CONTENTS

04 Voice of the sector: Change must happen

05 Opinion: Bridging the short-term skills gap?

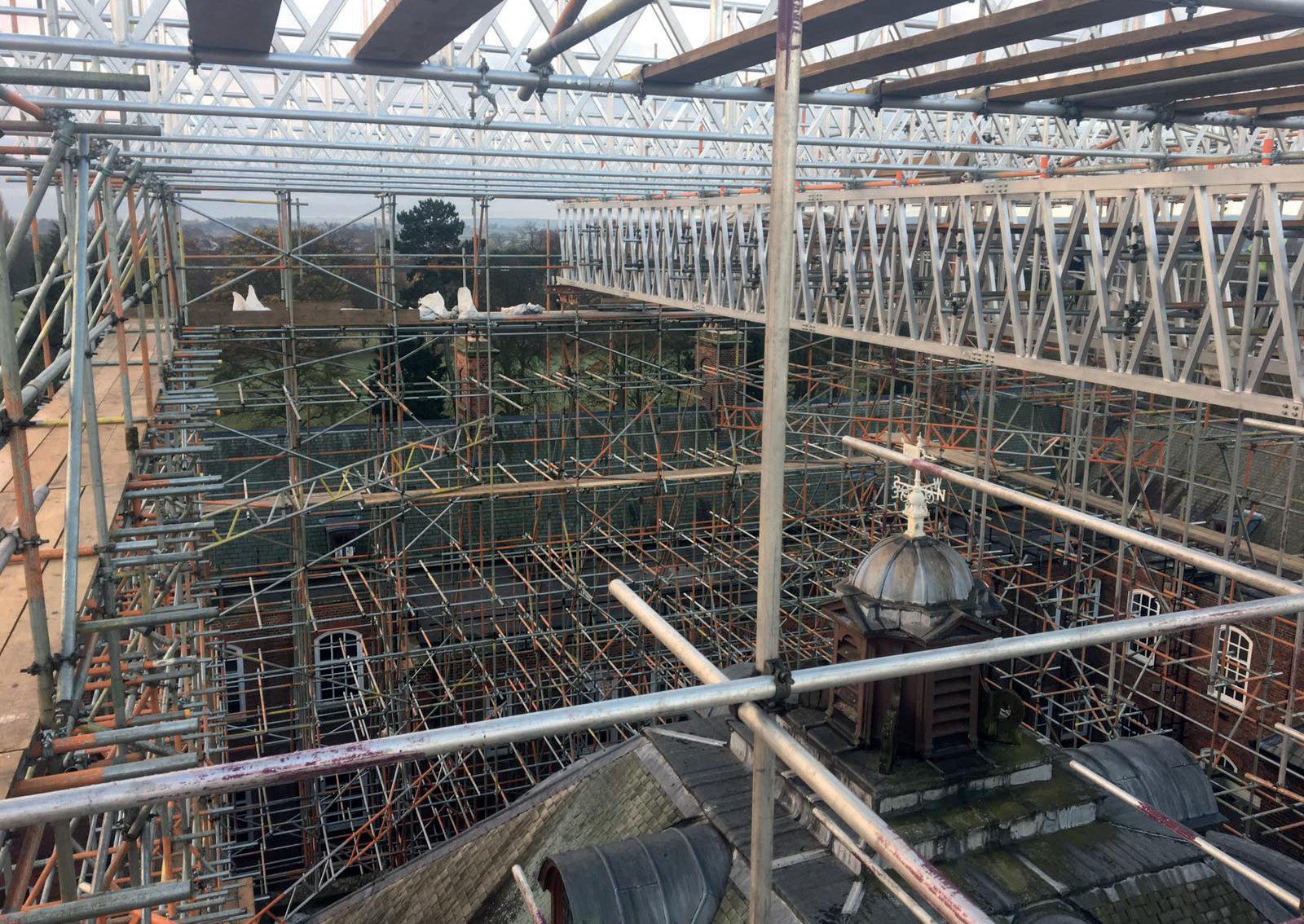

08 Project News: Temporary roof at Grace Academy Solihull

10 Commercial: Risks in design responsibility for temporary works

14 Technical: Bridge beam development

16 Site Report: CCS Scaffolding contracted to A14 major infrastructure project

18 Trade: News from FASET and FLTA

20 Health & Safety: Emergency preparation

21 Skills & Training: What ’s happening in our sector?

FRONT COVER:

Kier contracted Formark Scaffolding to provide extensive scaffold works to enable repairs to three buildings in Bow, East London.

Carillion collapse puts payment in the spotlight

The Carillion collapse has illustrated the lack of payment security in the UK construction industry and the devastating impact on small firms up and down the country. Leading trade association the Specialist Engineering Contractors’ Group (SEC Group) is calling on Parliament to take steps to finally tackle bad payment practices in the construction industry.

Estimates of supply chain losses look likely to top £1 billion and commentators have said that some of these losses could have been avoided if measures had been in place to provide security of payment to Carillion’s supply chain.

Professor Rudi Klein, chief executive at SEC Group, said: “If all payments to the supply chain had been routed through a project bank account (PBA), rather than through Carillion’s accounts, firms would have received their monies.

“Moreover, there would have been less disruption to the progress of works on public sector projects. Millions of pounds of retention monies have been lost. These were monies withheld – ostensibly as security in case of defects – to bolster Carillion’s working capital.”

SEC Group is calling on Parliament to insist that the Government supports the Construction (Retention Deposit Schemes) Bill (‘the Aldous Bill’) which had its First Reading on 9 January 2018; and SEC Group invites the Government to legislate to require that PBAs are put in place for all construction works over £1 million.

Professor Klein is also demanding that the Government issues strong guidance to all public sector procurers and that if lead contractors do not pay their supply chains within 30 days (as already required under the Public Contracts Regulations 2015), they should be barred from bidding for public sector works for a period of at least two years.

Robert Candy, chief executive at the Scaffolding Association, said: “Carillion’s move into liquidation has put their huge supply chain, which includes many scaffolding contractors, at risk of losing millions of pounds. We support demands to stop payment abuse and ring fence cash retentions.”

FIND OUT MORE

Turn to page 4: Change must happen

Industry-led training initiative to increase capacity

The Scaffolding Association has unveiled plans to increase training and skills delivery capacity for access and scaffolding contractors by setting up the Access Industry Training Scheme (AITS), an employer-led training solution that will help to expand the training and skills development capacity in the access and scaffolding industry.

CONTACT US

EDITORIAL

Editor: Adrian JG Marsh

Assistant Editor: Jenny Gibson

Telephone: 01926 420 660

Email: newsdesk@accesspoint.org.uk

AccessPoint, Althorpe Enterprise Hub

Althorpe Street, Leamington Spa CV31 2GB

Design: Matthew Glover

SUBSCRIPTIONS newsdesk@accesspoint.org.uk

ADVERTISING

Advertising enquiries: Adam Turner Tel: 01926 420660 adam.turner@campbellmarsh.com

Scaffolding Association

Tel: 01386 764 945 www.scaffolding-association.org

Email: info@scaffolding-association.org

ISNN: 2055-2033 (Print)

AccessPoint magazine is published on behalf of the Scaffolding Association by Campbell Marsh and the views expressed in this journal are not necessarily those held by the Scaffolding Association or the publishers. The publishers shall not be under any liability in respect of the contents of the contributed articles. The Editor reserves the right to edit, abridge or alter articles for publication.

Last year the Scaffolding Association commissioned research into the availability of training for new entrants in the access and scaffolding sector. The survey found that one fifth of training centres was either unreachable or unable to offer training dates. The survey also found that only six courses out of 30 were scheduled to be run in London – an area that represents 40 per cent of total construction demand.

The CITB also confirmed its plans last month

to exit direct delivery of training through the National Construction College, the main provider of scaffold and access training in the UK. Dave Mosely, the NASC training director and CISRS manager, has written to NASC members to say he fears that the uncertainty in the interim period could have a negative effect on course availability.

Robert Candy, chief executive of the Scaffolding Association, said: “Clearly there are concerns around course availability, which is why the Association has established the Access Industry Training Scheme to increase training capacity and offer new opportunities for both our members and the wider industry.”

FIND OUT MORE www.access-its.org

Amicus approved as FORS member

Insurance specialist Amicus, an insurance broker partner to the Scaffolding Association, has been approved as an Associate member of the Fleet Operator Recognition Scheme (FORS).

Amicus specialises in the transportation, manufacturing and construction industries, having particular skill in working with the higher risk areas of the construction industry where the perception of risk can often discourage many of the traditional players from becoming involved.

With Amicus becoming a FORS Associate member, FORS Silver or Gold accredited companies, or those working towards those levels, can now access exclusive discounts on fleet insurance from Amicus, which has negotiated preferential rates with some of the UK’s largest fleet underwriters.

FIND OUT MORE www.amicus-insurance.co.uk

VR reveals UK manufacturing plans

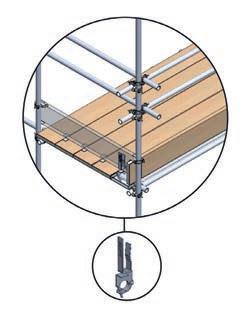

VR Access Solutions, a leading UK-based manufacturer, supplier and designer of access and scaffolding products and services, has unveiled plans to begin manufacturing its Turnlok system at a new facility in North West England as part of a three-year plan to centre all its manufacturing in the UK.

Julian Sanders, VR’s managing director, said: “This move is part of our commitment to deliver the highest standard of customer service and meet growing demand for our range of products and services.

“The new investment from VR will create 20 new jobs initially and see manufacturing certified to BS EN 1090-1:2009; A1:2011 EXC3; and ISO 9001:2015.”

The new facility is expected to start shipping products during the spring.

Audit success for Formark

Formark Scaffolding has become an audited member of the Scaffolding Association after successfully completing the independent audit process.

Last year was Formark’s 25th in business, so rounding off 2017 with a successful audit was extra special. Managing director Mark Coote Snr told AccessPoint: “Becoming an audited member of the Association will lift the profile of Formark as a bona fide scaffolding contractor. For many potential clients, such as main contractors and public authorities, this could be a key to acceptance on their tender list.

“Audited membership provides a level of comfort to all our clients that we take health and safety very seriously and endeavour to continue upgrading our policies and procedures regularly.

“As expected, the audit was a very thorough and exhaustive investigation of our company, demonstrating the high standards set by the Scaffolding Association for membership at this level.”

Specialists in Construction Insurance

especially scaffolders, demolition contractors, formwork & concrete suppliers

Amicus is a specialist broker to the Construction and Scaffolding Industries. We have been working with the Scaffolding Association since 2015 and are proud to insure many of the UK’s leading Scaffold companies.

We really understand scaffolding insurance and we love it. We even employ some former scaffolders within our business so you can be 100% confident that we really do talk your language!

All that expertise, enthusiasm and industry knowledge means that you can trust Amicus to not only find the best insurance to protect you, your business and your employees, but that you can also rely upon us to do it at the most competitive price.

Why not give us a try!

We Promise you:

• Real people, who can listen, who understand your industry and can give you honest advice

• Specialist knowledge with an informal approach

• Quick answers, either yes or no

• Providing policies relevant to your business and within your budget

• No hidden terms and conditions that are not relevant to your business

• First rate claims support (we have our own specialist team)

• No tick box approaches

• No call centres

• Not forgetting about you until renewal time

To discuss your insurance requirements, or to find out how we can help you, contact Richard Evans or Adam Scott on 0208 669 0991 or email us at richard.evans@amicus-insurance.com or adam.scott@amicus-insurance.com

Take back control

For anyone who has taken the plunge and set up on their own they’ll soon tell you that collecting cash for work done is an absolutely critical part of managing your own business. So it comes as no surprise that plans to protect payment are very welcome from the access and scaffolding sector.

These days it’s unusual for a news broadcast or newspaper not to carry something about the unmitigated cock up at Carillion. It’s no wonder that regulatory agencies and MPs are falling over each other to unpick the reasons and ramifications. Sadly, too little too late.

Pat on the back goes to the Scaffolding Association for supporting plans from the Specialist Engineering Contractors’ Group to ring fence and protect cash retentions. The sooner the protection is put in place the better it will be for the whole supply chain. Carillion was holding on to £800 million of supply chain money (not theirs) in cash retentions and it has gone up in smoke, never to be seen again.

The advent of the Access Industry Training Scheme is good news for the whole industry. At a time when CITB is withdrawing from training it is good to learn of plans to increase capacity and help to deliver new skills for access and scaffolding contractors (see page 21).

And it is these skills that are in demand across the country, particularly on infrastructure projects. CCS Scaffolding is well underway with a year-long contract to provide scaffolding for significant improvements to the A14, which is currently the UK’s biggest road construction project. As an audited member of the Association, CCS has demonstrated the highest standards – turn to page 16 and find out more.

Equally (on page 14) we learn more about the humble bridge beam and how it has evolved into the versatile and capable stalwart of our sector. Now we have a range of beams available from various manufacturers in various sizes, weights and strengths, meaning we can span further, build higher and support more loads than we ever could. This clearly demonstrates the pivotal role our sector holds in the construction life cycle.

The commitment to delivering the highest skills safely remains a top priority. Without effective controls and pre-planning to prevent problems, the sector will not move forward. Taking back control of your cash and skills development will make the access and scaffolding sector stronger and more stable.

Adrian JG Marsh EditorChange must happen

The collapse of Carillion last month sent shockwaves across the supply chain. Its huge debt pile was just too much, and the compulsory liquidation has put thousands of companies and many jobs in the supply chain at risk.

The events surrounding Carillion are yet another example of the construction industry underperforming. There is a general impression that our industry does not deliver good value for its customers. In part, this is due to the unusual nature of the industry, where, unlike a production line, each building is a one-off. But in addition, the nature of contracting arrangements means that it can be an adversarial industry with significant potential for disputes.

At a time when we all need more skilled resources, the headlines generated by Carillion will inevitably put people off considering construction as a viable career option. What grabbed the public’s attention was a business that had no assets, did not pay its bills and didn’t actually do any of the work…! Unbelievable – but true.

The events surrounding the collapse have also exposed a large number of contracts being awarded to a small group of contractors. Cartels and elitist clubs that try to ring fence sources of work is not an uncommon experience. All we want is a level and fair playing field to compete for work. Restricting tender lists to elitist clubs only goes to drive up costs and reduce competition. We believe that fair competition encourages innovation and service improvements.

According to Carillion’s latest set of accounts, it was holding more than £800 million in retention payments owed to subcontractors. This makes the campaign by Peter Aldous MP to protect and ring fence retentions money even more important.

The Scaffolding Association fully supports the campaign led by the Specialist Engineering Contractors’ Group (SEC Group) to protect retention money that, in reality, belongs to specialist contractors. Last month, we were delighted to be accepted as a member of SEC Group; this is further recognition of the contribution the Association is making to raising standards in the industry. What is clear from recent events is that the very nature of how construction does business needs to be reconsidered.

And to be able to deliver on the growing demand for services in the access and scaffolding sector, we also need to tackle the dire skills shortage. The withdrawal of the CITB from direct training has exposed a weakness in developing existing skills and also attracting new entrants into our sector. Existing providers just don’t have the capacity to meet current demand, let alone growing demand, especially in the housing sector. Our members want to make sure their workforce has the right skills so that they can deliver a safe and efficient service that helps them deliver on their objectives.

Technical challenges can only be overcome with the right skills and resources. And this is why the Association is unveiling plans to establish the Access Industry Training Scheme –AITS (see page 21). The new scheme is an employer-led initiative that has been devised to fill a skills gap in our sector.

When we talk about ‘filling the skills gaps’, we’re talking about two fundamental issues facing access and scaffolding specialists. On one hand, we need to attract new entrants and train them; while on the other, we must ensure that existing tradespeople maintain skills at the right level but also learn new, safer and more efficient ways of working, and, in doing so, progress as far as they want to take their career.

We advocate a contemporary solution to training that allows the access and scaffolding supply chain to develop skills that suit individual businesses and meet the needs of their clients. While core skills remain unchanged, different markets (e.g. off-shore oil and gas, office blocks and housing) demand different skills at different levels.

The Association remains committed to helping members, and the wider industry, protect technical standards, develop skills and improve profitability. To achieve this, change must happen.

Robert Candy Chief executive Scaffolding AssociationBridging the short-term skills gap?

Is it now the time to act before the market tightens and salaries and wages start to experience upward pressure? This may well be the case with the construction industry in a state of flux following the collapse of Carillion. There are fears over thousands of job losses because the company directly employed 20,000 in the UK, and its tentacles reached far and wide into the supply chain. On the day of liquidation, the industry giant was the main contractor on 57 construction projects worth a staggering £5.7 billion (according to Barbour ABI).

During January we saw a 50 per cent increase in enquiries from tradespeople of all types looking for work. While contractors reported that recruitment pressures had eased, this may, in part, have been because the Carillion supply chain was swiftly laying off subcontract labour, while retaining their own direct labour. We’ve also seen larger schemes taking longer to be given the go ahead adding to increases in availability.

However, talk to contractors around the country and they are still positive. Contracts that have been stalled are beginning to come to the market and those billions of Carillion’s contracts will be re-allocated. And on top of

this there is strong demand in the housing sector adding pressure.

Last month Build UK found that 8 per cent of contractors reported that the recruitment of skilled labour had been more difficult than during the final months of 2017. And the number of trades and professions where contractors reported widespread recruitment difficulties doubled. The sudden increase in availability may, therefore, only be a blip and it is likely that the recruitment of key trades, including scaffolders, and also surveyors, supervisors and managers, will continue to be problematic.

Recruitment difficulties are also impacting on labour costs. Rising labour costs, combined with material cost increase, puts added pressure on overall building costs – in a competitive market, this can eat into margins.

It becomes even more imperative that specialists have the right resources to deliver solutions that are not only safe and of the highest quality, but can also deliver contracts efficiently, on time and to agreed budgets.

For businesses that have ambitions to grow and maintain a sustainable capability, ensuring a steady and reliable supply of skilled resources is business critical. At a time when a pool of skilled

guarantee your place

For more information, contact Joseph Trotman on joseph.trotman@wembleystadium.com 0208 795 9626 or visit clubwembley.com

resources has leaked into the market, because of Carillion and some contract delays, there is underlying demand that will create the evils of inflation in the months ahead. Now is the time to take advantage and secure skilled resources before pressure builds again.

Ben Alderton The Construction Recruitment Company www.crcukltd.co.ukFilling the skills gap has been a significant challenge for a large proportion of specialist contractors, and scaffolding is no different from any other trade.

Ben Alderton, from The Construction Recruitment Company, warns of pent-up demand likely to soak up skills during the first half of 2018.

Club Wembley, the ultimate way to enjoy one of the most iconic stadiums in the world.

BSI Kitemarked scaffold boards from Gilray Plant

Kent-based Gilray Plant has been supplying a wide range of scaffolding products and accessories for over 45 years. And when Gilray Plant went into manufacturing scaffold boards 10 years ago, managing director Ralph Wilson decided from day one that Gilray’s boards would be made to BS 2482:2009 and bear the BSI Kitemark symbol.

Using state-of-the-art machinery, Gilray’s scaffold boards are all machine-stress-graded, meaning that flaws invisible to the human eye will be detected. Taking a belt and braces approach, the company’s board operatives are also trained to grade the timber visually, with their knowledge being audited every six months by the British Standards Institution.

All timber used by Gilray in the manufacture of scaffold boards comes from sustainable sources with Chain of Custody certification. For bulk orders, the boards can be branded and banded with customers’ names.

www.gilray.co.uk

Sayfa Systems’ Sentry Rail receives patent award

The Sentry Rail from Sayfa Systems has been granted a patent.

Sentry Rail is a lightweight extruded aluminium counter-balance handrail and safety barrier which can be used on roofs with a pitch of up to 10 degrees.

Approved for use to BS EN 13374:2013, the particular feature for which the patent was awarded to Sentry Rail is the use of a grooved slot which acts as the threads of a screw, enabling bolts to be inserted and fixed into it at any point on the length of the extrusion.

This design feature allows for great flexibility, enabling the system to be accommodated to awkward roof layouts and for infinite adjustment when fitting to allow for minor roof variations, always ensuring perfect alignment of the installation.

The rail has been designed to complement modern and sophisticated architectural styles with raked uprights and curved supports that blend function with design.

www.sayfasystems.co.uk

Icopal has it covered for Marlborough College

Selected for its strong, reinforced structure, the Kederflex HFFR temporary roof and facade covering system was installed as a climate shield to provide effective cover from rain and snow as well as to keep out the sun’s harmful UV rays.

As the roofing was scheduled to take three months to complete, containment sheeting was essential, particularly as Marlborough College’s Wiltshire location means the building is susceptible to gale-force conditions during certain months.

Kederflex has a unique eyelet fastening system – specific to Monarflex products – that makes it possible for the sheeting to be secured to the centre of a working area, therefore lowering the likelihood of disturbance from higher wind speeds.

In addition, Kederflex allows in plenty of natural light, despite the special white flame-retardant tinting, and provided a pleasing aesthetic finish that appeared in keeping with its surroundings.

www.monarflex.co.uk

Scotti Co reveals new website calculator to demonstrate weight savings

Scotti Co has launched a new website service to help contractors work out what potential savings there could be by using Scotti fittings as a method of securing toe boards.

Scotti fittings are designed to remove the need to install ‘Deadmen’ – a vertical tube attached to the handrails able to reach down and attach the toe board.

Matt Johnson of RDG Engineering said: “Weight can be a critical factor when designing jobs, so anything that can help designers and scaffolding contractors improve efficiency is valuable to the market.”

An analysis of a potential project where a tower (16 x Lifts) was to be built on top of a gantry revealed that by replacing the Deadmen on the tower, there was a 7 per cent weight saving.

The Scotti Co website calculator can help contractors work out what potential savings there could be. Mr Johnson concluded: “Where weight saving is an issue, every fitting counts.”

www.calculator.scotticlip.co.uk

Tool@rrest launches work-at-height rucksack Avontus teams up with Trimble

Tool@rrest has introduced a new rucksack for safe working at height that features 11 internal tether points and fixed 316 Marine-grade stainless steel karabiners.

One aspect of working at height that can be overlooked with regard to tethered tools is their safe transportation and storage when ascending or descending. The new Tool@rrest Rucksack provides operatives with a secure storage solution and, when used in conjunction with Tool@rrest lanyards, ensures that tethered tools are safe and comply with policies for the prevention of dropped objects.

The new Tool@arrest Rucksack is UK manufactured using 1000-denier PU-coated water-repellent nylon. Features include 50mm high-tenacity polyester webbing, which is fully adjustable to fit all sizes, and heavy duty nylon buckles.

Alongside the 11 internal tether points and fixed karabiners are three internal reinforced tool compartments with a reinforced base. www.toolarrest.co.uk

Avontus and Trimble have announced a partnership that is set to provide a more streamlined and productive way for concrete contractors and formwork providers to estimate, plan and manage their formwork operations.

Avontus has incorporated Trimble’s Tekla Structures software into its Quantify inventory management to support concrete contractors with the unique challenges they face with needing an accurate and understandable design to avoid costly delays that can affect the entire project.

Tekla Structures provides powerful 3D modelling and BIM capabilities to speed up the creation of detailed formwork plans and give contractors full visualisation into how formwork is planned.

Brian Webb, CEO/founder of Avontus, said: “The bottleneck in inventory management has always been the lack of an easy-to-use bill of materials. When shipping equipment for multiple pours to a site, it’s very important to consolidate formwork materials into a unified list to ship exactly what’s required, get the job done and allow formwork to be returned as soon as it’s no longer needed.”

www.avontus.co.uk

OIL, GAS & CHEMICALS POWER & ENERGY MINING & REFINING PROJECTS

Our experienced customer driven team provides a seamless service from product development, supply chain management, production, quality control, delivery and local engineering support available for fast, effective solutions where required.

Godiva sets up weatherproof cover for new academy roof

Coventry-based Godiva Access & Scaffolding has completed the design and installation of a temporary roof at the Grace Academy in Solihull, West Midlands.

Godiva was appointed to install the temporary roof by prime contractor Airsculpt, which had been contracted to install a new tensile fabric roof structure at the academy and needed reliable weatherproof cover during the installation period.

To devise a solution that minimised on-site installation and erection time, Godiva worked in partnership with AT-PAC, which provides industrial scaffolding solutions that are custom-designed to meet the individual challenges of any job site.

One key element of the bespoke design developed through collaboration between Godiva and AT-PAC was an innovative seam clip. This was devised to tie the temporary roof of the main building and minimise the potential impact of wind.

FIND OUT MORE www.godivagroup.com

RhinoDeck Benefits

Risks in design responsibility for temporary works

Barrister Professor Rudi Klein highlights important considerations for temporary works contractors in relation to design responsibility and liability.

Design is about making a judgement or choice in relation to a wide range of matters from aesthetic appeal to the size or amounts of required components or materials. In the case of temporary works, design considerations will often be focused on:

• eliminating or reducing health and safety risks (in accordance with the Construction (Design and Management) Regulations 2015).

• eliminating or reducing the risk of any adverse impact on the permanent works.

• minimising the need for temporary works.

• ensuring compliance with all relevant standards.

Design of temporary works

Temporary works such as scaffolding are enabling works that facilitate the construction of permanent works. Very often the design of temporary works can be just as important as the design of the permanent works. But design teams can be reluctant to design all or part of any proposed temporary structures. Some engineers will, in fact, exclude design of temporary works from their appointments. This could leave the contractor, therefore, with a responsibility for designing the whole or part of the temporary works.

Scenario 1: Design team designs the full extent of the temporary structure

Let’s assume that the design team draws up a detailed specification for a temporary structure against which the contractor has submitted their bid. In this scenario, is the contractor free of all risk relating to the adequacy of the design of the structure? The answer is – generally – “yes”. I say, “generally” because there could be exceptions.

What happens if the contractor later discovers that the design is not sufficiently adequate to support the construction of the permanent works? This becomes a major risk to the contractor because it is assumed that they have bid on the basis that they can deliver the structure in accordance with the specification. If it then transpires that they will have to incur extra costs in order to make the design workable, they may not be able to recover these costs. They could, of course, ask for a written instruction to carry out a variation but the other side could ‘dig its heels in’ and argue that the cost is down to the contractor. After all, the contractor had priced on the basis of the specification and if they now had to incur extra cost in making the design work, it was down to them.

The best way to address this risk is to make clear that you have priced on the basis of the specification and that you will claim any extra costs incurred as a result of implementing the specification.

Case law has made it very clear that a contractor has a duty to warn the other party where they discover shortcomings in the design, especially where those shortcomings have implications for health and safety. If health and safety risks are involved, the contractor must be persistent about their warnings. If they continue to be ignored, they may even have to remove themselves from the job rather than persisting with a design solution that imports serious health and safety risk – whether to their own employees, to employees of other project participants, or to the public at large.

Scenario 2: Design team partially designs the temporary structure

If you are left to complete the design of a temporary structure, this is a high-risk scenario. You will, in effect, be taking responsibility for the whole of the design. This was the outcome of a case decided almost 15 years ago. You should, therefore, check carefully the design handed down to you before completing it.

The best way to deal with this risk is to insist that you will only take responsibility for design insofar as you have provided it.

Scenario 3: You are to have sole responsibility for the design of the temporary structure

This scenario imports the greatest risk. Inevitably, the design will have to be reasonably fit for purpose. Are you in a position to guarantee this? Possibly not, especially if you’ve not received sufficient information about the permanent works to enable you to produce a design that is adequate in all respects, including compliance with industry standards and with health and safety regulations.

Moreover, you are unlikely to obtain professional indemnity insurance cover for fitness for purpose obligations unless those are reduced to the exercise of reasonable skill and care in carrying out the design.

Summary

Temporary works contractors must always be mindful of risks associated with design responsibility since the implications of taking on such responsibility are potentially huge. Always seek advice if you are unsure whether you have such responsibility and liaise closely with your insurers to ensure that you are adequately covered.

BBi protects scaffolders with A-rated insurance scheme

Scaffolders can now benefit from a new scheme offered by insurance specialist BBi Berns Brett. The independent broker and Scaffolding Association member is one of only a few brokers in the industry that can offer insurance cover from A-rated insurers.

Some regard insurance as a necessary evil. However, not all policies are the same and it is worth taking the time to make sure your insurance will provide for any accidents or claims. Tragic accidents can, and do, happen in the access and scaffolding sector, and the added risks of working at height and exposure to the elements usually translate into higher insurance premiums. Finding the right level of cover can be challenging.

BBi’s new insurance scheme offers a flexible and comprehensive solution with no height or depth restrictions and high indemnity limits (£5 million as standard but up to £100 million can be accommodated). Built-in health and safety advice also helps businesses to identify

any risks that can be reduced by investing in new equipment, better procedures or training.

David Skinner, BBi Berns Brett’s managing director, said: “Well-run businesses, with good risk management and a proven claims record, can reduce their insurance costs without

compromising on the quality of cover or quality of the insurer.”

MPs to conduct inquiry into serious injury and fatalities while working at height

The All Party Parliamentary Group (APPG) for Working at Height has launched an investigation into serious injury and fatalities while working at height.

The APPG is chaired by Alison Thewliss, the SNP MP for Glasgow Central, and it is now open for evidence submissions from interested stakeholders. The APPG will consider this evidence and produce a report and recommendations on how the frequency of serious injuries and fatalities can be reduced.

Alison Thewliss, Chair of the APPG for Working at Height, said: “That 18 percent of people killed at work did so as a result of a fall from height is a shocking statistic. The APPG for Working at Height has brought together concerned MPs from several parties to investigate the reasons for falls from height and ensure current regulations are sufficient for protecting workers at height in the UK.”

Stacey Underhill, head of external affairs at the Scaffolding Association, said: “It is vital that those working at height have the necessary skills and appropriate equipment to remove all manageable risks. This inquiry will give our members the opportunity to highlight areas of concern and bring them to the attention of the All Party group of MPs.”

Submissions need to reach the inquiry on or before 2 March 2018 and should be sent to the Working At Height APPG, 32-34 Great Peter Street, London, SW1P 2DB.

FIND OUT MORE www.workingatheight.info

Contractors report rising costs and skills shortages

A State of Trade Survey has found that rising costs and shortages of skilled labour are the major challenges facing construction in 2018.

The survey, which was undertaken by Glenigan for Build UK, found that firms have seen widespread increases in material costs. Rising labour and material costs have increased overall building costs, with 42 per cent of firms reporting an overall increase in costs.

Tender prices rose slightly from the previous quarter, with just 8 per cent of firms reporting a rise in tender prices during the quarter. Overall profit margins were unchanged on the previous quarter, but 9 per cent of firms reported that they were up on a year ago.

When it comes to payment, 33 per cent of contractors reported that the average wait was 46 days or more.

The number of trades and professions where contractors reported widespread recruitment difficulties doubled with the recruitment of bricklayers, cladders, construction/site managers, mechanics/fitters, scaffolders, surveyors, site supervisors and construction project managers among the most problematic.

Where contractors had experienced difficulties in recruiting staff, firms cited lack of skills as being an issue in 60 per cent of cases, with lack of experience and required qualifications cited as factors in 64 per cent and 50 per cent of cases respectively. FIND OUT MORE

Two-thirds of those running small and medium-sized (SME) construction firms are facing a construction skills shortage, according to the Federation of Master Builders (FMB).

Key results from the FMB’s latest State of Trade Survey, which is the only quarterly assessment of the UK-wide SME construction sector, include the fact that more than two-thirds (68 per cent) of construction SMEs are struggling to hire skilled trades – the highest figures since records began in 2008.

Construction SME workloads grew at a slightly slower rate than in Q3 2017, but new enquiries and expected workloads slowed more sharply; expected workloads among those firms building new homes showed a negative net balance for the first time since 2013.

Brian Berry, chief executive of the FMB, said: “Skills shortages are sky rocketing and it begs the question who will build the new homes and infrastructure projects the government is crying out for? The government has set itself an ambitious target to build 300,000 homes every year in England alone. As a result, the wages for these increasingly scarce skilled tradespeople continue to rise sharply; that’s a simple consequence of supply and demand.”

FIND OUT MORE www.fmb.org.uk

Scaffolding contractor fined following safety breach

The Health and Safety Executive (HSE) has fined a specialist scaffolding contractor after an employee suffered serious injuries.

Derby Magistrates’ Court heard how, on 22 February 2016, at a site in Chaddesden, Lee Gaskin was injured during the loading of bins of scaffold fittings onto a lorry using a Hi-Ab lorry-mounted crane. The Hi-Ab arm knocked him from the bed of the lorry to the ground and he suffered significant injuries to his arms.

An investigation by the HSE found that Benchmark Scaffolding Limited, Mr Gaskin’s employer, failed to properly plan the lifting of scaffolding parts onto a lorry, provide clear instructions and supervision, and ensure that the lifting of scaffold parts was carried out in a safe manner.

Benchmark Scaffolding Limited of Hanwell, London, pleaded guilty to breaching Regulation 8(1) of the Lifting Operations and Lifting Equipment Regulations 1998 and was fined £40,000 and ordered to pay full costs of £1,968.63 and a Victim Surcharge of £170.

Two-thirds of construction bosses can’t find key resources, says FMB

Bridge beams – now stronger, lighter and more versatile

Looking back 20 years, steel ladder beams and steel unit beams were all we had. Although they were strong, robust and versatile, their use was limited due to their weight – or, more accurately, their strength/weight ratio. Where a unit beam wasn’t sufficient, we had the giant leap to a Mabey Bridge, massively strong,

un-versatile and heavy. Even though they still have their place today – ladder beams especially are particularly versatile – in my experience, scaffolders aren’t keen on them.

Developing better beams

Demand for improved beams was initially driven by the need to span temporary roofs further, moving from 450 deep aluminium beams to the 750 deep beams used in system temporary roofs from the likes of HAKI. Inevitably, these beams were adopted and used for other applications.

As the scaffolding sector has developed, more and more beams have been introduced, with the use of aluminium saving weight, and a deeper beam achieving increased strength. Now we have a plethora of beams available from various manufacturers in various sizes, weights and strengths, meaning we can span further, build higher and support more loads than we ever could.

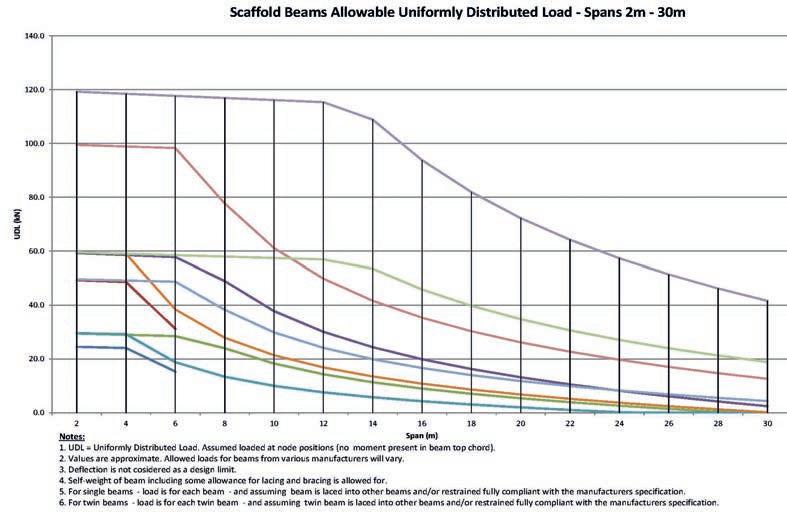

Beam strengths

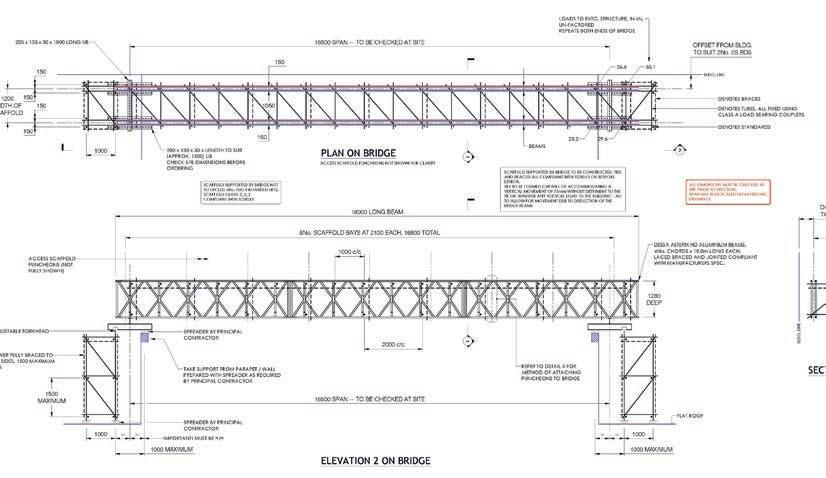

Figure 1 is a useful comparison for relative beam strengths. We can see that steel unit beams, even in pairs, are pretty useless at spans over 20m; at this length, the allowed load on a twin steel unit beam is 13 kN (1.3t) – this is only 0.65 kN/m along the full length of the beam, equivalent to a single lightweight platform. Whereas the modern aluminium beams will span well beyond 20m towards 30m and still offer a good, useable safe load capacity.

You can see in Figure 2 an example of when we were asked to design a 16m span bridge to support a tall and therefore heavy scaffold. The combined dead and imposed load the bridge needed to support was around 170 kN (17.0t), which did not include the bridge beam’s self-weight. The comparison graph (Figure 1) shows that the safe working load (SWL) for a twin 1200

In this AccessPoint Technical article, Chris Harrison, director at Apex Scaffold Design, discusses how bridge beams have evolved into the versatile and capable stalwarts of our sector that they are today.Figure 1: Comparison of relative beam strengths. Figure 2: Design of a 16m span bridge to support a tall and heavy scaffold.

beam is around 90 kN and therefore 180 kN for a double pair (4No. total – pair inside + pair outside), which is what we adopted – DESSA Asterix HD beams in this particular case.

Figure 1 also shows that for 750 aluminium beams/steel unit beams, each pair will support around 35 kN/20 kN respectively. This indicates that a total of 5No. double chords (10No. total) of 750 beams and 9No. double chords (18No. total) of steel unit beams would be necessary. Practically, this isn’t a workable solution –and this situation demonstrates how the development of stronger beams is allowing us to span further and build higher.

Challenges of working with stronger beams

The example in Figure 2 demonstrates one of the issues presented by these deeper, stronger beams. By spanning further and building higher, the loads supported at each end of the bridge are increased. In the steel

ladder/unit beam days, a good rule of thumb was one standard per beam chord; the end reaction from each beam would, generally, not exceed the coupler or standard capacity, but this is no longer the case.

Large heavy duty bridges require large heavy duty support towers, as can be seen in the example where the end reactions were over 110 kN (11.0t) in total at each end. Heavy duty support towers with forkheads and steel spreader beams were required to support the loads, and in this particular case to spread the loads onto the supporting structure.

Another challenge is linked to the fact that beams have always been reliant on how they are laced and braced. And as stronger beams allow us to span further and build higher, this becomes even more important. Any beam’s bending capacity is directly connected and reliant on how the beam is laced and braced; the published figures for any beam will be based on the

optimum restraint arrangement which will be stated by the manufacturer. If beams aren’t laced and braced correctly, this will significantly reduce the beam’s capacity.

Deflection can also become an issue, particularly as the span increases, and should be carefully considered in the design. In general, deflection limits adopted by engineers in the design of permanent structures need not be applied and can be relaxed when designing bridge beams in scaffold structures. Most of the new stronger beams are manufactured from aluminium which, by its nature, will deflect more than a comparable steel beam. As spans increase, we need to consider not only the aesthetics of excessive deflection but also the integrity of the scaffold/structure being supported.

An example of this are the ties in an access scaffold supported by a long span beam. In this case, the tie arrangement will need to be

such that it can accommodate the vertical movement resulting from the deflection without detriment to the tie and fabric to which it is attached.

What’s the future?

We already have even stronger beams coming to market. Apollo has a 1500 deep X beam capable of supporting some very impressive loads. They are more than double the strength of 1200 deep lattice beams and boast a capability of a 30m span being able to support 10 tonnes shared by two beam chords. This beam was recently used by Tiger Scaffolding and Alwyn Richards on their impressive project for North Yorkshire County Council in Northallerton (the AccessPoint Spring 17 Site Report) to span 20m and support a large temporary roof. How deeper and stronger do we think beams can go?

Chris Harrison TISrtuctE EngTech www.apexscaffolddesign.comCCS Scaffolding contracted to major infrastructure project

Audited Scaffolding Association Member

CCS Scaffolding is well underway with a year-long contract to provide scaffolding for significant improvements to the A14 – currently the UK’s biggest road construction project. Jenny Gibson spoke to Edward Farrell, health and safety executive at CCS, to find out more.

On a 21-mile stretch of the A14 between Cambridge and Huntingdon, a 2,200-strong construction team is busy upgrading the dual carriageway to three lanes, including the creation of a new 17-mile bypass south of Huntingdon that will have four lanes in each direction. This much-anticipated and much-needed infrastructure project will add additional capacity, boost the local and national economy, and cut journey times by up to 20 minutes.

Kent-based CCS Scaffolding, along with sister company Sian Formwork, is one of the many subcontractors helping to deliver this upgraded road system, which is due to open to traffic by the end of 2020.

on many occasions previously – to remove time pressures and allow CCS and Sian Formwork to concentrate on other aspects of the project.”

On appointment, CCS’s site manager attended programme and progress meetings to ensure materials and labour resources were on-site as required to meet the project’s programme objectives.

Mr Farrell continued: “The interaction between the scaffold design team and the client’s temporary works team helped to make sure that the designs for some bridge abutments were fully approved, and ready for when the structure was released to us.

“This avoided delays and meant our scaffolders could help to keep the programme on schedule.”

Scope of works

Contract award

The specific contract awarded jointly to CCS Scaffolding and Sian Formwork is for Section 2 of this A14 Highways Project. The award, given by the A14 Integrated Delivery Team on behalf of Highways England, involves the construction of various abutments and piers for the required bridge works.

CCS’s health and safety executive, Edward Farrell, described the tender process. He said: “From the outset we had to take into consideration the planning, the materials and the complexity of the structures required, along with the specific deadlines all aspects needed to be complete by.

“Given the largescale structures and multiple bridges, we decided to work with a dedicated scaffold design company – one we’d worked with

The structures across Section 2 of the A14 project were all generic abutments and wing walls, all tasks that CCS and Sian Formwork had performed as a joint venture many times before. The BN03 structures had three separate sets of abutments all around 60 metres long, 8 metres high and 1.8 metres thick. This scale required multiple boarded lifts and for all structures to be freestanding with buttresses installed at regular intervals, and with high amounts of kentledge, to ensure the safety and structural stability of the scaffold for Sian Formwork and other contractors needing to install bearing pads and large heavy duty steel bridge beams.

Improving productivity

CCS used a system scaffold solution to increase production rate and enhance safety processes while erection, adaption and dismantle occurs at BN05 structures.

For one of the BN05 sections, pre-set formwork shutters were made for sets of three round columns for the bridge sections to sit on. Mr Farrell explained: “Once we’d started the section and we were erecting scaffolding for the circular piers, we soon came to the conclusion that by

using a system scaffold approach there was a quicker and safer way to erect these specific shaped columns.

“This also meant we were able to overcome any safety issues with regards to working at height by installing our guardrails via our advanced guardrail tools.

“This had the benefit of saving a large amount of labour and time resources by not using tube and fitting and not needing to install half lifts

or installing edge protection via scaffold steps,” he explained. CCS has an average of 20 scaffolders on-site and commenced the contract in March last year. As a whole team with Sian Formwork, there are around 60 operatives working on this A14 project.

FASET announces 2017 Award Winners

Safety net and temporary safety systems global trade body FASET held its annual awards and AGM in December, providing an opportunity for members to demonstrate great work carried out throughout the year and honour employees who have significantly contributed to the member company and the wider safety net and safety systems sectors.

The 2017 FASET Awards were independently judged by Ray Cooke, head of Construction Sector Safety Unit at the HSE; Gary Walpole (Grad IOSH), technical and health and safety officer at the National Federation of Roofing Contractors; Mark Keily, QHSE director at Nationwide Platforms and Tony Seddon, FASET’s managing director.

The Winners and Highly Commended in the four categories – Staff Merit, Health and Safety and Training, Excellence of Work and Contributor to FASET – are as follows:

Staff Merit

Winner: Daniel Lewis of G&M Safety Netting Ltd

Joint Highly Commended: Josh Rowe of Nationwide Safety Ltd; Michael Rance of Nationwide Safety Ltd; and Simon Day of Prodeck Fixing Ltd

Health and Safety and Training

Winner: PMC Safety Netting Ltd

Joint Highly Commended: Structural Metal Decks Ltd; DTE Scaffolding; and Safety Netting Ltd

Excellence of Work

Winner: Structural Metal Decks Ltd

Highly Commended: AMP Access Solutions Ltd

Contributor to FASET

Winner: Rob Harris of 3 Education

Highly Commended: G&M Safe Deck Ltd

Scaffolding Association and the FLTA team up with member offer

In a new partnership with the Fork Lift Truck Association (FLTA), Scaffolding Association members can now get a 10 per cent discount when joining the FLTA’s Safe User Group. Members interested in taking up this discounted offer should email info@scaffolding-association.org for information.

Being better informed about forklift trucks is essential for site and yard safety. They account for more than 1,300 deaths and serious accidents every year, with accidents involving forklift trucks potentially resulting in life-changing injuries, including crushed bones, de-gloved limbs, long-bone fractures and amputations.

Keeping accidents at bay takes constant vigilance underpinned by expert, independent help. This is where the FLTA’s Safe User Group (SUG) can help with its step-by-step site-safety guide, available free and exclusively to SUG members. This practical 26-part programme allows you to benchmark your operations and then introduce tried-and-tested improvements, often at low or no cost.

In addition, you’ll receive regular health and safety newsletters, a member’s magazine and Safety Alerts – all supported by fact sheets, technical bulletins, handbooks and free, expert helplines. Members also receive a discounted invitation to attend and participate in the UK’s only national, annual fork lift safety conference.

FIND OUT MORE

www.fork-truck.org / info@scaffolding-association.org

FASET’s managing director, Tony Seddon, said: “It’s been a very tough year for judging, as the quality and standard of entrants was so high – reflecting the great work our members are doing to drive up standards in the safety net and safety systems industries.

“Congratulations to all our winners and a special mention of thanks to our out-going chairman, Rob Harris, who dedicates so much time and energy to FASET and the

safety systems sector. I am pleased he will continue to serve on the Board.”

Sponsors of the FASET 2017 awards were Huck Nets, Nationwide Platforms, CSCS and SpanSet UK Ltd, with main event sponsors being Genie Lift.

During the awards, £2,360 was raised for the construction charity Lighthouse Club by FASET members.

FIND OUT MORE www.faset.org.uk

Amicus provides ‘first response’ cover for FFI

Amicus has teamed up with specialist HSE consultancy Consalium to offer a ‘fees for intervention’ (FFI) solution tailor-made for the construction industry, particularly those working at height.

For those scaffolding companies who attended the Access Industry Training Scheme health and safety conference, the subject of fees for intervention will be only too familiar. A ‘fee for intervention’, or ‘FFE’, is charged by the HSE to cover any time it spends investigating a potential breach, even if it does not result in a prosecution. At £129 per hour, these fees can run into thousands of pounds and are completely outside of a company’s control.

The construction industry is seen as a major source of potential fees and anyone working at height

is a natural target. Over £30 million of fees have been collected in the first year and the figure is set to rise. Aside from the monetary amount, having a successful FFI claim against you also puts you higher up the list for a repeat visit, therefore prevention is better than cure.

The less time the HSE spends looking at your business, the cheaper the FFI is going to be. Having the guidance of an expert who knows the way the HSE thinks, what it is looking for and how best to handle the situation will minimise the time the inspector needs to spend with you and, therefore, the cost.

Amicus’s insurance package in partnership with Consalium gives a ‘first response’ cover which provides immediate telephone advice from an HSE-trained

consultant to guide you on what to say, what documentation to make available and how to format your response. It will also include onsite representation, if required. These early decisions can make all the difference, and having someone on side who knows the system and the procedures from the inside will help ensure you get a fair hearing.

Amicus has also negotiated with one of the UK’s most respected insurers to provide an ‘HSE Recovery’ policy which covers the costs of FFI, which are normally excluded from insurance policies.

FIND OUT MORE

Paul Beck (Amicus) on 0208 669 0991 www.amicus-insurance.co.uk www.consalium.com

Prepare for the emergency… before it becomes an emergency

As an industry, we are used to the concept of planning to prevent accidents. It is entrenched in the way we think and dictated by our laws that require us to undertake risk assessments before we start work. However, we know that incidents do happen and yet very rarely do companies plan for what to do when they occur. Craig Varian, operations director at health, safety and temporary works consultancy Consalium, outlines five top tips for effective emergency planning.

It is common sense that failing to effectively deal with an incident or accident can have huge consequences for an organisation, contractually, financially and reputationally. For some sectors, emergency planning is standard practice; however, construction companies involved in a sector which routinely has the highest injury rate in the UK often do not have any effective planning for the aftermath of an incident.

Evidence has consistently proven that planning for an incident increases your effectiveness when something arises. This is because planning alerts you to deficiencies in your response, and, we all know that it isn’t helpful if the first time you need to consider how to respond in a critical situation is when things are going wrong and you are under large amounts of stress.

Very serious incidents are, thankfully, rare, but emergency planning can be used for incidents that all scaffolding contractors will face regularly from car accidents to minor injuries.

My top five tips for any emergency planning are as follows:

1. Proactively plan your emergency response

Dealing with an important question such as “Who calls the next of kin?” (and knowing where the up-todate details are kept) will help to highlight any deficiencies in your response before implementing your response is required. It means that much of the response is managed before something happens, allowing you to concentrate on

decisions that will require your immediate attention in an emergency, which will often be a stressful situation.

2. Take leadership with incidents

This is important to ensure you don’t allow other organisations to control incidents that could adversely affect you. What is your policy on your staff providing statements to the principal contractor? What information will you provide to your client? Who will complete your investigation? Will you share this? What information is provided in your RIDDOR?

How you respond to these questions can result in vastly different outcomes for your organisation. Remember, any documents you provide could be used later in a legal case. Consider the advice your car insurers provide to an individual if involved in a car accident: “Do not admit liability until you have spoken to your insurer”. This doesn’t mean lying or not cooperating; the purpose of such advice is that if there is likely to be a claim/legal case, you are entitled to protect yourself. When there is potential for a legal claim, such advice is applicable to organisations.

3. Prepare for the worst and remember the ‘ABC’

In this situation, the ‘ABC of investigation’ stands for Assume nothing, Believe no one, Check everything, i.e. get photos, statements, measurements to back up what you have been told.

It has been shown that the best evidence is captured in the first

hours after an incident. In a situation where someone injures themselves, it makes sense to carry out a full investigation in anticipation that someone may claim. The best-case scenario is that they are not badly injured and you can use the i nvestigation to prevent a future incident. Whereas, if you neglect to carry out the investigation and later learn that they are claiming damages, evidence that may have helped your case will inevitably be lost.

4. Get advice early on

When considering who you will get advice from, think about your insurance broker, solicitor and H&S consultant. Legal cases and claims can result in substantial financial (and reputational) loss. It’s better to have advice and not use it than to need advice and not have it.

5. Be honest and ethical

Everyone will make mistakes; accidents will happen. If you are found to lie or conceal facts, not only is this illegal but it will harm you both legally and reputationally.

Having no strategy for dealing with incidents places your business and employees at nnecessary risk.

This is especially true for scaffolding companies who operate in a high-hazard industry and face risks every day.

By following this advice, you will be protecting your business and employees against one of your greatest risks.

A catalyst for change

Last year the Scaffolding Association commissioned research into the availability of training for new entrants wanting to start a career in the access and scaffolding sector. As part of this research, 24 training centres from across the UK were contacted and the results proved very worrying:

• Four centres were unreachable, despite a series of attempts to contact them.

• Two centres were unable to offer scheduled future training dates at the time of contact.

• 10 centres were able to offer scheduled future training dates but with a wait ranging from four to 12 weeks.

• Of the 30 potential course dates being offered around the UK across a 12-week period, only six were scheduled to be run in the London area and 13 were being offered in the North of England.

How can one of the most project-critical sectors in the construction sector hope to deliver the service the industry needs without an accessible training regime? Well, our 300 plus members told us; with great difficulty. Access and scaffolding needs an effective and sustainable flow of new entrants and the continuing development of skills among the existing workforce.

Even the most recent survey for the main contract representative body, Build UK, found that labour availability issues impacted on contractors’ business performance, with 20 per cent saying that labour shortages had resulted in the late completion of work and a third saying that it had prevented them bidding for work. Rising labour and material costs have increased overall building costs, with 42 per cent of firms reporting an overall increase in costs.

Following the construction industry’s call for reform, the CITB has set out its strategy, which includes proposals to exit direct delivery of training through the National Construction College, the main provider of scaffold and access training within the UK. In November last year Dave Mosely,

the NASC training director and CISRS manager, wrote to NASC members and said he feared that the uncertainty in the interim period could have a negative effect on course availability.

Clearly, existing capacity is not enough to meet demand and new resources are required to ensure that the skills the construction industry expects from the access and scaffolding sector are available.

While the Association has sought to participate in existing structures and help shape the skills and training debate in scaffolding, obstacles have been placed in front of us and prevented our members receiving the recognition they deserve.

Concerns about training capacity, and the direction of travel from the existing groups claiming to represent access and scaffolding, has led the Association to establish the Access Industry Training Scheme (AITS). AITS is an employer-led training solution that will provide increasing capacity and new opportunities for both our members and the wider industry. It will help to satisfy the training and skills development needs for the access and scaffolding industry.

The first training course was held last year and a schedule of courses are now available to access and scaffolding contractors to boost skills and technical capability of their employees and subcontractors.

Through AITS, we will be able to develop structured career pathways that are easily accessible and offer continuing opportunities for personal growth and development. With AITS, the industry will become a far more attractive prospect to attract, train and retain new entrants.

Training in the scaffolding and access industry has stagnated. It’s time to break down the existing system and build something that is both fit for purpose today and future-proof for tomorrow. This is why AITS is stepping forward and turning concepts into reality.

FIND OUT MORE www.access-its.org

The access and scaffolding sector is facing a critical skills and training shortage. The CITB is pulling out of direct training and recent research has found that there is not sufficient capacity to meet demand. Stacey Underhill from the Scaffolding Association explains how it plans to deliver an industry-led training solution.

AND SERVICES

ADS Security Installations Limited www.adssecurity.co.uk

Consalium Limited www.consalium.com

PcP Grating Limited www.pcpgratings.co.uk

Godiva wins scaffolding contract for Coventry’s tallest new building

Coventry-based Godiva Access & Scaffolding has been awarded the contract to provide scaffolding services to Winvic Construction during the construction of Coventry’s tallest new build.

Godiva will use more than 900 tonnes of scaffolding to help Winvic construct the new 1,192-bedroom student accommodation complex in two towers, one 23-storeys and a second at 14-storeys. The scheme, located on the corner of Fairfax Street and Cox Street, forms part of a city-wide rejuvenation project that follows the announcement that Coventry will be City of Culture 2021.

The new win bolsters a growing order book for Godiva, which is working on contracts across the West Midlands.

Colin Taylor, managing director at Godiva Access & Scaffolding, said: “This is a fantastic win for us that will help to create 20 new jobs. We have a really strong background in working on skyscraper construction so to be able to work on what will become such a prominent feature in Coventry’s sky line is hugely rewarding as we can really showcase our skills in this area.”

FIND OUT MORE www.godivagroup.com

Calling all members

Are you working on an interesting project that you’d like to share with AccessPoint readers? Why not shout about it to members of the UK’s fastest growing trade association? We’d love to hear from you!

Send us your story with any relevant images to newsdesk@accesspoint.org.uk

AITS delivers health and safety event

The Access Industry Training Scheme (AITS) was host to a health and safety conference in December to provide guidance for people with health and safety responsibilities working within the scaffolding industry.

AITS is an employer-led scheme established by the Scaffolding Association to fill a skills gap in the sector and drive up standards. Event delegates received presentations and took part in workshops on topics including Corporate Risk Management, Health and Safety Management Systems, Policy and Practice, and Plan, Do, Check, Act.

Key informative sessions on Fees for Intervention and updates on Sentencing Guidelines were led by former Health and Safety Executive (HSE) inspector Craig Varian from Consalium, a specialist construction consultancy.

The day focused on enabling practical understanding of how to assess the risks to business and implement and improve safety management systems.

WellMax provides scaffolding for boutique hotel development

WellMax Scaffolding was appointed in 2016 by McLaren Construction to provide access and scaffolding services during the redevelopment of Camden Town Hall Annexe, a 1970’s concrete frame office building, which is being transformed into a 270-bed luxury boutique hotel.

The hotel is due to open later this year.

Scaffolding Association to join SEC Group

The Scaffolding Association is to join the Specialist Engineering Contractors’ Group (SEC Group), the leading subcontractor trade association.

SEC Group has been instrumental in campaigning to protect subcontractors and promote productivity improvements across the supply chain. Recently, its chief executive, Professor Rudi Klein, has led a campaign to protect cash retentions and introduce project bank accounts.

Mercer secures Manor Place contract

Mercer Scaffolding is well underway with a £1 million scaffold contract for a new 270-home residential development in South East London for Durkan and on behalf of Notting Hill Housing Group.

Alongside the new homes, new commercial space has been created within under-utilised existing buildings and within the railway arches that cut through the site. The development has retained the listed heritage structures, 33 Manor Place and the neighbouring former Pool Building, for residential and commercial uses respectively.

The Manor Place development is situated over a railway on a main line into London Bridge. Mercer is constructing the scaffolding system, including stair access, protection fans and loading towers, to prevent risks around the railway elevations.

www.mercerscaffolding.com

Q Scaffolding takes on New Oxford Street contract

Q Scaffolding has been contracted by main contractor Oakwoods for the scaffolding at 112-116 New Oxford Street, London, to provide access for window decoration and complex heritage stoneworks at the mixed retail and office building.

In addition to the independent scaffold, Q Scaffolding erected full-height framing for an advertising banner.

Renovation works at New Oxford Street are expected to complete during 2018.

Robert Candy, chief executive of the Scaffolding Association, said: “This move is further recognition of the Association and demonstrates the growing acceptance of the contribution we are making to raising standards and demanding improvements in safety.”

Association appoints vice-president

Karl Degroot has been appointed as the vice-president of the Scaffolding Association.

Mr Degroot has more than 30 years’ experience of the scaffolding industry and is the contracts director at Coventry-based Godiva Group.

His experience embraces commercial, residential, events, railways, power generation and industrial projects. Prior to joining Godiva, Mr Degroot was responsible for establishing the Yorkshire and East of England business for Lyndon Scaffolding; he was operations director at Connect Scaffolding in London and led one of the scaffolding teams at the London 2012 Olympics, delivering packages at eight venues.

In his early career, he was trained at GKN, where he spent 16 years in various roles. Mr Degroot is a member of the Scaffolding Association National Committee and a former regional chairman of the NASC.

Robert Candy, chief executive of the Scaffolding Association, said: “We are delighted that Karl will be our vice-president. He is hugely experienced and we look forward to working with him as we strive to improve the understanding, safety and standards of scaffolding across the construction industry.”

CASS Green Card success

CASS has received a Green Card from ISG for exceptional work on the Tunsgate Quarter retail development in Guildford.

The CASS team were commended for constantly meeting deadlines and ensuring that health and safety on-site was maintained at all times, including making regular suggestions and recommendations to the site management team.

In addition, positive feedback was received from Karen Olivier, the health and safety manager for ISG (Tunsgate), who commended the team’s sterling efforts in maintaining the high quality of work on-site and highlighted how the team had worked tirelessly for ISG, demonstrating an exemplary attitude even under difficult conditions.

Nick Carey, operations director at CASS, said: “This Green Card and feedback shows how dedicated and informed the CASS team are on-site. They set a great example of the work ethos at CASS.”

• NEW CONSTRUCTION

• DEMOLITION

• OFF SHORE

• NETWORK RAIL & LONDON UNDERGROUND (PRODUCING FORM C, FOR SUBMISSION)

• POWER GENERATION & LINE CROSSING

• AIRLINE MAINTENANCE

• REFURBISHMENT

• MARINE

Our aim is to deliver high-quality designs to meet the demands of BS EN 12811-1, TG20:13 and EN1991-40:2005. All designs are compliant with BS5795:2008 +A1:2011 Code of Practice Temporary Works.

Scaffold design is at the core of our business. At VR we combine extensive engineering experience with the latest technology.