Mari-Len De Guzman

Mari-Len De Guzman

Sheraton

September 23rd – 25th, 2025

On

VOLUME 16, ISSUE 3 | MAY/JUNE 2025

Reader Service

Print and digital subscription inquiries or changes, please contact customer service

Angelita Potal

Tel: (416) 510-5113

Fax: (416) 510-6875

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor Jean Ko Din jkodin@annexbusinessmedia.com

Associate Editor Seyitan Moritiwon smoritiwon@annexbusinessmedia.com

Contributors Imani Black, Mari-Len De Guzman, Lynn Fantom, Katie Maximick, Leah Stoker

Associate Publisher / Advertising Manager Jeremy Thain jthain@annexbusinessmedia.com +1-250-474-3982

Account Manager Morgen Balch mbalch@annexbusinessmedia.com +1-416-606-6964

Account Coordinator Catherine Giles cgiles@annexbusinessmedia.com

Media Designer Svetlana Avrutin savrutin@annexbusinessmedia.com

Audience Development Manager Urszula Grzyb ugrzyb@annexbusinessmedia.com 416-510-5180

Group Publisher Anne Beswick abeswick@annexbusinessmedia.com 416-410-5248

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

PUBLISHED BY ANNEX BUSINESS MEDIA 105 Donly Drive South, Simcoe, ON N3Y 4N5

Aquaculture North America is published six times a year by Annex Business Media. The authority for statements and claims made in Aquaculture North America is the responsibility of the contributors. Reference to named products or technologies does not imply endorsement by the publisher.

Subscription rates (six issues) Canada: $37.74+Tax Within North America: $48.96 CAD Outside North America: $63.24 CAD

To subscribe visit our website at www.aquaculturenorthamerica.com

Printed in Canada ISSN 1922-4117 Publications Mail Agreement #PM40065710

RETURN UNDELIVERABLE CANADIAN ADDRESSES TO 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Annex Privacy Officer

Privacy@annexbusinessmedia.com Tel: 800-668-2374

The contents of Aquaculture North America are copyright ©2025 by Annex Business Media and may not be reproduced in whole or part without written consent. Annex Business Media disclaims any warranty as to the accuracy, completeness or currency of the contents of this publication and disclaims all liability in respect of the results of any action taken or not taken in reliance upon information in this publication.

Next Ad Deadline

The advertising deadline for the July/Aug issue is June 17. Don’t miss the opportunity to be part of this publication. For more information, or to reserve space in the next issue, call our advertising department at +1.250.474.3982 jthain@annexbusinessmedia.com

Next Editorial Deadline

The editorial deadline for the July/Aug issue is June 2. Contact Jean Ko Din at jkodin@annexbusinessmedia.com for details. Material should be submitted electronically with prior arrangement with the editor.

BY JEAN KO DIN

Occassionally, I like to read more deeply on surrounding aspects of aquaculture as part of my ongoing education. I sometimes feel that by broadening my knowledge, I am better equipped to curate stories for this industry.

But this time, I went down the rabbit hole of Canada's Impact Assessment Act. It is a piece of legislation that outlines the different factors that must be considered to ensure the sustainable development of major projects. Within it, I came across the term community knowledge.

It is defined as "knowledge held by individuals or shared by a community which build up over time through direct use of, or interaction with, a resource or environment." Basically, the government acknowledges that an integral part of an impact assessment has to do with engaging local stakeholders to supplement the information and formal studies that are being conducted.

Within that, the government differentiates Indigenous traditional knowledge from the broader community knowledge. The legislative language is designed so that Indigenous knowledge holders are given a distinct role in the community consultations on a foundation that respects the worldview of Indigenous peoples.

Overall, the inclusion of community knowledge is meant to expand the types of data and evidence collected during an assessment of any major project's environmental, health, social, and economic impact.

I'm sure there are many of you reading this who may have strong feelings right now about whether or not this level of consultation is taking place within government agencies, and those feelings are valid. But this is not the reason why I bring this up. Rather, this legislation got me thinking more about how we go about acquiring this knowledge and sharing it with others in the community. How do community members contribute to enhancing the collective

wisdom of the North American aquaculture industry?

If you read my editorials often enough, you know that I'm going to say that participation in this publication is my answer. I see this Business-to-Business (B2B) publication as a community publication.

Through these pages, the aquaculture industry has the distinct opportunity to share information with each other and empower themselves to bring about change in the systems in which they work within. It's about each individual aquaculturist collecting scientific knowledge, as well as local insights to develop a holistic understanding. The more informed a community is, the stronger and more sustainable the progress becomes.

Maybe now is not the time to sit back and allow leaders to fight your battles for you. Maybe it is about strength in numbers. If it is true that a problem shared is a problem halved, then a problem shared with hundreds of thousands of colleagues across the continent cannot be a burden at all.

I admit the unprecedented times ahead will make it very difficult for many of us to stay engaged all the time. For the sake of my own mental health, I have to limit myself to doomscrolling for a maximum of one hour a day. But that doesn't mean I turn off entirely. I have to watch the news. I have to educate myself on the issues. I have to engage in the causes that I believe in. Because, I know that the worst thing I can do is not contribute to a community knowledge that is harder to dismantle than any individual institution.

Many decades from now, I imagine how future generations will look back at this historical time. Will they look on us with pride for standing up for each other, or will they see us as a cautionary tale?

As always, we hope to provide you with stories that aid your work both in your daily life and in the wider industry. We hope you stay engaged and share your thoughts, especially with me at jkodin@annexbusinessmedia.com. | ANA

Aquaculture North America’s Editorial Advisory Board: Ian Roberts | Sandra Shumway | Jason Mann | Jeanne Mcknight | Mykolas Kamaitis | Jamie Baker

Study maps best site for sustainable offshore aquaculture

Cornell University researchers have found an optimal location to site an offshore aquaculture farm powered by waves.

They used marine spatial planning to map areas off the northeastern coast of the United States, offering a model for sustainable development that minimizes conflicts among marine industries.

The optimal site, located southwest of Acadia National Park, is one of the farthest feasible sites from shore. This highlights what the researchers found to be the cost-lowering benefit of siting a wave-powered aquaculture farm (WPAF) farther offshore, where the wave availability is greater than in closer, more sheltered areas.

“The goal of the study was to show that you can use marine spatial planning to understand all of these different data sets to drive decisions on where to place systems to reduce conflicts,” Maha Haji, senior author of the study, told Cornell Chronicle.

Many offshore farms are powered by diesel generators, which consume fossil fuels and release greenhouse gases into the atmo sphere. A WPAF reduces these problems by using wave-energy converters to capture the kinetic energy from ocean waves and

Their study, published in the journal Renewable Energy, is “the first that rigorously looked at, in the case of the Northeast, the potential conflicts that might exist with existing or coming industries,” Haji said, who’s also an assistant professor in the Sibley School of Mechanical and Aerospace Engineering.

Haji said to find a location for a WPAF, multiple variables must be assessed, including the physical ocean qualities for aquaculture, such as temperature, salinity and dissolved oxygen; the best wave energy location based on wave height and frequency; and the impact of other activities taking place in that ocean area, such as commercial fishing traffic, shipping lanes, military zones, marine-protected areas and, increasingly, offshore wind farms.

They evaluated over 7,000 locations before narrowing the selection to 52 feasible sites off the coast of Maine and finally to the one optimal site.

Sinking to floating.

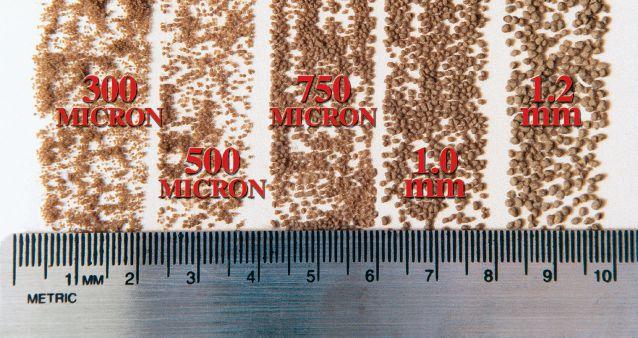

Sub-millimeter to pellet.

The research was supported by the National Oceanic and Atmospheric Administration’s Sea Grant program.

NOAA releases updated National Seafood Strategy Implementation Plan

National Oceanic and Atmospheric Administration (NOAA) Fisheries has published an updated National Seafood Strategy Implementation Plan.

The National Seafood Strategy Implementation Plan focuses on the commercial fisheries and aquaculture components of NOAA Fisheries’ work to sustainably manage marine fisheries and produce seafood responsibly.

It outlines NOAA Fisheries’ direction over the next five years to support a seafood economy and enhance the resilience of the seafood sector against climate change and other stressors.

When you select an Extrusion Processing System from Extru-Tech, you have a complete Universe with the ability to maintain size yields over 95%.

NOAA has highlighted four goals in this plan:

1. Maintain or increase sustainable wild-capture production through fisheries science, fisheries management, and habitat conservation.

2. Increase sustainable U.S. aquaculture production through management and regulatory efficiency and aquaculture science.

3. Foster access to domestic and global markets for the U.S. seafood industry. This will be done by increasing public awareness of the availability of U.S. seafood, identifying and developing U.S. seafood markets and promoting fair seafood trade.

4. Strengthen the entire U.S. seafood sector by supporting U.S. commercial fishing, marine aquaculture and associated seafood sector, modernizing and maintaining U.S. seafood infrastructure.

NOAA Fisheries is also building partnerships to implement some cross-cutting pilot initiatives. Many NOAA Fisheries offices, along with stakeholders, will participate.

As your business evolves, you have the flexibility to change your finished product without the need for significant capital expenditures.

The Atlantic Canada Fish Farmers Association (ACFFA) has appointed Tom Taylor as its new executive director.

Taylor has over 25 years of experience in the aquaculture

In an industry where aquafeed can represent 50% of your operation cost, don’t gamble. Contact Extru-Tech and optimize your flexibility and profitability.

sector and has served on different industry boards, including as chair of the board of directors of ACFFA since 2018. He has also held board executive roles with organizations such as the Canadian Aquaculture Industry Alliance, the Aquaculture Association of Canada, and the Bay of Fundy Business Council.

“With his deep knowledge and proven commitment to coastal communities, Tom is well-positioned to guide ACFFA in advocating for the responsible growth of Atlantic Canada’s fish farmers and supply chain,” said David Seeley, interim chair of ACFFA.

Taylor is taking over from Susan Farquharson after nearly 10 years of leadership.

“Fish farming is a vital, ever-evolving industry that provides sustainable seafood and supports thousands of families in Atlantic Canada. I look forward to working with the team, our members and partners to sustainably grow the sector as well as the continuation of our award-winning wild Atlantic salmon recovery efforts,” said Taylor who started the new role on March 24.

Taylor has also led feed production, forecasting, and operational planning teams at Cooke Aquaculture Inc., Charlotte Feeds Inc., Northeast Nutrition Inc., and ShurGain Atlantic.

Oregon, the only West Coast state that permits net pen farming, could ban it if a bill is passed into law.

Rep. Mark Gamba, D-Milwaukie, who is sponsoring House Bill 2965, said the practice of net pens can degrade aquatic ecosystems and harm native fish populations.

Oregon Public Broadcasting reports that while environmental groups argue that fish clustered together in net pens can affect surrounding waters negatively, some opposing the legislation say it’s premature, and could hinder efforts to produce sustainable seafood in the Pacific Northwest.

“Oregon is the only state on the West Coast lacking appropriate controls of net pens.” Gamba said at a House committee hearing.

“I’m concerned this may cause Oregon to become a magnet for an industry that is not known for being particularly careful.”

Rep. Mark Gamba, D-Milwaukie is sponsoring a bill that could ban net pen farming in Oregon state waters.

He cited a 2017 incident when a net pen collapsed on the Puget Sound, releasing over 200,000 non-native Atlantic salmon into the wild.

“This bill would only ban marine net pens because we know that these operations cause some of the worst impacts,” said Amy van Saun, a senior attorney with the Center for Food Safety Portland office.

Oregon ranks below its neighbours California and Washington in aquaculture seafood production.

Randy Bentz, the president of the Oregon Aquaculture Association, opposes the government closing the door entirely to an industry that is still developing ways to more sustainably and safely farm fish in estuary and ocean waters, as demand for more seafood grows.

“I believe this bill is unnecessary, in that it addresses a problem that doesn’t currently exist, and that it will harm future growth and innovation in this state,” he said.

BY IMANI BLACK

Imani Black is an aquaculture professional, aquaculture advocate, and industry trailblazer with a decade of experience in oyster farming and hatchery management across Maryland and Virginia. As the Founder of Minorities In Aquaculture and a graduate with a master’s degree in Ecological Anthropology from the University of Maryland Center for Environmental Science, she is dedicated to fostering workforce inclusivity and equity through mentorship, education, and advocacy. [imanib@mianpo.org / www.mianpo.org / @imaniiiblackkk]

In aquaculture, the question of what’s truly valued in a career is central to workforce development: Is it advanced degrees—like Master's or PhDs in fisheries, hatchery/RAS systems, animal husbandry, or larvae production?

Or is it certifications in handson skills like marine mechanics, welding, or other trade qualifications?

This question is at the heart of workforce development in aquaculture, and in my opinion, the answer isn’t as straightforward as we might hope.

The biggest misalignment

within the question I see exists between academia and the commercial sector. Academia often prioritizes advanced degrees and research, viewing Master’s/ PhD credentials and publications as the gold standard of true expert-level success.

On the other hand, within the commercial sector, hands-on skills and practical knowledge are just as, if not more, valuable than having a high degree.

Yes, it’s useful to know the physiological response of shellfish within changing environmental

conditions while working on an operation, but many would argue that it’s more useful to possess the ability to troubleshoot mechanical systems, manage equipment, and maintain operations that are vital for day-to-day farm and overall successful operation production/ management.

In fact, those who understand the mechanics of aquaculture systems and can solve immediate operational issues are often the most valued in the commercial industry. Their technical expertise ensures the efficiency and smooth running of operations. However, after working for

six years after undergrad in oyster hatcheries, nurseries, and farms, I realized when pursuing my Master’s degree that my commercial career gave me a completely different perspective on the industry compared to most of my classmates who went straight to grad school.

While they focused on the research and data they could collect in collaboration with oyster farms, I found myself thinking more about the logistics, maintenance, and the additional labor that would be required by farmers and their teams to achieve their research goals.

So, I’ll ask you: Does it matter if someone’s career path doesn’t follow the traditional educational route but instead focuses on years of hands-on experience?

If someone has spent over five years working within the industry – running hatcheries, managing animal production/ husbandry, troubleshooting mechanical systems – are they just as valuable as someone with a degree and an impressive academic record in terms of aquaculture workforce needs?

For me, based on my own journey, experience matters. In many cases, it can be far more valuable than a degree, especially when it comes to solving real-world problems. While someone may not look strong on paper academically, their practical field experience equips them to tackle challenges and apply research in ways a resume can’t always capture.

And if someone with more hands-on experience later chooses to pursue higher education to strengthen their industry knowledge, should we penalize them because their past academic record, particularly a lower GPA, doesn’t meet institutionalized standards?

The aquaculture industry needs both innovative researchers and skilled workers who can apply their knowledge in practice. While degrees provide theoretical knowledge, hands-on experience is crucial for day-today success. Sustainability is key to the industry’s long-term growth, requiring a workforce that adapts, innovates, and solves problems creatively.

As the industry grows, a skills gap threatens productivity and innovation, making workforce development essential. We must prioritize attracting, training, and retaining skilled

professionals. To build a sustainable workforce for tomorrow, we must engage the next generation of our workforce to continue to be intentional about their contributions within the future of aquaculture.

One major barrier to this right now is the lack of awareness and consideration towards having a career in aquaculture, and recognizing the multi-disciplinary occupational opportunities that truly are within our development. In order to show them the way, all sectors of our industry must raise awareness about the diverse roles available, from farm management to research.

The industry collaborating with universities, community colleges, and vocational schools to create aquaculture-specific curricula is key, along with offering scholarships, internships, and mentorship programs to attract multidimensional talent.

Additionally, standardized training and certification programs are crucial to ensure workers have the skills needed for success in both entry-level and advanced roles.

The aquaculture industry needs both innovative researchers and skilled workers who can apply their knowledge practically. While degrees provide theoretical knowledge, hands-on experience drives day-to-day success. Equally critical to long-term growth is sustainability, requiring a workforce that can adapt and innovate.

With rapid industry growth comes the challenge of a skills gap, threatening productivity and innovation. To ensure continued success, we must prioritize workforce development, attracting, training, and retaining skilled professionals.

The real question isn’t whether scholars or deckhands are more valuable. The question we should be asking ourselves is: How do we bring both together to create a workforce that’s innovative, adaptable, and ready to lead aquaculture into the future? | ANA

For over 35 years oyster growers worldwide have trusted our

Oyster Tray and S4000 nursery tray, to

half-shell oyster for today’s demanding consumers.

BY LEAH STOKER

is the founder of FishPros Network, a platform dedicated to connecting talent and companies across the aquaculture and fisheries industries. (leah@fishprosnetwork.com)

Crafting a lifecycle approach to attracting and retaining top performers for your company

In today’s competitive job market, attracting and retaining top talent is more than filling open roles—it’s a strategic process that defines your company’s success and reputation.

Much like the lifecycle of a fish, from spawning to migration, every stage of the employee journey is crucial. Companies that adopt this full-circle mindset build trust, loyalty, and a resilient employer brand that reverberates far beyond company walls.

The hiring process is often a candidate’s first impression of your organization. Whether you’re working with in-house recruiters or external partners, it’s essential that they align with your company values and are known for treating candidates with respect.

Crafting a best-in-class candidate experience means partnering with recruiters who are regarded for their professionalism, clearly communicating your company’s mission and opportunities, and maintaining a process that is efficient, transparent, and candidate-centric. Even those who don’t secure the job will remember how they were treated, and that perception will follow your company’s reputation within the industry.

Beyond the recruitment phase, building a strong talent attraction strategy requires consistency in foundational practices.

A compelling employer brand that highlights authentic employee stories, community engagement, and company achievements will position your organization as a sought-after workplace. Offering competitive, market-aligned compensation and benefits, coupled with a demonstrated commitment to diversity, equity, and inclusion, strengthens your appeal. Equally important is creating

Even those who don’t secure the job will remember how they were treated, and that perception will follow your company’s reputation within the industry.

a hiring process that is streamlined, respectful, and clearly communicated to all candidates. When executed well, these steps create a natural draw for high-quality talent and bolster your company’s credibility.

Once a candidate accepts an offer, onboarding becomes the next critical step in reinforcing your employer brand promise. A smooth onboarding experience is marked by personalized welcomes, setting clear expectations, introducing new hires to mentors and teams, and equipping employees with the tools and resources necessary to thrive from day one. A strong onboarding process encourages early engagement and productivity while laying the foundation for long-term retention.

Top talent stays where they see growth and opportunity. Companies with a reputation for investing in employee development foster loyalty and strengthen their employer brand. Providing professional development opportunities – such as certifications, workshops, and mentorships

– alongside internal mobility pathways and wellness support, creates an environment where employees feel valued and challenged. This, in turn, motivates them to become ambassadors for your organization.

An employee’s departure is not the end of the relationship. Offboarding with care can significantly impact your company’s long-term reputation. Conducting thoughtful exit interviews, recognizing contributions, and encouraging alumni to remain part of your broader network reinforces goodwill. When employees leave on good terms, they carry positive stories into the industry, influencing future hiring opportunities.

Each stage of this lifecycle – from recruitment to offboarding – shapes how your organization is viewed internally and externally. In close-knit industries, like aquaculture and fisheries, where word-of-mouth travels quickly, a strong employer reputation is a competitive advantage. Companies that consistently apply these best practices demonstrate that they value people, promote growth, and prioritize integrity.

Attracting and retaining top talent is not just about filling seats; it is about crafting a journey that leaves lasting impressions. Aligning recruiting partners with your values, providing meaningful growth opportunities, and ensuring dignified offboarding builds a reputation that attracts talent like a well-baited hook and supports your business for years to come.

We have skimmed the surface here. If you want to expand on the conversation, reach out anytime. In the next issue, we will expand on these principles, beginning with a deep dive into how to create a best-in-class candidate experience. | ANA

Fleming College is expanding its expertise in Aquaculture with the introduction of warm water species and research husbandry in its renowned Aquaculture Co-op program.

The program will now include Zebra fish along with new equipment and program content to expand students’ knowledge and skills. Fleming will also add hands-on training in Aquaponics to the curriculum to further prepare graduates for the workplace.

“Adding a warm water species to the program and its associated equipment gives students a broader set of skills and opens increased job opportunities in the industry,” says Jon Carter, Coordinator of Fleming’s Aquaculture program.

Aquaculture is the only program of its kind in Ontario. A graduate certificate, it includes a co-op placement and extensive hands-on learning in the College’s onsite fish hatchery.

The program is continually evolving to ensure it stays aligned with industry. Last year it added the new course Aqua Certifications and Welfare, which focuses on relevant provincial and federal legislation regarding aquaculture operations, including the various certifications aquaculture operations can achieve to ensure consumer confidence in the product.

For those working in the industry and seeking to upskill, Fleming has launched a series of 10 Aquaculture courses that can be taken online from anywhere and provide foundational training in fish culture techniques and operations.

With a self-directed learning approach, participants can start any time and work at their own pace. Each course consists of short lectures or modules that cover basic aspects of operations in the field, including the biology of cultured fish, feeding and nutrition, sea cage rearing systems, biosecurity management, fish health, harvesting practices and more.

For businesses that require research and development resources, Fleming’s Centre for Innovative Aquaculture Production (CIAP) has opened a new hatchery onsite at Fleming’s Frost Campus in Lindsay, Ontario. With modern technology, tools and equipment, CIAP can support complex, long-term research projects and tackle larger issues that are important to industry. The hatchery’s customizable infrastructure has allowed the college to expand into commercial species research.

We invite you to learn more flemingcollege.ca

Maine women find alternative ways to use farmed kelp

By Lynn Fantom

Never underestimate what might happen when two multi-tasking moms go for a walk.

Towards the end of Covid, Krista Rosen and Inga Potter –an attorney and marine biologist – embarked on a stroll near the pre-school in southern Maine which their children attended. Potter, who was teaching environmental science at York County Community College at the time, couldn’t help but talk about climate change.

As Rosen listened to how seaweed captures carbon and makes the ocean less acidic, she

thought, “It’s like a miracle crop that can improve the marine environment and then help to replace things we use every day that are not so environmentally friendly.”

Before the hour had elapsed, Rosen said to Potter, “I’ll be your partner!” The two started working on farming permits that week.

“It was very much a lifechanging day,” Rosen says now.

Their company, Cold Current Kelp, today grows Saccharina latissima in Portsmouth Harbor and the Piscataqua River, where the waters of New Hampshire

and Maine meet and mingle. They hold two Limited Purpose Aquaculture (LPA) licenses, with a footprint of 800 square feet.

The Maine Department of Marine Resources began issuing this type of license, at the suggestion of shellfish growers, to streamline permitting. Because of that, it has been successful at attracting research projects and entrepreneurs to study new techniques and species before scaling up.

And that’s exactly what Rosen and Potter are doing in their venture, which currently offers a line of facial oils branded KelpGlow. The products are

“traceable down to the latitude and longitude coordinates off the coast of Maine,” Rosen says. But their vision is much larger than traceability. Most of the kelp currently farmed in the U.S. is used for food, such as the kelp cubes and sea-veggie burgers developed by Maine neighbor Atlantic Sea Farms. Potter and Rosen are focused on high-value uses of kelp “off the plate.” Their initiatives come at a time when entrepreneurs globally are bringing to market seaweed-based products like compostable food containers, laundry pods, polybags for apparel, medical scrub wear, rope and fishing lines.

Most U.S.-grown kelp is used for food, but Cold Current Kelp is pioneering research and product development in skincare.

“We get a lot of joy being out on the water,” says marine biologist Inga Potter who founded Maine-based Cold Current Kelp with attorney Krista Rosen.

Not only is there a market for cosmetic products created with natural, sustainable ingredients but “the use of seaweed-derived ingredients has increased in recent years as a result of the many scientific studies that have proven the potential skincare properties of seaweed bioactives,” writes Lucía López-Hortas, a chemical engineer in Spain.

The big opportunity for “blue beauty” exists because of the polysaccharides present in brown kelp. Studies—predominantly in Europe—have found that these complex sugar molecules protect skin cells from UV damage, promote the production of collagen, suppress agents related

And that’s also where the two Maine moms may have a strategic advantage for their business.

A major asset on their team is Bob Leipold, a PhD in chemical engineering whose tenure with companies including DuPont, Merck, and Pfizer gave him deep expertise in biotechnology and pharmaceutical modelling. He also is Rosen’s uncle.

Potter and Rosen seeded their first lines at the end of 2022. They farm, harvest, stabilize, extract, formulate products, package and ship themselves.

Both women have a strong commitment to being on the water. “We’ve always been very hands-on,” says Potter. They harvest the kelp in small batches and dry it in a greenhouse— a stabilization method they prefer because “it doesn’t require any

energy input, and it’s the gentlest way to preserve those bioactive compounds that are in the kelp,” Potter says.

“We also manufacture the product ourselves, literally,” says Rosen. “We have a space in Kittery [Maine] where we’re making our extract and blending it with the oils. We are filling the bottles and putting them in boxes and shipping them ourselves.”

She speaks with a sense of satisfaction as someone once confined to the towers of Manhattan, doing legal research, writing briefs, and drafting complaints (with success, by the way).

Last summer, the company won a highly competitive Small Business Innovation Research (SBIR) grant of US$175,000 offered by the U.S. Department of Agriculture (USDA). One

to inflammation, and inhibit bacteria associated with acne and atopic dermatitis—”a lot of really positive effects on skin health,” says Potter, who holds a Ph.D. in zoology and Masters in biology.

Scientists are not known for their hyperbole, but one Danish researcher described these effects as “remarkable.”

A British scientist wrote that the macroalgae derivatives are “renowned for their myriad biological benefits.”

But, before consumers rush out to buy and apply seaweed lotions, they should note that there is a rub. Essential to the bioactivity of these compounds is how they are extracted from the kelp.

focus has been how to optimally extract the polysaccharides.

“Unlike conventional methods, the proposed extraction will not use toxic solvents and is expected to result in higher extraction yields in less time,” Leipold wrote in the project summary developed for the SBIR grant. The method that the Cold Current Kelp perfects will become its own intellectual property, a benefit of the SBIR grant.

Another area of research inquiry is the time of harvest. Rosen points to “literature saying that the longer you leave kelp in the water, the more polysaccharides it develops.” So, Cold Current Kelp has experimented harvesting in summer versus spring, performing extractions on each batch separately. There are “some really encouraging and exciting results,” Rosen says. “But it is still early stage.”

Current Kelp and the University of New Hampshire (UNH) to work together on the diversification of seaweed species on a kelp farm. In February, Potter and Rosen seeded dulse, testing different water depths as well as substrates.

In addition to rope, which is used for kelp, they are examining bendable pipe, the type that might be used in plumbing, as an alternative that would alleviate whale entanglement risks.

“Dulse hasn’t been widely farmed, so those protocols aren’t really in place.” Success could mean an additional source of revenue for kelp farmers.

AQUI-S New Zealand Ltd.

sales@aqui-s.com +64 45870389

www.aqui-s.com

LinkedIn: AQUI-S New Zealand Ltd

In addition to the SBIR grant, Cold Current Kelp also received a USDA Rural Development Value-Added Producer Grant for US$24,700 in December to help it develop new products and reach wider markets.

And last year, NOAA Fisheries awarded a Saltonstall-Kennedy grant of US$300,000 to Cold

U.S. government grant funding has clearly made a difference in what these two entrepreneurs can do in research and development, both for their own business and the seaweed sector—where Asia and Europe now have the competitive edge.

We are a GMP-certified manufacturer of aquatic anesthetics, located in New Zealand with distributors worldwide. Sedating fish during the many unavoidable aquaculture handling events improves fish welfare by reducing physiological stress and physical injury, resulting in less fatigue, damage, and mortality. Our mission is to promote humane, fish-friendly handling solutions to maximize fish welfare throughout the production cycle, producing healthier animals with a greater return on investment. Contact us for more information on the sedation of fish and crustaceans!

Asked whether they fear future constraints due to the Trump administration budget cutting, Potter replies, “As far as grants, I’m just an optimist. I feel this is a really positive thing for our country and our planet. Maybe it won’t be the focus of this administration, but I feel there’s so much possibility for small business growth and innovation.”

“In the life cycle of kelp farming, this would be an unfortunate time to lose grant funding because it is such a nascent industry,” Rosen adds. “This is when we need it most. We need to improve the farming technology, the processing technology, the secondary processing technology, the value-added process.”

Collaboration to benefit aquaculture’s future “Outreach to students and the community is something that

we feel strongly about. I think raising awareness not only about seaweed’s environmental benefits but the potential uses of kelp is an important part of what we’re doing,” says Potter. They have met with local high school students interested in aquaculture. For a semester, Rosen worked closely with Brown University students in an environmental studies course. They make time to answer emails, have coffee with students, and speak at career planning events.

They also now have important experience to share with those who are interested in aquaculture careers involving seaweed. “Something we were told when we started in this industry – and that I think still holds true – is you can’t just get a boat and start growing kelp and expect to be a full-time kelp farmer. You really need a place to sell it. So, unless you’re just doing it as a hobby and to learn, you really need a plan with what to do with it when it comes out of the water if you’re going to make money.”

The opportunity ahead Looking back just a few years, Krista says, “I would go to conferences about kelp farming which pretty much only talked about food-related processing and sales avenues. I assumed that we were late to the game as far as other uses. But that’s not necessarily true. We’re really just starting this journey of learning the science behind kelp.”

She hints that one outcome of their SBIR-funded research may be new products that are both quantifiably effective and safe for skin and hair.

”Our goal is never to have a huge farm,” Potter adds. “Our goal is to know intimately a farming process. Hopefully, someday, we can create enough high-value uses that we’re encouraging other people to be farming as well.”

“This is really just the beginning,” she says.| ANA

Mari-Len De Guzman

An expanding aquaculture sector in Maine has prompted a multi-year, interdisciplinary collaborative research project to gain a better understanding of the seafood sector’s value chain.

The findings paint a picture of the challenges and opportunities facing Maine’s seafood producers as they strive to expand their markets; but they also reinforce the state’s unique value proposition when it comes to fresh, delicious seafood.

“Covid had impacted markets pretty dramatically. As you know, the restaurant sector closed down almost overnight. And so, we were trying to understand the alternative options for growers in terms of getting their product to market. So that was the genesis for that project,” says Sebastian Belle, executive director of the Maine Aquaculture Association (MAA).

The MAA spearheaded the collaborative research project titled, Expanding Maine’s Blue Economy, involving researchers from the Gulf of Maine Research Institute

(GMRI), the University of Maine’s School of Economics, and the Island Institute, with funding from Maine Sea Grant.

The project began more than four years ago and included interviews with seafood producers, wholesalers, processors, distributors, retailers and chefs. It provided insights on the entire seafood supply chain, and identified bottlenecks in and opportunities for expanding the market for Maine’s seafood produce.

One interesting finding from the study was the shift toward direct distribution, where growers have begun shipping directly to consumers, either through mail or by creating their own local distribution networks, Belle notes.

“And some of the growers were learning some hard lessons about what’s the cost of direct distribution versus what’s the return on investment. A lot of people were excited about direct distribution,” he adds.

This trend toward direct-to-consumer distribution, facilitated by online e-commerce

platforms, gained increased traction during and after the pandemic.

“We saw that as a trend. But what we didn’t see and what we discovered was that sometimes growers don’t accurately account for the costs in doing that. They get excited about the price they’re being paid, but they’re forgetting that there are additional costs in terms of shipping, in terms of how you collect the money,” Belle says.

The study also revealed that despite a strong market for Maine-grown seafood across the U.S., many of the products remain within the state.

“We were surprised at the level of distribution within the state. We thought a lot more product was going out of the state, but it turned out that the markets within Maine were very strong and were definitely accounting for a significant portion of the product that was being grown here in Maine,” says Belle.

This may be changing soon, however, as the same study has revealed nearly 85 percent of producers are planning to expand their business within the next two to three

years. To do this, industry must address current challenges, particularly when it comes to logistics and the distribution network.

One aspect of the project is an assessment of the seafood supply chain, identifying the businesses involved and the bottlenecks in expanding the market. This part was conducted by scientists at GMRI, examining the “middle of the supply chain,” assessing how producers are getting their products to market and what their biggest challenges are.

“There was a heavy reliance on the existing infrastructure, which was not necessarily suitable for shellfish aquaculture, for example,” notes Kanae Tokunaga, senior scientist at GMRI. “They had to hitchhike with the lobster (truck), for example. There is an established lobster supply chain that can move products from Maine to out-of-state. If there’s a space in the truck, they can take shellfish products. But what if the lobster fishery had a lot of products that they needed to transport?”

Maine is the leading source of lobster produce in the U.S. and holds a relatively

stable infrastructure for storage, processing and distribution. Many shellfish producers in Maine, on the other hand, are typically smaller, boutique growers with no established distribution network for handling the product from farm to market.

“They are utilizing existing seafood infrastructure that are built for lobsters and groundfish, and they are not always suitable and up-to-standard for products like oysters that require more stringent food safety care,” notes Tokunaga.

The limited availability of canneries within the state was also identified as a challenge for producers, serving as a bottleneck for innovation in value-added products or for prolonging shelf life, Tokunaga adds.

Maine is famous for its pristine waters that produce some of the freshest, tastiest seafood. This attribute can be a double-edged sword for producers, particularly those located in the rural parts of the state, as they struggle to get their products to market the quickest way possible.

And the issue is not just logistics; it’s geography.

“If you follow the coast of Maine, north and east towards Canada… that area is very rural and is dominated by lobster fishing right now,” explains Christian Brayden, project manager with the Maine Aquaculture Association. Getting seafood products from these rural areas to the cities and main markets, like Boston and Portland, can take several hours. Oyster farmers, for example, would have very limited options for selling their oysters.

“There aren’t enough farmers in that area that the local shellfish dealers would want to buy oysters. They’ll buy clams, they’ll buy lobsters, but there’s not enough oysters around for them to buy. Then (the farmers) are stuck with trying to sell oysters on a really local scale, maybe out of the back of their truck or to local restaurants,” explains Brayden.

“Especially for a really small farmer, they can’t always afford the time or the money to drive to Portland or drive to Boston… So there’s this really big mismatch between people who want some aggregated pickup,

the

whether it’s a van that picks up from multiple farms or filling a small reefer truck. But to get their product to market more easily and cheaper is a really big issue.”

With a majority of aquaculture producers in Maine indicating they plan to expand their business in the near-term, this logistical challenge is increasingly relevant.

Brayden says there has been a big focus on oysters and connecting oyster growers to new markets. This aspect of the project looked at consumer preferences to gain insight on where these new markets are and what their buying patterns are.

“Then the other part is the logistics of it. Through this work, we’ll be able to better identify patterns of people who have different methods that work for them. For some people, (that might be) direct to consumer, shipping oysters via UPS overnight to, say, Utah,” Brayden says.

With a majority of seafood growers planning to expand their market, scalability becomes an important consideration. But expanding seafood production is not as easy, or as quick, as one would hope.

Leasing and permitting for new farms can take up to three years, so even when a grower begins the process of expanding production, it can still take some time before a scaled-up operation can be fully in place.

“We’re looking at four years before your first oyster sold and your first dollar back,” says Brayden. “The expansion is taking a lot of time to happen. It’s a very bottom-up approach for these small businesses all across Maine who are trying to grow just bit by bit, but it takes time to do it.”

He adds, however, that many producers that began their journey to expand their business

a few years ago are now starting to reap the rewards, particularly in the oyster sector.

“They’re the ones who are really driving these new markets that they’re trying to pursue,” Brayden says.

There is also the question of, ‘How big is too big?’ Part of Maine’s charm is its ‘boutique’ style aquaculture, where quality always trumps quantity.

GMRI’s Tokunaga says it’s something producers in the state will have to reflect on.

“In order to move up to the next level of market, there also needs to be some volume. Maine has really done a good job of establishing brand recognition, especially among the oyster aquaculture. And that comes with the idea that they are boutique farms producing high-quality products, capturing the premium in the market,” she says.

The risk of increasing production volume is potentially losing out on that premium market.

“How do you achieve both?” asks Tokunaga. “That can also be an identity issue for Maine’s seafood sector.”

Challenges and bottlenecks, notwithstanding, Maine’s aquaculture sector has been steadily growing.

Data from the MAA shows that since 2007, the economic impact of aquaculture has skyrocketed from $50 million to $137 million, with some 200 farms creating more than 700 full-time employment.

The diversity of the state’s aquaculture sector has also flourished, not only with the species produced – shellfish, crustaceans, finfish and seaweed – but the systems in which they are grown, both at sea and on land.

Logistically, fresh products from Maine can reach 130 million consumers just within a 24-hour truck drive – Chicago to the east and Atlanta to the north. “We are very well-positioned to hit those markets with fresh product,” says Belle.

The state also benefits from some of the highest water quality levels among other U.S. jurisdictions, consistently ranking in the top five across the country.

“We also still have a working waterfront in Maine,” Belle points out. “In many of the other states, particularly on the East Coast, the working waterfront has essentially disappeared or been consolidated into industrial hubs like Gloucester or New Bedford. But in Maine, virtually every community you go to along the coast of Maine still has a working waterfront, and aquaculture has become part of that working waterfront.”

For its part, the MAA has established programs and initiatives designed to help growers build and succeed in their business, through advocacy, business support services, workforce development and research.

“We view this as an economic development exercise,” says Belle. “In order for economic development to occur, you need a business climate which is going to support people’s willingness to risk capital. You need a business climate that people can come into and

say, ‘Okay, I think there’s some predictability here, and I think that we are willing to risk some capital.’”

Belle is also optimistic about the sector’s sustainable growth prospects, as more young people enter the aquaculture sector, oftentimes with fresh, innovative ideas that will further propel the sector to reach its growth potential.

“We won’t become a China (in the aquaculture world), but we will see slow but steady growth in the sector,” Belle says. | ANA

Customized for your fish farm, hatchery or research operation!

Customized for your fish farm, hatchery or research operation!

Customized for your fish farm, hatchery or research operation!

Our Commercial LSS Packages are custom engineered to meet your specific needs.

Our Commercial LSS Packages are custom engineered to meet your specific needs.

Our Commercial LSS Packages are custom engineered to meet your specific needs.

• Marine and Freshwater

• Marine and Freshwater

• Marine and Freshwater

• Mechanical filtration

•

• Mechanical filtration

• Mechanical filtration

• Chemical filtration

• Chemical filtration

•

• Chemical filtration

• Ultraviolet disinfection

• Ultraviolet disinfection

• De-gassing towers

• De-gassing towers

• De-gassing towers

• Wide variety of flow rates

• Wide variety of flow rates

• Wide variety of flow rates

• De-gassing towers

• Flow control valves

• Flow control valves

• Flow control valves

• Protein skimmers

• Wide variety of flow rates

• Protein skimmers

• Flow control valves

• Ultraviolet disinfection

• Chemical filtration

• NEMA enclosed controls

• NEMA enclosed controls

• Protein skimmers

• Variable frequency-drive pumps

• Variable frequency-drive pumps

• Ultraviolet disinfection

• NEMA enclosed controls

• Bio-filter towers

• Bio-filter towers

• NEMA enclosed controls

• Bio-filter towers

• Bio-filter towers

• Protein skimmers

• Temperature management

• Variable frequency-drive pumps

• Temperature management

• Temperature management

• Variable frequency-drive pumps

• Temperature management

All our systems are pre-plumbed and fully water tested prior to shipping. Call us today at 206.937.0392 www.AquaticEnterprises.com

All our systems are pre-plumbed and fully water tested prior to shipping. Call us today at 206.937.0392 www.AquaticEnterprises.com

All our systems are pre-plumbed and fully water tested prior to shipping. Call

All our systems are pre-plumbed and fully water tested prior to shipping. Call us today at 206.937.0392 www.AquaticEnterprises.com

JBT Marel and Ace Aquatec join forces to advance fish welfare

JBT Marel, a food processing solutions company, has entered a partnership with Ace Aquatec, an aquaculture technology company, Ace Aquatec.

By combining Ace Aquatec’s Humane Stunner Universal (A-HSU) with JBT Marel’s fish processing portfolio, they will offer customers a product line for the entire seafood value chain, covering harvesting and processing solutions with data insights software.

According to a press release from Ace Aquatec, fish processors will benefit from the integration of solutions from both portfolios with improved processing results, lowered production costs, higher profits, and full traceability of the production process.

“Our strategic partnership with Ace Aquatec strengthens our commitment to innovation, sustainability, and improving fish welfare. By combining our expertise in food processing with Ace Aquatec’s stunning technology, we can deliver a comprehensive, humane, and efficient solution that enhances seafood processing and meets the demands of clients and

consumers alike,” said Skuli Sigurdsson, vice president of fish, JBT Marel.

The partnership aims to drive positive change in fish slaughter, handling, and processing. Together, JBT Marel and Ace Aquatec will be able to offer customers a seamless product line for the entire seafood value chain covering harvesting and processing solutions with data insights software.

“Kicking off 2025 as a strategic partner with a global company like JBT Marel is a great boost for everyone at Ace Aquatec, and for those striving to improve fish welfare standards globally. This partnership will enable the delivery of comprehensive in-line solutions for the aquaculture sector and reflects our shared commitment to transforming the seafood processing industry globally,” said Nathan Pyne-Carter, CEO of Ace Aquatec.

KOA Biotech secures €2M to advance waterborne infection detection in aquaculture

KOA Biotech, a Barcelona-based biotech company, has secured a €2 million (US$ 2.1 million) investment round led by Swanlaab Innvierte Agrifood-Tech, together with Fund F and Faber.

The biotech company has developed a biosensor system that is capable of early detection of waterborne infections. This can prevent the spread of infections in water, reducing mortality caused by infectious pathogens and the use of antibiotics in fish farms.

“Infections in fish farms are a growing problem, causing losses of up to 30 percent of production (economically estimated globally

at over US$6 billion),” said Sira Mogas, CEO and founder of KOA, which develops solutions for the aquaculture sector.

This investment round will enable KOA to advance its technological development and consolidate its technology in the sector, and also implement its commercial plan.

“Investing in technological and innovative companies like KOA is key for the development and value creation based on the research conducted in this sector in Spain, as well as a lever for the development and differentiation of the country’s agri-food sector, with a global impact,” said Nora Alonso, general partner of Swanlaab Innvierte Agrifood-Tech.

SEAPA, a company that designs plastic products specifically for oyster growers, has released a new product.

The new REVO floating system was built on the SEAPA GTX platform, enabling farmers to shift from floating lines to intertidal longline systems without changing baskets and additional handling.

One of the system's features is bio-fouling resistance. It has larger spaces which allow it to desiccate and reduce the buildup of biofouling on the basket and oysters.

It was manufactured to be used with the GTX. And features three grip-style handles, which simplify the connection and removal of baskets’ floats and the rope shaft frames.

According to information from the website, “Our helix rotates the basket in either direction without modifications or additional parts. Minimizing costs and simplifying efficiencies.”

It’s also said to have easy maintenance and provides the option to remove the baskets independently from the float and the line so that existing grading systems can be used.

Manatee Holdings Ltd., a shellfish aquaculture farmer, has established a Bitcoin Treasury Reserve alongside a unique Geoduck Inventory Reserve.

According to a press release from Manatee, it’s “the first company in the industry” to do so, and this is a step in financial strategy and aquaculture investment.

This move is to attract investors seeking diversified asset exposure while offering Bitcoin holders a double-hedging opportunity. Manatee Holdings’ Bitcoin Treasury Reserve allows the company to diversify its financial base.

“We’re opening the door for a new class of investor—one that sees the potential in digital currency and sustainable food systems. This is not just about financial diversification; it’s about pioneering a future-proof investment model,” said Lourdes Gant, co-owner and managing director of Manatee Holdings Ltd.

The Geoduck Inventory Reserve leverages the valuation and global demand for geoduck–a large clam found along the West Coast of Canada–ensuring the company maintains a natural asset base.

“This is a transformative moment for the aquaculture industry. By combining a Bitcoin Treasury Reserve with our Geoduck Inventory Reserve, we are offering investors a double hedge strategy—one rooted in the future of digital currency and the other in a premium, sustainable seafood product,” said Gant.

Send your latest products or supplier news releases to the editor: jkodin@annexbuesinessmedia.com

What species are you considering? RAS or open water system?

Will you need a grant or funding? We provide entrepreneurs and business startups professional support and world class facilities to develop their aquaculture ideas. Contact us today to see how we can help turn your aquaculture idea into a reality.

BY KATIE MAXIMICK

Katie Maximick is a communications professional grateful to be born and raised on the unceded territory of the K’ómoks First Nation. She started out in aquaculture in 2018 before transitioning to support First Nations engaging with the federal and provincial governments on the future of salmon farming in their traditional territories. Elbows up.

First, I want to be clear that although the topic of this op-ed is my viewpoint from supporting First Nations working with salmon farming in their territories, I am not Indigenous, nor do I speak for First Nations or Indigenous peoples. This is my opinion and observation based on my first-hand experience working with First Nations and their participation in Canada’s imposed transition of salmon farming in British Columbia.

For the past few years, I have been a communications and government engagement coordinator for First Nations in British Columbia (B.C.) who united to fight for their right to decide as sovereign Nations whether, if, and how they host salmon farms in their coastal territories.

Many of these Nations’ socioeconomic well-being is tied to salmon farming and is therefore tied to decisions about the sector made by politicians 5,500km away. Up to 60 percent of a Nation’s total revenue can stem from salmon farming. Revenue from partnerships with salmon farming companies, meaningful jobs, and Indigenous-owned businesses (like net-washing and water taxis) all directly benefit these communities and the social health of their people.

As you can imagine, the Government of Canada’s unilateral decisions and deadlines for the sector (based on activism rather than science) are a literal threat to these remote communities and their people.

This critical dialogue between these Nations and the Government of Canada has taken me to Ottawa many times since 2022 where my role as a note-taker in meetings has shown me the underbelly of the federal government. I learned the hard way how, regardless of party, politicians must tow their party’s line on salmon farming even if their personal opinion and values vary from their party’s stance – even if that party’s stance will hurt people.

More than a few meetings turned heated, and many more grew emotional as Indigenous

Be accomplices. Speak up. Step up. Use your privilege if you have it. Pressure Ottawa and provincial leadership to invest in building capacity for these Nations.

leaders shared their Nation’s history, the ongoing impacts of colonization on their communities, states of emergencies due to suicides and overdoses, and what would happen if the government simply shut down the salmon farming sector in their territories against their will. As tough as these topics were to hear for many politicians (some would openly cry), they have the privilege of not having to experience it first-hand.

It has been more than difficult for me to watch this unfolding. I’ve seen a hypocritical lack of empathy, respect, and understanding from many politicians, particularly those whose parties tout reconciliation with First Nations. To say that I have been disenchanted by how our government operates would be an understatement. I have often felt helpless over the years, but I’m inspired by the resilience of the Indigenous leaders I am proud to know and support. I’ve also come to realize that I can help by using my skills and my voice to help amplify theirs.

Due to the impacts of ongoing colonization, many First Nations (particularly remote

ones) lack the capacity to fight back against the government or outside influences like wealthy, urban activists. It’s a lop-sided fight, to say the least.

So how can non-Indigenous people help First Nations and Indigenous groups fight for their economic self-determination (regarding salmon farming and beyond)?

Be active allies, or as Chief Crystal Smith of the Haisla Nation urges, be accomplices. Speak up. Step up. Use your privilege if you have it. Pressure Ottawa and provincial leadership to invest in building capacity for these Nations so they can fully manage their communities, participate in Canada’s economy, and pull themselves out of government-caused poverty.

Remind politicians that reconciliation with First Nations cannot be cherry-picked to suit opinions on a Nation’s choice of how they participate in the economy.

Salmon farming meets Canada’s goals of increasing food security and affordability. With the current trade war between Canada and USA., Canadian consumers are looking for Canadian products in the grocery store. B.C. farmed salmon is not only Canadian-grown but 100 percent grown in partnership with First Nations.

I am writing this column anticipating a federal election in Canada on April 28. The upcoming election gives the Government of Canada, and whatever party forms power, an opportunity to finally do right by these First Nations and the sacrifices they’ve made fighting for their right to farm salmon in their traditional territories. The next Prime Minister and Minister of Fisheries can turn the page on the B.C. salmon farming story to a more promising, respectful, and collaborative chapter.

With the current geo-political uncertainty we’re seeing unfold in the world and attacks on the sovereignty of nations, what is timelier than endorsing Canadian-grown food while protecting the sovereignty of Canada’s First Nations? | ANA

Empyreal 75 creates more space in the aquaculture diet by reducing the need for other, more costly forms of protein, such as fish meal or other protein concentrates. This gives you expanded flexibility to be more creative with your formulations and diet design—so you can deliver higher-value products to your customers.

Empyreal75.com