Automechanika Frankfurt

Frankfurt Exhibition Grounds

8 – 12 September 2025 www.automechanika.messefrankfurt.com

AAPEX 2025

The Venetian Expo & Caesars Forum Las Vegas 4 – 6 November 2025 www.aapexshow.com

SEMA Show 2025

Las Vegas Convention Center 4 – 7 November 2025 www.semashow.com

Automechanika Shanghai

National Exhibition and Convention Center (Shanghai)

2 – 5 December 2025 www.automechanika.messefrankfurt.com

Automechanika Dubai

Dubai World Trade Centre 9 – 11 December 2025 www.automechanika.messefrankfurt.com

PRI Show 2025

Indianapolis, Indiana, USA 11 – 13 December 2025 www.performanceracing.com/tradeshow

Australian Auto Aftermarket Expo 2026

Melbourne Convention & Exhibition Centre 14 – 16 May 2026 www.autoaftermarketexpo.com.au

Collision Repair Expo 2026

Melbourne Convention & Exhibition Centre 14 – 16 May 2026 www.collisionrepair.com.au

Chairman

Azzco Garage

Factory 2, 411 Old Geelong Road

HOPPERS CROSSING VIC 3029

Ph: 03 9360 0255

E: ivan@azzcomelbourne.com.au

Cece Crash Repairs

Noranda Service Centre

2/3 Cobbler Place MIRRABOOKA WA 6061

Ph: 08 9376 1155 E: nor_serv@bigpond.net.au

Pezs Auto Electrics

18 Waine Street FRESH WATER NSW 2096

Ph: 0421 406 460

15 Charles Street NORWOOD SA 5067

Ph: 08 8362 5440 E: admin@cececrash.com.au

Commerical Auto Parts Australia

1/23 Letcon Drive

DANDENONG SOUTH VIC 3175

Ph: 1300 132 272

E: info@commercialautoparts.com.au

Divideit

51/53 Perrott Drive ROCKYVIEW QLD 4701

Ph: 07 4936 1143 E: admin@divideit.com.au

Dredge Machinery

40 Wakaden Street GRIFFITH NSW 2680

Ph: 02 6964 6166 E: bajaco@bigpond.com

Evolve Technik

3A Clipsal Drive BAYSWATER NORTH VIC 3153

Ph: 1300 980 898 E: cf@evolve-technik.com.au

Foster Cars & Off Road

92 Main Street FOSTER VIC 3960

Ph: 03 5682 2166

E: info@fostercarsandoffroad.com.au

Grimshaw Automotive

3/30 Clements Ave BUNDOORA VIC 3083

Ph: 03 9467 6328 E: desieurohaus@gmail.com

Harvey’s Towing Service

3820 Mount Lindesay Highway

PARK RIDGE QLD 4125

Ph: 07 3297 0911

E: light.vehicle@harveysmechanical.com.au

Max Oddie Automotive Repairs

29 Moore Street LEICHHARDT NSW 2040

Ph: 02 9552 2054 E: maxoodi@bigpond.com

Newcastle Auto Electrics

111a Bourke Street CARRINGTON NSW 2324

Ph: 02 4961 5998 E: dean@nae.com.au

Repco Authorised Service Airport West (Georges Dynamic Autos)

33 Hood Street AIRPORT WEST VIC 3042

Ph: 03 9335 6549

E: georgesdynamicautos@gmail.com

Repco Authorised Service Daylesford (Courtot Automotive)

2 Mink Street Daylesford VIC 3460

Ph: 03 5348 3167

E: courtotautomotive@outlook.com

Repco Authorised Service Terang (Aitken Bros Autos Terang)

146 High Street Terang VIC 3264

Ph: 03 5592 1184 E: aitkenbrosautos@gmail.com

Repco Authorised Service Wendouree (Neale Goad Automotive Wendouree)

206 Burnbank Street WENDOUREE VIC 3355

Ph: 03 8373 7463

E: paul@nealegoadgroup.com.au

Roof Space

Level 1, 201 Elizabeth Street SYDNEY NSW 2000

Ph: 02 8296 0489

E: marketing@roofspace.com.au

Sydney Performance Centre

2/19 Sleigh Place WETHERILL PARK NSW 2164

Ph: 1300 888 793

E: info@sydneyperformance.com.au

Tasman Auto Electrics Pty Ltd

U6/7 Cessna Way CAMBRIDGE TAS 7170

Ph: 03 6265 8032

E: info@tasmanautoelectrics.com.au

Tyreplus Phillip 6-8 Botany Street PHILLIP ACT 2606

Ph: 02 6282 3410 E: phillip@tyreplus.com.au

DIRECTORS

I’ve just returned from Autocare 2025 and what an incredible few days it was in Brisbane

Australia’s largest skills and training event for the automotive industry delivered an extraordinary experience – uniting professionals from every corner of our sector for two powerful days of education, innovation and connection.

Autocare has grown into much more than a training convention. It’s a national platform where we chart the course for the future of automotive service and repair.

The energy throughout the venue was incredible. Seeing the Convention Centre halls filled with engaged workshop owners, technicians and apprentices was a sight to behold. It was fantastic to see the smiles on people’s faces, the aisles full of conversation, and even the nearby pubs and restaurants buzzing with our people networking, building relationships and sharing ideas.

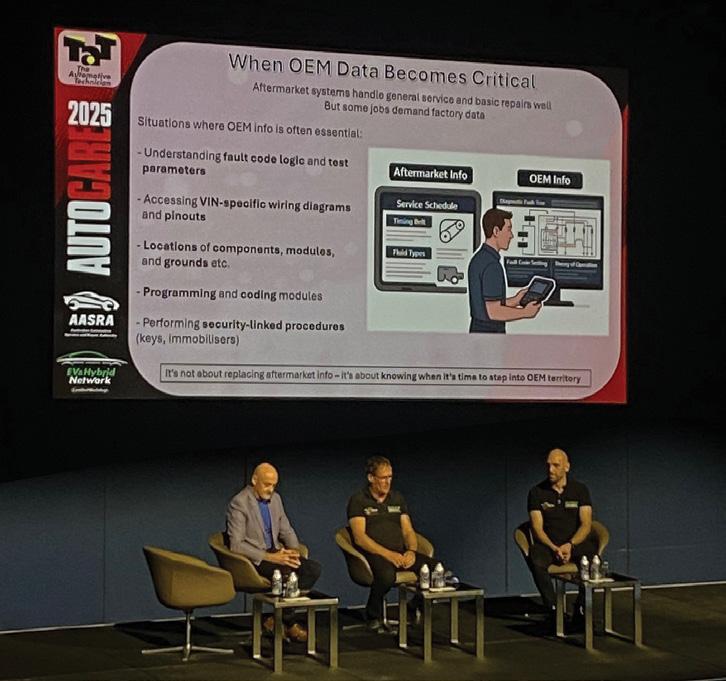

No other event offers the level of training Autocare offers, and 2025 featured over 40 training and panel sessions across two purpose-built programs.

The Technical Training Program took things to another level, with in-depth sessions led by some of the best in the world – including Brandon Steckler, Keith Perkins and Tomi Oliva – who joined Australia’s top trainers to deliver advanced content on diagnostics, EVs, ADAS, J2534 programming, network failure and diagnosis, oscilloscope essentials, diesel and emission control diagnostics, and more. Technicians gained the information they need to accurately and efficiently service and repair the latest generation vehicles.

Running alongside that, the Workshop Management Program delivered some of the most informative and practical business education I’ve seen. The content, topics, speakers and panels were exceptional, covering the future of the industry, AI integration, skills shortages, the all-makes repair model, EV impacts, marketing, productivity, how to leverage Australia’s Motor Vehicle Information Scheme

(MVIS) to enhance diagnostic and repair capabilities and more. The sessions were tailored for business owners and delivered real-world strategies to help them grow and adapt in a changing environment.

A defining moment at Autocare was the launch of the new ADAS Industry Code of Conduct.

This national Code brings practical, sector-specific guidance to one of the most important safety issues in modern vehicle repair: calibration of Advanced Driver Assistance Systems. It’s a first for our industry – designed by and for the aftermarket – and provides technicians across mechanical, windscreen, tyre and collision with clear procedures, checklists and decision-making tools to ensure these life-saving systems continue to function as intended after repair.

ADAS isn’t just a technology trend – it is a foundation of future mobility. With vehicle systems like AEB and lane-keeping assist now standard, our industry needs to step up to ensure we’re servicing them safely and consistently. This Code is our proactive response. It shows that we’re willing to lead from within – without waiting for government intervention. I want to thank Craig Baills, Lesley Yates, the Automotive Repairers Council of Australia (ARCA), and all those who contributed to what is truly a game-changing initiative for our sector.

The Autocare Trade Show stepped up in 2025, with more than 120 exhibitors bringing the latest workshop tools, diagnostic equipment, parts and service solutions to life on the trade show floor. The size and quality of the show was an impressive and complementary part of the convention.

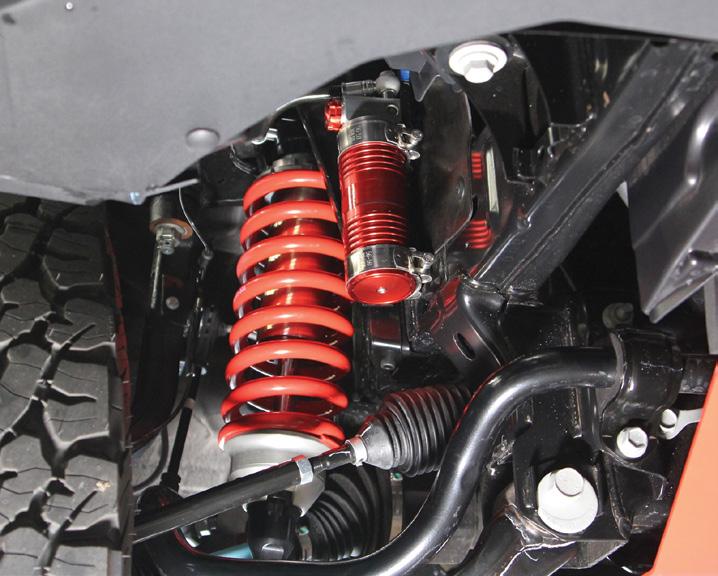

Another standout was the National Light Vehicle Modifications Summit. This unique forum brought together influential regulators and key voices from the 4WD and modifications industry for a powerful day of interactive, high-impact discussion. The content and calibre of attendees will have farreaching and long-standing influence over how government engages with our industry on key issues like VSB 14, ROVER, GCM/GVM upgrades, EV, ADAS, NVES and more.

With apprentice tickets heavily discounted as part of Autocare’s commitment to foster the next generation, it was fantastic to see so many young automotive professionals at the event. Complementing this initiative, was the Flying Spanners competition, showcasing young talent in an engaging, high-energy format – it was a massive highlight and a huge success.

I was also proud to see more female leaders and workshop owners take the stage than ever before. The AAAA is committed to fostering an inclusive and representative industry, and I know the next

generation of professionals – regardless of gender – will be inspired by their leadership. Autocare doesn’t happen without the support of many. Thank you to our exceptional trainers, presenters and exhibitors. Thank you to our Platinum Partner mycar Tyre and Auto, our Diamond Partners Brembo and Supercheap Auto Trade, and all of our supporting sponsors. A special thanks to MSE Events Group for delivering the event to such a high standard, and to our AAAA Board and staff for their commitment and hard work behind the scenes. And finally, thank you to every delegate, workshop owner, technician, apprentice and trade visitor who created a large, highly engaged Autocare audience. Your energy, your passion, and your willingness to invest in yourselves and your teams made Autocare 2025 truly special.

We are an industry that never stands still – and Autocare proved once again that we are united, capable, and ready for the future.

Stuart Charity Chief Executive Officer

Capricorn Group

CEO Brad Gannon is excited for the new financial year

The beginning of a new financial year always fills me with optimism about the possibilities in front of Capricorn and the industry as a whole.

This year, we are proud to be celebrating the United Nations International Year of Cooperatives with the theme ‘Cooperatives build a better world.’

As a board member of the Business Council of Co-operatives and Mutuals (BCCM), I am always proud to celebrate the contribution of cooperatives and mutuals and their important role in protecting and benefiting their members. It’s also a terrific opportunity to reflect on Capricorn’s legacy.

For 51 years, Capricorn has been operating on cooperative principles, ensuring that every decision we make will benefit our Community.

Originally founded by a group of 17 Golden Fleece service station owners in Western Australia, Capricorn has grown to have more than 30,000 Members across Australia and New Zealand.

That legacy of doing what’s right for our Members, our People and Preferred Suppliers hasn’t changed over this time.

As we look towards the next 50 years, we remain committed to listening and adapting for our Community.

Speaking of adapting, last month Capricorn celebrated the launch of its first Ecommerce Partner — JB Hi-Fi Business.

This partnership will make it easy and simple for Members to purchase items they need for their business online via a Capricorn Trade Account, while still getting all the benefits they know and love.

Tickets are now available for Capricorn’s Gala Dinner and Trade Shows. These events bring together people from throughout our industry and the whole Capricorn Community in six different cities. It is a wonderful way to connect and learn from Preferred Suppliers at the Trade Shows and celebrate a fantastic year at the Gala Dinners. I hope to see you there.

For more on Capricorn Society memberships, visit www.capricorn.coop

VSB 14 sets out the national guidelines for light vehicle modifications

The Australian Automotive Aftermarket Association (AAAA) is calling on the Federal Government to ensure the review of Vehicle Standards Bulletin 14 (VSB 14) remains a top priority — warning that the momentum achieved so far must not be allowed to stall.

VSB 14 sets out the national guidelines for light vehicle modifications. While technically a voluntary document, it is used by state and territory road agencies to assess roadworthiness and compliance.

But inconsistencies in how VSB 14 is interpreted and applied have led to confusion, delays and frustration for industry and certifiers alike.

The appeal follows the 2025 National Light Vehicle Modifications Summit, where Aaron De Rosario from the National Transport Commission (NTC) addressed more than 200 delegates with an update on the VSB 14 review.

Held as part of the Autocare 2025 Convention in Brisbane, the Summit brought together certifiers, engineers, manufacturers, compliance specialists, regulators, and enforcement agencies from across the country.

It is the only national forum where all sectors of the light vehicle modifications ecosystem gather to share insights, identify barriers, and collaborate on practical reform.

AAAA Chief Executive Officer Stuart Charity said the level of engagement at the Summit underlines the importance of the review — and the widespread desire across industry and government for nationally consistent, modern, and workable standards.

“We have a rare opportunity to address decades of regulatory inconsistency and confusion,” Stuart said.

“The current state-by-state patchwork of rules is costly, frustrating, and inefficient for both industry and regulators.

“The VSB 14 review is our best chance to fix that — to deliver a clear, practical and safety-focused national framework.”

The AAAA has written to the Honourable Catherine King MP, Minister for Infrastructure, Transport, Regional Development and Local Government, encouraging her to maintain strong Ministerial oversight and ensure the review does not slip down the government’s priority list.

“Reform at this scale only succeeds when it is visible at the highest levels,” Stuart said.

“We understand the Minister is managing a wide range of national priorities, but this one matters.

“National consistency matters. So does productivity — and a streamlined, harmonised regulatory system will deliver real productivity gains across manufacturing, engineering, certification and enforcement.”

The AAAA emphasises that time lost to navigating conflicting jurisdictional requirements represents a significant productivity burden, particularly for small and medium-sized businesses.

“This is a government that rightly wants to lift productivity — and VSB 14 is a textbook example of how smart regulation can reduce red tape, lower compliance costs, and unlock efficiency,” Stuart said.

Stuart also praised the NTC for its leadership of the review process and thanked Mr De Rosario for engaging directly with National Light Vehicle Modifications Summit delegates.

“Having Aaron in the room sent a clear message that government is listening — and that collaboration is valued. That momentum now needs to be maintained through the next stage of the review,” Stuart said.

“This is not about lowering standards — it’s about raising confidence. We want a clear, fit-forpurpose system that supports innovation while upholding safety.

“The industry is ready to play its part. But we need a framework that reflects the complexity and capability of modern vehicles and modification practices.”

…but we had better start responding

When the United States announced a 100 percent tariff on Chinese electric vehicles (EVs) in 2024, it made global headlines.

The stated reason? National security and economic sovereignty. The real message? Trade barriers are back and the politics on national sovereign capability is driving the bus. But here in Australia, we can’t afford to just watch from the sidelines because the truth is, we’re already in this trade war.

Australian automotive exports to the US are now subject to a 25 percent tariff. Our steel and aluminium exports? Hit with a 50 percent tariff. And if you were fortunate to dodge those bullets you still receive the 10 percent baseline reciprocal tariff.

These are punitive trade measures that weren’t aimed at us, but we’ve been caught in the crossfire. And that means we need to stop asking whether tariffs affect us. They already do.

We’re one of the most open car markets in the world. We import almost everything we drive. That openness gives us access to innovation, but it also leaves us deeply exposed when the global rules change.

So instead of outrage, we need a strategy. What should Australia do now?

Our federal government has tools – it should use them

We can’t rewrite US trade policy, but we can support our local industry to adapt and thrive. One of the best tools already in our kit is the Export Market Development Grants (EMDG) program.

In an era of rising protectionism, EMDG just became even more important. It helps Australian businesses take their products to new markets including, the high-performing 4WD, performance,

and offroad component manufacturers that Australia is known for.

From digital campaigns to trade shows, EMDG supports real export activity. But it needs more visibility, quicker approvals, and renewed investment. This is the right policy tool, at the right time.

Double down on where we lead

Australia won’t be restarting mass car manufacturing. But we don’t need to. Our strength is in high-performance, high-ingenuity specialist manufacturing: 4WD suspension systems, offroad accessories, performance tuning, workshop equipment, and niche diagnostics.

These are sectors where AAAA members already lead the world.

The federal government should treat these industries as national strategic assets and support them accordingly, especially in export development and global market access.

Secure diverse and stable vehicle supply

As global tensions escalate, Australia must protect access to vehicles, parts, and technology from a range of countries.

That means smarter trade diversification, welcoming new market entrants, and ensuring our local settings encourage, not hinder, open competition and resilient supply chains.

Use domestic policy to defend fair competition

Tariffs aren’t the only barriers that matter.

Technical regulation – from emissions to telematics to ADAS servicing can quietly shape or shrink an industry.

Australia must continue to build policy frameworks that defend competition, ensure repair access, and reflect our unique driving conditions.

Lesley Yates, AAAA Director of Government Relations and Advocacy info@aaaa.com.au

Australia didn’t pick this trade war but we’re already in it.

The resilience and ingenuity that we have seen first-hand from our local manufacturers is a testament of our industry.

We respond, we adapt, and we overcome. We don’t sit on the sidelines and let our fate be controlled by others, we fight and shape our own future, but we shouldn’t have to do this alone.

It is time for our government to back the sectors where we lead the world, support our exporters with real tools like EMDG, and build a more resilient, fair, and forward-looking automotive market.

If you would like to offer your thoughts on this subject, please email advocacy@aaaa.com.au

The AAAA will make a detailed submission to the review

The Australian Automotive Aftermarket Association (AAAA) has welcomed the Federal Government’s announcement of a formal review into the Motor Vehicle Service and Repair Information Sharing Scheme (MVIS) — Australia’s first Right to Repair law — which came into effect in July 2022.

“This is a law we are incredibly proud of — because we fought for it,” AAAA Chief Executive Officer, Stuart Charity, said.

“We spent ten years building the case, standing firm against powerful multinational car companies, and working with government and regulators to make Australia the first country outside the United States to legislate a mandatory data sharing regime for motor vehicle service and repair.”

The review, led by Treasury as part of the Albanese Government’s National Competition Policy reform agenda, will assess whether the Scheme is meeting its legislated objectives, including:

• Promoting competition in the service and repair market.

• Supporting consumer choice of repairer.

• Ensuring affordable and fair access to service and repair information.

• Protecting safety and security information.

• Supporting technical training and workforce capability.

• Providing effective dispute resolution.

“The law was a game-changer for our sector,” Stuart said.

“It gave independent workshops fair access to essential repair information and helped drive down costs for consumers.

“But the way vehicles are built, serviced and connected has changed rapidly — and the law must evolve with it.”

The AAAA will make a detailed submission to the review and has identified several key areas where reform is urgently needed:

• Telematics and real-time vehicle data: as more diagnostics move online, access to telematics data is essential. The current law excludes telematics, leaving independent repairers at a growing disadvantage.

• Access to online logbooks and service histories: the Scheme does not cover electronic logbooks, allowing manufacturers to use service history as a lever to steer customers away from independent workshops.

• Clarity for data aggregators: these thirdparty platforms help translate complex OEM information into practical repair workflows. The current treatment of aggregators under the law creates legal uncertainty and could jeopardise access.

• Standardised access tools and costs: some manufacturers limit access to information via locked-down proprietary tools. AAAA is calling for support for open, standardised protocols like SAE J2534 to reduce costs and barriers.

• Better training access for safety-critical systems: repairers must meet ‘fit and proper person’ tests to access high-voltage and security-related data — but training is not

always available or recognised, creating unintended blocks.

• Transparent pricing and stronger enforcement: the law requires ‘fair market value’ for data access, but enforcement remains weak. Some brands still charge excessive fees or restrict access in breach of the rules.

Stuart also warned that the review must not be used as an opportunity to water down the law.

“We know from experience that global car manufacturers will try to crawl back into the Australian public policy debate to reclaim control. We cannot let them succeed,” Stuart said.

“This law was designed to serve consumers, small business workshops, and Australia’s technical workforce — and we must defend and improve it, not retreat from it.”

The Scheme applies to all passenger and light goods vehicles built since January 2002 and is backed by enforcement powers held by the ACCC. Dispute resolution and industry compliance are overseen by the Scheme Adviser, the Australian Automotive Service and Repair Authority (AASRA).

The consultation period runs until 5 August 2025, with details available on the Treasury website.

The AAAA also welcomes Assistant Minister Andrew Leigh’s decision to reappoint AASRA as Scheme Adviser for a further two-year term — a move that signals confidence in AASRA’s role and provides valuable continuity and industry support as the Scheme matures.

“Right to Repair is not a one-off win — it’s a long game,” Stuart said.

“This review is our opportunity to finish what we started: a future-proof law that guarantees fair access to repair information and puts consumers firmly in the driver’s seat.”

For more from the AAAA, visit www.aaaa.com.au

The Australian Automotive Aftermarket Association (AAAA) is urging NSW Premier Chris Minns to step in and halt a deeply flawed plan to mandate specific training for electric vehicle (EV) servicing — warning that the policy is based on poor analysis, is out of step with every other state, and risks serious consequences for EV owners and small businesses.

The AAAA understands that the Premier’s office is now taking an interest in the issue and says that now is the time to act — before the proposal does real harm.

Under the plan, every technician who performs work on an EV — no matter how routine — would be required to complete a rigid skill set (AURSS00064), even if their existing training already covers safe working practices.

The model has been widely criticised for misunderstanding how modern workshops operate and how risk is managed by teams with task-based roles and clear internal training systems.

“This is not good policy — it’s a mess,” AAAA Chief Executive Officer, Stuart Charity, said.

“No other state is doing this. The model is flawed, the consultation process has been poor, and the regulatory impact assessment is frankly embarrassing.”

The Regulatory Impact Statement (RIS), released to support the proposal, fails to include any economic modelling — not a single estimate of the cost to train staff, nor any quantification of the cost to businesses.

With EVs currently making up just two percent of workshop throughput, the cost burden is significant — but completely unaccounted for.

“The easiest path for many workshops will be to simply stop servicing EVs,” Stuart said.

“The RIS didn’t even attempt to quantify this training mandate as a business cost. There’s no modelling, no course availability analysis, no unintended consequences examined.

“How do you put forward a Regulatory Impact Statement with zero cost estimates and call it complete?”

The AAAA says the proposal is based on outdated assumptions — particularly the false belief that industry won’t train unless forced to do so.

“This is white-collar snobbery masquerading as regulation,” Stuart said.

“It assumes that unless the government intervenes, our industry will operate unsafely.

“That’s simply not true. We train because we are

The AAAA has awarded Stephen Kasapis for his outstanding contribution to the automotive industry

The Australian Automotive Aftermarket Association (AAAA) was proud recently to award Stephen Kasapis with a Special Recognition Award.

Stephen was bestowed with the Award in honour of his exceptional contribution to the automotive repair and service industry.

Sadly, Stephen passed away shortly after receiving the Award.

Across his career, Stephen had built a reputation as a respected business owner, mentor and advocate for higher standards in diagnostics, training and workshop performance. But the AAAA says what truly set him apart was the way he consistently gave back – supporting others with generosity, humility and a passion for collaboration.

Beyond the success of his own business, Stephen was also instrumental in driving positive change through his involvement with industry groups such

as The Automotive Technician (TaT) network and the Garage Network.

He also played a key role in introducing the DPF Doctor program to Australia, helping workshops navigate complex diesel diagnostics with confidence.

Throughout the industry, Stephen’s influence has been deeply felt. Many of his peers, both in Australia and internationally, have reached out to share how his mentorship, technical knowledge and willingness to help have shaped their careers.

Automotive leaders such as Maurice Donovan, Jeff Smit, Darryl Blacker, and international trainers like Brandon Steckler, Frank Massey and Darren Darling have all acknowledged Stephen’s significant impact.

“Stephen’s legacy is one of service, leadership and integrity,” AAAA Chief Executive Officer, Stuart Charity, said.

professionals — safety is core to what we do, and to how we build trust with our customers and our teams.”

The industry is also alarmed by the so-called “transition period” being discussed by the Office of Fair Trading — a three-to-five-year window in which the regulations would apply but not be enforced.

“Let’s be clear — this is not a real transition,” Stuart said.

“It’s not written into the regulations. It’s just a nonenforcement promise that could be revoked at any time.

“That leaves workshops in an impossible position — either break the law and hope for the best or refuse EV work and let the backlog grow.”

The AAAA is calling on Premier Minns to intervene, request a full reassessment of the proposal, and ensure that any EV policy is evidencebased, nationally aligned, and developed in true consultation with industry.

“We know your office is now aware of this issue — and rightly concerned. There’s still time to stop this from becoming a political and operational disaster,” Stuart said.

For more from the AAAA, visit www.aaaa.com.au

“He embodied the values of our industry at its best.”

This award stands as a tribute to a career that has uplifted not just businesses – but people.

All at the AAAA and AAA Magazine send their heartfelt condolences to Stephen’s family and friends at this sad time.

The event was held at the RACV Royal Pines Resort on the Gold Coast

The Evolve Auto Festival 2025 was held on 24 May on the Gold Coast, with more than 300 industry professionals coming from across Australia for a full day of learning, connection, and celebration.

This year’s event featured 14 powerhouse training sessions across both technical and business streams, led by global leaders like ZF, Bosch, ATE, MAHLE, Schaeffler and Valeo.

From EV diagnostics and drive-by-wire systems to workshop profitability and consumer engagement, the agenda was built to equip workshops for the road ahead.

“We wanted every attendee to walk away with something they could apply on Monday — and the feedback tells us we nailed it,” hsy autoparts Head of Customer Relationships and Marketing, Nick Redmond, said.

“But let’s be clear: Evolve isn’t your typical trade show. It is a festival. Think fresh oysters by the dozen, tomato juice shots and lime wedges, sports-themed activations, and free-flowing conversation — all in a setting designed to feel more like a celebration than a trade show.

“We built Evolve to break the mould. It is a space where the aftermarket can learn, grow, and enjoy the ride together.”

A key highlight of the event was the Hands-On Hub, where technical innovation met practical engagement.

Attendees had the opportunity to test equipment, speak directly with technical reps, and explore workshop solutions designed to meet the demands of a rapidly evolving industry.

“With planning already underway for Evolve 2026, the future is looking bright for Australia’s aftermarket. Until next time — keep learning, keep growing, and keep evolving,” Nick said. For more information, visit www.hsy.com.au

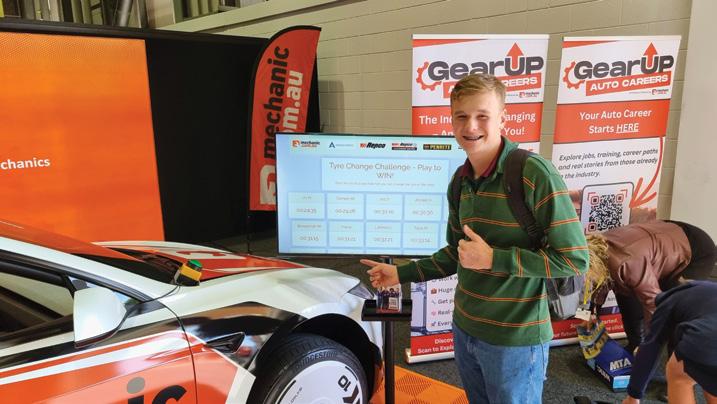

The campaign, backed by the AAAA, is designed to offer a united industry response to the skills crisis

It is no secret that Australia’s automotive industry is facing a critical skills shortage.

For years, the alarm bells have been ringing across workshops, supplier networks, and service chains.

A new initiative has been designed to present a united industry response to this crisis.

“The number of apprentices entering the trade hasn’t kept pace with demand, and many Australians — whether they’re just starting out or looking to build a new future — are still unaware of the opportunities across this diverse, innovative sector,” Mechanic.com.au Managing Director, Ryan Davis, said.

“For the first time in a long time, there’s a sense of momentum. And at the center of it is GearUP Auto Careers — a bold, hands-on initiative with the potential to reshape the future of our workforce.”

Launched by the team at Mechanic.com.au, GearUP is said to be more than just a campaign — it is a call to action for the entire industry to come together.

“The program aims to attract and inspire the next generation of technicians, specialists, and support staff by meeting them where they are: at career expos, community events, and online,” Ryan said.

“It is designed to showcase the variety of rewarding careers available across the automotive industry — from skilled trades to emerging technical and customer-facing roles – and to do so in a way that is modern, engaging, and aligned with the expectations of a new generation.”

At the recent Adelaide Careers and Employment Expo, GearUP delivered its inaugural activation, and Ryan reports the impact was immediate.

“Students lined up to take part in a live tyrechanging challenge using a Tesla wrapped in race livery, and the excitement was palpable,” Ryan said.

“But more importantly, the conversations that followed were grounded in real opportunity: what skills do I need to get started? How do I land my first job in the industry? What kind of lifestyle can an automotive career offer — whether on the tools or behind the scenes?”

Backed by the Australian Automotive Aftermarket Association (AAAA) as a foundation partner, GearUP is a reflection of what’s possible when the industry unites behind a shared mission, says Ryan.

“With a national vision from day one, the initiative is now scaling up — bringing activations to major cities and working toward broader reach over the coming years with high-energy career expo activations, an online platform for career discovery, and deep integration with schools, employers, and training organisations,” Ryan said.

“Crucially, GearUP isn’t trying to solve the crisis alone — it is creating the structure for collaboration. From small workshops to national brands, everyone has a role to play in shaping the workforce of tomorrow.

“Industry support, particularly through financial partnerships, will be vital to scaling the program’s reach and long-term impact.

The automotive aftermarket is often praised for its resilience and adaptability. But the skills shortage is a challenge that no single business or organisation can overcome alone.

“GearUP offers a chance to be part of the solution — to not just talk about the problem, but to take meaningful, coordinated action.

“As the industry gathered at Autocare recently to explore the future of automotive technology and training, it was another perfect time to consider our shared responsibility in workforce development.

“GearUP Auto Careers represents a rare opportunity: a purpose-driven initiative with the infrastructure, vision, and leadership to make a lasting difference.”

The AAAA says it is proud to support GearUP and encourages all stakeholders — from manufacturers and suppliers to workshop owners, educators, and policymakers — to explore how they can get involved: because solving the skills crisis isn’t just about filling jobs, it is about building an industry that’s vibrant, inclusive, and ready for the future.

For more information, please contact Ryan Davis at Mechanic.com.au on ryan@mechanic.com.au or 0403 558 385.

New research from mycar Tyre and Auto highlights a growing sense of hesitation among Australian drivers when it comes to adopting electric (EV) or hybrid vehicles

The second annual mycar Mobility Index shows a noticeable drop in interest, with just 23 percent of internal combustion engine (ICE) drivers planning to switch to an EV or hybrid – down 12 percentage points from 2024.

Based on a survey of 2,020 vehicle owners, the 2025 report reveals that perceptions around battery longevity, running costs, and resale value continue to concern drivers.

A quarter of ICE drivers remain sceptical about EV battery life and cost of ownership, while only five percent would consider buying a second-hand EV. By comparison, hybrids are seen as more financially accessible, with 23 percent citing lower upfront costs as a key factor.

However, the research suggests that confidence – not curiosity – is the missing link in broader EV adoption.

Nearly a quarter of respondents say they would consider buying a new EV or hybrid if it came with modern features and a strong warranty.

“This year’s Mobility Index shows a noticeable shift in sentiment,” mycar Chief Customer Officer, Adele Coswello, said.

“While interest is growing, many Australians still have concerns. That’s why we’re investing in EVready stores and mobile servicing vans to help customers transition smoothly.

“And whether it’s simply switching from petrol to diesel or stepping from ICE to hybrid or EV, our team is committed to helping drivers with that transition.”

mycar says the study also finds Australians remain wary of other emerging technologies.

Only 19 percent said they would be comfortable using a fully autonomous vehicle, and just one in three using adaptive cruise control (32 percent) or lane assist (31 percent).

An even smaller number say they have used brake assist (28 percent) or assisted parking (22 percent). Meanwhile, large vehicles remain a top choice, with nearly half of Aussies who drive these vehicles prioritising interior space, comfort, and elevated driving positions.

Cost-of-living pressures continue to shape vehicle maintenance behaviours. Two-thirds (66 percent) of drivers have changed their habits due to rising expenses, one in six (17 percent) vehicle owners admit to extending the time between regular services to save money, and 12 percent are attempting DIY servicing.

Namely, over 90 percent of Aussies prefer a physical store for servicing. Of this 90 percent, over a third (37 percent) prefer to use an independent or local mechanic, 33 percent prefer a dealership, 19 percent prefer a chain, nine percent DIY and two percent prefer a mobile technician.

Drivers were also asked what influences their choice of servicing provider. Trust and reliability were the most common factors at 46 percent, with three in ten basing their decision on a previous positive experience.

In addition, 45 percent said that quality of service is a key factor for them. And finally, just over two in five Australians choose their service provider based on the proximity or cost, reports mycar.

To read the full report, please visit www.mycar.com.au/ media/pdf/mycar-mobility-index-2025.pdf

The Allan Labor Government says it is helping to boost local manufacturing by cutting operating costs and slashing money off energy bills

Minister for Energy and Resources, Lily D’Ambrosio, recently visited Fuchs Lubricants – a lubricant manufacturing business – who received $49,000 through the Victorian Energy Upgrades (VEU) program to explore the installation of a heat pump for its pre-heating oil operations.

If implemented, the heat pump could cut the site’s gas usage by 25 percent, saving 2.4 Terajoules of gas each year and around $125,000 each year. Fuchs will reportedly be able to payback their investment in the heat pump in less than two years. The business case also identified ways to improve energy efficiency through waste heat recovery, optimising excess heat from boilers, and reducing temperatures required for their blending processes, reducing gas usage.

Fuchs is one of 36 facilities that took part in the $1.6 million Large Energy User Electrification

Support program that funds feasibility assessments for businesses that use large amount of energy.

These feasibility assessments provide business cases for energy efficiency upgrades through the VEU such as upgrading hot water boilers, furnaces, ovens and dryers that help them cut down their energy costs and save money.

Fuchs would also be able to receive a discount of up to $45,000 through the VEU program for the installation of the heat pump upgrade.

Since 2009, the VEU program has helped more than 170,000 businesses and 2.4 million households upgrade their appliances and equipment and slashing more than $440 million dollars off energy bills.

“We’re helping businesses unlock thousands of dollars of energy savings by upgrading their equipment and appliances to more energy efficient models,” Minister D’Ambrosio said.

“We’re supporting local businesses to improve their operations to be more energy efficient and save on running costs,” Member for St Albans, Natalie Suleyman, said.

The VEU program is the largest energy efficiency upgrade program in Australia and through a $5.9 million investment the Victorian Budget 2024/25 the program will be reviewed and modernised so it can continue to help Victorians slash their energy bills. For more information visit, www.energy.vic.gov.au/ businesses/victorian-energy-upgrades-businesses

The organisation says it is “not fit for purpose”

The Victorian Automotive Chamber of Commerce (VACC) is calling for fundamental reform to address power imbalances in the insurance repair industry.

In late June, the VACC submitted a comprehensive response to the draft 2025 Motor Vehicle Insurance and Repair Industry (MVIRI) Code of Conduct, unequivocally rejecting the proposed code as “not fit for purpose.”

In its submission, the VACC states that the draft code fails to address the power imbalances between insurers and repairers, disregards the professional expertise of automotive repair specialists, and lacks the structural reform required to ensure the integrity and viability of a truly self-regulating industry.

“We do not support the current draft code. Rather than creating a fair and balanced regulatory framework, this draft threatens to entrench the existing power imbalances that have plagued our industry for decades,” VACC Chief Executive Officer, Peter Jones, said.

The submission, informed by extensive feedback from VACC members across Victoria and Tasmania through written submissions and industry forums, identifies several critical failings in the proposed code. The draft code grants insurers excessive control over repair methodologies, parts selection, and pricing structures while marginalising the professional expertise of qualified repairers.

Noted as particularly concerning are provisions such as Clause 6.2(c), which grants repairers “permission” to include essential costs like paint, parts, and

mandatory environmental levies, highlighting shifts in authority that legitimise insurer overreach.

The VACC commissioned The Honourable Michael Whitten KC, one of Australia’s pre-eminent barristers, to examine the draft Code. His analysis reportedly identified significant technical drafting issues and highlighted how the draft Code reflects a bias towards insurers whilst failing to support fair market conditions.

Daniel Clough, an experienced competition law barrister, prepared the submission in consultation with VACC members, with the VACC stating this has ensured it is both legally sound and grounded in practical industry realities.

“The depth of concern expressed by our members during this consultation process has been extraordinary. From small family-owned workshops to larger repair operations, the message has been consistent – this draft Code does not address the fundamental issues facing our industry,” Daniel said.

Specifically, the Code Administration Committee (CAC) requires urgent reform to be more representative, transparent, and accountable to all stakeholders, including consumers, says VACC, which is calling for the CAC to be restructured to include independent members, end-user advocates, and technical experts.

VACC says the draft Code also fails to adequately regulate the use of artificial intelligence in assessments, potentially creating unfair advantages for well-resourced insurers.

JAX Tyres & Auto returns with Put A Cap On Breast Cancer campaign

JAX Tyres & Auto is returning with its Put a Cap on Breast Cancer campaign in support of the National Breast Cancer Foundation (NBCF) and its vision of Zero Deaths from breast cancer.

The campaign first launched in 2023 and has already raised just shy of $30,000 for NBCF, helping to provide funds to support world-class research focused on precision prevention, the early detection of breast cancer, stopping the progression and recurrence of breast cancer, and treating hard-to-treat and metastatic breast cancer – research that ultimately saves lives.

Until the end of October, all 93 JAX Tyres & Auto stores will have pink caps available and will be encouraging customers to swap their regular tyre valve caps to the pink tyre valve caps to raise awareness of breast cancer and show support to those diagnosed, with all donations going directly to NCBF.

JAX Tyres & Auto is making 21,000 pink valve caps available to represent the 21,000 Australians

diagnosed with breast cancer every year and is aiming to surpass last year’s total amount raised.

Since its inception in 1994, NBCF has invested over $200 million into more than 600 world-class research projects , with the death rate from breast cancer being reduced by over 40% in that time frame.

“We’re proud to be associated with NBCF and to be playing our part in supporting its mission to Zero Deaths from breast cancer,” JAX Tyres & Auto Chief Franchising Operations Officer, April Harwood, said.

“This is our third year of working with the National Breast Cancer Foundation and signing up again, after the success of the two previous years, was a no-brainer.”

“It is great to have JAX Tyres & Auto back as a supporter of ours for a third year,” National Breast Cancer Foundation Chief Executive Officer, Associate Professor Cleola Anderiesz, said.

“The organisation has a significant network across Australia and we’d love this year’s ‘Put A Cap on Breast Cancer’ campaign to be the most successful yet.

It states the motor vehicle insurance and repair industry has long been recognised as suffering from structural power imbalances, noting that the 2005 Productivity Commission identified that major insurers wield strong negotiating power with generally much smaller repairers. This situation has only intensified with increased market concentration and technological complexity.

“Repairers are highly skilled professionals whose work underpins both road safety and consumer confidence. They are best placed to prepare repair estimates that reflect proper work methods and parts required to return vehicles to manufacturer standards,” Daniel said.

The VACC is advocating for substantial reforms, including mandatory payment for repair estimates requested by insurers, reciprocal timeframes requiring insurers to accept or reject estimates within five business days, fair dispute resolution processes with appropriate cost allocation, and robust warranty arrangements that don’t unfairly burden repairers.

For more information, visit www.vacc.com.au

“Our vision is simple – we want to end deaths from breast cancer in Australia.

“We’ve made significant progress and are very grateful for the support of JAX Tyres & Auto and other organisations for their support of breast cancer research, but we recognise that the job’s not done yet.”

To find your nearest JAX Tyres & Auto store and pick up your pink valve caps, visit www.jax.com.au

For further information on the National Breast Cancer Foundation, visit www.nbcf.org.au

The show injected momentum into Southwest China’s automotive industry

The Chengdu International Trade Fair for Automotive Parts and Aftermarket Services (CAPAS Chengdu) concluded on 24 May 2025 at the Chengdu Century City New International Exhibition and Convention Center.

The 11th edition set new records in terms of scale and exhibitor participation with 21,896 visitors and 773 exhibitors across 52,000sqm of exhibition space, and showcased the latest advancements in new energy and connectivity across the entire supply chain, highlighting the progress of transformation in Southwest China’s automotive industry.

A line-up of 23 concurrent events centred on technological innovation, industry education integration, supply chain cooperation, and automotive culture.

“Southwest China’s automotive consumer market is dynamic, with the growth of used cars, maintenance services, and customisation fostering a diverse and fast-evolving aftermarket,” Messe Frankfurt (Shanghai) Co Ltd General Manager, James Yu, said.

“Global brands are also increasing their presence in the market, underscoring the region’s strategic importance in China’s automotive landscape.

“CAPAS successfully engaged with global industry peers to explore this potential, receiving positive feedback from various stakeholders who praised the show for facilitating business trading, technological exchange and supply chain cooperation.

“Looking ahead, CAPAS will continue enhancing services to support the regional industry’s advancement.”

The next edition of CAPAS will take place from 21 to 23 May 2026. The show is jointly organised by CCPIT-Auto, Messe Frankfurt (Shanghai) Co Ltd and CCPIT-Sichuan.

For more information, please visit www.capas-chengdu.com or email auto@hongkong.messefrankfurt.com

Fifth Quadrant takes a look at why smart aftermarket decisions start with your local market

Spend five minutes on a trade show floor, and you’d think the aftermarket had already gone fully electric.

EVs dominate the conversation, driven by government policy, OEM marketing, and media noise. But when you look at the data, a more grounded reality emerges.

At Autocare 2025, we asked a simple question: are we overhyping EVs?

Let’s start with the facts. Battery electric vehicles currently account for just two percent of the Australian car parc.

As it currently stands, we are forecasting that they will reach seven percent by 2030 (with another three percent being Plug-In Hybrid).

That still leaves petrol and hybrid drivetrains making up the vast majority of vehicles on the road, and in your workshop, for the next decade. What does this mean for aftermarket businesses? It means a blanket “go electric or go home” mindset isn’t just unhelpful, it’s potentially damaging.

Servicing EVs isn’t a binary choice, it is a commercial decision. And the right answer depends entirely on where you are, who your customers are, and what kind of business you want to run.

In the latest AAAA research study, we identified three core segments of workshop operators:

• Leaders (21 percent) – already investing in EVs, ADAS and advanced diagnostics. Typically, metro-based, larger in scale, and more likely to see EVs in their bays today.

• Developing (59 percent) – focused on the here and now. Investing in tools and people, but cautious on EVs until demand is more visible.

• Foundational (20 percent) – smaller, often regional, businesses working hard to stay viable. Limited headroom for investment and, in most cases, little current relevance for EVs. They are clearly likely to have vastly different approaches to electric vehicles. And here’s the key point: all of those strategies are valid. For some, there’s a clear and present case to build EV capability today. For others, the smart play is to keep an eye on market shifts, but wait until the business case makes sense.

Even within ‘Leader’ workshops, we’re not seeing wholesale reinvention. Just 26 percent feel that their technicians are well prepared to service these vehicles, with others still investing in tools, training and equipment. Many still outsource electrical work.

What we’re seeing is selective capability-building, adding battery conditioning, scan tools, or basic ZLEV safety procedures, not full-service EV transformations.

This doesn’t mean inaction. It means measured action. Think about:

• Your local parc. What’s selling in your postcode?

• Your services. What EV-adjacent work can you credibly offer today?

• Your upskilling plans. What training or tooling keeps your team future-ready without stretching the business?

Make no mistake, the volume is coming. In 2030 alone, 377,000 battery electric vehicles are forecast to be sold.

Based on today’s servicing patterns, around one in three will enter the aftermarket within just three years. That means by the early 2030s, more than 100,000 new EVs will be looking for servicing outside the dealership network.

For the right workshop in the right location, that’s not just a statistic, it’s a clear opportunity. But right now, the real opportunity for the aftermarket isn’t about jumping on the hype, it is about making deliberate, commercially sound decisions that keep your business strong today and ready for what’s next.

Don’t get caught up in the volume of the conversation. Focus on the substance. Because in the end, strategy, not noise, is what drives longterm success.

This column was prepared for AAA Magazine by Fifth Quadrant, the AAAA’s partners in the AAAA Aftermarket Dashboard which is delivered to AAAA members each quarter. For more information about their services, visit www.fifthquadrant.com.au or contact Ben Selwyn on ben@fifthquadrant.com.au

The ARSF is the official charity partner for the 2025 Century Batteries Ipswich Super 440

Century Batteries has named the Australian Road Safety Foundation (ARSF) as the official Charity Partner for the 2025 Century Batteries Ipswich Super 440, which returns to Queensland Raceway this August.

As naming rights sponsor, Century Batteries will use the high-profile event to highlight the ARSF’s work in reducing road trauma through education, advocacy and national initiatives like Fatality Free Friday and Rural Road Safety Month.

The partnership reflects Century Batteries’ longstanding focus on road safety and community impact, and offers a timely platform to raise awareness among drivers, fans and the broader automotive trade.

Century Yuasa Batteries Marketing Manager Australia and New Zealand, Andrew Bottoms, said the Supercars event presented an important opportunity to bring attention to the Foundation’s work.

“Partnering with the ARSF as part of the longawaited return to Queensland Raceway allows us to drive awareness around a cause that matters deeply – not just to our business, but to our retail partners, customers, families and communities we work with every day,” Andrew said.

“The Foundation’s work in fighting to reduce road trauma and driving awareness around safer driving behaviours is vital – especially at a time when regional communities and road users continue to be overrepresented in national statistics.”

The charity partnership reflects a shared focus on commitment, wellbeing and practical road safety outcomes, and highlights the important role the wider automotive industry plays in prevention, awareness and education.

“Our trade network – from battery retailers to local workshops – is on the front line of vehicle safety,” Andrew said.

“Whether it’s through regular maintenance, battery checks or honest conversations with customers, these everyday interactions can make a real difference, and our work with ARSF is a chance to support a vital cause while reinforcing the important role our industry plays in keeping Australians safe on the road.”

Australian Road Safety Foundation General Manager, Donna Caley, said the partnership offers a valuable platform to reach new audiences with life-saving messages.

“Working alongside Century Batteries allows us to

National Windscreens Group is now known as NWG

One of Australia’s largest independently owned windscreen companies, the National Windscreens Group, has taken the bold move to rebrand.

The 38-year-old company, which has 12 companyowned locations and 150 operating around the country, is now known as NWG.

NWG Chief Executive Officer, Campbell Jones, says the reason for the change was simple.

“We are no longer just a windscreen company,” Campbell said.

“Our remit extends much further. Each location is deeply committed to not just vehicle glass repair and replacement, but to the rapidly emerging and increasing safety and security technologies.

“We are investing in delivering highly specialised Advanced Driver Assistance Systems (ADAS)

services for the auto repair industry, especially in collision.

“These services are critical for vehicle performance and more importantly passenger safety. Minor accidents can compromise this functionality, leading to significant risks.”

Last year the company secured investment from boutique corporate advisory firm Nash Advisory and Capital and have made significant changes.

“This has included enhancing our tools and technology, partnering with leading suppliers and stakeholders, and most importantly, investing in our people,” Campbell said.

“All of which, collectively, will allow us to provide the best possible experience for our customers.

“Moving forward we have many goals including

champion the importance of road safety resilience and empower drivers to be better prepared for every journey,” Donna said.

“By connecting with the motorsport community and the broader automotive sector, we’re able to reach Australians with critical education around safer choices, and continue our efforts to reduce the impact of road trauma in communities nationwide.”

With road safety a shared responsibility across every part of the automotive ecosystem, Century Batteries says the charity partnership is a small but powerful step in highlighting the role we all play – from the workshop floor to the driver’s seat. To learn more about its extensive range of products and to understand how your business can benefit from becoming a stockist, Century Batteries invites you to contact your local Century Yuasa representative on 1300 362 287. For more information, visit www.centurybatteries.com.au

being a leading player in the automotive sector, but our priorities are expanding our footprint, enhancing our digital capabilities and promising to be the best partner.”

Campbell said transitioning from National Windscreens to NWG is the start of a new era.

“We are entering a phase of growth and expansion and unwavering focus on delivering exceptional customer service, and we intend to lead the industry with innovation and dedication,” Campbell said.

For more information, visit www.nwg.com.au

VASA and REDARC are set to provide exclusive insider access to Australian advanced manufacturing

VASA is excited to announce tickets are now on sale for an exclusive behind-the-scenes experience at REDARC Electronics’ cutting-edge manufacturing facility in Adelaide, hosted by company owner and Managing Director Anthony Kittel on Friday, 29 August 2025.

As well as a tour with Anthony of the REDARC factory, attendees will also be treated to thermal management training by Schaeffler’s Matthew Symington before attending the ARC Award presentation for Refrigerant Management (mobile sector) and a networking dinner at Rydges South Park Adelaide.

VASA says this premium full-day event offers automotive industry professionals a rare opportunity to witness Australian advanced manufacturing at its finest, combined with specialised training and networking opportunities that culminate in the presentation of the prestigious Australian Refrigeration Council Award for Refrigerant Management in the mobile sector.

Exclusive factory access with industry leader

The day will begin at REDARC Electronics’ headquarters with a light lunch and welcome from Anthony Kittel, before small groups embark on guided tours of the state-of-the-art manufacturing facility.

This rare insider access is set to provide delegates with firsthand insights into the innovation and precision that has established REDARC as a leader in automotive electronics manufacturing.

Following the factory tour, attendees will participate in a comprehensive training session on thermal management systems, delivered by Matthew Symington from Schaeffler Australia. The session will cover critical developments in engine cooling and water pump technology, including diagnostic techniques for newgeneration water pumps, the operation and correct replacement procedures for VW Group thermal management modules, electric vehicle cooling system advancements, and preview insights into emerging technologies set to transform the automotive aftermarket.

Recognition and networking

The day will then transition into an elegant evening at Rydges South Park Adelaide, where delegates will enjoy networking opportunities and dinner featuring keynote presentations from industry leaders Dr Greg Picker (Executive Director of Refrigerants Australia and Chair of the Australian Refrigeration Council) and Kylie Farrelley (General Manager of Refrigerant Reclaim Australia).

The evening will culminate with the presentation of the annual Australian Refrigeration Council Award for Refrigerant Management (mobile sector), recognising excellence in environmental stewardship and professional standards within the automotive air-conditioning industry.

Exceptional value

Tickets are available to anyone in the automotive industry and VASA members will receive

The company says “it is just getting started”

After years of building a trusted name in Ute accessories, Mountain Top has now officially become RealTruck.

It explains this change isn’t just about a new logo –it is about unlocking “something bigger.”

Backed by global strength and local expertise, RealTruck says it brings together the best of both worlds: smart, tough accessories designed for how Aussies use their Utes.

“The transition from Mountain Top to RealTruck isn’t just a name change. It marks a strategic evolution,” RealTruck ANZ Marketing Coordinator, Geetan Rathod, said.

“We’re aligning with a global powerhouse in the OEM and aftermarket space, offering customers access to a much broader product portfolio, while still delivering the quality and utility they have come to trust.”

This exciting new era is already gaining momentum

with the introduction of the Revolver X4s –RealTruck’s latest roll cover, designed for both form and function, and now available for Mid-size Utes and Full-size US trucks.

Unlike traditional covers, RealTruck states the X4s features a low-profile, canister-free design that allows for complete bed access.

Further, it states they are built tough with heavy-duty aluminium slats and topped with a matte-black, industrial-grade vinyl overlay, offering both security and style in one sleek package.

“This cover is for the doers. For the ones who need their gear secure, their tub accessible, and their setup looking sharp. The X4s delivers all that without compromise,” Geetan said.

“But RealTruck isn’t stopping there. With a lineup of roll covers, tub racks, cargo management, protection, and functional solutions tailored for Australia’s most-loved Utes, from the Ford Ranger and Toyota Hilux to the Isuzu D-Max and all-new

substantial savings with tickets priced at $260 plus GST, representing more than 20 percent off with an exclusive $70 member discount.

Partner dinner tickets are available for $110 plus GST, allowing companions of full ticket holders to join the evening’s networking dinner and awards presentation at Rydges South Park Adelaide.

VASA says the combination of exclusive manufacturing facility access, cutting-edge technical training, and industry recognition makes this event an unmissable opportunity for professionals in the automotive air-conditioning, electrical, and thermal management sectors.

With limited capacity due to the exclusive nature of the factory tour, early booking is strongly recommended to secure your place at this unique industry event.

For more information and to book tickets, visit www.vasa.org.au/redarc2025/

Triton, RealTruck is here to elevate what your Ute can do.”

RealTruck hits Melbourne Show

From August 22–24, 2025, you will be able to see it all up close at the Melbourne 4x4 Show on Stand RC216 at the Melbourne Royal Centre. From hands-on demos to expert advice, RealTruck says this will be your chance to experience the RealTruck difference firsthand.

“It is about function. It is about backing you up on the job, on the trail, and everywhere in between,” Geetan said.

For more information, visit www.realtruck.com.au

The new code was officially released at Autocare 2025

The Australian Automotive Aftermarket Association (AAAA) has launched a new national ADAS Industry Code of Conduct, providing the automotive industry with practical, sector-specific guidance on how to manage one of the most critical safety issues in modern vehicle repair: calibration of Advanced Driver Assistance Systems (ADAS).

Developed by the Automotive Repairers Council of Australia (ARCA), the Code was officially released at Autocare 2025 and is the first of its kind in the country – designed by and for the aftermarket to bring clarity and consistency to ADAS calibration practices across workshops, windscreen services, collision repairers, and tyre specialists.

ADAS features such as Autonomous Emergency Braking (AEB), lane-keeping assist, blind spot monitoring and adaptive cruise control are becoming standard in new vehicles.

These systems are not just driver aids – they are safety-critical technologies that will play a pivotal role in reducing road fatalities and serious injuries. By 2030, it is estimated that 43 percent of the Australian car parc will be fitted with ADAS. Yet until now, the aftermarket has operated without consistent guidelines and an agreed national framework to assess whether calibration is required following service or repair.

This gap could lead to ongoing confusion, inconsistency, and – at times – uncertainty about legal and safety responsibilities.

AAAA Director of Government Relations and Advocacy, Lesley Yates, said the Code is a vital step in ensuring vehicle safety systems continue to function as intended throughout a vehicle’s life.

“ADAS isn’t just a feature or an optional extra – it is the foundation of future automotive technology. It’s the beginning of the next technological revolution,” Lesley said.

“The road safety regulators are right to put their faith in technologies like AEB. These systems will save lives.

“That’s why AEB is now mandatory under ADR 98/00 for all new vehicles. But that regulation only governs what happens when a vehicle enters the market.

“What happens after that – when the vehicle is repaired, a windscreen is replaced, or when the suspension is modified – is just as important. Until now, there’s been no shared national approach to when and how calibration should occur.

“This Code gives us the tools to fix that. It empowers workshops with clear steps, real-world examples, and sector-specific guidance. And it shows that our industry is willing to lead from the front—not wait for someone else to impose rules on us.”

The Code introduces a decision model to help technicians determine whether ADAS calibration is required.

It also includes checklists and recommendations around documentation and communication with customers. It is designed to complement existing OEM procedures while also addressing gaps where no guidance exists.

ARCA Chair and Owner of Highfields Mechanical, Craig Baills, said the Code reflects the kind of collaboration the aftermarket is capable of when the stakes are high.

“We’ve had to bring together a lot of perspectives – mechanical, collision, tyre, windscreen, tool suppliers, trainers, and more. And we’ve done it,” Craig said.

“This is a practical document. It doesn’t live in theory – it lives in the workshop. And it’s something that every business, regardless of size or specialty, can use to lift their game and protect their customers.”

The ADAS Code also acknowledges a deeper industry transition: from assisted to automated driving. ADAS is widely recognised as the precursor to autonomy – the building blocks on which self-driving capability will be built.

“If we don’t get ADAS right, we don’t get autonomy at all,” Lesley said.

“Public trust in autonomous vehicles will depend on our ability to maintain and service these systems accurately and consistently. Calibration isn’t just a workshop procedure—it’s a national safety issue.”

AAAA Chief Executive Officer, Stuart Charity, said the Code demonstrates what AAAA is uniquely positioned to do.

“This is exactly what a leading national industry association should be doing – bringing people together, fostering collaboration, and producing practical solutions to real-world problems,” Stuart said.

“It’s a clear signal to government and to the broader industry that we take our responsibilities seriously – and that we can lead from within.”

What’s next?

The ADAS Code is not a one-off document. It has been developed as a living standard, with regular review and refinement planned as vehicle technology continues to evolve.

The AAAA will reconvene the ADAS Technical Working Group in six months to evaluate industry feedback, explore any new technical developments, and determine whether refinements are needed.

The AAAA also plans to brief government regulators on the Code, making the case that voluntary, industry-led frameworks can deliver both safety outcomes and business certainty –without the need for blunt regulatory intervention.

“We’ve built a national ADAS Code because we know where the future is heading,” Lesley said.

“We’ve done the work. And we’ll keep doing the work – because that’s what leadership looks like.”

The ADAS Industry Code of Conduct is available now via the AAAA and ARCA websites at www.aaaa.com.au/adas-code/

Amongst the more than 97,000 attendees was an Australian delegation led by the AAAA

The 30th edition of Autopromotec – a biennial international exhibition of automotive equipment and aftermarket products which was held in Bologna, Italy, across May 21-24 – recently concluded with record numbers.

Organisers state the 2025 edition was one which not only confirmed the centrality of the event for the sector but also strengthened its role as a global reference hub for innovation, training and sustainability.

Across the four days, 97,348 attendees were registered, with a 17 percent share of foreign professional operators from 130 countries (131 with Italy), testifying to the event’s increasingly international vocation.

Autopromotec also stood out for the highest average daily attendance of professional operators at European level, with 24,337 average attendees per day over the four days of the fair. The average daily attendance of the 2025 edition also surpassed that of 2019, another record edition of the exhibition.

There were 1692 companies participating in this 30th edition, of which 61 brands were represented, with a 45 percent share of foreigners from 46 countries, Italy included.

Amongst these visiting participants was a delegation led by the Australian Automotive Aftermarket Association (AAAA).

“The AAAA is proud to have led a delegation of Australian businesses to Bologna, Itay for the 30th edition of Autopromotec – one of the largest automotive aftermarket trade shows in Europe,” AAAA National Membership and Marketing Manager, Nigel Bishop, said.

“Despite its long history as a leading international trade show, Autopromotec was largely unknown in Australia until relatively recently.

“The show’s international delegation program, supported by the Italian Trade Agency, has been providing opportunities for AAAA members to travel and visit the show since 2017.

“The success of this program is evidenced by the greatly increased awareness and high demand for delegate positions, with Autopromotec now firmly positioned as an international trade show of choice; particularly for businesses involved in workshop equipment, digital tools and diagnostics.”

The Australian delegates were supported by a team of representatives from the Italian Trade Agency, who facilitated B2B meetings in a dedicated area within the show.

International guests were also treated to a thoughtfully curated social program, which included an on-site welcome party and an exclusive off-site cocktail party at the newly opened Museum of the History of Bologna – a highlight of which was the display of incredibly well-preserved Roman chariot ruts in a section of cobbled road.

Autopromotec also set the stage for the Global Automotive Right to Repair Roundtable, an event facilitated by the AAAA.

“Right to Repair is a global movement, and the roundtable in Bologna at Autopromotec brought together industry leaders from around the world to align on strategy and share insights,” AAAA Chief Executive Officer, Stuart Charity, said.

“It is a powerful reminder of how much we can achieve when we align internationally.

“We’re proud to ensure Australia’s independent repairers have a strong voice in shaping the future of fair data access.”

The automotive aftermarket is truly a globally connected industry.

“With many AAAA members having developed deep relationships with suppliers and distributors from all over the world, it is astounding that Autopromotec flew under the radar here in Australia for so long!”

Nigel said.

“Programs like this highlight the fact that there are

still so many new opportunities to be discovered by exploring further afield.

“We are so very thankful to the teams at Autopromotec and the Italian Trade Agency for investing in the international delegate program, and for once again inviting AAAA members to explore this outstanding trade show. Keep any eye out for the next opportunity to visit Autopromotec in 2027!”

Amongst the delegates were Vascar Auto Director, Basil Papageorge; Italian Automotive Spares Company Director, Domenic Fragale; JAX Tyres & Auto Chief Franchising Operations Officer, April Harwood; and Mobile Tyre Shop Chief Executive Officer, Travis Osborne.

“Autopromotec 2025 exceeded my expectations as a highly professional and well-organised international event,” said Basil.

“The scale of the expo, the diversity and professionalism of exhibitors, and the evident focus on emerging technologies made it a truly valuable experience for me. The event struck a good balance between showcasing cutting-edge solutions and enabling meaningful, businessfocused conversations.

“The chance to connect face-to-face with key decision-makers and explore potential collaborations that would be difficult to initiate remotely was a major advantage. The hospitality and networking opportunities outside the trade floor also made the experience memorable and productive.

“Being part of the AAAA delegation was an outstanding experience. It was great to meet fellow Australian automotive colleagues and participate in the show with them, including members from AAAA. There was a sense of shared learning, professional support, and national representation that made the experience both practical and inspiring.

“For any AAAA member looking to expand their global supply chain, build partnerships, or stay ahead of trends in the automotive aftermarket, opportunities like Autopromotec are invaluable.

The exposure to international markets, the chance to validate ideas and products in person, and the support provided through the AAAA network make it a highly worthwhile investment.

“The biggest takeaway was clarity around international market opportunities and the confidence to move forward with a new product line in Australia. I left with confirmed supplier relationships, a deeper understanding of competitive positioning, and several new ideas for product expansion and differentiation. The trip also reinvigorated my strategic thinking about the business and affirmed the importance of staying globally connected.

“I think the AAAA’s role in facilitating these types of experiences cannot be understated. Their leadership, coordination, and presence on the ground made all the difference. The team did a great job, were exceptionally hospitable, and it was a pleasure being there with them – thank you AAAA.” For Domenic, it was his second time as part of the visiting AAAA delegation to the event.

“My impression of the event has always been great. It is a massive event, it shows by the amount of national and international visitors they get. The scale of the event is on another level, and it is worth attending to experience range of products that are available within the industry,” Domenic said.

“Meeting the other Australian delegates and also other international guests was a real highlight for me, as I find it very beneficial in assisting in networking and making connections within the automotive industry.

“Being part of the AAAA delegation the second time round was just as exciting as my previous visit. I find being part of the delegation does open the door to meet new people within other sectors of the automotive industry and form new relationships within Australia. The added benefit is the Autopromotec events that are held during the expo allow you to network with people within the international industry which can lead to new business opportunities back home.

“I would highly recommend other AAAA members to try and take advantage of future opportunities. We are generally stuck in our day to day lives within our own little bubble that it is a great opportunity to meet new people within the industry that may view things in a different perspective.”

April was quick to praise the Italian Trade Agency and the AAAA following her trip to Autopromotec.

“Autopromotec Expo is a must visit for any workshop owner considering further investment or exploring an expansion of their business,” April said.

“The target audience is genuinely catering to all streams of the automotive aftermarket with large halls to satisfy repair and servicing, tyres, paint, panel and more all the way through to car wash. Attendees are definitely delivered all corners of the market in one location by all the major leading brands and manufacturers of equipment (in particular).

“Visiting the show as part of the AAAA delegation was terrific – personally it gave me an opportunity to meet new Aussie business owners that I otherwise wouldn’t have crossed paths with, plus reconnect with others that I hadn’t seen in some time.

There was plenty of sharing about one another’s businesses, highlights of the expo features and general camaraderie enabled by the trip.

“I would highly recommend this opportunity to others in future – the Italian Trade Agency provides a format that facilitates meetings with potential partners of the future, or connection with companies that you may already be dealing with.

In addition to these one-to-one meetings, the trade show is adjacent which allows these suppliers to showcase in person their range.

“The Autopromotec Expo definitely gave me an eye-widening insight into the pipeline of technology that will soon be filtering into our industry – getting this first-hand exposure was my key highlight and take away.”

Travis was another who placed great value in the one-on-one meeting opportunities while lauding the

sheer scale and importance of the Autopromotec event.