Our commitment and dedication to the Canadian turkey industry has spanned the last 60 years. Today, the lasting relationships we have developed, ongoing investments in research and the performance of our products are assurances that Canadian turkey farmers will continue to benef ifit from the advantages Hybrid Turkeys has to offer:

> a network of trusted Canadian distributors

> aff iliations with agriculture research institutions

> a team of global technical experts

Partnering for your success.

INDUSTRY: Joint Venture

Aviagen Turkeys to offer Canadian growers more choice By

Lianne Appleby

THE BEAKER: Is Being Hungry Good or Bad? By Karen

Dallimore

PRODUCTION: Defining Sustainability For poultry, it’s already an unspoken rule By Karen

Dallimore

IN THE BARN: Running Like the Wind Choosing the right fans for your building By

Shawn Conley

PRODUCTION: Leg Issues in Meat Birds

Industry discusses the subject at the hatchery, feed and farm level

By Melanie Epp

CONSUMER ISSUES: Food

How food inflation rates will affect the poultry industry this year

By Treena Hein

FEED: Edible Insects

University of Wageningen researcher shows that insects have great potential for use in feed and as biofuel By Karen Dallimore

BY KRISTY NUDDS

It’s a message that we hear repeated often: interest in farming from the public has never been higher than it is right now.

This interest is fueled by many factors, including the local food movement, health awareness, economics, and concern for the environment and animal care.

Overall, interest in farming can be considered a good thing — consumers have been disengaged with how food is produced and the many challenges farmers and food industries face for too long. The opportunity for engagement is great, and consumers are willing to learn and listen.

Unfortunately for the poultry industry, the message consumers are hearing lately is not a positive one. Undercover animal activist videos portraying improper handling of turkey breeders, pullets and broiler chicks has gained national media attention and rattled retailers.

Of course the videos are meant to be sensational and promote the mandate of Mercy for Animals, the activist group behind them. But they point to several issues, like it or not, that need further discussion and consideration.

When such videos are released, industry goes into defense mode and says that animal care protocols are in place and should be adhered to; if not, employees are reprimanded and/or fired. This is true, but are employees being watched all of the time, and if so, who is responsible for this monitoring? Do employees have a complete understanding of what is expected with respect to animal welfare? Ultimately, it lies with the farm or business owner, and its importance needs to be made clear.

The Farm & Food Care Foundation (FFC) emphasizes having an animal care code of conduct for your farm or business in writing, and be willing to enforce

it (information on developing your own code of conduct is available on our website www.canadianpoultrymag.com, in the article “Employees Handling Animals?”).

Industry also points to national guidelines, the Codes of Practice for Poultry, which are currently being updated (the current Codes were written in 2003). These guidelines are being coordinated by the National Farm Animal Care Council (NFACC), an organization made up of a diverse stakeholder group that consists of government, enforcement, animal welfare and farmer representatives. The NFACC has been reviewing and updating eight national animal welfare codes since 2010 and six are complete — but poultry is not one of these. Federal funding (provided by Agriculture and Agri-Food Canada) has lapsed and the application for renewed funding is currently stalled.

This is unfortunate because it gives activists fodder to argue that government and industry don’t care about poultry welfare.

Although the Canadian poultry industry has been a leader amongst livestock industries in terms of developing its own animal care programs, it is open to criticism from pundits that the programs are self-serving. Having an updated code of practice from what is perceived as a thirdparty interest group (the NFACC) will add an additional level of transparency.

Hopefully funding will resume and the new code will be available by the end of the year. In the meantime, industry needs to focus on ensuring that existing practices are adhered to at all times, because when lapses are caught on camera nobody wins. n

JUNE 2014 Vol. 101, No. 5

Editor

Kristy Nudds – knudds@annexweb.com 519-428-3471 ext 266

Digital Editor – AgAnnex Lianne Appleby – lappleby@annexweb.com 226-971-2133

Publisher/Sales Manager

Marilyn White – mwhite@annexweb.com 519-400-2424 888-599-2228 ext 237 • fax: 888-404-1129

Account Coordinator

Mary Burnie – mburnie@annexweb.com 519-429-5175 • 888-599-2228 ext 234

Media Designer

Kelli Kramer

Group Publisher

Diane Kleer – dkleer@annexweb.com

President

Mike Fredericks – mfredericks@annexweb.com

Mailing Address

P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

Publication Mail Agreement #40065710

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO CIRCULATION DEPT., P.O. BOX 530, SIMCOE, ON N3Y 4N5.

email: subscribe@canadianpoultrymag.com.

Printed in Canada ISSN 1703-2911

Circulation e-mail: subscribe@canadianpoultrymag.com Tel: 866-790-6070 ext 201 Fax: 877-624-1940

Mail: P.O. Box 530, Simcoe, ON N3Y 4N5

Subscription Rates

Canada – 1 Year $30.00 per year (with GST $31.50, with HST/QST $33.90)

GST – #867172652RT0001

USA – 1 Year $ 66.00 USD Foreign – $75.00 per year

Occasionally, Canadian Poultry Magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2014 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

1 2 3

easy as 1, 2, 3. and still maintaining exceptional litter conditions.

Got Lubing? Contact your local Lubing Distributor for more detailed information.

Glass-Pac Canada

St. Jacobs, Ontario

Tel: (519) 664.3811

Fax: (519) 664.3003

Carstairs, Alberta

Tel: (403) 337-3767

Fax: (403) 337-3590

Tel: (519) 657.5231

Fax: (519) 657.4092

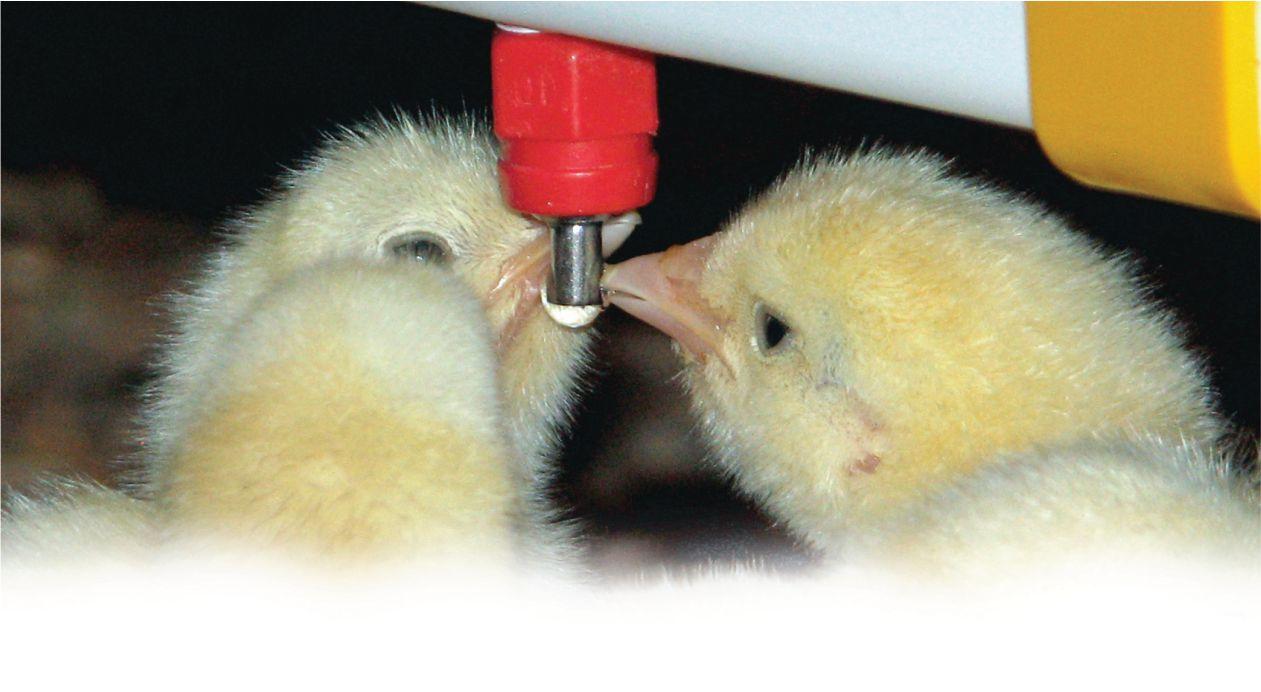

1) Large bottom pin that holds a drop of water to attract day old birds to nipple / great starts / average first week mortality below 1%.

2) Greater side flow with minimal triggering force allows all birds to easily trigger the nipple and get off to a great start. Great Starts = Fantastic Finishes!

3) Both, vertical and side action, deliver the Opti-mum flow rates and ability to grow a 4 lb small bird up to a 10 lb Jumbo bird with the same nipple. After hundreds of house updates, customers are consistently seeing improved weight gains of up to 1/2 lbs/bird with dry litter conditions!

Tel: (450) 263.6222

Fax: (450) 263.9021

griculture Minister Gerry Ritz has announced an investment of over $100,000 to Egg Farmers of Canada (EFC) to integrate its existing assurance systems into a single system that will be known as the National Quality Code for eggs.

The streamlined National Quality Code program will provide egg producers and graders with an all-in-one certification program that addresses food safety, traceability and animal care. Once implemented, the code could enhance the competitiveness of the poultry sector by strengthening its capacity to make credible and verifiable claims.

Minister Ritz said in a release “Canada’s hard-working egg producers help drive our economy while putting

world-class products on our kitchen tables. This new quality assurance system will help industry meet growing consumer expectations and will enhance the competitiveness of the industry overall.”

This investment is being made through the Assurance Systems stream of Agriculture and Agri-Food Canada’s (AAFC’s) AgriMarketing Program, a five-year, up to $341-million initiative under Growing Forward 2, Canada’s national agricultural policy framework.

This project builds on funding previously provided to Egg Farmers of Canada through AAFC’s Canadian Integrated Food

Safety Initiative to develop the Canadian Egg Industry Traceability System.

Peter Clarke, Egg Farmers of Canada chairman, said in a release that EFC is “extremely pleased to receive funding from Agriculture and AgriFood Canada for the development of a National Quality Code for eggs. Through this project, and in collaboration with our egg boards and supply chain partners, we hope to deepen the preference Canadians already have for Canadian eggs by raising the bar on excellence across the pillars of food safety, traceability and animal care.”

Canadian livestock industries have a new option to supercharge feed performance through a unique “multiples” approach to feed acidifiers from Canadian Bio-Systems Inc. (CBS Inc.)

Maxi-CID, an acidifier for swine and poultry diets, is now available through a new purchasing option as part of the CBS Inc. “Power of 5” program targeted to Canadian producers and industry.

The Power of 5 is an integrated program that allows

The Public Service Alliance of Canada (PSAC), the union representing federal food inspectors, says budget cuts have chopped a team upholding food safety standards and

customers to get the combined benefits of five of the top CBS Inc. products in one purchase and a customized application approach, designed for overall more cost-effective and exceptional results.

The company says acidifiers should be considered and selected just as carefully as enzymes and other feed enhancers, as part of a strategy to get the most value and synergistic benefits from the combined advantages of each of these products.

that’s left consumers in the Vancouver area vulnerable.

The union says Metro Vancouver became the only major metropolitan centre in the country without food inspectors dedicated to consumer protection when the team was disbanded in January.

PSAC officials say it means ground meat inspections have been more than halved com-

An insurance product available from the Lloyd’s market has been deemed acceptable for use by Manitoba egg produc-

ers, reports the Canadian Underwriter

A ruling by Manitoba Farm Products Marketing Council in January means that egg producers are not limited to purchasing their Salmonella insurance from the Manitoba Eggs Farmers (MEF) but can buy other private insurance products, according to a press release from mutual insurance company Lloyd’s insurer

Maxi-CID is formulated to reduce and optimize pH levels in monogastrics species to enhance feed efficiency and animal performance, while creating an environment that limits the threat of a range of other undesirable microorganisms - for example, minimizing the colonization of key pathogens such as Salmonella and E. coli

The Power of 5 suite of products includes Biogal-S Plus, Maxi-Gen Plus, Maxi-Cid, NutraMix and Mico-Bac.

pared with last year, there will be no cooking oil inspections and far fewer independent food retailers will be checked.

An online report from the Canadian Food Inspection Agency confirms planned spending on the food safety program will drop by $35 million and the agency will employ 192 fewer inspectors by 2016-17.

AEGIS London.

3D Poultry Disease Insurance, a product available from Canadian Lloyd’s broker Hub International, in conjunction with Toronto’s A10K and certain underwriters at Lloyd’s, has been deemed by the MEF as a suitable private insurance alternative to the Canadian Egg Industry Reciprocal Alliance (CEIRA) policy, AEGIS said.

2014

June 15-17, 2014

CPEPC/CMC Convention, Westin Harbour Castle Hotel, Toronto, Ont. For more informaiton, visit: www. cpepc.ca

June 18-20, 2014

Canada’s Farm Progress Show, Evraz Place, Regina, Sask. For more information, visit: www.myfarmshow.com

JULY 2014

July 8-9, 2014

North American Manure Expo, Springfield, Mo. For more information, visit: www.agannex.com/ manure-manager/manureexpo

July 14-17, 2014

Poultry Science Association annual meeting, Texas A&M University, Corpus Christi, Texas. For more information, visit: www.poultryscience.org/ psa14 or email: psa@assochq.org

SEPTEMBER 2014

September 9-11, 2014

Canada’s Outdoor Farm Show, Canada’s Outdoor Park, Woodstock, Ont. For more information, visit: www.outdoorfarmshow.com

OCTOBER 2014

October 7-9, 2014

Poultry Service Industry Workshop, The Banff Centre, Banff, Alta. For more information, visit: www.poultryworkshop.com

Eli Lilly and Company has announced that it will buy Novartis AG’s animal health business for $5.4 billion in cash to strengthen and diversify its existing animal health unit, Elanco.

Upon completion of the acquisition, Elanco will be the second-largest animal health company in terms of global revenue.

Lilly will acquire Novartis Animal Health’s nine manu-

facturing sites, six research and development facilities, a global commercial infrastructure with a portfolio of approximately 600 products, and an experienced team of more than 3,000 employees.

The acquisition will greatly expand and complement Elanco’s product portfolio, R&D and manufacturing capabilities, and commercial presence in key geographies.

TNew

he Farm & Food Care Foundation has received a five-year pledge of $75,000 from New-Life Mills. The announcement was made at the annual meeting of Farm & Food Care in Milton on April 16.

Bruce Christie, chair of the Foundation, said, “This donation by New-Life Mills is a direct reflection of the company’s long-time commitment to Canadian agriculture and its farmers.”

Bill Revington, General Manager Farm Division with New-Life Mills said, “We think it’s important for

JANUARY 2015

January 27-29, 2015 International Production and Processing Expo (IPPE),World Congress Center, Atlanta, Georgia. For more information, visit: www.ippexpo.com

January 29-31, 2015 Pacific Agriculture Show, Tradex Exhibition Centre (Abbotsford Airport), Abbotsford, B.C. For more information, visit: www.agricultureshow. net

March 18-19, 2015 Midwest Poultry Federation Convention, Saint Paul RiverCentre, Saint Paul, MN. For more information, visit: www. midwestpoultry.com or email: ldurben@midwestpoultry.com

Canadians to understand where their food comes from and how it’s raised. We heartily support the initiatives of Farm & Food Care because we feel they promote agriculture while communicating an interest in food and feed quality, animal welfare, sustainable farming and corporate responsibility. We look forward to continuing to work with Farm & Food Care on these issues.”

Each year over the five year agreement, representatives of the Foundation and New-Life Mills will meet to determine funding priorities.

We welcome additions to our Coming Events section. To ensure publication at least one month prior to the event, please send your event information at least eight to 12 weeks in advance to: Canadian Poultry, Annex Business Media, P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5; e-mail knudds@annexweb.com; or fax 519-429-3094. Please write ‘Event Submission’ in the subject line.

“We worked with FCC to expand our business.”

Dion

Wiebe, President, Rossdown Natural Foods, Abbotsford, B.C.

When you talk financing with FCC, we’ll listen

Ready to expand? We learn how you want to grow, then create a financing package that helps you do it. Work with the leading lender to agriculture, agribusiness and agri-food in Canada. Let’s talk business. fccfinancing.ca

CPRC made a significant change to its funding process in 2012 by moving to a two-stage system. This new method includes an initial call for Letters of Intent (LOI) followed by a full proposal from a short list of projects drawn from the LOIs. The change allows CPRC to better tailor the research it supports to industry-identified priorities as laid out in the National Research Strategy for Canada’s Poultry Sector (the Strategy), available from the research page of CPRC’s website, www.cp-rc.ca. CPRC is now able to provide feedback to researchers (prior to the full proposal stage) on LOIs that are of interest but that may not fully address priority issues. This allows the researchers and CPRC to discuss changes in the objectives and/ or work plan to more closely align the project with industry priorities.

CPRC’s call for LOIs was cancelled in 2013 so that funds allocated for research for that year could be directed to the new Poultry Science Cluster. The 2014 call for LOIs was issued in April with submissions due June 1st. This year’s call also included some additional changes to better align the LOI calls with industry priorities.

CPRC has used the following five research categories for funding calls for many years:

• Avian Gut Microbiology

• Environment

• Food Safety and Poultry Health

• Poultry Welfare and Behaviour

• Novel Feedstuffs

CPRC also funds projects that are of significance to the Canadian poultry industry, but may not fit into the broad research programs listed above. Researchers may apply for funding for this category of research at any time throughout the year according to the CPRC policy on ad hoc proposals.

While the categories have suited CPRC’s purpose, they do not encompass all those identified in the Strategy that CPRC and industry have put so much effort into developing. The nine Strategy research categories are:

• Economic viability

• Genetics

• Food safety

• Animal Health Products

• Poultry health

• Poultry welfare

• Environment

• Functional and innovative products

• Poultry feedstuffs

The CPRC Board of Directors decided, at its March meeting, to align its categories with those in the Strategy. CPRC will now issue calls for LOIs based on individual categories or groupings of the Strategy categories. Groupings will be of similar types of research and some will closely reflect the categories that CPRC used through 2012. This year’s call for LOIs was for two category groups:

• Food Safety and Animal Health Products

• Genetics, Poultry Health and Poultry Welfare

LOIs do not have to address all aspects of each group but can target one or all of the priorities within the group. CPRC’s Board will review this approach at its July meeting as well as set the research categories that will be used for the next several years. This information will be posted on the CPRC website. The ad hoc category will be retained.

Many researchers and industry stakeholders have dealt with CPRC through Gord Speksnijder. Gord attended his first CPRC Board meeting in October 2003

and took over as Executive Director from Dave Nodwell a year later. Gord moved into the Research Coordinator role with CPRC in mid-2011 when operations were relocated to Ottawa. Gord has decided to step back from CPRC into an advisory role because of increased demands on his time from the family farm and a growing family. The CPRC Board, member staff associated with CPRC and CPRC staff are sorry to lose the regular input and exceptional advice that Gord has brought to the organization. His unique ability to view research from the point of view of a trained researcher and active farmer has been an asset that will be sorely missed. We wish Gord and his family all the best in their future endeavours.

The CPRC Board of Directors is appointed each year by its Member Organizations and consists of one representative from each of the five members. The 2014 CPRC Board was reappointed without change at the Annual General Meeting in March. Information on Board members and CPRC activities is available in its 2013 Annual Report posted on the website.

For more details on any CPRC activities, please contact The Canadian Poultry Research Council, 350 Sparks Street, Suite 1007, Ottawa, Ont. K1R 7S8, phone: 613566-5916, fax: 613-241-5999, email: info@ cp-rc.ca, or visit us at www.cp-rc.ca. n

The membership of the CPRC consists of Chicken Farmers of Canada, Canadian Hatching Egg Producers, Turkey Farmers of Canada, Egg Farmers of Canada and the Canadian Poultry and Egg Processors’ Council. CPRC’s mission is to address its members’ needs through dynamic leadership in the creation and implementation of programs for poultry research in Canada, which may also include societal concerns.

TD is committed to helping farmers build for the future.

Dave Jeffries and his sons, Roland and Ernie, know a thing or two about farming. So, when it was time to expand the business, they naturally chose a bank that knew how to help. At TD, they found Agriculture Specialist Vince Puchailo, who helped implement a succession plan that involved Dave’s brother. Vince’s understanding of the complex process even impressed the lawyers handling the sale. A personalized approach to agriculture finance, like Vince’s, is something all TD Agriculture Specialists bring. Maybe it’s time you brought one to your farm.

by Lianne Appleby

When it comes to genetics, it’s no secret that choice is fairly limited for Canadian turkey growers. In the 100th anniversary (March 2013) issue of Canadian Poultry, Dr. Peter Hunton wrote: “…in the past 100 years, poultry breeding in Canada has evolved from hundreds (or perhaps thousands) of small, independent farms that did very little in the way of selective breeding, to the point at which most breeding work is done by a handful of multinational companies whose products are distributed and multiplied on an international basis.”

The companies that have survived concentration therefore strive to maintain a competitive edge, and ensure that the products and services they provide to their customers are meeting the needs of the market. But for Aviagen Turkeys, competitive innovation doesn’t always happen as a result of strategic meetings around a boardroom table – sometimes it’s simply the fruit of casual conversations with growers like Tyson Schlegel. It was one such chat - with Rob Walker, a technical sales representative with Aviagen - that a general dialogue about the Ontario turkey industry and what it needs to grow and progress, sparked some more legitimate ideas.

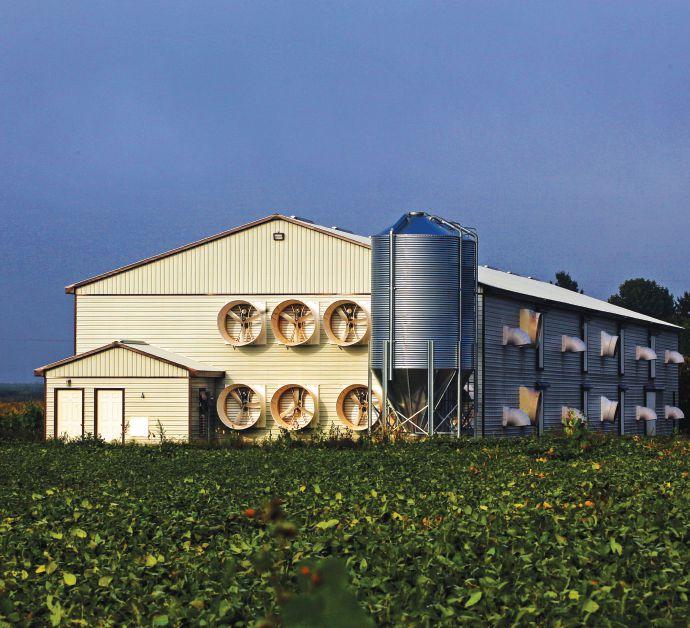

Construction has started on two stateof-the-art breeding facilities, in Bruce Township (pictured here) and will include two lay barns, one tom barn and an egg room, with two more lay barns to be built in the near future and a 5th planned for future expansion.

“We were just sitting down, about two years ago, throwing ideas out,” says Schlegel, who, at that time owned Great Lakes Poultry Farms Ltd., and has since acquired Belwood Poultry Ltd, with his father and brother. “We talked about the notion of a new hatchery, of perhaps expanding, and the potentials that could happen from there.”

Previously a wholly commercial turkey operation, Schlegel says the decision to move into breeders as well is 100 percent “new” for the family-owned operation. Schlegel’s Father, Peter, has been

involved with poultry all his life, becoming involved in the commercial chicken industry in 1950. He then diversified and entered the turkey business with purchases of commercial turkey farms in the Wingham area in the early 1990s. Tyson purchased his own two farms near Lake Erie while still attending the University of Guelph in 2000.

Not long after his chat with Walker, the junior Schlegel was in more serious talks with Aviagen Turkeys’ President, Jihad Douglas, about the concept of a joint venture. The Schlegels already wanted to grow their business and were known to Aviagen as open-minded growers who understand the Ontario market well. Similarly driven by a vision to be able to supply Ontario and Eastern Canadian turkey farmers with quality poults, with core values that matched, the fit seemed perfect.

The venture itself can be broken into two parts. First, Belwood Poultry Ltd. will serve as the breeder farm operation – for now, at least. Breeder flocks are already on the ground in older barns, but new breeder barns are currently being built.

Says Schlegel, “Construction has already started on two stateof-the-art breeding facilities. The first, in Bruce Township, has the capacity for 8,000 breeders. The second farm is in Ashfield Township. There, we have four lay barns going up, one tom barn and an egg service room. It will house about 16,000 breeders, with capacity for about 20,000.”

The proposed complex will be enclosed, so that employees won’t leave until the end of the day. Use of tunnel ventilation will mean less interference from the outside. In fact, the whole concept is modelled on primary breeding complexes, maintaining the same high level of biosecurity. Based on a more European design, the facility will use a lot more concrete than in traditional breeder barns.

Second is the construction of a breeder hatchery, to be built in Southwestern Ontario within the next two years. The exact location will be finalized after considering factors such as airport and border access, and ready supply of labour. Canadian Select Genetics (CSG) has the responsibility to market the breeder eggs produced.

“The hatchery will be a facility with extremely high-biosecurity and state-of-the-art design for operating efficiencies. It will use single-stage hatching incubator machines and will meet and exceed all Canadian Food Inspection Agency requirements (CFIA) for hatching egg export opportunities. The ability to achieve the required results as mandated by the ownership structure will require a highly qualified team of veterinarians to add and oversee the complete health quality of this program.” says Douglas.

When asked about capacity, Douglas, Schlegel and Jorge Cota of CSG admit that that’s one big factor yet to be determined, but what they will ensure is that whatever the initial capacity the venture, the plan is to allow for an easily expandable business process as the market grows. The farm and building design, therefore, is vitally important.

“What we can say is that it will be large enough to supply Ontario and Eastern Canada,” says Douglas. “It will be at least that big, and able to export internationally.” From a primary breeder business viewpoint, having a hatchery in Canada will potentially allow Aviagen to offset disease risks by having production in several countries.

Cota notes, “We’ll work in collaboration with hatcheries we have in the U.S. so we can work as a back-up to them in case of disease issues. That will create a lot of synergies in terms of moving product back and forth and dealing with disease issues. Secure supply on each side of the border is very important to being able to serve our customers.”

As the President of Aviagen Turkeys, Douglas will be handsoff once the venture is off the ground, leaving Cota to serve as

the general manager, while Schlegel will formally be the president. While focus will be on the hatchery and marketing of the eggs (currently, all eggs are being exported to the U.S., until the hatchery is built), Cota says CSG will also play a large role in the management of the farms. Douglas adds that there are specific areas of Southwestern Ontario where they know that labour is easier to find – the key is to ensure that anyone they hire has the proper technical expertise.

The fact that the Schlegels are growers and can identify themselves with other growers quite easily makes face-to-face perhaps the best way of marketing the new endeavour. Further opportunity to grow the business and service the market may arise after operating for a while, so Schlegel says they’ll be doing ongoing business reviews to ensure they’re on the right track. Logistically, the goal of serving local producers works in the short term but neither Schlegel or Douglas rules out export of eggs from the breeder farms to countries outside of North America - hopefully to create a strong and sustainable international business.

“If you look at the history of the multiplier-breeder business, nobody has invested in any new facilities for at least the last 10 years in Ontario,” notes Schlegel. “I think we’re one of the few that have invested money in brand new barns. In fact, we did a lot of research and visited some of Aviagen’s existing barns in the U.S. to see what we could do here.”

Determining what type of genetics best suit the Ontario and Eastern-Canadian markets is key to the venture.

“We have several products that could fit the Ontario market,” says Douglas. “We have the large product, the Nicholas 700 and which is a market leader worldwide. We have the option to do ‘super selection,’ which would place more genetic selection on the toms – something like 25 per cent. That will enhance the performance of the final product. It doesn’t impact the reproductive traits because we are selecting more on the male side.

“Poultry

- Dr Martin Clunies

“We have other options, if they fit the Ontario market and Eastern Canadian market, such as the Nicholas 500. Our newer product, the Premium, will be tested in Ontario shortly. Our focus, when it comes to genetics is threefold: give choice to the consumer; practice super-selection; and test options that could specifically fit the Canadian market. We look at weight, feed conversion, yield, liveability / legs and welfare – all of them as a package, because we have a balanced selection program.

“I think the options in Ontario were getting limited,” says Douglas. “We will be allowing the industry to have the luxury of choice. We believe that it’s in the best interest of the customer to have healthy competition. It’s good for us, it’s good for the competition and it’s good for the market. The risks are too high if you don’t have those options for Ontario and Eastern Canada. We need to be smarter, healthier, more innovative and more service responsive than our competition. If you are a good supplier, provide good service, good quality poults, good genetics and build relationships, you’re going to be rewarded by having good customers.”

Before anything moved ahead though, Schlegel is quick to point out that he and Douglas met with many fellow turkey growers - including the Chair of Turkey Farmers of Ontario, Ingrid DeVisser - to share their vision and ensure that it had support.

“We’ve been very transparent with the Ontario marketing board about the whole thing,” says Schlegel. “We told them how we see things working and what our plans are. We made sure we had support from the beginning.

“With us being a larger turkey grower, to have control and be part of the process to ensure that we’re getting as good of a poult possible on our farm is key,” says Schlegel. “We know what the returns are and we want to make sure all growers in Ontario and Eastern Canada have access to good, quality poults.” n

BY KAREN DALLIMORE

Broiler birds are known for their fast growth rates and voracious appetites but that growth potential creates an issue for breeding hens. How do we feed these birds without creating health problems with fat hens?

Masters candidate Krysta Morrissey of the Department of Animal Science, University of Guelph, described in her recently published paper how the selection for fast growth is correlated with obesity-related health problems, including increased susceptibility to lameness, cardiovascular disease, and premature death.

In North America, the practice of skip-a-day feeding is commonly used to avoid these health problems in parent stock. Broiler breeding hen rations are restricted by up to 75 per cent of the ad lib intake ingested by their broiler counterparts. Two times the daily ration allocation is typically fed every other day, and the feed allocations are often entirely consumed in less than ten minutes.

But this practice has raised welfare concerns, particularly in the United Kingdom (UK) where skip-a-day feeding is negatively perceived. Does skip-a-day feeding cause an increase in behavioural symptoms indicative of hunger?

As Morrissey describes in her paper, “Because broiler breeders have such large appetites, these severe dietary restrictions result in symptoms of chronic hunger. In behaviour thought to be indicative of frustration (such as pecking at nonfood objects), increased general activity and aggression, excessive drinking, and increased feather pecking.”

Morrissey’s research compared feeding regimes, skip-a-day versus daily feeding, and investigated “alternative” diets. Fibre and appetite suppressants were added to broiler breeder rations to possibly reduce stereotypic behaviour associated with hunger.

In her study, six groups of hens were observed by video monitoring from 11 to 28 weeks of age. Two control groups compared a typical ration (C) fed every day and on skip-a-day (SAD) frequency, while the remaining four groups were fed “alternative” diets with added fibre, (40 per cent soybean hulls), and either feed grade (F) or purified (P) Calcium propionate, on daily and skip-a-day routines.

Morrissey hypothesized that the alternative diets, F and P, would result in reduced hunger symptoms, expressed by reduced aggressive behaviours, such as excessive drinking, object pecking and feather pecking. She also hypothesized that SAD feeding frequency would increase behavioural indices of hunger and result in worse feather condition.

The birds were observed during and immediately following feeding, assuming that aggressive behaviour would increase at feeding time and would reveal more significant differences.

She found that both diet and frequency of feeding affected behaviour. The control birds on both daily and skip-a-day feeding routines were more active, displayed more feather pecking and object pecking. This increase in aggressive behaviours following feeding was less obvious with the SAD feeding frequency, presumably due to an increased satiety over the daily-fed birds in the control group.

The fibre and appetite suppressant diets, regardless of feeding frequency, resulted in fewer symptoms of hunger, presumably due to the larger volume of feed being ingested and the resulting increase in satiety.

“As hypothesized, we found that high-fiber diets including an appetite suppressant reduced behavioral indices of hunger, as indicated by the increased time spent resting, and decreased time spent feather pecking and object pecking and aggression. However, even with the alternative diets, some level of hunger was still present, as not all oral stereotypic behavior was completely abolished during rearing.”

She also suggested that, “Chronic hunger may be unavoidable as Hocking [1993] found that ad lib fed broiler breeders still spent a significant amount of time feeding throughout the night, suggesting a level of hunger sufficient to cause feeding behavior during the dark period when there normally would not be.”

Morrissey later investigated the birds’ preference for the diets, finding no dietary preference between the control ration (C) and the bulkier fibre and appetite suppressant ration (F). It is possible that the differences between the two diets were too subtle for the birds to detect. While the results did not support her hypothesis that the birds would prefer the bulkier ration, they did at least show that the alternative feed wasn’t aversive to the birds.

Her research provided no strong evidence to support the hypothesis that daily feeding would suppress hunger more effectively than SAD or vice versa. While Morrissey’s research did not generate behavioural data that would allow recommendations regarding skip-a-day feeding, she does suggest that producers adapt a dietary feeding regime that includes a fibre source and possibly an appetite suppressant that may improve broiler breeder welfare.

Morrissey’s work appears in Poultry Science 93:285-295. The Growing Forward I Poultry Cluster, Canadian Poultry Research Council and the Poultry Industry Council provided funding with special thanks to Margaret Quinton (University of Guelph) and Hank Classen (University of Saskatchewan) as well as the assistance of the Behaviour Laboratory at the University of Guelph. The birds were donated by Aviagen, via Horizon Poultry.n

For poultry, it’s already an unspoken rule but consumer pressure may mean proving it

BY KAREN DALLIMORE

Sustainability is simply long-term thinking, making sure we look after tomorrow while we look after today. Farmers already know this: unless farming is balanced on the three pillars of sustainability — looking after the environmental, economic and social needs of production — long-term viability will not be ensured.

But to consumers, sustainability has now become a buzzword. They are starting to realize that at our current global population growth rate we’re faced with a potential need to feed 9 billion people by 2050. At the rate we’re going, we will eat our planet. Water, soil, energy, all can be easily depleted but not so easily replaced. While farming practices and scientific advances will contribute to higher production, we will end up bankrupt if we don’t plan to use our natural resources wisely.

Under increasing consumer pressure it may no longer be good enough to just practice sustainable production — you may have to prove it. Is this an opportunity or a restriction? What does the actual word “sustainability” mean to the future of farming?

Although the Canadian poultry industry doesn’t have a formal sustainability plan, existing on-farm programs and planning speak to sustainability

For fish farmers, sustainability is already a household word. By the mid-1990s, aquaculture was already implementing world-class standards. Fish farmers realized early that demonstrating sustainability would be critical to their

industry, not only to maintaining and growing their market, but also to look after their natural and social resources. While farm-raised fish now supply half of our global demand for human consumption, Karen Tracey, Executive Director of the Northern Ontario Aquaculture Association, told the audience at the 2014 Farm & Food Care

Conference in Milton, Ont., that the demand for farmed fish will rise to 70 per cent of global market share by 2030.

The media assault that resulted from heightened food safety fears was the original driver of sustainability in aquaculture, said Tracey. While food scares were easily fuelled, they were not so easily corrected. Food retailers became the target of a strategic focus on the marketplace, where groups such as Greenpeace rated retailers according to their sustainability practices. Like it or not, this pressure can close doors in a hurry.

Retailers, not wanting to be shamed, fed into what Tracey called a “seafood certification jungle” of more than 30 fishery and aquaculture labeling programs worldwide, which led to great confusion in the marketplace. Seventy to eighty per cent of these accredited standards contain the same criteria, but the confusion arose within the remaining twenty to thirty per cent — and this is where the labels tried to differentiate themselves. Tracey said when you meet one certification standard it’s not so hard to meet the others, but it causes a lot of confusion for all stakeholders — farmers, consumers, processors and retailers.

Fish farmers knew that more regulations were not the answer. In Ontario, aquaculture is covered by more than 20 acts of legislation. The Ontario Ministry of Natural Resources issues the fishfarming license but then defers regulation to others, such as the Ontario Ministry of the Environment, Canadian Food Inspection Agency for fish health, or Transport Canada for farm siting in relation to navigation of waterways.

In the marketplace, producers knew that a solid production framework had to be in place in order to compete globally. Pressure to become more sustainable wasn’t going to go away; it was only going to intensify. The best answer would be third-party audits and certification.

At first the industry didn’t understand the rationale or cost surround-

ing this new word, sustainability. Surprisingly though, while certification was not initially embraced, it has turned out to be a positive experience.

“The biggest challenge for farmers was recording data,” said Tracey, “but once you get your mindset into it (third party certification), (farmers) found greater efficiencies at the farm level that they didn’t embrace before.”

On the farm, underwater cameras now monitor feed consumption, reducing the amount of waste feed that supplies the benthic community of bugs and worms and wild fish that feast under the nets. In ocean fisheries, threebay management is now standard, allowing for site recovery. Fallowing sites has been the subject of research by the Department of Fisheries and Oceans,

New and Innovative rectangular rounded design offers more feeder space, and allows baby chicks to easily move between feeder and drinker lines.

When used as a complimentary feeder the TURBOGROW 2 is placed between your feeder pans and filled automatically with a feed dispenser. It can also be used as supplemental feeder for manual filling when needed.

Baby chicks have easy access to feed while not allowing them to enter the pan which keeps the feed free of contamination

Elimination of paper under your feed lines will significantly reduce the amount of feed wasted and insures clean fresh feed.

showing that site recovery occurs within a few months with absolutely no trace left after seven years. Technical improvements in containment pens have significantly reduced escapes, and fish health is increasing through the use of vaccines and brood stock screening, reducing the need for antibiotic use. The future will

also embrace innovation and research into novel feeds and nutrient recycling.

Tracey acknowledged that even though sustainability has become a part of everyday aquaculture there are still a lot of challenges ahead. She would like to reduce unnecessary duplication of efforts and conflicting requirements

as well as increase buyer and consumer confidence through more consistent messaging. And in some cases, refute expectations of certain standards that are unreasonable.

At a minimum, certification has maintained or increased market access, providing worldwide consumer assurance. Within the next three years a new Global Seafood Sustainability Initiative will attempt to assimilate the smorgasbord of sustainability certification into two or three global standards.

So if Tracey hit rewind, what would she say now? “Just jump right in and do it. If consumers are demanding it, be pro-active.”

Just jump in and do what? Fish can’t fly and poultry can’t swim. Does a consumer push for sustainability mean the same thing to aquaculture as it does to feather culture? Are there lessons to be learned?

“We don’t talk about sustainability the same as aquaculture,” answered Lisa Bishop-Spencer, Communications Manager at the Chicken Farmers of Canada (CFC), “it’s an unspoken rule already.”

In general comparison, farming implies some sort of intervention in a production cycle, allowing improvements such as feeding and predator protection for the stock or product being raised and ownership of the product. So in this context, fish and poultry are both farmed. In terms of market access, there isn’t the same international pressure on Canadian poultry that there is on fish. And for poultry, under supply management it’s the poultry farmers themselves, not the consumers, that have been leading the way.

The CFC has a five-year strategic plan in place that looks at responsible stewardship, risk management, consumer-driven growth, value-chain efficiency, competitiveness and system management. The current evolutionary document covers

2014 through 2018, helping to identify and respond to the needs of consumers and producers.

While the central thrust of the document does not include the word sustainability, it covers everything else from providing profitable industry growth, managing markets, and eliminating the preventive use of Class 1 antimicrobials to addressing media myths and public concerns.

The strategic plan also includes moving forward with the On Farm Food Safety Assurance Program (OFFSAP), which has received full government recognition in compliance with HACCP rules. While there are variations among the provinces, at present, 95 per cent of poultry farmers meet compliance in Canada: they’ve passed the third party audit.

“We are extremely good planners,” said Bishop-Spencer. There is a lot of protocol already in place. Over her 14 years with CFC, she is noticing that the government wants to regulate less, but someone has to take charge; the feather industry has taken a lead role rather than being told what to do.

Having a strategic plan not only drives increased efficiency in the industry, but the plan also serves consumers, to offer them a wide choice of different brands and feeding protocols.

“Whatever they want they can find it,” said Bishop-Spencer, although they may have to pay a premium. New labeling, set to launch this month, will brand fresh chicken, letting consumers know that a Canadian farmer raised it. This designation will either appear as a label or be integrated into an existing label.

But what about that word “sustainability”? How can poultry farmers prove to the consumer that their industry is looking after the future? It’s not enough to say “trust me” when the consumer is saying “show me.”

Poultry farmers already have incredibly stringent record keeping with strong repercussions for non-compliance,

Bishop-Spencer explained. “We don’t have a sustainability plan but I think it’s all there.”

Ask any farmer and they’ll tell you they’re responsible to their land, their birds, their customers, the system that allows them to grow their birds, and ultimately, to their children, says

Bishop-Spencer. “Sustainability means leaving a positive legacy and frankly, that’s something that just makes sense.” n

For more on production, visit www.canadianpoultrymag.com.

Key Principle:

Water spillage happens when more water is discharged from the drinker than can be retained in the bird’s beak. Lower column pressure means less water discharged from the drinker with each activation; higher pressure means more water discharged. Therefore, use low column pressure for birds with small beaks and increase pressure as birds (and beaks) grow.

Applying this management principle will prevent excessive water spillage, thus avoiding wet litter conditions. Dry litter promotes healthier birds, increases growth rate and reduces pododermatitis.

Key Directive: Keep beak size in mind and adjust column pressure accordingly to minimize spillage. Find best management practices and much more at Ziggity’s Poultry Watering U website.

Adjust water column pressure based on beak size. Supply no more than the bird’s beak can retain during the drinking process.

A service of www.PoultryWatering.com

• How-to videos

• Poultry Watering U news

• Management downloads

BY SHAWN CONLEY

There are many input costs that must be considered in the management of a poultry building, and one of the biggest factors affecting input cost is fan configuration. The obvious cost lies with the equipment itself; however, the electricity used to run the fans will, over time, cost much more than the initial setup cost because bird performance is directly influenced by air quality, temperature and wind speed. Whether you have an existing building, or are considering building something new, it’s very important to get the fan selection right and configure them in the barn for ideal performance. Spending an extra couple of thousand dollars up front can make you tens of thousands or hundreds of dollars down the road.

There are two parts to the fan sizing equation: minimum ventilation fans, and cooling fans (which could be for cross or tunnel ventilation). This is really where electricity cost is going to factor into the decision. There are some general rules of thumb for establishing the numbers and sizes of fans that should be used in different configurations. Our minimum ventilation fans should handle about one CFM (cubic feet per minute) per square foot of floor space, and will be run by time, not variable

It’s very important to get the fan selection and configuration right to achieve ideal performance

speed, for two reasons. Variable speed fans are extremely inefficient, and variable speed almost always results in air dropping from inlets directly to the floor. Once we have the correct minimum ventilation fans, the remaining fans should all be 48” or larger to maximize efficiency and minimize the number of openings in the wall that would allow air leaks. We will need to be in the vicinity of about 10 CFM per square foot for cross ventilation, and the numbers for tunnel will be based

on the desired air speed, which should range anywhere from 500 – 800 feet per minute depending on bird density and farm location. This would mean as much as 12-14 CFM per square foot.

The larger the fan, the more efficient it is. CFM / Watt is the best measure of a fan’s usage of energy. A 12” fan can be as inefficient as 6 CFM / Watt, a 24” is around 13, 36” around 16-17 CFM / Watt, and fans over 48” can range from

20 all the way up to 27 CFM / Watt. So, what does this translate to in electricity cost? Assuming a cost of $0.20 / Kw hr, and maintaining a constant 100,000 CFM of exhaust for 24 hours straight, it would cost nearly $60 to run 12” fans, and as little as $15 to run fans larger than 48”. Running 24 to 36” fans can range from $30-35. The clear conclusion we can draw here is that it is significantly less expensive to run larger fans, 75 per cent or more in some cases. If we could get away with running only 48” plus, that would be great, but in most buildings (with the exception of large turkey finishers) we need some smaller fans.

To accomplish the goal of 1 CFM per square foot, we need to know that a 12” fan only produces about 1250 CFM at 0.10”wc, 18” is about 3500, 24” is about 6500, and a 36” is close to 10,000 CFM. These days, almost all fans are sold with cones on the outside, so about 10 per cent more CFM can be attained, although I tend to dismiss this number because fans are rarely perfectly clean and maintained. Larger fans can be from 20,000 – 25,000 CFM at 0.10”wc. It is extremely important to look at the ratings provided by manufacturers and prorate them to actual static pressures in a barn. Many manufacturers will provide fan capacities at 0.05, when actual numbers are 0.08 – 0.12 or more. This can translate to a 15 per cent or greater reduction in capacity that needs to be calculated when deciding how many fans to install.

The take home message on minimum fans is that we need 1 CFM / square foot, and that we want to utilize the biggest fans possible while allowing flexibility to run as little as 50 CFM per 1,000 birds if heaters are exhausted outside, and 75 if they exhaust indoors. We don’t want to run a timer fan less than 20 seconds out of five minutes. For example, for easy calculation, if we take a 50 x 500’ barn (25,000 square feet), and place 25,000 birds in the front half of the barn, keeping in mind that air

exchange and some heat is needed in the non brood area, we will need about 25,000 CFM for total minimum ventilation, and as little as 1,875 CFM the first day. The best configuration here is four 24” fans, totalling 26,000 CFM in capacity, but capable of running a pair of fans at 43 seconds out of five minutes. A second, but less symmetrical configuration would be three 36” fans at 30,000 CFM total capacity, and running a single fan at 56 seconds out of five minutes. This is a little less desirable for even distribution of air, but it does maximize efficiency, saving about $6.40 per day when starting birds.

Our larger fans are, in a way, more simple. We want to use the largest fans we can fit in the wall, and make sure we reach our target for air movement. The most common sizes being used in new construction are now 54” fans that will move about 25,000 CFM of air. Using our previous example, in a cross ventilated barn, a 10 CFM per square foot target would require 250,000 CFM in total. Ten fans evenly spaced throughout the sidewalls, five per side, would adequately exchange the air.

In a tunnel configuration with a target air speed of 600 feet per minute, we need to calculate the cross sectional area of the end wall and multiply by the air speed to get the CFM requirement. Assuming a 10’ average ceiling height, 50’ x 10’ x 600’ / min = 300,000 CFM, so we need 12 of our 54” fans at the exhaust end to pull the air. There is an option in this case to go to a 50,000 CFM, 72” exhaust fan, requiring only 6 large fans, although it may be beneficial to substitute two 54” fans for one 72” fan to more smoothly transition to the remaining five 72” fans from the four 24” minimum fans. It is not ideal for fan life to run the 72” fans for the transitional ventilation, which should run up to about 3 - 5 CFM per square foot though the sidewall vents.

Configuring fans is one of the most effective ways to increase profits by reducing long-term input costs. Spending a few extra dollars per month on financing to get the most efficient fans pays off many times over when considering running cost vs. initial setup cost. Take the time to get it right, and invest in the future profitability of your business. n

l

l

l

l

l 3-step heat exchange

l cross flow recuperator

Industry discusses how genetics, feed or hatchery health can play a role

BY MELANIE EPP

At a recent Poultry Industry Council (PIC) Science in the Pub event, producers, scientists and industry men and women gathered to discuss the causes of leg issues in meat birds: feed, genetics or hatchery health issues. Each, it was concluded, plays a role in leg health.

Research shows leg issues during grow-out are one of the major causes of culling and late mortality in heavy broilers. Leg issues don’t just occur during grow-out, though; they are possible during the first few weeks’ of growth as well.

While the incidence of clinical lameness is said to be typically less than 2-3 per cent, broilers that are affected sub-clinically can also experience reduced walking ability, an issue that later affects feed conversion and growth. Economic impacts can extend beyond live production losses, too. In fact, research shows that leg issues can increase costs per kilo of live weight, as well as costs at the processing level. Lame birds, says a 2008 leg heath report by Edgar Rondon of the Department of Poultry Science at North Carolina State University, spend more time lying in litter and bring more contamination to the processing plant. Increased contamination, he says, can create issues at the food safety level.

Birds are tested for their genetic potential – heart-lung function, leg strength,

The cause(s) of leg problems in broilers is complex, and seldom involves just one factor. Everything’s involved from the genetics of the bird to breeder health and nutrition, the operation of the hatchery, physical injury, broiler farm management and broiler nutrition.

livability and growth – in high-hygiene environments, says Scott Gillingham, Canadian Regional Business Manager for Aviagen Inc.

Rapid growth can cause leg issues in broilers, says Gillingham, which is why

Aviagen looks for traits that will provide the best cross for supporting skeletal strength. Highly susceptible birds are not only recorded, but rejected and removed from the breeding program as well, as are those that exhibit either clinical or subclinical issues.

“We look at bone deformities, crooked toes, etcetera, as an opportunity under

clinical evaluation [to see] whether or not these birds are robust enough to fit the program,” he says.

The breeding program, he says, has been going on for a long time. In fact, the broilers of today are nothing like the broilers of the ‘50s, says Gillingham. Considering today’s yield requirements, birds of that generation wouldn’t make it in the program.

“We have seen leg deformities and improvement in such,” says Gillingham, who suggests that bringing out genetic potential requires more stock. In order to get that stock, he says, the industry must work together.

“I think communication amongst us is critical – nutrition, health, genetics, academia, management, on-farm. We’re going to continue with genetic improvement until you say stop.”

Don Copeland, PIC Vice Chair, agrees with Gillingham about the role of genet-

ics, but thinks that when it comes to leg issues, it’s not just one issue.

“In my history of broiler growing, there’s very seldom just one isolated cause of leg problems,” says Copeland. This is a very complex issue. Everything’s involved from the genetics of the bird to breeder health and nutrition, the operation of the hatchery, physical injury, broiler farm management and broiler nutrition.”

Hatching a chick is still basically the same, but there are some differences that need to be taken care of, he says. The weak point in a broiler, he continues, is in its legs.

“Anything you do is going to show up in the legs,” he says. “Hatcheries have found with today’s high-yielding type birds that we need to run the hatcheries different than we did. Temperature and

humidity settings need to be adjusted to match the new breeds.”

Bacterial loads need to be minimized too, says Copeland, mentioning major bacterial issues, like salmonella and staphylococcus.

“They’re always out there,” he says. “The issue is can you keep the numbers down? It’s a numbers game. If you can minimize it at all the different points in the system, you’re going to get through. If you put that in the bird and then stress the bird, it’s going to show up. It may not be legs – it may be other things – but a lot of them cause these issues.”

Every new generation of broiler is capable of increased growth rates, says Copeland. “It just continues, so we have to adjust the way we are managing for it.”

The original Multi-Carbohydrase.

Superzyme is a complex blend of enzymes designed to target indigestible components of livestock feed. Backed by sound science, Superzyme is at the forefront of enzyme technology.

“Any weakness in the production process from the breeder to the hatchery and into the broiler farm can disrupt the normal growth pattern, and this seems to inevitably show up as a leg problem,” he concludes.

Dr. Blake Wang, Poultry Nutritionist with Wallenstein Feed & Supply Ltd, says that genetics and nutrition can be factors for leg weakness. And more research, he says, is necessary to explore the relationship between incubation conditions and leg problems.

There is some research to show that incubation distress also causes leg issues in meat birds, says Wang.

“High incubation temperatures are really bad during the last phase of embryo development. That will affect muscle and bone development. The rea-

son is that high temperatures will speed up embryo growth.”

Ingredients, he says, can also affect leg health, especially rancid fat and undercooked soybean meal. High calci-

um diets are problematic, too, he says. To minimize issues, Wang suggests that producers evaluate feed, making sure that it isn’t perhaps too good. That and follow their nutritionist’s recommendations. n

How food inflation rates will affect the poultry industry this year

BY TREENA HEIN

Here’s some good news in a downtrodden economy: inflation for grocery items in Canada will stay stable or rise by only one per cent in 2014, according to Kevin Grier and Janalee Sweetland at the George Morris Centre in Guelph, Ont. In addition, chicken sales are likely to increase.

In terms of recent inflation trends for grocery items, Grier and his colleague, Sweetland, say the Statistics Canada Consumer Price Index shows the 2013 inflation rate was one per cent compared to the previous ten-year average of three per cent. “The inflation of store-purchased food over the past four years has sharply decreased,” Grier says. “Price increases for restaurant food has also been on a downward trend over that period of time.” The cost increases for all other (non-food) items has averaged two per cent over the past ten years, with a recessionary price decrease in 2009.

Food prices, Grier explains, are strongly correlated with the cost of animal and vegetable products (eggs, cranberries, flour, etc.) as well as other inputs such as raw materials, electricity and transportation fuel. “Food manufacturer raw material costs have been in decline or stable over the past two years,” he notes. “As such, it is reasonable to assert that food prices will not be under any upward pressure at all during 2014.”

Currency exchange rates also affect food prices, but again, stability is indicated. Currency exchange rates over the past ten years have been increasing, but recently, the reverse has been true.

The inflation of store-purchased food over the past four years has sharply decreased, according to the

Increasing exchange rates can make imported goods cheaper, says Grier, causing prices for domestic goods to lower so that they remain competitive, and there is long-term trending pressure from increasing currency rates that will result in lower Canadian food pricing.

According to Grier, another reason that food prices will generally remain stable is Canada’s economy. “It’s expected to continue to strengthen only slightly over the next two years, with the Bank of Canada projecting 2.3 per cent growth in GDP in 2014,” Sweetland points out. “Other projections for the Canadian economy are less optimistic, and relatively slow economic growth does not typically coincide with an environment in which prices are able to be greatly increased.”

Consumer confidence — another factor affecting food prices — rose somewhat in 2013, but it remains well below

pre-recession levels. “Cautious spending habits don’t support an environment that is conducive to aggressive price increases,” explains Sweetland. “It’s a well-established fact that during slow economic times, significant numbers of consumers seek to lower their grocery bills by substituting for cheaper options.” She notes that as a recession progresses, this becomes less intense, but that it has the effect of creating habits amongst consumers to substitute lower-priced items when prices begin to creep upwards. Slower growth in per capita incomes and an increased focus on building household savings has also helped to keep food inflation tepid over the past several years.

However, the most significant factor that will keep a lid on rising food prices this year is the increasing competitiveness among the various grocery outlets operating in Canada. The opening of new Target stores and further aggressive

expansion into the grocery business by Walmart and Costco are playing an important role in this battle for the consumer dollar. Grier believes competition at the grocery store will continue to be intense, and will be the most persuasive of the influences over food prices in 2014.

“Research done by CIBC Institutional Equity notes that Walmart is going to try to increase its share of the grocery market through changing its store conditions, running a stronger flyer, sharpening its assortments and improving its fresh departments in 2014,” Grier adds. “Asian grocers are also expanding, with CIBC identifying over 90 in the Greater Toronto Area, and probably 200 nationally. They are continually lowering their prices and improving distribution, thereby attracting more and more non-Asian customers.” He adds that in Canada, ethnic grocers probably sell as much food as Walmart does.

The one important exception to stable food prices, however, is meat. “Cattle and hog supplies are tight and meat prices will be under upward pressure,” Grier says. Chicken prices were exceptionally volatile in 2013 and strong demand this year will put prices on the upswing, but they won’t approach the price of beef. Grier thinks that during 2014, the chicken industry can “sit back and watch the beef industry lose share” at grocery and foodservice outlets. “Grocers are already scared away from beef for featuring [as a star product], and are even looking to turn more counter space over to chicken and pork,” he notes.

A good time, then, for aggressive marketing of poultry products and eggs? When asked if Chicken Farmers of Canada will be putting any special efforts into marketing this year related to high beef prices, the association did not specify. Egg Farmers of Canada chose not to comment.

A January 2014 Food Price Outlook report from the United States Department of Agriculture’s (USDA) Economic Research Service states that beef and veal prices in the U.S. will likely increase three to four per cent this year over 2013 levels. It also states “many retail beef prices are at or near record highs across the country, even after adjusting for inflation. Currently, [we] forecast that beef prices will rise more than most other prices in 2014.”

The report states that poultry prices in December 2013 were three per cent over December 2012 levels, and that U.S. poultry prices (including turkey) are expected to rise more than overall grocery prices in 2014 due to strong anticipated demand. Egg prices rose 5.8 percent in the past year. “However, egg production is forecast to expand in 2014, and inflation for this category is expected to be in line with the historic average.”

Readers can obtain the George Morris Centre report, Canadian Chicken Market Review for a free two-month trial by emailing kevin@georgemorris.org n

University of Wageningen researcher shows that insects show great potential as a source of feed, biofuel, and immune booster

BY KAREN DALLIMORE

For over 30 years entomologist Dr. Arnold Van Huis has been studying insects. Now, as he releases his first insect “cookbook”, Van Huis find himself at the leading edge of a revolution that may see insects not only providing a source of protein to people, but to livestock as well.

As a special guest lecturer to the newly-formed Livestock Research Innovation Corporation (LIRC), Van Huis lured an audience at the University of Guelph into a web of insect intrigue that presented them not only as tasty, but nutritious too.

“People in the tropics don’t eat insects because they’re hungry, they eat them because they’re delicious,” said Van Huis. He admits that he knows very little about cooking but what he did contribute to the cookbook — simply called ‘The Insect Cookbook’ — was many interesting facts about edible bugs.

For instance, Mopane caterpillars are boiled and dried on the soil in Botswana, where their importance as a food source is reflected in their image appearing on a coin. Locusts are very popular food,

Dutch researcher Dr. Arnold Van Huis sees insects as good future prospects for food and feed security

with recent plagues being celebrated as offerings at markets in Egypt to as far as Israel. Weaver ants are harvested in South East Asia by poking bamboo sticks into their nests and harvesting the disturbed insects into baskets; palm weevil larvae are harvested when their nibbling can be heard in the trunks of cut palms. They are delicious barbecued; so are dragonflies.

Only 5,000 species of insects — 0.1 per cent of all species – are harmful, but those species have generated the most attention while generating a negative attitude towards insects. Van Huis and his colleagues at the University of Wageningen in the Netherlands have made an inventory of edible insects totaling 1950 species, only a tiny percentage

of the five million species in the world. In Mexico, 350 species have been recorded, but that number doesn’t reflect so much the frequency of eating insects, but more the activity of researchers studying entomophagy (the practice of eating insects).

One recent study has found that the black soldier fly can replace up to 50 per cent of a fishmeal ration; the same fly also contains enough fat to have the potential to be used as biofuel. Other insects with industrial feed potential include houseflies, termites, silkworms and grasshoppers. Can the housefly save the world? One kilogram of fly eggs turns into 380 kg of larvae in 72 hours.

Take the mealworm, for example. Unlike a cow, we can use the whole insect, not just particular body parts. Mealworm larvae are now used for human consumption, providing a similar protein content to beef but with more polyunsaturated fatty acids, more iron and more zinc.

And what if insects could be used prophylactically in poultry feed? Current research at the University of Wageningen is investigating the role of the insect exoskeleton to strengthen the immune system of poultry with the possibility of addressing the issue of antibiotic resistance.

Many insects can be ground and mixed with other products for human food. In a blind taste test, nine out of ten preferred a meatball made with half insect ‘meat’. Van Huis doesn’t suggest performing similar taste tests on unsuspecting friends though — often it is the emotional component of eating insects that may cause a violent reaction if they find out after-the-fact what they have eaten.

In some countries it is cultural acceptance that stands in the way of dining on insects; in others it is compliance with regulations that don’t yet recognize insects as food or feed.

In the Netherlands and Belgium, about 10 species of insects can be eaten while it is hoped that the European

CURRENT RESEARCH AT THE UNIVERSITY OF WAGENINGEN IS INVESTIGATING THE ROLE OF THE INSECT EXOSKELETON TO STRENGTHEN THE IMMUNE SYSTEM OF POULTRY WITH THE POSSIBILITY OF ADDRESSING THE ISSUE OF ANTIBIOTIC RESISTANCE.

THE LARVAE OF THE MEALWORM (PICTURED HERE) IS USED FOR HUMAN CONSUMPTION, PROVIDING A SIMILAR PROTEIN CONTENT TO BEEF BUT WITH MORE POLYUNSATURATED FATTY ACIDS, MORE IRON AND MORE ZINC.

Union (EU) does not label the insects as a “novel food”, requiring further proof that they cause no harm. As of June 1, 2013, the EU has allowed the use of insects in aquaculture but fallout from the BSE crisis still blocks their inclusion in feed for poultry and pigs. Van Huis expects that this issue will be solved

within two years with insect producers in Europe recently uniting to form pressure groups.

Another problem is that insects are considered livestock. Just like you

can’t slaughter your pig on your farm, insects also need to go to a slaughterhouse. Van Huis predicts that this issue will be addressed within a year. And even though the insect brain is considered too small to have a “pain centre” they still need to be humanely slaughtered, by hot water blanching, freezing or grinding, to respect animal welfare concerns.

Is rearing insects an efficient use of feed? Insects can be raised on safe waste products such as leftovers from vegetable processing, converting these sources to an interesting, high protein product. Van Huis compared the conversion ratio of 2.1 kg feed into edible product by crickets grown on commercial grains to 25 kg of feed for cattle, 9.5 kg for pigs and 4.5 kg for poultry, however current commercial production costs are high in comparison to these other protein sources; to be

competitive, insect rearing will require automation and a greater knowledge of insect husbandry.

Of course there are some challenges and risks. Van Huis points to contamination as the highest potential risk of eating insects, pointing to the need for hygienic production procedures. There have been some isolated incidences of parasites, but cooking will decrease that risk. There may be some issues with allergies, and in that case food would have to be labeled so that consumers would be aware of any risks. On the production side, chemical contamination of insect feedstuffs can kill the insects before their time.

What about quarantine regulations? These need to be respected so that no insects that may cause potential harm to the economy or ecology will be imported. House crickets and mealworms are everywhere, but locusts are

from the tropics and won’t survive a northern winter. There are 20,000 cricket farms in Thailand, huge insect factories in Mexico, and large cockroach companies in China.

Despite the challenges of cost of production, regulations and consumer attitudes, Van Huis sees insects as good future prospects for food and feed security. Insects are getting a lot of attention in the Netherlands from both research and private enterprise. Van Huis looks to be a leader, noting that developing countries seek to copy western lifestyles, and as far as he is concerned, if they see the Dutch eat insects they might just say, “Why not, [they] do it already?” n

For more on poultry research, visit www.canadianpoultrymag.com.

Not all poultry farmers maximise the full potential of their birds. Both kept in cage or floor systems, for a good performance during the production period, the management should be correct and efficient. But how do you know that what you are doing is right? Your chickens continuously send out signals: about their health, how well they know their way around their surroundings and whether they feel happy and comfortable.

Do you recognise the signals your chickens are giving? Do you know the difference between abnormal, runny droppings and healthy caecal droppings? Are you able to identify abnormalities of the egg and trace this back to the cause? And do something about it?

If you recognise the signs that point to potential problems, then make sure you are armed with information to take the appropriate steps to get your flock back on track. But to do so, you must know all the ins and outs of your own farm and be able to assess the impact these changes will have on your animals.

BY LESLIE BALLENTINE

Ihaven’t met a serious farmer who didn’t consider himself or herself to be sustainable minded. In fact, history tells us that farmers and hunters were the first to recognize the notion when it was defined in the 1987 Bruntland Commission report. Originally limited to environmental considerations, today “sustainable” has become a value-laden buzzword. And now, with dozens of interpretations of what is (and is not) sustainable, the term is showing up beyond niche markets. According to one marketing guru, sustainability is one of the 10 most used business words today. It has also reached the point where producers can no longer ignore it, even if they still don’t know what it exactly means.

Anyone looking to buy and sell sustainable food faces a slew of confusing concepts, opinions and terms that make it difficult to identify the qualities that make one food item more sustainable than another. The fact that the term “sustainable food” has been co-opted by nearly every special interest group with their own agendas only adds to the confusion.

Today, the so-called “pillars of sustainable food” embrace environmental, economic and social dimensions. A growing number of issues related to food safety, animal use, and products of new technologies are also being put under the sustainability microscope.

The problem in defining sustainability is that it depends on your perspective, while determining what makes something unsustainable is subject to manipulation. If food makers can be convinced that they will lose social licence, business, or reputation — companies are apt to demand their suppliers change methods simply to sustain themselves.

policies are negotiated with farmers and suppliers, outcomes still vary. Despite collective agreement within the food industry to not compete on the basis of sustainability, it is plausible that a privatized regulatory strategy is an attempt to differentiate products from those of competitors. Leveraging varying attributes not only allows marketers to charge more for products based on the affluence and insecurities of their clientele, but to gain goodwill as well. The end result of course is no standard set of standards.

The announcement by McDonald’s earlier this year to begin buying “verified sustainable beef” globally by 2016 and the adoption of “sustainable seafood” by restaurants and grocery stores alike are a sign of things to come for the poultry industry too.

I like to believe that most food companies are well-intentioned opportunists

I like to believe that most food companies are well-intentioned opportunists. Unlike in the past, they now typically have entire departments devoted to sustainability, managed with the staff to define the terms and set the targets. In this way, many food companies are setting themselves up as arbitrators of “sustainable” health, welfare and safety by introducing their own regulations, procedures and standards —often exceeding those we entrust to our governments.

The mantra in Canada has long been “better to self-regulate than have the government do it for us,” yet even when company