BY DON HORNE

This show is one week long – and good luck trying to take it all in with all five days.

Heavy hitters like Caterpillar, CASE, Liebherr, Link-Belt and Komatsu will be there among more than 1,800 exhibitors in Las Vegas, Nev., and the sheer volume of equipment displays are dizzying, to say the least.

It’s CONEXPO-CON/AGG, and it is the greatest show on earth when it comes to construction.

Beyond the array of equipment that stretches beyond the eye can see, the show is jam-packed with educational sessions.

For example, “Crane 101” looks at the importance of site prep before a crane arrives on a jobsite, what your team needs to understand when a crane is onsite and understanding how to select the right crane for your project.

The “Qualifications of Onsite Personnel for Cranes” session examines the national consensus standard (ASME), and the updated qualifications for onsite personnel for cranes that went into effect in December of last year.

The roles, responsibilities and qualification requirements for the jobsite will all be examined in detail.

“Best Practices for Oversized Cranes & Specialized Carrier Permits” is crucial for those who want to understand the need to adequately plan for the numerous regulatory hurdles facing movement of an oversize/overweight vehicle or load; learn the best way to work with government officials who are critical to the success of the move; and perhaps more importantly, to learn what you can do to advocate for better permitting rules and regulations.

These are just three examples from one day – and there are many, many more sessions available.

Going into the 2023 show, there are issues from last year that not only continue to plague the industry but are more important than ever before to confront now.

At October’s SC&RA workshop in Dallas,

Texas, there was a call to examine how the industry does business – and a fundamental need to change how the crane and hoist industry does business in the next three-tofive years.

How do we create efficiencies? How do we deal with the rising price of assets?

Insurance rates are going up, and certainly interest rates are going up as well.

And while crane rental companies are getting little to no pushback on the modest rate increases they have been putting in place, they are not even close to where rental rates should be.

Raising rates three to five per cent in the last three years simply hasn’t been enough.

The rate structure is supposed to be based on equipment replacement costs –and they are nowhere near where they should be.

It was pointed out at one of the Dallas sessions that many times, you can’t get the jib for the crane that you ordered; or if you can get that jib, the question is: when are you going to get it?

We sent out a survey to our readers back in November of last year, and I would like to thank those who took the time to fill it out and provide feedback; we get better by listening to you.

For those who may have missed the survey, we basically asked your input on where you saw the crane and hoist industry today, and what you would like to see from us insofar as coverage and content in the magazine.

One respondent was very specific in how the industry needs to improve – safety and accreditation:

“By requiring crane inspectors to be certified by a national board. Right now, it’s the Wild West. Pretty much anyone can say they are a crane inspector,” wrote one man.

Amen to that.

Don Horne

Reader Service

Print and digital subscription inquiries or changes, please contact customer service

Angelita Potal

Tel: (416) 510-5113

Fax: (416) 510-6875

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

EDITOR | DON HORNE dhorne@annexbusinessmedia.com

NATIONAL ACCOUNT MANAGER | LAURA GOODWIN lgoodwin@annexbusinessmedia.com • 289-928-8543

MEDIA DESIGNER | BROOKE SHAW bshaw@annexbusinessmedia.com

ACCOUNT COORDINATOR | KRISTINE DEOKARAN kdeokaran@annexbusinessmedia.com

AUDIENCE DEVELOPMENT MANAGER | URSZULA GRZYB ugrzyb@annexbusinessmedia.com • 416-510-5180

CONTRIBUTORS | Chris Ward, Emily Newton

GROUP PUBLISHER | DANIELLE LABRIE dlabrie@annexbusinessmedia.com

COO | SCOTT JAMIESON sjamieson@annexbusinessmedia.com

PUBLISHED BY ANNEX BUSINESS MEDIA 105 Donly Drive South, Simcoe, ON N3Y 4N5

Crane & Hoist Canada is published six times a year by Annex Business Media. Reference to named products or technologies does not imply endorsement by the publisher.

Subscription rates (six issues) Canada: $37.00 + tax per year • USA: $37.00 USD Send cheque or VISA/Mastercard number to Subscription Department, Crane & Hoist Canada, 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1. Fax orders to 416-510-6875. Or subscribe online at www.craneandhoistcanada.com

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO: Crane & Hoist Canada. CIRCULATION DEPT. 111 Gordon Baker Rd., Suite 400, Toronto ON M2H 3R1

PRINTED IN CANADA ISSN 1923-788X

Publications Mail Agreement #PM40065710

Annex Privacy Officer

Privacy@annexbusinessmedia.com Tel: 800-668-2374

contents of Crane & Hoist Canada are copyright ©2023 by Annex Business Media and may not be reproduced in whole or part without written consent. Annex Business Media disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in

Next Advertising Deadline: January 2, 2023

Don’t miss the opportunity to be part of this exciting industry publication. For more information, or to reserve space in the next issue, call Laura Goodwin at our Advertising Department Tel: +1-289-928-8543 lgoodwin@annexbusinessmedia.com

Next Editorial Deadline: January 4, 2023. For writers’ guidelines and submission requirements get in touch with the editor, Don Horne, at dhorne@annexbusinessmedia.com

MEMBER OF:

Telehandler simulator training pack to make its debut at CONEXPO

CM Labs Simulations is bringing new training solutions to CONEXPO-CON/AGG 2023, designed for the construction, infrastructure, and utility markets.

“Now, more than ever before, CM Labs’ customers need the best possible operator learning outcomes – quickly and safely,” said Lisa Barbieri, VP of Marketing and Product Management. “Our physics-based Smart Training technology and advanced reporting insights from our Instructor Operation Station (IOS) will future-proof training programs and recruitment needs.”

CM Labs will demonstrate the full suite of simulation training products and feature several new products in ‘simulation pods’ at Booth N11563 in the North Hall at CONEXPO from March 14-18, 2023, in Las Vegas, Nev.

Along with two additions to the Excavator Training Pack –the Grapple Tool and 360-degree Tiltrotator – is the Telehandler Training Pack.

The Telehandler Training Pack features fixed, telescopic boom with forks and bucket attachments. The Telehandler Simulation exercises offer various steering modes and load-handling activities.

Instructor Operator Station (IOS) enables trainers to monitor,

assess, and engage trainees from a single workstation. IOS integrates with any of CM Labs’ training simulators. Updates to the IOS allow remote instructor monitoring, live multi-user curriculum management, as well as new back-end reporting features. The IOS supports trainers with objective insights on key metrics related to safety violations, fuel efficiency, cycle times, and managing excessive wear and tear on equipment.

innovative tool that offers a high level of transparency for our customers, reassuring them that the proposed equipment is as described, and helping to minimize disputes,” says Andrei Geikalo, founder and CEO of MYCRANE. “Crane rental providers will also find the Inspections App useful. In the case of bare rentals, for instance, our app may provide proof of discrepancies between the outgoing inspections and incoming inspections when the equipment is confirmed off-rent and being returned to the crane provider, because it will be so simple to verify the condition of the equipment.”

The app, available in more than 35 languages, makes use of Artificial Intelligence to verify data such as location of the crane and the authenticity of registration documents.

By following push notifications from the app, images of the crane can be uploaded, along with key data about the equipment. Only live image and video recording can be accepted, while in-app fraud detection and recognition is another feature of the app.

According to MYCRANE, the new app is particularly useful where clients impose the condition and maximum age of equipment, or where clients have specific requirements around inspection.

more demand.

“They all feature excellent lift capacities and longer boom lengths as well compact carrier designs that are highly roadable, fuel-efficient and require less overall maintenance. Bigge has been increasingly successful with Tadano AT retail sales and is continuing to increase orders for these models based on their overall success on the combined fronts of both retail and rental fleet additions,” says Kuhlman.

The new additions include the GR-1300XL-4 from the Tadano Rough Terrain line, as well as longer-reach Teleboom Crawlers like the GTC-2000 and GTC-1600.

PCL Construction announced that Jason Idler has been promoted to chief operating officer and will lead the organization’s heavy industrial sector as part of the organization’s overall succession planning strategy.

A new Inspections app allows customers to rent lifting equipment with confidence.

Downloaded via the Apple or Android stores, the free MYCRANE Inspections App helps prevent fraud and reduces risk by digitalizing the crane rental inspection process.

“Our new app is another

Bigge Crane and Rigging – one of the largest Tadano fleet owners with more than 600 Tadano cranes in their rental fleet – became a little bit bigger with new purchases at October’s bauma 2022 that include a large quantity of rough-terrain, all-terrain and telescopic boom crawler cranes.

Tadano America Regional Business Manager Dave Kuhlman says the 130 to 600-ton All-Terrain machines are seeing

“Jason possesses a wealth of knowledge in the Heavy Industrial world,” said Dave Filipchuk, PCL’s president and CEO. “His deep experience and substantial knowledge of our operations across North America will be essential as he works to extend our reputation as industry leaders. We are proud to welcome him to the PCL office of the CEO leadership team.”

He succeeds Roger Keglowitsch, who is retiring after 30 years of service with PCL.

Boom trucks are offering operators increased asset utilization as they steadily muscle in on jobs once reserved for larger cranes

Two decades ago, the gulf between boom trucks and their larger counterparts was clear for all to see. More recently, that distinction has become less obvious — and four leading trends are the chief reasons for such striking shift.

Boom trucks have now well and truly grown up, even closing the performance gap on their larger siblings. And, according to Bob Ritter, product manager at National Crane, that situation looks set to continue.

“We’re seeing four main trends, with the most general one being the way they’re nibbling into the traditional markets of other cranes,” he said. “There’s been a definite increase in technology and features trickling down from more traditional cranes and being adapted to improve productivity.”

These operator-centric enhancements are perfecting the lifting experience while maintaining the flexibility enabled by a boom truck’s more adaptable design.

It’s hard to ignore the increasing

although it is leading the autonomous journey, has had significant bumps along the way.

But… will construction ever see a “no-entry” site where no humans are on the job, or indeed, necessary?

Perhaps, said Halder, but it’s still years away.

meaningful safety improvements. The code of practice was put together with input from various associations, engineers, suppliers, and health and safety professionals.”

attention autonomous construction equipment is receiving.

But will we ever get to the time where humans are rare on a jobsite? And is that even the point?

First, a quick review.

All industries, including construction, have been the beneficiaries of U.S. defense research, said Bibhrajit Halder, founder and CEO of SafeAI. This included the DARPA (or Defense Advanced Research Projects Agency) Grand Challenge in the early 2000s, designed to accelerate autonomous vehicle technologies.

“That was a trigger point,” said Halder, whose company concentrates on bringing autonomous solutions to construction and mining. “It was a massive success that really sparked autonomy in this country.”

In 2014, the Society of Automotive Engineers established six levels of autonomy, going from Level 0, indicating vehicles with completely manual controls, to Level 5, in which there is zero human interaction in operating a vehicle.

“No one has a true Level 5 system yet,” said William Nassauer, manager of product strategy for Komatsu America’s autonomous systems, mining technology solutions. That assessment, of course, includes the automotive sector, which,

But there will be a tipping point. For example, let’s say using autonomous machines gives a 20 per cent improvement in productivity. “The moment one contractor completes a $100 million project for $80 million because of autonomy, it’s game over,” Halder said. “Everybody has to do it because you can’t compete anymore.”

The Residential Construction Council of Ontario (RESCON) and its industry partners have released a comprehensive best practices guide which is targeted to serve builders and trade contractors when erecting, operating and dismantling tower cranes.

“Health and safety is our top priority. Through the use of a continuous improvement model, we will continue to focus on the safety of the residential construction sector,” says RESCON VP Andrew Pariser, who is chair of the association’s safety committee. “By documenting best practices that exceed legislative and regulatory requirements, we can make

The document, officially called the Construction Industry Code of Practice: Safe Use of Tower Cranes, outlines what mechanical, electrical and structural inspections are required prior to erecting a tower crane on a building site, the methodologies and safe practices that should be followed when erecting the crane, and what functional and operational tests are needed before it is put into operation.

RESCON and its members as well as the Ontario Formwork Association (OFA) and James Wilkinson, P.Eng. of Wilkinson Technical Services Inc., played a critical role in developing the guide, along with RESCON’s crane safety committee and health and safety committee.

The guide covers pre-erection inspections and reviews, initial erection on the project, and safe operating practices, including climbing and dismantling procedures. It outlines what inspections must be done, documentation requirements and engineering inspections necessary at the pre-and post-erection stages, and what is required if multiple cranes are on a project. There is a checklist of documents that must be retained at the project by the constructor and project management team.

Easy handling

Intelligent counterweight system, slabs interchangeable for all CC cranes. The right crane for the job

Boom extensions, luffing jib, Boom Booster Kit, and other attachments can be added as needed.

IC-1 Remote

IC-1 Remote gives you access to advanced real-time diagnostics and much more.

Easy rigging

Quick-connection system allows superstructure to be installed or removed in less than 15 minutes.

Designed for maximum performance on challenging terrain and minimum setup complexity, Tadano lattice boom crawler cranes provide enormous versatility thanks to their rugged and adjustable crawler carrier. Moreover, the optimized transportation dimensions and weights significantly reduce transportation costs. And with an awesome lifting machine, you will get unrivaled service. From top technicians to our new parts warehouse in Houston to the convenient call center, Tadano is invested in your success.

Learn more about Tadano lattice boom crawler cranes at www.tadanoamericas.com.

Reducing red tape, lower interest rates and skilled workers are key to health of crane industry within the residential construction sector, say RESCON VP

By Don Horne

We sat down with Andrew Pariser, the new Vice President of RESCON (Residential Construction Council of Ontario), to talk about the association’s new comprehensive best practices guide that was produced to serve builders and trade contractors when erecting, operating and dismantling tower cranes.

Pariser, who is also chair of the association’s safety committee, told Crane & Hoist Canada magazine how much time and effort went into putting together the guide:

Andrew Pariser: The joint Crane Safety Committee was formed in the summer of 2021 and met regularly to:

• Set the scope and scale of the project;

• Identify industry best practices;

• Consult with leading experts (health and safety professionals, engineers, members of RESCON and OFA (Ontario Formwork Association), and others);

• Create a draft;

• Consult with members to ensure buyin and accuracy; and

• Finalize the document.

CHC: What issues did you see as paramount in addressing in the guide?

Pariser: This document highlights the leading safety practices on-site and codifies our collective approach to safety. This guide is about ensuring and building a culture of safety. In order to do that you need to commit and implement a continuous improvement model and attitude. Cranes are very important to construction and a central piece of all high-rise projects. As a result, it makes sense that to improve a culture of safety you focus on the critical aspects of the project. In this case we chose to focus on cranes.

Our health and safety approach and committees will continue to focus on a culture of safety and continuous improve-

ments and will continue to lead efforts that improve safety. This will include updating this guideline as well as creating other guidelines.

CHC: The message of “safety” has been topof-mind in the crane industry. How does the guide address safety concerns for tall cranes?

Pariser: This best practice guide covers all cranes and works to identify potential hazards as well as the steps that all parties must take to ensure safety. This guide will facilitate communications between all parties as they create safety plans and comply with construction regs, legislation, and manufacturing instructions.

CHC: What can governments and associations do to help reinforce the message of good safety practices?

Pariser: Government and associations

need to continue to do what we are doing now. We need to make sure safety is always our number one priority and we need to continue to work together in a tripartite fashion (government – labour – management). When all parties come to the table looking for solutions only good things happen.

CHC: Ontario has made new residential construction a priority. How can the crane sector help to facilitate the expected growth in new condo and apartment builds?

Pariser: In short, you cannot build a midrise or high-rise without a crane. As a result, the crane sector can help by increasing the number of crane operators available. There is currently a shortage of crane operators.

CHC: What challenges are facing expedited growth for new high-rise construction?

Pariser: Three challenges include:

1. Approval process – Present systems are overly slow, bureaucratic and unresponsive and we need to act now to change them if developers are to meet the target of building 1.5 million homes over the next 10 years.

1. Labour supply – Over the next 10 years we need more than 100,000 skilled trade workers in the construction industry. Shortages include compulsory trades like crane operators and elevator installers, but also include specialized skill sets that do not require a certificate. These include high-rise forming, concrete and drain, bricklaying and the finishing trades.

1. Economic uncertainty – The residential sector (as well documented) is heavily impacted by interest rates. Inflation has remained stubbornly high which has led to oversized increases from the Bank of Canada. Economic uncertainty and increasing interest rates is a major strain on the residential sector.

Courtesy of TNT Crane

While many developers and managers prefer to push major projects to summer, this is not always a feasible option for time-sensitive projects and certain industries. As providers of mobile cranes for projects in various industries and environments, the team at TNT Crane & Rigging knows how difficult it can be to complete a project in winter.

4 Common Winter Hazards that Affect Crane Operation

1. REDUCED VISIBILITY

Fog, rain, snow, and sleet are all more common throughout the winter months. Each of these weather conditions can significantly reduce visibility, making lifts more difficult for even the most experienced and

skilled operators.

While visibility conditions can be somewhat predicted through the weather forecast, some weather conditions may occur without warning. If visibility is severely impaired, lifts may need to be postponed until conditions improve.

2. HIGH WINDS

Every crane has a different capacity or rating for wind resistance. For example, some mobile cranes are rated to resist winds up to 40 km per hour, while others can resist winds up to 55 km per hour.

It is important to keep an eye on the weather forecast to stay informed of poten tial periods with high wind speeds. Much like impaired visibility, high winds can put a stop to a project until conditions improve.

3. ICE BUILDUPS

Operating a mobile crane in icy weather can be extremely hazardous. Loads may freeze to the ground and become more difficult to lift. Additionally, ice may form on loads and crane booms, further impairing lifting ability. Be sure to perform all safety checks on load materials and major crane components to ensure that they are free of ice to determine if the lift is safe to complete.

4. FREEZING TEMPERATURES

Extreme cold can increase strain on oper-

By Chris Ward

The transportation industry is expected to grow substantially in Canada by 2030, and heavy equipment hauling will account for a big portion of it. But some construction and industrial machines are more challenging to transport – and cranes are definitely in this category.

Learning how to transport a crane safely, especially over long distances, is essential. Why? Finding the right crane for a job a few miles away from the work site is not always possible. Therefore, transporting a crane over long distances across Canada is standard practice. Thus, here’s an overview of how the process works.

Cranes are among the most challenging construction equipment to store, transport, and operate. But since they’re indispensable in many cases, the design takes into account potential logistics problems.

Big cranes and tall tower cranes necessitate dismantling and reassembling for transport. Fortunately, smaller cranes or telescopic cranes are easier to move from point A to B. In many situations, telescopic crawler cranes are big enough to complete the job.

Transporting heavy equipment and machinery like cranes involves complex logistics. Like all other countries, Canada has strict transportation rules that shippers must follow, such as road weight limits, underpass height limits, cargo width restrictions, etc.

And don’t forget those special permits. Permits can take a long time to acquire without experience and connections in the industry.

Veteran heavy equipment shippers know the ins and outs of the transportation industry and how to ensure the crane reaches its destination on time and undamaged, and they can share this knowledge to prove their value to customers. Here are some good

examples of why it can also be expensive to ship a crane across long distances here: www.a1autotransport.com/shipping-acrane/.

Perhaps even more critically, experienced shippers understand the requirements of practical transportation. Not every crane operator or owner knows the best way to transport a crane. On the other hand, heavy equipment haulers deal consistently with various crane types.

That means they know when it’s possible to ship them assembled and when it’s not.

Heavy equipment haulers use many types of trailers to move cranes between worksites. It all depends on the size and weight of the crane and whether it’s fit for transporting fully assembled.

Flatbed trailers are often used to haul heavy equipment. Their weight limit of 48,000 pounds might not always support direct crane transportation, but it can be enough to carry disassembled crane components over long distances.

Double-deck trailers can carry longer pieces of equipment, up to 65 feet. Another option is a lowboy trailer. This type of trailer has two deck heights and can accom-

modate taller components.

Unless a crane is small enough to be transported as a whole, the shipper may need to utilize multiple trailers and drivers to relocate a trailer. That’s another reason it’s important to work with experienced crane haulers. Shipping companies that specialize in moving heavy construction and industrial equipment have entire trailer fleets at their disposal.

Three primary factors affect shipping costs: dimensions (size), weight, and distance. Size and dimensions dictate much of the logistics of the job.

The dimensions may call for using multiple trailers, professional disassembly, or even getting oversized load permits. Weight is always a determining factor in shipping costs, whether you send documents via courier or cranes across the country with a heavy equipment hauler. Again, the weight dictates specific transportation requirements like permits, loading equipment, trailer types, driving speeds, etc.

A crane’s size and weight are indicative of the job’s complexity. Bigger cranes may need special equipment and trained operators even for loading and unloading procedures. They could also need additional safety gear during transport, require experts to supervise the disassembly processes, etc.

Then there’s the distance. Calculating the distance is always interesting, but scheduling shipments weeks or months in advance can help lower transportation costs.

By Emily Newton

People who want to operate cranes or hoists in Canada must earn heavy equipment certifications, and the specifics vary by province. Here’s a look at what is required, and the differences from province to province.

How Can Someone Become a Crane Operator in Canada?

Most companies hiring for crane or hoist operator positions require candidates to have completed secondary school. Additionally, people must either finish an apprenticeship program or earn the proper heavy equipment certifications.

Beyond those general requirements, the certifications people must get vary depending on where they work. Generally, a person contacts the appropriate regulatory authority and shows proof of relevant work or classroom learning experience. The regulator then reviews the information and determines if it qualifies the person to sit an exam and attempt to get certified.

What Are the Options for Getting Crane and Hoist Operator Certifications?

Most people in Canada receive their heavy equipment certifications by completing apprenticeships at approved training centres. These educational options typically last from one to three years.

During these programs, people learn valuable safety principles for operating heavy equipment. For example, they must ensure equipment attachments and prospective loads are always within the stated capacity. Students also learn things

such as how to assemble and disassemble cranes and perform maintenance on the equipment.

All apprenticeships involve a minimum of hands-on training hours, plus five to six days of classroom instruction per week. People take their certification exams before finishing their apprenticeships.

However, some provincial authorities allow candidates to take certification exams after showing they have sufficient classroom and real-world experience outside of apprenticeships. People might do that if they’re already familiar with other heavy construction equipment and want to transition into using cranes and hoists.

What Do the Certification Tests Entail?

The certification process includes achieving minimum scores on both written exams and practical assessments. People pay third-party assessors to oversee the hands-on skills tests.

One such company in Alberta that certifies crane operators breaks down what someone must know to pass the practical assessments. The information also clarifies that people must show the same skills regardless of the crane certification type. Those exams have four parts:

• Hand Signals: The person must correctly interpret gestures given to them by the individual providing the assessment.

• Rigging Knowledge: This section requires someone to answer two rigging questions correctly while referring to provided charts.

• Pre-Operational Inspection: This part asks a person to complete a crane inspection checklist, includ-

ing assessing the rigging. The test-taker must understand the respective Occupational Health and Safety (OHS) regulations for rigging, wire ropes and attachments but can consult the appropriate OHS document during the exam.

• Crane Setup and Operation: In this phase, people must show they can take the proper steps to get a crane ready for use, including blocking and stabilizers. Then, they must operate the crane with and without a load.

Here are the details of the certifications available and which locations require or make them optional.

1. Mobile Crane Operator Trade Certification Compulsory in:

• Nova Scotia

• Québec

• Ontario

• Manitoba

• Alberta Voluntary in:

• The Northwest Territories

• All other provinces

People may also need provincial licenses if their jobs require driving mobile cranes on public roads.

2. Tower Crane Operator Trade Certification Compulsory in:

• Nova Scotia

• Québec

• Ontario

• Manitoba Voluntary in:

• Prince Edward Island

3. Hydraulic Mobile Crane Operator Trade Certification Compulsory in:

• Québec Voluntary in:

• Prince Edward Island

4. Hoist Operator Trade Certification

Compulsory in:

• Québec

• Ontario

• Manitoba

• Alberta<bu Voluntary in:

• New Brunswick

• Saskatchewan

• British Columbia

• Nunavut

• The Northwest Territories

5. Red Seal Endorsement

People working as qualified mobile crane and tower crane operators in Canada can take examinations to earn Red Seal endorsements. They show the person has met national trade standards to work across Canada.

6. Provincial-Related Certifications from Regulatory Authorities

Many places in Canada treat crane operator roles as regulated occupations. That means these workers must earn certifications from the relevant regulatory authorities.

However, once a person gets certified in a regulated trade within one of the provinces below, they can transfer to another province that regulates crane and hoist operators. In such cases, a person can start working there without sitting another certification examination. That’s possible under the Canadian Free Trade Agreement, which aims to remove unnecessary barriers that could restrict business.

Alberta

Alberta Apprenticeship and In-

dustry Training regulates the industry in this province. It offers the following certifications: Crane and Hoisting Equipment Operator with the following subcategories:

• Commercial Mobile Crane Operator

• Wellhead Boom Truck

• Hydraulic Mobile Crane

• Tower Crane

• Boom Truck

• Mobile Crane

British Columbia Industry Training Authority

British Columbia and the British Columbia Association for Crane Safety are the regulatory authorities for the following certifications:

• Boom Truck Operator (Stiff or Folding Unlimited)

• Tower Crane Operator

• Operator of Mobile Hydraulic Cranes (80 Tonnes and Under)

Manitoba Apprenticeship Manitoba offers these certifications under the Crane and Hoisting Equipment Operator category:

• Boom Truck Hoist

• Tower Crane

• Mobile Crane

New Brunswick

The Government of New Brunswick provides these certifications through its Post-Secondary Education, Training and Labour arm:

• Hydraulic or Lattice Mobile Crane

• Mobile Hoisting Equipment

Newfoundland and Labrador

People can get certified through the Government of Newfoundland and Labrador’s Apprenticeship and Trades Certification Division within the Department of Advanced Education, Skills and Labour. The following options exist:

• Boom Truck

• Mobile Crane

• Tower Crane

Nova Scotia

The Technical Safety Division within Labour and Advanced Education is the regulatory authority here. It provides certifications for:

• Tower Crane

• Overhead Traveling Crane

Ontario

People deal with Skilled Trades Ontario when getting crane certifications here. The options are:

• Hoisting Engineer for Mobile Cranes

• Hoisting Engineer for Tower Cranes

Prince Edward Island

Those on PEI can look at these two certifications:

• Hydraulic Mobile Crane

• Tower Crane

Québec

The Commission de la Construction du Qu<1>é<1>bec is the regulatory authority here. People can receive Crane Operator certifications in this province.

Saskatchewan

The two regulatory authorities here are the Saskatchewan Apprenticeship and Trade Certification Commission and Occupational Health and Safety Division. Those organizations issue these certifications:

• Mobile Crane

• Hydraulic Mobile Crane

• Tower Crane

• Grutier/Grutière (Crane Operator)

• Boutefeu/Boutefeue (Blaster)

Prove Your Skills

Show employers you have the foundational skills to work safely and effectively.

Emily Newton is the

Editor-in-Chief

of Revolutionized Magazine. She regularly covers news and trends in the construction and industrial sectors.

By Don Horne

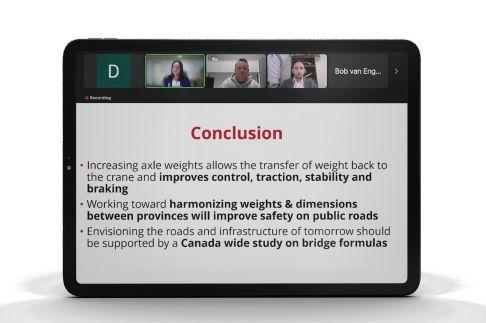

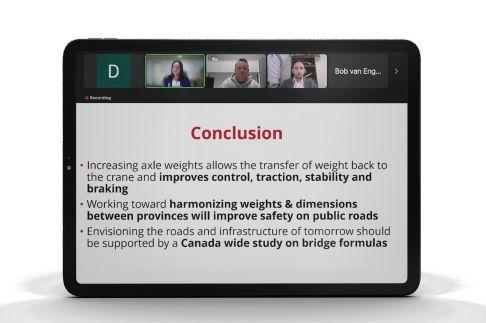

The Crane Rental Association of Canada (CRAC) hosted an online presentation on the National Task Force on Vehicle Weights and Dimensions Policy, sharing the results from the Alberta All-Terrain Cranes Pilot Project.

The biggest takeaway from the project is that the industry proved that it could move cranes efficiently, safely and in a more cost-effective manner with just a few adaptations.

Through the pilot project, the axle weights were increased, proving to all the regulatory bodies and different levels of government that the size of dollies could be reduced and tail swing, alleviating the amount of support equipment required for a move.

“It was a really big win and helped to open their eyes to see what we had been up against,” said Mike Lavoie, Operations Manager Myshak Crane & Rigging during the presentation.

CRAC Executive Director Claire Bélanger-Parker chaired the presentation, along with co-chairs

Mike Lavoie and Justin Andrews, Regional Business Manager Canada & Wester USA, Tadano America.

Among the impacts on safety that were noted during the project were:

• The ability to keep the outriggers, jibs and auxiliary winches on the cranes;

• Driving on slippery, muddy or inclement road conditions with added axle weights increased traction, far safe and less stressful;

• With a reduced amount of tail-swing, there wasn’t a single incident in ban season, and a definite reduction in near misses;

• A reduction of pinch/crush point injuries from outrigger removal/installation; and

• A reduction of man hours and the potential for incidents and near misses by not having to reconfigure equipment during spring ban.

Andrews pointed out that all-terrain’s adaptive steering went a long way to protecting roads.

“We expect this amendment to the Pilot Project will demonstrate that all-terrain cranes are engineered to protect pavement integrity and travel safely on Canadian highways,” says Mark Danderfer, Co-Chair of the Boom Dolly Research Committee (BDRC). “This important amendment would not have been possible without the collaboration of the Ministry of Transportation and the extraordinary input and dedication of my Co-Chair, Justin Andrews, Regional Business Manager for Western USA & Canada for Tadano America.”

The Boom Dolly Research Committee has a three-prong approach: Advocate for changes to provincial regulations; develop best practices and research technical solutions.

After the results from the National Task Force on Weight & Dimension Policy meeting were unveiled, CRAC pointed out that thanks to Alberta members providing feedback, it is opening the doors to multiple possibilities “not only for Alberta but also for the rest of Canada.”

The Boom Dolly Research Committee has a three-prong approach: Advocate for changes to provincial regulations; develop best practices and research technical solutions.

World record: A mobile crane with a 90-meter telescopic boom – fully carried with 12-ton axle load! Our latest innovations, integrated for safe and powerful crane operation: ECOmode, ECOdrive, VarioBase®Plus, VarioBallast®, Auto-Ballast, SingleEngine concept and WindSpeed load charts for maximum safety when operating. The versatile and economic fast deployment crane with the record telescopic boom length brings any fleet to new heights! www.liebherr.com

Courtesy of Graham Construction

The City of Edmonton’s Groat Road Bridges and Road Renewal project set challenging requirements. Despite approaching the end of its service life, the city wanted the nearly 65-year-old, 330-metre-long four-lane bridge forming a critical transportation route over the North Saskatchewan River repaired rather than replaced.

The entire superstructure’s deck, girders and portions of piers and abutments – 13,000 tonnes of concrete – was to be demolished. Traffic normally averaging approximately 40,000 vehicles per day had to flow throughout construction. Widening of the shared use path from 2.4m to 4.2m on the bridge was completed to meet the City’s requirements. In-stream work faced regulatory hurdles including schedule restrictions for fish spawning, and physical constraints to how much of the River could be impacted at any given time. And the project needed to be completed in under three years.

Although many factors and people contributed to the project’s completion on-budget at $45.6 million and within the 33-month schedule, Graham Construction’s successful execution hinged on a bold temporary works innovation conceived before the project even began. In brief: the superstructure demolition and reconstruction were completed from above instead of below. There, project execution centred on a custom-designed and constructed, rail-mobile gantry crane system – the first such solution ever used in Canada.

“The process amounted to sawing the

old bridge down the middle, repairing one half of the bridge, keeping two-way traffic open on the other side, then flipping the process and repeating,” explains Jim Murray, the City of Edmonton’s Project Manager. “This was no easy task, people driving by don’t realize how complex it is.”

And continues Murray, “In the first half we struggled, this was something new, it was quite stressful because we knew if we didn’t get that first half flipped over for traffic, we weren’t going to be successful.”

In addition to the river bridge itself, the contract called for rehabilitating two bridges, one to the north of the river and one to the south of the river along with the rehabilitation of 5 km of roadway and on/ off ramps. The City had previously selected DIALOG as designer and engineer of record, and the firm would later remain on-site through contract administration. Graham was selected as general contractor in January 2018 based on a combination of price and relevant experience. “On a project with this kind of complexity and risks – a critical river bridge in the centre of Edmonton – we don’t hire somebody for whom this is their first try at it,” notes Murray.

In 2017 Graham began delivering an equally complex project in its widening of

Calgary’s Crowchild Trail bridge. The company resolved similar in-stream restrictions concerning the Bow River by hanging temporary works off the bridge sides, averting the need for traditional in-stream berms. “Groat Bridge couldn’t be executed like Crowchild,” notes Stephanie Grundke, Graham’s Project Manager. “But it too required complex temporary works with a large focus on traffic management.”

The work on Groat Bridge required a more extensive rehabilitation than Crowchild. Before landing the contract, Graham had identified regulatory and schedule risks associated with the use of in-stream access to perform the major rehabilitation activities. Fish spawning windows would significantly reduce the available in-stream construction periods. The initial concept was to have four phases of in-stream berm during allowable construction periods, dividing the project into quarters.

Fortuitously, a Graham employee attending an industry conference met an acquaintance from COWI North America, Ltd., and the two began brainstorming, explains Melissa Jennings, the COWI engineer who performed design work on all of the major temporary works. In a histor-

ic photo of a previous construction project, the COWI employee had noticed a gantry crane system being used to build a bridge. Could this be done on the Groat project, enabling year-round construction, uninterrupted by seasonal and regulatory constraints?

The two companies had worked extensively together in the past, notes Grundke. “They are really receptive to coming up with solutions that are conducive to construction, the people there are very practical, they understand construction and they tailor their designs accordingly,” she notes. Now, Graham brought COWI in as construction engineer on the Groat project, and the two teams set to work.

What took shape was an arrangement of two mobile gantries, each with 40-tonne capacity, mounted in tandem. They could be used individually to lift up-to-40-tonne bridge deck panels, or together to lift 80-tonne sections of the bridge girders. The existing bridge was comprised of seven spans and six castin-place girder lines; three girder lines were to be removed in the first phase. The gantries would run on two parallel supports. One was the “runway beam”, a large, very strong temporary steel girder placed overtop of the old bridge’s middle girder and running the length of the bridge. The other was a triangular truss placed outboard and supported by steel brackets which were tensioned across the pier using high-strength rods.

“It became an iterative process,” recalls Jennings. “Senior engineers would sketch out what it could look like, then we had internal discussions, then we reviewed it with the contractor to make sure it was feasible, each iteration improved it.” She describes this process as “highly collaborative. I felt like I really gained a lot being able to work with Graham.”

Getting the runway beam, truss and bracket system installed and running was a large part of the overall project. There were many technical constraints involved in installing the system including accommodating the existing geometry of the bridge to “fit” the support system accommodating the bridge’s existing design which included rocking piers and hinges in the existing girders, as well as critical tolerances for the rails and gantries, anchorage of the pier brackets and runway beam without

conflicting with existing rebar, plus concerns about the bridge’s deficient shear strength. And, of course, it had to remain open to traffic. The design package analyzing the impacts of the runway beam on the existing bridge girder over which it would be placed alone ran to 1,000 pages. “It’s a simple concept to understand, but there were all these different pieces involved, and designing it to handle the large loads during demolition was quite complicated,” Jennings explains. “It became a weirdly elegant solution that was quite challenging to carry out.”

“This was a huge deal,” agrees Murray. The gantry scheme required review and approval by the director of the city’s Integrated Infrastructure Department. The gantries needed to remove 400 pieces of concrete of up to 80 tonnes each according

to a prescribed order of removal aimed at maintaining the bridges structural integrity through all stages of the process.

“First we cut the concrete deck between the girders and lifted those pieces away using the gantry cranes, and then would cut and lifted the girder pieces out,” recalls Grundke. “The sequence followed to remove the girder segments, at times leaveing unbalanced girders cantilevered over the river, so we would secure these with ‘strongback’ steel pieces anchored to the gantry’s support steel.” Demolition took about four months for each phase, much of it in the winter. “In addition to staying below the 80-tonne combined capacity of the cranes, we also needed to control the sequence we picked each piece to ensure that loads transferred to the support system were as designed,” notes Grundke.

“Many of the girder lifts were near the cranes capacity by design. It was critical that our team treated every lift as seriously as the first one.”

Phase I demolition was very challenging, recalls Murray. “As they started removing pieces of deck, we found the deck was delaminated in places, so we needed a new plan to get the deck panels off in one piece,” he says. COWI developed a new plan to revise the anchoring of the panels.

Importantly, the gantry crane approach proved sound and, with experience and adjustments, the work became more efficient. Consequently, says Murray, “The second half was far smoother and easier. We had learned lessons, so we were prepared for everything, plus we had half of the bridge rebuilt which was much stronger than the original.” To further protect the river below during the actual concrete cutting, Graham installed a mobile containment system beneath the bridge to catch the water/concrete slurry during cutting. The concrete slurry was vacuumed and filtered and then reused for subsequent cuts.

The gantry cranes remained active during reconstruction, which included hauling rebar, formwork, the new steel girders, and other heavy loads. Graham’s innovative work sequencing saved time by having the false deck formwork, and rebar installation commence immediately upon placement of each span of new girders, rather than waiting until all seven spans were fully installed. That too, notes Jennings, “Required a lot more detailed calculations of where one expects the steel to be, elevation-wise,

rather than just measuring the girders once installed.” But the significant time gained proved well worth the added effort.

In October 2020 the refurbished Groat Bridge officially opened on-schedule, with a large ceremony and news media present, delivering a great result for the City of Edmonton and the millions of motorists, cyclists and pedestrians who will use it over its 50-year rated lifespan. Graham’s runway beam was later sold, with parts of the truss repurposed for the Kicking Horse Canyon project at Golden, B.C. Graham has been asked to speak about the gantry-crane approach at several industry conferences.

Sums up Grundke: “It not only helped us meet Edmonton’s contract requirements, but it was very beneficial from an environmental standpoint; completing major demolition and reconstruction activities from above significantly reduced impacts to the North Saskatchewan River and its users.”

Welcome to our “new” New Equipment and Products section to start the new year.

We’ve gleaned a selection of what’s new on the Crane & Hoist Canada website, presenting a highlight of new products and equipment from the past few months.

If you would like to be included in the next issue of Crane & Hoist Canada magazine in this section, please email me, Don Horne, at dhorne@annexbusinessmedia.com, and put in the subject line New Products.

Please keep the submissions to five (5) paragraphs or less –under 200 words – and attach a high-res image in a png or jpeg format.

We cannot guarantee that all submissions will be included, due to time and space constraints.

Manitowoc launches the new Grove GRT8100-1 roughterrain crane

Manitowoc used its attendance at bauma 2022 to launch its latest rough-terrain crane: the Grove GRT8100-1. This exciting upgrade of the hugely popular GRT8100 will be available from 2023 and offers a series of improvements over the original GRT8100.

Many of the enhancements stem from a new chassis that shares commonality with the chassis from the proven 120 t capacity GRT8120. There’s also an updated engine and transmission package, and a new, wider cab with enhanced operating features.

“The GRT8100 has been a popular choice with customers worldwide. With the GRT8100-1, we have taken a great crane and made it even better,” said Federico Lovera, product manager for rough-terrain, industrial, and lattice boom crawler cranes at Manitowoc. “The new Grove GRT8100-1 will go into production at our U.S.

on and off the jobsite, while also minimizing disruption to traffic and the surrounding area.

The speed and simplicity of assembly is aided by Manitowoc’s Crane Control System (CCS), which improves the efficiency of communication between the crane and on-site staff. The technology also enables the lifting and distribution ropes to be fixed at ground level, reducing assembly work required in the air.

Considering the lack of manpower availability that we are experiencing these days, it is no surprise that companies are using them more and more” said Drolet.

Thanks to its mixed use, the TurboFarmer 65.9 will meet all the challenges in terms of handling and moving very heavy loads.

and Italian factories simultaneously, allowing deliveries to customers around the world to begin in early Q2.”

Manitowoc unveiled the latest addition in its Potain MDT City crane range at bauma 2022, the 6t capacity MDT 159, which fills the gap between the MDT 139 and MDT 189. With a 60 m maximum jib, the crane is suited to small to midsized building projects of up to 10 floors, and it has been specially designed for tight urban jobsites.

The topless concept is ideal for multi-crane work sites as it reduces the clearance needed for other cranes passing overhead or underneath. The cranes are also famously easy and quick to install, so it’s no surprise that considerable planning went into the transport of the MDT 159. Just three containers are needed to transport the crane’s full upper section. This reduces the complexity of getting the crane

In an effort to lighten the ever-increasing burden of handling and moving heavy loads in all industries, MANULIFT is establishing itself as a performance gas pedal with the TurboFarmer 65.9 from world-renowned equipment manufacturer Merlo, for which it has exclusive distribution in Canada.

The company’s president and CEO, Martin Drolet, said that this new product is a piece of equipment that will revolutionize the daily lives of businesses.

“The TF 65.9 is truly a unique model, designed to handle the most difficult jobs. Its load capacity of 6,500 kg, in addition to its great maneuverability in tight spaces, makes it one of the most compact and efficient machines for repetitive and robust tasks,” said Drolet in a burst of enthusiasm for its maneuverability and operating speed, which give it almost Formula 1 performance status.

“Telescopic handlers can compensate and make up for certain productivity deficits.

Gorbel is pleased to introduce a new tractor drive for motorized movement of its cranes. The drive delivers industry leading power and performance while being a fraction of the size of other mass-produced tractor drives on the market. The combination of this tractor drive’s smaller size and proven Gorbel quality enables customers to motorize their systems with full confidence.

For both new and existing Work Station Cranes, this newly designed tractor drive by Gorbel provides precise motorized movement. Its precision drive assembly and the specialized design of its drive wheel, which has a molded polyurethane thread, achieves a smooth acceleration and long life. The drive wheel also has a spring-loaded compression adjustment, allowing for constant pressure and smooth, responsive operation.

With ⅓ HP and an 18000 RPM induction motor, this tractor drive is ideal for heavy and awkward-shaped loads, operations that require tall trolley saddle heights, as well as operations where the operator needs to maintain safe distance

from the load. Whatever the needs of your operation, the tractor drive can deliver peak performance, as its standard and fast options are both available with programmable speeds. Indeed, its Variable Frequency Drive (VFD) Controller has both a soft start and soft stop, and can be set for single, double, or triple speeds.

Lightweight, with a modular drive design and bolt on truck and trolley connections, the tractor drive provides considerable ease of installation. The standard drives are configured for 208-460 volt 3 phase power, and a 575 volt is also available. The tractor drive also comes with an industry leading two-year warranty.

For more information, visit: www.gorbel.com.

Liebherr has expanded its heavy lift ship crane portfolio with an 800-tonne capacity crane – the LS 800 E.

“The growth of wind turbines is leading to increasingly heavy individual component weights. In addition, the handling of large components requires a longer outreach of the cranes used than is often the case in the market,” said Liebherr. The manufacturer added that the supply of heavy lift vessels with cranes offering a maximum lifting capacity of 800 tonnes is lower than the expected future demand.

In addition to the much larger dimensions of the crane, the LS 800 E design also includes an all-electric drive concept. All sections of the crane are electrically driven. As a result,

the machine achieves higher energy efficiency and thus significantly reduces the ship’s CO2 emissions.

“We have many years of experience with all-electric drives from the port equipment sector, among others,” Gregor Levold, sales director for Liebherr Offshore, Ship and Port Cranes, added. “As usual, the development of the crane is done completely in-house. We can also cover the procurement of individual components largely in-house at Liebherr.”

Hiab has announced a new generation of Loglift forestry cranes, said to offer improvements to safety, performance and reliability.

The first crane available is the Z boom Loglift 18Z which comes with long lower arm and a three-section telescopic boom, for an outreach of 10.4 metres and a load moment of 18 tonne/metres. Maximum capacity is five tonnes at a three-metre radius, while the crane can handle 1.4 tonnes at its maximum radius of 10.4 metres.

The crane has a new boom geometry which delivers more power in critical areas and an increased outreach. All hoses and cables are placed inside the boom system or fully protected, while larger hydraulic tubes help improve flow to help maintain lower oil temperatures. Operators benefit from a more ergonomic high seat operating post, with sturdier access ladder, while a cab is optional. The view from the high seat has

been improved with a wider field of vision and several new safety features such as an illuminated emergency stop button and better illumination.

A new modular design helps dealers of body building companies install the new cranes faster and easier.

Liebherr is expanding its series of flat-top cranes with the 300 EC-B 12 Fibre and 270 EC-B 12.

According to the company,

both machines are ideal for sites requiring heavy hoists and meet all the main requirements placed on a modern crane fleet.

The 300 EC-B 12 Fibre features the Liebherr fibre rope, which Liebherr claims to deliver significantly better performance values than similar cranes that feature a steel rope. Also, the fibre rope has a longer service life, which lengthens ropechanging intervals, making operation more economical and increasing the crane’s availability.

The 300 EC B 12 Fibre has a 70-metre jib and delivers a lifting capacity at the jib head of 3,250 kg and the steel rope version of the 270 EC-B 12 with a 70-metre jib has a lifting capacity at the jib head of 2,850 kilograms.

The new cranes will replace the existing Liebherr 250 EC-B and 278 EC-B Fibre models.

Manitowoc is expanding its boom insert offering with the new Wide Boom Plus kit for its MLC300 lattice-boom crawler crane. The new inserts will give crane operators extra reach by lengthening their booms up to 429.8 ft (131 m) when used in combination with the VPCMAX® and extended upper boom points. They will be particularly useful for assembling wind turbines.

The height of utility-scale, land-based wind turbines has increased nearly 60% in the last

two decades, reaching an average of 295 ft (90 m) in 2020 in the U.S. Wind turbines are expected to keep growing in size in the coming years, as building the turbines to higher elevations enable the wind towers to harness stronger winds. The new Manitowoc boom inserts will enable the 386 USt (350 t) MLC300 to construct these increasingly tall wind towers.

Brennan Seelinger, Manitowoc’s product manager for crawler cranes, said wind turbine work above 295 ft (90 m) currently requires a 450 USt (400 t) or larger crane, which can result in higher costs for operation and transportation.

igus®, the world leader in motion

plastics and moving cable management systems, has introduced the rol e-chain® P4HD.56.R – a new heavy-duty energy chain cable carrier designed for long travels, high speeds, heavy cable loads, and Industry 4.0.

Over the past 25 years, container ships have grown larger and larger as shipping companies continue to seek economies of scale and fuel efficiency. Currently, the world’s largest container vessel is the Ever Alot, with a carrying capacity of 24,004 containers and measuring 400 metres long by 61.5 metres wide, with a draft of 17 metres.

The recent development of ultra-large container vessels (ULCV) is changing the industry and putting new pressure on terminals to provide deeper drafts and taller ship-to-shore (STS) cranes to service these mammoth containers efficiently.

This enlargement also affects the cable carriers that guide the energy and data cables for the crane trolley. They have to withstand unprecedented loads: travels of over 130m, cable weights of up to 10kg/m (over 20kg/m for motor-driven trolleys), and accelerations of more than 1m/sec2 are standard for Triple E-class STS cranes. In other applications, travel distances of several hundred meters, cable loads of up to 50kg/m, and accelerations of 8m/sec2 and more can be achieved.

Wooster Products’ FLEX-TRED® anti-slip tapes enhance safety in industrial environments by providing a higher coefficient of friction on the applied surface, whether wet or dry.

Many industrial areas can be slippery when wet, and FLEX-TRED® Tape provides an easy solution. Available in rolls of various widths, standard die cut shapes, or in custom die cuts to suit specific requirements, this heavy-duty safety surface is easy to install and provides durable pedestrian safety on slippery surfaces. It bends over sharp 90°angles without fracture and can be bent repeatedly without cracking or failure of the bond. FLEX-TRED® is ideal for application such as machinery surfaces, gas/brake pedals, forklifts, mowers, snow groomers, tow motors and forklifts, on platforms, scaffolds, cherry pickers, and ladders, and more.

Wooster has been making custom die cut patterns for many years and has thousands of patterns in their library. Prospective customers may find an existing pattern close to that desired, thus saving a custom die cut charge.

Available in various colours and patterns, including fluorescent colours and NITEGLOW® Glow in the Dark. In areas where a heavy exposure to liquids is anticipated, easily applied VOC-free FLEX-TRED® Edge Sealing Compound seals the edge to most surfaces. For additional information visit www.WoosterProducts.com

Since the alternative drive of the LB 16 unplugged quickly established itself on the market as a Gamechanger, the design has been extended to further product areas. Today, the electrified unplugged series comprises crawler cranes as well as piling and drilling rigs.

An outstanding feature of the battery-powered unplugged units is zero emission. They do not produce any exhaust fumes and are extremely quiet. This strikes the right note especially in noise-sensitive regions and finds favour with construction site personnel and residents. Whether London, Paris or Oslo – the concept has already been successfully applied in these metropoles.

The battery is charged using a conventional jobsite electric supply. Operation can continue as normal while charging. In order to change to battery operation, you just need to pull out the plug, therefore: unplugged. Whether attached to the electric supply or not, the performance and range of application remains unchanged.

All six models are available in both conventional and battery-operated versions and have identical performance specifications.

The latest system is the Gradient Travel Aid for the safe negotiation of slopes and inclines. The crane’s control system automatically calculates the centre of gravity and warns the operator before the crane leaves the safe area.

No matter how challenging your needs, BKT is with you offering a wide range of OTR tires specifically designed for the toughest operating conditions: from mining to construction sites. Sturdy and resistant, reliable and safe, able to combine comfort and high performance.

BKT is with you, even when work gets tough.

For info: Western Canada 604-701-9098 Eastern Canada 514-792-9220

We are offering immediate availability on today’s most popular cranes from Manitowoc, Grove and National Crane. All backed by North Americas leading distributors.

Capacities range from: 110-716 TON LATTICE BOOM CRAWLER CRANES, 65-550 TON ALLTERRAIN CRANES, 30-165 TON ROUGHTERRAIN CRANES, 40-115 TON TRUCK MOUNTED CRANES.