WELCOME

ROLL CALL FOR NEW SCAFFOLDING ASSOCIATION MEMBERS

A A A Scaffold Limited

0121 553 1611

Adl Scaffolding Limited www.adlscaffolding.co.uk 07929 515054

Any Day Scaffolding Limited 07375 549437

Austins Cradles (Eastbourne) Limited www.austinscradles.co.uk 01323 645544

Blackrow Group Limited www.blackrow.co.uk 01472 889200

Braintree Scaffolding Ltd www.braintreescaffoldingltd. co.uk 01245 377785

Chester Scaffolding Services www.chesterscaffoldingservices. co.uk 07921 523324

Diamond Scaffolding & Access Limited www.dsa-nw.co.uk 07724 717423

CONTACT US

Editorial

T: 0300 124 0470

E: info@accesspoint.org.uk

Advertising

T: 0300 124 0470

E: marketing@scaffolding-association.org

Scaffolding Association

T: 0300 124 0470

E: info@scaffolding-association.org www.scaffolding-association.org

Elev8 Scaffolding Ltd www.elev8scaffolding.co.uk 01253 963459

FPS (Bath) Ltd T/A First Point Scaffolding www.fps-scaffold.co.uk 07874 069346

G.A.D Scaffolding Limited www.gad-scaffolding.co.uk 07889 822038

High & Mighty Scaffold Limited www.highandmightyscaffold. com 01424 834400

IAC Scaffolding www.iacscaffolding.co.uk 020 8309 5476

JME Scaffolding Ltd www.jmescaffolding.co.uk 01271 445495

Kitts Scaffolding Limited www.kittsscaffolding.com 01883 337870

KTM Access Limited 07939 238520

Subscriptions

AccessPoint is distributed to members of the Scaffolding Association and other selected access and scaffolding businesses.

If you wish to receive a copy of AccessPoint or would like to amend or cancel your subscription, please call 0300 124 0470 or email info@scaffolding-association.org

Next Gen Scaffolding & Access Ltd www.nextgensa.co.uk 07957 613294

Royale Scaffolding Ltd www.royalescaffolding.com 07542 442591

S Scaffolding Limited 07545 787194

Safeway Scaffolding 01803 329099

Stone Cross Scaffolding Ltd 07866 856981

Top Tier Contracts Ltd T/A Top Tier Scaffolding www.toptierscaffolding.co.uk 07912 608311

Ultimate Construction Group Ltd www ultimateconstruction group.co.uk 07990 489130

Up North Scaffolding Ltd www.upnorthscaffolding.co.uk 07301 594720

AccessPoint is published on behalf of the Scaffolding Association. The views expressed in this journal are not necessarily those held by the Scaffolding Association. The Scaffolding Association shall not be under any liability in respect of the contents of the contributed articles. The Editor reserves the right to edit, abridge or alter articles for publication.

ISNN: 2055-2033 (Print)

© All editorial contents AccessPoint 2025 Printed by Tewkesbury Printing Company

Designed by Gladstone Design

Vertex Scaffolding Solutions Ltd

www.vertexscaffolding.co.uk 07859 417742

Viking Scaffolding (South East) Limited

www.viking-scaffolding.com 01634 827094

Hermeq UK Limited www.hermeq.com/uk/en 0800 043 2520

MEMBER SUPPLIER MEMBER SERVICE PR0VIDER

Ensise Ltd www.ensise.com 07712 743348

NETA Training www.neta.co.uk 01642 616936

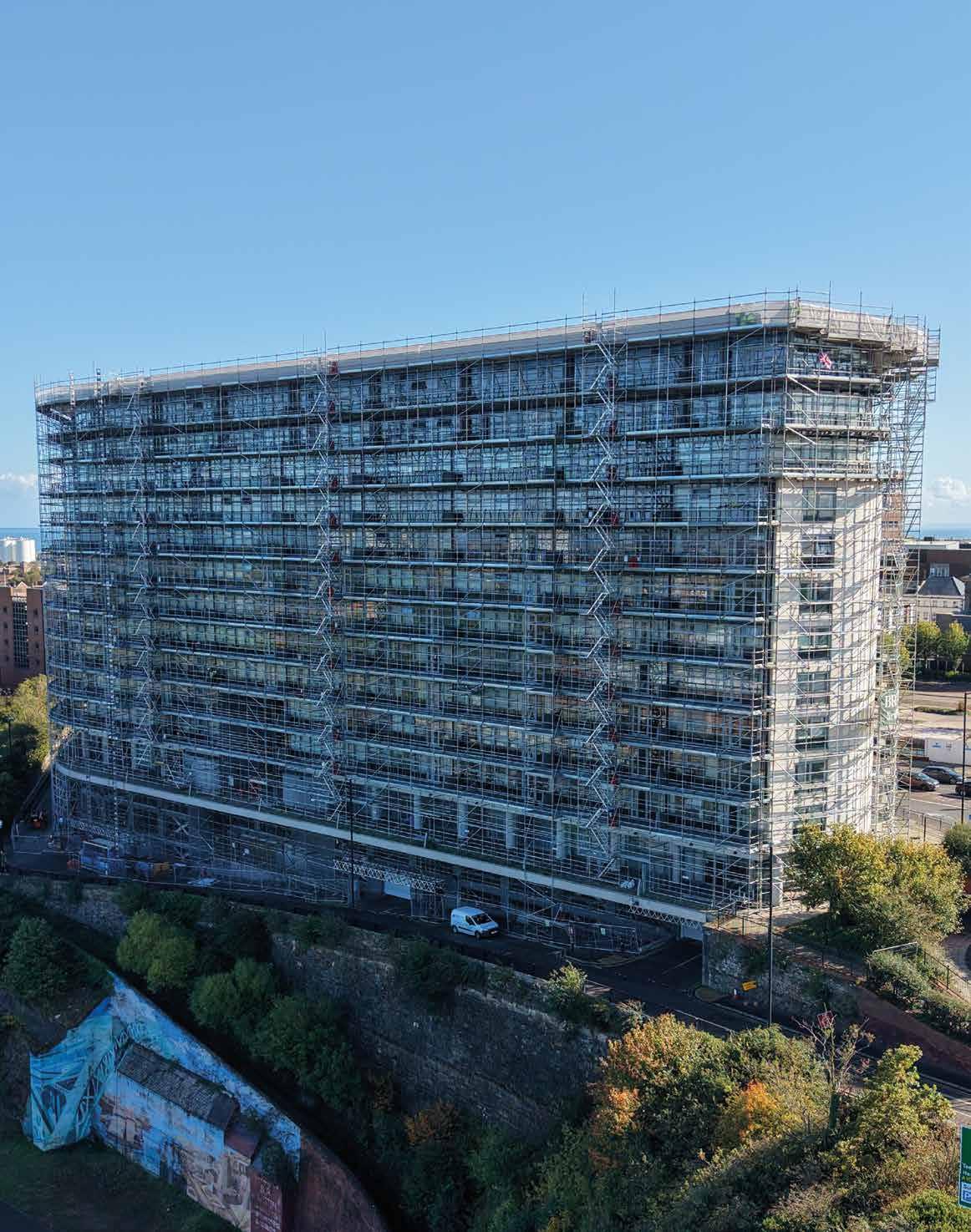

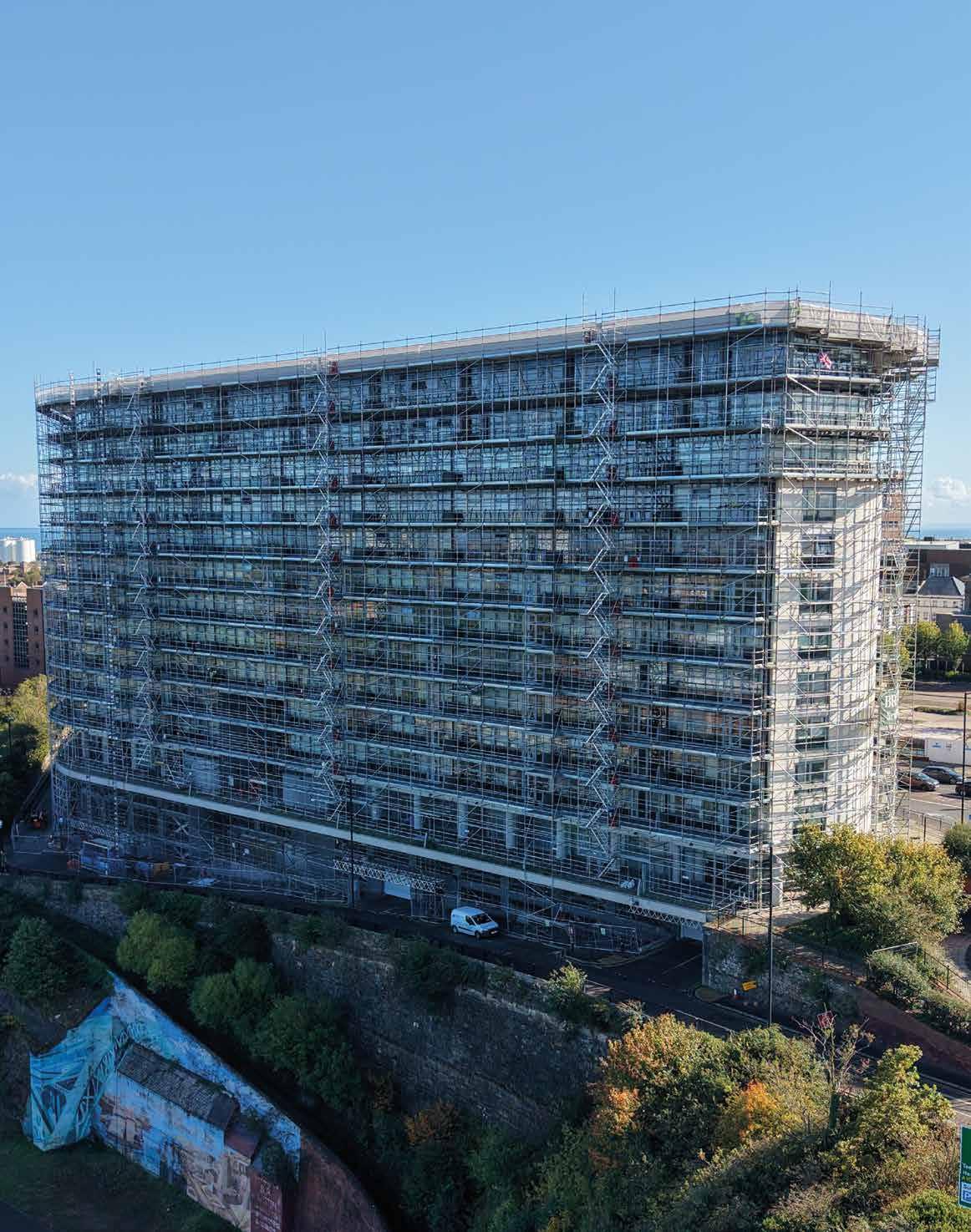

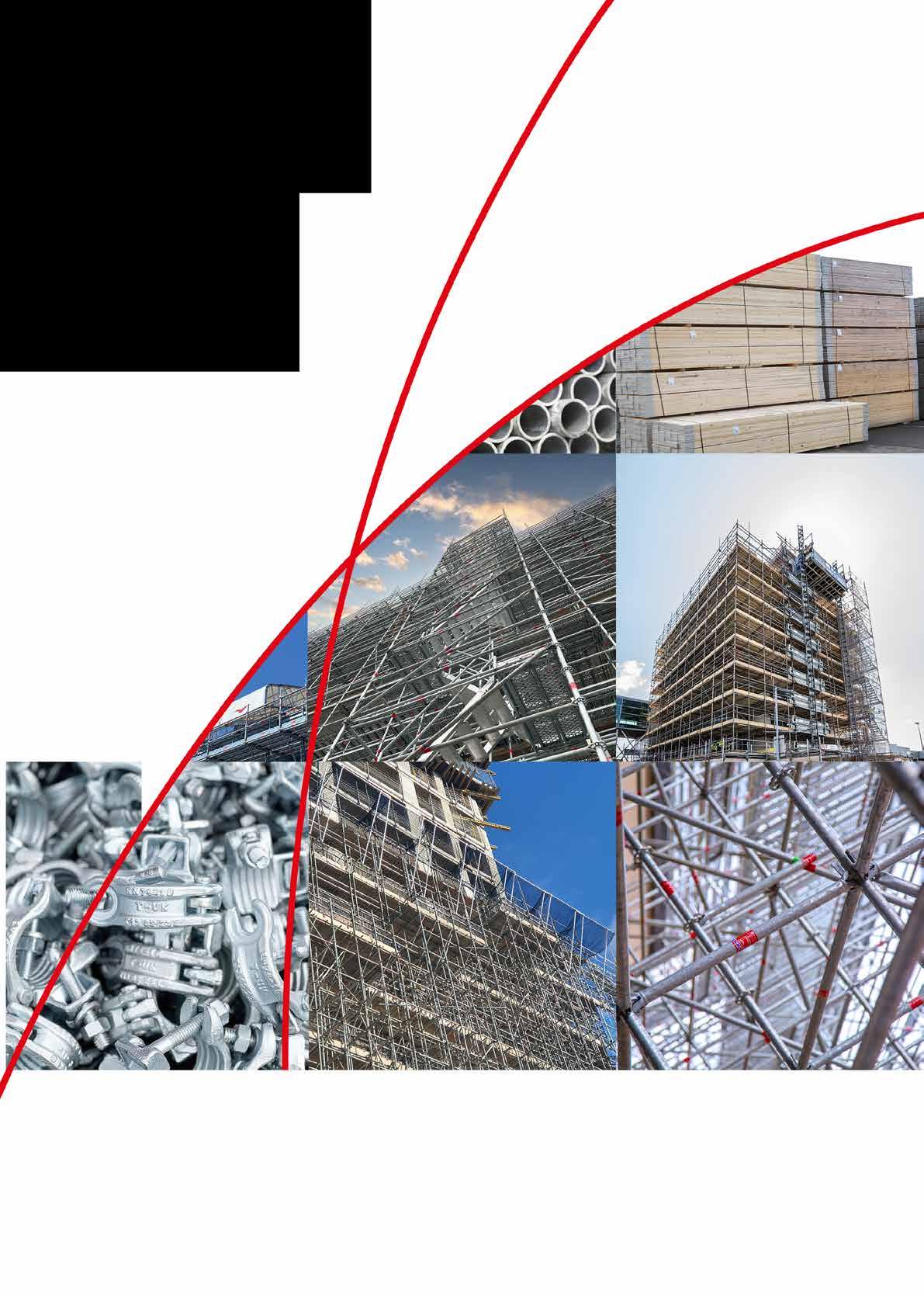

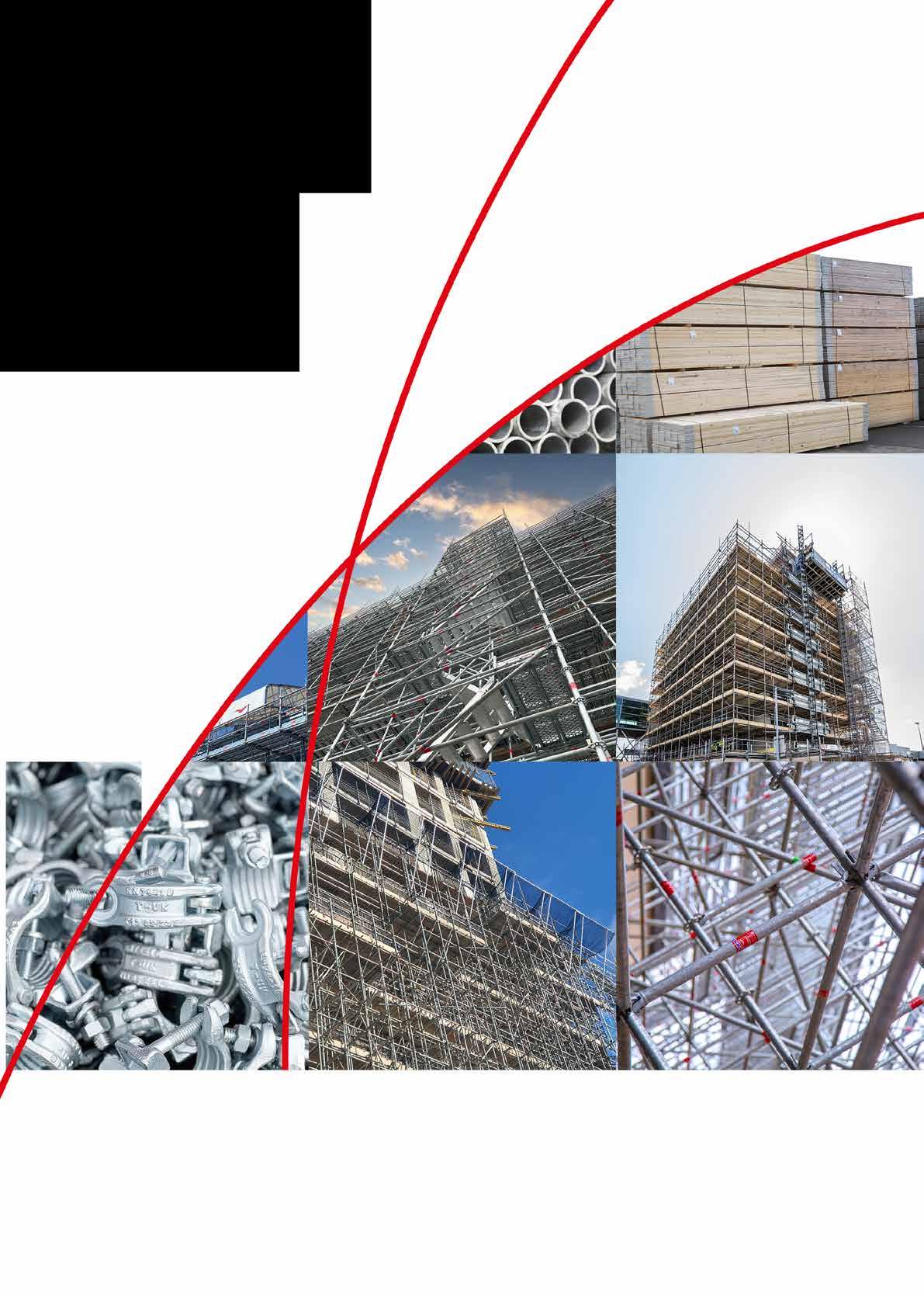

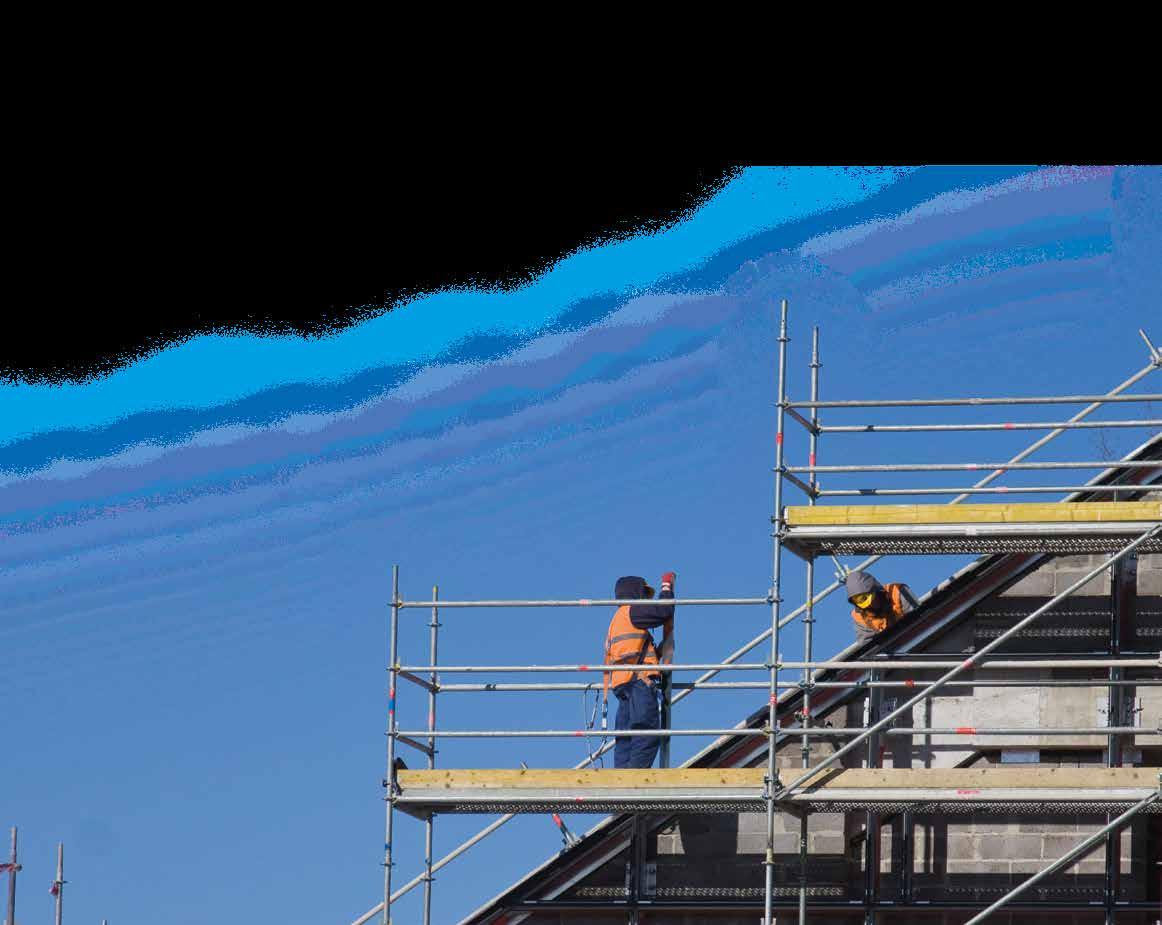

Cover and inside front cover images: Brogan Scaffolding Ltd

NEWS

P3-5 Stories from the sector

COMMENT

P6 Robert Candy, CEO of the Scaffolding Association, shares some important milestones

WELLBEING

P7 Mental Health First Aiders – a workplace’s first line of support

INTERVIEW

P8-9 An interview with David Abraham, Managing Director at Fulcrum TRANSPORT

P10 DVSA discusses the importance of securing loads

EVENTS

P12-13 National Scaffolding Week

PROJECTS

P14-15 Brogan deliver multi-elevation scaffold success

P16 SMS create complex weatherproof working area to remove RAAC

P17 4C Access ace football pitch project

LEGAL

P19 Holmes & Hills answer what you need to have in place before you down tools due to non-payment

ARMED FORCES

P20 The Scaffolding Association signs the Armed Forces Covenant

P21 Ian Pickard discusses why the scaffold industry needs the skills of our armed forces

COMMERCIAL

P24 The Scaffolding Association joins Build UK

P25 Choosing the right business structure for your scaffolding company

P27 uCheck looks at background checks and the costs of non-compliance

P28 A guide for self-employed scaffolders on Making Tax Digital

SKILLS & TRAINING

P30 What are CITB’s Employer Networks?

PRODUCT

P31 PERI UP Public Stairs

The Scaffolding Association joins the National Home Improvement Council

The Scaffolding Association is proud to announce it has joined the National Home Improvement Council (NHIC), furthering its commitment to raising standards, improving safety, and supporting sustainable growth across the construction and home improvement industry.

Established in 1974, the NHIC is the umbrella organisation for the UK’s home improvement sector, representing a wide range of organisations involved in housing, retrofit, energy efficiency, and building quality. The Council provides a strong collective voice on policy and practical

delivery, working closely with government and industry stakeholders to ensure the UK’s homes are fit for the future.

By joining the NHIC, the Scaffolding Association ensures that the voice of the scaffold industry is represented within this influential coalition. Scaffolding is a critical enabler for home improvement and retrofit works, underpinning the safe delivery of essential projects ranging from energy efficiency upgrades to vital repairs and maintenance.

Scan here to find out more:

Olivia Kamara becomes CISRS qualified scaffolder after release from HMP Style

Olivia Kamara, a former resident of HMP Style, has successfully transformed her life and career prospects by becoming a fully CISRS qualified scaffolder – thanks to dedicated training and support from Fulcrum Scaffold Safety & Training Ltd.

During her time at HMP Style, Olivia enrolled on Fulcrum’s specialist scaffolding training programme, designed to give individuals in custody practical skills and industry-recognised qualifications. Demonstrating outstanding commitment and resilience, she completed her CISRS training, alongside achieving the GQA Level 1 Award in Construction Health & Safety and passing the CSCS test.

Following her release, Olivia has now secured full-time employment as a qualified scaffolder – an achievement that highlights both her determination and

the transformative impact of targeted vocational training.

“At Fulcrum, we strongly believe that practical skills, real qualifications, and industry support can change lives,” said a spokesperson from Fulcrum Scaffold Safety & Training Ltd. “Olivia’s journey is a testament to what can be accomplished when someone is given the right tools and the chance to prove themselves. We’re incredibly proud to have been part of her success.”

Olivia’s story also sheds light on the broader importance of rehabilitation through skills training. By equipping individuals with the qualifications required in industries like scaffolding, training providers and industry partners help break down barriers to employment – offering people meaningful opportunities for a fresh start.

Now thriving in her new role, Olivia is not only helping to build structures on site, but also rebuilding her own life and future – setting an inspiring example for others who might follow the same path.

Scan here to find out more about Fulcrum Scaffold Safety & Training Ltd:

New ‘Partner a College’ programme unites

home builders and colleges to support construction students

A national initiative has been launched to transform how young people enter the construction industry. The Partner a College programme, developed by the Home Builders Federation, has confirmed the colleges and builders that will form the two-year pilot to bridge the gap between education and employment, and ensure students gain the practical, job-ready skills the industry needs.

Currently, less than 40% of construction students in further education enter the

sector, and many employers, particularly smaller firms, struggle to navigate an overly complex education and apprenticeship system. Designed to close the gap, the Partner a College programme’s collaborative model works to align curriculum content with realworld site demands, ensuring students gain the practical, job-ready skills employers need.

Scan here to find out more:

CITB and DWP agreement to support career opportunities in the construction industry

A new agreement signed by the Construction Industry Training Board (CITB) and the Department for Work and Pensions (DWP) will enable thousands of people to benefit from on-the-job training and career opportunities in the construction sector.

The agreement, signed at the newlylaunched Green Plant Academy at the Earls Court Skills Centre, is a major step

in the Government’s drive to get Britain building and get Britain working as part of its Plan for Change.

More than 40,000 industry placements will be funded through a further £100 million from the Government, alongside a £32 million contribution from the CITB.

Scan here to find out more:

Sole trader fined after worker suffered serious injuries

A worker suffered serious injuries after falling from a flat roof that did not have any edge protection. Leading to a sole trader being fined following a prosecution by the Health and Safety Executive (HSE).

It was the second time Gary Smith, trading as GJ Smith Roofing, had failed to provide edge protection on a job, with the HSE previously taking enforcement action against him.

Smith pleaded guilty following the incident on 15 December 2022, when a team of roofers and labourers were working on his behalf, replacing a flat roof on a house in the Luton area.

At around 11am, one of the workers was carrying large wooden boards across the roof, when he inadvertently stepped off the edge of the roof falling a distance of about 10 feet. He suffered

a fractured vertebra in his back and a broken ankle.

The HSE investigation found the task had not been properly risk assessed and planned, which meant that edge protection around the flat roof had not been put in place, despite it being reasonably practicable to do so. Following HSE intervention, edge protection was installed before work re-commenced.

Gary Smith of Watling Street, Dunstable, pleaded guilty to a breach of Regulation 4(1) of the Work At Height Regulations 2005. He was fined £2,125 and ordered to pay costs of £5,445 at a hearing at Luton & South Bedfordshire Magistrates’ Court on 29 July 2025.

Scan here to find out more:

Update to DVSA’s brake testing guidelines

The Driver and Vehicle Standards Agency (DVSA) is offering new methods for loading HGVs and trailers for brake testing, aiming to save time and money for operators.

The DVSA has approved load simulation brake rollers for annual testing. Using this method, vehicles may not need to be loaded before being presented for testing. Vehicles that are currently exempt from laden brake testing will still be exempt. It is considered best practice to test even if an exemption applies.

Laden brake testing can take a long time and loading a vehicle for testing can be costly for operators. This option gives another way to test vehicles. It could be applied to vehicles which are difficult or costly to load for testing.

It could potentially save time and money, and reduce the environmental impact of heavily laden vehicles driving just for a brake test.

Scan here to find out more:

Manager’s Toolkit launched to support Neurodiversity in Construction

The National Federation of Builders (NFB), in partnership with Interclass, CITB, and Genius Within, has launched the ‘Neurodiversity in Construction: A Manager’s Toolkit.’

The toolkit is the next stage in the groundbreaking ‘Neurodiversity in Construction Programme,’ which has already trained hundreds of workers within the industry through eLearning, training workshops, and a webinar aimed at raising awareness.

From creating psychologically safe teams to implementing reasonable adjustments, the toolkit has been developed with insight from industry experts and is shaped by lived experience to provide straightforward guidance, checklists, and practical tools.

Scan here to find out more:

CSCS Statement on Industry Accreditation (IA) cardholders

CSCS released a statement to say that it is aware of the changes announced by CITB regarding training grants and the early closure of enhanced funding for those transitioning from Industry Accreditation (IA) CSCS cards.

The enhanced grants are now available until the end of 2025 – not March 2026 as originally promoted.

This means that IA cardholders who

need to complete an NVQ to retain a CSCS card should put a plan in place without delay. While the changes to funding may reduce the timeframe to claim the enhanced CITB grant rate, the requirement to hold a recognised qualification has been publicised for several years.

Scan here to find out more:

Late payments consultation

The Government’s ‘Backing your business: our plan for small and medium-sized business’ has been published to help start, grow and build resilience of small business. This plan includes legislating to end late payments which costs the UK economy £11 billion per year and closes down 38 UK businesses every day.

To support this, the Department for

Business and Trade have launched a consultation seeking views on proposed legislative measures to ensure companies pay their suppliers quickly and on time.

This consultation will run for 12 weeks and close at 11:59pm on 23 October 2025.

Scan here to find out more:

State of Trade survey findings published

The UK construction industry is picking up pace in 2025, with an increase in workloads and enquiries for new work. The downside is that homeowners may still face longer waits, rising prices, and even cancelled projects, reports the new SME State of Trade Survey, carried out by the Federation of Master Builders (FMB) and the Chartered Institute of Building (CIOB).

More projects are underway, and more workers are being hired. However, despite this recovery, many firms are still struggling to find skilled tradespeople and manage rising costs, and that could mean disruption for homeowners planning renovations or new builds.

A severe shortage of skilled tradespeople is holding projects back:

• 61% have been directly affected by shortages, causing job delays (49%) and cancellations (23%).

Scan here to find out more:

CITB joins industry leaders for first Construction Skills Mission Board meeting

The Construction Industry Training Board (CITB) joined fellow members at the first meeting of the Construction Skills Mission Board - setting a strategy for recruiting an additional 100,000 workers a year by the end of this Parliament.

Senior leaders from across construction and Government Ministers have launched the construction sector skills mission, to ensure the sector has the workforce it needs to deliver.

The Board was established by the Construction Leadership Council (CLC) to support the Government’s commitment to invest an additional £625 million in construction skills, to support the delivery of a national infrastructure and construction pipeline of £725 million, as well as building 1.5 million new homes, and retrofitting an additional 5 million homes.

The Board is chaired by CLC co-chair Mark Reynolds. The Deputy Prime Minister and Secretary of State for Housing, Communities and Local Government,

joined the first meeting alongside other Ministers, representatives of the supply chain and training organisations.

The Board will develop specific initiatives and actions to deliver the mission, while supporting the Government to shape, develop and deliver skills policy. The actions will focus on 5 key areas to drive increased recruitment. They are:

• Confidence to employ and invest

• Clear new entrant pathways

• Access to provision & support to train

• Funding that works

• Reliable and rewarding careers.

The Board will work with industry bodies to ensure these actions are rolled out across the sector. The CLC is keen to ensure that all parts of the sector can be involved in the Mission, understand the plans and policies being developed to drive investment in skills and play a role in the subsequent work to recruit this new workforce. Any organisation that would like to support the mission can do so

through engagement with their relevant trade body, Mark said:

“We have seen real ambition from the Government through its commitment to 1.5 million new homes, clean power by 2030, and a renewal of our public infrastructure; and that ambition has been backed by significant funding commitments around skills. Construction will be essential to delivering growth and investment across the UK; and so it is vital that we now step up as a sector.

The Construction Skills Mission Board represents a new partnership between industry and government, working together to find industry-led, collaborative solutions to delivering the workforce of the future. I am delighted that we have seen such strong support from Ministers and some of the most important leaders in our sector – and I hope everyone will play their part in the delivery of this essential mission.”

Scan here to find out more:

Comment

Welcome to the latest issue of AccessPoint. I am pleased to share some important milestones for the Scaffolding Association that strengthen both our influence and our ability to represent members at the highest levels.

We have recently joined Build UK, positioning scaffolding and access at the heart of national construction policy and debate. This partnership ensures our industry’s voice is heard on critical issues such as safety, skills, procurement, and sustainability.

Alongside this, we are now members of the National Home Improvement Council (NHIC), reflecting our commitment to supporting safer, greener, and higher-quality homes. Scaffolding plays a vital role in retrofit and improvement, and this membership ensures our perspective is included in shaping future housing policy and standards.

We have also recently signed the Armed Forces Covenant, a public commitment to support those who serve, or have served, in the armed forces, and their families. For the Scaffolding Association, this means recognising the unique skills, discipline, and experience that veterans and reservists can bring to our sector, and working with members to create pathways into scaffolding careers. It also reflects our wider commitment to social responsibility and to playing our part in supporting the communities we serve.

I continue to represent the Association on the Board of the Trade Association Forum (TAF), the body that brings together and supports over 175 trade associations across the UK. This role strengthens our networks, gives us access to best practice across a wide range of sectors, and ensures the scaffolding and access industry has a voice in shaping the future of trade associations themselves.

You may have seen that a “shake-up in scaffolding training governance” has been announced. We are working to fully understand the implications for the sector and to ensure that any changes are in the very best interests of the industry. Training and competence remain at the heart of safety and professionalism, and we will continue to make sure the scaffolding workforce is properly supported in a fair and transparent way.

All of this comes at a time of continued political change. The recent reshuffle has produced yet another new Construction Minister. In fact, over the past decade the portfolio has averaged two ministers a year - meaning that the outgoing minister, Sarah Jones MP, has actually lasted longer in post than most of her predecessors. However, this constant churn is far from ideal. Frequent reshuffles undermine continuity, slow down decision-making, and make it harder to build the lasting relationships that industry needs with government. And it is not just Westminster: across the devolved nations we are also working hard to establish new connections, strengthen engagement, and ensure scaffolding is recognised as an essential part of construction policy at every level.

Looking ahead, the Chancellor has confirmed that the Autumn Budget will be delivered on 26 November. We will be making a detailed submission on behalf of our members, focused on three core areas: payment, procurement, and people. The Chancellor faces an enormous challenge in balancing the nation’s books, but if the government is serious about delivering on its pledge to build more homes, it must also recognise the need to support scaffolding - and the wider construction industry - to make that happen.

Thank you for your continued support. These are challenging times, but by working together and making sure our voice is heard, we can continue to raise standards, champion progress, and secure a stronger future for our industry.

ROBERT CANDY CHIEF EXECUTIVE, SCAFFOLDING ASSOCIATION

Training and competence remain at the heart of safety and professionalism, and we will continue to make sure the scaffolding workforce is properly supported in a fair and transparent way.

Mental Health First Aiders – a workplace’s first line of support

Paying attention to workplace mental health has never been more important, especially in construction. Becoming a Mental Health First Aider, or supporting a workmate to do so, could make a significant difference – and even save lives.

Construction can be a rewarding and varied industry to work in. But it’s also one where pressures can be high, and people can be more likely than average to experience work-related stress and other mental health issues.

What is mental health first aid?

Mental health first aid is:

• spotting the signs and symptoms of common mental health issues

• providing non-judgemental support and reassurance

• guiding a person to seek professional support.

What is a Mental Health First Aider?

A Mental Health First Aider (MHFA) is a volunteer who, alongside their day job, looks out for their workmates by checking on their mental wellbeing, offering to talk or listen to their concerns, and directing them to expert help should they need it. These volunteers aren’t counsellors or therapists – they’re concerned colleagues doing their bit for others.

A person who volunteers for the MHFA role must be comfortable in their own mind and not be suffering with mental wellbeing issues. The MHFA must be a good listener and discreet – any information given must be treated as strictly confidential unless the individual feels it needs to be shared.

What are the benefits of holding Mental Health First Aid certification?

The primary benefit is quite obvious –supporting a workmate at their darkest time and possibly saving their life. Statistics show that each employee’s absenteeism and presenteeism costs a company around £1,300 per year.

If an employer spends £1 on helping an employee through their issues, the employer’s return is said to be £5, measured in less absenteeism, less presenteeism, and greater productivity.

Having an MHFA within the company or available via phone (usually a worker on a nearby site) can help people to start on the road to recovery. It is genuinely possible for a person to have poor mental health, find a way to manage and still lead a rewarding life. Some just need counselling or medication to help ‘take the edge off’ their issues so that they can move forward.

Taking part in a Mental Health First Aid course:

• raises awareness of mental health issues

• encourages early intervention to aid recovery

• increases confidence in dealing with mental illnesses

• reduces stigma around mental health issues.

How to become a Mental Health First Aider

In the first instance, interested employees need to discuss becoming a MHFA with their employer, who would need to decide whether the individual is suited to the role and whether their work duties allow the extra responsibility.

Mental Health First Aid England is the leading licensed provider of MHFA training in the UK – its courses give people the skills and confidence to recognise the signs and symptoms of the most common mental health issues and help them effectively guide a person towards the correct support, whether that be self-help, an employer assistance programme or NHS services.

Scan here to find out more about MHFA England:

An interview with

David Abraham Managing Director at Fulcrum Scaffold Safety & Training Ltd

Q. What first got you interested in the scaffolding and access industry?

A I was “encouraged” to leave school in the early 80s and soon found myself working for my uncle’s scaffolding company. It wasn’t exactly by choice, but I was a fit lad back then and quick with the banter - the rest, as they say, is history.

Q. What has been the most rewarding part of your career so far?

A For me, the most rewarding part has been seeing the real-world impact of my work. Whether that’s helping to raise safety standards, supporting organisations through change, or mentoring people as they grow in their careers - knowing that I’ve played a part in improving outcomes for individuals and businesses is hugely satisfying. In addition, our prison and community projects have been hugely rewarding not just for me, but all the team at Fulcrum. Giving young men and women a second chance - helping to tackle the labour shortage and close the skills gap. Proud to be working alongside some incredible people at HMPs, the Ministry of Justice, local councils, Procure Plus, and the many scaffolding businesses who have supported this initiative, including the Scaffolding Association.

Q. What do you see as the main priorities for the Scaffolding Association in the next 12 months?

A For me, the Scaffolding Association’s priorities over the next 12 months should be clear:

1. Raise competence and training standards across the industry, ensuring clients recognise scaffolding as a professional, skilled trade - not just a commodity.

2. Tackle the labour shortage by attracting new talent into scaffolding, supporting apprenticeships, and encouraging employers to invest in their workforce in partnership with training providers.

3. Push for fairer commercial practices - faster payments, smarter procurement, and reducing duplication in accreditations.

4. Strengthen safety and compliance, with a particular focus on the new building safety regime coming into force.

5. Promote the reputation of our industry - celebrating the excellent work scaffolders deliver and ensuring our voice is heard at the national level.

If we focus on those 5 things, the whole sector moves forward.

Q. What role does the Association play in supporting its members day to day?

A The Association is a constant source of advice, guidance, and advocacy. On a practical level, members can access support on compliance, training, and contracts. Strategically, the Association represent their interests with regulators, policymakers, and industry bodies. For many businesses, especially SMEs, having the Association as a trusted partner means they don’t have to face challenges alone.

Q. What are the biggest challenges facing the scaffolding and access sector right now?

A The scaffolding and access sector is under real pressure at the moment. We’re dealing with a skills gap, rising training costs driven by changes in training schemes, and ongoing regulatory uncertainty. Businesses must constantly balance commercial demands with the non-negotiable need to maintain high safety standards, while also responding to growing expectations around sustainability from clients and government. These challenges aren’t insurmountable, but they do require strong industry collaboration and clear representation.

Q. Is the government doing enough to support the scaffolding and access industry and, if not, what more needs to be done to help businesses in the sector grow to meet demand?

A The government has made some positive steps, but there’s still more to be done. Initiatives like the £600 million investment to train 60,000 construction workers by 2029 and the £275 million boost to apprenticeships in England are encouraging. However, the scaffolding sector faces unique challenges, including a significant skills gap and rising training costs. Changing Skills Bootcamp funding so it’s issued locally through the DWP has been a mistake, creating confusion and limiting access. To truly meet demand, we need more targeted investment in scaffoldingspecific training, clearer regulatory frameworks, and stronger support for businesses to navigate these challenges.

Q. Following the recent shake-up in scaffolding training governance, what steps should be taken to make sure the changes are positive for the industry and the workforce - and what is the Association doing to ensure this?

A The key will be ensuring that training is fair, transparent, and accessible, while keeping safety and competence at the core. The Association is engaging closely with stakeholders to understand the implications and to make sure the voice of our members is heard. Our priority is that the workforce continues to be properly supported and the industry benefits from any reforms.

Q. How do you think the industry can improve safety standards further?

A Safety has always been a priority, but we have to keep embedding a culture where it’s non-negotiable. That means ongoing training, investing in competent supervision, and open reporting so lessons are learned. It’s disappointing to see social media videos of scaffolders working unsafely and unsafe practices being accepted. Clients also need to recognise the value of quality contractors who do the job properly, rather than driving everything on lowest cost. Tools like digital inspections can help identify risks early and prevent incidents.

Q. How do you see technology changing the scaffolding and access industry in the future?

A Technology is set to transform scaffolding and access in a big way. Tools like 3D modelling, drones for remote inspections, and real-time reporting will make planning and monitoring safer and more efficient. We’re also looking for innovations that improve worker wellbeing, helping reduce risks from manual handling, noise, vibration, and dust. These tools help identify hazards earlier, improve training, and allow companies to track compliance more effectively. While scaffolding will always rely on skilled people, embracing technology can make their work safer, healthier, and more productive.

Q. What more can be done to attract young people into scaffolding, access and wider construction industry careers?

A Attracting young people into scaffolding and construction starts with raising awareness of the opportunities the industry offers. We need to show that it’s a skilled, professional, and rewarding career,

not just a temporary job. Initiatives like National Scaffolding Week, which the Association runs, play an important role in celebrating success stories and inspiring the next generation to consider a career in scaffolding and access. We work closely with local schools and constantly have young people ready to join the industry, but we struggle to find employers willing to take them on. This is mainly due to most construction sites having age limits of 18 or 21. Engaging with schools, offering apprenticeships, mentoring, clear career progression, accessible training, and highlighting modern technology, safety, and wellbeing improvements will make the industry even more appealing.

Q. How do you see the scaffolding and access sector contributing to sustainability in construction?

A The scaffolding and access sector can contribute to sustainability by reusing materials, designing systems efficiently, and adopting smarter, energy-efficient working practices. By reducing waste and improving efficiency on site, we help lower the industry’s carbon footprint while maintaining safety and quality.

Q. What advice would you give to someone starting out in the scaffolding and access industry today?

A Firstly, do not post poor content on social media and take every opportunity to learn and never compromise on safety. This is an industry where skill and professionalism really matter, and if you build your reputation on those foundations, you will go far. Always seek good training and mentoring, ask questions, and be patient as you develop your skills. It’s also important to embrace change - new techniques, technologies, and expectations. The industry is evolving, and those who grow with it will have rewarding and longlasting careers.

Securing loads: A legal, moral, and business responsibility

In this article, Mark Horton, Enforcement Policy, DVSA, discusses the importance of securing loads.

It seems obvious to say that any load on any vehicle needs to be secured effectively to prevent it from moving and potentially falling off, causing all sorts of problems to other road users.

As a responsible operator you will know this and no doubt have done the appropriate risk assessments, delivered training to your drivers and other employees involved in loading vehicles and demonstrated the sort of due diligence required to maintain an operator licence. Failing to do this can, of course, be detrimental to your business. This could mean financial penalties for an insecure load, attending an inquiry before the Traffic Commissioner (who may take disciplinary action against your licence), or reputational damage if negligence results in serious injury or worse.

It may come as no surprise if I tell you that I have lost count of the times a driver or operator has said that they have been doing something in a particular way for ‘x’ number of years without any problem. I’ve been driving since I was 17 without ever being in a serious accident but I still put my seat belt on and not only because it’s a legal requirement but, well, just in case.

I’m a firm believer in the basic premise that drivers and operators don’t intentionally set out to cause problems on the road network. ‘Things’ get in the way, after all you have a business to run, employees to pay, commitments to fulfil.

You might not pay as much attention to securing a load for that small job down the road as you might on the larger job 30 miles away but of course you should.

The tragedy is that it often takes something horrific to happen in order to get our attention. One of those tragedies happened in the run up to Christmas in 2022. 11-year-old Harry Dennis was sat in the passenger seat of his family car when a scaffolding board, protruding from the side of a light goods vehicle travelling in the opposite direction, struck the car and Harry. He was taken to hospital by air ambulance but tragically died two days later.

Russell Le Beau was driving the vehicle and admitted to causing death by dangerous driving, receiving a custodial sentence of 4 years and a 7 year driving ban. The investigation found that the scaffolding had not been secured in any meaningful way. The judge residing over the case concluded that Mr Le Beau had been operating in this way for the last 15 years and that an accident was inevitable.

I was fortunate to meet Harry’s mum, Maria Dennis, earlier this year. She is determined to ensure Harry’s death was not in vain and has worked with the Sussex Police getting the message across to other road users. Maria won’t mind me quoting her:- “Most things are simple, that you can change yourself. Just double check your load is secure or turn off your phone so you don’t fiddle with it. One simple thing that should have been done

wasn’t and that took Harry’s life away in the blink of an eye”.

DVSA have published load security guidance on GOV.UK providing details of your responsibilities and how to ensure your load is secure. The section on scaffolding and other parts in the guidance will help you to be compliant with the law and most importantly to hopefully prevent accidents.

It doesn’t need to be complicated, you just need to have a safe and effective method to secure the different loads you carry on the different vehicles you use. Risk assess each load/vehicle and come up with a plan. Write it down so that anybody involved in the process knows what they are doing. Train your staff, either do this yourself or approach an outside provider. Make sure the equipment you use to secure the load is in good condition and replace at the first signs of wear. Review your processes as well, listen to feedback from your drivers to further inform your decisions and methods.

We will work with your industry where we can to improve our guidance so you’re not on your own. You might be surprised to find out that we are approachable and want to prevent accidents more than we want to deal with the aftermath.

Mark Horton Enforcement Policy, DVSA

National Scaffolding Week

It brings us great pleasure to announce the next National Scaffolding Week (NSW) will take place between the 6th and the 10th of October 2025. NSW is a one of its kind event – bringing a much-needed platform to the scaffolding and access industry for the first time to help raise the profile of careers and achievements within the sector.

NSW provides the opportunity to shine a light on the diverse and wide range of career options and skills training available within the sector and inspire a new generation, or those looking for a new challenge, to take up a role within the scaffolding industry

Not only will NSW promote scaffolding as a viable and rewarding career option for those from all walks of life, but it will also provide a platform on which to highlight some of the great achievements of the organisations and individuals already operating within the sector and showcase best practice, innovation and determination

Get involved

There are plenty of ways you can get involved with NSW whether you’re currently working within the sector, are looking to change careers or are just about to embark on your first role after leaving school – there’s something for everyone

During the course of the week, NSW will be bringing you awards, competitions, access to a wide range of educational resources and fi t-hand l k t h t it’ lik t k ithi th i d t

Nominate your Scaffolding Star

There are some incredibly inspiring, resilient and dedicated people in the scaffolding and access industry, if you know of someone who deserves to be recognised for their efforts, show them your appreciation with a nomination in our Scaffolding Star awards.

We’re looking for the absolute stars of the scaffolding industry, those

Join the conversation

NSW wouldn’t be possible without you We’ love to see everything you get up to during NSW on social media, by using the hashtag #ScaffWeek, you can join in the conversation and we’ll be able to engage and share directly with your content

6th-10th October 5

We have created a handy social media toolkit for you to download which includes images, logos and some ideas to get you started on social media as well as details of our social handles and some other handy social media tips!

By tagging us on the relevant social channel we can share your posts and engage directly with you

Don’t forget!

One last thing – don’t forget to sign up for the newsletter! We’ll send regular updates up until NSW to keep you updated with all the latest news and events planned for the week

By signing up to the newsletter you’ll also be amongst the first to hear about the competition criteria as well as details and deadlines for nominating your Scaffolding Star.

To sign up for the newsletter visit: www nation

Brogan deliver multi-elevation scaffold success

Fully audited members of the Scaffolding Association, Brogan Scaffolding Ltd, have provided a comprehensive access package for complex cladding replacement work on a landmark Sunderland building where no two elevations were the same.

Positioned in the heart of the city and with one façade facing directly onto the North Sea, the Echo 24 building presented an array of logistical and structural considerations. Andy Phillips, Managing Director at Brogan, explained:

“There were many restrictions that affected the process of this project. There are city centre roads on all 4 sides of the building, businesses operating from within, and residents coming and going at all times. During the planning stage, we had

to carefully consider all of this to develop a plan that allowed work to progress smoothly without causing disruption.”

Principal Contractors, Bell Building Products, tasked Brogan with providing safe, adaptable access to every side of the building. The variety of conditions meant each elevation required its own bespoke approach. To achieve this, Brogan enlisted the expertise of JM Scaffold Design to produce tailored designs that could be implemented safely and efficiently.

Andy added:

“One of the specific requirements in the project brief was that no timber materials were permitted on site. We therefore opted for an AT-PAC System to ensure everything used was steel.”

Rather than a single method, Brogan engineered 4 distinct solutions — one for each elevation — each responding to its own set of technical and logistical demands.

North elevation

The North side was constructed from a ground floor balcony that overhung a road. This balcony required propping from underneath, with every prop standard aligning with the scaffold standards above.

In addition, all staircases on this side had to be cantilevered from the third lift, continuing up to 40m high. This was necessary due to the road beneath, which prevented the stairs from reaching ground level.

One of the biggest difficulties was transporting materials. With only a single-lane road available, a 4-way Moffett forklift was used to deliver equipment, followed by a Hiab to offload materials into a loading bay during out-of-hours operations, reducing city centre disruption.

A major road closure was also required to allow a 100t crane to lift in a large beam section. To streamline this, the beams were pre-assembled in Brogan’s yard, transported in sections, rebuilt within the closure, and then craned into position during a nightshift.

South elevation

The South elevation had to be constructed over an underground car park with a rock face, which demanded a creative solution. The team installed substantial propping below ground level to provide the necessary stability for the scaffold structure above.

West elevation

The West elevation proved to be one of the most complex areas. The building here sits on a splay and the roof steps up at the same time. A 30m high beam installation was required, lifted into place using a crane during restricted hours, with work commencing only after 9pm.

This elevation also bore the full brunt of exposure to the North Sea. At 47m high on the corner, wind conditions funnelled by the river created particularly difficult working conditions on certain days, requiring constant vigilance and adjustments by the team.

Project in numbers

Over 350t of AT-PAC system scaffolding

Over 120t of tube and fit scaffolding for propping

Over 300 rising metres of stairs

Over 500 jacks throughout the build

East elevation

On the East side, access was complicated by the need to build partly on the road itself. This meant a full road closure was required, which will remain in place for the duration of the scaffold’s presence. The remaining half of the elevation was beamed over during night shifts, allowing the team to progress while minimising disruption.

One persistent difficulty throughout the project was the building’s central location. Andy explained:

“The logistics of delivering materials were complicated throughout. With single-lane roads, city centre traffic, and very little laydown area, this was one of the key considerations from day one.”

Despite these obstacles, Brogan’s team managed the project effectively, turning potential setbacks into opportunities for innovation. The result was a landmark success for the company and the city. Andy reflected:

“Completing the North elevation was my favourite part of this project. It was fully boarded with 3 main cantilevered stairs. It’s the biggest building in Sunderland, and the first thing you see when travelling across the main bridge. We were also fortunate to have all local labour on the project, so for a Sunderlandbased scaffolding company, it was incredibly rewarding to be involved in such a monumental scheme.”

SMS create complex weatherproof working area to remove RAAC

South Molton Scaffolding Ltd (SMS), who are Assessed Members of the Scaffolding Association, have provided a complicated weatherproof system and support scaffold to remove the Reinforced Autoclaved Aerated Concrete (RAAC) within the roof space at Petroc College, Barnstaple Campus.

SMS successfully created an intricate system to create the perfect working environment for Principal Contractor, Pearce Construction, to undertake the work.

The start date of the project fell within term times of the college, meaning the ground floor of the building was live throughout, along with the rest of the college. This meant that the brief had extensive requirements, Dominic Stoneman, Director at SMS, explained:

“An accessibility access ramp had to be kept clear and spanned to keep it operational. We also had to erect a pedestrian public access staircase as part of the enabling works to divert the public, and public of the college, to a different building as the existing staircase would be taken out of use whilst the project was live.”

There were many areas of the building that were not load bearing, which meant that careful consideration was required throughout the design stage. SMS recruited the help of Raptor Scaffold Designs to overcome the many challenges the building created, Dominic commented:

“The reception canopy was not load bearing, so this needed to be beamed over with 12 rows of 780 Apollo beams to carry the imposed loads of the temporary roof. This was the main challenge of the whole project. Where we anticipated and designed the scaffold to land was on the higher building parapet wall, however, after close inspection this wasn’t what the engineer expected from the historic building drawings. Therefore, we had to remove the parapet structure until we found the concrete frame of the building which was load bearing. We then had a steel RSJ installed and bolted in to accept the imposed lateral loads for us to then be able to erect the scaffold from this point to carry the end of the beam section. It sounds complicated, but it went very smoothly.”

Crane lifts were needed to complete the erection, which required thoughtful deliberation, Dominic stated:

“Having the crane lifts were always going to be a bit of a challenge due to limited space and the college

being live, we overcame this by completing all lifts on the weekends. This meant a big shift was done and we managed to build 90% of the HAKI System roof in a single Saturday shift.”

Despite a 2 week delay starting on site due to some structural issues, SMS still managed to hand the scaffold over 4 days early, and the entire project was a huge success from start to finish, Dominic concluded:

“The college and client were very pleased with the scaffold we provided and especially the way our teams conducted themselves professionally. I would like to thank our client and the college for being so accommodating to the team and trusting us with this large project. I would also like to thank my on-site team and all the other members of staff who jumped in to help out on weekends and whenever it was needed! We planned it, we scheduled it and as you can see, we delivered.”

4C Access ace football pitch project

4C Access (UK) Limited, who are Assessed Members of the Scaffolding Association, have successfully utilised scaffolding to provide a cost-effective alternative to create a new outdoor coaching section at Ace of Sports Coaching Academy.

Grassroots youth football teams across the country often face significant challenges in securing all-weather training facilities. A plight that Stuart Cossins (Owner/Managing Director of 4C Access), who coached his son’s team for several years, was all too aware of. This meant that when the challenge to design and build a temporary structure that could be transformed into a 4G football pitch with family viewing area was proposed, it was an instant ‘yes’ from Stuart, he commented:

“Due to local planning restrictions preventing the construction of a permanent structure at the venue, John Jones (Head Coach and Owner of Ace of Sports) and Mike Price (Bespoke Build and Contractors Ltd) reached out to enquire whether their vision could be realised using a temporary scaffolding-based solution. The idea was quite unique, showcasing scaffolding to create such an amazing space certainly made my ears prick up.”

The brief for the project was to create a workable 4G pitch that accommodated up to 25 children aged 5–16.

Stuart explained that the project faced 5 key challenges:

1 2 3 4 5

Local planning restrictions: Strict regulations prevented the construction of a permanent structure, necessitating an alternative approach.

Solution: To bypass restrictions, the temporary scaffolding-based facility was implemented, complying with local regulations while providing the needed training space.

Scaffolding design: Developing a safe, stable, and weather-resistant scaffolding structure for training was technically complex.

Solution: A robust design was created with collaboration from structural experts to ensure a stable, weather-resistant scaffolding setup, equipped with secure anchoring and protective features for safety and usability.

Weather variability: Ensuring the facility could support training in diverse conditions such as wind or rain required careful planning.

Solution: The design incorporated adjustable coverings or windbreaks, enabling consistent training in varied conditions.

Cost and resource management: Balancing the budget for materials, labour, and maintenance while meeting safety standards was critical.

Solution: Cost-effective materials and efficient contractor partnerships kept the project financially viable while maintaining high safety and quality standards.

Integrating innovation with practicality: Aligning the innovative training vision with a functional, temporary structure posed design and operational challenges.

Solution: The scaffolding facility was tailored to support John Jones’ coaching methodology, with regular safety checks and coach feedback ensuring it met both educational and practical needs.

This model provides a cost-effective, adaptable alternative to traditional facilities. By utilising scaffolding, clubs can bypass planning hurdles, as these structures are typically classified as temporary and require less stringent approvals.

Mike from Bespoke Build concluded:

“Exceptional service is not just about meeting expectations; it’s about exceeding them with genuine care and attention to detail. Having Stu and the 4C Access team on board for this project was a no brainer. I explained the vision and the attention to detail in the design and the delivery is clear to see.”

Know a local club that could benefit?

Stuart gave some tips to help bring this solution to life:

Grassroots teams can explore fundraising initiatives and grant opportunities to cover the costs of scaffolding materials, installation, and maintenance. Local community crowdfunding campaigns, supported by parents, coaches, and businesses, can raise funds while fostering community engagement. Additionally, grants from organisations like the Football Foundation, Sport England, or local council sports development programs often support innovative projects that enhance youth sports access. These funding avenues can help cover expenses, making the scaffolding solution financially viable for even the smallest clubs.

Clubs interested in pursuing this model can contact local scaffolding providers or consult with organisations like Bespoke Build to explore tailored solutions, while leveraging fundraising and grants to make their vision a reality.

4C Access (UK) Limited www.linkedin.com/in/stuart-cossins-7a258084

Ace of Sports www.aceofsports.co.uk

Bespoke Build and Contractors Ltd www.bespokebc.com

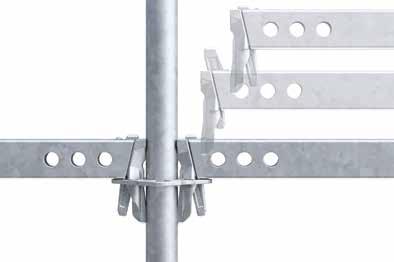

Onsite testing services available nationwide by our fully qualified CFA Installation & Testing Teams

Our all-in-one solution for rigorous pull-shear testing on anchors and eye safety bolts up to 25kN.

Designed to help you seamlessly align with global industry standards like BS8539, BS7883, NASC guidance TG4:19, and AEFAC guidance TN05, this kit is a fusion of technology and durability.

www.360degreesconsultancy.co.uk/pull-testing/

What you need to have in place before you down tools due to non-payment

In this article, the Scaffolding Association’s legal partners, Holmes & Hills, discuss what contractors need to have in place before downing tools due to non-payment.

In construction, “downing tools” is often used as a throwaway comment when a contractor has decided that they are no longer going to attend the site unless they are paid for the works carried out. The trouble is that two wrongs don’t make a right and whilst you may think it is leverage – you could be on the receiving end of a breach of contract claim, termination and a claim for damages.

What contractors fail to understand is that you may well have a statutory right to suspend works under s.112 of the Housing Grants, Construction and Regeneration Act 1996 (“Construction Act”). The right to suspend permits a contractor to stop works if they have not been paid by the final date for payment. Your contract may also include a right to suspend, but what does suspension actually look like?

Statutory Right

If your contract does not contain an express term allowing for a party to suspend works, all construction contracts are covered by the Construction Act, and you can rely on s.112. Under this section, an unpaid party can suspend work if all or part of the notified sum remain unpaid by the final date for payment and can suspend performance of all obligations under the contract.

Under this section, an unpaid party is also entitled to an extension of time to the completion date to cover the

period of suspension and remobilising to site. You would also be entitled to the reasonable costs of doing so.

It is important to note that an unpaid party can only suspend works for the notified sum, not the amount the party believes is due to them. For example, if you make an application for payment for £120,000, but the other side serve a valid pay less notice for £100,000, you would not be able to suspend works for non-payment of the balance of £20,000 (assuming the £100,000 is paid).

What

do you need to do?

In terms of what to put in place before putting down tools, it is important to make sure your suspension notice is valid.

Under a statutory right to suspend, it can only be served after the final date for payment and must give the debtor 7 days’ notice of your ‘intention’ to suspend. What this means in practice is you must wait until the 8th day before you actually ‘down tools’. The notice would state something like “under our application of X date, you have failed to make payment of X and we hereby give you notice of our intention to suspend works if payment is not made within 7 days”. Due to the risk of getting this part wrong, we highly recommend you do not suspend works without first speaking with a construction specialist solicitor (like us).

Why is it so important to get this right?

If you wrongfully suspend works, it is highly likely your client will notify you of such and, if necessary, terminate your contract for that breach. It is not a defence to that breach to say, “but they owed me money”, you have a contract and a statutory right for a reason – so use it.

Contractual Right

You may find that your client has issued you a contract whereby your right to suspend works is on a much longer period of time i.e. on 30 days’ notice. This does not overrule the statutory right, but it does complicate matters as to the timing of the notice of suspension and we would encourage you to seek legal advice or when in doubt, comply with the longer provision under the contract.

To conclude, suspension is a useful tool in getting the other party to make payment, however, you simply cannot just put down your tools and walk off site without considering the consequences. If you are unsure about what you need to do before you down tools, seek legal advice. The Construction Department at Holmes & Hills are always happy to help scaffolding contractors and provide advice in relation to suspension due to non-payment.

Scan here for more information:

Proudly supporting those who serve: The Scaffolding Association signs the Armed Forces Covenant

We are delighted to share that the Scaffolding Association has signed the Armed Forces Covenant - a public promise to support those who serve, or have served, in the armed forces, along with their families.

For us, this is about more than a signature. It’s about recognising the unique skills, discipline, and experience that veterans and reservists bring to our sector and working with our members to open up real pathways into scaffolding careers. It also speaks to our wider commitment to social responsibility and to playing our part in supporting the communities we serve.

On 24 July 2025, our Chief Executive, Robert Candy, signed the Covenant on behalf of the Association. In doing so, we joined thousands of organisations across the country who have pledged to ensure the Armed Forces Community is treated with fairness, respect, and understanding.

The Covenant is a national promise. It acknowledges the sacrifices made by Service personnel and their families, and it calls on employers, communities, and individuals to make sure that no one is disadvantaged because of their service.

For our industry, this commitment creates some clear opportunities:

• Showcasing the value and transferable skills that armed forces personnel bring into scaffolding.

• Encouraging inclusive recruitment, so that veterans, service leavers, and reservists feel welcome in our workplaces.

• Supporting apprenticeships, training, and reskilling that give Service leavers and their families a strong start in our industry.

• Recognising and celebrating the Armed Forces Community through events such as Armed Forces Day, Remembrance, and National Scaffolding Week.

Reflecting on the signing, Robert Candy said:

“By signing the Armed Forces Covenant, the Scaffolding Association is making a clear statement: our industry values the contribution of the Armed Forces Community, and we are committed to supporting them. This is not only the right thing to do, but it also brings huge benefits in terms of skills, experience, and leadership qualities that veterans and reservists can offer our sector.”

In the months ahead, we will be working closely with our members, training providers, and industry partners to make sure the Covenant delivers real, practical benefits for the Armed Forces Communitywhile helping to strengthen the scaffolding and access sector for the future.

Our industry values the contribution of the Armed Forces Community, and we are committed to supporting them.

Building bridges: Why the scaffold industry needs the skills of our armed forces

In this article, Ian Pickard, Managing Director and Health & Safety Consultant at IDP Safety Services Ltd, discusses why the scaffolding industry needs the skills of our armed forces. Ian served in the Territorial Army, rising to Warrant Officer Class 2 and Battery Sergeant Major, and is currently a Mental Health First Aid Instructor and Co-Founder of SWAG (Sussex Wellness Action Group).

The scaffolding industry, like much of construction, is facing a major skills shortage. It is estimated that more than 300,000 additional tradespeople are needed to meet demand – a shortfall that puts real pressure on projects across the country. Meanwhile, every year thousands of men and women leave the armed forces, equipped with discipline, training, and experience that could make a real difference in industries like ours.

From service to scaffolding

For many veterans, moving from military life into civilian employment can feel like a big step. But as Scaffolding Association member Ian Pickard of IDP Safety Services explains, the skills gained in the forces often provide the perfect foundation.

Ian spent almost two decades in the Reserves, rising to senior leadership roles. During that time, he developed technical expertise, leadership ability, and a confidence that he says continues to shape his career today.

“The armed forces trains its people to the highest standards,” Ian reflects. “You learn discipline, teamwork, and problem-solving – but also how to lead, how to stay calm under pressure, and how to deliver results. Those are skills you carry with you for life. I wouldn’t be doing the job I do now without that experience.”

Why employers should take notice

Scaffolding is built on teamwork, precision, and a strong safety culture – all qualities that align closely with military training. Veterans bring reliability, adaptability, and a readiness to take on responsibility from day one.

“Ex-forces staff are well turned out, reliable, hard-working, and adaptable,” Ian says. “Businesses that take on veterans often go on to hire more, because they see the positive impact straight away.”

A call to action for the scaffold industry

Ian Pickard, CMIOSH, FIIRSM, RSP, OSHCR, MInstLM

With such a significant labour gap to fill, the scaffolding industry cannot afford to overlook this pool of talent. Ex-forces personnel already have the discipline, skill, and mindset to succeed – whether that’s getting started on site, stepping into supervisory roles, or moving into leadership positions over time.

As Ian puts it:

“We need to tap into these skill sets and use them to strengthen our industry. Veterans are ready to contribute – we just need to give them the opportunity.”

Ian’s journey started in 1986 at Woolwich barracks where he did his basic training. He went on to serve for 18 years in the Territorial Army now known as the Reserves, to the rank of Warrant Office Class 2 and Battery Sergeant Major.

Ian has over 40 years of experience in the construction industry. Having worked with some of the UK’s leading house builders and gaining qualifications in plant training, health & safety and NEBOSH, Ian founded IDP Safety Services in 2002 with his wife Lisa.

Ian is both Managing Director and Health & Safety Consultant at IDP Safety Services and has won multiple awards for his outstanding work.

In addition, Ian is a Mental Health First Aid Instructor for MHFA England, and is a Co-Founder of SWAG (Sussex Wellness Action Group).

The Scaffolding Association joins Build UK to champion progress across construction

The Scaffolding Association is proud to announce that it has formally joined Build UK as a Trade Association Member — marking a significant step forward in its commitment to championing positive change and greater recognition for the scaffold industry.

Build UK is recognised as the leading collective voice for construction, bringing together all sectors, contractors, clients, and specialist trade associations to address the sector’s biggest challenges. The Scaffolding Association’s membership means that the voice of the scaffold industry will now be heard at the heart of these crucial national discussions.

The Scaffolding Association and Build UK share a common goal: to raise standards, improve outcomes, and ensure that specialist contractors are supported and valued across the entire supply chain. From promoting safer working environments and supporting competency and training, to improving payment practices and procurement, both organisations are focused on delivering meaningful, long-term progress.

By joining Build UK, the Association can:

• Influence strategic decisions that impact our members, ensuring that scaffolders are fairly represented on issues such as regulatory reform, sustainability, and workforce development.

• Support efforts to streamline prequalification through the Common Assessment Standard, helping members reduce duplication and save time and resources.

• Promote the professionalism and capability of our members to major clients and contractors through collaborative engagement.

• Drive improvements in commercial practices, including fair payment terms and greater visibility for specialist contractors.

For members of the Scaffolding Association, this move strengthens their voice within the wider construction landscape.

Robert Candy, Chief Executive of the Scaffolding Association, comments:

“Joining Build UK marks a significant moment in the Association’s continued journey to support and represent all sectors of the scaffold industry at a national level.

Since our formation in 2011, we have worked to create an open and inclusive organisation that amplifies the voice of our members and provides unbiased, practical support to businesses across the industry.

This partnership reflects our shared priorities with Build UK — from raising safety standards and strengthening training, to improving competence and establishing consistent, fair procurement practices. It will enhance our ability to influence policy, collaborate with key stakeholders, and promote best practice throughout the supply chain. By joining Build UK, we are ensuring that our members’ contribution is recognised and championed within a collective, progressive vision for the industry.”

This alignment with Build UK will open further opportunities for members to engage with national campaigns, shape industry initiatives, and access guidance developed in collaboration with major contractors and stakeholders.

“We are delighted to welcome the Scaffolding Association as a Trade Association member of Build UK. Its commitment to improving standards across the scaffolding sector will strengthen our collective voice and support our shared goal of driving positive change across the industry.”

Suzannah Nichol OBE, Build UK Chief Executive, stated:

Choosing the right business structure for your scaffolding company

Starting or growing a scaffolding business in the UK means making an early decision about how to structure it: as a Sole Trader, a Limited Company (Ltd), or a Limited Liability Partnership (LLP).

Each comes with different implications for liability, tax, contracts, and credibility in the construction industry. While health & safety duties, licensing, and insurance requirements apply equally, the structure you choose will affect how clients, insurers, and regulators view your business.

Limited Company (Ltd)

Setting up as a limited company creates a separate legal entity. This offers limited liability, meaning your personal assets are usually protected if something goes wrong. It also boosts credibility — larger clients, councils, and construction firms typically prefer working with companies.

Drawbacks

• Higher admin: must file annual accounts, confirmation statements, and tax returns.

Sole Trader

Many scaffolders start out as sole traders because it’s simple and cheap. You just register with HMRC and report profits via Self Assessment. There’s no need to file accounts at Companies House, which means greater privacy and less admin.

Drawbacks

• Unlimited liability — personal assets (house, savings, vehicles) are at risk if something goes wrong.

• Insurance may be harder to obtain or more expensive.

• Less credibility with councils and main contractors, limiting access to bigger contracts.

Best suited for

• Scaffolders starting out on their own.

• Small-scale work with low overheads.

• Those willing to accept personal financial risk.

• Public disclosure of directors’ details and financials.

• Directors are still personally liable for health & safety breaches. Best suited for

• Scaffolders aiming to grow and secure bigger contracts.

• Businesses needing reinvestment in plant, vehicles, or safety systems.

• Firms that want stronger client trust and scalability.

Limited Liability Partnership (LLP)

LLPs combine the liability protection of a company with the flexibility of a partnership. Profits ‘flow through’ to members, who pay Income Tax individually. This avoids corporation tax, but removes the ability to retain earnings in the business.

Drawbacks

• More complex setup than sole trader — must register at Companies House and file annual accounts.

• Less privacy than sole traders due to public filings.

• Can be less familiar to insurers and clients compared to Ltd companies. Best suited for

• Partnerships of two or more scaffolders.

• Teams who want liability protection but prefer income taxed directly to members.

• Scaffolders who value flexibility but don’t need the reinvestment advantages of a Ltd.

Conclusion

For scaffolders, liability and credibility are the two biggest factors when choosing a business structure. Sole trading is quick and easy but risky, especially given the safety-critical nature of scaffolding. Limited companies strike the best balance of protection, tax efficiency, and client confidence — making them the go-to choice for most growing scaffolding firms. LLPs can work well for partnerships, but they lack the tax planning and reinvestment benefits of a company.

Ultimately, if you aim to secure public contracts, expand your workforce, and invest in equipment, forming a limited company is usually the strongest route.

EASIER. SAFER. SMARTER.

As an industry-leading provider for scaffolding and construction safety products, TRAD UK has always championed innovation. Our comprehensive range sets new standards for access equipment and safety systems.

Our efficiency and safety are matched by the highest levels of service delivered by our experienced team and nationwide support network of depots. So, it’s easier than ever to find the right solution for your project.

Background checks: what are the costs of non-compliance?

Good health & safety starts all the way back during the hiring process, before anyone ever steps on site. In a high-risk industry like scaffolding, employers have to consider if a candidate will be responsible, capable, and trustworthy – and a solid background check can help with that.

In this article, Associate Members of the Scaffolding Association, uCheck, talks you through your legal duties as an employer when it comes to background screening, and the potential costs of noncompliance so you can make safe, informed hiring decisions.

What the law says

Many background checks are optional – but others, like Right to Work checks, are mandatory, and must be completed for every applicant. If you’re found to be in breach, you could open yourself up to £60,000 in fines for every illegal worker you employ.

A CITB report from 2022 found that 9% of construction workers were employed by an agency. Whilst recruitment agencies have the responsibility to complete a Right to Work check before providing employees, it’s also good practice to double-check these documents for extra legal protection and assurance

Other checks

For the most part, scaffolders and construction workers don’t need DBS checks. But it all depends on the project at hand. For example, if you’re working around children or vulnerable adults (e.g. erecting scaffolding at a school or care home) then your workers will need an Enhanced DBS with Barred Lists check. This will check your employees’ criminal record history and also see if they’re barred from working around vulnerable groups.

Under the Safeguarding Vulnerable Groups Act 2006, anyone found to be working around vulnerable groups when they’re not supposed to could be jailed for up to five years, or fined

For extra peace of mind, it’s a good idea to carry out an ID check. Digital ID checks are faster and more secure than manual ID checks, and can validate documents from over 200 countries – great if you’re working with overseas workers or those on a temporary work visa!

Why checking matters in the scaffolding industry

The scaffolding industry can be an incredibly risky sector. And trusting unverified workers – whether via bad credentials or from unchecked agency suppliers – puts both projects and people at risk.

Competence isn’t optional. The law requires that everyone working around scaffolding must be properly trained, or under a trained professional’s supervision. This helps keep everyone safe and compliant under both the Work at Height Regulations 2005 and the Health and Safety at Work etc. Act 1974. Good screening checks make sure you’re employing the right people, helping to keep everyone safe on site.

uCheck: Keeping companies safe since 2002

uCheck help take care of your admin legwork and work to get your background and screening checks returned as quickly as possible. You can find everything all in one place via their platform, giving you the tools to make smart, informed hiring decisions.

As a Scaffolding Association member, you can sign up to uCheck today and get free registration. Simply scan the QR code and enter code SAUCHECK or give them a call on 0300 140 0022 and remember to quote “The Scaffolding Association.”

Making Tax Digital: A quick guide for self-employed scaffolders

With the introduction of Making Tax Digital (MTD) for Income Tax fast approaching, the Scaffolding Association has produced this practical guide to help self-employed scaffolders understand the upcoming changes – and what to do now to prepare.

What is Making Tax Digital?

Making Tax Digital (MTD) is a government initiative aimed at transforming the way businesses and self-employed individuals report their taxes. MTD requires taxpayers to keep digital records of their income and expenses and to submit tax information to HMRC through compatible software, rather than using paper records or annual tax returns.

What it means for scaffolders

If you are self-employed here is what you will need to do for MTD:

Keep digital records

Use software (or an app) to log income and expenses from your scaffolding jobs.

Send info quarterly

Every 3 months, you will need to send a summary of your income and expenses to HMRC.

Final end-of-year submission

At the end of the tax year, confirm your income and tax owed – similar to your current Self Assessment.

Key dates you need to know

• 6 April 2026 – MTD becomes mandatory for sole traders earning over £50,000.

• 6 April 2027 – Extends to those earning over £30,000.

If you are earning under £30,000, you will not be required to join, but you can opt in.

6 April 2026

6 April 2027

6

Get used to digital record-keeping

Scan here to find out more about the upcoming changes. 2 3 4 5 6 1

Start logging income and expenses digitally – even if you are still submitting a paper tax return this year as this will make the switch seamless.

Choose and test software early

Try out MTD-compatible software before it becomes compulsory. Most offer free trials which can help find one that works best for you.

Separate your business finances

If you have not already, open a separate business bank account. This will keep your records clean and easier to track in your software.

Gather receipts digitally

Use an app or phone camera to snap and store receipts. Some apps even sort them into categories automatically.

Sign Up for a Government Gateway Account

You will need this to link your tax software to HMRC. It is free and only takes a few minutes to set up which you can do on the website: gov.uk/personal-tax-account

Speak to an accountant

A tax advisor can help make sure you are claiming all allowable expenses (like PPE, tools, travel) and that you’re MTD-ready well before the deadline.

16,000

4,500

What are CITB’s Employer Networks?

Employer Networks are an initiative set up and funded by the CITB, aiming to simplify the way you get the support and funding you need to access the training you want. It is all part of the service.

They have two main objectives: 2 1

Make it easier for you to access training and funding

The training can be in anything that supports construction employers. These could be the trade skills you need right now or something you will need in the future - such as net zero, digital skills or mentoring. And because the Employer Networks help organise it all, you do not need to complete any paperwork to apply for funding.

To bring together employers at a local level to inform CITB on training needs

To advise how funding should be prioritised and allocated, and to effectively use training provision to address immediate and future skills needs in their region.

Employer Networks have been piloted since July 2022 and have proven to be successful in helping more employers to train and offer them support.

I’m really excited about Employer Networks – this is about putting employers in the driving seat to identify and address their skills challenges and how best CITB can align our funding and resources to support their skills needs.

I would encourage employers in the Network areas to get involved and use their voice to shape training provision.

Tim Balcon, CITB Chief Executive

Through 2024, CITB rolled out the initiative to provide GB-wide coverage, with many Networks now live.

Scan here to find out more and to check your Local Employer Network: