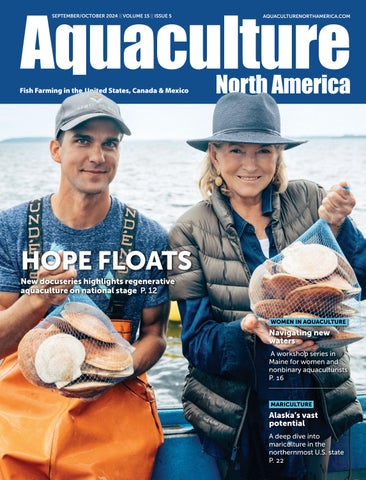

HOPE FLOATS

New docuseries highlights regenerative aquaculture on national stage P. 12

WOMEN IN AQUACULTURE Navigating new waters

A workshop series in Maine for women and nonbinary aquaculturists P. 16

MARICULTURE

Alaska’s vast potential

A deep dive into mariculture in the northernmost U.S. state P. 22

By Mari-Len De Guzman

By Lynn Fantom

By Seyitan Moritiwon

By Nancy Erickson

VOLUME 15, ISSUE 5 | SEPTEMBER/OCTOBER 2024

Reader Service

Print and digital subscription inquiries or changes, please contact customer service

Angelita Potal

Tel: (416) 510-5113

Fax: (416) 510-6875

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor Jean Ko Din jkodin@annexbusinessmedia.com 437-919-1107

Associate Editor Seyitan Moritiwon smoritiwon@annexbusinessmedia.com

Contributors Mari-Len De Guzman, Nancy Erickson, Lynn Fantom, Matt Jones, Laura Kraft, Haleh Mawson, Ben Normand, Jennifer Ruesink Associate Publisher / Advertising Manager Jeremy Thain jthain@annexbusinessmedia.com +1-250-474-3982

Account Manager Morgen Balch mbalch@annexbusinessmedia.com +1-416-606-6964

Account Coordinator Catherine Giles cgiles@annexbusinessmedia.com

Media Designer Svetlana Avrutin savrutin@annexbusinessmedia.com

Audience Development Manager Urszula Grzyb ugrzyb@annexbusinessmedia.com 416-510-5180

Group Publisher Anne Beswick abeswick@annexbusinessmedia.com 416-410-5248

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

PUBLISHED BY ANNEX BUSINESS MEDIA 105 Donly Drive South, Simcoe, ON N3Y 4N5

Aquaculture North America is published six times a year by Annex Business Media. The authority for statements and claims made in Aquaculture North America is the responsibility of the contributors. Reference to named products or technologies does not imply endorsement by the publisher.

Subscription rates (six issues) Canada: $37.74+Tax Within North America: $48.96 CAD Outside North America: $63.24 CAD To subscribe visit our website at www.aquaculturenorthamerica.com

PRINTED IN CANADA ISSN 1922-4117 Publications Mail Agreement #PM40065710

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1 UNITED STATES MAILING ADDRESS

Aquaculture North America, 815 1st Ave, #93, Seattle, WA, 98104

Annex Privacy Officer Privacy@annexbusinessmedia.com • Tel: 800-668-2374

The contents of Aquaculture North America are copyright ©2024 by Annex Business Media and may not be reproduced in whole or part without written consent. Annex Business Media disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication.

Next Ad Deadline

The advertising deadline for the Nov/Dec issue is October 1. Don’t miss the opportunity to be part of this exciting aquaculture publication. For more information, or to reserve space in the next issue, call our Advertising Department at +1.250.474.3982 jthain@annexbusinessmedia.com

Next Editorial Deadline

The editorial deadline for the May/June issue is October 4. Contact Jean Ko Din at jkodin@annexbusinessmedia.com for details. Material should be submitted electronically with prior arrangement with the editor.

Sharing our good stories

The reason why I’m always writing about the importance of sharing stories throughout the industry is because I want to remind readers about the importance of visibility.

How can a person care about something if they don’t know anything about it?

As I’ve said in previous issues, the aquaculture industry rarely enjoys the attention of mainstream media. And so, when aqua farm stories share the spotlight with the likes of television personality Martha Stewart, actress Shailene Woodley, and two Michelin star chef José Andrés, it’s a big deal.

For the aquaculturists who were featured in this nationally televised docmentary series, Hope in the Water, it is a rare moment of pride for the industry to share with the public about the work that they do, without having to defend against anti-aquaculture misinformation or fight for political influence. It was a breath of fresh air, one that this industry doesn’t get to enjoy these days.

In many areas across the continent, the aquaculture industry is fighting for its seat at the table of North America’s food economy. Traditional net pen farming’s future is being called into question. Momentum is stalling for emerging mariculture opportunities. Recirculating aquaculture systems and other major farm projects are struggling to keep the lights on. And, government bodies and its officials are caught in a political tug-of-war as mounting pressure for votes looms for Canada and the United States.

These challenges continue but in this issue, we get to celebrate. We celebrate the good work that is happening in our community. We celebrate the sustainable practices that have taken the industry into the 21st century. We celebrate the investment that has been made to support the continued growth and innovation that will fuel the hope that will continue to drive aquaculturists forward and prove its role in the future of feeding the world.

Speaking of celebrations, every year we like to dedicate our September/October issue to the stories of women in aquaculture. This is our third year hosting our Women in North American Aquaculture (WINAA) Summit. The virtual event, which takes place on Sept. 5 at 11 a.m. EST, will bring together female thought leaders to talk about their work in empowering the men and women of the industry. With all that I had menitoned before, it’s no surprise why we chose “Advocacy in Action” as the central theme for the virtual event.

We collaborated with Seafood and Gender Equality (SAGE) to share about their latest work to ensure women and gender-neutral people get into these decision-making, leadership positions in aquaculture.

We also gather together Indigenous women leaders to talk about how their aquaculture partnerships have impacted their local economies and what they believe is the way forward.

We also collaborated with Women in Caribbean Aquaculture (WiCA) that supports women scientists of Caribbean origins dedicated to the growth of aquaculture in the Caribbean region.

We are so happy to be sharing the platform we have through Aquaculture North America to talk about why the work of these impact leaders matter.

Please don’t misunderstand and think that this virtual event, or the larger WINAA program, is strictly for the female professionals that read our pages. This program makes visible a minority half of the aquaculture world, but their work and their leadership brings change to the whole workforce.

We share these stories to bring light to work that would otherwise go unnoticed in the day-to-day running of a farm. And I hope you continue to share them with me at jkodin@annexbusinessmedia.com.

JEAN KO DIN

OYSTER GRADING TECHNOLOGY

at its finest.

SED Water Grader for seed and juvenile oysters. Fast but very gentle, significantly lower mortality rates than dry barrel or shaker graders.

Mississippi Aquaculture Center expanding

The University of Southern Mississippi’s Thad Chochran Marine Aquaculture Center is in the process of expanding with a new oyster hatchery and research center. Oyster hatchery manager, Megan Gima, said the expansion is being funded through the Resources and Ecosystems Sustainability, Tourist Opportunities, and Revived Economies of the Gulf Coast States Act (RESTORE) which provides funds for protecting natural resources, ecosystems and wildlife habitats.

“Through the Oyster Council, Mississippi came up with this plan where they wanted to start restoring the oyster reefs and increasing the off-bottom oyster aquaculture industry,” said Gima. “It’s going to be state-of-the-art and relying on recirculating artificial seawater so that we’re not constrained by events that happen, whether it be storms, freshwater or temperature events. We can control our water quality and parameters more.”

Gima said the end goal, and the reason why the RESTORE Act was applicable, was to put more oysters into the Gulf. This could significantly benefit the state’s oyster sector, which has not had a harvest from public reefs since 2018.

“The other thing is the environmental implication that those oyster reefs provide,” added Gima. “They’re filtering water, taking out sediment. They provide the nursery for a lot of our marine species here in the Gulf. But they also provide protection from storms. When we’re losing the reefs, we’re losing all those benefits. Through the oil spill, the amount of hurricanes, Katrina, all these big freshwater events have drastically depleted the oyster reefs over a couple of years.”

The design for the new facility has been completed and construction is set to begin in early 2025. This project was paid for (in part) with federal funding from the U.S. Department of the Treasury and the Mississippi Department of Environmental Quality under the Resources and Ecosystems Sustainability, Tourist Opportunities, and Revived Economies of the Gulf Coast States Act of 2012 (RESTORE Act).

– Matt Jones

NOAA recommends $220M for restoration projects

National Oceanic and Atmospheric Administration (NOAA) is recommending about US$220 million for 32 transformational habitat restoration and coastal resilience projects in 2024, and an additional $66 million for future years.

These projects will help protect coastal communities and ecosystems from climate change and will aid in the recovery of threatened and endangered species.

“This is a historic investment in strengthening the climate resilience of our nation’s coastal ecosystems and communities,” an article from NOAA reads.

One of the largest obstacles to recovering threatened and endangered species is degraded habitat. Many of the projects will make progress in recovering these species by restoring the habitats they depend on for food, protection, spawning, and rearing.

Many of these projects will restore habitats in urban areas and benefit tribes and historically underserved communities that live close by.

Projects include The California State Coastal Conservancy, The Southeast Alaska Watershed Coalition, and The Louisiana Coastal Protection and Restoration Authority.

Light and density adjustments reduce lumpfish aggressiveness: study

Researchers have found that hatcheries can reduce lumpfish aggressiveness toward younger lumpfish by altering light conditions and fish densities inside tanks.

“Lumpfish are crucial in addressing the high demand for cleaner fish in salmonid farming, but their aggressive behaviour, including cannibalism, poses a challenge,” said station scientist Elizabeth Fairchild, a research associate professor with UNH’s College of Life Sciences and Agriculture (COLSA). “Understanding the factors that exacerbate lumpfish aggression and providing guidelines for mitigating this behaviour to aquaculturists, are essential for increasing hatchery production and rearing efficiency.”

The researchers at the University of New Hampshire and the New Hampshire Agricultural Experiment Station, found that especially for smaller lumpfish, instances of tail fin nipping as a sign of aggression lessened when the fish had 12 hours of light followed by 12 hours of dark (versus constant light) and when the density of fish was reduced.

These management conditions become less influential as lumpfish grow larger, allowing for more flexibility in rearing practices, said Fairchild. However, further research is needed to explore the long-term impacts of these conditions and to develop comprehensive guidelines for lumpfish rearing.

The researchers said that integrating lumpfish, a cleaner fish that feeds on sea lice off salmon, into aquaculture farms is a sustainable mitigation strategy. The most impactful species, Lepeophtheirus salmonis, can cost an estimated US$1.3 million per farm over a two-year production cycle in sea lice infestation management.

Fairchild and her co-authors, Brittany Jellison, an assistant professor in UNH’s biological sciences department, and Shelby Perry, a master of science student in COLSA’s marine biology program published their research in the North American Journal of Aquaculture.

The current mitigation methods for sea lice, including waterjets, hot water showers and other mechanical and thermal treatments, aren’t fully effective and can harm the fish, resulting in lower growth and survival rates for the salmon.

Perry said finding the best environmental conditions for lumpfish development is crucial, as it enhances their effectiveness as cleaner fish in aquaculture settings.

“By adopting these recommendations, fish farmers can improve lumpfish hatchery production, reduce juvenile mortality and enhance the sustainability of salmonid farming through effective sea lice management,” she said. “And increasing aquaculture sustainability and efficiency is vital to meeting the future demand for animal protein, as well as protecting the planet we live on.”

Women-owned kelp farm awarded USDA funds for skincare research

Cold Current Kelp, a regenerative ocean farm and skincare company in Maine, has been awarded US$175,000 in Small Business Innovation Research (SBIR) funds through the USDA.

The award will support the company’s research and development for the use of kelp extract in skincare and other applications.

Cold Current Kelp’s research project will determine the feasibility of using a relatively new green extraction method to obtain bioactive compounds from Maine-grown sugar kelp.

The proposed extraction will not use toxic solvents and is expected to result in higher extraction yields in less time, Cold Current Kelp mentioned in a press release. The project will also examine the effects of a variety of extraction conditions as well as the age of kelp at harvest. It will then identify, characterize, and quantify resulting compounds of interest.

“We are thrilled to be awarded funding and to partner with the USDA’s Agricultural Research Service to advance scientific discovery that will unlock promising applications of kelp outside of nutrition,” said Dr. Inga Potter, co-founder of Cold Current Kelp and a marine biologist. “As a regenerative, renewable crop that restores ocean health, kelp offers many benefits to our environment and economy, and this research will allow us to expand its use as a sustainable alternative to ingredients in other industries.

The company anticipates the project will be a step toward producing natural, non-toxic ingredients with quantifiable bioactive

compounds that can be used by the company to create effective skincare products.

“Our analysis of the bioactive compounds of kelp extract has the potential to further establish kelp’s credibility as a sustainable, effective, non-toxic ingredient for the natural skincare sector, where consumer demand is strong and growing,” said Krista Rosen, cofounder of Cold Current Kelp. “The nutrient-rich compounds act as antioxidants and are anti-inflammatory, protect against UV damage, and inhibit the breakdown of collagen and elastin. We are excited to scientifically quantify these compounds, and give consumers a better understanding of how kelp can benefit their skin.”

YOUR PRODUCTION CYCLE THROUGH THE USE OF OXYGEN

Our OXYMAR® generation and injection systems ensure a continuous and uninterrupted high-volume supply of oxygen and air

Krista Rosen and Inga Potter are the founders of Cold Current Kelp.

PHOTO: COLD CURRENT KELP

First Nations groups take DFO to court over licence renewals for B.C. salmon farms

Two First Nations in British Columbia are taking legal action against the federal government and two fish farm companies after the government decided to allow fish farms to operate in B.C. for five years.

Fisheries and Oceans Canada (DFO) had been phasing out the fish farms, but in June, they extended licences for another five years, allowing Grieg Seafood and Mowi Canada to continue to run 14 farms. The ‘Namgis and the Kwikwasut’inuxw Haxwa’mis First Nations said in federal court applications that the decision infringes on their Aboriginal rights, a report from the CBC states.

The ‘Namgis application made claims of fish stocks of pink, coho, chinook and sockeye salmon becoming “severely depleted,” prompting the nation to stop fishing for those stocks in the Nimpkish River, build a hatchery and start a pilot project for a land-based fish farm facility. The nation established The Kuterra facility, the first Atlantic salmon aquaculture facility in Canada that uses recirculating aquaculture system (RAS) technology.

rights-holder Nations, and the regulations are typically stricter than those imposed by the DFO, the press release states.

“Our sector has consistently stated that we will not farm where we do not have consent, and we have stayed true to that commitment,” said Brian Kingzett, BCSFA executive director.

The application stated the fish farms licensed by Minister Diane Lebouthillier are along crucial points of the migratory routes of wild Pacific salmon they have been fishing on. The ‘Namgis said the minister is mandated to protect and conserve fish, but the fisheries department has allegedly ignored that mandate since it began regulating fish aquaculture.

The Kwikwasut’inuxw Haxwa’mis First Nation’s application accused the federal government of licensing the fish farms without proper consultation.

“For consultation to be meaningful, a decision-maker must engage in consultation efforts in good faith and with an open mind,” the application read. “A consultation process that provides no opportunity to inform or change the course of the decision is merely an opportunity to ‘blow off steam.”

B.C. Salmon Farmers Association (BCSFA), in response to the nations’ applications, said the organization respects and recognizes First Nations’ rights and titles over their traditional territories.

Many salmon farming agreements have Guardian programs with the

Net pen farms have faced opposition for potential risks to the wild salmon population

PHOTO: MOWI CANADA WEST

DEEP DIVES BY BEN NORMAND

Navigating waters begins with vessel stability

Anyone who operates or has operated small vessels on fish farms has one – that story about heeling or listing entirely too much because of a mistake you made as the operator. Maybe you loaded incorrectly and went out in rough conditions. Maybe you were pushing the limit already and you were hit by the wake of a passing vessel. No matter the cause, we can all attest to the feeling of your stomach jumping up into your throat

until the vessel comes back to an acceptable degree of list or heel.

My story involves attempting to pick up a waterlogged buoy and because I assumed it would be a rapid and easy lift, I didn’t bother to tie myself off to the anchor chain to prevent my drifting while the crane and load was high. However, it was NOT an easy and fast lift, and a wind gust pushed me away from the buoy in a hurry while I was lifting it.

profifeed BeltFeeder

fish -

A wise skipper I once knew told me “Your vessel will tell you if it’s leaning too far through your feet.” I didn’t know what he meant until that moment, but it clicked when I could feel it hanging at that degree of list and not trying to right itself for what felt like an eternity. Thankfully, through some quick and creative maneuvering, and the work of my excellent deckhand, we rectified the situation and continued our work without incident.

Any situation like this can be categorized as “hard learning,” and if you’re working in aquaculture, there will be other instances of it. However, the great part about working in a small, tight-knit community like ours is that we can learn from each other’s hard learning moments. And so, I present to you my list of vessel stability must-knows:

Know the difference between list and heel.

Both cause your boat to lean towards port or starboard. Listing is caused by an internal force such as the placement of cargo, or the sloshing of water on your deck. Heeling is caused by an external force such as waves or wind. These forces will work together to amplify each other.

Understand your vessels hull shape and displacement strengths/weaknesses.

This will help you determine how and to what degree you will heel and list. Hulls that are shaped in such a way that the further they list or heel, the more water they displace, are very stable.

Flat bottomed vessels will remain stable and resist listing quite well, but I have been told they will feel fine until the precise moment that they’re not (i.e. they start to capsize). I have not, nor do I have plans to, confirm this through experience

The downside a flat bottom of course is that, without a keel, they are more susceptible to drift caused by current or wind, which, if you’re lifting a load, can present unique stability challenges. They are also less efficient when moving through the water

A v-hulled boat can travel very efficiently through the water, especially at high speeds, but are much more prone to excessive heeling and listing. Pronounced chines can help reduce this susceptibility.

Many work boats strike a balance – much wider and flatter towards the stern to create more displacement as the vessel heels or lists, while maintaining a pointed bow to achieve efficient movement

If you’re an operator, there is a good chance you were not involved in the design of your work vessel. A sound understanding of the hull characteristics will help you to make smarter choices based on the unique strengths and weaknesses of your vessel

Get a vessel stability assessment done

Regulatory requirements around this vary quite a lot from jurisdiction to jurisdiction, but generally larger vessels will need to have one done. However, I advocate for having them done on all your vessels or vessel classes. This assessment will give you a realistic picture of what loads and crane operations are safe for your vessels. Having this written record shows due diligence, should an incident occur.

Trust your gut

So much of smart and safe vessel operation comes down to judgement on the part of the operator.

You should never be operating outside of the bounds of your SOPs and the vessel stability assessment, unless in an emergency, in which case the standard shifts to doing what they can to save human life without endangering their own.

Within the bounds of these policies, however, you must always assess conditions, work tasks and make a call on how to carry out the work safely. In a very real legal sense, the safety of that vessel and the people on board are your direct responsibility. If your gut tells you something isn’t safe, listen!

Good managers will understand if you can’t carry out a task because it is unsafe, or will understand you’re developing your sense of judgement and will coach you through the decision.

On the flipside, the judge will not care that you were just following orders and carried out unsafe work.

Secure your loads

If you absorb nothing else from this column it’s this – secure your loads. If you are in rough conditions, as you heel, loads can shift suddenly and violently, and cause you to list excessively, potentially resulting in a capsize.

Remember, listing and heeling will amplify each other. In rough conditions, strap loads to the deck, or tie them to bollards, tie down points or the deck in such a way that they will not slide.

When using your crane, the farther a load is from your keel (or centerline), the more it will cause you to list. This is true in all dimensions. If you lift a load directly over your keel, but very high in the air, small movements of that load will have an outsized impact on your degree of list. Similarly, if you have a load suspended far off one side of your vessel, you will list much more.

You will have to have loads far from your centerline. Plan accordingly. If you must lift a heavy longline, for example, secure counterweight on the opposite side of the vessel. If you’re unloading totes, and the wharf is on your starboard side, unload the port side totes last.

Wishing you happy, stable sailing!

HOPE FLOATS

New docuseries shares stories of regenerative aquaculture

in U.S.

BY MARI-LEN DE GUZMAN

Martha Stewart may be a household name but it’s not typically associated with aquaculture. This may soon change with the launch of a new documentary series that puts the spotlight on some of the world’s innovators in sustainable seafood harvesting and production. Stewart is among celebrities and high-profile environmental advocates featured in

the three-part, character-driven docu series titled, Hope in the Water, from award-winning producer Andrew Zimmern and multi-awarded, acclaimed storyteller David E. Kelley. The series premiered on June 19 on PBS.

“Fresh seafood has always been a big part of my life,” Stewart’s voice is heard at the beginning of Episode Two, as she joins scallop farmer Andrew Peters on his boat to check on the sea scallops at his farm on Penobscot Bay in Maine.

“I was anxious to see what Andrew and his crew were doing out there in Penobscot Bay,” Stewart continues.

Peters is the owner of Vertical Bay, one of only a handful of sea scallop farmers in the United States. He proceeds to explain to Stewart the process of farming scallops from seed to market size, which takes approximately three years.

The long and tedious process of growing sea scallops from spat to harvest is not lost on Stewart as she helps Peters attach the scallops to the dropper line – called the ‘ear hanging’ technique – after tiny holes had been drilled through one corner of the shells.

“To see a group of young men trying to do something a little bit different with a fishery business in America is very encouraging,” Stewart says.

Media attention

Peters is not new to being in front of a camera, having been featured in an episode of reality show, The Lost Kitchen, hosted by local celebrity chef, Erin French. His company was also part of an NOAA-led informational video series on sea scallop aquaculture.

These publicities are helping put Vertical Bay on the radar of consumers and the food industry across the U.S. For Peters, being part of these productions not only helps raise the profile of his business but also that of the sea scallop farming industry, which is still in its infancy.

“We’re on a bit of a mission to grow our business, but also grow the industry as well because there’s a lot of potential in Maine for scallop aquaculture,” Peters says.

As a small business venture in an even smaller scallop farming industry in the U.S., to be featured in the media or on TV shows, is always a welcome opportunity, says Peters, but these publicities do not necessarily translate to an overnight success, let alone a sudden jump in sales.

It certainly creates some level of familiarity with his product, but the heavy lifting still needs to be done, particularly around educating consumers about farmed scallops versus wild catch.

“I think every little bit helps, whether it’s a print piece here, a little video clip there, or an Instagram tag here. It’s all incremental, and it’s just a slow snowball,” Peters says. “(But) we’re still having to reach out.”

“I say, ‘Oh, yeah, I farm scallops,’ and they say, ‘Oh, cool. That’s really great. You farm oysters!’ There’s just this disassociation of farming scallops with ‘farming.’ It’s definitely a great opportunity to have our story told,

Maine sea scallops farmer, Andrew Peters, was featured alongside Martha Stewart, in a new PBS docuseries called Hope in the Water.

The Native Conservancy kelp farm is also featured in the docuseries to share details of Indigenous Peoples’ deep relationship with the ocean as a food source.

whether it’s in our words or somebody else’s words. It’s really helpful for communicating what we do.”

Lending an ‘ear’

Sea scallop aquaculture in the state of Maine has been developing over the last two decades, thanks to technology adopted from Japan’s scallop aquaculture industry.

The farming life cycle starts with spat (or larvae) collection in the wild. They are then kept in submerged nets where they develop until they are ready for grow-out. The ear-hanging technique is one way to grow out juvenile scallops.

It involves drilling a tiny hole in the ear of the scallop shell and using it to tie the scallops to vertical lines that are then submerged in the water to allow the scallops to grow to market size.

This labour-intensive process takes about three years, according to Peters, but it’s well worth the wait.

“We can harvest year-round, but we choose to harvest in the summer months, when the scallops are packing on fats and sugars, as they’re getting ready to spawn. And their meats are therefore bigger,” Peters explains. The bigger the meat, the higher the yield.

Dune Lankard talks about the growing mariculture industry in Alaska, specifically kelp and seaweed aquaculture.

Dune Lankard, executive director of the Native Conservencay was also main character in the documentary.

The lengthy process is also where sustainability meets profitability. Like other shellfish, scallops are filter feeders, therefore they don’t require artificial feeding. The farm simply provides an optimal environment for them to grow and nature does the rest.

“(Scallop farming) offers us the opportunity to grow a truly sustainable, regenerative product… We’re really just providing them a wonderful habit for them to literally hang out and grow up,” Peters says.

Kelp is on the way

Alaska native and Native Conservancy executive director, Dune Lankard, is also a main character in the documentary Hope in the Water. Highlighting regenerative kelp farming in Alaska, Lankard details the Indigenous People’s deep relationship with the ocean as a food source.

“What we’re hoping with this ocean-farming industry is that we’ll be able to help Indigenous People change their relationship with the sea and the food sources that they traditionally have harvested for thousands of years,” Lankard says in the second episode, “Farming the Water.”

Based in Cordova, Alaska, the Native Conservancy is “devoted to the protection and restoration of Native ecosystems for coastal communities in Alaska, with a focus on Indigenous food sovereignty and cultural revitalization.”

Kelp has been a staple in Indigenous Peoples’ dining tables for hundreds of years, and the episode, through Lankard’s storytelling, highlights the innovative and sustainable ways Alaskan Natives are now farming and harvesting this versatile seaweed.

“I believe we can work together and figure out how to restore the ocean. We’re just going to have to work a little harder and a little smarter.”

Hopeful take on climate change Hope in the Water offers a positive spin and a welcome respite from the usual “doomand-gloom” scenarios associated with climate change conversations.

Offering a hopeful path forward, the series focuses on positive, innovative solutions to saving the planet through real-life storytelling.

“Through Hope in the Water, we are on a mission to reimagine a planet where both ecological balance and food abundance are possible,” says David E. Kelley in a statement announcing the launch of the documentary. “Our series is a fresh take on how we can rewrite menus worldwide that will create meaningful and lasting impact for generations to come.”

Kelley is best known as writer and producer of some of the best known television hit series, including Chicago Hope, Ally McBeal, Big Little Lies, Boston Legal and most recently, Presumed Innocent starring Jake Gyllenhaal.

Hope in the Water is part of a larger multiyear campaign spearheaded by Fed by Blue, a not-for-profit advocacy group advancing responsible food production and protection of the world’s waters.

“Fed by Blue is working to amplify efforts that are bringing new pathways, new dialogue, and new perceptions about the importance of foods that come from water. Helping to develop a docuseries on this topic has been an anchor for our greater work,” says co-founder Jennifer Bushman in a statement.

Navigating new waters

A workshop series in Maine for women and nonbinary aquaculturists

BY LYNN FANTOM

Acouple of years ago, the CEO of a leading oyster company was asked, “Are you doing anything special to recruit people?”

“Beyond begging?” he replied.

Today, though, government-funded diversity, equity, and inclusion (DEI) programs are emerging as an important way to address workforce shortages. One such effort, the Maine Aquaculture Hub’s 2024 Women in Aquaculture Series, shows how a strategically structured program can attract and retain talent for industry, plus earn high marks from participants.

With funding from National Oceanic and Atmospheric Administration (NOAA) Sea Grant, this initiative was designed specifically for women and nonbinary aquaculturists. It was developed in collaboration with Maine’s Aquaculture in Shared Waters training program, which started in 2013 to help lobstermen and other fishers diversify into shellfish and seaweed aquaculture.

The workshop series for women comes at a time when industry leaders, educators, and investors are exploring how to overcome the barriers to DEI, according to a 2022 report by the Meridian Institute, which advocates

A half-day workshop on ergonomics highlighted ways to perform physical tasks better and avoid injury—something everyone working on the water needs to know.

a model it defines as “exposure, inclusion, belonging, ownership.”

Many women are taking the lead, with their own creative approaches. Gabby Bradt of New Hampshire Sea Grant produced a documentary to generate exposure. Blair Morrison of Mobile Bay National Estuary Program and Marcy Cockrell of NOAA Fisheries Office of Aquaculture have spearheaded a biennial conference specifically for women in aquaculture, not only to offer training but to develop a sense of community. Imani Black, founder of Minorities in Aquaculture, runs an internship program connecting women of color with aquaculture work.

And three women—Annie Fagan of Maine Sea Grant, Dr. Annie Langston-Noll of Maine Aquaculture Innovation Center, and Jaclyn Robidoux of Maine Sea Grant— are the directors of the new Women in Aquaculture Series.”

What women want

Attitudes regarding training needs among women in aquaculture “run the gamut,” Fagan emphasized when she spoke with Aquaculture North America.

PHOTO: K. TENGA-GONZÀLEZ, MAINE SEA GRANT

PHOTO: ANNIE FAGAN, MAINE SEA GRANT

“Some of them don’t find their gender to be a barrier or a problem, and some of them do,” she said.

It is not unusual to hear from women, she added, that aquaculture is a more approachable sector compared to traditional fisheries.

“Anecdotally, many women generally have really positive things to say about the industry—that it’s a welcoming place and there are people eager to teach you and help you get started,” she said.

That’s backed up by considerable organizational heft. The Maine Aquaculture Hub, which was formed to help the industry overcome barriers, has a steering committee made up of seven organizations: University of Maine School of Marine Sciences, Maine Sea Grant, Maine Aquaculture Innovation Center, Coastal Enterprises, Inc., Maine Department of Marine Resources, the Aquaculture Research Institute, and Maine Aquaculture Association.

But research shows there is still a need to better assist women’s entry into aquaculture, especially with hands-on training. Plus, some women have reported they feel uncomfortable when they are offered help in work situations, thinking that it implies a belief that they don’t know what they are doing or need physical assistance. Others think there is bias when their status as the owner/operator of an aquaculture business is met with doubt or surprise. Some cite the need to adapt gear.

Skills and connections

The new workshop series was developed based on feedback from post-course surveys of the Aquaculture in Shared Waters program and a needs assessment conducted in 2023 by Dr. Teresa Johnson of the University of Maine.

This year it consisted of six workshops, four two-hour sessions offered virtually and two full-day in-person events. The program ran from February to May. The 41 participants from Maine included a mix of owner/ operators, employees, and those looking to get involved in aquaculture in new ways. The instructors were all women.

Topics included building social license, business and financing opportunities for women, marketing, ergonomics, and emotional well-being. Some content was new. Other material was similar to that in Aquaculture in Shared Waters training, “but folks wanted to have more of a gender lens on it,” Fagan said.

For example, a review session on maritime skills included knot-tying, splicing/line work, coastal navigation, and trailering. “Trailering is tough for everybody to learn. And for people in Maine accessing their farms from a public landing, it doesn’t always feel like a super open, non-judgmental space to learn how to drive a trailer and to back it up,” Fagan said.

Networking and connecting with other women in the industry was key. “For our in-person sessions, we had meetups

We are your source for professional aquatic and aquaculture products and services.

Our hands-on experience allows us to offer practical solutions to your situation, big or small.

We have years of experience in retrofit and new construction and understand your needs. Contact us today to learn more!

Workshops, like this one on navigation, gave participants the opportunity to learn skills in an environment that was welcoming and nonjudgmental. PHOTO: K. TENGA-GONZÀLEZ, MAINE SEA GRANT

from knot-tying (here) to trailering, built confidence.

afterwards. We always stayed on after the Zoom was over. People wanted to just hang out and chat,” Fagan said. “Some of those connections turn into people working together on the water or deciding to start a co-op or a million different things.”

Building confidence

“A consensus among the group was that manual skills and the business side (like interacting with the public and employees) had been picked up here and there, but never was it set out as ‘here’s what you need to know,’” said one workshop attendee, Eden Divney, land manager of Bangs Island Mussels in Portland. She valued that in this new series.

Checking off those core competencies built confidence. “If I’m in a situation where I have to tell this guy that what he’s saying is very disrespectful, I can stand on the ground of I know what I’m talking about,” she added.

Divney, born and raised in Maine, said that trade industries are so male-dominated that “it almost becomes intimidating to want to take a step into any of these roles.”

“Frankly I am often also intimidated to ask for help because of the old adage, ‘Oh, the little lady can’t do it by herself’,” echoed another participant Kristin Isfeld, who grew up in southern Virginia. Since moving to Maine in 2020, she launched Latitude 43 Farms to grow kelp and also works in a boatyard.

“Having all women together gave us an opportunity to realize what we did know and feel comfortable saying, ‘Gosh, I didn’t really know that’ and not feel stupid because the other women are not going to shame us,” Isfeld added.

Expanding upon Divney’s view, she said, “The overall culture of the working waterfront is that it’s a man’s world,” adding that in Maine it is also a world where commercial fishing centers on lobstering, clamming, and rockweed harvest.

“If you’re outside that and you don’t come from a fishing family, then you’re an outsider and you have to find your way in. And it’s not always easy,” she reflected. “I’m not from away. I’m from far away.”

Hearing from other women

Both Divney and Isfeld valued the opportunity to hear from other women about their experiences.

Divney gave an example of a tactic she learned: “If you are in this situation where a big dude is making snide comments, the conditioned response is laughing it off and moving on,” she said. “But instead, you can ask, ‘What did you mean by that? Could you explain that to me?’ It’s not necessarily a negative confrontation, but a different way of holding people accountable.”

Not all interactions are like that, though. According to Isfeld, one woman who

Hosted By:

PHOTO: K. TENGA-GONZÀLEZ, MAINE SEA GRANT

“encounters a lot of hate and aggression from people who don’t want her in the space basically just navigates it with her middle finger stuck up in the air and moves on.”

Isfeld herself is a sponge for knowledge. She first attended the Shared Waters training, then the women’s series, and this summer Aquaculture Bootcamp, a five-day hands-on workshop.

She said she wanted to attend the women’s workshops to find out how other farms are harvesting kelp, what equipment they’re using, whether they’re making their own value-added products or selling to someone else, and what that has been like.

“The women in this group were very open and willing to share their knowledge and experiences, good and bad. I find that more so than in groups of men, where, in my experience, the level of competition is different and maybe they don’t necessarily want to share all their secrets,” she said.

The next wave

“Momentum with women’s involvement in the industry has been building over the last

few years,” said Dr. Emily Whitmore of the Maine Aquaculture Innovation Center, who was a session instructor.

And now a series of women’s gatherings, both regional and statewide, has just been funded by the Nature Conservancy for the next two years. A project team of women, both farmers and representatives of Maine aquaculture organizations, has formed to determine details.

These gatherings provide “a structure for a network to form organically,” said Whitmore. Such a network could provide further knowledge exchange among women and the opportunity to connect with others who are at different points in their aquaculture careers. “I think it’s also really important for women to have a space to talk about gender barriers they’re facing,” Whitmore added.

Something then triggered her to recall the workshop trailering session she herself had attended. “When I got home, I thought, ‘I can drive my camper like that,’” she said, acknowledging the female instructors.

“It’s really inspiring and empowering to see people like you doing what you want to do.”

"THE FUTURE OF FOOD IS BLUE, AND WOMEN ARE AT THE FOREFRONT!"

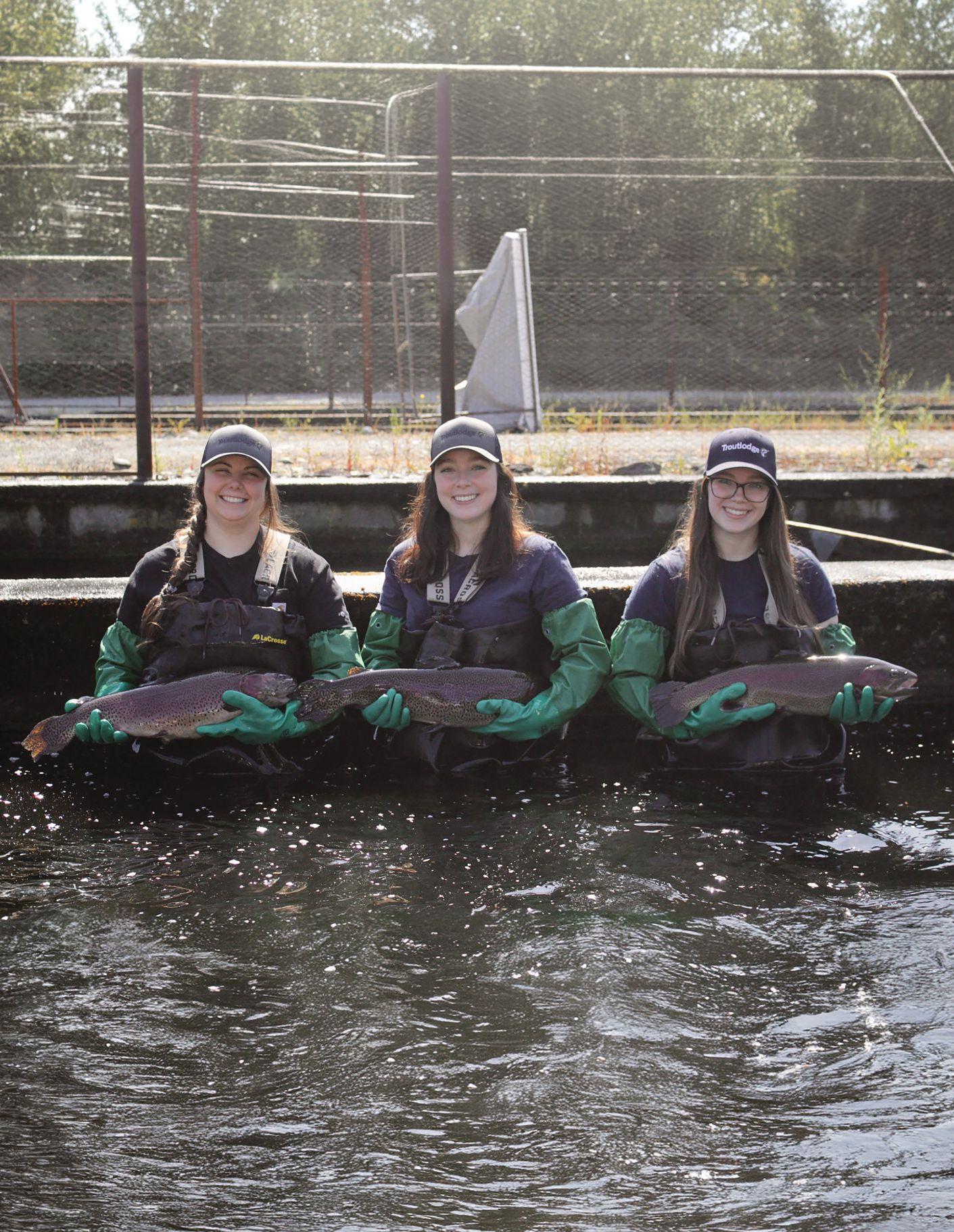

quaculture is a dynamic industry thriving on sustainability, and innovation. At BioMar, we are proud to work with exceptional North American women who shape aquaculture development. Here, we celebrate the inspiring journeys and contributions of three remarkable women in BioMar.

DR. KYLA ZATTI: Pioneering Sustainable Fish Nutrition

Kyla, Sustainable Nutrition and Raw Material Lead at BioMar, has made groundbreaking strides in fish nutrition and sustainability. Her journey began at the University of Saskatchewan, exploring fish nutrition during her undergraduate studies. She pursued a Ph.D., enhancing fatty acids in rainbow trout diets. In 2017, she joined BioMar Global R&D in Norway, leading sustainable fish nutrition research. In 2023, Kyla authored a paper demonstrating that algae oil can replace fish oil in aquafeed without compromising taste, health, or growth.

DR. HELEN HAMILTON: Championing Sustainability Helen, Global Sustainability Manager at BioMar, has dedicated her career to sustainability. Growing up in Sealy, Texas, Helen pursued degrees in chemistry and mechanical engineering, followed by a Ph.D. in Industrial Ecology. Joining BioMar in 2020, she developed the LCA Tool to assess BioMar’s products’ environmental performance. Last year, Helen presented the first LCA for Ecuadorian farmed shrimp, showcasing her commitment to reducing aquaculture’s environmental impact.

MONICA JUAREZ

CEBALLOS: Driving R&D in Aquaculture Monica, Senior Scientist at BioMar Group, has significantly advanced fish feed nutrition. Growing up in Mexico City, Monica pursued Food Technology, driven by her

awareness of food supply challenges. Her journey led her to Norway, where she studied Biotechnology and focused on aquaculture’s role in the food chain.

At BioMar, Monica has excelled in both Sourcing and R&D, documenting and implementing various raw materials in fish feed formulations. Her work spans multiple species, highlighting her innovative contributions to the industry.

“The future of food is blue, and women are at the forefront!”

The achievements of Kyla, Helen, and Monica underscore the crucial contributions of North American women at BioMar. Their dedication to innovation and sustainability paves the way for future

Read more about these amazing women at www.aquaculturenorthamerica.com/ ve-sponsor/biomar/

Inside the PODCAST

Sharing stories from women in aquaculture in North

America

BY SEYITAN MORITIWON

In this year’s edition of the Women in North American Aquaculture (WINAA) podcast, we spoke to four driven people, who saw a need for a gap in the aquaculture sector and decided to do something about it. They’re business owners, mothers, wives, scientists and most importantly, women. Here are snippets from their podcast episodes.

Amy Stone, president of Aquatic Equipment and Design Inc.

WINAA: How did it feel starting your business 10 years ago?

Amy Stone: Scary, of course. But I kind of had this strange level of peace that this was the right thing to do. I think, if you don’t believe in yourself, then nobody else will believe in you. And I know that sounds cheesy, but the reality of it is, I had to believe that I could do it, or it wasn’t going to happen. It’s hard to explain this. It’s nerve-wracking because you’re doing something new. You

have people expecting you to pay them every two weeks. You know, there’s a lot of responsibility with having employees, but at the same time, there’s always a sense of calm behind it all that says we’re doing the right thing.

WINAA: What does having a woman-owned business entail?

Stone: I mean in terms of being certified as a woman-owned business. You have to own 55 percent of the business. At least in the United States, you have to own 55 percent of the business and prove to the government that you are the decision maker for the company, and that is true for our company.

But in terms of whether I had any issues doing anything as a business, meaning like what, there was no outward discrimination against a female-owned business in my experience. I already had 15 years of experience in the business when I started it, as a salesperson. So, all of the vendors knew us. I mean, we had very good relationships.

WINAA: Any new projects to be on the lookout for?

Stone: We purchased the aquaculture suite of products from Aquaneering in February, so we’re busily putting together that offering to be able to release that to public. And then also

education. Getting people to understand aquaculture when they’re younger is easier than it is when they’re older. And so we’re focusing on education as well, and providing systems that can be used in middle schools and high schools and colleges to teach aquaculture.

Juli-Anne Russo, CEO and founder of the Caribbean Aquaculture Education and Innovation Hub

WINAA: How did you start the Caribbean Aquaculture Education and Innovation Hub?

Juli-Anne Russo: I realized that people within the aquaculture industry were working in isolation, and so even within a small space, they were not really interacting with each other, and so knowledge was not being shared. I also noticed that before the pandemic, how aquaculture had declined significantly, and in Jamaica in particular—because I had

not travelled to other islands then—tilapia is the only idea of what aquaculture could be. And being a small island, the thought of mariculture is not something that’s even thought about.

So, I really saw a gap there that needed to be filled. So in 2021, we started officially doing networking events online to kind of join farmers, anyone that’s interested in aquaculture within Jamaica, the Caribbean region itself, and then we brought knowledge from outside globally to these networks so that people could learn about what else was happening in the world.

WINAA: How’s that going?

Russo: I thought I was the only scientist, woman scientist. It so happened there were other scientists around the Caribbean, or outside the Caribbean, like me, who are actually doing research, aquaculture research. And we got together, 10 of us got together.

Last year, we got sponsored by BioMar, and we formed the Women in Caribbean Aquaculture. So that was the next step that we really wanted to highlight more women because we then realized that of all the scientists throughout the Caribbean, it was majority women. And then we realized that there are more women working in the aquaculture sector than we realized, and it’s not been documented. We would really like to have more data and to really capture exactly what women are doing. We really do have more women in R&D than we thought, and so we wanted to be able to highlight women, and we want to start having programs for that.

WINAA: Is the goal to have aquaculture as a course of study in schools?

Russo: Every aspect of science is needed for aquaculture, whether it’s engineering, building the systems, understanding water chemistry, understanding about where does the water go, the environmental aspect, the sustainability, the biology, every part of science is needed for aquaculture to develop where it needs to go sustainably. And so, yes, I would love for it to be a part of the STEM courses, and then as it progresses, we need more R&D, because only through R&D can we have innovation, and from innovation we have entrepreneurs, so we also have the business side of it as well.

Lauren

Enz,

the founder of Searenity Seafoods

WINAA: what does sustainability mean for your business?

Laura Enz: I always think about that it’s low impact to the community, that it’s being harvested or farmed in. So, it’s not impacting that resource. At the end of the day, to me, sustainability means future. As a mother of two, it’s always very important to me that I know that we are really looking to be able to support the growth of seafood consumption in the future for our children, and doing it in the right way is really important.

WINAA: How do you maintain a work-life balance?

Enz: I have an incredible team that’s working with me. Kelly and Nina, and they’re both veterans. They both have been doing this for a very long time. They’re great role models for me on how to balance life. So, without them, I wouldn’t be able to do what I’m doing. I think one thing I learned, be very purposeful and efficient in your time, right? So you’ve got to prioritize, and sometimes that means maybe something that you really want to do, you can’t do that day because you have to focus on something that needs your attention at the moment. But balance is critical in this race of life and work that we do as women.

WINAA: What’s your goal for the next five years?

Julie Kuchepatov,

founder of Seafood and Gender Equality (SAGE)

WINAA: Do you think women aren’t getting into the seafood sector as much as they should?

Julie Kuchepatov: Fifty percent of people involved in global seafood production, according to the FAO, are women. So we’re already here, like, we’re here in numbers, right? But the problem is, is that very few of us make it to these C-suite or executive leadership positions.

We really want to see more women, and more diversity, honestly, in leadership, because we know for a fact that that leads to more innovation that leads to more equity, it leads to a better bottom line, so it’s more profitable. And who doesn’t want that? Essentially, we just want to see a more diverse workforce at all levels, including at the leadership level.

WINAA: In what ways is SAGE helping to ensure that women get into these positions of leadership?

Kuchepatov: We have the podcast, The Conch. And then we also have a program called the gender equality dialogues, which I also mentioned. And so this is really to engage the North American seafood industry and their executive leadership, which is almost all men in dialogue around gender equality, and what it means and what it can bring for you and your business.

These dialogues are meant to bring people in the room executive leadership in the room to align, understand that there’s issues, recognize these issues, and then create some solutions through commitments that are actionable and equip them with the tools and the knowledge that they need to actually fulfill these commitments that they’re making. Know

Enz: To make sure that I underpromise and overdeliver with every client, producer, farmer, resource that I bring on and that I hit the ball out of the park, and connecting them with their targeted audience. At the same time, I really want to make sure that Searenity is one of those consultants that any of these corporate buyers think of when they’re thinking about seafood.

Alaska’s vast potential

A deep dive into mariculture in the northernmost, westernmost U.S. state BY

NANCY ERICKSON

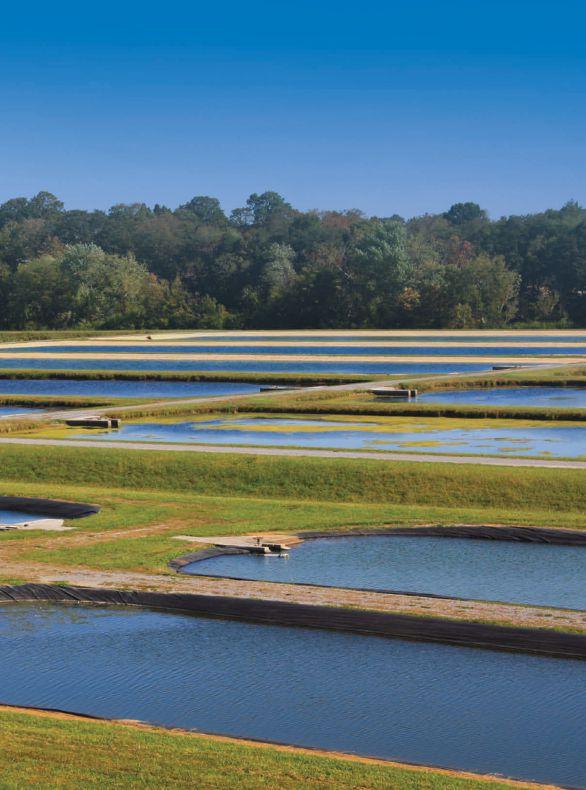

It’s hard not to get excited about mariculture in Alaska.

With more coastline than the rest of the United States combined, Alaska is blessed with ample room to expand its mariculture industry, focusing on farming shellfish and seaweed. The primary species grown include oysters, blue mussels, and sugar, ribbon and bull kelp.

“I would describe Alaska’s aquaculture industry as burgeoning,” states Alicia Bishop, National Oceanic and Atmospheric Administration (NOAA) Fisheries Alaska Regional Aquaculture Coordinator. “Mariculture is defined as the farming of aquatic plants and animals in the marine environment. It’s a subset of aquaculture, which can also include freshwater farming. When you hear it used in Alaska, it only refers to the farming of shellfish and seaweeds. Mariculture in Alaska does not include finfish farming, which is prohibited by Alaska Statute.”

The number of oysters sold to farms and the public increased from 4,956,594 in 2022 to 9,454,388 in 2023, according to an Alaska Department of Fish and Game (ADF&G) report. Pounds of seaweed harvested per year measured very little when the industry kicked off in 2017 to almost 900,000 pounds in 2022.

To enhance the growing interest of farming bull kelp in Alaska, a number of research projects are targeting how to optimize growth of the species.

PHOTO: NOAA FISHERIES

The Alaska Department of Natural Resources (ADNR) has seen a steady increase in the number of new leases authorized since 2017, reports Kate Dufault, ADNR’s program manager for the Aquatic Farm Leasing Program. According to Dufault, there were 59 aquatic farmsite leases managed by ADNR in 2017. Currently in 2024, ADNR manages 79 such leases.

Opportunities for mariculture development were bolstered in 2016 with the formation of

the Alaska Mariculture Task Force, with a goal to develop the state’s industry towards a $100M industry by 2040.

In 2022, the Alaska Mariculture Cluster (AMC) secured a US$49-million grant from the Economic Development Administration’s Build Back Better Regional Challenge (BBBRC) to support acceleration of an Alaska mariculture industry focusing on shellfish and seaweed aquaculture opportunities. The AMC is lead by Southeast Conference, the state and federally designated regional economic development district for Southeast Alaska and is comprised of a statewide coalition of Tribal and rural communities and industry champions with a goal of creating wealth in coastal Underserved Communities.

As the largest state by far in the U.S., travel distances in Alaska are vast, measuring 1,420 miles north to south and 2,500 miles east to west - much of it accessible only by plane or boat.

Encompassing a wide variety of climate variations, NOAA has identified three areas in Alaska that show high potential for commercial aquaculture:

• Southcentral Alaska is the hub for shellfish growth, with Kachemak Bay in Homer

Workers harvest kelp at a farm in Doyle Bay operated by Seagrove Kelp Company in Southeast Alaska near Prince of Wales

producing the largest amount of oysters in the state and within driving distance of Anchorage, the state’s largest city.

• Western Alaska stretches from Kodiak Island approximately 250 air miles southwest of Anchorage west to the Aleutian Islands - a land of unpredictable weather largely determined by the Bering Sea and the Gulf of Alaska. Kodiak is the largest producer of seaweed in the state.

• And down the panhandle of Southeast Alaska is an area supporting a moist, mild climate with abundant rainfall and lush vegetation, much like Kodiak.

These three areas have great potential for aquaculture industry growth, says Bishop. “The largest bottlenecks for the industry throughout the state are access to markets and logistical issues. Alaska covers a vast area with limited roads and infrastructure for testing, processing and shipping. This can make it difficult for farmers to meet shellfish sanitation requirements in a timely manner, process their products and ship them to buyers. While there is a lot of potential for seaweed products, Alaska needs access to new and emerging markets that can tap into the unique species we can grow.”

Island. PHOTO: NOAA FISHERIES

Shipping logistics are easier in the more densely populated hubs of Southeast and Southcentral Alaska, Bishop continued. Many of the more urbanized areas along the coast, such as Homer, Kodiak, Cordova, Ketchikan, Sitka, Juneau and many others are surrounded by small clusters of aquaculture farms. However, Western Alaska has fewer large population hubs, which can mean lower conflicts with other ocean user groups, but transportation logistics can be tricky.

“But there are farms in all three regions, so clearly farmers can make it work,” Bishop adds.

Western region

Kodiak resident, Lexa Meyer, has deep experience in both managing the first and largest permitted kelp hatchery in Alaska and as a mariculture researcher and educator. Located on an archipelago of islands similar to Hawaii, Meyer is co-owner with her husband of their kelp farms, under the name Alaska Ocean Farms. The couple brought their commercial kelp hatchery online within the past year and hopes to grow at least 150,000 feet of kelp seed for a variety of farms this fall.

“We’re a vertically integrated farm here, responsible for our own seed, all the farming and we’re also thinking about moving into processing as well,” Meyer said. “This year we grew both bull kelp and sugar kelp- about 25,000 pounds of each species – that was just for a processing trial. We have a couple of potential buyers for different markets including fertilizers, and health and beauty care products, so we’re running our own processing trials.”

Meyer said farmers in her area are limited in options for processors.

“All of our potential buyers have said, ‘If you have a stabilized product, we’ll take it.’ They’re not interested in coming here and setting up their own processing due to costs involved,” she added.

Buyers have been found for both of the couples’ bull and sugar kelp, which was stabilized at ambient temperature and shipped south to the Lower 48 in regular shipping containers.

“We’re very well connected here in Kodiak because of our seafood processing industry’s need for regular cargo vessel sailings via Matson Transportation, Samson Tug and Barge and other small carriers between here and Seattle,” she said.

Meyer said mariculture is doing quite well in her area and has the capacity to expand, but is in need of big buyers.

Alaska Ocean Farms also has hopes of expanding to oyster farming and has a small test area.

“I have talked to folks about markets and it sounds like there are robust markets for shellfish primarily in the state and not even counting the potential for selling oysters to the Lower 48 or even other countries, so we’re excited about adding oysters and diversifying,” she said.

However, oyster seed and gear to rear them are pricey compared to the cost of a kelp farm. Their current seed supplier is 791 miles away in Prince of Wales Island in Southeast, which adds higher shipping costs in addition to the seed.

Meyer said she and her fellow farmers are doing important groundwork in this field, but it takes time to build an industry, sometimes decades.

“Giving us more time and more understanding as we try to get ourselves up and going is key to success in this industry. And patience. Patience from everyone across the board,” said Meyer.

Southeast region

As of 2023, Southeast Alaska boasts 690 permitted acres for aquaculture, the highest in the state.

In addition, the panhandle of various islands stretching along the eastern border of our Canadian neighbors also boasts international

A happy worker shows off the size of oysters harvested by Juneau-based Salty Lady Seafood Company. Total Alaska aquaculture sales in 2022 were $1.9M with $1.5M from shellfish sales.

PHOTO: NOAA FISHERIES

Kelp continues to grow on spools in the Alutiiq Pride Marine Institute laboratory. Kelp starts produced here will go to farmers across Prince William Sound and lower Cook Inlet.

PHOTO: SOUTHERN DIPPER PRODUCTIONS

investment from an up-and-coming biotech and mariculture startup known as Kelp Blue, according to Juliana Leggitt, Alaska Mariculture Cluster project manager.

Kelp Blue was recently approved for a 121-acre kelp farm lease at Sea Otter Sound near Prince of Wales Island. The company has also applied for two additional kelp farm licenses in the Gulf of Esquibel near Klawock on the west shore of the island.

“Indigenous communities throughout the state have been stewards of these resources for generations and provide us with knowledge, insights and guidance as the AMC BBBRC project is implemented. This collaboration is critical for ensuring a sustainable industry that keeps the health of our communities and ocean in mind,” said Leggitt.

Southcentral region

Behind every successful mariculture farmer are hatcheries doing the research and providing needed seed.

The Alutiiq Pride Marine Institute (APMI) located in Seward on Resurrection Bay was issued the state’s first shellfish hatchery permit in 1992. Re-branded from a shellfish hatchery to a marine institute, APMI began producing kelp string in 2020 on a test basis and now produces well over 100,000 feet of seed string for a variety of customers, ac cording to Mariculture Director Jeff Hetrick. Plans are in the works to increase that to 200,000 feet in 2024 with distribution to ten commercial farms in Prince William Sound and Kachemak Bay.

Back in the laboratory, rows of 2-by-15 inch plastic pipe line the walls, wrapped with 200 feet of nylon twine inoculated with kelp spore solution. The string is monitored and controlled with temperature and light until the plants germinate at approximately six weeks. Then it’s off to the farms where the spools are unraveled onto grow lines suspended by buoys approximately seven feet below the surface and monitored for sixto-seven months until harvest in the spring.

APMI is a major subsidiary of the Chugach Regional Resources Commission, a tribal consortium representing the nat ural resource interests of seven tribes in the Prince William Sound and Cook Inlet region of Southcentral Alaska.

Commercial Filtration Systems

Commercial Filtration Systems

•

Commercial Filtration Systems

Customized for your fish farm, hatchery or

Commercial Filtration Systems

Customized

Customized

Customized for your fish farm, hatchery or

Our Commercial LSS Packages are custom engineered to meet your specific needs.

Commercial LSS Packages are custom engineered to meet your specific needs.

• Marine and Freshwater

• Marine and Freshwater

• Mechanical filtration

• Marine and Freshwater

your specific needs.

• De-gassing towers

• De-gassing towers

• De-gassing towers

• Wide variety of flow rates

• Mechanical filtration

• Mechanical filtration

• Chemical filtration

• Chemical filtration

• Chemical filtration

• Mechanical filtration

• Ultraviolet disinfection

• Ultraviolet disinfection

• Ultraviolet disinfection

• Chemical filtration

• NEMA enclosed controls

• NEMA enclosed controls

• Ultraviolet disinfection

• NEMA enclosed controls

• Bio-filter towers

• Bio-filter towers

• NEMA enclosed controls

• Bio-filter towers

• Bio-filter towers •

All our systems

• Wide variety of flow rates

• Wide variety of flow rates

• Flow control valves

• Flow control valves

• Flow control valves

• Protein skimmers

• Protein skimmers

• Protein skimmers

• Variable frequency-drive pumps

• Variable frequency-drive pumps

• Variable frequency-drive pumps

• Temperature

• Temperature management

• Temperature management All our systems are pre-plumbed

“Alaska’s ultimate success with mariculture will be the result of ingenuity and stubbornness,” Hetrick said. “We have everything in place to be successful: a favorable regulatory environment, public financial support and insatiable markets for clean sustainable seafoods. It has taken a long time but I think we’re almost there.”

CanadianPond.ca Products. Ltd. Officially Launches SalmoAir Upweller for Aquaculture.

anadianPond.ca Products Ltd

C(CanadianPond) is an established innovation company that is known for their proprietary linear diffuser trademarked under Bubble Tubing. “Bubble Tubing is at the core of our business since 2005 and is now incorporated into the engineering and patent pending SalmoAir air diffuser used as an upweller.” says Mario Paris, CEO and founder of CanadianPond. CanadianPond knew they had a great product when aeration authority Gerald Shell from GSEE inc quoted in 2011 “Overall, the results obtained for the Bubble Tubing were uniformly excellent and produced some of the highest SOTE values GSEE Inc. has observed.”

Cermaq Canada, a world leading salmon farming company, implemented as early as 2017 many successful bubble curtains to manage HABs with the help of CanadianPond’s Bubble Tubing technology. Alongside the bubble curtains, trials and designs of new upwellers were tested in real salmon farming conditions. Over the years, Cermaq Canada’s managers provided invaluable feedback.

Salmon pen aeration targets one main objective, which is upwelling or transporting cooler, well oxygenated water from the depth up to the surface. Most farms rely on diesel compressors to provide the air flow and correct pressure to aerate, mix and upwell. The energy costs and carbon footprint to operate these upwellers can be substantial and it begged the question: “Could this be done more efficiently?”. After listening closely to Cermaq’s farm managers and Brock Thomson, Innovation Director at Cermaq Canada, it became clear to CanadianPond that little, if any, innovation had occurred in fish farming pen aeration for more than a decade. CanadianPond decided to develop a new prototype and the newest and most innovative diffuser in decades was born, the unique SalmoAir. Field testing proved its advantages and Cermaq Canada adopted them as their main upweller. By design, SalmoAir diffuser simplifies the daily operation for workers while preventing salmon injuries. It is also much more durable than competitive products, especially in these often extremely rugged environments. In operation for more than two years now, here is what Cermaq’s Brock Thomson Innovation Director has to say about the use of SalmoAir:

Q: Has the SalmoAir diffusers been beneficial for salmon at Cermaq?

R: Salmon welfare and the welfare of the surrounding ecosystem are of utmost importance at Cermaq. We farm live animals, and we take great

pride ensuring they are given optimal care. Our team has observed that the SalmoAir diffusers produce an impressive lift rate at lower air flow rates in comparison to other options that we have tested at a commercial scale. Having strong upwelling water circulation in our cages improves the conditions the fish are reared in, improving the overall welfare status of the population. The added benefits are the design features on the diffusers that limit the potential for wounds from fish inadvertently contacting the diffuser.

Q: Is there a gain in energy saving, fuel consumption and carbon footprint when using Canadianpond.ca Products Ltd.’s equipment?

R: Cermaq Canada is committed to reducing the carbon footprint of their operations worldwide. Our commitments to the United Nations Science Based Targets outlines our aspirations for meaningful reduction in our footprint by 2030. These commitments require the organization to be mindful of impact when adopting or participating in the design of new technology. The opportunity then to work on the development of a product that addressed energy efficiency, coupled with more certainty around our upwelling needs, was extremely attractive. The SalmoAir has assisted us in optimizing our upwelling systems by providing more efficient upwelling without increasing our fuel needs. This combination of in-water technology efficiency coupled with a new generation of compressor available in the market has delivered on meaningful savings in fuel and associated carbon emissions.

Q: What guides Cermaq in adopting new aeration equipment like SalmoAir?

R: We are always looking for solutions and innovations that will reduce cost, optimize animal welfare, reduce impact to the surrounding ecosystem, address the concerns of our indigenous partners

and ultimately generate sustainable profit for the business. Having the SalmoAir has clearly helped us create value which is in line with our mission.

Q: What prompted Cermaq to share its innovation success?

R: One of our core values is long term perspective and we are known to share information pro-actively. The adoption of the SalmoAir diffuser has been extremely well received by workers and managers of fish farms to the point where it is now our firstchoice upwelling diffuser. Cermaq also thinks that it’s important to show transparency to our stakeholders who may not see what is happening on those remote farms.

In fall 2023, CanadianPond, in partnership with the Canadian Centre for Fisheries Innovation (CCFI), invested in an extensive third-party validation study to measure the upwelling efficiency of SalmoAir. C-Core Engineering and Marine Institute in Newfoundland were appointed as the scientific third party to perform in ocean tests and to create a computer model simulation of the upwelling effects generated by upwellers. These models were validated during the test phase done at The Launch in Holyrood, Newfoundland. The end results now allow CanadianPond the capacity to create CFD models of any farms to design and optimize air flow, placements and quantities of upwellers required in each fish pens to achieve the best management practice possible (BMPs). Technical findings will be published soon.

If you would like more information about this diffuser, please contact the CanadianPond team at: info@canadianpond.ca

Cooke Aquaculture celebrates 19th consecutive year as Canada’s best managed company

Family-owned business, Cooke Aquaculture Inc. was recognized as a 2024 Platinum Club winner as part of the Canada’s Best Managed Companies awards program.

This is the 19th consecutive year that the company has received this recognition. Platinum Club members are winners who have maintained their best-managed status for seven years or more.

“We are delighted to be recognized as one of Canada’s Best Managed companies again this year. It’s a credit to our people, as their commitment and dedication to their work that really make it possible for our company to achieve this distinction year over year,” said Glenn Cooke, CEO of Cooke.

“This designation is an important one for us because it holds us accountable and ensures we are demonstrating best practices in all areas of our business.”

Canada’s Best Managed Companies is one of the country’s business awards programs recognizing innovative and world-class businesses. Applicants are evaluated by an independent panel of judges with representation from program sponsors and special guests.

“The 2024 Best Managed winners exemplify the highest Canadian business standards of innovation, adaptability, and bold leadership,” said Lorrie King, partner, Deloitte Private, Global Best Managed leader and co-leader, Canada’s Best Managed Companies program. “Their relentless ambition, determined focus, and strategic agility have led them to remain competitive on the world stage, creating sustainable economic growth in an evolving global market.”

The 2024 cohort of Best Managed companies share common themes such as having a people-centric culture, targeting effective ESG strategies, and accelerating operational digitization.

Industrial Netting announces sale on clam netting

American net and meshing company, Industrial Netting has marked down one of its products.

The OV1670 - Clam Netting 3/4” Light Duty Polypropylene - 14-ft x 200-ft is now going for $111.

The company advertizes it as a black

polypropylene net with nominal 3/4” openings. It has fused joints and is UV Stabilized for maximum service life and is able to unfolds to 14’ x 200’. The discounted price lasts as long as the supply lasts.

Industrial Netting is a major supplier of netting and mesh components to the filtration industry and other industrial and commercial marketplaces.

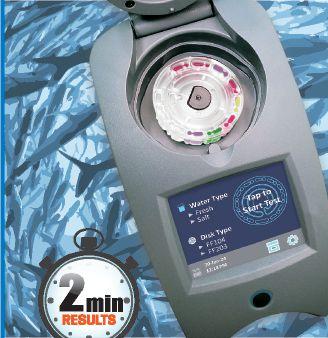

Aquasend’s miniDOT® Clear Logger effective in hydroponics and aquaculture

Aquasend, a water quality monitoring company, said a large-scale hydroponics and small-scale aquaculture farmer used its miniDOT® Clear Logger and reported accurate and economical continuous monitoring.

The miniDOT® Clear Logger’s clear plastic housing contains a real-time LCD of dissolved oxygen (DO) and temperature levels in virtually any water system. Its oxygen-sensing optode uses a fluorescence method to determine DO concentrations and its custom sampling frequency can be set anywhere from once per minute to once per hour, with data recorded to the logger’s internal SD card. It’s powered by two AA lithium batteries for easy in-field replacement.

In one hydroponics operation, the farmer explained that two miniDOT® Clear Loggers helped him prove a long-held suspicion of cycling inadequacies.

“By placing the loggers on opposite ends of a single tank, the farmer demonstrated inconsistencies in the water quality that had not been reflected by the facility’s fixed monitoring system,” a post from Aquasend reads.

The farmer also secured the miniDOT® to one of the many slow-moving rafts hosting seedlings. He was able to accurately monitor water conditions where they mattered most to the plant’s growth and further refine the facility’s production process.

Mørenot Aquaculture releases first environmental product declarations

Mørenot Aquaculture, a norwegian aquaculture supply company has published its first environmental product declarations (EPDs).

An EPD offers a detailed and scientific analysis of a product’s environmental impact throughout its life cycle. The company said its EPDs have been prepared in accordance with international standards and provide detailed information on resource use,

energy consumption, emissions and waste management related to the production of the company’s products.

“The publication of our first environmental declarations is an important step towards increased transparency and responsibility in our environmental work. At the same time, this gives us the opportunity to improve our products by identifying where in the value chain there is the greatest potential for environmental improvements, such as in recycling and reducing CO2 emissions,” said ESG Manager Liv A. Lund.

HOSTED BY Ian Roberts

Product line manager mooring, Ingrid Høydal and ESG manager, Liv A. Lund

CHECK OUT OUR MOST POPULAR EPISODES

Available to download on your favourite podcast platform

Commissioning to success James Tuller, Pure Salmon Technology

The ongoing study of off-flavour John Davidson, Freshwater Institute

The start of a Florida aquaculture hub Megan Sorby, Pine Island Redfish

Disrupting on a smaller scale Yosuke Kurihara, ARK Inc.

Eel entrepreneurship Sara Rademaker, American Unagi

Episode extras on rastechmagazine.com/podcast

1

CLEANER FISH BIOLOGY AND AQUACULTURE APPLICATIONS

What is RAS and what does it take to get qualified? Take the academy’s online courses to further your knowledge:

• INTRODUCTION TO RAS (2 modules, total 3 hrs)

• RAS WATER TREATMENT PROCESSES (5 modules, total 7.5 hrs)

• RAS OPERATIONS (3 modules, total 4.5 hrs)

1 2024-06-17 3:27 PM

Cleaner Fish Biology and Aquaculture Applications reviews and presents new knowledge on the biology of the utilised cleaner fish species, and provides protocols in cleaner fish rearing, deployment, health and welfare.

The latest knowledge is presented on specialist technical areas such as cleaner fish nutrition, genetics, health, immunology and vaccinology, welfare, transport and fisheries. Specific chapters detail cleaner fish developments in the main salmon-producing countries.

Contributions from over 60 leading researchers and producers give an exciting mix of information and debate.

$350.00 | Item #1912158218