Annex Publishing & Printing Inc. P.O. Box 530, Simcoe, Ontario N3Y 4N5 (800) 265-2827 or (519) 429-3966 Fax: (519) 429-3094

Editor | Laura Aiken laiken@annexweb.com (416) 522-1595

Assistant Editor | Brandi Cowen bcowen@annexweb.com (888) 599-2228 ext. 278

Sales Manager | Ed Cosman ecosman@annexweb.com (519) 429-5199, (888) 599-2228, ext 276

Sales Assistant | Barb Comer bcomer@annexweb.com (519) 429-5176, (888) 599-2228, ext 235

Production Artist | Emily Sun esun@annexweb.com

Group Publisher | Martin McAnulty mmcanulty@annexweb.com

President | Mike Fredericks mfredericks@annexweb.com

Publication Mail Agreement #40065710. RETURN UNDELIVERABLE CANADIAN ADDRESS TO CIRCULATION DEPARTMENT, P.O. BOX 530, SIMCOE, ON N3Y 4N5 e-mail: ncuerrier@annexweb.com

Printed in Canada, All rights reserved. Editorial material is copyrighted. Permission to reprint may be granted on request. ISSN 0383-7920

Circulation

e-mail: ncuerrier@annexweb.com Tel: 866-790-6070 ext. 208 Fax: 877-624-1940

Mail: P.O. Box 530, Simcoe, ON N3Y 4N5

Subscription Rates

Canada - 1 Year $42.00

(plus 5% GST - $44.10)

U.S.A. - 1 Year $60.00

Occasionally, Ground Water Canada will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

The evolution of F.C. Hammond Well Drilling Ltd.

Ground Water Canada touches down in sin city for the NGWA Expo.

Drill safety is about more than being careful.

Commitment to customers still comes first for Summers Drilling.

4 EDITORIAL: RALLYING THE YOUTH

Let’s get our young people excited about drilling. By Laura Aiken

6

28

Tapping geothermal heat in Montreal

Next spring, a 35-storey mixed-use office tower and condo project will be built at the mouth of the Quartier-International district of Montreal. From the outside, the Altoria will glisten like other glass towers in Toronto and Vancouver – but what lies below its foundation will help define the next generation of urban offices, reports the Globe and Mail.

Water well drilling needs to be more top of mind for today’s youth.

by Laura Aiken

One Sunday afternoon I mastered the art of undisturbed couching with a 12-hour marathon of the reality show Gold Rush Alaska on the Discovery Channel. In a nutshell, it’s a program about a bunch of guys who lease a plot of Alaskan land and spend the summer mining for gold with little experience, lots of breakdowns (equipment and mental) and the gumption to still be drilling when all others have long packed up for the winter. Now, wouldn’t it be neat if they were drilling for water in some remote and mighty part of the world? I would love to see a reality marathon of that because television has this peculiar ability to glamorize anything, even freezing your arse off in Alaska. Drilling could use a little glamour right now to inspire its next generation.

I hear a lot of rumbling about succession concerns and lack of young, qualified, experienced drillers coming up in the ranks behind the generation looking to retire. It’s a valid worry, and one that many different trades are grappling with.

Life is demanding – but it is also fun – and that is the real world we should be preparing the next generation for.

Here are some perhaps unsurprising stats for you from the Canadian Apprenticeship Forum-Forum canadien sur l’apprentissage: “While 60 per cent of parents say that they would be likely or very likely to recommend a career in the skilled trades to their children, 59 per cent of young people say that their parents have not encouraged them to consider skilled trades. Furthermore, 72 per cent of young people say their school guidance counsellors have not encouraged skilled trades as an option and 37 per cent of young people aged 13 to 24 said their schools did not have information readily available about careers in skilled trades.”

Campaigns such as Skilled Trades/A career you can build on (www.careersintrades.ca), are attempting to remedy this problem before this country experiences the Conference Board of Canada’s estimated shortage of one million

workers by 2020. These are important and needed steps. But youth seems to need more than sound information to make sound decisions. The millennials like to get excited about stuff and are recognized as a highly creative generation. The nice thing about the power of television is that it makes a hard day’s work for the honest pay look really cool while rallying allegiance to the everyman’s capitalist dream. However, if future historians had nothing but our television programming to go by, they would think we were a bunch of aspiring singers.

My point is that while there are campaigns countrywide to address the labour shortage in skilled trades, water well drilling needs to be more top of mind for today’s youth. Perhaps high school guidance offices are the place to start promoting the industry. Perhaps there is an opportunity for you to go to your local high school and speak about your profession. If there is a grass roots opportunity to be involved, get involved.

A recent survey for the Canadian Apprenticeship Forum-Forum canadien sur l’apprentissage, conducted by Ipsos-Reid, “showed that 47 per cent of youth and 41 per cent of parents hold the view that many skilled trades are physically demanding.”

Yes, they certainly can be. But all jobs require some physical exertion, whether it’s the eye and spine strain of a desk worker, or the sore soles of a shoe salesman. Physically demanding shouldn’t be a dirty word in a country striving for better fitness. Life is demanding – but it is also fun – and that is the real world we should be preparing the next generation for.

NEXT ISSUE: The next issue of Ground Water Canada will focus on succession planning and feature a guide to the CanWell show. Look for it this spring!

Solinst Canada hosted the third Solinst Symposium at its Georgetown, Ont., facility. The two-day event ran from Oct. 27 to 28, and focused on “Enhanced Monitoring and Remedial Methods for Contaminated Groundwater.” The lineup of speakers came from various educational institutions across Canada and the United States, as well as environmental practitioners from consulting firms and remediation companies.

The presentations reinforced a theme that has been seen throughout the past three symposiums – the need for high-resolution data in order to properly and accurately assess the extent and movement of contaminants in ground water. The speakers introduced tools that can be used to gain this data, including the Point Velocity Probe (PVP) and Passive Fluxmeter (PFM). Other speakers focused on large-scale fieldwork and experiments that helped characterize contaminants and assessed the effectiveness of different remediation strategies.

For more on the 2011 Solinst Symposium, including highlights from the 2009 and 2010 symposiums, visit www.solinst.com/Symposium/.

ITT Corporation has announced plans to separate into three independent, publicly traded companies: ITT, Xylem and ITT Exelis.

ITT Corporation’s board of directors has unanimously approved a plan, under which ITT would execute tax-free spinoffs to shareholders of its waterrelated businesses and its defense and information solutions segment. ITT shareholders will own shares in all three companies following the completion of the transaction.

ITT will continue to trade on the New York Stock Exchange as an industrial company that supplies highly engineered solutions in the aerospace, transportation, energy and industrial markets.

Xylem will be listed under the symbol “XYL” and ITT Exelis will be listed under “XLS.”

A WRC Purifying employee was killed in a car crash Nov.8.

Garret Stubbe, a 16-year-old co-op student with WRC, died when the company cube van he was driving collided with an SUV at Oxford County Road 13 and Quaker Street, west of Norwich, Ont.

Also dead is George Shelton, 80, of Ingersoll. Shelton was driving a silver SUV at the time of the crash.

Both victims were declared dead at the scene. Police are working to determine the cause of the collision.

Grundfos Pumps unveiled its Water Technology Center, a new facility for promoting innovative water research and developing sustainable solutions in Fresno, Calif.

Niels Due Jensen, Grundfos chairman and son of the company’s founder, cut the ribbon at the official opening of the centre, which offers a space for government, academic institutions and startups to share and gather information on irrigation, water monitoring, wastewater treatment and other water technology.

Ashley Swearengin, mayor of Fresno, applauded Grundfos’ investment in the city.

“Thanks to innovative companies such as Grundfos, Fresno sets the standard in water technology throughout the world,” Swearengin said. “With its new water technology centre, Grundfos is further investing in commercializing new water technologies that can benefit our entire region.”

To promote innovation in the water industry, the centre will also partner with groups like the International Center for Water Technology at Fresno State University, Central Valley Business Incubator, and companies like Climate Minder and Aquacue.

“Grundfos is the company I will work with into the future of protecting that resource,” said architect John Picard, an expert in building efficiency. He said Grundfos “gets it” when it comes to the future of water.

“Their vision and their commitment is what we need to sustain water in this world,” Picard said.

The centre will offer research entities access to Grundfos resources, helping to catalyze solutions to water scarcity challenges. It will function as a hub for linking research with business development.

The ceremony also featured addresses from Water Technology Center head Henrik Skov Laursen, Central Valley Business Incubator CEO Kirk Nagamine, and William Covino, provost of California State University, Fresno.

Thirty organizations, delivering projects in five countries, will share more than $4 million for programs that help protect watersheds and improve access to clean drinking water through the RBC Blue Water Project.

“Since we launched the RBC Blue Water Project in 2007, we have now provided funding to over 450 organizations around the world that care about protecting and preserving water,” said Gordon M. Nixon, president and CEO, RBC, in a news statement.

“I congratulate this newest group of grant recipients. Their work is critical to the protection of the world’s valuable water resources, and we are proud to support them in their efforts.”

RBC’s 2011 funding will support a range of projects from wetland and shoreline restoration to water quality monitoring and sharing of sustainable water management practices in agricultural regions. More than 180 organizations applied for 2011 Leadership Grants.

The RBC Blue Water Project is a 10-year, $50-million philanthropic commitment to supporting organizations that protect watersheds and ensure access to clean drinking water in Canada and abroad. Since 2007, RBC has committed more than $32 million in single and multi-year grants to 454 organizations, including the 30 recently announced. Earlier in September, RBC also announced a commitment of $1.1 million to ONE DROP’s Project India, a program to educate and improve access to safe drinking water and sanitation in Orissa, one of India’s poorest states. This is part of RBC’s 10-year, $10 million pledge to ONE DROP. For more information on the RBC Blue Water Project, as well as grant guidelines and application forms, visit www.rbc.com/bluewater.

What you’ll need to know to cash in on your creativity.

by Christine Hykamp and Richard Weber

Are your margins under pressure?

Consider your eligibility for SR&ED tax credits. The Scientific Research and Experimental Development (SR&ED) program allows qualifying companies to receive money back in the form of a refund, a reduction in taxes payable, or both.

Canada Revenue Agency’s (CRA’s) SR&ED program provides a valuable tax incentive to companies for eligible expenditures related to the pursuits of a technological advance. Did you know that advancements in your business that result in increased efficiency, reduced waste or new and improved products may be eligible for SR&ED tax credits?

Often this program is underutilized in the ground water drilling and geothermal industries because of the misconception that the technology already exists. For example, SR&ED tax credits were successfully claimed by an Ontario firm who integrated various green technologies into an advanced thermal closed loop system. A few Atlantic Canada companies have advanced technology using coastal aquifers to improve efficiencies of thermal heating and cooling. A key point in each was that the solution was

based on analysis, developing a test system and collecting data to determine how to further improve the system. Although there is a strong technological base in the ground water drilling and geothermal industries, it is important to recognize that when traditional design and equipment fails to function or functions with less efficiency than calculated you may have a starting point for an eligible SR&ED project. Another roadblock to the program is the lack of widespread knowledge in how to set up and conduct an eligible SR&ED project.

In very general terms, the federal SR&ED tax credit is 35 per cent of eligible SR&ED expenditures for qualifying small and mediumsized private Canadian companies. The credit may also be refundable. Refundable credits are either applied against taxes otherwise payable or refunded to the taxpayer when the credit is greater than the tax liability for the year. For larger companies, the federal SR&ED tax credit may be reduced to 20 per cent of eligible SR&ED expenditures and is non-refundable. Non-refundable credits are applied against taxes otherwise payable or they carry forward and can be applied against income taxes in future years (or

You may be more innovative than you think and eligible for a special tax credit.

also carried back) if the SR&ED tax credit is greater than the tax liability for the year.

Most provinces and territories have SR&ED tax credits as well. For example, in Ontario the SR&ED tax credit is generally 10 per cent of eligible SR&ED expenditures for qualifying companies and the credit is refundable. Nova Scotia, New Brunswick, Newfoundland and Labrador have a 15 per cent refundable credit. Refundable credits range from 15 per cent in the Yukon, Saskatchewan, 10 per cent in Alberta and 10 per cent nonrefundable credit in British Columbia.

To determine if a SR&ED claim makes sense for your business you need to answer the following questions.

Do you have eligible work? If you are systematically conducting experiments and analysis that involves engineering, design, mathematical analysis, computer programming, data collection and testing in a lab by computer simulations or in the field in order to overcome technological obstacles that you, your suppliers, your customers and the industry at large cannot resolve, then you are likely performing SR&ED. Similarly, if the path to new and improved products or more efficient or environmentally friendly processes is not routine or straightforward, start the clock and keep track of related expenditures.

Do you have eligible expenditures attributable to the technological advance? All labour, materials consumed (or transformed) and contract costs for eligible services that are directly attributable to the SR&ED project can be claimed. A common disappointment with smaller companies can occur if the owner/ operator contributes time to the SR&ED work but does not take a salary from the corporation. Labour costs need to be from T4’d employees or eligible contract expenditures. Most claims take advantage of the proxy method in which 65 per cent of the claim labour costs are also added to compensate for overheads. You may have some capital expenditures in order to perform your SR&ED; however these must be fully dedicated or greater than 50 per cent in use for SR&ED and you need to be able to prove there is no cross-utilization by your regular operations.

Do you have acceptable documentation to substantiate your expenditures? The CRA expects that you will have a time log or time sheets for each person on each of the projects claimed. Several manual and electronic solutions exist so ask your advisor for any and all tools they may have. Materials consumed must be substantiated by invoices dated within the fiscal period of the claim. Contract expenditures must be from Canadian suppliers and supported by invoices detailing the eligible service and acknowledging that the SR&ED and Intellectual Property acquired from the work belongs to you. It is important to note that the contract expenditure is claimed in the fiscal year in which the service is delivered, not necessarily paid for. Capital purchases have several rules; the most important is it must be new equipment.

The CRA expects that you will have dated documentation and evidence . Items such as project planning documents, design of experiments, project records and notebooks, records of trial runs, minutes of meetings, test protocols, test data and analysis of test results would be valuable. Evidence such as photographs, videos, samples, prototypes and scrap needs to be dated and initialled at the time it is created. A full listing of acceptable supporting evidence can be found in the CRA’s T661 Guide to SR&ED.

If you wish to conduct and claim SR&ED, identify at least one technical resource and a costing resource and have them trained so that the SR&ED projects are proactively planned (where possible!) and expenditures are continuously tracked throughout the year. Organizing an SR&ED team and detailing the project status at regular intervals during the fiscal year will result in a solid, supportable claim generating a tax credit that you can perhaps roll right back into making the next technological advance.

Christine Hykamp, P. Eng., M.Sc. Eng., is senior engineer, SR&ED Services at Business Improvement Group, Inc. Richard Weber, CA, is tax principal at Fuller Landau LLP. If you would like to learn more about SR&ED, contact the Business Improvement Group at 1-877541-5551 or Fuller Landau at 416-6456500 to arrange a no-charge on-site visit to determine your SR&ED eligibility.

Buying a business can be as natural a fit as putting on your wellworn boots, even if that business isn’t quite your expertise. Norm Yearly found himself in these very shoes in 2005.

by LAURA AIKEN

Yearly, who started Muskoka Pump Service in 1974 in Huntsville, Ont., began putting pumps in for F.C. Hammond Well Drilling Ltd., which was owned by Tom Hammond. Hammond’s father Frank was the first driller in Huntsville, says Yearly, dating all the way back to 1926. When Yearly learned Hammond wanted to sell, he took a leap of faith.

“Ninety per cent of my business was putting in pumps for Tom so I thought it was a natural step to buy the well-drilling business, it was an expensive way to go but that’s what happened,” says Yearly with a chuckle. “It’s just a bigger business, that was all, had employees for a change – for years and years and years it was

only me . . . It wasn’t that difficult, really.”

Daughter Julie Denning, the office manager, can’t help but jump in there: “It’s a big step to buy a business when most people are thinking about retiring at his age. It’s a big investment.”

I have to agree.

Yearly has never run a drill rig or driven a big truck and expects he never will, but his son Jeff, who wasn’t in the water industry at the time, jumped into the business after the 2005 sale. Jeff’s stepson Mike Murray now handles much of the pump side.

Yearly kept all the staff when he bought Hammond Drilling. One man worked for a year and then he retired, but not before

teaching Yearly’s son how to run the rig. Another driller was around until last year, and Denning started with Hammond in 1992.

Jeff seems like the natural successor to the business, to which Yearly says he certainly hopes so.

“He’s always been mechanically inclined, but the problem is he loves drilling – I’d like him to get in here and run the business. It’s very hard to run the business when you’re drilling because they start at 7 a.m. and work until five, six, seven sometimes longer and he couldn’t get all these notes you see [he points to a phone covered in yellow sticky notes] and there’s three wells to see, if you’re working 12 hours a day.”

And he does love what he’s doing,” Denning adds. “He loves the drilling; it’s very difficult for Dad to retire –that’s the big question – how’s Dad going to retire?”

To which Norm replies with a smile: “I don’t know whether I could retire. I’d have too much time to think about everything that’s wrong with me.”

Retirement isn’t the only thing on the mind of Hammond Well Drilling. Denning says it’s been a tough year for staffing and they are finding a general lack of experienced, licenced drillers. The company, which usually drills about

100 wells a year, lost one driller to retirement last December and then his trained assistant decided in July to leave them in favour of drilling for diamonds in South Africa. She says she’s done a lot of advertising online but isn’t having much luck.

“There’s a big gap and it’s getting worse,” says Yearly. “There are no licensed tradesmen coming along. I go to a meeting or show and . . . it’s mostly all old people there, but we do need people, we’re going to run out of them . . . . It’s a mindset: everyone wants to sit in front of one of those computers, and not too many people want to get their hands dirty.”

Denning: “And work long hours and be called at 10 at night or . . .”

But the business does have one member with a special skill, says Denning, and that’s Murray and his witching or dowsing/divining for water.

“He gets a couple of copper wires, or you can use willow sticks, and where they cross is where the water is – he’s more right than wrong and generally right. Mikey says if they really cross and if he keeps walking and they straighten, that’s how wide the vein is. Then he’ll take a piece of copper wire and he’ll hold it out and it will bob, and every bob is a

foot and he’ll tell you how deep the well is. It sounds like hocus pocus but he’s witched two or three. He’s quit telling the customers how deep the water is, but he’ll do it and tell me and he’s pretty accurate,” says Yearly.

Yearly goes on to tell me of a time years and years ago about another fellow in town who witched for wells. The man witched a well for him and told him the water was 18 to 20 feet deep. It was a dug well, and Yearly started digging at noon until he got to 17 feet and said it was just powder dry.

“I called him and said you blew it this time. There’s no water down there; it’s dry. So he said, ‘how deep did I tell you to go?’ I said 18 to 20 feet. He said, ‘how deep are you?’ I said 17, and he said, ‘you silly old fart – you’re not deep enough.’ So I went back out and kept digging. I was 17 and a half feet deep and it was just like someone had drawn a line through the earth and below that there was just water trickling in through the hole and two inches above it just dry. Unbelievable.”

Yearly’s 38 years in drilling have given him countless great stories in the field, from witching for water to drilling for some of Canada’s wealthiest families. Seems like buying F.C. Hammond Well Drilling was a natural fit indeed.

Canadians were well represented in Las Vegas. The 63rd NGWA Ground Water Expo and Annual meeting ran from Nov. 29 to Dec. 2 at the Las Vegas Convention Center, with no shortage of Canadians on the floor or in the booths.

There were 274 Canadian attendees in the NGWA database. On the floor, we found a great group of Canadian companies waving the flag: Atlas Manufacturing Ltd., GeoRocFor Inc., Structural Composite Technologies Ltd., Watergroup, Solinst, GP Fiberglass Ltd, Boshart Industries, Foremost Industries, Maxidrill, International Pipe, the Canadian Ground Water Association

promoting CanWell and Heron Instruments.

The mood on the show floor was positive and with a record number of exhibitors at 325, the NGWA can safely call this show a great success. In the 63-year history of the NGWA Ground Water Expo, this was the 14th best attended event, with a total attendance of 4,267 from all sectors of the industry

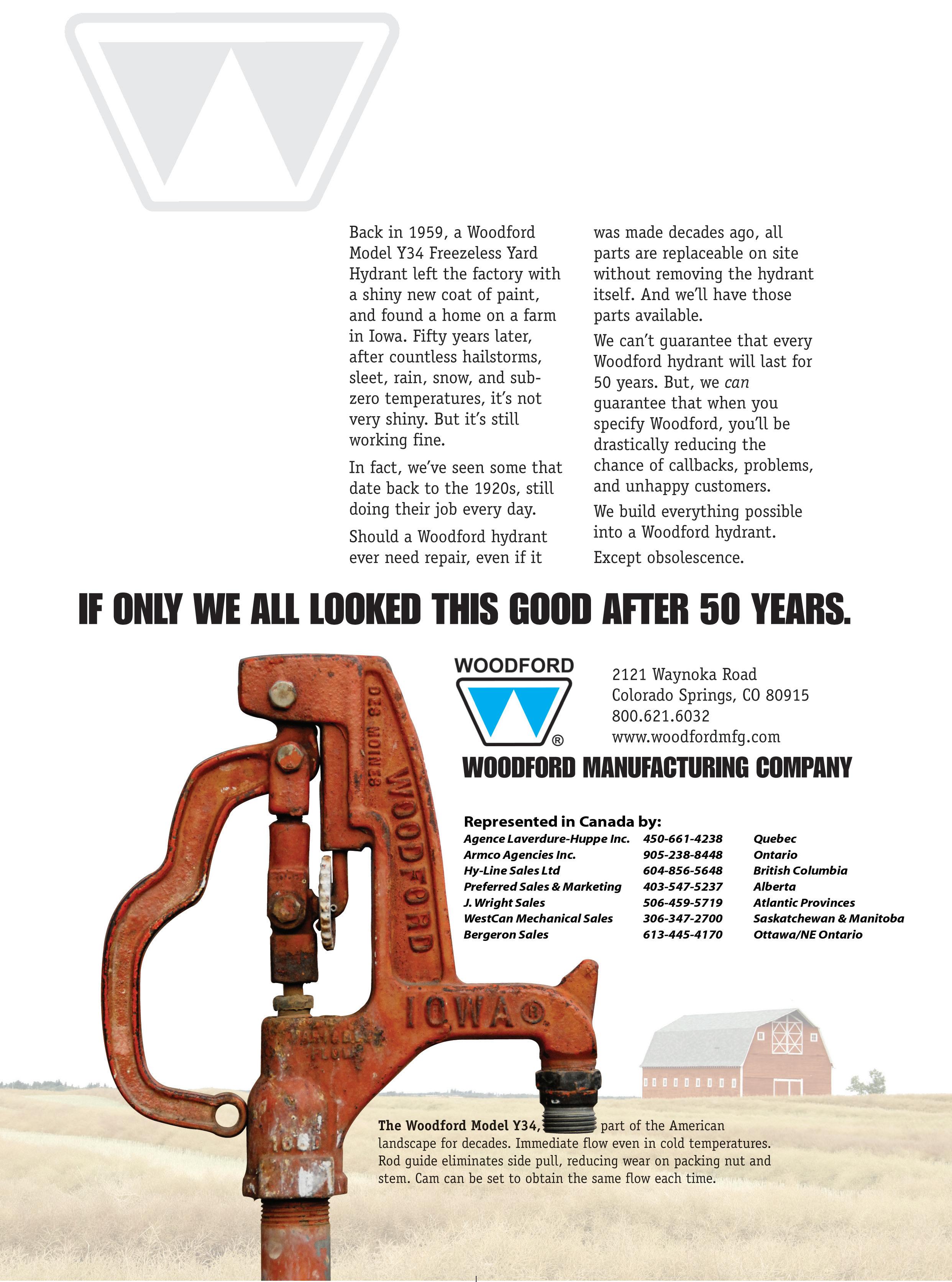

The SpeedStar 30K, mounted on a 6 x 4 truck, is perfect for shallow municipal or deep residential water wells. 25,000-lb. singleline winch combined with the hydraulic rod spinner makes tool handling fast and easy. This is the flagship of the GEFCO water well line, and has been for decades.

by LAURA AIKEN

– water well drillers and contractors, manufacturers and suppliers, and scientists and engineers, reported the NGWA in a press release. All 50 United States were represented, along with D.C., Guam, and Puerto Rico, in addition to 34 other nations.

The 2012 NGWA Expo is scheduled to take place Dec. 4 to 7 and will be returning to Las Vegas before it hits Nashville in 2013.

n Hoisting capacity (hook load) — 30,000 lbs. with tophead travel of 29 ft.

n Dimensions — length: 35’ 6”; width: 8’ 6”; height: 13’ 3”

n Field-proven PTO power design reduces maintenance costs and noise

n Hydraulic rod spinner

n Carousel options available

Gary

Safety is the most important aspect of drilling, asserts Gord Bailey, Resources Drilling and Blasting program co-ordinator at Fleming College in Peterborough, Ont.

by TREENA HEIN

There are a number of ways to ensure you’ve done all you can to protect the well-being of you and your staff. Read on for great ideas on how to keep your worksite safe.

Weather is one of these considerations that could be overlooked.

“Weather plays a big role in drilling safety,” says Bailey. “If it’s cold, clothing can restrict your movement and can reduce peripheral vision. If it’s hot, you may remove safety clothing. In the heat, you can also get

dehydrated and that can affect your thinking.”

It’s easy to get caught up in the day-to-day grind and bypass routines that just don’t seem that necessary. But letting your guard down to go about your daily business is an invitation for accident.

“Other than the obvious things like loose clothing I think apathy is the greatest danger around drilling rigs,” notes Brad Myers, secretary-manager of the Alberta Water Well Drilling Association. He notes that all drilling rigs manufactured in Canada since the early 1990s have emergency shutdowns, and adds

that “daily testing of them should be routine, but I suspect it isn’t done that often.”

Besides the action of drilling itself, Bailey notes that hazards at the site need to be accounted for. “The ground is getting crowded with many things like high voltage and natural gas lines, so you need to do a thorough check before you begin,” he says.

Many old drills don’t have guards, and that’s a big concern in Bailey’s view.

“None of the guards meets Ontario standards, and a lot of our equipment is old and it’s difficult to retrofit it without causing more problems.”

Top head cages/guards reduce the chances of employees being injured during drilling, agrees Laibe Corporation sales representative Blake Fahl, but he notes that drill rod loading and catwalks are another area of concern. “Laibe Corp supplies drilling rigs into other worldwide markets, [and] these additional markets will demand safety options that can be intergraded into the water well drilling rigs,” he notes.

“Most designs are typically installed on our new rigs, but we will try and include installation options that can be used to upgrade rigs already working in the field.”

Fleming College and the Ontario Ground Water Association have met with the Ontario Ministry of Labour with regard to guarding issues, and Ministry spokesperson William Lin confirms that staff there are currently creating a bulletin with directions and recommendations on guards. No date has been set for completion at this time.

Water well and mining drill manufacturer Atlas Copco offers a variety of safety guards on their drilling equipment. However, Peter Walsh, a business line manager at the company’s Mississauga, Ont., office says, “The working area at the base of the machines is particularly challenging, as drillers need clear and ‘clean’ access in and around the platform [for] casing installations and pipe handling.” To

address this, Atlas has installed an automated pipe-handing system on water well equipment, but Walsh notes, “this system is not equal to the manual handling of the pipe, so there is a reluctance from the market to accept these systems.” He adds that while “there is a mandate from regulating bodies in most areas of the globe to enforce water well equipment operators to use these automated systems… the challenge we have today is to have operator acceptance.”

Observations from Schramm Drilling Rigs are similar. “Instead of focusing on guards, because they impede the drilling process and are often therefore removed by drilling crews, we looked at the causes of injuries with drilling and looked for solutions to prevent accidents, which occur with handling drill pipes, tools and tubulars,” says Bruce Mackay, Schramm’s vice-president of product support. About five years ago, Schramm made changes to its water well and geothermal drilling systems by expanding the use of “drill pipe lazy susans.”

“These revolving devices are mounted on the drill’s mast and allow a worker to more safely manage drill pipe, without the need for handling drill pipe with slings and requiring a second person,” he says. “Our lazy susan allows a single driller to avoid handling these things, making the job much safer. [It] handles up to 15 pieces of 20- or 25-foot-long drill pipe, for a total of up to 375 feet, which is enough for most geothermal jobs.”

Deep water wells that reach greater depths can be addressed with an articulating loading arm (which can remove drill pipe from a rod box or support truck and safely present to the tophead) or the Schramm Loadsafe pipehandling system (which handles drill pipe, casing and all other tubulars).

“The more safe we make our industry, the more professional it’ll be,” Bailey asserts. “When there’s an accident, it affects everyone, and so everyone should be taking responsibility for safety issues.”

He highly recommends a “tailgate safety meeting” every morning to go over the jobs for the day, identify potential hazards and safety issues, brainstorm what could be done and what actions should be taken. “Some companies don’t do it, and everyone should,” Bailey says. “Incorporate it into your routine.

Meyers agrees. He believes proper initial training/orientation is critical, but that this must be followed up with regular safety meetings and refreshers.

“[Not having regular reminders] lets panic cloud your actions when trouble occurs,” he says. “We’ve lived by that philosophy and remained ‘lost time accident’ free for over 30 years in our company.”

There are many ways to help make your day safer for you and your crew. Regular meeting help your crew remember what to do in an emergency. Equipment developments such as automated pipe handing and “lazy susans” allow for safer handling.

Be aware and diligent throughout your day, and stress the need for awareness. Apathy is just plain dangerous and accidents are not a lesson one wants to learn the hard way.

Treena Hein is a science writer based in Ontario.

Technology may have changed in the 95 years since Summers Drilling installed its first water well, but for this third-generation family business, quality work and committed customer service are timeless.

Summers Drilling is a family-owned and -operated company located in Stony Plain, Alta. Founded by James Summers and Norman Akley in 1917, the company’s first wells were drilled by a horse-driven rig. In those days, they charged $1.25 per foot, and customers provided room and board for both driller and horse for the duration of the job.

“I remember even as a little kid, at five years old, I could run that rig and build the casing,” says Dave Summers, the grandson of James Summers, the great nephew of Akley, and the current owner of Summers Drilling. He remembers travelling to jobs with his father Jim, the second-generation owner, and watching the horse go around and around, slowly drilling down to tap the water hidden below.

These days, the company relies on a different type of horsepower, but talking to Summers, I can sense the pride behind the fact the original horse rig has been restored to working order and could be used. The rig is just one of many traditions passed down through the company’s history.

Exceptional customer service is the foundation Summers Drilling is built on. Referrals account for almost 90 per cent of the company’s work; advertising and website traffic generate just 10 per cent of the jobs they take on. With

by BRANDI COWEN

statistics like that, one thing is clear: a satisfied customer represents a valuable marketing tool.

During the boom of 2007 and subsequent bust of 2008, the number of wells the Summers Drilling team installed held fairly steady. They drilled approximately 130 wells in 2007, and about 120 wells the next year.

“Even when it was booming, we did a little more work, but we didn’t take on a

whole pile of extra and hire just anybody to do it all. We were committed to a certain quality of work,” Dave explains.

He credits the “years and years of people knowing our work” with the company’s ability to secure a relatively consistent number of jobs under wildly different economic conditions.

Creating a satisfied customer often starts with educating that customer about water wells, making sure they

understand how a well system works and have realistic expectations for the one they’ve chosen to install.

“The biggest challenge for us out here right now is educating people on water wells compared to cisterns,” says Dave. In the past, many land developers in the region chose to build cisterns rather than invest in more expensive wells. Now homeowners looking to replace their cisterns are exploring what wells have to offer.

One key tool in educating customers is the 8,800-square-foot, state-of-the-art office building Summers Drilling opened in Stony Plain in 2008. The space features a showroom outfitted with a functioning constant pressure system that staff use to demonstrate how a well system works. Curious customers can also check out the various materials and casings that go into a well system. The company’s four drilling rigs are kept in back of the building.

Following up on a job well done is another component of the customer service strategy. At the six-month mark, Summers Drilling calls new well owners to check in and make sure they’re satisfied with their wells. This simple phone call helps keep the company top of mind when it comes time to service the well. It’s a wise marketing move, considering service jobs account for approximately 40 per cent of Summers Drilling’s income.

From first contact with the customer, right through to the end of the well’s life, Summers says their customer service strategy is guided by the principle of “doing good honest work for an honest dollar.”

“There’s not a place that I’ve worked at that I don’t think I could go back and have a coffee. The customer isn’t always right, but you’ve got to treat them good.”

Just as the business has been passed down from father to son, so has a strong commitment to customers from all walks of life. Summers Drilling has a tradition of helping others that seems to grow stronger over time.

“[My father] drilled a lot of wells for people in the past that didn’t have the money and never knew when they’d be able to pay him. He knew their kids needed water, so he’d go drill them a well. It wasn’t steady, but he did lots of that,” says Dave. “I’ve kind of done the same thing. We have to do our business, but if someone’s really stuck, we’ll give them a longer term to pay.”

One customer, raising four children and dealing with a cancer diagnosis, took eight years to pay off her well, but pay it off she did. This extended payment period isn’t an option they can offer to everyone, but the Summers Drilling team does what it can to make life a little easier for customers who find themselves in a tight spot.

This commitment to helping others is also evident in the aid work the company and various members of the Summers family have been involved with over the years.

In the 1980s, the United Nations (UN) approached Jim Summers about taking on some paid drilling work in Africa. A World University Service professor familiar with the

Accurately marked each mm or every 1/100 f ft Certified Traceable to National Standards Tape splice option maintained

company’s reputation for quality work had recommended Summers Drilling for a project. Jim was reluctant at first, declining several times before ultimately signing on.

It took six months to purchase equipment, ship it all overseas, and get everything in order to start drilling. The project really got underway in 1986, when they began drilling using four rigs purchased with proceeds from sales of the song Do They Know It’s Christmas? The record-smashing single, recorded by 44 pop superstars performing under the name “Band Aid,” raised millions for relief efforts during the 1984-85 famine in Ethiopia.

Twenty-six years and two covers of Do They Know It’s Christmas? later, those four rigs are still at work in Ethiopia. The country is once again facing a severe food crisis.

Working with the UN inspired Water For Life in Africa (WFLA), a charitable organization dedicated to ensuring poor, rural villages have access to safe, clean drinking water. Dave’s parents, Jim and Regina, and his brother, Robert, a licensed well driller and professor in the University of Alberta’s Department of Earth and Atmospheric Sciences, founded WFLA in 2002. The organization drills wells that villagers can maintain themselves without investing in lots of high-tech equipment that may be costly to maintain and repair. Often the wells are hand dug and hand drilled. When the hydrogeology of an area requires it, WFLA may rely on more advanced drilling methods to tap into the water table. Villagers are asked to contribute labour and funding to each well project, giving each community a sense of ownership over their well.

WFLA recently completed six wells not far from Lilongwe, the capital of Malawi. In the spring, they’ll return to drill an additional six wells.

“It’s true aid,” says Dave. Time is given freely to the project, and all expenses – including airfare and hotels – are paid for out of pocket. “Our family takes a lot of pride in it. That’s one of the key things that keeps us going. It takes all of the stress of just doing everyday business and gives us something a little different.”

“You’ve got to help people too. What you give all comes back to you in the long run.”

The list of projects Summers Drilling has been involved in is long: installing water wells and hand pumps for Alberta’s

provincial parks; drilling the elevator shaft for West Edmonton Mall; delivering temporary water services and all new wells for the town of Wabamun, Alta., after a 2005 CN train derailment spilled 196,000 litres of oil into the lake supplying the town’s water; and various aid projects in Africa.

For a company with such an impressive record, Summers Drilling’s secret to success is remarkably simple: “Do good work and be honest and look after your customers,” says Dave. “Nobody minds paying for a good job, but you have to give them service.”

Own the Best Geothermal and Water Well Grouting Equipment Available Anywhere!

• 0-35 GPM at pressures up to 500 PSI

• 5x8 piston pump with chrome liners

• 80 gallon SS taper cone bottom mixing tank

• 24 HP Honda

• Powder coat paint

• Spool capacities range 200’-1,000’ grout line

• Hydraulically-driven forward and reverse

• Smooth 360 degree swivel base

• Powder coat paint

• 5 reel models

Fill, mix, pump a batch of grout in just 90 seconds with the Geo-Loop 50-500. Call the experts for your grouting needs. Check

by Stan Marco

The term “trenchless technology” is a drilling application that we don’t often associate with geothermal loop installations . . . but we should.

Given advancements in horizontal boring equipment over the past few years, this technique has become both an economical and a feasible option when it comes to installing geothermal loops and has earned its place in the geothermal space.

When I think of trenchless technology, what immediately comes to mind is the running of natural gas lines, fibre-optic or utility cables. Horizontal boring is ideal for this purpose because the cables can be run under existing obstacles and roadways with minimal disruption to the land.

That’s what makes this approach so effective for the laying of high density polyethylene (HDPE) geothermal pipes.

In past columns, I have referred to the open and closed loop systems commonly used for laying the HDPE geothermal pipes that feed into the heat pump. Open loop systems are commonly used on properties that have an existing water well, while closed loop systems refer to a continuous geothermal loop that is placed in the ground either horizontally or vertically depending on the expanse of the property. Water runs through the loop in perpetuity extracting or rejecting heat to the ground as needed.

Consider the urban homeowner who wants to leverage the benefits of geothermal technology to heat and cool his house. His house sits on a heavily landscaped piece of land. This would appear to rule out a traditionally excavated horizontal closed loop system given a five-ton geothermal system would require a minimum of 5,000 square feet of ground space to bury the pipe. The option we would then tend to lean

towards is a more expensive vertical closed loop system because it allows us to install the length of pipe needed to ensure maximum heating and cooling efficiency in a much smaller area. It does, however, require between 900 and 1200 feet of drilling to accommodate about 1800 to 2400 feet of continuously looped HDPE pipe.

And what about the rural homeowner who doesn’t have well access and whose home is situated on two acres of treed land? A horizontal closed loop system would appear to be the best option given the land mass available, but the homeowner has dense bush on his property and doesn’t want it disturbed. So what now?

There is an option to fulfil both these homeowners’ needs. It’s horizontal boring.

These compact and powerful machines are flexible enough that they can handle both urban and rural landscapes given their capacity to bore holes into the overburden over significant distances. You can control the direction of the boring head to pinpoint accuracy leading to minimal surface disruption.

Like minimally invasive surgery, horizontal boring is practically invisible to the naked eye. The start and end holes in the ground are small and have little impact on the property. It’s the least invasive and most reliable way you can effectively install geothermal pipe.

The deeper you bore diagonally into the ground before boring horizontally, the higher the efficiency you will generate for the heat pump. In horizontal closed loop systems, we normally bury the HDPE geothermal pipe evenly spaced in a series of parallel six-foot-deep trenches. To achieve the same performance using horizontal boring, we need to go down a minimum of nine feet because the pipes we’re

Continued on page 27

Cby TREENA HEIN

aring for our fresh water is a conundrum for Canada. All levels of government and many agencies are involved, and discussions about our most valuable resource seem to teem with indecision, too many differing directions and outdated policies.

Canadian attitudes towards fresh water are also outdated, according to many. A potential answer: adopting a national water conservation strategy where Canadians become serious about how much water they use. That’s the conclusion of a new report titled Climate Change Adaptation and Water Governance by the Adaptation to Climate Change Team based at Simon Fraser University in British Columbia.

“Canadians are wantonly wasteful of our most precious natural resource, and with climate change impacts already being felt across the country, it is clear that we need to manage water much more carefully,” says the report’s lead author, Bob Sandford. He is also the Canadian chair of the United Nations’ “Water for Life Decade” partnership in Canada. “We must not assume we have an endless abundance of fresh water. Our water security is much more fragile than Canadians generally assume.”

Sandford supports water metering as a way to reduce water usage. This, he suggests, does not have to interfere with water as a human right provided that the amount of water needed to assure human health and dignity is affordable or even free. After that, however, the supply of water should be

subject to economic controls that respect its true value.

“We use 329 litres on average per day per person in Canada, there are places like Munich, Germany, where they use 100,” he says. “We have billion-dollar infrastructure projects that enable people to continue the most wasteful water practices in the world. By reducing water use, transport and processing, we save water and energy.”

However, at the municipal level, metering is often an unpopular political move. “The question is, who will have the courage to lead?” asks Sandford. “Calgary is putting in meters, and calling themselves leaders, but Los Angeles did this 100 years ago. We have to realize how far behind we are.”

There are some water initiatives in place. The Canadian Council of Ministers of the Environment (CCME) has the goal of developing national strategies for ground water management and protection, and establishing guidelines for use by provinces and territories. However, the CCME typically only meets once a year. The Groundwater Information Network was created last year, a joint federalprovincial project intended to fill water-related knowledge gaps. In late August, the federal

government announced funding of $20 million for the creation of the Southern Ontario Water Consortium, a $60-million-dollar project wherein select public agencies and companies will be able to develop new water technologies for both Canadian and world markets.

It’s headquartered at the University of Waterloo, with seven other universities, over 70 private companies, municipal governments and not-for-profit organizations involved. Technologies relating to waste water treatment, ground water management and the detection of contaminants will be tested at the Consortium’s platform on the Grand River and adjacent watersheds in the London, Waterloo, Guelph, Hamilton and Toronto areas.

Those heading the project say what makes the consortium so valuable is how it integrates all elements of water management into a single platform; no such R&D arrangement exists anywhere

in the world, leaving water research up until this point rather fragmented. It’s hoped that use of the group’s testing platform will lead to the development of innovative monitoring and data collection/analysis technologies, as well as technologies relating to waste water reuse and systems able to treat more challenging types of ground water and surface waters. Priority will be given to companies with research and development capacity in southern Ontario.

Senior advisor Walter Stewart says water conservation was a key idea behind the creation of the consortium.

“Watersheds around the world are under pressure like never before, and better models of water usage are needed to reduce these pressures,” he says.

“The Grand River has massive growing urbanization, massive industrialization and agricultural use, and therefore provides an excellent location for the project.”

He adds, “The integrated aspect of the platform is very attractive to companies. We are open for business and collaboration, and adding partners all the time.

Principal investigator Jim Barker believes the need for such an R&D hub has never been greater. “Cities are now spending millions of dollars on upgrading their water treatment plants, and the faster we can have proven technologies developed on the platform, the better. Municipalities and industry want to know it works, so the proven aspect is very, very important.”

While Sandford applauds the development of new water technologies that will promote conservation, he says development of effective policies is just as, or even more, critical.

“Water policies at the provincial/ territorial or federal level have not

kept pace with changing political, economic and climatic conditions,” he says. “The last federal water policy was tabled over two decades ago and remains largely unimplemented.”

The government of B.C. is in the process of modernizing its Water Act, which dates back to 1909, and will address the protection of aquatic environments, improvement of water governance arrangements, the introduction of more flexibility and efficiency in water allocation, and regulation of ground water use. At the same time, however, Sandford notes that at present, out-of-date B.C. regulations put ground water resources at risk through industrial processes such as coal-bed methane extraction. “Better regulation should be put in place first if these activities are to be effectively regulated,” he says. “We also need a better understanding of the link between ground and surface water. Our understanding and managing of water is far behind other countries.”

Sandford says there is also a serious issue in that most infrastructure grants that municipalities receive can be spent as the municipality sees fit.

“Some spend it on politically expedient projects that ignore the need for ongoing maintenance of critical, but often invisible, water infrastructure. Everywhere you look there are deficits of policy and practice.”

In Alberta and other places, municipalities are given total decision-making power over their water supply sources. The provincial government there supports regional water lines where “they make sense to ensure a safe, secure water supply,” Carrie Sancartier, a public affairs officer with Alberta Environment, recently stated, “…[but] at the end of the day, it is up to the municipality to decide based in its own unique circumstances.”

Sandford believes that such policies are in urgent need of reform. “This is why we need true leadership at the provincial and federal levels,” he says.

He is pleased to note that, in his opinion, the government of the Northwest Territories is showing true leadership. It recently created a water stewardship document called Northern Voices Northern Waters (NVNW), which contains massive reforms and a framework for reasonable water conservation measures. “This means other provinces can do it too,” says Sandford.

He is currently on a 16-city national speaking tour to promote the report’s key recommendations. “I also want to inspire and motivate the provinces to take a look at NVNW and how its principles can immediately be incorporated and used in southern Canada,” he says. “At each stop, we are including local panel reaction to our recommendations. We need to speed up water policy reform in all provinces and at the national level, so we can adapt to climate change challenges that are already beginning to appear. New relationships are needed between the provinces/territories and the federal government. We’ve got 100-year-old water policies, created at a time when there was much less industry, agriculture and population. We have to act fast and act now.”

Treena Hein is a science writer based in Ontario.

Continued from page 22

laying into the bore will be next to each other rather than spaced. We can achieve increased performance with two pipes together in a bore hole at 10 or more feet of depth, surpassing an open trench horizontal closed loop system that lays pipe two feet apart in six-foot-deep trenches.

Horizontal boring can easily and effectively bypass existing utility systems below the ground such as power, water, sprinkler and sewage lines. For instance, we recently installed 48 horizontal 500-foot bores under an existing golf course without interrupting regular club play. Once the horizontal tunnel beneath the ground had been bored, the same machinery was then used to pull the 1,000-foot lengths of HDPE pipe back between the starting and ending holes. The space between the pipe and ground of the bored-out tunnel is then filled with bentonite grout mixture to seal it in place and provide maximum thermal conductivity.

During the golf course geothermal installation we successfully drilled 16 such holes underneath the golf course and sprinkler systems at the 10-foot level. An additional 16 bore holes were to go at the 20-foot level but unknown obstructions about 180 feet out caused us to change our plans and simply bore the loops at the 30-foot levels instead. The last 16 bores were then located at the 40-foot depth to complete the project. When all was said and done, the small holes we drilled merely looked like divots. Covered with grass, no one was the wiser that we’d even been there installing more than 15 kilometres of 1.25-inch PE100 pipe.

Horizontal earth boring offers an appealing alternative to home and business owners who are seeking minimal surface disturbance with installation. In the case of the urban homeowner, we can drill beneath common areas, where permitted, to generate the linear footage required to install geothermal pipe horizontally without the excessive disruption to the land’s surface.

In the case of the rural homeowner, we can complete the installation without disturbing the trees on his property. Of course, the horizontal boring is not limited to closed loops and can be used to run open loop and domestic water lines from the well head directly into the customer’s basement or mechanical room.

Depending on your needs, new and used boring systems can include tooling, boring, tracking, grouting and vac setups and run between $60,000 bare bones and $280,000 fully loaded.

As always, it’s important to select the right loop system when installing geothermal systems based on the home or business owner’s needs and what will ensure maximium heat pump efficiency over the long term. If the equipment is available and ground conditions allow, consider horizontal boring as a viable option on your next geothermal installation.

Stan Marco is a well-respected and highly sought after geothermal knowledge expert and educator. He is an active member within the ground water community, a board member with the Canadian GeoExchange Coalition and cofounder and CEO of GeoSmart Energy & GeoSmart Drilling Services.

Geoprobe 78 series rigs are billed by their maker, Geoprobe Systems, as able to deliver more power, offer more options, and outperform other rigs in the field with increased speed and efficiency. The 7822DT and the truck-mounted 7800 are designed to help users offer a wider range of services utilizing a compact platform. The 78 series offers large-diameter tooling and augering, air rotary, pavement cutting, mud rotary, and concrete coring. Geoprobe Systems says the series is well suited for environmental sampling, standard penetration testing (SPT) for geotechnical projects, and overburden sampling and classification for mining applications.

More information is available at www.geoprobe.com or at 1-800-436-7762.

This rig has a 200-horsepower diesel engine with 15,000 pounds of pull-down and 15,000 pounds of retract. Diedrich’s sonic head creates up to 30,000 pounds of force and up to 120 r.p.m. of rotations. The rig also features a Bean pump and 20,000pound winch. Diedrich bills this rig as relatively quiet by industry standards. www.diedrichdrill.com

Pentair Inc. has developed a new Hybrid Deionization (Hybrid DI) system with CrossCharge technology, which the company says is the first electronic water purification system that is practical for residential applications. Hybrid DI systems using CrossCharge technology

will be the first to offer consumers the benefits of a reverse osmosis (RO) system and those of a water softener without requiring salt.

The CrossCharge technology within Pentair’s Hybrid DI system was developed through a partnership with the Dutch firm Voltea. The new technology uses capacitive electrodes to remove hardness and purify water without employing salt.

http://boelterlincoln.com/clients/pentair/Pentair.html

Solinst’s Levelogger Edge is a precision instrument designed to provide reliable datalogging of water level and temperature measurements. This product offers consultants, researchers and waterprofessionals a compact method of recording data in remote locations without requiring ongoing maintenance.

www.solinst.com

Sonic Drill Corporation’s sonic drill rigs are designed to be robust, reliable and profitable when used in drilling projects around the world. To help illustrate the advantages of sonic drilling, the Sonic Drill Corporation prepared the following examples of real-life projects that showcase the technology’s capabilities in the drilling industry:

Community college extension: A sonic drill was brought in as the “rescue rig” for a geothermal installation at Vancouver’s Langara community college.

Conventional rig: Three rigs on site, two months’ drilling, 18 holes installed, 10 days per hole.

Sonic drill rig: One rig on site, two weeks’ drilling, 23 holes installed, one to two holes per day.

Sonic’s drill rigs can be used in geothermal, environmental and mining applications. www.sonicdrilling.com

Heron Instruments offers power reels for tape lengths of 300 metres (1,000 feet) and over.

The power reel is designed to make taking level readings in deep wells faster and less strenuous. All power reels are available in a 12V or 120VDC, and with a large double frame

to allow for easy fastening on drill rigs or truck beds. www.heroninstruments.com

The retro-fit geothermal drilling market has use for a compact geothermal drill that can

get into tight, hard-to-access geothermal job sites and still be able to effectively drill the job. Simco says it has solved this problem.

The ever-popular, fieldproven Simco 2400 SK-1 has been upgraded with many of Simco’s other geothermal drills features to make this highly productive, rubbertracked, limited-access drill. www.simcodrill.com

This portable drilling system is designed for use in areas that were considered inaccessible by traditional drilling methods.

Created as a cost-effective solution for the environmen-

tal sampling of soils between five and eight metres deep, this versatile drill successfully navigates city streets, active gas stations, parking lots and environmentally sensitive areas. And, because it’s portable, the drill can be carried into heavy bush or moved by a small vehicle such as an ATV.

A standard two-inch diameter, 30-inch-long splitspoon sampler is used in most soil conditions. The Pionjar 120 allows crews to install monitor points for either ground water or soil gas, horizontally or vertically, indoors or outdoors. Standard size for the Pionjar 120 is 1.7-inch-diameter PVC, other sizes include 0.75-inch and 2-inch.

www.sonicsoil.com

In

by Pam Lontos

reality, getting and using a list of strong testimonials is easier than you think.

If you’re like most people, the words from a fellow consumer have more weight than even the best ad copy. That’s why no matter what you’re selling, you need to use testimonials from satisfied customers. Getting and using a list of strong testimonials is easier than you think. Look over your customer files and choose the people who exemplify the best-case scenario. Say to them, “I’d love for you to share your experience with us. Would you please write a short testimonial?” Most people will cheerfully say yes. Often, if someone declines your request it’s because they’re busy or feel they don’t have writing skills. Offer to write the testimonial for them and have them review it.

Chances are you’re sitting on a pile of testimonials and don’t even know it. Go back through your past correspondence from customers. Are there a few nice sentences in some of those messages? If so, ask the person if you can use their words in your marketing materials.

A testimonial that simply says what a wonderful company you have is not saying anything meaningful for the reader. A specific testimonial will speak to results, for example: “Joe’s Drilling put my well in for $2,000 less than other company in town.” The more specific a testimonial is, the stronger it sells for you.

Each word of the testimonial should have value. If someone writes you a page-long testimonial, edit out any words that don’t directly address the end result. This doesn’t mean you change the meaning of what someone writes; you simply edit out the parts that don’t contribute to the meaning. For example, if someone writes a page about everything your company did to help them save 30 per cent on their heating and cooling bills, you can condense it to one sentence, as in “As a result of ABC Company’s installation in our home, we saved 30 per cent on our monthly utility

bill.” Often, the more words you take out, the stronger the testimonial becomes.

Rather than attribute your testimonial to “John S., Alberta,” use the person’s real name, company name, title, and/or location whenever possible. This makes your testimonial more believable.

For print ads, it’s best to have testimonials stand alone from the text rather than try to weave them into the ad copy. Other marketing pieces that should feature your testimonials include your website, brochures, direct mail pieces, postcards, billboards, newsletters, and even social media updates.

Each time you receive a kind letter from a customer, highlight the parts that state benefits to the customer and file it in a big binder. Keep the binder of testimonials in your office or wherever is best for customers to browse through. Or, create a page on your website where you feature all your testimonials. Frame some of your best testimonial letters and post them on your walls. Again, highlight the best parts so your customers can easily see the benefits.

The next time you’re writing copy for a marketing piece (and struggling with what to put) simply go to your past testimonials. It’s always better when someone else sings your praises, so let your customers sell for you.

Pam Lontos is president of Pam Lontos Consulting. Pam consults with businesses and experts in the areas of sales, marketing and publicity. Pam founded PR/PR Public Relations and is a past vice president of sales for Disney’s Shamrock Broadcasting where she raised sales 500 per cent. She is the author of I See Your Name Everywhere: Leverage the Power of the Media to Grow your Fame, Wealth and Success. For more information on her consulting services, call 407-522-8630, e-mail PamLontos@gmail.com, or visit www. PamLontos.com.