Latest-Generation Versatility

The AW169 is the brand new 4.5 tonne class twin-engine helicopter.

Featuring an advanced glass cockpit, state-of-the-art avionics, 4-axis digital autopilot, full digital electronic engine control (FADEC) and dual channel Flight Management System (FMS) for reduced pilot workload and increased passenger comfort.

Based on the operationally proven, market-leading AW139 platform and belonging to the AgustaWestland ‘Family’ of products (with AW189 and AW139), mixed-fleet operators can leverage the advantage of a common design philosophy across platforms.

LEADING THE FUTURE

MATT NICHOLLS is editor of Helicopters

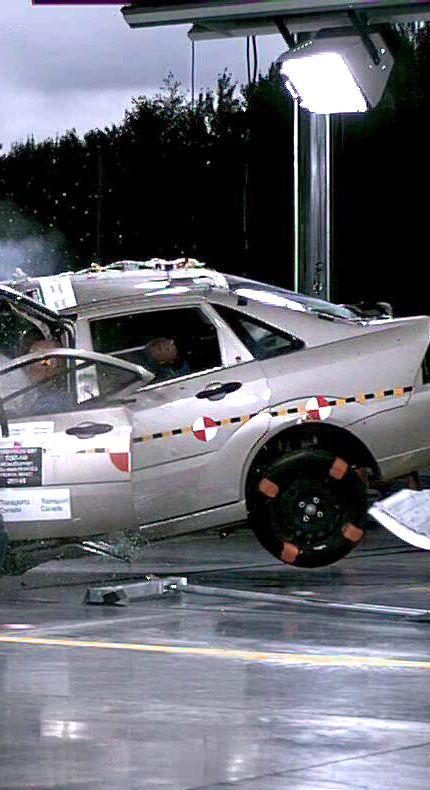

ver the past couple of years, Helicopters western correspondent Paul Dixon and I have had spirited conversations with RCMP Sgt. C.V (Cam) Kowalski about the shocking rise in the number of laser attacks against Canadian rotary and fixed-wing pilots.

The discussions were disturbing, and frankly, I’m appalled at the stupidity and lack of awareness, understanding and respect individuals that partake in such incomprehensible activities have for the pilots, crew and members of the public at large.

Laser strikes on aircraft are on the rise and it’s a disturbing trend. In 2014, there were 502 reported incidents, which represents a 43 per cent increase from two years prior. So far this year, there have been 282 strikes across the country.

Laser strikes against aircraft are not unique to Canadian skies. Last year, the FBI launched a national information campaign, offering a $10,000 reward in helping identify perpetrators. Since the FBI began tracking laser strikes in 2005, statistics reflect a more than 1,100 per cent increase in in the deliberate targeting of aircraft by people with hand-held lasers.

The severity of these criminal acts is wide-ranging: high-powered lasers can permanently scar a pilot’s vision for life, stealing their career and livelihood. On a grander scale, a laser strike on an aircraft places the lives of those in the cockpit – and innocent citizens on the ground –in grave danger for a potentially horrendous accident. And while pointing

Not A Bright Idea

Getting Tough to Eliminate Laser Strikes Against Pilots

government. Alice Wong, Minister of State (Seniors) and Lisa Raitt, Minister of Transport, launched a national awareness campaign to shine light on this critical issue and explain – and it’s incomprehensible to me that the word “explain” needs to be attached to something like this –why shining a laser at an aircraft is not a good idea.

“It should be a no-brainer that pointing lasers at any part of an aircraft is dangerous,” Wong noted. “This awareness campaign will help Canadians better understand the serious risks and consequences of pointing a laser at an aircraft. By working closely with our partners, we can help to reduce the number of incidents at Canada’s airports.”

Craig Richmond, president and CEO of the Vancouver Airport Authority, reiterated the need for safety in and around major airports. “At YVR, our number one priority is safety,” he said. “We are working with our partners to increase education and awareness about the impact of laser strikes.”

The federal government’s campaign is based on a multi-phase approach. The first phase provides the public with information that clarifies specific dangers and consequences of pointing lasers into airspace and how incidences can be reported. The second phase, to be implemented this summer, includes digital advertising, awareness videos and a direct mail campaign near three major airports.

Transport Canada (TC) has also launched tc.gc.ca/NotABrightIdea, which provides Canadians with information to better understand the dangers of pointing a laser at an aircraft. TC is also working with police, other government departments, and the aviation industry to protect pilots, passengers, and people on the ground. They are encouraging all citizens that if they see a laser pointed at an aircraft, to report it to their local police.

In 2014, there were 502 reported incidents, which represents a 43 per cent increase since 2012.

a laser at an aircraft is a criminal offence – if convicted, under Canada’s Aeronautics Act an offender could face up to $100,000 in fines, five years in jail or both – there are those that continue to put pilots, and the general public, in the line of fire.

Kowalski has taken a leadership role in putting an end to these reprehensible acts. His work, as well as those of his team members at the RCMP, NAV CANADA and the Vancouver International Airport, has been invaluable and, in early June, more support came from the federal

“Suspects who choose to target aircraft with lasers show a careless and wanton disregard for the safety of the pilots, passengers and the communities surrounding airports,” Kowalski said. “Those caught will be prosecuted according to both federal and provincial acts and will be subject to substantial fines and jail time.”

The federal government’s campaign to eliminate laser strikes is an important step in working to eliminate these despicable acts. Let’s hope it lights a fire under citizens from coast-to-coast and shuts the blind on those whose only purpose is to destroy, corrupt and harm.

Big Spring for Airbus Helicopters Canada

While much of the industry experienced a sluggish start to the 2015 season, that wasn’t necessarily the case for Airbus Helicopters Canada.

The Fort Erie, Ont.-based OEM made plenty of news in the first few months of the year with some major signings and expansions in key sectors.

In early June, Airbus and Niagara Helicopters hooked up on a significant piece of business, as the world-renowned Niagara Falls, Ont.-based operator added four new aircraft to its fleet. The new H130s will be used by Niagara to fly customers in a variety of operations including sightseeing excursions, charter flights, aerial surveillance, film photography, external loads and more in and around the Niagara region.

Annie Pierce, vice-president and general manager of Niagara Helicopters was understandably thrilled with

the enhancement of the Niagara fleet when Helicopters caught up with her during the fleet renewal ceremony at Airbus Canada’s Fort Erie plant. “It’s a deal that will certainly enhance our position in the marketplace, no question,” she said. “It will provide customers with a safer, enhanced riding experience, reduce noise to the community and more.” The H130 was an excellent choice for her helitourism operation, Pierce noted, given its visibility footprint, quietness, comfort and performance.

Romain Trapp, Airbus

Helicopters Canada’s president and CEO, called the deal a further extension of the strong relationship the two companies have developed over the years.

The Niagara deal was not the only significant newsmaker for Airbus Helicopters Canada in the spring, as the firm also added Mirabel HeliSupport as its eastern Canadian maintenance centre for private and corporate clients in the Quebec/Eastern Canada region. And the news didn’t stop there: the company also opened a new office at the Mirabel Helico complex in

SALVAGED PARTS GET NEW LIFE

The Abottsford, B.C.-based team of Corey Steinberg and Kelly Loewen are giving new life to salvaged helicopter parts for Bell and Sikorsky helicopters.

The dynamic duo have formed a new business venture that provides quality parts to customers at a lower cost than purchasing new – and it’s helping the environment to boot.

Steinberg and Loewen currently own several ventures including Power Hydraulics, Magnatech Inspections and Heli-Hydraulics. They jumped into this market when they realized there was a need for used helicopter parts and a glut of helicopters on the

Quebec is home to more than 200 Airbus helicopters representing almost one third of the Airbus Helicopter fleet in Canada. The 43,000 ft. Mirabel Helico facility will offer customers aircraft sales, training, technical support and parts ordering options.

“We see this location as offering tremendous benefit for our customers,” Trapp said. “In addition to the services offered by Airbus Helicopters, is the proximity to Mirabel Heli-Support, a newly authorized Airbus Helicopter Service Centre.”

market with valuable parts hidden within. Currently the company has disassembled a Sikorsky S76-A aircraft and thus far has seen great interest from the industry.

“It seemed to make sense for us to move into this area,” Steinberg said, “especially when we have the in house capability for hydraulic maintenance, NDT work and a machine shop at our convenience.”

To find out more info and check out the parts for sale, go to www.powersystemsltd.ca

Simply Relentless

Bell Helicopter’s impressive new super-medium 525 Relentless took to the skies for the first time July 1 at the company’s facility in Amarillo, Texas, much to the delight of staff, members of the design team and flight crew.

Introduced to much fanfare at Heli Expo in 2012, it marked a significant milestone for the company, and is a crowning achievement for the growing Bell helicopter portfolio.

HELICOPTERS MAGAZINE P.O. Box 530 105 Donly Drive South Simcoe ON N3Y 4N5 Tel.: 519-428-3471 Fax: 519-429-3094

The new Bell 525 Relentless will be a good option for a variety of missions. (Photo courtesy of Bell Helicopter)

“We are proud to have achieved this milestone,” noted Matt Hasik, executive vice-president of commercial programs at Bell Helicopter. “We have diligently executed our schedule to design, develop, build and test the aircraft, and look forward to the next phase of flight testing as we work towards certification. The marketplace has been awaiting the transformational capabilities of the Bell 525 and we continue to see growing customer demand from around the globe for this aircraft.”

In many ways, the 525 is an aircraft designed by operators for operators. Input from a customer advisory panel was crucial to the aircraft’s overall design, as requirements for operational safety, payload and range, cabin comfort and configuration and reliability were all built into the design.

One of the unique characteristics of the Bell 525 is the ability to perform CAT-A takeoffs and landings, to and from a helipad at maximum gross weight. Even in the event that one of the two engines fails, the Bell 525 provides sufficient power to maintain occupant safety while lifting off with a single operational engine.

“The first flight test started with taxi testing and maneuvers and then went into an initial hover, performing various hover maneuvers and then tested low speed handling qualities with winds gusting to 20 knots,” said Jeff Greenwood, senior flight test pilot at Bell Helicopter.

Bell Helicopter currently has more than 60 helicopters reserved under letters of intent for the 525. The aircraft can be configured to suit a number of missions, including corporate work, oil and gas, parapublic, aerial firefighting and HEMs.

A Green Perspective

Airbus Helicopters has introduced a new aircraft it hopes will help make its mark as an environmentally conscious option for operators.

The new Bluecopter demonstator made its debut in July at Airbus’ Donauwörth facility in Germany after some 28 flight hours of testing. The new light medium twin incorporates transversal technologies that can be applied across the Airbus product line.

“By bringing together the best of our company’s innovation, we are opening the way for a new generation of rotorcraft that will have lower noise levels, burn less fuel and are more efficient to operate,” explained Marius Bebesel, program manager of research and innovation – the point person behind the Bluecopter demonstrator. “With Bluecopter, we have met our goals of decreasing fuel consumption by as much as 40 per cent, significantly

The innovative Bluecopter demonstrator offers a bold new look of the helicopter of tomorrow. (Photo courtesy of Airbus Helicopters)

reducing C02 emissions, and lowering noise to approximately 10 decibel effective perceived noise (EPNdB) below ICAO noise certification limits, while maximizing payload and the passenger comfort.”

The new aircraft sports many technological innovations including Airbus’ signature Fenestron, with additional performance improvements from the shrouded tail rotor achieved through optimized blade and stator designs. The acoustic liner integrated in the

Fenestron’s shroud and the active rudder on the tail fin contributes as well to the reduced noise footprint of the Bluecopter.

The Bluecopter development was accomplished in a timeframe of a short-term skunk works project, largely covered by company self-funding. Certain technologies integrated into the demonstrator were developed in the framework of Europe’s Clean Sky joint technology initiative and Germany’s LuFo-IV research program.

Toll Free: 1-888-599-2228 Website: www.helicoptersmagazine.com

EDITOR MATT NICHOLLS email: mnicholls@annexweb.com 416-725-5637

MEDIA DESIGNER BROOKE SHAW

CONTRIBUTING WRITERS

RICK ADAMS, DAVID CARR, BRIAN DUNN, PAUL DIXON, WALTER HENEGHAN, FRED JONES, JAMES MARASA, CARROLL MCCORMICK, COREY TAYLOR

NATIONAL ADVERTISING MANAGER MENA MIU email: mmiu@annexweb.com 905-713-4351

ACCOUNT MANAGER KORY PEARN email: kpearn@annexweb.com 519-902-8574

ACCOUNT COORDINATOR

STEPHANIE DEFIELDS email: sdefields@annexweb.com 1-888-599-2228 ext. 257

GROUP PUBLISHER MARTIN MCANULTY email: mmcanulty@annexweb.com

DIRECTOR OF SOUL/COO SUE FREDERICKS RETURN UNDELIVERABLE CANADIAN ADDRESSES TO ANNEX PUBLISHING & PRINTING INC., P.O. BOX 530, SIMCOE, ON N3Y 4N5 CANADA. email: subscribe@helicoptersmagazine.com

Published five times a year by Annex Publishing & Printing Inc.

Printed in Canada ISSN 0227-3161

CIRCULATION email: subscribe@helicoptersmagazine.com Tel: 1-450-458-0461 ext 208 Fax: 877-624-1940 Mail: P.O. Box 530 Simcoe, ON N3Y 4N5

SUBSCRIPTION RATES

Occasionally, Helicopters magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above. No part of the editorial content of this publication may be reprinted without the publisher’s written permission ©2015 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Helicopters Magazine is a corporate member of the

Helicopters Magazine is an associate member of the following Canadian aviation associations:

COLUMN

Having recently returned from the U.K., I was struck by a number of interesting observations – the Guinness tastes better, there are video cameras EVERYWHERE and there is a pervasive presence of “safety” equipment. Safety vests are worn by virtually every worker on a job site, by bicyclists and motorcyclists alike and many workplaces have visible elements of safety promotion. Now, I can’t say for certain that the U.K. is a safer place to work than Canada, but it is striking for sure.

One other thing I learned from my visit is that the Royal Air Force (RAF) has adopted International Civil Aviation Organization (ICAO) compliant Safety Management Systems (SMS) into its operations. The decision to follow this path stems largely from the fallout from a fatal accident of a Nimrod jet in Afghanistan in September 2006, which killed all 14 servicemen on board. The accident was followed by a number of investigations, coroners’ inquests and ultimately by a formal inquiry by Sir Charles Haddon-Cave, called “The Nimrod Review.” (I might note that both the board of inquiry and the review are worthwhile reads).

The review provided a bleak picture of organizational dysfunction within the RAF and among several of its suppliers and expressed grave concerns with the means by which risk was being assessed and managed, especially within the Nimrod fleet. The review eventually led to the U.K. government unreservedly accepting responsibility for failing to exercise an appropriate duty of care towards the dead servicemen and

Taking the Lead

If the RAF Can Do It, Why Can’t the Rest of Us?

(SCs) and Certification. The MAA provides the structure that identifies risk, establishes a mechanism for safety assurance and clearly delegates responsibility for every operation to a defined duty holder. From my observations, all the elements of an SMS – safety policy, risk management, safety assurance and safety promotion – are well-established in the decision-making processes within the RAF.

It was interesting to listen to the language of these career air force officers and NCOs – the discussions around risk, risk management and risk assessments. In addition, they have adopted many of the processes of the oil and gas producing community (OGP) including more advanced tools such as BowTie and Just Culture language. There appears to be a significant level of “buy in,” into this new safety paradigm, understandable given the intense scrutiny the air force underwent after the Nimrod review.

The key element, as well, that is front and centre, is the concept of “duty of care” of the senior leadership towards the servicemen involved in the activity in question. There is a real consciousness around which leader is identified as the “duty holder” regarding the assessed risk and whether all has been done to reduce risk to a level as low as reasonably practical (ALARP). This being completed under the ever-present possibility that the operation which is being risk managed may not necessarily eliminate all risk of injury or death, but that the risk to life is clearly identified and owned. Some of the risk is explicitly owned and signed off by the chief of the air staff.

Having clearly defined processes lets every player in the system know their duties and responsibilities. ‘‘ ’’

led to a wholesale shift in philosophy regarding risk management, duty of care and safety assurance.

The Military Aviation Authority (MAA), a parallel body to the Civil Aviation Authority (CAA) was also created. As part of the Defense Safety Authority (DSA), the MAA, as an independent organization, is responsible for the regulation, surveillance, inspection and assurance of the defense air operating and technical domains. It ensures the safe design and use of military air systems. The MAA aims to bring a new approach to Air Safety Governance through the use of clearly defined Duty Holders (DHs), a focus on Risk to Life and a new regime for Safety Cases

So this begs the question: Why such resistance elsewhere? If a major government agency like the RAF and the U.K. Ministry of Defense can successfully implement an ICAO-style SMS, why cannot other countries? While I acknowledge there is a certain over-burden associated with establishing and fostering safety management systems, there are also significant paybacks. Having clearly defined processes lets every player in the system know their duties and responsibilities. The same goes with goal setting, assurance practices and promoting safe activities. The RAF was motivated as a result of a terrible accident and from an intense round of scrutiny in its aftermath. But there are many levels now that are motivated to understand the “new system” and to move forward, to embrace the new paradigm and to employ SMS as a best practice within one of the world’s most storied organizations.

Walter Heneghan is the vice-president for Health, Safety and Environmental Protection with the Summit Air Group of Companies, Ledcor Resources and Transportation, based in Edmonton and throughout Western Canada.

PAUL DIXON

took a day off from the continuing hunt for Amazon’s secret Canadian drone testing facility for a reality check. That would be the opportunity to attend a recent Vancouver Entrepreneur Forum on the subject of UAVs

The aprés-work event attracted a wide range of Vancouver’s younger business community to hear about things that fly from a diverse panel already well-versed in the business. The meet and greet was a great read on the crowd and introduced me to a whole new segment that may or may not play a large role in taking UAVs forward.

These were the young entrepreneurs and recent MBA grads and erstwhile venture capitalists – people of the generation that is still on the rise, looking for the next big thing. They’re not the technical minds, they’re the business minds and the intriguing thing is that these young minds are going to see uses for UAVs that the experienced or “mature” isn’t willing or able to consider. It was a meeting of the minds – entrepreneurs, operators and potential investors.

The evening’s panel discussion was moderated by Paul Bennett of Aerobotika, a company that offers a wide range of services for those looking to get further into the business applications of UAVs. Members of the panel included the director of marketing for a major commercial real estate firm who uses UAVs in developing new marketing programs for both urban and rural properties; a lawyer with a major national law firm who handles the unique legal challenges and

The UAV Frontier Applications, forecasts for future drone implementation

perspective of those who are doing it now and not simply as pie-inthe-sky optimists.

Bennett set the table for the panel with the statement that Canada is a “drone powerhouse” and there are hundreds of potential startups on the verge, which seemed to surprise many in the audience. Adding to the audience’s surprise was having Transport Canada (TC) in attendance for the Q&A session and hearing that “yes,” Canada really is out in front, at least for now. Leveraging the last few years of UAV development to keep Canada out front is going to take continued active participation from TC, but it also requires a reality check on the part of the end user and a big push on the technology front before UAVs are truly ready for prime time. These are the major roadblocks as seen by the panel members that need to be overcome:

• People don’t grasp the level of technology. These are not toys that can be flown right out of the box. Sensors need to be calibrated and systems need to be maintained to a high standard;

• People who don’t know the rules governing the operation of UAVs and make no effort to educate themselves;

• Operations limited by battery capacity. Battery technology has to increase by a huge factor before UAVs move out of the backyard;

• Before UAVs can move out of the backyard and beyond line-ofsight operations, sense and avoid technology has to be developed that works at this level. Like your average teenager, you need a high level of confidence that your UAV will come home when it is supposed to and not get into trouble when it’s out there on its own.

It was a meeting of the minds – entrepreneurs, operators and potential investors. ‘‘ ’’

issues associated with the emerging world of UAVs and robotics; a university geography professor who uses UAVs as part of his study of the uses of remote sensing as a tool for mapping and monitoring a wide range of ecosystems around the world; and a local post-secondary institution that has added a UAV program into its media production department with the aim of exposing the potential of UAVs to students in as many disciplines as possible – marketing, 3D modeling, inspections, geo-mapping, forestry, wildlife observation and as many uses as students can come up with. In a nutshell, it was a group of people who can talk about the future uses of UAVs from the

If you decide that UAVs have a place in your future or your business’ future, then you are going to have to grapple with trying to figure out just what it is you want to do, or more importantly, what it is that using the UAV will do for you that can’t be done any other way. Then you’re going to have to figure out if this is something you can do yourself – owning and operating your UAV or is it going to be more expedient to contract with a dedicated UAV operator to provide the services as you need them?

I left the forum after the panel discussion concluded as the noshing and sloshing portion of the evening ramped up. The room was buzzing and the excitement was palpable. It might not be the Wild West era of UAV development, but there’s still a lot of dust in the air. Giddy up!

Paul Dixon is a freelance writer and photojournalist living in Vancouver.

COREY TAYLOR

The more we do things, the easier they become and, more importantly, the more normal they seem. Pushing the limits has been something pilots have struggled with since 1903, and none are immune.

A few years ago, I departed Victoria airport and was proceeding northwards through Sansum Narrows in what were obviously degrading weather conditions. Visibility was dropping, the ceiling lowered and rain was swirling around the edges of the front bubble while leaving those streams of what looks like viscous water on the side windows, which can have an almost hypnotic effect. I could feel my grip on the cyclic getting tighter and started to slump down in my seat in an attempt to see under the clouds that I was skimming.

This is the point where the internal conversation usually begins, which can be a source of some embarrassment (and elevated stress levels amongst aircraft occupants) when an overly sensitive intercom shares that mental struggle with the passengers. This is probably when I should have turned around, as I still had enough visibility to make a turn with reference to a shoreline. But I thought if I could just make it a mile or two further, the weather would improve and I would be past (under) the massive powerlines that feed electricity to the Island from the mainland.

The more we put ourselves into situations approaching overload,

Raising the Training Bar

The Importance of Low Visibility, Scenario-Based Decision-Making

my brain had been so completely fooled when the driveshaft sheared that I thought my drink was going to fall over and spill. As I reflected on that flight and the physical reactions my subconscious brain was causing in my body, it was apparent that the realism of this experience was as close to real life as you can get without actually being in an aircraft, in a situation one should never be in. And all for under $200,000 delivered, with an operating cost under $100 per hour.

FTD-based low visibility and scenario-based decision-making training should be mandatory in Canada with what is available in terms of training aids and their associated cost. I’m sure somebody can nitpick (and will) the details about motion and fidelity to a given type of aircraft, but the counter point to that is “what do we do now”?

FTD-based low visibility and scenario-based decisionmaking training should be mandatory in Canada.

the more likely it is we will be faced with additional pressures we’re no longer able to deal with. Such was the case on this day as suddenly, at an altitude of around 200 feet, airspeed of 40 kts and with visibility under half a mile, the tail rotor driveshaft sheared. The sense of being almost ejected from the pilot’s seat was incredible, but I have to give myself credit for my quick reaction in letting go of the collective and diving across the centre console to grab the drink I had placed on the co-pilot side floor before it spilled its contents.

Yes, I was in a simulator, or more specifically a “Flight Training Device” or FTD. There was no motion component to this device yet

Currently low visibility training, coupled with pilot decision making is mandatory for commercial pilots in Canada, especially when a company wishes to exercise the rights of the Ops Spec for flight down to one half mile. We go out in a helicopter on what is often a blue sky day, ask the pilot to estimate half a mile and then practise doing turns to get out of bad weather – all while pretending the overwhelming peripheral cues don’t exist. This is not realistic and, I daresay, almost useless. In comparison to what low-cost FTDs can bring to the table, the required inflight training is like learning to swim from the deck of the pool. Since low-cost technology is available that is almost sure to help prevent accidents by helping pilots know when to call it a day, it seems obvious this type of training should be required in Canada. At the very least, this type of training would be a far better substitute than training in a classroom and an aircraft in good weather, for those with access to such devices. Unfortunately, this is not the case in our current operating environment. An operator still has to conduct training in classroom and an aircraft in order to comply with Canadian laws, regardless of how much superior training they conduct. This means an operator pays twice for the same training, with the more expensive portion being the one of little comparable benefit. Operators struggling to make ends meet can’t afford to pay twice. So, once again safety suffers in favour of compliance.

Corey Taylor is vice-president of Global Business and Product Development for Great Slave Helicopters.

RICK ADAMS

Helicopters are not the main event at the Paris Airshow; the annual Airbus-Boeing commercial aircraft derby garners the most attention.

Nonetheless, the rotary sector generated plenty of interesting news and speculation this year from major manufacturers and niche players alike.

The dominant discussion was United Technologies Corporation’s intent to sell or spin off Sikorsky Aircraft by the end of this year. The deal went final as Helicopers was going to press, as Lockheed Martin stepped up to the plate to the tune of $9 billion.

UTC and its predecessors have owned the iconic Igor Sikorsky’s legacy for 85 years, but CEO Greg Hayes, who took over the US$65billion conglomerate last November after the abrupt resignation of Louis Chenevert, said the $7.5 billion helicopter operation no longer “fits” with their portfolio of Pratt & Whitney engines, Otis elevators, Carrier air conditioners and Kidde fire extinguishers.

Sikorsky, of course, is strong in the large-cabin sector, (S-76, S-92) favoured by the offshore oil and gas industry, which president-since-April Bob Leduc says accounts for 80 per cent of its commercial sales. With the recent 40 per cent drop in oil prices and reduced exploration, many customers are deferring deliveries, awaiting more efficient future models. Leduc said a new mediumlift model is planned “around 2020,” but that of course will be determined by the new owners.

After Sikorsky lost in April to Airbus Helicopters on a contract from

Paris Potpourri

The 51st Paris Air Show Featured Business Buzz, Clever Concepts

A pair of Bell 505 Jet Ranger X prototypes are test flying, and the first certification is expected to be via Transport Canada.

The first flight of the clean-sheet Bell Relentless 525 took place July 1, delayed by supply chain issues and the regulatory hurdles for fly-by-wire controls. The entry into service target is now 2017. In Paris, Bell announced a letter of intent from Milestone Aviation Group for 20 of the super-medium 525 models.

Bell also has an agreement with the Urals Civil Aviation Plant in Yekaterinburg, Russia to assemble 407GXP light single-engine helicopters. This is the first time the Fort Worth, Texas-based company has handed over assembly to a foreign partner. The first three aircraft are expected to be ready before the end of the year.

Airbus is looking to eventually replace the Super Puma, nagged by accidents and rotor shaft problems, with its new “X6” twin-engine heavy-lift concept.

The five-blade main rotor design reflects the recently launched H160 medium helicopter (maiden flight June 13), but the X6 will incorporate fly-by-wire control and a full de-icing system. Fuel burn and overall operating costs are expected to be 20-25 per cent less than current-generation aircraft. CEO Guillaume Faury told reporters that first flight could be in the “early 2020s” and service entry within seven to eight years.

Toronto-headquartered Vector Aerospace, Airbus, and Rockwell Collins also announced an agreement in Paris to jointly develop Pro Line Fusion integrated avionics upgrades for Airbus platforms. Missionspecific operational profiles will feature offshore platform approaches, hover in place, and extended searchand-rescue patterns.

Airbus is looking to eventually replace the Super Puma, nagged by accidents and rotor shaft problems.

Poland for 70 multi-purpose military choppers, the Stratford, Conn. OEM announced job cuts of 1,400. They also operate Schweizer and Keystone Helicopter completions.

The Sikorsky speculation spilled over to Bell Helicopter, which in April had announced a workforce reduction of 1,100 worldwide, including 300 more positions at Mirabel in Quebec (which is down to about 1,200 staff, roughly 40 per cent less than a year earlier).

But Textron chief executive Scott Donnelly said, “We love our helicopter business. It’s a profitable business. It’s a great technology business. We’re investing a lot.”

Thales is eyeing civil helicopter markets (law enforcement, emergency medical), as well as business jets and military aircraft, for a simplified helmet-mounted display system called TopMax.

The HMD shows basic flight info, navigation data, and engine parameters, and is claimed to be compatible with night vision goggles.

Finally, former Sony chief financial officer Robert Wiesenthal is leading start-up company Blade, which hopes to be the “Uber of helicopters,” providing on-demand shuttle services ordered through an online app. Last I knew, that was called a charter service.

Rick Adams is chief perspectives officer of AeroPerspectives, an aviation communications consultancy based in the south of France, and is editor of ICAO Journal. He has been writing about technology and training for 30 years.

COVER STORY

Exploring the Quest for More

0ur Top 20 Under 40 leaders

BY MATT NICHOLLS

So what exactly makes a great corporate leader? Where does the drive to transform an organization and help it reach new levels of productivity, efficiency and profitability come from?

Truly great leaders have a unique ability to handle multiple projects with skill, determination and an inherent grace under pressure that most people do not possess. Innovative and creative, they have a rare ability to make those around them more efficient, productive and motivated.

It’s a rare combination indeed, and once an organization unearths such talent, it usually works hard to ensure superstars have room to develop, grow and flourish. In Wings and Helicopters third annual Top 20 Under 40 report, we highlight some of these top achievers – men and women who have transformed their organizations in maintenance, business operations, flight operations and more.

The 20 individuals featured here were carefully selected by our editorial team following an online contest that ran earlier this spring. Candidates were nominated by colleagues based on their influence to drive change, leadership skills, commitment to clients/colleagues, and their forward thinking towards the industry as a whole.

Featured alphabetically, our Top 20 Under 40 achievers represent the resourcefulness, commitment and dedication organizations are craving in today’s marketplace. On behalf of the nominees, candidates and winners, we thank you for your support and salute the achievements of all who participated.

Since graduating from Georgian College’s aviation management diploma program in 2003, Josh has been a friend, colleague, and mentor to many aviation professionals for more than a decade. From humble beginnings, Josh assisted the Canadian Aviation Expo at the Oshawa Municipal Airport from 2001-2006, and later joined the operations staff at CYLS for his co-op and extended full-time employment. He furthered his aviation experience in 2005 by joining the executive FBO ramp at Skyservice CYYZ, always carrying with him a positive attitude and the aspiration for continuous personal growth.

TITLE: MANAGER, FLIGHT

COORDINATION, CHARTER AIR TRANSPORTATION SERVICES (CATS)

LOCATION: MISSISSAUGA, ONT.

Josh Calder, 34, has certainly made the most of his opportunities in his developing aviation career.

The work/life balance of maintaining a professional career and being an exemplary father – while completing his bachelor of science in technical management with Embry-Riddle Aeronautical University – is a testament to his commitment in providing a fully supported knowledge base to every aspect of his work.

This enduring pursuit led him to become the successful flight coordination manager within two different organizations over the past

decade. It is here that Josh provided leadership and managerial oversight to his team members and flight personnel alike.

Josh’s experience was instrumental when he joined the start-up team at Charter Air Transportation Services Inc. (CATS) in Toronto as the manager of flight coordination. He structured and set up the complete flight coordination department – and continues to provide leadership and oversight to the rapidly growing operation.

NAME: PAUL CAMPBELL TITLE: DIRECTOR, ENGINEERING SERVICES, AVMAX GROUP OF COMPANIES LOCATION: CALGARY, ALTA.

Paul Campbell, P.L. (Eng.), 37, was recruited to transform the engineering department at the fast-growing Avmax Group of Companies in 2011 and that’s exactly what he did.

First on the agenda: a Transport Canada Design Approval Organization (DAO) to reduce project cycle times by eliminating the need for external delegates. He then focused the department for growth in modifications, repairs and part design approvals to support the large fleet of regional aircraft owned or managed by Avmax, and at the same time, reached out to support other local operators with their engineering projects.

Paul’s transformative efforts extend beyond Avmax, touching grassroot initiatives. He is active in the community, having recently completed a long-term involvement with the Air Cadets. As a teen, he earned his private pilot’s licence as an air cadet and is passionate about giving back to a program that helped him gain precious leadership skills.

Paul’s philosophy of working to develop young leaders also extends to his fast-growing engineering team at Avmax where he has hired new and recent graduates to engineering roles. A proud graduate of the Southern Alberta Institute of Technology Aeronautical Engineering Technology Program, Paul has 15 years of modification and repair design experience in a variety of key areas. His combination of experience, skill and grass roots involvement perfectly illustrates what this award is all about.

Curtis Nadon (left), Josh Calder (below left) and Paul Campbell (below right) are some of our Top 20 under 40 winners.

NAME: ROBERT CARNEY

TITLE: CHIEF FLIGHT INSTRUCTOR, BRAMPTON FLIGHT CENTRE

LOCATION: CALEDON, ONT.

Rob Carney, 37, has demonstrated dedication in providing outstanding flight training for emerging pilots for the past 15 years.

Rob is the chief flight instructor at the Brampton Flight Centre. Through his tenure at BFC, Rob has actively worked towards the development of professional pilot training. He has played an integral part in the implementation of the BFC IATPL program and the BFC-Sheridan College collaborative degree program.

Rob strives to achieve a level of training that goes above and beyond the expected standard. He has been involved in the training of four Webster Memorial Trophy finalists, three of whom achieved first place and one who achieved runner up. As a Class 1 instructor and flight examiner, Rob has transferred knowledge to a wide variety of pilots now in various sectors throughout the aviation industry.

Rob is a graduate of the Humber College Flight and Aviation Management program and he recently completed his graduate in Aviation Management from of University of Newcastle. He is currently completing his master’s degree in aviation where he is specializing in human factors and organizational safety. In August, Rob will join Seneca College as an aviation professor.

NAME: MALLORY DELUCE

TITLE: PILOT, PORTER AIRLINES

LOCATION: TORONTO, ONT.

From a very young age, Mallory Deluce, 27, has had a keen interest in aviation.

Mallory's passion for aviation has deep roots that run within the family, including her uncle, Robert Deluce. Robert is thePresident and CEO of Porter Airlines. Her father and brother are also commercial pilots.

At 22, Mallory started working on obtaining her pilot’s license after graduating from university. She obtained her private license at St. Thomas Flight Centre in St. Thomas, Ont. For her multi-engine and instrument ratings, she went to the

Professional Flight Centre at Boundary Bay Airport, just south of Vancouver, then came back to St. Thomas Flight Centre to acquire her commercial license and build flying time.

In June 2013, Mallory was hired by Air Georgian as a first officer. Mallory’s Air Georgian training began with ground school where she learned about the company operation and about the Beechcraft 1900. After ground school, she trained on a Beech 1900 simulator.

When not soaring in the clouds, Mallory can often be found on the ice – playing hockey. She is an accomplished hockey player and has excelled on a number of top levels. She is also a strong advocate for grass roots development, having done numerous media interviews talking about her experiences both as a pilot and a hockey player.

Mallory has recently accepted a pilot position with Porter Airlines and will continue her career journey while continuing to be a positive advocate for the industry at all levels.

NAME: MATHIEU DEMERS

TITLE:

VICE-PRESIDENT/GENERAL MANAGER, AVIANOR

INC.

LOCATION: MIRABEL, QUE.

Graduating from Ecole Polytechnique of Montreal as a mechanical engineer in May 2005, Mathieu Demers, 31, joined Pratt & Whitney Canada as a quality engineer on the PW300 engine certification program where he developed expertise in statistical and manufacturing processes.

Mathieu continued his career as an engineer in 3D design and modelling at the automotive group of Dassault Systems in Montreal. Moving back to aerospace, he was then selected to lead a new design program for the cabin interiors of the Falcon 7X and 900 business aircraft from Dassault Aviation.

Mathieu joined Avianor in July 2010 as a project engineer and quickly rose to lead the growing engineering department as well as working more closely with company ownership. He has taken on the positions of engineering director, project management director and special projects director of manufacturing operations and maintenance.

In June 2014, he was promoted to vicepresident and general manager, a position created by the owners to allow them more time to focus on business development.

Since that time, he has surrounded himself with a young team of dynamic managers to support the growth of the company and its ambitious goals.

NAME: JAY DILLEY TITLE: PRESIDENT, HAWKAIR LOCATION: TERRACE, B.C.

As a truly authentic and inspiring leader, Jay Dilley, 36, continually pushes the boundaries of success.

In 2013, Jay was named president of Hawkair. He is a member of the Young President’s Organization, holds the Chartered Financial Analyst Designation, a master of science in management, honours bachelor of commerce and a diploma in aviation studies.

An ardent believer of continuing professional development, Jay has earned certificates in Safety Management, Integrated Management Systems, Auditing, ISO 9001 Lead Auditor and Financial Modelling. He has also taught courses for Aurora College and Athabasca University.

A board member of the Northern Air Transport Association since 2010, Jay is a committed member of the aviation community. Prior to Hawkair, Jay was vice-president of business services for Summit Air, and had spent eight years in Yellowknife where, among other career highlights, he integrated two charter companies ahead of schedule.

Most recently, he launched the airline industry’s first Women in Leadership Executive Development Program to create a culture of awareness, inclusiveness and opportunity for women in aviation.

Through his commitment to transparency and communications, Jay is consciously raising the leadership of those around him – he never tires of making those around him better.

NAME: SUNDEEP DHUNNA

TITLE:

SENIOR SOFTWARE ENGINEER, AVERSAN INC.

LOCATION: MISSISSAUGA, ONT.

Dedicated, meticulous, accomplished, invaluable. All of these words can be used to describe Sundeep Dhunna, P. Eng., 34, a talented senior engineer at Aversan. These words also describe the ideal

aerospace engineer, and in Sundeep’s case, he certainly lives up to the “ideal” part of the description.

Co-workers often get excited when working with Sundeep on a project and for good reason. They describe him as a type “A” personality who is passionate, innovative, and motivated to do whatever it takes to see a project through to its end, always doing it right.

Sundeep is also known for adhering to, and advocating for, the needs of his team, having an open ear, and setting a good example for his junior staff. Junior engineers often refer to Sundeep as “special forces” – the person you bring in to solve a unique issue in the most efficient and effective way possible.

Sundeep started at Aversan 10 years ago as a fledgling junior engineer, eager to show off his talent and potential. His drive and motivation to produce quality work allowed him to advance his career at an exceptional rate, rising quickly to a senior software engineer. In his time with Aversan, Sundeep has achieved a number of significant accomplishments such as designing the COMAC C919 operational software for the cockpit control system – a first for Aversan at the time.

Dependable and adaptable, Sundeep is the kind of employee you can always count on to get the job done right.

NAME: CHRISTA GLOVER

TITLE: CHIEF PILOT, UNIVERSAL HELICOPTERS

LOCATION: GOOSE BAY, N.L.

Christa Glover, 31, is the chief pilot of Universal Helicopters Newfoundland and Labrador LP, owned and operated by the Nunatsiavut Group of Companies. UHNL is one of Canada’s oldest helicopter companies operating a fleet of 19 light and intermediate helicopters in some of Canada’s most challenging environments.

Christa grew up in a small Coastal Labrador town (Pinsents Arm) of 75 people and had a passion for aviation since a very young age. She started her career 10 years ago with Universal Helicopters and continues to pursue her love for aviation with the company, earning respect and a strong working relationship with both her colleagues at UHNL and its clients.

Her flying career has taken her to all parts of Newfoundland and Labrador and north of 60, into Canada’s High Arctic. She has also honed her skills doing her time in the bush,

conducting long line drill moves, wildlife capture and forest fire suppression.

Now, as chief pilot and a senior aviation manager – and being an aboriginal as well –she has become a role model for others in the industry and those contemplating an aviation career. At a young age and being the only female pilot in the company, this environment may be intimidating to some, but Christa is first to acknowledge that she has an experienced support team of aviation professionals, maintenance and flight crew who support her 100 per cent.

NAME: CAREL ISSID

TITLE: LEGAL COUNSEL, ELEMENT AVIATION FINANCE

LOCATION: MONTREAL, QUE.

A determined, motivated professional with a deep thirst for knowledge and seeking the truth. That’s a great way to describe Carel Issid, 35, legal counsel for the

Canada’s leading national aerospace event

WELCOMES

WORLD THE

November 17-18, 2015

Shaw Centre Ottawa, Canada

aviation finance division of Element Financial Corporation (EFC).

Carel possesses outstanding interpersonal skills and has a great team ethic, which helps her handle multiple tasks under pressure, in a context of tight deadlines and constantly shifting priorities. As she will attest to, a lawyer or legal counsel must, in addition to being an advisor who provides legal expertise, take on a strategic role and excel in developing pragmatic solutions. Carel thrives in her current work environment where entrepreneurial spirit, originality and audacity are encouraged and supported by the company’s senior leadership team.

Carel has a multitude of roles at EFC including:

• Acting as main counsel with respect to aircraft finance (commercial loans and equipment leasing agreements, as well as the purchase and sale of large-ticket equipment, syndications and portfolio acquisitions).

• Leading and managing a variety of fixed wing and rotary wing commercial and business aviation transactions originated by the Element Aviation Finance vertical.

• Identifying potential risk areas arising from the complex and diverse financing arrangements (which often involve cross-border components) extended by the company and issue recommendations in order to minimize the same.

It’s a large portfolio to be sure, but Carel still finds room to donate her time to speak at various events including the Equipment Leasing and Finance Association’s Legal Forum, and to appear as a panellist in the “Winter is Coming: Advanced Roundtable on Cross-Border and Canadian Finance Issues.”

Carel was a finalist in the category “Lawyer of the Year” (in house practice), Young Bar Association of Montreal “Leaders of Tomorrow” Gala in 2012 and continues to generate accolades from clients and staff for her dedication, hard work and innovation.

NAME: BHARTVEER JASWAL

TITLE: AIRCRAFT MAINTENANCE

TECHNICIAN, AVMAX GROUP OF COMPANIES

LOCATION: RICHMOND, B.C.

For 33-year-old Bhartveer Jaswal, having a career in aviation is the fulfillment of a lifelong dream.

Bhartveer started his career with the Langley Museum of Flight and worked his way up into a variety of key supervisory and management roles in aircraft maintenance. At

a very early age, he given the responsibility to set up AMO for an airline. Over the past few years, he has improved and streamlined maintenance processes for several companies.

A self-learner who motivates and inspires others in being the best they can be in the industry, Bhartveer takes initiative in carrying out maintenance tasks efficiently and with the highest standards of quality.

Bhartveer has honed his craft by gaining experience in aircraft maintenance on a number of aircraft including the Cessna 172, King Air, Beech 1900s, Dash 8 and Q400. With Avmax Aviation Services in Vancouver, he caters to the maintenance needs of various customers with their aircraft maintenance requirements.

Bhartveer’s dedicated work habits and commitment to excellence make him a key part of the Avmax team – and a worthy recipient for this honour.

NAME: DIANA KELLY

TITLE: MANAGER, ACC OPERATIONS, WINNIPEG INFORMATION REGION, NAV CANADA

LOCATION: WINNIPEG, MAN.

At age 36, Diana Kelly has risen to a position of major responsibility within NAV CANADA.

As manager of ACC Operations at the Winnipeg Flight Information Region, Diana works closely with customers and bargaining agents, and leads nearly 200 professionals that include shift managers, air traffic controllers, and other operational specialists who provide services in Manitoba, Saskatchewan and northwestern Ontario.

Diana was appointed to her current role in April 2014. She is one of the first women (and among the youngest) ever to hold this leadership position at NAV CANADA, leading the way for other women in a traditionally maledominated field.

Diana’s outstanding leadership abilities, work ethic and initiative come shining through in a number of ways:

• As manager of ATC Operational Requirements from 2012-14, she led the transition from flight-data strips to a paperless environment within high-level specialties and at Flight Service Stations across the region.

• Her team developed highly successful “safety bear pit” sessions that bring together frontline operational staff and pilots to discuss safety issues and to break down barriers – a collaborative approach

that has been identified as a national best practice.

• She is an active member of NAV CANADA’s national Performance Based Navigation (PBN) Working Group, overseeing implementation of more efficient air routes and ascent profiles for the company’s airline customers across the country.

Diana studied education at the University of Alberta (with a minor in German), before becoming a terminal controller and later enroute controller at NAV CANADA’s Winnipeg Area Control Centre. In 2008, she became a unit procedures specialist, and soon after was named shift manager – the youngest at the time and the first female shift manager at the ACC. She has continued her training to complement her various ATC roles and hone her management skills at NAV CANADA.

Diana is known and respected for her hard work, personal initiative, drive and strong communication skills. She is a next-generation leader at NAV CANADA who will shape the company’s future in the years to come.

NAME: STAN KULIAVAS

TITLE: VICE PRESIDENT, SALES & BUSINESS DEVELOPMENT, LEVAERO AVIATION LOCATION: TORONTO, ONT.

Stan Kuliavas, 35, has always been passionate about aviation . . . so much so, in fact, that he was legally able to fly airplanes before he was legally able to drive a car.

Stan is the vice president of sales and business development for Levaero Aviation in Toronto, overseeing the planning and execution of the growth strategy of the company.

A licensed pilot and graduate of EmbryRiddle Aeronautical University, Stan has nearly a decade of aviation experience, and OEM product involvement. He most recently spent six years as a board member of the St. Michael’s Young Leaders group, raising funds and awareness for St. Michael’s Hospital in Toronto, and currently volunteers with various other charitable organizations.

Stan has also sponsored and supported various grassroots efforts such as Careers in Aviation Expos throughout Canada to help inspire both students and adults alike looking to enter the field of aviation. He has also helped with the annual Girls Fly Too event recognizing women in aviation and inspiring girls and women of all ages to explore the various fields of the aviation industry.

In addition, Stan has taken part in a

relief mission with colleague John Tory, president and CEO of Private Air, to Attawapiskat, First Nation when the reserve was declared a state of emergency in December 2011 for poor living conditions. They co-led a relief trip to Attawapiskat with the help of Global Medic and flew a PC-12 up to the reserve to deliver 100 children’s winter coats and emergency relief.

Stan was one of the driving forces behind the recent rebranding of Pilatus Centre Canada into Levaero Aviation, a company with almost 20 years experience in the aviation industry. Stan has always been passionate about the aviation industry and continues to find ways to discover ways to innovate, lead and find new strategic ways to grow both Levaero Aviation and help develop and grow grass routes aviation initiatives.

NAME: JESSE MEYER TITLE: ASSOCIATE VICE PRESIDENT, COMMERCIAL, FORT MCMURRAY AIRPORT AUTHORITY

LOCATION: FORT MCMURRAY, ALTA.

Since joining the Fort McMurray Airport Authority in 2012, Jesse Meyer, 30, led the rebranding of the airport, significantly expanded the food and retail options in the new terminal, and lobbied airlines for additional direct air service to Fort McMurray, amongst other accomplishments.

Jesse is the associate vice-president, commercial for YMM, working in a dynamic, creative and fast-paced environment at Canada’s fastest growing airport. He has a broad senior portfolio including promoting the retention and growth of air service, business development, and corporate communications. This calls for the ability to build strong relationships with airline and commercial partners, local and provincial tourism organizations and business stakeholders. It’s an accomplishment that Jesse has achieved with tremendous success.

Jesse has also become involved in tourism in the Fort McMurray region. He sits on the Board of the Directors for Fort McMurray Tourism, and is involved with media, communications, and promotions for the Western Canada Summer Games 2015 Wood Buffalo. He also sits on the Marketing & Communications Committee of Airports Council International – North America (ACINA).

Jesse holds a master’s of business administration in airport Mmanagement from EmbryRiddle Aeronautical University, as well as a bachelor of commerce in marketing from the

University of Alberta. Before joining the Fort McMurray Airport Authority, he held positions at the Vancouver Airport Authority, Embry-Riddle Aeronautical University, and Vancouver General Hospital.

NAME: HEATHER MCGONIGAL

TITLE: DIRECTOR OF FLIGHT OPERATIONS, FIXED/ROTARY WING, TRANSWEST AIR

LOCATION: SASKATOON, SASK.

At 38, Heather McGonigal is Transwest Air’s director of flight operations, a training captain, and SAAB 340 line captain. Heather has always had a strong interest in aviation. In her high school years, her attainment of her PPL was financially assisted by a scholarship that she was awarded by the Ninety-Nines Inc. and also by working as a swimming pool

Be Prepared for Take Off

Upgrade your Commercial Pilot License and Group 1 Instrument Rating credential to become a Commercial Airline Flight Operations First Officer

It’s time to elevate your career to new heights with Seneca’s Airline Pilot Flight Operations Graduate Program.

• Gain the expertise to transition to a national airline First Officer

• Extensive multi-crew flight training in turboprop and jet flight simulation devices using LOFT models

• An opportunity to interview with Jazz Aviation LP (select qualified graduates) for direct entry positions

For more information or to apply: senecacollege.ca/fulltime/APF.html

Seneca: A national leader in aviation education for 45+ years.

lifeguard. She continued this work while completing a bachelor of arts degree and worked towards her CPL and Instructor Rating.

Heather accepted a job at Morgan Air in Calgary and was soon flying charters and teaching multi-IFR. She became chief flying instructor, and in May of 2000, accepted a Jetstream first officer position at Air Sask in Saskatoon.

Shortly after she joined the team, Air Sask and Athabaska Airways merged to form Transwest Air in September 2000. Heather was upgraded to a Jetstream captain and a training pilot and was promoted to the SAAB 340 four years later. She was further appointed to senior management positions, which she has now held for several years.

Heather’s ability to inspire loyalty and to lead others as part of a team approach to the organization’s operations is perhaps best illustrated in the development of Transwest Air’s SMS program. Under Heather’s leadership, Transwest was one of the first operators in its category grouping to develop and implement a viable SMS.

Heather takes a particular interest in mentoring young women who are interested in an aviation career. She also teaches Canadian Aviation Regulation classes at the

Saskatchewan Polytechnic Commercial Pilot Program in Saskatoon.

Heather is first vice-chair on the ATAC board of directors and is expected to become chair in November of this year. She would be the youngest chair and only the third woman to do so in the 80-year history of the association.

Heather is an excellent ambassador of Canada’s air transport industry and a strong role model for aviator’s everywhere.

NAME: CURTIS

NADON

TITLE: CHIEF FLIGHT INSTRUCTOR, MOUNTAIN VIEW HELICOPTERS LOCATION: CALGARY, ALTA.

At 35, Curtis Nadon is certainly well accomplished.

He currently holds the position of chief flight instructor (CFI) at Mountain View Helicopters

(MVH) at Springbank Airport in Calgary. Curtis holds a forest technician diploma, Commercial Helicopter Licence with a Class 1 Instructor Rating and is a pilot examiner and

approved check pilot.

Curtis’ Forest Technician education steered him towards a seasonal job as a fire ranger for the Ministry of Natural Resources in Ontario. As a fire ranger, he spent countless hours flying to and from fires in Bell 205’s – which sparked his initial interest in aviation. At 23, he decided to purse a career as a helicopter pilot.

Considerable industry research led Curtis to relocate from his home in Newmarket, Ont. to Calgary to attend MVH Flight School. After completing his initial training, Curtis was hired by MVH to fly tours at the Horseshoe Canyon in Drumheller, Alta.

After getting his start flying tours, Curtis’ flying career took off – literally. He landed a job in northern Alberta flying the R44 Helicopter for Gemini Helicopters, mainly in the oil patch. After a couple years, an instructor position became available at MVH. Curtis applied for and accepted the position, and was trained as a Class 4 Instructor. He achieved his Class 1 Instructor Rating in 2008 and in 2013, took over as chief flight instructor.

Curtis did not stop flying operationally when he began his flight training. MVH encourages instructors to work with other

companies in the summer to build their experience. Curtis accepted the challenge and now holds type ratings on a wide variety of helicopters.

At MVH, Curtis works with a team of five flight instructors to train the industry’s future helicopter pilots. His good natured, patient personality combined with a strong work ethic have made him an invaluable asset to MVH . . . and the industry.

NAME: FRANK NEUBAUER

TITLE: SENIOR POLICY ADVISOR, AIR POLICY DIRECTORATE, TRANSPORT CANADA LOCATION: OTTAWA, ONT.

Frank Neubauer, 37, works in an environment characterized by high geopolitical stakes and significant implications for the Canadian aviation sector and the economy in general.

As a senior policy advisor – a role he has had since 2009 – Frank has consistently demonstrated a superb client service attitude, excellent judgment in his advice to

senior officials and ministers as well as great leadership and initiative.

Frank is an outstanding aviation professional who manages complex international files directly affecting the viability of the Canadian air industry. He was instrumental in conducting the multi-sector consultations that led to the development of Canada’s international air policy (called the Blue Sky policy).

Frank has worked closely with Canadian aviation industry associations in a number of capacities:

• Managing Canada’s participation in the Canada-European Union (EU) Joint Committee, a bilateral consultative body created under the comprehensive CanadaEU Air Transport Agreement.

• He is a lead technical advisor to Canada’s chief air negotiator for the negotiation of air transport treaties with countries around the world.

• He has been a key advisor to federal government negotiators regarding some aviation matters in the context of international trade negotiations such as the Trans-Pacific Partnership and the Canada-EU Comprehensive Economic and Trade Agreement

• He also leads the implementation of the

Workshops and symposium

NEW! iAuditor workshops

DTI has partnered with SafetyCulture to bring authorized workshops to North America on the ins and outs of iAuditor. This fully mobile app, can not only change the way you perform audits today, but can be a cornerstone to your QA in the future.

Canada-United States Open Skies Agreement and discussions on civil aviation matters with the Government of China Frank has consistently demonstrated exceptional dedication to his team, his department and the Canadian aviation sector. He proactively engages with stakeholders from Canadian airports and international carriers and is highly regarded for his expertise.

NAME: MIKE SPINA

TITLE: PROGRAM MANAGER, FIELD AVIATION LOCATION: MISSISSAUGA, ONT.

From an early age, Mike Spina, 34, decided to pursue a career in aviation. His passion for flying and aircraft would guide his education and eventually lead him into a career in the aviation industry.

Mike graduated from Georgian College in Barrie, Ont. in 2002, having successfully completed Georgian’s aviation management program. Upon graduation, he entered the

A consortium of highly trained and experienced professionals offering consultation and workshops in:

• SMS Gap Analysis

• QA Program Gap Analysis

• SMS, QA & Audit Training

• MCM & MPM audit & formatting

• SMS & QA Manual auditing

• Corrective Action Plan Assistance

January 3, 4 & 5, 2016 Coronado Springs Convention Resort, Disney World, Florida.

Three days of professional workshops and consultation featuring guest speakers Luke Anear, CEO of Australia’s famed Safety Culture Software Company and Joshua Yeamans, U.S. representative of the famous Iauditor software. Register today, space is limited. DTI contains the group to less than 100 invitees.

For more information about iAuditor and other workshops already scheduled please visit our website. www.dtitraining.com | 1-866-870-5490

commercial airline sector and over the course of the next five years, held various operational management roles with Air Transat, Royal Airlines and Jetsgo.

Mike acquired valuable operational, technical and commercial experience throughout this phase of his career and, after taking on ever-increasing management responsibilities, Mike decided it was time for a change in direction and sought interesting opportunities that would allow him to further develop his professional skills.

In 2005, at the age of 24, Mike joined Field Aviation, a company well known for its capabilities in the modification of aircraft for special mission applications. Mike joined the program management department at Field Aviation, where he continued to further develop his expertise and studied program management.

In his role as program manager at Field Aviation, Mike heads a team of skilled professionals involved in the design, fabrication, integration, testing and certification of modifications to aircraft that will configure them as highly sophisticated platforms operating in roles such as border patrol, maritime surveillance and search and rescue (SAR).

Mike has successfully managed a number of high profile and complex aircraft programs for Field Aviation in recent years, including U.S. Customs and Border Protection, Icelandic Coast Guard, Swedish Coast Guard, Australian Coast Watch and most recently, Boeing’s new Maritime Surveillance Aircraft. Integral to the overall success of Field Aviation is the contribution of talented aviation professionals, including Mike.

NAME: AMANDA SARGINSON

TITLE: ASSOCIATE, EMOND HARNDEN, LLP

LOCATION: OTTAWA, ONT.

Amanda Sarginson, 37, began her career in aviation 10 years ago as the sole human resources manager at First Air in June 2005. Amanda now practices law with Emond Harnden LLP and represents more than 30 aviation clients across the country.

As a member of the First Air team, Amanda never shied away from a challenge, was the chief spokesperson for negotiations with the dispatch group and supported the negotiation teams for the pilots, maintenance employees, flight attendants and ticket and cargo agents. She played an active role in the grievance and arbitration process for all of the unionized groups.

Ever seeking a challenge, Amanda made the difficult decision to leave First Air to conquer her next mission, law school. Excelling in this endeavour as well, she graduated on the Dean’s Honour List from the University of Ottawa in 2011. During law school, Amanda continued to work for First Air and joined Emond Harnden LLP as a student after her first year to deepen her understanding of the legal environment.

Amanda is now an associate with Emond Harnden LLP and provides employee and labour relations advice. Her practice includes assisting employers in hiring and terminating employees, drafting policy manuals, defending human rights applications, conducting investigations and representing the employer at mediation, arbitration and collective bargaining. She has also appeared before a Coroner’s Inquest, Human Rights Tribunal/Commission both federally and provincially, Small Claims Court, and the Superior Court.

Amanda is passionate about educating those in the industry. Over the past four years, she has provided numerous practical workshops to operators attending the annual conferences for HAC, NATA and ATAC.

NAME: JOHN TORY

TITLE: PRESIDENT/CEO, PRIVATE AIR

LOCATION: TORONTO, ONT.

Since entering the aviation industry more than 10 years ago, John Tory, 35, has had a mindset of continuous improvement.

From the early stages of John’s career, the Pilatus PC-12 has played a key role in his development, and it remains a mainstay of his career as Toronto’s Private Air grows under his leadership. Private Air is a division of Levaero Canada, formerly, Pilatus Centre Canada.

A natural leader, John’s stewardship at the helm of Private Air involved guiding the company through the recent recession, and positioning the business for growth in its wake. A customer-oriented executive with a keen awareness of for strategic operations, John’s ability to apply big-picture strategic and political elements growth strategy and day-to-day operations helps give Private Air operational flexibility through customized client solutions.

John’s constant drive for improvement, growth and expanded capability have put Private Air on a growth trajectory across several areas of focus. John maintains his

commercial pilot rating and is active and proficient on the Pilatus PC-12.

John is a monocular pilot, having lost the sight in his left eye at the age of 14. And although his main role is president and CEO, he still flies in the line once or twice a month. He is also an active demonstration and training pilot. He has thousands of hours of flying time on the Pilatus PC-12 and has trained PC-12 pilots in a variety of roles including private, commercial, medevac and law enforcement.

In 2011, John was part of a relief mission with colleague Stan Kuliavas, vice-president of sales and business development for Levaero Aviation. The relief mission was organized when Attawapiskat, First Nation reserve was declared a state of emergency for poor living conditions. John flew a Pilatus PC-12 used for the mission onto a 3,500-foot gravel runway covered in ice and snow. John is an active volunteer in both the industry and his community.

NAME: PHIL WOOD TITLE: DIRECTOR OF MAINTENANCE, BAILEY HELICOPTERS INC.

LOCATION: FORT ST. JOHN, B.C.

Phil Wood, 38, is a licenced aircraft maintenance engineer at Bailey Helicopters Ltd. in Fort St. John, B.C. who grew up as a local farm kid 13 miles north of town.

Wood graduated from Northern Lights College AME program in 1998, and began his apprenticeship with Northern Mountain Helicopters (NMH), then onto Airborne Energy Solutions and Vancouver Island Helicopters (VIH) for the long term of 10 years.

Phil began his next career endeavour with Bailey Helicopters in 2012 starting as an engineer, moving into the position of the quality assurance manager and was then promoted to the position of director of maintenance. Building a team of hardworking, experienced and outgoing co-workers, Phil is a respected leader who has a positive attitude, exceptional work ethic and a good sense of humor to help conquer adversity.

All of Phil’s hard work, dedication and commitment have opened many more doors of opportunity along the way. Driving results forward, Phil is a confident, trustworthy leader committed to excellence and efficiency.

Bailey Helicopters has a very bright future with Phil and his maintenance team leading the way.

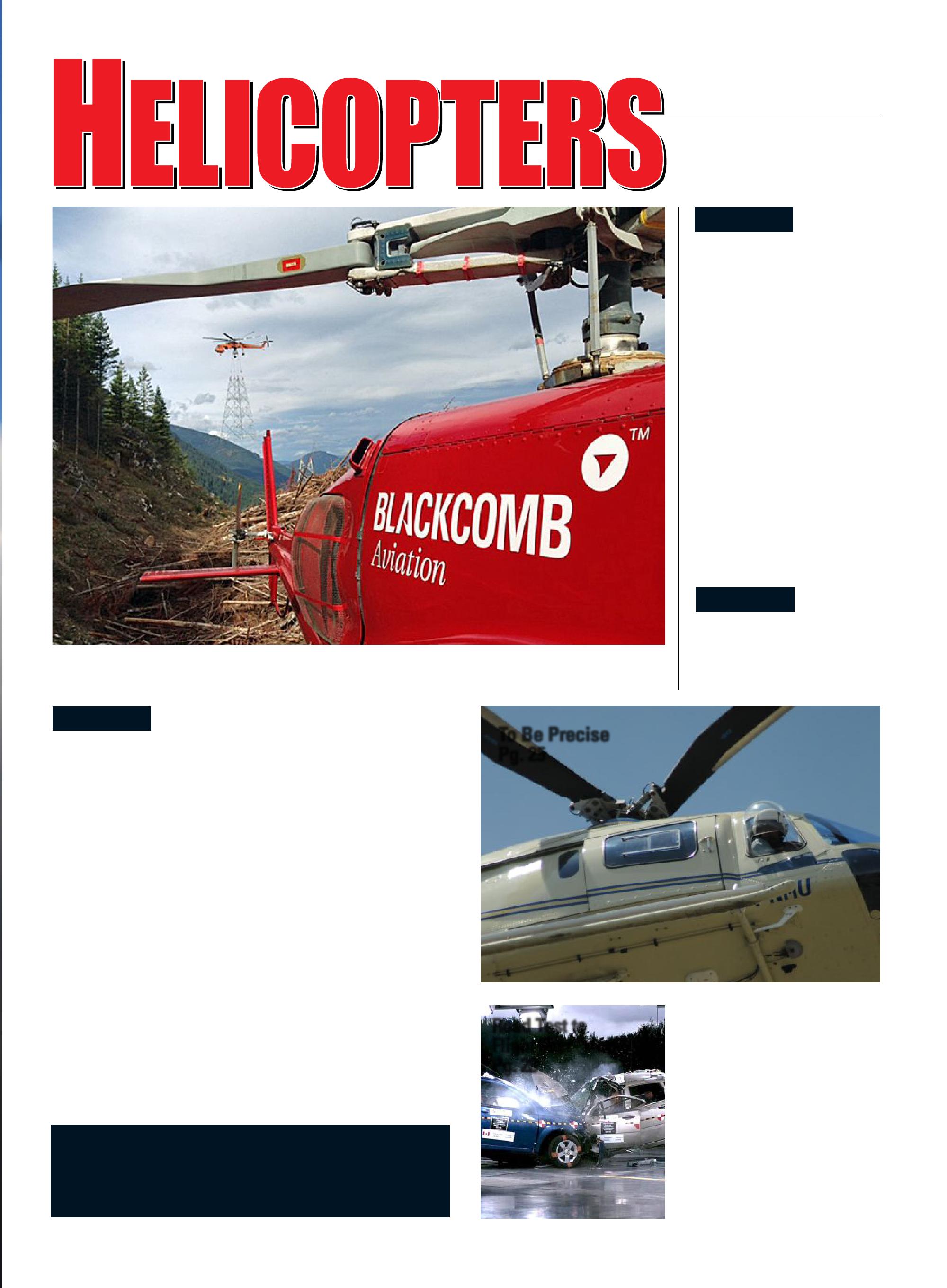

Below: A Mustang Helicopters’ Bell 212 delivers tower leg. (Photo courtesy of

Powering British Columbia

A Small Army of Helicopter Operators is Working Hard to Juice up the ILM

BY PAUL DIXON

he history of electrical generation and distribution in British Columbia is a series of construction projects ranging from “big” to “really big.” One of the largest projects in decades is the new ILM (Interior to Lower Mainland) 500KV high-voltage line. The new line parallels an existing 40-year-old 500KV line on a 247 kilometre journey from the Nicola sub-station outside Merritt in B.C.’s Interior to the Meridian substation in the Vancouver suburb of Coquitlam.

TLike an advancing army of skeletal robots, 641 giant steel towers seem to march over towering mountain peaks and down across valley floors on their journey from the semi-arid scrubland of B.C.’s Interior down to the coastal rain forest. BC Hydro’s current power transmission system was built during the 1960s and ’70s. The ILM project is the first 500KV transmission line built in Western Canada in more than 25 years.

Most of the dams and generating stations in B.C. are located far from the population centres of the Lower Mainland and Vancouver Island. Expanding the capacity of the transmission system will

meet future demands for power on a wide scale, as B.C. is part of the Western Interconnect, an interconnected power grid serving B.C., Alberta, western U.S. states and parts of northern Mexico. Construction of the ILM is part of a forward-planning process looking ahead as far as 30 years into the future.

When the ILM is energized next year, it will be more than a decade since work first started on the project. Much has changed since the original 500KV line on this route was erected more than 40 years ago. While planners had the foresight to make the rightof-way wide enough to accommodate a second line in the future, there has been a significant shift in process since then. Environmental assessment took more than three years and the public consultation process which included 60 First Nations saw numerous court challenges before approval was finally granted.

Given the challenging geography of the province, helicopters are an essential tool in BC Hydro’s operations across the province. The utility has been proactive in implementing safety protocols to minimize the risk and maximize safety in helicopter operations for its employees, contractors and the public. Hydro’s Aviation

There was potential to drop the sockline into the river or the energized line and that would have been catastrophic.

Operations Department was recognized for its leadership role in aviation safety, with the awarding of the 2014 Back and Bevington Air Safety Award by the B.C. Aviation Council. The award is presented annually to an organization that “demonstrates the most significant contribution to air safety in areas like aircraft operation/ design, accident investigation/prevention, flight training, engineering and airport operation/design in the province of B.C.”

Devin Dukeshire, BC Hydro’s transmission field operations manager for the ILM Project, spoke with Helicopters about the thought and preparation that goes into every project. In the end, success is predicated on relationsips. “A lot of the (rotary) vendors are organizations we have used throughout the years and we’ve built those relationships,” Dukeshire said. “On this project, we’ve had multiple vendors and helicopters – lights, mediums, heavies and extremes, right through the whole project.”

At Hydro, all employees or contractors who use helicopters have to have basic helicopter training. “Basic training,” as Dukeshire explains, “is just to give people awareness, something more than a simple pilot refresher before you jump into the helicopter.” There’s a test that concludes the training as part of the rigid documentation process. The basic course is just that, intended primarily for anyone getting in or out of a helicopter. Beyond that, there’s multi-day training for everyone working in the wires, power

A Valley Helicopters’ Bell 206 LR with a newly erected tower. (Photo courtesy of Valley Helicopters)

line patrols, vegetation or aerial surveys in and around the power line system.

While this training is good for three years and applies to both contractors and pilots, it simply allows you to get into a helicopter and fly a patrol. Beyond that, Dukeshire notes, there’s specific training and sign-off for more complicated procedures. “We have more than 20 procedures in place, from installing sock lines, hover exit, touch and go, Class D – all that stuff. You have to be trained in that as well if you want to work under the helicopter or from the helicopter. The procedures were developed with the Field and Aircraft Operations people in our Work Methods Department.”

Andrew Bradley, vice-president of operations for Blackcomb Aviation, has considerable experience working with BC Hydro. When it comes to safety, they always take a leadership role. “They make sure what we are doing and what we’re supposed to be doing, is right. And not just us, but their own managers from BC Hydro as well. It’s always a work in progress.”

Brad Fandrich, general manager of Valley Helicopters, has been involved with the ILM project from its inception. Several types of helicopters and operators have been used, and it’s fascinating to see the various aircraft working in unison.

“There’s been a lot of different helicopter types, a lot of different operators and it’s certainly an interesting time,” Fandrich says. “Helifor did a lot of clearing of the right of way, so they were using their Vertol and flying fallers in with a 500. Mustang had a 214B doing legs and concrete work. Heliquest came in with a 205 and the K-Max for logging, hanging some glass and doing some legs. VIH had a Kamov doing legs and some other heavy lift such as excavators. Ascent has had a 212, Twin Ranger and 902 doing a lot of the wire in the towers.”