News and views about the access and scaffolding industry TAF Magazine of the Year 2018 WINTER 2018/19 ISSUE 007 £3.75

NEWS –

and news across the sector Page 22 SITE REPORT: Mercer on-site at Leicester Square p16 GUIDANCE: Testing scaffold anchor ties p12 AGM REPORT: Creating new opportunities for the sector p21

ASSOCIATION

Projects

CONTENTS

Crackdown on suppliers who don’t pay on time

Scaffolding Association holds annual general meeting

The government has announced that the failure of companies to demonstrate prompt payment to their suppliers could result in them being prevented from winning government contracts. The move is part of a new prompt payment initiative to ensure all government suppliers and subcontractors benefit from being paid on time.

The new initiative will come into force in autumn 2019 and will ensure the government only does business with companies that pay their suppliers as agreed.

Cabinet Office Minister Oliver Dowden said: “Paying invoices promptly is vital in providing healthy cash flow, particularly for smaller businesses, who are the backbone of the UK economy, to help them survive and thrive.

The Specialist Engineering Contractors’ (SEC) Group said that such measure was long overdue. SEC Group’s Professor Rudi Klein said: “For some years we have been advocating a yellow/ red card policy for public sector procurement. In other words, poor payers should be warned about their payment performance and then banned from public sector contracts if their performance doesn’t improve.”

FIND OUT MORE www.accesspoint.org.uk

More than 300-tonne scaffold installation enables refurb of Army’s top tactical trainer

On Tuesday 18 September, the Scaffolding Association held its annual general meeting (AGM) at the Union Jack Club in London.

The meeting, which was attended by more than 100 members, gave an insight into how the association is growing, the benefits members can take advantage of and plans for the upcoming year.

Scaffolding Association chief executive Robert Candy opened the AGM with a welcome to members, thanking them for their continued support as the Association goes from strength to strength. Now the largest trade association in the scaffolding and access sector, the Scaffolding Association has more than 350 members and continues to grow.

Discussing the awareness campaign driven by the Association throughout 2018, head of external affairs Stacey Underhill provided an overview of industry groups where an active contribution has been given to address sector issues, concerns and initiatives.

The Association made a call to its members to actively participate in the technical committees and working groups currently in action, to help further the industry reach. To get involved, email stacey@scaffolding-assocation.org

FIND OUT MORE Turn to page 21

CONTACT US

EDITORIAL

Editor: Adrian JG Marsh

Assistant Editor: Faye Callaghan

Telephone: 01926 420 660

Email: newsdesk@accesspoint.org.uk

AccessPoint, Althorpe Enterprise Hub

Althorpe Street, Leamington Spa CV31 2GB

Design: Matthew Glover

SUBSCRIPTIONS

AccessPoint is distributed to members of the Scaffolding Association and other selected access and scaffolding businesses. If you wish to receive a copy of AccessPoint or would like to amend or cancel your subscription, please contact either info@scaffolding-association.org or call 0300 124 0470.

ADVERTISING

Advertising

The recent refurbishment of one of the Army’s most significant training assets was made possible thanks to a team of fast-working scaffolders.

The Combined Arms Tactical Trainer (CATT), which is based at Warminster, underwent a major £1.9m upgrade over August and September.

Aspire Defence is contracted by the MOD under Project Allenby/Connaught to build and maintain soldiers’ living and working accommodation at military garrisons across Salisbury Plain and at Aldershot.

Wolverhampton-based SCP Forgeco, one of the UK’s leading suppliers of Acrow props, scaffolding and general construction products, has established a new Export Division in response to growing demand from the Caribbean, Middle East and Australasia.

2055-2033

(Print) AccessPoint magazine is published on behalf of the Scaffolding Association by Campbell Marsh and the views expressed in this journal are not necessarily those held by the Scaffolding Association or the publishers. The publishers shall not be under any liability in respect of the contents of the contributed articles. The Editor reserves the right to edit, abridge or alter articles for publication. 04 Voice of the sector: A catalyst for change 05 Opinion: Manage your drivers –protect your business 10 Commercial: Milestone payments and reverse charge VAT 12 Guidance: Anchor ties 14 Technical: Design of facade retention scaffolds 16 Site report: Mercer Scaffolding on-site at Leicester Square 20 Health & Safety: On-site traffic management 21 AGM: Report from the Scaffolding Association AGM

To access the high ceiling within the CATT, around 324 tonnes of scaffolding were erected by contractors Ideal and S&K – totalling over 14 miles of scaffold boards and more than 20,000 metres of tube.

Brian Martin, programme manager for ADSL Warminster & Larkhill Garrison, explained: “The scaffolders were exemplary. This was the largest internal job they had ever taken on and, in just one week, they completed an installation that would normally take a month.”

FIND OUT MORE www.accesspoint.org.uk

SCP Forgeco is a major manufacturer and distributor of more than 1,000 products covering access and formwork equipment, scaffolding, groundworks and events. The Group acquired SCP in 2017 and in addition to the world famous Acrow Prop, it is the sole approved manufacturer of the innovative Klawz, ScottiClip and Tamer scaffold fitting and the Safelinx scaffold board retaining systems.

Mr R Dale, group managing director at SCP Forgeco, said: “The new Export Division will spearhead growth outside the UK and build on our world-wide supply chain partner relationships.”

FIND OUT MORE www.scp-props.co.uk

02 ACCESSPOINT MAGAZINE | NEWS www.accesspoint.org.uk

SCP Forgeco sets up Export Division © All editorial contents AccessPoint 2018 Printer: Tewkesbury Printing Company

enquiries: Adam Turner Tel: 01926 420660 adam.turner@campbellmarsh.com

Belfast-based Advanced NI Scaffolding is providing access and scaffolding services at the new George Best Hotel. The Grade B1 listed Scottish Mutual Building, in Belfast city centre, is being transformed into a luxury hotel and museum that celebrates the life of the iconic footballer, both on and off the pitch.

Scaffolding Association Tel: 0300 124 0470 www.scaffolding-association.org Email: info@scaffolding-association.org ISNN:

FRONT COVER:

Cost pressures cast shadow over construction

The construction industry experienced modest growth in the third quarter of 2018, following a weather-related boost to activity in Q2, according to a quarterly survey of product manufacturers, contractors, civil engineers and SME builders by the Construction Products Association (CPA). However, rising materials and labour costs, economic uncertainty and a narrowing forward workload is causing concern.

The CPA’s Construction Trade Survey for 2018 Q3 shows that during the quarter, 27 per cent of product manufacturers, 25 per cent of main contractors, 16 per cent of SME builders and 10 per cent of civil engineering firms reported an increase in activity, although output was reported lower for one-third of specialist contractors.

Rebecca Larkin, senior economist at the CPA, said: “Beneath the top-level growth rate, firms throughout the supply chain are grappling with a narrowing base of activity led by private housing and infrastructure work and rising costs for labour, raw materials and fuel.”

www.accesspoint.org.uk

Interserve sells scaffolding and industrial contracting arm

Interserve has completed its exit from industrial contracting with the disposal of its scaffolding and related insulation and painting business.

The fire sale of industrial services will see Interserve suffer an £8.4m loss against book value. It confirmed it had struck a deal to sell its Interserve Industrial Services (IISL) business to Enigma Industrial Services Holdings for £3.6m with a further cash settlement of £1m subject to meeting targets in 2018 and 2019.

IISL suffered an operating loss of £4m last year on £67m revenue and had assets of £47m.

FIND OUT MORE www.interserve.com

Proplant Scaffolding passes Audit with flying colours

Proplant Scaffolding is in its 18th year of business – completing and passing Scaffolding Association

Audited Membership was one of the objectives set out by the directors in early 2018.

Operations director Shaun Fennessey told AccessPoint: “Becoming audited by the Scaffolding Association will provide added comfort to our existing clients and also to potential new clients.

“As a fully Audited Member of the largest trade organisation in the UK scaffolding and access sector, it shows the company’s commitment and attitude towards health and safety and its awareness of the need to continually improve.

“The audit itself was very thorough and professional, investigating all parts of the business thus ensuring a very high standard of compliance which is required for membership at this level.”

www.scaffolding-association.org/membership-levels

OIL, GAS & CHEMICALS POWER & ENERGY MINING & REFINING PROJECTS

Our experienced customer driven team provides a seamless service from product development, supply chain management, production, quality control, delivery and local engineering support available for fast, effective solutions where required.

NEWS | ACCESSPOINT MAGAZINE 03 NEWS www.accesspoint.org.uk

FIND OUT MORE

FIND OUT MORE

GLASGOW 01236 280120 ABERDEEN 01224 443636 LONDON 020 8310 3559 LEEDS 01977 670510 BIRMINGHAM 01902 882781 UNITED KINGDOM PRODUCT CATALOGUE 2017 AT-PAC RINGLOCK

COMPLETE SCAFFOLDING SOLUTIONS

AT-PAC HAS UNPARALLELED EXPERTISE AND PROFESSIONALISM WHICH ENABLES US TO CONSISTENTLY DELIVER COMPLETE SCAFFOLDING SOLUTIONS.

| WWW.AT-PAC.COM

AT-PAC Ringlock is a modular system scaffold which enables users to quickly and efficiently erect, use and dismantle temporary work structures. The AT-PAC Ringlock system conforms to European standards BS EN12810 and BS EN12811 and it is compliant with NASC Code of Practice for System Scaffold.

Respect for the supply chain

Last month, Greg Clark MP, the Secretary of State for Business, praised the role of specialist contractors and how they are delivering a world-class construction and engineering industry. And at the heart of that industry is the vital need to create a safe and highly skilled workforce – but it can’t deliver if it is starved of cash.

The government’s new prompt payment initiative (see page 2) will ensure all government suppliers and subcontractors benefit from being paid on time. Importantly, bad payers will, in future, be prevented from winning government contracts.

Poor business practices have no place in our sector and equally we must maintain pressure to drive out poor safety practices. Recent research into on-site safety shows a 74 per cent rise in traffic management breaches on construction sites, putting scaffolding contractors at risk of colliding with vehicles and machinery (see page 20).

And it’s not just on-site where risks are present. Increasingly more police forces are challenging bad drivers to take a roadside eyesight test. As police have the power to immediately revoke the licence of any drivers who fail the roadside eye test (see page 5), this could prove to be a major issue for employers who rely on their fleet for deliveries.

As an integral part of the supply chain, we must all play our part to contribute to performance improvement. In this issue, we took a trip to London’s Leicester Square (turn to page 16) to see a fine example of innovative access and scaffolding solutions. An integrated approach combining design and installation is creating safe and efficient access at the new £300 million five-star hotel, leisure and cinema complex.

Early involvement of scaffolding specialists has proved crucial in saving time on an already tight construction programme. Pre-construction planning, some innovative thinking and positive attitudes can, and are, making a real difference to performance with this contract.

What’s clear from Mr Clark is that the government has respect for specialists. But respect is a two-way process, so this sector must refocus and continue to deliver safely, to the right standard and with high levels of efficiency.

Adrian JG Marsh Editor

A catalyst for change

When the Scaffolding Association was formed, we wanted to provide advice and support for specialist contractors active in the access, scaffolding and temporary structures sector who were not served by existing trade bodies.

The Association has grown to have more than 350 members. Through this growing membership, we now represent contractors that employ over 10,000 qualified scaffolders. There are believed to be approximately 50,000 card-carrying scaffolders in the UK working for more than 5,000 scaffolding contracting companies.

Bringing more contractors into membership will encourage higher standards of safety and technical performance, which will drive up efficiency and develop a more highly skilled workforce that the construction and engineering industries need.

We have developed good relationships with other industry groups and contractors, such as the HSE and the Home Building Skills Partnership. We are also the only scaffolding representative of the Specialist Engineering Contractors’ (SEC) Group, whose members account for 35 per cent of construction output in the UK. It lobbies for fair supply chain payment and has a network of key contacts in government and industry.

More main contractors are accepting our members onto their supply chain lists, so there are increasingly new work opportunities available to Association members. Equally, clients have access to a greater pool of credible specialists that offer more competition and high standards of service.

We are also committed to providing our members with a route map to help them embrace and share best practice. Safety and technical quality are pivotal in our approach as members can progress through our interrelated membership categories, win more work and become more profitable.

The Association is not in competition with the NASC because we serve different membership groups. While we do have more member companies than the NASC, our vision is not about size and power; our vision is to be inclusive and accessible, and work in partnership so that our sector can tackle the challenges we face.

For example, safety is a critical component, so by working with the HSE and as a member of CONIAN, the leading construction industry safety network, we are able to represent the views of SMEs in our sector.

We all agree that the sector faces a skills shortage and with the CITB pulling out of training there is a lack of available localised training to meet growing demand. Some 70 per cent of scaffolders work for companies not represented by the existing training structures. If we are to raise both standards of training and continuous skill improvement, training and skills certification should be more sensitive to the capacity of the many, not just the few.

The whole sector should strive to work together, challenge outdated attitudes and improve understanding throughout the supply chain. We want the access and scaffolding sector to have a safety-led culture that exemplifies creativity, innovation and engineering quality.

If we can achieve this, it will help the sector to attract and keep the best talent, so everyone involved experiences a safe and rewarding career.

Robert Candy Chief executive Scaffolding Association www.scaffolding-association.org

04 ACCESSPOINT MAGAZINE | COMMENT COMMENT www.accesspoint.org.uk

Manage your drivers –protect your business

You will already be aware that, as an employer, you have legal obligations to any employees who drive while at work. In addition, there are areas that you should focus on to protect yourself from prosecution and ensure that your own insurance is not prejudiced.

Karl Jones from Amicus highlights the area of driver vision and accident and conviction recording.

Eyesight tests are a current hot topic, with three police forces in Thames Valley, Hampshire and the West Midlands asking any motorist stopped from September 2018 to read a number plate from 20 metres.

As the police have the power to immediately revoke the licence of any drivers who fail the roadside eye test, this could prove to be a major operational issue for employers who have staff operating company vehicles to deliver their services to their clients. Imagine having even 5 per cent of your operational workforce unable to use your vehicles to provide your services, get to site or move goods.

The data from the trial, which is supported by road safety charity Brake, is going to provide up-to-date insight into the extent to which poor driver vision is a factor in automotive accidents, but the feedback from other bodies is already causing concern. Research by the Association of Optometrists published in

November 2017 found that around 35 per cent of optometrists saw patients in the preceding month who continued to drive, despite being told their vision was below the legal standard.

A 2012 study by insurance firm RSA estimated that poor vision caused 2,874 casualties in a year, and with more people working into their sixties and beyond, it’s likely to be a growing problem for businesses with company vehicles.

Darker mornings and nights

The winter months will also involve a greater percentage of travel during the hours of darkness, when defective vision is generally even less effective, so now’s the time to get your drivers’ eyesight checked out.

It’s not a huge stretch to envisage a situation where a company (or the directors or senior managers of that company) is held legally liable for allowing a driver with vision below the legal standard to operate a company vehicle that

caused an accident arising because of that poor vision, and because the company had failed to check robustly enough.

If you insure a fleet of vehicles, you will be required to make a declaration about your drivers’ conviction records at renewal, but how many companies actually check and record this?

With the DVLA enabling employers to access details (with the relevant information and a code from their employee), asking for hard copies should be a thing of the past. Once again, as a business, you are protecting yourselves from having your insurers suing you because they had to settle a third-party claim (as part of their legal obligations under the Road Traffic Act) caused by a driver with serious convictions that they may have not wanted to insure had they known about them.

Declaring accidents

It’s also a popular misconception that the drivers of company vehicles don’t have to declare accidents involving company vehicles to their personal insurers, and vice versa. As a fleet operator, getting all the drivers of company vehicles to sign a declaration confirming the position regarding their own personal accident history should form part of your own internal pre-renewal exercise. You don’t want to be in the firing line if an employee with a chequered accident record causes an incident in one of your vehicles and your insurers didn’t know about their history.

Karl Jones Amicus www.amicus-insurance.co.uk

OPINION | ACCESSPOINT MAGAZINE 05 OPINION www.accesspoint.org.uk

RAM Tracking vehicle tracking app

RAM Tracking vehicle solutions can be accessed any time via the smartphone app enabling users to respond faster to last-minute or emergency jobs, even when they are out of the office.

Helping to instil safety, RAM Tracking’s vehicle trackers monitor driver behaviour such as speeding, harsh braking, swerves and accelerations, also producing a report that accurately shows the hours a driver has been driving. This way, users can ensure drivers are taking the appropriate breaks and not driving longer than is legally allowed in a day.

With these features, the RAM Tracking solution helps to minimise the risk of dangerous driving habits within the workforce while providing users with an easy-to-use user interface which allows vehicles to be tracked nationwide.

www.ramtracking.com

SMART Scaffolder software update adds chimney stack estimating

SMART Scaffolder has added the ability to estimate for chimney stacks for the first time to the software as part of its latest update for 2019.

Constantly evolving and adding new functionality to its design, estimating and TG20:13 compliance software, SMART Estimator easily creates a realistic looking 3D model. These estimates produce accurate prices for labour and materials in an automatic quote together with professional looking drawings, material lists and weights.

The SMART Estimator solution is modular so users only pay for the functionality they need and can add modules as their business grows.

Commenting on the update, Ian Chambers, sales and marketing director at SMART Scaffolder, said: “This year’s release really focuses on those features most requested by our customers and there are more new features that will appear over the next few months.”

www.smartscaffolder.com

KIT Design launches X-Form Scaffolders’ Vest

UK workwear company KIT Design, which specialises in the design and manufacture of high-quality technical wear, has introduced the X-Form Scaffolders’ Vest.

KIT Designʼs original X-Form Anti-Stress equipment vest system features a core chassis that spreads the weight of carried equipment evenly across the body for significantly higher levels of comfort and support. This X-Form capability has now been incorporated into a special vest for scaffolders – the new Scaffolders’ Vest – a hi-vis equipment vest that works in unison with a harness and can connect to a lanyard via a back opening.

Pushing PPE design and manufacture to new heights is KIT Design’s Life Equipment Vest, a multi-purpose vest which combines a fully certified self-inflating bladder built into an X-Form vest.

Combining all-day comfort with original technical features results in industry-leading performance, durability and value. All X-Form vests can be customised to include a choice of lightweight and breathable technical fabrics in a range of colours, interchangeable pockets and fastenings, body lengths, reflective tapes, and badging and radio dockets. As standard, all X-Forms provide 20cm of adjustability for easy sizing and can be worn over layered clothing, harnesses, body armour and seasonal coats.

www.kitdesignworks.co.uk

Real-world vision with the latest Scaffold Designer

The latest update to Scaffold Designer, from Avontus Software, enables engineers to review drawings in augmented reality (AR) when paired with the Scaffold Viewer app. Benefiting both customers and crews, this new feature allows the structure to be viewed in full 3D.

In a similar way to carrying out a final check on-site at actual scale, users can ensure that their scaffold meets the customer’s needs before unloading the first base jack.

AR Scaffold Designer now gives users complete control of scaffolds for circular tanks. With a flexible and effective workflow, key requirements are automatically generated to produce a circular scaffold to specifications.

In addition, structural components such as slabs and beams can now be identified and detailed, allowing complex work environments to be modelled with ease. Whether hanging a scaffold from a pipe rack or under a bridge, users can clearly communicate the proposed scaffold to customers and crews, without needing an entire drawing package from an engineer.

www.avontus.co.uk

Norscaff appointed Ireland distributor by SCP/Forgeco

Norscaff has been appointed as the approved distributor of SCP, Forgeco & MSUK equipment for Ireland.

Norscaff supplies system scaffolding, tube and clip scaffolding alongside alloy towers, fencing and barriers, and scaffold boards. It has network and resources to supply scaffolding, access systems, and fencing and barriers locally and nationally from its depots in Dungannon and Belfast in Northern Ireland and from Dublin in Eire.

Dale R Dale, SCP Forgeco’s group managing director, said: “Norscaff is the ideal partner to help SCP Forgeco to provide customers with our extensive range of scaffolding and non-mechanical construction equipment. Our products include the innovative Forgeco ‘Klawz’ Fitting that they’ve successfully brought into the Irish market.

“The appointment builds on a successful relationship that SCP Forgeco and Norscaff have enjoyed for many years.”

https://norscaff.supplies

06 ACCESSPOINT MAGAZINE | PRODUCTS PRODUCTS

www.accesspoint.org.uk

New precision steel tubes from SSAB

SSAB Form Tube Plus is a new family of precision steel tubes that provides a combination of bendability, dimensional accuracy and superior surface quality suitable for high-gloss painting and chrome plating.

The tubes, which are protected with thin plates to help prevent transportation and handling damage, thus providing a scratch-free surface for the user, can be used in furniture manufacturing and demanding light-engineering applications.

Product manager Anders Klang at SSAB Europe explained: “Dimensional accuracy ensures cost-effective automatic manufacturing and telescoping solutions. In some cases, it could even substitute cold-drawn tubes. Furthermore, chrome plating and high-quality painting can be directly applied to the surface.”

SSAB Form Tube Plus comes in two steel grades, E220 and E420 (the number stands for yield strength). Choosing high-strength SSAB Form Tube Plus 420 enables significant weight savings to be achieved without compromising the usability of the tube. The products meet and exceed all requirements of EN 10305-3/5. They are delivered with a cold-rolled (S3) surface and +CR2 delivery condition.

www.ssab.co.uk

Trademagic launches aluminium ladder guard in line with HSE guidance

Trademagic has launched a new ladder guard –Tradeguard – to prevent unauthorised access to scaffold by members of the public. In line with the recent HSE safety alert, there is an increasing awareness to stop unauthorised access onto scaffolding.

HSE guidance states that the ladder guard should cover at least six rungs of ladder, which will prevent a foot being placed on at least five rungs. It must also make each rung unusable and be locked or padlocked when not in use.

The Tradeguard aluminium ladder guard, which is British made, is quick and easy to install and comes with a heavy duty padlock and chain. Available in two widths (315mm and 250mm), the guard is HSE complaint with a length of 1,650mm.

www.trademagic.co.uk

New tool bag available from Tool@rrest

Tool@rrest has added to its ever-expanding range with the new wide-mouth bag. Measuring 53cm wide and 30cm high and with a durable plastic bottom, the new tool bag also comes with an over-shoulder strap as well as a carrier handle.

Inside the bag are eight strategically placed marine grade stainless steel locking carabiners from which users can attach their tethered tools as well as a small zipped internal pocket, ideal for pens, scribers or small parts. The bag also features an attachment point for the Tool@rrest 360 degree retractable lanyard.

The bag can be purchased as a single item (part number TA500051) or as a complete unit which includes the retract and 2 x 1m coil lanyards (TA500052).

www.toolarrest.co.uk

HAKI releases new stair chart

HAKI has released a new Stair Chart PDF, designed for all sector users of the HAKI Stair Tower range, which is built to meet global working at height regulations simply, safely and adaptably.

The new chart now covers suitable applications and sector uses, accurately tested load classes and permissible people per lift.

Charles Stratford, HAKI UK engineering manager, said: “There’s a movement right now to make identification of suitable temporary works equipment easier, including better visibility of the limitations of such equipment.

“Users on-site may not have the same level of understanding as the manufacturer in terms of product limitations, such as the number of people permissible per lift. The challenge with any stair system is that it can be purchased for one application, then moved to various sites and be exposed to different volumes of footfall.”

Through this review, HAKI has increased the rating of some products, which are all outlined in the product sheet. The HAKI Stair Chart can be downloaded from the website.

www.haki.com/product/haki-stair

08 ACCESSPOINT MAGAZINE | PRODUCTS PRODUCTS www.accesspoint.org.uk

RhinoDeck Benefits

PRODUCTS | ACCESSPOINT MAGAZINE 09 PRODUCTS www.accesspoint.org.uk A HIGH-LOAD DECK WORK PLATFORM SYSTEM FOR A SAFER, FASTER BUILD

• Access work and load platform • Accepts loads of up to 600 kgs/m2 • Completely free-standing and totally stable • All components are lightweight and easy to handle • Rapid assembly – 50 m2/hour with no special tools • Excellent access below decks for pallets • All steel manufacture for a long productive life Please contact us for a brochure or method statement T: 01509 502155 email: info@sayfasystems.com www.sayfasystems.co.uk Sayfa Systems UK Ltd, Jubilee House, No. 3 Gelders Hall Road, Shepshed, Loughborough, Leicestershire, LE12 9NH

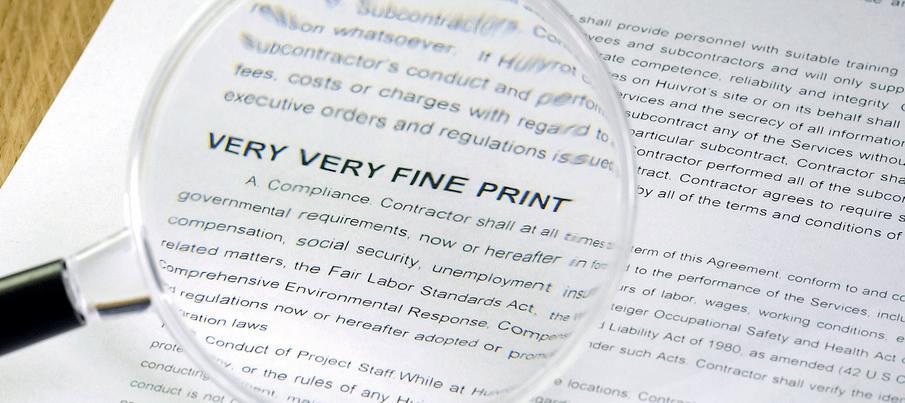

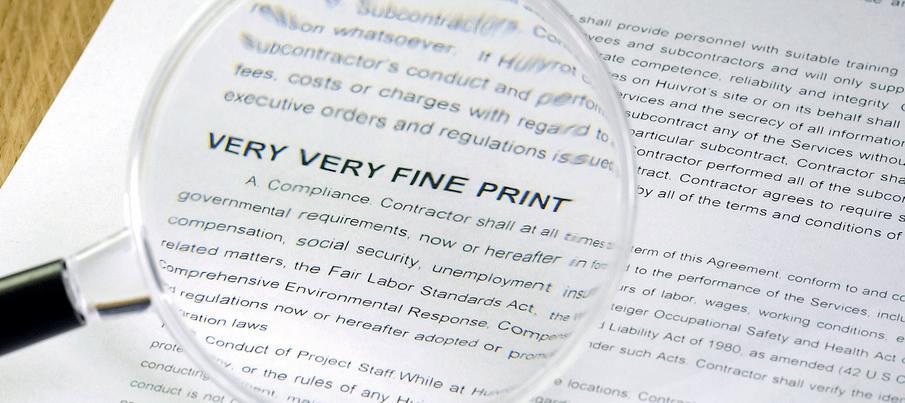

Make sure your milestone payments are adequate

Barrister Professor Rudi Klein considers a recent case where milestone payments were not an adequate mechanism for payment.

The law

It is often forgotten that one of the most important provisions in the 1996 Construction Act requires that construction contracts have adequate mechanisms for payment.

“Every construction contract shall provide an adequate mechanism for determining what payments become due under the contract and when.” (emphasis added) Section 110 (1)(a)

The case of CIMC MBS Ltd v BENNETT (Construction) Ltd (18 July 2018)

The application of the above statutory provision was tested in a recent case by a subcontractor. The subcontract was to design, supply and install pre-fabricated bedroom units. The units were to be made in China, shipped to Southampton and taken to a London hotel where they were to be installed. The subcontractor’s payment regime comprised five milestone payments. These were as follows:

1. 20 per cent of contract sum was to be paid on execution of subcontract.

2. 30 per cent was to become payable on sign-off of the prototype room in China by

the contractor, employer and hotel operator.

3. 30 per cent was to be paid on sign-off of snagging items by the contractor, employer and hotel operator.

4. 10 per cent was to become payable on sign-off of units in Southampton.

5. 10 per cent was to become payable on completion of installation and snagging.

A payment dispute arose which resulted in the subcontractor suspending his work for non-payment. The matter ended up in adjudication where the subcontractor asked the adjudicator to decide that milestones 2, 3 and 4 were not an adequate mechanism for payment. There was no criteria for governing the signing-off process and neither was there any time limit over which the process had to be carried out.

The adjudicator decided that the milestones complied with the Act.

The decision of the court

The subcontractor then went to the court for a declaration that the milestones were non-compliant with the Act. The aim of the payment provisions in the Construction Act were to provide certainty. Milestones 2 and 3 lacked certainty. There was no indication

of what was involved in the process of sign-off and neither was there a due date for sign-off.

The court held that milestone 4 was Act-compliant; the only sensible interpretation of “sign-off” within this milestone was the delivery of the units from the ship at Southampton.

Observations

The sign-off requirements in respect of milestones 2 and 3 appeared to be excessively convoluted. What would happen, for example, if the contractor, employer and hotel operator were to disagree among themselves? There would never be a sign-off! Consequently, the subcontractor would never get its milestone payments.

In the event that the contract payment provisions do not provide for an “adequate mechanism” for payment, the Scheme for Construction Contracts will apply. The Scheme’s provisions include a requirement for monthly periodical instalments. Firms are likely to prefer milestone payments, but unless the milestones are Act-compliant the statutory fall-back position is periodical payments.

Scaffolding contractors should always read their payment provisions at the outset. If there are any doubts, they should be resolved before ‘pen is put to paper’.

10 ACCESSPOINT MAGAZINE | COMMERCIAL COMMERCIAL www.accesspoint.org.uk

A change to the way VAT is accounted for

New legislation has been finalised by HMRC which will completely change the way that companies record and claim back VAT. This measure will mean that when doing business with another VAT registered business, the customer will be liable to account for the VAT in respect of those purchases rather than the supplier. This is known as the reverse charge.

HMRC describes this new approach as an anti-fraud measure that will remove the opportunity for fraudsters to charge VAT and then go missing before paying it to the Exchequer – a measure set to recover £75m by 2023.

To prepare, businesses should identify instances where they supply services to other businesses in the construction sector (rather than to a consumer of those services) and determine whether the services are included within the list of those specified, which include:

• construction, alteration, repair, extension, demolition or dismantling of buildings or structures (whether permanent or not), including offshore installations

• construction, alteration, repair, extension or demolition of any works forming, or to form, part of the land, including walls,

roadworks, power-lines, electronic communications apparatus, aircraft runways, docks and harbours, railways, inland waterways, pipe-lines, reservoirs, water-mains, wells, sewers, industrial plant and installations for purposes of land drainage, coast protection or defence

• installation in any building or structure of systems of heating, lighting, air-conditioning, ventilation, power supply, drainage, sanitation, water supply or fire protection

• internal cleaning of buildings and structures, so far as carried out in the course of their construction, alteration, repair, extension or restoration

• painting or decorating the internal or external surfaces of any building or structure

• services which form an integral part of, or are preparatory to, or are for rendering complete, the services described above including site clearance, earthmoving, excavation, tunnelling and boring, laying of foundations, erection of scaffolding, site restoration, landscaping and the provision of roadways and other access works

If you have any queries, speak to your accountant.

COMMERCIAL | ACCESSPOINT MAGAZINE 11 COMMERCIAL www.accesspoint.org.uk 匀 吀 伀 倀 夀 伀 唀 刀 䈀 伀 䄀 刀 䐀 匀 圀 䄀 刀 倀 䤀 一 䜀 吀 䠀 䤀 匀 圀 䤀 一 吀 䔀 刀 匀 䄀 䘀 䔀 䰀 䤀 一 堀 䈀 伀 䄀 刀 䐀 刀 䔀 吀 䄀 䤀 一 䔀 刀 刀攀挀漀洀洀攀渀搀攀搀 戀礀 琀栀攀 一䄀匀䌀 椀渀 琀栀攀 吀䜀㈀㨀㜀 䜀甀椀搀愀渀挀攀 㔀 㐀 ㌀ 㐀 㘀 㜀 㠀 簀 匀 愀 氀 攀 猀 䀀 匀 䌀 倀 䜀 爀 漀 甀 瀀 ⸀ 甀 欀 伀 爀 瘀 椀 猀 椀 琀 甀 猀 漀 渀 氀 椀 渀 攀 眀 眀 眀 ⸀ 匀 䌀 倀 䜀 爀 漀 甀 瀀 ⸀ 甀 欀

From 1 October 2019, the way businesses account for their VAT will change with the introduction of the ‘reverse charge’. James Howard from chartered accountants Haines Watts provides an overview.

Scaffold anchor ties – be thorough with preliminary and proof testing

There are more than enough reasons to ensure your scaffolding is safe and secure, and one important part of this is to test the scaffold anchor ties. Jonathan Craig from Hydrajaws, which develops and manufactures portable testers for testing the crucial holding force of anchors and fixings in construction materials, runs through the two types of site testing to consider with scaffold.

An anchor may be strong enough and specifically approved for the job, but if it is installed incorrectly or into a weak material, it will be compromised and potentially fail. That’s why testing on-site in the actual working conditions is so important.

In BS 8539:2012 Code of Practice for the selection and installation of post-installed anchors in concrete and masonry, there are two types of site testing to be considered with scaffolding: preliminary tests and proof tests.

Preliminary tests

As the name would suggest, preliminary tests are performed on anchors before the scaffolding is erected at a site. This is normally required when tying into masonry or other base materials where the anchor manufacturer cannot provide characteristic load data.

A preliminary test generally involves installing anchors into the masonry on-site and pull testing the anchors to a required load. It is strongly suggested to avoid pull testing these anchors to failure, as this is likely to cause unwanted damage to the building.

Proof tests

On all jobs, proof tests of scaffold ties are required. These proof tests are not designed to be a check on the manufacturer’s load test data, but to be a check that the anchors have been installed correctly (to the manufacturer’s recommendations)

and that the substrate is capable of taking 1.25 times the working load of each anchor.

A minimum of three anchors or 5 per cent of the anchors installed (whichever is the larger number) are to be tested per scaffold. It is best practice to spread these tests around the scaffold, in particular if different anchors have been used in different sections, or if these anchors have been installed by different teams.

What happens if a scaffold tie fails?

Should a scaffold tie fail a pull test, then the frequency of anchor testing doubles. The frequency doubles again should a second anchor fail. In a situation where more than two anchors fail, then 100 per cent of the anchors require proof testing and it also advisable that both the anchor used and the installation method are re-visited. Should this be required, then it is important to use a reputable anchor company with a strong technical department.

Pull test recording

In line with BS 8539, the results of the pull tests need to be formally recorded and retained with the site documentation relating to the scaffold structure. Traditionally, these results were recorded manually, noting down the load achieved.

As with many aspects of inspections and testing, a recent development is a digital process to record the results of these tests. This digital method enables the pull tester to show that they have complied with the testing element of BS 8539, both with regard the load applied and that the load was held for the specified length of time.

A digital process for testing will also then collate the data into a comprehensive site test report.

FIND OUT MORE www.hydrajaws.co.uk 12 ACCESSPOINT MAGAZINE | GUIDANCE GUIDANCE www.accesspoint.org.uk

With a proof test, a minimum of three anchors or 5 per cent of the anchors installed (whichever is the larger number) are to be tested per scaffold.

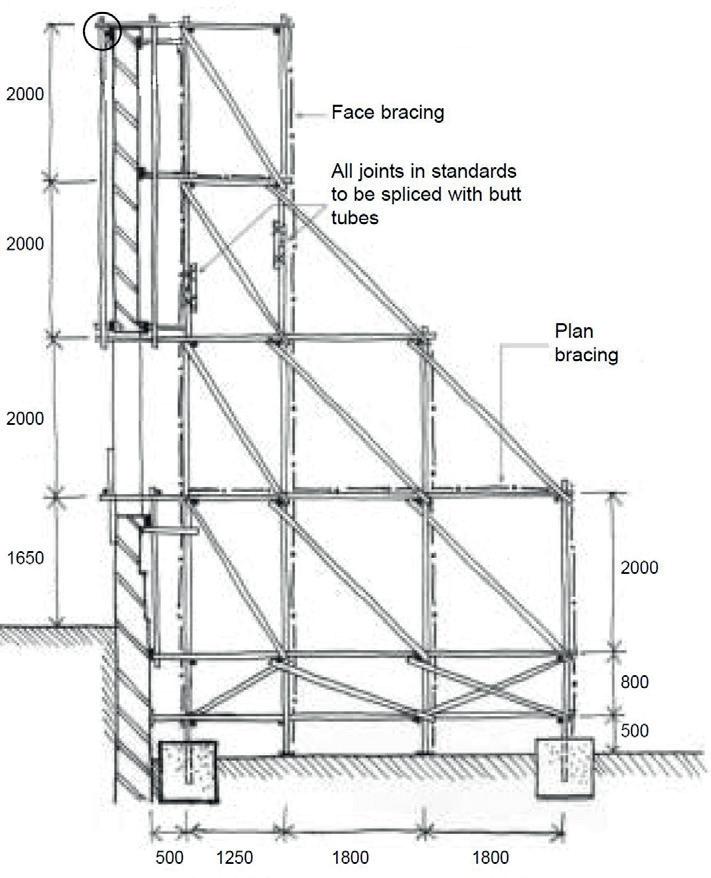

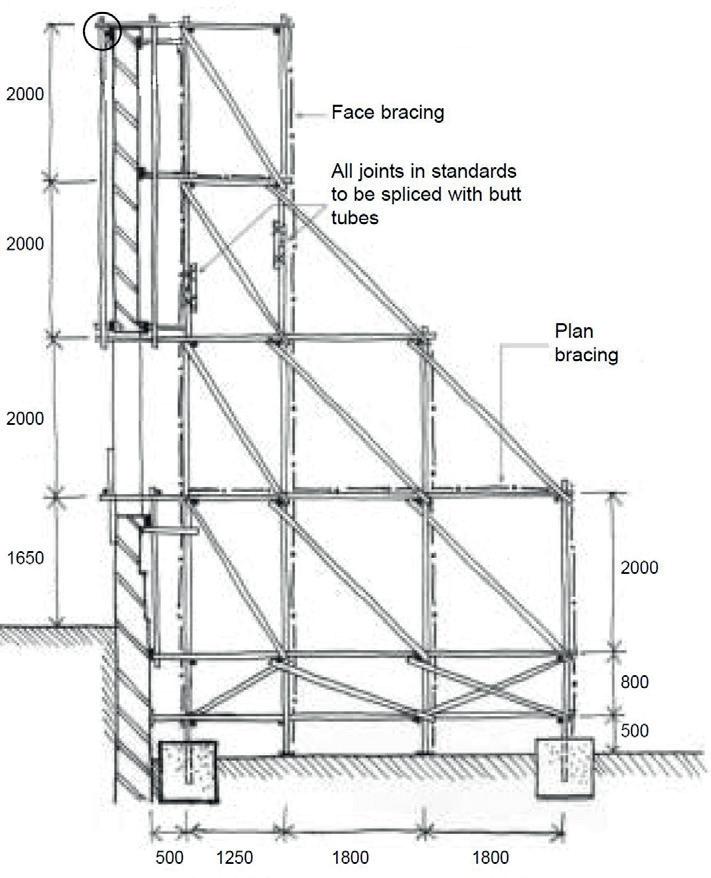

Design of facade retention scaffolds

Facade retention scaffold design has many considerations. Ivik Masek BSc (Hons)

IEng MICE, from design consultants 48.3, provides guidance on the design considerations associated with retention schemes and answers common questions in this technical article for AccessPoint.

of all areas. The external walls of UK buildings constructed pre-1900 are likely to be of full loadbearing thickness. A wall’s condition can vary in areas due to long-term water intrusion causing wall ties to corrode or the timber to rot.

Fixing to the structure

First, understand how the facade is restrained, then attempt to replicate the pattern of restraint using scaffolding, e.g. lateral support points at floor locations. Ideally, the facade ties are fixed through the window opening to avoid drilling into or through the masonry. Timber scaffold boards or packing are often used to achieve good contact with the facade and prevent damage from the steel scaffold tubes. With listed buildings, the fabric of the building must be protected.

Design considerations

A summary of the main design considerations is provided below:

1. The scaffold needs to resist horizontal loading by wind. Consider the wall to be solid (worst case). See BS EN 1991-1-4 clause 7.4.1 (freestanding walls) or clause 7.2.2 (vertical walls of rectangular plan buildings).

2. Additional horizontal load due to out-ofplumbness.

3. Accidental impact loads. If a risk assessment identifies impact from demolition/ construction activities as a risk, then the following impact loads must be considered: 10 kN from 1m above ground. 25 kN below (due to vehicle impact). See CIRIA C579 clause 8.5.

4. Demolition sequence. Number of walls being demolished. Establish the sequence of work required to maintain stability.

Raking, flying and dead shores are all types of retention systems. A raking shore consists of rakers (diagonal braces) that provide lateral support to walls.

The ratio of bracing height to width at ground level is between 1:1 and 2:1. Flying or horizontal shores is a system used to restrain party walls or front and rear walls with proprietary scaffold beams. It is ‘flying’ because it does not bear on the ground. Dead shores are used to provide vertical support to roofs, walls or floors.

A facade retention scaffold is similar to a raking shore because it provides lateral support to the facade of a building. These scaffolds are typically required when restoring listed buildings, improving the internal structure of a building or the stability of the facade has been compromised. The scaffold is generally required from the start of the demolition/repair work until the completion of the new structure/repairs.

Understanding the structure

It’s essential to establish the facade’s construction (brickwork/stonework) and current condition

CIRIA C579 lists contributory factors in failures of retained facades, some of which are directly related to the design of facade retention scaffolds.

Lack of appreciation of the technical issues. HSE Guidance Note GS 51 states that the design of any facade retention system will be carried out by a chartered civil or structural engineer who is experienced in and understands the type of work being undertaken.

Inadequate investigation of the existing construction. Site visits are vital to better understanding the building. An internal and external visual inspection will help identify the general construction, fabric, floor locations and overall condition, which should be included in the design brief and form part of the design.

Tying scaffolding for support to a facade. Consider the adequacy of connections between the facade and the scaffold retention structure. It’s also important to consider the possibility of local failure of the fabric between the scaffold ties.

5. Rigidity & Stability. Factor of safety (FOS) 1.5 against overturning. FOS 2.0 against sliding. See CIRIA C579 clause 8.14.

6. Assumed ground-bearing pressures. Weak soil under the kentledge can cause the scaffold to tilt and damage the facade.

7. Depth of any basements, cellars or vaults. The additional depth will increase the lever arm when calculating overturning moments.

8. Access requirements to the facade for repair works.

9. Joints in standards/uprights or bracing. All joints should be spliced to resist uplift/ tensile forces.

10. The site constraints will influence the proposed design solution. Limited space on-site can increase the kentledge requirements significantly. A simple solution such as taking up the parking bays can reduce the overall project costs.

11. Site visits: most facade retentions schemes will require access to the interior of the building. If the condition of the structure is unknown, then safe access is not possible. Existing services should also be considered.

14 ACCESSPOINT MAGAZINE | TECHNICAL TECHNICAL www.accesspoint.org.uk

Typical section through scaffold (extract from CIRIA C579, 7.5.1 The raking support).

12. Stiffness. Limiting the deflection will preserve the integrity of the retained structure. High limits on deflection results in very expensive scaffolds. Max. deflection limit of height(H)/750 with floor to floor limits of 5 mm over 3.0 m. e.g., the deflection limit for a retention structure 7.65 m high is 10.2 mm.

Responsibilities

CIRIA C579 stresses that there must be “ownership” of the scheme at all stages from inception to completion of the whole of the works. An early appointment recommended for facade retention work is that of a suitably qualified and experienced temporary works co-ordinator (TWC). All parties must be aware of their responsibilities under CDM Regulations, which stipulate that all relevant information about the site should be provided by the client.

Notes

This guidance is intended as an aide to those seeking to design a basic facade retention scaffold. The reader is advised to refer to the CIRIA C579 guidance for further information. Facade retention scaffolds must be rigid structures, therefore additional material (i.e. transoms, ledgers, standards and bracing) will be required. Kentledge is often required and when supported on the scaffold can further

increase the components needed. Furthermore, the designs typically require a BS 5975 Category 2 check, all of which contribute to the overall cost of a facade retention scheme.

References

1. CIRIA (2003) Retention of masonry facades – best practice guide. CIRIA C579, London, Construction Industry Research and Information Association.

2. GOODCHILD, S L and KAMINSKI, M P (1989) Retention of major facades. The Structural Engineer, vol 67, no 8, 18 Apr, pp 131–138

FIND OUT MORE

Ivik Masek 48.3 Scaffold Design Ltd

www.483scaffolddesign.com

TECHNICAL | ACCESSPOINT MAGAZINE 15 TECHNICAL www.accesspoint.org.uk

Get in early and improve performance

London’s Leicester Square is taking another step to building a world-class tourist environment, and scaffolding specialists from Mercer are providing access and scaffolding solutions so that safe and efficient access is possible at the new £300m five-star hotel, leisure and cinema complex. Adrian JG Marsh reports.

said: “It’s important to build scaffold safely and of a quality that is commercially viable. We weighed up everybody’s access requirements on every floor and devised a scaffold design that would help Blue Sky Building achieve greater cost certainty at tender stage and reduce risk.

Orange Street Loading Gantry

Site access is always a challenge in central London, compounded by limited pavement space to the south on Orange Street. So, the heavy duty gantry at 50 metres long and seven metres high maintains safe access at street level and also provides a base for the scaffolding on the south facade.

“We started looking at various options for the scaffolding eight months in advance of appointing a scaffolding contractor,” said Lawrence Baptist, the construction director at Blue Sky Building. “This approach allowed us to develop a clear scope of works to suit the contract and it meant that when we went to tender, the contractors were bidding on a level playing field.”

Located on Leicester Square, the new hotel will aptly be called The Londoner, and it is scheduled to open in 2020. The new complex is being built across 15 levels, six below ground and nine above – 35 metres above ground and 35 metres below.

The Londoner Hotel will have 350 rooms including 15 suites, five concept restaurants and a spectacular rooftop bar, state-of-the-art ballroom for up to 1,000 guests, two new Odeon Luxe cinemas and a unique subterranean spa.

Blue Sky Building appointed 48.3 Scaffold Design as the independent scaffold consultant earlier this year. From the outset, 48.3 analysed the programme and the requirements of each package contractor in detail.

Ben Beaumont, managing director at 48.3,

16 ACCESSPOINT MAGAZINE | SITE REPORT

SITE REPORT www.accesspoint.org.uk

“While we provided a base design, we also included options to use at a later stage. For example, we didn’t know where the ties would go as the facade design had not been detailed.”

Mr Baptist explained that the 48.3 design helped Blue Sky Building to overcome some critical path tasks: “Their proposal for the North–South elevation to support the hoarding and gangway for the stone mason has helped to improve safety and productivity.

“And along the South elevation, they overcame restricted access by proposing a heavy duty loading gantry across Orange Street. This allowed the scaffolding to be sprung from it to provide access to the facade and deliveries without compromising either safety or progress.”

Mercer, a Scaffolding Association Audited Member, won the prestigious contract in a competitive tender against a roster of London’s top scaffolding contractors and work started on-site last September.

“We’d been following the project for some

time and had offered Blue Sky Building some early pre-construction advice about the scaffolding,” said Adam Millgate, the operations director at Mercer.

“Once we were appointed (as scaffolding contractor), we retained the services of 48.3 and worked with them to develop the scaffold design in detail. The site is quite tight and we proposed a smart approach that minimised deliveries and improved on-site efficiency.

“We opted to use some benefits of a Layher system for hoists, staircases and loading platforms, with tube and fitting in areas where it is more efficient.”

The shape of the building and having to move pallets of stone around meant that the scaffolders had to carefully consider access from the loading platform around the perimeter at each level.

With a pallet of stone weighing up to 350kg, the loading bay areas were designed to have a 10kN capacity. Some elements of scaffolding,

especially around the bullnose feature fronting Leicester Square, would not be possible in system scaffold so tube and fitting was used.

The scaffold design gave Blue Sky Building greater flexibility and helped with sequencing, as Mr Baptist explained: “It’s a very involved scaffold package. Three of the elevations have windows all recessed while on the fourth elevation the windows step out. Windows go in before the scaffold gets erected and then the stone mason follows the scaffolders.

“On the East elevation, Mercer proposed an alternative approach to allow the SFS and cement board to be fixed more quickly and easily than expected. This has helped to create savings to the programme.”

The scaffolding is up to nine boards wide. Every lift has had to be buffalo-boarded to enable safe movement of the stone masons’ trolley. And with every lift there is a Niko Rail around the perimeter. Here, sections of track are bolted to a structural 50mm transom to allow electric chain block trollies to lift and carry the stone blocks into position. This virtually eliminates manual handling of the stone, making it safer and quicker to install.

Mercer’s site manager, Lee Read, said: “We’re a quarter of the way through the programme and now starting to peak at about 25 scaffolders. There are three stage adaptions to every elevation and every lift. In addition, there are ongoing safety works on 16 risers, some 9m x 6m, four escalators, cinema room scaffolding, and there is also 400 metres of handrails to be installed per floor. And we’re providing scaffolding for internal trades including blockwork contractors and the fire board installers around the fresh-air ducts.”

The highly prestigious hotel and leisure complex is not only helping to transform Leicester Square but it is also a showcase for early involvement. Pre-construction planning, some innovative thinking and positive attitudes can, and are, making a real difference to performance.

PROJECT TEAM:

Developer: Radisson Blu

Main Contractor: Blue Sky Building

Scaffolding Design Consultant: 48.3 Scaffolding Design Ltd

Scaffolding Contractor: Mercer Scaffolding Services Ltd

SITE REPORT | ACCESSPOINT MAGAZINE 17 SITE REPORT www.accesspoint.org.uk

SEC Group praised by Business Secretary Greg Clark

former chairman of the National Infrastructure Commission, said: “The achievements of SEC Group in improving commercial practices for the majority of SMEs in the UK’s construction industry are impressive.

“If there is only one body in the construction industry that has made a real difference over 25 years, that body must surely be SEC Group.”

Although SEC Group was established 25 years ago, it has a 57-year lineage of representation and achievement. Today, it represents the largest sector (by value) in the UK’s construction industry. Firms in the specialist engineering sector are responsible for designing and installing/assembling complex systems, structures and products as well as operating and maintaining them throughout the lifecycle of the building or structure.

Mr Clark praised SEC Group for its work on behalf of construction SMEs, commenting: “I would like to congratulate the Specialist Engineering Contractors’ Group on its 25th anniversary and to thank them for all the work

they have done over the years in representing SMEs in the construction industry, which I saw at first hand when chairing the Carillion Taskforce.”

Adding his congratulations, Lord Adonis,

The Scaffolding Association is an active member of SEC Group and members benefit from a key role in ensuring policy-makers are aware that the quality and sustainability of our built environment is dependent upon having a thriving and growing specialist engineering sector. For this reason, the focus for SEC Group’s work has revolved around campaigning for more collaborative procurement and delivery models, and a more equitable payment system for SMEs.

All that

enthusiasm and

means that you can trust Amicus to not only find the best insurance to protect you, your business and your employees, but that you can also rely upon us to do it at the most competitive price. www.amicus-insurance.co.uk

18 ACCESSPOINT MAGAZINE | INDUSTRY NEWS AND SKILLS INDUSTRY NEWS AND SKILLS www.accesspoint.org.uk Specialist

scaffolders Amicus is a specialist broker to the Construction and Scaffolding Industries. We have been working with the Scaffolding Association since 2015 and are proud to insure many of the UK’s leading Scaffold companies. We really understand scaffolding insurance and we love it. We have even employed some former scaffolders within our business so you can be 100% confident that we really do talk your language!

insurance for

Why not give us a try!

discuss your insurance requirements, or to find out how we can

us

www.amicus-insurance.co.uk

expertise,

industry knowledge

To

help you, contact Karl Jones, Rory Boylan or Adam Scott on: 0208 773 5395 or email

at karl.jones@amicus-insurance.com

Compass London Market Broker of the Year 2015/16

FIND OUT MORE www.secgroup.org.uk

The Specialist Engineering Contractors’ (SEC) Group is celebrating 25 years as a representative body, and during its anniversary year, it has received praise for its work from Greg Clark, the Secretary of State for Business, Energy and Industrial Strategy.

Construction industry to benefit from major skills boost

The government has announced a series of new ‘hubs’ based at live construction sites to train up thousands of workers and help tackle skills shortages in the construction industry.

Education Secretary Damian Hinds announced that 26 innovative partnerships had won a share of the £22 million Construction Skills Fund to set up the new ‘hubs’, which will train more than 17,000 people to be job and site-ready by March 2020.

The winning projects, including Southwark Construction Skills Centre in South London and Liverpool Waters Construction Hub in the North West, have collectively committed to training up over 7,000 people into permanent jobs by the end of the programme. With an estimated 158,000 new construction workers needed in the UK over the next five years, the scheme will help create the skilled workers to meet this challenge.

Mr Hinds said: “It is vital that we have a strong workforce post-Brexit. The Construction Skills Fund will ensure more people gain the skills they need to forge a successful career and help create the skilled workers we need to deliver on our housing ambitions.

“To support this drive further, we are transforming technical education including introducing a new T Level in construction, a high-quality technical qualification which will be rolled out from 2020. Whether building new homes or contributing to major infrastructure projects to keep our country connected, working in construction means helping to shape Britain in the months and years ahead.”

www.gov.uk/government/news/construction-industry-to-benefit-from-major-skills-boost

Van drivers urged to check weights

Younger drivers are being urged to make sure they don’t overload their vehicles and make their driving licence invalid.

Experts from LeaseVan.co.uk say many younger van drivers may not be aware that their driving licence limits them to driving vans which weigh less than 3,500kg when fully loaded – including the weight of the driver themselves.

The rule only applies to motorists who passed their driving tests after 1 January 1997. If they plan to exceed this weight, they need to take an additional driving test.

But many van drivers fail to factor in the weight of their van’s load and instead wrongly assume that just because the van itself is below 3,500kg, they should be safe.

Most medium-sized vans, including the iconic Ford Transit, typically weigh around 2,000kg, but when fully loaded with items along with the weight of a one- or two-man crew, can easily exceed the 3,500kg limit. If a driver was involved in a road accident and their van was found to be over the weight threshold, the driver would not be qualified to drive it and therefore their insurance would be invalid.

Tradespeople are urging their customers to visit a local weighbridge and check their van’s fully loaded weight if they are unsure.

Anyone who needs to drive heavier loads should enquire with the DVLA about gaining an additional driving qualification to allow them to drive larger vans. The weight limit does not apply for drivers who passed their driving test before 1 January 1997.

FIND OUT MORE www.gov.uk/guidance/driving-a-van

Apprenticeships vital for tackling future workplace challenges

A survey of employer-members undertaken by The 5% Club highlighted that less than 2 per cent of businesses are fully confident that their employees are well placed to take advantage of the rising use of new technology, whereas 78 per cent of businesses surveyed strongly believe that ‘earn and learn’ training opportunities, including apprenticeship schemes, can help address future changes in the workplace.

The 5% Club – a movement of more than 340 employers providing ‘earn and learn’ opportunities to develop skills and talents – is strong in construction and counts the Scaffolding Association as a partner.

According to the training and skills campaign group, an ageing workforce, a continuing skills gap across sectors and the rising use of new technology, such as Artificial Intelligence, are all challenges which businesses can positively tackle by providing employees with the right on-the-job training and relevant skills.

In the survey to mark The 5% Club’s 5th birthday, employermembers were asked about important challenges facing their sector and the role of earn and learn training. Key survey highlights included 91 per cent of respondents agreeing that earn and learn training can significantly help to address the continuing skills gap crisis, and 67 per cent stating that apprenticeships are critical for upskilling an ageing workforce.

FIND OUT MORE www.5percentclub.org.uk

MORE

FIND OUT

INDUSTRY NEWS AND SKILLS | ACCESSPOINT MAGAZINE 19 INDUSTRY NEWS AND SKILLS www.accesspoint.org.uk

Safe traffic management on a scaffolding site

visible even if traffic flow is suddenly redirected.

Recent research into on-site safety shows a 74 per cent rise in traffic management breaches on construction sites, putting scaffolding contractors at risk of colliding with vehicles and machinery.

Visibility is key

For contractors working at height and on busy sites, visibility is crucial. One misplaced step or an unseen operative could result in a serious incident.

The best solution is to provide consistent lighting around the site at all times. Those working on scaffolding towers will benefit from agile safety lighting that can be attached to tubing, masts and cranes to keep all areas adequately lit. Overhead mast lighting is powerful enough to illuminate walkways, keeping workers alert to trip hazards, falling objects and oncoming vehicles.

However, it’s not just pedestrians that benefit from a well-lit site. With machinery and vehicles such as forklifts often suffering from blind spots, drivers need help seeing what’s around them.

Other recommended precautions include lining vehicle routes with reflective traffic cones and using safety signs. Illuminated or reflective signs can be used around the site to guide traffic, label different areas, alert staff to hazards and warn the need for safety equipment.

They’re safer apart

According to industry research, the most common cause of traffic management incidents is a failure to keep pedestrians and drivers safely separated. With workers entering and navigating the site by car or foot and operating mobile machinery – plus the added traffic

of deliveries and visitors driving onto site – it’s vital that routes are clearly outlined and heavily signed.

Start by drawing up traffic flow designs, including allocating vehicle and pedestrian lanes, and parking areas and loading areas. Once they’ve been approved, use traffic management solutions to implement them. Traffic separator blocks provide a sturdy enough barrier to keep vehicles out of the way of one another, and a safe distance from scaffolding towers or workers. Many products can be filled with water or sand, making them heavy enough to withstand strong winds or bumps from vehicles.

There’s plenty to consider when it comes to organising on-site traffic, including whether to use one-way or dual lanes. One-way lanes are safer;

however, depending on the size of your site, you could send drivers on a long round-trip. An option for combatting this is to add designated turning circles in driving lanes so vehicles can manoeuvre without risking crossing into other lanes or colliding with pedestrians.

What’s always important is choosing the safest route, not the quickest or most convenient.

Special considerations

Scaffolding sites aren’t permanent, so it’s important to make both the team and the site adaptable to sudden change.

One of the easiest ways to stay agile to on-site changes is ensuring all contractors and visitors are kitted out with full health and safety gear. Workers in hi-vis jackets will still be clearly

Sites should also be adaptable to visitors, deliveries and periods of heavier traffic. One way to ensure this is using a mix of heavier, more permanent barriers along with lighter, moveable traffic cones. In instances of heavy traffic, use cones to create temporary traffic lanes or pedestrian routes to alleviate congestion.

Visitors and deliveries won’t be aware of the safest routes on-site, so it’s important to allocate set routes for entering drivers. Each route should be fitted with precautions such as speed-limit signs and mirrors where larger vehicles are likely to have blind spots or lanes are narrow.

When allocating a delivery spot, make sure there’s enough room for large objects to be safely lifted off the truck. Scaffolding tubes, boards and towers can be awkward, so allow room for vehicles to turn safely without endangering surrounding workers.

20 ACCESSPOINT MAGAZINE | HEALTH & SAFETY

Chris Pendrey, SHEQ manager at Actavo Direct, outlines how you can control traffic on-site to avoid injury while also avoiding disruption and keeping processes efficient.

HEALTH & SAFETY www.accesspoint.org.uk

Creating new opportunities for the sector

More than 100 members attended the Scaffolding Association AGM in London during autumn to learn about expanding work opportunities, better training and managing contract risks. The AGM also gave insight into how the Association is growing, the benefits for members and plans for the upcoming year. Natasha Marsh reports.

Industry knowledge-sharing

Stacey Underhill updated on the Association’s awareness campaign – showcasing its offering at Safety and Health Expo, London Working at Height Seminar and UK Construction Week – and the industry groups where the Association has actively contributed to addressing sector issues, concerns and initiatives.

meaningful careers.

The Association’s vice president, Karl Degroot, urged all scaffolders to consider joining The 5% Club, highlighting how everyone needs to do their bit in making sure our sector has the right people with the right skills, for now and for the future.

Member benefits

At the Scaffolding Association’s AGM, chief executive Robert Candy revealed that the Association was now the largest trade body in the scaffolding and access sector, with more than 350 members and continuing to grow.

Audited Member accreditation

Addressing one of the Association’s key objectives, which is to ensure members have fair access to work, Stacey Underhill, head of external affairs, explained that during the last 12 months the Association has specifically targeted clients with restrictive procurement policies. To address a distinct hurdle for businesses to get onto the supplier list of clients, the Association has negotiated that Scaffolding Association Audited Members are now accepted onto tender lists (for a full client list, contact stacey@scaffolding-association.org).

The new Audited Supplier membership was outlined. This will enable suppliers and manufacturers to demonstrate that they meet their

relevant regulatory requirements and that the standards they adhere to provide specifications that ensure their products work the way the end user expects them to. For industry suppliers to become an Audited Supplier member – which recognises management system certifications like ISO 9001:2015, ISO 14001:2015 and ISO 45001:2018 – Association members complete a two-stage audit, undertaken by an independent and impartial assessor.

Collaborating for a stronger voice

Speaker Professor Rudi Klein, chief executive of the Specialist Engineering Contractors’ (SEC) Group, referenced the synergies between the Association and SEC Group (of which the Association became a member in February 2018), highlighting how effective collaboration creates a stronger voice for specialist contractors, whether the challenge is payment security, delivery processes or professionalising the industry.

A highlight of this campaign was leading a panel session at Safety and Health Expo, chaired by AccessPoint editor Adrian Marsh, to address Working at Height. Actively engaging in these forums to share knowledge across the industry is valuable to those working in the access and scaffolding sector. The Association will establish its own technical committees and working groups to harness the breadth of experience of its members.

Developing skills for the future

One way the Scaffolding Association has demonstrated commitment to developing the people in its sector is by becoming a partner of The 5% Club. Gill Cronin from The 5% Club spoke about this industry-led initiative of more than 300 employers – particularly strong in construction – that focuses on developing the skills and talents people need to become more employable and create

Wrapping up, Association president Russell Maxwell-Smith recognised how difficult it can be to gain leverage with stakeholders, emphasising the importance of members engaging with the Association and supporting the work they undertake on their behalf.

In his closing statement, he stressed the importance of creating a combined voice with a consistent message when dealing with sector-specific and industry-wide issues.

Members were reminded of the suite of benefits they have access to all year round. From legal advice to marketing support, website presence to exposure in newsletters, these benefits all contribute to the growth of the members’ businesses.

To express interest in getting involved with any Scaffolding Association initiatives, contact stacey@scaffolding-assocation.org

SCAFFOLDING ASSOCIATION AGM | ACCESSPOINT MAGAZINE 21

FIND OUT MORE

SCAFFOLDING ASSOCIATION AGM

www.scaffolding-association.org

www.accesspoint.org.uk

Left to right: Scaffolding Association president Russell Maxwell-Smith, chief executive Robert Candy and vice president Karl Degroot.

The Scaffolding Association has more than 40 Audited Members.

WELCOME TO NEW SCAFFOLDING ASSOCIATION MEMBERS

www.accesspoint.org.uk Keep

SCAFFOLD ERECTION

Access Group Services

www.access-scaff.co.uk

Advanced Scaffolding (SW) Limited

www.advancedscaffoldingltd.co.uk

Anglewest Scaffolding Limited

www.anglewest.co.uk

A & R Elite Scaffolding Limited

www.arelite.co.uk

Best Price Scaffolding – 01237 476161

BVL Scaffolding Co. Limited 0208 640 5500

Diamond Scaffolding (South East) Limited

www.diamond-scaffolding.com

Direct Hire and Scaffolding Limited 01708 524150

D W G Scaffolding Limited 01883 741818

Harlequin Scaffolding Solutions Limited

www.harlequinscaffolding.co.uk

J&B Pro Access Limited

www.jbproaccess.co.uk

J&K Scaffolding (Northampton) Limited

www.jkscaffolding.co.uk

Jelson Limited – www.jelson.co.uk

Kent County Access Limited

www.kentcountyaccess.co.uk

Landfall Scaffolding Limited www.landfallscaffolding.co.uk

M.J. Stapleton & Son Limited

www.stapletonscaffolding.co.uk

MKS Scaffolding Limited

www.mksscaffolding.co.uk

Niall Scaffolders Limited

www.niallscaffolders.com

No Limit Scaffolding Services Limited www.nolimitscaffolding.co.uk

Passim Services Limited

www.passimservicesltd.net

Portway Scaffolding Limited

www.portwayscaffolding.co.uk

Premier Scaffolding Specialists Limited

www.premierscaffoldinglondon.co.uk

PTG Scaffolding Limited

www.ptgscaffoldingltd.co.uk

Reunited Scaffolding

www.reunitedscaffolding.co.uk

Safe Access Scaffolding Limited

www.sascaffolding.com

Scaffolding London Limited

07970 348177

SKY 4 Limited – www.sky4ltd.com

Texo Scaffolding and Construction Limited www.texoscaffolding.co.uk

Topps Scaffolding Limited www.toppsscaffolding.co.uk

Totem Scaffolding Limited www.totemscaffolding.com

Tubes Scaffolding (Oxford) Limited www.tubesscaffolding.net

PRODUCTS AND SERVICES

Hydrajaws Limited – www.hydrajaws.co.uk

Mercer secures Springfield Park contract

30 January 2019

Technical Committee Meeting

13 February 2019

NI Construction Show, Belfast

26 February 2019

Health and Safety Committee Meeting

March 2019

Regional Member Forums

3 April 2019

Temporary Works Conference in Birmingham

IIRSM and Scaffolding Association event

18–20 June 2019

Safety and Health Expo

www.safety-health-expo.co.uk

19 September 2019

AGM – London, Union Jack Club

Godiva supports seven-storey Manchester housing scheme

Godiva Access & Scaffolding has been awarded the contract for a new seven-storey housing scheme that features 101 one- and two-bedroom apartments in Malta Street, Manchester.

Godiva was appointed to deliver both the design and erection of the scaffolding solutions for the project, which has a total value of £240,000 and is expected to take 40 weeks.

Each of the 68 two-bedroom and 33 one-bedroom apartments will have either a glazed cantilever balcony or a Juliet window and an open plan kitchen diner with integrated appliances. The development will provide 82 CCTV-covered parking spaces, along with cycle storage and roof-mounted solar panels.

Karl Degroot, managing director at Godiva, said: “Winning this fantastic project is testament to the success we are already enjoying in Manchester, having only opened an office here earlier this year. Again, it demonstrates our capability when working at height, currently being epitomised on another one of our projects – the highest new-build in Coventry.

“We’re delighted to be working with Russell’s Construction on this project.”

Mercer Scaffolding has secured Springfield Park for Weston Homes, a new development of 502 luxury one-, two- and three-bedroom apartments in the heart of Maidstone that is set to be the tallest residential building in the area, offering sought-after views over the River Medway and Kent countryside.

Mercer supervisor Shaun Chapman and his team of 15 scaffolders have already commenced work on-site, installing the fully designed scaffolding, part of which is to be erected on a steel gantry to create access for the public into the sales and marketing suites. The first block will be 18 storeys and installed using cantilevered loading bays. The team worked closely with 48.3 Scaffold Design throughout the design and tender stage, building a complex scope for the two-year programme of works.

Gavin Cardno oversees the project for Mercer. He said: “It will be an impressive site once complete. I’m looking forward to managing it – it’s right on my doorstep.”

FIND

Allied Access celebrates launch of new brand identity

Construction supplier Allied Access has celebrated the launch of its new brand identity at a special event attended by a host of clients and industry colleagues.

Allied Access, formerly known as Allied Scaffolding, has undertaken the rebranding exercise to reflect its changing business. Although scaffolding remains a key component of its integrated approach to safe access, mast climbers and hoists are now a significant part of the company’s access portfolio.

Pete Ferris, Allied Access’s commercial director, said: “Our new identity is bigger, brighter and bolder, reflecting the business we are now and the business we’re going to be.

“The launch event was a great success and it was fantastic to see so many of our clients attend. For some, it was the first time they had heard about our humble origins. We’ve changed a lot since the early days back in the 1980s, and we’ll continue changing to meet the needs of our clients.”

22 ACCESSPOINT MAGAZINE | ASSOCIATION NEWS

ASSOCIATION NEWS

an eye out for latest events at www.scaffolding-association.org/events

OUT MORE www.alliedaccess.co.uk

FIND

OUT MORE www.mercerscaffolding.com

FIND OUT MORE www.godivagroup.com

Royal touch to Leeds Access Company heritage project

Leeds Access Company has once again teamed up with project conservator Ellin Belton on a specialist project at Alnwick Castle, having first worked together on an English Heritage project at Brodsworth Hall, Doncaster.

The latest project sees Leeds Access providing birdcage scaffold access for the conservation cleaning of the iconic castle’s state dining room, which will be carried out in two phases over four weeks.

Lee Cole, director at Leeds Access Company, commented: “This was a challenging project, with access into the room being particularly tricky. We had to install an external loading scaffold and pass all of our materials through a small window. All scaffold boards also had to be wrapped to protect the room from external debris and dust.

“The need for careful handling was paramount due to the age and history of the castle.”

During the project, Alnwick Castle was visited by HRH The Prince of Wales, making this the second project the company has worked on that involved the prince. In 2014, it worked with the Prince’s Regeneration Trust on Middleport Potteries in Burslem, Stoke-on-Trent. The project ‘The last working Victorian Pottery’, ran for over 12 months.

Mr Cole added: “It’s been a great experience working at Alnwick Castle and, while testing to say the least, it was a nice surprise and absolute pleasure to meet Prince Charles in the process.”

FIND OUT MORE www.leedsaccesscompany.com

Force Scaffolding celebrates hat-trick of successes

Force Scaffolding is celebrating a string of successes in recent months, including securing two sizeable scaffolding contracts from one of the country’s largest house building companies.

In addition, two of its office staff, Claire and Lisa, have successfully completed an intense three-day estimating course in preparation for what is predicted to be another strong year in 2019.

The company has also received a series of positive reports from the Health & Safety Officer inspecting one of its major commercial clients, after successfully scaffolding a 12-storey student apartment block in Derby city centre.

FIND

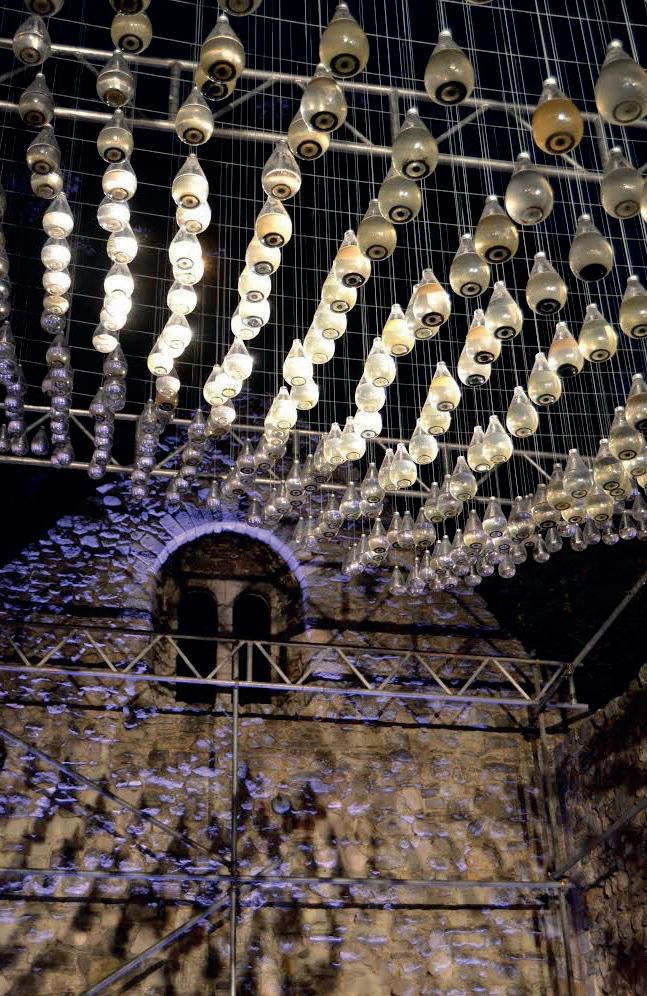

JPS makes light work of art installation