A chat with Viola R. MacMillan Award recipient John Robins

SAFETY IS NOT OPTION

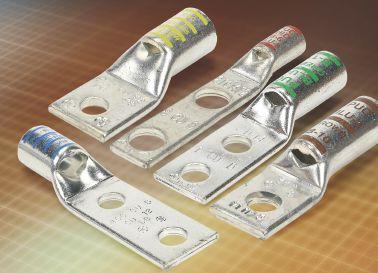

Starting at $202.00

Intrinsically Safe Isolators and Barriers

Safety Relays

Starting at $126.00

Isolating barriers prevent potential ignition sources by ensuring that only a safe amount of energy resides in electrical circuits located in hazardous areas.

AutomationDirect, a trusted supplier of industrial and automation products for over 30 years, offers high-quality safety products at prices low enough to protect even the simplest systems.

Safety relays monitor safety input devices and use positive guided contacts and redundancy to prohibit machine operation when hazardous conditions are detected.

Safety Light Curtains

Starting at $540.00 Sender/Receiver Pair

Safety light curtains use an array of photoelectric beams to sense intrusion into protected areas, providing protection for processes requiring open and frequent access.

Safety Controllers

Starting at $376.00

Safety controllers manage safety functions for single machines or an entire plant. Their modular design minimizes wiring and offers expansion capabilities.

Fast free standard shipping* is available for most orders over $49 U.S., and that includes the brokerage fees (when using an AutomationDirect nominated broker). Using our choice of carrier, we can reach most Canadian destinations within 2 to 3 days. *Free shipping does not apply to items requiring LTL transport, but those shipments can take advantage of our negotiated super-low at rates (based on weight) that include brokerage fees.

See Web site for details and restrictions at: www.automationdirect.com/canada

Machine Guarding

Components starting at $45.50

Machine guarding systems protect personnel from injury by using physical barriers to restrict access to hazardous machinery and equipment.

Trapped Key Systems

Components starting at $223.00

Trapped key systems use a series of mechanical locks and keys to control and ensure safe access to running equipment or machines.

IEC Safety Contactors

Starting at $78.00

Safety contactors provide a safe and reliable way to control electrical power in industrial and commercial applications.

Gate Boxes

Starting at $466.00

Gate boxes provide high-level RFID-coded interlocking, tamper-proof guard locking, and machine control in one unit.

3M announced that it was exiting the PFAS manufacturing space and would be discontinuing PFAS use throughout its product portfolio by the end of the year.

For all our readers in the plastics and chemicals sectors, I’m certain the term “forever chemicals” is well known.

For our readers in other process sectors that may be less familiar with the term, it’s used to describe a family of thousands of synthetic chemicals known as PFAS (Per- and Polyfluoroalkyl Substances). These chemicals are used in a vast array of products.

For consumers they can be found in non-stick cookware, stain-repellent fabrics, dental floss and soft contact lenses, just to name a few items. In the various process sectors, they can be found in some of your maintenance teams regular go-to items such as o-rings, hoses, hydraulic fluids, electronics and electrical equipment, refrigerants, paints, coatings, and fire retardants. The PFAS family of chemicals are dubbed “forever chemicals” due to their near indestructible nature. Industries use many of the products created with them because the chemicals give those items enhanced resistance to heat, pressure, chemical and friction stressors.

Needless to say, the family of PFAS chemicals has become a regular ingredient in the products we interact with on a regular basis. So, why bring this up? It’s because there is a movement taking place across much of the globe to restrict the use of these chemicals due to potential health risks they can pose to people.

Some of our neighbours to the south have already imposed PFAS-related bans.

On January 1, 2025, the State of Minnesota’s first prohibitions related to products containing intentionally added PFAS went into effect under Amara’s Law (2024 Minnesota Statutes - 116.943 Products Containing PFAS). This law currently falls under 11 product categories of intentionally added PFAS: carpets or rugs, cleaning products, cookware, cosmetics, dental floss, fabric treatments, juvenile products, menstruation products, textile furnishings, ski wax, and upholstered furniture.

There are other U.S. states that have PFAS-related legislation in the process of being put into law as well. On the federal

level, the U.S. Environmental Protection Agency implemented the final National Primary Drinking Water Regulation (NPDWR) for six PFAS on April 10, 2024. The EPA stated that “over many years the final rule will prevent PFAS exposure in drinking water for approximately 100 million people, prevent thousands of deaths, and reduce tens of thousands of serious PFAS-attributable illnesses.” The EPA also announced that $1 billion in funding would be available through the Infrastructure Investment and Jobs Act to assist U.S. states and territories with testing and treatment of public water systems and private wells to address PFAS contamination. Canada is also doing its own research related to restrictions related to PFAS chemicals, and the Europe Union is also in the process of planning a ban on PFAS in consumer products with exemptions for essential industrial uses. What is the potential impact for Canada’s process sectors? Disruption within supply chains has the potential to come sooner rather than later. Back in 2022, 3M announced that it was exiting the PFAS manufacturing space and would be discontinuing PFAS use throughout its product portfolio by the end of 2025. As a major producer of the PFAS family of chemicals, this has the potential to create a shortage of the products manufactured using these chemicals. This is significant because there are currently no equivalent substitutions for many PFAS chemicals. In the short-term, supply chain disruptions could begin taking place for many products as other manufacturers step in to fill 3M’s shoes. In the long-term, it is very possible that PFAS bans and restrictions will only continue to grow, and with no suitable replacement currently available for thousands of products, this could end up posing a significant challenge for the many sectors that rely on the products made from these chemicals.

ANDREW SNOOK, editor editor@cpecn.com

Reader Service

Print and digital subscription inquiries or changes, please contact Angelita Potal Customer Service Tel: 416-510-5113

Fax: (416) 510-6875

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Audience Manager

Anita Madden 416.510.5183 amadden@annexbusinessmedia.com

Brand Sales Manager Pat Lorusso 416.518.5509 plorusso@annexbusinessmedia.com

Editor Andrew Snook 416.510.6801 editor@cpecn.com

Account Coordinator Barb Vowles 416.510.5103 bvowles@annexbusinessmedia.com

Group publisher/VP Sales Martin McAnulty mmcanulty@annexbusinessmedia.com

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

CPE&CN is published bi-monthly by:

Annex Business Media 111 Gordon Baker Rd, Suite 400, Toronto, ON M2H 3R1 T: 416-442-5600 F: 416-442-2230

© All materials in this publication are copyright protected and the property of Annex Business Media., the publishers of Canadian Process Equipment & Control News magazine.

For permission on reprinting or reproducing any materials, e-mail your requests to cpe@cpecn.com

Canadian Postmaster send address corrections to: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Canadian Process Equipment & Control News assumes no responsibility for the validity of claims in items reported.

Annex Privacy Officer privacy@annexbusinessmedia.com Tel: 800-668-2384

PUBLICATION MAIL AGREEMENT #40065710

Printed in Canada ISSN 0318-0859

The Chemistry Industry Association of Canada (CIAC) has named Greg Moffatt as the association’s new president and CEO, effective Jan. 13, 2025.

“Following a thorough and highly competitive process, Greg emerged as the clear choice to lead the CIAC into the future and the board of directors was excited to confirm him in this role,” stated Rocky Vermani, Chair of the CIAC Board of Directors and senior vice-president of sustainability and innovation at NOVA Chemicals. “Greg brings significant experience in public affairs and is very knowledgeable of our chemistry industry, our issues, our people, and the importance of Responsible Care in guiding everything we do.”

Moffatt has held a variety of positions within the CIAC over the past nine years, including his most recent role as executive vice-president for the past year. Previous positions include regional director of Western Canada; senior director of business and economics; and vice-president of policy and corporate secretary.

“As we continue to advance the critical role of chemistry and plastics in shaping a sustainable, competitive, and innovative economy, I am committed to championing Responsible Care and driving strategic advocacy for Canada’s chemistry and plastics sector,” Moffatt stated. “By fostering industry impact through collaboration and maintaining the highest standards of integrity and accountability, we are paving the way for growth in a sector that is essential to the Canadian and global economy and that benefits both society and the environment.”

Vermani thanked outgoing president and CEO Bob Masterson for his dedication to the industry.

“CIAC and its members recognize the tremendous effort and dedication outgoing president and CEO Bob Masterson gave to the industry throughout his 15 years with the association, and nine as its leader,” he said. “During his tenure, Bob was instrumental in helping the association grow into one of the premier advocacy groups in Canada.”

AFC Industries (AFC) has announced that it has acquired Aurora, Ont.-based IRWIN Industrial. The purchase allows AFC to expand its Canadian footprint.

“Canada is an important market for us and we recognized we would need additional resources and infrastructure in

Canada for it to reach its full potential. We were looking for a Canadian partner whose culture and approach to the business would fit well with ours. Irwin quickly rose to the top of the list, and we are thankful to be able to add them to the AFC family,” stated AFC CEO Kevin Godin.

IRWIN was founded in 1970 and specializes in customized vendor-managed inventory programs and supply chain solutions for unique components across a

broad range of industries.

“We are excited to join the AFC team. We see in them the same perseverance, commitment to exceptional service, and values that are at the core of how we approach our customer relationships. I am confident that together we will be able to continue to grow and to do it the right way,” stated IRWIN owner and president Glenn Irwin. The terms of the deal were not disclosed.

Labelle: (514) 916-5895

Fax: (514) 500-5802

Email: jc@belletek.com

The Canadian Association of Petroleum Producers (CAPP) has appointed Cenovus Energy president and CEO Jon McKenzie as the new Chair of CAPP. McKenzie had been on the board serving as vice-chair of the association since November 2023. He has more than 30 years of finance and operations experience, primarily in the Canadian oil and gas industry.

“Jon’s strategic leadership and business acumen, paired with his extensive industry experience, will enable him to effectively guide the work of the Board,” said Lisa Baiton, president and CEO of CAPP. “I’m excited to continue working closely with him in this expanded role to enhance the positive impact our oil and natural gas sector can have on Canada’s future and to create more prosperity for Canadians.”

The association has also named ARC Resources president and CEO Terry Anderson as its vice-chair until December 2025. Anderson has led ARC’s engineering, production, and operations teams for the past 20 years. ARC is the largest Montney producer in Canada.

“Terry has been instrumental in ARC’s transformation into one of Canada’s largest conventional oil and gas companies. His strong governance standards and vision for value creation will support new opportunities for the sector to drive economic growth and provide affordable energy to all Canadians,” added Baiton.

Outgoing Chair Paul Myers will continue to work with CAPP as a director of the board, and in his role as president of Pacific Canbriam Energy a Director at CAPP.

Valmet has appointed David Nelson, vice-president of sales and marketing, North America, as the company’s interim head of its North American business, succeeding Jukka Tiitinen as of January 1, 2025.

Nelson has more than 35 years of

experience in pulp, paper, and related industries, with a proven track record of leadership and strategic impact. The company stated that Nelson will assume his new interim role in addition to his current responsibilities.

Before taking on his current role, Nelson led Valmet’s Services Sales Team in North America, and was the director of sales, U.S. North, from 2008 to 2020. He has also held a variety of leadership, sales, and engineering positions across Valmet, Metso, and Beloit Corporation.

During his interim role, Nelson will report to Valmet’s president and CEO Thomas Hinnerskov.

“David is a trusted senior member of the N.A. team, and I am very happy about this interim solution. I want to thank David for accepting this additional responsibility for the time being,”Hinnerskov said.

TASI Measurement recently announced that it has acquired Accutrol, LLC, a supplier of airflow control and measurement solutions for critical environments such as laboratories, hospitals, pharmacies, and research spaces.

TASI Measurement stated that the Danbury, Conn.-based Accutrol will continue to operate independently at its current location while joining TASI Measurement’s HVAC Division, which also includes ONICON Inc., based in Largo, Fla.; and that senior leaders of Accutrol including Tim Berry, vice-president of sales, and Brian O’Rourke, vice-president of engineering, will continue in their roles and report to Bill Valentine, who leads the HVAC Division for TASI

Measurement.

“We are excited to welcome Accutrol to our team. They have a long history of providing innovative products, superior technical assistance, and excellent customer support,” notes Valentine. “We look forward to collaborating with, and investing in, this talented team as they continue to advance Accutrol.”

“We are pleased to have found a like-minded long-term partner in TASI Measurement, which knows our markets, customers, and applicationspecific solutions, and is committed to investing in continued business growth and our exceptional talent,” stated Fred George, founder of Accutrol.

Accutrol’s notable products include the AccuValve low-pressure drop air flow control valve and AVC Fume Hood Control System, both of which have received AHR Innovation Awards.

Workplace Safety North (WSN) and Ontario Mine Rescue (OMR) have appointed Derek Budge as new Chair of the Board of Directors.

Budge has nearly 40 years of experience in the mining industry, including a strong background in safety and leadership. While working as a miner for 14 years starting in the early 1980s, Budge became a certified worker safety representative through training with the Ontario Natural Resources Safety Association (now part of WSN). His passion for safety led him to get advanced training in mine rescue and safety management. Over his career, Budge has held a variety of safety-related roles,

including his current position at Redpath where he has worked the past 24 years.

“My journey has given me a deep understanding of both the hands-on and management aspects of safety,” Budge said.

Budge has served as Vice-Chair for Workplace Safety North (WSN) and Ontario Mine Rescue (OMR) for the past two years under Chair Lydia Renton.

“Being part of WSN is my way of giving back to the mining industry that shaped my career,” Budge said. “I’m excited to work alongside WSN president and CEO Mike Parent, Vice-Chair Eric Haapamaki, and the entire Board to advance the organization’s vision and mission.”

In his position as Chair, Budge stated that his focus will be implementing the updated WSN strategic plan, which prioritizes innovation, adapting to recent technologies, and operational excellence.

His goal is to ensure WSN remains a leader in promoting workplace safety across industries.

“WSN must stay flexible and ready to tackle new challenges,” Budge said. “Our vision is to make sure every worker comes home safe and healthy.”

Budge will oversee the work of the WSN Board and its four committees, ensuring they stay aligned with the organization’s goals.

president and majority owner, Cindy Cole works to transition the business, her husband Kirk Cole (vice-president of sales) and brother Mark McKee (vice-president and partial owner) will continue their roles in the business post-close.

“This is a tremendous opportunity, and we look forward to bringing customers an expanded product and service offering while supporting Motion’s growth initiatives. We are very pleased to join forces with this global

industrial leader,” stated Cindy.

“M.B. McKee is a well-established, high-quality business and a perfect strategic fit for us,” said James Howe, president of Motion. “The complementary product offering and customer-centric approach will supplement and extend our presence and scale in the region. We are thrilled to welcome the talented M.B. McKee team to Motion and look forward to their contributions in upcoming years.”

He also plans to strengthen partnerships and continue promoting programs like Ontario Mine Rescue, which he calls a critical part of worker safety.

Budge has worked in both unionized and non-unionized environments and served several industry boards. He has been a Certified Registered Safety Professional (CRSP) since 2005.

“My experience in mine rescue has given me a deep appreciation for the vital role that the WSN Ontario Mine Rescue program plays in the industry,” said Budge. “I’m committed to using my diverse leadership experiences to support the WSN mission and help shape its future.”

Motion Industries, Inc. has signed a definitive purchase agreement to acquire the operating assets of M.B. McKee Company, Inc.

The transaction is expected to close at the end of January 2025, subject to customary closing conditions.

Established in 1943, M.B. McKee is a family-owned distributor of mechanical bearings, belts, chain, conveyor systems/ components, motors, drives and power transmission components. End markets include industrial, commercial equipment, agriculture and textile.

Employing approximately thirty team members, the company is headquartered in Lubbock, Texas, with two locations in Amarillo and Hereford. As M.B. McKee

Whether level, limit level, density, interface or mass flow: Radiationbased process instrumentation delivers precise measuring results in industrial production and handling processes, and that even under the most difficult operating conditions. The non-contact measurement is not affected by the media and provides highest safety and reliability. Flexibility through detector variety: You can choose between different types of detectors. Detector can thus be optimized for widely different applications becoming the specialist for your particular measuring task. Advantages ▪ Simple mounting and operation

www.vega.com

safety features

and diagnosis

Developed acc. to IEC 61508

Qualified up to SIL2, SIL3 in

By Andrew Snook

n December 17, 2024, Alberta Premier Danielle Smith and Premier of Newfoundland and Labrador Dr. Andrew Furey spoke at an event at the Empire Club of Canada titled, “Canada’s Energy, Resource and Climate, A National Discussion.” The event gave both premiers an opportunity to discuss ongoing initiatives related to energy and security taking place in both provinces.

OPremier Smith focused on security at the Alberta border, and the importance of legislation to protect the oil and gas sector,

both of which are key for ensuring a strong trade relationship with the U.S.

“For Canada, a strong economy depends on good relations with the United States, our most important trading partner,” Smith told the crowd. “President-Elect Donald Trump has strong concerns about border security, and he’s using that as a reason to announce an imposition of a significant 25-per-cent tariff on all Canadian goods.”

Smith said the tariff would be devasting to Canada’s economy. To try and alleviate Trump’s concerns, Smith told the crowd that along with Alberta, the premiers of Ontario, Quebec and Manitoba have told the federal government that it needs to “step up when it comes to border security.”

Alberta has announced that it will increase its border security funding to assist with preventing the entry of illegal immigrants, drugs and firearms from entering the province.

“We’re creating a $29-million fund to create new border teams. Those teams will be part of our provincial law enforcement agency, which is the Alberta Sheriffs. We have seven teams of sheriffs that are ramping up security and cracking down on illegal drugs and firearms and people who are along our shared border with the United States,” Smith said.

Alberta’s portion of Canada’s shared border with the United States is 298 kilometres in length. The province plans to have its new border teams in place early this year. It will also create a twokilometre-long border zone to help sheriffs prevent illegal crossings into the province. Smith stressed that while Alberta is being proactive in its response to President-Elect Trump’s concerns, it has no interest in battling border issues alone.

“This doesn’t mean that Alberta intends, or even wants to, go it alone. Obviously, our teams will work closely with the RCMP and with the Canada Border

Services Agency. But we do recognize the need and the expectation to do more, and we are, because if Canada succeeds in maintaining proper border security, I expect that we will continue to have a very strong relationship with United States, as we always have,” Smith said.

Smith stated that Alberta began planning out an enhanced border security plan 18 months ago in an effort to battle deadly fentanyl shipments from entering the province.

Energy exports, particularly oil and gas, continues to be a vital portion of the trade between the U.S. and Canada. Smith told the crowd that the province will do everything it can protect the industry from overly aggressive federally-imposed emissions caps.

“We provide affordable energy for American states. We have the ability to be a leader in energy security, and we should not discount the incoming administration’s commitment to energy security. We must recognize that Alberta is uniquely positioned in all of the world as the perfect partner for the United States in achieving that objective,” Smith said. “So, it’s therefore, in our view, utter foolishness for the Canadian government to enact an energy production cap that would result in a massive curtailment of

oil to the United States.”

Referring to future emissions targets set by the Government of Canada, Smith said its “excessively aggressive” targets will result in a reduction in oil and gas production that will have major financial repercussions for Alberta and rest of the country.

“The only way it can be achieved is by shutting down production of oil and gas, because cuts are going to be required to meet these irresponsible time frames,” Smith said. “We’ve heard from business leaders, from industry experts and many others from across Canada, who’ve raised concerns about the cost of this dangerous policy, because when it’s in place, this production cab would require a cut of 1 million barrels per day by 2030 and 2 million barrels per day by 2035, and that is not just me saying it. It is the Conference Board of Canada. It is Deloitte. It is S&P Global.”

Smith stated that estimates from Conference Board of Canada forecasts indicate that 150,000 workers across the country will lose their jobs, and that tens of billions of dollars will disappear from Canada’s GDP and government revenues, which will devastate the country’s economy and public spending.

“We’ve calculated in our province alone that we would lose about $12 billion in revenue from various sources, which is about half the amount that we

Mike Van Soelen takes questions from the crowd for Alberta Premier Danielle Smith, and Newfoundland & Labrador Premier Dr. Andrew Fury take questions during the Empire Club of Canada event.

spend on our entire public health system,” Smith said.

To protect oil and gas production, Smith stated that the province would lean on legislation from the Alberta Sovereignty Within a United Canada Act.

“We recently brought forward a motion in the Alberta legislature, and the motion declares that our government will launch an immediate constitutional challenge when, and if, this federal production cap becomes law,” Smith said. “It also outlines aggressive measures that our government will use to stop the cap from being implemented in Alberta. And to give you an example of the kind of things that we intend to do, we will prohibit any provincial entities from enforcing the cap. We will declare oil and gas production facilities to be critical infrastructure and prevent people, including federal agents, from entering onto those properties without our permission.”

Smith stated that the province would make a condition of the licensees within the sector to report their emissions to the provincial government.

“I would much rather work with Ottawa to get our oil and gas to market. I’d much rather that Alberta and Canada benefit from the sale of oil and gas, rather than the benefit going to dictatorships around the world with much worse environmental and humanitarian records,” Smith told the crowd.

on what you can control

By Richard Kunst

The recent buzz around U.S. President Donald Trump’s proposed tariffs has many Canadian businesses—and their American counterparts—feeling uneasy. For exporters and domestic manufacturers alike, the concerns are real:

• Higher costs

• Tighter margins

• Shifting trade dynamics

But while these challenges are significant, they are far from insurmountable. In fact, businesses that take a proactive approach have an opportunity to emerge leaner, stronger, and more competitive—regardless of the tariff environment.

So, how do you prepare for this potential shake-up? The answer lies not in panic but in process. By optimizing efficiency, businesses can offset rising costs and navigate an uncertain trade landscape with confidence.

Many businesses don’t realize how much money they lose due to inefficiencies lurking within their operations. From redundant workflows to production bottlenecks, wasted time and resources quietly erode profitability.

Now is the time to take a close look at your processes. Conduct a deep dive to identify where things slow down or break down:

• Are there delays in production?

• Is there unnecessary waste in materials or time?

• Where are the most significant cost sinks in your operation?

For many businesses, these inefficiencies can be corrected without major capital investments. Simple adjustments often deliver significant savings that make all the difference when costs rise.

Lead time reduction is one of the most effective ways to improve margins and gain an edge. Why? Faster production and delivery mean less inventory, fewer delays, reduced waste, and quicker cash flow.

Optimizing workflows—whether through better resource allocation, automation, or streamlined processes—can help you turn orders around more efficiently. In a tariff-driven environment where

costs are climbing, speed and agility become critical competitive advantages.

For example, one of our client’s productions was bogged down by inefficiencies that seemed minor at first glance. However, by implementing Lean methodologies, we cut their lead times by 80% and significantly reduced costs. Not only did they regain their competitive position, but they also strengthened their ability to weather tariff-related pressures.

Your employees are your frontline problem solvers. They see the daily struggles in your operations and often have keen insights into where resources are wasted or workflows could be improved.

Empowering your team to contribute to the process improvement journey can drive significant, sustainable change. It also boosts morale— showing employees that their input matters and that they play a critical role in navigating these challenges.

The key here is collaboration. Engage your teams in identifying issues, brainstorming solutions, and implementing changes. This not only optimizes processes but builds a culture of continuous improvement.

When we begin working with a client, we often measure what we call Demonstrated Output— the actual performance of their processes, including all the inefficiencies and “noise” that have crept in over time.

Then, we compare that figure to the Theoretical Output—what the operation could achieve

under ideal conditions.

The result? Demonstrated Output is typically only 50 per cent of Theoretical Output. This means there’s often massive untapped potential, and much of it can be unlocked with simple process improvements—not expensive overhauls or new equipment.

This is an important reminder for businesses facing tariffs or rising costs: You may already have the resources you need to stay competitive. The real challenge is ensuring they’re optimized.

Tariffs and shifting trade policies are largely out of your control. But your internal operations? That’s where you hold the power. Businesses that thrive in a high-tariff environment are the ones that focus on what they can influence: efficiency, agility, and smarter processes.

Instead of reacting to higher costs with panic, use this as an opportunity to reassess and improve. The path forward isn’t about cutting corners—it’s about maximizing what you already have.

If you’re ready to uncover opportunities within your operations, start by asking: Where is our potential going unrealized? Whether it’s lead times, inefficiencies, or team engagement, the room for improvement is often much greater than expected.

By taking control of your processes, you can transform challenges into competitive advantages—no matter what trade policies come your way.

The Lutz B200 Horizontal Container Pump is designed to pump liquid out of stacked containers and containers that are not accessible from the top. Due to the pump’s compact construction, emptying at limited room height is possible. It is available with quantities up to 20 gpm; delivery head up to 262 ft.; and viscosity up to 100,000 cps. The housing material is comprised of 316Ti/316L stainless steel. The pump features a centrifugal pump with axial impeller in a compact design. It directly connects to the bottom outlet vale of the IBC with a standard union nut (S60 x 6). The pump has a variable drive concept (different universal and air-driven motors); is easy to disassemble; and no suction line is necessary, so there is significantly lower product release when disconnecting. Explosion-proof versions are available.

Vissers Sales Corp www.VissersSales.com

AutomationDirect has added Southwire flexible metal conduit to their growing selection of electrical conduit and wiring solutions.

Southwire’s Alflex type RWA (Reduced Wall Aluminum) and Galflex type RWS (Reduced Wall Steel) conduits are built using a metal strip that is helically formed into a continuously interlocked flexible metal conduit which can withstand impact and crushing forces.

Southwire’s Alflex type RWA and Galflex type RWS are designed for use with connectors intended for NEC Type FMC (Flexible Metal Conduit) and are REACH/RoHS-2 compliant. Alflex type RWA is manufactured with a lightweight, high-strength aluminum alloy 66% lighter than steel and has superior corrosion resistance. Galflex type RWS is hot-dipped for a heavy zinc, rust/corrosion resistant coating. AutomationDirect https://www.automationdirect.com

KROHNE OPTIWAVE 7500 Radar Level

Transmitter

KROHNE, Inc.’s OPTIWAVE 7500 radar (FMCW) level transmitter for demanding liquid

applications such as narrow tanks with long nozzles or where internal obstructions such as agitators or heating coils are visible. This technology provides an ideal solution for a wide range of level monitoring and measurement applications across a range of industries. With a small beam angle and negligible dead zone, this 2-wire 80 GHz FMCW radar is the optimal choice for continuous, non-contact level measurement in both extremely small or very high tanks (up to 100m/328 ft). Impressively, the level radar signal

can even pierce through tank roofs made of non-conductive materials to achieve pristinely accurate measurements. The product can measure various media including liquids, slurries, and pastes, and its measuring range for liquids spans 0-100 m / 0-328 ft.

KROHNE www.krohne.com

By Andrew Snook

There are few Canadians whose names are more synonymous with junior mining than John Robins, Co-founder and Principal of Discovery Group. Over an impressive 35-year career in prospecting and finance within the mining industry, his work has been key for transforming multiple mineral discoveries into successful companies including Kaminak Gold, Northern Empire, Stornoway Diamond, and most recently, Great Bear Resources and Great Bear Royalties. Robins’ accomplishments have been instrumental for generating more than $1 billion in mineral exploration expenditures across Canada, Latin America, and Australia. His work has also been instrumental in more than $3 billion in mergers and acquisitions within the mining industry.

In 2008, Robins was awarded the Spud Huestis Award for significant contributions to mineral exploration in B.C. and the Yukon. Fourteen years later, he was recognized for his accom-

plishments again. This time by the Association for Mineral Exploration (AME), where he received the Murray Pezim Award in 2022 for his contributions to the financing of exploration and development projects over the past two decades.

Only a few years later, Robins is now being recognized again by his industry peers for his decades of hard work and dedication in the mining industry with the Prospectors & Developers Association of Canada’s (PDAC) 2025 Viola R. MacMillan Award, named in honour of PDAC’s longest serving president. The honour is awarded to one person a year that made a significant contribution to the financial side of the industry; is a recognized leader in raising funds for a particular area, development or project; and used new or innovative financing methods. When Robins was informed that he had won the award, he was shocked.

“It was a total surprise. I didn’t have this even remotely on my radar,” he says.

“It was humbling to find out that I am

being recognized by my peers for what I’ve done during my career. Early on in my career in the 80’s, I actually met Viola McMillan in Toronto at the PDAC conference. So, it’s interesting that 40 years later I’m receiving an award named after her. I am very humbled by it, and it’s definitely a career highlight for me.”

There were several people that influenced Robins on his career path over the years. But the first, and most influential, was his father, Jack Robins.

“As a kid, my father was a forest ranger in Alberta, and I spent most of my summers in the outdoors with my dad. He would spend most of the summer out in the field with my mom,” Robins recalls. “My dad was an amateur prospector and collected fossils and rocks. So, early on, I had a major connection with the whole concept of prospecting and exploring.”

When it came time to go to university, Robins originally decided to study forestry at the University of British Columbia. But after one year, he realized it wasn’t the right path for him. Fortunately, at the same time, he had chosen to take a geology course as an elective.

“It was taught by this great professor

but we didn’t really focus on geology. It was more about his travels around the world and the adventures that he had. It really resonated with me,” Robins says. “The next year I switched from forestry into geology and that set the tone for where my career was going.”

After graduating university, Robins broke out on his own as a prospector and claimstaker, working with a couple of partners over a good portion of his career. Eventually, he realized that working in this manner- kept access to capital restricted, so he branched out and started working with larger firms.

“I started getting involved in some of the public companies because you had access to more capital, and you could spend more money on the projects that you really liked, and things just kind of evolved from there,” he says.

Robins spent a great deal of his career travelling across Canada prospecting and working with mining companies, including significant amounts of time in B.C., the Northwest Territories, Yukon, and Nunavut.

“I spent a lot of time working in the eastern Arctic, which was an absolutely fascinating part of the world to work in, and a place that very few people – not

just Canadians – ever get to spend time in,” he says. “I’ve been right up on to Ellesmere Island, prospecting all over the north. That’s still one of the real highlights in my career.”

Working in the Arctic gave Robins a great appreciation for the importance of logistics and working in harsh environments.

“The seasonality of working in an area where the winter is -60C is really challenging. You have to plan a full year ahead, and that taught me a lot of things that I carry through to this day,” he says. “You really understand the importance of the logistical side of our industry. That that was a big learning experience. Every place is different. Every jurisdiction is different.”

Robins also worked on a wide variety of mining projects in Australia, Africa, and Europe, largely focused on the finance side of the business. He’s currently working on financing mining projects in France.

“If you had asked me five years ago if I would want to do exploration in France, I would have said, ‘Probably not.’ It’s got its own nuances, but it’s been a remarkably positive experience so far,” he says. “France has been an interesting experience. We’re about to start a drill program there. It’s got some of the most prospective geology on the planet that has been completely overlooked over the last 50 years.”

Back home, challenges persist for Canadian companies to attract investors in the mining sector. To help Canada’s mining industry grow and flourish, timelines for permitting need to improve drastically.

“Our timeline for permitting and the regulatory regime in Canada, has become paralyzing. We’re being left be -

hind globally because it takes so long to even just get a drill permit,” he says. Robins compared Canada’s permitting timeline to his recent experience in France.

“We applied for drill permits in a region of France that has not seen any form of exploration at all for decades, and we got our environmental certificate and our drill permits, in less than two months. In British Columbia for example, I think the average timespan for this is something like four to six months, and in some cases, it can take up to a year. That’s a systemic problem across Canada,” he says.

The regulatory burdens placed on Canada’s mining industry are pushing investors away. The most challenging part is that it isn’t one specific type of regulatory burden that is hampering development in Canada’s mining sector. Robins says it includes environmental permitting, construction permitting, and a lack of overall leadership from the federal government. While he’s frustrated by the regulatory burdens, he still continues to work on projects within Canada.

“I’m still very involved in the Yukon with Fireweed Metals, which has one of the world’s biggest undeveloped zinc deposits. It’s continuing to grow and may end up being the world’s largest undeveloped zinc deposits,” he says. “We also have the world’s highest grade and largest tungsten deposit there, and it’s super exciting. We’re lucky that we have strong financial backing from the Lundin Mining family, but it’s still frustrating that it takes so long to permit the simplest things.”

While he considers himself an environmentalist, Robins understands the importance of the resource industry to Canadians.

“Our well-being as a country is so tied to the resource industries,” he says. “But I’m also a realist. We need copper. We need zinc. And as much as people don’t like it, it’s going to take us 20 years to get off oil and gas, and Canada’s blessed with some of the world’s largest resources. We should be like Norway, for example, that’s leading a lot of the green initiatives. Where’s all that money coming from? Oil and gas. We should be extracting in the most responsible way possible our oil and gas, and putting that money into environmentally friendly things, developing more carbon-neutral resource technologies.”

Robins’ son, Chase, is now starting his career in finance and mining engineering. While he admits that most young people don’t consider pursuing a career in mining or other resource sectors, he also believes people’s outlooks are starting to change.

“There’s no career like one in the mining industry if you have a sense of adventure in you.”

“I think in Canada that the resource sectors aren’t something that most people think of when they’re starting out a career,” he says. “But I think that’s changing a little bit, because there’s an awakening within people that we actually need metals, and mining isn’t all bad.” What advice did Robins give to his own son about the mining sector?

“There’s no career like one in the mining industry if you have a sense of adventure in you, and you like to travel around the world,” he says. “People always talk about prospectors getting gold fever, and that’s real. I still get it today, although I’m not out banging rocks in the woods too much anymore. It’s an incredibly exciting career. It’s not going to get replaced by AI, like so many prospects in the software industry. A lot of people look to the tech industry as being that exciting future. A lot of that is going to disappear with AI, I think. Whereas with the resource industry, if we’re going to be successful in this move to decarbonizing our world, mining has never been more important than it is today.”

Looking back, Robins says he’s been blessed to have the career he’s had.

“I’ve had such amazing life experiences, and the opportunities to work with really great people in the industry. I really enjoy working with some of the younger people coming along as well, because I really do believe that mining is integral to our future as a society and to our country,” he says. “I’ve had a great career. I love it. I have no regrets in anything that I’ve done.”

MoistTech Corp’s Explosion Proof Sensor is designed to revolutionize moisture measurement in hazardous environments. The sensor combines the power of near-infrared technology with robust safety features, providing unparalleled accuracy and reliability in explosive atmospheres. This innovative sensor offers superior protection through a certified explosion-proof enclosure with conduits, unions, elbows, and nipples for secure external connections. Even in challenging conditions, the sensor’s versatility allows accurate and consistent moisture measurement offering an impressive moisture range from 0-99% with parts per million (PPM) sensitivity. The sensor requires one-time factory calibration and features a drift-free optical design that minimizes downtime and reduces operational costs. Holding prevalent international certifications, the Explosion Proof Sensor ensures compliance with global safety standards. It provides significant advantages for industries, including improved product quality, optimized production processes, reduced energy consumption, and enhanced dust prevention that decreases explosion risks.

MoistTech

www.moisttech.com

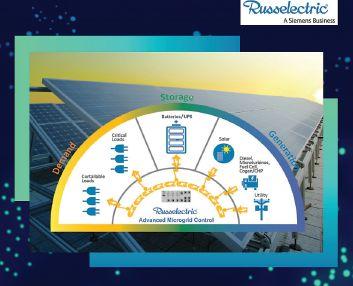

Russelectric’s Advanced Microgrid Controls Solution is an integrated hardware and software platform designed to optimize facility power management and enhance resiliency in critical sectors. This comprehensive solution may present significant benefits, including energy cost reduction, carbon footprint minimization, and improved business continuity during grid outages.

The Advanced Microgrid Controls Solution is a modular, scalable, and seamless integration of

hardware and software components. At its core, the system utilizes Russelectric’s transfer switches, switchgear, and power controllers to provide comprehensive integration of a facility’s onsite demand and generation assets. The solution connects, controls, and optimizes facility generation assets such as generators, battery back-up, photovoltaic arrays, and loads, delivering benefits from a wide range of distributed energy resource (DER) technologies. Ideal for critical sectors such as healthcare and

data centers, Russelectric’s Advanced Microgrid Controls Solution improves business continuity during grid outages through dynamic islanding capabilities, fast and reliable decoupling, automatic black start of backup generators, and seamless grid resynchronization. Additionally, the Advanced Microgrid Controls Solution helps reduce energy costs and minimize carbon footprint while improving facility power quality.

Russelectric www.russelectric.com

The UFK 1.1100 EX is an advanced solution for transferring liquids at high flow rates with low pulsation. This self-priming, three-diaphragm pump offers flow rate up to 11.5 liters/minute and is run-dry safe.

be held March 2 to 5, 2025

The Prospectors & Developers Association of Canada’s (PDAC) annual conference is coming back to the Metro Toronto Convention Centre in downtown Toronto.

This popular show dedicated to the mining industry features more than 600 exhibitors showcasing the latest mining-related technologies from around the world.

One of highlights of the show is the Northern Ontario Mining Showcase (NOMS), which has more than 110 exhibitors and interactive displays showcasing innovative products and services.

The Core Shack offers companies a unique venue to display their core samples, offering attendees a close-up look at new and ongoing projects. In addition to core samples, attendees will have the opportunity to view maps, charts and a variety of technical information.

The Investors Exchange offers companies and individual the opportunity to

learn about investment potential with 440 junior mining companies, mid-sized producers, major mining companies, financial institutions and prospectors to discover new business opportunities.

PROSPECTORS TENT

Get to the heart of the industry with a visit to the Prospectors Tent. Self-employed prospectors will be there to discuss their maps, samples and claim results.

The SMC brings together geoscience students and industry professionals to highlight innovative student research on projects essential for the successful evolution of the modern mining industry. Students (BSc, MSc, PhD) working on projects linked to mineral deposits including mapping, mineralogy, geochemistry, geophysics, environmental and hydrogeology have the opportunity to share their research with an audience of academics and industry professionals.

An initiative aimed at showcasing the diverse work of talented Indigenous artists and artisans from coast to coast to coast.

The annual convention hosts a wide range of presenters, industry experts and facilitators offering their knowledge, strategies, new concepts, case studies and more.

Access to capital is the lifeblood of the mineral exploration industry. This program creates a forum for dialogue on a range of topics related to the financing of mineral exploration.

This popular series features up-to-theminute information on select exploration and development companies’ current activities and investment potential. This series continues to be of strong interest to investors, highlighting the scope of com-

modities and stages of development represented at the convention, now including micro-cap companies.

Exploration Insights will showcase research on new concepts and ideas relevant to our industry today. This series of high-profile technical and academic presentations will offer insight into current and topical subjects.

The keynote program features four themes designed to inspire and educate: commodity outlook, mining industry outlook, technology and innovation, and discovery of the year. Presenters will discuss new and exciting concepts and explore the compelling challenges of mineral exploration and development in 2025. The premium lineup includes Mike Henry (BHP), Flavia Tata Nardini (Fleet Space Technologies), and the Thayer Lindsley Award recipient.

Uncover the fundamentals of building cooperative, respectful and mutually beneficial partnerships between Indigenous communities and the minerals industry. This program brings Indigenous-owned companies, communities and individuals together with industry representatives to share experiences, exchange ideas and network. Indigenous leaders, industry experts and legal professionals share their visions of prosperity and reconciliation with PDAC’s global network.

INVESTMENT LEADERS FORUM

Top newsletter writers and other professionals who inform investment decisions in the mining industry gather at this session to present their thoughts, charts, research reports, and ideas on the criteria they use to select profitable investments in the resources sector.

Learn from industry leaders as they share key insights and case studies throughout this exclusive series of presentations.

These are in-depth educational sessions led by presenters with expertise in a variety of different subject matter. Sessions range from a half-day to two days in length. Short courses are ticketed – purchase online before they sell out!

This program allows students and early career individuals an unrivalled opportunity to connect with industry professionals from around the world. Learn about the diverse range of careers and attend engaging presentations to stay up to date on exciting industry developments.

SUSTAINABILITY PROGRAM

Join a facilitated multi-stakeholder dialogue

and peer learning on key issues related to responsible exploration and mining. This program features presentations and conversations that examine the innovative ways in which mineral exploration and mining companies are working to improve their sustainability. Both challenges and successes will be presented, as well as lessons learned.

Industry experts discuss current and emerging

trends, technologies, research and analysis in a dynamic series of presentations. Presenters share their practical experience, insights and a look to the future. Topics include commodity outlook, critical minerals, geophysics, decarbonization, technology and more.

For more information, visit: www.pdac.ca.

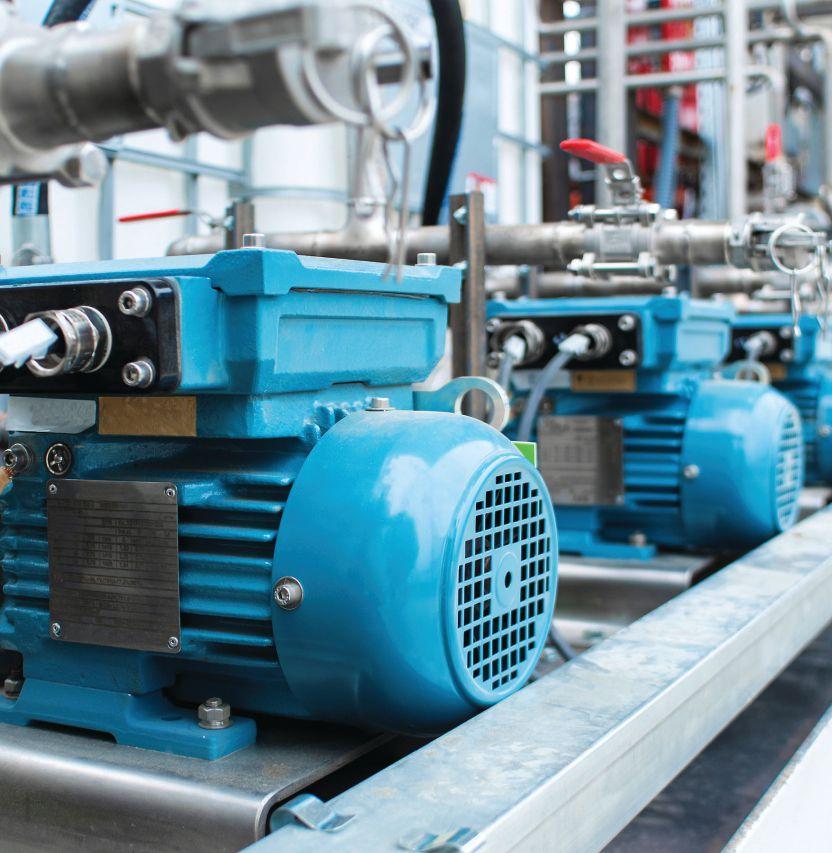

By Michael Wright

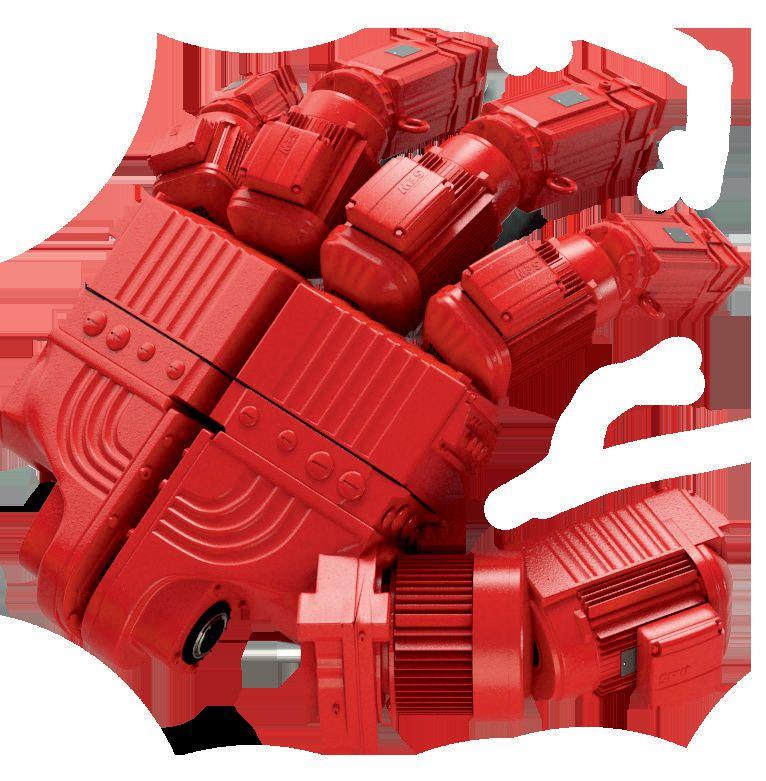

Abusiness cost that is too often ignored by plant management is the maintenance of a spare parts inventory. Unfortunately, this can rapidly add excess overhead to your operation. Not only does it tie up funds which could be applied more profitably elsewhere, but many spare components such as electric motors will degrade over time from corrosion, moisture absorption, and brinelling of the bearings (unless you pay the cost for HVAC in your motor storage building while having a worker rotate the shaft on every motor each month, grease each motor annually, and apply rust inhibitor to the shaft as required).

It is, therefore, wise to reduce the number of spares needed to keep your plant running; but not by letting some “bean counter” do it based on statistics, but instead by standardizing as many of your major components as possible so that the overall number of different spares can be reduced.

In my last column, I discussed motor frame sizes and pointed out that manufacturers tend to use the same castings for different horsepower (HP) ratings simply by drilling multiple holes in the motor base and labelling them differently. Sometimes they even use the same frame size designation for more than one HP rating of motor.

Although this standardization by the manufacturers is intended for their benefit and not that of the consumer, it does provide the opportunity for plant managers to standardize their motors and therefore reduce the number of different spares and probably the overall number kept in inventory.

For example, for 1,800 RPM motors, the 1HP (industrial) will have a 143T frame while the 1.5HP and 2HP will have 145T frames. However, the castings for each motor will be identical as will the shaft size and length.

Now given the minimal price difference between 1HP, 1.5HP, and 2HP motors, and the minimal cost of upgrading your “electrics” as required, do you really want to inventory 1HP, 1.5HP, and 2HP motors, or would you rather add a couple of extra 2HP motors to “spares” and drop the smaller ones altogether?

It is wise to reduce the number of spares needed to keep your plant running by standardizing as many of your major components as possible so that the overall number of different spares can be reduced.

However, I now need to address how the use of motors that are “bigger than they need to be,” will affect efficiency. This is where science, experience, and common sense need to be employed to deal with the misguided belief that using the smallest motor possible will somehow improve efficiency.

The energy consumed by a motor falls under the following categories:

• Shaft load

• Friction and windage

• Iron and copper losses

The shaft load is obvious; if a 2-HP motor is driving a load that only requires

1HP, then the energy consumed by this component will be exactly the same as that consumed by a 1-HP motor. Friction and windage are functions of the size of the cooling fan and the bearings used in the motor. And given that all three motors listed in this example are made with the same mechanical components, this loss will be the same for each motor.

Without going into a lot of technical jargon, iron and copper losses can be best summed up by looking at how much waste heat will be produced by a given motor when it is operating.

Considering that a 2-HP motor has

heavier windings and more iron in it, it will actually run cooler than would a 1-HP motor under the same load conditions. In this case, the 2-HP motor will be the more efficient option.

Although the above example is somewhat trivial, the same thought process can be applied to all of the different motors manufactured with identical castings right up to and including 150HP.

However, we must now look at the issue of “power factor,” the ratio of energy stored in a motor windings and then released back into the power system on an alternating basis versus the amount of energy that is consumed to do work or produce heat.

Although there will be some engineering involved if you choose to standardize on motors based on frame size, the potential savings in spares inventory will make it worthwhile.

This storage and release of energy can be seen when an amperage reading is taken on the motor, but it does no work, produces no heat, and can’t be seen by the utility kilowatt-hour meter. However, on medium-sized commercial, and virtually all industrial operations, the utility will employ “demand metering” which can detect the “poor power factor” of the motor loads and can hit you with a nasty surcharge on your monthly bill.

So, although it is true that motors which are “bigger than they need to be” will have a poorer power factor than motors which are loaded to their full rating, all plants which are billed for demand load by the utility should employ power factor correction systems. Then the mar-

ginal cost between a system designed to correct for smaller motors which operate at 100-per-cent load versus a system designed to handle motors operating at lower load levels is minimal.

Although there will be some engineering involved if you choose to standardize on motors based on frame size, the potential savings in spares inventory will make it worthwhile. And a side benefit is that the fewer different spares that you have, the less time it will take for the maintenance workers to find the correct replacement motor in the spares warehouse, and the sooner your plant will be up and running after a failure.

MICHAEL WRIGHT is an electrical engineer with more than 50 years of experience in heavy industry. Although he has done an extensive amount of PLC/DCS programming and upgrading of power systems, he is a very strong generalist with a broad knowledge of hydraulics, pneumatics, power transfer, welding practices, mining equipment, mobile equipment, process control strategies, pumping systems, rock mechanics monitoring, mechanical maintenance practices, MRO procurement contracts, energy management, and cost control. As such, he specializes in problem prevention as a subject matter expert (or as a fixer on “problem projects”). It is his belief that safety is not a “priority” but is a way of life; that good engineering makes life simpler and easier for others; and that the best ideas come from those with calloused hands and dirty coveralls. He can be reached at: mawright@sasktel.net.

By Alex Caruana

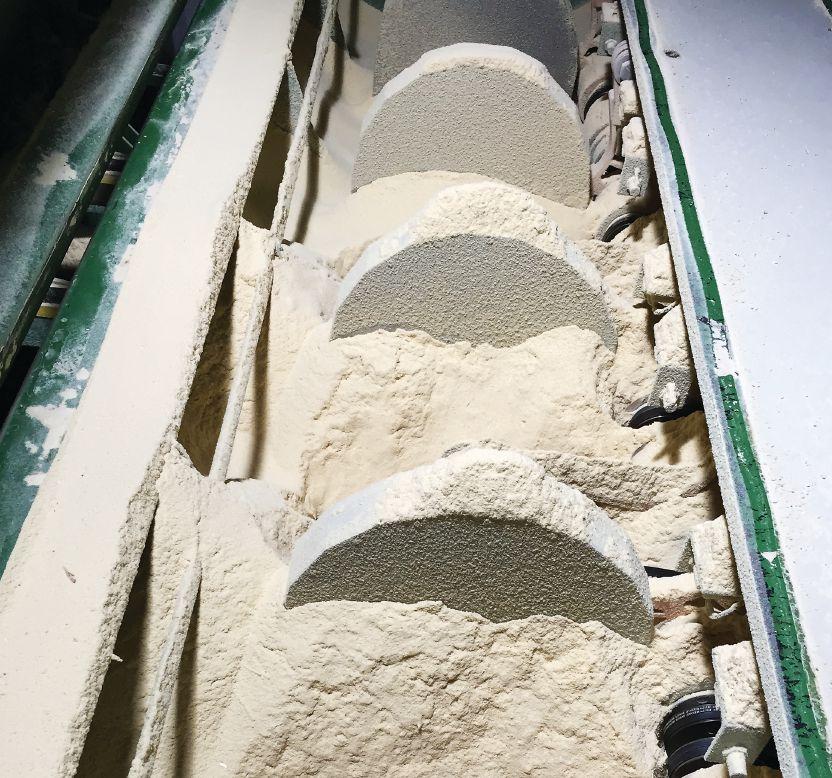

If you have a vibratory or static screen in your process, it is likely that this quiet hero shakes reliably day after day. But when screens fail, they often have a nasty way of reminding us of just how important they really are. Therefore, in this article, we’ll take a look at some of the most common screen issues and how to stay ahead of them to keep your operation running smoothly and safely. Whenever working on vibratory screens, there are a few overarching considerations to be made. If the work is non routine, a pre-job plan is most certainly best practice. Regardless of the frequency of work, however, lock, tag and try practice should always be followed. It’s important to assume that nothing is interlocked in the process, and locks should be placed on the screen itself, as well as feed and discharge conveyors. In general, the goal is to eliminate hazards by reducing the need for maintenance and, where possible, removing hazards entirely through solutions like modularity (discussed further below).

Firstly, let’s talk about establishing a baseline. You cannot manage what you do not measure, so it stands to reason that a screen should be measured when it is in good operating condition, ideally when freshly commissioned. Many operations assume that their screens are calibrated to their bespoke application, but this may or may not be the case. When purchasing a brand-new vibratory screen, take the time to look closely as you’re about to embark on a sizeable purchase. Two very good things to ask are whether the screen will be calibrated to your application with screen media installed and set up to reflect actual operating weight and center of gravity, and if a baseline diagnostic will be provided upon commissioning. With regards to baseline diagnostics, these should be done with the screen in place, on the sup-

porting structure, operating both loaded and unloaded. Proper diagnostics should include critical frequency, structural movement/ support, side plate deflection, orbit measurements in at least six positions, measurement of the spring heights, clearance to static items, drive/driven speeds, drive direction and any notes on feed conditions.

Diving quickly further into critical frequency, also known as resonant frequency, this is the point at which the screen’s natural movement is amplified, causing erratic motion. Operating at or near critical frequency can lead to failures such as frame or side plate cracking and a loss of screening efficiency.

Once the baseline diagnostic file is established for a vibratory screen, this should ideally be conducted seasonally to monitor any changes from commissioning as they happen. This will keep the operation well-informed on whether preventative maintenance is required. Any screening issue that causes a failure is basically creating a hazard that can be eliminated in the form of an unplanned shutdown. By monitoring ongoing conditions against a baseline, maintenance can be planned and executed during scheduled shutdowns with safety as top of mind.

Now, let’s move on to screen media,

particularly side tension screen media, which is very common. Select side tension screen media specific to each area of the screen to even out the wear of ‘hot spots’ like feed zones or under spray nozzles with lesser frequently worn areas. This creates a balance by using higher open area (lower wear) media in spots where it’s most efficient and higher wear (lower open area) media in heavy-duty areas. Ideally, a whole deck level would wear out evenly, indicating that balance has been achieved.

When selecting a new screen, consider options like double crown media, which reduce the size of the side tension units required. For

example, on an 8-foot-wide screen, single crown media means approximately 32 square feet per section, whereas its double crown counterpart would reduce that to approximately 16 square feet. This means lower unit weights for maintenance staff to handle, and safer work in general. Having worked with large format side tension media personally, I can speak about the hazards it exposes staff

to. Just to name a few, hazards can include loss of balance, slips and trips, cuts due to sharp edges, and even temporary open spaces where staff could fall through when media is being swapped out. Punch plates, in particular, can be extremely bulky and awkward, especially when side tensioned. If punch plate is your selection, very much consider a bolt-down format, since tensioning punch plate can

be a strenuous task and expose your screen to over-tensioning, which can lead to bowing in side plates. Bolt-down formats can often split screen sections down to more manageable sizes (like the double crown concept) and eliminate the need for tension.

Now, if side tension screens are what you’re using, ensure that crown rubber (also referred to as bucker bar covers or rail covers) is maintained along with the media replacements. Too often, crown rubber degradation leads to lack of tension, premature wear due to media flexing, and degradation of the stringers themselves (where they scallop like the edge of a bread knife). All of this leads to a situation where without replacing the stringers, they then cut the inadequately supported crown rubber, aggravating the whole process of premature failures. Again, here, the idea is that proper initial maintenance practices will lead to less failures and less exposure to hazards because of reduced maintenance requirements.

Modularity is another key factor in making screen maintenance safer. The idea of reducing, like in the above example, from 32 square feet to 16 square feet can be a game changer. That said, this can be done very effectively down to 1-2 square feet by using modular media. Smaller weights and sizes are easier to handle, reducing strain and awkward handling. Plus, the open spaces created when swapping out sections of media are much smaller increments, reducing the likelihood of falling through said opening. Just like side tension media, modules come in a variety of wire styles, punch plate, rubber types, and polyurethane compounds, offering an entire range of wear versus open area balances. Similar to side tension, balancing high wear media into ‘hot spots’ can balance out those areas such that they do not need maintenance as frequently. By negating the need for tension systems, impact guns are also removed from the equation, reducing noise exposure. The use of non-tension

May 22 - 24, 2025 Delta Downtown Calgary

The CPCA annual conference is a must-attend for professionals in the process control industry to gather knowledge and network with colleagues. With a mix of education from thought-leaders and exciting social events, you will leave the conference better informed, connected and engaged in a host of

and learn how to adapt in an

modules also means that work is usually contained within the side plates of the screen, no longer requiring staff to work on the outside the screen or at heights nearly as often. Modular media is most frequently supplied in synthetic materials, which also reduce noise emissions by approximately half of what the human ear perceives. This means that in many cases, noise reduction requirements are reduced within easily achievable amounts (one level of noise protection as opposed to two). Noise reduction also means that any member of staff can hear other hazards or their two-way radios more clearly. In cases where screens are on open towers, noise reduction also carries the benefit toward any neighbouring areas.

We talked about baseline and seasonal diagnostics earlier on, but it is important to point out that diagnostics are not comprehensive condition assessments. Once operational, it’s essential to assess the integrity of components like side plates, stiffeners, spring conditions, motor base tension, belt alignment, deck frame integrity, diagonal support condition, and feedbox and discharge lip conditions. One circumstance I see very frequently is that condition assessments look for perforations, later leading to patch welds or “fish-plating”. Once perforations are present, material ingresses into components like cross members and alters the balance of the screen along with its integrity. By using ultrasound to measure steel thickness in indicator areas (such as feed zone cross members), you can stay ahead of perforations and avoid more costly repairs. If field fixes like welding on cross members are considered, this is best done when the base steel is still intact, since field fixes seldom restore overall integrity.

While more robust vibrating screens are required to carry the weight of protective items, there is good purpose to considering these extra layers of protection when the screen is being purchased new. This way, wear zones can be exposed by replaceable items like feedbox liners, cross member protectors, and magnetic cross tube covers. In a perfect world, you’d replace a worn liner instead of needing to repair the base components. Executing and reviewing condition assessments should be part of any screen maintenance program, focusing on keeping all maintenance planned rather than reactive.

Finally, let’s discuss material selection with fire safety in mind. With so much discussion of synthetic materials like

Diagnostics are not comprehensive condition assessments. Once operational, it’s essential to assess the integrity of components like side plates, stiffeners, spring conditions, motor base tension, belt alignment, deck frame integrity, diagonal support condition, and feedbox and discharge lip conditions.

rubber and polyurethane, it is important to understand the nature of these materials. Polyurethane and rubber are bracket terms for materials which can be formulated in numerous ways. Cast-in-place polyurethane, for example, is made through an exothermic reaction, giving off heat as it is cast. Once exposed to heat, like a hot bolt being cut above the screen, it will readily produce and spread flames. Injection molded polyurethane is made through an endothermic reaction, absorbing heat to form itself. Exposed to the same hot bolt, injection-molded polyurethane will reform itself, stubbornly resisting spread and ignition. Thus, while most synthetics will burn when exposed to extreme levels of heat, the difference in their levels of resistance can be critical. Rubber is another good example of this, with soft materials like gum rubber that chutes are lined with frequently being quite easy to set aflame, whereas standard media rubber and conveyor belts will resist ignition quite significantly. Most

synthetics can be made with flame retardants within the material, too, which could be key to your operation. Be aware that cast-in-place and injection-molded polyurethanes can look very similar, as can different rubber types. Hence, it is important to both know your synthetic material and expect your media supplier to reliably guide you in selecting the best materials for your operation.

In summary, maintaining vibratory screens safely and efficiently involves careful planning, regular diagnostics, and strategic choices in screen media and modularity. By establishing a baseline, monitoring critical frequency, and selecting the right materials, you can reduce unplanned downtime and improve overall safety. Keeping these practices in mind will help ensure your screens continue to be the quiet heroes of your operation, minimizing hazards and maximizing uptime.

By Diane Cave

If you’ve ever asked yourself “where did this DHA thing suddenly come from and why is it so important?” or “Why is there such a push for all facilities to have a completed DHA?” Well, you’ve come to the right place. In the world of combustible dust, the DHA has been a hot topic for years.

The easy answer to this is compliance with codes and standards, predominately the many NFPA guidelines. Digging into the specifics of NFPA 652, section 7.1.1.2 states that “for existing processes and facility compartments, a DHA shall be completed by September 7, 2020.” Section 7.1.4 goes on to say that the DHA should be review and updated at least every five years. Regulation can differ by jurisdiction. There we have it. Case closed! Codes and standards say it must be done, so it must be done! Not so fast. I’m all for following directives, but I’d like to know why I have to jump on board before I do! So, let’s put the mandated reasons aside and let’s look at the practical side of things.

In my 20-plus years in the industry, I have witnessed a fair amount of jaw dropping things done (or not done) around combustible dust. More often than not productivity, cost, or convenience are prioritized over safety. This pertains to all aspects of combustible dust: electrical area classification, dust collection, interlocks, safeties, design, start ups, the whole gambit. So, who are these malevolent actors, callously putting their people at risk? The unfortunate truth is that it’s not in one area, or one industry, it’s uniform across the board. Due to the complexity of it, combustible dust really is not an area where you want things to be done poorly or by the uninformed. When we look back at the most consequential combustible dust incidents of the past century the common theme is decisions that were uninformed, cheap or outright reckless. If you don’t believe me, do a YouTube search for “combustible dust explosions.”

This brings us back to the questions of the importance of a DHA. First, the objective. A DHA is a fact-finding mission to help us understand combustible dust risk. In my opinion the objective of the DHA is not to fix problems but to inform of current hazards and risk witnessed during the DHA. This pertains to process and procedure around combustible dust hazards (both explosion and fire). The objective is to identify the hazards, communicate where the highest risks are, and provide rough ideas on what actions are

A DHA is a fact-finding mission to help us understand combustible dust risk.

required to mitigate the risk. The report will not to solve all the combustible dust hazard issues. It will however assist the diligent reader in what the problems are, where to start, and ultimately how to move the facility towards a safer work environment. If completed and compiled correctly, the DHA is a very useful and powerful tool in the hands of a diligent employer.

To recap. Combustible dust is in a lot of industries, and the risk is typically handled and protected against poorly. To protect against that risk, we start with a DHA report. The objective is to outline what the hazards are, what the highest risk is and a general path forward to mitigate those hazards. I think you can start to see how the pieces fit together. Think of it as a (explosion proof) flashlight in a dark, dusty room. Yes, the DHA is something that is mandated to be completed, but it should not be thought of as just checking a box. If done correctly, it can be used to outline where issues in a facility are and how to keep the people (foremost), property and process

safe. This knowledge is ultimately the importance of a DHA.

DIANE has spent the past 20-plus years working with the design, installation and retrofitting of dust collection systems in industries ranging from sawmills and grain installations to food and beverage and specialty chemicals. Diane’s expertise covers all aspects of dust collection systems from troubleshooting system issues, upgrading systems to meet current codes and standards. Diane has also assessed hundreds of dust collection systems for combustible dust hazards using the latest NFPA codes and standards and completed numerous dust hazard assessments. She can also provide advice and design experience for explosion protection systems, vessel retrofits, Pred verification, and static bonding and grounding. Diane has conducted numerous webinars and training session for clients and industrial publications. She has multiple articles published in various industry magazines.

By Cyrus Moulton

t a time when synthetic plastic has polluted nearly every corner of the globe and appeared in food and in the human body, Northeastern University researchers have developed a new plastic that dissolves in water.

A“The kind of impact that human-made materials are making on the living world is resulting in climate change, pollution and more,” says Avinash Manjula-Basavanna, a senior research scientist at Northeastern University. “One of the ways that we are able to address this is to

Northeastern University researcher Avinash Manjula-Basavanna developed a plastic that dissolves in water.

Researchers see the new plastic as useful for detergent pods, among other applications.

make materials sustainable and also make materials which are smart or intelligent.”

Manjula-Basavanna and Neel S. Joshi, associate professor of chemistry and chemical biology at Northeastern, call their bioplastic MECHS — an acronym for Mechanical Engineered Living Materials with Compostability, Healability and Scalability.

The researchers presented their discovery in a paper published in the journal, Nature Communications

The study showcases the researchers’ most recent work with engineered living materials, which use living cells to produce functional materials.

Manjula-Basavanna and Joshi explain that such materials have notable assets.

First, the nature-inspired solutions can be made to regenerate, regulate and/or respond to external stimuli such as light and can even heal itself. Secondly, unlike the plastics that are polluting the planet and our bodies, the materials are biodegradable in water and even the compost bin.

“Plastic pollution being a global problem, we are focusing on targeting the low-hanging fruit of plastic packaging.”

“Right now we use a lot of conventional nonbiodegradable plastics for applications they don’t need to be used in at all,” Joshi says. “If we replace that with our plastic, you could just flush it down the toilet and it would biodegrade.”

But while engineered living materials have been manipulated to adhere, catalyze and remediate, and be either soft or stiff, such materials have not been scalable for widespread production.

That’s where MECHS comes in.

MECHS consists of engineered E. coli bacteria with a fibre matrix to create a paperor film-like material.

The fibres give MECHS several desirable properties. It means that MECHS can stretch like plastic wrap, and can be genetically engineered by adding proteins or peptides to make it more or less stiff. And it is healable — a small amount of water disentangles the fibres, which then re-entangle as the MECHS dries.

Meanwhile, a lot of water or a trip to a compost bin causes the material to dissolve. In fact, it dissolves much faster than other biodegradable plastics, the researchers found. Finally, the material can also be easily mass produced in a process similar to paper manufacturing.

Manjula-Basavanna and Joshi envision that the product could be used for what they call “primary packaging” — that filmy plastic that protects the screen and case of your iPhone, for instance. Detergent pods for dishwashers or

washing machines are another potential use.

Even proteins embedded in the fibres could provide fertilizer as it breaks down if MECHS were used as a pot for plants.

“Plastic pollution being a global problem, we are focusing on targeting the low-hanging fruit of plastic packaging, which comprises nearly one-third of the plastic market,” Manjula-Basavanna says.

He notes that the typical lifespan of this packaging could be a few days to two years.

“For such a short lifespan of packaging, the petrochemical plastics that can take hundreds of years to biodegrade are unnecessary in many cases and thus a sustainable alternative like MECHS due to its biodegradability, flushability, and mechanical tunability could be a game changer,” Manjula-Basavanna says.

CYRUS MOULTON is a Northeastern Global News reporter.

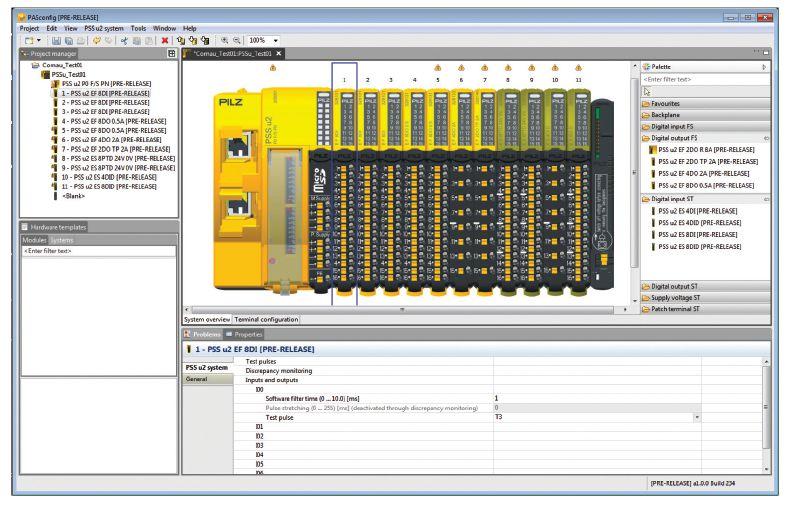

As industrial automation demands grow, so does the complexity of I/O systems. The need for increased safety and efficiency has led to a surge in the number of I/O points required to communicate with PLCs. To address this challenge, distributed I/O systems offer a cost-effective and flexible solution.

Pilz’s PSSuniversal 2 (PSSu2) is a powerful distributed I/O system designed to simplify and optimize industrial automation. It supports both Profinet - Profisafe and Ethernet/IP - CIP Safety, providing a unified platform for both safety and standard I/O.