ABOUT THE COVER

Taipei AMPA

Taipei Nangang Exhibition Center, Hall 1 & 2

23 – 26 April 2025 www.taipeiampa.com.tw

Automechanika Kuala Lumpur

Kuala Lumpur Convention Center, Malaysia

15 – 17 May 2025 www.automechanika.messefrankfurt.com

Autopromotec

Bologna, Italy

21 – 24 May 2025 www.autopromotec.com/en

Autocare 2025

Brisbane Convention & Exhibition Centre

20 – 21 June 2025 www.autocare.org.au

Automechanika Shanghai

National Exhibition and Convention Center (Shanghai)

2 – 5 December 2025 www.automechanika.messefrankfurt.com

Automechanika Dubai

Dubai World Trade Centre

9 – 11 December 2025 www.automechanika.messefrankfurt.com

Wayne

Bryant Chairman

4x4 Offroad Centre

6/828 High Street

KEW EAST VIC 3102

JH Automotive

345 Avoca Street

RANDWICK NSW 2031

P: 0492 941 111 E: info@4x4oc.com

Autovision Automotive Performance Centre

Unit 2/6 Clay Court

THOMASTOWN VIC 3074

P: 03 9077 7322

E: autovisionautomotive@hotmail.com

Bluechem Australia

Unit 4, 63 Brunel Road

SEAFORD VIC 3198

P: 0498 880 115

E: neil@bluechemaustralia.com.au

Crank Motor Werkes Pty Ltd

51/566 Gardeners Road

ALEXANDRIA NSW 2015

P: 0411 817 120

E: admin@crankmw.com.au

D + D Automotive Performance

124 Parrmatta Road

CROYDON NSW 2132

P: 02 8097 4278 E: info@ddap.com.au

Dee’s Automotive

81 Princess Ave

ROSEBERY NSW 2018

P: 02 9662 4422

E: info@deesautomotive.com.au

Dom’s Mobile Mechanic

423/14 Baywater Drive

WENTWORTH BAY NSW 2127

E: domsmobile2024@gmail.com

Foxman Automotive

5/54 Chegwyn Street

BOTANY NSW 2019

P: 02 9314 6199

E: botany@tyreplus.com.au

P: 0424 144 987

E: jhautomotiveservicing@gmail.com

Johnson’s 4WD 61 Lucas Street

BERSERKER QLD 4701

P: 0402 086579

E: nathan@johnsons4wd.com.au

Rajab Racing Developments

1/45-47 Stanley Drive

SOMERTON VIC 3062

P: 03 9303 7915

E: rajabracing@gmail.com

Repco Authorised Service Epping (Affordable Mechanics Epping) 13 Mary Court

EPPING VIC 3076

P: 03 9279 2838

E: info@afmepping.com.au

Tunehouse 11 Chalder Street

MARRICKVILLE NSW 2204

P: 02 9557 4000

E: jim@tunehouse.com.au

VSD Star Motors 141 Burwood Road

HAWTHORN VIC 3122

P: 03 9830 0452

E: mercedes@vsdstar.au

SECRETARY

DIRECTORS

As the 2025 federal election approaches, our industry faces a pivotal moment

Key policy and regulatory decisions will shape the future of Australia’s automotive aftermarket industry. The next government’s stance on emissions regulations, workforce development, and trade policies will have a lasting impact on businesses, supply chains, and the broader automotive ecosystem.

It is more important than ever for industry leaders to stay informed and engaged, ensuring our sector’s needs are not just considered but actively represented in policy discussions.

Here at the AAAA, we are already at full alert, activating our advocacy expertise to safeguard the future prosperity of our incredible and vitally important sector of the economy.

Here is a hit list of the issues we are most focused on and what decisions on these issues mean for our industry:

National Vehicle Efficiency Standard (NVES): the introduction of the NVES in January this year is set to reshape Australia’s new vehicle market. While its goal is to reduce CO₂ emissions, the stringent targets are likely to have an impact on the availability and affordability of petrol and diesel vehicles. This shift will have ripple effects across our industry, impacting servicing patterns and parts demand. We need clear, industryaligned policies that balance environmental goals with consumer choice and market stability.

The changing face of the new car market: with the new vehicle efficiency standards in place, we anticipate a wave of new car brands entering the Australian market, particularly from China. While increased competition can drive innovation, we’ve seen what happens when brands exit the market just as quickly as they arrive – leaving workshops and consumers scrambling for parts and service information. The industry must advocate for policies that ensure vehicle brands operating in

Australia are committed to long-term support for owners and repairers alike.

The push for road-user charging on Zero and Low Emission Vehicles: the shift to electrified vehicles (EVs) is gaining momentum, but so is the discussion around how we replace lost fuel excise revenue. The Australian Automobile Association is pushing for a national road-user charge for ZLEVs to ensure all motorists contribute fairly to road funding. While fairness in road funding is essential, we must ensure the approach is equitable. Our industry needs to be actively engaged in these discussions to prevent policies that create unintended consequences for vehicle owners.

Skills shortages – the challenge we cannot ignore: the most urgent issue facing our industry isn’t just policy – it’s people. We are in the grip of a skills crisis, with almost 60 percent of automotive apprentices failing to complete their training, and businesses struggling to find qualified technicians. Wage pressures, cost-of-living challenges, outdated training models, and an evolving technological landscape means we must push for better apprenticeship pathways, government incentives, and training reforms that prepare the next generation for the future of vehicle servicing, particularly in the EV and ADAS space.

Future proofing the Motor Vehicle Information Sharing Scheme: while the introduction of the MVIS has been overwhelmingly positive, industry feedback has highlighted that new technology and car manufacturer loopholes are preventing the Law from fully delivering on its promise of supporting consumer choice and delivering fair competition. Practical, no/low-cost refinements to the Scheme Rules could enhance compliance and ensure the Law operates as intended –without legislative changes. Key improvements include mandating independent repairer access to telematics data, compelling the car manufacturers to licence repair and service information to data aggregators, facilitating independent repairer access to online service books, fixing the loophole requiring proprietary diagnostic tools to access data and a solution for Advanced Driver Assistance Systems (ADAS) active dynamic testing which is creating safety concerns for consumers.

Trade policies and supply chain stability – the hidden battle: global supply chains remain unpredictable, and potential new trade policies could add further volatility. The cost and availability of parts continue to be a concern, and it’s critical that

any new government policy supports a stable, competitive supply chain that ensures workshops can continue to meet customer demand without excessive price increases.

The industry’s role in shaping policy: This election presents an opportunity for our industry to have its voice heard loud and clear. We must engage with candidates, advocate for policies that support fair competition, and push for regulations that consider the realities of our sector.

At the AAAA, we will continue to work tirelessly to ensure that policymakers understand the needs of independent repairers, parts suppliers, and the broader aftermarket community.

The road ahead is uncertain, and we’re all aware that politics is a complicated and challenging arena, but one thing is clear: we must be part of the conversation, shaping the policies that will define our industry’s future. Let’s make sure our voices are heard.

Our advocacy efforts on behalf of the industry are only possible with the support of our valued members. If you’re not yet a member, now is the time to join us and shape the future of our industry.

And finally, don’t forget to register for Autocare 2025, the most valuable automotive training event for technicians and workshop owners, June 20 – 21 in Brisbane.

You can get your tickets at www.autocare.org.au

Stuart Charity Chief Executive Officer

Capricorn’s Rising Stars Awards will recognise more apprentices than ever before

Supporting the Capricorn Community of Members, Suppliers, and our People is something I am really passionate about.

That is why this year I am thrilled we are expanding our Capricorn Rising Star Awards to celebrate more apprentices than ever before.

CEO

For the first time, we will be announcing Region Winners from each of our Capricorn Zones (Western Australia, South Australia/Northern Territory, Queensland, New South Wales, Victoria/Tasmania and New Zealand) as well as a Capricorn Rising Stars Overall Winner.

The awards celebrate and recognise outstanding apprentices and continues to show, regardless of the challenges facing the industry, that the future of the industry is bright.

I had the privilege of meeting last year’s winner, Megan Toia, at our WA Gala Dinner and Trade Show last year.

Megan’s commitment to her job, and her passion for supporting other regional apprentices was clear to everyone she spoke to.

I am proud Capricorn has played a role in supporting her journey and I look forward to seeing what she achieves in her career.

Rising Stars nominations are now open, so if you’re a Capricorn Member please consider nominating your outstanding apprentices.

Once an apprentice is nominated, they will receive an application to complete to tell us more about their journey. Please encourage your apprentice to complete their application before the end of May.

The competition is open to apprentices from all types of Member workshops and disciplines; from panel and fabrication to auto-electrical, general mechanical, heavy diesel, and more.

In closing, I want to say a special thanks to our longterm program sponsors, Castrol, Repco Australia, and The Workshop Whisperer, for supporting this valuable automotive aftermarket industry recognition program.

Brad Gannon

Group CEO – Capricorn Society Ltd

You can find out more at www.capricorn.coop/rising-stars

Autocare is coming to Brisbane this June

Autocare 2025, Australia’s largest automotive training event, is set to deliver an unparalleled learning experience for workshop owners and managers seeking to drive efficiency, futureproof their business, and boost profitability.

Hosted by the Australian Automotive Aftermarket Association (AAAA) and sponsored by mycar Tyre and Auto, Autocare will take place across 20 – 21 June at the Brisbane Convention and Exhibition Centre (BCEC).

The event will feature a comprehensive Workshop Management Training Program to help business owners and managers navigate rapid technological advancements and a shifting car parc and deploy best practice strategies to ensure they stay competitive and successful in a fast-changing industry.

The exclusive training program will cover topics including key industry trends, AI integration in workshops, talent acquisition and retention, the future viability of the ‘all makes and all models’ repairer model, strategic marketing, navigating workshop risks, staff productivity, leadership innovation, anticipating and adapting to the needs of tomorrow’s customers, the ADAS national industry code, the impact of EVs on the aftermarket, maximising OEM data, and more.

Attendees will gain actionable insights that can make an immediate positive impact on their businesses, learning from respected industry leaders with firsthand experience and real-world expertise on navigating today’s challenges with proven results.

“Autocare 2025 is a must-attend event for workshop owners and managers who want to take their business to the next level,” AAAA Chief Executive Officer, Stuart Charity, said.

“With rapid advancements in technology and shifts in the car parc, staying ahead means understanding and adapting.

“The Workshop Management Training Program will provide the tools and knowledge needed to grow, innovate, and thrive in an evolving industry.

“We have gathered the industry’s best and brightest all in one place to share their expertise and help workshops succeed in an increasingly complex and competitive landscape, and this level of valuable expert training is only available at Autocare.”

In addition to the Workshop Management Training Program, Autocare 2025 will feature a Technical Training Program designed for technicians and apprentices.

This program will provide hands-on sessions covering advanced diagnostics, servicing next-generation vehicles, and mastering cutting-edge tools and techniques to keep up with rapid technological advancements in vehicle repair and maintenance.

Alongside these world-class training programs, attendees can explore the free to industry Trade Show featuring over 120 leading companies showcasing the latest automotive products and services, while a fantastic networking event on the show floor will offer valuable opportunities to connect with industry peers in a dynamic setting.

The National Light Vehicle Modifications Summit will also run alongside Autocare, a game-changing event that brings together aftermarket leaders, manufacturers and regulators to collaborate on national vehicle standards, to protect the future of the industry.

The AAAA invites you to join thousands of technicians, business owners, and industry leaders during two transformative days of learning and networking in Brisbane.

To invest in your future and reserve your place at Autocare, visit www.autocare.org.au

Sponsorship opportunities and exhibitor spaces are also available. For more information, email partnerships@autocare.org.au

The battle for Right to Repair (R2R) has just taken another major step forward

In the United States, a Federal Judge has upheld Massachusetts’ landmark automotive telematics Right to Repair law, paving the way for independent repairers to access critical vehicle data.

This ruling is significant – not just for Massachusetts, but for the global fight for the rights of car owners, consumer choice and fair and open competition.

At the heart of this law is telematics, the real-time vehicle data that modern cars generate and send wirelessly to manufacturers.

Until now, vehicle manufacturers have had complete control over this information, often restricting access to their own network of authorised dealerships and locking independent repairers out of key diagnostics.

The Massachusetts law forces car makers to create a standardised, open-access platform, allowing vehicle owners and workshops to retrieve the data they need via a mobile app.

It ensures that independent repairers have the same access as dealerships, preserving competition and consumer choice.

How will this work in practice?

The Massachusetts law requires that all 2022 and newer vehicles with telematics systems include an open-access data platform that enables real-time mechanical data sharing.

This will be accessible via a secure, standardised interface, allowing independent repair shops to diagnose and repair vehicles without relying on dealership-only tools.

Vehicle owners will be able to authorise repairers to access their car’s telematics data through a mobile app, putting them back in control of their vehicle’s service options. Automakers have pushed back, citing cybersecurity risks and arguing that telematics data should remain proprietary.

However, the law includes provisions that allow manufacturers to implement secure thirdparty systems, balancing security with fair data access. This ensures that independent repairers can perform diagnostics and repairs without manufacturers controlling the entire process.

How Massachusetts compares to Australia

Australia has already led the way with the world’s first mandatory national Right to Repair law for automotive service and repair, introduced in 2022.

This law compels vehicle manufacturers to provide independent workshops with diagnostic, repair, and service information at a fair market price. However, the Massachusetts ruling goes further by explicitly including telematics data, something Australia’s current law does not fully address.

As vehicles become more connected, telematics will replace the traditional onboard diagnostic (OBD-II) port as the primary way to access repair data. Without telematics access, repairers risk losing visibility into the very systems they need to service.

How does Australia compare to other countries?

Globally, Australia is ahead of many nations, but there are still gaps that need to be addressed.

• European Union: Since 2018, the EU has required that independent repairers receive full access to repair and diagnostic data, including telematics, under Regulation 2018/858. However, some workshops argue that the cost of accessing this data is still too high.

• United States (beyond Massachusetts): There is no federal Right to Repair law for vehicles yet, but the REPAIR Act (H.R. 906) is under discussion to expand R2R nationwide. Other states, like Maine, are considering laws similar to those of Massachusetts.

• Canada: Currently debating its own Right to Repair legislation, modelled after Massachusetts’ law. Canada’s existing voluntary agreement from 2009 does not cover telematics, highlighting the need for new laws.

• New Zealand: Discussions are underway, particularly around ensuring independent workshops can access scan tools and passthrough technology similar to the US and EU.

What’s next for Australia?

We cannot assume that our existing Right to Repair laws will remain fit for purpose as technology evolves.

Lesley Yates, AAAA Director of Government Relations and Advocacy info@aaaa.com.au

The Australian Competition and Consumer Commission (ACCC) has already acknowledged that connected cars present new challenges for repair access.

As we’ve seen globally, car makers will continue to resist opening up telematics data, arguing cybersecurity risks and intellectual property concerns.

But the fundamental principle remains unchanged: If you own the vehicle, you should have the right to decide who repairs it. Independent workshops must have access to the same data as dealerships to ensure fair competition.

Massachusetts has set a precedent, but the battle for data access isn’t over. Australia needs to stay ahead of the curve and ensure that our Right to Repair framework evolves with the technology. That means strengthening laws to include secure but open telematics access – before automakers lock the independent sector out for good.

The AAAA fought hard to secure Australia’s Right to Repair law, and we won’t let it fall behind. We are already in active discussions with the federal government about how our law needs to keep pace with telematics, scan tools, data aggregators, and online service books.

The belief in fair and open competition will always need champions, and AAAA will continue to fight to ensure independent repairers and workshops have the access they need to keep serving Australian motorists.

The fight for Right to Repair has always been about fairness, competition, and consumer choice. It is time we made sure connected vehicles don’t become the next frontier of manufacturer control. If you would like to offer your thoughts on this subject, please email advocacy@aaaa.com.au

The Australian Automotive Aftermarket Association (AAAA) congratulates its sister organisation, the Auto Care Association, and President and Chief Executive Officer, Bill Hanvey, on their landmark victory in Massachusetts.

This ruling upholds the 2020 Right to Repair law, requiring automakers to provide independent repairers with access to telematics data – an important step forward for consumer choice and fair competition in automotive repair.

AAAA Chief Executive Officer, Stuart Charity, said this decision highlights the need for urgent reform in Australia, where the Motor Vehicle Information Scheme (MVIS) provides world-leading access to service and repair data, but excludes telematics.

“Australia has the best Right to Repair legislation in the world, and the Federal Government deserves credit for this landmark reform. However, technology has rapidly evolved, and our law must keep pace,” Stuart said.

“Modern vehicles rely on telematics to diagnose and repair faults, yet independent repairers in Australia are locked out of this crucial data.

“The Massachusetts ruling confirms that telematics access is both legally viable and essential for a fair repair industry.

“If we don’t act now, Australian consumers and independent workshops will be left behind.”

Technology in the automotive sector is advancing at an unprecedented rate. Increasingly, vehicles now receive wireless software updates that impact how key systems operate, meaning repairers need real-time access to vehicle data.

New safety features, including autonomous emergency braking, lane-keeping assistance, and adaptive cruise control, require dynamic calibration and updates to function correctly. These technologies save lives, and it is vital that independent repairers have access to the information to service and maintain these systems for the life of the vehicle.

Unlike in the US, updating Australia’s law does not require new legislation: a straightforward amendment to the MVIS Scheme Rules could close the telematics gap.

The AAAA is calling on the Federal Government to act now and ensure independent workshops have fair access to repair data for today’s highly connected vehicles.

The changes required to modernise Australia’s Right to Repair law are minimal, yet the impact on the industry would be enormous.

Australia has led the world in securing fair access

to vehicle data, and must continue leading, ensuring the MVIS remains fit for purpose.

The AAAA remains committed to ensuring Australia remains a global leader in Right to Repair and looks forward to working collaboratively with the government and industry stakeholders to bring this legislation up to date.

“We stand ready to assist in this reform process and have written to Minister Andrew Leigh to begin this critical dialogue,” Stuart said.

“Now is the time to future-proof our law and ensure Australian consumers continue to have genuine choice in vehicle servicing and repair.”

For more from the AAAA, visit www.aaaa.com.au

Hundreds of mechanics have taken advantage of free EV related courses

The Australian and Queensland Governments’ TAFE initiative offers fee-free classes to advance knowledge in automotive trades.

In 2024, more than 400 mechanics engaged in TAFE Queensland Electric Vehicle (EV) training.

A new course was introduced in 2023 entitled ‘Battery Electric Vehicle Inspection and Servicing Skill Set.’ This past year, more than 300 students took part in the class.

Small business owner Ali Abbas was one of the first students to complete the course.

He said he was interested in expanding his knowledge related to electric vehicles in order to increase business.

“These vehicles are becoming more and more common, so I wanted to upskill so I could confidently work on them and advertise that I’m doing so in order to boost my business,” Ali said.

The goal of the TAFE Queensland teachers is to ensure that every student becomes highly capable and confident in the targeted skills related to EVs.

“Being certified is a good thing, but to really feel confident and comfortable that I am able to do this work and advertise it to my clients is even better,” Ali said.

TAFE Queensland – SkillsTech General Manager, Stephen Gates, recognises the importance of EV training for automotive apprentices as electric vehicles become more prevalent.

“Upskilling Queensland’s automotive industry to work on the vehicles that are becoming more popular means not only training qualified mechanics and business owners but also apprentices,” Stephen said.

“There is the new EV apprenticeship for dealerships and other businesses working exclusively on these

vehicles, but for most apprentices a base level of knowledge will also be needed across their career.”

Thousands of apprentices are currently enrolled and can opt to take elective EV units to enhance their training.

Other EV training is offered through various TAFE Queensland courses, including the Hybrid and Electric Vehicle Skill Set, Certificate III in Automotive Electric Vehicle Technology, and Certificate III in Light Vehicle Mechanical Technology. For additional information about EV training and automotive training in general, visit www.tafeqld.edu.au/automotive

After a groundbreaking inaugural event in 2023, the National Light Vehicle Modifications Summit is set to return to Brisbane on June 20, 2025

This highly anticipated event offers a unique opportunity for the aftermarket modifications industry to collaborate with regulators and advocate for practical, balanced policies that support both innovation and safety.

Hosted alongside Autocare 2025, Australia’s premier automotive training convention, the Modifications Summit will feature a full day of interactive sessions designed to address the most pressing challenges and opportunities facing the vehicle modifications industry.

Building on the success of the first event, which led to the formation of the VSB 14 Technical Working Group and advancements in the ROVER regulatory system, the 2025 Summit will delve into critical industry topics, including the national review of VSB 14, stateby-state inconsistencies in modification regulations, and the evolving ROVER approval process.

Discussions will also cover GCM/GVM upgrades, ADAS calibration, EV modifications, and future technology standards; explore the impact of the recently introduced New Vehicle Efficiency Scheme (NVES) on larger diesel and petrol vehicles; examine the link between modification and certification; develop strategies for stronger industry advocacy; and highlight the role of research and testing in shaping the future of vehicle customisation.

AAAA Director of Government Relations at the

Australian Automotive Aftermarket Association (AAAA), Lesley Yates, emphasised the importance of this event.

“Our industry is the backbone of Australia’s automotive innovation. We take vehicles and make them better – safer, more functional, and fit for purpose,” Lesley said.

“The Summit is the only event where industry and regulators come together in one room to collaborate, address key issues, and shape the future of vehicle modifications.

“If you’re a modifier, this is your chance to have your say and ensure your voice is heard.

“The stakes are high this year. Policies like the ROVER rollout and the VSB-14 review will determine the future of vehicle modifications in Australia.

“By attending the Summit, you’ll be directly engaging with the regulators shaping these policies, ensuring our industry is equipped to meet these challenges head-on.”

Adding to the value of this key industry event is the exciting addition of respected automotive YouTube personality and vehicle modifier Alan Butler, also known as ‘Turbo Yoda.’

As the former host of The Skid Factory, Alan brings firsthand experience and deep insight into vehicle modification and Australian car culture.

His perspective will provide valuable context on the real-world challenges and opportunities facing the modification community today.

The 2025 Modifications Summit will provide a platform for attendees to network with industry peers, brainstorm solutions, and celebrate the achievements of Australia’s world-class aftermarket sector.

Following the Summit, attendees can connect further at the dedicated Autocare networking event and explore the latest innovations at the Autocare Trade Show, featuring 120 leading companies.

Modification Summit participants can also add further value to their experience by joining Autocare’s workshop management or technical training sessions the next day, ensuring they leave with both industry insights and practical business or technical skills to strengthen their operations.

To secure your place at the table for the Modifications Summit and learn more about the event, visit www.autocare.org.au/modsummit

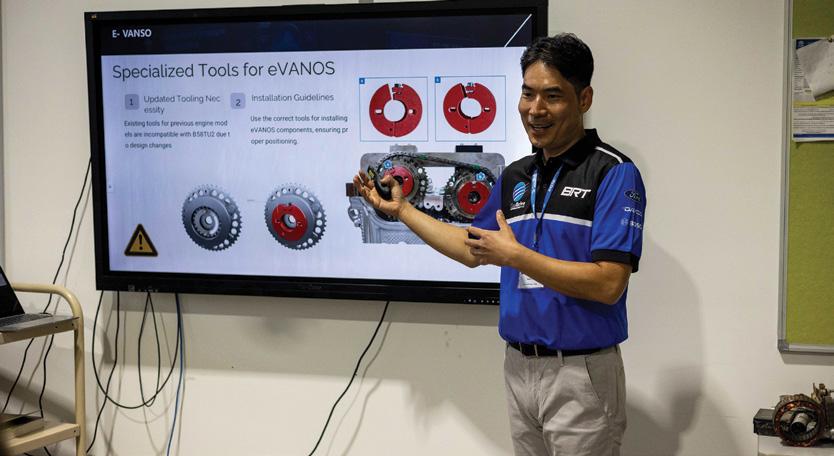

The organisation continued its support of the Kids with Cancer Foundation in 2024

CoolDrive Auto Parts conducted multiple campaigns and incentives to contribute funds for families in their time of need through the Kids with Cancer Foundation.

“The Kids with Cancer Foundation works tirelessly to provide much-needed financial assistance to children aged 0-18 diagnosed with cancer, standing as a beacon of hope and support for families navigating the arduous journey of a childhood cancer diagnosis,” CoolDrive Auto Parts Executive Chairman, John Blanchard, said.

“These funds raised by CoolDrive will be utilised by the Kids with Cancer Foundation to contribute to its essential services and support initiatives, ensuring that the lives of these young warriors and their families are made more manageable during such challenging times.”

During June and July last year, CoolDrive donated a percentage of proceeds – totalling more than $7,000 – from its ‘Electrical Extravaganza’ promotion to the Foundation.

CoolDrive also partnered with the Blanchard Racing Team to deliver a dream-come-true for some of these warriors, with the opportunity to revel in the high-speed excitement of Supercars racing.

Selected children and their families were treated to an unforgettable day at the racetrack during the Supercars Sandown race weekend in September, where they received an exclusive VIP experience, and the chance to jump in one of the BRT Supercars for a hot lap experience.

“The special guests felt the roar of the engines and the rush of the race up close, giving them a day of adrenaline-fuelled joy amidst their courageous

battles. The event was marked by wide grins and laughter, a testament to the success of the experience in kindling positive spirits,” John said.

“Contributions, no matter how big or small, can make a remarkable difference in the lives of children and families who rely on the Foundation’s invaluable assistance. After all, the race against childhood cancer is a race we should all be invested in winning.”

To learn more about, or to support the Kids with Cancer Foundation, please visit www.kidswithcancer.org.au

Further information on CoolDrive Auto Parts is available via www.cooldrive.com.au

With rocketing theft numbers in Victoria, RACV says security checks are essential

RACV is encouraging Victorians to keep vehicle security top of mind with the latest Victorian Crime Statistics Data revealing car theft levels in Victoria are at a ten-year high.

Car thefts are up by almost 25 percent, with more than 23,248 thefts or attempted thefts of motor vehicles recorded across Victoria in the 12 months to June 2024 – a 4,500 offence increase in twelve months.

Items stolen from inside vehicles increased by 17.2 per cent with 9,000 offences. Attempted theft alone also showed a spike of 43 percent with 2,760 offences.

“Opportunistic thieves will break into or enter a car and take possessions that are easily visible from outside the vehicle, often using the opportunity to steal the car itself,” RACV General Manager Motoring Products, Jeff Ames, said.

“It is crucial to protect your vehicle, including when it’s parked at home, in the street or even in secure carparks. If your car is parked at home in a driveway, this doesn’t mean it’s completely safe either – don’t forget to lock the doors, wind up windows and ensure nothing valuable is in plain sight.

“Number plates rank as one of the top items stolen from cars which can then be fitted onto stolen vehicles and used to commit crimes including ram raids, fuel theft, and burglaries, plus the cost impacts and inconvenience to the car owner.”

RACV suggests the following car security checks: install anti-theft screws on all number plates (visit a Neighbourhood Watch’s Safe Plate event); remove valuables from vehicles; always lock your car; use secure parking if possible, like a locked garage or park behind a locked gate; and review and update your car insurance to ensure you’re covered.

For more information about how to minimise the risk of vehicle theft, visit www.racv.com.au or www.nhw.com.au

The show will be held across May 15-17

Malaysian government policies and a shifting market landscape towards AI, digitalisation, electrification, energy efficiency, and sustainability have resulted in the country becoming an attractive investment destination, driven by demand for sustainable products and solutions in the automotive industry.

This year, Automechanika Kuala Lumpur 2025, taking place on 15 to 17 May, features an expanded showcase across six halls at the Kuala Lumpur Convention Centre.

The exhibition will showcase the evolution of the Malaysian market through new zones, the return of specialised areas that spotlight new mobility solutions, the vibrant automotive culture at autoFEST@KL, and green development throughout Southeast Asia, all around the fairground.

Under its Green Investment Strategy (GIS), Malaysia is targeting seven key areas of investment potential: bioenergy, carbon capture, circular economy, energy efficiency, green hydrogen, green mobility, and renewable energy.

Nearly all of these areas intersect with the automotive sector, and green mobility, in particular, is gaining prominence in Malaysia.

The drive for sustainable development has prompted leading automotive brands to enter the Malaysian market, further enhancing its appeal for auto investors and stakeholders.

“Malaysia is gaining significant traction from foreign investments and government policies aimed at sustainable technologies,” Messe Frankfurt (HK) General Manager, Fiona Chiew, said.

“Together with Malaysia’s ASEAN chairmanship for 2025, this positions the country to strengthen its leadership in the Southeast Asian automotive industry.

“However, the development spurred by these changes is rapidly reshaping the market, and local players must prioritise workforce training, skill development, and modern technologies to adapt effectively.

“The innovations at the 2025 edition of Automechanika Kuala Lumpur are vital for Malaysia and the global automotive industry in meeting the rising demand for charging technologies, electric parts and solutions, and automotive talent, fuelled by the energy transition.”

To address the new ideas, technologies, and innovations in the market, the Automotive Mobility Solutions Zone makes a return in 2025.

The area will explore innovative solutions based

on the latest advancements in green mobility as a response to the heightened focus on new energy efficiency, new materials, advanced technologies, and more.

Exhibitors will cover topics such as AI and autonomous driving, automotive manufacturing and automation, connectivity, electrification and digitalisation, energy, logistics, and warehousing and supply chain.

Other zones and events addressing the latest trends and popular subcultures include the Automotive Repair, Maintenance and Care / Body and Paint / Accessories and Customising Zone, as well as the Collision Repair Training Workshop. These will present the latest repair and maintenance equipment and techniques for all drive technologies and vehicle concepts, along with diagnostic solutions, smart repair systems, and infotainment technologies.

Parts and Components, Electrics and Electronics, and Commercial and Fleet will also return as core product categories of the show.

Once again, autoFEST@KL will spotlight exciting aspects of automotive culture, featuring exhibits on Japanese Domestic Market (JDM), motorsports, and Esports and gaming, creating an interactive experience within the fairground.

This year’s event will also see the return of EMMA Malaysia, showcasing a variety of car audio modifications.

To enhance the experience, DIY workshops will facilitate learning and knowledge sharing through high quality demonstrations.

In addition to established highlights, the debuting Outdoor, Camping, Campervan and Caravan Zone will showcase a range of self-contained campervans with lightweight camping gear as well as luxurious campervans for glamping, as interest in green living rises among Malaysian youth.

For more information, please visit www.automechanika-kl.com or email the organisers at autoasia@hongkong.messefrankfurt.com

In 2025, Capricorn will award six Region Winners as well as an Overall Winner

Capricorn, Australia and New Zealand’s largest automotive aftermarket member organisation, has announced its renowned Rising Stars Apprentice of the Year Award will be expanded in 2025 to recognise and reward more apprentices than ever before.

“We’re thrilled to announce that this year Capricorn will be awarding Region Winners as well as an Overall Winner in the Rising Star Awards,” Capricorn Chief Executive Officer – Trade, Andrew Zadow, said.

“Our Rising Stars Awards provide an opportunity for Capricorn Members to nominate apprentices who

show initiative and a real appetite for being in the industry.

“Over the past seven years we’ve continually been amazed by the quality of the nominations, so this year we’re increasing the awards to allow us to recognise star apprentices from each of our main regions, as well as an Overall Winner.”

The Capricorn Rising Stars program is an annual competition run by Capricorn in partnership with industry sponsors (Castrol, Repco and The Workshop Whisperer) to celebrate top apprentices in the automotive aftermarket industry in Australia and New Zealand.

In 2025, Capricorn will award six Region Winners from Western Australia, South Australia /Northern Territory, Queensland, New South Wales/Australian Capital Territory, Victoria/Tasmania and New Zealand as well as an Overall Winner.

There is more than $30,000 in prizes up for grabs and the competition is open to apprentices from all types of workshops and disciplines; from panel and fabrication to auto-electrical, general mechanical, heavy diesel and more.

The ACIA’s Annual General Meeting was successfully held on 25 February 2025

The Australian Collision Industry Alliance (ACIA) is a not-for-profit entity established to promote rewarding career paths and ensure the sustainability of the collision repair industry. Through funding and support from a wide range of industry stakeholders, the ACIA strives to develop and drive innovative programs to attract and retain people for the industry.

The ACIA’s Annual General Meeting provided an opportunity to review the organisation’s recent achievements, discuss future strategies, and address key organisational matters.

A key moment was welcoming new board member Jason Trewin. With more than 35 years in the automotive industry – from starting out as a panel technician to becoming a seasoned leader –Jason brings invaluable experience and a fresh perspective.

“I’m excited to join ACIA. My lifelong passion for cars and commitment to innovation drive me to help shape a dynamic future for our industry,” Jason said.

During the meeting, a comprehensive overview of ACIA’s performance and strategic direction was shared. Key highlights from the presentation included:

• Embedding the ACIA mission and organisational identity.

• Highlighting achievements and showcasing success stories, including the introduction of six new apprentices to the industry through ACIA initiatives in 2024.

• The presentation of the audited financial report for the fiscal year ending 2024, demonstrating increased revenues from memberships and provisions to support future initiatives.

Future strategies were also discussed.

“Looking ahead, we discussed initiatives focused on building career events and enhancing our presence in the collision industry,” ACIA Board Member, Rob Bartlett, said.

“This includes increasing our visibility through social channels, particularly on TikTok, and organising member events and resources. We plan to enhance our website as the primary platform for communication and marketing strategies.

“Additionally, we aim to foster partnerships, collaboration, and fundraising efforts to ensure sustainability moving forward.

“Emphasising digital transformation, the expansion of collaborative partnerships, and

“We know from our State of the Nation research that over 54 percent of Members find it challenging to find good staff, including apprentices,” Andrew said.

“We hope by raising the profile of apprentices in the automotive aftermarket we can encourage people to consider joining the industry.

“Through our Rising Stars Award we have discovered some outstanding advocates for the industry.

“Individuals who might only be at the start of their journey but have shown that they are the industry leaders of the future. I’m looking forward to meeting more this year.”

Nominations for the Awards are open now and close on Saturday, 31 May 2025.

For more information, please visit www.capricorn.coop/rising-stars

sustainable development initiatives will be key to our long-term success.

“The insights shared in our presentation highlight the momentum we have built and our commitment to steering ACIA towards an even brighter future.

“With strategic enhancements and innovative initiatives on the horizon, we are well-positioned to lead in our mission.”

For more information, visit www.theacia.com.au or contact Hiliary Bradbury at info@theacia.com.au

This is the fourth consecutive year AutoGuru has received this honour from ProductReview.com.au

AutoGuru has proudly announced its recognition as a 2025 Best Trades Comparison Website by ProductReview.com.au.

This accolade reflects AutoGuru’s dedication to providing an easy way for Aussie drivers to find a repairer, get quotes, and book car services and repairs online across Australia.

AutoGuru says being selected for this award highlights its strong customer ratings, consistent review quality, and ongoing commitment to meeting the needs of Australian car owners and repairers alike.

“We’re grateful to our customers, our trusted network of auto repairers, and the dedicated AutoGuru team for making this achievement possible,” AutoGuru Chief Executive Officer, Eden Shirley, said.

“Helping Aussies save time and take the guesswork out of finding a reputable mechanic to confidently book car servicing has always been our mission, and this recognition underscores the trust we’ve built with our community.”

The annual ProductReview.com.au Awards recognise businesses delivering outstanding customer experiences, based on several factors such as review count, sentiment scores, and recent customer feedback.

Winning this award four years in a row reinforces AutoGuru’s position as a leading car service and repair booking platform in Australia’s automotive services industry.

“…Have used AutoGuru on several occasions now for differing motoring needs & have not been disappointed with any of my choices. It does make things so much easier than ringing around, just put in your details & just wait for the quotes to roll in,” AutoGuru customer Leon said via www.productreview.com.au

AutoGuru.com.au offers Aussie drivers seamless access to a nationwide network of trusted auto repairers, where users can read verified reviews, get instant quotes, and can conveniently book services in just a few clicks 24/7.

AutoGuru also offers the convenience of flexible payment options through Afterpay, humm and Zip, and Uber vouchers to take the pain away from the drop off or pick up process.

AutoGuru says its retail marketplace continues to help automotive repairers acquire new customers, and provide an easy online booking process with transparent pricing using their customisable labour rates and parts markups.

“AutoGuru has been a great channel to boost

It is important to check in on your mates’ mental health after the holidays

As the festive season fades and everyday routines take over, the focus shifts from celebrations to the daily grind.

Torque It Out Mental Health Service is operated by Wheelnutz Garage in Queensland. It says that for those in the automotive trade, this transition can bring its own set of challenges, with work pressures and personal stresses often taking centre stage.

Amidst this backdrop, it is crucial to recognise the signs of mental distress in colleagues and know how to support them effectively.

Recognising when a coworker might be struggling with thoughts of suicide starts with paying attention to changes in behaviour and mood.

Someone who was once talkative and engaged might become withdrawn, avoiding conversations or isolating themselves during breaks.

Mood swings, irritability, or uncharacteristic sadness can also be indicators that something deeper is going on.

If a normally reliable worker starts missing deadlines, making unusual mistakes, or losing focus, it could be a sign that they’re struggling.

Sometimes, the biggest clue is in what they say –offhand comments about feeling trapped, being a burden, or having no reason to go on should never be ignored.

Broaching the topic of mental health can feel daunting, but a simple check-in can make all the difference.

The best approach is to find a private, quiet moment to talk, free from distractions. Expressing concern in a straightforward, non-judgmental way is key – something as simple as, “I’ve noticed you don’t seem yourself lately. Everything alright?” can open the door to a conversation.

Listening is just as important as asking. Let them talk without interrupting or rushing to offer solutions. Sometimes, people just need to be heard.

If you’re worried they might be having thoughts of suicide, ask them directly. It can feel uncomfortable, but saying, “are you thinking about suicide?” won’t put the idea in their head – it shows you care and are taking them seriously.

If they say yes, encourage them to seek professional help and offer to support them in finding it, whether

our online exposure, leading to a steady flow of new customers,” Fume Garage Business Owner, Mariah, said.

“The flexible payment options offered by AutoGuru are great for our customers, and we value having our reviews and extras showcased on our profile page.

“The system is easy to use so bookings can be reviewed and confirmed quickly. We would recommend AutoGuru to other businesses if they want to increase their online presence and acquire new customers.”

More than 92 percent of respondents to AutoGuru’s Annual Retail Member Survey in November 2024 stated that it’s worthwhile being an AutoGuru member.

To learn more about AutoGuru and why it has been recognised as one of the best trades comparison websites, AutoGuru invites you to visit www.productreview.com.au/i/awards

For information about AutoGuru retail marketplace membership, visit www.autoguru.com.au/memberships

it is through a GP, a crisis hotline, or a local mental health service.

Checking in shouldn’t be a one-time thing. Follow up, ask how they’re doing, and let them know they’re not alone. Even small gestures like grabbing a coffee together, cracking a joke, or just taking the time to listen, can remind them that someone cares.

In the automotive trade, where mateship runs deep, looking out for each other’s mental health is just as important as looking out for safety on the job. As we settle back into routine, let’s make sure checking in with a mate is part of it. A simple conversation could save a life.

For more information, visit www.wheelnutzgarage.com

A comprehensive smart mobility exhibition platform is just weeks away

Taiwan External Trade Development Council (TAITRA) will present Taipei AMPA and E-Mobility Taiwan under the new “360° Mobility Mega Shows” brand at Nangang Exhibition Hall 1 from April 23-26, 2025.

Running concurrently, Autotronics Taipei will join the lineup, collectively establishing Asia’s most comprehensive mobility industry exhibition platform.

In 2024, these flagship shows attracted over 50,000 professional visits and media representatives from 120 countries.

The 2025 edition, themed “Drive Smart, Drive Sustainability,” will focus on three key areas: Diverse Innovation, Sustainable Future, and Mobility Ecosystem.

The exhibition will feature 13 specialised zones covering parts and components, customising and accessories, automotive lighting, mobility technology, autonomous and electric vehicles, and motorcycle components, showcasing the latest technologies and future trends.

With the global automotive industry’s shift toward electrification and smart technology, the newly established Mobility Technology and Mobility

Energy Solutions areas will feature industry leaders, Such As Cub Elecparts, Delta Electronics, Etreego, Hd Renewable Energy, Shihlin Electric, Texas Instruments, and Zerova Technologies. Organisers state these companies will showcase cutting-edge mobility solutions and innovative technologies.

In the automotive components sector, leading manufacturers Aisin Elite, Gordon, Kuo Chuan Precision, Nan Hoang, and Sonar Auto Parts will demonstrate their technological expertise, while Eagle Eyes and Just Auto Lighting will lead the automotive lighting segment with innovative lighting solutions.

Industry forecasts project Taiwan’s automotive electronics production value to exceed NT$600 billion in 2025, with electronic components expected to make up over 50 percent of total vehicle costs.

The automotive electronics zone will showcase leading manufacturers including E-Lead Electronic, Jet Optoelectronics, Kai Suh Suh, Mitac, Msi, And Ta Ya Electric Wire and Cable, highlighting Taiwan’s competitiveness in the global market. To foster industry exchange and innovation,

TAITRA will host key events, including the “360° Mobility Forum,” where industry experts share insights on global market trends and technological developments.

Additionally, the fourth annual “ESG Achievement” event, in partnership with international certification authorities, will recognise companies demonstrating excellence in sustainable development, encouraging broader industry adoption of sustainability practices.

The 360° Mobility Mega Shows demonstrate Taiwan’s innovative capabilities in the mobility sector while providing an excellent platform for industry professionals to collect, explore global trends, and foster business opportunities.

For more information and pre-registration, visit www.taipeiampa.com.tw/en/

Kangan Institute staff Bev Williams OAM has been recognised for her exceptional contributions to vocational education

The experienced automotive industry placement coordinator was presented the World Federation Colleges and Polytechnics (WFCP) Awards of Excellence Lifetime Achievement Award (Gold) in Jamaica late last year.

The award celebrates Bev’s instrumental role in guiding more than 1,000 students as they transition from foundational studies to their next career steps, establishing a proven track record of connecting students with valuable work and apprenticeship opportunities.

The prestigious award follows national recognition for Bev in 2023 when she was awarded the Medal of the Order of Australia (OAM) on the King’s Birthday 2023 Honours List.

“What an absolute honour to not only represent not Kangan Institute but Australia. I’m extremely overwhelmed, excited and grateful to the people who took the time to nominate me,” Bev said. Based at Kangan Institute’s Automotive Centre of Excellence in Docklands, Bev primarily supports students who have completed pre-apprenticeship courses in automotive and are seeking to enter the industry.

Her recommendations have led to placements with a diverse range of employers, including

manufacturers, dealerships, and group training organisations.

Student success and great teammates drive Bev’s passion and love for the work she does.

“What makes me passionate? Small wins. When you see a student gain an apprenticeship and achieve the outcome they were hoping for on enrolling,” Bev said.

“I am lucky to work with great teachers who really support students and make the classroom a safe, fun place to learn.

“The students see Kangan Institute as the TAFE of choice and often ask if their employer will let them return to the Automotive Centre of Excellence as an apprentice.”

Held at the WFCP World Congress in Montego Bay, Jamaica, the 2024 Awards of Excellence celebrated remarkable contributions to skills development and wider economic and social development, with awards across 14 categories presented to individuals and organisations from all over the world.

“Kangan Institute is honoured to have Bev as part of our team. Her unwavering dedication to bridging the gap between training and the workplace has

impacted countless students,” Kangan Institute Chief Executive Officer, Sally Curtain, said.

“Bev was first awarded with a Medal of the Order of Australia (OAM) on the King’s Birthday 2023 Honours List.

“This recent award is a testament to Bev’s significant role in shaping the future of the industry and her commitment to fostering the next generation of automotive professionals, placing her among the best in the field globally.”

For more from Kangan Institute, visit www.kangan.edu.au

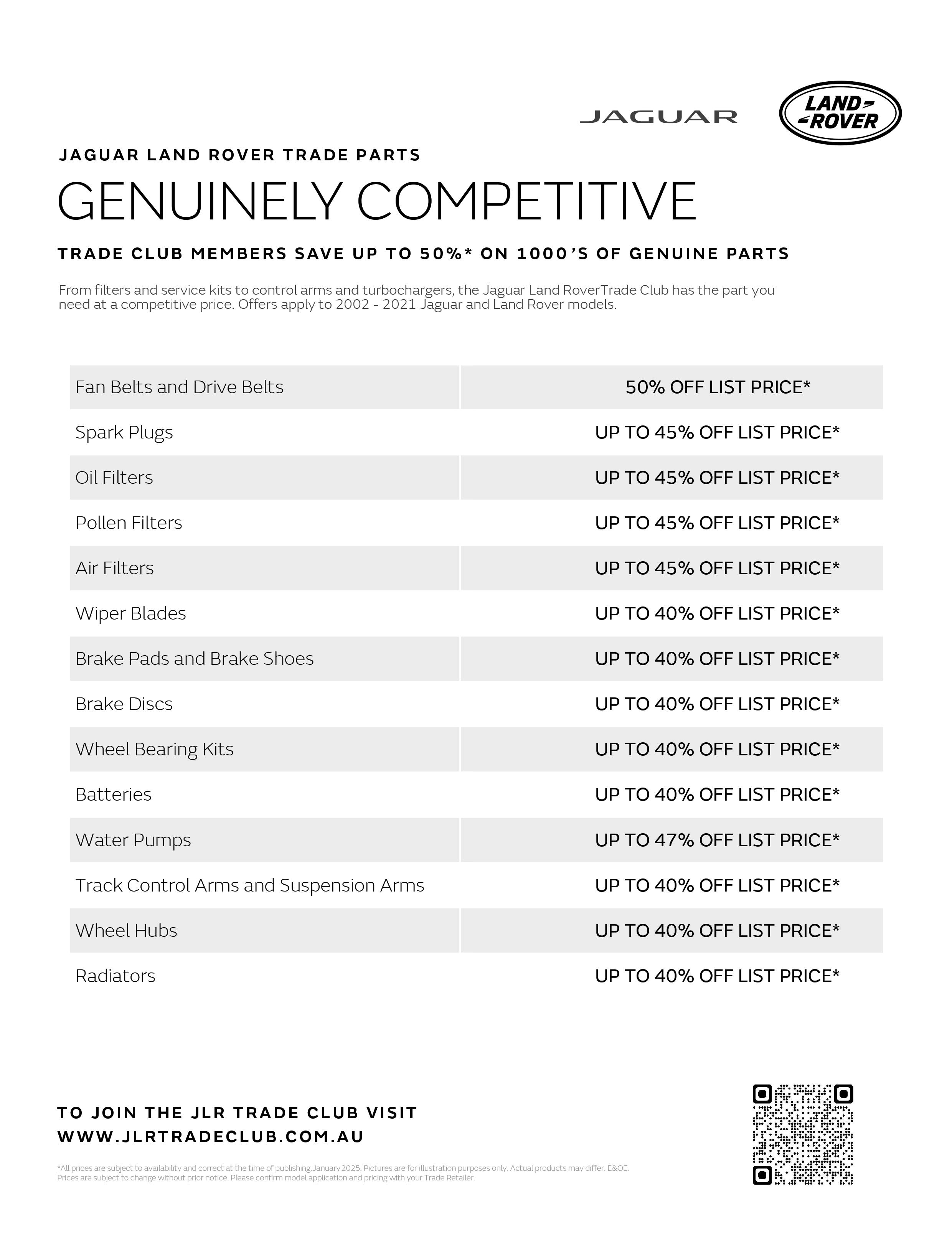

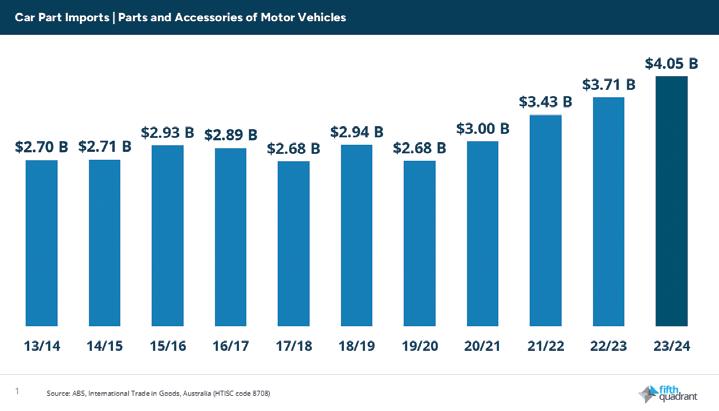

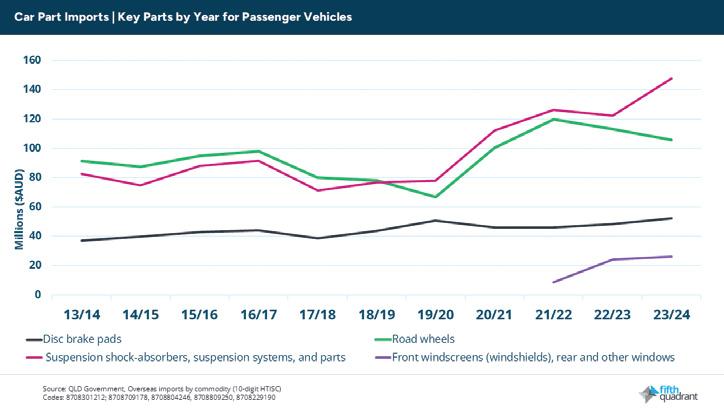

In this article, Fifth Quadrant takes a look at the figures around parts importing

Australia’s automotive aftermarket has reached a significant milestone, with parts imports hitting $4.05 billion in 2023-241.

This represents a 50 percent increase over the past decade (up from $2.70 billion in 2013-14), although the growth has really occurred since 2019-20, with the market largely static over the preceding period.

The increase in value is clearly outpacing natural car parc growth, meaning that despite the increasing complexity of modern vehicles it can’t all be associated with increased volumes for standard consumable parts.

While we can see increases in these categories, it also talks to the increasing amounts being spent on vehicle upgrades and improvements and the associated opportunities for aftermarket providers servicing the Australian market.

The Australian automotive aftermarket has witnessed a significant increase in suspension component imports, rising approximately 80 percent since 2019-20 to an annual landed value of around $145 million.

This surge aligns with feedback from Australian 4WD brands and other suppliers, indicating heightened consumer interest in suspension upgrades and enhancements.

Additionally, road wheel imports experienced robust growth between 2019-20 and 2021-22, increasing by about 70 percent during this period, before stabilising at approximately $105 million over the past year.

In contrast, disc brake pad imports have shown steady progress, consistent with overall car parc growth, maintaining an annual import value of around $50 million.

A notable development is the emergence of automotive glass imports as a distinct category. Recently separated from broader classifications, the annual value of front windscreen and other automotive window imports now exceeds $20 million, reflecting the evolving dynamics of the automotive parts import sector.

China’s automotive parts evolution: meeting Australia’s diverse needs

Over the past decade, China’s role in supplying automotive parts to Australia has been transformed.

In 2013-14, the US led as Australia’s primary source of automotive parts imports, totalling $498 million.

By 2023-24, China had surged ahead, more than doubling its exports to $915 million annually off the back of substantial enhancements in the quality and reliability of Chinese-manufactured parts.

While China was historically recognised for providing cost-effective automotive components, its manufacturers are now leveraging advanced manufacturing processes and improved quality control measures to deliver a more comprehensive product offering that lets Australian mechanics select parts that align with specific customer needs and budget constraints.

In contrast, traditional automotive manufacturing

nations have experienced mixed outcomes in their export relationships with Australia. For instance, South Korea has seen a decline in its market share, highlighting the challenging nature of the global automotive parts industry.

$99m +13%

Korea $220m $98m -55% Italy $44m $83m +88%

In conclusion, Australia’s automotive aftermarket is experiencing significant growth, with parts imports reaching $4.05 billion in 2023-24 – a 50 percent increase over the past decade.

This surge, particularly from China, reflects advances in quality and a diversified product range that meets the varied needs of Australian mechanics.

For aftermarket suppliers and workshops, maintaining flexible sourcing strategies is essential to capitalise on emerging opportunities in this dynamic global market.

This column was prepared for AAA Magazine by Fifth Quadrant, the AAAA’s partners in the AAAA Aftermarket Dashboard, which is delivered to AAAA members each quarter.

For more information about their services, visit www.fifthquadrant.com.au or contact Ben Selwyn at ben@fifthquadrant.com.au

1 QLD Government, ‘Overseas imports by commodity (10-digit HTISC) and country of origin’

Notice of Intention to cease carrying on business in New Zealand

On the 7th of March 2025 notice was given, pursuant to section 341 of the Companies Act 1993, that the Australian Automotive Aftermarket Associated Limited (Company Number: 8854228), a body incorporated in Australia but having a place

of business in New Zealand and registered as an overseas company, intends to cease carrying on business in New Zealand.

The company will give notice to the Registrar to remove Australian Automotive Aftermarket

Associated Limited from the overseas company register not earlier than three months after the date of publication of this notice.

For more information, email advocacy@aaaa.com.au

The AAAA warns car manufacturers to not mislead consumers about their ACL rights

On the 12 month anniversary of the Federal Court ruling against Mazda Australia, the Australian Automotive Aftermarket Association (AAAA) is calling on all car manufacturers to ensure they do not mislead consumers regarding their warranty and consumer guarantee rights under Australian law.

In February 2024, the Federal Court fined Mazda Australia $11.5 million for misleading and deceptive conduct, making false representations about consumer guarantees, and failing to meet obligations under the Australian Consumer Law (ACL). The ruling sent a clear message that misleading consumers about their statutory rights will not be tolerated.

“This decision was a wake-up call to all car manufacturers,” AAAA Chief Executive Officer, Stuart Charity, said.

“The ACL is clear: consumer guarantees cannot be limited, excluded, or overridden by manufacturer warranties.

“Yet, too often, we see manufacturers and dealers telling customers they have no right to a refund or replacement under a warranty, despite the clear protections provided under the ACL.”

In 2021, the Federal Court found that Mazda misled customers who experienced significant and recurring vehicle faults within two years of purchase.

Instead of honouring their obligations under the

ACL, Mazda falsely insisted that repair was the only remedy available, despite multiple failed attempts to fix the faults.

The Court determined that Mazda failed to properly consider consumer guarantee provisions, did not seek appropriate technical advice, and prioritised its commercial interests over consumer rights.

“This ruling reinforced that manufacturers must act in good faith and ensure they provide accurate information about consumer rights,” Stuart said.

“Consumers rely on their vehicles for work, family, and daily life, and they deserve to be treated fairly when things go wrong.

“Manufacturers cannot mislead consumers by implying that their only option is repair, nor can they refuse to honour these rights based on arbitrary warranty terms.”

Many consumers believe extended warranties provide additional protection. However, in many cases, extended warranties cover repairs and replacements that are already protected under the ACL, meaning consumers may be paying for rights they already have.

Under the ACL, goods must be of acceptable quality, fit for purpose, as described or demonstrated, and free from defects. If a failure is minor and can be remedied, the consumer is entitled to a repair within a reasonable time.

However, if the failure cannot be remedied or is a major failure, the consumer has the right to a refund or replacement under the ACL, regardless of any manufacturer or extended warranty.

Additionally, some extended warranties contain terms that imply consumers must service their vehicles at the dealership or use ‘genuine’ parts.

This can be misleading if consumers are not informed that such requirements do not affect their rights to a remedy under the ACL for failures covered by consumer guarantees.

Car manufacturers cannot void consumer rights based on servicing choices alone. Extended warranties also often come with strict conditions, exclusions, and limitations, leaving consumers without the coverage they expected.

The AAAA urges the ACCC to continue its scrutiny of misleading warranty practices in the automotive sector and will continue to advocate for stronger consumer protections.

For more from the AAAA, visit www.aaaa.com.au

TAPA 2025 will be held across 3-5 April 2025 at the Bangkok International Trade and Exhibition Centre

The Thailand International Auto Parts and Accessories Show 2025 (TAPA 2025) is set to bring together leaders in the auto parts, accessories and related services from Thailand and around the world.

The premier trade show will present new products and innovations in the auto parts and accessories industry which organisers state will surely broaden your business horizon whether you’re a manufacturer, exporter, buyer/distributor or importer.

TAPA 2025 will feature a complete range of auto parts and accessories products including engines and transmissions, brake systems, steering systems, body parts, electrical/ electronics, suspensions, interiors/exteriors and others from more than 500 international manufacturers on an area of 20,000 square meters.

The show is expected to attract more than 8,000 visitors from around the world, providing them with an opportunity to connect and negotiate with the industry leaders while updating the latest trends, knowledge, technologies and innovations.

Organisers explain that the show is being organised under the theme of “Sustainable for the Future,” signifying the development of the global auto parts and accessories industry with a focus on sustainability to answer the needs of the modern world.

TAPA 2025 will also feature a variety of exciting activities such as seminars on hot topics and

product showcases featuring innovations in automotive, road safety products, electronic auto parts, and more.

TAPA 2025 is organised by Thailand’s Department of International Trade Promotion in collaboration with related associations in Thailand’s auto parts industry.

For more information, visit www.thailandautopartsfair.com

Approaching its first anniversary, this important initiative is making strong inroads in the name of industry diversity

The ‘Accelerating Progress for Women in Automotive’ program was launched by five very passionate and industry-leading women with a special International Women’s Day breakfast in 2024.

Now a year on, the steering committee has grown, two core programs are underway, and the group is operating under a new moniker – AAAAWomen – after having received official endorsement from the Australian Automotive Aftermarket Association (AAAA).

“Our members went to AAAA with a request that we combine efforts to drive diversity forward in our industry’s workforce, particularly in the areas of recruitment and retention, and we are so pleased that our program is now officially endorsed by the Association,” AAAA Director of Government Relations and Advocacy, and AAAA Women Steering Committee member, Lesley Yates, said.

“Research shows that if you start to work on women’s participation rates, if you make that the initial focus, you start to see greater diversity unfolding in other areas that are underrepresented in our industry.

“That is why we started what is now known as AAAAWomen, and we are enthusiastically working with those currently employed in the workforce to encourage women to see the automotive aftermarket as a career option.

“Working under the banner of AAAA, we have a modest set of activities in place now that we are really proud to support.

“It is a strategic decision to approach what we are doing in this way – it is easy to be all talk, to take on a lot of activities but not meet them, especially when every member of our steering committee have full-time commitments.

“Because of this, we decided to focus on two main projects, which we feel are the perfect next steps forwards in pursuing our overarching goal of supporting and retaining women employees and

working together to increase the participating of women in our industry.”

These projects are the recently held 2025 International Women’s Day Breakfast, and the launch of a Connecting Circles program which will evolve across the coming 12 months.

“Our second International Women’s Day Breakfast brought together women from our participating brands and the industry on the 6th of March, and it was a great way to kick our 2025 activities into gear,” Lesley said.

“Like our 2024 breakfast, it was a very special event, creating an important discussion of ideas.

“We have also started the first steps in launching our Connecting Circles program, which is informed heavily by the highly successful Women in Autocare program in the United States.”

The idea of Connecting Circles is to bring together groups of women under common issues, either based on sector – such as women in distribution, women in retail, women as small business owners and so on – or on the issues – such as work-life balance, for example.

Under these topics, these ‘circles’ meet online for 45 minutes once a month. They are not necessarily a committee or brought together to achieve a specific task, they are about bringing together women to share experiences and connect, and help the members find opportunities and support.

“Not only do these circles provide important opportunity for idea generation, for change, and for support, they drive forward the critical notion that the women in our industry are not alone,” Lesley said.

“Our first Connecting Circle was held in late February with a cap of 25 members and was something of a pilot preceding the evolution of the program – it was basically a connecting circle on the topic of connecting circles, looking at the purpose, the model, the topics, and the formats moving forward, and we are very excited by what came out of that and what lays ahead for our program.”

Stay tuned to the next edition of AAAM for more on the IWD Breakfast and the first Connecting Circle.

AAAA Women is driven forward by steering committee members: Amotiv Chief People Officer, Barbara Harrison; GPC Chief People Officer, Aileen Hayes; Penrite Oil Head of Strategy and Customer Engagement, Priscilla Robb; BAPCOR Chief People and Culture Officer, Meryl Dooley; and new members, Accelerate Auto Business Manager Ange Wall, and Australian Collision Industry Alliance (ACIA) Executive Administrator

and Auto Glass Association (AGA) Secretariat, Hiliary Bradbury.

“Our two new members bring critical small business experience to our group and we have been very pleased to welcome them,” Lesley said.

“While our panel is made up of some pretty impressive names from our industry, our group is not ‘a BAPCOR thing,’ or a ‘GPC thing,’ it is a united front under the industry-wide representative banner of the AAAA.

“Together, we are committed to undertaking a well-considered and effective social endeavour program to advance the cause of women in automotive, and we can’t wait to see what we can achieve across 2025.”

To learn more about AAAAWomen, please email Lesley Yates on advoacy@aaaa.com.au

MAHLE is completing the next important step in its transformation

The automotive supplier explains it is streamlining its group structure to become faster and more efficient in the implementation of its strategy, MAHLE 2030+. The changes include the reorganisation and merger of business units in order to strengthen the strategic areas of electrification and thermal management, both structurally and in production.

The Group Management Board is also being downsized from seven members to four.

Merger of business units

Four existing business units were merged to form two new business units.

The former business units “Engine Systems and Components” and “Electronics and Mechatronics” now operate under the name of “Powertrain and Charging.”

The activities of the former business units “Filtration and Engine Peripherals” and “Thermal Management” have been merged in the new business unit “Thermal and Fluid Systems.”

The Aftermarket business unit with its established product range and additional competence in electrification and digitalisation will be continued as a separate business unit under the name of “Lifecycle and Mobility.”

“MAHLE is doing its homework for the transformation,” MAHLE Chairman of the Group Management Board and Chief Executive Officer, Arnd Franz, said.

“Through these far-reaching changes, we will make our business ready for the future.

“We are accelerating the implementation of our group strategy which will position us as an innovative and sustainably profitable shaper of future mobility.”

In the course of these changes, MAHLE will acquire all the remaining minority interests, amounting to almost 25 percent, in the thermal management specialist MAHLE Behr GmbH and Co KG.

“Following several major acquisitions in the thermal management field, this step will successfully complete the integration of this business in the MAHLE Group,” said Franz.

With this new group structure, the MAHLE Management Board now consists of the following four members: Arnd Franz (Chairman of the Management Board, CEO and Labour Director); Markus Kapaun (Chief Financial Officer); Jumana AlSibai (responsible for “Thermal and Fluid Systems”); and Georg Dietz (responsible for “Powertrain and Charging”).

Former members, Dr Beate Bungartz, the previous Labor Director; and Martin Weidlich, previously responsible for the merged business unit of “Filtration and Engine Peripherals,” have now resigned from the group. Meanwhile former member Martin Wellhoeffer, who was responsible for the merged “Electronics and Mechatronics” business

unit, has transferred to the “Thermal and Fluid Systems” business unit as Chief Operating Officer (COO).

“Through the reorganisation and the resulting streamlining of the Management Board, we will significantly improve the integration of our group and be able to make more effective use of synergies,” Chairman of the MAHLE Supervisory Board, Professor Dr Heinz K. Junker, said.

“On behalf of the MAHLE supervisory bodies, I would like to thank the Management Board Members Dr Beate Bungartz and Martin Weidlich, for their excellent and dedicated work.

“Equally, the supervisory bodies and I would like to thank Martin Wellhoeffer for his considerable commitment as a Management Board member. We are convinced Martin will forge ahead with the operational excellence and transformation as COO of what is to be our largest business unit in the future.” For more from MAHLE, visit www.mahle.com

The consultation period opened on 5 March and lasts for eight weeks

A revised draft of the Motor Vehicle Insurance and Repair Industry Code of Conduct is now available for public consultation, with submissions encouraged from the motor vehicle insurance and repair industry, government stakeholders and interested parties.

Stakeholders can choose to make their submissions publicly via the website or confidentially by direct correspondence to the Motor Trades Association of Australia (MTAA) or the Insurance Council of Australia (ICA).

The consultation period will close on 29 April, 2025. All consultation materials will be made available on a dedicated website, including a summary of the Code review; the draft Code and explanatory memorandum; and draft constitution and committee charter

Stakeholders are asked to provide feedback on the draft Code, including specific operational questions identified as requiring further industry input.

MVIRI CAC Chair, George Manos, said the Committee was working hard to finalise the consultation platform.

“There has been a high level of interest about the consultation, and we want to make the process straightforward and streamlined for industry.”

George said.

“The MTAA and ICA will also lead targeted consultations with their members and other key stakeholders, ensuring diverse perspectives are heard.”

In addition to consultation on the draft Code, the Committee is taking steps towards formal incorporation as an association.

“Dr Michael Schaper’s 2023 independent review of the Code called for the Motor Vehicle Insurance and Repair Industry Code of Conduct Administration Committee to incorporate as a formal entity responsible for holding its assets, intellectual property and finances,” George said.

“Following legal advice and consideration of the best interests of the industry, the MTAA, ICA and the MVIRI CAC have determined that incorporating as an independent association is an important first step towards its modernisation.”

A copy of Dr Schaper’s report can be found on the Motor Vehicle Insurance and Repair Industry Code of Conduct website at www.abrcode.com.au/resource-centre as well as the MTAA website www.mtaa.com.au and the ICA website at www.insurancecouncil.com.au

For more information, please visit www.abrcode.com.au/resource-centre

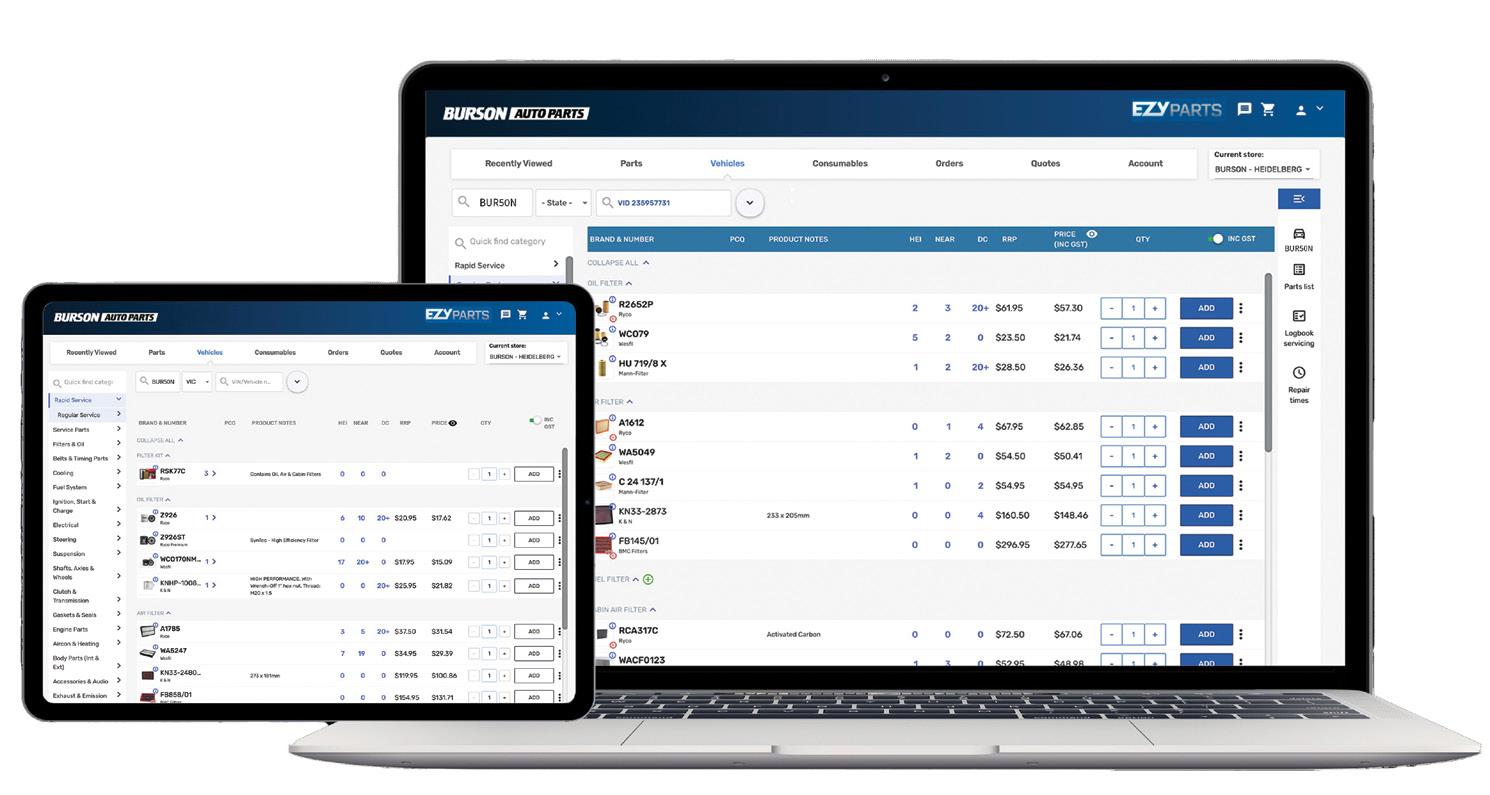

For more than a decade, Burson Auto Parts’ EzyParts platform has been a trusted go-to for mechan-ics and workshop owners looking to streamline their parts sourcing

Whether it is a simple service or a complex repair, having quick and reliable access to the right parts is critical to workshop efficiency and profitability.

But much like the automotive industry itself, EzyParts is always evolving to ensure workshops across Australia have the fastest, most accurate, and most reliable parts sourcing experience possible.

From live stock visibility and rego-based searches to technical data integration and Workshop Management System (WMS) compatibility, EzyParts continues to push the boundaries of what a modern ordering platform should be. What is EzyParts?

“EzyParts is a one-stop ordering platform, designed to make sourcing parts as fast and seamless as possible,” Burson Auto Parts Sales and Projects General Manager, Frank Petruccelli, said.

Available to Burson trading account holders on desktop and mobile, EzyParts lets mechanics find, order, and receive parts without unnecessary delays.

“When you input a rego, EzyParts doesn’t just find the parts you need, it suggests additional relevant components based on that make and model,” Frank said.

For those trickier repairs that require uncommon or specialised parts, EzyParts provides real-time stock availability across both nearby Burson stores and local distribution centres.

“That way, you’re not just limited to the 30,000+ SKUs available in-store – you also get access to an additional 200,000+ SKUs from our distribution network,” Frank said.

“And depending on your location, you could have the parts within an hour, or by the next day.”

For Burson Auto Parts’ Head of Digital Operations and Network Support, Tim Tummons, workshop efficiency is about more than just fast deliveries, it is about confidence.

Having grown up in his parents’ spare parts business, Tim understands that mechanics don’t have time for guesswork when sourcing parts.

“With EzyParts, mechanics can be 100 percent sure they’re getting the right part delivered exactly when they need it,” Tim said.

“That means no more telling customers, ‘I think I can get this part today, so I think you’ll get your car back tomorrow.’”

By eliminating uncertainty, EzyParts helps workshops reduce turnaround times, improve efficiency, and increase profitability.

“When you know exactly where your parts are coming from, you can be more accurate with job scheduling, avoid costly delays, and provide better customer service,” Tim said.

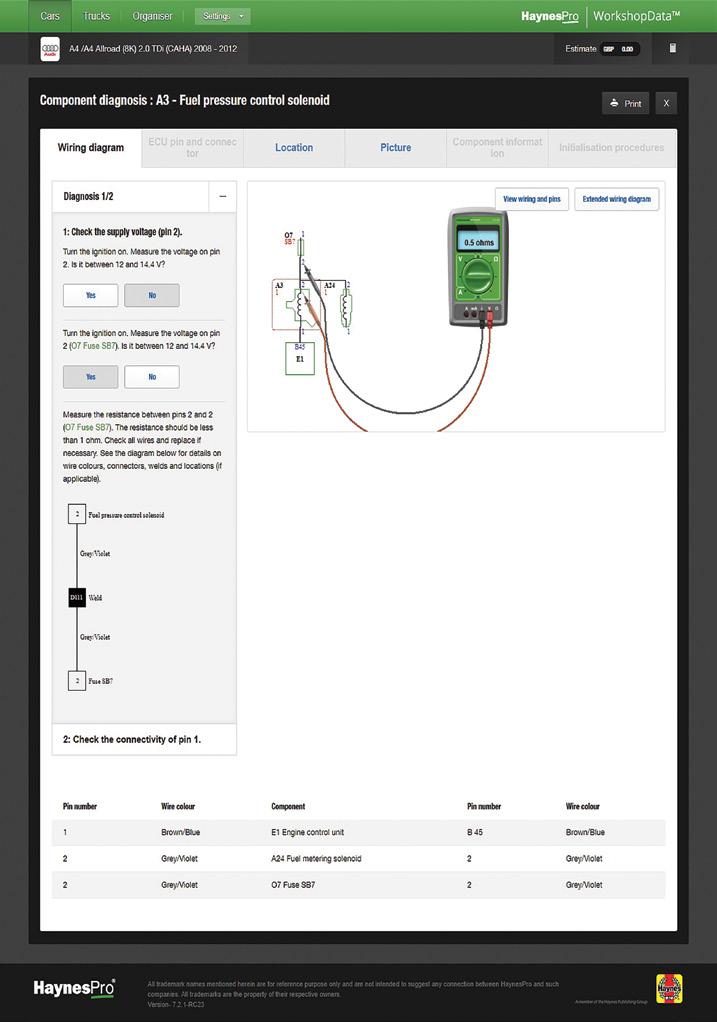

Introducing EzyData: smarter diagnostics at your fingertips

Burson Auto Parts has newly launched EzyData by integrating HaynesPro, a leading digital repair resource, directly into the platform.

This will take workshop efficiency even further, by providing mechanics with a comprehensive online workshop information system.

“This is how many UK workshops have been operating for the past decade,” Tim explains.

“They realised that having accurate, reliable technical data reduces mistakes, saves time, and ensures safer, more efficient repairs.”

EzyData was designed to help automotive professionals diagnose and fix issues at a faster rate. It can be launched directly from EzyParts, saving valuable time when working on complex repairs.

“EzyData provides OEM-based repair data, stepby-step guided diagnostics, ADAS calibration information, and multiple fault code analysis tools,” Tim said.

Instead of relying on Google or YouTube for DIY solutions, mechanics can now access trusted

technical data from HaynesPro within EzyParts, which will reduce time spent searching online and see more time spent on providing a quality service.