AUTOMATE NOW PLUS

SENIOR PUBLISHER

Stephen Dean (416) 510-5198

SDean@canadianpackaging.com

EDITOR

George Guidoni (416) 510-5227

GGuidoni@canadianpackaging.com

ART DIRECTOR

Lisa Zambri

lzambri@annexbusinessmedia.com

ACCOUNT COORDINATOR

Barb Comer (888) 599-2228 ext 210 bcomer@annexbusinessmedia.com.

AUDIENCE DEVELOPMENT

MANAGER – TEAM LEAD

Barbara Adelt (416) 510-5184

badelt@annexbusinessmedia.com

CEO

Scott Jaimeson sjamieson@annexbusinessmedia.com

Innovative Automation Solutions

SENSORS: Inductive and Capacitive Proximity Sensors • Photoelectric Sensors • Level Sensors • Ultrasonic Sensors • Magnetic Sensors • Limit Switches • Safety Interlocks

SWITCHES: Solid State Relays • Contactors and Overloads • Soft Starters • Definite Purpose Contactors • Mini Circuit Breakers • Electromechanical Relays • Pushbuttons and Pilot Devices

CARLO GAVAZZI has the solution for your application needs, whether it’s our industry leading solid

energy meters, contactors, motor controls, monitoring relays or sensors, now available with IO-Link communications.

CONTROLS: Energy Meters • Current Transformers • Transducers • Power Supplies • Panel Meters • Time Delay Relays • Current-, Voltage- and Phase Monitoring Controls

BROADCAST NEWS

Why our upcoming webinar is the online event you can’t afford to miss this month

We know that spring is always an exceptionally busy time for everyone in our line of work, but if you have time to take in only one webinar this month, make sure it’s our very own Where Automation and Sustainability Intersect.

Scheduled to air nationally at 10:00 am EST on May 16, the two-hour webinar will explore how today’s CPG manufacturers and brandowners can leverage many exciting new automation technologies to improve the environment profile of their products and their manufacturing operations in our collective quest to usher in the new Circular Economy of the future.

Structured to avoid the usual banal greenwashing sloganeering, this exclusive online symposium brings together high-level senior executives from leading Canadian food manufacturing companies and major suppliers of automation technologies that can help manufacturers achieve meaningful performance breakthroughs in their sustainability journey with frank discussion of top-of-mind issues impacting the sustainability of their operations.

Jointly moderated by Canadian Packaging editor George Guidoni and Tom Egan, vice-president of industry services at PMMI, The Association for Packaging and Processing Technologies , we believe that the lively panel discussion is a worthy follow-up to PMMI’s landmark industry report released about a year ago, titled Sustainability and Technology: The Future of Packaging and Processing. (see image on the right)

Featuring key observations from prominent CPG industry executives and thought-leaders contained in that report, our webinar will provide various valuable tips and recommendations on how CPG companies can use modern automation technologies like robotics, vision systems, AI (artificial intelligence), digitization, Big Data, Cloud computing, additive manufacturing and other breakthrough automation technologies to reach and surpass their ESG goals for the greater good of the industry and the planet.

Click on this link to register for the webinar on May 16 at 10 AM EST. https://us02web.zoom.us/webinar/register/ WN_Q8uzEP-qScS66FnOEWo1OQ#/ registration

Sustainability and Technology – the Future of Packaging and Processing EPR/ESG

Workforce

Digitalization

George Guidoni, Editor, Canadian Packaging

Tom Egan, VP, Industry Services, PMMI

THE DREAM MACHINES

Midwest

U.S. packaging machinery manufacturer embraces bold innovative thinking and leading-edge automation technologies to become a leading force in the retail-ready packaging market

By George Guidoni, Editor

The ability to think outside the box can be an exceptionally powerful competence and competitive advantage in the packaging machinery business—especially when it results in a much better box.

Founded in 1973 in Minneapolis, Minn., family-owned end-of-line packaging equipment manufacturer Delkor Systems (www.delkorsystems.com) has enjoyed a remarkable period of brisk growth and expansion in recent years by leveraging its expertise in robotics and automation technologies to not only provide world-class robotic corrugated case and paperboard carton packaging lines, palletizing and other related packaging equipment for its CPG industry customers, but also set new retail industry benchmarks for shelf-ready packaging excellence and sustainability.

A neat row of Trayfecta G Series carton formers being assembled and tested at the Delkor Systems state-of-the-art production site in Minneapolis, which manufactures over 300 highly automated machines annually.

Nowadays employing about 350 people at a state-of-the-art, 300,000-square-foot manufacturing complex located nearby the main bridge connecting Minneapolis with its Twin City of St. Paul, the company’s relentless rise to industry prominence began in earnest in 1999 when its former sales manager Dale Andersen purchased the company from its original founder Jim Duddleston, himself a notable packaging pioneer credited with inventing one of the first machines for packaging liquid milk in paperboard cartons. A graduate of the University of Minnesota with a B.S. in Food Science and Technology, along with an MBA from the Carlson School of Management, Andersen’s thorough knowledge of the company and its key customers— acquired in his 12 previous years as a Delkor employee—were an exceptionally useful asset in transitioning the company from a standard “brown box” cartoning machine-builder into an innovation-driven, high-tech manufacturing powerhouse focused on providing complete automated packaging solutions for clients demanding maximum shelf impact for their brands.

“The one key thing I learned during those early years was just how important packaging design is to a successful machinery solution,” Andersen told the Canadian Packaging magazine in a recent interview.

“Making package design an integral part of the entire circle of responsibility is what makes Delkor different from much of our competition,” says Andersen, citing the company’s on-

site Package Lab packaging design center equipped with state-of-the-art package prototyping and testing equipment.

“We’re one of the few OEMs, maybe the only OEM making case-packers and carton equipment that has a dedicated packaging lab and packaging engineers on staff,” says Andersen, adding the company employs 50 full-time engineers across its operations.

“It’s a value-added service that we provide free of charge to our customers,” he says, “because we believe it’s critical for us to be able to work with the customer on the package design.

Says Andersen: “We are very focused on innovation and are willing to spend the money to have the right team in place to provide valuable innovation in terms of packaging designs, machinery designs, and the way they come together on the packaging lines.

“We can do a design turnaround in 24 hours,” he relates, “and we often have customers come here to see us test the designs, validate them, and see how they work on the machine.

“We know what designs work best with our equipment,” says Andersen, “and being able to test them on our machines internally is an amazingly powerful capability.

“So instead of taking months going back and forth with corrugated companies testing different designs to suit the application, we can quickly provide our customers with innovative solutions that streamline the customer’s usage of packaging materials and making their packaging process more efficient.

Delkor makes extensive use of FANUC high-end robotics across its end-of-line packaging machinery range.

Samples of popular pouched snack products standing upright inside the Cabrio Case shelf-ready boxes.

“We are willing to spend the money to have the right team in place to provide valuable innovation in terms of packaging designs, machinery designs, and the way they come together on the packaging lines.”

“We also understand what the mass merchandisers are looking for,” says Andersen,” citing relentless pressures by leading mass merchandisers and Club Store operators across North America to make their vendors supply more of their products in efficient and attractive retail-ready packaging and shelf displays requiring minimal in-store handling.

As Andersen relates, the company’s knack and affinity for retail-ready packaging were first unleashed about eight years ago when its vice-president of engineering, Rick Gessler, came up with an innovative new shelf-ready box design, called Cabrio Case, initially intended to facilitate upright shelf packaging for bags and stand-up pouches of cheese products. Made from a single corrugated blank for

optimal material usage and die-cutting precision, the patented tray-hood retail-ready package quickly attracted interest from retail giant Walmart as an alternative to displaying the bags of cheese by hanging them on steel racks by the pre-applied hang-holes just above the upper seal.

Easy to open on the shelf with a single swift motion with no cutting required, the Cabrio Case—easily produced alongside other traditional cases on Delkor’s Trayfecta line of case formers—features a perfectly-pre-cut tray front to provide perfect presentation for the product inside the case, standing up or laid-down flat, with its wrapped tray corners and machine-cut front edges and sides facilitating a clean and tidy look for the entire shelf.

Moreover, the one-piece corrugated construction used to make Cabrio Cases helps to reduce the corrugated usage by up 30 per cent compared to conventional two-piece box designs, according to Delkor, which Andersen says was also a major factor in Walmart’s quick embrace of the innovative new box design.

As Andersen recalls, the Cabrio Case was originally developed for leading U.S. dairy producer Schreiber Foods, who asked Gessler to join its marketing team for a presentation at Walmart’s global headquarters in Bentonville, Ark., just as the retailing giant was deciding what its first generation of retail-ready packaging was going to look like.

According to Andersen, the presentation went so well that Walmart soon began redesigning the cheese aisles of its stores soon after to accommodate what was at first simply called “Rick’s box” before being granted a patent.

“Today, approximately 65 per cent of all cheese sold at Walmart in the U.S. is packaged in Cabrio cases,” states Andersen, crediting the design’s flexibility, material savings and ease of handing for enticing packaged foods manufacturers across many other product categories for adopting the Cabrio Case for their retail-ready packaging solutions.

As Andersen points out, Cabrio Case packaging allows users to save an average of 20 per cent per box in material costs compare to other retail-ready designs while helping them improve their packaging sustainability profile.

“It provides a tremendous reduction in the use

of corrugated,” he extols, “and you can only imagine what it means in terms of sustainability.”

Notably, the use of the Cabrio Case design is offered to customers for free with the purchase of a Delkor case-packer, says Andersen, as one of the many value-added features used to market the company’s high-end equipment.

According to Andersen, the introduction of the Cabrio Case and other innovative packaging to the market will hasten the end of the CPG industry’s long-standing reliance on using the standard RSC (regular slotted case) boxes for their secondary packaging needs.

“The RSC box was originally invented by corrugated companies about 60 to 70 years ago as a pop-open box designed specifically for manual hand-loading of packaged products into a brown box—it was never intended for automation,” he states.

“The RSC box doesn’t really fit into the plan for a highly efficient and sustainable solution for corrugated packaging,” says Andersen, adding that automating secondary packaging lines simply to run RSC boxes faster dilutes the efficiency and productivity benefits that automation is expected to deliver.

“When we first developed the Cabrio case, we saw there was a lot of so-called retail-ready packaging out there that were really just RSC cases with tearaway perforations,” he recalls, “and it just looked terrible on the shelf with the bits of torn corrugated debris messing up the shelves, terrible graphics and generally poor product presentation.

(Top) Cabrio Case boxes being loaded with pouched product inside the Delkor LSP Series case-packer. (Bottom) Delkor’s vice-president of engineering Rick Gessler.

“Also, using robots to top-load RSC cases present a lot of problems because there is a lot of dimensional variance between the RSC cases themselves, just because of the way they are made,” Andersen adds.

“Because it is not a precision process, you may have up to a quarter-inch variation from

remarkably

box to box, which really doesn’t work well with robots.”

In contrast, the robotic loading of precision-cut Cabrio Cases on Delkor case-packing equipment results in highly repeatable, high-efficiency, high-speed loading process with exact product placement and great shelf impact at the point of sale, Andersen contends.

“I predict that five years from now there will be very few large and medium-sized companies using RSC boxes,” he proclaims. “You will probably see some small companies using it simply because they may not yet have the money for automation, but we are seeing a trend to

widespread replacement of the RSC box.”

As Andersen explains, the widespread use of robotic technologies across all of Delkor’s machinery product lines has also enabled the company’s engineers to significantly reduce the changeover times on Delkor machinery—making it a highly attractive capital investment proposition for busy high-volume packaging lines across a fast-growing swath of CPG industries.

For companies serving multiple Club Store and other large retailers, the quick changeover capability is a priceless asset, Andersen asserts.

“There are probably close to 20 different designs of Clubs Store retail-ready packaging used by Walmart, Costco, Sam’s Club and other mass merchandisers,” Andersen explains, “and being able to switch from one to another within minutes, without any human intervention, is a big part of the efficiency equation.

“We spent about three to four years developing a new approach to how you design a packaging line,” he relates, “which resulted in the launch of new patented case forming technology that enables producers to switch from one shipper [box] style to another in under three minutes,” he states.

“That three minutes for the case former and eight minutes for the entire line,” he enthuses.

“There is no other machine in the world I’m aware of that has this capability.

“That innovation alone has enabled Delkor to more than double its sales over the last three years,” Andersen reveals, “because it solves a

(Left) Offering

quick format changeovers, the versatile Trayfecta S Series case forming machine running Cabrio Case boxes during machine testing on the Delkor Systems plant floor.

very important problem.

“It allows a producer to be able to ship whatever the mass merchandiser wants efficiently— without having an adverse impact on production or having to have two lines instead of one.”

Andersen adds the company thorouchly enojoed displaying its latest patented case-packing technology at the recent Bakery Showcase

2024 trade show and conference in Toronto, May 5-6, 2024, signalling the company’s growing interest in the promising Canadian market.

Says Andersen: “We were running our Trayfecta G corrugated case former and our Model 350 corrugated case closer to demonstrate the ability to change over to any shipper style—including brown boxes, retail-ready formats, and the full range of Club Store trays—in just three minutes.”

As Andersen relates, Delkor Systems has already completed 10 different packaging line installations for Cabrio Case packaging at some of Canada’s largest CPG manufacturers—including the country’s leading confectionery and cheese producers—and the overwhelmingly positive feedback from those Canadian custom-

ers to date has been exceptionally encouraging.

The continuous improvement and refinement of leading-edge technologies is firmly embedded in the company’s culture, according to Andersen, because it enables Delkor to respond faster to the ever-growing packaging changes upgrades that major retailers demand from their vendors.

“All mass merchandisers compete with each other via their packaging,” he says, “so accommodating any changes to that packaging in timely manner is critical.

“Whatever the market wants today, it will be different next year,” Andersen declares. “For us, that means having a flexible machinery design that can handle all the different shapes, sizes and product diversity of whatever the customer

(Top) Delkor Systems owner Dale Andersen (left) welcoming NBC reporter Tom Costello to the company’s plant last August to film a story on the role of automation and robotics in today’s fast-changing job markets.

(Bottom) A peek inside the sanitary design case-packer undergoing testing and validation at the Delkor Systems plant.

Delkor Systems director of field service Justin Marquardt (front center) surrounded by his team of about 30 highly skilled field technicians in front of a robotic case-packer.

needs.

“I am very proud to say that about 80 per cent of the machines we sell today did not even exist six years ago,” says Andersen, citing several recent new machinery innovations that include a new high-speed case-packer for glass bottles, capable of packing 380 bottles per minute, and a case-packer for small confectionary pouches, offering throughput speeds of up to 360 pouches per minute.

Nowadays manufacturing about 300 machines per year, Delkor’s key systems include:

• The Trayfecta series automatic case-forming machinery;

• Several brands of automated and robotized

case-packing equipment, including LSP, MSP and V series machines;

• Various carton and case closing machines for tri-seal and flange seal cases, cartons, stackable club store trays and retail-ready packages;

• Robotic palletizers incorporating FANUC brand palletizing robots.

As Andersen estimates, “About 60 per cent of all the machines we make are intended for processing flexible packaging, with the reminder for rigid packaging formats.

“Our machines can work with glass bottles, flexible plastic pouches and bags, large-sized industrial bag weighing up to 10 kilograms …

Samples of Cabrio Case retail-ready packaging already being used by Some of Delkor Systems’ highprofile Canadian customers.

pretty much the whole gamut of product shapes and sizes,” says Andersen, adding all Delkor equipment installations are looked after by the company’s highly skilled field service technicians.

“Our field service department reports directly to me,” Andersen states. “These people are given a very high profile because they interact with our customers every day.

“Every machinery solution we supply to the market has our total technical support because that is the best way to establish ourselves as a real partner to our customers,” he concludes.

“And our customers really appreciate that partnership as a critical factor for the efficient operation of their packaging line for many years to come after the initial installation.”

www.delkorsystems.com

Aerial view of the 300,000-square-foot Delkor Systems manufacturing campus.

Advanced proximity switches help satisfy Ontario machine-builder’s need for speed LITTLE WONDERS

There are indeed many rewards for machine builders who sweat the small stuff. The latest iterations of many tiny but essential components like sensors, cameras and switches can pack a great deal of innovation for their diminutive size.

For Pro-Line Automation Systems (www.prolineautomation.com) of Woodbridge, Ont., adopting Festo’s SDBT-MSX— the world’s first proximity switch with auto teach-in—eliminated a small but previously necessary step for achieving final operational readiness of their highly advanced, automated CNC fabrication systems for window and door manufacturing.

The SDBT-MSX ’s auto teach-in feature automatically learns and sets the correct final switching point when the machine is turned on the first time, unlike legacy proximity switches which need follow-up manual tuning after commissioning.

With many proximity switches on each ProLine machine, the time savings from no longer having to make this follow-up adjustment really add up.

Pro-Line is extremely busy, as are its customers across North America, facing strong demand as the continent ramps up efforts to launch more residential construction.

Single family, multi-unit and high-rises all have windows made by Pro-Line customers using its machines.

The company has seen its sales almost double over the past five years, says owner Vinode Ramnauth, and it’s embarking on a U.S. expansion with the potential to double sales again over the next two years.

The company is an eager early adopter of new technologies that makes its staff more efficient. It’s already the biggest user of the SDBT-MSX in North America for that reason.

This feature-rich proximity switch is one example of the advances Festo (www.festo.

com) is making in designing next-generation components, large or small.

Besides incorporating performance enhancements, it makes simplifying installation, commissioning and configuration points of emphasis. Proximity switches are affixed to pneumatic actuators to signal the PLC or controller that the full extension of the piston has been reached. They are invariably one of the least expensive functioning components on a Bill of Materials.

The SDBT-MSX is the most advanced in its class of magnetic proximity switches. About the size of a baby’s pinky finger, you probably wouldn’t notice it on a machine unless you looked for it.

First and foremost, what makes it special is the auto teach-in feature.

The diminutive Festo SDBT-MSX proximity switch, shown here affixed at the top of a round ISO cylinder, is the world’s first such sensor with auto-teach-in for simple, fast one-and-done commissioning.

www.rajones.com www.coesia.com

The Festo SDBT-MSX, affixed here to a compact rectangular cylinder, is unique technology incorporating auto teach-in feature to sets the switching point the first time, and never needing follow-up adjusting like legacy proximity switches.

When setting up a legacy proximity switch, a technician generally locates the actuator in the machine prior to commissioning, affixes the switch in the T slot or bracket of the actuator at the approximate end position of the extended piston. Since commissioning that legacy switch requires a power supply, it’s generally done when the machine is turned on for the first time, which usually does not happen under full com-

pressed air load.

When the machine is eventually turned on under full load, each such switch must be finetuned.

That adjustment usually takes just a couple of minutes per switch, but once multiplied by the number of switches on a machine—often several dozen and sometimes in difficult-to-reach locations—those extra minutes turn into hours

of staff time. (Occasionally, those post-commissioning adjustments must be made at the end user, a much larger allocation of time, plus travel expenses.)

Conversely, the initial set-up of the SDBT-MSX doesn’t even require a power supply. The switch can be affixed to the actuator at a work bench, prior to installation.

Once the actuator is in place, the SDBT-MSX cable is plugged into the controller. When the machine is powered on for commissioning and completes just four cycles, the SDBT-MSX’s auto-teach capability automatically sets the correct final switching point without impacting the application.

“For us, not having to go back after commissioning and powering on the machine to individually adjust the position of each sensor is a huge time-saving, and helps streamline our production,” says controls engineer Andrew Nauth.

Additionally, the end-stroke tolerance on the SDBT-MSX can be adjusted easily on the device within a range of 2-15-mm to adapt to different operating conditions.

Typically, a standard cylinder switch may have a 2-mm detection range, fine for when the piston is hitting a hard stop on metal.

However, with vinyl or polymers that have some give, a soft stop can be a challenge for a legacy switch.

Many of Pro-Line’s CNC systems are cutting vinyl, and signalling the piston end stroke often

requires a detection range greater than 2-mm. On some machines, Pro-Line has had to employ two legacy proximity switches on the same actuator to achieve a wider detection range, an additional cost in componentry, PLC logic and staff time.

“So, being able to use just one switch, the SDBT-MSX, and adjust the tolerance to get the same result is definitely an advantage,” says Nauth.

Using its capacitive teach button, the SDBT-MSX can be programmed for PNP (negative load) switching output or NPN (positive load), NO (Normally Open) or NC (Normally Closed) operation, so machine builders can bulk-purchase just one variant for all situations.

For Pro-Line, that represents another potential cost efficiency, as it has began designing new models with remote I/O. ”Right now we are buying (pre-defined) NPN (switches), but when we start using remote I/O, on those machines we will be using PNP,” says Nauth.

“For us it’s a big advantage to be able to stock the same switch for all machines, and not need multiple pre-defined types.”

Aa a ‘set-it-and-forget-it’ technology, SDBT-MSX As a solid-state device, it’s rated for hundreds of millions of cycles, and is likely to outlast any actuator on which it is mounted.

As such, it’s a tiny but ideal solution for new builds and as a direct replacement for legacy switches on existing machines.

www.prolineautomation.com

www.festo.com

www.schneiderequip.com

TIME TO CONNECT

Fortress puts digital data to work to ensure optimal networking connectivity and compliance

To encourage a smarter food safety culture, the U.S. Food Safety Modernization Act (FSMA) —signed into law in 2011—placed great emphasis on enhanced record-keeping, techbased end-to-end traceability, and improved predictive analysis.

As declared by the former FDA (Food and Drug Administration) deputy commissioner and food traceability pioneer Frank Yiannas, “A standardized, data-driven approach to traceability and record-keeping helps create a harmonized, universal language of food traceability.

“This will help pave the way for the industry to adopt and leverage more digital, interoperable, and tech-enabled traceability systems both in the near term and the future.”

Developed by Toronto-based product inspection technologies stalwart Fortress Technology (www.fortresstechnoloy.com) to create a centralized database of live and recorded data that assists food processors to automate QA (quality assurance) documentation, the Contact 4.0 real-time web-based remote machine monitoring solution monitors the performance of inspection equipment, tracks

events, and documents all potential product risks.

As such, it turns potentially massive data streams into tightly monitored operational insight.

With food processors becoming increasingly dependent on accurate data to ensure the distribution of safe food to consumers, the current approach to food safety requires stringent rec-

ord-keeping procedures.

Contact 4.0 enables food processors to securely collect and compare processing data.

By automating the entire data logging process, Contact 4.0 helps to remove the risk of human error, while also prompting operators to test inspection equipment.

Manually monitoring food inspection machine performance can be extremely labor-intensive, thereby adversely impacting productivity. Even those companies that have upgraded

legacy systems continue to gather data on a machine-by-machine basis, rather than integrating and analyzing information side-by-side and building up a full performance picture.

“Automated and networked data extraction and real-time monitoring are proven to enhance production efficiency and minimize machine downtime,” says Fortress Technology’s regional sales manager Eric Garr.

As a real-time web-based remote machine

monitoring solution, Contact 4.0 enables food processors to review, collect data and securely oversee the performance of multiple Fortress metal detectors, checkweighers or combination inspection machines connected on the same network.

Moreover, Contact 4.0 eliminates many of the cumbersome functionality challenges that enterprising companies usually encounter—notably infrastructure, data storage, security and

scalability.

From viewing live event logs and performance verification checks, to quickly accessing records to support a recall event, Contact 4.0 offers processors a robust, simpler and safer way to rapidly stream and share performance data.

Providing secure access via a web appliance and 24/7 monitoring of multiple units, Contact 4.0 sits on the same network as the Fortress digital metal detectors, checkweighers or combination systems.

Compiling and communicating data events channeled through a compact web appliance located on the same LAN as the inspection machines, Contact 4.0 fully complies with all international food safety management standards, including HACCP , BRC and GFSI/SQF.

Food processors can use Contact 4.0 to define and customize their data filters, whereby rejects, faults, changes in parameters, passed tests, and failed tests, are all accurately logged and time-stamped for regulatory compliance.

Historical or live batch reports from checkweighers can also be viewed, which include histograms to provide a visualization of product weight distribution over the production run.

To extract the data, authorized users simply log into the web interface via a browser on any networked device, including laptops and tablets.

“This is one of the critical benefits of a web-

based interface,” notes Carr.

The cohesive reporting system allows relevant staff to troubleshoot performance issues remotely, whereby the reports can be configured and emailed daily, per shift or weekly.

Test failure, fault or non-conformity events can trigger an automatic email alert, detailing when an event occurred on a specific machine.

With Contact 4.0, event and machine performance information is stored securely for a minimum of 10 years.

There is also the option to extend storage capacity to 20-plus years, which can either be located on the internal storage of the appliance or a centralized network database.

Better traceability, accountability, and faster identification and corrective actioning of faults leads to a safer food supply chain, while investigating contaminant events can be initiated by simply pressing a button.

Says Carr: “For businesses with multiple data sources, web-based solutions offer the level of flexibility and the middleware layer required to collate meaningful information from different machines, with minimal effort or human intervention.”

As Carr relates, “Fortress intentionally kept the front-end structure simple to help to keep data manageable, while delivering meaningful quality oversight for production and quality managers”

Once installed, additional licenses can be added to incorporate more Fortress inspection equipment, while users can also subscribe to receive optional software support and software updates as new features become available. www.fortresstechnoloy.com

A single compact Contact 4.0 Adapter can extract data from multiple inspection machines connected on the same network.

RIDING THE TUBE

PackSys Global relies on monitored changeovers with digital position indicators from SIKO in tube welding machines

By Michaela Wassenberg

Large tubes, small tubes, long tubes, thick tubes, flat tubes, miniature tubes—tubes are produced in countless sizes and formats for oral care, cosmetics, and in the pharmaceutical industry.

Many of the machines that produce the packaging for toothpaste and cosmetic products come from PackSys Global AG (www.pack-

sysglobal.com) in Rüti, Switzerland.

The company’s focus on efficient processes, high output, and ease-of-use for its customers is achieved through increased digitization, automation, and streamlining of mutiple process steps. An important aspect that significantly influences process reliability is the proper machine changeover, notably y the adaptation of settings to accommodate various tube formats.

To achive this, PackSys has integrated a monitored changeover solution from SIKO GmbH (www.siko-global.com) , German specialists in sensors and positioning systems, in order to increase the ease-of-use of its tube welding machines and ensure the safe adjustment of the various units.

PackSys Global AG, which belongs to the Brückner Group, specialized in systems for

the production of plastic tubes, also supplying hot-stamping machines for applying decorative metallized coatings, roll cutting and folding machines for plastic closures, as well as packaging machines for cans, tubes and closures to transport them to the filler.

Many of the company’s machines require regular changeovers. The most common method to accomplish this is to use mechanical

The FlexSeamer tube welding machine from Packsys Global offers high speed and reliable operation.

position indicators that are manually set to a position value stored in the documentation. This has a high potential for error, as values may be read and set incorrectly. Especially in the case of frequent adjustments for different tube variants at several positions, the integration of digital position indicators for monitored changeovers is a worthwhile alternative.

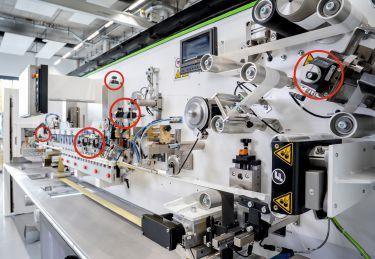

From the plastic laminate to the finished tube, the FlexSeamer is easy to operate and reliable thanks to monitored changeovers from SIKO (markings).

The FlexSeamer machine is used to unwind a flat belt material, a plastic laminate, from a large roll of material.

Depending on the product requirements, the processed plastics are usually material blends that must have good barrier properties in order to minimize the amount of oxygen reaching the product inside, while limiting the diffusion of aromatic substances out of the tube.

The plastic sheet is folded lengthwise, formed into a tube, and then provided with a longitudinal weld seam—transforming the flat material into an endless tube.

The switch to digital position indicators was tested during the development of a new tube welding machine, the FlexSeamer.

The choice for the digital AP05 position indicator with IO-Link interface from SIKO was made for several reasons.

It stood out due to its compactness, universal applicability regardless of the axis orientation (vertically or horizontally), and intuitive readability thanks to two LED lights.

The displays are used at approximately 10 positions throughout the system, for example, to check settings like the thickness or length of the plastic laminates or a varying print image.

Another SIKO position indicator, the AP10S, is used to monitor the positioning during linear movements.

The plastic tube isthen cut into individual sections by a rotary blade. This is the actual body of the tube into which the cosmetic, toothpaste, or pharmaceutical product will later be filled. In a subsequent machine, known as the “Header & Capper,” a so-called shoulder with threaded and capped ends is placed on one of the two sides.

The other side is left open so that the contents can be inserted through this opening during filling process, before the final transverse weld seam can be applied.

What sets the new welding machine apart is that it features a high speed of 250 tubes per minute, long heating and cooling sections designed for modern laminate types, and intuitive, fast, and reliable operation thanks to the digital capture of most settings.

While mechanical position indicators only display the actual value of a position, digital position indicators also show the target value of a setting.

For example, the dimensions for a particular type of tube are stored as a recipe in the machine control system and are then transferred to the respective indicators via IO-Link. An operator must then adjust the setting to match the actual and target values. This is the only way to continue with the production process.

Reliable indicators here include the two LED lights, which illuminate green only when the values match. As long as a red light remains illuminated on the system, the process must be stopped and readjusted.

For Aitor Henao, head of marketing and ommunications at PackSys Global, the advantages of such a solution are obvious.

“Formats can be quickly and easily adjusted,” he says. “Any product can be reproduced at any time with exactly the same settings because the dimensions are stored as a recipe for each variant.

“This means a consistently high level of quality because the processes are stable and reliable at all times.”

Emanuel Heusser, group manager automation engineering in R&D, emphasizes another aspect that is relevant to quality.

“It is often only when products are subjected to random destructive testing, which requires a great deal of effort, that the effects of an incorrect setting become apparent,” he says.

“However, if the digital position indicators ensure that the same settings are used throughout the production process, there is no need for

The AP05 (top) and AP10S (bottom) position indicators always guarantee reliable machine settings for the production of a wide range of tube variants.

downstream quality control.

“This is a significant added value of monitored changeovers.”

Increasingly, digitized solutions are providing support even in times of skilled labor shortages, as Henao points out.

“Years ago, there was one skilled worker who had been with the company for 20 or 30 years, who knew exactly where to make adjustments based on experience, and had ‘magic fingers’ when a setting no longer worked perfectly.

“However, today we have a very flexible labor market where skilled workers are rare.

“Intuitive operation that enables process-safe settings without in-depth knowledge of the machine helps companies address the shortage of skilled labor.”

There are many factors to consider when deciding on a monitored changeover. Positions requiring frequent adjustments are ideal for such an investment in digital monitoring.

Another argument can be the costly downtime associated with format changeovers, as reducing set-up times can be critical.

For rare adjustments or situations where incorrect settings are immediately noticeable, PackSys Global continues to use mechanical position indicators from SIKO. These indicators allow for easily controlled position values.

Another option from SIKO’s range of solutions are the compact, fully-automatic positioning drives. These drives allow size adjustment at

“Years ago, there was one skilled worker, who had been with the company for 20 or 30 years, that knew exactly where to make adjustments based on experience, and had ‘magic fingers’ when a setting no longer worked perfectly.

Aitor Henao, Head of Marketing & Communications, PackSys Global AG

Emanuel Heusser, Group Leader, Automation Engineering, R&D, PackSys Global AG

the touch of a button and moreover, and they are also easy to use in hard-to-reach areas of a machine.

The added value of the monitored changeover can be illustrated using an example setting of the the print mark sensor.

To cut the tube section, the cut must be made in the correct position relative to the print image. This is done by applying printed marks to the laminate, which are detected by sensors. The mark is located in a different place on the

circumference of the tube depending on the print image. Therefore, the position of the sensor on the circumference must always be slightly different in order to detect this print mark.

The position of the print mark sensor can be recorded in degrees and stored in the recipe thanks to the AP10S position indicator.

This means that the operator does not have to go into the machine to position the sensor relative to the print mark. Instead, the target positioning values are stored for each print image.

For Heusser, the universal applicability of the AP05 on both vertical and horizontal axes was a major plus.

“The display is angled at 45 degrees and can be configured via the software in regards to how it should be positioned,” Heusser states. “This also makes it easier for us to stock different products for vertical and horizontal axes.

“The actual integration proved to be straightforward, both regarding both the mechanical design and the electronic integration.”

Heusser’s assessment of the cooperation with SIKO is also positive.

“There has always been a great deal of goodwill, as SIKO aims to make wishes and suggestions a reality,” he says. “For example the AP05 was specially designed with IO-Link for our FlexSeamer project.”

Looking ahead, Aitor Henao sees a clear trend towards digitization and automation of systems, especially in the area of changeovers.

“These small details, such as the LED display, make all the difference,” he states. “They improve the quality of our machines and services—helping customer companies to focus on their business.”

www.packsysglobal.com

www.siko-global.com

The modern FlexSeamer tube welding machine with positioning systems from SIKO for optimized changeovers.

THE INCREDIBLE BULK

How to increase profits and productivity by upgrading critical bulk bag filling equipment

Manufacturers in the food and beverage sector continually seek methods to boost their operational efficiency and are prepared to invest in superior machinery when the expected returns justify the expenditure. However, the potential advantages of upgrading bulk bag filling systems are frequently underestimated.

In food and beverage processing, bulk bag filling stations play a pivotal role in ingredient packaging, enhancing the speed and efficiency of the packing procedure.

With an array of models available, these systems range from hand-operated setups to semi-automated units.

Semi-automatic fillers can significantly increase productivity and the bagging rate by

By integrating advanced bulk bag filling equipment, companies can realize substantial gains in productivity.

Spiroflow Bulk Bag Filler Top View

Spiroflow Bulk Bag Filler with Conveyors

Conveyors are almost always part of an integrated system with fillers because as soon as you get material in or out of the bag, you need to take it somewhere.

automatically introducing a pallet to the machine and removing filled bags, reducing the time required to manually handle every pallet and filled bag.

While many systems enhance the speed of bagging operations, there is a continual opportunity to refine and improve efficiency and output.

By integrating advanced bulk bag filling equipment, companies can realize substantial gains in productivity by increasing the number of bags

filled per hour—allowing more product to fit in existing bags, and even facilitating a transition to smaller bag sizes.

“These types of upgrades can substantially reduce operating costs, increase production throughput, reduce shipping costs, and even help processors recover lost revenue,” says Don Mackrill of Automated Handling Solutions (AHS), which provides engineering solutions that incorporate specialty conveyor, material handling, and automation equipment technologies.

Spiroflow CTE Bulk Bag Filler

In food and beverage processing, bulk bag filling stations play a pivotal role in ingredient packaging, enhancing the speed and efficiency of the packing procedure.

Within the portfolio of solutions offered by AHS is Spiroflow (www.spiroflow.com), which offers a comprehensive range of bulk filling and discharging equipment, including bulk bag fillers, bulk bag unloaders, and additional equipment needed for automated bulk handling of materials.

A highly experienced material handling and system integration expert, Mackrill offers some key advice that can help to cost-effectively optimize the bulk bag filling process.

As he points out, products sold by weight must be filled to the advertised weight. To avoid the possibility of underfilling, manufacturers frequently opt to fill packages more than necessary, which results in lost revenue that can accumulate over time. Inconsistent fill weights only increase potential losses.

“Processors don’t get paid for the extra pounds if they overfill the bag,” says Mackrill.

“If they can improve the weighing accuracy, they are not giving away as much free product.”

Switching to a bulk bag filler that offers precise weighing accuracy can effectively resolve this issue.

“If you can improve the weighing accuracy of your current bulk weighing system from +/- 5 pounds to +/- 1, you are no longer overfilling as much.

“From an accounting perspective, that is recovered revenue that goes right to the bottom line,” says Mackrill.

When the bagging rate exceeds 30–35 bags per

Spiroflow Gain in Weight Bulk Bag Filler

When processors use a bulk bag filler that offers precise weighting accuracy, they are not giving away as much free product.

hour, pre-weighing the material in a hopper above the filler should also be considered.

“Pre-weighing the ‘shot’ of material while a bag is being densified and removed from the system and the next bag is rigged, significantly increases the bagging rate,” says Mackrill. He notes that

Spiroflow Rise & Fall Bulk Bag Filler

Upgrading bulk bag filling equipment to a more efficient system that can compact or densify the material in each bag offers significant cost-saving opportunities.

some bulk bag filler systems such as the CTE from Spiroflow are capable of filling more than 40 bags per hour if the material is pre-weighed.

To further enhance the precision of weighing, it is important to consistently fill hoppers with equal amounts of material and align this process

with the pace of bagging operations.

Even minor factors such as the volume of material in the silo that feeds the hopper can upset the timing.

“As the weight of the material in the silo decreases, so does the flow rate, which makes it dif-

ficult to predict how fast product is going to come out,” explains Mackrill.

“If you can consistently match the conveying rate into the hopper with the bagging rate, then you can dial in a very tight weighing accuracy.”

Upgrading bulk bag filling equipment to a more efficient system that can compact or densify the material in each bag offers significant cost-saving opportunities.

One effective strategy for reducing packaging costs is to efficiently increase the density of the product in each bag.

By doing so, it may be possible to purchase smaller bulk bags while still shipping the same quantity of product.

On the other hand, for powders with bulk density less than 25–30 punds per cubic foot, it may be possible to increase the product capacity within the existing bag size.

This allows food and beverage processors to consistently approach the maximum weight restrictions permitted on truck trailers and avoid additional shipping expenses incurred when the weight falls below the limit.

Maximizing the amount of product in existing packaging dimensions can lead to increased production efficiency, potentially reducing the time required to operate the production line to achieve the desired quantity of goods. Any surplus capacity can be used to accommodate increased demand and support the sale of additional products.

Mackrill notes that enhancing material densi-

“Processors don’t get paid for the extra pounds if they overfill the bag.”

fication leads to a “ripple effect” of savings.

“You’ll weigh out every trailer and over time fewer trailers will be required to transport the total product weight within a specific timeframe,” he explains.

“Additionally, the increased capacity of each bulk bag results in filling fewer bags, thereby reducing packaging costs.”

Another benefit is improved bag stability. Some dry materials will entrap or entrain air between the particles more than others, and those that do require more vibration or densification to drive out the air between the particles.

When that is not the case, the bulk bags can become unstable and tip and fall during transport, handling or storage.

This can put operators at risk of injury, damage product, and increase operational costs.

“Unstable bulk bags can topple off a pallet while being moved by forklift, or they can lean or slump over in a truck trailer as it bounces down the road—making unloading difficult and even posing a safety hazard,” says Mackrill, adding that the primary purpose of a bulk bag filling machine is to “produce a safe and

stable bulk bag.”

To improve bulk bag stability and safety, some equipment is specifically designed to compact difficult fill material such as powders, granules, or flakes that are easily aerated.

The CTE bulk bag filler from Spiroflow, for example, utilizes patented cone table densification that deaerates the material with a flattened angle of repose—resulting in a very safe and stable bag.

The speed at which powders are compacted in the bag also impacts productivity.

“If it takes you 20 minutes to vibrate through the pallet into the bag [with your current machine] to the point where you can safely handle it, replacing it with a machine that can do the same in two minutes dramatically improves productivity,” says Mackrill.

Increasing the productivity of bulk bag fillers may require an upgrade or redesign of the conveyor system that transports products to the fillers.

However, it can be difficult to select the optimal mechanical conveyor system. This is the case when purchasers are relatively uninformed about the specific attributes and advantages unique to

each conveyor type available on the market.

The most critical aspect to consider is the type of product that the processor is trying to convey.

Issues such as product flowability, abrasiveness and cohesiveness should always be considered, while product degradation or the need to maintain a blend may also be key aspects to consider in some applications.

For food-grade applications, hygiene specifications and the ability to clean-in-place are naturally important considerations.

According to Mackrill, there are several categories of enclosed conveyors that meet these requirements, including aero mechanical, flexible screw, and tubular cable drag designs.

“Conveyors are almost always part of an integrated system with fillers, because as soon as you get material in or out of the bag, you need to take it somewhere,” he explains. “We want to do that in a fully enclosed environment so that we’re not letting dust out into the plant, not losing product, and not leaving the conveyor open to humidity or rain [if some of the conveyor is outdoors].”

Because every material handling scenario is unique, dealing with difficult powders or delicate, sticky products presents its own set of challenges.

To resolve these issues, food processors can benefit from the guidance of expert powder conveying integrators that have implemented various equipment types in complex applications over decades.

application, but also optimize it for their specific type of food and process.

Spiroflow has a wealth of experience consulting on these matters and offers enclosed aero mechanical and flexible screw conveyors, as well as tubular cable drag conveyer systems from another AHS company, Cablevey Conveyors (www.cablevey.com).

“Tubular cable drag conveyors are going to be extremely gentle. Mackrill says.

“Our aero mechanical conveyors are a little harder on product but are extremely quick, while flexible screw conveyors are very cost-effective in getting product from point A to point B.”

To ensure optimal results, Mackrill recommends rigorous testing of powders. Food and beverage producers are invited to submit their products for analysis to assess the materials’ flow characteristics.

Food and beverage manufacturers who acknowledge the untapped potential of optimizing their bulk bag filling systems stand to reap considerable rewards.

As the crux of efficient packaging operations, state-of-the-art automated bulk bag filling solutions can help food and beverage processors increase productivity and streamline operational costs in a way that is sure to impact the bottom line.

www.spiroflow.com

www.cablevey.com

An experienced integrator can not only help a processor select the best type of conveyor for their DEL WILLIAMS is a technical writer based in Torrance, Ca.