KNOW Pressure

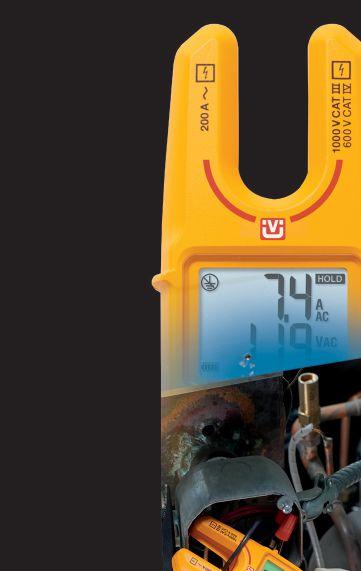

Proven Pressure Sensors/Gauges

Get great prices on our vast selection of accurate dependable pressure sensors and gauges. Choose from electronic and mechanical switches, transmitters and vacuum transducers, digital switches and transmitters, digital and dial pressure gauges and differential pressure transmitters.

Digital Pressure Switches/Transmitters

Digital Pressure Gauges

EPS Series starting at $234.00

• Stainless steel housing with IP67 rating

• Ranges from vacuum to 5800 psig

• Selectable display units include: psig, bar, mbar, kPa, MPa, inH2O, and inHg

• Two discrete outputs: NO or NC

• Analog output on select models

• Large 2 color, 4 digit display

• Simple pushbutton setup

QPS Series starting at $69.00

• Two digital outputs (NPN or PNP) and a 4-20 mA analog output

• Two vacuum to pressure ranges (-14.5 to 14.5 psi and -14.5 to 145 psi)

• Tri-color digital LCD display

Air Differential Pressure Transmitters

DPTA Series starting at $105.00

• Highly stable capacitive sensing element

• Positive, negative, and bi-directional pressure measurement

• Pressure ranges from 0.1 to 25 inches of water column

Pressure Transmitters and Vacuum Transducers

SPTD25 Series starting at $99.00

• 4-20 mA or 0-10V outputs

• Ceramic or stainless steel sensing elements

• M12, DIN connectorized, and cabled models

Mechanical Pressure Switches

MPS25 Series starting at $82.00

• Sensing ranges from -15 psi to 7500 psi

starting at $100.00

• ±0.5% accuracy

• Simple 2-button operation with option to show peak pressure

• Wide variety of pressure unit selections

Dial Pressure Gauges starting at $6.50

• 1.5”, 2.0” and 2.5” diameter dials

• Steel (IP52) or stainless steel (IP65) cases

• Sensing ranges from vacuum to 6000 psi

• 1/4 inch NPT male process connection

• Snap-acting SPDT, 3 Amp, mechanical switch output

Electronic Pressure Switches

PSD25 Series starting at $89.00

• Sensing ranges up to 5800 psi (400 bar)

• Long Life - over 50 million switching cycles

• Mechanical adjustment dials rotate quickly to establish the setpoint and reset point

• No calibration required

Orders over $49 get FAST FREE SHIPPING

Our shipping policies make it easier than ever to order direct from the U.S.!

Fast free standard shipping* is available for most orders over $49 U.S., and that includes the brokerage fees (when using an AutomationDirect nominated broker). Using our choice of carrier, we can reach most Canadian destinations within 2 to 3 days. Order by 6pm ET and in-stock orders ship the same day!

*2-day free shipping does not apply to drop-ships, or orders requiring LTL transport, but those shipments can take advantage of our negotiated super-low flat rates (based on weight) that include brokerage fees.

See Web site for details and restrictions at: www.automationdirect.com/canada

A robotic piano player delights crowds at the Morsettitalia stand at Hannover Messe.

PHOTO: MANUFACTURING AUTOMATION.

NOTABLE TWEETS

@sciemetric

You’re already collecting #data on your #mfg line—now put it to work. Learn about effective #dataanalysis from Sciemetric Product Manager

David Mannila in @AutomationMag’s May 2018 issue.

@FluidPowerTips

Great news! Magna supports Skills Ontario with $125K investment

@ODG_Gear

It’s the start of a new school semester, and ODG is pleased to welcome the arrival of several new co-op students from UWaterloo and Laurier. A co-op experience is a valuable part of post-secondary education!

@CiscoCanada

Why should manufacturers care about #blockchain?

@JenniferKR shares a few reasons in @ AutomationMag http:// cs.co/6010DjMFk.

BY ALYSSA DALTON

The pursuit of continuous improvement

Several weeks ago, my latest Centre Stage interviewee, Samuel Bouchard, CEO of Robotiq, told me Canadian manufacturers need more guts (to automate), noting they are typically too shy when it comes to investing in new technologies. (Read more of our conversation on page 16.)

That got me thinking — what impact can timidness have on business success?

A 2016 research report from Deloitte concluded the Canadian economy is stuck in neutral because of an overwhelming number of Canadian businesses – nearly 90 per cent – aren’t courageous. In the report, The Future Belongs to the Bold, Deloitte found that courage businesses outperform their peers, often experiencing greater revenue growth and creating more jobs.

According to the research, 69 per cent of courageous businesses saw a boost in revenues from the previous year over 46 per cent of fearful businesses. Meanwhile, fearful firms were twice as likely to see their revenues fall compared to their courageous counterparts.

“Courageous businesses are the high-flyers propelling the Canadian economy forward. When they reach peak performance, we all benefit. But if we truly want to succeed as a nation, we need more business leaders to be bold and test the limits of what they think is possible,” said Frank Vettese, managing partner and chief executive of Deloitte.

“Risk-taking is but one element of being courageous, but it’s a powerful means to drive growth, and propel both companies and our country forward.”

In an increasingly competitive economy, all businesses must continuously strive for operational excellence.

Last year, McKinsey & Company asked five executives with experience in lean management about the lessons they learned when helping their organizations sustain continuous improvement. One interviewee was Scott Powell, director of operational excellence at Export Development Canada (EDC).

An export credit agency, EDC strives to help Canadian companies grow and succeed internationally. In 2007, it began its own lean journey and has explored both a bottom-up and top-down approach to lean sustainability.

When asked for advice for leaders who wonder what happens after an intensive transformation ends, Powell responded, “You have to keep trying, and when something doesn’t work, try something else — keep learning, keep improving.

“It’s easy to think that you are doing really well at this across the organization when in fact you may not be. A few years ago, we made that discovery when we asked the Shingo organization to assess our lean-management maturity. Our score was much lower than we expected. Initially that was hard to hear, but it meant we had a lot more opportunity waiting for us.”

In the spirit of continuous improvement, I have taken on a new editorial role at Manufacturing AUTOMATION’s parent company Annex Business Media, and this will be my final issue. It has truly been a pleasure serving this publication and industry for the past four years. I wish you all the best and hope our paths cross again soon. | MA

EDITORIAL ADVISORY BOARD

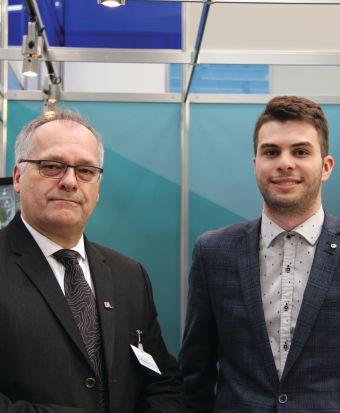

MCCRUDDEN, Vice-President, Business Development, Festo

DAVID MCPHAIL, President and CEO, Memex Automation

Your resource for Canada’s industrial automation news

EDITOR

Alyssa Dalton adalton@annexbusinessmedia.com

PUBLISHER

Klaus B. Pirker kpirker@annexbusinessmedia.com

VICE PRESIDENT & EXECUTIVE PUBLISHER

Tim Dimopoulos tdimopoulos@annexbusinessmedia.com

ART DIRECTOR

Graham Jeffrey gjeffrey@annexbusinessmedia.com

ACCOUNT CO-ORDINATOR

Debbie Smith dsmith@annexbusinessmedia.com

CIRCULATION MANAGER

Urszula Grzyb ugrzyb@annexbusinessmedia.com Tel: 416-442-5600 ext. 3537

COO

Ted Markle tmarkle@annexbusinessmedia.com

PRESIDENT & CEO Mike Fredericks

CONTRIBUTING WRITERS

Paul Hogendoorn, Kay Jenkins, David Price, Jennifer Rideout, Rite-Hite, Jonathan Wilkins

Manufacturing Automation is published seven times a year by:

Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON, M2H 3R1 Tel: 416-442-5600

Fax: 416-442-2191

Printed in Canada ISSN 1480-2996

Publication Mail Agreement #40065710

CIRCULATION

email: lmalicdem@annexbusinessmedia.com

Tel: 416-510-5187

Fax: 416-510-6875

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON, M2H 3R1

SUBSCRIPTION RATES

Canada — $42 per year

United States — $74 (US) per year and Foreign — $84.50 (US) per year

Students — $20 per year

ANNEX PRIVACY OFFICER

email: privacy@annexbusinessmedia.com

Tel: 800-668-2374

Occasionally, Manufacturing Automation will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

The contents of Manufacturing Automation are copyright © 2018 by Annex Publishing & Printing Inc. and may not be reproduced in whole or part without written consent. Annex Publishing & Printing Inc. disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication.

We acknowledge the [financial] support of the Government of Canada.

AUTOMATION UPFRONT

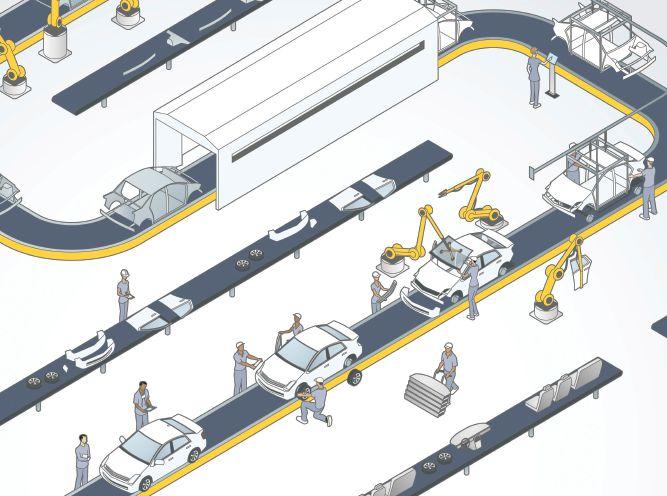

AUTOMOTIVE

Toyota commits $1.4 billion to upgrade two Ontario plants

The Ontario and federal governments are contributing $220 million toward a $1.4-billion upgrade project at two Toyota manufacturing plants, creating 450 new jobs and securing more than 8,000 manufacturing jobs in the province.

The automaker says the investment will help establish Cambridge and Woodstock as Toyota’s North American manufacturing hub for the RAV4, including hybrid versions.

The investment will support factory retooling, research and development, new automation technology in the paint and plastics shop, as well as provide specialized worker training, including up to 1,000 co-op placements.

“Ontario has always been a great home for Toyota Motor Manufacturing Canada. We benefit from investments in technology, innovation and industry as well as the high-skilled workforce we’re fortunate to have as our team members,” Toyota Motor Manufacturing Canada president Fred Volf said. “With our Ontario government partners, today we celebrate the results of our past 30 years of manufacturing in Canada, and continue on the path of building for our future.”

This landmark investment comes at a time of uncertainty in the North American auto industry.

“Standing up for auto workers in Ontario is about making sure our province stays competitive during a time of rapid economic change, and building the kind of global partnerships that support long-term prosperity,” said Kathleen Wynne, premier of Ontario. “This is a vote of confidence in our talented workforce and our entire province.”

Vehicle assembly and auto parts production supports more than 100,000 jobs, and numerous spin-off jobs, across the province.

TOP HONOURS

This year’s Best Workplaces in Canada have been named

Kudos to all the companies who have been recognized as part of this year’s Best Workplaces in Canada, an annual ranking that helps organizations assess, improve and sustain specific

Production boost: Toyota says the investment will establish the two plants as the North American manufacturing hub for the RAV4.

AUTOMATION UPFRONT

business culture. Special congratulations go to the following firms in the industrial automation space:

• 3M Canada Company

• Cadence

• Electromate Inc.

• IndustryBuilt Software

• Industry Training Authority

• JMP Engineering Inc.

• Lakeside Process Controls Ltd.

• LMI Technologies Inc.

• Peer Group

• Phoenix Contact Ltd.

• Rittal Systems Ltd.

• SAP Canada

• True North Automation

The 2018 Best Workplaces in Canada list is compiled by Great Place to Work Institute Canada. The competition process is based on two criteria: Two-thirds of the total score comes from confidential employee survey results; the remaining one-third of the score

comes from an in-depth review of the organization’s culture, including an evaluation of HR policies and procedures. This offers a representation of the organization from an employee perspective and an overall portrait of the workplace culture. Together, they provide data relative to the five trust-building dimensions of a great place to work: credibility, respect, fairness, pride and camaraderie.

“Thank you to our employees, and congratulations to them for making Rittal one of Canada’s Best Workplaces for the fourth year in row. This is an amazing achievement and I am immensely proud of our team we have and the great work they all do. This is our highest ever ranking in the current category,” said Tim Rourke, president of Rittal Canada.

This year’s list received more than 400 registrations and over

80,000 employee participants in the Best Workplaces in Canada survey, rolling out to impact over 300,000 Canadian employees.

for various industries, including electronics, medical, automotive, food, plastics processes, mechanics and painting. It offers a line of four-axis TP fast pickers and TS SCARA robots, as well as six-axis TX and TX2 collaborative robots.

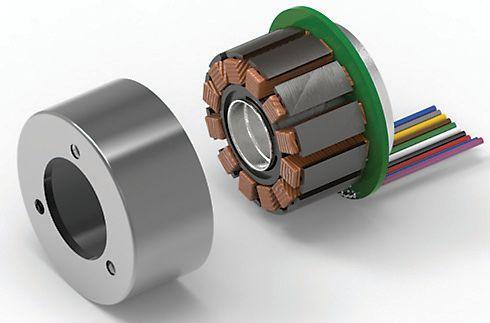

Hollow Bore Absolute Encoder

“Creating a ‘Great Place To Work’ has been pivotal in driving employee satisfaction and engagement,” said Warren Osak, founder and president of Electromate. “Numerous empirical studies have shown that highly engaged employees are more productive and deliver a higher level of customer satisfaction than unengaged employees, and much of our competitive advantage stems from the positivity in our workplace.”

ROBOTICS

Stäubli and Schneider develop integrated robotic solutions

Stäubli Robotics and Schneider Electric have further developed their partnership by signing a long-term agreement to integrate customized Stäubli TS series, four-axis SCARA robots into EcoStruxure Machine, Schneider’s IoT-enabled, open and interoperable system architecture and platform. Named Lexium STS series, the robots are described as being fully integrated into the architecture of Schneider Electric’s PacDrive motion control solution.

Stäubli Robotics develops specialized robotics solutions

“Our EcoStruxure architecture and platform is built on a foundation of openness which is reinforced by this partnership,” said Ali Haj Fraj, SVP Machine Solutions, Industry Business Schneider Electric. “Integrating Stäubli robotics will accelerate the execution of EcoStruxure Machine, our machine-centric automation architecture that enables machine builders to design smart machines through advanced digital technologies and open standards and so reduce their time-to-market and engineering costs, while improving machine performance.”

PRODUCTION

New production line to create more than 100 jobs

Food and food services business Dr. Oetker Canada says it is investing in a new, high-speed frozen pizza manufacturing line that will help create 103 jobs and retain 115 positions in London, Ont.

The company explains the new line will use high-speed press technology to manufacture both the smaller (1 to 2 serving

size) and the larger (family-size) pizzas, estimating the plant’s overall production rate will nearly double from 10,000 to 18,000 pizzas per hour.

The investment will help Dr. Oetker Canada invest in a new production line that includes dough preparation, baking, toppings, freezing and packaging equipment. The Ontario government is committing up to $7 million in the project through the Jobs and Prosperity Fund – Food and Beverage Growth Fund.

Located in Mississauga, Ont., Dr. Oetker Canada Ltd. is the Canadian division of the Oetker Group.

ARTIFICIAL INTELLIGENCE

AI firm secures $6 million from investors

Raven Telemetry, an Ottawa-based artificial intelligence

Efficiency gains: The new funds is expected to nearly double the factory’s per-hour production rate.

company for manufacturing, has raised $6.1 million in equity financing from angel investors.

Contributors include Fresh Founders, Rob Lander (former president and CEO of Stackpole), Luc Levesque (former VP at TripAdvisor), Rob Ashe (former CEO at Cognos), Jacket River, HBS Angel Investors of New York, and several others.

Founded in 2013, Raven

developed what it describes as the first Augmented Industrial Management (AIM) platform for manufacturers. Using mobile hardware, software and Cloud-based analytics driven by AI, Raven aims to improve manufacturers’ profitability with real-time recommendations and productivity insights.

“Expanding our client base makes our technology

better — the more data we get, the stronger the AI gets,” said Raven CEO Martin Cloake. “This practical application of AI in manufacturing to guide behaviour has never been done in this space. We’re excited to lead the way. Manufacturing is still fundamentally a people business, so analysis without people taking action is valueless. The biggest opportunity is to change what people do, rather than simply report what happened.”

INTERNATIONAL

MEXICO

Global technology provider Bosch is investing 100 million euros (C$155.5 million) in a new smart factory for electronic components in Celaya, Mexico.

The company anticipates creating more than 1,200 additional jobs at the new 21,000-square-meter

SENSORS: Inductive and Capacitive

Proximity Sensors • Photoelectric Sensors • Level Sensors • Ultrasonic Sensors • Magnetic Sensors • Limit Switches • Safety Interlocks

Whether it’s our industry leading range of solid state relays and contactors, or our vast range of sensors, motor controls, energy meters and voltage/current monitors, CARLO GAVAZZI has the solution for your application needs.

Contact us today, and one of our field sales representatives will show you why we are one of the fastest growing automation companies worldwide. We’ll even provide a free evaluation sample to qualified OEMs.

location in the coming years.

“Bosch is committed to Mexico. The country is and will remain an important market and a hub for our global manufacturing and development network,” said Stefan Hartung, member of the Bosch board of management.

According to the company, the new plant will employ a manufacturing execution system to collect data and share production information in real time, aiding in preventive maintenance and higher product quality, it says. The system also digitally connects the plant to the Bosch Group’s global manufacturing network.

In total, Bosch operates 10 manufacturing locations around the country and has already introduced the use of smart technologies, for example at its Mobility Solutions sites in Toluca and Juárez.

Overall the Bosch Group employs around 16,000 associates

and is active with all four of its business divisions in Mexico.

CZECH REPUBLIC

Augmented reality company expands operations

OPS Solutions, maker of Light

Guide Systems, an augmented reality tool for manual assembly and manufacturing processes, is expanding its presence with a new European headquarters in the Czech Republic.

Light Guide Systems Classic is designed to reduce errors and improve manufacturing and assembly processes by projecting a digital operating canvas directly onto any work surface, providing audio and visual prompts, guidance, pacing and direction. Meanwhile, Light Guide Systems Pro incorporates the proprietary software into Sprout Pro by HP PC platform for a portable solution.

The new facility will serve as the European operations base and will provide the launch point to expand sales and business partnerships.

“In the last several years, we have experienced an increase in the demand for our AR technology for manufacturers across Europe and Asia,” said founder, president and CEO Paul Ryznar. “The time is right to further expand our global presence and become a permanent part of the manufacturing landscape in Europe.”

DEAL MAKERS

Siemens and Orange Business Services develop IIoT solutions

Telecommunications operator Orange Business Services and factory automation equipment

provider Siemens say they have joined forces to help drive the adoption of the Internet of Things (IoT) in the industrial sector by simplifying integration and promoting IoT innovation.

The partnership aims to help businesses connect their machines and physical infrastructure to the digital world, allowing them to translate the data they produce into actionable business results, as well as optimize the supply chain, develop digitally enhanced products to increase customer satisfaction and create new business models.

The alliance is built around Siemens’ MindSphere, the Cloud-based open IoT operating system, and Datavenue, the Orange IoT and data analytics modular offering. Orange will bring its global cellular connectivity, consulting, system integration and application development skills to the partnership.

“Orange Business Services supports Siemens’ MindSphere Global Ecosystem with its leading IT, system integration and application development expertise, ultimately benefiting our joint customers. The global IoT connectivity offering from Orange supports requirements where digital products and digital processes can be integrated in our MindSphere platform. Our customers will now benefit from worldwide coverage, which supports new business models and scalability,” said Kai Brasche, vice president, MindSphere Partner Management EMEA at Siemens.

The partnership will initially focus on Europe, starting with solutions to be rolled out in Germany and Austria.

“We are delighted to partner with Siemens in the MindSphere Ecosystem in the industrial sector. By combining our strengths we are providing industrial enterprises with new opportunities to exploit their data and unleash the power of IoT to drive significant competitive advantage,” said Olivier Ondet, senior vice president, IoT and Analytics, Orange Business Services. | MA

PHOTO: BOSCH

Job alert: Bosch expects the new plant will add more than 1,200 jobs.

MOVERS AND SHAKERS

Peter Hanna has joined the Harting team as the new territory sales manager for Ontario, where he will leverage an “extensive background” in HVAC design and sales to help customers adopt the company’s industrial connectivity and edge computing solutions, says the company. Harting explains Hanna’s appointment will help enhance the company’s ability to provide personal support in the country’s largest market at a time when it plans to introduce new technologies designed to increase productivity in conventional and Industry 4.0/ IoT production environments. Hanna earned a Bachelor of Mechanical Engineering

and a Master of Engineering specializing in solar energy, both from McMaster University in Hamilton, Ont.

Lafert North America, a manufacturer of metric AC Motors, metric gearboxes and coolant pumps, has announced two new inside sales team members. Joel Fernandes brings nine years of sales experience to Lafert with time spent in the construction and power distribution industry. A graduate of the University of Toronto, the company says Fernandes brings the “ability to problem solve and provide the support required to meet industry needs.” Jesse Sagoo brings 12 years of technical sales experience in the power distribution market segment. He holds an Electrical Engineering Technology designation from Humber College.

MOVE SECURELY INTO THE CLOUD

WAGO Cloud

Amazon Web Services

Other Cloud Services

Travis Hester

The Woodstock, Ontario-born head of General Motors Canada is moving to head Cadillac, the global automaker’s luxury car division. Steve Carlisle will replace Johan de Nysschen, who is leaving as head of the Cadillac group, as it prepares to bring out the XT4 compact utility vehicle. Carlisle began his career in 1982 as an engineering co-op student at GM’s Oshawa Truck Plant, rising the ranks to become president of the Canadian operation in late 2014. He is succeeded by Travis Hester, who began his GM career in 1995 in Australia. Since moving to the United States in 2005, Hester has held engineering positions in the U.S. and China. He became GM’s vice-president for global product programs in 2016.

Direct Field to Cloud Connection with the PFC Series Controllers

• IIoT-ready with native MQTT and TLS encryption

• Built-in VPN and Firewall for increased network security

• Simplify data routing and reduce latency

• Interface with existing controls via onboard fieldbus gateways

www.wago.ca/pfccloud

Not-for-profit consortium

Excellence in Manufacturing Consortium (EMC) has named Kim Wolf field service advisor for the Ontario communities of Kitchener, Waterloo, Cambridge, Guelph and Brantford. With “extensive experience” in consumer goods manufacturing and food processing, Wolf previously held several leadership roles with Campbell Soup, McCormick Canada and The Original Cakerie.

Vanair is welcoming Matthew Johnson as its new sales manager for the Midwest Region and Canada. In his new role, Johnson will be responsible for developing and executing strategic plans in the territory to increase sales, recruit new distributors for growing markets, and develop sales plans for new distributors and provide follow up support for them. | MA

INDUSTRY

WATCH

BY PAUL HOGENDOORN

Paul Hogendoorn co-founded FreePoint Technologies. “Measure. Analyze. Share. Don’t forget to share.” He can be contacted at paul.hogendoorn@getfreepoint.com or www.getfreepoint.com.

Building bridges and chasing dreams

The Sydney Harbour Bridge was completed in 1932. It was designed and built by British firm Dorman Long and Co Ltd., taking eight years to build, using more than 6 million rivets. It is the sixth longest spanning-arch bridge in the world and the tallest steel arch bridge, measuring 134 metres from top to water level. (I know first hand, as my granddaughter and I walked over the top of it during our recent visit to Australia.) Until recently, it was also the world’s widest long-span bridge, at nearly 50 metres — which is an amazing fact, since it was originally designed to accommodate two lanes of traffic, or 50,000 cars per week. Today it accommodates 1 million cars a week, has eight lanes of traffic, plus two rail lines, and a generous foot path. It is definitely a testimony to the forward-thinking minds of those who brought it to life.

It was built at a cost of 10 billion pounds, borrowed from Great Britain, and paid back fully in 1986. The life expectancy was originally predicted to be 80 years but is now estimated to last 300 years. The Australians are justifiably proud of their bridge.

An equally fascinating story is the one of Paul Cave, the entrepreneur that came up with the idea that tours across the structure would be good for tourism for the area, not to mention a good business idea. While it took

The first big test of an idea, or an entrepreneur, is a test of commitment – are you willing to swim against the stream long enough to give your idea a chance?

eight years to build the bridge, from start to finish, it took nine years to get his “bridge climb” idea from dream to reality. As you might imagine, there were a lot of discussions with state and local government bodies, community groups and many experts on safety, logistics, media, heritage and conservation issues. As the story was informally told on the tour I took with my granddaughter, when Cave first approached the authorities with the idea, they assigned someone to the task of assessing the idea’s merits and possibilities. The conclusion of that study was a list of 64 reasons why it couldn’t be done. Undaunted, he thought it would take two years, but it took nine, and it proved to be more than he could do himself. When he got near the end, he had to find two other local business people who believed in that vision and were willing to invest their money to see it come to fruition.

That got me thinking about how that is not too different than what many entrepreneurs experience; for every one person that has a differentiated idea they are willing to invest their time in, there seems to be 64 reasons – or 64 people eager to tell you – why it can’t be done. It also made me realize that getting a good idea off the ground takes more than time, energy and resources, it takes a few early believers to put their shoulder to the wagon

as well. When I look back at the two ventures – adventures – I have been involved with, including the current one, several names and faces quickly come to mind. Sometimes they were investors, sometimes early adopting customers, and sometimes coworkers who shouldered the load day to day, or challenge to challenge. It is nearly impossible to do alone.

The first big test of an idea, or an entrepreneur, is a test of commitment – are you willing to swim against the stream long enough to give your idea a chance? And, are there any others that believe too? There will be plenty of detractors, but all you need is a couple of believers willing to make a commitment too. Cave obviously did, investing his time and his own money until he was able to attract others to help him see the idea come to fruition. And today, nearly 4 million people have taken the tour, each one forming indelible memories of the bridge, the courage of the workers who built it, and the foresight and engineering mastery of those who designed it. And who knows how many more will be inspired by his story of persistence, in spite of all the opposition he faced. As I stood at the top of it, I know I was. More importantly, my granddaughter was too.

To all those who have helped me pursue my dreams, or helped build bridges, thank you. | MA

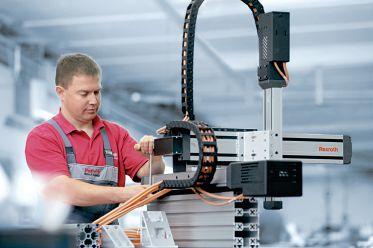

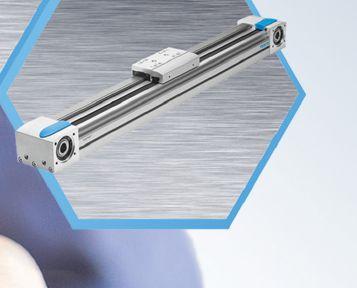

Single Source Motion Control Solutions

Complete motion control solutions - from Mechatronics, Conveyance, Assembly Handling, and Tightening Systems, to Linear and Electrical Drives and Controls Technology

Rely on Bosch Rexroth, the world leader in drive and motion control technologies that power today’s most advanced manufacturing systems.

Our automation solutions drive your manufacturing performance with fast throughput, precision, repeatable efficient motion control with maximum uptime. We’re set to help you achieve this with the industry’s most advanced conveyor technologies, electric drives and controls, linear motion components and systems, as well as production tools and tightening systems. All equipped for fast changeovers, and ready for Industry 4.0.

Smarter, more productive automation starts with the right technology. Make your move to Rexroth’s motion control solutions today. We Move. You Win!

Order your free Factory Automation Resource Kit: www.boschrexroth.ca/factoryautokit For expert advice call 1-855-REXROTH (739-7684) or email us at info@boschrexroth.ca

Rite-Hite is a manufacturer, seller and servicer of loading dock equipment, industrial doors, safety barriers, HVLS fans, industrial curtain walls, and more — all designed to improve safety, security, productivity, energy savings, and environmental control.

The basics of barrier safety

Industrial facilities are inherently dangerous and use a variety of barriers to protect people, products and property. In some instances, these barriers may simply separate pedestrian traffic from other internal vehicle traffic. In other facilities, barriers may be employed to keep people away from automated processes and machinery or to protect employees against falls.

Barriers may also be used to protect production equipment and/or the building itself from vehicle damage. In all cases, barriers play an important role in helping facilities operate safely and efficiently. An appropriate safety barrier should only be selected after evaluating the application criteria.

I n heavy equipment operation zones, safety barriers also are frequently used, and for good reason. Consider this, the Association of Workers’ Compensation Boards of Canada says 241,508 lost time claims took place in Canada in 2016. Meanwhile, according to OSHA, roughly 34,900 people are seriously injured and 85 killed every year in forklift-related incidents across the U.S.

The barriers used in these

Installing safety barriers is a cost effective, yet important investment that can help prevent accidents and injuries.

applications are designed to absorb the energy of a vehicle impact, protecting plant personnel from potentially life-threatening injuries. Barriers are often applied at the edge of loading docks to protect pedestrians from accidentally stepping off, as well as forklift and other vehicle operators from inadvertently rolling over the edge. Safety barriers can also be applied to protect sensitive equipment or structural elements in a facility, saving repair costs and downtime.

One of the simplest forms of safety measures are yellow lines painted on facility floors to designate pedestrian walkways.

Although walkways are common in industrial facilities, they are increasingly being augmented with physical barriers. These barriers add a vertical visual component and create a physical barricade between pedestrians and potential hazards, enhancing safety.

Danger above the plant floor

In mezzanine and elevated work platform applications, safety barriers can be implemented near edges where loading and unloading take place. This

safety precaution can help prevent falls, which is a major issue every year – there were nearly 650 fatalities due to workplace falls to a lower level in 2015, according to a report from the U.S. Bureau of Labor Statistics. There are several considerations facility managers should keep in mind when contemplating safety barriers applications:

• What are the maximum gross loads and speeds of the material handling equipment expected to impact the barriers?

• Is there sufficient space to allow the barrier to sustain maximum deflection when impacted?

• Is repair or replacement acceptable after a barrier impact creates permanent deformation?

• Are barriers permanently installed or do they need to be removed on a regular basis?

The impact rating of a barrier is often difficult to define. Many manufacturers rate industrial barriers based on their ability to stop an impact of 10,000 lbs. at 4 mph – which has been

a common industry benchmark for more than 30 years. However, while this rating provides a meaningful reference for a specific load at a specific speed, it fails to define several key variables:

• How is the barrier’s performance affected as the mass of the impacting vehicle increases?

• How is the barrier’s performance affected as the impacting vehicle’s speed increases?

• How severely was the barrier damaged by the impact? Is replacement necessary?

• How much did the barrier deflect during impact? Did it stop the load soon enough to prevent injury or damage?

Barriers absorb an impact by distributing the impact energy into the materials that comprise the barrier. As the barrier absorbs energy, the materials that comprise it elongate and the barrier deflects. There are two components

13%

Of the 241,508 lost time claims that occurred in 2016 in Canada, 13 per cent occurred to 50-to-54-year-olds, according to the Association of Workers’ Compensation Boards of Canada.

to barrier deflection. During the impact, the barrier deforms elastically to the point at which energy reaches equilibrium. After most impacts, the barrier returns to its original position. After a severe impact, the barrier may sustain permanent deformation. Before installing a barrier, the user must consider the maximum elastic deflection to ensure adequate personnel and equipment protection.

Installing safety barriers is a cost effective, yet important investment that can help prevent accidents, injuries and damage to products or equipment. Before selecting barriers to invest in, consider all of the application requirements. Once these site-specific variables are determined and understood, a user can select the best barrier(s) to meet their safety and protection needs. | MA

Revolutionary Industrial PC

www.advantech.com

Next Generation of Industrial PC With Flexible Expansion

The MIC-7000 series is a compact, fanless, modularized industrial PC platform that support flexible expansion using Advantech’s innovative i-Module technology. The fanless and ruggedized design ensures that these systems can withstand the demands of harsh industrial environments. Furthermore, their small footprint enables them to fit easily into most factory environments.

GOING DIGITAL

BY JENNIFER RIDEOUT

Are you IIoT ready? Probably not

It’s been more than a year since this column’s first piece on the Industrial Internet of Things (IIoT). That article encouraged Canadian manufacturers to adopt technologies that take advantage of the IIoT to improve production and performance. The challenge – at the time – was that few Canadian manufacturers understood the value of the IIoT, and were falling behind international competitors as a result.

The challenge today is less about knowledge. Manufacturers today know that competitors are adopting advanced technologies to deliver better products at a lower cost. They understand the benefits of these technologies but how to implement them successfully is proving to be an emerging challenge.

This fact was underscored with the release of a study earlier this year at the IoT World Forum. The study revealed only 26 per cent of IoT projects are considered a complete success. For the other 74 per cent, those projects were still in progress, delayed or failed outright.

With the odds of failure – and the stakes – so high, some manufacturers are simply opting out of the benefits an IIoT deployment brings — let’s change that. Here are seven steps to ensure the success of your IIoT project:

1. Start small

If you focus on your entire plant, success is much less likely. Try starting with a smaller project in a key focus area — perhaps an area that has the most downtime, the most maintenance, the highest energy consumption, and so forth. This sets you up for the best return on your investment.

2. Define success

Determine what you are trying to achieve, then measure it before and after any IIoT project. For example, what is your unplanned downtime key metric today? Where do you want it to be? When do you plan to meet that benchmark by?

3. Gain internal company IT and operations alignment

The days when operations can implement network-related projects without

IT are gone, or at least close to extinction. Success is more likely achieved by working closely together. You also need executive buy-in. Not only can this help drive support across your organization, it may help secure budget approval by aligning with corporate objectives such as sustainability or security.

4. Understand and address security risks

Connecting data from the factory to the enterprise – or opening up remote access all the way down to the plant floor – can create potential security risks. With any IIoT project, your attack surface is likely to expand. Carefully evaluate the potential risks and their impact, then tackle the most pressing concern first. Find a trusted partner to perform a security assessment to help you evaluate and prioritize your concerns.

5. Free up data from disparate networks

Make sure you fully understand the different networks in use, as well as the data you want to capture for analysis. Do you have Controlnet, Devicenet, CAN or other networks? Do you want to install a myriad of different gateways to translate that data to the Industrial Ethernet? Or do you want to overlay new PLCs and monitoring equipment to gather data for analysis? These different technologies can create a complex network of potential failure points on your factory floor. You may decide the extra complexity and risk are not worth it and explore changing all controls to Industrial Ethernet.

With more than 80 per cent of

Connecting data from the factory to the enterprise –or opening up remote access all the way down to the plant floor – can create potential security risks.

industrial fixed assets being more than 20 years old, changing to newer controls with Industrial Ethernet communications may be worth the investment.

6. Avoid data overload

Keep your dataset manageable. Use basic statistical analysis to look for outlier data, and consider using Edge analytics to reduce the data volume for later analysis. Find a partner who has experience with analytic software designed to look at manufacturing data, and glean actionable results from that data.

7. Cultivate a technologyfocused culture and IoT expertise

You need new technology to achieve the promise of many IoT benefits, and you need the expertise of people, vendors and partners to get there. Your IT department holds significant expertise in orchestrating data flows in your plants and enterprise. Engage them in this process from the beginning.

The reality is you are probably not ready to deploy a successful IIoT project – few companies are – but by following the steps outlined above, you can begin to mitigate the risks of an IIoT deployment and start experiencing improvements in your production quality, efficiency and accuracy. Investing in these solutions can require massive resource investments, so ask yourself — do you want to do it right or do it over? | MA

My thanks to my colleague, Scot Wlodarczak, for allowing me to use his Seven Steps to Success in this column.

Jennifer Rideout is the manufacturing marketing manager for Cisco Canada. She is responsible for developing go-to-market strategies for the manufacturing sector in Canada, including channel alignment and content development. She can be contacted at jerideou@cisco.com.

As Quebec-based Robotiq marks its 10-year anniversary, CEO SAMUEL BOUCHARD reflects on the industrial robotics evolution he has seen over the past decade.

MA: How did Robotiq start?

SB: The company stemmed from a university spin-off from Université Laval between myself and two classmates at the lab during our graduate studies. We knew robotics would be booming at some point so we decided to start something new together. We licensed the technology from the robotics lab, which was a robotics hand that had been developed over the course of 10 years. Part of [the innovation was developed] for the Canadian Space Agency and there were some projects where the hand was supposed to end up on the Canadarm on the International Space Station. While that didn’t end up happening, we did develop an industrial version, [kicking off] our start.

For the first year or so, to be perfectly honest, we didn’t have much success — we were trying to solve the custom tooling problem in robotics but there were a few problems in our plan. The first was the timing — it was 2008 and it was a pretty bad time for automation and manufacturing in general so the [industry] as a whole was not very willing to try new things. Manufacturers were just focusing on trying to survive. Also, we were working to bring flexibility and ease-of-use to the market, but industrial robotics at the time really focused on uptime, repeatability, precision and speed, which wasn’t a great fit with our offering. A few years later however, cobots entered the market which really aligns with our [mandate]. We added a second product – one that is a little simpler and more suitable for cobots – allowing users to deploy robots on their own with plug-and-play modules and that’s when things took off for us. When we formed Robotiq, we were ahead of what the [industry]

wanted so the first product wasn’t a great market fit at the time. Luckily the market evolved in our favour. We are now at about 80 employees and we [intend] to hire more this year. In a couple of weeks, we will move to a new, larger office. With our 10-year anniversary this year, we will hold a celebration at our annual friends and family day this summer.

MA: How have you seen robotics evolve over the years?

SB: I’ve seen the robotics industry move toward increased ease-of-use. Ease-of-use might sound technical but it has significant business impact. Mainly, if workers can deploy and program [robots] on their own, a manufacturer’s return on investment will greatly improve and as a result, we’ve seen a new category of robotic applications. There was a kind of ‘no man’s land’ for projects below the $250K mark before — these projects weren’t too interesting for some system integrators because they were too small and the overhead was too high, as well as large million-dollar-projects that require an integrator because of the large amount of work to be [completed] in a short project timeframe. There was a real area in the market that was underserved and through the arrival of cobots and plugand-play ecosystems, a new market opportunity has been created. Most of our customers are first-time robot users and the simplicity and cost-effectiveness is [what appeals to them].

MA: To what extent are cobots being implemented?

SB: A lot — the market is growing 60-70 per cent year after year. What we’re seeing today though, is not necessarily collaboration, it’s coexistence. It’s very rare in

factories that the robot will ac tually collaborate with the human where they will be working handin-hand or passing parts from one to another. It’s more that the cobot is completing its task and there is a human working separately beside it. At this time they don’t interact much. The [main benefits] of cobots are ease-of-use, ease of programming and ease of integration, which then results in strong ROI. The thing about collaborative robots is that they don’t need to grow roots in each and every function of your business. It’s bottom-up auto mation – all you need is one specific station you want to automate and you can [proceed] with that [implementation] without impacting the whole factory. This really falls into the continuous improvement mindset. The manufacturing floor is a living thing for most companies; it’s changing all the time. We are a manufacturer ourselves, so we [understand] there are always slight modifications or improvements to the products in place, with new products being introduced and old products being discontinued. The factory floor is a really dynamic place so if you have the ability to easily adjust your robot – which is very much the case of cobots – this allows for more seamless integration on the floor.

MA: How would you describe the state of automation in Canadian manufacturing?

SB: We export 95 per cent of what we manufacture outside of Canada and the sad thing is we are exporting productivity. We

Obsessed with robots? Sign up at AutomationMag.com to receive Robotics Insider, a new quarterly e-book produced by Manufacturing Automation would really like for Canadian manufacturers to have more guts to automate. Traditionally if you look at the data, Canadian manufacturers are really shy [when it comes to] investing in automation and new machinery. Today’s manufacturers are solving labour challenges with robotics, and [if left unaddressed], this problem will not go away. What the [industry] needs to realize is this will continue to grow every year and there is no better time to try and solve it than now. While it may not be an urgent problem now, it’s a very important one. I think Canadian manufacturers need to be more proactive and invest in technologies, and they need to start now. | MA

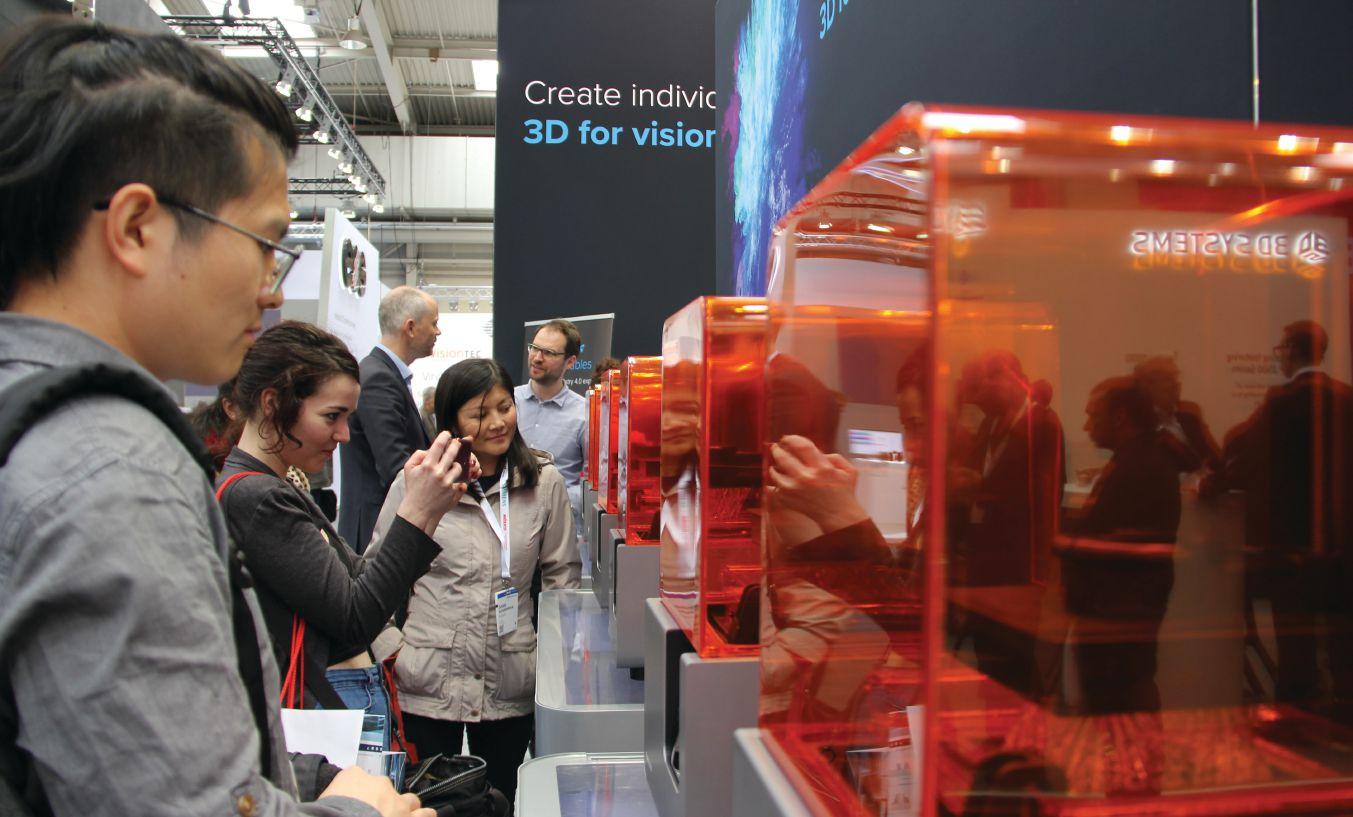

HANNOVER HIGHLIGHTS

Celebrating innovation, collaboration and a Canadian presence at the technology show

BY ALYSSA DALTON

Held April 23-27, mo re than 200,000 visitors and 5,000+ exhibitors came together for the 2018 edition of Hannover Messe, the world’s largest industrial technology trade fair. With this year’s lead theme of Connect and Collaborate, it is clear that in the ever-increasing shift toward Industry 4.0, data analytics, advanced robotics, augmented reality and the digital twin will be key.

The power of data

One use-case scenario presented by VINCI Energies, Actemium and Axians showcased the future of digitalization, where datasets from a KUKA LBR iiwa robot, the newly launched NavVis M6 indoor mobile mapping system and a VINCI Facilities monitoring device are captured, processed and cross-referenced for

real-time remote monitoring and maintenance. At a glance, the user can view the live movements of the digital twin and other bi-directional data using the Microsoft HoloLens and even perform remote servicing through augmented reality if needed.

Meanwhile, the Food and Beverage showcase at the Siemens’ booth highlighted an application case study of DME Brewing Solutions, a Prince Edward Island-based equipment provider for craft brewers. Using the Simatic IT R&D Suite, breweries can

generate a digital twin of their envisaged product with all the relevant data as early as the R&D stage. This “end-to-end digitalization” enables the downstream processes to be simulated in Siemens’ Plant Simulation PLM Software under realistic conditions, allowing manufacturing workflows and production equipment to be tested without any disruption to actual production.

Beckhoff Automation introduced a range of new products at the show, including four new EtherCAT I/O terminals for energy management – EL3443,EL3453, EL3423 and EL348 – for basic monitoring of the supply network and process control to high-end power monitoring. Historically, users wouldn’t have diagnostics after a fuse blows but these terminals help protect the equipment while providing

“No company can do it alone — if you want to create real value for [your] customers, you have to collaborate with other partners in the industry.”

analytics for root-cause analysis, explained Joe Ottenhof, Beckhoff Automation Canada general manager.

“What we’re trying to do is add as much functionality as we can; it’s very indicative of how Beckhoff feels about automation...and [how we view] EtherCAT as well. We want to eliminate specific boxes that have to be integrated through data links or proprietary protocols and [create] a more efficient operation,” Ottenhof said.

Just as new market streams and divisions are being created by the digital transformation, today’s vendors are also experiencing a transformation of their own.

“The most exciting thing [right now] is everything becoming connected. This creates significant opportunities for us as suppliers,” said Uwe Scharf, executive vice president Global Business Unit Industry, Rittal GmbH & Co. KG. “The Connect and Collaborate theme here at Hannover is really true — we are connecting and collaborating with our customers but also with the other companies here at the show,” Scharf said. “No company can do it alone — if you want to create real value for [your] customers, you have to collaborate with other partners in the industry.”

Accelerating robot-based automation

In the robotics zone, Team Alberta was one of five finalists competing for the 2018 KUKA Innovation Award. This year’s competition focused on robots that can interact inside and out of the industrial environment, with emphasis on direct support for humans. Throughout the week, Team Alberta, and the other finalist teams from Italy, Germany and the United States, presented their concepts to the judging panel and show visitors.

The Robot Vision research group from the University of Alberta presented image-guided motion control of robot arms and hands, implementing processes that enable the robot to learn from humans through observation, gestures and dialogue. The goal is for the robot to be in a position to grip various

everyday objects, workpieces and components and to sort them independently, even if new, unknown objects are included. The team explains this means future robotic systems will be able to work with humans even in unstructured environments.

While Team CoAware from Italy was named the winning team on the fourth day of the show, Team Alberta say they have enjoyed showing their presentation.

“We have been demonstrating how the robot can adapt to its surroundings and pick up different objects. Right now we’re showing the robot comb hair [on a mannequin] and the audience seems to really like that,” said Team Alberta member Zichen Zhang.

For a fair comparison of the concepts, KUKA provided each of the final teams with a flexFellow — a mobile robotic unit on which a LBR iiwa robot is mounted. A 3D vision system from start-up company Roboception was also available.

A provincial investment

This year, Investissement Québec partnered with Chambre de commerce du Montréal métropolitain (CCMM) for their first trade mission to Hannover Messe. The 40-person delegation included APN Global, Kinova, VKS and Investissement Québec, who proudly exhibited in the Quebec Pavilion.

“We [wanted] to bring innovative manufacturers to Hannover to show what’s going on in Quebec and to try and attract European businesses to Canada,” said Jean-Christophe

Lambert, advisor, international market development at CCMM.

This is the second time VKS has attended the show. After visiting Hannover for the first time in 2017, the company approached Investissement Québec to see if there would be interest in organizing a Quebec stand.

“We were really looking at expanding our name. We’ve been present within North America and this has given us the opportunity to showcase ourselves on the international level and really multiply our business,” said Kyle O’Reilly, VKS director of sales. “For me it makes sense to any company that’s in manufacturing...to take the leap of faith and join this mission and see what it brings to them because for us, it’s been incredibly beneficial.”

Lambert calls the inaugural trade mission to Hannover Messe a success and says they will likely organize another trade mission to the 2019 tradeshow. “We hope to bring twice the number of exhibitors next year.” | MA

SNAPSHOTS FROM HANNOVER MESSE

A crowd gathers to watch a friendly game of robot soccer – or is it football? – at the T-Mobile booth.

Voith Robotics presents its self-teaching Panda robot series.

Trying on the Microsoft HoloLens at the Eaton stand.

Meet Roboy, a humanoid robot developed by 100 research labs and countless students and scientists from the Technical University of Munich.

The Visual Knowledge Share (VKS) team from Châteauguay, Que. VKS is a webbased application that creates and shares digital work instructions, while capturing productivity data. It can connect with machines, tools and other software.

Scanning “everything and everybody,” the Pepperl+Fuchs intelligent multisensor system makes detected data available in the Cloud for future use.

Stéphane Agnard and Antoine Proteau of APN Global, which is made up of six manufacturing companies.

Sylvain Durocher of Investissement

Québec and Jean-Christophe Lambert of Chambre de commerce du Montréal métropolitain (CCMM).

Learning about six use cases of predictive maintenance at the Lufthansa Industry Solutions booth.

igus describes its new robolink Apiro as offering “countless” possible components combinations.

and François

Festo showcases the BionicWorkplace, designed for more effective machine-human cooperation through artificial intelligence, robotics, voice recognition and wearables.

Many demonstrations highlighted the power of virtual and augmented reality, allowing attendees to explore the smart factory through artificial intelligence and IoT machine vision.

Jérôme Bédard

Boucher of Quebec-based Kinova, a manufacturer of assistive and medical robotics.

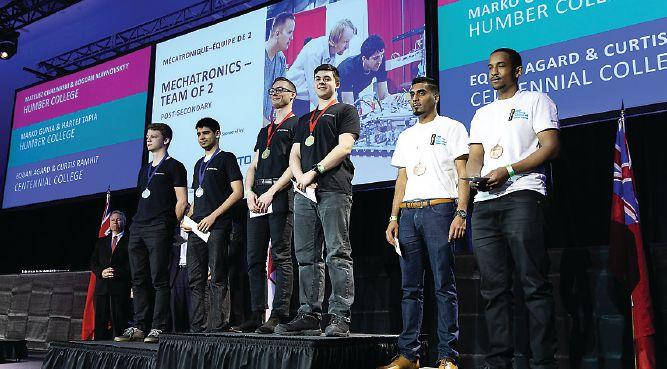

INVESTING IN THE FUTURE GENERATION

BY ALYSSA DALTON

Training programs and initiatives

Skills Ontario has received a $125,000 investment from Magna International in support of the 2018 Skills Ontario Competition, Skills Ontario Young Women’s Initiatives, and Skills Ontario Summer Camps. The new funds build on the company’s investment of $100,000 in 2017 that supported experiential learning, skill development, and mentorship opportunities to more than 3,000 youth across Ontario annually through Skills Ontario Young Women’s Initiatives and Summer Camps.

Learning with real-world equipment

In a move to help strengthen engineering education, Omron Automation Americas is providing hundreds of thousands of dollars’ worth of real-world equipment to Georgian College. It is also donating software and providing training to the faculty so they can enhance their skills on and know-how of the new equipment. Students will be able to put their knowledge into practice by using a new set of PLCs to simulate assembly line production in one of the college’s electrical labs.

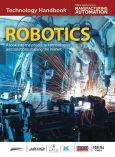

A commitment to robotics and coding education

The Government of Saskatchewan has announced new coding and robotics opportunities for middle years and high school students in the province. The elective courses will be available to all Saskatchewan high schools, while Grades 7-9 teachers can also introduce students to coding and robotics. “Our government is following through on our commitment to develop Saskatchewan students’ computer coding skills that will help prepare them for emerging careers in science, mathematics, engineering and technology,” said Deputy Premier and Education Minister Gordon Wyant.

Collaborating over additive manufacturing

Additive Metal Manufacturing (AMM) is offering Mohawk College’s Mechanical Engineering Technology and Non-Destructive Testing students an opportunity to work directly with industry on research and development projects aimed at helping manufacturers adopt additive manufacturing technology. AMM president Norman Holesh says the collaboration will help fill the need for skilled workers who have hands-on experience with technology and commercial experience of working with real customers. | MA

One Integrated Platform for All

of

Your Automation Needs

One platform for electric automation means seamless connectivity. From electromechanical actuators when joined with servo motors and servo drives to complete positioning systems, motion control solutions as well as entire handling systems and decentralized control solutions - always with the right software and interface.

BETTER DATA DELIVERED

How the IIoT is revolutionizing the manufacturing plant

BY KAY JENKINS

Ask any number of plant executives what their greatest pain point is and chances are ‘inefficiency’ will be a common response. Executives are expected to produce more with less, cutting out time-consuming practices while maintaining optimal customer service. The problem is this strategy often fails to factor in downtime and inefficiencies out of the crew’s control.

But what if we could transform the plant manager into a pseudo-psychic, addressing equipment failures days, or even weeks, before they interrupt operations?

To some extent, the Industrial Internet of Things (IIoT) has already made this possible by providing deeper access to critical data. But soon, the IIoT will deliver a level of data analysis that will radically change the way we approach plant operations. It’s no wonder the IIoT market is expected to reach more than

US$900 billion by 2025, according to a 2017 Grand View Research study.

The answer to how IIoT will affect your plant lies in how you manage data. Take a closer look at what the IIoT means for your maintenance operations and, ultimately, your bottom line.

The data doesn’t lie

Before the IIoT, maintenance looked backward instead of forward — responding to machinery errors after they happened. Data capture gave the maintenance team an idea of what went wrong, but this information was only available after the fact. Plants could be saddled with costly repairs on top of the revenue already sacrificed to downtime.

The IIoT has helped refocus maintenance priorities on prevention. Sensors located on critical machinery talk to the plant’s Enterprise Asset Management system through a Predictive Maintenance Module (PdM). These sensors learn what optimal

$934B

Grand View Research predicts the IIoT market will be worth US$933.62 billion by 2025, largely driven by growing demand and adoption of Cloud computing and the scalability of IPv6-3.4X 10^38 IP address.

operation feels like, so as a critical part begins to malfunction, they can alert the crew while it is still functional. By isolating maintenance data from operational data, the PdM declutters information, helping the plant manager make a more informed decision on how to approach preventive maintenance.

The benefits of an IIoT-enhanced plant touch all corners of the operation. Your maintenance team can reduce the amount of time it spends identifying errors, which in turn increases productivity and may be able to repair parts rather than replace them, slashing the maintenance budget. Your operations staff doesn’t spend their workday waiting for an out-of-commission machine to come back online. Your management faces fewer roadblocks in the quest to meet ever-increasing customer expectations.

Much like how AI-enabled assistants have already simplified our everyday tasks, IIoT-enabled technology will help cut down on redundant processes and resource-consuming repairs. As IIoT-enabled devices become more affordable and pressure for greater efficiency rises, there is no better time to invest in a connected plant.

Where do I start?

If you’re interested in implementing

The

benefits of an

IIoT-enhanced

plant touch all corners of the operation.

IIoT-enabled tech, you’ll need to do some background work first. Consider these three steps to gain better data:

• Determine your pain points

Spend a few days examining every plant process and observe the machinery in action and speak with its operators. Gathering this information helps you make a more informed decision during the buying process. You want to make sure your IIoT investment is right for your unique problem.

• Prioritize areas for IIoT implementation

Create a roadmap for IIoT implementation and start with the pain points that need to be addressed immediately. Ensure your initial sensors are placed on machinery that malfunctions irregularly or require the most time to repair.

• Consider moving to the Cloud If you’re looking to implement IIoT on a budget, maintaining advanced technology inhouse will be cost-prohibitive. Whichever solution you choose to interpret your IIoT-enabled devices, Cloud-based Enterprise Asset Management systems are cheaper to implement and can turn around data analysis faster than onsite solutions.

Investing in efficiency

It won’t be long before IIoT is a plant standard — demands on production will be too great to function without it. The good news is IIoT is now prevalent enough that upgrading your plant is an affordable process. If you need to glean more information from your operational data, it’s time to consider how IIoT-enabled devices can improve your processes. | MA

Kay Jenkins is business leader at AssetPoint, where she directs the software developer’s TabWare EAM solution, as well as parent company Aptean’s Axis ERP and Activplant MES solutions. Prior to her current role, she served as AssetPoint’s EVP of Research and Development for 13 years.

THE CYBERSECURITY ARMS RACE

Increased connectivity is exposing businesses to the threat of physical disruption and system failure from malicious hacking attacks

BY DAVID PRICE

Online remote access technology is increasingly allowing manufacturers to view and operate automated production line machinery from anywhere at any time, providing unprecedented oversight and efficiency gains. From national grid automation to multi-location production lines or a building’s boiler and sprinkler systems, more and more hardware and devices are not only accessible online but the systems that host and track them are also increasingly centrally interlinked.

This advance in connectivity has taken place over a relatively short period of time, with the Internet of Things (IoT) revolution having only really gained commercial momentum in the last decade. Remote access to automated manufacturing lines and related hardware provides invaluable real-time oversight of a facility, helping to reduce downtime and provide efficiency and cost savings. Indeed, there is little doubt remote online connectivity is the ideal solution for managing and monitoring multiple machines at numerous locations.

As well as the ability to control and access hardware remotely, such technology is enabling far greater and more accurate data

collection on asset usage and efficiency. This operational data can automatically feed into central systems and inform other decisions and the overall strategy for a business. This data, in effect, becomes an absolutely crucial part of a company’s intellectual property (IP) and ongoing business development.

Data, data everywhere

Naturally, there are risks to online connectivity as well as opportunities. Critical to the success of remote access and monitoring tools is the level of protection against cyber threats. Cybersecurity breaches are already costing manufacturers millions of dollars, with companies facing highly targeted attacks on an almost daily basis.

A 2018 study by Toronto, Ontario-based Scalar Decisions found the number, sophistication and severity of cyber attacks on companies in Canada are on the rise, steeply. We’re not just talking about malware, data breach or ransomware attacks targeting IP theft and extortion, as disruptive and wide-ranging these can be. For some time now, hackers have been targeting physical damage and even system failure through cyber attacks.

According to a survey by Kaspersky, more than 320 malicious codes were discovered in industrial control system components by security researchers in the second half of 2017. The systems affected operated critical processes from electricity and water plants

to manufacturing factories. The report found most of the malicious codes could be exploited by hackers remotely without authentication.

Everything is so interlinked it is possible for hackers to send a malicious code to an industrial control, boiler, production line or safety control to cause physical damage. Imagine a boiler being hacked, a sprinkler pump being pushed to its max, or a production line running three times faster than normal. Malicious code could also spread to central data and control hubs, resulting in wider data breaches that cause maximum disruption and downtime.

Property damage and business interruption are all well established components of the arsenal of hackers. From the Stuxnet computer worm attack which damaged critical uranium enrichment facilities, to the NotPetya attack in the U.S. which disrupted production of a large pharmaceutical’s medicines and vaccines, hackers that gain remote access to a client’s automated, Internet-enabled production line can result in property damage, business interruption and even full system failure. And that’s not to mention the risk to life such breaches represent.

Protection gaps

Developers of remote monitoring and control technology for manufacturing automation are working hard to close any protection gaps, with many now offering device-level cybersecurity as standard, particularly with remote control and monitoring options. Critically, the solution must be holistic — the same level of protection must cover each and every IoT-device operating in a facility, with additional protections when feeding data from hardware into the main computer hubs.

It takes one weak link in the chain to allow hackers in.

A s well as selecting the right device-level security, risk management measures should also include network security management, passwords, firewalls, virus protection and biometric security access measures if necessary. A clear backup strategy is also critical. If your business keeps regular, isolated and accurate backups of its data, this will lessen the damage potential of a ransomware attack. This backup strategy counts as much for back-end data storage as it does for front-end websites — keeping a clean and up-todate backup of your website may prove invaluable in the event of a distributed denial of service attack, for instance.

Companies should also ask themselves whether third-party suppliers have access to any of their systems and, if so, move

quickly to ensure appropriate cybersecurity measures are part of all supplier audits before third parties are allowed anywhere near their systems.

Remember back in 2014 when a major U.S.-based retailer faced penalties of almost US$19 million after suffering a huge data breach? The initial cyber intrusion was traced back to the fact that network credentials were stolen from a third-party refrigeration, heating and air conditioning subcontractor that has worked at a number of its locations. Third parties, often unknowingly, represent a significant and unexpected back door for hackers to gain access to your company’s data and control systems.

Cybersecurity as a KPI

Certainly any IoT, remote access-enabled manufacturer should make cybersecurity a main focus. Just as factories champion the

Rugged...Smooth...

number of accident-free days as a key measure of their health and safety success, businesses should track any attempted cyber attacks they detect and champion their successful deflection as a key performance indicator for the group Manufacturers, particularly those with automated lines and remote connectivity that could find themselves targets for physical damage attacks, should seriously consider actively planning for a cyber breach — a kind of hacking fire drill, if you will. Conducting annual dry runs of different cyber breach scenarios could give your business the edge when it comes to minimizing downtime and regaining control if the worst were to happen.

W hat would you do if your production line suddenly went into overdrive due to a malicious

attack? Do you have a cyber breach notification plan? Do you have a cyber risk management strategy? Does your cyber insurance cover physical disruption or system failure? Many cyber insurance policies for manufacturers explicitly exclude this risk, so it is well worth checking.

Cyber is a new, constantly developing risk. It is important to partner with companies that make it their business to spot any potential gaps that could leave your business vulnerable. It is a cybersecurity arms race, but a consistent, well thought-through approach covering all the bases, including how your business would respond and be protected in the event of a successful attack, is not only sensible but may well prove critical to recovery and continued operation. | MA

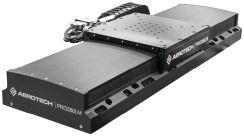

PRO-LM Series Linear Motor Stages

Aerotech’s PRO-LM series linear-motor stages offer a cost-effective, high-performance solution for positioning applications that require smooth, precise motion. A linear motion guide bearing system, high-performance brushless linear servomotor, protective hard cover and side seals make the PRO-LM series ideal for applications such as laser machining, medical component manufacturing, and other applications requiring high accuracy and extremely smooth motion in a production environment. With a wide variety of sizes and load capacities, there is a PRO-LM stage to match your needs and exceed your expectations. Contact Aerotech today to learn how a PRO-LM stage can improve your up-time and application throughput.

Travel to 1.5 m

• Direct-drive linear motor for smooth, precise motion and high speed

• Linear motion guide bearing system means long life and minimal downtime

Fifty-seven different models with travels ranging from 50 mm to 1.5 m to ideally match almost any application

Unique side-seal design provides superior debris protection increasing up-time and keeping your process moving

Also available with a linear motor or high-speed ball screw!

David Price is Divisional Director & Head of USA Team at Endeavour Insurance Services. He and his team specialize cyber insurance for automated manufacturing lines through Ensconce.

vertical sideseal design provides superior protection from debris.

CONNECTIVITY

Inverters deliver 1 kVA sine wave output

CTP 1000-F7W is the latest addition to Absopulse Electronics’ line of low profile DC-AC inverters with three-phase pure sine output voltage. The 1 kVA units provide three-phase outputs of 208 Vrms continuous (line-to-line) at 60 or 400 Hz, or 380 Vrms or 400 Vrms continuous at 50 or

SENSORS

Liquid level capacitive sensors

Carlo Gavazzi has launched CD34 liquid level capacitive sensors designed to detect water-based liquids through non-metallic walls, like plastic or glass. According to the company, the sensors automatically account for the thickness of plastic or glass walls and compensate for any residual films, moisture or foam accumulation while sensing the presence of the liquid to be detected. The sensor is packed with a universal bracket, which enables mounting versatility for a variety of surfaces, circular (e.g. sight glass, round containers) or flat. The CD34

60 Hz. They operate from 48 V, 96 V, 110 V, 125 VDC or custom DC input voltages. Absopulse says the use of silicon carbide semiconductor technology contributes to 90 per cent conversion efficiency at full load, “ensuring high power density and significantly smaller size than earlier three-phase 1 kVA inverters.”

www.absopulse.com

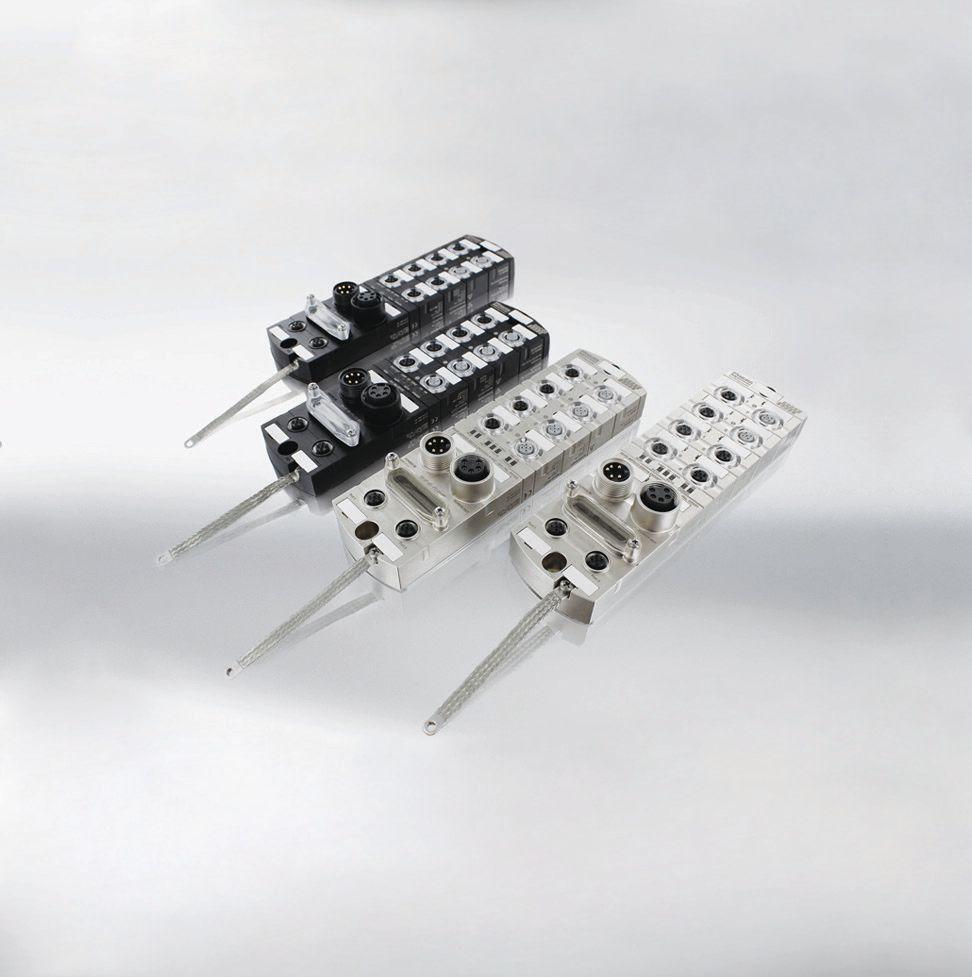

Isolated digital I/O modules

Advantech has announced its USB-5800 series of isolated digital I/O modules for industrial control applications that require easyto-install portable digital I/O capabilities, particularly for systems without PCI/PCIe slots, it says. Featuring SuperSpeed USB 3.0 capabilities, the I/O modules provide data transfer speeds of up to 5 Gbps, extend the system I/O functions, and support daisy chaining for easy I/O expansion, Advantech explains. The front-facing LED indicators, ID switch, and terminal blocks provide users access for installation and maintenance. To help protect against sudden

failures or disconnection, the USB-5800 series features Auto Recovery technology, which the company says ensures zero failures. The USB-5800 modules support various development tools, including C#, C++, LabVIEW, VB.Net, MFC, BCB, VB6, Java, Delphi, and Qt.

www.advantech.com

TSN-enabled controllers

NI has unveiled the CompactRIO Controllers that feature NIDAQmx and Time Sensitive Networking (TSN), which it says marks the industry’s first fully supported implementation of TSN – the next evolution of the IEEE 802.11 Ethernet standard. As industries such as automotive, oil and gas, and aerospace continue to implement the IIoT, acquiring accurate, reliable

works out of the box for most applications, as it’s capable of detecting the media (liquid) with a conductivity of 50mS/cm, notes the company.

www.gavazzionline.com

Parker icountPD online particle detector

Wainbee is distributing the icountPD online particle detector from Parker, describing it as a permanently mounted laser detection particle counter for monitoring equipment conditions. What makes the icountPD detector stand out is its capability of displaying and communicating data in ISO4406/NAS1638 and relative humidity, explains Wainbee. Employing up-to-the-minute laser technology in solid-particle detection, recommended applications for the icountPD include: mobile equipment in forestry and agriculture, industrial equipment,

wind turbines and lubrication systems in power generation, and maintenance applications. Parker manufactures three versions of this particle detector: The standard design for test stands, filter carts, flushing skids, and similar uses; the icountPDR for mobile equipment and use in non-hazardous outdoor conditions; and the icountPDZd for offshore platforms and other potentially dangerous applications.

www.wainbee.com

Industrial lasers for machine shops

BEA Lasers has announced the availability of its full line of industrial laser modules, some of which are now offered in new sizes. The full line includes: MIL series, MIL RA series, GPL series, SEN series, MIC series, and IND series. These industrial laser diode modules each include a housing (with right angle options) and cable apparatus, many with a connector, to alleviate hard

wiring for replacements, explains BEA. The units are offered with a choice of green or red laser light and a crosshair pattern, and all include laser dot and line patterns. Other patterns are available on request. Most industrial laser families are available with 1 MW, 3 MW or 5 MW output power. Each laser module in the MIL and MIL-RA series also includes a DIN rail switching power supply with 85 to 264 VAC. Suitable for use in factories, machine shops and other harsh industrial environments, BEA industrial lasers are designed for the alignment and positioning of products, components and machine parts.

www.bealasers.com

and synchronized data across distributed nodes has become more challenging. As a result, companies must keep pace to ensure their systems are ready to meet these evolving requirements. NI says the new controllers feature: submicrosecond synchronization with TSN over standard Ethernet for synchronized, distributed measurements and control; shorter time to measurement because of the NI-DAQmx driver software; and open processing at the edge of the IIoT with the NI Linux Real-Time OS. www.ni.com

IP69K-rated limit switches

Steute Industrial Controls’ series of ES 98/EM 98 safety-rated limit switches offers positive-break NC contacts to monitor the opening of a machine guard/access door. Available with a variety of actuator styles, the corrosion-resistant metal housing and IP69K rating are designed to provide reliable operation in challenging environments, says the company. Other features of the series include: an operating

temperature range of -20 to 90 degrees C; an actuating head that can be rotated 4 x 90°; and rocking lever adjustable in 10° increments.

www.steutewireless.com

Linux-ready Cortex-A7

HMI & OPERATOR INTERFACE

PID controller capabilities added to HMI solution