PRESERVING HISTORY

INNER CITY OVERCOME MONUMENTAL CHALLENGES AT SKINNERS HALL

5 Steps to achieve carbon neutrality

ENVIRONMENTAL ScaffOil: eco-friendly lubricant

INNER CITY OVERCOME MONUMENTAL CHALLENGES AT SKINNERS HALL

5 Steps to achieve carbon neutrality

ENVIRONMENTAL ScaffOil: eco-friendly lubricant

Absolute Access Services Limited

www.absoluteaccessservices.co.uk

07971 064409

Access Contractors UK Ltd

www.access-contractors.co.uk

07856 957471

Access Solutions Kent

www.ask-scaffolding-services.co.uk

07870 598680

APA Height Access Limited

www.apagroup.uk

07595 284475

Apollo Scaffolding Southern Ltd

07956 073423

Border Scaffold Services Limited

www.borderscaffolding.co.uk

01432 352530

C C S S Limited

www.ccscaffold.co.uk

01495 769169

Cantilever Scaffolding Ltd

www.cantileverscaffolding.co.uk

07984 170033

Cherry Scaffolding Limited

020 7101 4299

CJB Scaffolding Ltd

www.cjbscaffolding.co.uk

01603 894 052

Connect Scaffolding Services Limited

www.connectscaffoldingservices. co.uk

01844 215082

Culmex Scaffolding Ltd

07936 471232

Curtis Scaffolding Limited

www.curtisscaffolding.co.uk

01579 340645

DMAC Scaffolding Solutions Limited

www.dmacscaffolding.co.uk

07961 526889

Ducker & Young Scaffolding Limited

www.duckeryoung.co.uk

01993 703082

Elite Scaffold Access Ltd www.elitescaffoldaccessltd.co.uk

01902 351105

Group-Industrial UK Limited

www.groupindustrial.co.uk

01642 688665

Editorial

Enquiries: Alison Hurman

T: 0300 124 0470

E: alison@scaffolding-association.org

Advertising

Enquiries: Trish Meyer

T: 0300 124 0470

E: trish@scaffolding-association.org

Scaffolding Association

T: 0300 124 0470

www.scaffolding-association.org

E: info@scaffolding-association.org

London Safe Scaffolding Ltd 07552 219179

MRH Scaffolding Ltd

www.mrhscaffolding.co.uk 07514 031277

MW Access Solutions Limited 07471 508915

Peoples Safety Ltd

www.peoplessafety.co.uk 01324 578782

R & D Scaffolding Southeast Limited

www.rdscaffolding.com 07850 391677

SM Scaffolding Ltd

www.smscaffold.co.uk 07497 617447

South Western Scaffolding Limited

www.southwesternscaffoldingltd. co.uk 01305 267352

V and J Scaffolding Limited 07850 089137

Veritas Group (Yorkshire) Ltd www.veritas-group-yorkshire.co.uk 0113 534 7006

Subscriptions

AccessPoint is distributed to members of the Scaffolding Association and other selected access and scaffolding businesses.

If you wish to receive a copy of AccessPoint or would like to amend or cancel your subscription, please call 0300 124 0470 or email info@scaffolding-association.org

Curtis Scaffolding Limited

www.curtisscaffolding.co.uk

01579 340645

DMAC Scaffolding Solutions Limited

www.dmacscaffolding.co.uk

07961 526889

360 Degrees Consultancy Ltd

www.360degreesconsultancy.co.uk 07787 408544

Advance Construction Advisors Ltd 07944540487

uCheck Limited

www.ucheck.co.uk 0300 140 0022

Vertex Training & Consultancy Ltd

www.vertexscaffoldingsafety.co.uk 07920 557234

Alsure Limited www.alsure.com 0121 622 6122

AccessPoint is published on behalf of the Scaffolding Association. The views expressed in this journal are not necessarily those held by the Scaffolding Association. The Scaffolding Association shall not be under any liability in respect of the contents of the contributed articles. The Editor reserves the right to edit, abridge or alter articles for publication.

ISNN: 2055-2033 (Print)

© All editorial contents AccessPoint 2023

Printed by Tewkesbury Printing Company Designed by Gladstone Design

P3-5 NEWS

Stories from the sector

P7 COMMENT

Robert Candy, CEO of the Scaffolding Association, discusses Net Zero in the UK construction industry

P8-9 COMMERCIAL

Citation: simplifying sustainability

P11 LEGAL

Holmes & Hills Solicitors: A sustainable shift in construction contracts

P13 ENVIRONMENTAL

5 Steps for scaffold companies to achieve carbon neutrality

PROJECTS

P14 Riverside demolition

P15 Network Rail rolling roof

P16-17 Grade I listed renovation

P18 High-rise system scaffold

P19 FEATURE

Creator: a decade of change in scaffolding design

P20-21 TRANSPORT

Road Haulage Association: A greener future for industry

P22-23 PRODUCTS

New and recent innovations

The Scaffolding Association is pleased to announce it has been shortlisted in three categories at the Memcom Excellence Awards 2023, including for this magazine!

The categories are as follows:

• Best Magazine – Circulation <20k (Access Point)

• Best Event on a Shoestring <£20k (Scaffolding Conference)

• Best Campaign on a Shoestring (National Scaffolding Week)

Created to shine a spotlight on successful membership organisations and inspire the leaders of tomorrow, the Memcom Membership Excellence Awards are open to professional bodies, trade associations, membership charities, trade unions and the wider not-for-profit membership sector.

With 34 awards in six categories, the Awards cover a vast area from strategy to leadership, from engagement to publications and from individuals and teams who really make a difference. Each of the awards is judged by an independent panel, chosen for their expertise in that particular field.

The Memcom awards recognise the creativity and hard work driving up the standards of the membership sector and shine a light on the organisations that are increasing value for their profession as well as wider society.

The winners of the 2023 awards season will be announced at an evening awards ceremony at the Hilton Bankside in London on the 26th September 2023.

The Scaffolding Association, the UK’s largest trade association for the scaffolding and access sector, is thrilled to announce the achievement of a significant milestone: exceeding 600 members within its vibrant and expanding community.

This remarkable accomplishment highlights the company’s commitment to delivering exceptional service and providing an unparalleled experience to its valued members.

Since its inception, the Scaffolding Association has endeavoured to build a community that fosters collaboration and inclusivity. The dedication and support of each member have been instrumental in shaping the Scaffolding Association’s success and solidifying its growing position in the scaffolding and access sector.

With each new member, the Scaffolding Association expands its network of professional organisations that share a common vision and ambition for the

industry. This collaborative community enables members to connect, exchange ideas, and work in unison on groundbreaking projects, driving innovation and propelling the industry forward.

The growing membership base has enabled the Scaffolding Association to diversify its offerings, providing an even broader range of services and benefits to meet the evolving needs of its members. Combining the expertise, skills, and perspectives from the breadth of its community, the Scaffolding Association proudly remains the largest trade association in the sector.

As the Scaffolding Association looks ahead, it remains committed to its core values of fair competition, community, and inclusion. By fostering an inclusive and supportive environment, the Scaffolding Association will continue to attract top talent, provide unrivalled opportunities, and impact the scaffolding and access landscape.

WellMax Scaffolding Limited, who are Audited Members of the Scaffolding Association, have been selected as finalists in four categories at the prestigious Construction News Specialist Awards, these are:

• Access & Scaffolding Specialist of the Year

• Outstanding Contribution to Specialist Construction

• Project of the Year by a Specialist Contractor (> £2m)

• Specialist Contractor of the Year (turnover > £25m)

The awards ceremony is set for 7th September 2023, at the Hilton London Metropole.

Russell Maxwell-Smith, Managing Director at WellMax, commented:

“A tremendous achievement and honour for WellMax to be chosen as finalists for four categories this year. This is real testament to the hard work and efforts of all our team.

We are currently at the final stage of the awards, delivering presentations to the Construction News judging panel, made up of influential construction and trade individuals. Thereafter, we tentatively await to hear the results at the Awards Event in September. Wishing the best of luck to all.”

CASS Supplies Limited (CASS), who are Audited Members of the Scaffolding Association, have recently completed a second tree planting day as part of their commitment to helping the environment but also rewarding the areas that their team are involved in by planting near the client sites.

The first tree planting took place in Newbridge fields in Newport and the CASS team planted 1000 trees/ hedgerows. CASS work with Carma and The Green Task Force who support the rehabilitation of veteran’s seeking employment.

The second tree planting day took place at the end of March, which was the end of the planting season and this time it was at two sites in Abergavenny. This time CASS worked with Morgan Sindall, who are currently building a new school in the area, and they were keen to get involved and together the teams planted 2000

trees. Again, the teams worked alongside Carma and The Green Task Force to give back to the local community.

Tom Gent, CASS Managing Director, commented:

“The CASS team had an amazing day, not only did the team do something outside of their daily roles but it was great to be in the outdoors and giving back to the community.

As a company we wanted to contribute to helping the environment but also support the veterans and the tree planting days have been a great success. I know that the CASS team involved thoroughly enjoyed the days, regardless of the aches and pains the following day!

CASS will continue to lead on these schemes, and we look forward to the next stage at the end of the year.”

More: www.cassuk.com

Less than 50% of young people who receive a qualification in construction go on to find employment or apprenticeships in the sector.

To combat this, a partnership has been formed between the Department for Education, BACH, NOCN, the Association of Colleges (through CITB), CITB themselves, and the Home Builders Federation. The aim of the partnership is to increase the number of young people who progress from study programmes and traineeships into jobs and apprenticeships in the construction sector.

The partnership has looked to two colleges, Hartford Regional College and Western College, who are achieving a 90% progression rate into jobs and apprenticeships at the end of their study or traineeship programmes. These colleges are achieving their success through building work preparation and experience into the curriculum, and by developing relationships with local employers.

Scan to find out more.

The Construction Industry Scaffolders Record Scheme (CISRS) will once again, with the support of a group of their approved training centres, be offering a number of subsidised CPD courses across the UK in the coming months.

CISRS has reached an agreement with a number of training providers that will enable them to deliver the CPD programme for up to £50 per delegate over this summer.

Since its inception over 25,000 operatives have retained their CISRS status after successfully completing the 2-day programme.

Over 100 of these subsidised CPD courses have been made available at locations up and down the country, benefitting 1000s of individuals and seeing CISRS reinvest around £400,000 back into its stakeholders, those holding the industry recognised qualification and card.

More centres than ever have joined up to this summer’s initiative and CISRS greatly appreciates their help in redistributing funds back into the industry.

Scan to find out more.

PERI has appointed Ian Hayes as its UK Managing Director following the departure of Alasdair Stables at the end of April 2023. Alasdair Stables stepped down from the position last month to take a career break after leading the UK business for 10 years.

Ian, who officially joined the business at the start of May, has previously held leadership positions across the construction industry, spending the last six of his 23-year tenure at RMD Kwikform as its CEO/ Divisional Managing Director. During this time, he was responsible for all aspects of the business, including its 1,500 staff and operations in over 40 countries with a turnover of £200m. Prior to RMD Kwikform, Ian was the Commercial Services Director at Lafarge, serving on the Aggregates and Concrete UK Executive Board.

PERI is confident that Ian’s experience and knowledge of the industry will enable him to successfully lead the business towards its long-term goals.

CISRS and training centres to offer a series of summer subsidised courses

The UK Health Security Agency (UKHSA) has launched a new Heat-Health Alerting (HHA) service in partnership with the Met Office.

The new system will focus more specifically on the health impacts that high temperatures could have on the health of the population.

A dedicated platform for these alerts has gone live, including the current alert status for all regions of England. Any HHAs will contain the following information when issued:

• headline weather conditions expected in the coming days

• an outline of what impacts might be expected

• a brief overview of the regional impact assessment

• links to additional information, advice and guidance

During the core alerting season, which is in place between 1 June and 30 September, UKHSA and the Met Office will monitor the weather forecasts. Where episodes of hot weather are identified, a joint dynamic risk assessment will be carried out and the appropriate alert issued. Scan to find out more.

Minister for Industry and Economic Security, Nusrat Ghani MP, has joined industry leaders to launch a plan to eliminate the use of diesel from most UK construction sites.

Over the last year, representatives from across the industry have collaborated on the development of Zero Diesel Sites Route Map, a key element of the Construction Leadership Council’s CO2nstruct Zero programme to decarbonise the industry.

The launch took place on HS2’s Old Oak Common Station construction site, which is progressing towards cleaner construction as part of HS2’s target for all

its sites to be diesel-free by 2029. There are currently an estimated 300,000 items of Non-Road Mobile Machinery (NRMM) used by the UK construction sector. Typically, such plant is powered by diesel consuming 2.5 million tonnes of oil equivalent (Mtoe), generating significant carbon emissions.

The Zero Diesel Sites Route Map sets out practical measures to reduce this volume by 78 per cent by 2035, in line with the UK’s Sixth Carbon Budget published in 2021. Scan to find out more.

Cameron Hardy, Senior Cad Technician at Creator Scaffold Design, has taken on the National 3 Peaks challenge to raise suicide awareness and fundraise for the Samaritans.

Cameron and his friends took on the challenge which involves climbing the highest peak in each of Scotland (Ben Nevis - 1345m), England (Scafell Pike - 978m) and Wales (Yr Wyddfa - 1085m), on the 23rd of June. It involved 23 miles of walking, 6400m of altitude ascent/descent and 462 miles of driving, all within 24 hours.

Cameron stated:

“We chose to complete the National 3 Peaks as our fundraiser because the time we have spent in the outdoors as a group being able to talk freely about how we feel without judgement is something that has helped us through our struggles and we would now like to try and give it a bit back to others by helping raise awareness of this topic.”

The group successfully completed the challenge and have raised well over their target of £2000, but you can still donate via their Go Fund Me page by scanning here:

Creator are also celebrating their 10 year anniversary and have written a feature on how the industry has changed in those 10 years, you can read that on page 19.

FIND US INSIDE

ALL YOU NEED, WHEN YOU NEED IT.

In June 2019, the UK government legislated a Net Zero emissions target by 2050. Then in October 2021 the Net Zero Strategy was published with the intention of setting out a pathway to reaching that target – a legal obligation for the government to meet I might add.

So, what is Net Zero? According to the dictionary, Net Zero is ‘a target of completely negating the amount of greenhouse gases produced by human activity, to be achieved by reducing emissions and implementing methods of absorbing carbon dioxide from the atmosphere.’

It simplified terms, it’s the balance between greenhouse gases produced vs those taken out from the atmosphere.

In 2019, carbon emissions generated in the operation of buildings via the use of electricity and the burning of fossil fuels for heating and cooking (“operational” carbon emissions) accounted for 23% of total UK emissions.

An additional 7% of carbon emissions were “embodied” into buildings during the manufacturing and construction stages as a result of the energy used in those processes.

If you’ve not read the report, these few outtakes alone are enough to indicate the sheer scale of the challenge that we face, and they only relate to construction and buildings.

Think about all the other industry sectors and everyday activities that are going to need to change – and change quickly.

Afterall, 2050 is only 27 years away. Sounds like a long time but let’s go back 27 years to 1996. That was the year England crashed out of the European Championships thanks to the infamous penalty missed by Gareth Southgate. It was the same year that the Spice Girls released their debut album, and it was the last year of John Major’s reign as Prime Minister before Tony Blair took Labour to that landslide victory.

The point is, most, regardless of whether you’re into football, 90’s pop music or politics, will remember these things happening like they were yesterday – the same amount of time (27 years) which we now have to reach Net Zero.

While meaningful progress on decarbonisation in the construction industry still appears to be relatively slow, no doubt somewhat affected by the prevailing politico-economic forces over the past 12-months or so, it is becoming more widely accepted within the construction industry that the scale of the challenge requires a substantive update of UK regulation.

Take for example those embodied emissions I mentioned earlier - all the emissions created in producing construction materials. The absence of any regulations tackling embodied carbon leaves this sizeable source of carbon emissions uncontrolled.

So, back to my opening question – Where are we? The answer is, I’m not convinced anyone knows – at least with any degree of accuracy!

ROBERT CANDY CHIEF EXECUTIVE, SCAFFOLDING ASSOCIATION

According to a recent RICS’ report, Decarbonising UK Real Estate, the built environment accounts for around 30% of total annual carbon emissions in the UK.

Simplifying sustainability:

With 59% of businesses losing out on work because of poor environmental, social, and governance (ESG) credentials*, Scaffolding Association Partners, Citation, explains how to open a world of opportunities through a more sustainable business.

Sustainability isn’t just for bigger businesses. Increasingly, it’s becoming a sought-after credential for smaller businesses, especially when it comes to winning more work. It brings a whole host of benefits, too – and not just protecting the environment.

It can make your small business more resilient, more productive, help you retain your people, reduce accidents

and improve safety. But what do good ESG practices look like and how do you get started?

Having just created a new, free Sustainability Hub for their clients, Adrian Brine from award-winning HR and Health & Safety outsourcing company Citation, gives his top tips for building a more sustainable business.

According to the Institute of Occupational Safety and Health (IOSH), about two in five UK workers don’t trust that their employers have their safety and health in mind or are supportive of their physical and mental health.

There’s a strong correlation between employees feeling they aren’t looked after at work and not giving their best or feeling loyal toward their employers. That could be pretty devastating for business in light of the current recruitment challenges in the UK. So, consider these good-practice points:

Put the physical and mental health of your employees first by offering wellbeing programmes, flexible working arrangements, and building a supportive work environment. Encouraging a good work-life balance – whatever that may look like – can help productivity and performance skyrocket.

ESG and sustainability always boil down to doing things the right way, before all else. So from employee contracts and policies to people development and customer relations, having clear processes and procedures that your whole business engages with is a top priority.

You’re responsible for making sure your people, customers, stakeholders, and anyone else who interacts with your business is safe. So don’t cut corners. From risk assessing all your activities to investigating incidents, doing things by the book helps you save money and protect your people.

According to The Guardian, businesses could see a 33% reduction in energy costs from sustainability initiatives, and the Environmental Protection Agency has found you could reduce waste by up to 50% from efficient recycling initiatives. Sustainability isn’t just good for the planet - it can also improve efficiency, reduce operating costs, lower risk, give you access to more opportunities for growth (clients and investors like a green business), and make you more resilient. Consider:

A study by The Carbon Trust found that UK workplaces could save more than £300 million per year if they educated and engaged employees on the benefits of energy efficiency. Engaging them with your goals can help you find smart solutions, get champions to lead the sustainability cause in your business, and improve retention and productivity.

Reducing waste in all forms is so important. That’s everything from cutting paper and packaging use to reducing food waste, and can be achieved with clear policies and processes. Recycling and reusing materials can also help you boost those green credentials, as well as using greener materials.

You may not have employees jet-setting across the world on a regular basis. But you can still be more sustainable as a small business by encouraging things like lift sharing, public transport, and raising awareness of greener transport options like electric vehicles and cycling.

Research by the World Business Council for Sustainable Development (WBCSD) has found that businesses that embrace sustainability can reduce their operating costs by up to 20%, and Forbes has found that sustainability initiatives increased productivity for businesses by 20%.

Good ESG processes just make good business sense – it’s that simple, really. Introducing sustainability into your day-today operations doesn’t just reduce your environmental and social impact, but also can help you secure that ever-important competitive advantage over your business rivals by reducing costs, driving continuous improvement, and boosting your reputation.

How do you make sure it’s clear to everyone – from regulators and stakeholders to clients and employees – what your business is about? Clear policies and procedures. From waste management to data processing, strong and clearly communicated paperwork keeps everyone on the same page.

Too many businesses get complacent when it comes to regularly reviewing and monitoring risks – and that leads to costly accidents, reputation damage, and poor employee engagement. So don’t take that risk – make sure you’re constantly assessing all your work activities and environments.

Taking a step back and engaging your employees to help spot any opportunities to cut your resource use and waste is a smart way forward. Think energy-efficient technologies, strict waste management processes, and quality or environmental management systems like ISO 9001 and 14001.

Interested in taking your first step towards better environmental performance? Download Citation’s FREE ISO 14001 checklist to see how easily you can get started with the Standard – Scaffolding Association members can even get preferential rates, when you work with them for your business compliance and growth needs!

And if you’re interested in support with creating a more sustainable business through great HR and Health & Safety, just give them a call on 0345 844 1111.

Scan to download your free guide

*Source: DWF

THE LOW WEIGHT

HIGH STRENGTH

MULTIFUNCTIONAL SOLUTION

In recent years, the global construction industry has experienced a significant shift towards sustainable practices, driven by growing concerns about environmental impact and the need to combat climate change.

In response to this pressing issue, construction companies and clients are increasingly incorporating green credentials clauses into their contracts. These clauses outline specific sustainability requirements and expectations, creating a legal framework that promotes eco-friendly construction practices and encourages the adoption of green technologies.

The rise of green credentials clauses:

The inclusion of green credentials clauses in construction contracts signifies a profound shift in the industry’s approach to sustainability. Previously, environmental considerations were often treated as optional or secondary concerns. However, with mounting evidence of the environmental impact of construction activities, both public and private entities have recognised the need for change.

Green credentials clauses are contractual provisions that establish sustainability targets, standards, and commitments to be met during the construction process. These clauses typically cover a range of environmental factors, such as energy efficiency, waste reduction, use of ecofriendly materials, and adherence to relevant environmental regulations.

Benefits of green credentials clauses:

1. Environmental impact mitigation: By incorporating green credentials clauses, construction contracts have the potential to minimise the environmental footprint of construction projects. These clauses encourage the use of renewable energy sources, energy-efficient designs, sustainable materials, and responsible waste management practices. Consequently,

they contribute to reduced carbon emissions, conservation of natural resources, and the preservation of ecosystems.

2 Market differentiation and reputation: Construction companies that prioritise sustainability and adopt green practices gain a competitive edge in the industry. Demonstrating a commitment to environmental responsibility through green credentials clauses can enhance a company’s reputation, attract environmentally conscious clients, and open up new business opportunities. Clients, investors, and stakeholders increasingly value organisations that actively contribute to sustainability objectives.

3. Future-proofing investments: Incorporating green credentials clauses future-proofs construction projects by considering long-term sustainability. Buildings and infrastructure developed with a focus on energy efficiency and environmental performance are more likely to comply with evolving regulations and meet the expectations of future occupants. This proactive approach ensures that projects remain viable, adaptable, and resilient in the face of changing environmental standards and market demands.

Challenges and considerations:

While the adoption of green credentials clauses in construction contracts is a positive step towards sustainable development, several challenges must be addressed:

1. Practical implementation: Clear definitions, standards, and metrics are essential to ensure the effective implementation and evaluation of

green credentials clauses. Industry-wide collaboration and the establishment of recognised frameworks can facilitate consistent application and assessment of sustainability practices.

2. Cost implications: The integration of sustainable technologies and materials may initially result in higher construction costs. However, long-term savings can be achieved through reduced energy consumption, lower maintenance expenses, and improved occupant satisfaction. Proper cost-benefit analyses and financial incentives can help mitigate these initial investment concerns.

3. Contractual risk management: Green credentials clauses should be carefully drafted to allocate responsibilities, set realistic targets, and establish mechanisms for monitoring and verification. Parties must consider potential risks, liabilities, and dispute resolution mechanisms related to sustainability commitments. Green credentials clauses are playing an increasingly pivotal role in construction contracts, fostering a more sustainable and environmentally responsible approach to building projects. By formalising sustainability commitments and requirements, these clauses promote the adoption of eco-friendly practices, reduce environmental impact, and enhance the industry’s overall green credentials. With growing awareness of the urgency to combat climate change, the integration of green credentials clauses in construction contracts represents a significant step towards a more sustainable future.

More: www.holmes-hills.co.uk

As an industry-leading provider for scaffolding and construction safety products, TRAD UK has always championed innovation. Our extensive range sets new standards for access equipment and safety systems.

Our efficiency and safety is matched by the highest levels of service delivered by our experienced team and nationwide support network of depots. So it’s easier than ever to find the right solution for your project.

TRAD Safety Deck

ALTRIX Roof System

Catch Fan

PLETTAC METRIX

Lift Shaft Gate

Fabrication

It is becoming increasingly important for scaffold companies to prioritise carbon neutrality. Not only does it contribute to protecting our planet for future generations, but it also aligns with legal and economic requirements. By becoming carbon neutral, scaffold companies can meet contractor expectations, reduce energy use and costs, minimise material waste, and significantly reduce their carbon footprint. Here are five steps scaffold companies can take to achieve carbon neutrality.

1 2 3 4

Embrace renewable energy:

Transitioning to renewable energy sources is a fundamental step towards carbon neutrality. Companies should consider changing their electricity supplier to a renewable energy provider. Many large energy companies now offer sustainable energy options as their core provision. By making this switch, companies can reduce their reliance on fossil fuels and significantly decrease their carbon emissions.

Implement waste reduction policies:

Developing a waste reduction policy is essential for companies aiming to become carbon neutral. Instead of solely relying on recycling, companies should focus on reducing overall usage, this includes minimising paper consumption and plastic usage. Embrace digitalisation by implementing electronic invoicing and digital scaffold inspections to reduce paper waste. Explore recycling schemes for materials such as timber and even hard hats to ensure responsible waste management.

Optimise fleet and logistics:

Efficient fleet and logistics management can contribute to carbon neutrality. Companies should prioritise detailed journey planning to optimise routes and minimise fuel consumption. Consider using speed limiters on vehicles to promote fuel efficiency. Furthermore, switching to a fuel supplier that offers 100% carbon offset options can further reduce emissions. Implementing vehicle replacement strategies with low-carbon alternatives can also contribute to carbon neutrality goals.

Foster an environmentally conscious culture:

To achieve carbon neutrality, companies must cultivate a culture of environmental responsibility among their workforce. Provide training and awareness campaigns to educate employees about the importance of environmental protection. Encourage staff to suggest innovative ideas and foster engagement. Additionally, prioritise local labour for projects whenever possible to minimise carbon emissions associated with transportation.

Source sustainable materials and operations practices:

Scaffold companies should evaluate their material choices and operational practices. Consider sustainable alternatives for hired-in plant equipment, such as HVO (Hydrotreated Vegetable Oil) or electric vehicles (EVs). Explore current recycling and disposal policies, aiming to send waste materials for recycling rather than incineration. Extend the lifespan of components through increased servicing and maintenance schedules, reducing the need for replacements and minimising waste.

Conclusion:

By following these five steps, companies can make significant progress towards carbon neutrality. Actively pursuing carbon neutrality not only benefits the environment but also enhances business efficiency and reduces costs. Start your journey to carbon neutrality today and be a leader in the construction industry’s transition towards a sustainable future.

Two Members of the Scaffolding Association, Double Scaffold Design Limited (Associate Members) and Another Level Scaffolding Limited (Assessed Members), have combined their expertise to help facilitate complex demolition project at the Royal Victoria Dock, London.

The Millennium Mill, a derelict 20thcentury flour mill in West Silvertown, London, is undergoing a major renovation as part of a £3.5 billion redevelopment of Silvertown. Rhodar Industrial Services Ltd, a renowned demolition company, has been contracted to demolish the former Rank Hovis Premier Mill, situated in the heart of the London Docklands. The building will be demolished in 3 phases over a 10-week period using traditional demolition methods and high reach machinery.

This complex demolition project required meticulous planning and innovative solutions to ensure the safety of the surrounding areas and the efficient execution of the task at hand. Double Scaffold Design were instructed to design a scaffold that would act as a protection screen to prevent falling debris entering London’s prestigious Royal Victoria Dock during structural demolition activities. An innovative and complex design was required, Ben King, Divisional Manager & Design Engineer at Double explained the comprehensive scaffolding solution they formulated:

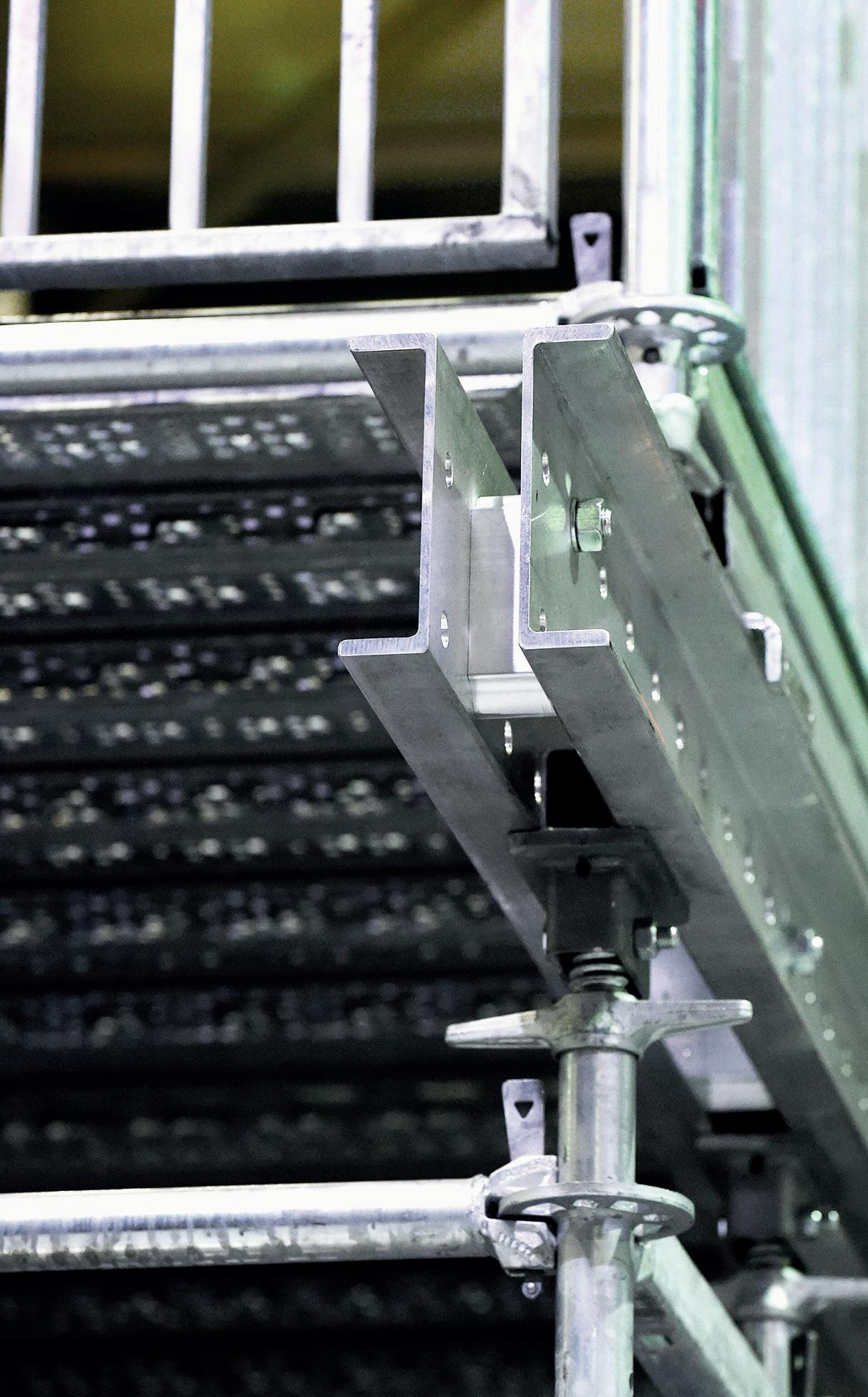

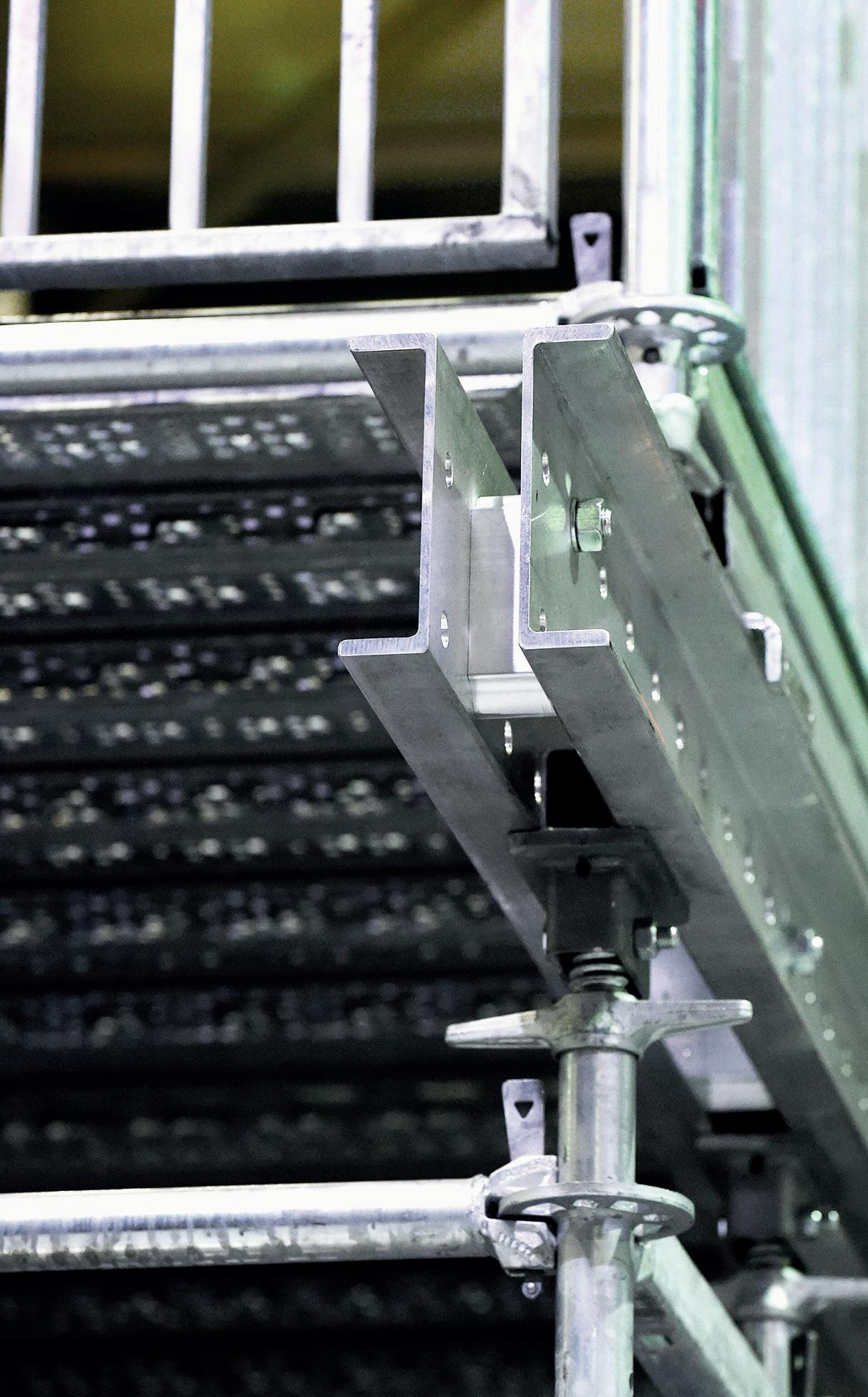

“Aluminium X beams were needled out of the building to allow a scaffold to be punched up and provide a screen. Due to the demo sequencing the scaffold had to remain 3m above the building line which meant the scaffold was designed to have 6.0m of untied scaffold above top tie.

However, we were having some trouble with the amount of untied scaffold above the last tie when a floor was removed. We were currently tied in at floor levels however to minimise the amount of untied scaffold we explored the option to tie into columns and whether it was feasible to box tie to the columns when the floor above was removed.

Structural engineering company, Perega, suggesting bracing into the building however upon inspection the floor timbers were discovered to be in a state of disarray and unsuitable. However, it was confirmed that the tie loads were acceptable below the floor beam/pattress location.”

It was not just the nature of the works to be undertaken and the condition of the building that required careful consideration, the exposed location of the old Mill also created additional challenges, as Ben remarked:

“We assessed using structural analysis to account for the cantilever effect of sheeted scaffolding above top tied level, allowing us to ensure the scaffold frame was capable of withstanding the wind loads imposed. To provide an economical design, we investigated wind directions and local topography to minimise equipment requirements, which was particularly worthwhile in this location with such high wind exposure.”

Ben detailed a number of the solutions that they used to overcome the challenges of this project:

• Tying through windows

• Reducing amount of untied scaffold above top tie and installing sheeting up to handrail height.

• Ensuring components were capable of managing the maximum wind loading, bracing was required with supplementary couplers and upright splices needed 2No. couplers per joint.

• X beams were required to cantilever out the building and bridge between supports.

• The uplift at the rear of the cantilever was managed by anchoring to the ground using tie bars with M12 Excalibur bolts.

Once the design was complete, a pontoon was installed to allow easy erection of the scaffold and provide protection to the river, and the project was a huge success.

UK System Scaffold Hire Ltd (UKSSH) and J Gunn Scaffolding Limited (which was working for the principal contractor Colt Construction Limited), collaborated to create an innovative rolling roof using Haki systems to overcome challenges to provide weather protection for major maintenance works to be carried out at National Rail’s depot in Crewe.

The two Scaffolding Association Members, UKSSH (Associate Members) and J Gunn (Audited Members) joined forces to come up with a solution to a complicated problem.

When UKSSH and J Gunn initially received the brief to provide a temporary roof for renovation works for National Rail, it soon became apparent that they were going to have to come up with a unique solution, Gary Griffiths, MD at UKSSH explained:

“It is over 130 years since the battle between George Stephenson and Isambard Kingdom Brunel to establish a standard gauge between the rails across the UK was finally settled.

However, not even the visionary rail pioneers could foresee how modern scaffold solutions would evolve, so it’s no surprise that when it comes to renovating and maintaining the buildings that our Victorian predecessors designed to provide the necessary infrastructure, the challenges are far from standard.”

Gary described the first challenge that they had to overcome:

“There is permanent racking on one side of the building that prevented the construction of a “standard” (1235mm) width roof support along one elevation, while a pedestrian walkway along the opposite wall necessitated a wider support than usual on that side of the building.”

However, this was not the only feature of the building that required consideration, Gary continued:

“There were inconsistent distances between roller shutter doors along the side of the building which meant that each scaffolding bay had to be carefully calculated – each to a different width – to ensure unhindered access to the doors while the renovation work progressed.”

However, this was not the only innovative solution UKSSH and J Gunn came up with, Gary continued:

“The design of the 24-metre-wide x 15-metre-long roof featured a 22-degree pitch – an innovation which meant that the support scaffold for the rolling track along each side of the 88-metre long building could be one lift less than would be required for a (more usual) 15-degree pitch roof.”

By working together, UKSSH and J Gunn rose to the challenge and successfully delivered the project on time and on budget.

Jon Gunn, MD of J Gunn Scaffolding, commented:

“This was the latest collaboration between ourselves and UKSSH, just like us, the team at UKSSH has years of experience in working on Network Rail projects, so the commercial, technical and health and safety requirements are second nature to them – it’s part of their DNA.

UKSSH proved that the system scaffold of Associate Members of the Scaffolding Association, Haki, were more than up to the complex task, Gary commented:

“Working with J Gunn, we designed a 770mm wide support scaffold with a 2 board cantilever above the permanent racking and a 1.9 metre support scaffold above the pedestrian walkway.”

Their commitment to delivering on time and on budget is equally impressive; UKSSH has the same “can do” attitude as us and always want to achieve the same goals – it is a “one team” approach that pays dividends.”

Gary concluded:

“This is just the latest of a number of successful projects with Jon and his team and typifies the benefits of working with like minded individuals who place an emphasis on safety and quality”.

More: www.ukssh.co.uk

www.jgunnscaffolding.co.uk

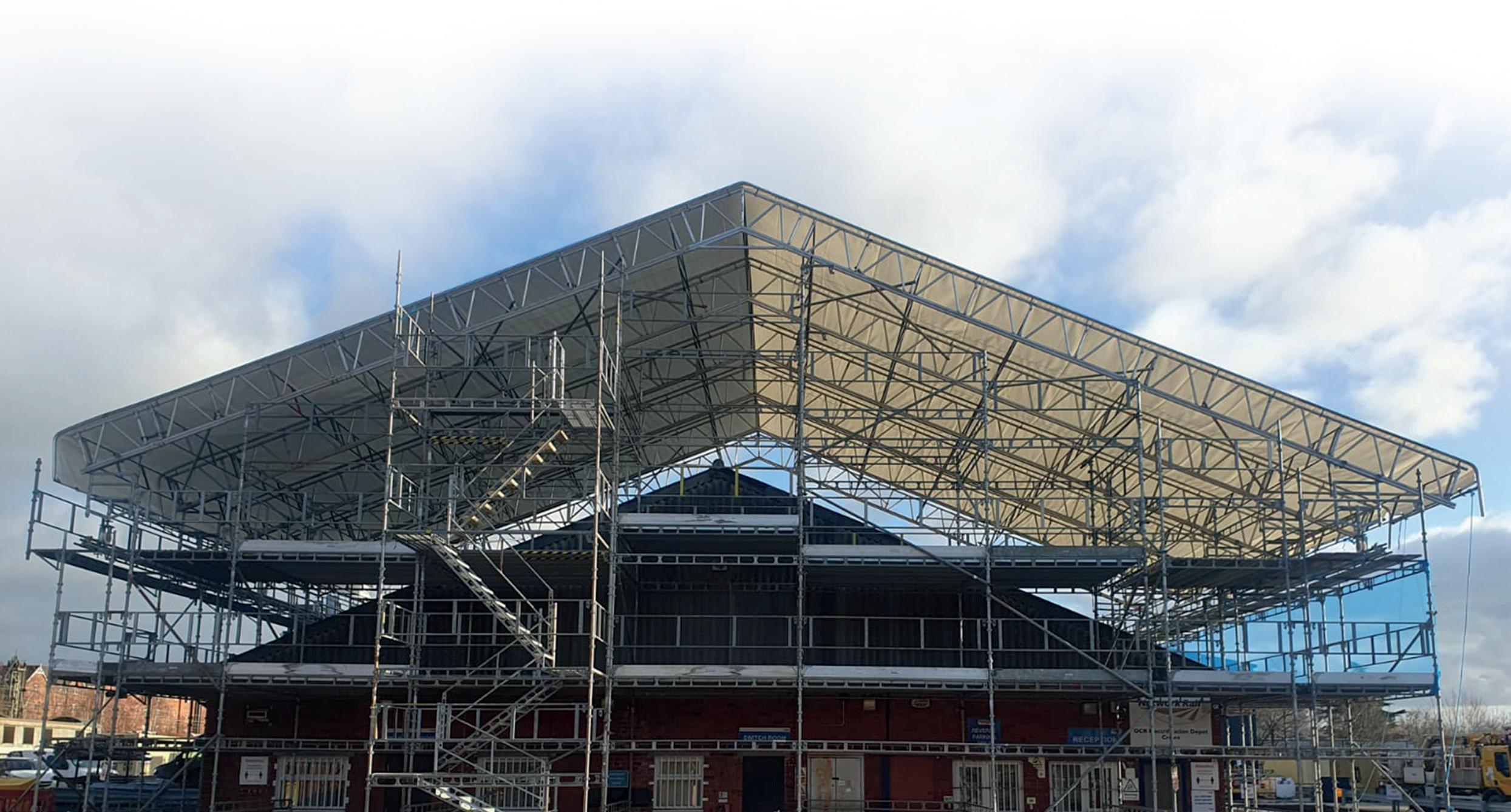

The Skinners’ Hall building is an Ancient Scheduled Monument that is protected by Historic England and legislation, now currently undergoing a multi-millionpound renovation. The project started in May 2022 and is expected to run for approximately 24 months. To aid the works ICS were tasked with providing a myriad of complex scaffolding solutions.

ICS tendered for the project alongside their valued client Rooff, Ben Ramsey, Director from ICS explained how they became the successful bidder on the contract:

“What made us different was our recognition that the scheme was logistically challenged and required a different approach from conventional schemes. Working with Rooff, we proposed a detailed scheme in principle, complete with full 3D modelling and aerial route path for lifting apparatus, which provided an alternative from the traditional logistical approach provided that had negative conservation and environmental impact, and ultimately value engineered what has become the cost-effective working model and scheme awarded to us and our client.”

This was a complicated project that had a list of unique challenges to overcome.

Firstly, Skinners’ Hall is a profound building with great historic importance, Ben from ICS explained further the impact this has:

“The Skinners’ Hall is a Grade I Listed building and Ancient Scheduled Monument, meaning all constructionstyle works must be approved before taking place. A detailed request is required to be submitted to Historic England, which is sent to a Sectary of State for approval. We were wholly aware of the reduced options presented in loading, tie, and stability options achievable from the building, along with reduction in manufacture and delivery constraints relating to water and fire damage. ICS prepared in depth tie,

stability and design capability analysis and mitigation, along with in depth procedural documents which were presented and then approved after conjoined review. Some elements were overturned, such as provision of external clad heat shrink wrap, even after expansive information provision, many meetings and procedural review which could have benefited the weather and moisture protection elements, it was deemed a non-starter for protection of the Scheduled Ancient Monument ”

One of the fundamental elements to this project was the stipulation that there was to be minimal reliance on the building as a supporting structure whilst providing complex canopied weather protection, meaning ICS had to take an innovative approach to erect the scaffolding.

It was a complicated project that required a number of Stakeholders to work closely together, this included two members of the Scaffolding Association: HAKI Limited and Prime Scaffold and Structural Designs Limited (PSD). Ben explained how the process worked:

“HAKI worked closely with ICS from the beginning to end, as one of the project key suppliers they provided early engineering support in achieving what could be utilised from their shop floor, to achieve the contract award. HAKI then worked in synergy with ICS and PSD, to provide supplier assistance on the design, procurement, training, and delivery of the scheme.”

Ben continued:

“The design process was one of the most complex to conceive, onboard and manage for all, with a completely non-standard scaffold roofing challenge that not only had to stand alone in its primary function with minimal building support, then suspending a complex pneumatic undercarriage of continuous 1 Tonne SWL NIKO Track runway system; serving all the projects lifting requirements.

The concept model, design and delivery pushed the boundaries of what is considered both normal and achievable on a scaffolding project, especially where it interfaced and served a Grade 1 Listed structure.”

Skinners’ Hall project key metrics

• 1380m2 Plan of HAKI System 750 AL Roofs

• Foundation and support scaffolds below roofs covering 8500m3, weighing approximately 250 Tonnes

• 2000m2 of timber decking, based on 3700m of scaffolding lifts

• 28,000m of scaffolding tubes

• 30,000 Scaffolding Couplers

• 1500m of Aluminium Beams

• Approx. 100m network of Type 27.00

Niko Aerial Runway System, including high end pneumatic switches

Fundamentally, the safety of the building was paramount throughout, which meant some innovative solutions were required:

“Protection from the elements is key within this scheme, therefore bespoke systemised guttering was produced along with large scale complex temporary roofing and lifting structures, which both repel and collect rainwater, transporting it to a series of prescribed watercourse outlets, preserving the exposed parts of the building during the works cycle.”

One of the key features that sets this project apart is the multi-point continuous 1-Tonne SWL lifting structure, Ben explained:

“Due to the size of the building and complexity of the project, a bespoke 1-Tonne SWL lifting structure was conceived and installed. This enabled

materials to be transported without compromising the integrity of the monument or safety of workers on site. This is approximately 100M worth of network, with pneumatic switches all suspended from engineered combinations of roofing structures.”

The project has been a huge success and has even resulted in ICS, working in collaboration with Rooff, being awarded the City of London ‘Gold Award’ under the Considerate Contractors Scheme (CCS).

Ben concluded:

“ICS are proud to be at the forefront of innovative solutions as a key provider on the scheme. In recognition, special thanks go to the Inner City whole delivery team, our key clients at Rooff, and the Skinners’ Company.”

The concept model, design and delivery pushed the boundaries of what is considered both normal and achievable on a scaffolding project, especially where it interfaced and served a Grade 1 Listed structure.”

Ben Ramsey, Director from ICS

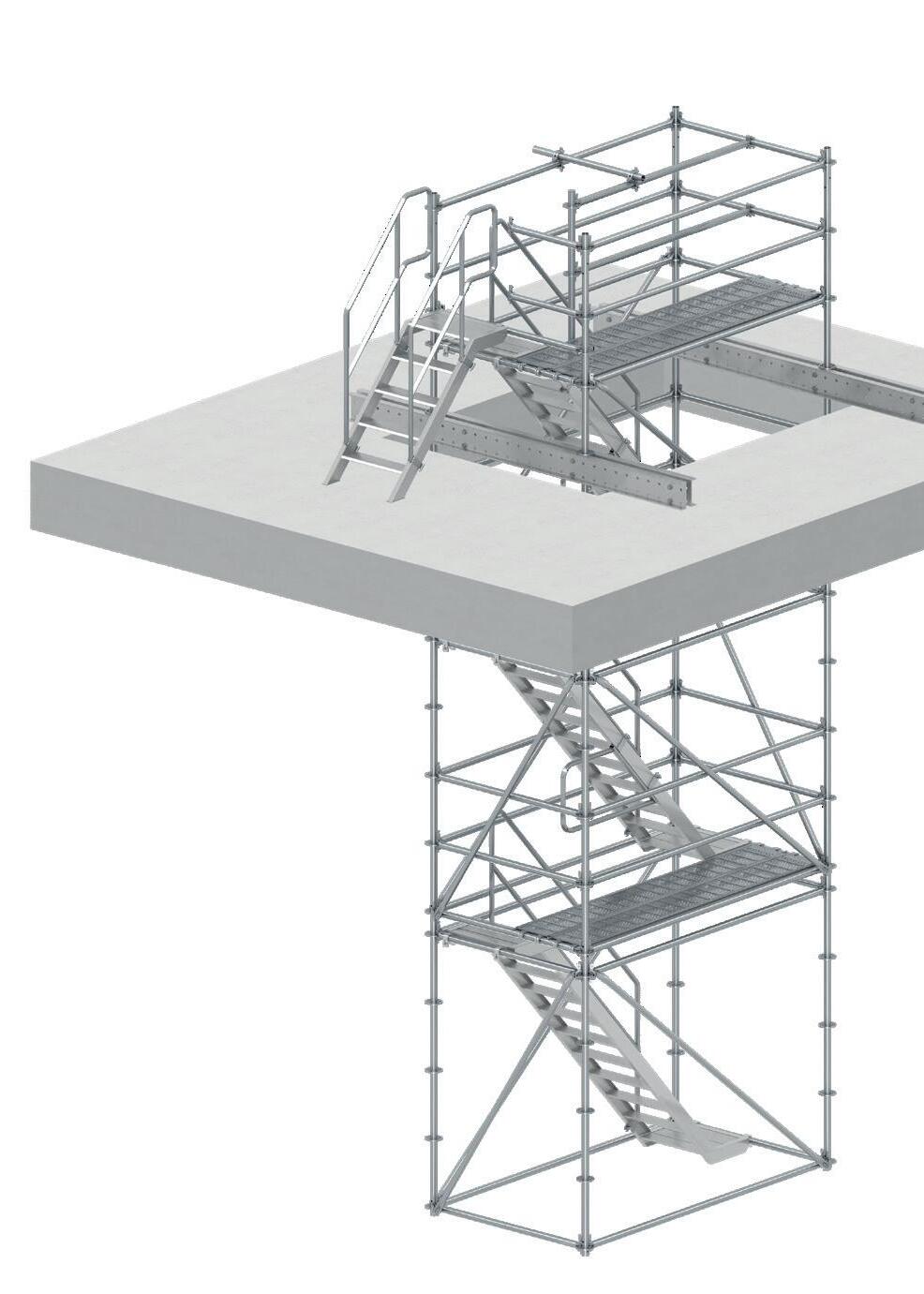

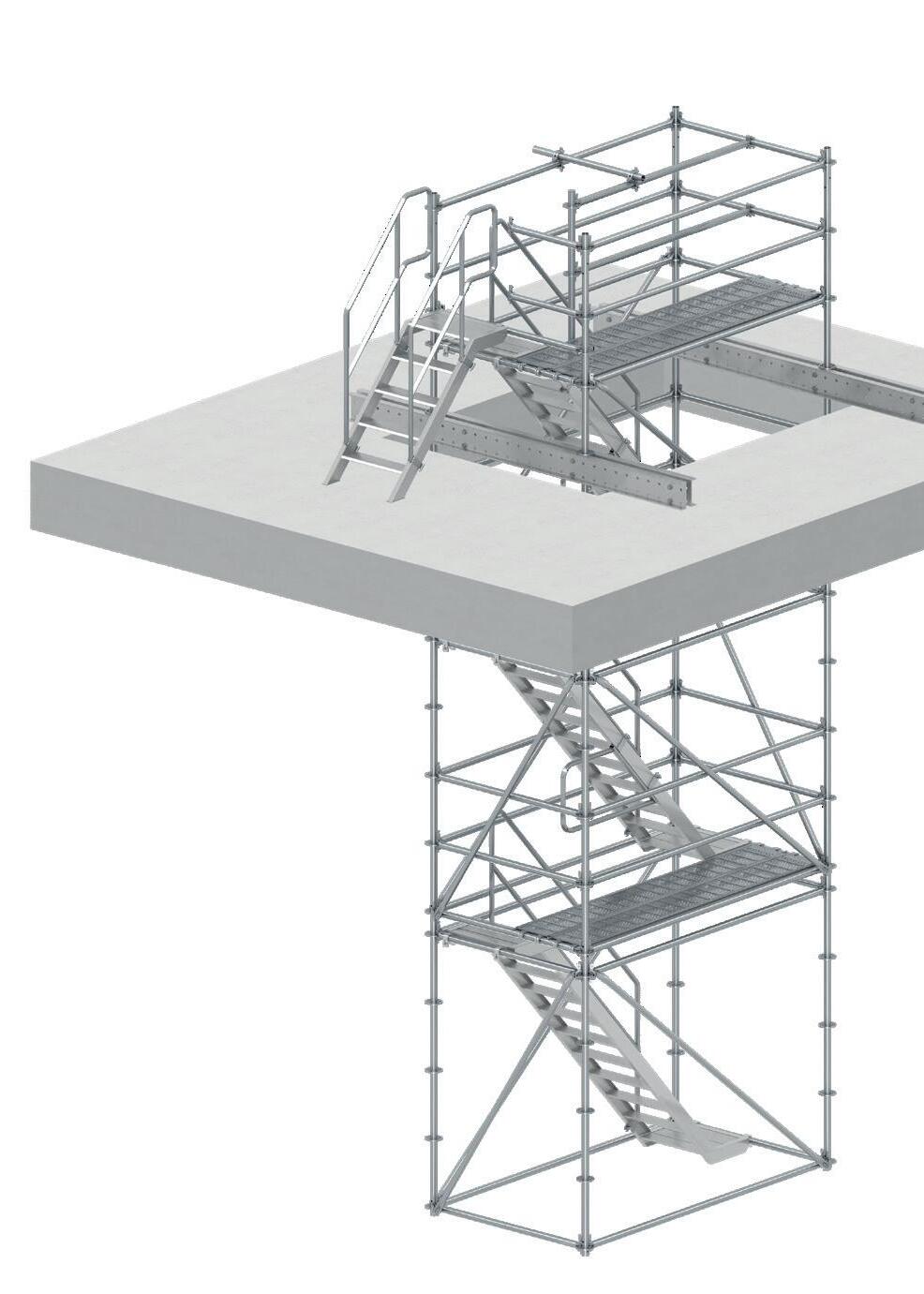

Skill Scaffolding has completed a challenging project at Grosvenor House in Basingstoke, thanks to the world’s leading scaffolding system, Layher.

Southampton-based Skill Scaffolding has recently completed a successful elevenstorey high-rise project at Grosvenor House in Basingstoke, thanks in part to the use of the Layher Allround System.

The project was commissioned by Arena Business Centres, a company that regenerates older buildings, giving them a new lease of life and converting them into modern serviced office spaces. The company manages everything in-house rather than employing a main contractor. It plans to turn the formerly abandoned building into 56,000 square feet of exceptional flexible office space.

According to James Wall, Business Development Manager at Skill Scaffolding, the scaffolding project began in June 2022 and presented two significant challenges. He said:

“The first was managing the scaffold leg loads imposed on a floating concrete slab that had lower loading capabilities than what the scaffold leg loads would impose.

In collaboration with Layher UK, we quickly devised a propping solution to support the slab from beneath, enabling forklifts to move freely and material storage above ground. We also propped the entire surrounding area to ensure safety and stability.”

The second challenge was keeping one corner of the building free of scaffolding from the ground level to approximately the 2nd/3rd floor (8-10m from the ground) to allow for a new build extension planned for a large open reception/foyer area.”

Skill Scaffolding worked closely with Layher UK’s expert design team and the client’s engineers to devise a solution that worked for all parties.

Giant prefabricated steel “goalposts” were installed by the client across this corner section, from which Skill Scaffolding based out their scaffold. This kept the entire corner free for ground-level new build works while still allowing full façade access above for remediation works.

Throughout the project, Skill Scaffolding relied heavily on the Layher Allround System, which offered several benefits. The system was easy and quick to erect, which helped to speed up the project timeline. It also provided superior safety and ease of inspection, making it easier for Skill Scaffolding to identify and address issues quickly. Additionally, the system offered clear walkways on all

boarded lifts, with no ledger bracing, and the use of Layher’s gap decks helped avoid gaps between the inside deck and the main deck.

Skill Scaffolding had one gang of highly-skilled scaffolders on the job for most of the project’s lifespan, supported additionally by their cuttingedge KEWAZO Liftbot in parts. The successful completion of the project is a testament to the expertise and professionalism of Skill Scaffolding, as well as the quality and effectiveness of the Layher Allround System. Overall, the project at Grosvenor House in Basingstoke is an excellent example of how the right combination of skills and equipment can lead to a successful and efficient construction project. In conclusion, Skill Scaffolding’s successful project completion at Grosvenor House in Basingstoke highlights the importance of using the right equipment and collaborating effectively with clients and industry partners.

Sean Pike, Managing Director of Layher Ltd, UK said:

“The challenges faced during the project demonstrate Skill Scaffolding’s ability to think creatively and devise practical and effective solutions that meet the client’s needs while maintaining safety and stability”.

James Wall concluded:

“The successful use of the Layher Allround System also underscores the importance of investing in quality equipment that can save time, improve safety, and increase efficiency on construction sites”.

More:

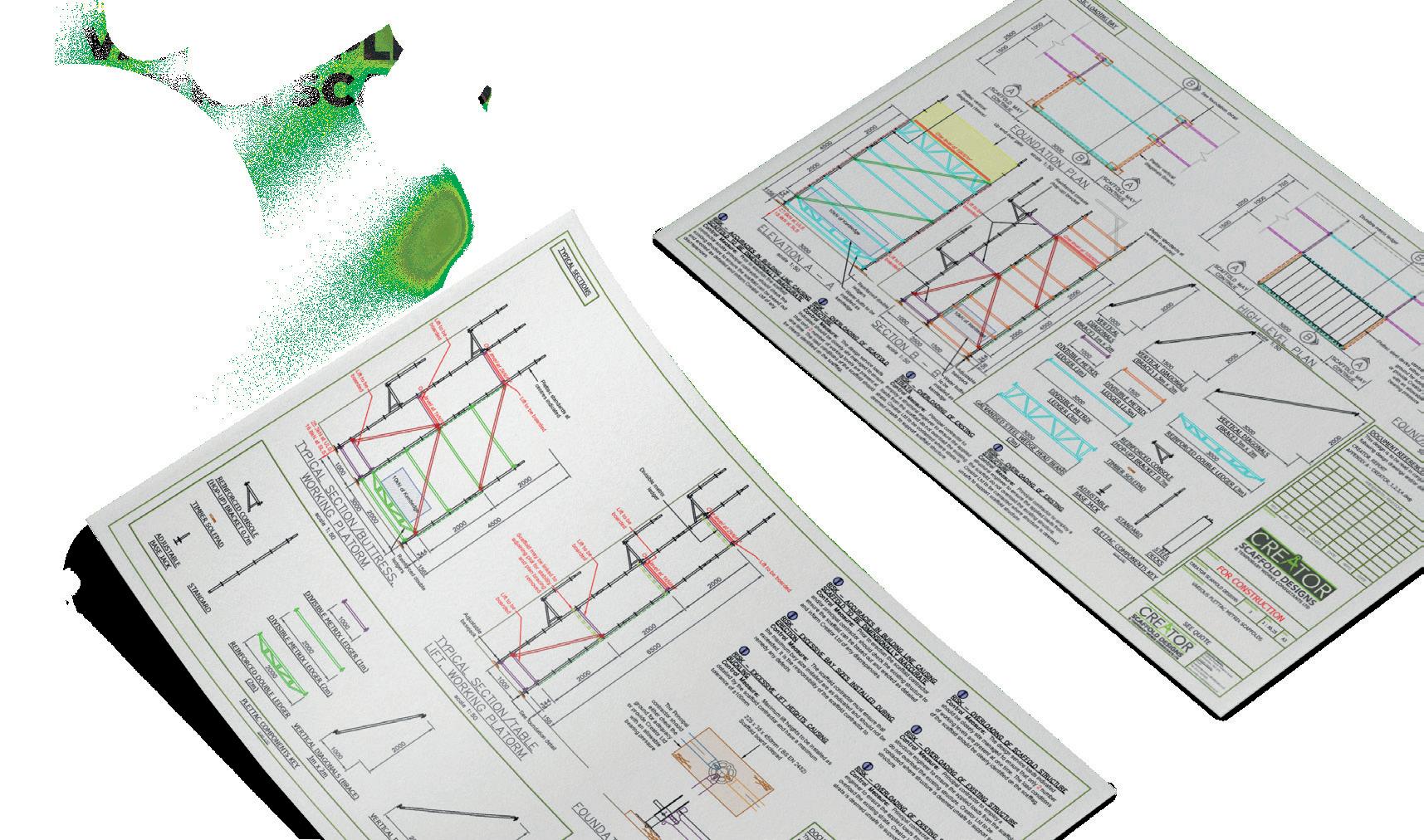

Founded by Ryan and Bradley Berry, former temporary works engineers, the company has grown from a humble cabin to a modern design office with a team of 15 and counting. In this article Creator reflects on the significant transformations that have occurred in scaffolding design over the past 10 years.

This emphasis on risk assessment has elevated safety and structural robustness in scaffolding projects. This industry-wide shift necessitates stringent checking procedures, both contractually and in engineering, to ensure suitable, practicable, and economical design solutions. Adhering to these requirements

Ryan explained:

“When entering the industry graduates can now build on their recent learning and hone their skills in an industry that would have usually dictated they started again and learned what they had been told was no longer relevant.”

Ryan concluded:

Traditionally, scaffolding and temporary works relied on permissible stress design based on older British Standards. However, the industry gradually transitioned to the limit state design approach, following the release of BS EN 12811-1 in 2003. This change was driven by the need for more efficient and sustainable design solutions.

Ryan commented:

“It is this shift in design philosophy that inspired the inception of Creator. We have been successfully using this approach for the last 10 years and have demonstrated various benefits for its use. It was driven by the want to create efficiencies through design to benefit both economically and environmentally.”

Regulations like CDM 2015 and BS 5975 have led the industry to embrace a riskbased approach. Stringent checking procedures ensure design solutions are suitable, practicable, and economical.

is crucial for ensuring safety and robustness in scaffolding structures.

Ryan continued:

“All at Creator understand and appreciate the need for a safe and robust design. We have risen to this challenge and thrive upon it, producing detailed and accurate designs which have been appraised by some of the most stringent checking engineers around.”

The impact on the talent pool

Engineering courses began to cover limit state design and left permissible stress design behind, this expanded the talent pool entering the scaffolding industry.

Here at Creator we are an advocate of the limit state design approach and have proven that the shift is not only possible but successful. It is this change that we would invite others to follow and align themselves with permanent works engineers making the skill gap between the two sectors much shorter and the communication between the two simpler.

In the past, change has been forced by major incidents or technological advancements however the industry is growing naturally as more awareness and appreciation is given to it and this can only be a good thing. It shows there are no gaping flaws in how the sector practices. Complacency can soon put an end to that thought and this organic growth must continue.”

More: www.creator-scaffolddesigns.co.uk

The Road Haulage Association (RHA) is the only UK trade body with sole responsibility for the operators of commercial vehicles – trucks, coaches and vans. Therefore, it is their role as an industry sector representative to inform and collaborate with other key stakeholders as required, national, regional, local, commercial or private business etc. In this article the RHA discusses the greener future of industry transport.

Our members range from owner drivers to operators with fleets in excess of 1000 vehicles. However, the majority of our 8.5k membership are SMEs.

One of the key challenges that all businesses, regardless of sector, are currently facing is going green.

This is an area in which our sector has made significant progress. For example, the road freight sector has reduced its NOx emissions by 70% since 2013.

We all know that Net Zero is coming but what does the road map for achieving it look like? Right now, we don’t have one.

Government is committed to meeting its UK Net Zero commitments by 2050.

We know that by 2035, the sales of new diesel HGVs below 26 tonnes will stop and by 2040, the sale of all new HGVs, regardless of weight, will also stop.

However, we know that all types of vehicles and life-cycle costs need to be covered and that the timing of their introduction must be considered to avoid ‘stranded assets’.

There needs to be rigorous testing on vehicle capability, operation impact and changes in mindset.

In our view, the future for vehicles weighing under 18 tonnes will be electric. These are the vehicles we will see doing short-range duty cycles – typically, urban multi-drop or regional operations between distribution centres.

These will be the vehicles most often used by those working within the scaffolding industry.

Vehicles in this group are already appearing on the market, with our understanding of how they operate increasing on an almost daily basis.

However, for vehicles weighing over 18 tonnes, the jury is still out as to what the fuel of the future will be. That’s principally because there is no accepted technology that gives the required range or performance characteristics for all use-cases and, in particular, for long-distance journeys.

Time is now ticking to meet the Government’s phase-out dates and so, we are actively working through the issues that prevent the acquisition of zero emission HGVs and coaches at scale.

Broad issues preventing the acquisition of zero emission HGVs:

• Cost: Specifically, how the capital cost of zero emission vehicles can be brought down.

• Infrastructure: Ensuring that the means to power these vehicles is in place.

• Performance: Key if operators are to invest with confidence.

• Upskilling: Our workforces must be equipped with the abilities to maintain these vehicles.

• Mindset change: We are clear that the transition to Net Zero is transformative. It will affect every aspect of business operations –whether it be investing in depots and staff training to introduce these vehicles, through to the reporting of emissions-reduction to win contracts and satisfy regulatory obligations.

This is scary and high-risk stuff, particularly when our starting assumption is that the public will expect the same exceptional levels of service that they enjoy today to continue. So, the bar is set high, and the RHA is committed to guiding our members through the challenges that lie ahead.

In today’s world, no organisation can afford to stand on its own; to isolate its members. That is why collaboration is crucial. We want to ensure that the needs of small businesses are understood and supported. Small businesses do not have the buying power of larger corporations yet are integral to our economy in providing the highly specialised services that all of us rely on.

Collaboration will ensure that the journey to Net Zero succeeds.

More: www.rha.uk.net

There are Government grants available to provide small and medium sized businesses with funding to install electric vehicle charge points and relating supporting infrastructure for their staff and fleet vehicles.

In our view, the future for vehicles weighing under 18 tonnes will be electric. These are the vehicles we will see doing short-range duty cycles – typically, urban multi-drop or regional operations between distribution centres.”

eScaff is a new scaffold management software set to help the industry simplify project management with a one stop shop for

This simple to use software is set to revolutionise your organisation with everything you need stored and managed in one place. eScaff can be accessed remotely by all members of staff, meaning inspections can be done on site and update the office instantly, for example. It gives users the ability to see exactly where the business is at any moment.

With features including, but not limited to:

• Health and safety documentation

• Staff profiles with the ability to assign tasks

• Setting prices and quoting jobs

• Email details including handovers, inspections and RAMS to stakeholders, at a click of the button

• Complete vehicle management system

• Have a complete overview of live projects

• Complete inspections online

The system is flexible and can run on PC, Mac, Tablet, or iPhone/Android phones, you can even print everything out and keep the paperwork. eScaff offer a 30-day free trial and free training.

More: www.escaff.uk

Focus Factory’s Safe Step is a working platform that can be installed on hanging/suspended scaffolds to allow the user to stand in a place where there is no suitable and safe surface.

Safe step is an innovative product, ergonomically designed and built using only high quality and tough materials, introducing both safety and efficiency into your workplace.

Designed to reduce the risk of workplace accidents thanks to the anti-slip finish that is resistant to water, grease, and most chemical compounds.

Features

• Weight 4.5 kg

• Dimensions 40.0 x 30.0 x 16 cm

• Maximum load up to 250 kg

• Anti-slip finish

• Water and grease resistant

What’s more, once the system is installed, it can be easily ‘lifted and shifted’ to another work area without disassembly.

The unique minimal-parts design means the Safe Step can be installed and ready to start work in minutes, minimising the time you spend on-site and the costs that come with it.

More: www.focusfactory.co.uk/product/safe-step

Forgeco Limited’s range of Scotti Ties are unique, patented products that are designed to retain toe boards in a neat and safe fashion. These simple, but effective, fittings replace the need of ‘Deadmen’ to install toe boards as per industry standard.

There are four different Scotti Tie’s in the range:

• Ledger Tie

• Transom Tie

• System Transom Tie

• Aberdeen Tie

The Scotti Tie’s are significantly more efficient than the traditional solution, the 5 components (1x tube and 2x double fittings and 1x toe board fitting) required for ‘Deadmen’ can be replaced with just 1x Scotti Tie. This makes the easy-to-use Scotti Tie much more cost effective and reduces labour time considerably.

With the heaviest in the range weighing only 1.53kgs, Scotti Tie’s also significantly reduce manual handling, and they also take up a lot less space to transport/store.

More:

www.forgeco.co.uk/products/scotti

BIGBEN ScaffOil is a superior scaffolding lubricant and penetrating oil, specially formulated for the scaffolding industry to release clips and brackets leaving a long lasting lubrication.

ScaffOil has been formulated to remove rust, corrosion, grease and other contamination from scaffold fittings and screw threads.

BIGBEN has also ensured that the ingredients used for the blend come from trusted sustainable sources. These sources allow the ScaffOil to be created without the worry of depleting or damaging the Earth’s natural resources.

ScaffOil is also biodegradable and therefore avoids pollution, having been developed to easily decompose by bacteria/living organisms – limiting and avoiding any potential damage.

Key features of ScaffOil:

• ScaffOil will easily find ways into all the crevices that other penetrants fail to reach, bringing “dead” clips back to life

• ScaffOil does not dry and leaves a protective coating

• ScaffOil is extremely economical, requiring only a short spray to release even the most stubborn clips and brackets

• ScaffOil allows clips to be left out, even in severe weather conditions

• Safe and reliable

• Available in 210 ltr drums, 25 ltr drums and 5 ltr tubs

use ScaffOil

• ScaffOil can be used in any industry where a long lasting lubricant is required

• It will protect all metals from rust and corrosion

• ScaffOil can be sprayed in situ where applicable to release clips and fittings. It is also recommended to be used in a Dip Tank, immerse the parts to be released and leave to soak

Scan to find out more

All Scotti Tie’s meet the BS EN 12811-1 load requirements and can be used with Tube and Fit, System Scaffolds and ReadFix builds.