Editorial Board

Geoff Mutton

Jeff Smit

Technical Editor

Jeff Smit

Sub-Editor

Cameron McGavin

Scan Data Director

Rod Maher

Technical Research

Brendan Sorensen

Technical Assistance Moderator

Scott Thomas

Technical Contributors

Brendan Sorensen

Mark Rabone

Frank Massey (UK)

Jack Stepanian

Sam Nazarian

Jason Smith

Clinton Brett (Diesel Help)

Technical Assistance Team

Deyan Barrie Andrew Kollosche

Sideth Chiv Maurice Donovan

Gil Sher Anthony Tydd

Wayne Broady Jason Smith

Marty Hosie Jack Stepanian

Mark Rabone Rob Romano

Daniel Armer Jack Mackay

Gary O’Riain

Associate Team Members

Gary Homan Peter Hinds

Columnists

Geoff Mutton (TaT Biz)

Advertising Enquiries

Paul Woods,

National Advertising Manager

E: pwoods@tat.net.au

Ph: 0494 044 958

Graphic Design

Brigid Fraser

E: production@tat.net.au

PH: 0413 009 122

Affiliated Associations

AAAA – info@aaaa.com.au

Capricorn Society Alliance Supplier

VASA – secretary@vasa.org.au

Jeff Smit

Everybody I speak to in the trade is saying the same thing – 2025 certainly seems to be living up to all expectations.

My most recent New Year’s resolution was to try and slow down, find a better work-life balance and enjoy my working time during the year.

I’m not sure how you’re travelling with your New Year’s resolutions but I’m finding myself as busy as ever and the workshop is flat-out. With so much planned for 2025 – whether it’s conferences, training events or international travel for work – it doesn’t look like I’m going to fulfil the promise I made on December 31. Talking to a lot of people within the trade, the same old issues we faced in the past are still presenting a challenge to us all.

The staff-shortage situation doesn’t seem to be getting much better – in saying that, however, my own workshop is fully staffed with an experienced team and, touch wood, I hope it can stay that way for the foreseeable future.

I know I’m in the minority when it comes to staffing levels, so I feel for everyone out there who is desperately looking for good technicians to be able to service and maintain their customer’s cars.

We have been and will continue to attend a lot of training events over the course of the year – whether it’s the Institute of Automotive Mechanical Engineers (IAME) Automatic Transmission Conference, the Australian Automotive Aftermarket Association’s (AAAA) Autocare training convention or the upcoming HSY EVOLVEauto Festival, Repco Authorised Service Conference and Century Batteries Auto-Electrical Conference – which just goes to show how learning is going on out there. Add in all the other networks and groups conducting training and there is clearly a lot

happening in this space within our industry. It’s a far cry from not that many years ago, when quality training really was hard to find.

It’s also great to see so much networking happening in our industry. The camaraderie that comes with networking helps us all, not just technically but on a personal level.

It’s not only important to look after ourselves but each other as the pressures and stresses of our careers and jobs can take their toll. I hope everyone is doing their best to look after each other – as my 2025 proves, finding that perfect work-life balance isn’t easy but it’s so important.

From a TaT point of view, things couldn’t look better. We have seen an increase in technicians signing up as members, which has been personally rewarding. We have also made great improvements to the website, including a new and improved search mechanism so our members can find the valuable information they’re looking for.

A big thanks to Rod Maher, who has been putting in countless hours to make these improvements to the website. The feedback we have received to date has been very positive and drives us to continue to improve the services and information that our members are looking for.

I hope to catch up with as many of you as possible at a training or trade event soon.

Brendan Sorensen

For many of us who’ve been in the game since the days of worm-androller steering boxes, idler arms and leaking banjo bolts, the shift to electric power steering (EPS) has been one of the most significant evolutions in vehicle control systems.

While EPS has brought gains in fuel economy, packaging and the ability to interface with advanced driver-assist system (ADAS) technology, it’s also created a whole new world of failure points – many of them electronic in nature and, more importantly, often invisible to the eye.

Unlike hydraulic systems, which mostly failed through fluid leaks, pump noise or mechanical wear, EPS systems rely on modules, motors and sensors, all fed by high-current power and intertwined with the vehicle’s CAN network.

As a result, repair strategies have shifted. Instead of checking for belt slippage or fluid contamination, we’re now deep in wiring diagrams, scoping CAN lines, load-testing relays and chasing intermittent faults that only show up when the interior heats up on a summer afternoon.

We’ve seen a rise in TaT member Technical Assistance cases and Repair Solutions in recent years related to EPS. Here, we’re taking a look at some of those Repair Solutions, pulling out common themes and pitfalls that other technicians can learn from.

Burnt modules and CAN disruption: 2018 Holden Colorado (Repair Solution HOLRG18450)

This case is a great reminder that module failures don’t always present as steering faults alone. This Colorado came in on a tow truck, showing no crank and no comms to critical modules. The owner had noticed

an EPS warning light shortly before it failed entirely. The real giveaway came after some solid detective work – the ‘common enable’ fuse (F33) blew instantly on key-on.

Inspection revealed the EPS motor had overheated and burnt out, causing a direct short on both the comms line and the enable circuit. Interestingly, disconnecting the EPS motor restored comms to most modules but not the ECM or traction control module (TCM) – further digging revealed those CAN lines passed through the EPS unit itself. Jumping the CAN lines externally finally restored full network functionality. Dirty underbodies contaminating connectors, close-fitting bull bars rubbing on wiring and manufacturers mounting electric racks way too low on vehicles considered to be an ‘off-roader’ were common traits among failures in several vehicles with the EPS module mounted in the rack. This one’s a must-know for rural workshops and 4WD specialists.

When the cluster’s to blame: 2005 Mitsubishi Colt (Repair Solution MITRG05317)

This Colt presented with heavy steering and the EPS code, C1541 – Failsafe relay stuck on. Voltage drop on the power and earth supplies, along with rack resistance, were all within spec. The repairer had access to a donor vehicle and compared EPS module signals between the two – a sound approach when the right hardware is on hand.

The root cause ended up being the instrument cluster, which sits in the CAN loop. Swapping it out not only restored steering assist but resolved an unrelated delayed-start issue. A good reminder that EPS faults can originate from unexpected places in the network.

Relay rework: 2008 Toyota Estima (Repair Solution TOYGS08317)

This Estima arrived on a truck with dead EPS and the code, C1554 – Power steering power supply relay failure. Voltage-drop testing confirmed good power and grounds to the module and tapping on the EPS module under the dash would temporarily bring the system to life – a classic sign of failing relay contacts.

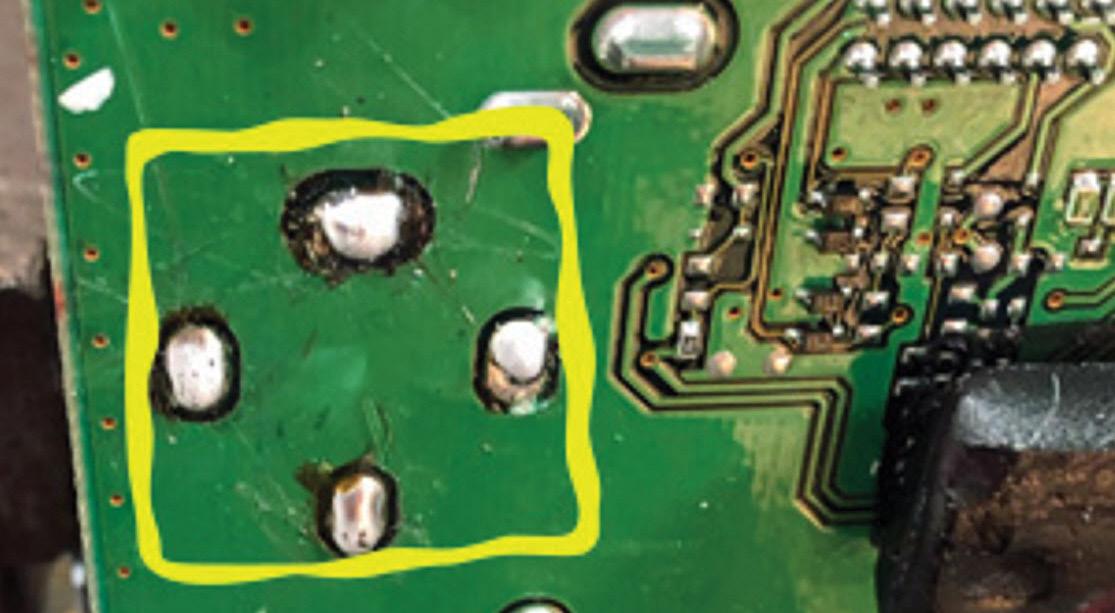

The module was removed and disassembled, revealing a failed internal relay for the EPS pump (pic 1). Rather than replacing the whole unit, the technician installed an external heavy-duty relay, hardwired to the original printed circuit board (PCB) traces (pic 2 and 3). EPS operation was restored and confirmed under all conditions. The repairer also speculated this failure may have caused the previous

battery to discharge, possibly due to the pump being latched on.

We’ve seen similar C1554 faults in other Toyotas too, notably a 2010 Corolla (Repair Solution TOYZR10317). That case even lists direct RS Components part numbers for relay replacement: 815-5091 (40A) and 8113090 (70A – pins trimmed to fit) (pic 4).

Module failures and software sensitivity: 2012 Honda Odyssey (Repair Solution HONOD12317)

This Odyssey had an EPS light on with no steering assistance and no EPS module detected by a Snap-on scan tool. However, switching to an Autel scan tool revealed the code, 32-09 – Motor current correlation Researching Honda service info and Acura Technical Service Bulletin #19-021, the repairer confirmed the code pointed to an internal module failure, with no option for repair.

It’s important to note that while a secondhand module was considered, none with a matching ECU ID were available – matching part numbers and software IDs are critical as the module can physically look the same for many incompatible Honda models. Ultimately, the repairer installed a new module (part number 39980-SLE-J01) and carried out a steering-torque relearn procedure. EPS assist returned to full operation with no further issues.

Feedback faults and intermittent torque: 2011 Mazda 6 (Repair Solution MAZGH11336)

A curious complaint came in on this Mazda 6 – the EPS seemed fine when turning right but was heavy turning left. No fault codes were logged and scan-tool live data looked normal. However, raising the vehicle on a hoist with the ignition on provided a surefire diagnostic clue – the front wheels would steer themselves to full lock without any driver input. A giveaway of an internal torquesensor issue.

Mazda offers a revised input shaft and sensor kit for this exact problem (part number GS8U-32-12Y, pic 5). Fitting the revised part solved the asymmetrical steering

issue. This case is a great example of when mechanical behaviour doesn’t match what the scan tool is telling you and how simple observational tests can still trump data when it comes to EPS faults.

Other notable EPS issues in the database

• 2006 Suzuki Swift (Repair Solution SUZEZ06317)

Code C1142 – Motor circuit failure. Inputs all tested OK but the module refused to output drive voltage. Even substituting the motor with a test bulb didn’t fool it. A matching control unit and rack from a 1.6 M16A resolved the fault.

• 2009 Subaru Outback (Repair Solution SUBBR09317)

Heavy steering and audible chatter at idle, with C0013 logged. Replacement rack resolved issue – note that Hitachi and KYB variants are not interchangeable.

• 2010 Hyundai i30 (Repair Solution HYUFD10321)

By now, almost every workshop has dealt with the worn rubber coupling causing knocking in Hyundai electric columns. But what’s new is the same type of failure showing up in Toyota EPS motors. Toyota offers a steering damper (part number 45254-28040) to repair this – something to keep in mind when that familiar Hyundai steering knock turns up in a RAV4 (pic 6)

So what’s changed in the steering game?

Hydraulic-steering diagnostics focused on pressure, leaks and mechanicals. In contrast, EPS faults increasingly point toward electronic failures – not surprising considering EPS modules are high-current, always-active components. Effective EPS diagnosis now relies heavily on:

• Confirming robust power and ground under load.

• Verifying CAN communication.

• Interpreting module fault codes with context and subcodes.

• Understanding the internal architecture of the modules involved.

And when parts do fail? While new genuine parts are always the preferred option, there’s no denying that repairs can come down to sourcing exact-match replacements or being confident enough to rebuild these high-cost components at a circuit level.

For the tech-savvy diagnostician, EPS provides a rewarding challenge – and a clear opportunity to add value.

Fifteen years ago, the average Australian automotive workshop was a very different place.

Back then, most of the vehicles we worked on were mechanically straightforward and much simpler. Diagnostics could often be performed with a test light, a multimeter and a solid understanding of the fundamentals. Workflows were based around handwritten job cards, service intervals followed a simple time or distance schedule and the relationship between technician and customer was largely built on trust and familiarity (pic 1)

Today, we find ourselves in a different world. Vehicles have become rolling computers, brimming with complex electronics, software-driven systems and increasingly sophisticated drivetrains. Advanced driverassistance systems (ADAS), hybrids and plug-in hybrids are now routine in many independent workshops. Fault-finding requires scan tools, oscilloscopes, access to OEM data and – more often than not – a very different kind of technician mindset.

Given this seismic shift in vehicle technology, it’s only natural to ask: has the way we manage our workshops kept up?

While many workshops have invested heavily in the tools and training needed to service modern vehicles, the front-of-house operations – customer engagement, job flow, time management, communication – haven’t always evolved at the same pace. Yet in today’s competitive market, those areas are just as important to a workshop’s success as what happens under the bonnet.

Modern customers are fundamentally different to those we served a decade or two ago. They’re time poor, tech savvy and used to seamless digital experiences in every other aspect of their lives. If they can track a parcel in real time or schedule a GP appointment from their smartphone, they expect no less from their aftermarket workshop.

This has led to an increased demand for services that go beyond just fixing the vehicle. Customers now expect flexible drop-off and pick-up times, courtesy cars, contactless payment options and real-time updates on the status of their service. They

want transparency, convenience and, above all, clear communication.

Some workshops have responded by extending their trading hours. Others offer online booking platforms or digital vehicle inspections complete with photos and videos. These changes may seem small but they go a long way in building trust and keeping customers coming back.

Behind the scenes, workshop-management software has undergone a quiet revolution. The days of whiteboards, duplicate job cards and guesswork are quickly disappearing. In their place, we’re seeing the widespread adoption of cloud-based management systems that integrate all aspects of the business, from customer communication to parts ordering, technician time tracking, invoicing and reporting. Getting approval for any repair or servicing additions is made a lot easier via a platform like Vehicle Visuals, which is a visual educational tool for workshops to use to educate and explain what and why repairs are required (pic 2). These systems don’t just help manage the day-to-day, they also offer insights into the overall health of the business. Labourrecovery rates, technician efficiency, job profitability and customer retention can now be tracked in real time. This visibility allows owners and managers to make informed decisions, identify bottlenecks and streamline operations.

Digital job cards, for example, allow technicians to update progress from a tablet on the workshop floor. Parts can be ordered with a few clicks and customers can approve repairs via text or email. These efficiencies reduce downtime, eliminate paperwork and speed up turnaround, benefiting both the workshop and the customer.

Efficiency is no longer optional

Running a productive and profitable workshop has always been the goal but in today’s environment it’s absolutely critical. Rising costs, skilled-labour shortages and growing competition mean every hour counts.

Technician efficiency is no longer something that can be guessed or assumed – it must be measured. Modern workshopmanagement systems allow workshops to track how long technicians spend on each job, how those times compare to labour estimates and how much unbilled time is being lost each week. Over time, this data becomes invaluable.

Not only does it help with job allocation and training decisions, it provides a basis for reviewing labour rates and refining service offerings. Knowing where the workshop is gaining – or losing – time and money enables owners to make strategic improvements.

Artificial intelligence (AI) is not science fiction anymore. While we may not yet have

robots fixing cars, AI is already being used in ways that directly impact how we manage and run our workshops.

In diagnostics, for instance, some scan tools and platforms are now powered by AI, offering guided repair suggestions based on aggregated data from global networks. This can significantly cut down the time spent chasing intermittent faults or obscure error codes.

AI also plays a role in scheduling, helping optimise workshop calendars based on past job durations, technician skill sets and parts-

delivery times. It can even assist in parts procurement – suggesting suppliers based on price and availability – and customer engagement with automated service reminders, chatbot-style enquiry handling and follow-up communications.

In the near future, connected vehicle platforms could allow workshops to remotely monitor vehicle health and predict service needs before a fault occurs. This kind of predictive maintenance could reshape how workshops engage with customers, moving from reactive repairs to proactive servicing.

It’s clear the vehicles we work on have changed. But the workshops that will thrive in the next 10 to 15 years will be those that also evolve how they operate.

This means embracing technology, not just in the workshop but at the front counter, in the office and in customer communication. It means treating workshop-management software as an essential tool, not a luxury. And it means investing in systems and training that allow the business to operate efficiently and transparently.

That said, not everything should change. Personal service, trust and professionalism remain as vital as ever. Technology should enhance the customer experience, not replace the human touch. The best workshops will continue to combine technical excellence with warm, reliable service.

As the automotive industry continues to accelerate into a connected, electrified and data-driven future, the way we run our workshops must keep pace. Change can be challenging but with the right tools, mindset, and leadership, it also presents some of the most exciting opportunities the aftermarket has seen in decades.

Clinton Brett

Now

we have injectors out of the way, it’s time to share my insights into the suction control valve (SCV).

Well, that and the many abbreviations this type of valve can be labelled as – inlet metering valve (IMV), fuel metering valve (FMV), fuel volume-control (FVC) valve and fuel control valve (FCV), all of which are a direct influence on the fuel flow in the common-rail diesel (CRD) system.

I like to refer to these components as fuel volume-control valves (pic 1). This way you should have a better understanding of why and what you are testing.

These types of valves do not create, nor do they regulate, the fuel-rail pressure. Their role is to influence the fuel pressure by altering the amount of fuel flow required for the pump to create the pressure, which is delivered to the injectors via the rail, and ensuring the same amount of fuel flow and pressure is delivered to each injector. As well as the outlet fittings, every rail also has the fuel-rail pressure sensor mounted and, in some cases, fitted with a pressure regulator.

I’ll go into more depth about fuel-rail pressure regulators in the next part of this series. For now, back to valves.

The fuel control valves we’re discussing are located on the high-pressure pumps. They are electronically controlled using pulse width modulation (PWM), otherwise known as duty cycle.

There are two operating methods of fuel volume-control valves – normally open and normally closed. Normally open means it can be in the open position, allowing fuel to enter the fuel pump, without any electronic current supplied to the control valve (pic 2).

A normally closed type means the valve requires electronic current to move, allowing the ports to be exposed so fuel can pass through (pic 3).

This valve’s function is to control the volume of fuel from the fuel tank to the fuel pump. This pump, which is often referred to as the high-pressure pump, is not to be confused with the fuel pump in the vehicle’s fuel tank. It is a component that creates a much higher pressure fuel delivery from the lower pressure feed into the rail, which is then distributed to all the injectors evenly at the same time.

This high-pressure pump is located on the engine and driven by gears, belts, chains or a flywheel.

This design and name control valve is the most recognisable terminology in all sectors of the automotive industry (pic 4). SCVs, as they are commonly referred to, are fitted to the Denso CRD fuel systems found on Toyota’s HiLux, Mitsubishi’s Triton, Nissan’s Navara and Holden’s Colorado.

When dual-cab utes started to become the market’s highest selling diesels around 2005, the light-vehicle automotive repair industry’s desire to start taking on diesel work also jumped.

Unfortunately, this is also where I have witnessed the most common misdiagnosis of the CRD system. Simply because

most mechanics think this is an on/off fuel solenoid – and don’t have the correct diagnostic pathway – they just end up throwing one on without any prior testing of fuel supply.

One of the many reasons I started Diesel Help was to educate those who didn’t sign up for diesels at the beginning of their apprenticeships.

A popular fault code has been, P0089 –SCV stuck. Many scan-tool manufacturers adapt this terminology to most of the fuel-system errors category but also use the abbreviation SCV when reporting fault codes and specified fuel-valve data.

By the way, P0089 is often to do with an alteration or replacement of an individual component of the CRD fuel system. In many cases, the cause has been a simple fuel-filter replacement. A process most overlook when replacing a fuel filter is performing a relearn, which can reduce further complications. Other SCV-related faults have been caused by replacement with the incorrect part number. We have seen this a lot on the Nissan Navara YD25. There are three different designs of SCV fitted to this Navara and, as it is now a 20-year-old vehicle, most are onto a second or third engine, meaning technicians have no assurance the vehicle they’re working on has the original engine, let alone ECU.

The best way to determine everything matches up is to order directly from the

dealership and confirm the vehicle ID number (VIN) matches the pump and SCV part numbers.

There is a big but, though – if contemplating replacing only an SCV in a vehicle that has reached more than 200,000km, I strongly advise replacing the entire CRD system. When one weak link is replaced, the next becomes more vulnerable.

When the SCV is the actual failure, often it is worn out or contaminated, either by water, petrol, dirt or even filter paper. Due to its direct exposure to the fuel supply immediately after the fuel filter, the SCV commonly clogs up with micro-size filter fibres when the filter breaks down – an issue experienced by both OEM and some aftermarket fuel filters.

These fibres can become stuck between the hydraulic piston valve and the walls and are often a result of overdue fuel filter replacement, fuel additives or poorly engineered and designed filtration. From my experience, probably the best developed and evolving aftermarket fuel filter I have seen and worked closely with is Ryco (pic 5 and 6).

Over the past eight years I have developed a strong relationship with this household name and leading filtration manufacturer. We find it invaluable to approach all contributors to any current issue experienced in the industry. Remember, an issue won’t be resolved if no one is informing them of any issues. Ryco has been very upfront and transparent with projects we’ve worked on, working in the background to deliver a successful outcome and better future for aftermarket filter replacement.

This is where long-term experience in a chosen field is priceless. When a fault code appears on the scan tool displaying IMV, technicians have all too often searched for a fault within the air-intake system.

The word ‘inlet’ refers to the fuel inlet of the high-pressure fuel pump. This Delphi design (pic 7 and 8) has been around in production since the early 2000s. Though the fuel pump’s design has changed slightly and now uses a different pumping action, the IMV has remained very much the same. The IMV is a normally open proportional solenoid valve. One side of the coil has a permanent 12V feed. The other side is connected to ground by the ECU with varying frequency and pulse width. This controls the piston position against the return spring, which in turn controls the fuel flow through the filter screen and out of the valve end face. So when a

normally open type is unplugged, the fuel continues to flow.

The coil resistance is typically 5.3 ohms (Ω) at 20ºC when checked with a multimeter. In part six of this series, we will continue exploring the control valves fitted to pumps and rails.

The following engine performance conditions could indicate a failed IMV.

Symptoms observed

Does not start

Engine stops

Noise, smells, leaks

Fault type

Does not fill

Possible causes

IMV seized after immobilised

Pumping shut off IMV broken/blocked

Sealing failure

Leaking between body and IMV

The check-engine light (CEL) in this 2012 Isuzu D-Max was on and the engine would not rev higher than 2000RPM (i.e. limp mode).

Confirmed the CEL in the workshop and a road test confirmed the power issue.

A full system scan with my Snap-on Zeus uncovered the following fault code:

• P0045 – Turbocharger nozzle control solenoid circuit fault.

No freeze-frame data was available. Recorded and cleared the code, then road-tested the vehicle again and the issue returned after about 1km of normal driving. The engine lost

power when the CEL returned. Back in the workshop, tested the solenoid (two-pin) with 12V and earth directly and it was operating OK.

Next, referred to the wiring diagram to test the wiring. The ECU controlled the earth by pulse width modulation (PWM) to the solenoid. The other pin was 12V constant.

Key-on/engine-off (KOEO) and the wiring tested fine. The control signal was good from the ECU by scope and the

power supply was constant. Performed a wiggle test – no change.

Testing the wiring key-on/ engine-running (KOER) showed the 12V supply dropping intermittently.

Followed the harness from the fuse box in the engine bay to the engine and found a rubthrough point from contact with the rear of the starter-motor housing. The wire that supplied 12V to the solenoid was compromised.

Removed the starter motor to allow more access and stripped the wiring harness of protective tape and conduit to repair.

Repaired the compromised wire and reinsulated the harness. Reassembled, cleared any codes and tested operation – it was all OK.

Diagnostic time for this job was three hours and repair time three hours.

Jake Rhoades

Rohan Fox Automotives

MUNDARING, WA

Autocare 2025, Australia’s premier automotive-training convention, will deliver an exclusive opportunity for technicians to take their diagnostic and advanced vehicle-system skills to the next level.

Held on June 20-21, 2025 at the Brisbane Convention & Exhibition Centre (BCEC), the most valuable training event on the automotive calendar will provide hands-on learning from top international and Australian trainers, equipping technicians with the confidence and expertise needed to tackle modern vehicle complexities while boosting workshop efficiency and profitability. The highly anticipated Technical Training Program will feature cutting-edge topics, with a strong emphasis on J2534 programming for many of the most popular brands of vehicles.

These sessions are designed to demystify advanced vehicle programming, helping technicians develop a structured approach to resolving programming challenges while taking full advantage of Australia’s Motor Vehicle Information Scheme (MVIS) right-torepair law and access to full manufacturer repair and service information.

Mastering advanced diagnosis skills means technicians and workshops no longer need to outsource complex programming tasks – saving time, reducing costs and keeping control over their workflow and customer service.

Leading international trainers, including Brandon Steckler, Keith Perkins and Tomi Oliva from the US, will join Australian experts such as TaT’s very own Jeff Smit and Brendan Sorensen, Darren Todd (Bosch) and Clint Flower and Sumin Kim (CoolDrive Auto Parts). Their collective expertise will offer deep insights into diagnostic workflows and the latest technology trends to help technicians stay ahead of the curve.

Beyond programming, the training program will cover other highly sought-after topics: scan-tool data interpretation for pinpoint accuracy in diagnostics, developments in EV and hybrid-vehicle systems, battery

and charging-system advancements, network-failure diagnosis and effective troubleshooting techniques, Picoscope essentials for in-depth waveform analysis, diesel and emissions-control system diagnostics, precision a/c diagnosis and more.

‘Autocare 2025 is all about empowering technicians to master modern diagnostics and be at the forefront of industry advancements,’ said Australian Automotive Aftermarket Association (AAAA) CEO Stuart Charity. ‘By gaining expertise in advanced diagnosis and programming, technicians can reduce reliance on external specialists, improve service turnaround times, increase workshop revenue and take control of their career trajectory.’

• Secure your place at autocare.org.au

The Autel MaxiSys Ultra S2 represents a significant leap forward in automotive diagnostics, with new additions marking what genuinely feels like the dawn of a new era of scan tools.

As a long-time user of the original MaxiSys Ultra, I was particularly excited to see what advancements the Ultra S2 brought to the workshop.

Speed and performance

Speed always matters when your income depends on tool efficiency. With its classleading upgraded Qualcomm octa-core 2.7GHz processor and substantial 12GB of RAM, the Ultra S2 boots quickly, taking around 18 seconds from startup to readiness and navigates faster than my new Android smartphone. This means less time sitting between loading menus and more time getting the job done.

Fault scanning and network topology

Full vehicle fault scanning and easy access to associated freeze-frame data is intuitive. Information can be conveniently saved as PDF reports or screenshots and I frequently used the ability to attach photos – such as dash warning lights or test findings – to reports, which can then be uploaded to cloud storage or emailed. Autel’s Network Topology Mapping visually maps vehicle control modules, clearly illustrating their interconnections and communication status. Faults are easily identifiable by colour coding – red for active faults, green for nofault modules and grey for non-responsive modules. Taking network communication analysis further, a new addition allows technicians to manually and continuously ping each module, particularly valuable for diagnosing intermittent communication faults. Technicians can wiggle wiring or connectors while pinging to quickly identify when a module or network leg returns online.

Live-data analysis

Equally impressive is the Ultra S2’s approach to traditional live-data analysis. The tool offers multiple data-viewing formats – text, bar graphs, gauges and waveform graphs – each suitable for different diagnostic contexts. A valuable addition is a one-press option to quickly change all data parameter IDs (PIDs) to your desired view (i.e. graphs) or switch

between views for each PID individually. Graphing overlays work exceptionally well, even allowing you to select PIDs into multiple graphing overlays (pic 1). This is no trouble space-wise on the slightly increased 13.7inch touchscreen, which has had its anti-glare properties improved to make it very usable even in direct sunlight. The ability to merge and group data streams is a masterclass, enabling you to create and save custom PID groups for the vehicle (e.g. throttlerelated parameters), significantly enhancing productivity when you need to leave live data to view something else on the tool and then return, or when verifying the fault is repaired by bringing up the same saved data group. Also of note is the ability, on suitable vehicles, to view data from multiple modules simultaneously – a major advantage if you’ve ever experienced the frustration of needing to monitor two PIDs that live in separate modules during a test drive.

Complementing traditional live data, graphical diagnostics (pic 2) quickly became a favourite feature. Modern vehicles produce vast amounts of data and interpreting this effectively can be overwhelming. The Ultra S2 addresses this brilliantly through intake and exhaust-system graphical diagnostics. On supported vehicles, relevant live-data PID readings display next to graphical layouts of actual vehicle systems, enabling technicians to observe component interactions clearly. This OE-inspired approach, similar to how newer manufacturers such as Tesla display live data, significantly improves diagnostic accuracy and efficiency.

The new VCMI2 (for ‘Vehicle Communication and Measurement Interface’) serves as a comprehensive hub, integrating diagnostic communication over the very latest of

protocols such as diagnostics over internet protocol (DoIP) and CAN FD, oscilloscope functions, a multimeter, waveform generator and remote expert connectivity into one versatile device. The oscilloscope functionality is genuinely top-tier, featuring advanced performance and usability enhancements that rival standalone professional oscilloscopes. It holds a scope rookie’s hand with built-in user guides for testing a huge array of components and systems but also lets power users stretch their legs with reference waveforms, math channels, measurements and a waveform library. It’s particularly handy being able to split the large screen to view live data at the same time a component testing with the scope (pic 3). The VCMI2 is J2534 compatible, facilitating module programming via Autel’s built-in cloudbased service or through direct connections with OEM software.

A standout capability is the Ultra S2’s integration with Autel’s Remote Expert platform. This feature enables technicians to connect remotely with specialists, facilitating expert-level diagnostics, programming and guidance for complex tasks without needing external specialists physically present. This significantly broadens workshop capabilities, allowing challenging jobs to be handled confidently in-house.

AI technician assistant – ‘MAX’

As artificial intelligence (AI) starts to touch every area of our lives, Autel leads the charge in ushering in a new era in diagnostic tool usability with its integrated AI technician assistant, ‘MAX’. This innovative assistant provides voice-controlled navigation of tool and diagnostic functions, enabling technicians to initiate scans, access menus and execute tasks hands-free. Initially a novelty, MAX soon became part of my workflow. Commands such as, ’Hey Max,

open service reset’ while I filled out the logbook saved multiple steps and time spent navigating menus. A Ford Everest arrived with an AdBlue fault regarding the reductant level – instead of thinking what module to look in and what the PID would be called, ’Hey Max, show reductant level’ presented me a choice of PIDs relating to reductant/AdBlue level (pic 4). Max understood commands in a noisy workshop environment and I managed to find a few shortcuts such as, ‘Hey Max, open adaptations’ – since I hadn’t given a specific adaption, he presented me a list of all available adaptations, helping me to know if there was something I should be doing to finish the job after bolting the new part on.

Autel’s DVI system further solidifies the Ultra S2 as a diagnostic hub rather than just a scan tool. Using its high-quality 16-megapixel camera, technicians can quickly document a vehicle’s condition upon arrival. The impressive AI scan automatically circles exterior damage such as dents and scratches in captured photos, complemented by easy-to-use manual annotation tools. You could choose to export this alone as a PDF report as many workshops are now routinely recording vehicle damage before work starts or continue on with the full green, yellow, red-style digital vehicle inspection provided to give a full vehicle inspection report.

Data handling is another strong point. Diagnostic results, freeze frames, live data recordings, oscilloscope captures and vehicle histories can be easily stored, managed directly on the tool and shared via email or SMS.

Although the tool’s extensive capabilities prevented me from exploring every feature thoroughly – honestly, each menu could easily justify its own review – the potential for deeper workshop integration is clear, whether standalone or combined with other Autel products such as advanced driver-assist system (ADAS) equipment or battery testers,

etc. The comprehensive digital manual clearly highlights its adaptability in advanced automotive scenarios and provides clear instructions on efficiently utilising the tool. I’m often asked which scan tool I recommend at trade shows and training sessions. Previously, this involved numerous follow-up questions about specific workshop needs. I can honestly say Autel has increasingly become the go-to tool, offering something for everyone. The Autel MaxiSys Ultra S2 elevates this further, delivering advanced diagnostic capabilities, extensive functionality and practical AI-driven features, placing it firmly ahead of many contemporary options. It not only met but exceeded my expectations, making it an exceptional investment for workshops seeking to future-proof their diagnostic capabilities.

• Scan the QR code to watch my detailed video review.

Customer complaint

The battery warning light was on and the alternator wasn’t charging.

Problem summary

Checked the vehicle and found the alternator was not charging.

The battery’s open-circuit voltage was 12.2V. Its charging voltage at idle was 12V and slowly dropping.

Diagnostic sequence

Scanned the vehicle for DTCs – none were present.

Checked the voltage read by the powertrain control module (PCM) – it was 11.8V (correct).

Checked the commanded alternator output – it was 100 per cent.

Checked voltage drop from the battery’s B+ post to alternator B+ – it was zero volts (OK).

Checked voltage drop from the battery’s Bpost to the alternator case – it was 0.01V (OK).

The alternator on this vehicle has two terminals:

1. Battery sense (BS).

2. Alternator field control (FC).

Checked the voltage at the BS terminal – it was 9.7V connected and 11.8V disconnected (harness side).

Checked the voltage at the FC terminal (pic 1) – it was -1V>1V analogue wave connected and 0.5V>0.6V erratic square wave disconnected (at 50 per cent duty cycle commanded by the scan tool, harness side).

Located the wiring for the alternator at the PCM, then load-tested the wires from the

PCM to the alternator – it was OK, with no voltage drop.

Applied power to the FC terminal (harness disconnected, applied to alternator) to force the alternator to full-charge mode – the charge voltage jumped to around 14V and the charge current jumped to around 100A. This indicated the alternator was capable of charging, even if it wasn’t up to its specification (please note the alternator was only at idle speed – higher RPM would most likely allow it to produce higher output).

Connected the test light to the FC terminal (harness side) and commanded 50 per cent duty cycle for the alternator – the test light did not light up at all.

Found information on the charging system (for the Dodge Caliber of the same year), which stated the PCM monitors the voltage at the alternator (BS terminal) and battery voltage internal to the TIPM (fuse box) and decides an output based on both.

Both the BS and TIPM indicated a low voltage. The PCM should have been outputting a high duty cycle to command the alternator field (FC terminal). I’d expected the waveform on the FC terminal to be a 0V>12V duty cycle, which was not what it was showing. The data showed the PCM was attempting to command 100 per cent output from the alternator.

Bench-tested the old alternator (pic 2) – it was capable of producing 18V and 50A. The measured waveform also indicated a short circuit in one or more diodes.

Disassembled the original alternator and found two shorted (exploded, now open) diodes (pic 3).

I suspect the original alternator had failed, causing incorrect voltage/current to the

PCM and the PCM to fail – either by spiking the PCM or shorting the FC terminal internal circuit.

I believe the PCM was not capable of commanding the FC terminal correctly, meaning the alternator circuit could not charge.

I recommended the workshop send the ECM away for repair.

The workshop stated the repairer had found faults within the PCM related to the concern. Pic 4 shows load test of a new alternator on car with 12V to the FC terminal applied.

Diagnostic time was two hours, taking into account preparation and research. Repair time not supplied.

Special thanks to Deyan Barrie and Jeff Smit for their help with information on this system. TaT thanks Gary O’Riain (GO Diagnostics, Gulgong, NSW) for providing this case study via TaT Share, adapted for this Repair Solution.

The car would lose power and sometimes stall when accelerating above 2400RPM. The engine would sometimes also knock and rattle.

When the vehicle stalled, it could be restarted with no issues until you revved it up to 2400RPM again.

Carried out a test drive and confirmed the concern.

Found the car did begin to lose power when accelerating above 2400RPM. If you attempted to accelerate through the fault, the engine would stall completely nine times out of 10.

When this happened, you could – without cycling the ignition – turn the key straight to start and the engine would fire without any prolonged cranking or issues.

If you lifted your foot off the accelerator and allowed the engine to return to idle (i.e. around four to six seconds of foot-off), you could then accelerate normally – up to 2400RPM, when it would happen again. If you lifted your foot off for a short period and then re-accelerated, the engine would begin to knock/rattle and have no power. The car was not blowing smoke.

Checked for DTCs and none were present. The Bosch suction control valve (SCV) and fuel filter had previously been replaced, so checked a fuel sample – it was OK.

Connected a clear hose from the fuel filter to the inlet of the high-pressure (HP) pump – there were no signs of bubbles or any air ingress.

No in-tank pump or hand primer was fitted to the car (a hand primer comes in a separate kit), so checked the crankshaft position and camshaft position sensors when the vehicle faulted – both sensors were working normally.

Checked the fuel-rail pressure (FRP), SCV and fuel-pressure regulator (FPR) voltages when the vehicle faulted – they were OK. There was no sudden drop or change in the FRP reading or SCV control when the vehicle faulted and the FPR worked normally, only releasing fuel when the key

was turned off or following a throttle stab. Checked the resistance and capacitance of each injector:

1. 184 kiloohm (kΩ)/3.75 microfared (uF)/230kΩ@100V/190kΩ@250V between terminals/open line (OL) to ground from each terminal.

2. 184kΩ/3.71uF/220kΩ@100V/180kΩ@ 250V between terminals/OL to ground from each terminal.

3. 178kΩ/3.71uF/ 230kΩ@100V/210kΩ@ 250V between terminals/OL to ground from each terminal.

4. 179kΩ/3.79uF/220kΩ@100V/170kΩ@ 250V between terminals/OL to ground from each terminal.

5. 178kΩ/3.68uF/230kΩ@100V/190kΩ@ 250V between terminals/OL to ground from each terminal.

6. 178kΩ/3.80uF/170kΩ@100V/120kΩ@ 250V between terminals/OL to ground from each terminal.

This injector initially tested ‘low’ @ 250V, then the second test showed 100kΩ. The third test showed 120kΩ. I was not able to repeat this low reading with more tests (between terminals).

A faulty injector made sense given the lack of smoke – an injector bringing down the high-voltage charging circuit for the remaining injectors – but did not explain the knocking/rattling.

Monitored the mass air flow (MAF) and manifold absolute pressure (MAP) readings when the vehicle faulted – they were OK. Similar to the FRP, however, they would slowly decrease after faulting (pic 1).

Connected a T-piece into the boost system – when faulting, the boost pressure would reach around 14psi. This was less than specified but could have been due to incorrect fuel mixture/timing/control or an air-inlet issue.

Carried out numerous full-system scans to check all modules for DTCs.

Found multiple fault codes but none that could cause this fault and none that were repeatable every time the car faulted:

1. P0725 – Engine rotation – current (TCM).

2. P0732 – 2nd gear incorrect ratio –history (TCM).

3. P1705 – TP sensor – history (TCM)

Only present once, not on initial inspection, and was not reproduced after multiple test drives with the car faulting.

4. C1109 – Battery voltage out of range –history (ABS)

Only present once, not on initial inspection, and was not reproduced after multiple test drives with the car faulting.

5. P1525 – Auto speed control/cruise disabled – history (ECM).

Connected an external fuel source (specifically a Diesel Help Eliminator) directly to the HP pump to eliminate potential fuelinlet issues or contaminated fuel – there was no change to the fault.

Monitored the exhaust-gas recirculation (EGR) position and found it did not change much during normal driving (3.41V to 3.84V). The EGR valve did a full cycle/sweep with the key off (i.e. to clean the valve), showing it was capable of moving.

Found the MAF reading at idle was around 16 grams per second (g/s), indicating the EGR valve was closed.

Fitted a blanking plate to the EGR valve to completely eliminate a possible EGR issue –there was no change to the fault.

This did not set any EGR ‘low-flow’ DTCs either, leading me to suspect the EGR had been tuned out at some point, but it was not the issue.

Checked the entire fuel system and found the return lines on the left side of the engine had been altered (i.e. fitted with aftermarket hose clamps) and a return valve had been damaged/not fitted correctly.

Checked the operation of this return valve – it was faulty. The valve was not capable of retaining vacuum/pressure in either direction. (Continued bottom p 21)

Customer complaint

The vehicle’s check engine light (CEL) was on.

Problem summary

The vehicle also had a vacuum-related noise.

Diagnostic sequence

The vehicle was received from another workshop, where it had recently received a rocker-cover gasket replacement to repair oil leaks.

The problem had apparently started after the rocker cover was removed.

In addition to the CEL, the vehicle was idling high and had a distinct high-pitched vacuum noise.

A scan of the vehicle returned the code, P0171 – System too lean (bank 1). Smoke-tested the inlet manifold and there were no leaks.

Removed the belt to make sure the noise remained.

Rechecked the codes and P0171 was still present.

Checked the fuel trims – both long and short-term were at 35 per cent positive.

Checked the positive crankcase ventilation (PCV) valve and breather one-way valve.

Removed the rocker cover to inspect the port running through the cylinder head to the inlet manifold (pic 1).

Suspected an inlet-manifold issue, so removed and checked. There were no visible internal cracks and the passages feeding the PCV circuit appeared intact. Found a lot of information about the earlier model version of this engine and turbo version relating to PCV valve/valve-cover issues.

Checked the vacuum pump – it was OK. Refitted the valve cover and used a snip of a Coca-Cola aluminium can to block off the vacuum supply from the inlet manifold – the noise went away and fuel trims improved. Checked various sources and went online to Partsouq (pic 2), where I found a diagram showing a PCV valve restrictor that appears to only be supplied as part of the cover.

There were also some pictures of used covers online and I could see the port in the valve cover did, in fact, have a restrictor. With the cover off again, went fishing and was able to find a brass restrictor lying under the camshafts, resting near a valve spring.

Fault description

The vacuum restrictor had detached and was missing from the rocker-cover PCV assembly (pic 3).

Fault solution

Replaced the brass vacuum restrictor (pic 4).

Recommended time

Diagnostic time was three hours, taking into account preparation and research. Repair time was three hours, taking into account the location of parts and carrying out the repair to a tested outcome.

Tips for TaT

The rocker-cover gasket for this engine is not easily available.

Repair solution by TaT Tech Team member Wayne Broady.

The return system for these piezo injectors requires a pressure of 10 bar (140psi) to be maintained to keep the hydraulic servo body within the injector correctly filled. The fitted valve was not capable of doing this.

Ordered a replacement fuel injector returnline/pressure-valve assembly (pic 2 and 3).

Fault solution

Replaced the return-line/pressure-valve assembly (from the injectors to the output of the valve, pic 4).

Carried out a test drive and the vehicle was

OK. There was no stalling, no loss of power and no DTCs – everything was working correctly.

Recommended time

Diagnostic time was eight hours, taking into account preparation and research. Repair time was three hours, taking into account the location of parts and carrying out the repair to a tested outcome.

Repair Solution by TaT Tech Team member Gary O’Riain.

Customer complaint

The customer was unable to start or charge the car.

Problem summary

Confirmed the vehicle was unable to go into ‘Ready’ mode.

Diagnostic sequence

Retrieved the following fault codes:

• P3176 00C0 – EV/HEV inverter condenser.

• P311C – EV/HEV high voltage sys.

Obtained a factory data subscription for the vehicle, allowing me to find the code-setting parameters and troubleshooting tree for fault codes.

The service information read: If DTC P3176 is displayed with DTC P311C, perform diagnosis for DTC P311C.

So we followed the P311C service information, which gave the following three DTC detection conditions:

• Li-ion battery current: 5.5A or more; Input voltage to traction motor inverter: 24V or less.

• Li-ion battery current: less than 5.5A; Input voltage to traction motor inverter: 24V or less.

• Difference between li-ion battery voltage and input voltage to traction motor inverter: 100V or more

Live data showed high voltage (HV) at the battery and the HV negative contactor circuit and the positive pre-charge circuits commanded on when attempting to enter Ready mode, while there was no HV voltage present on live data at the inverter.

As expected, it then never attempted to activate the main positive contactor. Pic 1 shows what should be the correct turn-on sequence.

This suggested a problem with the HV contactors. Approval was gained to remove the battery pack to allow access for testing. The vehicle was depowered, the battery pack was removed and the battery pack opened using a putty knife to cut the waterproof seal of the case (pic 2).

Using a wiring diagram and 12V, we manually energised each contactor to test the resistance through the contactors while they were ‘on’ (pic 3).

We found the pre-charge resistor was always reading open circuit.

While not a separate part to purchase from Nissan, research of the markings on the precharge resistor (pic 4) showed it was a 40W, 30-ohm horizontal cement resistor.

The ‘J’ after the 30 ohm indicated a plus or minus five per cent tolerance on the ohm rating. We were able to match up a suitable replacement with the same specifications from an online electronics retailer for $20.

As expected, the new pre-charge resistor measured 30 ohms rather than open circuit. We now had continuity through the precharge contactor circuit.

The battery pack was reassembled and resealed using generic silicone caulk obtained from Bunnings, refitted to the vehicle and the service grip reinstalled. The vehicle could now enter Ready mode and accept a charge.

The pre-charge resistor in the contactor junction box was open circuit, not allowing start-up contactor sequence to finish.

Sourced and fitted a suitable replacement pre-charge resistor.

Diagnostic time was one hour, taking into account preparation and research. Repair time was nine hours, taking into account the location of parts and carrying out the repair to a tested outcome.

Repair Solution by TaT Tech Team member Jeff Smit.

Injectronics has more than 40 years of experience in the automotive aftermarket and over those four decades has built a solid reputation for innovation, quality, sustainability and taking advanced vehicle-system skills to the next level.

Among its specialised services is the repair and remanufacture of anti-lock braking system (ABS) hydraulic pump blocks (HPBs) and electronic ABS control modules. These components are critical to a vehicle’s safety systems. The ABS HPB plays a vital role in regulating brake pressure, preventing wheel lock-up during braking. Working in tandem with the electronic ABS control module, the HPB ensures balanced brake pressure across all four wheels, which helps maintain steering control and shortens braking distance.

Faults are commonly seen in the ABS HPB in vehicles such as the Mitsubishi Lancer, Holden Captiva, Suzuki Swift, Mazda 3 and more. Injectronics’ experience shows these vehicles are prone to issues including but not limited to:

• C1073 – Pump motor control circuit fault.

• C121D – Pressure sensor circuit fault.

• C2116 – Pump motor voltage low.

• Inability to bleed brakes.

• No fluid delivery from one or more block outlets.

Meanwhile, electronic ABS control-module faults often present with error codes including C0550, C01130 and C01632 or codes linked to wheel-speed sensors. These issues typically trigger dashboard warning lights or lead to compromised braking. It’s important to note these faults are separate from the ABS HPB and relate specifically to the control module.

Injectronics provides repair or replacement options for both units individually, saving customers from unnecessary replacements and reducing costs.

Ordering an exchange ABS HPB from

Injectronics can be a smart, reliable solution. Each unit is skilfully remanufactured with CNC precision, electro-hydraulically tested and shipped in a protective cover to ensure safe delivery and ease of installation.

Injectronics also offers fast, accurate repairs of the electronic ABS control module. A 48hour turnaround keeps vehicles off the road for less time, while in-stock exchange-item HPBs are dispatched the same day, getting customers moving even faster.

• For more information go to injectronics.com.au

With many consumers struggling with increasing day-to-day expenses, the unexpected cost of a major repair like a turbo replacement can wreak havoc on the family or business finances.

Garrett’s ‘Original Reman’ program is a budget alternative, offering competitively priced, remanufactured OE spec turbos for older vehicles.

What are Original Reman turbochargers?

Original Reman turbochargers are assembled by Garrett using a combination of new and refurbished components. Every Original Reman turbocharger undergoes a comprehensive process of disassembly, inspection, repair and reassembly to restore it to the exact original specification of the vehicle manufacturer. All Original Reman turbochargers are covered by the same manufacturer’s warranty as their genuine OE counterparts.

How are Original Reman turbochargers made?

Original OE units are carefully inspected and every component assessed for wear and damage. With the help of a grading system, Garrett technicians decide which turbo parts should be replaced, cleaned, repaired or reconditioned to restore each unit to optimal performance.

Having access to Garrett’s extensive engineering databases allows the technicians to quickly determine the correct specification for each unit. The reassembly phase is equally rigorous, with Garrett technicians fitting each component utilising their expertise to set the turbocharger’s intricate balance and tolerances.

Once reassembled, each Original Reman unit undergoes rigorous testing, with various operating conditions simulated to guarantee its reliability, efficiency and emissions performance. All units are then calibrated using the same processes applied on Garrett’s OEM production lines.

What vehicles are covered by the Original Reman range?

Garrett’s Original Reman program covers popular petrol and diesel-powered vehicles seven years or older. There are vehicles added to the program every day, so if your customer’s application is not currently covered, there is a good chance it will be added in the future.

A 2011 Hyundai Santa Fe with 215,774km on the clock came in with the battery light illuminated while the engine was running.

Checking the charging system showed a steady 14V and the light would dim but not fully turn off when monitoring from ignition to engine running.

A scan of the vehicle showed no fault codes. Testing the alternator by disconnecting its plug and grounding the light terminal caused the battery light to illuminate, while applying power turned it off.

However, with the alternator disconnected, the battery light remained dimly lit when it should have been completely off.

Suspecting an issue with the alternator’s light-power output, I replaced it – but the fault remained.

Studying the wiring schematic revealed the battery-light circuit passed through the interior fuse panel before connecting to the

Why opt for a Garrett Original Reman turbo?

Original Reman turbos offer OE fit, performance and emissions compliance, providing a cost-effective, aftermarket alternative for private or business owners who may be looking to save on replacement costs without compromising on quality. Original Reman turbos are covered by the same manufacturer’s comprehensive warranty as their genuine OE equivalents. Choosing a remanufactured turbocharger supports sustainable practices by extending the lifespan of existing components. This reduces the demand for new raw materials and promotes an environmentally conscious business philosophy

• GCG Turbos has been Garrett’s Master Distributor for OEM and aftermarket products for more than 45 years and carries a comprehensive range of Garrett OEM and Original Reman turbochargers. For more information call 1300 TURBOS, email sales@gcg.com.au or go to gcg.com.au

gauge cluster and body control module (BCM).

The BCM wasn’t receiving the alternatorlight signal and further investigation inside the fuse panel uncovered a failed diode resistor.

This faulty diode was allowing current to leak into other components, reducing voltage to 8V and keeping the light dimly illuminated.

Replacing the interior fuse panel resolved the issue – the battery light was finally out for good.

Diagnostic time for this job was three hours and repair time was one hour.

Hayden Wolfenden

Albany Autolec

CENTENNIAL PARK, WA

In a trade where experience, continual learning and shared knowledge are key, TaT’s Technical Videos page is one of the most practical and powerful resources available to our members.

Designed with busy technicians in mind, it offers a diverse collection of visual learning material ranging from real-world repairs and diagnostic walkthroughs to tool demonstrations and advanced programming techniques.

Whether you need a tip to save time on a challenging diagnosis, want to see a new tool in action or are looking for inspiration from fellow technicians around the country, the Technical Videos page delivers. It’s a digital toolbox you can access at any time –and it’s constantly expanding.

A well-organised hub of knowledge

The page is divided into six clearly labelled, tabbed sections, each designed to make it easy to find exactly the type of content you are after:

1.

This is one of the most active sections on the page and showcases real-world jobs handled by TaT’s technical team and TaT members alike. These videos are unfiltered workshop wisdom – diagnostic and repair challenges tackled head-on, shared for the benefit of fellow technicians. In many cases you will find links to related Repair Solutions, tying it all back to our extensive knowledge base.

Also among the most frequently visited sections, this tab doesn’t focus on complete repairs but rather helpful insights that might give you an edge. These are short, sharp videos offering handy tips related to common diagnostic headaches or helpful techniques for specific repair jobs. Sometimes it’s just that one trick you didn’t know you needed until now.

As the name suggests, this section features videos highlighting tools and equipment that are either new to the market or worth a closer look. You’ll find demonstrations, usage guides and honest reviews – whether it’s a scan tool, scope or a specialist accessory you’ve never seen before. If a tool’s a game-changer in the workshop, you’ll likely see it here first.

4. Scan Data

This tab is a niche part of the page but valuable. It provides members with the opportunity to share known-good scantool data, helping others establish reliable baselines for comparison and validation. While it’s not as frequently updated as the other video sections, it remains an essential resource for those chasing elusive fault patterns.

5. TaT Technical Videos

This is where things get a little more advanced – perfect for the ‘propeller heads’ in the room. In this section, we delve into emerging technologies, showcase in-depth diagnostic case studies and explore procedures that are still relatively new to many workshops. For example, module programming may still be unfamiliar territory to many technicians but we have created multiple videos that walk you through the process for various makes and models. It’s where bleeding-edge meets practical application.

6. TaT User Guides

Need a hand navigating the TaT website? This section is your go-to. Here you’ll find short, focused videos that explain how to make the most of the resources available to you as a TaT member, from accessing scan data and fault codes to lodging a tech-help request. It’s your shortcut to maximising the benefits of your membership.

One of the features we’re incredibly proud of is how easy it is for members to contribute. Do you have

something valuable to share with the network? Simply click the ‘Share your videos’ button on the page. From there, you can upload one of your videos (up to 250MB) or simply paste a YouTube link. Whether it’s a clever fix, an interesting scope capture or a demo of your latest workshop toy, it could be the video that helps a fellow tech out of a jam.

Every video on the page includes a description, the name of the video creator and any relevant links. Whether it’s a new tool featured in our Equipment Reviews section or a job that links back to a Repair Solution, we ensure the supporting material is right there at your fingertips.

For our internal team and members who like to share helpful content, we have added a handy ‘Copy to clipboard’ icon below each video. With one click, the video link is copied and ready to paste into a technical support reply or email. Yes, it’s a minor feature but a big help when you’re trying to guide someone toward a useful visual aid during a diagnostic discussion.

While you may have seen some of our videos on Facebook or YouTube, it’s worth noting that what’s shared publicly is just the tip of the iceberg.

We occasionally post select ‘gem’ videos online as a teaser – insightful and engaging clips designed to entice potential members – but the full library, with all the nitty-gritty detail, remains a benefit exclusive to TaT members.

The Technical Videos page isn’t just a library –it’s a living, evolving resource built by and for automotive professionals. It reflects the heart of what TaT is all about – practical knowledge, shared experience and a no-nonsense approach to helping workshops around the country work smarter and stay current.

If you haven’t explored this section of the site in a while, we encourage you to revisit. You never know what small gem might become your next big time saver in the workshop.

As new electric vehicles (EVs) become more widely available, it is vital to understand how the battery management system (BMS) is incorporated into these vehicles.

Most full EVs (FEVs) operate between 250V to 400V DC. In order to attain these high voltages, most manufacturers have opted to use lithium-ion batteries (in the order of 3.65V on average), connecting the batteries in series/parallel configurations to ultimately achieve the required kilowatt-hour (kWh) rating (see parts one, two and three of this series, TaT issues 102, 103 and 104).

A dedicated electronic control module, namely the BMS, is assigned to oversee the wellbeing of the batteries (pic 1).

Which brings us to where we left off in part three, but with two additional inserts – a high-voltage electronic circuit breaker (HVECB), often referred to as a ‘contactor’ (pic 1a, blue) and high-voltage manual service-disconnect plug for technicians wishing to carry out a service and/or diagnose the electrics of the symptomatic vehicle (pic 1b, yellow).

In this article, we will attempt to gain a generic insight into what the BMS is and how it achieves its role.

Please note that each and every manufacturer has its own unique terminologies and methods of achieving the BMS’s role. For specific locations, applications, methodologies and terminologies used by different makes and models, readers are urged to access their respective OEM’s website portal.

The HVECB is fitted in series with the source of the high-voltage (HV) supply to simply interrupt the current flow and isolate the supply voltage to the vehicle (pic 1a). For example, and to name only two scenarios:

a) In the case of a vehicle accident where the body chassis may have caused a short or a current overload with the main HV supply cable or…

b) In the case of electrical leakage that may have occurred between the core cable of the HV supply (and shielding) and/or vehicle chassis (earth/ground).

Therefore, whenever either of these scenarios occurs, the HVECB (pic 1, insert a, blue) will be activated by the body control module (BCM) to open-circuit the electrical voltage supply, hence interrupting the current flow – safeguarding the attending emergency crew at the scene of the accident (and so forth).

A HV manual service-disconnect plug (pic 1, insert b, yellow) is also fitted to the EV for non-emergency personnel to interrupt the HV supply when wishing to carry out service/diagnostics or remove and replace components.

The BMS is effectively no different from any of the familiar control modules used in internal combustion engines, from the ECM and traction control module (TCM) to the anti-lock braking system (ABS), with a secondary role in the function and performance of HV batteries. The BMS uses the same principles as any other ECM and performs the following:

a) The control module (i.e. BMS, pic 1, blue), based on information inputted from its sensors (multiplexed or hard-wired), will compare and/or cross-correlate based on its internal algorithms and preprogrammed flowcharting parameters (See TaT issue 73, page 6).

b) It will then execute the required interventions (pic 1, blue arrow from BMS to battery block).

Let’s now examine a few of the BMS’s inputs, starting with battery temperature sensors (BTSs).

Again, each and every manufacturer has a unique proprietary topology. While some measure the temperature of each individual battery, others limit the number of sensors to battery modules (see part three).

Every battery, due to its chemistry, has an inherent resistance – albeit very small – electronically termed ‘battery internal resistance’ or BIR (pic 2, yellow).

These are very small – in the order of thousandths of an ohm, or milliohms (see TaT issue 79, pages 32-33).

Therefore, whenever any battery completes a circuit via a load (pic 2, red), the charged cells (see part one) and electromotive forces (EMFs, pic 2, red/green) will give rise to a current flow (pic 2, purple).

This, in turn, results in a voltage drop (pic 2, brown) across the BIR (pic 2, yellow). And it is this voltage drop, multiplied by the current flowing through BIR, that gives rise to internal power loss – exhibited in the form of heat.

Indeed, from our point of view, we say the battery is getting hot. However, with temperature sensors in place (pic 1, orange), the BMS not only manages temperature control but also circumvents any thermal runaway by controlling and managing the charging and discharging circuits.

The main current-draw sensor (pic 1, grey) is used for overall battery block current-draw measurements. This can be in the form of:

• Hall effect sensors – similar to the ones used on the negative battery terminal of internal combustion engine (ICE) vehicles.

• A shunt-resistive circuit – where the voltage drop across the shunt is measured by the BMS, which is indicative of the amount of current flowing through the circuit (see TaT issue 96, page 30) However, depending on the OEM’s design, individual temperature, voltage and current sensors are also fitted to each and every cell

(or group of cells [modules]) to monitor and control their over/ undercharging conditions.

Based on information gathered from these sensors – along with other parameters gathered via CAN bus – the BMS performs the following calculations based on its algorithm:

State of charge (SoC) – The fuel gauge

SoC is similar to a fuel gauge, indicating how much ‘fuel’ is left. Electrically, SoC is effectively an estimation or a measure of how much charge remains.

However, as with all batteries, the capacity to deliver peak performance diminishes with time, affecting how much electrical energy is available.

As time progresses, it becomes apparent the ‘scale’ (on the fuel gauge) needs to be recalibrated (from full to empty).

This recalibration process becomes an interplay between calculated SoC and state of health (SoH) values (see ref 1).

State of health (SoH) of battery – Recalibration of fuel gauge

Simply put, SoH is an estimated measure of a battery’s overall health at a given point in time (see ref 2).

For example, in the process of recalibrating the electrical fuel gauge, the BMS not only monitors SoC but:

• Tracks the performance of various parameters such as battery usage time, temperature, individual cell voltages, current draw and number of charge/discharge cycles.

• Records and analyses these behaviours over time.

• Using its internal algorithm and flowcharting logic, calculates the SoH value – which then forms the basis for recalibrating the fuel gauge.

This ensures accurate display of the remaining available battery charge and allows a more precise estimation of the remaining energy (see ref 3).

Another secondary but equally important role of the BMS is to balance each individual battery cell with its neighbouring batteries. When batteries are newly manufactured, each one will have its own unique BIR and EMF values (pic 2, yellow and red). Slight variations occur due to electrochemical differences in manufacturing. When these batteries are placed in a loaded circuit (pic 2, red load):

• Current begins to flow (pic 2, purple).

• With BIR of ~70 milliohms.

• And EMF values ranging from 3.6V to 3.7V (see ref 5 and 6).

Then the effective nominal supply voltage (pic 2, blue) will vary depending on their internal BIR and EMF – even if the differences are small.

These variations become more pronounced when batteries are arranged in series or parallel configurations.

To achieve maximum power transfer (MPT) from the battery pack to the load, the batteries need to be balanced or equalised (TaT issue 79, pages 32–33).

It is the BMS’s role to minimise cell-voltage deviation to as little as 30 millivolts (mV) — or the last two digits of a nominal battery voltage of 3.651V (see ref. 7).

How is cell balancing done? Well, that’s for our next series of articles. Until then, consider these questions:

• How do DC-to-AC inverters generate AC voltage?

• What would be the root mean square (RMS) voltage of the sine wave in pic 3 (yellow) with a peak-to-peak (P-P) voltage of 700V (pic 3, purple)? Hint: see ref 4.

Please note, these articles are designed to illustrate the why and how of EVs, reinforced with basic theory. However, readers must be warned that contact with high voltages is potentially fatal. If you wish to measure high voltages, all safety measures and precautions must be followed, including the use of CAT III-rated DMMs, gloves and so forth. These procedures must only be attempted after completing industrystandard depowering training.

For more information, visit TaT’s EV training pages.

1. researchgate.net/publication/377526524_Review_on_Modeling_ and_SOCSOH_Estimation_of_Batteries_for_Automotive_ Applications

2. sciencedirect.com/science/article/pii/S2352152X21000864

3. ieeexplore.ieee.org/document/9503153

4. allaboutcircuits.com/tools/peak-to-peak-voltage-calculator/

5. ineltro.ch/media/downloads/SAAItem/45/45958/36e3e7f3-20494adb-a2a7-79c654d92915.pdf

6. sciencedirect.com/science/article/pii/S2352152X21000864

7. researchgate.net/publication/349355185_Evaluation_and_ Comparative_Study_of_Cell_Balancing_Methods_for_LithiumIon_Batteries_Used_in_Electric_Vehicles

Jason Smith

Although this technical article is of a very untechnical nature, it does follow the theme of workshop management and highlight two things required in a modern workshop: managing staff and problems, while also acknowledging modern technicians must sometimes fix or repair unusual problems in unusual ways.

Due to unavailability of parts, poor quality parts or human error, technicians are now having to repair items, systems or components in ways we never used to. The repair we’re exploring here was required because someone broke something and didn’t own up, leaving a real conundrum on how to rectify the problem. Some of my TaT Tech Team colleagues encouraged me to share this unusual case and repair.

The car

Nissan Qashqai J11, 05/2017, MR20DD engine with 80,000km on the clock.

The infotainment system (radio) had a broken button – the arrow forward/back button (pic 1 and 2). While this may sound quite trivial, a night with the dash lights on revealed a very distracting and bright amber LED where the button was missing. Without going into too much detail, the vehicle had been returned to the owner with the broken button after some minor damage was repaired on the driver’s door by a panel shop. Someone had reversed into the customer’s car and hadn’t left a note, so it became an insurance job. The damage was minor but the panel shop decided to probably oversell the job and go over the top with the insurance quote — therefore, a lot of the car ended up getting painted, which meant many components had to be removed and refitted.

After the repairs, the car was returned to the owner. Numerous faults were now present: the radio/infotainment system button was broken and missing, the right-side outside remote mirror wasn’t working, the right-front door lock wasn’t working, interior trims were missing, the seat-belt mounting bolts different and so on. Most of these items had

already been rectified by me or the panel shop.

Back to the radio. The panel shop had promised a new radio to the owner. After some months, the panel shop finally coughed up two second-hand infotainment systems, which the customer wanted me to fit.

Prior to the car arriving, I did some research into installing a new radio into a J11 Nissan Qashqai. I was told by a reliable source that the radio should fit straight in with no coding or programming required. I don’t know if this was the case for a second-hand unit – I didn’t ask. In all fairness to me, I had been told a new radio would be supplied, not a second-hand unit.

The car arrived for a service and the infotainment-system replacement. I removed the original infotainment unit from the dash – this was reasonably easy to do with the use of some plastic levers and trimremoval tools.

Next, I had a choice between two secondhand units. One presented clean with minimal scratches and damage. The second unit looked very second-hand, with dirt and lots of scratches in important places. All part and identifying numbers were carefully checked on both units, and all appeared to be in order for a quick, painless swap.

1

2