WELCOME

ROLL CALL FOR NEW SCAFFOLDING ASSOCIATION MEMBERS

SCAFFOLD CONTRACTOR

AGA Scaffolding Ltd

www.aga-scaffolding.co.uk 020 8746 9448

Another Level Scaffolding (Midlands) Limited 0116 260 7332

CKJ Services Limited www.ckjscaffoldingservices. co.uk 07915 217604

Coles Scaffolding Limited 01638 720067

Dearne Valley Scaffolding Limited www.dearnevalleybrickwork. co.uk 07809 721438

Full House Scaffolding Limited www.fullhousescaffolding.co.uk 07908 744304

Hickery Brothers Scaffolding Limited www.hickerybrothers.co.uk 07831 823376

CONTACT US

Editorial

T: 0300 124 0470

E: info@accesspoint.org.uk

Advertising

T: 0300 124 0470

E: marketing@scaffolding-association.org

Scaffolding Association

T: 0300 124 0470

E: info@scaffolding-association.org www.scaffolding-association.org

SCAFFOLD CONTRACTOR

K J Tonner Building Services Ltd www.kjtbuilding.co.uk 01763 252922

Kitts Scaffolding Limited www.kittsscaffolding.com 01883 337870

LIT Construction Group Ltd www.litconstructiongroup.co.uk 07769 896229

Marsh Scaffold Ltd www.marshscaffold.co.uk 07780 462648

Mode Scaffolding Ltd www.modescaffolding.com 07475 868145

Powell and Johnson Scaffolding Ltd www.pjscaffoldingltd.com 07511 021727

Precision Scaffolding Ltd www.precisionscaffolding.co.uk 01271 603133

Subscriptions

AccessPoint is distributed to members of the Scaffolding Association and other selected access and scaffolding businesses.

If you wish to receive a copy of AccessPoint or would like to amend or cancel your subscription, please call 0300 124 0470 or email info@scaffolding-association.org

SCAFFOLD CONTRACTOR

Pro Scaffolding Solutions Ltd 07825 599262

RC Scaffolding (Exeter) Limited www.rccontracting.co.uk 07494 023675

REKO Contractors Ltd 07759 229543

Scaff & Co UK Ltd www.scaffcoukltd.com 07788 620930

SJR Scaffolding Limited www.sjrscaffolding.com 07585 806584

Southern Projects Limited www.southern-projects.co.uk 07919 604759

Speed Scaffolding Ltd www.speedscaffolding.co.uk 07732 943394

Square Scaffolding Solutions Ltd 07738 062043

AccessPoint is published on behalf of the Scaffolding Association. The views expressed in this journal are not necessarily those held by the Scaffolding Association. The Scaffolding Association shall not be under any liability in respect of the contents of the contributed articles. The Editor reserves the right to edit, abridge or alter articles for publication.

ISSN 2514-3719 (Print)

© All editorial contents AccessPoint 2025

Printed by Tewkesbury Printing Company

Designed by Gladstone Design

SCAFFOLD CONTRACTOR

Synergy J Limited www.synergyj.co.uk 07596 566072

Tear Scaffolding Specialists Limited www.tear-scaffolding.co.uk 01792 712117

Watson & Son Scaffolding Ltd www.watsonscaffolding.com 07359 756923

MEMBER SERVICE PR0VIDER

Architectural Decorators Limited T/A AD Construction Group www.theadgroup.co.uk 020 8269 6377

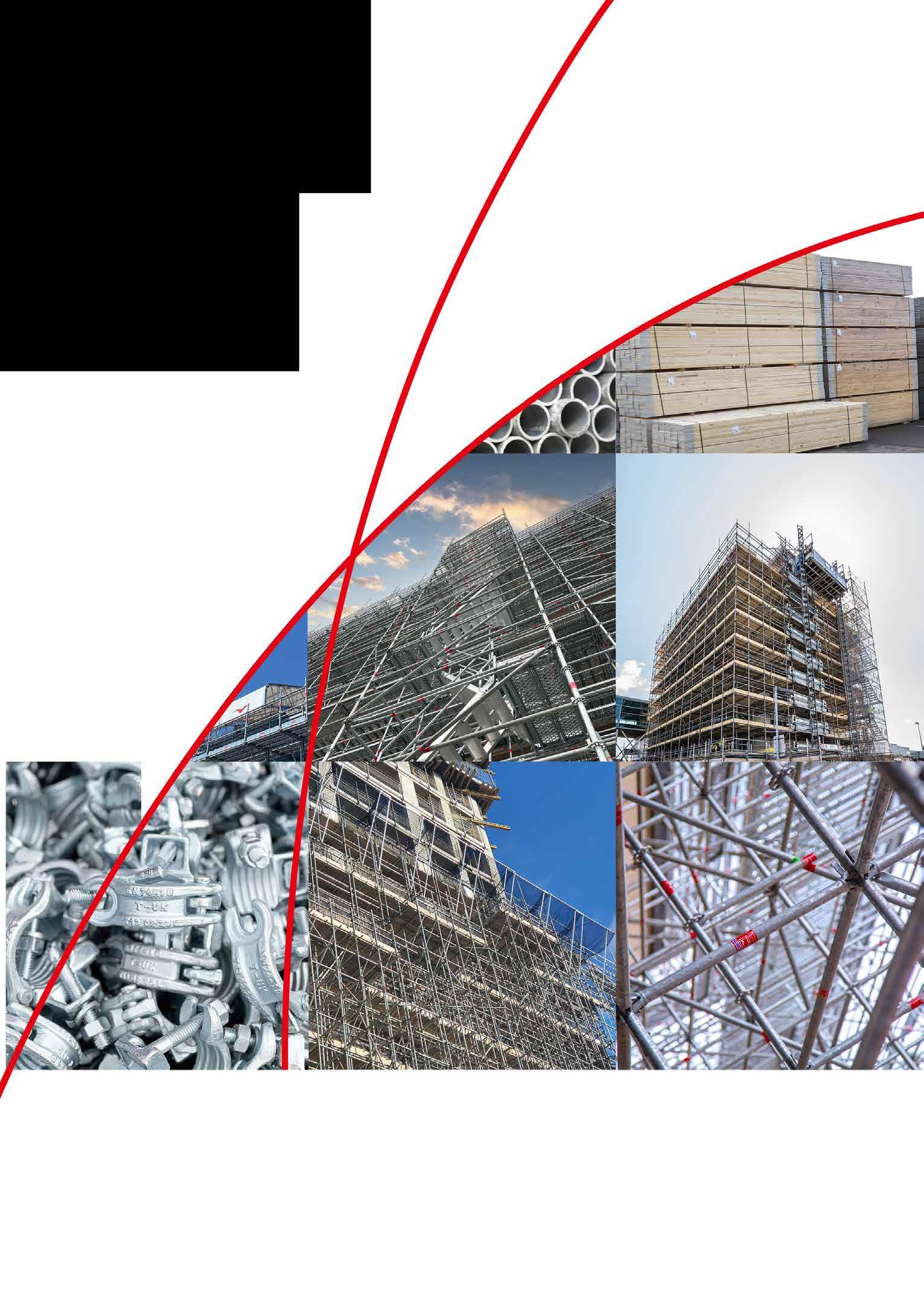

Cover and inside front cover images: Hammac Scaffolding

CONTENTS

COMMENT

P4 Reflections from the CEO

The Scaffolding Association’s Chief Executive reflects on the last 12 months.

NEWS

P5-8 Sector Updates

Explore all the latest news and developments shaping our industry.

BUDGET

P9 Autumn Budget 2025

What it means for the scaffolding and construction industry.

INTERVIEW

P10-11 In Conversation with David Thomas, Trustee of the No Falls Foundation:

We speak about fall prevention, safety leadership and the No Falls Foundation’s work.

GUIDANCE

P12-13 The Growing HAVS Risk Facing Scaffolders

Understanding HAVS risks and what employers can do to protect scaffold workers.

P15 Winter Working: 10 Practical Measures for Scaffolders

Practical, ready-to-use tips to help scaffolders stay safe this winter.

P30-31 UK Power Networks: Staying Safe Around Overhead Power Lines

Safety essentials for scaffolders working near overhead lines.

P32 Disclosure & Barring Service: Why Basic DBS Checks Matter

Why DBS checks support safer practices and professionalism in scaffolding.

PROJECTS

P16-17 First Choice

Two Scaffolding Association members join forces to overcome challenging access constraints for major cladding works.

P18-19 Speed

Members combined skills to produce an intricate bridged access design.

P20-21 Hammac

What happens when the call comes from DIY SOS: Children in Need Special, and how this the team rose to the challenge.

P22 MBM

We highlight the meticulous planning and safety management behind providing access for asbestos removal.

LEGAL

P24 When WhatsApp Messages Become Contracts

An important look at how everyday messaging apps can form binding agreements.

COMMERCIAL

P25 Citation: Why Cyber Attacks Threaten Every Business

Understanding rising cyber risks and ways scaffold companies can stay protected.

PRODUCT

P28 ITP: Using Scaffold Sheeting on Demolition Projects

A closer look at best practice for scaffold sheeting in demolition environments.

TRANSPORT

P29 Driving for Better Business: Responsibilities in Poor Weather

6 9 10 12 17 18 20 22 24 25 31 28 32 29

What scaffold-related vehicle operators need to consider when conditions deteriorate.

WELLBEING

P33 1.9 Million Workers Affected by Work-Related Ill Health

We look at the latest HSE statistics and what they reveal about mental and physical health across the workforce.

EVENTS

P34-35 ScaffStar Winners 2025 & National Scaffolding Week Highlights

Celebrating this year’s winners and how National Scaffolding Week 2025 celebrated excellence across the sector.

Comment

As we approach the end of another year, it feels like an important moment to pause, reflect, and take stock of where we are as an industry - and, crucially, where we are heading.

The past twelve months have been marked with change, continued uncertainty in national policy, and a great deal of noise across the business and wider construction landscape. Yet through all of this, the scaffolding and access sector has shown exactly what it does best: resilience, professionalism, and an unwavering commitment to keeping projects safe, compliant, and moving.

It has been a year in which the Scaffolding Association has taken major steps forward on behalf of our members. Our new memberships of Build UK and the National Home Improvement Council have strengthened our influence and ensured that scaffolding is represented in the rooms where decisions are made - whether the conversation is about skills, housing retrofit, procurement reform, or the future of construction safety. These partnerships are already helping us shape policy in a way that reflects the realities facing scaffolding contractors on the ground.

This year I have also continued to sit on the Construction Leadership Council’s People & Skills Workstream, helping to represent the scaffolding and access sector within one of the most important forums for industry-wide workforce strategy. This role allows us to highlight the skills shortages our members face, push for clearer training pathways, and ensure that competence, professionalism, and safety remain central to conversations about the future construction workforce. It is vital that scaffolding - too often overlooked - has a strong voice in these discussions, and we will continue to use that platform to champion the needs of our industry.

We have also deepened our work across the wider trade association community through the Trade Association Forum. This has given us access to best practice from every corner of the economy, and helped us champion the importance of high standards, strong governance, and member-led representation. Our sector has a long-overdue story to tell, and this year we have been telling it more clearly, more confidently, and more widely than ever before.

Of course, it has also been a year of challenges. Rising operational costs, uncertain procurement pipelines, inconsistent training governance, and the continued churn of ministers - particularly in the construction portfolio - have all created pressure for contractors of every size. The Autumn Budget provided some welcome measures, but many of the underlying issues facing scaffolding SMEs remain unresolved. That is why the Association has doubled down on its engagement with government, making the case for fairer contracting, accessible training pathways, and a more stable policy environment that allows businesses to plan ahead.

We have also taken steps that speak to our wider purpose as an organisation - including signing the Armed Forces Covenant and strengthening our commitment to social responsibility. These actions are about more than sentiment; they reflect a belief in the importance of bringing new talent, new skills, and new perspectives into our sector, and in supporting the communities we work within every day.

As we look towards the year ahead, our priorities remain clear. We will continue to push for reform where it is needed, for unity where it is lacking, and for recognition of the skilled, safety-critical work our members deliver. We will expand our influence, strengthen our partnerships, and ensure that scaffolding has a strong, credible voice at every level of government. And above all, we will keep working to raise standards, champion competence, and support businesses through the challenges and opportunities that lie ahead.

To all our members: thank you. Your commitment to professionalism and safe working is what defines this industry. On behalf of the entire team at the Scaffolding Association, I wish you a restful Christmas break and a successful, safe, and positive year to come.

ROBERT CANDY CHIEF EXECUTIVE, SCAFFOLDING ASSOCIATION

Our sector has a longoverdue story to tell, and this year we have been telling it more clearly, more confidently, and more widely than ever before.

The Scaffolding Association attended London Build 2025 on 19–20 November, as the UK’s largest construction show marked its 10th anniversary at Olympia London.

This year’s event brought together more than 38,000 professionals, alongside 750+ speakers and 450 exhibitors, offering a valuable platform for industry engagement, collaboration and discussion.

Robert Candy, Chief Executive of the Scaffolding Association, joined industry leaders to explore how the sector can strengthen its approach to wellbeing on the panel “Mental Health in the Construction Industry: What Needs to Change?”

Robert was joined by representatives from Bowmer & Kirkland, CIOB, KierBam, PRP Architecture and VolkerFitzpatrick

to discuss the need for stronger leadership, openness, and practical action across all levels of the workforce.

Speaking after the session, Robert commented:

“Mental health conversations must evolve into meaningful action. We all have a responsibility to create environments where people feel supported, valued, and able to speak up without stigma.”

Across the event, the Association team met with members, partners and stakeholders from across the scaffold industry, with London Build once again

demonstrating its value as a hub for learning, networking and industry-wide collaboration.

Scaffolding Association announces partnership with CQMS to strengthen member support on safety and compliance

The Scaffolding Association is pleased to announce a new partnership with CQMS Ltd, a trusted provider of health and safety consultancy, assessment, training and supply chain management services. The agreement, formalised through a Memorandum of Understanding, establishes a collaborative relationship designed to enhance the support available to Association members.

As an approved partner, CQMS will offer Scaffolding Association members access to a wide range of safety-focused services, including SSIP and Common Assessment Standard (CAS) assessments, supply chain management solutions,

consultancy support and health and safety training. Guidance throughout the Safety-Scheme assessment process is provided at no additional cost, ensuring members receive expert assistance from application to approval.

With more than 15 years’ experience, CQMS is recognised as a UKAS Accredited Inspection Body, an SSIP Registered Member, and a Build UK Recognised Assessment Body, providing one of the most efficient and costeffective routes to achieving health and safety approval.

Scaffolding Association members can also benefit from preferential pricing

across CQMS assessment packages, including SSIP assessments and CAS Premium and Elite options, offering both value and flexibility for businesses of all sizes.

For more information or to speak to the CQMS team, members can contact:

Tel: 01476 566 665

Email: enquiries@cqms-ltd.com

Web: https://cqms-ltd.co.uk

Supporting safer roads for the scaffolding and access sector

Road safety is a critical, yet often overlooked, part of daily operations for those working within the scaffolding and access sector. Whether transporting equipment, collecting materials, or travelling between sites, changing weather conditions and seasonal hazards

can significantly increase risks. As a strategic partner of Driving for Better Business, the Scaffolding Association fully supports its mission to promote safer, smarter driving across the industry. Members are encouraged to make use of the wide range of free resources,

including tools, checklists and guidance specifically designed for operators and drivers working in high-risk, mobile industries such as scaffolding.

More

www.drivingforbetterbusiness.com

360 Degrees Consultancy opens new office at Ashton Old Baths to support Manchester’s scaffolding sector

360 Degrees Consultancy Ltd has officially opened a new office at Ashton Old Baths, strengthening its presence across Greater Manchester and the North, expanding its support for the region’s growing scaffolding and construction industries.

The new office was formally opened by Robert Candy, Chief Executive Officer of the Scaffolding Association, during a launch event attended by clients, partners, and members of the 360 Degrees team.

The occasion carried particular significance for 360 Degrees Consultancy, as the Scaffolding Association was the company’s very first consultancy client. Having Robert Candy cut the ribbon was therefore a fitting and symbolic milestone in the business’s continued growth.

“Our partnership with the Scaffolding Association helped shape the early direction of 360 Degrees,” said Karl DeGroot, Director at 360 Degrees Consultancy. “To have Robert open our new Manchester office feels like things have come full circle. This space represents our commitment to serving scaffolding companies across the North West with the same expertise and personal service that have driven our success so far.”

Located in the historic Ashton Old Baths, a restored Victorian landmark turned modern business hub, the new office provides 360 Degrees with a strategic base to support clients across the Manchester and wider Northern scaffolding market.

Commenting on the opening, Robert Candy said:

“It’s fantastic to see 360 Degrees continuing to grow and investing in the regions that need expert consultancy support. Their work with scaffolding contractors has consistently helped raise standards and strengthen compliance across the industry and our wider membership.”

The expansion marks another milestone in 360 Degrees Consultancy’s development, reflecting increasing demand for practical, competent advice in areas such as health and safety management, compliance auditing, and business improvement within the scaffolding and construction sectors.

More www.360degreesconsultancy.co.uk

Workers can spot qualification fraud — but many unsure how to report it

A new survey from Ofqual, CITB and CSCS shows that while most construction workers feel confident spotting the signs of qualification fraud, 78% don’t know how to report it. Respondents overwhelmingly agreed that reporting concerns is vital for safety, but many were unclear on the correct process or worried about confidentiality.

Qualification fraud ranges from fake certificates to “fast-track” courses or cheating during tests, and can lead to fraudulent CSCS cards being used to access sites. Workers are often the first to recognise when someone’s realworld skills don’t match their claimed qualifications.

To support clearer reporting, partners reminded workers to:

1. Check CSCS cards using the CSCS Smart Check app or website

2. Trust their judgement if a worker’s ability doesn’t align with their qualifications

3. Report confidentially to intel@cscs.co.uk or through Ofqual’s complaints procedure Anonymous reporting is available, and concerns are investigated based on evidence, not the identity of the reporter.

Scan here to find out more:

Build UK marks 10 years of industry collaboration

The Scaffolding Association’s Chief Executive, Robert Candy, attended Build UK’s 10th anniversary celebration at The Lookout at 8 Bishopsgate in London on the 19 November, joining more than 200 members and industry stakeholders for an evening recognising a decade of collaboration and progress.

Supported by sponsors Citation, CONSTRUCT, John Sisk & Son, Keltbray, Multiplex, People’s Pension, Quintain and Willmott Dixon, the event highlighted the milestones Build UK has achieved since its formation in 2015. Over the last ten years, the organisation has played a central role in uniting the construction industry around shared priorities, driving improvements in skills,

procurement, safety, and supply chain performance.

Speakers reflected on Build UK’s impact to date and its ambitions for the decade ahead, emphasising the importance of strong partnerships and industry-wide cooperation. For the scaffold industry, Build UK’s work has helped strengthen

representation, improve standards, and support greater alignment across the wider construction landscape.

The event marked not just ten years of Build UK, but the collective commitment of its members and partners who continue to work together to build a safer, more productive and forward-looking industry.

Celebrating the CBI’s 60th anniversary, a milestone for UK industry and the scaffolding sector

This year marks the 60th anniversary of the Confederation of British Industry (CBI), a significant milestone for an organisation that has long championed the interests of UK enterprise. For six decades, the CBI has brought together businesses of all sizes to drive economic growth, influence policy, and promote a competitive and sustainable business environment.

As proud members of the CBI, the Scaffolding Association recognises the vital role the organisation plays in giving industry a collective voice. The scaffolding and access sector, central to the UK’s construction ecosystem, benefits deeply

from the CBI’s leadership on issues such as skills, productivity, regulation, and economic strategy. Through our membership, we help ensure that the needs, challenges, and contributions of scaffolding businesses are heard at the highest levels of government and industry dialogue.

The CBI’s 60th anniversary provides an opportunity not only to celebrate its achievements but also to reflect on the importance of collaboration across all parts of the construction supply chain. As our sector continues to evolve, embracing new standards, safer working practices,

SIMIAN celebrates 20 years at the forefront of training and safety

SIMIAN is marking 20 years as one of the UK’s leading construction and scaffolding safety training providers. Established in 2005, the organisation has grown from a small team of industry specialists into a nationally recognised training and consultancy partner supporting businesses across the construction industry.

From its starting point in Warrington, SIMIAN now operates three core training centres in Warrington, at the London Academy of Sustainable Construction in London, and at SOMAX in WestonSuper Mare, supported by satellite centres in Menai, Kent, and Letchworth. In recent years, SIMIAN has expanded its capabilities with the introduction of roofing training delivered from a dedicated roofing centre in Warrington,

reflecting its commitment to meeting the changing needs of the industry.

Managing Director, Simon Hughes said:

“Reaching 20 years in business is an incredible achievement and a proud moment for our entire team. Over the years, our team has grown, our training centres have expanded, and our services have evolved, but our commitment to excellence has never wavered.”

As SIMIAN celebrates this milestone, the organisation continues to focus on raising standards, improving safety, and supporting skills development across the UK.

Scan here to find out more:

and modern methods of construction, the influence of organisations like the CBI remains essential in shaping a strong and future-ready business landscape.

Robert Candy, Chief Executive Scaffolding Association, stated:

“We congratulate the CBI on reaching this milestone and look forward to continuing our shared commitment to supporting UK industry, empowering businesses, and championing the scaffolding sector’s crucial role in building the nation’s future.”

More www.cbi.org.uk

Companies House confirms mandatory identity verification from November 2025

From 18 November 2025, all new and existing company directors and people with significant control (PSCs) will be required to verify their identity with Companies House. The move is designed to give greater assurance about who is setting up, running, owning and controlling companies in the UK, strengthening the reliability of the register and supporting efforts to tackle economic crime.

Companies House says the new verification system has been built to be “simple, secure and robust”. Since its

voluntary rollout in April, more than 1 million individuals have already completed the process.

Chief Executive, Andy King said:

“One million identities verified is an important milestone, but it’s only the beginning. Identity verification will help make sure that the people setting up, running and controlling companies are who they say they are. This will make our data more reliable and less open to misuse, supporting a more transparent and trusted business environment.”

Individuals can verify their identity either:

• directly with Companies House using GOV.UK One Login, or

• through an Authorised Corporate Service Provider

Verification typically takes minutes, and users receive a personal code. From 18 November, directors and PSCs must use this code and a verification statement for each role they hold and will also be able to check due dates for all roles on the register.

Scan here to find out more:

Open Doors 2026: a chance for scaffold businesses to inspire the next generation

Booking for Open Doors 2026 opens on Monday 12 January, giving scaffold businesses a prime opportunity to highlight the vital part scaffolding plays in delivering some of the UK’s most high-profile construction projects.

With over 100 events already registered, visitors will be able to see behind the scenes at sites including Buckingham Palace, the Natural History Museum –Unlocked, Edgbaston Cricket Ground and Aintree Hospital — all environments where professional access solutions are essential.

Running from 23–28 March, Open Doors continues to draw strong interest from schools, colleges and universities, offering

a platform for scaffold contractors to promote career pathways in safety, design, access engineering and site operations.

Scaffolding companies taking part are encouraged to upload their events ahead of the Christmas break to maximise visibility and engagement with young people exploring industry careers.

More www.opendoors.construction

Update on the Employment Rights Bill

The Government has reached agreement with unions and business groups on key changes to the Employment Rights Bill, allowing it to progress as planned. The qualifying period for unfair dismissal will be reduced from 24 months to 6 months, while existing day-one protections against discrimination and automatically unfair dismissal remain in place.

New day-one rights to sick pay and paternity leave will also be introduced from April 2026, supporting millions of workers and giving businesses time to prepare for the changes.

Scan here to find out more:

Assessment bodies renew approval for common assessment standard

The seven Recognised Assessment Bodies for the Common Assessment Standard — Achilles, Compliance Chain, Constructionline, CQMS, SCCS, Smas Worksafe and Veriforce CHAS — have successfully passed their annual competency review, confirming

approval for another 12 months.

For scaffolding businesses, this provides valuable continuity. The Common Assessment Standard is now widely used across construction to streamline prequalification, helping scaffold contractors demonstrate strong safety, quality and

compliance standards without undergoing multiple assessments.

To find out more about the Common Assessment Standard and the Recognised Assessment Bodies, scan here:

80% of readers are specialist contractors who purchase products and services

16,000 access and scaffolding professionals

4,500 individual addresses

Autumn Budget 2025 – what it means for the scaffolding and construction sector

The Autumn Budget 2025 offers some reassurance that the Government remains committed to infrastructure investment and major public projects.

This continued focus is welcome, particularly for the construction industry and the specialist trades - including scaffolding - that make safe, efficient project delivery possible. However, despite several positive measures, several significant challenges facing scaffolding contractors remain unaddressed.

For scaffolding businesses operating in a safety-critical environment, rising costs, skills shortages and unstable procurement practices continue to dominate daily pressures. While the Budget touches on these issues, it falls short of providing the clarity and targeted support needed to protect SME contractors that uphold high standards and invest heavily in compliance, training and safe working.

One of the headline announcements was the introduction of free training for under-25 apprentices, a welcome step towards encouraging young people into construction. However, the scaffolding sector needs a far broader, fairer and more transparent approach to skills development if it is to attract and retain the workforce required to meet the UK’s ambitions on housing and infrastructure. This includes reforming training pathways, improving funding routes for SMEs and ensuring qualifications remain robust and recognised.

Several wider tax and workforce changes were also announced. Salarysacrifice pension contributions above £2,000 per year will attract National Insurance from 2029, and tax rates on

dividends, savings and property income will rise by two percentage points. Personal tax thresholds will remain frozen from 2028–29, gradually moving more employees into higher tax bands. For contractors managing tight margins, these cumulative pressures could affect wage expectations and staff retention.

Business rates remain a frustration. While reductions continue for retail, hospitality and leisure, there were no new reliefs for industrial, construction or yard premises - despite scaffolding businesses often occupying large, highvalue sites for storage, transport and materials handling.

Fleet-related announcements offered mixed results. The 5p cut in fuel duty has been extended to September 2026, providing short-term relief for diesel fleets widely used across construction. Electric vehicle support has been expanded - including charging infrastructure and rate exemptionsbut no new measures were introduced to support sectors reliant on HGVs or specialist vehicles where viable zero-emission alternatives do not yet exist. This remains a significant gap for construction transport.

Wage announcements will also affect employers: from April 2026, the National Living Wage will rise to £12.71 per hour, and the National Minimum Wage for 18–20-year-olds will increase to £10.85. While supporting workers during a costof-living squeeze, these increases will add further cost pressures on labour-intensive trades.

Commenting on the Budget, Robert Candy, Chief Executive of the Scaffolding Association, said:

“Our industry plays a vital role in keeping construction sites safe and keeping projects of all sizes moving. While there are some helpful measures in this Budget, many of the underlying issues facing SME contractors remain unresolved. We need a clear plan that supports skills, improves procurement, and helps businesses manage the rising cost of operating. The Scaffolding Association will continue to make the case for practical changes that support our members and the wider construction sector.”

In the weeks and months ahead, the Association will continue engaging with ministers and officials to ensure scaffolding and other specialist trades are not overlooked. Members wishing to discuss the Budget or its implications for their business are encouraged to get in touch.

An interview with

David Thomas

No Falls Foundation Trustee

David is also the former Director and Secretary of the Temporary Works Forum (TWf) and spent nearly a decade as a HM Principal Specialist Inspector (Construction) for the Health and Safety Executive (HSE).

Q. Could you start by sharing your career journey and what first drew you into temporary works, scaffolding and work-at-height safety?

A My early career was in civil and structural engineering and management consultancy, but I’ve also spent time in research, health and safety enforcement, steelwork fabrication and construction, product design, training, and promoting good practice. The journey has been more varied than I ever expected, yet height safety and temporary works have been recurring themes throughout. I’ve seen new safety legislation emerge, the growth of awareness and training, and the devastating impact of fatalities. I’ve experienced both excellent and poor planning, as well as unnecessary bureaucracy. Over time, these experiences pushed me towards roles where I felt I could influence outcomes for the better.

Q. You’ve held influential roles across the industry, including with the Health and Safety Executive (HSE) and the Temporary Works Forum (TWf). What key moments shaped your path into safety leadership?

A Many moments have shaped my outlook, but two stand out. The first was at HSE, where I had the opportunity to drive better standards and became involved in accident investigation and litigation. Once you witness the human consequences, you never forget them. The second was at the TWf, where I helped guide the forum into a new phase of collaboration and influence. Ultimately, my journey has been shaped by the continued need for learning, sharing mistakes, and raising the baseline across the industry.

Q. How has the scaffolding and temporary works sector evolved during your career?

A It has improved immensely. When I started, temporary works was often misunderstood, undervalued, or simply ignored - and the term itself was barely used. Today, we have structure, training, design processes and much better oversight. There is still work to do, especially among SMEs, but progress has been significant. The best projects now treat scaffolding as an engineered solution, while others still view it as something that “just happens”. That mindset must change, and clients are crucial in setting expectations and standards.

Q. Competence remains a major concern. What practical steps should companies take to improve Designated Individual (DI) and Temporary Works Coordinators (TWC) capability?

A Start by ensuring your board has formally appointed a Designated Individual (DI) - without one, you’ve missed the first essential step. Then appoint competent Temporary Works Coordinators (TWC) and/or Supervisors (TWS). Competence is more than attending a short course; it’s the balance of knowledge, skills, experience and behaviours. Every job is different. Invest in proper training, mentoring and ongoing support, and recognise that competence develops over time - you cannot tick-box your way to it.

Q. BS 5975-1: 2024 makes it clear that every company involved in temporary works must appoint a competent DI - yet many don’t. Why is that?

A It’s hard to say. Some companies still believe temporary works only matter on large projects. Others misunderstand the requirements, worry about cost, or want to avoid perceived “hassle”. But BS 5975-1 is unequivocal: if you have, or may have, temporary works, they must be managed by a senior personthe DI - who develops and oversees the organisation’s procedures. Without this leadership role, people are exposed to unnecessary and serious risk.

Q. Drawing on your accident investigation experience, what are the most persistent or misunderstood risks in work at height?

A The biggest issues are poor planning and familiarity. People become comfortable with routine tasks, and that’s when corners get cut. This is often called the “normalisation of deviance” and over time, a lower standard becomes the new normal because nothing bad has happened - yet many serious falls occur during routine activities: stepping down, reaching, moving a board, making unauthorised alterations. The danger lies in the mundane, not the dramatic. Always ask, “What’s different today?”.

Q. With changes in BS 5975-1: 2024, what developments will influence day-to-day practice the most?

A The latest edition isn’t revolutionary, but it provides welcome clarity. Roles and responsibilities are more clearly defined, which should lead to better practice and fewer site misunderstandings. But procedures alone aren’t enough - leadership is essential. Everyone must feel able to question or challenge unsafe decisions without fear.

Q. For readers who may not know, what is the No Falls Foundation and why is its work important?

A It’s the UK’s only charity dedicated solely to preventing falls from height - which makes it invaluable. Falls from height remain the leading cause of workplace deaths, and the Foundation fills a vital gap through research, education, awareness and support for affected families. As a Trustee, I would encourage every company to consider becoming a Supporter or donate (https:// nofallsfoundation.org/index.php/getinvolved/supporter-scheme/)

Q. No Falls Week is becoming a fixture in the safety calendar. What impact is it having?

A It’s getting organisations talking meaningfully about work at height (https://nofallsweek.org/). It provides a moment for companies to pause and reflect on their own practices. I strongly urge scaffolders and temporary works professionals to take part - use the resources, share the messages and get involved. If you can support the charity financially as well, even better. Every contribution helps.

Q. In your view, what is the core mission of the TWf today?

A To share knowledge openly. The TWf brings together people from across construction to discuss issues honestly and develop practical guidance. Encouraging a culture of openness is its greatest contribution.

Q. You’ve written about major milestones such as the Bragg Report. How far has the industry come, and what remains to be done?

A The industry has come a long way. Temporary works is now recognised as an engineering discipline in its own right. Yet incidents and poor practice persist, and challenges remain. When the TWf began, it involved only a handful of committed individuals with a simple mission. Today, it is a nationally respected body with influence far beyond what was originally envisaged. I expect continued growth, especially in sharing knowledge, producing guidance, training and digital learning.

Q. How well is the scaffolding industry engaging with TW processes today?

A There are pockets of very good practice, but overall engagement remains poor. Many still cling to outdated habits. The sector must look closely at what ‘good’ looks like, and I encourage leaders and directors to engage seriously with the principles set out clearly in BS 5975-1.

Q. What “must-do” actions should scaffolding and access contractors focus on today?

A First, appoint a Designated Individual (DI). Next, establish and implement robust temporary works procedures. Ensure all scaffolds are properly designed - unless they are genuinely standard, recognised configurations. And invest in training; competence repays itself many times over.

Q. What does excellent collaboration look like?

A It begins with early conversation. Everyone needs to understand the plan, the loadings, the sequence and the constraints. Early dialogue reduces problems on site. Safety is never optional, and the consequences of getting it wrong - financial, legal and human - far outweigh any investment in getting things right.

Q. What role should digital training toolssuch as TWf’s eLearning - play?

A They are an excellent way to raise awareness quickly and make learning more accessible. However, they cannot replace real-world experience. Competence requires doing, reflecting and learning over time.

Q. You were awarded the Institution of Civil Engineers’ Garth Watson Medal in 2023. What did that recognition mean to you?

A It was unexpected and humbling. I saw it as a recognition of the collective efforts of many people I’ve worked with at HSE and the TWf. The award reflected a shared contribution.

Q. Now that you’re retired from full-time roles, what keeps you engaged in the industry?

A I stay involved because I care. If I can continue to support, mentor or contribute to safer practice, it feels worthwhile. I’ve seen the consequences of things going wrong far too often. If sharing my experience helps others avoid those outcomes, then the time is well spent.

The Hidden Danger in Every Fitting. The Growing HAVS Risk Facing Scaffolders!

Protect your team today. Review your vibration exposure, tighten your controls and stop Hand-Arm Vibration Syndrome (HAVS) before it stops your scaffolders.

The health effects of HAVS at work

HAVS is one of the most persistent but least talked-about risks facing the scaffolding sector. It is a hazard that creeps in quietly over months and years, building through the repeated use of impact wrenches, drills and cutting tools that scaffolders depend on to keep projects moving.

When exposure becomes routine, the damage can be life-changing. Early warning signs like tingling fingers or fading grip strength can be brushed off as fatigue, yet they often signal the start of conditions that can limit a scaffolder’s confidence and capability both on site and at home.

When is it hazardous?

The risk becomes significant when exposure is regular and frequent, something that is common in scaffolding where impact wrenches may be used for hours each day. Occasional or short bursts of vibration are far less likely to cause harm, but repeated daily use can lead to permanent health issues over time.

What is HAVS?

HAVS is the transfer of vibration from tools and work processes into the hands and arms. For scaffolders, this most commonly comes from impact wrenches tightening fittings, reciprocating tools for tube cutting and hammer drills for fixing ties when dismantling stubborn sections. Other equipment, such as concrete breakers or disc cutters used around access installations, can also contribute.

What health effects can it cause?

Prolonged exposure can cause a range of related conditions known collectively as HAVS. It can also trigger specific diseases such as carpal tunnel syndrome. Both conditions can have a serious effect on a scaffolder’s dexterity, grip and long-term ability to work safely at height.

What are the symptoms?

Catching symptoms early is essential so employers can intervene before permanent damage occurs. Early indicators include:

• tingling or numbness in the fingers

• struggling to feel small objects or fittings properly

• noticeable loss of hand strength

• fingers turning white in cold or wet conditions and becoming painful as they warm back up

Do you have a HAVS problem on your scaffolding jobs?

You may need to take action if any of the following sounds familiar:

scaffolders report tingling or numbness after using impact wrenches power tools are used for extended periods with no rotation of tasks workers regularly use tools such as:

impact wrenches

• disturbed sleep.

For some scaffolders, symptoms may appear within months; for others, it may take years. Without action, the symptoms are likely to worsen and may become permanent.

All these symptoms can impact far beyond the workplace, but also everyday activities at home.

grinders or disc cutters

percussion drills

hammer-action tools are used for more than around 15 minutes a day

rotary or cutting tools are used for more than an hour a day.

The HAVS exposure calculator

HSE hand-arm vibration calculator can assist you in calculating exposures.

www.hse.gov.uk/vibration/assets/docs/simple-hav.xlsx

DIGITAL TIE TESTING?

Onsite testing services available nationwide by our fully qualified CFA Installation & Testing Teams

Our all-in-one solution for rigorous pull-shear testing on anchors and eye safety bolts up to 25kN.

Designed to help you seamlessly align with global industry standards like BS8539, BS7883, NASC guidance TG4:19, and AEFAC guidance TN05, this kit is a fusion of technology and durability.

www.360degreesconsultancy.co.uk/pull-testing/

Practical Steps to Protect Scaffolders During Winter

Winter presents a unique set of challenges for scaffolders. Shorter days, cold metal components and wet or icy boards all increase the likelihood of incidents. The Scaffolding Association has outlined practical measures below to help everyone stay safe when conditions deteriorate. This could make a great Toolbox talk!

Working with tubes, fittings and system components becomes noticeably harder in low temperatures. Cold exposure can reduce grip strength, slow decision making and make precise tasks such as tying, fixing or levelling far more difficult. Visibility is another major concern. Scaffolders often work close to site traffic and plant. Being struck by vehicles remains one of the leading causes of fatal workplace injuries. Slips and trips are also a significant risk. Wet or icy boards, ramps and access routes can turn hazardous very quickly.

The following ten steps are tailored specifically for scaffolding operations and can help reduce risk throughout the winter season.

Begin each shift with a winter safety briefing

Toolbox talks should cover weather changes, reduced daylight and site-specific risks. Scaffolders should feel confident stopping work and reporting hazards if boards are icy, access is unsafe or visibility has dropped.

Include stretching and mobilisation exercises at the start of the day

Scaffolding work involves heavy lifting, repetitive movements and awkward positions. Cold muscles are more prone to strains. A short warm-up helps prepare the body for lifting tubes, carrying boards and other repetitive work.

4 6 8 9 10 3 7 10 2 1

Ensure PPE and clothing are suitable for cold work at height

Layering helps maintain warmth. Footwear should provide strong grip for wet boards and gloves must balance insulation with dexterity. Helmet liners should fit safely beneath hard hats without affecting harnesses.

Improve visibility with photo-luminescent hard hat markings

Scaffolders moving between lit and darker areas, especially on multi-level structures, benefit from hard hat stickers that glow in low light. This is particularly useful during early starts, evening breakdowns or complex lifts.

Use high-visibility clothing that meets EN ISO 20471

Hi-vis gear increases visibility around site vehicles and lifting operations. Choosing colours that stand out from the wider workforce helps teams remain visible during lifts and loading operations.

Check winter signage and site access routes

5

Clear danger signs should be placed near icy decks, frozen ties, temporary ramps and loading bays. Signage is required whenever risks remain after reasonable controls have been applied.

Schedule warm-up breaks and provide heated rest areas

Cold metal quickly drains hand and body warmth. Heated cabins, hot drinks and drying rooms for wet harnesses, gloves and clothing help maintain grip, concentration and safety.

Strengthen vehicle and loading-bay safety

Reverse-parking policies, segregated loading zones and exclusion areas reduce risks. Ensure operatives and drivers are trained, and consider online modules to support learning.

Promote steady energy levels through balanced eating

Working in cold, physically demanding conditions requires consistent energy.

Balanced meals help maintain focus better than high sugar or excessive caffeine.

Support mental health during darker months

Seasonal affective disorder [SAD] can affect wellbeing. Access to reliable mental health resources, including Mental Health First Aid England, helps scaffolders recognise symptoms early and seek support when needed.

Scaffolding Association Members are First Choice for Complex Cladding Project

Fully Audited Members of the Scaffolding Association, First Choice Scaffolding Ltd, and Designer Members, Tubular Techniques Ltd, teamed up to provide roof level support for cradle platforms to facilitate cladding works on the Ashburton Triangle, London.

Rolfe Contracting Ltd are the Main Contractors who have been tasked with the cladding replacement works on the building, which is situated close to railway lines and the nearby Emirates Stadium.

It was the location of the building that dictated that access for the works was to be achieved with cradles, which were installed by South West Cradles UK Ltd. Marcus Killick, Head of Health and Safety at First Choice, explained:

“Temporary works were required at roof level to support cradles for the cladding works on some elevations due to the proximity of the railways. We had to provide working platforms whilst allowing the Arsenal FC Museum to remain operational.

In addition, we had to ensure the public was adequately protected due to the high footfall on Arsenal’s matchdays, which also created some issues with timings available for works.”

In addition to the location, the very nature of the building also meant careful consideration was required at the design stage. Kyle Drewett, Senior Engineer at Tubular Techniques Ltd, clarified:

“Due to the construction make-up of the roof, limited to no vertical loading was permitted, with only support coming from the parapets and isolated steel frame structures on the roof.

We had very limited areas to support from and minimal information on the building construction, with on-site opening up works required across all roof areas.

The method of construction for the roof was found to vary throughout, and the roof also has many level changes and a steep sloped section.”

This project was multifaceted and complex, Marcus commented:

“The main challenge was the roofbased temporary works which required a great number of beams to ensure it was adequately secured and avoided the railway lines running past two sides of the building. In conjunction with Tubular Techniques, we found the right solution to meet the client’s needs.”

When asked about the solutions used to overcome these challenges, Kyle added:

“As we were hanging cradles over the roof it is a high-risk structure with downforce and uplift forces to consider.

Our main challenges were supporting our cantilevering beams with the downforce situated on the parapet

and how to resist uplift to the back of the beams.

To ensure a solid footing we cut pockets into the parapets around the perimeter, inspecting each one to determine a detail. To resist uplift we needed to transfer the loads back into the permanent structure, with alloy beams installed at different angles and additional scaffold beams connecting to the isolated steel frames.”

Kyle also mentioned that his least favourite part of the project was:

“Having limited information on the permanent structure support for our scaffold. In addition, different construction techniques throughout made it difficult to ensure the scaffold is safely supported.”

Tubular Techniques also had to take into account how the scaffold was going to be erected, Kyle continued:

“A section of the roof had a steep slope, so access was limited. Therefore, flexibility needed to be considered within the design for when First Choice came to erect the support scaffold.”

Once the design was confirmed, it was over to First Choice to bring the project to life, which brought its own set of unique complications, Marcus explained:

“The amount of materials required on the roof and getting the beams to the roof level was a challenge. Large amounts of material could not just be delivered and stored at roof level, so the beams needed to be lifted manually day to day.”

The location of the building also provided the First Choice team with some problems that they overcame with precise planning, Marcus commented:

“With the Emirates Stadium next door, we had to guarantee that we finished work early on match days to ensure the public were suitably protected.”

It was not just the Stadium that affected the erection of the project, Marcus continued:

“The process of gaining clearance from the railway did create some delays to some of the temporary works construction.”

The excellent communication between all the various teams was fundamental in the success of this project, Kyle concluded:

“When designing and erecting a scaffold which is constantly requiring adaptation throughout the project, communication and confidence between engineer and scaffold site team is key. Being able to see First Choice erect the scaffold as per design, which was developed from our continued discussions and changes, was my favourite part of the project.”

The amount of materials required on the roof and getting the beams to the roof level was a challenge. Large amounts of material could not just be delivered and stored at roof level, so the beams needed to be lifted manually day to day.

Marcus Killick, Head of Health and Safety at First Choice Scaffolding Ltd.

When asked about his favourite part about the project, Marcus concluded:

“The project team from the client were always helpful and appreciated our efforts in getting them the best solutions for their requirements.

Also, our Managing Director, Dale Hope, is an Arsenal fan so he was very happy to display our work so close to his club.”

Overall, the project was a huge success due to the exceptional collaboration of all the teams involved, and the structure has been handed over to the clients to facilitate the cladding replacement works.

Bridged Scaffold Built on Precision by Scaffolding Association Members

Scaffolding Association members Speed Scaffolding Ltd and Prime Scaffold & Structural Designs Ltd (PSD) combined their expertise on an intricate bridged access scaffold project at Kirk House, West Drayton.

The scaffold was required to provide access to the roof to facilitate the construction of additional flats in the loft space of the existing residential building.

The project brief came with strict requirements, Lukasz Krawczyk, Director at Speed Scaffolding, explained:

“Access was required to all elevations, and we had to ensure the scaffold did not obstruct the underground car park located beneath the building. Clear access for vehicles and pedestrians had to be maintained throughout the project. We had to maintain full access for residents and avoid blocking parking bays or pathways at all times.”

The car park situated under the building was the main consideration for this project. Vipin Bariya, Design Manager at PSD, commented:

“One of the main requisites of the design brief was that all entrances to the car park had to be bridged and kept clear of scaffolding. We also had to ensure that sufficient head height in the car park area was maintained throughout.”

There were further complications that required precise planning, Lukasz stated:

“The scaffold had to be erected without placing any load on restricted areas, while still providing full access to all elevations.”

All these considerations were taken into account from the very beginning, Vipin added:

“The challenging part was not to ground any scaffold in the neighbouring property, or in the rear car park area. It was good that a site survey was carried out and all these constraints were discussed in detail, which meant that all of them were taken care of during the design process.”

Once all the information had been gathered, PSD developed solutions for the complex nature of the job, Vipin explained:

“We overcame these challenges by designing cantilevered beaming that was fixed to the columns with special shear ties and bridging the full length of the scaffold.”

There were some final restrictions that affected the design process, Vipin continued:

“There are rainwater pipes that run the full height of the car park columns where the ties were to be installed. To overcome this, we had to cut out scaffold beams, with backpropping and additional bolted ladder beams installed.”

With all factors taken into consideration, PSD conducted precise calculations and produced a highly detailed final design.

Then it was over to the Speed Scaffolding team to bring the drawings to life, Lukasz explained:

“The main challenge was installing the heavy-duty beam work over the underground car park and ensuring all loads were safely transferred to approved load-bearing points. This work was highly complex and required precise coordination with the design engineer. We overcame this by following the structural drawings exactly, planning each stage in advance, and using experienced advanced scaffolders to handle the beam installation safely and accurately.”

With thorough planning, Speed Scaffolding implemented a staged installation, Lukasz mentioned:

“Coordinating around residents and other contractors also added pressure, but we managed it effectively through careful coordination and precise timing.”

When asked about his favourite part of the project, Lukasz stated:

Due to the building being residential, there were further considerations required for the installation. Lukasz continued:

“Additional challenges included maintaining uninterrupted access for residents, working in very tight areas around the perimeter of the building, and coordinating our programme with multiple contractors. Despite the complexity of the heavy-duty beams and the confined working areas, we managed these challenges through careful planning, clear communication with the client, and maintaining strict safety controls throughout the project.”

“Seeing the complex design come together exactly as planned was my favourite part. It was rewarding to deliver such a technical scaffold safely and professionally while meeting the client’s strict requirements. This was one of the most technically demanding projects we have undertaken. It really showcased our teams’ skill, precision, and commitment to delivering safe scaffolding solutions in challenging environments.”

Vipin added:

“My favourite part of the project was finding the right solutions for everyone involved. It was an interesting, bridged scaffold and I enjoyed working with Speed Scaffolding, especially with Lukasz.”

With the exceptional collaboration and combined expertise of PSD and Speed Scaffolding, the project was a huge success, Lukasz concluded:

“This project demonstrates how complex scaffolding installations can be successfully delivered when design, planning, and on-site execution work together. Despite restricted load points, tight working areas, and the need to maintain access for residents at all times, the scaffold was erected safely, efficiently, and strictly in accordance with the engineered design. It highlights the importance of competent scaffolders, good communication, and strong collaboration between the design team and the site team.”

Building More Than Scaffolds: How Hammac Scaffolding Helped Build Hope for Children in Need

Taking part in the DIY SOS: Children in Need Special marked one of the proudest moments for the Scaffolding Associations’ audited member Hammac Scaffolding’s journey. When the call came asking the company to support an extraordinary community build for a charity close to its heart, there was no hesitation. This was not simply another project. It was an opportunity for the team to use its skills, teamwork and values to help create a life-changing space for families who desperately need it.

Building from the ground up

Unlike many other projects, the Hammac team stepped into a brandnew timber frame build, meaning the structure required complete support from the ground up.

The freestanding scaffold had to be engineered with absolute precision. With no existing walls to brace against, every lift, board, brace and tie needed to be strategically placed to maintain full stability. This presented a technical challenge, as well as an opportunity for the team to demonstrate its skill, accuracy and pride in its craft.

For Hammac Scaffolding, this was scaffolding in its purest form. Building the backbone of a space that would soon become a sanctuary for families supported by Children in Need.

Challenges that made the team stronger

No DIY SOS project comes without challenges, and this one was no exception. Limited space and unpredictable weather meant the team had to think on its feet.

Another unique challenge was the pace and scale of the build. DIY SOS transformations happen in days rather than weeks, and coordinating scaffolding adjustments between multiple trades while maintaining safety can be intense, particularly as this was the company’s biggest build to date. Still, the team thrived under pressure. The scaffolders communicated constantly, supported each other and approached every request with calm determination.

Inside the structure, a large staircase had to be repeatedly taken up and put back down as different phases progressed. This required continual adaptation, with the team reconfiguring the scaffold quickly without compromising safety or slowing down the other trades who relied on them.

These challenges did not slow the Hammac team down. They strengthened it, highlighting exactly why Hammac Scaffolding takes pride in its work. Despite the show’s famously tight timelines, every change was handled with professionalism, good humour and perseverance.

Why this project mattered

Children in Need holds a special place in communities across the UK. Its work supports children facing illness, disability, complex family circumstances and emotional struggles. Being part of a project that would offer these families a safe and supportive environment was incredibly meaningful for Hammac Scaffolding.

For the team, scaffolding is not merely metal and boards. It is the foundation for something better. Something that enables others to do life-changing work. Knowing that the structure they built will help create a space filled with comfort, care and hope is a feeling that will stay with the company for a long time.

Pride in the team and the community

Hearing Nick Knowles introduce Hammac as “the specialist scaffold team” was a moment of immense pride for the company. Yet what stood out even more was the atmosphere on site. Businesses from across Northwich and the surrounding areas arrived in force. People donated their time, skills, materials and energy simply because they wanted to help. It was community spirit at its finest.

The Hammac team represented not only the company but the values it stands for. Reliability, integrity, craftsmanship and being there when it matters most. The scaffolders worked tirelessly, supported one another and brought positivity to every stage of the build. The company could not be prouder of them.

The emotional impact

The most powerful part of the experience for Hammac was not the scale of the scaffold or the complexity of the build. It was understanding who it was all for.

For Hammac Scaffolding, this was not just a structure. It was the foundation for a space that will offer comfort, safety, support and hope to families facing incredibly difficult times. For the team, that meant everything. Many are parents themselves, many have deep ties within the community, and all felt the emotional weight of helping build something that will touch so many lives.

Hammac Scaffolding did not simply build a scaffold. The team helped build hope. And that is something every member can be proud of.

As a local Northwich business, being part of something so meaningful was a reminder of why the company does what it does. Projects like this bring people together, strengthen communities and show the true power of generosity and teamwork. Hammac Scaffolding is grateful to have played its part, proud of what was achieved and inspired to keep supporting the communities it serves in any way it can.

MBM Stacks Up on Asbestos Removal Project

Fully Audited members of the Scaffolding Association, MBM Scaffolding Ltd, who specialise in licensed asbestos scaffolding services, exercised meticulous planning and attention to detail, to successfully create a safe working environment for asbestos removal at West Burton Power Station.

The project formed part of the early enabling works ahead of large-scale asbestos removal and eventual demolition of the power station. The power station itself contains complex internal steelwork, elevated pipework, and varying floor levels. This required careful consideration when designing bespoke scaffolding to be used to provide safe access for MBM’s clients, Omega Environmental Services Ltd, the Licensed Asbestos Removal Contractor (LARC).

For the removal of hazardous materials, such as asbestos, it is essential to form a secure and airtight enclosure to prevent any contamination, Mitchell Caswell, Commercial Director at MBM, explained one solution they adopted for this purpose:

“To meet the specific requirements of the asbestos removal process, we integrated ranch boarding into the scaffold structure. This simple but effective method provided a controlled workspace that allowed the LARC team to perform their duties safely and efficiently while maintaining the scaffolds, structural integrity.”

When it comes to ancillary asbestoslicensed scaffolding operations, it is not just the design of the structure that requires attention to detail, there are stringent requirements for the entire process, Mitchell clarified:

“Even though the station was decommissioned, the site remained tightly regulated, with overlapping contractor activities and live exclusion zones. Work sequencing had to be planned around licensed enclosure areas, air-testing schedules, and waste transfer routes.

All works were carried out within designated enclosures and supervised transit routes, meaning materials, equipment, and personnel movements led to constant communication with the licensed removal contractor to avoid crossing over to each other’s zone of work. This demanded exceptional coordination, discipline, and adherence to asbestos regulations and MBM’s in-house asbestos Standard Operating Procedures.”

The requirements of power stations mean that they are generally built tall with a compact footprint, this brought its own set of unique challenges, Mitchell explained:

“There was restricted access and limited laydown space for materials,

the solution we came up with included constructing a temporary loading platform. The platform enabled more effective storage and handling of materials, ensuring that all components required for the task were properly positioned and accessible.

The platforms were strategically placed so that at a later stage, they can be transformed into a working platform for the asbestos removal team.”

The building had restricted access points and deteriorated flooring, this affected the logistical approach to delivering the project, which was done in phases, with scaffold materials manually transported through narrow, controlled gantries. Despite the project’s complexity, the MBM team’s expertise ensured every challenge was met successfully, Mitchell quipped:

“The toughest challenge of all was navigating the fine line between stringent safety measures and practical execution, but one that was needed to ultimately safeguard everyone involved.”

The MBM team are specialists in licensed asbestos scaffolding services, and they excel when the stakes are stacked high, this is clearly shown in the success of this project, Mitchell concluded:

“The highlight of the project was coordinating and streamlining the logistics of the works across four Boiler Houses and four Turbine Halls. From the basement level right up to the 140ft level. Managing the flow of men, materials, and access requirements across such a vast, multi-level structure showcases MBM’s capability to deliver complex, large scale industrial scaffolding operations.”

EASIER. SAFER. SMARTER.

As an industry-leading provider for scaffolding and construction safety products, TRAD UK has always championed innovation. Our comprehensive range sets new standards for access equipment and safety systems.

Our efficiency and safety are matched by the highest levels of service delivered by our experienced team and nationwide support network of depots. So, it’s easier than ever to find the right solution for your project.

Can WhatsApp Messages Form a Binding Contract?

“I never signed anything.”

It’s a familiar line in construction disputes, but a recent court decision shows that a contract doesn’t need a signature at all. In fact, a short WhatsApp exchange can be enough to create legally binding obligations.

Background

Jaevee Homes engaged Fincham Demolition to carry out works at a former nightclub site in Norwich. Jaevee Homes Ltd v Steve Fincham (t/a Fincham Demolition).

The agreement wasn’t formed through a standard subcontract or formal negotiation; instead, it came together through a series of emails and WhatsApp messages. These covered start dates and an understanding that Fincham would submit monthly payment applications.

Although Jaevee later emailed a formal subcontract and purchase order, neither document was signed, acknowledged or returned. The work nevertheless went ahead.

Fincham then submitted four invoices. None were paid. Jaevee argued the invoices didn’t comply with the requirements of the Construction Act or the Scheme for Construction Contracts and claimed Fincham was in breach.

Crucially, Jaevee hadn’t issued pay less notices in response to any of the invoices, meaning the sums applied for became due by default.

Fincham referred the dispute to adjudication and secured an award of £145,896.31, plus interest and adjudicator’s fees. When Jaevee refused to pay, the matter moved to court.

What the Court Decided

The court focused on one short WhatsApp exchange:

Why This Matters for Scaffolding Contractors

“Are we saying it’s my job mate so I can start getting organised?” “Yes.”

The judge held that this was enough to show a clear offer and acceptance. Despite the informality of the medium, the exchange demonstrated an intention to create legal relations.

The fact that key terms - such as payment provisions - hadn’t been finalised didn’t matter. Those missing terms were simply implied by the Construction Act and the Scheme.

Three of the four invoices were found to be valid payment applications and therefore payable.

Many contractors rely on WhatsApp and similar messaging apps for quick updates and day-to-day coordination. This case confirms that those same messages can unintentionally form a binding contract. If the conversation shows agreement on the essentials, the law may treat it as enforceable, even if no formal subcontract is ever signed.

It also underlines the importance of payment notices. Failing to issue a pay less notice will almost always result in the full amount of an application becoming payable, regardless of any disputes about the work itself.

How to Reduce the Risk

If you want to avoid informal messages being treated as the contract itself, say so clearly at the outset. Terms like “subject to contract” in early correspondence can help. Make sure your written subcontract or purchase order is issued promptly and chase for confirmation of acceptance before work starts. Keep clear records, and be cautious whenever discussing job details or prices via messaging apps - these can become part of the contractual picture.

If you need support reviewing communications, drafting robust subcontract terms or protecting your payment position, the Construction Team at Holmes & Hills is available to help on 01206 593933.

Fincham:

Jaevee:

Hidden Cyber Risks on Every Job Site

Why scaffolding and construction businesses can’t afford to ignore digital safety

As an Associate Member of The Scaffolding Association, Citation supports businesses with HR and Health & Safety expertise. But that’s no longer enough. The industry’s becoming more digital, and you need to look for cyber security support. That’s where Citation Cyber’s support comes in, helping businesses like yours strengthen digital defences and protect against growing cyber threats.

For most scaffolding businesses, safety comes first. Harnesses, handrails, inspections – they’re all second nature. While you understand physical safety well, a different kind of risk is catching firms off guard: cyber threats.

It’s easy to assume cyber attacks only affect big corporations with complex IT systems. In reality, the opposite is now true. Today, even the smallest scaffolding company relies on digital tools like job management apps, inspection software, site cameras, digital scaffold tags, payroll, messaging platforms and cloud-based reporting. Each one improves efficiency but also creates potential entry points for cyber criminals.

Digital job sites are rising

Technology has quietly transformed the sector. You use tablets for inspections. Cloud tools store project reports.

WhatsApp groups coordinate teams. Cameras stream site footage. Even RAMS, toolbox talks and handover notes are often stored online.

This shift has made operations smoother, but it means scaffolding SMEs hold more valuable data than ever. And with UK cyber attacks rising sharply this year, criminals are targeting small businesses they view as easier to breach.

A single phishing email or compromised device can delay projects, corrupt inspection reports or expose sensitive client information. In some cases, companies have been locked out of their own systems entirely.

Site risks hiding in plain sight

Many risks come from everyday oversights, not complicated hacking:

• Shared or poorly protected site Wi-Fi

• Unpatched or older tablets used for inspections

• Personal devices used for business tasks

• Weak or reused passwords

• Fake emails disguised as job instructions or invoices

• Malicious QR codes (quishing) placed on site or sent via text

• Outdated apps or ignored software updates

These small gaps can open the door to big problems, and often businesses don’t realise until it’s too late.

Cyber safety is the new site safety

The encouraging part? Strengthening cyber safety doesn’t need to be expensive or technical.

A few simple steps go a long way:

• Use strong passphrases

• Turn on multi-factor authentication

• Keep devices and apps updated

• Train staff to spot phishing

• Back up essential data regularly

• Treat QR codes with care

• Report suspicious emails immediately

Just like physical safety, cyber safety protects your people, your operations and your reputation, and prevention is always easier than recovery.

Support for scaffolding businesses

As part of its support for members, Citation – alongside Citation Cyber –helps scaffolding businesses put the right foundations in place. From Cyber Essentials certification and vulnerability scanning to cyber awareness training and incident response planning, we make it easier for SMEs to stay secure and compliant.

Because whether you’re building a scaffold or securing a server, strong foundations matter.

As a Scaffolding Association member, you can get access to preferential rates on our suite of cyber solutions, just scan here to enquire and use code SCAFMEMBER.

Help Us Understand How Our Sector Supports the Armed Forces Community

Following the Scaffolding Association’s recent signing of the armed forces Covenant, we are launching a short survey to understand how many of our members currently employ veterans, service leavers, reservists, or Armed Forces family members – and how many would consider doing so in the future.

This work is essential. Our industry benefits enormously from the skills, discipline, and leadership qualities that armed forces personnel bring. Many already work across scaffolding and access roles, yet we know there is far more potential to create pathways into our sector. To target our work effectively, we need an accurate picture of what support already exists within our membership and where the biggest opportunities lie.

Whether you already employ armed forces personnel or you would consider recruiting from the armed forces Community, we need your insight.

Your responses will help us to:

• Understand how widely the armed forces community is represented across our membership.

• Target guidance, opportunities, and support where it’s needed.

• Ensure our Covenant commitments deliver real, measurable benefits for both employers and the armed forces community.

We invite all members to take part. Please scan the QR code and complete our short 1-minute survey of just three questions.

1. Is the owner of the business ex-armed forces?

2. Do you already employ ex-armed forces personnel?

3. Would you consider recruiting from the ex-armed forces community?

Your input will directly influence how we support veterans, service leavers, reservists, and their families – and how we help the scaffolding sector embrace the valuable skills they bring.

Scaffold Sheeting for Demolition Projects: Design and Installation Guidance

In demolition projects, scaffold sheeting plays a critical role in containing dust, debris, and other hazards while ensuring safety and compliance with environmental regulations.

Proper consideration of each design and installation requirement is essential to maximise its effectiveness. Dave Gilmore of scaffold sheeting manufacturer, ITP Ltd, explains the steps you can take to ensure a safe and controlled environment during demolition projects.

Choosing the right scaffold sheeting

Before installation, it’s important to select sheeting that’s suitable for your project.

• Material: Common sheeting materials include reinforced polyolefin, highdensity polyethylene or PVC.

• Strength: Ensure the sheeting is durable enough to contain debris and withstand wind and project-specific conditions. You should always refer to BS 7955 to ensure that sheeting conforms to the necessary strength requirements.

• Perforations or Non-Perforations: Choose non-perforated sheeting for better dust containment.

• Flame Retardancy: We recommend flame-retardant scaffold sheeting for all projects. Under the terms of the Joint Code of Practice on the Protection from Fire of Construction Sites and Buildings Undergoing Renovation, for all contracts valued over £2.5m (or part of a larger contract valued over £25m) it’s recommended that flame retardancy standards are independently certified by one of two approved bodies, Warrington Certifire or BRE Global/Loss Prevention Certification Board (LPCB). Failure to comply may risk the ceasing or withdrawal of insurance. If the sheeting has printed branding or graphics, make sure that the product’s flame retardancy is certified for its printed form.

Installing the sheeting

We recommend overlapping sheeting as proper overlapping prevents gaps that can allow dust and debris to escape:

• Overlap each horizontal sheet by at least 6 inches (15 cm).

• For vertical overlaps, use at least 4 inches (10 cm).

• To maximise weather protection, rows of scaffold sheeting should be installed so that each row of sheeting is overlapped on the outside by the next row of sheeting above. However, the opposite (see illustration) is recommended when sheeting is being used in demolition as this method keeps the debris and dust inside the scaffold.

• Check for sharp edges or protrusions that could damage the sheeting.

• Do not install sheeting on the inside of scaffolds as it will be unable to detach whenever suction forces are experienced. In high winds, this may put excessive forces on the scaffold structure leading to its collapse.

Securing with Fasteners

Use appropriate fasteners to keep the sheeting in place. A common type of fastener are elasticated toggle ties which typically secure the sheeting at regular intervals along the scaffolding poles. ITP’s Powertie toggle ties are ideal for hightension areas as they provide flexibility and prevent tearing.