Features include:

C-more Headless HMI priced at: $599.00

• HDMI video/audio output with multiple resolutions

With the C-more headless HMI, you can display your factory floor data how and where you choose. The new CM5-RHMI has all the powerful functionality of the C-more Touch Panel HMIs, but without display size restrictions. This HDMI-enabled device works with televisions, monitors, projectors, and most any other HDMI display device or use the C-more Remote HMI mobile app and/or the embedded Web Server if you prefer no local display at all. The choice is yours!

• Video: VGA 640x480, SD 720x480, XGA 1024x768, HD 1280x720, FHD 1920x1080

• Audio: use USB audio adapter (not included)

• Works with most HID-compatible resistive and pCap touch screen monitors

• The USB A port allows support for most industrial touch screen monitors in the market

• Multiple connections

• (2) Ethernet, (1) RS-232, (2) RS-485, (1) RS-422 ports support programming and device connections

• USB-B port for programming, monitoring, and configuration

• (4) USB-A ports for USB HID devices such as USB hub, pen drives, touch screen displays, keyboard, mouse, and bar-code scanners

• SD card slot for log files, project memory, or graphic media

• 90MB of user memory

Fast free standard shipping* is available for most orders over $49 U.S., and that includes the brokerage fees (when using an AutomationDirect nominated broker). Using our choice of carrier, we can reach most Canadian destinations within 2 to 3 days.

*Free shipping does not apply to items requiring LTL transport, but those shipments can take advantage of our negotiated super-low at rates (based on weight) that include brokerage fees.

See Web site for details and restrictions at: www.automationdirect.com/canada

The easy-to-use C-more HMI design software can be downloaded free of charge from our webstore. Get started on your project today or take it for a test drive. Download as often as you need, no license or key required.

Get your copy now at: www.go2adc.com/cmoreswcm5

25-26 The latest products and technologies.

A single PoE cable enables facilities to easily add and reconfigure a range of computing equipment wherever needed without regard to existing electrical outlets

97%

The percentage of respondents from a 2023 poll by CME members that want the government to treat critical aspects of Canada’s transportation system as essential services.

Industries across the country breathed a sigh of relief as the federal government forced binding arbitration to stop the work stoppage related to Canada’s two Class I railways, Canadian National (CN) and Canadian Pacific Kansas City (CPKC).

The process sector is particularly sensitive to these kinds of work stoppages due to their heavy dependence on rail infrastructure to transport their goods to ports so they can be shipped to markets around the world. The mining, chemicals and plastics, wood products, agriculture and energy sectors experience heavy disruptions when any type of work stoppages take place. And recently, the sectors have been hit hard as they’ve had to deal with disruptive work stoppages in both their rail and port infrastructure in the past two years.

In July 2023, the Port of Vancouver experienced a highly disruptive work stoppage where over 7,400 workers walked off the job. According to the Canadian Manufacturers & Exporters (CME), the B.C. ports labour dispute cost Canadian manufacturers an average of $207,000 per day.

CME conducted a poll of its members from July 11 to 23, 2023. The results stated that “nine out of 10 affected manufacturers said the strike disrupted their supply of raw materials or components, while 70 per cent reported that it negatively impacted their relationships with customers, hurting already fragile supply chains.”

In the same poll, CME asked its members what reforms they would want to see prevent further labour disruptions. The result was that “95 per cent said they are in favour of reforms that that would allow the government to impose binding arbitration on striking workers, while another 97 per cent of respondents want the government to treat critical aspects of Canada’s transportation system as essential services.”

A few months after the B.C. ports strike had been resolved, another labour dispute shut down the St. Lawrence Seaway.

Dennis Darby, president CEO of the CME stated, “These disruptions are not only damaging the Canadian economy, but also jeopardize the country’s reputation as a reliable partner.”

The CME added that it urged the federal government to “proactively address the increasingly frequent supply

chain disruptions in order to preserve Canada’s competitiveness and global reputation, as well as provide much needed stability to Canadian manufacturers.”

When labour disruptions take place, I feel very conflicted. Over the course my working career I’ve been an independent contractor, worked for non-unionized companies, worked for unionized companies as a student, worked for unionized companies as a union member, and even held a position as a union representative. I understand the value of organized labour, and that it plays an important role in helping sustain Canada’s shrinking middle class. But that said, I believe there have to be better ways to get both sides to come to mutually beneficial agreements than waiting for work stoppages to take place.

Companies and employees need to find pre-emptive solutions that work for both sides. In the global economy that companies now find themselves competing in for market share, anything that disrupts their supply chains damages the confidence of potential and existing customers. In some sectors, this can also be highly damaging for investor confidence. Think of the mining sector, for example, where projects from start to finish can take decades to get up and running. These projects rely on massive investments, and these types of investors are in short supply. Canada is literally competing for these investment dollars with every other country’s mining operations. And while we have an abundance of resources in comparison to some countries, if investors don’t believe our sector can extract them, process them, and ship them to market in an efficient and cost-effective manner, then those investor dollars are lost, and those resources will stay in the ground. Less projects means fewer workers, and reduced revenue coming into all levels of governments for funding the building and maintaining our road infrastructure, health care and education systems, and many other important aspects of our day-today lives.

Work stoppages hurt everyone. Hopefully, one day in the near future, companies and organized labour will find ways to better avoid these costly delays.

Reader Service

Print and digital subscription inquiries or changes, please contact Angelita Potal Customer Service Tel: 416-510-5113

Fax: (416) 510-6875

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Audience Manager

Anita Madden 416.510.5183 amadden@annexbusinessmedia.com

Brand Sales Manager Pat Lorusso 416.518.5509 plorusso@annexbusinessmedia.com

Editor Andrew Snook 416.510.6801 editor@cpecn.com

Account Coordinator Barb Vowles 416.510.5103 bvowles@annexbusinessmedia.com

Group publisher/VP Sales Martin McAnulty mmcanulty@annexbusinessmedia.com

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

CPE&CN is published bi-monthly by:

Annex Business Media 111 Gordon Baker Rd, Suite 400, Toronto, ON M2H 3R1 T: 416-442-5600 F: 416-442-2230

© All materials in this publication are copyright protected and the property of Annex Business Media., the publishers of Canadian Process Equipment & Control News magazine.

For permission on reprinting or reproducing any materials, e-mail your requests to cpe@cpecn.com

Canadian Postmaster send address corrections to: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Canadian Process Equipment & Control News assumes no responsibility for the validity of claims in items reported.

Annex Privacy Officer privacy@annexbusinessmedia.com Tel: 800-668-2384

PUBLICATION MAIL AGREEMENT #40065710

Printed in Canada ISSN 0318-0859

ANDREW SNOOK, editor editor@cpecn.com

Process improvement is like climbing. With a strong partner, you can overcome any obstacle.

Just as athletes rely on their teammates, we know that partnering with our customers brings the same level of support and dependability in the area of manufacturing productivity. Together, we can overcome challenges and achieve a shared goal, optimizing processes with regards to economic efficiency, safety, and environmental protection. Let’s improve together.

German sensor company SICK and the Swiss measurement and automation technology specialist Endress+Hauser have agreed on a strategic partnership. Endress+Hauser will take over worldwide sales and service of SICK’s process analyzers and gas flowmeters, with a joint venture to be established for their production and further development. The aim of the partnership is to provide customers with increased support in increasing their efficiency and sustainability. SICK and Endress+Hauser signed a joint memorandum of understanding for a strategic partnership in October 2023. Since then, the project has been examined and plans for implementing the cooperation have been drawn up. Following approval by the respective supervisory bodies, representatives of both companies have now signed a corresponding agreement. The closing of the transaction is planned for the turn of the year 2024/2025 and is subject to approval by antitrust authorities. As a key aspect of the strategic partnership, Endress+Hauser will take over sales and service for process analysis and gas flow measurement technology completely. Around 800 specialized sales and service employees in 42 countries will transfer from SICK to Endress+Hauser. The global Endress+Hauser sales network will enable additional customers to be acquired, more industries to be reached and new applications to be developed, the company stated.From 2025, the production and further development of process analyzers and gas flowmeters will be the responsibility of a joint venture in which each partner will hold a 50-per-cent stake. It will employ about 730 people at several locations in Germany. The joint venture will work closely with Endress+Hauser’s competence centers to drive product innovations forward efficiently.

“This strategic partnership opens up opportunities for growth and develop-

ment for SICK and Endress+Hauser. We are taking this path because by collaborating and networking we can achieve more together in a reasonable amount of time than either side could on its own – all this for the benefit of our customers, employees and both companies,” said Dr. Peter Selders, CEO of the Endress+Hauser Group.

ABB and Komatsu have signed a strategic collaboration agreement to collaborate on the development of integrated solutions that will help bring net zero emissions for heavy industrial machinery a step closer to reality. The collaboration brings two global leaders together to share industry expertise and products in a bid to create world-class solutions, ranging from renewable energy generation to fully electrified mining equipment. Decarbonization of mobile mining equipment is needed to help mine operators achieve their greenhouse gas reduction targets. ABB and Komatsu’s collaboration is geared towards reducing diesel consumption and ultimately eliminating it through the electrification of mine operations. Innovation has been, and will continue to be, the primary catalyst for ABB, Komatsu, and mine customers to reach their carbon reduction goals.

“We’re pleased to embark on this collaboration with ABB and are excited to leverage one another’s industry leading products and technological expertise to help move mining operations toward net zero emissions, empowering a sustainable future where people, business, and the planet thrive together,” said Dan Funcannon, senior vice-president of surface haulage for

Komatsu.

With the collaboration, ABB and Komatsu are deeply committed to providing customers with a portfolio of interoperable solutions to meet their specific needs. Recognizing the varying stages of electrification standards across the mining industry, ABB and Komatsu are focusing on haulage, loading, and auxiliary equipment. This approach aims to build a comprehensive portfolio of production and support equipment to accelerate adoption into our customers’ operations.

“By working together, we will tackle electrification and make a revolutionary difference to the way mining companies operate their sites in the near future,” said Joachim Braun, division president, ABB Process Industries. “We recognize the strategic importance of this agreement and believe there will be mutual business benefits and potential technology solutions for the mining market. Collaboration across the industry has already been proven to enable real and faster progress and we look forward to driving what happens next.”

After 15 years with the association and nearly a decade as CEO, Bob Masterson, president and CEO of the Chemistry Industry Association of Canada (CIAC) informed the Board of Directors in May of this year that he will be resigning his position by March 31, 2025. The search process for his successor is underway.

“The time is right for CIAC and myself to move on to our next chapters. While we have accomplished a great deal, I am most honoured to have

worked with a team that has built a Great Place to Work Canada Certified organization for three straight years,” said Masterson. “It has been a privilege to lead this association and work for an industry and Board of Directors which are guided by their commitment to Responsible Care.”

“We are deeply grateful for the visionary leadership and dedication that Bob has brought to the association. His contributions have been invaluable, and we wish him all the best in his future endeavours,” said Apala Mukherjee, Chair of the Board for CIAC.

The new president and CEO will need to be able to juggle the priorities of a diverse group of stakeholders. Reporting to the Board of Directors, the new CEO will provide strategic organizational oversight and leadership for the association, driving the development and execution of plans that align with and advance CIAC’s mission, vision, purpose, and values. The CEO will ensure the association delivers exceptional value to its members and continues to be a trusted source of information to an ecosystem of stakeholders.

CIAC represents the majority of the chemistry and plastics industry in Canada. Our members are innovators, solution providers, and world-class stewardship pioneers.

Dan Nguyen, deputy executive director, CPCA.

EXECUTIVE DIRECTOR

The Canadian Process Control Association (CPCA) has appointed Dan Nguyen as the association’s deputy executive director.

“Dan has a verifiable track record of streamlining processes, maximizing staff performance, and exceeding growth targets in his various operational and people management roles. From events and operations to motivational speaking, food bank management, and more recently, certification and council management; Dan is always eager to bring his strategic thinking, problem-solving, and communication skills to elevate any organization he has the privilege of connecting with,” stated Peter Waite, executive director of the CPCA.

“It is with great eagerness that I look forward to working with the CPCA Board of Directors and committees to deliver key knowledge and networking opportunities for our valued members,” Nguyen said. Nguyen can be reached at: dnguyen@cpca-accp.org.

EXAIR, a leading company in engineered compressed air solutions and static elimination, and BETE, an engineered spray nozzle and spraying systems manufacturer, recently announced a definitive merger agreement under which EXAIR has acquired BETE.

The EXAIR/BETE merger will allow both companies to significantly enhance product offerings and customer engagement. The

combined market reach and engineering capacity will drive innovation and product value to a worldwide network of customers, distributors, resellers and OEMs. This merger also enables a diversified portfolio of products by integrating BETE’s pioneering technologies and engineering acumen with EXAIR’s deep knowledge of compressed air products. This synergy will address a broader spectrum of market demands, fostering a new era of invention, EXAIR stated.

LOUD, MEGA DUSTY, ULTRA

WHAT CAN

WITH ALL

THE 6X®. FROM

Dust, noise, temperature fluctuations – VEGA developed the VEGAPULS 6X radar level sensor for precisely such conditions. Ideal for all bulk solids and all plant operators who want to maximise the productivity of their processes.

With a strengthened go-to-market strategy, the merger enhances both company’s ability to provide high quality, precision engineered products to all levels of the market, big or small. EXAIR and BETE will be able to bring unparalleled support to large scope projects, OEM relationships, a worldwide network of distributors, and directly to end users, EXAIR stated.

“For our valued customers and partners, this merger means improved service, new products, and competitive prices. You will benefit from the combined expertise of two industry giants coming together to deliver comprehensive solutions that meet your needs,” said Kirk Edwards, president of EXAIR.

“We are committed to a seamless integration process, focused on our shared vision of quality, advanced engineering, and service. We look forward to bringing together our teams, cultures, and communities. We are, without a doubt, better together,” Tom Fitch, president of BETE.

The Board of Directors of Nestlé has appointed Laurent Freixe, currently executive vice-president and CEO Zone Latin America (LATAM), as CEO of Nestlé S.A., effective September 1. The board has also nominated Freixe as a candidate for the Board of Directors at the 2025 Annual General Meeting.

CEO Mark Schneider has decided to relinquish his roles as CEO and member of the Board of Directors. Over his eight years with the company, he has actively shaped the company’s portfolio, in line with Nestlé’s strategy and with a focus on high-growth categories like coffee, pet care and nutritional health products.

“Leading Nestlé for the past eight years has been an honour for me. I am grateful for what we have achieved, having transformed Nestlé into a future-proofed, innovative and sustainable business. I would like to thank the entire Nestlé community for what we have accomplished together and wish Laurent all the best in his new role,” Schneider stated.

Freixe joined Nestlé in France in 1986. Since then, he has continuously progressed within the company, assuming various positions of increasing responsibility across different businesses, markets and zones. He successfully managed Zone Europe during the financial and economic crisis, from 2008 until 2014. He then took over as CEO of Zone Americas, where he accelerated growth. Following the creation of Nestlé’s new Zone structure in 2022, Freixe was

named CEO Zone Latin America, where he has been successfully leading through challenging conditions.

He has been a member of the executive board for 16 years and, as such, has played an important role in strengthening the strategic direction of the company and its portfolio. With his profound understanding of Nestlé’s culture and values, he has led several global corporate initiatives to improve productivity, increase operational efficiency, simplify processes and drive innovation. Additionally, Laurent Freixe is committed to developing future leaders and talents, as evidenced by his active role in the Nestlé Leadership and Training Programs as well as the Nestlé Needs YOUth initiative, which promotes youth employment.

“I am privileged to have been given the opportunity to continue building and strengthening Nestlé, and I am excited to take on this responsibility. There will always be challenges, but we have unparalleled strengths, such as iconic brands and products, an unmatched global presence, leading innovation and execution capabilities, and above all, exceptional people and teams. We can strategically position Nestlé to lead and win everywhere we operate,” Freixe stated.

Less than three per cent of municipal waste in Canada is currently being converted into energy, and none of these existing projects are capturing and storing their carbon dioxide emissions. With landfills accounting for 23 per cent of methane emissions in Canada, municipalities and corporations across the country are looking for innovative ways to reach their landfill diversion and sustainability targets.

Alberta’s government is providing $2.8 million through Emissions Reduction Alberta for a $6.1-million front-end engineering and design study led by Varme Energy. This funding helps get Canada’s first facility that uses carbon capture to turn municipal waste into clean electricity closer to construction.

“Alberta is a global leader in carbon capture, utilization and storage technology, and the best place for innovative projects like this one to thrive. Varme Energy is tapping into our province’s exceptional geology, workforce and expertise to advance a landfill elimination solution that will reduce emissions and continue Alberta’s reputation for delivering clean, secure energy to the world,” stated Rebecca Schulz, Minister of

Environment and Protected Areas.

“Alberta is a leader in responsible energy development. I am proud to see our government continue to invest in new, innovative technologies that will help ensure our power grid is affordable, reliable and sustainable for generations to come,” added Nathan Neudorf, Minister of Affordability and Utilities.

The future facility will be built on Gibson Energy land within the Designated Industrial Zone in Alberta’s Industrial Heartland, with operations estimated to begin in 2027. Here, solid waste from municipal landfills will be converted into electricity for the grid, with the captured carbon injected into one of Alberta’s carbon sequestration hubs. The facility is expected to capture and store about 185,000 tonnes of carbon dioxide annually.

“Emissions Reduction Alberta is proud to provide provincial funding to this first-in-Canada project. The study is an important first step to realizing a large-scale municipal waste-to-energy facility with carbon capture and storage. This project not only reduces emissions, but also sets a new standard for how we provide clean, reliable energy from waste destined for landfills,” stated Justin Riemer, CEO, Emissions Reduction Alberta.

By incorporating carbon capture into the waste-to-energy process, all of the greenhouse gas emissions that are typically released from a waste-toenergy facility will instead be captured and sequestered underground. This helps reduce methane emissions from waste that would normally decompose at the landfill, and ensures all carbon is captured and stored deep in the earth, creating a carbon-negative system where the process stores more carbon dioxide than it emits.

“We are thrilled at how Varme has been embraced by Alberta. The magnitude of support, encouragement and collaboration we’ve received from the Government of Alberta, and Albertans at large, has been beyond our expectations. This direct provincial financial support is a significant de-risk that will help bring our project to a positive final investment decision. Emissions Reduction Alberta’s support demonstrates how Alberta’s TIER carbon pricing system is a powerful tool for converting our historical emissions levies into future emissions reductions, modern jobs and economic activity,” stated Sean Collins, CEO, Varme Energy.

Source: Government of Alberta.

By Andrew Snook

This past August, more than 9,000 railway workers were locked out during contract disputes by Canada’s only two Class I railways, Canadian National Railway Co. (CN) and Canadian Pacific Kansas City (CPKC). Thanks to the federal government forcing binding arbitration, the work stoppage only lasted four days, but the results could have been much more dire and the situation still resulted in significant delays to rail shipments across the country, slowing down supply chains for many industries that Canadians rely on for goods and products that are essential for a modern way of life.

Why would such a short work stoppage among two companies have such a profound impact? The Canadian rail system is comprised of 48,010 route-kilometres of track, of which approximately 71.8 per cent is owned by CN and CP (CN owns 45 per cent of the route-kilometres of track, while CP owns 26.8 per cent – the remaining 28.2 per cent is owned by a combination of other railways).

Statistics Canada reported that the total annual freight transported via rail in 2023 was 375.1 million tonnes, up 2.2 per cent from the previous year (Source: Railway carloadings, December 2023). The processing sector makes up a large

percentage of those goods being transported. This is especially true for the mining sector, which has accounted for about 50 per cent of total rail freight revenue for nearly a decade, according to the Mining Association of Canada (MAC).

“We are the largest single shipping sector in volume, and that is by both rail and marine modes,” says Geoff Smith, vice-president of government relations for the MAC.

How important is the mining sector for Canada’s GDP? In 2021, mining sector exports comprised 22 per cent of the total value of products exported in Canada. Of those exports, 54.1 per cent were shipped to the U.S.; while the U.K. (9.7 per cent) and the European Union (8.3 per cent) were also significant importers. The MAC stated that reliability in the domestic supply chain is vital for strengthening mining industry investment, which already has its share of challenges as Canada battles competing countries for attracting investors to the sector. Work stoppages at major railways do not help matters.

“When we talk about marketing our critical minerals to the world, we’re in a race against other countries to get them out of the ground through timely permitting, and then to market via a reliable transportation network; reliability and reputation matters,” Smith says.

Even when a labour strike only lasts a

small amount of time, a massive number of resources are burned preparing and planning for potential work stoppages.

“Even if the strike lasts a few days, mining companies have spent weeks and potentially months on long-term planning. That time would be better spent working with local partners, growing our businesses, and marketing Canadian minerals and metals to the world,” Smith says.

The chemicals and plastics sector are also heavily reliant on rail transport and is heavily affected by any work stoppages that take place. The Chemistry Industry Association of Canada (CIAC) published a release thanking Federal Minister of Labour Steven MacKinnon on taking action to end to the rail labour disruption quickly.

“Past experience has shown that once rail service is disrupted, for each day of disruption, it can take three days or more to return to service once labour issues are resolved. Things will continue to be tight and will need monitoring, but this will be a big relief to our members and to all Canadians,” the CIAC stated.

Canada’s chemicals and plastics sector generates approximately $115 billion in shipments globally on an annual basis. On average, the sector uses about 500 railcars a day with product valued at approximately $76 million a day.

“Your ability to operate is a function of how much storage you have on site before receiving inputs to those chemical processes and outputs, because when you’re producing chemistries, there’s also byproducts from your processes that you’ve got to be able to deal with. It’s not a simple, one in and one out,” explains Greg Moffatt, executive vice-president for CIAC. “The industry is 100-per-cent dependent on a functioning, reliable rail system to be able to bring goods and empties to facilities and to move them to customers.”

Critics argue that sectors like chemicals and plastics could switch to trucks, but that is not a practical solution for many products.

“Some of these products can only move long distances by rail. Chlorine would be one of them,” Moffatt, says. “And for every railcar that you have to put on the road, you need three trucks. So, that’s 1,500 extra trucks a day, and then that’s 1,500 extra drivers needed, and there’s just not that capacity in the system to be able to shift. It’s expensive, and it’s an issue of capacity, too.”

are typically located close to the necessary feedstocks, so they need to have dependable rail option to move products to ports.

“We’ve got abundant, well-priced feedstock, and so, that’s why you see these chemical manufacturing operations located where they are,” Moffatt says. “Transportation by rail is one of those things that companies need to think about. And those that are here and operating are very concerned about the impacts of what’s becoming a dysfunctional rail transportation system.”

From pulp and paper to dimensional lumber, and wood pellets, the forest products sector is also heavily dependent on rail infrastructure for moving its goods. Canada’s wood pellet sector is especially vulnerable to labour disruptions.

“Western Canada’s wood pellet plants rely on railways to move an annual $500 million worth of production to British Columbia’s coastal ports for shipment to global electric power generators,” says Gord Murray, executive direc-

The topic of lack of chlorine for safe drinking water was one of the reasons that the federal government stepped in and imposed binding arbitration. The CIAC stated that the work stoppage “threatened to lead to significant public safety impacts, as 96 per cent of Canadians rely on safe drinking water that needs chlorine and chlorine derivatives.”

While chemical sectors in many other regions of the world are located close to tidewater near ports, Canadian operations

tor of the Wood Pellet Association of Canada (WPAC). “We have no economic alternative to rail transportation. Our customers rely on us to provide consistent fuel deliveries to their power plants so they can provide electricity to millions of citizens in homes, schools, hospitals and businesses around the world.”

Despite only lasting a few days, the recent work stoppage was a high-stakes situation for the wood pellets sector.

“We were forced to close plants, lay off workers, delay shipments and experience damage to our industry’s reputation as a reliable global supplier,” Murray says. “It took an intervention by Canada’s labour minister to force the parties into arbitration and to get the railways operating again. While the minister’s order was controversial and seen by some as unfairly interfering in the collective bargaining process, the wood pellet industry was immensely relieved to be able to resume operations and continue supplying

“A disruption in rail service and the business supply chain is a disruption to the Canadian economy.”

our customers. A prolonged work stoppage would have caused us irreparable damage.”

While pipelines are a major form of transportation for crude oil, close to five per cent of Canada’s crude still moves by rail, so the sector is still affected by railway labour disruptions.

“Canadians rely on the products shipped by rail each day, including energy products that run their vehicles and help power their homes and businesses. A disruption in rail service and the business supply chain is a disruption to the Canadian economy, which the country can ill afford at a time when Canadians are already struggling with higher costs,” says Lisa Baiton, president and CEO of the Canadian Association of Petroleum Producers (CAPP).

To stress the importance of a quick resolution to the coming labour disruption on Canada’s railways, more than 80 industry associations and over 40 chambers of commerce from across Canada, shared their concerns in a formal letter submitted to the federal government:

Dear Prime Minister and Ministers, We are writing to urge you to immediately intervene and do everything necessary to avert a disruption in Canada’s Class I railways.

A concurrent or sequential work stoppage at both major railways will leave Canadians with access to fewer goods and products, driving up prices and exacerbating affordability challenges. A failure to act swiftly will also put the livelihoods of millions of workers in jeopardy.

A disruption to our railway system will have an immediate impact on thousands of businesses from coast to coast and to commuters in several major urban centres. All of Canada’s ports, logistics and warehouse operators, and suppliers will be affected, while a prolonged stoppage will quickly lead to shortages of supplies for numerous industries, forcing businesses to suspend their operations and furlough their employees. Factoring in the millions of Canadian jobs that would be impacted, the magnitude of the

More than 80 industry associations and over 40 chambers of commerce from across Canada, shared their concerns in a formal letter submitted to the federal government.

Get material handling equipment at the rates, time, and terms that work for you. Whatever you need to succeed, we deliver.

LARGER INVENTORY FLEXIBLE RENTALS DEDICATED SUPPORT

Find the right machine for the job from brands you trust like Clark, Sellick, JLG, & Doosan-Bobcat.

With 24/7/365 support and proactive maintenance, we’re committed to maximizing your uptime.

Only need equipment for a short time? Get the equipment you need with customized rental solutions.

Scan to Learn More or contact your Brandt Representive today.

disruption is daunting.

Our international reputation and relationship with our trading partners is also at stake. Canada’s railways transport $380 billion worth of goods annually – that’s over $1 billion each day – and account for half of the country’s exports. A prolonged railway strike will also surely weaken Canada’s negotiating position in advance of the renewal of the Canada-United States-Mexico Agreement in 2026. A loss of confidence from our most important trading partner would take years to repair.

The uncertainty around the potential of a nationwide rail strike has already forced businesses across the country to adjust their operations.

We are respectfully asking that you safeguard the well-being of Canadians and the country’s reputation as a reliable trading partner by ensuring that a disruption to our national railway system does not occur.

To support this effort, we would like to propose a meeting with you and a select group of association leaders as soon as possible. This meeting would provide an opportunity to discuss our concerns in detail and to explore how we, Canada’s business community, can support the government in preventing any potential disruption.

Thank you for your attention to this urgent matter.

Between the recent strikes on rail and port infrastructure, Canada’s supply chains have experienced significant disruption over the past two years.

The 2023 BC Port Strike, which involved more than 7,400 workers going on strike, caused billions of dollars of products to sit idle at the Port of Vancouver, which moves approximately $305 billion in goods to more than 170 trading economies, according to the port’s website.

What could Canada be doing differently to try and prevent further labour disruptions?

Moffatt says we should look to our neighbours to the south for the answer to our rail disruptions. He says the U.S. hasn’t experienced the same disruptions in their supply chain as Canada as it relates to rail.

“I think what you see in the U.S. is that when the U.S. has been faced with largescale direct disruption in their rail system, Congress has moved very quickly in a non-partisan way to force the system to go back to work and operate (sometimes pre-emptively), and that’s just something that we don’t see here in Canada.”

Moffatt adds that the U.S. has been more adept in signaling to labour and business that these kind of disruptions

on key supply chain pinch points are not going to be tolerated.

“Part of the government’s decision, Minister McKinney’s decision, when he directed the Canadian Industrial Relations Board to end the lockout and the strike and initiate binding arbitration, he also signaled an upcoming review of why the rail system has been experiencing the disruption that it has over the years. We will be active participants in that process on behalf of our members,” he says. “We would also say that that review should not be focused solely on rail. It should be focused on our port infrastructure. Because while the rail system is up and running, there’s uncertainty on the west coast with the potential for disruption with the west coast ports.”

Moffatt says there’s also some uncertainty around the Port of Montreal and active negotiation in the other ports, like Port de Trois-Rivieres that needs to be observed.

“These are all critical pieces in Canada’s supply chain to be able to move goods to market, and to be able to receive goods for Canadians, and inputs to manufacturing processes,” he says. “We are an export dependent economy, and our Achilles’ heel right now is our transportation system.”

Propgram to help end users find system integrators for automation projects

For end users wanting to incorporate more automation in their operations but lacking the in-house capability to make it happen, Festo Canada has a solution to overcome that barrier. The company’s new Certified System Integrator Program will match an end user with highly skilled system integrators, providing the validated know-how and expertise to turn the aspirational into the realizable. Festo’s Certified System Integrator Program is suited for Canadian end users and projects of all sizes. The program ensures that participating system integrators are equipped with comprehensive technical knowledge and commercial benefits. They are certified by Festo Canada after successfully completing the company‘s extensive online training for multiple competencies, including mechanical, controls, and motion, based on Festo products, including the latest servomotors and drives, remote I/O systems, PLCs and motion controllers. That knowledge covers all of Festo’s portfolio. Festo www.festo.com/ca/en

Flowline EchoBeam LR80 FMCW Radar Level Sensor

AutomationDirect has added the new Flowline LR80 EchoBeam FMCW (Frequency Modulated Continuous Wave) radar level transmitter featuring Flowline’s 80 GHz radar technology that is unaffected by most media, processes, or environmental factors. Using the change in frequency between the transmitted and reflected signals, the EchoBeam level sensor can measure liquids up to 32.8’ (10m) or bulk solids up to 16.4’ (5m) and provides a 4-20 mA output signal. Its rugged PVDF thermoplastic housing offers a high IP68 protection rating, making it ideal for applications such as tanks, sumps, canals, reservoirs, or transfer stations. The wireless LevelTap app connects over Bluetooth for easy configuration and quick access to level information, statuses, and settings from the safety of the ground or a nearby catwalk.

The Flowline Echobeam LR80 FMCW radar level sensor is CSA approved, FCC approved,

and CE marked. AutomationDirect www.automationdirect.com

Orange Research is a global leader in filtration, level and flow monitoring. Their differential pressure gauges, flow meters, switches and transmitters are designed and manufactured in the U.S. and utilized in the most demanding environments. Customers worldwide rely on them for

rugged, reliable and cost-effective solutions. Available in Canada from Cameron Instruments. Cameron Instruments www.cameroninstruments.com

Ranges: 0-10" WC to 0-150 PSI

Accuracy: +/-0 1 or 0 25% FS

Titanium construction

FMC Approved, Intrinsically Safe VL2213 PMC-STS,

Accuracy: +/-0 1 or 0 25% FS

Ranges: 0-50" WC to 0 300 PSIG

1" Process Connection, 1/4" NPT female Polyurethane molded cable; FMC Intrinsica

UNIMEASURE

UNIMEASURE

Linearity: 2 - 5” Ranges (±0

Ranges (±0.15% FS); Other Ranges

Repeatability: ±0 015% FS

Construction: Aluminum Cover & Baseplate

Wire Rope: Ø.016 Stainless Steel

Operating Temperature: -40°C to 95°C

Operating Humidity: 100% RH

50,000,000 Revolutions minimum

Ingress protection: IP-65 (NEMA 4)

By Matt Hale

onventional wastewater treatment in many regions consists of three distinct phases: primary, secondary, and tertiary. The primary treatment involves the mechanical removal of solids by sedimentation or flotation and is followed by a secondary treatment which removes organic matter through microbial decomposition. A further final, or tertiary, treatment may also be required depending on the final destination of the wastewater – such as re-entering the mains water supply.

CThe choice of secondary treatment depends on a number of factors including the wastewater’s chemical and biological oxygen demand (COD & BOD), operational and maintenance costs, sludge production, desired effluent quality, and microbial concentration. The choice is generally between aerobic or anaerobic treatment, although a combination of both methods can also be used.

In recent years, we have seen a steady increase in the use of anaerobic digestion treatment techniques for the treatment

of wastewater (and other effluent streams). But before we can examine what is driving this, it is important to understand the differences between aerobic and anaerobic treatment, as well as the pros and cons of each.

AEROBIC

Anaerobic and aerobic systems are both forms of biological treatment which use microorganisms to breakdown and remove organic materials from wastewater. The key difference between aerobic and anaerobic treatment is the presence of oxygen. Aerobic treatment is typically applied to efficiently treat low strength wastewater (with relatively low BOD/ COD values) when the treatment requires the presence of oxygen. In contrast, anaerobic treatment is typically applied to treat wastewater with higher organic loading.

In aerobic treatment, oxygen (air) is used to circulate the material, providing the right conditions for aerobic bacteria to reproduce. These bacteria assimilate and then break down organic matter and other pollutants like nitrogen and phosphorus into carbon dioxide, water, and biomass (sludge). As the name suggests, anaerobic digestion utilizes bacteria which do not need oxygen. They break down organic material in the wastewater into methane, carbon dioxide, and biomass (digestate).

Some of the factors in favor of aerob-

ic treatment include the fact that it has less odors (as hydrogen sulfide and methane are not produced), and nutrient removal from the wastewater to the sludge can be more efficient – meaning that treated water can often be discharged directly into the environment. However, oxygenation of the wastewater can require large amounts of energy (or a large surface area for the treatment lagoon) and untreated biosolids can settle out from the process – requiring further treatment or disposal. The capital investment (and space) required for aerobic treatment is usually greater than that needed for anaerobic facilities.

While there are pros and cons to both approaches, anaerobic digestion (AD) has a number of advantages, including:

• AD is better at dealing with slurries with higher solids content;

• AD produces biomethane gas which can be captured and used as a renewable energy source (including providing the energy to run the AD plant itself);

• AD produces less sludge (digestate) for a given volume of wastewater;

• The stable digestate produced by AD is easily converted into a valuable biofertiliser;

• AD plants generally have a smaller footprint than aerobic treatment.

While the final choice of aerobic or anaerobic wastewater treatment will depend on the unique situation of each

treatment facility, the advantages outlined above, together with greater utilization and uptake of AD technologies including enclosed digesters and upflow anaerobic sludge blanket (UASB) systems, means that the use of anaerobic digestion is rapidly increasing in the wastewater sector, either as the main secondary treatment, or to further process the biosolids produced by aerobic processes.

As the points above show, one of the major benefits of anaerobic treatment is its improved energy efficiency and the lower volume of residual solids produced as digestate. However, when designing or upgrading an AD plant there are numerous ways to maximize operational efficiency – improving both economic returns and environmental performance.

External digester heating (for example, using HRS DTI Series heat exchangers) offers a number of advantages over heating systems which are located in the digester. External heating can be checked, cleaned, or serviced at any time without the need to empty (or enter) the digester. Other benefits include the fact that external systems can be designed so that one heat exchanger array heats more than one digester, and the improved thermal performance reduces heating requirements and improves the overall energy efficiency of the AD plant. Operating life is often considerably greater compared to internal heating units, and routine maintenance is more straightforward.

Cooling and recovering the heat from exhaust gases can increase the efficiency of combined heat and power (CHP) plants used to generate electricity from biogas. Using HRS G Series heat exchangers on the exhaust recovers energy which can be used elsewhere in the plant, including feedstock and digester heating, pasteurization and digestate concentration.

The HRS BDS Series is an efficient solution to cool and dehumidify biogas for combustion. The system condenses up to 90% of the water contained in the gas, which is continuously separated before the clean biogas is ready for use as a fuel in the CHP engine, and an optional heat recovery step can reduce energy costs by up to 20%.

The HRS DPS (Digestate Pasteurization System) is designed to effectively and efficiently pasteurize digestate, feedstocks, sludge, and similar materials, allowing operators to maximize the efficiency of their overall process while meeting regulatory requirements and increasing potential markets for digestate as a biofertiliser. Traditional single tank pasteurization units simply dump this heat afterwards, meaning they are incredibly wasteful and inefficient. In contrast, the DPS recaptures this heat and uses it again, making it up to 70% more efficient than traditional single tank ‘heat jacket’ type

pasteurization systems.

After digestion and biogas production, the digestate is often separated mechanically into solid and liquid phases. The HRS DCS (Digestate Concentration System) uses an evaporation process to concentrate the digestate, meaning that the volume is decreased, reducing the costs of storage, transport, and application. Using a multi-stage evaporation process, the liquid digestate volume can be reduced by up to 80%. Unlike other technologies, the HRS DCS increases the

content of crop nutrients whilst recapturing energy for use in the subsequent concentration phases, increasing energy efficiency and reusing the condensate elsewhere in the AD plant, preventing additional discharge to the environment.

MATT HALE is the global key account director for HRS Heat Exchangers

By John Stark

n today’s technologically advanced environment, providing an uninterrupted power supply to mission-critical applications such as data centres, healthcare facilities, and telecommunication infrastructures is crucial. A disruption in power can result in severe consequences, including data loss, compromised patient care, and communication breakdowns. It’s vital to recognize that not all transfer switches are created equal.

IAutomatic transfer switches (ATS) are key to safeguarding these environments by delivering a reliable means of power management. Their fundamental design, critical components, and the materials and manufacturing methods significantly impact long-term reliability and ease of maintenance. Investing in a high-quality

ATS is not merely a choice; it is a necessity for protecting critical operations.

Automatic transfer switches not only protect individuals — such as patients and employees — and sensitive electronic equipment, but also ensure the safety of operators conducting maintenance and operations on the ATS itself. The cost of downtime can be substantial, arising from damage to expensive and difficult-to-replace equipment, direct losses during outages, and the indirect high costs associated with halting business operations, which can severely affect a company’s financial standing and reputation. While significant problems with power supply are somewhat rare, when they do occur, they can be catastrophic. An electrical fire, for instance, can bring down a hospital or data centre for months.

An ATS is designed to automatically transfer the electrical load from the primary power source to a backup source, such as a generator, upon detecting a failure or outage in the main power supply. This swift transition is essential for mission-critical applications, where even a momentary power interruption can have detrimental effects.

In the event of a utility outage, the ATS automatically activates, initiating the generator. Once the generator reach-

es its operational speed—typically within 10 seconds—the switch transfers power to the emergency generator. During this transition, the load supplied by the transfer switch will experience a brief interruption of about 10 seconds, unless it is coupled with a battery backup. In that case, the battery backup kicks in immediately.

One of the primary advantages of well-constructed ATSs is their speed. These systems can instantly detect power failures and initiate the transfer process, significantly reducing the risks associated with downtime. Unlike manual transfer switches, which require human intervention, automatic systems provide a seamless transition that enhances the reliability of power delivery.

Designing a robust automatic transfer switch demands a meticulous approach across all facets. These systems must withstand considerable short circuit stress, as demonstrated by published withstand rating tables. To ensure reliable, trouble-free operation with a minimum of maintenance for decades rather than just two or three years, three fundamental factors are crucial in their construction: superior materials, precision machining, and high-performance design and engineering.

To achieve exceptional performance, it is crucial to use components made from high-quality materials. High-quality ATSs have contacts crafted from extruded 100-percent copper, ensuring flexibility and durability. In contrast, lower-quality ATSs often rely on a casting process, where copper powder is poured into a mold, heated, and solidified. If the mold is flawed, the resulting components can become brittle.

Premium ATSs are constructed using precision machining, a labour-intensive and costly method. By machining all copper contact parts from solid extruded copper on a lathe—rather than using casting, forging, or stamping—durability is significantly enhanced.

Additionally, high-quality ATSs incorporate robust solid steel threaded rods and aircraft-grade joints, boosting durability and enabling them to withstand demanding conditions. These systems also feature carefully machined actuator arms, linkages, and other purpose-built components. In contrast, lower-quality ATSs frequently depend on molded plastic for these mechanical parts or use aluminum parts, compromising their overall integrity.

Intelligent and meticulous design and engineering are essential. For example, it is vital to eliminate any wiggle room that might lead to mechanical misalignment by rigorously testing systems under real-world stresses. Lower-quality ATSs often utilize rails with oval slots secured by nuts and bolts. If these fasteners become loose, the rails can shift, causing misalignment that necessitates a service call for correction.

Every detail is important—from bus bars being precision formed, cut, and punched of solid silver-plated copper to guarantee the integrity of the construction.

QUICK-BREAK, QUICK-MAKE, PRELOADED TRANSFER

open-transition transfer, the contact mechanism is securely locked in position until the overcenter position is reached. The preloaded springs then instantaneously open the closed contacts (quick-break) and instantaneously close the open contacts (quick-make) with a momentary break in between. During a closed transfer the springs act in the same manner, only in a quick-make, quick-break fashion. These features provide for rapid full arc interruption, under maximum voltage and amperage. This

considerably reduces contact erosion and increases the useful life of the switch, as well as the safety of operators. In conclusion, investing in high-quality ATSs is a prudent decision for ensuring an uninterrupted power supply, and reducing the risk of catastrophic business, health and safety consequences.

JOHN STARK is a product line manager for Russelectric, A Siemens Business, which designs, builds, and services on site power control systems.

While quality materials and fundamental construction and design principles are vital, features can be equally crucial. For example, a critical component mandated in many states is the bypass isolation unit, which functions as a switch within a switch. In the event of a switch failure, an operator can quickly access the bypass handle to manually transfer any available power to the load. This process allows for the isolation of the automatic portion of the unit of various bypass configurations. Once bypassed, the automatic system can be easily isolated, enabling technicians to rack out the automatic switch and disconnect it for maintenance or repairs.

All Russelectric transfer switches feature preloaded high tensile springs and an overcenter mechanism driven by an electric operator for opening and closing the power contacts. Even the manual bypass function in these units use this method. During an

A single Power over Ethernet cable enables facilities to easily add and reconfigure a wide range of computing equipment wherever needed without regard to existing electrical outlets By Del Williams

Pharmaceutical manufacturers that need to power a wide array of computing equipment now have an option that can dramatically ease the addition of new hardware when regular outlets are not readily accessible: Power over Ethernet (PoE). With PoE, electrical power is provided through the network switch and passes through a single Ethernet cable alongside data. This allows system integration and network installers to deploy powered devices in locations that lack electrical circuitry.

With the newest improved standards in high-power PoE, 802.3bt

Type 3/4 PoE can now provide sufficient wattage, up to 100 watts, to power devices such as flat screens, panel PCs, thin clients, and workstations commonly installed in pharmaceutical cleanrooms.

“The original PoE standards and specifications could only provide up to 30 watts of power, which was sufficient for certain types of devices, but not flat screen displays, PCs, or workstations,” says Paul Shu of ARISTA Corporation, a leading provider of computing platforms and visualization display products for pharmaceutical manufacturing environments.

The new IEEE 802.3bt standard increases the power up to 100 W by

With the newest improved standards in high-power PoE, up to 100 watts can now be provided to power devices such as panel PCs.

providing power over four pairs of wires, compared to the previous technology’s ability to power over

just two pairs.

“This increase in wattage allows PoE to a level that will power most pharmaceutical computing equipment,” adds Shu. “As an added benefit, the new standard boosts energy efficiency by minimizing power loss in the cable, potentially cutting power loss in half.”

Pharmaceutical manufacturers can now deploy a PoE enabled device within 330 feet of the network switch using a single Ethernet cable. This eliminates the cost and inconvenience of having an electrical contractor run wiring. These devices are particularly suitable for applications and locations such as cleanrooms, where it may be costly

or difficult to run extra wiring.

“Although cleanrooms often have access to power, high-power PoE can streamline installation in locations where an added computer may not have readily available power and network cable connections are ubiquitous in those environments,” says Shu.

If the network switch does not provide PoE functionality, or the available PoE utilizes an earlier standard and does not provide enough power to drive the computing equipment, a POE injector can be installed. Since standard Ethernet cables can provide both data and power, there is no need to upgrade that cabling.

Arista provides a wide range of workstations, waterproof panel, and thin client PCs that can be powered by PoE. To maximize the use of space in constrained pharmaceutical facilities, many of these items are available in wall, ceiling, and pedestal-mounted versions.

Like other computing platform elements in pharmaceutical manufacturing environments, the PCs are designed and tested to withstand the high humidity and moisture generated dur-

“The pharmaceutical industry needs greater flexibility in powering all manner of computing devices.”

ing manufacturing, as well as the caustic chemicals used for cleaning.

To accomplish this, the equipment is built using stainless steel NEMA 4X/IP66 enclosures.

Since individual pharmaceut ical facilities often have unique requirements, the PoE powered computing systems can be further customized if needed. Depending upon the level of change needed, the process can range anywhere

Arista offers a range of workstations, waterproof panel, and thin client PCs that can be powered by PoE.

from six to eight weeks for minor customization to several months for more extensive projects.

Today, the pharmaceutical industry needs greater flexibility in powering all manner of computing devices throughout a facility. PoE-enabled workstations and PCs can quickly and easily receive power through an existing network cable. With no need for an electrical contractor or costly rewiring, pharma plants can easily add or reconfigure the needed computing equipment whenever and wherever required for greater efficiency.

DEL WILLIAMS is a technical writer based in Torrance, California.

For the latest news, visit: www.cpecn.com

CPCA is pleased to announce the launch of our brand-new logo, now in both of Canada’s official languages. It’s more than just a new look; it represents our thriving industry and the bright future we have ahead of us with a dynamic new database and user-friendly website to be unveiled soon.

CPCA is the only association that provides a range of reports containing statistical information, analysis and peer comparisons by region, industry and product. CPCA’s completely confidential reports help you develop a strategic business plan, capture growth opportunities and make sound and strategic business decisions.

Participating members can:

• Gauge your share of the market

• Measure overall company performance

• Monitor industry trends year over year and analyze total market growth or decline

• Identify overall market size, regional demographics and economic shifts

Bookings Report

Compensation

Businesses driving their digital transformation journeys are demanding access to all data in their process systems, from sensors and actuators to the PLCs, drives, and HMI/SCADA. This requires the combining of IT and OT networks, Ethernet as a backbone, and automation devices that have been enabled with Time-Sensitive Networking (TSN) functions.

By Thomas Burke

Industry 4.0 and digital transformation is an undeniable global trend. This trend will have an impact on all aspects of production lines and machines in a modern plant.

The purpose for digital transformation isn’t a new concept. Kaizan is a concept that has been around since the mid-1900s. Embodying the philosophy of continuous improvement, Kaizan brings profound benefits to any organization by fostering a culture where every incremental change contributes to overall efficiency and quality. This approach not only streamlines operations and reduces costs through the elimination of waste, it boosts morale and job satisfaction but also ensures that the organization remains adaptable and responsive to market changes, thereby promoting a sustainable competitive edge.

What digital transformation adds today, is the leverage of technology to improve access to more data, facilitating decision making at a far faster pace than ever before. Even making data available for automated analysis and actions.

But today, plants are still mostly dominated by machines that are performing their intended functions as initially designed and delivered. Developed by OEMs, they run at the speeds, quality, and reliability that they were initially designed for. When they require

routine maintenance, it is generally done on a schedule, to avoid unexpected downtime. Machines of this type perform their functions, but with little opportunity for improvement.

Industry 4.0 is about leveraging new technologies for the benefit of continuous improvement. While there are close to a dozen Industry 4.0 technologies, including additive manufacturing and augmented reality, the technologies most relat-

ed to machine and process operations would include the Industrial Internet of Things (IIOT), cloud and artificial intelligence.

The latter Industry 4.0 technologies are delivering the opportunity for major efficiency improvements through the access of additional data and improved context. Machines and processes can be monitored and analyzed for performance, quality, and reliability, offering the ability to operate or

tune them to maximize KPIs to benefit the user.

Monitoring process data requires attention to the following: Providing external access to all variables in a process or machine; Instrumenting a process with additional sensors to enable greater context of operation; and Adding new capabilities, based on new knowledge, that can deliver a competitive advantage.

PROVIDE EXTERNAL ACCESS TO ALL PROCESS VARIABLES

In the past, this has been one of the greatest challenges, primarily because communications within a plant fall into various categories and have differing requirements.

There is typically a control network and a supervisory network. Some communications require deterministic performance for processes such as motion control, or high reliability for safety. Other communications are less demanding

and are for informational purposes. Often, a gateway for these communications becomes the controller – PLC, or the operator interface. Ideally, there should be a common backbone for all communications.

“Greater access to process data means the opportunity to better understand the operations...”

The most common backbone for IT communications is Ethernet. The improvement in Ethernet performance is greatly outpacing that if the niche industrial transports, based on the needs of a much larger IT market. In 2016, Ethernet specifications were improved to include support for Time Sensitive Networking (TSN). This was the missing link to enable Ethernet as the backbone for improved process automation, combining Information Technology (IT) networks and Operational Technology (OT) networks, the combining of control and information communications within a network. With new products on the market that support TSN, machine builders can now deliver equipment with a common Ethernet TSN backbone, enabling direct data access with the entire machine, from controller to sensors and actuators, from the IT network.

Greater access to process data means the opportunity to better understand the operations, provided there is enough context to enable an understanding of the data. For example, a piece of equipment may be running hotter than usual because it is running faster, under greater load, or because the ambient temperature is higher that day.

Startup performance will vary based on a cold start or a warm start. If your process isn’t properly instrumented for context, making sense of your data will be more challenging. Varying operating conditions also requires a loosening of alarm levels, the early warning system to process failures. A common backbone will enable the introduction of many more sensors, perhaps completely unrelated to the actual operation of a machine, but critical to understand the context of your process operations, to benefit future analysis.

As a machine user in your process, your competitive advantage is your final product, and making that product as efficiently and of the highest quality possible. A smarter machine will certainly help. Machine builders have a different requirement. Their competitive advantage is in the engineering of the machine, for both end-product

quality, and machine performance. In an Industry 4.0 world, for both the user and the machine engineer, the competitive advantage may very well be in the machine analytics that can be provided. Are you scheduling maintenance based on operations, or a schedule? Are you able to view similar machines and identify which will provide the best rate of return, and schedule appropriately? Are you able to connect remotely and have access to enough data, and context, to properly troubleshoot a machine, and eliminate the need for travel and coordinated visits? Can you add new sensors that unlock a greater understanding to the operation of your machine, when needed, installing, or accessing video cameras for example? Are you delivering Digital Twin analytics, modeling process conditions and dynamically adjusting alarm levels based on the current context of operation?

Industry 4.0 technologies are unleashing a new wave of innovation that is sure to increase performance, improve quality and reduce costs. With new technology

and market share. Many businesses are currently in their digital transformation, and it is key for automation specialists to support them now with future-oriented devices. Even more, with typical life cycles of 20 to 25 years for automation components, adding future-oriented technologies, such as TSN, in factories is key to drive differentiation and competitiveness in the short run, while being able to adapt over the long run.

For those who think maybe now is not the time for action, a clear parallel can be drawn between TSN and mobile phone technology, which has been quickly transitioning from 2G to 3G, 4G and recently 5G. Instead of waiting for the “next” technology, competitive manufacturers promptly implemented these advancements within their products as the technology landscape continued to evolve. This helped them to address immediate market demands. Most technical specialists will agree that any given technology continually evolves and therefore waiting for it to be “finished” is a futile strategy that will see their companies falling behind.

key uses cases while also providing the convergence benefits that are offered by TSN, such as CC-Link IE TSN. This is the first open and widely supported network technology that combines gigabit bandwidth with TSN functions.

TSN BASED PRODUCTS ARE IN THE MARKET. MORE ARE COMING.

such as Ethernet TSN, we will see machines shift from their original designed for purpose and fixed performance to those that can offer quantified performance, quality and cost metrics, and that will improve over time, based on OEM analytics and feedback.

TSN is an innovative Ethernet technology defined by enhancements to the IEEE 802.1 standards. This is quickly proving its essential role in the Connected Industries of the Future thanks to its unique ability to support convergence on the factory floor as well as between IT and OT worlds. Its importance is being acknowledged by several sectors, which are demanding automation solutions with TSN capabilities.

Device vendors may be wondering if the time is right to adopt TSN. In fact, there is a strong case for taking action now. Implementing this technology within their products today is a safe bet that can enhance competitiveness

There are existing vendors of TSN products and there is an ecosystem of TSN users. We are no longer talking only about futures. Compliant products were introduced in 2018 and TSN is becoming a competitive advantage in motion control, robotics, and other high-performance markets. The benefits of TSN are spreading to all applications and markets as more and more solutions are delivered and costs are reduced through normal supply and demand processes.

Furthermore, the addition of TSN isn’t an all or nothing proposal. There are many applications where segments of a network can be TSN enhanced, delivering Islands of TSN for improves machine or process performance.

Ultimately, this technology is just a “pipe” and therefore, industrial Ethernet protocols of different types are still required to cover the remaining application use cases, such as safety and motion control. It is important for device manufacturers to understand that TSN cannot replace all industrial Ethernet connectivity. Instead, manufacturers should leverage an industrial Ethernet solution that supports all

As a result of the many development methods available, device vendors can make sure that the right technical solution is available for the specific product they want to deliver. For instance, software protocol stacks are ideal for businesses interested in quickly implementing TSN-based solutions, as they offer perhaps the fastest method to enhance existing products by reducing in-house development time and costs. Furthermore, they are generally portable, so they can be applied with minimal changes. When performance is more important, hardware solutions are best suited to ensure TSN conformance. These include Application Specific Integrated Circuits (ASICs), also referred to as dedicated communication Large Scale Integrations (LSIs), as well as Field Programmable Gate Arrays (FPGAs).

Ultimately, while TSN will change over time, as all new technologies do, automation vendors can benefit from considerable gains by providing innovative capabilities to their devices now, and leverage firmware upgrades for future compatibility. There is broad acceptance of TSN today, and the ecosystem continues to grow rapidly. By leveraging this open network technology, both device vendors and machine builders can tap into new market opportunities quickly, futureproofing their businesses and their customers’ operations.

THOMAS J. BURKE is the global strategic advisor for CC Link Partner Association (www.cc-link.org). He is the former OPC Foundation president and executive director, and pioneered the OPC Unified Architecture (OPC UA) as the foundation of information integration and interoperability. He has a bachelor’s degree in theoretical mathematics from John Carroll University (Cleveland, Ohio), and a master’s degree in computer engineering from the University of Dayton (Dayton, Ohio).

Magnetically coupled pump

NETZSCH Pumps & Systems recently announced the NEMO R. MY Magnetically Coupled Pump, an innovative pump designed to meet the most demanding requirements of industries requiring leak-free pumping solutions. It is ideal for use in chemical, pharmaceutical, paint, and food applications to convey highly viscous product. The NEMO R. MY Magnetically Coupled Pump features a hermetically sealed design, eliminating the risk of leakage. The pump utilizes a magnetic coupling to transmit torque, ensuring a completely sealed and robust system. This design enhances safety and reliability, making it ideal for handling aggressive, toxic, or abrasive product. It is designed to handle a wide range of viscosities, from low-viscosity fluids to highly

viscous, shear-sensitive substances. NETZSCH www.pumps-systems.netzsch.com

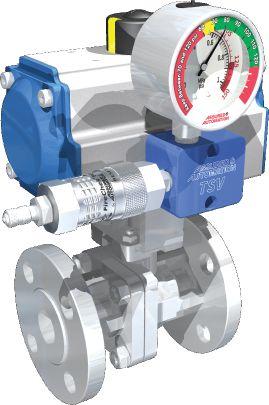

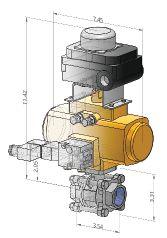

Hayward Flow Control has launched its new 3-Way Ball Valve lines, the TWH and LAH Series, with enhanced features and benefits. The TWH and LAH Series incorporate a new handle and lock plate design as well as an ISO5211 actuator mounting flange as standard. The additional features allow for easy actuation as well as superior indication and control of the valve flow. In addition, Hayward will also offer the TNH (90-degree ball) Series, TPH (180-degree ball) Series, and LNH (90-degree ball)

Series as part of its’ family of 3-way valve solutions. All series feature integral handle stops to aid in proper operation corresponding to the ball selection. Initially available in sizes 1/2” – 2” / DN15 – 50, the TWH and LAH Series features an ISO5211 top works and a GFPP lock out plate on all valve sizes. Available in PVC and CPVC materials, with PTFE Seats, the TWH and LAH

Series is fully pressure rated for 150 PSI / PN10 at 70°F/23°C non-shock across all sizes and materials. All valves are offered with IPS, DIN/EN or JIS socket, threaded and flanged end connections for global use.

Hayward Flow Control

www.haywardflowcontrol.com

Actuators for water heater applications

Warren Controls’ ARIA Series actuators are designed for correcting commercial steam-fired water heaters that had previously been driven by oversized steam valves. This accessory has been designed by Warren Controls specifically for their electrically actuated industrial control valves. With its inherent 12-bit hall-effect feedback, the ARIA actuator delivers exceptional controllable linear resolution,

exceeding 2,000 parts per inch. This feature enables seamless auto-recalibration for achieving maximum valve flow coefficient (Max Cv) capacity as per the actual demand. Users can select from three different calibration strokes: 10 millimeters (mm), 15 mm, and 20 mm, allowing precise adjustment to meet specific installation requirements. Moreover, if additional capacity is needed, recalibrating the valve to its full stroke is straightforward. Upon deployment, when the local water heater temperature controller signals 100 percent demand, the valve operates within the designated calibrated stroke value, ensuring superior controllability and optimal performance.

Warren Controls

www.warrencontrols.com

Remote control for Conveyor Smart Motors

Applied Motion Products has introduced the CPBD-A-C remote control module that connects to the back of the CSM34 Conveyor Smart Motor and can be mounted where conveyor operators can easily access it. With the remote-control module, users can configure their motion profile, monitor system status, and manually jog the conveyor system to the desired position without being next to the CSM34 Conveyor Smart Motor. The CSM34 Conveyor Smart Motor powers the remote-control module, so it does not require any additional power module to operate. Features include direct plug-in connection; on the fly speed change; speed settings remotely; five-digit, seven-segment motor status display; push-button configuration and jog motion; and quick panel mount installation.

Applied Motion Products www.applied-motion.com

Positive displacement pumps for industrial pumping applications

Vogelsang has released its EP series, a line of positive displacement pumps, which was designed specifically around the typical requirements of industrial pumping applications, including those of the

oil and gas market.

The EP series handles extreme conditions and constant high pressures. A heavy-duty gearbox allows for a uniform pressure output of up to 260 psi (18 bar), making it one-of-a-kind in its category. The pumps of the EP series consist of a one-piece housing that can reliably pump abrasive, chemically aggressive, and explosive flow media at temperatures of up to 392F (200C). Helical gears in the gearbox ensure smooth performance and reduce noise emissions. Pulsation-free conveying reduces wear on the adjacent pipeline while providing a low-shear pumping action.

Vogelsang www.vogelsang.info

KROHNE’s ENVIROMAG is an advanced electromagnetic flowmeter engineered specifically for the water and wastewater industry in North America. Designed with long-term reliability and durability in mind, the ENVIROMAG offers a cutting-edge solution for accurate flow measurement in various water and wastewater applications. Certified with NSF approval for potable water, it ensures safety and compliance with stringent North American standards. The unit features a robust design suitable for direct burial installations, with a NEMA 6P rating that guarantees protection against water ingress and environmental challenges. The ENVIROMAG comes equipped with multiple communication options,

making it versatile and compatible with a wide range of control systems. The features are tailored to meet the specific needs for a variety of applications. It offers short inlet and outlet runs, remains unaffected by contamination, solids, fibers, and slurries, and requires no maintenance. Each unit is wet calibrated, complete with a calibration report, and comes with continuous self-diagnostic features. Additionally, the ENVIROMAG is NSF approved with a hard rubber liner and is available with a virtual reference that eliminates the need for grounding rings. It is also hazardous area approved for added safety and compliance. The ENVIROMAG is versatile and suitable for a wide range of applications, including wastewater processes, desalination processes, irrigation networks, potable, chlorinated, and fluorinated water systems, clean water processes, water distribution networks, and cooling stations for district heating. KHRONE www.khrone.com

Rotary electric vibrators