” explains Sultana. “Now we’re starting to see the machine shop pull ahead in terms of productivity, and other areas are looking to implement the system.”

Of course, staff in those areas will be engaged every step of the way to determine if the system needs to be tweaked to meet their unique requirements. After all, the key to the machine shop’s success, says Sultana, is that employee engagement and communication were – and still are – a priority | MA

The open remote I/O system o ers maximum flexibility for the adaptation of existing system environments with head modules for PROFINET/PROFIsafe, Ethernet/IP and CIP Safety. A simple substitution of the head module allows the communication within di erent networks. Wide ranges of safe and standard I/O modules are available.

MOBILE ADOPTION

Assessing rugged mobile computing needs in Industry 4.0 smart factories

BY JOHN GRAFF

The Industry 4.0 movement is completely up-ending manufacturing as we know it, and advanced mobile solutions, robotics, artificial intelligence, sophisticated sensors and the Internet of Things (IoT) are all playing a role in ushering in this next industrial revolution. According to VDC Research, the demand for mobile solutions that are more intuitive and easier to learn is a key pressure for warehouse environments undergoing mobility transformations.

The study notes that the only way the smart factory vision can be achieved is to implement mobile technology, which will then allow manufacturers to digitalize paper processes, improve communications, and provide full visibility into the complete flow of operations. While operating this smart factory may be a manufacturer’s dream,

Industrial operations demand indestructible mobile devices that can survive any daily hazard without fail, and can be easily removed from service should maintenance be required, without forcing a forklift or worker to go offline.

currently only 44 per cent of factory floors support shop floor control through the use of mobile devices. The majority of facilities still manage everyday tasks via paper-based processes — leading to inefficiencies, human error and redundancies. That is why manufacturers need to first focus on creating paperless factories.

However, it’s not enough to ditch paper for just any data-processing device.

Corporate computers are too fragile to be

used in a manufacturing environment and typically aren’t located close enough to the plant floor for real-time database input. And, it’s a well-known fact in the manufacturing industry that non-ruggedized devices will never meet the high-quality design standards required both inside and outside the four walls. These features include damage-resistant screens, industrial strength frames, and shock- and vibration-resistant solid-state drives (SSDs).

That’s why rugged tablets and detachable

2-in-1 laptops are becoming pervasive beyond just supervisors and other employees who walk and work. The highly mobile form factors are now preferred over fixed terminal PCs on forklifts. There’s a misperception that forklift-mounted computers are immune from the common drop hazards given their more stationary nature. Yet, they are still at the mercy of human handling — including the ink pens, screwdrivers or other tools that workers tend to keep in hand and improperly use to interact with touchscreens. Forklift computers are also subjected to constant temperature changes that occur during picking and putaway in cold storage facilities, hot loading docks and high humidity environments.

In other words, industrial operations demand indestructible mobile devices that can survive any daily hazard without fail, and can be easily removed from service should maintenance be required, without forcing a forklift or worker to go offline. Fast, reliable and highly scalable mobile computers are also mandatory for manufacturers who require widespread distribution of accurate, real-time information in order to maintain precision operations; as production demands increase, logistics become more complex and delivery timelines tighten.

For these reasons, many manufacturers are fast-tracking investments in what they’re told are easy to deploy, easy to manage, all-in-one single vendor

mobility bundles that are prepackaged with “highly compatible” hardware, software, accessory and security components.

Steps for success

Bundled solutions fail to meet high performance, low-cost paperless factory expectations and will prevent you from scaling to smarter technologies. The devices included in these bundles are not built to last very long and offer limited compatibility with legacy peripherals and more advanced technology platforms such as IoT, sensors and wearables, if compatible at all.

To ensure today’s mobility investments will remain viable in a truly automated and smart factory environment:

1. Enlist the help of manufacturing mobility experts, not just mobile technology providers. They will help you formulate a best-in-class Industry 4.0-ready mobility solution based on a rugged mobile computing platform that addresses your specific business challenges, aligns with your business goals, and easily integrates with your IT architecture. They will also help you identify which workflows to mobilize to improve business processes so that you don’t waste time and money on solutions that will never solve anything.

2. Develop an architecture foundation that includes hardware,

According to VDC Research, 44 per cent of factory floors currently support shop floor control through the use of mobile devices.

software, security and performance requirements. Then, examine digital assets to ensure they are delivering the right information, at the right time, to the right device. Remember: No two rugged tablets, laptops or handhelds are the same. The ratings you see on paper only tell you so much about the quality, performance and lifecycle reliability of mobile computers. Find the operating system (OS) and feature set that best support your specialized workflows and smart factory operations, just as you would look for specialized production line equipment. Don’t be quick to dismiss Android; recent advancements in security, MDM and overall OS flexibility have made it a very viable enterprise-grade computing option for factories, warehouses and distribution centres.

3. Calculate the TCO and ROI of your mobile technology options. Calculators can help you determine a more accurate figure – beyond the hard costs – and secure executive buy-in for your mobility project. It will prove just how significant an impact rugged mobile computing solutions can have on operational efficiency and, therefore, stability and profitability in volatile markets. | MA

John Graff is the vice president of marketing for Xplore Technologies.

INVESTING IN ROBOTICS

BY ALYSSA DALTON

Scale.AI supercluster

Quebec-based Netpak Packaging recently announced a multimillion-dollar investment in its Montreal plant, securing a range of new production line equipment, with the goal to become “one of the most modern packaging converting facilities in North America.” The Canadian packaging and commercial printer says its focus is on “automation, high quality standard, increased productivity and speed though state-of-the-art technology.”

Through the investment, Netpak has acquired two palletizing robots, which it says will help improve the working conditions and safety of its employees.

“Robotization will increase production flexibility and maximize productivity and efficiency,” notes the company.

A fully automatic waste paper baler machine was also installed in the plant, increasing the productivity of its three diecutters and eliminating the two old cardboard compactors. The printer has also equipped its five folder-gluers with glue detection systems from Baumer hhs (Xtend3), which will reject unglued boxes.

C.R. Plastic Products Netpak Packaging

Based in Stratford, Ont., C.R. Plastic Products will spend $5.2 million, along with $785,139 from the province, on a proprietary robotic assembly line and other new equipment. The company, which produces outdoor furniture made from up to 100 per cent recycled plastic, says the enhancements will help increase productivity, expand its product line and grow into new international markets. The company anticipates 12 new jobs will be created from the project.

“We are excited to partner with the Ontario government on this project as we expand our business. This significant investment will help C.R. Plastic Products improve our production capacity to meet increasing customer demand, so we can continue to compete globally,” said Bruce Ballantyne, vice-president finance and administration.

Since its establishment in 1994, the family operation has broadened its furniture lines into dining, loungers, deep seating and accessories with sales around the world.

Scale.AI has been named one of five technology groups — or superclusters — that will each get a piece of up to $950 million under the Government of Canada’s Innovation Superclusters Initiative. The investment, which will be matched dollar for dollar by the private sector, is expected to create more than 50,000 middle-class jobs and grow Canada’s economy by $50 billion over the next decade.

The Quebec-based Scale.AI (Supply Chains and Logistics Excellence.AI) supercluster will focus on building intelligent supply chains through artificial intelligence and robotics.

NEW PRODUCTS

PROGRAMMABLE CONTROL

All-in-one PLC+HMI+I/O capabilities

Unitronics describes the UniStream 5” as a multi-function programmable logic controller in a compact hardware profile, delivering PLC+HMI+I/O capabilities built into a single unit. The all-in-one controller is available in two series: UniStream 5” and UniStream 5” Pro. Both series support SNMP, VNC, FTP, SMS, email and communications via GSM/ GPRS modem. The Pro version also offers a built-in Webserver, audio jack and video support, as well as SQL – a plus for system integrators and OEMs adapting to Industry 4.0. UniStream 5”, with its colour touchscreen, aims to reduce space and wiring requirements and, according to the company, eliminates the need to set up Panel-PLC communication. Built-in I/O configurations vary according to model, offering digital, analogue, high-speed and temperature I/Os. Users can expand the configuration up to 2,048 I/O points. Meanwhile, built-in COM ports include Ethernet, 1 USB host and 1 Mini-B USB device ports; additional add-on ports for serial and CANbus are available. Other features of the UniStream include auto-tuned PID, data logging, data tables and recipes, data sampling displayed via built-in trends and gauges, alarms, multi-level passwords, and plug-and-play communications for CANopen, CAN Layer2, MODBUS, EtherNet/IP and more. www.unitronics.com

Series motion controller and AMKAMAC I/O. AMK says the KE/KW servo motors combine an “extremely compact design with a cost-effective modular structure” that provides several flexible combination options for machine builders. With a choice of cooling systems, single- and multi-axis solutions, and a choice of controller cards, AMK describes the system as “ideal for highly dynamic positioning tasks requiring maximum energy efficiency.” The controllers are available as control cabinet motion controllers and as complete units with touch displays. In each case they have programming in CODESYS, visualization and motion control rolled into one. The KE/KW controller cards are application-oriented and work with all

SENSORS

Extended range AC powered proximity sensors

Centralized control portfolio promises maximum efficiency

The AMKASYN centralized control and drive portfolio from AMK Automation includes KE/KW servo converters, KE/ KW controller cards, the A

major communication protocols, which the company says provides scalable functionality and machine safety capabilities. Rounding out the portfolio is the AMKAMAC I/O, featuring a modular design that can be installed without tools. The portfolio is suitable for various applications, including: palletizing, pick and place, labelling, order picking, printing, and machine tooling. http://us.amk.systems

Expanded I/O capacity

Idec has released its MicroSmart FC6A Plus, a PLC with up to 2,060 local I/O. With its expanded I/O capacity, the FC6A Plus can control and monitor the largest machines or entire small-scale manufacturing facilities, says Idec, adding that basic instructions can be executed in the speed of 21 nanoseconds and program memory is 800 kB (100K steps). Two models

are available, each with 24 VDC input power. The 16 I/O model has eight inputs, and eight relay or transistor outputs. The 32 I/O model has 16 inputs, and 16 transistor outputs. Each model also includes an integral 0-10 VDC analogue input with 12-bit resolution. Each model can accommodate up to three plug-in discrete, analogue, serial communication or Bluetooth cartridges. Each discrete cartridge has four discrete I/O points, either four inputs or four outputs. Each analogue cartridge has two analogue I/O points, either two inputs or two outputs. Up to 63 I/O expansion modules can be added. The FC6A Plus also includes an optional Bluetooth wireless communication adapter, giving users the power to monitor the PLC and download/upload programs from a PC or laptop with Bluetooth capability. All models have two built-in RJ45 Ethernet ports. Optional plug-in communication cartridges can be added to create two additional RS232C/RS485 ports. With the addition of serial communication modules, up to 33 RS232C/RS485 serial ports are supported. www.idec.com

New V3 series AC powered inductive proximity sensors from AutomationDirect are available in 8, 12, 18 and 30 mm sizes. Extended sensing distances for these new sensors range from 2 mm shielded and 4 mm unshielded for 8 mm sensors to 12 mm shielded and 18 mm unshielded for 30 mm sensors.

The sensors operate on 20-250 VAC/VDC input voltage with N.O. and N.C. output options available. According to AutomationDirect, the sensors are short-circuit protected and have a yellow LED status indicator that is output energized. www.automationdirect.com

Sensors available for purchase online

Hoffmann + Krippner has announced a new product addition to its redesigned online shop. In addition to Sensofoil linear and rotary membrane potentiometers, cleanroom/ medical keyboards and emPC A/RPI Industrial PCs, the shop