West Coast snack-food pioneer combines automated packaging precision with hand-crafted product quality to serve up a winning chip sensation Story on Page 16

Delivering Results.

With Heat and Control, you have a partner with the scale to support your success, the innovation to advance your operations, and a commitment to quality that will help you offer better products for consumers.

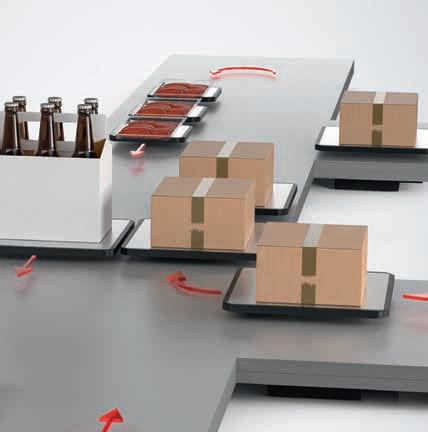

COMPLETE SNACK PACKAGING SOLUTIONS

• Accumulation

• Horizontal motion conveying

• Incline, belt and bucket conveyors

• Filling and multihead weighing

• Bagmaking and casepacking

• Checkweighing and seal checking

• Foreign object and defect inspection

• Controls and information systems

We are successful when you are successful. That’s why we apply creativity, engineering excellence, and determined perseverance to every project to help our customers get the performance their business demands—whether measured by flavor, efficiencies, sustainability, improvement, or innovation.

Oct. 23-26, 2022 Booth N-4706, McCormick Place Chicago, IL USA

info@heatandcontrol.com | heatandcontrol.com

West Coast potato chip innovator invests into a fully integrated packaging line at its new production facility ascompanay coninues its rise part up the industry’s pecking order.

New high-speed vacuum-packing machinery enables thriving Quebec seafood producer to expand its retail product portfolio.

COLUMNS

FROM THE EDITOR

4 George Guidoni

Sustainability a destination: not just a journey.

CHECKOUT

56 Julie Saunders

Joe Public speaks out on packaging hits and misses.

ON THE COVER

Thick crunchy slices of freshly kettle-cooked all-natural Hardbite brand potato chips filling up the high-precision Ishida multihead scales with bulk product at the start of a packaging run at the new Naturally Homegrown Foods production plant in Surrey, B.C.

Cover photography by David Buzzard.

New packaging makes authentic Italian meatballs literally fly o the shelves.

Boutiqueco ee roaster enjoying the perks of recent end-of-line packaging upgrade.

Leading Dutch fresh produce processor achieves unfailing accuracy and precision with new multihead weighscales.. PRE-SHOW REPORT

A selection of exciting new technologies to be unveiled at the upcoming PACK EXPO International 2022 exhibition in Chicago, Sept. 23-26, 2002.

If familiarity ultimately breeds resentment and contempt, there may be truth to the notion that the flood of industry reports, studies and action plans releases by governments, corporations and NGO (nongovernmental organization) activists on packaging sustainability and circularity my be doing more harm than good in the long term by simply wearing out the public interest in what should be a top-of-mind issue.

Naturally, it’s a challenge that will have to be collectively addressed by all stakeholders, but always blaming the government for the lack of coherent recycling policies, or consumers for making wrong choices in the grocery aisles, is an outdated refrain that will not get the packaging industry very far.

SEPTEMBER 2022 | VOLUME 75, NO. 9

Reader Service

Print and digital subscription inquires or changes, please contact Angelita Potal, Customer Service Tel: 416-510-5113

apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Senior Publisher Stephen Dean | (416) 510-5198 SDean@canadianpackaging.com

Editor George Guidoni | (416) 510-5227 GGuidoni@canadianpackaging.com

Account Coordinator

Barb Comer | (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com

Audience Development Manager Barbara Adelt | (416) 510-5184 Fax: (416) 510-6875 badelt@annexbusinessmedia.com

300 MILLION

Tonnes of plastic waste generated globally each year

Bu consistently pointing out how bad things really are with the environment and how little time we have to fix it, the authors of these widely-publicized reports run the risk of simply spooking the general public into a state of defeatist resignation—based on the notion that all hope is lost—rather than energizing industry and consumers to redouble their sustainability e orts.

Fortunately, a new white paper from PMMI The Association for Packaging and Processing Technologies o ers a healthy dose of practical advice on how to accelerate the industry’s combined e orts to lower its collective carbon footprint, rather than just preach to the converted.

Released just in time for the upcoming PACK EXPO International 2022 packaging technologies and materials exhibition in Chicago, the 2002 Achieving Packaging Sustainability report outlines clear and concise five-pillar action plan that focuses on end solutions instead of the obstacles facing them and rightly so: we are all far beyond the problem acknowledgment stage by now.

As the study proclaims, “There isn’t a discussion to be had about the validity of reducing the carbon footprint across the global CPG industry.

“It goes without saying that we need to strive for it, as does every industrial sector. It doesn’t only benefit the environment, after all.”

Says PMMI: “Sustainability presents an opportunity for businesses facing increasing competitive and economic pressures to gain value and competitive advantage as they respond to environmental concerns and the pressures of resource scarcity, population growth and higher and more varied consumer expectations.

“But how to go about it is the challenge,” PMMI acknowledges.

Leading by example, however, can provide the inspirational spark the CPG industry needs to get moving into the direction of a truly circular economy.

As the report soundly points out, packaging machinery OEMs (original equipment manufacturers) have a critical role to play in getting the industry moving on the fast track by helping their end-users reduce the costs of their switch to more sustainable materials and packaging formats through further automation and compatibility with new-generation packaging materials made from a wide range of natural and recovered feedstocks.

“The fact is that CPGs cannot achieve true sustainability unless the OEMs and packaging manufacturers that supply them get involved,” says the report, citing global packaging machinery manufacturer Syntegon Technology as a case in point.

Nor only is the company installing LED lighting and solar panels at its plants, it is also designing its new CNC machines to use as little cutting oil as possible—further reducing the overall carbon footprint downstream.

“Syntegon has been looking into paper forming, where they are trying to find a way to replace blister packs using paper, as well as to reduce energy consumption of their machines—such as by reducing the use of energy intensive hot glue in packaging operations with the use of lock-forming,” the report notes.

“OEMs also have a crucial part to play in energy-saving in the industry,” PMMI says, noting increasing calls in Europe for introduction of mandatory carbon footprint ratings for all new machines.

“There doesn’t appear to be a clamor as yet for this measure in America,,” PMMI says, “but the baton will likely be taken up in the not-too-distant future.”

And frankly, the earlier the better.

GEORGE GUIDONI, editor GGuidoni@canadianpackaging.com

Media Designer Brooke Shaw | (519) 428-3471 bshaw@annexbusinessmedia.com

COO Scott Jamieson SJamieson@annexbusinessmedia.com

Annex Business Media

111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1; Tel: 416-442-5600.

Canadian Packaging, established 1947, is published 10 times per year except for occasional combined, expanded or premium issues, which count as two subscription issues.

PRINTED IN CANADA ISSN 008-4654 (PRINT), ISSN 1929-6592 (ONLINE)

PUBLICATIONS MAIL AGREEMENT NO. 40065710

SUBSCRIPTION PRICE PER YEAR (INCLUDING ANNUAL BUYERS’ GUIDE: Canada $78.50 per year,USA $179.50 (CDN) per year, Outside Canada $203.50 (CDN) per year, Single Copy Canada $10.00, Outside Canada $27.10.

From time to time Canadian Packaging will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy O icer

Privacy@annexbusinessmedia.com

Phone: 800-668-2374

DISCLAIMER: No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2022 Annex Publishing & Printing Inc. All rights reserved. This publication is for informational purposes only. The content and “expert” advice presented are not intended as a substitute for informed professional engineering advice. You should not act on information contained in this publication without seeking specific advice from qualified engineering professionals. Canadian Packaging accepts no responsibility or liability for claims made for any product or service reported or advertised in this issue. Canadian Packaging receives unsolicited materials, (including letters to the editor, press releases, promotional items and images) from time to time. Canadian Packaging, its a iliates and assignees may use, reproduce, publish, republish, distribute, store and archive such unsolicited submissions in whole or in part in any form or medium whatsoever, without compensation of any sort.

We acknowledge the [financial] support of the Government of Canada

New RTD beverage ready to explode in the crowded market

The explosive growth of RTD (ready-todrink) alcoholic beverages in recent year has unleashed a tidal wave of product innovation and experimentation, but a young British Columbia entrepreneur is looking to really blow the marketplace up with her one-of-akind SakeBomb pre-mixed cocktails made with Japanese rice wine.

Stefana Prodeo, Founder & CEO, Bomb Beverages Inc.

Crafted in B.C. and using premium saké as its base, the SakeBomb o ers a premium-quality spiked sparkling water with best-in-class nutritional attributes—including low sugar, low calories, and low carbs—and using the natural sweetness of high-quality saké to deliver a rich, unique taste that is further enhanced with real fruit flavors.

A brainchild of serial local entrepreneur Stefana Prodea, founder and chief executive o cer of Bomb Beverages Inc., the SakeBomb is marketed as a BFY (better-for-

you) adult RTD beverage currently available in three flavor varieties that include Berry Blast, Lime Drop and Peach Smash.

Packed in slim 355-ml direct-printed aluminum cans supplied by Vancouver-based Alna Packaging, the SakeBomb cocktails are currently sold in individual cans or in 12-can multipacks—containing four cans of each flavor—packed in highly decorative paperboard cartons supplied by Ellis Packaging Limited of Pickering, Ont.

Currently available only in B.C., the SakeBomb beverages are expected to be rolled out across Canada in the near future, according to Prodea.

“SakeBomb is truly a dream brand for us,” says Prodea, adding that a portion of all proceeds form the brand’s sales is dedicated to funding the local its BombWomen mentorship programs aimed at developing a new generation of women entrepreneurs

“Not only have we created a delicious, innovative RTD cocktail, but we are also making waves in the alcohol beverage industry with our focus on female empowerment,” Prodea states.

“It’s a dynamite combo that tastes like a much-needed change in the market,” she says, “and it is only just the beginning of what’s to come.”

Since opening their doors in 1996 as one of Ontario’s first craft brewers, Muskoka Brewery has worked relentlessly to adapt to a rapidly evolving market and ensure there is a beverage for everyone that comes to the table thirsty.

While continuing to push the envelope but staying true to their roots, the independently owned brewer has recently expanded its capabilities to brew a new Juicy Hard Seltzer Squeeze the Day and Wandr, a non-alcoholic sparkling tea infusion, as part of a major expansion of its product portfolio this past summer.

Nestled in the heart of southern Ontario’s cottage country in Bracebridge, Ont., Muskoka Brewery has built up an exceptionally loyal customer base in the province over the years with popular beer brand such as Detour Session Ale and Mad Tom West Coast IPA, among others, and its foray into the RTD beverage market was a natural extension of its keen understanding of the beverage market trends, according to the company.

“We have crafted a line-up this year that has something for everyone and something for every occasion,” says Muskoka Brewery’s director of marketing Sarah Au.

“With individuals moving towards adopting drinks that fit into a more active lifestyle, these new beverages will let people can unwind with a beverage that aligns with their goals.”

Adds company president Todd Lewin: “At the core of our values is being welcoming by encouraging everyone to reach for a Muskoka beverage that fits their lifestyle.

“As we have from Day One, what we strive to do is to craft iconic experiences for Canadians, one glass at a time,” he states.

Coca-Cola’s massive capital investment a big boost for its B.C. bottling operations

Coca-Cola Canada Bottling Limited has announced plans for a massive $42-million capital expansion of its Lower Mainland operations in the Vancouver area.

The investments—including a $24-million upgrade of its bottling facility Richmond, B.C. and construction of a new nearby sales/ warehouse/distribution facility—are intended to “help the company meet the evolving needs of customers in British Columbia and enable its capability to grow in the market,” according to Coca-Cola Canada.

“We are a family business, and as the Lower Mainland’s local bottler, we’re very committed to investing in our local business for the long-term,” says Coke Canada Bottling’s chief executive o cer Todd Parsons.

“We’re guided by our mission to deliver optimism and create a better future for our customers, consumers and communities.” Parsons states.

“By increasing our manufacturing capacity and consolidating our warehouse and distribution operations, we’re ensuring we’re able to grow our business and continue to make, distribute, merchandise and sell B.C.’s favorite

beverages for many years to come.”

Scheduled for operational start-up in the spring of 2023, the new manufacturing line at the Richmond manufacturing facility will enable the use of pre-form bottles, add capacity and help decrease packaging emissions.

For its part, the new sales, warehouse and distribution center (DC) will combine the capabilities of its existing DCs in Richmond and Coquitlam to significantly expand its storage capacity, according to Parsons, while enabling seamless product distribution from production to delivery via the company’s iconic Red Truck delivery vehicles.

Slated to open in the spring of 2024, the new DC will also house

Coke Canada’s local fleet and equipment service operations. Operating on 24/7 and 24/5 schedules throughout the year, Coke Canada Bottling currently employs about 550 people at its Lower Mainland operations.

Servicing a region from Vancouver to Hope, B.C., the company produces nearly 20 million cases of product annually—comprising over 210 SKUs (stock-keeping units) and 18 packaging formats—including popular brands such as CocaCola, Canada Dry, A&W and Monster energy drinks, as well as the Dasani brand bottled water sold in 100-percent recycled PET (polyethylene terephthalate) plastic bottles.

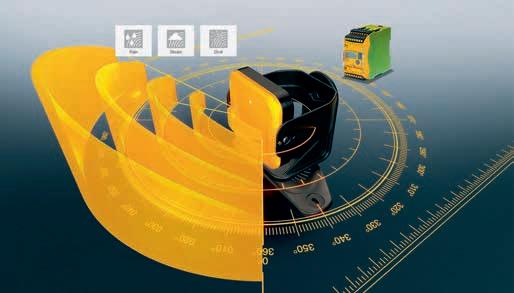

SENSORS: Inductive and Capacitive Proximity Sensors • Photoelectric Sensors • Level Sensors • Ultrasonic Sensors

Magnetic Sensors • Limit Switches • Safety Interlocks

CARLO GAVAZZI has the solution for your application needs, whether it’s our industry leading solid state relays, energy meters, contactors, motor controls, monitoring relays or sensors, now available with IO-Link communications. Contact

Leading industrial adhesives manufacturer H.B. Fuller Company of St. Paul, Minn., has entered into a strategic partnership in North America with Enimac, a globally operating manufacturer of tape application equipment serving customers in over 30 countries worldwide. According to the companies, the agreement e ectively combines the respective market application expertise of both companies with advanced knowledge on pressure-sensitive adhesive tapes to support the growing e-commerce packaging industry. “As the e-commerce packaging market begins its next wave of exponential growth, the agreement with Enimac strengthens our presence in the market by leveraging our performing tape and their application technology expertise to provide quality solutions and technical support to a wide range of packaging makers,” says Tania Montesi,

H.B. Fuller’s global e-commerce packaging business development manager.

Kingsey Falls, Que.-headquartered corrugated packaging group Cascades Inc., has announced the launch of the company’s northbox XTEND line of isothermal meal boxes said to be 20 per cent more e icient than the company’s current like of home delivery meal boxes. To be produced on a newly commissioned line at the company’s Cascades Enviropac plant in York, Pa., the new northbox XTEND features a special new moisture barrier that helps to keep the insulation rigid, while enabling the packaged food to stay fresh longer in transit and requiring less ice. “We’re pleased to innovate with our customers to o er them a variety of high-performance and adaptable isothermal packaging solutions,” says Luc Langevin, president and chief operating o icer of Cascades

Specialty Products Group. “Since 2007, our recycled cardboard meal boxes have been perfected to meet operational and environmental challenges,” Langevin adds. “Our expansion plan in the market is rolling out as anticipated, reinforcing our role as a strategic partner that works in close proximity with customers.”

St. Louis, Mo.-headquartered rigid packaging plastics manufacturing group TricorBraun has been honored with two 2022 AmeriStar Packaging Awards from the Institute of Packaging Professionals (IoPP) in recognition of the company’s innovation and packaging excellence in the Food: Shelf Stable category.

• Designed by the company’s TricorBraun Flex flexible packaging division, the Brandywine Co ee Roasters package utilizes a pocket zipper to replace the traditional tin tie used on co ee bags for opening and

closing, with the bags themselves made from 60-percent compostable and renewable material.

• The NERDS Twist & Mix pack, produced for Ferrara Candy Company, features a custom polypropylene (PP) base, enabling consumers to twist the customclarified PP lid on one circularshaped, five-compartment package to mix and match their perfect combination of NERDS Candy flavors. “We are honored to receive these prestigious awards, recognizing packaging innovation in partnership with our customers,” says TricorBraun president and chief executive o icer Court Carruthers. “This recognition acknowledges our team’s dedication to serving our customers’ needs.”

Milwaukee, Wis.-headquartered Regal Rexnord Automation Solutions has completed a rebranding project to update its corporate name from the former Arrowhead Systems moniker. The rebranding reflects the company’s recent acquisition by Regal Rexnord, a leading global manufacturer of industrial powertrain solutions, power transmission components, electric motors, electronic controls, and

specialty electrical components and systems. Under its new name, Regal Rexnord Automation Solutions will continue to provide industry-leading industrial process automation solutions—including conveyors, palletizers and depalletizers—to the food-and beverage, aluminum can, and consumer staples (household goods, hygiene products, etc.) industries.

Leading Swedish industrial packaging and logistics services group Nefab AB has been awarded the 2002 German Packaging Award in the Sustainability category for the company’s highly innovative fiber-based solution for Lib (lithium-ion) batteries. Developed as an alternative to the traditional hard-torecycle EPP (expanded polypropylene) materials, the EdgePak Straw system is a mono-fiber solution that is fully recyclable and can handle weight loads of up to 350 kilograms per box, with up

to four-layer stackability during transport. Featuring UN certification for the transport of dangerous goods, the EdgePak Straw system provides an ideal recyclable solution for one-way Lib shipments, according to Nefab, and it can be applied to many other heavy products shipped through demanding supply chains. “We are extremely honored with this prize and happy that the German Packaging Award jury noticed the unique qualities of Nefab EdgePak Straw,” says Sebastian Wachauf-Tautermann, vice-president for sales and marketing at Europe Nefab Group. “We are also grateful to our LiB customers with whom we collaborated to develop this innovative solution that addresses two of the biggest challenges: the growing need for sustainability and cost reductions across the entire supply chain.”

Leading German flexible packaging materials manufacturer SÜDPACK has formed a long-term partnership with Clean Cycle Investments for commercializing the advanced (chemical) recycling CARBOLIQ technology developed by leading German recycling specialists Recenso GmbH. According to the partners, the

promising technology can help make currently non-reusable packaging materials suitable for recycling and for the Circular Economy of the future. Tests at a joint disposal center in Ennigerloh have shown that numerous material fractions, as well as mixed and contaminated plastic wastes can be converted into a valuable resource. The process is claimed to achieve virgin-grade quality plastics by using with the recovered oil said to provide the same virgin-grade quality plastic films as those made from fossil fuels. So far, the partners have successfully applied the technology both for resource recovery from their own recyclable material flows as, well as for recycling packaging materials from processing and from end customers. “In a wide range of applications, for example in the food industry, highperformance multilayer films with e ective protective functions are the most e icient solutions for keeping all

kinds of food fresh, and they’ll re-main the best choice in the future,” says Dirk Hardow, business unit manager at SÜDPACK. “However, the drawback is that they can’t be mechanically recycled. Now CARBOLIQ o ers a key system component for creating a Circular Economy in the food packaging industry, which can’t be achieved solely with mechanical recycling, and also due to existing legislations. So we see our investment in CARBOLIQ as an opportunity for SÜDPACK to expand the definition of plastic waste recycling beyond just mechanical recycling.”

Global digital cutting and finishing systems supplier Kongsberg Precision Cutting Systems (Kongsberg PCS) has appointed Global Imaging Inc. of Louisville, Co., as an authorized distributor of its digital finishing solutions for North America. “Global Imaging has developed the best network of distributorships available, and this new partnership enables our two companies to work together to significantly boost availability of our innovative digital cutting tables throughout the U.S. and Canada,” says Heather Roden, Kongsberg’s sales director for the Americas region.

Eastey, a division of Engage Technologies Corporation, has introduced the model EB80 automatic bundler series, equipped with the company’s renowned hot knife technology to ensure consistent positive sealing of polyethylene film. Featuring 80-inch seal width to accommodate larger product like doors, windows, larger corrugate bundles, etc., the EB80 bundler is welded onto 0.25-inch cold-rolled steel frame and designed to handle day-to-day abuse of even the most demanding bundling applications— utilizing two rolls of single wound film mounted on the same side of the machine and an upper and lower power film unwind for ease-of-use.

Eastey (Div. of Engage Technologies Corp.)

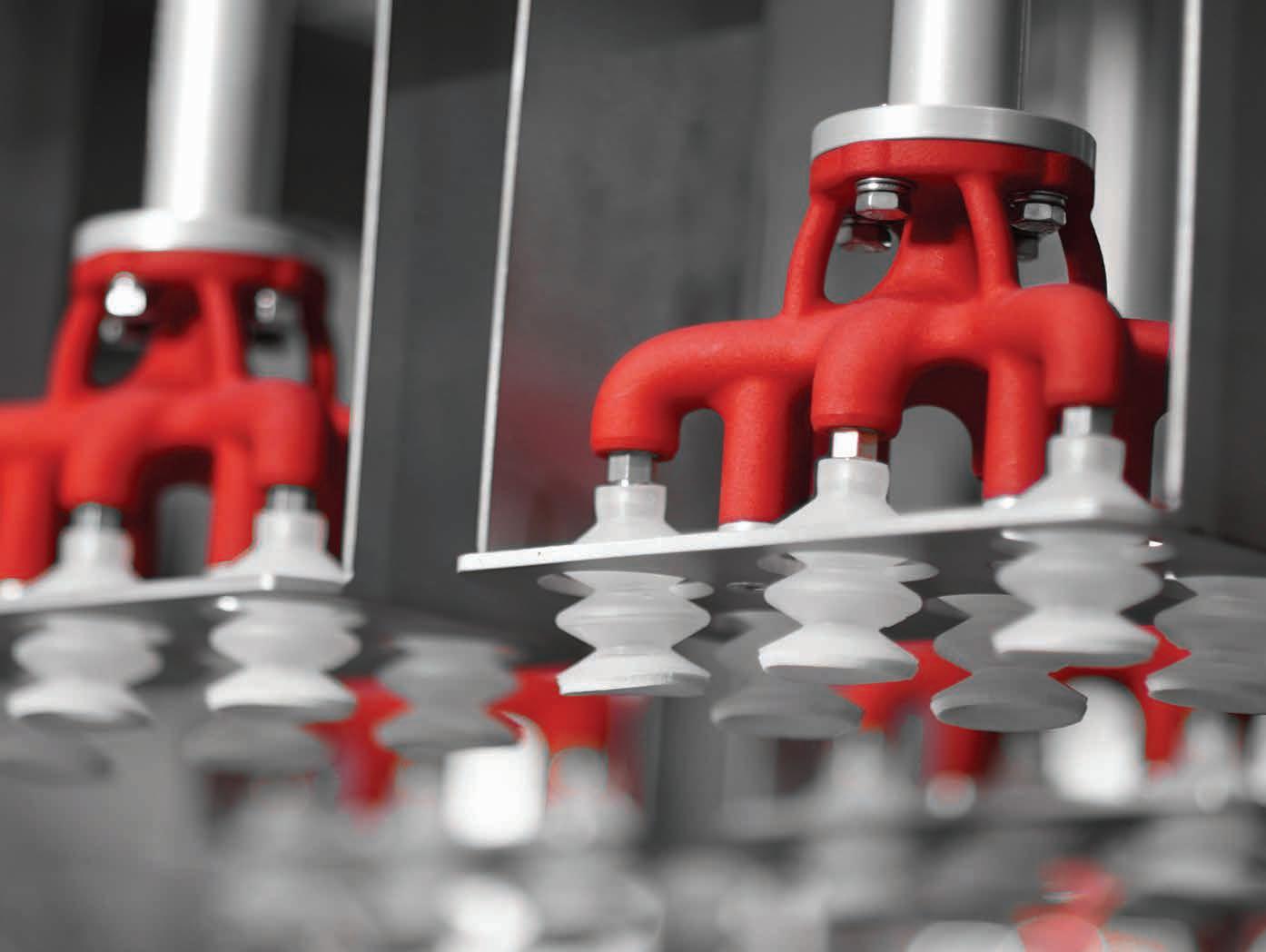

Designed to enhance operations involving the use of collaborative robots (cobots), Piab’s clever end-of-arm (EOAT) vacuum tool piCOBOT is now available with a generic electrical interface as well as several options for mechanical mounting plate dimensions in accordance with the ISO 9409-1 standard, enabling it to be configured to work with any collaborative robot. By o ering generic compatibility for piCOBOT, Piab is answering calls from manufacturers of cobots wishing to use the company’s unique vacuum EOAT in collaboration with their cobots. Through a user-friendly online configuration tool, Piab’s customers can choose between a generic electrical interface with a standard cable, or one specified by Universal Robots. Featuring Piab’s proprietary and highly e icient COAX vacuum technology, the piCOBOT comprises a vacuum pump unit and a gripper unit fitted with suction cups, which are available in a wide range of sizes and payload capacities to let customers tailor their own application solutions.

Piab

The new Helical Modular Chute (HMC) from Interroll Corporation is designed to provide optimal optimum use of available workspace with a simple and easy solution for vertical transport and product transfer in confined spaces. With a durable and robust steel construction, the new HMC serves a wide range of material handling applications for the retail and e-commerce, warehousing and distribution applications, as well as for the courier, express and parcel sectors. With its small footprint, the flexible chute seamlessly suits many diverse material flow requirements to accommodate a broad range of product quantities, sizes, and various packaging formats such as cartons, case, trays, bags, etc., while o ering the versatility attributes of 700-, 900-, 1,100- and 1,250-mm conveying widths, a decline angle between 18 and 26 degrees, an entry slide width of 2.5 meters, as well as an arc angle range between 90 and 180 degrees for optimal operational flexibility. Interroll Group

The new AirMax Pro Smart Breather from Regal Rexnord is designed to keep gearboxes running longer by utilizing Perceptiv connected technology to monitor gearbox status in real time. Developed to prevent leading causes of gearbox failure caused by lubricant contamination or corrosion inside the box due to abrasion, erosion, fatigue and corrosive wear, the AirMax Pro Smart Breather extends the life of industrial lubricants by preventing contamination with desiccant breathers; removes contaminants with filtration systems; and detects lubricant problems with visual oil analysis. In addition, the breather detects and records any unusual spikes in humidity and water ingress by integrating with Regal Rexnord’s Perceptiv connected technology, which uses Cloud-based technology to track, report, communicate and share performance data—enabling users to monitor the status of their equipment through a variety of modules, sensors, and other connected products with early detection of system upsets. Regal Rexnord Corp.

• ltra ig s d for ig st roducti it

• 4 or it and ri r

• obust industrial build it ad anc d auto ation

• xt nd d acuu for corrugat d rinting

• Six configurations: 4 for board, 2 for rolls

auro S ill continu to s t us a art

Dan Deveau, President, Cameron Advertising

By Lee Metters

Environmental concerns surrounding unrecycled plastic waste have prompted a rise in alternative ‘sustainable’ solutions which look and feel like traditional plastic but can be composted at end of life, helping to combat excess waste.

These solutions sound great in principle, but it far less straightforward in practice. In fact, many people in the industry are starting to recognize that improper use of compostable plastic packaging could do more harm than good.

A primary concern with compostable plastic is disposal. If a consumer incorrectly disposes of a compostable plastic container in a recycling bin, it can contaminate the recyclable waste around it.

This contamination may adversely a ect waste recovery and recycling systems, which have evolved to manage common packaging materials.

Introducing new materials can be problematic. Indeed, existing MRFs (Materials Recovery Facilities) have been designed to segregate and handle

materials that we value and materials that councils want to recycle—such as PET, aluminum, steel, glass and cardboard.

When new materials are introduced, there is no guarantee that they will flow as they need to, or they may inhibit the ability of the system to capture existing target materials.

Just a small amount of compostable material can contaminate standard plastic recycling streams—leading to the waste of vast quantities of recyclable material.

In light of these issues, leading global climate action group WRAP (Waste and Resources Action Programme) recently published new guidance materials to help businesses make informed choices when considering the use of compostable packaging.

“Businesses need to be clear on when it is viable to use compostable plastics, given the complexities surrounding current treatment infrastructure,” says WRAP’s resource management specialist

“It is critical that end markets for recycled plastics are not compromised; people need clear instructions not to place compostable plastics in the recycling bin.”

The key to the successful use of compostables is finding areas where collection and recycling of single-use plastics is problematic and where compostable materials could help to divert food waste from landfills.

For example, hard-to-recycle, heavily food-contaminated items do not currently have an ideal waste stream for disposal.

Such items can cause issues when placed in traditional recycling streams and can contribute to methane emissions caused by the anaerobic break-

down of residual food waste sent to landfill.

This latter point is key to any discussion surrounding compostables. With methane from landfill being a significant contributor to global GHG (greenhouse gas emissions), governments worldwide are committing themselves to the introduction of mandatory household food waste collection programs.

Some of the upcoming regulations include:

• European Directive (EU) 2018/851, mandating the introduction of separate collection of food waste as of January 1, 2024, within the European Union.

• U.K. government’s Resources and Waste Strategy, which pledges the introduction of separate collections for household food waste in the U.K. by 2023.

As the scenarios below outline, these upcoming regulations present a considerable opportunity for compostable plastic packaging when used correctly:

One of the most cited scenarios where compostable packaging could come in useful is with food contact packaging, where the product is heavily contaminated by food waste and di cult for consumers to clean, such as microwavable ready-to-eat meal trays.

Instead, a compostable microwavable tray could be placed into a food waste bin in areas where industrial composting facilities exist or, depending on the material, into a home composter. Any leftover food within the tray would then become compost, rather than food waste sent to landfill.

This would also reduce the number of trays being sent to landfill and improve the quality of recyclables by keeping contaminated products out of recycling bins.

Flexible plastic wrap is a popular feature in food and beverage applications in everything from single-serve condiment sachets to pre-packed, readymade salads and convenience pouches.

However, these materials can be challenging and costly from a recycling perspective, as they can stick together and get tangled with other recyclables. Compostable plastics could have a role to play here—especially where products are contaminated with food, as in the case of single-serve sachets. In such a scenario, compostable packaging and any leftovers could be disposed of together in a food waste bin for collection and treatment.

Certain items regularly end up in home compost, or organic waste collection, despite containing conventional, non-compostable plastic. Such items include tea bags, which many consumers incorrectly assume to be entirely compostable, and fruit and vegetable stickers that are often disposed alongside fruit and vegetable peelings.

In these instances, where conventional plastics regularly end up in organic waste, it makes sense to switch to compostable alternatives to improve the quality of the final compost.

Interestingly, WRAP highlights tea bags as one of the only areas where compostable plastic packaging should always be used in place of traditional plastics, because they are regularly placed within the organic waste collection.

Ensuring consumer awareness of correct disposal methods is of the utmost importance when considering the use of compostable plastic solutions. Manufacturers using compostable plastics should ensure that all items are clearly labeled to avoid the risk of compostable materials being disposed of inappropriately and contaminating the natural environment or conventional plastic recycling systems.

Considerations should bear in mind the di erences in regional recycling systems. When using industrially compostable materials, for example, brands should advise how to dispose of an item in the absence of an industrial composting facility.

WRAP advises that manufacturers consider the introduction of special labeling to inform consumers how items should be disposed of, rather than using vague statements, such as ‘100-percent

compostable,’ without disposal information. Where on-pack space is at a premium, information could be included within a 2D code, such as a QR or Data Matrix code, to provide easily accessible information to consumers via a smartphone or tablet. The beauty of using a 2D code for such applications is that a brand is not limited in the amount of information it can provide.

Standards such as GS1 Digital Link could be utilized to identify a consumer’s location and provide personalized information based on their regional recycling capabilities—potentially even linking to the nearest available recycling point.

In addition, brands can use product coding and marking to assist in the identification of packaging types at recycling centers and allow for the removal of compostable material that has ended up in plastic recycling. Projects supporting such initiatives include Holy Grail 2.0, which utilizes digital watermarking for product identification.

There is no doubt that compostable materials are an exciting new development in the packaging market. However, as with any switch in materials, the use of compostable plastic packaging requires careful consideration. In addition, any brand considering a switch in packaging solutions should enlist responsible and experienced supply chain and manufacturing partners to minimize the risk of change.

All brands should partner with an experienced coding and marking provider who can support sustainability design with coding solutions for compostable plastics, advise on appropriate labeling choices, and help ensure products will be accepted by retailers, valued by consumers, and trusted by everyone with an environmental conscience.

LEE METTERS is group business development director at product coding technologies group Domino Printing Sciences in Cambridge, U.K.

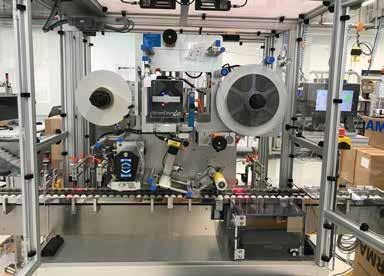

Packaging Equipment

Packaging Materials

Preparation & Processing

Portioning & Slicing

Automation & Integration

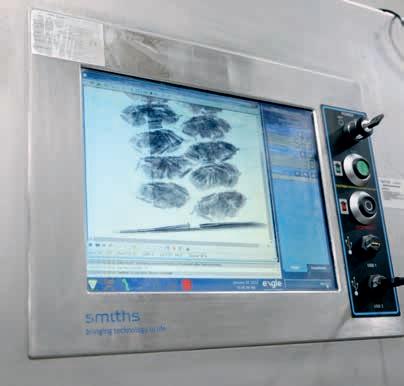

Inspection & Verification

Labelling & Coding

Dough Processing

Packs from our MULTIVAC packaging machines provide more than just a way to get your product from production line to dinner plate.

They also provide consumer convenience, product protection, marketing and labelling real estate, and even help to reduce global food waste.

We have been extending the shelf life of food for over 60 years, helping manufacturers like you to innovate fresh ideas in Processing and Packaging.

Isn’t it time we helped you?

West Coast snack-food pioneer builds up remarkable brand loyalty for its all-natural chips with daring product innovation and world-class packaging excellence

By George Guidoni, Editor

Photos by David Buzzard

Despite being one of the world’s most universally beloved snack foods, potato chips carry a fair big of historic baggage from their traditional unflattering portrayal as a poster child for unhealthy eating and poor nutritional habits.

But thanks to companies like Naturally Homegrown Foods of Surrey, B.C., legions of Canadian consumers with a shared fondness for the thin, seasoned potato slices cooked to crispy, crunchy perfection can rest easy knowing that not all potato chips are created equal—far from it.

As the only potato chip manufacturer operating in all of British Columbia, the privately-owned company’s unique

kettle-cooking process and the use of all-natural ingredients have enabled it to cultivate a strong and loyal fan base among Canadian consumers increasing looking for innovative BFY (better for you) snacking options without compromising on taste, quality and overall gratification they crave from their favorite munchies.

Originally launched in 1998, the company’s flagship Hardbite brand of potato chips, recently expanded to include root vegetable chips in its portfolio, tick many of the boxes that make it an attractive choice in today’s marketplace driven by a pronounced trend towards health-andwellness and sound nutritional awareness. No GMOs? Check. No transfats? Check. Gluten-free? Check. Peanut-free? Check. Kosher-certified? Check. No artificial ingredients or preservatives? Doublecheck.

“The consumer is seeking brands that they can trust and align with who they are,” says Naturally Homegrown Foods president and co-owner Kirk Homenick, who acquired the Hardbite business from its original founder in 2011.

“One key area that the consumer is currently seeking is transparency as it relates to ingredients,” Homenick says.

“Trust is an increasing attribute that consumers are seeking today, and we address this through our Non-GMO Project verification and by sourcing [ingredients] as close to our facility as possible.”

Kettle-cooked via a consistent batch process to ensure superior taste profile and a healthy satisfying crunch in every bite, the Hardbite brand enjoyed early local success among the health-conscious West Coast consumers, but the fledgling upstart lacked the capital resources and marketing clout to really grow the brand outside of its home confines.

That all changed when Homenick and his business partner took over the company and renamed it as Naturally Home-

grown Foods, while leveraging the Hardbite anchor brand’s growing popularity to make significant market share gains by introducing exciting new flavor varieties and high-impact brand packaging inspired by Mother Nature and the great outdoors.

With pack sizes ranging from single-serve 150-gram pillow-packs to Club Store multipacks containing up to 32 bags in assorted flavor varieties, “We o er a broad range of SKUs (stock-keeping units) to appeal to di erent consumers and snacking occasions,” Homenick states.

“Our SKUs range in di erent flavor profiles and pack sizes,” says Homenick, citing Hardbite All Natural and Hardbite Salt & Vinegar as the company’s bestselling flavors.

“That said, we have seen tremendous consumer demand for new and innovative flavors,” Homenick relates, pointing to recent market launches of the new Hardbite Spicy Dill Pickle, Apple Cider Vinegar, and Spicy Ketchup varieties.

In addition to expanding its ‘classic’ Hardbite range of potato chips, the company has also diversified into the production of chips made from root vegetables such as carrot, beet and parsnip, while also introducing a new range of BFY potato chips kettle-cooked in avocado oil.

The growing product portfolio and warm market reception has enabled Naturally Homegrown to secure national distribution for its brands across Canada, Homenick relates, while also opening up new export opportunities to enter the fast-growing global market estimated at US$32.2 billion in 2020.

“We have benefited from strong brand awareness and heritage in the Western Canadian geography, which is our home base,” Homenick relates.

“We have also historically expanded our geographic reach into Eastern Canada and the U.S markets,” Homenick adds.

“Most recently we have gained significant distribution in Japan, Taiwan and South Korea,” he confides, “and we will be launching in Australia by the end of 2022.”

Not surprisingly, all this robust product development and marketing activity gained momentum around the same time that the company began making major capital upgrades to its manufacturing operation with a continuous influx of automated processing and packaging equipment to cut labor costs and boost line e ciencies and productivity.

The company’s comprehensive capital upgrades over the last several years have resulted in a complete transformation of Naturally Homegrown from a boutique niche manufacturer into a highly competent and competitive snack-food manufacturer capably holding its own against huge multinational brand-owners dominating the current industry landscape.

“The snack food industry is large and highly competitive,” says Homenick, cit-

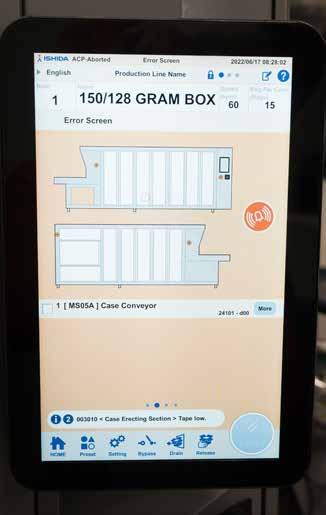

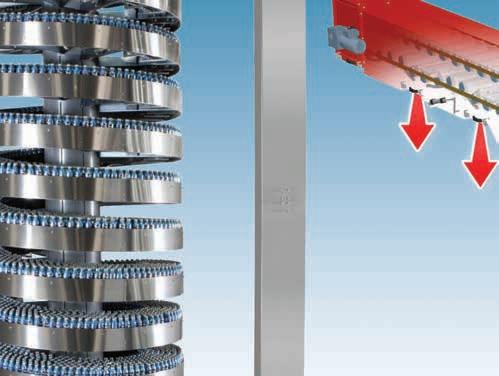

The state-of-theart Ishida model CCW-RV automatic weighscales are key to the continuous high-speed batch production process requiring gentle product handling and optimal weighing precision to reduce product giveaway and ensure high yields on the new integrated packaging line expertly installed at Naturally Homegrown’s new Surrey production facility by Heat and Control Canada.

ing Frito-Lay, Campbell Soup, Old Dutch Foods, Hain Celestial, UTZ Brands and Kellogg as perennial industry heavyweights.

“Nevertheless, regional brands do have advantages in the areas where they produce,” he points out, “because value and brand loyalty are very important consumer attributes in those home markets.

“Consumer decision triggers in the snack market can be very impulsive,” he says, “and they are often based on product value, price, brand recognition and loyalty.”

Homenick says he is especially upbeat on the company’s prospects in coming months and years following completion of a milestone move of its manufacturing operations this past spring to a brand-new, 43,000-square-foot production facility in Surrey, roughly a half-hour drive from downtown Vancouver, employing about 85 full-time sta .

“One of the big strategic advantages of this facility is that we are located close to a number of our key customers, as well as suppliers of our ingredients,” says Homenick, crediting local engineering services provider LaPorte Engineering for the first-rate project management expertise in laying out the new facility and commissioning new equipment.

“We are very grateful for the support that they provided us,” says Homenick, adding the new plant has been consistently running three daily shifts around-theclock since coming online.

Having already completed a third-party HAACP (Hazardous Analysis Critical Control Points) certification, the new facility is planning to complete the globally recognized SQF (Safe Quality Foods) certification audit by the end of this year, says Homenick, adding the new facility was been designed and built with sucient room to accommodate future capacity expansions.

“We currently have three packaging lanes in the facility,” he says, “which allows us to produce a variety of di erent flavors

Machine operator prepping up a new roll of high-barrier film to run through the new Ishida Inspire vertical bagmaking system used to package Hardbite brand chips in flexible pillow-packs at speeds of over 100 packs per minute, depending on bag size.

and pack styles simultaneously.

“We have made significant changes to our operations over the past five years,” Homenick relates, “as we have completely automated our packaging area.”

Says Homenick: “Packaging really is the face of our brand and our best way to communicate with our consumers.

“I expect our packaging will continue to evolve in the coming years,” he states.

“I also anticipate that we will see advances in packaging that address the recyclability of the materials that the snack industry uses, while enhancing shelf-life and product quality.”

Last year, Naturally Homegrown’s packaging savvy and expertise received prestigious industry acclaim and recognition by winning the coveted Canadian Grand Prix Best New Product Award of the Retail Council of Canada in the Savory Snacks category for its large-format Club-style Explorer Pack multipack comprising 32 bags of the company’s bestselling chip flavor varieties—including Rock Salt & Vinegar, Spicy Dill Pickle, Ketchup and Wild Onion &Yogurt flavors.

Says Homenick: “Over the course of the past five years our organization has diligently grown the Hardbite brand of snack food products, increasing distribution and launching new products.

“We are on-trend with our brand attributes of o ering BFY options, along with innovative flavors and pack sizes to meet our consumers’ needs.”

To get the new plant to run immediately at full production mode without incurring any downtime at its former existing location, Naturally Homegrown worked closely with Heat and Control Canada Inc., headquartered in Cam-

bridge, Ont., to acquire and to install high-performance packaging and processing equipment—raising the new facility’s line and process e ciencies to world-class levels.

Heat and Control Canada is the Canadian subsidiary of Heat and Control Inc. Based in Hayward, Ca., the renowned food manufacturing technologies group is one of the world’s leading manufacturers and distributors of modern industrial processing, coating, seasoning, conveying, weighing, packaging, inspection and controls systems—o ering best-of-breed food production technologies as standalone machines or as fully-integrated, custom-engineered end-to-end line solutions.

As Heat and Control Canada’s general manager Chris Jenkins recalls, “The recent move to a new location this past spring required careful coordination, since Naturally Homegrown needed to

The Inspira

features automatic film centering and tension control to ensure consistent product quality.

The Inspira bagmaker’s large touchscreen HMI panel ensures user-friendly operation.

Close-up of a pillow-pack being filled inside the Inspira bagger.

Clockwise from Left: The Markem-Imaje model SmartDate X65 thermal-transfer overprinter used to apply barocdes and other variable information onto the running film web; a full side view of the new Ishida model ACP-701 multifunctional case-packer capable of packing up to 150 packs per minute; a stack of corrugated shipping containers being fed inside the ACP-701 case-packer.

Above: The ACP-701 case-packer’s HMI control panel can store over 500 pre-set bag and case sizes, packing patterns and other key variables for quick changeovers.

keep production running at the old plant while they installed and commissioned the new facility.”

Despite the many logistical challenges unleashed by the COVID-19 outbreak, Jenkins and his team worked tirelessly with Naturally Homegrown to develop a high-speed, end-to-end packaging and product inspection solution capable of continuously handling up to 120 bags per minute.

“The Heat and Control after-sales support, including project management and on-site field service technicians, made our job much easier at a time when everyone continued to deal with COVID-19 related travel issues and shipping industry delays,” Jenkins recalls.

“Like a lot of food manufacturers today, Naturally Homegrown recognizes the advantages of increased automation and the improved e ciencies associated with total system solutions,” Jenkins relates.

The chip-making process at the Surrey plant begins with the arrival of raw potatoes and vegetables, which are quickly sorted, washed and pre-processed before being placed inside the batch kettle fryers in the plant’s processing area.

After the product is sorted again to remove any defects, namely undercooked or overcooked chips, the cooked product is accumulated, seasoned according to recipe, and moved on to the packaging area, where is packed inside pillow bags and into boxes or display-ready shipping containers.

To make the process run as smoothly as possible, while ensuring optimal product safety, Heat and Control designed and assembled a high-performance integrated packaging solution comprising:

• Two models of CCW-RV automatic multihead weighscales manufactured in Japan by Ishida Co Ltd, a long-time global equipment partner

with Heat and Control.

O ering a robust combination of advanced software, digital filtering, and precise feeder control to reduce product giveaway and to ensure higher yield, CCW-RV weighers provide a highly ecient and operator-friendly solution, according to Jenkins.

• A brand new Ishida Inspira series VFFS (vertical form/fill/seal) bagmaker designed to ensure consistent, superior forming/sealing performance of up to 200 bags per minute, featuring cutting-edge motor drive technology for exceptionally precise positional jaw control at the point of sealing, along with quick and easy

changeovers.

Joining the two existing Ishida Astro series bagmakers moved in from the company’s previous production facility in Maple Ridge, B.C., the Inspira bagmaker features a new splice table lightbar for easier and faster film splicing, simpler film feed with fewer rollers, and error-free forming of block-bottom gusseted, hem-seal and pillow bags, with fully automated film centering and tension adjustment.

Freshly cooked red and white potato chips being transferred side-by-side towards the Surrey plant’s high-speed packaging line to make bags of the Hardbite True North Spuds brand of chips. This limited-edition product combines the two di erent potato varieties in a playful tribute to Canada’s red-andwhite national flag colors.

According to Homenick, “We are excited to adopt the Ishida Inspira in our new facility.

“We have seen a shift in consumer demands towards portion- and snack-sized packs,” he says, “and the Inspira machine’s throughput rate of more than 100 bags per minute is very important to us.

“In the past these smaller sizes were di cult to pack e ciently,” Homenick notes, “but the new Inspira will allow us to stay on top of these consumer trends and needs going forward.”

• An Ishida model ACP-701R automatic case-packer. Designed as a compact high-speed case-packing solution for packing small and large bags inside boxes at speed of 150 units per minute (approximately 10 cases per minute), the new-generation case-packer combines case-packing, case aligning, bag packing, sorting, closing and sealing in one machine, while handling a wide range of bag sizes, case sizes and pack patterns.

Allowing users to store up to 500 preset case and bag sizes, pack patterns and other key variables via its large color touchscreen human-machine interface (HMI) terminal, the versatile case-packer can be automatically set up in less than three minutes without any tools or other manual operation—eliminating the risk of human errors and related downtime.

“We have been very happy with the new

Ishida automatic case-packer,” says Homenick, adding he was already impressed by the performance of the model ACP 700 case-packer that the company had previously installed at its old plant.

“In the current environment, where there has been a notable scarcity of labor in the marketplace, we have found that the ACPs have been critical for us to maintain our production run rates,” Homenick states.

To ensure optimal product quality and safety at all stages of the packaging process, Heat and Control also installed a pair of model THS/G21E drop-through metal detectors, manufactured in Italy by CEIA SpA, which are fully integrated with the Ishida weighscales and bagmakers to ensure reliable detection and removal of even the tiniest metallic particles that may have found their way into the product flow.

“It really provides a valuable ‘peace of mind’ for the Hardbite quality control team,” Jenkins points out, also citing incorporation of an Ishida model TSC-RVS bag thickness and seal checker at the entry point into the ACP-700 automatic case-packer.

Says Jenkins: “As the leading snackfood packaging team, Heat and Control and Ishida are both very familiar with high-speed packaging, but the Hardbite packaging film was a real challenge.

“It’s thick and makes a uniquely attractive bag,” he says, “but it’s not the easiest film to process at high speeds.

“Sending film to the Heat and Control packaging division o ce facility in Lancaster, Pennsylvania, and also to Ishida in Japan for testing was all part of a thorough process to ensure that Naturally Homegrown reached their production and

quality targets,” Jenkins relates, “and that they were totally satisfied with the Ishida system solution.

“At this stage, I am pleased to report that Hardbite is reaching all the expected targets in terms of output, manpower savings and overall e ciency associated with the Ishida high-speed packaging system.”

Homenick concurs: “All Heat and Control equipment comes with a level of confidence that you know will perform in a trusted manner.

“We feel extremely grateful for the ongoing support that we have received from their team over the years as they have helped support our growth.”

For his part, Heat and Control’s Jenkins is also proud of the trust, rapport and comfort levels that his company has built up with Naturally Homegrown.

“The experience of continuing to work with a unique outfit like Naturally Homegrown has been very rewarding for us at Heat and Control,” he states.

“Kirk and his team are extremely knowledgeable and very forthcoming with their challenges as they continue to grow their business.

“I believe Heat and Control is uniquely positioned in the industry to provide them with not only equipment solutions,” Jenkins concludes, “but also with an abundance of knowledge to help the Hardbite team solve any issues they may encounter with the various equipment they have acquired over the years.”

Heat and Control Canada Inc.

Ishida Co Ltd CEIA Spa

Please see a video of the fully automated packaging line, installed by Heat and Control at the new Naturally Homegrown Foods potato and vegetable chip manufacturing plant in Surrey, B.C., running in full flow on Canadian Packaging TV at www.canadianpackaging.com

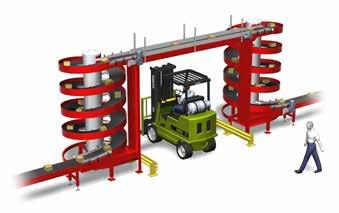

Ryson Spiral Conveyors need less floor space than conventional conveyors and are faster and more reliable than any elevator or lift.

Unit Load Spirals convey cases, totes and packaged goods smoothly on our slat style belts and come in 9 standard slat widths ranging from 6” to 30”. Available in powder coated carbon steel, stainless steel, wet environment and freezer versions.

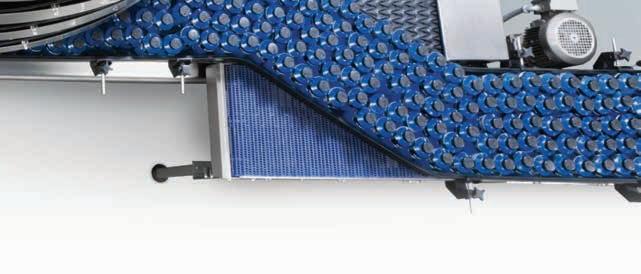

Mass Flow Spirals handle full and empty bottles, cans and jars in mass up to 2000 units per minute. Available in 4 different slat widths ranging from 6” to 20”.

Narrow Trak Spirals are super compact and designed to handle your smaller loads. Our 6” and 9” wide nesting slats can end-transfer small cartons and packages or side-transfer small bottles and containers in a single file or in mass at speeds in excess of 200 FPM.

Ryson’s Bucket Elevators combine vertical and horizontal transportation of bulk materials in one integral unit.

Ryson Bucket Elevators are designed for gentle handling and well-suited to transport a broad range of bulk products. Our signature feature is that they are completely enclosed with overlapping pivoting buckets, that prevent spillage and helps mitigate foreign debris.

Their modular design enables us to customize with ease. They can be configured with multiple inlets or outlets that can be controlled individually. The design makes them easy to install and modify. Available in three standard bucket sizes, yielding capacities up to 300, 700 or 1,800 cubic feet per hour. They can also be delivered in powder-coated carbon-steel, stainless-steel or wet environment versions.

All Ryson equipment is modular and built to order. No matter the application, the Ryson team is up to the challenge of finding solutions for your conveying needs. For application assistance or more information, give us a call or visit www.ryson.com .

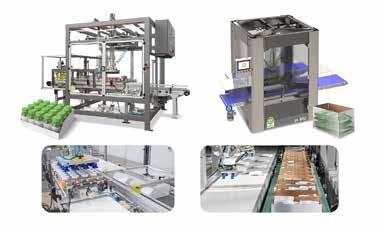

The lightline machines from Schubert can be delivered quickly and are exceptionally attractive in terms of price . With the preconfi gured machines, customers can adapt more fl exibly to market trends and signifi cantly shorten their time-to-market.

The LIGHTLINE CARTONPACKER consists of a single compact machine frame, and packs boxes, cans, bags or bottles into cartons and trays with or without a lid, wrap-around cartons and RSC cartons. It offers an affordable and space-saving possibility to automate packaging processes with the most effi cient technology on the market while ensuring the highest availability and packaging quality.

The world’s leading FMCG and private label manufacturers rely on Schubert. www.schubert.group

WHAT TYPE OF CARTON SHOULD IT BE?

Hardworking Quebec seafood processor leverages superior product quality and versatile packaging machinery to meet growing consumer demand

By Andrew Snook

Photos by Pierre Longtin

For over 35 years, Frandon Seafoods has been supplying high-quality fish products to the people of Quebec and beyond.

Starting out as a small distributor catering to Montreal’s foodservice industry in 1986, the company has since undergone multiple expansions.

Frandon Seafoods entered the retail market in 2009, and less than a decade later was acquired by Premium Brands Frandon is now an importer wholesaler distributor supplying primarily the Quebec and eastern Ontario markets.

Frandon services all sectors of the food industry including product development and innovation. Based in Saint-Léonard Que., the company employs more than

100 employees working two productions shifts (days and evenings), as well as a night shift for sanitation.

“We source our products from around the world,” says Éric Bissonnette, managing director for Frandon Seafoods, “but we like to put an emphasis on local products like lobsters, crab, Nordic shrimp, turbot and halibut.

“There are still lots of products that we need to market from our own waters to local markets,” Bissonnette says. “We serve foodservice customers, large and small retailers, regional distributors, fishmongers, manufacturers, home meal replacement products, and more.”

Since being acquired by Premium Brands in 2019, the combined resources of the two companies have allowed Frandon to grow considerably, taking advantage of additional capital and a coast-to-

coast distribution network.

In the past year, Frandon imported and sold over 10 million pounds of fish and seafood.

“We are part of a Quebec seafood distributor list that Premium Brands acquired in the latest couple of years which, combined, is making us the biggest in the province,” Bissonnette says. “Our ecosystem is very strong and very beneficial for all the di erent entities.”

Bissonnette adds that his knowledgeable team is also a big reason for the company’s success.

“We have a lot of experienced people in our organization,” he says. “Our knowledge of the products and the industry, combined with our variety of products and, most of all, our service excellence, is what really sets us apart from the competition.”

With production and processing of fish

products currently comprising about 35 per cent of the company’s business, Frandon is continuously investing in its processing and packaging lines at its state-ofthe-art 45,000-square-foot production facility.

“We are committed to becoming the biggest processor in the province,” Bissonnette says adding that Premium Brands has been extremely supportive of all of the company’s initiatives to grow its market share.

With food safety, quality and sustainability all being top priorities in all aspects of Frandon’s operations, the company has created a dedicated four-person team, led by its quality assurance director, mandated to ensure that all of its certification protocols—including HACCP (Hazard Analysis Critical Control Points) , SQF (Safe Quality Food), Ecocert and the federal permit—are stringently followed to the

letter and solidly implanted in the company’s work culture.

“More and more customers are looking for peace of mind when buying and eating seafood,” Bissonnette says.

“They want quality and sustainability in their plates,” he says, noting that the current labor shortages in the industry have created new challenges on the packaging side of Frandon’s business for ready-to-sell products.

“It (packaging) is becoming an important area of our business,” Bissonnette acknowledges. “Every day we are thinking of new ways to use the equipment so that we can meet all the requests we get.”

Two years ago, the company began accelerating its capital investment on the packaging side of the business with the purchase of a versatile P420 P-Series rollstock machine.

Manufactured by renowned Swiss

packaging machine-builder VC999 Packaging Systems, the P-Series machines are designed to run flexible, rigid, semi-rigid, skin and shrink films to produce superior air-tight packaging to ensure optimal product protection and freshness.

“This machine does rigid, flexible and skin-pack on the same machine without a die or mechanical adjustment,” says Carl-Michel Cloutier, sales manager for eastern Canada at VC999 Canada Inc. in Saint-Germain-de-Grantham, Que.

“We developed it five years ago when we started selling that machine specifically for the fish market,” says Cloutier, adding that supplies Frandon with rigid, flexible and breathable films for fish packaging through the company’s VC999 Materials Division unit.

Bissonnette says the biggest challenge related to packaging fish is its constantly changing size and shape, but that has been addressed with their investment in VC999 technologies.

“Fish has no standards as far size and shape are concerned,” he says, “but the VC999 is permitting us to adapt to most of them using di erent dies.

“It also lets us package either fresh or frozen products.

“We are also packaging marinated products,” Bissonnette points out, “and the VC999 P-Series machine is built in a way where the liquid marinade is well accepted into the package, creating no problem for packaging our skewers.”

According to Bissonnette, one of the main reasons that Frandon opted for VC999 technologies is for the company’s reliable service and knowledgeable sta .

“When you put a new packaged product out on the market, you can’t go back,” he says, “so you need to make sure you are well supported by your equipment company.

“Speedy service and parts availability are very important in case you have a breakdown,” Bissonnette says, adding that Frandon also benefits from VC999 Canada’s solid industry knowledge when developing new packaging concepts.

“Since we are still relatively new in this market segment, we also solicit them for advice when we are developing new packaging ideas,” Bissonnette says.

“Their know-how and experience are a huge help for us at that stage of product development.”

As Bissonnette relates, when the company started looking into purchasing packaging equipment for new products it was developing, VC999 was recommended as a packaging equipment supplier by the general manager of another sister-company owned by Premium Brands.

“VC999 Canada came up with the best overall package, including versatility, upgrading, service, fastest delivery and price,” Bissonnette recalls.

Managing director Éric Bissonnette praises the flexibility of the P420 machine to process a variety of di erent package formats, styles and sizes.

“We did our due diligence before signing up with them,” he adds. “We called at least five di erent companies that were using their products, and they all highly recommended them to us.”

As Bissonnette points out, the new VC999 P420 P-Series rollstock machine is actually the second piece of VC999 equipment that Frandon has purchased to date.

About five years ago, the company acquired the model XtraVac 860 vacuum-packing machine to be able to improve its packaging for the grocery retail market.

Since arriving at the plant, the new VC999 P420 P-Series rollstock machine has been extremely helpful for packaging the fresh fish products that Frandon offers, according to Bissonnette.

Due to the fragile nature of the product, and with fresh fish requiring an oxygen transfer aways from the product, all the adjustments in the vacuum process need to be very precise and steady.

“Once you have set your program, the equipment is very easy to use,” Bisson-

nette says. “It is a plug-and-play.

“Most ideas we have for new products are doable with the VC999 equipment we purchased,” Bissonnette relates.

“That is very important because we want to maximize our ROI (return-on-investment),” he says, “and also because of space-saving aspect, which is crucial in our environment.”

The robust P420 P-Series rollstock machine technology and the helpful VC999 Canada sta have provided an important competitive advantage for Frandon in terms of both productivity

and innovation.

“Basically, none of our projects and new ideas would have been feasible without it and their team,” Bissonnette extols.

“Those new ideas are increasing our purchase power as our volume increase and as projects gets developed.”

The P420 P-Series rollstock machine is equipped with one servo-driven moving punching/cutting station, so that Frandon can make any type of packing format or size they may require in the future.

Cloutier adds that the high-performance machine is fully equipped with all

“VC999 Canada came up with the best overall packge, including versatility, upgrading, service, fastest delivery and price.”

The VC999 P-Series P420 rollstock machine installed at the Frandon Seafood facility o ers throughput speed of 12 to 14 cycles per minute, depending on the product and pack size, which comfortably exceeds the plant’s current production speed requirements and provides plenty of room to boost production levels in the future.

the latest control technologies and multiple value-added features.

“This machine has a jumbo roll for the forming station, so that they can put on really big rolls, and not have to change forming rolls very often,” he explain.

“They also have a spacial loading grid to protect the loading area against contamination for marinated products,” he says, “and they have an on-site chiller so that so that they don’t have to use city water.

“It’s a real ‘green machine’ concept,” says Cloutier, adding that the machine’s throughput speeds of 12 to 14 cycles per minute o ers Frandon plenty of room to grow its production volumes over time.

“They don’t run at that speed right now because they don’t have enough production yet,” Cloutier remarks.

The P420 rollstock machine at the Frandon plant is connected to with a Markem-Imaje thermal-transfer printer—equipped with top and bottom labellers—to take care of all lot number and dating on the film, printing all the required variable product information at high resolution.

Some of the P420 rollstock system’s other notable features and attributes include:

• A swing arm HMI (human-machine interface) control panel;

• The p-Software programming suite, designed to control the machine’s operations with high eciency and ease of use;

• The IP 65-rated stainless-steel display enclosure;

• Intelligent integrated diagnostics;

• The Know Now! Machine/Production Metrics software for both live set-up and historic production data collection and reporting.

With sustainability is an integral aspect of Frandon’s operations, the company is

always looking for more eco-friendly packaging options as they become available.

“We work very closely with packaging manufacturers,” Bissonnette confides.

“Our products are very shelf-life-sensitive and come in many di erent shape and forms: therefore their support is of the utmost importance.

“Being a federal plant, HACCP & SQF certified, we need our materials to be of superior quality as well,” Bissonnette says.

So what does the future hold for Frandon Seafoods?

Bissonnette says the company is dedicated to developing new shelf-ready products and ideas for its customers while ensuring optimal product integrity and quality.

“We are definitely in expansion mode, and we welcome any product ideas or needs from our existing and new custom-

ers,’ he says. “We want to be the Quebec solution for ready-to-use seafood products in the province.

“Fish has very limited shelf-life,” he says, “so our proximity to markets will help us immensely.”

To conquer those markets, the company will continue to invest in new product and packaging development, according to Bissonnette, as well as install more automated packaging machinery.

“Frandon is well supported by our corporate department for all our product development initiatives,” Bissonnette concludes, “as it continues to be a growing segment for us.

“There is no doubt in our mind that further automation will be a key part of our future.”

VC999 Canada Inc.

Please see a video of the VC999 P420 P-Series rollstock vacuum-packing machine in action at the Frandon Seafood plant on Canadian Packaging TV at www.canadianpackaging.com

Scan the QR code to find your “breakthrough”.

© 2022 Honeywell Intelligrated. All rights reserved.

Are persistent bottlenecks cutting into profits and disrupting customer service levels? Leveraging advanced warehouse execution software, high-speed sortation, AS/RS shuttles and robotic automation, we can help you to clear hurdles and solve fulfillment challenges.

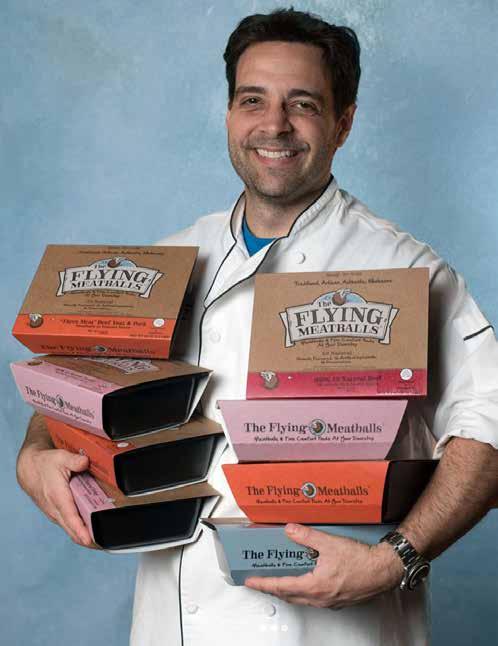

A family tradition quickly takes flight with a little help from its packaging friends

Featuring upscale, authentic Italian dishes, white glove service, and a setting that includes Grottescostyle painted ceilings and live piano during most meals, the Il Capriccio Ristorante in Whippany, N.J., has been a local fine-dining favorite for more than 35 years.

On any given evening at Il Capriccio, second-generation owner and executive chef Natale Grande warmly greets his patrons with a smile and handshake, calling them by name as he stops at the tables just as his father did—and sometimes still does—so that every guest feels like family.

Naturally then, when the enterprising chef Grande started looking at ways to expand the business, he was struck by the idea of o ering some of his family’s recipes in settings outside of the flagship restaurant.

When his mother asked him what dishes he thought would be popular to sell at retail or online, Grande answered with one of his own childhood favorites: the meatballs.

Handed down by generations and perfected in his kitchens at the restaurant and at home, this was the recipe he knew by heart. The challenge became how to package those meatballs in sauce so that in addition to tasting like they were fresh o of the stove, they were easy to ship, store, and heat in a home kitchen.

At first, Grande cooked and packaged meatballs in small quantities at the restaurant, which he started selling in one location, his family’s gourmet shop, La Famiglia Gourmet in East Hanover, a few miles away from Il Capriccio.

In only a matter of weeks, however, he couldn’t keep them in stock as they were literally “flying o the shelves,” at which point The Flying Meatballs brand and its signature logo was born.

After visiting a restaurant trade show and making an investment in some packaging equipment, the company’s equipment supplier suggested for Natale Grande to reach out to Sealed Air Corporation for help with package design and access to the company’s CRYOVAC brand food packaging materials.

New business development manager

Enterprising New Jersey chef Natale Grande holding up packs of The Flying Meatballs brand of ready-to-eat authentic Italian dishes packed in CRYOVAC sous-vide film pouches placed inside ovenable cooking trays.

Steve Daca and Account Manager Sherri Schall soon met with Grande one afternoon at the restaurant, carefully listening to his vision for The Flying Meatballs brand.Daca and Schall immediately started homing in on package performance needs like thermalization, durability, filling, transit, storage, and retail impact.. They o ered Grande access to resources like Sealed Air’s creative and design teams and training courses at the company’s Packforum research facilities, so

he could learn more about package thermalization.

They also visited The Flying Meatballs packaging plant to understand more about the floor layout and equipment Natale had purchased. Together they came up with a plan that allowed The Flying Meatballs to really start gaining momentum, with resources most small businesses simply can’t a ord at start-up. Over the past several years, The Flying Meatballs package has changed a few times, making modifications along the way to account for growing demand and a larger, more diverse supply chain.

Current packaging features a sous-vide flexible pouch placed into a pre-made ovenable tray, all surrounded by a printed, recyclable paperboard sleeve featuring the company’s iconic logo of a meatball with wings.

Now available in five di erent flavors, The Flying Meatballs product line continues to grow, with distribution expanding from the family store to local specialty retailers, then to regional retailers and now to national grocery chains, several sell-out appearances on the QVC shopping channel, and their new online direct-to-consumer store.

Using the knowledge gained as part of the process, the company now has secured more new business and invested in more packaging equipment to serve as a co-packer for several well-known brands of hot dogs and gourmet ready-meals for one of the most prominent DTC (direct-to-consumer) meat brands in the U.S.

Sealed Air Corporation

busy

Nestled in cozy Invermere, B.C., Kicking Horse Co ee is situated between the Purcells and the Rocky Mountains in the beautiful Columbia Valley.

The pristine resort town, which boasts a population of just over 3,000 people, is a popular year-round destination for tourists and a second home for many folks from Calgary and Edmonton in the neighboring province of Alberta.

Invermere is a quiet place where many people ride bicycles, aegerly partake in local cultural events, and enjoy the leisurely overall pace of life.

Many of these same charms are also instilled at Kicking Horse Co ee. From its humble roots of roasting co ee from a garage more than 25 years ago, Kicking Horse today sources its co ee beans from certified organic and fair-trade farming cooperatives around the world.

Organic and fair-trade farming means the co ee beans come from farming co-operatives who are dedicated to improving the biodiversity on their farms. This also means its co ee is shade-grown on small-scale farms, which aids in the biodiversity e orts of the land.

Another thing Kicking Horse Co ee is passionate about is the safety of its employees, recently noticing that aome areas of its packaging process required repetitive motions that could lead to injuries.

To minimize those concerns, while also adding more e ciency to its operation, the company turned to Wexxar Bel, a prominent case- and tray-forming and sealing machinery manufacturer based in Richmond, B.C., to automate these tasks at its end-of-line packaging process.

“It was always kind of a scramble,” recalls Jocell Valdez, production manager at Kicking Horse Co ee, describing the previous manual of process of filling

the boxes with product.

“Our packing team was always wrestling the boxes to the ground, and then packing six bags in it,” Valdez relates.

“There’s a lot of ergonomic issues with that type of repetitive motion—twisting and bending, and constant rotation—to try and avoid injuries.”

Operates three roasting lines over two daily eight-hour shifts, five-days-a-week, Kicking Horse was introduced to Wexxar Bel, a subsidiary of the ProMach group of packaging machinery manufacturing companies, during a visit to the PACK EXPO Las Vegas packaging technologies exhibition in September of 2019.

Soon after the show, Wexxar Bel recruited the services of Harlund Indus-

Top

An overview of the of the end-of-line packing area of the Kicking Horse Co ee roasting plant in Invermere, B.C.

Bottom One of the three Wexxar Bel Flex E Pack modular case-packing systems installed at the plant by Harlund Industries.

tries, leading Canadian-based distributor of coding, identification and related packaging equipment, to help design the ideal solution for Kicking Horse’s needs.

Harland Industries’ packaging and coding specialist Rob Vanstone began the process by auditing Kicking Horse’s packaging procedures as part of their review.

After discussing several options with the Kicking Horse management team, Harlund and Kicking Horse ultimately determined that installing the Wexxar Bel Flex E Pack system on all three lines would provide the best ROI (freturn-on-investment) moving forward.

The Flex E Pack system is a modular

packing solution that provides endusers with the flexibility to integrate the right case former, product delivery conveyor, work-cell and sealer that best meets their applications.

The Flex E Pack system matches the right components to each of these four segments to ultimately design a packing line tailored to customers’ exact needs.

Based on Kicking Horse’s needs, two workcells and product accumulation tables were needed to easily grab and pack the product into cases.

“One of the big advantages the Flex E Pack system brings is packaging on demand,” says Adrian Tomozei, Wexxar Bel’s regional sales manager for Canda and northwestern U.S..