Editorial Board

Geoff Mutton

Jeff Smit

Technical Editor

Jeff Smit

Sub-Editor

Cameron McGavin

Scan Data Director

Rod Maher

Technical Research

Brendan Sorensen

Technical Assistance Moderator

Scott Thomas

Technical Contributors

Brendan Sorensen

Mark Rabone

Frank Massey (UK)

Jack Stepanian

Sam Nazarian

Jason Smith

Clinton Brett (Diesel Help)

Technical Assistance Team

Deyan Barrie Andrew Kollosche

Sideth Chiv Maurice Donovan

Gil Sher Anthony Tydd

Wayne Broady Jason Smith

Marty Hosie Jack Stepanian

Mark Rabone Rob Romano

Daniel Armer Jack Mackay

Gary O’Riain

Associate Team Members

Gary Homan Peter Hinds

Columnists

Geoff Mutton (TaT Biz)

Advertising Enquiries

Paul Woods,

National Advertising Manager

E: pwoods@tat.net.au

Ph: 0494 044 958

Graphic Design

Brigid Fraser

E: production@tat.net.au

PH: 0413 009 122

Affiliated Associations

AAAA – info@aaaa.com.au

Capricorn Society Alliance Supplier

VASA – secretary@vasa.org.au

Hi, and welcome to our very first bonus addition of TaT.

This first bonus edition is wholly focused on automotive diagnostics.

I’ve been in the trade for many years and – just like you – I’ve seen first-hand the change in our industry.

If you look at how you spend your days in the workshop and on the workshop floor now compared to five, 10 or 15 years ago, it’s certainly very different. High-tech development has changed the modern motor vehicle dramatically and the same applies to the type of work we’re doing day in and day out.

Looking back at my workshop development, I certainly know the area of my workshop that has grown the most – it’s diagnostics. We are being asked to diagnose complex intermittent issues more and more and these types of jobs are certainly challenging. They certainly require a different mindset and approach to what we have been used to for so many years.

If you look up at the word ‘diagnostics’ and its meaning – ‘The practice or techniques of diagnosis, the art, science or method of diagnosis’ – it spells out pretty clearly why we have to approach these jobs differently and with a different mindset.

A phrase I came up with many years ago is even more relevant today: ’Swapnostics plus guessnostics does not equal diagnostics.’

Due to several pressures, whether it’s time or a backlog of work, far too many technicians revert to ‘swapnostics’ or ‘guessnostics’ to try and solve that challenging car at the back of the workshop. Sometimes it can work but in most cases it just frustrates you, causes you to lose time and costs you more money.

Just looking at the definition of ‘diagnostics’, it highlights that the process is a refined technique that requires practice. Ultimately, it is an art – there is science and method behind a successful and productive diagnosis of a problem vehicle.

So as we focus on diagnostics here, keep your mind open to different ways and techniques for determining the cause of a symptom in the next problematic car you examine.

I believe non-invasive diagnostics is key. My motto, which I’ve been promoting for many years, is ‘avoid pulling anything apart when possible before determining why you’re doing so’ and this bonus edition features many tools and equipment that will enable you to diagnose a problem without disassembling major components.

Having started my career as an auto electrician, I certainly advocate for not unplugging anything when possible and diagnosing as much as you can before unplugging or altering too much on the vehicle. Far too often, technicians manipulate or disconnect electrical connections, inadvertently changing or fixing the symptom they’re trying to diagnose.

I hope you all enjoy reading this bonus edition and I urge you to read all the great articles from the familiar writers and technicians that appear in every edition of TaT. I would also like to thank all those companies who have chosen to participate and advertise as it shows they are here to assist, help and educate us as technicians to the new ways of diagnosing the modern motor vehicle.

Please support them. As we approach the end of the financial year, you might have some additional funds to expand your diagnostic toolbox and let the government help in a small way with some tax concessions.

And don’t forget to utilise all the facilities on the TaT website if you are a TaT member. We have made great improvements to the searching mechanisms to help our members find the information that they’re looking for. We upload 20 new Repair Solutions every fortnight, as well as adding to our good scopescan database.

If you use the website on a more regular or daily basis, I can guarantee you one thing – it will help you out, saving you many hours of time and preventing much frustration and stress. g

Dan Armer

driver-assistance system (ADAS) technology has gone from being a luxury to a legal requirement on new vehicles in Australia.

Under the wider umbrella of ADAS you’ll find features such as automatic emergency braking (AEB), adaptive cruise control (ACC), lane-keeping assist (LKA) and blindspot monitoring (BSM) and these systems are now a core part of how modern vehicles keep drivers safe.

But with this technology comes complexity and technicians are now expected to understand and correctly calibrate these systems – every time they’re touched. Whether it’s a minor prang, a windscreen replacement or fitting a lift kit, if the calibration is out, things can go pearshaped fast.

Misaligned sensors don’t always trigger fault codes but they can cause the vehicle to react in unexpected ways – false emergency braking, vague steering, missed hazards or worse.

Here, we’re taking a look at some common calibration challenges, real-world case studies and what we need to do in the workshop to get it right.

Why calibration matters

ADAS sensors – radar, cameras, sometimes even lidar – rely on millimetre-precise alignment to function properly. You can’t just bolt them back on and call it a day. If a camera is angled just a degree too far left or a radar sensor is a few millimetres off-centre, the vehicle can misjudge its surroundings entirely. It might brake when it shouldn’t, miss sensing a car in front or veer toward the wrong lane line. These aren’t theoretical risks – they’re showing up in real jobs across the country.

We’re seeing more cases where something seemingly simple such as a bumper replacement or new windscreen leads to major ADAS problems down the track. And while the systems are getting better at flagging obvious errors, many issues still don’t set off warning lights or DTCs.

Radar troubleshooting: The sneaky stuff that catches you out

Radar diagnostics comes with its own headaches. One of the trickiest problems we deal with is intermittent failures – false positives that happen once or twice but

don’t show up on the scan tool. A bit of road grime, a decal over the sensor or even glare from a guardrail can be enough to trigger false braking events. Wet roads, tunnel walls and shiny vehicles can also throw off radar reflections, especially if the sensor isn’t aligned properly.

Sometimes the radar will be physically fine, with no codes showing up, but ACC or AEB just doesn’t behave as expected. The vehicle might struggle to lock onto the car in front, brake too late or overreact when merging. In those cases, a live data session is more valuable than a DTC – watching how the radar tracks vehicles and checking for offset angles can tell you if it’s pointing slightly off-axis.

Hidden physical damage is another common trap. A radar sensor might look fine on the outside but the bracket could be bent or there could be a micro-crack from a light nudge. Aftermarket bull bars or chrome bumper covers can also interfere with radar signals, even if they look like they’re ‘sensor safe’.

One thing that often gets overlooked is the workshop itself. Radar calibration needs a level floor, clear surroundings and the right lighting. Metal toolboxes, hoists or uneven concrete can all throw off the signal. If your calibration environment’s dodgy, your calibration results will be too.

And of course, don’t forget software. If the radar module hasn’t had the latest firmware update or completed its post-calibration learning cycle, you might still get poor performance. Always check manufacturer bulletins for updates and adaptation steps, especially when replacing a sensor.

Real-world cases: What actually happens when ADAS goes wrong

• Case 1: Toyota RAV4 with ACC not working post-collision

This 2021 RAV4 came in after a minor frontend shunt. The bumper had been replaced by a panel shop but the ACC refused to engage. The scan revealed a radarmisalignment code and, visually, the radar bracket was out by a few millimetres – just enough to throw everything off. A proper static calibration using the OEM target and a test drive sorted it. It was a classic example of how small sensor shifts can cause big system failures.

• Case 2: Honda Civic with LKA issues after windscreen replacement

Another job was this 2020 Civic that had its windscreen replaced. After the job, the LKA was erratic – sometimes too aggressive, other times not working at all. No major warning lights but a scan flagged the forward-facing camera as misaligned. Static calibration brought it back into spec and after a quick road test the system was behaving properly again. Just goes to show that even a slightly off-centre camera can throw off lane detection.

• Case 3: Nissan X-Trail false braking near overpasses

This one was more dramatic. A Nissan X-Trail started hitting the brakes on its own at highway speeds – no cars ahead, just open road. Minor front-end repairs had recently been completed on the vehicle. No DTCs but on inspection the radar bracket was angled slightly upward. It turned out the radar was reading overhead signs or the

overpass itself as an obstacle. We replaced the bracket, ran a static calibration and road-tested it. No more false braking.

Lift kits and ADAS: A problem waiting to happen

Lifted 4WDs are more popular than ever but throwing a suspension lift on a latemodel vehicle with ADAS can be a recipe for disaster. Changing the ride height can change the radar and camera angles, meaning a factory calibration will likely still pass in the shop but give incorrect readings on the road.

ACC might miss low vehicles altogether or AEB could trigger unnecessarily when approaching a hill or sign. Lane departure and steering-assist functions can also get thrown out due to altered yaw rate and steering-angle inputs.

In these cases, static calibration may not be possible. You may need to do a dynamic calibration (if available) and proper road test. As always, please follow manufacturer’s procedures. Some manufacturers are now offering adjustable radar brackets to compensate for altered ride height –something worth investing in if you’re working on modified vehicles regularly.

First, if the ADAS system’s been touched – whether it’s a bumper off, a windscreen out or the car’s been on the hoist for suspension work – recalibration should be performed. There’s no guesswork here; it’s either within spec or it’s not.

Second, stick to the OEM procedures. Aftermarket scan tools are great but they don’t all support every calibration method. Where possible, use the factory scan tool – especially for initialisation, coding, or software updates.

It’s also worth pointing out most

manufacturers now require a wheel alignment before calibrating long-range radars. This is to ensure the vehicle’s thrust angle is zero degrees – meaning it’s tracking straight and not crabbing down the road. If the rear wheels are pushing the vehicle slightly sideways, the radar’s forward aim will be skewed. You might get a calibration to complete in the shop but in real-world traffic the system could misread distance or lateral position. Always check alignment before starting radar work, especially after any collision or suspension repair.

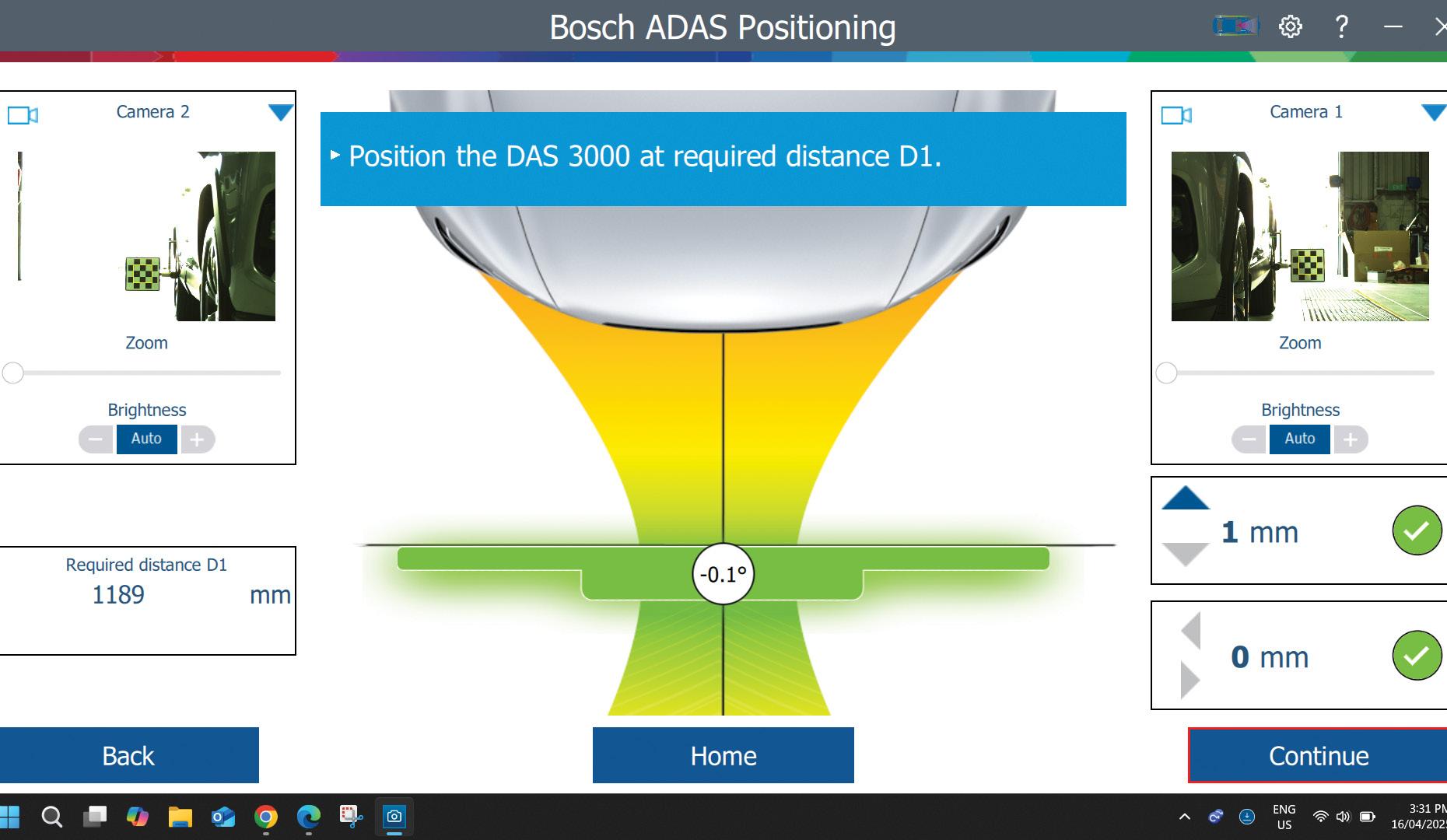

Third – and this can’t be overstated –document everything. ADAS is a safetycritical system and if a customer’s vehicle is involved in a crash you need to be able to prove the system was correctly calibrated. In my own workshop, I photograph every calibration target in use and capture the exact measurements taken during setup. For example, when using my Bosch DAS 3000 target frame, all positioning is automatically measured with millimetre precision. For manually positioned targets, I use a digital laser measurer and photograph both the measurement and target placement.

All of this gets attached to the invoice, along with a screenshot or printout showing proof of a successful calibration.

It’s an extra step but it’s worth it. In the unfortunate event that a crash investigation comes your way, documentation is your best line of defence to prove the ADAS was set up correctly at the time of the repair.

Finally, don’t just rely on the scan tool saying, ‘calibration complete’. You need to confirm everything with a proper road test. Make sure ACC engages and adjusts smoothly, AEB doesn’t trigger randomly and the car doesn’t fight you on gentle curves with LKA. The proof is in how it drives.

And have the conversation with the customer. If they’ve fitted a lift kit, aftermarket bars or just had work done

at another shop, they need to know that recalibration isn’t optional. Skipping it could mean their safety systems are no longer working properly – even if no warning lights are on.

ADAS is getting smarter at detecting its own faults. It cross-checks multiple sensors –radar, camera, ultrasonic, GPS – to validate what it’s seeing.

If the radar says there’s a car ahead but the camera doesn’t see it, the system flags a mismatch. This is called sensor fusion and it helps filter out false positives and improve accuracy.

Some systems also have self-diagnostic features that can detect sensor misalignment or blockage. They might not always throw a hard fault code but they’ll often flag reduced system performance or disable a function temporarily. These checks don’t replace proper calibration but they can help spot issues early.

ADAS calibration isn’t a ‘tick the box’ job – it’s a critical step that directly impacts vehicle safety. We’re now working on rolling computers with highly sensitive vision systems and if those systems are out of spec, the whole vehicle behaves unpredictably.

As techs, we need to treat calibration with the same care as brakes or steering. The right tools, the right targets, the right workshop setup, accurate wheel alignment and thorough documentation all make the difference.

With proper procedures and a solid understanding of how these systems work, we can keep customers safe, avoid comebacks and do the job right the first time. g

Brendan Sorensen

Beingresourceful has always been part of an independent technician’s job. Whether we’re chasing a strange electrical gremlin or reprogramming a module after a repair, it’s not just tools and training that get us through – it’s the information.

Access to that information has evolved significantly over the years and the introduction of the Motor Vehicle Information Scheme (MVIS) in 2022 marked a significant, almost seismic shift for our industry.

The formation of the Australian Automotive Service and Repair Authority (AASRA) as the central access point between independents and OEMs was part of that shift. In many ways it’s improved our ability to access technical information that was once out of reach. But increased access doesn’t always mean smooth sailing. In fact, it’s brought a new set of challenges – some of them surprising – to workshops across the country.

Rather than laying out a list of pros and cons, I want to share the workflow I typically follow when sourcing technical service, repair and diagnostic information, often referred to simply as ‘service information’ (SI). Sharing it might offer some useful perspectives as we all continue to adapt to a more regulated and fragmented information environment.

My workflow: Aftermarket first, OEM when needed

Like many of you, I rely on a couple of comprehensive aftermarket SI platforms. They’re fast, easy to navigate for the most part and cover a lot of the general service and maintenance work we do day-in, dayout – torque specs, fluid types, service intervals and common wiring diagrams are often readily available.

But when the job calls for something more specific – detailed theory of operation, manufacturer-specific fault code setting criteria, precise ECU pinouts under defined conditions, exact wire colours, obscure component locations or complex software

initialisation steps – you can find yourself coming up short.

In these cases I’ll often submit a tech request through the aftermarket platform. I’ve learnt in many situations the company has the data on hand but it hasn’t been uploaded to the live platform. If I’m not in a mad rush I’ll put in the request and move to another job. Often I’ll come back in an hour or two to find the info waiting, saving me from wasting time trying to guess or hunt it down manually. It turns waiting time into productive time elsewhere.

When that doesn’t pan out, when time is tight or the job clearly involves programming or security from the start – or when there are many variants of that particular model (there can be loads of variations depending on trim level and having the truly correct wiring diagram can be critical) – I go straight to the OEM portal.

Under the MVIS, we now have a structured pathway to access official OEM SI portals. The AASRA website itself (aasra.com.au) acts as a central directory, providing links to the various manufacturer portals and outlining their subscription costs.

For those manufacturers in the AASRA

scheme, your AASRA credentials allow an easier path of access as security vetting and ID have already been taken care of. For those non-participating brands (NPB), the portals are still listed and you will have to take care of satisfying login requirements directly with the manufacturer.

Importantly, even if it’s an NPB, any issues arising from difficulties in accessing SI with that manufacturer can still be followed up by AASRA by lodging a missing information report (MIR).

From there, the experience varies wildly. Some OEMs such as LDV are currently free, Tesla gives the majority of information free such as repair procedures and times, wiring diagrams and parts catalogues while requiring a subscription for access to the OE diagnostic software called ‘Toolbox’, which gives deeper theory of operation information.

Others offer excellent value – like Isuzu charging as little as $3 per hour for SI access. What a bargain – that’s less than the cost of a wiper blade for access to factory diagrams, wiring, fault code flows, repair procedures and more.

And let me be clear – these costs are passed on to the customer, just as we would with any part or tool required to complete a job. Service information is as

essential as a gasket or a sensor. It’s not a workshop loss; it’s a billed item. Factor the SI subscription cost into the job quote for larger repairs too – it’s a legitimate and increasingly essential part of the modern repair process.

Of course, some OEMs sit on the other end of the spectrum. High access costs and frustrating layouts can make using their systems a real challenge. But at today’s labour rates, less than 10 minutes at the vehicle without correct information costs the same as just logging in and getting what you need.

You’re not saving anything by avoiding it – quite the opposite. Wasted diagnostic time is far more expensive than a daily subscription.

Learn the landscape before the fire starts

Something I’ve found invaluable is logging into new OEM portals after hours, without a vehicle in front of me, and just poking around.

Look up a familiar vehicle, save a few useful documents, explore the navigation. You can offset the cost by saving a heap of technical service bulletins (TSBs), repair procedures and code criteria for known problem vehicles while you have access. Take note of guides for specific manufacturers on the AASRA site or PC requirement-type information in the manufacturer’s portal as it’s often that one little detail of having a specific version of Java or opening a

browser in administrator mode that allows the portal to work or not.

That way when you do start your journey into the complexities of the real vehicle at hand, you’re not spending your first hour learning how to download a wiring diagram while a car is half-pulled apart in the bay. Some portals are intuitive and easy. Others look and feel like they were built in the 1990s and never updated – because it’s true; some are archaic. Getting comfortable before the pressure’s on is one of the simplest ways to keep your stress levels down and your diagnostic accuracy up.

The AASRA effect: Access with an asterisk

AASRA plays an important role, especially in managing access to security-related information and holding OEMs accountable to MVIS compliance. There’s no denying it has brought some much-needed legitimacy and structure to what was previously an adhoc system. It provides the framework and security validation (via its SDRM portal) that allows manufacturers to confidently share information.

But that doesn’t mean the system is without frustration. The added layer of login credentials, dealing with specific verification steps for security or electric vehicle (EV) data (police checks, training certs), potential delays in approvals and lack of direct support in some cases can slow down the process.

It’s not always AASRA causing the

problem – they’re often stuck between the independents and the OEMs – but the difference is academic for the tech trying to fix a car today.

I have encountered my fair share of frustrations in communication and procedures in the teething stages of this scheme but understand that we are stronger together as a unified body and am grateful I even have an avenue to bring up disputes with manufacturers – we all know what chance we would have individually with certain hard-to-play-with manufacturers. The promise of access is real. But consistent, timely and usable access is what we still need to push for.

One of the most frustrating issues we face today, especially around programming, is the restriction by some OEMs to use only their branded vehicle communication interface (VCI).

If you’re a one-brand shop or someone doing programming work for other workshops, that investment might be justifiable, allowing you to offer true dealerlevel procedures with an independent’s touch. But if you’re a generalist, the idea of buying a $5000-plus tool that only works with one make is a hard pill to swallow. In some cases, that proprietary tool is genuinely required – it offers functions or security access not available anywhere else. But more often than not – as techs have discovered – it appears to be just a generic Bosch or Cardaq tool with a different case and maybe one resistor moved on the board. The software checks the branding and refuses to work unless it sees the OEMapproved version.

What really stings is when those same OEMs allow generic VCIs in other markets. Mazda, for example, supports the use of J2534-compliant VCIs in the United States. Here in Australia, only its branded tool is supported – even though the software and vehicle are the same. It’s hard not to see this as a deliberate attempt to restrict access and protect tool sales or the requirement of a trip to the dealer to keep the car within their grasp.

Some OEMs get it right. They publish compatibility lists and approve common J2534 tools. Others leave us locked out, unable to complete a job we’re otherwise perfectly equipped and trained to do. This kind of gatekeeping flies in the face of what MVIS was meant to achieve. Information is only truly accessible when it can be acted on – and that means with tools already widely accepted across the industry.

Real-world experience: The good, the glitchy and the ‘why me?’

Feedback from fellow technicians within the TaT community has been both reassuring and frustrating because I’ve experienced so many of the same challenges myself.

I’ve had jobs made infinitely easier by clean, accessible OEM portals with affordable access. And I’ve had jobs stalled by login failures, broken links, slow performance, incompatible browsers or software that wants me to pay with one browser and then use a different browser to access information. I’ve had tech requests go unanswered, programming failures that no one could explain (let alone help me fix, with some OEMs offering no support) and portals that seemed permanently ‘under maintenance’.

A common example of system limitations is dealing with a portal where critical DTC explanations aren’t available in the SI – they were only available if you had the OEM scan tool. Not ideal when you’ve just paid for access and are still left guessing.

Another common frustration is being locked out of all information for a model line (even basic mechanical data) if a hybrid variant exists and you don’t have high-voltage (HV) credentials because the OEM claims inability to separate the data.

These stories are common, which is why we need to keep sharing them, both to help each other navigate the quirks and to keep pressure on the system to improve.

Where to from here?

Every workshop needs to decide what model works best for them. If you specialise, then a full OEM subscription and official tool is easily the way to go. For most of us, a blend of aftermarket SI, OEM shortterm subscriptions and access to an approved J2534 VCI (where possible) is the most practical path.

Industry bodies continue to advocate for improvements such as pushing for universal pass-through programming standards and better access for data aggregators. The future likely holds further challenges, including the fight for access to telematics data. Treat SI as a legitimate workshop requirement. Build it into your job costing, just like parts and consumables. Don’t be afraid to spend the time learning a portal or chasing better support. And stay connected to others in the trade – we’re all facing the same battles. We’ve come a long way since SI was something you hoped your scan tool might include. MVIS and AASRA have brought us a

framework. Now it’s up to us to keep using it, keep improving it and keep making sure it serves the technicians on the floor – not just the policy makers and manufacturers.

Access is only the beginning. The real power comes when we can use it freely, confidently and fairly. g

Listed in $AUD including GST, ordered from best value through to the most expensive.

Tesla – repair procedures, Free Free

times, wiring diagrams

Tesla – theory of operation,

OE diagnostic software

Suggested future fees

What it is, what it does and how it does it

When the Motor Vehicle Information Scheme (MVIS) was introduced in 2022, the Australian Automotive Service and Repair Authority (AASRA) was appointed as scheme adviser.

The legislation ensures independent repairers have access to all the information they need to service or repair any post2002 passenger or light-commercial vehicle to the manufacturers’ specifications and standards.

Essentially, the legislation mandates that all service and repair information provided to motor-vehicle dealership networks and manufacturer-preferred repairers is also made available to Australian repairers and Registered Training Organisations (RTOs) to purchase at a fair market price.

AASRA quickly established its operational foundations and licenced software from the National Automotive Service Task Force in the USA, financed significant software modifications to comply with the MVIS legislation and established a basis for future growth and development.

Although there were many initial challenges, AASRA developed the independent repairer membership and continues to deliver value for these members by facilitating access to genuine OEM repair and service information, in the process attracting an ever-growing number of electric vehicle (EV) and vehiclesecurity professional members.

In addition, AASRA has supported the majority of the industry’s vehicle manufacturers to prepare and deliver compliant scheme offers, many of whom joined as participating brands from the outset.

Three years later AASRA continues to guide and support its members to further develop their service and repair capabilities that ensure their customers’ vehicles are serviced and repaired to manufacturer standards.

As scheme advisor, AASRA has the responsibility to ensure all members are current employees of a registered Australian automotive business and validates all additional documents and qualifications when a member requests an account upgrade. It maintains a registry of every manufacturer scheme offer on its website, provides an access gateway to service and repair information for all participating brands and guides members on how to navigate the various manufacturer portals. In addition, it acts to resolve any issues related to access, supply or price of manufacturer information. AASRA membership is open to employees of various Australian automotive business, such as mechanical workshops, collision repairers, automotive dealerships, locksmiths, automotive dismantlers/ modifiers and other organisations that provide automotive services. It is also open to training professionals employed by RTOs. In all cases it is the individual that becomes the AASRA member, not the automotive business. The member then gains access OEM portals where they can purchase service schedules, manuals and bulletins, repair procedures and wiring diagrams. In addition, there are two types of automotive upgrades which unlock additional safety and security information. A safety upgrade provides access to EV/hybrid vehicle information and is restricted to individuals holding an EV training certificate such as AURETH101 or equivalent. A security upgrade provides

access to key, radio and immobiliser codes and other security information and is restricted to individuals who have provided additional documentation to verify that they are a fit and proper person as defined in the legislation.

Today, an AASRA membership provides access to 34 participating brands, representing 87 per cent of the Australian car parc. AASRA works closely with all participating brands, as well as the current non-participating brands, and more recently the plethora of new brands coming into the market. In the past six months AASRA has expanded its network to include the Deepal, Geely and Jaecoo brands, with all recognising the value that AASRA brings to the Australian market.

Looking ahead, the rapidly changing automotive landscape will require technicians to adapt to the technological advancements on which the modern vehicle is built. As vehicles become more complex, technicians will need to invest in developing their own technical skills.

Whatever the future may hold, the independent automotive technician can have confidence that AASRA will be there every step of the way.

• For more information call AASRA on 1300 222 772 or go to aasra.com.au

Jason Smith

Isuzu M-UX, 08/2016, 4JJ1 3.0-litre turbodiesel, 237,000km on the clock

The vehicle was not running right, with the traction-control warning and check-engine light (CEL) coming on sometimes and the car going into limp mode. The problem was intermittent, with the customer stating the fault occurred about 70 per cent of the time when the car was driven. Sometimes if the key was cycled off then on, the car might run OK for a short time.

A lot of the diagnostic jobs myself and the entire TaT Tech Team get asked to look at have either been previously looked at by other workshops or are of an unusual, intermittent or complicated nature. Sometimes when previous work has been performed on a vehicle it can cloud the pathway forward. As you read on, you’ll see this partly happened to me on this job. Sometimes intermittent-fault jobs can become quite complicated and at times overwhelming if you don’t keep to a strict diagnostic path.

When the customer initially contacted me about this problem vehicle, she stated the problems had been ongoing for five months and numerous repairers had looked at the vehicle. Because there was a lot of information pertaining to the ongoing problem and previous work performed, I asked her to document the sequence of events over the last five months.

To her credit, she sent a two-page detailed document to me which made the sequence of events clear. It also made me feel pressure as one of the reputable repairers had stated the vehicle required almost $11,000 worth of work, including a new high-pressure diesel fuel pump and diesel injectors among other items.

To me, some of the events and symptoms really didn’t make sense. It’s important to mention one of the previous workshops had already replaced the common-rail fuel pressure sensor only, not the whole common rail, which is usual practice. Someone else had replaced the fuel filter and broken the fuel-filter mount. There was evidence of fuel spillage (not an ongoing leak) on the left side of the engine. I was also told there was DTC that would appear from time to time but unfortunately no one had documented it or could tell me what that fault code was. As you can see, this was all a bit confusing. Now onto the vehicle. Performed a full system scan and found two DTCs in the anti-lock braking system (ABS). Suspected these DTCs were unrelated, so documented them and moved forward.

During the initial road test, I was sitting with the scan tool connected – setting up which data parameter IDs (PIDs) I wanted to look at – when the engine sound changed and the traction-control light appeared after about three minutes of idle.

It’s important to note the change in engine sound was a bit like when you perform a small injector-quantity relearn on Mitsubishi diesel vehicles, when the high-pressure fuel system changes and you can hear what sounds like a straining noise in the way the engine runs.

This was indeed evident in the data stream I was seeing on the scan tool. The fuel pressure had risen from an uneven 30 megapascals (MPa) – which is correct for idle – to 80MPa or more and was still uneven.

When I set off on the road test the vehicle was in limp mode, displayed a harsh gearshift and would not upshift to top gear. A few hundred meters down the road I pulled over, cycled the key off and then on. The vehicle now drove normally without the traction control light showing but it still displayed the signs of uneven fuel pressure.

A little way down the road the vehicle once again entered limp mode and the traction control light came on. When not in limp mode, the fuel pressure was extremely erratic, constantly going up and down from its specified 30MPa at idle.

I also noticed at idle that if the fuel system pressure hit about 70MPa, that was when the traction control light would come on and the vehicle would enter limp mode (pic 1). It’s also worth noting when the vehicle was in limp mode, the exhaust-gas recirculation (EGR) valve stopped working. Don’t confuse the valve being commanded to stop working because of limp mode with a sticking EGR valve, which is sometime common on 4JJ1 engines like the one in this vehicle. I also noticed the fuel-temperature data PID sometimes would read minus 40ºC, which was obviously concerning (pic 2).

Returned the vehicle to the workshop and performed some basic checks and tests to start the full diagnostic assessment. During initial visual inspections I noticed the suction control valve (SCV), which is mounted to the side of the diesel high-pressure pump, had Texta and dirty marks on it – I noted this and moved on.

Smoke-tested the intake system and it was OK. I also took a minor fuel sample from the fuel-filter sediment bowl – it appeared OK with no contamination.

At this point I concentrated on the fuel temperature of minus 40ºC, which would normally indicate a possible circuit problem. However, on further investigation this turned out to be invalid data from my scan tool. Luckily I didn’t waste much time on this and quickly swapped it out to a different scan tool.

Road-tested the vehicle over the next few days and it would not fault but the following week it did start to fault again. During another road test, the CEL eventually appeared along with a fault code, P0089 – Fuel pressure regulator performance (pic 3).

Right from the start I had been concerned that the fuel pressure was never stable, especially at idle. It was constantly up and down, all over the place and nowhere near where it should be – a nice and stable at 30MPa at idle.

Launched a search for ‘DTC P0089 Isuzu’ on the TaT website and a few Repair Solutions and TaTassist cases were available. In short, the outcomes of the relevant Repair Solutions and TaTassist cases involved fitting a new SCV to solve the problem.

I decided to move forward and the fuel system certainly needed further investigation. Using the scan tool’s special-function menu, I adjusted the fuel pressure bi-directionally – I was able to control the fuel rail pressure up and down but the system pressure was still unstable.

This was an ‘always-open’ system, which meant if the SCV wiring connector was disconnected the system should go to full pressure. Did this with the engine running and the fuel pressure quickly rose to about 150MPa or more – correct operation.

Performed a high-pressure fuel systemdecay test by simply running the engine then

turning the engine off, then back on, key-on/ engine-off (KOEO), while monitoring the high-pressure fuel system data stream (pic 4). A slowish decline in the high-pressure fuel system should be present over more than approximately seven seconds. The results of this test appeared OK, ruling out any major leaks in the pump, rail or injectors. Wanting to properly rule out fuel contamination or cavitation, I removed the fuel filter, drained the fuel and disassembled into a clear container to check for contamination (i.e. water, petrol or metal filings). Noticed no obvious contamination, so allowed the fuel to sit for 30 minutes, then placed a magnet underneath to see if any metal or foreign bodies appeared – everything checked out fine (pic 5).

Reassembled the fuel filter and added a clear plastic line to the fuel line at the filter outlet. Started the engine and ran it while checking for small bubbles which could indicate air entering the system and cause the highpressure fuel pump to cavitate. Road-tested the vehicle and found no bubbles (pic 6). Next, connected the Pico scope to see if the powertrain control module (PCM) was controlling the SCV. Yes, I know this was pretty much covered when the scan tool was used to bi-directionally control the fuel pressure, but being the inquisitive person I am, I really wanted to see the scope pattern and compare it post-replacement of the SCV as that was the direction I had been thinking from the start of this diagnostic job.

To check the duty cycle, I set the Pico scope to the frequency setting. The pattern appeared infrequent and was not uniform, telling me the PCM was attempting to control the SCV.

It’s about now you are probably reading this and saying, ‘Just change the SCV’. However, this is where this job got cloudy because of other workshops that had looked at the vehicle and I was wondering why they hadn’t replaced the SCV. It seemed to be a definite point of concern and then there were the Texta marks on the side.

I’ll admit this did throw me. I really need to have fact-based evidence of a problem before just swapping a part. Looking at all the evidence, I believed I had what I needed to move forward with the job and the SCV needed to be replaced.

Replaced the SCV with an OE part (pic 7). Performed a fuel-system relearn with the scan tool in the special-function menu. Started the vehicle and noticed a nice, smooth idle. The fuel pressure read 30MPa at idle with no variation in the reading (pic 8) – spot on. Once again scoped the SCV and this time there was a nice, uniform and even frequency

or duty cycle (pic 9). Road-tested the vehicle and again noticed a nice, steady fuel pressure – a mirror image of the desired fuel pressure – and it was present all through the rev range, with the engine good at idle and showing good driveability (pic 10).

Road-tested the vehicle numerous times and noticed no further problems. Returned the vehicle to the owner, contacted her twice over the next few weeks and she reported no further problems – she was very happy.

During the replacement of the SCV, I found the top bolt – which is a 5mm cap screw or Allen key bolt – was damaged, making it difficult to remove. This got me wondering if a previous workshop had attempted to replace the SCV, couldn’t remove this bolt and just given up and quoted a new high-pressure pump. Or maybe the SCV had been replaced with a second hand or sub-standard new aftermarket part?

Stay on track with your diagnostic jobs, don’t let what others may or may not have done cloud your judgement too much. Keep in mind that even if a part has been replaced, that replacement part may be faulty. There are a lot of sub-standard aftermarket parts flooding our industry and they can cause sometimes unusual problems and diagnostic chaos.

Frank Massey

I’m going to revisit a topic I believe is becoming more relevant with current vehicle design and build techniques – noise, vibration and harshness, also known as NVH.

All my observations are based on the Pico NVH system, software and accessories.

Diagnostics should never be based on opinion, rather on fact-based assessment from evidential test data.

That said, when dealing with NVH without the use of accelerometers and microphones, that’s exactly what happens.

The motor vehicle is an increasingly complex series of systems constantly in motion and conflict.

So what exactly is vibration? It is an energy source: mass acting at a frequency, with amplitude and vector. It has three critical elements that must be clearly understood and defined if a successful conclusion is to be determined:

• Source – the origin of the mass imbalance.

• Transfer path – various components or structures that the vibration passes through.

• Respondent – the component our attention is drawn toward. You know the saying, size matters. Large-mass structures will have a lower frequency; lighter mass structures will have a higher frequency.

At this point, we must be careful. A high-mass imbalance would, under normal circumstances, have a greater amplitude. However, large-mass components can also act to absorb energy.

I’ll give you an example here relating to recent engine developments. In the past, engine blocks were manufactured from cast iron. Vibration was limited by heavy flywheels and robust engine mountings. The block itself would absorb some of the vibration.

Fast forward to current design criteria: engine blocks manufactured from magnesium or aluminium reduce mass – improving performance and handling – however, they act to amplify vibration and noise. Enter dual-mass flywheels and active engine mounts. I may come back to these later.

To muddy the creek even more, it’s also a general acceptance that the greater the amplitude, the nearer you are to the source. Consider this example: we have a road-wheel imbalance. Energy is transferred via the shock absorber, road spring, top-mount bush and eventually to the body shell.

The energy has a secondary path via the steering linkage to the steering wheel. This is what reacts and attracts your attention the most.

The position of the accelerometer will directly affect the amplitude. It’s an important consideration to change its position to locate the greater mass amplitude. The primary choice should be the driver’s seat frame.

It’s especially important to keep the direction, or vector, constant while evaluating the vehicle. The accelerometer is clearly marked with an arrow. Channel one is forward motion, channel two is vertical motion, with channel three lateral motion. Consider using a microphone in channel four – this can be used for spoken notations as you drive.

In case you’re thinking we’re stuck between a rock and a hard place, we have the ‘time domain’ option. This is where multiple accelerometers or microphones are employed. While it’s true that mass amplitude can be artificially increased by large, light structures such as body panels, it’s the time differential recorded between each sensor that cannot be artificially confused.

This option should be employed using scope mode outside of the NVH software platform. This allows real-time analysis and time displacement on the horizontal axis

Overlaying multiple channels, the sensor that reacts first will always be closer to the source. This technique is best used when diagnosing suspension and chassis noise or vibration.

Technique is the difficult part. You must have the cooperation and understanding of the driver – the owner and driver may be different. Is the concern genuine or a normal characteristic of vehicle operation? An owner trading up to high-pressure gasoline direct injection may feel they have noisy tappets or other engine problems when in fact it is the injectors they can hear.

Once the vehicle data has been entered, the software will separate the various frequencies – wheels, transmission, engine and other components such as gearing and final drive ratios – if sufficient data is available. This data is fed into the PC using a Mongoose or similar serial interface.

The most important variables are driving style and environmental influences. You must replicate the conditions of complaint or concern. You will require both smooth and rough-road conditions, setting exact driving styles.

Has the vehicle been modified? Almost everything we see through our Audi workshop has, whether it’s wheel size, tyre profile, engine output or – especially – suspension changes.

How we perceive vibration depends on frequency. We can see, feel and hear these conditions – often at the same time:

• 0-20 Hertz (Hz) = vibration only.

• 20-200Hz = vibration and noise.

• 200Hz+ = noise only.

Noise is a change in ambient air pressure interpreted through tiny receptors in our ears, converting movement into electrical signals to our brain. Hearing sensitivity is unique for everyone.

Many vehicles have active noise control (ANC); this will certainly mask or hinder fault finding. Active engine mounts employing Hall sensors and hydraulic actuators adjust engine vibration damping in real time.

Next, I’d like to discuss vibration orders – how many times does the imbalance take place per event frequency? For example, a worn driveshaft would have a T3 order (three events at wheel-speed frequency). A bent driveshaft may have a T2 order.

This brings me to my pet subject – combustion vibration anomalies. Crankshaft rotation speed, interpreted as a frequency through Mongoose, is represented by E1. Therefore, combustion contribution occurs at E0.5.

Combustion is a force applied to the piston crown by an expansion of cylinder pressure. Therefore:

• Force = mass x acceleration.

We can therefore use NVH to ascertain the contribution of combustion either in NVH or scope mode. The force of combustion can be attributed to mechanical efficiency, fuelling balance and ignition energy.

Given the complexity, and an increasing lack of access to powertrain systems, this becomes an immensely powerful tool.

Why not rely on misfire detect? Well, in my opinion, this often does not identify problems immediately – especially with fuelling correction, ignition set-back and air-fuel sensor activity.

This is where you should be looking. The problem is engine fuelling strategies running excess air as the norm can cause possible internal damage. Bore wash, etc may already be taking place.

I’d like to share two quite simple images to represent my point, taken from a port injection, 1.4-litre twin-cam homogenous-fuelled engine.

1. Normal combustion activity

Let’s begin discussing vibration amplitude on the vertical scale, measured in milli-gravity. Values below 10mg are considered normal. The crankshaft E1 is virtually zero. The event at 28Hz is a separate fault within the timing-belt assembly. E0.5 is also virtually zero.

Ignoring the 28Hz event as unchanged, note that E0.5 combustion balance remains very low. However, look how E1 crankshaft vibration has increased dramatically. The mass of the piston, conrod and big-end journal offset, without ignition contribution, has increased rotational imbalance. This engine has 180-degree crankthrow separation. The biggest increase is in the vertical plane (red) but also lateral (green) and longitudinal (blue).

A three-cylinder engine has excellent rotational balance. However, all three reciprocating events never cancel each other out. The result is longitudinal imbalance. Ford’s EcoBoost 1.0 reduces this with a smart front pulley and flywheel.

components that supply and regulate this electrical power – the battery, starting and charging systems – and why stable voltage is the foundation of everything we do in automotive repair and diagnostics.

The modern vehicle’s electrical load

Gone are the days when a vehicle’s electrical system only had to support headlights, ignition and a basic radio. Today’s cars and light-commercial vehicles may be equipped with (pic 1):

• Advanced driver-assist systems (ADAS): Including lane-keep assist (LKA), adaptive cruise control (ACC) and automatic emergency braking (AEB) – all relying on a network of sensors, cameras, radar and control modules.

• Electronic power steering (EPS): Fully

consistently and require voltage stability to perform correctly.

• Start-stop systems: Found in most late-model vehicles, start-stop systems increase demands on both the battery and starter.

• Infotainment and connectivity: Touchscreens, digital dashboards, smartphone integration and telematics all consume significant current.

• Hybrid and EV platforms: With both high-voltage propulsion systems and traditional 12V support systems, voltage coordination is paramount.

Each of these components requires a dependable power supply and even slight drops in system voltage can cause them to malfunction or go offline.

Modern batteries are no longer tasked with simply cranking the engine. They now serve as a buffer and power reserve for sensitive electronics, particularly during engine-off periods in start-stop systems.

Key technical points include:

• Absorbent glass mat (AGM) and enhanced flooded battery (EFB) types are designed specifically for vehicles with start-stop technology.

• A fully charged battery should hold a resting voltage of 12.6V to 12.8V. Under load, voltage should not dip below 11.8V (pic 2).

• Many hybrids and EVs include a traditional 12V battery alongside highvoltage packs (typically 200V to 800V) to power body and accessory systems.

Choosing the correct battery type is essential. Installing a standard flooded lead-acid battery in a vehicle designed for AGM or EFB can lead to chronic issues and premature failure.

The starter motor demands significant current – anywhere from 150A to 250A depending on engine type and size. Weak batteries, voltage drop through corroded terminals (pic 3) or resistance in cables can cause:

• Slow or laboured cranking.

• ECU errors or resets.

• Failure to start altogether.

• Voltage output typically ranges from 13.8V to 14.7V.

• Current output may exceed 200A in vehicles with high electrical loads.

• Charging output is often varied based on load demand, temperature and battery condition.

Smart alternators use dynamic control to reduce engine load, improve fuel efficiency and extend battery life (pic 4). However, that also means traditional test methods (such as looking for a constant 14V at the terminals) may no longer apply.

Real-world case studies: When voltage goes wrong

• Case study 1: ADAS failures in a European SUV

Case study 2: Incorrect battery type in a delivery van

A commercial vehicle used for frequent short trips had been fitted with a standard flooded battery rather than the required EFB. The result was intermittent no-starts due to poor recharge performance under stop-start conditions. Once the correct battery was installed and the system reset, the no-starts disappeared.

• Case study 3: Hybrid sedan with ‘Check hybrid system’ warning

A hybrid presented with a warning and wouldn’t go into ‘Ready’ mode. While the high-voltage (HV) battery was fine, the 12V battery was weak (11.4V). This triggered safety protocols in the hybrid ECU, disabling the system. Replacing the 12V battery restored function instantly. I strongly suggest

for the application.

2. Charging-system checks:

• Confirm alternator voltage and current output.

• Test ripple voltage must be less than 0.3V.

• Inspect drive-belt condition and tension.

• Test smart-charging system behaviour with scan tools.

3. Correct replacement procedures

• Register new batteries in vehicles with BMS where applicable.

• Use memory-saver tools to retain module settings.

• Check voltage drops across key circuits (starter, grounds, charging cables).

Electrical faults are among the most common and most misdiagnosed problems in modern vehicles – and becoming more and more common. In many cases, they boil down to unstable or insufficient voltage from the battery or charging system. As technicians, we need to think beyond the obvious and understand the deeper implications of poor voltage control (pic 5). It’s not just about starting the car anymore. From ECU communication to radar-sensor calibration, it all starts with a stable voltage. Get that right and everything else is much easier to diagnose and repair.

Make a change, check every vehicle battery, charging system and overall electrical system before anything else. g

With these solutions, MAHLE says you can maximise 4WD maintenance

Maintaining four-wheel-drive (4WD) vehicles can be challenging, given their rugged use and complex systems. From off-road adventures to daily driving, these vehicles require specialised care to stay reliable.

This is where MAHLE says its Workshop Solutions come in, designed with the needs of mechanics and technicians in mind to offer practical, efficient tools to keep 4WDs performing at their best.

At the heart of these solutions is the MAHLE Workshop Heroes campaign, which celebrates the dedication and expertise of automotive technicians who go the extra mile to deliver quality service.

One of the most common maintenance challenges in 4WD vehicles is keeping the a/c system in top condition. Dust, mud, and harsh environments can clog condensers and reduce cooling efficiency.

MAHLE’s ArcticPRO AC servicing units offer efficient refrigerant recovery, recycling and recharging to ensure reliable climate control. These units are built to withstand the demands of regular 4WD maintenance, saving time and improving accuracy.

After a vehicle has been off-road, MAHLE says it is a good practice to inspect the a/c system for leaks or debris build-up – keeping the system clean prevents long-term issues and improves customer satisfaction.

4WDs are becoming increasingly advanced, with electronic systems controlling everything from engine performance to driver-assistance features.

Diagnosing and maintaining these systems can be tricky without the right equipment.

MAHLE explains that its TechPRO diagnostic tools offer real-time fault detection and system analysis, helping technicians identify issues quickly. Additionally, advanced driver-assist system (ADAS) calibration tools make it easy to recalibrate sensors and cameras after repairs, keeping safety features accurate and reliable.

MAHLE recommends that you regularly update your diagnostic software to keep up with the latest vehicle models. This ensures your workshop can handle both old and new 4WD systems effectively.

Keeping 4WD vehicles running smoothly also requires efficient fluid management, especially when dealing with transmission fluids, oils and coolants.

MAHLE’s FluidPRO fluid exchange systems streamline fluid maintenance, reducing

contamination risks and improving service efficiency.

These systems are designed to meet the demands of workshops handling a wide range of 4WD models, with MAHLE recommending that the transmission fluid is regularly serviced in those vehicles that are frequently used off-road to ensure optimal performance.

MAHLE says it recognises the hard work that mechanics and technicians put into keeping 4WDs running smoothly.

It states its solutions are designed to make maintenance easier, faster and more reliable. From a/c servicing to diagnostics and filtration, MAHLE says it is committed to providing the right tools for the job, helping workshop heroes deliver the best service possible.

• For more information visit mahle-aftermarket.com or email sales.australia@mahle.com

Engineers have developed several communication protocols over the years, including controller area network (CAN – high, medium and low speeds), local interconnect network (LIN), FlexRay and Class II among others.

These protocols facilitate communication between automotive ECMs, enabling seamless data exchange.

Each communication protocol operates within different voltage ranges and understanding these voltage specifications is essential for effective diagnosis of communication signals.

While a digital multimeter can measure the voltages of these signals, using an oscilloscope to capture and analyse waveforms is the preferred method for ensuring signal integrity.

In part one of this series and following articles, we will systematically explore the what-ifs, whys and hows of diagnosing CAN-bus problems.

But before we dive into waveform analysis, let’s examine two diagnostic scenarios.

A common scenario in automotive diagnostics involves replacing a faulty component – say, a Hall-effect wheelspeed sensor – based on DTCs.

The typical workflow is as follows:

1. Replace the faulty sensor with a new or used one.

2. Clear the DTCs.

3. Road-test the vehicle and if the DTCs don’t reappear, return the vehicle to the customer with the appropriate invoice. This approach may seem efficient, but what happens if the customer returns a few days later with the same symptoms and DTCs?

The diagnostician is then faced with the following possibilities:

1. Option 1: The initial replacement part was faulty, requiring another replacement (hopefully under warranty).

2. Option 2: The issue is unrelated to the sensor and further analysis is needed to identify the true fault.

At this crossroads, if the diagnostician chooses the first option, they may encounter the same symptom after another repair. Alternatively, if the second option is selected, they may be left wondering if the anti-lock braking system (ABS) control module or wiring loom requires replacement next.

Scenario 2: No communication with the BCM (faulty BCM)

This isn’t a hypothetical case but a real-world scenario encountered during diagnostics.

Consider a scenario involving a Holden VE Commodore, where a technician observes the following:

• No CAN-bus communication between the scan tool and body control module (BCM).

• Warning messages on the dashboard indicating the battery isn’t charging.

• Dim brake lights, including the centre high-mount stop light (CHMSL), remaining on.

• Dim park lights staying on.

• DTCs pointing to a fault in the BCM. At this point, the diagnostician might confidently conclude the BCM needs replacement (either new or used).

But what if the symptoms aren’t caused by a faulty BCM at all? What if the issue stems from a ‘lifted’ earth at the connector terminal of the BCM, where the voltage has risen from zero volts to 5.6V?

Replacing the BCM would not have fixed the problem as the actual issue was the faulty earth terminal, not the BCM. Once the earth terminal was repaired, the symptoms cleared and the problem was resolved.

This example highlights the importance of properly diagnosing the root cause of symptoms, whether related to the CAN bus or not.

Simply replacing parts based on DTCs or visible symptoms without understanding the integrity of the electrical system can lead to misdiagnosis and unnecessary part replacement.

Before jumping to conclusions, it’s essential to:

1. Identify the true cause of the symptoms. 2. Ensure voltages and waveforms match manufacturer specifications.

A vehicle will likely misbehave if its ECUs, air-flow meters (AFMs) or other critical components lack proper power or grounding. Proper diagnosis ensures the correct issue is addressed, saving time, cost and unnecessary repairs with indiscriminate replacement of parts

Thanks to Bosch, CAN is a protocol, a computer language, a method for communicating and exchanging component data and parameters between:

• Dedicated ECUs such as ABS, the transmission-control module (TCM) and ECM (see figure 1: red, blue and orange).

• Connected across a loop of wire (see figure 1: purple).

• With two 120-ohm resistors placed at either end of the loop (see figure 1: 120ohm red), where:

- One side of the loop connects to pin 14 of the diagnostic link connector (DLC) (see figure 1: yellow).

- The other side of the loop connects to pin 6 of the DLC (see figure 1: brown).

This brings us back to the question: how do we diagnose CAN bus and communication signals?

For basic checks, we will first start with the DLC.

Basic check for DLC and CAN bus

As the name suggests, the DLC is the link between a vehicle’s internal network of ECUs, which communicate with each other (see figure 1) and the outside world (i.e. a scan tool).

The DLC allows the scan tool to access important data such as DTCs, actual parameter values and enable programming or resetting of targeted ECUs.

Since the next step in diagnosing CANbus issues involves the DLC, proper power supply and grounds must be available –not only for the ECUs (as per figure 1) but also the DLC so the scan tool can function appropriately.

As shown in actual captured waveforms (see figure 2):

• Pin 16 is the supply voltage, which is captured during engine cranking at 11V and during running at approximately 14V.

• Pin 5 is the signal ground.

• Pin 4 is the chassis ground, which is captured during engine cranking at 0.7V and during running at approximately 0.15V.

In future articles, we will expand on analysing waveform fidelity but for now let’s redirect our attention to the basic impedance checks of the CAN-bus loop.

Impedance of the CAN-bus

Terminating resistors of 120 ohms are placed at either end of the CAN-bus loop to reduce standing waves – more on this in later articles – during active communication between ECUs (see figure 1: red).

These resistors – often referred to as ‘balun’ terminating resistors (short for ‘BALanced

to UNbalanced’) – improves the electrical ‘clarity’ of the signal (waveform).

When measuring the ‘total’ resistance of these terminating resistors between terminals 6 and 14 (see figure 1 or figure 3: yellow and brown wires), the total resistance must measure 60 ohms (since the resistors are in parallel).

The actual location of these resistors can vary depending on the manufacturer’s make and model.

These resistors can be integral parts of dedicated ECU or physically located anywhere within the chassis (e.g. under the glovebox).

For the specific location of these 120-ohm resistors, technicians should refer to OEM data.

Important note: Resistance should only be measured between terminals 6 and 14 (see figure 3: yellow and brown wires) when CANbus communication is completely stopped (i.e. ignition off, key removed, all doors shut and vehicle left idle). This is because active voltage changes during communication interfere with a digital multimeter’s range for resistance measurement (ohms range and active voltage changes do not mix well).

The two wires of the high-speed CAN-bus loop (connected to DLC terminals 14 and 6 respectively) are known as the high and low sides of the CAN bus (see figure 3: yellow and brown wires).

When ECUs on the loop are idle and there is no communication taking place, both terminals (6 and 14) will have a steady ‘quiescent voltage’ of 2.5V (see figure 3: A purple and B blue).

However, as ECUs begin to communicate and exchange data, the following occurs:

• The high-side signal of the CAN bus (see figure 3, terminal 14) rises from 2.5V (A) to approximately 3.6V (B), hence the name CAN_H (high).

• The low-side signal of the CAN bus (see figure 3, terminal 6) drops from 2.5V (C) to approximately 1.3V (D), hence the name CAN_L (low)

This ‘push-pull’ signal arrangement, thanks to Bosch, allows ECUs to exchange information reliably.

From a diagnostic perspective, it is crucial to measure waveforms at the DLC’s terminals 6 and 14 (high and low sides of the CAN bus) and check for fidelity. The waveform should be free from abnormal signals or interference superimposed on the signal (more on waveform fidelity in later articles).

Diagnosing CAN bus begins with:

• Ensuring healthy supply voltages and grounds for all ECUs to facilitate communication and data exchange while active on the loop (see figure 1).

• It’s just as important to ensure proper supply voltages and grounds at the DLC so the ECUs on the loop can communicate with the outside world (via the scan tool).

• And the ‘total’ resistance of terminating resistors between terminals 6 and 14 (see figure 1 or figure 2: yellow and brown wires) must measure 60 ohms (approx.) since the two 120-ohm resistors are in parallel.

As the old adage goes, if there are no healthy supplies or grounds, nothing will work – or if it is, it will be very temperamental.

Until next time, can you guess what the waveform would look like if you were to ‘add’ the CAN_H and CAN_L waveforms together (see figure 3)? Would this be beneficial during the CAN-bus diagnostics stage?

And above all, how would you go about doing this? g

Brendan Sorensen

Modernscan tools are capable of far more than many technicians realise.

We’re well past the era of code reads and service reset – today’s platforms are powerful diagnostic hubs offering deep access to vehicle systems and intelligent testing routines that can significantly improve the speed and accuracy of diagnostics when used to their full potential.

Before diving into scan-tool functionality and the items to look for on a modern tool, I’ll start with a quick nod to a few core areas I consider non-negotiable in any evidencebased diagnostic workflow: OBDII generic mode and freeze frame data.

Whether freeze-frame snapshots are OBDstandard or manufacturer-specific, they’re your best shot at understanding the situation in which a fault occurred – what the vehicle was doing, what the conditions were and whether it’s something you can recreate.

These are fundamentals and something every scan tool is capable of but sometimes underutilised. For a deeper breakdown of how I use these, along with OBD Mode $06 data, in real-world diagnostics, I recommend checking out my Diagnostics: A Profitable, Evidence-Based Approach to Testing webinar, available via the TaT training site. With that foundation laid, let’s talk about what your scan tool should be doing for you in 2025 – and how to make sure it’s earning its keep around the workshop, not just on diagnostic jobs.

Don’t just pull codes:

Capture a story

One fault in a modern vehicle creates a knock-on effect in other modules, often giving pages of fault-code data due to what I call ‘sympathy’ codes – those nothing-type codes simply acknowledging another module reported a fault.

Writing codes on a whiteboard or in a notebook doesn’t cut it anymore. You need a reliable, repeatable method for documenting scan data across the entire job – from prescan to post-repair confirmation.

In our shop, we’ve set up dedicated systems based on what each tool is capable of, where some can email full vehicle scans or screenshots during the job directly to a dedicated Gmail account we’ve created (pic 1), while some can upload automatically to brand-specific cloud platforms.

This means I can access information from a job I looked at 18 months ago with just a quick search. Once it’s running smoothly, this kind of documentation workflow is invaluable, firstly for selling the value of the job at invoice time and especially for intermittent faults or ‘ever since you’ scenarios.

This extends well beyond fault codes –screenshots, freeze-frame data and livedata parameter ID (PID) data logs should all be captured routinely. Good tools make this painless. If your current tool doesn’t, consider that a limitation worth noting.

There’s no comparison between watching a moving number versus seeing a graph. Watching a fuel-rail pressure value move between 8000 and 9000psi might not raise an eyebrow unless you see that fluctuation plotted against steady inputs of RPM, throttle input, load and fuel-pressure regulator command or even target rail pressure if

available. Cause and reaction jumps out instantly.

Most of the time, I’m logging data with graphing enabled. I also rely on minimum/ maximum markers to alert me to brief dropouts – even if the fault only occurs once during a two-hour idle in the corner of the workshop, falling well outside the recordable buffer range, min/max info will still be displayed for the whole test period.

Better tools let you review logs with zoom functions on the tool itself but connecting to a PC with the tool’s own viewer software if available typically gives the best resolution and control (pic 2).

Favour tools that give access to live graphable data during bi-directional tests. Sometimes this is a manufacturer-specific test limitation but I certainly know I have tools that – when used on the same bi-directional test – allow me to look at data to see that the actuation was actually commanded, while others don’t allow me to see that data, leaving me wondering if the bi-directional command was ever even given, or if the scan-tool software for this actuation is bugged.

If you’ve ever had your scan tool crawl during a live-data session, you’ve likely fallen into the PID overload trap.

Tools can only refresh (display) so much data in real time. On the flipside, they can only display as much data as the network is providing and some networks, or particularly modules, are painfully slow.

These are even more reason to limit your PID selection to the bare essentials. The more PIDs you ask for, the slower the refresh rate. Some tools group data by system (fuel, emissions, heating, ventilation and a/c [HVAC], etc), but that can be restrictive if two critical PIDs live in different groups.

The better tools give you full control,

including the ability to select individual PIDs across multiple modules.

That last bit is becoming more of a factor –graphing rail pressure from the powertrain control module (PCM) and in-tank fuel pump current from the fuel-pump control module (FPCM), may show a correlation during the fault, even though the OEMs never thought to send the information to both modules.

This is where scan tools are heading –OE-style test plans that walk you through actuator tests, monitor feedback live and even offer interpretations (pic 3).

It’s no longer just ‘command the valve open’ – it’s ‘command the valve open, measure the slope of the manifold absolute pressure (MAP) response, compare it to expected behaviour and tell the tech whether it passed.’

Some tools are even venturing into guided component tests with live interpretation, where you’re walked through a procedure step by step, sensor data is assessed dynamically and – based on live readings or a pass/fail – the next-step suggestion in the test plan is given on the spot.

This isn’t about dumbing down diagnostics – it’s about speeding up the repetitive parts and letting you focus on the actual fault path while reducing the need to sift through thousands of pages of service information and diagrams manually.

Forget basic module lists. Top-end scan tools now offer vehicle-topology views which show you each module, how it connects to the network and whether it’s communicating, throwing codes or absent (pic 4).

This topology graphic can quickly highlight a dropped-out module that could otherwise go unnoticed on some other tools where I’ve

seen a non-communicating module simply not even listed in the full vehicle-scan report – you can’t go looking for it if you don’t know it exists.

Even if you’re not actively diagnosing a U-code, topology maps teach you a lot about different network architectures, improving your knowledge as you interact with the scan tool for day-to-day tasks.

Programming, coding and the pass-thru

J2534 pass-thru isn’t new but how your tool handles it is key.

Some come with J2534 vehicle communication interfaces (VCIs) that are widely recognised and accepted by manufacturers’ programming applications, while some aren’t recognised by certain manufacturers and therefore won’t work. Others integrate some coding and programming functions directly into the scan tool interface for certain brands using cloud-assisted systems, avoiding the need to purchase and use a manufacturer programming subscription for certain jobs. But be careful with cloud-based programming. When the tool auto-identifies the vehicle and picks a calibration from its internal database, you’re relying entirely on that being correct and current. One wrong match and you could have a bricked module. Use with caution and wherever possible cross-check the calibration number manually. In the case of fault-rectification software updates, the old and new calibration numbers may be shown on a technical service bulletin (TSB).

CAN-FD, EV diagnostics and gateway access

If your tool can’t speak Diagnostics over Internet Protocol (DoIP) or controller area network with flexible data rate (CAN-FD), it’s already behind.

These protocols aren’t coming – they’re here and necessary for communication during service and diagnostic work on modern vehicles.

Be careful. Some tools claim they’re ‘DoIP ready’ or ‘CAN-FD compatible’ but require a specific add-on VCI; these typically older tools can be upgraded simply by purchasing an updated VCI or OBD cable for the device. Electric vehicle (EV) and hybrid diagnostics is another emerging frontier. Scan tools are advancing the way they display items such as cell-level voltage, temperature and resistance spread using easier to decipher formats such as bar graphs or green/red colouring. Handy features such as showing min/max readings across 100-plus cells, even if specific PIDs for that were not supplied by the manufacturer – the scan tool has all the cell PIDs, so it can create these calculated outputs in certain high-voltage (HV) related areas of the tool.

And more impressive still, some scan-tool driven HV battery state-of-health (SoH) tests now incorporate artificial-intelligence (AI) driven, crowd-sourced data, comparing your vehicle’s readings to a database of thousands of other tests on the same vehicle model, giving you a real-world context of what’s ‘normal’ for that battery age and usage and incorporating this – along with actual battery-management system (BMS) PID readings – into printable reports for the customer.

Security gateways are a nuisance without proper tool support. Fiat Chrysler Automobiles (FCA), Mercedes-Benz, Renault, Nissan, Volkswagen Audi Group (VAG), Kia – you name it, everyone is moving toward restricted access.

Some tool vendors are stepping up, offering automated integration procedures on the tool to allow you to easily purchase manufacturerspecific gateway access, avoiding the labyrinth of manufacturer websites. Or – even easier – some are including certain gateway unlocks as part of their subscription pricing, so if the tool is in subscription you walk past the gateway without even knowing it was there.

A scan tool is a business investment. Make sure you know:

• How long the first subscription runs.

• What the annual renewal costs are.

• Whether extra fees apply for programming, gateway unlocks or remote technical assistance.

A cheap tool with expensive, mandatory renewals may end up costing more than a higher end unit with transparent pricing.

Similarly, if you already have multiple tools with high-end features such as pass-thru devices and oscilloscopes, a lower tier scan tool that forgoes these may offer the same scan-tool functionality but without the higher subscription price of the top-tier model with all the bells and whistles.

If a tool’s support is based in another time zone, you’ll struggle. For coverage, some tools are great for including 50 Chinese brands you’ve never heard of but when the day comes and it clears that XPeng’s service light it’s invaluable.

Such a tool needs to be backed up by

another tool that may not cover as wide a range but gets into every nitty-gritty reset, module and adaptation for the core brands that frequent your workshop.

The scan tool of tomorrow: Where we’re headed

Let’s look ahead. The tools we’re starting to see now hint at where diagnostics is going, with some already providing some of the features listed below, but when you put them together my vision of the future of scan tools is as such:

• You are viewing live scan-tool data of a sensor while overlaying expected values. Also on screen is a wiring diagram; swipe across and you see the pinouts. Connect your built-in oscilloscope and it auto-configures to suit the sensor, splitscreening to compare scan data versus live scope data.