ACTA FACULTATIS XYLOLOGIAE ZVOLEN

VEDECKÝ ČASOPIS SCIENTIFIC JOURNAL

Vedecký časopis Acta Facultatis Xylologiae Zvolen uverejňuje pôvodné recenzované vedecké práce z oblastí: štruktúra a vlastnosti dreva, procesy spracovania, obrábania, sušenia, modifikácie a ochrany dreva, termickej stability, horenia a protipožiarnej ochrany lignocelulózových materiálov, konštrukcie a dizajnu nábytku, drevených stavebných konštrukcií, ekonomiky a manažmentu drevospracujúceho priemyslu. Poskytuje priestor aj na prezentáciu názorov formou správ a recenzií kníh domácich a zahraničných autorov.

Scientific journal Acta Facultatis Xylologiae Zvolen publishes peer-reviewed scientific papers covering the fields of wood: structure and properties, wood processing, machining and drying, wood modification and preservation, thermal stability, burning and fire protection of lignocellulosic materials, furniture design and construction, wooden constructions, economics and management in wood processing industry. The journal is a platform for presenting reports and reviews of books of domestic and foreign authors.

VEDECKÝ ČASOPIS DREVÁRSKEJ FAKULTY, TECHNICKEJ UNIVERZITY

VO ZVOLENE 67 1/2025

SCIENTIFIC JOURNAL OF THE FACULTY OF WOOD SCIENCES AND TECHNOLOGY, TECHNICAL UNIVERSITY IN ZVOLEN 67 1/2025

Redakcia (Publisher and Editor’s Office): Technická univerzity vo Zvolene (Technical university in Zvolen); TUZVO Drevárska fakulta (Faculty of Wood Sciences and Technology)

T. G. Masaryka 2117/24, SK-960 01 Zvolen, Slovakia

Redakčná rada (Editorial Board): Predseda (Chairman): prof. Ing. Ján Sedliačik, PhD, TUZVO (SK)

Vedecký redaktor (Editor-in-Chief): prof. Ing. Ladislav Dzurenda, PhD, TUZVO (SK)

Členovia (Members): prof. RNDr. František Kačík, DrSc. TUZVO (SK) prof. RNDr. Danica Kačíková, MSc. PhD., TUZVO (SK) prof. Ing. Ivan Klement, CSc. TUZVO (SK) prof. Ing. Jozef Kúdela, CSc. TUZVO (SK) prof. Ing. Mariana Sedliačiková, PhD. TUZVO (SK) prof. Ing. Jozef Štefko. CSc. TUZVO (SK) doc. Ing. Hubert Paluš, PhD. TUZVO (SK)

Jazykový editor (Proofreader): Mgr. Žaneta Balážová, PhD. Technický redaktor (Production Editor): Ing. Michal Dudiak, PhD.

Medzinárodný poradný zbor (International Advisory Editorial Board):

Antov Petar Yordanov (Univ of Forestry, BG), Bekhta Pavlo (Ukrainian Nat Forestry Univ, UA), Deliiski Nencho (Univ of Forestry, BG), Hua Lee Seng (UiTM Cawangan Pahang, MY), Jelačić Denis (Univ Zagreb, HR), Kasal Bohumil (Tech Univ Carolo Wilhelmina Braunschweig, DE), Lubis Muhammad Adly Rahandi (Kyungpook Nat Univ, ID), Marchal Remy (Arts & Metiers ParisTech, FR), Németh Róbert (Univ Sopron, HU), Niemz Peter (Bern Univ Appl Sci, Architecture Wood & Civil Engn, CH), Orlowski Kazimierz A.(Gdansk Univ Technol, PL), Pohleven Franc (Univ Ljubljana, SI), Rogoziński Tomasz (Poznań Univ of Life Sci, PL), Teischinger Alfréd (Univ Nat Res & Life Sci, BOKU, AT), Smardzewski Jerzy (Poznań Univ of Life Sci, PL), Vlosky Richard P. (Louisiana State Univ, USA), Wimmer Rupert (Univ Nat Res & Life Sci, AT).

Vydala (Published by): Technická univerzita vo Zvolene, T. G. Masaryka 2117/24, 960 01 Zvolen, IČO 00397440, 2025

Náklad (Circulation) 80 výtlačkov, Rozsah (Pages) 164 strán, 13,64 AH, 13,91 VH

Tlač (Printed by): Vydavateľstvo Technickej univerzity vo Zvolene

Vydanie I – jún 2025

Periodikum s periodicitou dvakrát ročne

Evidenčné číslo: 3860/09

Acta Facultatis Xylologiae Zvolen je registrovaný v databázach (Indexed in): Web of Science, SCOPUS, ProQuest, AGRICOLA, Scientific Electronic Library (Russian Federation), China National Knowledge Infrastructure (CNKI)

Za vedeckú úroveň tejto publikácie zodpovedajú autori a recenzenti. Rukopis neprešiel jazykovou úpravou.

Všetky práva vyhradené. Nijaká časť textu ani ilustrácie nemôžu byť použité na ďalšie šírenie akoukoľvek formou bez predchádzajúceho súhlasu autorov alebo vydavateľa.

© Copyright by Technical university in Zvolen, Slovak Republic. ISSN (print) 1336–3824, ISSN (online): 2730-1176

01. VIDHOLDOVÁ ZUZANA – HÝROŠOVÁ TATIANA: COMPARATIVE COLOUR ANALYSIS OF THERMALLY MODIFIED SELECTED TEMPERATE HARDWOODS AND TROPICAL WOOD SPECIES USING PRINCIPAL COMPONENT ANALYSIS . 5

02. IVAN KLEMENT – TATIANA VILKOVSKÁ – PETER VILKOVSKÝ: DIMENSIONAL STABILITY OF BEECH BLANKS IN THE CONTACT DRYING PROCESS 13

03. PAVLO LYUTYY – PAVLO BEKHTA – JÁN SEDLIAČIK: MODELING AND ANALYSIS OF TEMPERATURE DISTRIBUTION ACROSS THE CROSS-SECTION OF FLAT-PRESSED WOOD–POLYMER COMPOSITES DURING COOLING STAGE 23

04. VERONIKA ŠUGÁROVÁ – LUKÁŠ ADAMČÍK – RICHARD KMINIAK: THE INFLUENCE OF TECHNICAL AND TECHNOLOGICAL PARAMETERS OF CNC MILLING ON THE SURFACE QUALITY OF BEECH PLYWOOD .......................................... 35

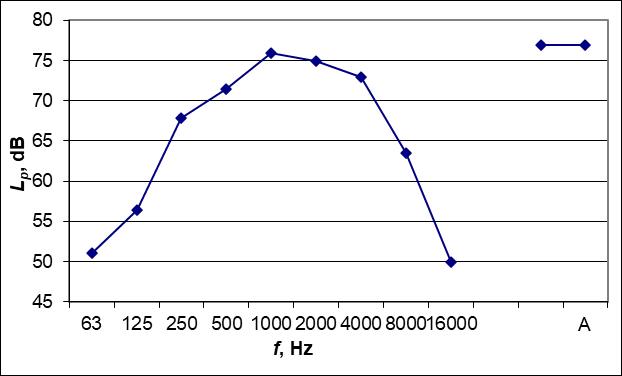

05. PAVLIN VITCHEV – ENGINDJAN HALIM: INFLUENCE OF THE CUTTING MODE ON THE NOISE EMISSION LEVEL DURING LONGITUDINAL-PLANNER MILLING OF LINDEN AND BEECH WOOD ............................................................................................................ 49

06 LADISLAV DZURENDA – NENCHO DELIISKI –DIMITAR ANGELSKI – PAVLIN VITCHEV – KRASIMIRA ATANASOVA: HEAT BALANCES OF CONCRETE PITS WHEN STEAMING OR BOILING UNFROZEN LOGS 61

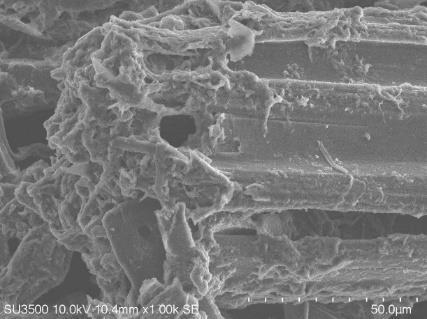

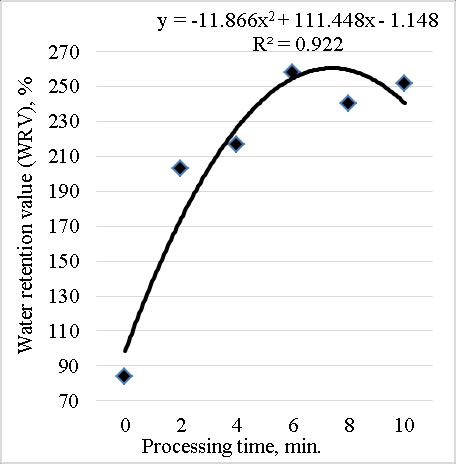

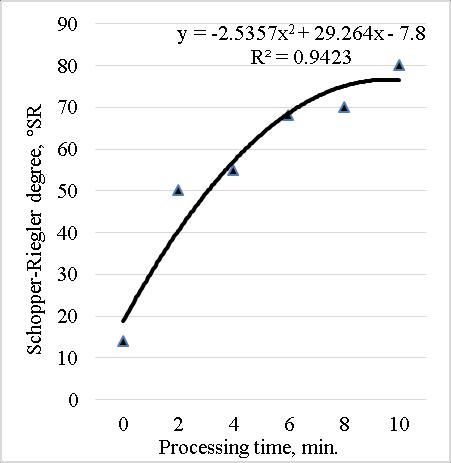

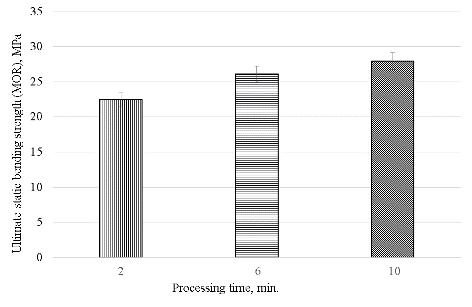

07. VLADIMIR YERMOLIN – MIKHAIL BAYANDIN – SERGEY ELISEEV – SERGEI KAZITSIN – NIKOLAY SMERTIN – LILIT KAZARYAN – TATYANA STREKALEVA: PRODUCTION OF BINDER-FREE BOARDS FROM BIODEGRADED ABIES SIBIRICA WOOD 75

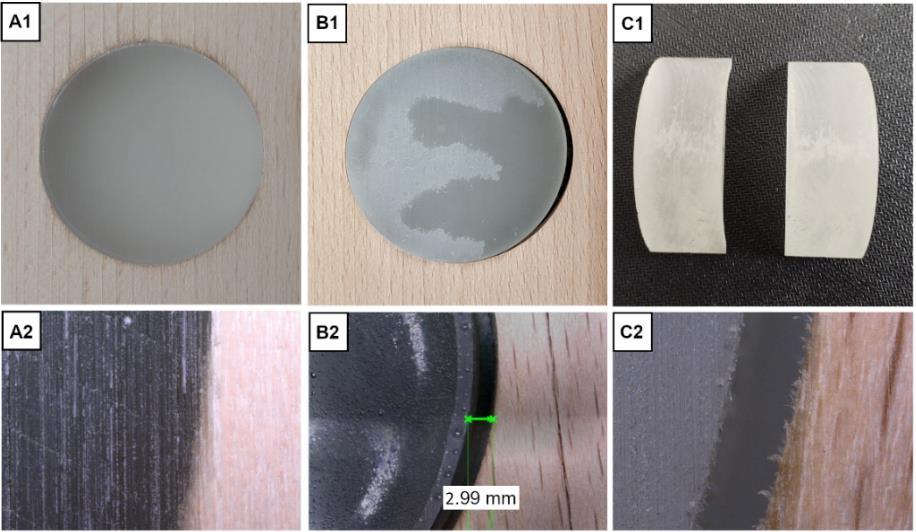

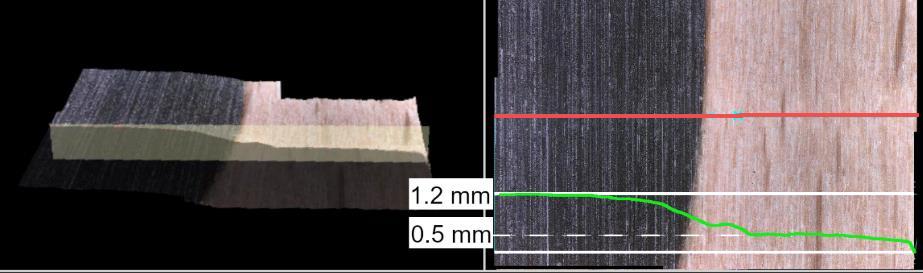

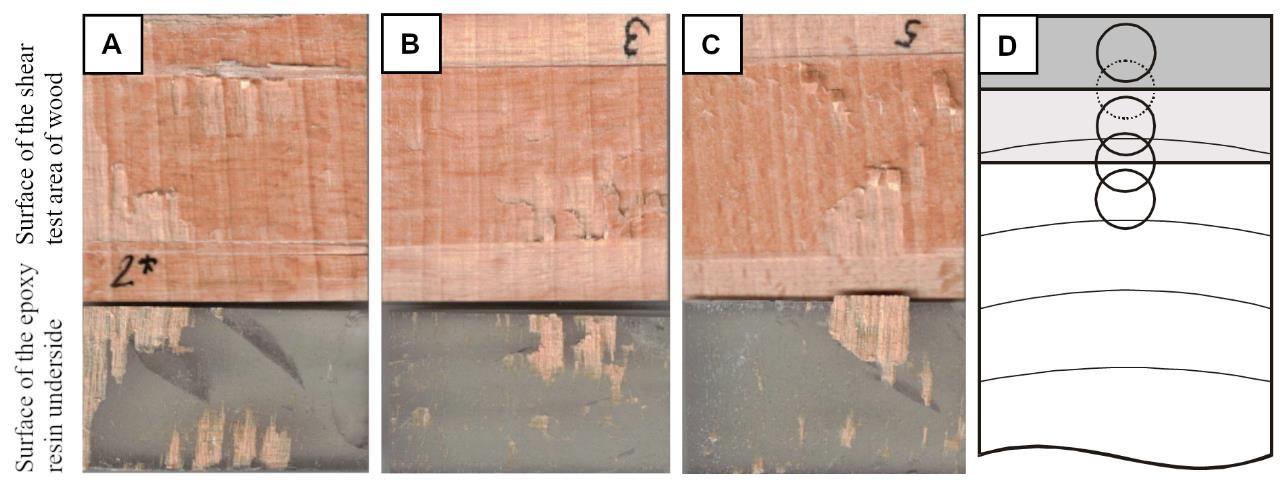

08. BARBORA SLOVÁČKOVÁ – RADEK KOVAŘÍK: DEFORMATION OF WOOD – RESIN PHASE BOUNDARY BY MOISTURE CONTENT CHANGES IN WOOD ...................................................................................

09 MARTIN ŠTOSEL – ALEŠ HÁZ – RICHARD NADÁNYI: BIOMASS FROM THE WOOD PROCESSING INDUSTRY AS A SOURCE OF PHENOLIC COMPOUNDS FOR VARIOUS CHEMICAL APPLICATIONS

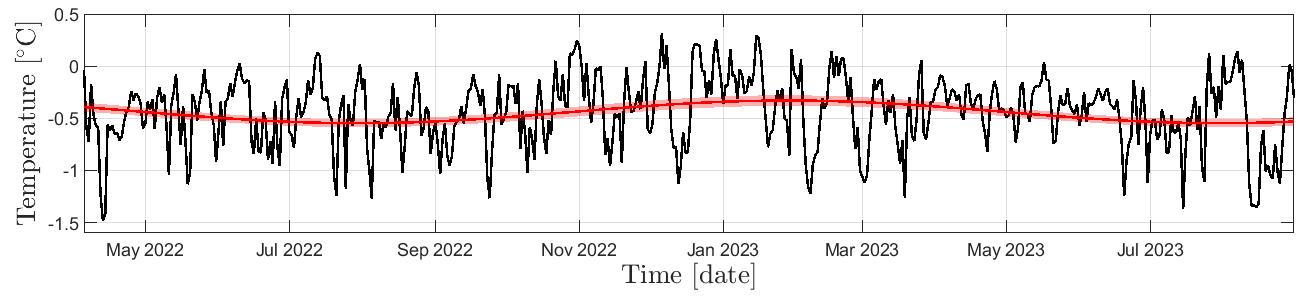

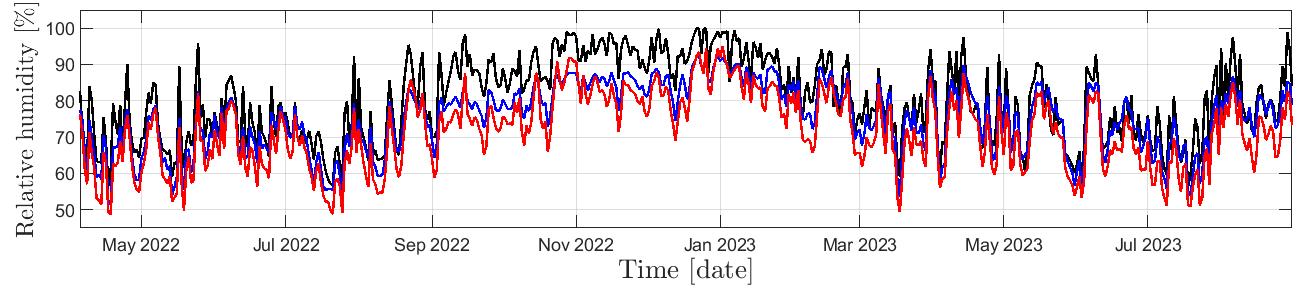

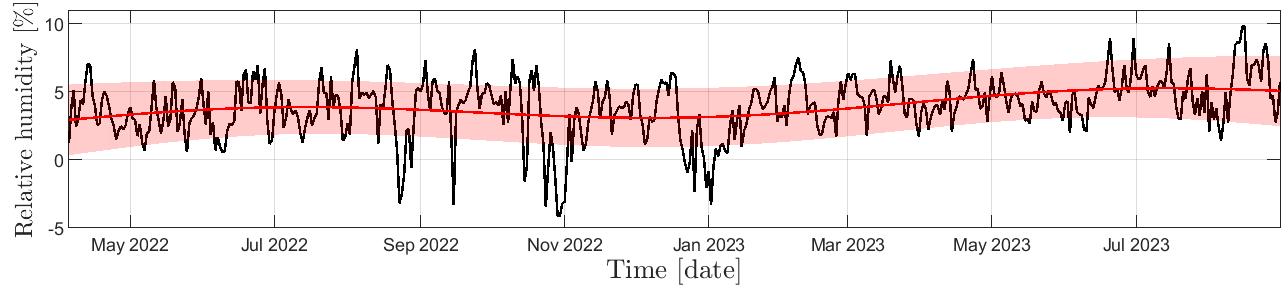

10. SLÁVKA POBUCKÁ – PAVEL KUČÍREK – KAREL ŠUHAJDA –JAN HOLEŠOVSKÝ: FOUNDATION OF TIMBER STRUCTURES –CRAWL SPACE HEAT AND MOISTURE ANALYSIS WITH AIR AGE SIMULATION AND OCCURRENCE OF MICROMYCETES 109

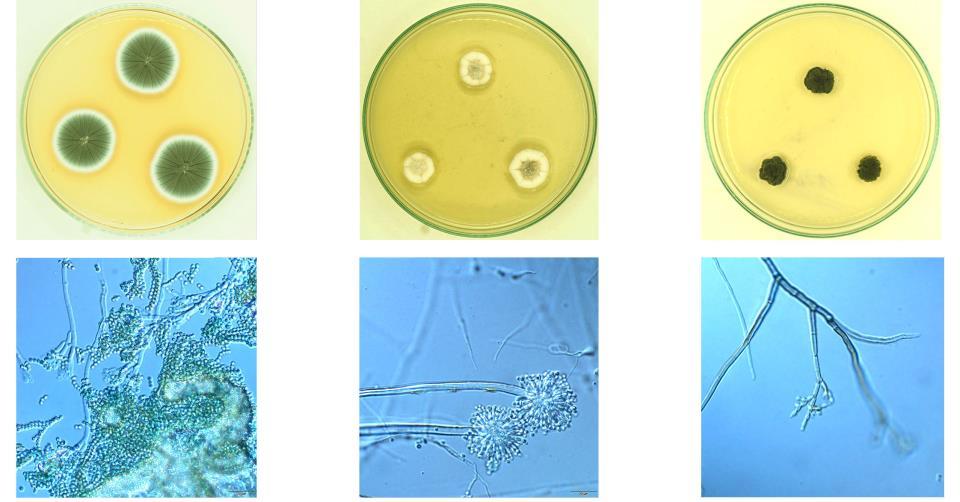

11. PATRÍCIA PANČÍKOVÁ – ZUZANA TONČÍKOVÁ: TYPOLOGICAL – ERGONOMIC EXPERIMENT ........................................

12

ANDREA JANÁKOVÁ SUJOVÁ – ĽUBICA SIMANOVÁ: MANAGING THE CORONAVIRUS CRISIS BY SLOVAK WOODWORKING AND FURNITURE ENTERPRISES IN THE CONTEXT OF AGILE APPROACH – CASE STUDIES

13. ERIKA LOUČANOVÁ – MARTINA NOSÁĽOVÁ: USING ARTIFICIAL INTELLIGENCE IN THE DEVELOPMENT OF MARKETING COMMUNICATION TOOLS FOR A SPECIFIC FURNITURE PRODUCT ..............................................................................

ACTA FACULTATIS XYLOLOGIAE ZVOLEN, 67(1): 5 12, 2025

Zvolen, Technická univerzita vo Zvolene

DOI: 10.17423/afx.2025.67.1.01

COMPARATIVE COLOUR ANALYSIS OF THERMALLY MODIFIED SELECTED TEMPERATE HARDWOODS AND TROPICAL WOOD SPECIES USING PRINCIPAL COMPONENT ANALYSIS

Vidholdová Zuzana – Hýrošová Tatiana

ABSTRACT

Thermal modification is an eco-friendly and cost-effective method for enhancing the optical properties of wood by darkening its colour throughout the cross-section due to chemical changes. In this study, the colour coordinates (L* , a *, b*) of thermally modified temperate hardwoods native to Central Europe were statistically compared to those of selected tropical species. The tested species ‒ European ash, European beech, paper birch, black locust, European hornbeam, and pedunculate oak ‒ were treated at 200°C for 3 hours. The analysis revealed that thermal modification effectively altered their colour, in some cases achieving a visual resemblance to tropical woods. Pedunculate oak and black locust closely resembled wengé, while European beech approximated the appearance of ipé. Other hardwoods only partially matched tropical tones. These findings confirm the potential of thermally modified local hardwoods to substitute tropical species in interior and furniture applications, supporting more sustainable and regionally focused utilization for biological stains

Keywords: colour; hardwood; PCA analysis; thermal modification; tropical wood.

INTRODUCTION

Woodcolouris afundamental physical-optical propertyclassified among macroscopic features that enable the visual differentiation of wood from various tree species. The colour arises from the presence of chromophores ‒ specific functional groups such as carbonyl (>C=O), conjugated double bonds (-CH=CH-CH=CH-, -CH=CH-), and aromatic rings ‒embedded in the chemical constituents of wood, primarily lignin and low-molecular-weight extractives (e.g., pigments, tannins, resins). These chromophores selectively absorb specific wavelengths of the visible spectrum of natural daylight, thereby generating the characteristic surface colour perceived by the human visual system. In addition to interspecific variability, wood colour may also vary within a single tree as a result of heartwood formation, ageing, or environmental and processing factors. (Hon and Minemura, 2000; Babiak et al., 2004; Gandelová et al., 2009; Dzurenda, 2023).

The visual appearance of wood, particularly its texture and colour, plays a crucial role in determining its suitability for interior design and furniture manufacturing (Tolvaj et al., 2013; Slabejová et al., 2016; Dzurenda, 2022). In recent years, there has been increasing interest in modifying the colour of temperate hardwoods to achieve the dark tones typically associated with tropical species. This shift is driven not only by aesthetic considerations but

also by the growing demand for environmentally responsible alternatives to tropical timber, whose harvesting often raises ecological and ethical concerns.

The color of hardwoods varies by species and is determined by the chemical composition of the wood, including cellulose, hemicelluloses, lignin, and extractive substances. While cellulose constitutes the majority of the wood cell wall and is inherently white, its colour is often masked by the hues of extractive substances, which, despite their low weight percentage, can dominate the wood's appearance. Hardwood colors range widely from light to dark shades, with longitudinal surfaces typically used for evaluation, as they are most visible on wooden objects. In contrast, cross-sections are often darker.

Temperatehardwoods without heartwood(e.g.,birch,hornbeam, maple, ash,lime,and aspen) tend to be light or light brown. Denser hardwoods (e.g., oak, pear, alder, walnut, and cherry) and conifer heartwood often exhibit darker colouring due to denser fibre layers, tannins, and other extractive substances. Tropical woods, with higher extractive content, display more intense natural colour, ranging from light yellows and pinks to deep reds, purples, and blacks, as seen in ebony (Hon and Minemura, 2000). Some tropical species, such as bloodwood (Haematoxylum campechianum L.), are so rich in natural dyes that they are used as sources of pigments for textiles and wood. The reddish-brown heartwood of logwood yields a dark red solution, which is utilised for biological stains such as hematoxylin and haematein (Ortiz-Hidalgo and Pina-Oviedo, 2019).

A quantitative assessment of wood colour is commonly conducted using the CIELAB color space (CIE 1976), the most widely adopted system in the wood industry (Katuščák and Kučera, 2000). This system classifies temperate and tropical wood species into the positive octant, with lightness (L*) values ranging from 20 to 90, redness (+a*) from 0 to 20, and yellowness (+b*) from 10 to 30 (Janin, 2001; Babiak et al., 2004). Compared to temperate species, tropical woods occupy a significantly broader section of the color space (da Silva et al., 2017; Meints et al., 2017; Vidholdová and Reinprecht, 2017).

Thermal modification is a well-established technique used to improve certain physical and aesthetic properties of wood. Conducted at elevated temperatures (typically between 160°C and 220°C) in an oxygen-deprived environment, thermal treatment leads to the degradation of hemicelluloses and the formation of chromophoric compounds, resulting in a darker and more homogeneous colour throughout the cross-section. These transformations also enhance dimensional stability and biological durability, making thermally modified wood an attractive material for indoor applications. This treatment modifies the chemical structure of hemicelluloses, cellulose, and lignin, reducing the wood’s hydrophilicity and alteringits properties (Hill 2007; Reinprecht and Vidholdová,2011; Vidholdová et al.,2019; Hill et al , 2021; Sandberg et al., 2021). Numerous studies have explored the effects of thermal treatment on the mechanical, chemical, and optical properties of wood. However, thereislimitedquantitativeresearchcomparingthecolour coordinatesofthermallymodified temperatespecieswith thoseofnaturallydarktropical woods.Such acomparison is essential for evaluating the potential of modified local hardwoods to serve as visual substitutes in high-end applications.

In this study, we investigate the colour changes induced by thermal modification in six temperate hardwood species native to Central Europe. Colour coordinates (L* , a *, b*) were measured before and after treatment at 200°C for three hours. To assess the visual similarity between modified temperate woods and tropical references, Principal Component Analysis (PCA) was applied to the colour data. The aim of this work is to statistically evaluate the effectiveness of thermal treatment in mimicking the colour tones of selected tropical tree species and to contribute to the broader goal of sustainable, locally sourced material substitution in the wood industry.

MATERIALS AND METHODS

Wood Material

The hardwoods used in this study – European ash (Fraxinus excelsior L.), European beech (Fagus sylvatica L.), paper birch (Betula papyrifera Marsh), black locust (Robinia pseudoacacia L.), European hornbeam (Carpinus betulus L.), and pedunculate oak (Quercus robur L. – sourced from round timber felled and processed in Slovakia.Wood samples with dimensions of150×15 × 300mm werepreparedbylongitudinal andtransversesawingfrom the central part of the lumber.

The tropical wood species selected for comparison included ipé (Handroanthus serratifolius), iroko (Milicia excelsa), makoré (Tieghemella heckelii), sapelli (Entandrophragma cylindricum), and wengé (Millettia laurentii). These samples were obtained as naturally dried and conditioned boards, maintained at a temperature of 22 ± 2.5 °C and relative humidity of 65% in a climate chamber for 3 weeks. The boards were purchased from the trading company JAF Holz Ltd., Slovakia.

Heat Treatment Procedure

The heat treatment of native hardwoods was conducted under atmospheric pressure at a temperature of 200 ± 2.5 °C for 3 hours using a laboratory heating oven (Memmert UFB 500, Germany). The treatment was carried out at the Department of Wood Technology, Faculty of Wood Sciences and Technology, Technical University in Zvolen. The process commenced by placing the absolute dry samples in the oven at room temperature, followed by agradual temperatureincreaseover45minutesuntil thedesiredtemperaturewas reached. The samples were maintained at this temperature for 3 hours and subsequently cooled in a desiccator under dry conditions.

Colour Measurements

Colour coordinates were measured using a Colour Reader CR-10 (Konica Minolta, Japan), which operates with a CIE 10° standard observer, CIE standard illuminant D65, and an 8 mm diameter sensor head. Prior to measurement, the samples were conditioned at a temperature of 20°C and an air relative humidity of 60%.The colour of wood was evaluated in the CIELAB colour space, specifically using the coordinates L* (lightness), a* (red-green axis), and b* (yellow-blue axis).

Principal Component Analysis

A multidimensional statistical approach was employed to evaluate the data using Principal Component Analysis (PCA) In this analysis, average values were used for each condition in the time-temperature domain for the colour variables. PCA served to assess the overall structure of the data, identifying relationships and correlations between variables, as well as their relative importance. The method facilitates the detection of statistical outliers and clustering of observations. It consists in reducing the original variables to a smaller number of new (latent) variables. Latent variables were extracted in the form of orthogonal principal components (PCs), which are linear combinations of the original variables. New variables (PCs) are required to reflect as much as possible the original variables. The first component (PC1) accounts for a maximal amount of total variance in the observed variables, the second component (PC2) accounts for a maximal amount of variance in the data set that was not accounted for by the first component PCs reflect the different effects of the original variables. Such effects can be seen from the PCA score plot, which shows the component

score of the two principal components for all observed wood samples. The score plot identifies clusters of similar samples, samples outlying and strongly different from others

Descriptive Statistics

To assess colour variation in wood samples, mean and standard deviation values for L* , a* and b* were calculated. To compare the colourimetric data of selected wood samples, graphical outputs in the form of boxplot were used. The statistical analyses were processed using software Statistica 14

RESULTS AND DISCUSSION

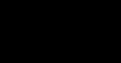

The colour coordinates of the native surfaces of the analysed tropical wood species and thermally modified hardwoods are summarised in Tab. 1. Among the tropical wood species, considerable variation was observed in lightness (L*), which ranged from 34.88 for wengé, representing the darkest material in the set, to 64.50 for iroko, the lightest. This wide rangeillustratesthenaturaldiversityofcolourationfoundamong tropical woods.Alltropical wood species exhibited positive chromaticity values, confirming the presence of red and yellowhues in theirnatural appearance.Specifically,theredness coordinate (a*)rangedfrom 8.00 in wengé to 16.68 in sapelli, while the yellowness coordinate (b*) ranged from 10.34 (wengé) to 25.32 (iroko). These findings are consistent with earlier studies, including those by Meints et al. (2017) and da Silva et al. (2017), which similarly documented high variabilityincolour coordinatesacrosstropicalwoodspecies.Suchvariabilityisoftenlinked todifferencesinextractivecontent,heartwoodformation,andotheranatomicalandchemical features that contribute to each species' distinctive optical properties. Tropical wood species are widely appreciated for their natural beauty, which is often enhanced by their rich colour tones and surface lustre. Their aesthetic attributes, in combination with favourable durability and mechanical characteristics, make them highly desirable in applications such as flooring, decorative veneers, furniture components, and high-end joinery.

woods

Inthegroupofthermally modifiedtemperatehardwoods,thecolourcoordinatesreflect the significant impact of heat treatment. The lightness (L*) of treated samples ranged from

Tab.

35.05 for black locust and pedunculate oak to 58.88 for European hornbeam. These values suggest a notable darkening effect compared to native untreated wood (not shown), a wellknown outcome of thermal processing due to the degradation of hemicelluloses and the formation of coloured degradation products. Like tropical woods, all thermally modified samples also exhibited positive a* and b* values, indicating reddish and yellowish tones. Although these values were generally lower than in tropical wood species, their mutual similarity is noteworthy. These colour shifts are likely related to the thermal degradation of hemicelluloses and the formation of conjugated structures, contributing to the darkening and enhanced chromaticity observed in treated samples (Sandak et al., 2015; Vidholdová et al., 2019; Hill et al., 2021; Sandberg et al., 2021). The observed variation in colour response among species suggests that inherent anatomical and chemical properties, such as density and extractive content, strongly influence the efficiency of thermal treatment in achieving tropical-like hues (Janin, 2001; Babiak et al., 2004; da Silva et al., 2017; Meints et al., 2017; Vidholdová and Reinprecht, 2017; Geffert et al., 2019 and 2020).

The overlap in chromatic coordinates between some thermally treated hardwoods and certain tropical woods suggests that thermal modification can effectively mimic the appearance of exotic species. This resemblance supports the potential of using locally available hardwoods as a visual alternative to tropical timber, reducing dependency on imported materials while promoting sustainable material use. From both ecological and economic perspectives, thermally modified woods offer an attractive solution for applications that require the warm, rich tones typically associated with tropical hardwoods.

Tofurther assess andquantifythedegreeofvisual similarity betweenthestudied wood species, a principal component analysis (PCA) was applied to the colourimetric data (L* , a * , b*). This multivariate approach enables a more detailed exploration of patterns in colour space and facilitates the identification of species clusters based on shared optical characteristics. The results of the PCA provide a complementary statistical basis to support visual observations, revealing the extent to which thermally modified hardwoods approximate the colour profiles of tropical woods.

The results of the principal component analysis (PCA) based on the L* , a *, and b* colour coordinates are shown in Fig. 1.

Fig. 1 PCA score plot of tropical and thermally modified wood species.

The first two principal components (PC1 and PC2) together explained 98.93% of the total variancein thedataset, with PC1accountingfor80.31% andPC2for18.62%.This high level of explained variance confirms the suitability of PCA for reducing dimensionality while preserving the essential structure of the data.

The PCA score plot differentiates the tropical wood species from one another, highlighting their distinct colour profiles. Notably, certain thermally modified hardwoods (e.g., black locust and oak) are positioned near wengé, indicating a substantial similarity in their colourimetric characteristics. This supports the assessment presented in Tab. 1 and reinforces the notion that thermal modification can effectively replicate the optical qualities of tropical woods.

Furthermore, the clustering pattern observed in the PCA plot – such as thermally modified European beech aligning with ipé and thermally modified birch resembling more – suggests that colour coordinates alone are sufficient to distinguish between species groups while also revealing overlapping tendencies between selected thermally modified and tropical woods. This finding provides a statistical basis for recommending thermally treated temperate species as a sustainable alternative to tropical timber in decorative and designoriented applications.

Based on the PCA assessment, four hardwood species thermally treated at 200°C for 3 hours, which exhibited a pronounced visual similarity to selected tropical woods, were positioned near them within the CIELAB space (Fig. 2).

CONCLUSION

The observed colour similarity between thermally modified local hardwoods and tropical wood species demonstrates that heat treatment can effectively alter the visual appearance of temperate wood, bringing it closer to the aesthetic qualities of tropical timber. Based on the experimental assessment, four hardwood species thermally treated at 200 °C for 3 hours exhibited a pronounced colour similarity to selected tropical woods.

Fig. 2 Comparison of CIELAB colour coordinates for tropical and selected modified hardwoods using boxplot visualisation.

Europeanbeech closely resembledipé,whilebirch approximatedmakoré; both pedunculate oak and black locust showed a colour match with wengé. Other thermally modified hardwoods only partially mimicked the appearance of tropical wood species, indicating a need for further optimisation.

To support and visualise these similarities, a principal component analysis (PCA) was performed using L* , a *, and b* colour coordinates. The first two principal components accounted for 98.93% of the total variance, clearly differentiating the tropical wood species and highlighting overlaps with selected thermally modified hardwoods. The PCA score plot confirmed the clustering of European beech with ipé, birch with makoré, and oak and black locust with wengé, providing a robust statistical basis for the visual observations.

These insights are highly relevant for the wood processing and furniture industries, offering opportunities to replace tropical wood species with thermally modified, locally sourced hardwoods, thereby combining aesthetic appeal with improved sustainability Future research should focus on refining treatment parameters ‒ such as temperature, duration, or pre-conditioning ‒ to achieve a closer resemblance for a broader range of species, and to deepen understanding of the link between thermal modification and resulting colourimetric transformations.

REFERENCES

Babiak, M., Kubovský, I., Mamoňová, M., 2004. Color space of the selected domestic species. in Interaction of Wood with Various Forms of Energy, Kurjatko, S., Kúdela, J., Eds.; Zvolen: Technical University in Zvolen, 113–117.

Da Silva, R A F , Setter, C , Mazette, S S , de Melo, R R , Stangerlin, D M , 2017 Colorimetry of wood from thirty tropical species. Ciência da Madeira (Brazilian Journal of Wood Science) 8, 1, 36–41. https://doi.org/10.12953/2177-6830/rcm.v8n1p36-41

Dudiak, M , Kminiak, R , Banski, A , Chuchala, D 2024 The Effect of Steaming Beech, Birch and Maple Woods on Qualitative Indicators of the Surface. Coatings 14, 117. https://doi.org/10.3390/coatings14010117

Dzurenda, L., 2022. Range of color changes of beech wood in the steaming process. BioResources, 17, 1, 1690. https://doi.org/10.15376/biores.17.1.1690–1702

Dzurenda, L., 2023. Natural Variability of the Color of Beech Wood in the Color Space CIE L* a * b* Forests, 14, 6, p.1103. https://doi.org/10.3390/f14061103

Gandelová, L., Horáček., P., Šlezingerová, J., 2009. The science of wood. Mendel University of Agriculture and Forestry in Brno. 176 p.

Geffert, A., Výbohová, E., Geffertová, J. 2019. Changes in the chemical composition of oak wood due to steaming. Acta Facultatis Xylologiae Zvolen, 61, 1, 19–29. https://doi.org/10.17423/afx.2019.61.1.02

Geffert, A., Geffertová J., Dudiak, M. Výbohová, E. 2020. Influence of steaming temperature on chemical characteristics and colour of alder wood. Trieskovea beztrieskove obrabaniedreva 12, 49–56.

Hill, C A , 2007. Wood modification: chemical, thermal and other processes. John Wiley & Sons. Hill, C., Altgen, M. Rautkari, L., 2021. Thermal modification of wood-a review: chemical changes and hygroscopicity. Journal of Materials Science 56, 6581–6614. https://doi.org/ 10.1007/s10853-020-05722-z

Hon, D N -S , Minemura, N , 2000 Color and discoloration. in: WoodandCellulosic Chemistry,2nd ed.; Hon, D.N.-S., Shiraishi, N., Eds.; CRC Press: New York, USA, 385–442. Hrčková, M., Koleda, P., Barcik, Š., Štefková, J., 2018. Color change of selected wood species affected by thermal treatment and sanding. Bioresources 13. https://doi.org/10.15376/biores.13.4.8956-8975

Janin, G., Gonçalez, J.C., Ananías, R., Charrier, B., Silva, G.F.D., Dilem, A., 2001. Aesthetics appreciation of wood colour and patterns by colorimetry. Part 1. Colorimetry theory for the CIE

Lab system. Maderas: Ciencia y Tecnología 3, 14. http://dx.doi.org/10.4067/S0718221X2001000100001

Katuščák, S., Kučera, J., 2000. CIE orthogonal and cylindrical color parameters and the color sequences of the temperate wood species. Wood Research 45, 9–21. Meints, T., Teischinger, A., Stingl, R., Hansmann, C., 2017. Wood colour of central European wood species: CIE Lab characterisation and colour intensification. European Journal of Wood and Wood Products 75, 499–509. https://doi.org/10.1007/s00107-016-1108-0

Ortiz-Hidalgo, C., Pina-Oviedo, S., 2019. Hematoxylin: Mesoamerica’s gift to histopathology. Palo de Campeche (logwood tree), pirates’ most desired treasure, and irreplaceable tissue stain. International Journal of Surgical Pathology 27(1), 4–14. https://doi.org/ 10.1177/1066896918787652

Sandak, A., Sandak, J., Allegretti, O., 2015. Quality control of vacuum thermally modified wood with near infrared spectroscopy Vacuum, 114, 44–48. https://doi.org/10.1016/j.vacuum.2014.12.027

Sandberg,D.,Kutnar,A.,Karlsson,O.,Jones,D.,2021.Woodmodificationtechnologies:principles, sustainability, and the need for innovation. CRC Press.

Slabejová, G , Šmidriaková, M , Fekiač, J , 2016 Gloss of transparent coating on beech wood surface. Acta Facultatis Xylologiae Zvolen 58, 37–44. https://doi.org/10.17423/afx.2016.58.2.04

Tolvaj, L , Persze, L , Lang, E , 2013 Correlation between hue angle and lightness of wood species grown in Hungary. Wood Research 58, 141–145.

Vidholdová, Z , Reinprecht, L , 2011 Thermowood Šmíra-Print, 89 p.

Vidholdová, Z , Reinprecht, L , Iždinský, J , 2017 Microbial resistance of tropical woods Zvolen: Technical University in Zvolen (in Slovak), Technical university in Zvolen, 67 p.

Vidholdová, Z , Sandak, A , Sandak, J , 2019 Assessment of the chemical change in heat treated pine wood by near infrared spectroscopy. Acta Facultatis Xylologiae Zvolen 61, 1, 31–42. https://doi.org/10.17423/afx.2019.61.1.03

ACKNOWLEDGMENT

This work was supported by the Slovak Research and Development Agency under the Contract no. APVV-21-0049 and APVV-21-0051.

AUTHORS’ ADDRESSES

Ing. Zuzana Vidholdová, PhD. Technical University in Zvolen Faculty of Wood Sciences and Technology Department of Wood Technology

T.G. Masaryka 24, 960 01 Zvolen zuzana.vidholdova@tuzvo.sk

RNDr. Tatiana Hýrošová, PhD. Technical University in Zvolen Faculty of Wood Sciences and Technology Department of Mathematics and Descriptive Geometry

T. G. Masaryka 24, 960 01 Zvolen tatiana.hyrosova@tuzvo.sk

ACTA FACULTATIS XYLOLOGIAE ZVOLEN, 67(1): 13 22, 2025

Zvolen, Technická univerzita vo Zvolene

DOI: 10.17423/afx.2025.67.1.02

DIMENSIONAL STABILITY OF BEECH BLANKS IN THE CONTACT DRYING PROCESS

Ivan Klement – Tatiana Vilkovská – Peter Vilkovský

ABSTRACT

Timber drying is a crucial process for a wide range of applications, including machining, processing, and final use. It enhances dimensional stability and improves mechanical and physical properties, as well as biological properties such as resistance to mould and fungal growth. The drying process is influenced by various factors, with primary objectives typically focused on minimising costs, reducing drying time, and achieving acceptable drying quality. Achieving an optimal balance between these objectives requires compromises among the rapid drying techniques. Contact drying has gained attention as a potential solution for speeding up the process. The application of contact drying, utilising heated plates at a temperature of 160°C, is investigated in the study. Three specific pressure levels were examined: 1.0 MPa, 1.4 MPa and 1.8 MPa. The results indicated a substantial increase in sample density during contact drying, with pressure playing a significant role in this effect. Additionally, the variation in sample thickness was more pronounced in tangential samples. Across both radial and tangential orientations, samples subjected to the contact drying method exhibited greater dimensional stability compared to those dried by convection.

Keywords: contact drying; beech blanks; press drying; dimensional stability.

INTRODUCTION

The European beech (Fagus sylvatica L.) is a native species of European forests. It accounts for 11.9% of Europe's forest stock (State of Europe's Forests 2020), with a proportion of 35.4% in Slovakia (Green Report 2023). Beech wood is in demand on the market because of its excellent physical and mechanical properties, good workability, and aesthetic appearance Konopka et al. (2021), Sedliačiková and Moresová (2022), Dudiak et al. (2024). The fundamental technological operations in beech wood processing include drying. This is a demanding hydrothermal process that requires constant attention due to the changes in wood properties during drying, the length of the drying process, the quality of the dried material, as well as its energy and economic demands, as reported in several scientific studies by Blomberg (2006), Kumar (2021) and Dzurenda (2022). After modification (by steaming, thermowood or heat treatment), beech wood acquires higher stability, durability, and extended possibilitiesofuse,including exterior(Tolvaj et al., 2009,Barcík andGašparík 2014, Dzurenda and Dudiak 2021, Suchta et al., 2021, Vidholdová and Slabejová 2021). In addition to the most common warm-air drying of timber and blanks in drying kilns, which is time and energy consuming, other drying technologies such as high-temperature drying

Barański et al. (2017), Klement et al. (2019) and contact drying Schmitdt (1967), Schrepfer and Schweingruber (1998) Kúdela and Rešetka (2012), Klement et al. (2022) and have also received research attention. Press drying or contact drying of wood is a method of wood drying processing. The main objectives of pressing are to increase the wood’s density, enhance its mechanical properties, and create a defined surface relief. The final properties of compressed wood are also strongly influenced by its dimensional stability following the pressing process (Kúdela andRešetka2012).Contact dryingisimplementedin apress where theheat from theheating plates is conductedfrom theupperandlowersurfaces ofthelumber inward towards the centre, in the direction of the plate thickness. Contact drying is a rapid method for removing moisture from wood. However, this quick-drying process and the high temperatures involved can cause changes in the wood, such as darkening its natural colour, and in particular species, severe cracking and honeycombing (Hittemeier et al., 1968, Heebink and Compton 1966). Contact drying offers several benefits, including keeping the wood flat during drying, improving its dimensional stability, reducing inventory requirements, and efficiently utilizing heat energy (Tang et al., 1994).

Significant research efforts by Hittemeier et al. (1968) focused on finding new products and processes to utilise this material better. One promising product is press-dried panelling, as described in a report by the U.S. Forest Products Laboratory. This process, knownas contact drying, involves applying heat to both sides ofa board using heated platens to remove moisture. The drying process typically occurs at temperatures ranging from 120 to230°C,withaplatenpressurebetween1.7MPaand2MPa.Whilecontact dryingprovides good contact with the board, it can result in thickness shrinkage and some defects, such as discolouration, cracks, and honeycombing. However, these colour changes may negatively affect the product for many uses, and the darker colour can even be more desirable than the original wood. The author also states in his work that boards of 1.5 cm thickness were dried to a final moisture content of 6% for about 25-75 minutes, while samples of 2.5 cm were dried for about 100-200 minutes, depending on the type of wood species (oak, ash, elm, beech etc.). from the point of view the density of pressed wood is primarily influenced by the degree of compression and the wood species (Blomberg et al., 2006). According to the authors Blomberg et al. (2006), for seven different wood species, including beech, pressed under constant pressure, the average density values ranged from 750 to 1100 kg·m⁻³, depending on the species; however, for beech wood, the values ranged from 700 to 800 kg·m⁻³. Comparable observations are in concordance with those of Zhou et al. (2018) and Simpson (1983), who researched density by contact drying. Samples were oven-dried temperatures at 115, 135, 160, 185, and 205°C, respectively. The thickness of the sample was dimensions of 50 mm (longitudinal) by 50 mm (tangential). Drying was underway, with the material placed between two plates and a pressure of 3.5 MPa applied in the radial direction. Contact drying created a curve of density: high density at the two surface regions that gradually decreased toward the core region. During contact drying, wood becomes plastic and can undergo large deformation under the combined effects of moisture, high temperature, and mechanical compression. As the drying process progressed, heat and water evaporation gradually moved inward, resulting in the densification of the core layer. Consequently, surface regions in the timber were compressed more than core regions, creating a density profile. Surface regions had a density ranging from 600 to 850 kg· m-³, and the core regions had a density of only between 400 and 450 kg· m-³ for maple wood (Simpson, 1983). Based on the cited work of Unsal and Candan (2008), the density and dimensional stability of lumber can be enhanced through the combined effects of thermal energy and compression treatment. As a result, studying the hot-press drying process of selected trees (pine, fir, poplar) holds significant theoretical value for promoting its efficient

and high-value utilisation. During hot-press drying, heat and mass transfer are critical factors influencing the drying behaviour of wood. The heat from the heating platens is conducted from both the upper and lower surfaces of the lumber inward toward the centre, following the direction of the board’s thickness.

The authors demonstrate that these conclusions were experimentally measured to investigate the effect of heating platens' temperature on the moisture state in poplar lumber with a moisture content (MC) above the fibre saturation point (FSP) during press drying. The maximum temperature and pressure were observed at the centre layer of poplar lumber during hot-press drying. As the temperature increased from 120 to 140 °C, the maximum temperature values rose from 111.2 to 127.3 °C, whereas those of pressure increased from 219.4 to 276.9 kPa. However, a delay occurred between the maximum values of pressure and temperature.

The aim of this article is to examine the effect of contact drying on the density and dimensional stability of wood. Specifically, beech wood, using temperatures of 160°C and under varying specific pressure levels of 1.0, 1.4 and 1.8 MPa.

MATERIALS AND METHODS

Beech wood (Fagus sylvatica L.) was used for experimental measurements. The samples were selected from two beech logs, each with a diameter of 40 cm and a length of 300 cm. The forest is located in the area known as Budča (475 m a.s.l.), which belongs to the University Forest Enterprise of the Technical University in Zvolen, Slovakia.

Radial and tangential samples were cut out from the log according to the cant sawing pattern. The dimensions of the drying samples were 120 × 800 × 30 mm (width × length × thickness).

The process of contact drying was conducted in a hydraulic single-storied press type CBJ 500-5 (TOS RAKOVNIK). The temperature of the heating plates was 160 °C. Three specific plate pressures of 1.0, 1.4 and 1.8 MPa were used. The group of samples was dried until the temperature measured at the centre of the sample reached the temperature of the pressing plate (tp = 155 °C). The contact drying was completed at that time.

One filling always consisted of samples from one radial (R) and one tangential (T) log.

The drying mode of contact drying consisted of three phases (I - III.). Samples were dried at a constant temperature (II.) after a gradual rise in temperature (I.) to 160 °C. The cooling phase was (III.) after reaching the desired temperature in the centre of the samples. The final phase was conducted at 20 °C.

Convection hot air drying in the Memmert HCP laboratory dryer was used to compare the changes in the monitored properties of the sample groups. According to ON 490651, the standard drying mode was applied to the given wood species, taking into account its thickness and initial moisture content. The samples were also cut to determine their initial moisture content and density. The initial and final moisture content (MC) of the wood was determined using the gravimetric method, as specified in STN EN 49 0103. The moisture content was calculated using Eq. 1

Where: mw is theweight ofthewet sample(g)and m0 istheweight oftheabsolutedrysample (g)

Oven-dried density was measured before and after contact drying. The measurement was performedunderlaboratoryconditions. Thedensity(ρ0)ofwoodat 0% moisturecontent was measured according to STN EN 49 0108. The oven-dried density was calculated using Eq. 2.

Where: m0 is the weight of oven-dried moisture samples (kg) and V0 is the volume of ovendried moisture samples (m-3).

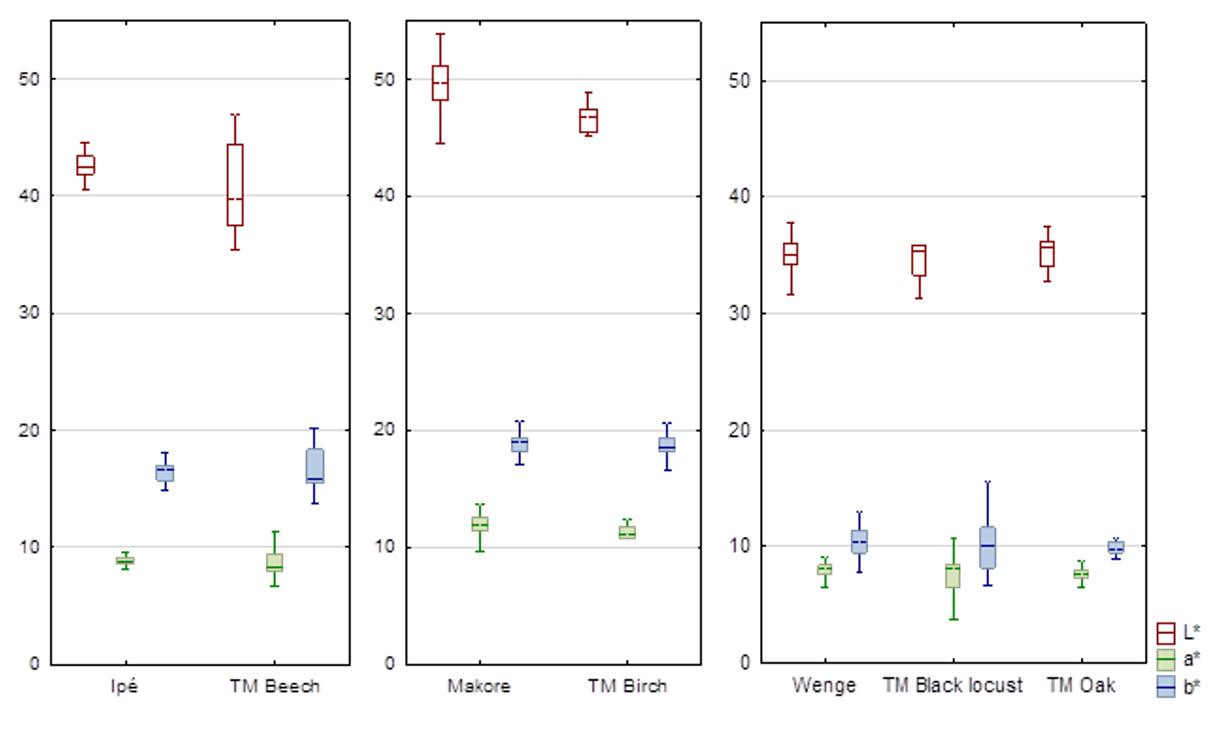

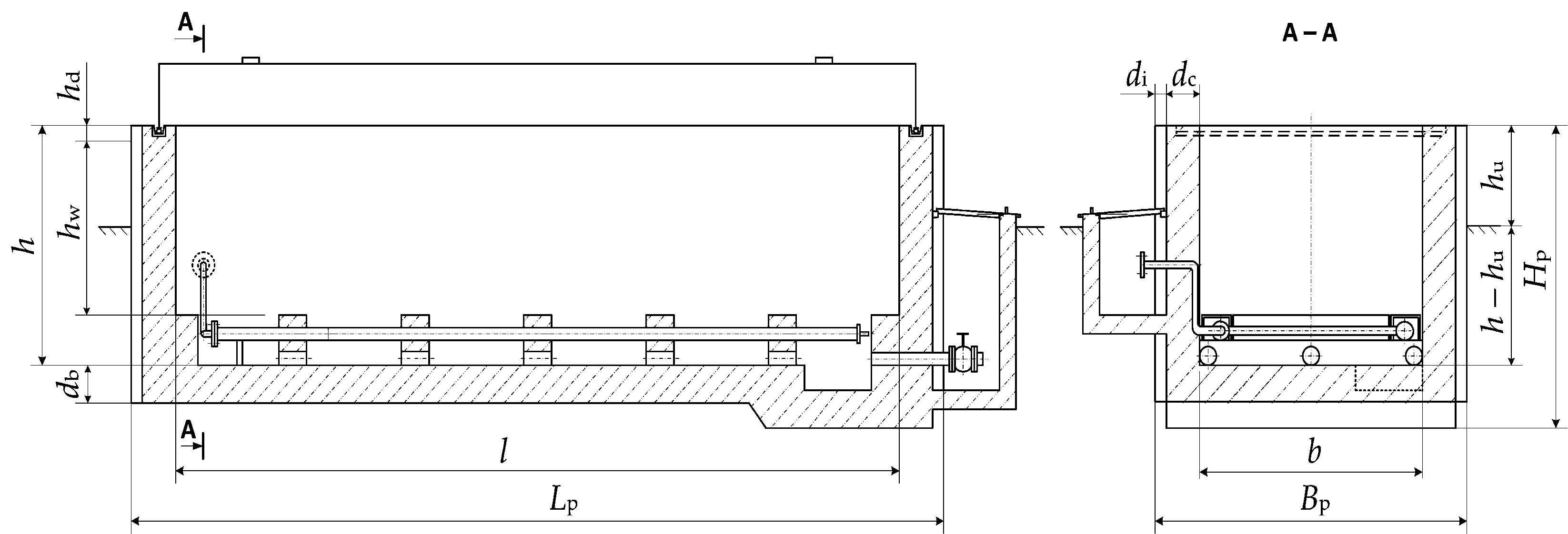

The thickness and width of the samples were measured before and after every contact drying with an accuracy of 0.01 mm. The samples were placed in an air-conditioning chamber at a temperature of 20 °C and a relative humidity of 60% after contact drying. Similarly, samples after convection drying were measured and conditioned. The dimensions of the samples were measured again after conditioning (Fig. 1).

Fig. 1 Scheme of measuring the thickness and width of samples.

All samples were still conditioned to an equilibrium moisture content of ≈20% and then the thicknesses and widths of the samples were measured. From these values, the stabilizing effect of contact drying on the width using the anti-drying factor was evaluated:

Where: bKV swelling of wood in width, dried by convection, transferred from one state of moisture balance to another (%), bKT swelling of wood in width, determined by the contact method, transferred from one wood state of moisture balance to another (%).

Effect of contact drying on thickness:

Where: hKV swelling of wood in thickness, dried by convection, transferred from one state of moisture balance to another (%), hKT swelling of wood in thickness, dried by the contact, method transferred from one state of moisture balance to another (%).

RESULTS AND DISCUSSION

Table 1 presents the measured average values of the initial and final humidity for individual groups of samples, as well as the total contact drying time. The average density values of the samples in the dry state, both before and after drying, are presented, along with an increase in average density resulting from contact drying.

Tab. 1 Initial and final moisture of the samples, drying time, and density of the samples.

It can be seen from the measured data that the initial moisture content of the samples ranged from 54.14%to 80.27%, andthe final moisture contentranged from 3.95% to 6.08%.Drying time was shorter for radial samples, while plate pressure had no effect on drying time, and the effect of sample type was also not significant. The drying time for contact drying is in the range of a few minutes, whereas conventional warm-air drying can take several hours or even days, which makes a significant difference in time requirements. For example, in the case of our sample beech wood, with a thickness of 30 mm and an initial moisture content of approximately 70%, the warm-air drying process would take approximately 169 hours. For a beech sample of the same thickness, the drying time for contact drying was approximately 110 minutes, so it is approximately 85 times shorter. Our measurements confirmed that the density after contact drying ranged from approximately 722 to 786 kg·m⁻³. As a result of contact drying, the density of the samples increased by an average of 92 kg·m-3, while the effect of plate pressure on the density value was confirmed.Alargerincreasein densitywas discoveredforradialsamples (averagevalue 102 kg·m-3). This difference was caused by the direction of the plate pressure. In the case of radial samples, the direction of the pressure was tangential, the densification, and thus the increase in density was greater. For tangential samples, the average value was 83 kg·m-3 . Blomberg et al. (2006) report that density after contact drying ranged from 700 to 800 kg·m-³ for beech wood specifically. As also shown by Jung et al. (1993), contact drying can affect the density of dried samples. According to Kúdela et al. (2018), the density distribution across the specimens in the pressing direction was not similar. The highest density values were observed in the surface layers (1–2 mm), gradually decreasing towards the centre. As the degree of compression increased, the density profiles across the specimen thickness (in the pressing direction) became more identical.

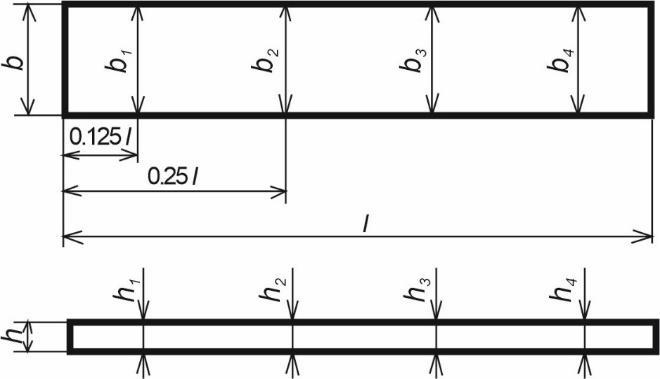

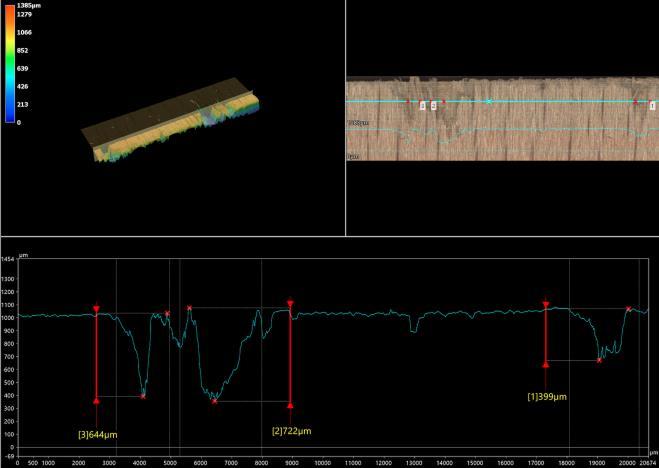

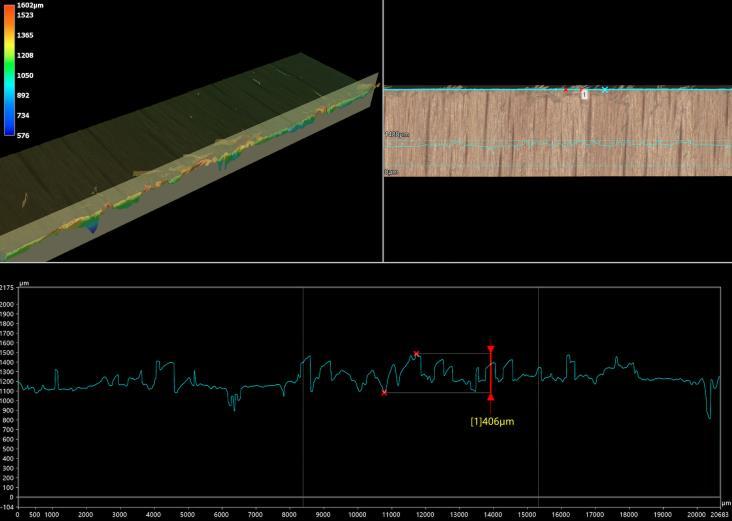

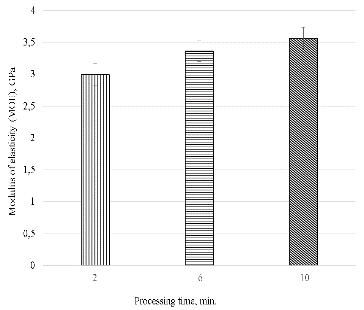

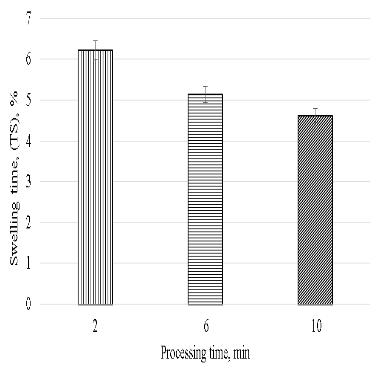

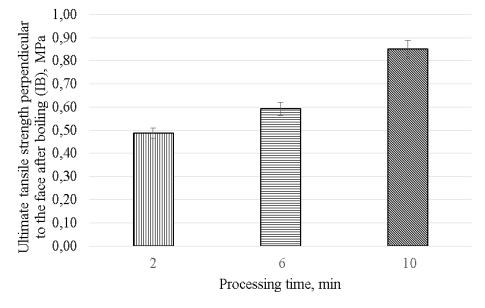

The change in the dimensions of the samples depending on the drying time are shown in Figures 2, 3 and 4.

Fig. 2 Thickness change at different contact drying pressures – radial samples.

In the case of radial samples, the influence of plate pressure was almost insignificant, and the differences in the change in the thickness of the samples at individual pressures were less than 1.0% (Fig. 2). The differences in the change of the thickness of the samples were caused by the fact that the direction of the pressure is in the tangential direction for the radial samples and the radial direction for the tangential samples.

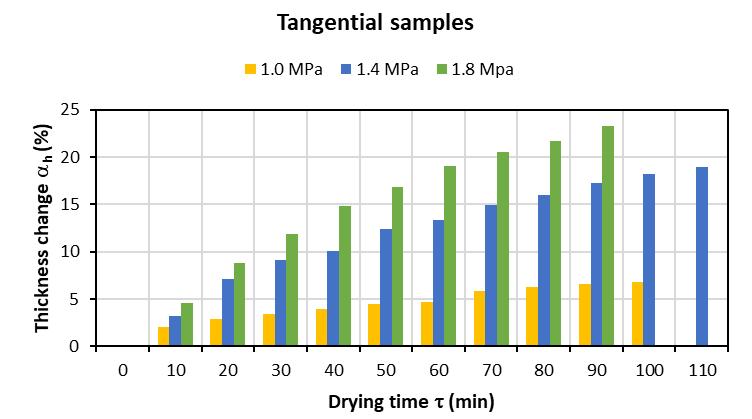

3 Thickness change at different contact drying pressures – tangential samples.

The influence of plate pressure during contact drying was more remarkable for tangential samples, where a thickness change of 6.75% was measured at a pressure of 1.0 MPa and a 23.3% change in thickness at a pressure of 1.8 MPa (Fig. 3).

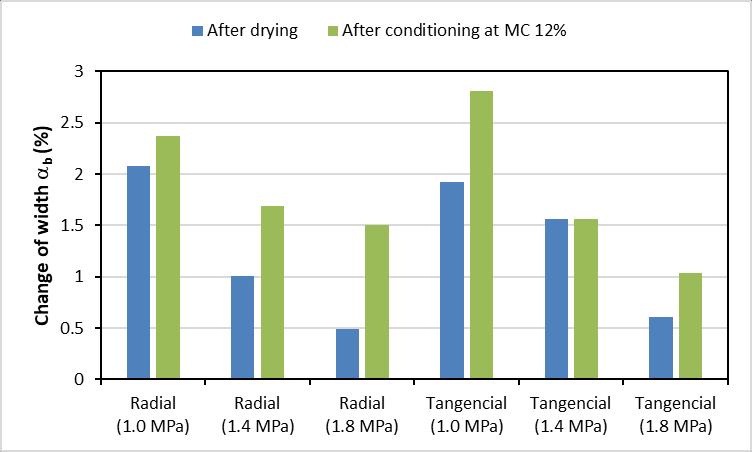

The values of the change in sample width are significantly smaller than the change in thickness (less than 3%). The effect of pressure on the change in width was confirmed for both radial and tangential samples (Fig. 4).

However, the effect of plate pressure is opposite to the change in thickness. As the pressure on the plates increased, the change in the width of the samples decreased. Greater values of the change in width were observed when evaluating the change in this dimension after conditioning the samples to a humidity of 12%. Based on the authors' work by Jung et al. (1993) and Hou et al. (2018), research was conducted on 24 mm thick samples using three species of coniferous wood (pitch pine, larch, and white pine), where the contact was dried under two-platen pressures of 0.17 and 0.34 MPa. The initial moisture content of the samples ranged from 30% to 89%.

Fig.

Results confirmed that an increase in the higher pressure caused thickness shrinkage. Other studies conducted by Kúdela and Rešetka (2012) confirm that dimensional stability is closely related to both the pressing temperature and the pressing time. Their experiments confirmed a noticeable improvement in dimensional stability as the pressing temperature and time were increased. These pressing conditions also resulted in a notable reduction in both the moisture content and the sorption capacity of the pressed wood.

Fig. 4 Width change at different contact drying pressures and samples.

This means that the thick swelling of the samples during contact drying was greater by the indicated Fh values at all pressures compared to convection drying. The bigger difference was with the radial samples. Some authors have also estimated the mechanical properties during contact drying, as shown by the cited work by Klement et al. (2022). The results showed a very favourable effect of contact drying on the change in the observed mechanical properties of beech wood. Increasing the bending strength enhances the use of wood in elements subjected to increased loads. Increasing the hardness of the surface after contactdryingwillallowtheuseofsuchdriedwoodinplaceswithhighstress,suchasfloors. Based onthemeasured changes in thedimensions ofthesamplegroupduringcontact and convection drying, the values of the anti-drying factor were calculated (Tables 2 and 3).

Tab. 2 Dimensional change during contact and convection drying and anti-drying factor: radial samples.

The difference before and after drying (%)

after air

Tab. 3 Dimensional change during contact and convection drying and anti-drying factor: tangential samples.

Measurements

The anti-drying factor F informs the stabilizing effect of contact drying compared to convection drying. The results of Fb mean that for both groups of samples and all pressures. The samples dried using the contact method are more dimensionally stable in terms of swelling than those dried using the convection method, particularly in terms of thickness swelling. The calculated Fh values were negative

CONCLUSION

The objective of this study was to assess the impact of contact drying on the changes in thickness and width of wood samples, as well as their overall dimensional stability and changes in density, depending on the pressure applied during the drying process. Samples with a thickness of 30 mm, exhibiting both radial and tangential grain orientations, were used for the experiment. Drying was performed at a plate temperature of 160°C, with pressures set at 1.0 MPa, 1.4 MPa, and 1.8 MPa. The results were then compared with those of conventional hot air drying.

Based on the data collected, the following conclusions can be drawn:

• contact drying proved to be highly efficient, reaching low final moisture content in a short period. In comparison to warm-air drying, which takes approximately 169 hoursforbeechwoodofthesamethickness, contact dryingshortenedthedrying time to less than 2 hours, approximately 85 times faster;

• radial samples dried faster than tangential samples, while the specific plate pressure had no significant effect on the drying time. During the contact drying process, the density of the samples increased considerably, with plate pressure playing a substantial role in this increase. For radial samples, the density increased by an average of 102 kg·m-3, while for tangential samples, it increased by 83 kg·m-3;

• the average thickness change for radial samples was 16.6%, with no notable effect from the plate pressure. However, plate pressure significantly influenced the thickness change for tangential samples, ranging from 7% to 23%;

• the width change in the samples during contact drying was nearly identical for both radial and tangential samples, with the highest values observed at the lowest plate pressures;

• in terms of dimensional stability during swelling, samples dried by contact drying showed greater stability compared to those dried by the convection method for both radial and tangential samples across all pressure levels;

• thickness swelling was greater forsamples dried by contact dryingcompared to those dried by convection, with the most significant difference observed in the radial samples.

REFERENCES

Barański, J., Klement, I., Vilkovská, T. and Konopka, A., 2017. High temperature drying process of beech wood (Fagus sylvatica L.) with different zones of sapwood and red false heartwood, BioResources 12(1), 1861-1870.

Blomberg, J, Persson, B., and Bexell, Ulf. 2006. Effects of semi-isostatic densification on anatomy and cell-shape recovery on soaking Holzforschung, vol. 60(3), pp. 322331. https://doi.org/10.1515/HF.2006.052

Dudiak, M., Kminiak, R., Banski, A., and Chuchala, D., 2024. The Effect of Steaming Beech, Birch and Maple Woods on Qualitative Indicators of the Surface. Coatings, 14(1), 117. https://doi.org/10.3390/coatings14010117

Dzurenda, L., Dudiak, M., 2021. Cross-correlation of color and acidity of wet beech wood in the process of thermal treatment with saturated steam. Wood Research, 66(1) 105–116. https://doi.org/10.37763/wr.1336-4561/66.1.105116

Dzurenda, L., 2022. Mode for hot air drying of steamed beech blanks while keeping the colours acquired in the steaming process. Acta Facultatis Xylologiae Zvolen. 64(1), 81-88. https://doi.org/10.17423/afx.2022.64.1.07

Dzurenda, L., Dudiak, M., Kučerová, V., 2023. Differences in some physical and chemical properties of beechwood with false heartwood, mature wood and sapwood. Forests 14(6), art. no. 1123.

Dzurenda, L., Dudiak, M., 2024 Homogenization of the Color of Beech Sapwood and False Heartwood by the Steaming Process. Forests, 15, 1009. https://doi.org/10.3390/f15061009

Esteves, B. M., and Pereira, H. M., 2009 Wood modification by heat treatment: A review, Bioresources 4(1), 370-404. https://doi.org/10.15376/biores.4.1.370-404

Forest Europe. State of Europe’s Forests 2020. Bratislava: Ministerial Conference on the Protection of Forests in Europe – FOREST EUROPE, Liaison Unit Bratislava, 2020. https://www.foresteurope.org

Hittemeier. M.E., Comstock G.L., Hann. R.A., 1968 Press drying nine species of wood. Forest Product Journal. 1968. 18(9):91-96.

Jung. S. H., Lee. H. N., Yeo. H., 1993 Press-drying of Plantation Softwood Lumber. Journal of the Korean Wood Science and Technology 21(3)

Klement, I, Vilkovská, T, Uhrín, M, Barański, J., Konopka, A., 2019 Impact of high temperature drying process on beech wood containing tension wood Open Engineering, vol. 9, no. 1, 2019, pp. 428-433. https://doi.org/10.1515/eng-2019-0047

Klement, I., Vilkovský, P., Vilkovská, T., 2020 The Effect of Contact-Drying on Physical Properties of European Beech (Fagus sylvatica L.). Forests 2020, 11, 890. https://doi.org/10.3390/f11080890

Konopka,A.,Chuchala,D.,Orlowski,K.A.,Vilkovská,T.,Klement,I.,2021.Theeffectofbeech wood (Fagussylvatica L.) steaming process on the colour change versus depth of tested wood layer. Wood Material Science & Engineering, 17(6), 420–428. https://doi.org/10.1080/17480272.2021.1942200

Kúdela, J , Rešetka, M., 2012. Influence of pressing parameters on dimensional stability and selected properties of pressed beechwood. I. Dimensional stability and density. Acta Facultatis Xylologiae Zvolen, 54(1): 15−24, Technical University in Zvolen

Kúdela, J., Rousek, R., Rademacher, P., 2018. Influence of pressing parameters on dimensional stability and density of compressed beech wood. European Journal Wood Products 76, 1241–1252 (2018): https://doi.org/10.1007/s00107-018-1298-8

Kumar B, Szepesi LG, Szamosi Z., 2021. Design and development of natural convective solar dryer. Multidiszciplináris Tudományok11(4):144–150. https://doi.org/10.3 592 5/j .multi.2021.4.18

Ministerstvo pôdohospodárstva a rozvoja vidieka Slovenskej republiky. (2023): Zelená správa 2023: Správa o lesnom hospodárstve v Slovenskej republike za rok 2022 [Ministry of Agriculture and Rural Development of the Slovak Republic. (2023): Green Report 2023: Report on Forestry in the Slovak Republic for 2022]. MPRV SR. https://www.mpsr.sk/zelena-sprava-2023/123 19005/

Sedliačiková, M., Moresová, M., 2022. Are Consumers Interested in Colored Beech Wood and Furniture Products Forests 2022, 13, 1470. https://doi.org/10.3390/f13091470

Schmitdt, J., 1967. Press drying of wood. Forest product journal 8(4) pp. 71-76. Schrepfer, V., Schweingruber, FH., 1998. Anatomical structure in reshaped press-dried wood. Holzforschung 52:615–622

Simpson, T. W., 1983. Maintaining timber quality in press drying by manipulating sawing patterns. Wood and Fiber Science. 1984. 16(3): 411-426.

Suchta, A., Barański, J., Vilkovská, T., Klement, I., Vilkovský, P., 2024 The impact of drying conditions on the surface color changes of pine wood BioResources 19(1), 656-669.

STN 490 108: 1993. Wood. Determination of density. Slovak Standards Institute. Bratislava. STN 490 103: 1993.Wood.Determination ofthemoisturecontent ofthephysical and mechanical testing. Slovak Standards Institute. Bratislava. Slovakia.

Tolvaj, L., Németh, R., Varga, D., Molnár, S., 2009 Colour homogenisation of beech wood by steam treatment. Drewno, 52(181), 5–17. http://yadda.icm.edu.pl/yadda/element/bwmeta 1.element.baztech-article-BAT8-0013-0043

Tang, YF , Hart, CA , Simpson, WT , 1994 A numerical model for heat transfer and moisture evaporation processes in hot-press drying, an integral approach. Wood Fib. Sci 26(1),78–90 Unsal, O., Candan, Z., 2008 Moisture content, vertical density profile and Janka hardness of thermallycompressedpinewoodpanelsas afunctionofpress pressureandtemperature.Dry. Technol., 26, 1165–1169

Vidholdová, Z., Slabejová, G., 2021. Colour Stabilisation of Surface of Four Thermally Modified Woods with Saturated Water Vapour by Finishes. Polymers, 13(19), 3373. Zhou, F , Gao., X., Fu.Z., Zhou. Y., 2018 Drying kinetics of poplar lumber during periodic hotpress drying. Drying Technology. https://doi.org/10.1080/07373937.2018.1426597

ACKNOWLEDGEMENTS

This work was supported by the Slovak Research and Development Agency under the Contract no. APVV-21-0049 and work was supported by the Scientific Grant Agency of the Ministry of Education, Science, Research and Sport of the Slovak Republic and the Slovak Academy of Sciences – project VEGA No. 1/0063/22.

AUTHOR´S ADDRESS

prof. Ing. Ivan Klement, CSc. Ing. Tatiana Vilkovská, PhD. Ing. Peter Vilkovský, PhD. Technical University in Zvolen, Faculty of Wood Sciences and Technology, T. G. Masaryka 24, 960 01 Zvolen, Slovakia klement@tuzvo.sk tatiana.vilkovska@tuzvo.sk peter.vilkovsky@tuzvo.sk

ACTA FACULTATIS XYLOLOGIAE ZVOLEN, 67(1): 23 33, 2025

Zvolen, Technická univerzita vo Zvolene

DOI: 10.17423/afx.2025.67.1.03

MODELING AND ANALYSIS OF TEMPERATURE DISTRIBUTION ACROSS THE CROSS-SECTION OF FLAT-PRESSED WOODPOLYMER COMPOSITES DURING COOLING STAGE

Lyutyy – Pavlo Bekhta – Ján Sedliačik

ABSTRACT

This study is aimed at formulating a mathematical model describing the thermal dissipation kinetics during the post-processing cooling of flat-pressed wood-polymer composites (FPWPC). The dependence of the composite cooling time and the spatiotemporal temperature distribution across its thickness on the wood particle content, initial surface temperature, and bulk density are elucidated in the study. Analysis of the core layer thermal profile revealed three distinct phases: an initial temperature rise, a thermal maximum, and a conduction cooling phase. The findings indicate that both the wood particle content and the initial surface temperature of the FPWPC significantly influence the rate of thermal dissipation. Elevated initial surface temperatures (200°C) resulted in an initially accelerated cooling rate followed by a deceleration. Composites with a higher wood particle content (60%) exhibited slower cooling rates, attributed to the lower thermal conductivity of wood compared to the thermoplastic polymer matrix, leading to enhanced thermal retention. The bulk density of the FPWPC plays a critical role in its thermal management, affecting its specific heat capacity, thermal conductivity, and convective heat transfer efficiency. The derived mathematical model has the potential to optimise FPWPC manufacturing processes.

Keywords: flat-pressed wood-polymer composites; post-processing cooling process; cooling time; cooling temperature

INTRODUCTION

Wood–polymer composites (WPCs) are considered promising materials due to their advantageous operational characteristics and broad applicability across various industrial sectors (Klyosov, 2006). WPCs can be manufactured using multiple processes, including extrusion, injection moulding, and compression moulding, depending on the intended geometry and application of the final product (Klyosov, 2006). Among these, extrusion is the most commonly employed method for WPC production in the United States and Europe (Rowell, 2005), primarily used to create continuous profiles with limited crosssectional complexity. In addition to extrusion, WPCs can also be produced via flat pressing in hot presses (Ayrilmis and Jarusombuti, 2011; Benthien and Thoemen, 2012; Lyutyy et al., 2014). This hot-pressing method has been the focus of significant academic research aimed at improving the structural and functional performance of flat-pressed WPCs (FPWPCs) (Ayrilmis and Jarusombuti, 2011; Benthien and Thoemen, 2012; Lyutyy et al.,

Pavlo

2014). Mathematical models have been developed to optimize the hot-pressing process, thereby enhancing efficiency and product consistency (Lyutyy et al., 2024). A critical yet often underexplored aspect of FPWPC production is the post-pressing cooling stage, which plays a crucial role in consolidating the composite final properties. Although some studies refer to this stage simply as the final cooling phase – typically concluding when the material reaches approximately 50 °C – they often lack a detailed examination of key process parameters, such as cooling time and the temperature of the cooling surfaces (Benthien and Thoemen, 2012; Benthien and Thoemen, 2013).

Previous research has investigated optimal cooling strategies for thermoplastic composites in the post-manufacturing phase (Sonmez and Eyol, 2000). One such study focused on determining the most effective cooling regime to reduce processing time during the cooling stage of APC-2 laminate press moulding. Additionally, an experimental investigation examined the thermal dissipation behavior of WPCs that were initially heated to 150°C in an electric furnace and subsequently cooled at ambient conditions (21°C) (Matthews et al., 2015).

Despite the recognized importance of the thermal dissipation stage in the production of flat-pressed wood–polymer composites (FPWPCs), a review of the existing literature reveals a significant gap in research addressing the mathematical modeling of the cooling process in these materials. Therefore, the objective of the present study was to develop a mathematical model capable of predicting the cooling duration of FPWPCs produced in periodical action presses. The goal was to determine the optimal cooling time required for the core layer of the composite to reach the polymer solidification temperature.

MATERIALS AND METHODS

Development of the mathematical model

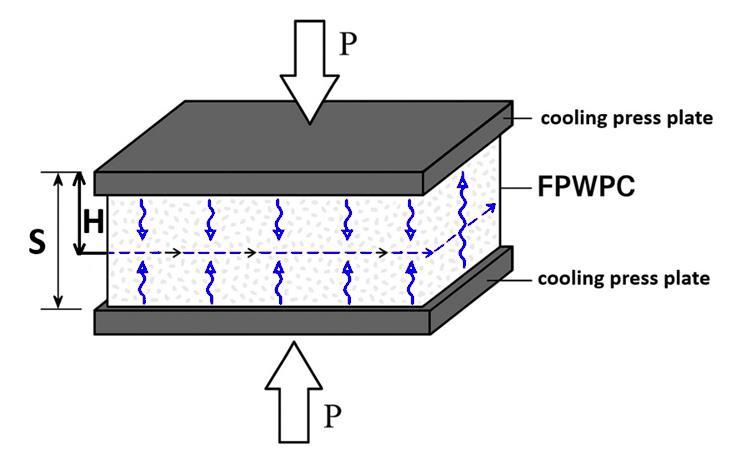

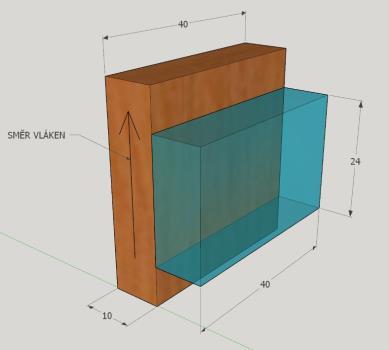

The time required to close and open the press plates, as well as the time to increase and decrease the pressure, are determined by the type of flat pressing equipment and any modifications made to it. Primarily, the cooling time for FPWPC panels is determined by the time to reach a predetermined temperature in the core layer (H) (Fig. 1).

Fig. 1 Cooling model of FPWPC after hot-pressing.

In the case of one-dimensional transient heat conduction, incorporating Fourier’s Law and principles consistent with the Second Law of Thermodynamics, the heat conduction equation takes the following form:

Where: T (x,t) – temperature at point x at time t; α – the thermal diffusivity (α), a property determined by:

Where: λeff – effective thermal conductivity of FPWPC; ρ – density of FPWPC; Cfpwpc –heat capacity of the FPWPC.

FPWPC consists from wood particles and thermoplastic polymer, therefore effective thermal conductivity of FPWPC can be calculated using formula:

Where: λwood and λpol – are the thermal conductivities of wood and polymer, respectively; φwood is the volumetric fraction of wood particles in the composite material, expressed as a fraction.

Therefore, the volumetric fraction of wood particles can be calculated in the following manner:

Where: VWPC is volume of FPWPC and Vwood is the volume of wood particles within the FPWPC.

The thermal conductivities of wood and thermoplastic polymer (in our mathematic we will choose high-density polyethylene (HDPE)) are determined using experimental linear equations (Prisco, 2014):

The specific heat capacity of the FPWPC can be calculated using the following equation:

Where: сW wood and сpol are the specific heat capacities of moist wood particles and thermoplastic polymer, respectively.

Then the specific heat capacity of moist wood particles, considering their moisture content, can be determined as follows (Thoemen and Humphrey, 2005):

The specific heat capacity of a HDPE is temperature dependent and can be calculated by (Gaur and Wunderlich, 1981):

An explicit scheme of the finite difference method is used for the numerical solution. The discretization in time and space is presented as follows.

Spatial distribution:

distribution:

Spatial step:

Where: S – thickness of FPWPC (S = 2 H).

Temporal step:

The discretization of the Fourier equation results in:

Where: Ti n – temperature at the i-th node at the n-th time step; T

– temperature at the adjacent nodes; – dimensionless coefficient.

Subsequently, the initial conditions can be formulated in the following manner. At the onset of the modeling process, the temperature distribution is defined through the thickness of the FPWPC:

And boundary conditions will be:

Within the numerical discretization:

The finite element method (FEM) was employed as the numerical approach for solving the boundary value problem. FEM is based on the principle of approximating a continuous function with a discrete model composed of piecewise constant functions defined over a finite number of subdomains known as finite elements. The geometric domain of interest is discretized into these elements, within which the unknown function is approximated using trial functions. These trial functions are required to satisfy both interelement continuity and the boundary conditions specified by the problem.

To implement the developed model, the Matlab R2021b (9.11) computational environment (MathWorks, Natick, MA 01760-2098, USA) was utilized, specifically the Matlab Partial Differential Equation Toolbox (PDE Toolbox), which supports FEM-based simulations. The toolbox graphical user interface (GUI), accessed via the functions “pdeinit” and “pdetool”, facilitates the interactive setup of the PDE model. This includes defining the geometry of the domain, specifying boundary conditions, selecting the equation type and its coefficients, generating a computational mesh, solving the problem, and visualizing the results.

Given that surface temperature after pressing, wood mass fraction, and board density are variable factors in the cooling process, a custom Matlab function, “calculate.m”, was developed. This function accepts these parameters as input and returns numerical simulation results, specifically, temperature distributions at the mesh nodes over time, presented in matrix form.

Graphical representations of the simulated data were generated for an FPWPC sample with a thickness of 18 mm, assuming a constant cooling platen temperature of 25 °C. The initial temperature of the core layer was set at 120 °C. The simulation was concluded when the temperature at the composite core decreased to 50 °C. The moisture content of wood particles was 3%.

The parameters used in the simulation of the FPWPC cooling model are summarised in Table 1.

Conditions

Initial surface temperature (оС)

Wood particles content, (%)

Density of FPWPC (kg/m3)

Values

160, 180, 200

20, 40, 60

800, 900, 1000

RESULTS AND DISCUSSION

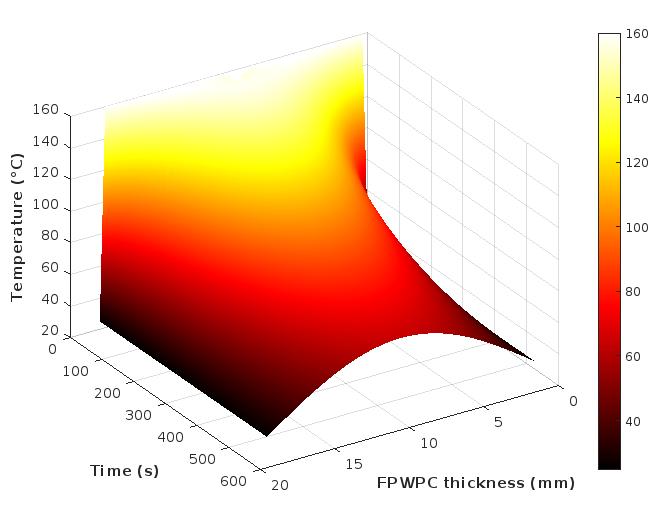

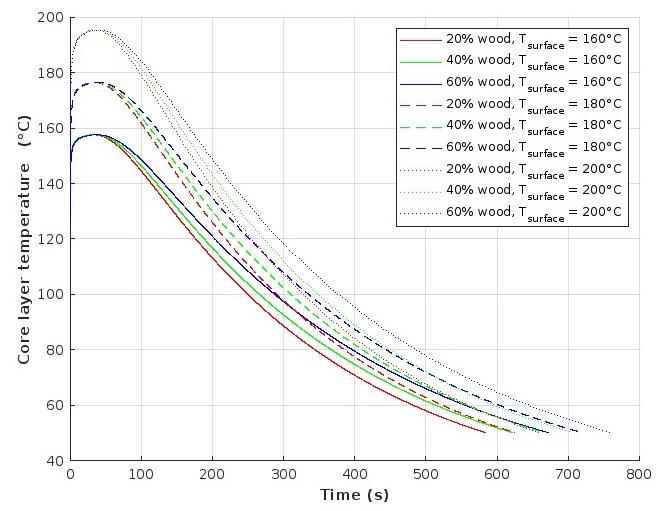

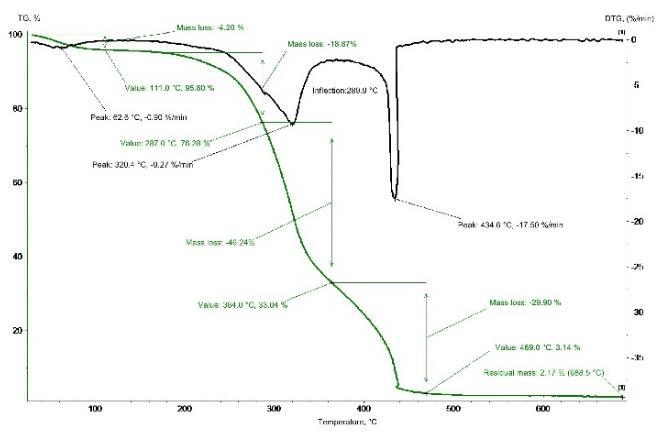

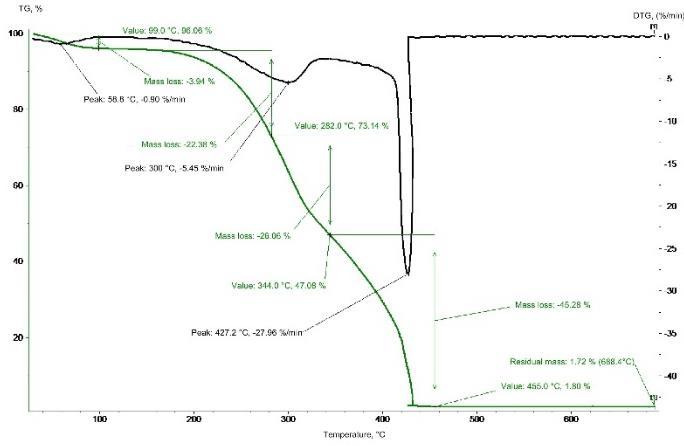

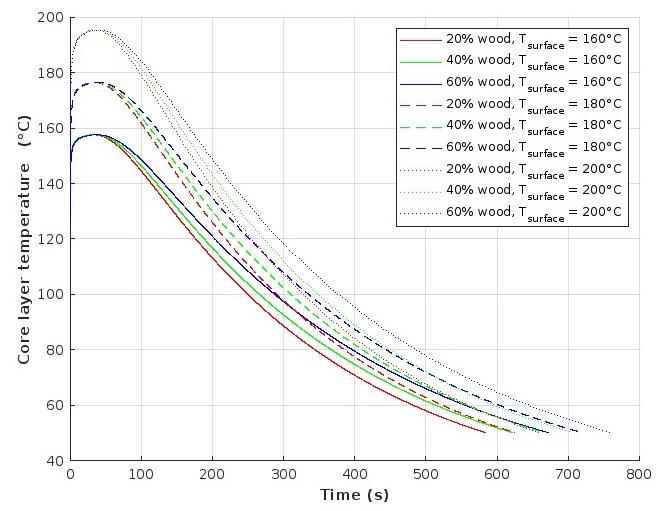

The execution of the mathematical model yielded a plotted relationship illustrating the dependence of the FPWPC cooling time on its initial surface temperature, as well as the spatiotemporal temperature distribution across the material cross-section throughout the entire cooling cycle (Fig. 2).

Tab 1 Variable parameters

Fig. 2 Temperature distribution within the FPWPC across its thickness until the internal temperature reaches 50 °C, with an initial surface temperature of 160 °C and a composite density of 1000 kg/m³.

The non-uniform cooling behavior of FPWPC along its thickness is evident and results from the varying heat transfer rates in different layers of the composite. At the onset of the cooling phase, the surface regions exhibit the highest temperature, corresponding to the press plate temperature during the hot-pressing stage. In contrast, the core layer initially exhibits a lower temperature – approximately 10 °C above the fusion temperature of the thermoplastic polymer (Lyutyy et al., 2024). However, as cooling progresses, the surface layers are the first to experience a temperature drop, while the core temperature continues to rise due to thermal inertia. This heat redistribution from the surface to the core creates a steep temperature gradient across the thickness of the material.

Temporally, the cooling of the FPWPC core layer can be divided into three distinct phases:

1. initial temperature rise (0~40 s);

2. thermal maximum (~40~60 s);

3. convective cooling phase (~60~800 s)

In the first phase – the initial temperature rise (0~40 s) a rapid increase in the core temperature is observed, particularly during the first 10–20 seconds. This occurs due to the significant temperature difference between the hotter surface layers and the cooler core. As heat from the surface begins to conduct inward, the core temperature increases sharply, driven by the established thermal gradient. The rate and duration of this temperature rise are influenced by factors such as the initial surface temperature, wood particle content, and bulk density of the FPWPC (Fig. 3). A greater temperature gradient between the surface and the core layers leads to a more extended transition period before the composite enters the cooling phase proper. It is important to note that the core temperature does not rise instantaneously; instead, it increases progressively as thermal energy accumulates in the upper layers before being conducted inward.

Fig. 3 Temperature distribution curves in the core layer of FPWPC over time at different initial surface temperatures and wood particle content, at a composite density of 1000 kg/m3 .

The second stage of the cooling process, referred to as the thermal maximum phase (~40–60 s), is characterized by the attainment of a peak temperature within the core layer of the FPWPC. This peak occurs as a result of delayed heat transfer into the core, a phenomenon governed by the thermal inertia of the composite. Initially, heat accumulates in the surface layers due to their direct exposure to the hot press plates. As the cooling process begins, this accumulated heat gradually diffuses inward, resulting in a temperature rise within the core and ultimately forming a distinct temperature peak.

Once the temperature in the core layer reaches its maximum, heat begins to dissipate more rapidly due to two simultaneous processes:

The part of the heat is transferred from the core to adjacent, cooler layers;

The surface of the composite, already in contact with the press cooling plates, begins to cool, reducing the thermal influx into the interior.

As a result, the core temperature gradually begins to decline, marking the transition to the third cooling phase. Notably, the magnitude and timing of the thermal peak are strongly influenced by both the initial surface temperature and the wood particle content of the FPWPC. A higher initial surface temperature (e.g., 200 °C) results in a more pronounced and earlier peak. Similarly, increasing the wood particle content delays the thermal maximum and elevates its magnitude due to the wood lower thermal conductivity compared to the thermoplastic matrix. For instance, at 20% wood content, the temperature peak is lower, and cooling begins sooner, whereas at 60%, the peak is higher and occurs later, indicating enhanced heat retention.

This phase can be further subdivided into three sub-phases:

Rapid temperature peak, especially for composites with high initial surface temperatures (e.g., 200 °C);

Gradual temperature stabilization, where the rate of increase levels off;

Onset of temperature decline, indicating transition into the cooling phase.

The third stage – the cooling phase (~60–800 s) begins once the core temperature peaks and subsequently decreases exponentially. The core does not cool instantaneously; instead, heat continues to transfer into deeper layers before being entirely dissipated. During the early stages of this phase, a significant temperature gradient exists between the composite surface and the press plates, driving rapid heat transfer. However, as this gradient diminishes, the cooling rate progressively slows. This transition typically occurs between 300 and 400 seconds.

The cooling rate in this phase remains dependent on both the initial surface temperature and wood content. FPWPCs with higher initial surface temperatures cool rapidly at first but exhibit slower rates later in the cycle. Meanwhile, composites with higher wood content (60%) exhibit slower overall cooling due to wood's lower thermal conductivity and greater thermal mass. As cooling progresses, the temperature curves of the core layer gradually converge toward an asymptotic value, stabilising around 50°C, indicating the completion of the cooling process.

The time evolution of this phase can be divided into two distinct sub-phases:

- Fast cooling (~160~300–400 s): Characterized by a rapid temperature drop accounting for approximately 50–70% of the total cooling time;

- Slow stabilization cooling (~300–400–800 s): The rate of cooling diminishes as thermal gradients decrease and the temperature in the core layer approaches equilibrium. Eventually, the core layer temperature stabilizes at a temperature close to the target threshold of 50 °C.

A comparison of the model-generated cooling curves with the experimental results reported by Matthews et al. (2015) reveals a substantial similarity. In their study, the cooling curve was divided into two distinct curves based on observations of different cooling rates near the melt temperature of 125 °C. Initially, the cooling rate decreased rapidly until it reached the hot-melt temperature of 125 °C of the composite material. We can see the same cooling dynamics in the curves shown in Fig. 2. At the beginning of the process, the surface layers of the WPC cool rapidly with a gradual transfer of heat to the inner layers, as a result of which the cooling process slows down and transitions to the slow stabilization cooling phase. However, it is essential to note that the referenced study measured surface temperatures under ambient cooling conditions, whereas the present model simulates forced cooling between press plates – conditions more representative of industrial FPWPC production.

In a study by Grzybek et al. (2024), the panel ability to absorb and release thermal energy of bio-based composites using sawmill by-products, recycled paper, and biobinders was investigated. During the cooling process, it is observed that all investigated samples start to cool down until they reach the phase transition temperature (solidification temperature), at which the samples start to change phase from liquid to solid. The starting temperature of the cooling process was 40 °C, and then it was placed in a climate chamber with a temperature set at 0°C. The cooling curves are similar to the last stage of FPWPC.

Similar cooling curves were also observed by García-Martínez et al. (2025), but in this case, cooling took place in an autoclave under pressure. At the same time, the material used for testing was a carbon fibre H-beam. Both experimental and model processes were investigated. The results show that both pressure and temperature variation curves follow a physically consistent pattern, confirming that the model operates correctly.

Additionally, the simulation revealed that composites with higher bulk densities (e.g., 1000 kg/m³) cool more slowly than those with lower densities (e.g., 800 kg/m³) due to their increased thermal mass and reduced heat transfer efficiency (Fig. 4).

Fig. 4 Curves of temperature distribution in the core layer of FPWPC in time at different densities and contents of wood particles and at an initial temperature of the composite surface of 160 oC.

Further insights results are supported by the findings of Deliiski et al. (2024), who investigated the thermal energy components necessary for thawing logs. Their study presents a comprehensive model for calculating the specific heat capacity and latent heat components of wood during phase transitions from a frozen to an unfrozen state. In the context of FPWPC cooling, the temperature range remains above freezing, and the understanding of energy components from thawing logs helps clarify the complex interplay of heat transfer, storage, and phase-related thermal inertia in wood-containing composites. This observation aligns with the non-uniform cooling profiles observed in the FPWPC cross-section, where surface layers cool faster while the core retains heat longer due to delayed thermal diffusion.

This behavior can be attributed to the fact that as the density of the FPWPC increases, so does its mass and, consequently, its capacity to store thermal energy. As a result, denser composites require more time to dissipate the accumulated heat, leading to a slower cooling rate. Although materials with higher density often exhibit greater thermal conductivity, promoting faster internal heat transfer, the increased heat capacity frequently outweighs this effect. Therefore, the net effect is that denser FPWPCs tend to cool more slowly than their less-dense counterparts.

CONCLUSION

It was observed that the cooling of flat-pressed wood-polymer composites (FPWPCs) is a non-linear process characterized by an initially rapid temperature drop followed by a gradual deceleration. One of the key factors influencing the cooling rate is the wood particle content. An increase in wood content leads to a reduction in thermal conductivity, thereby slowing down heat transfer and prolonging the cooling duration of the composite inner layers. In addition to the wood content, the thickness of the FPWPC significantly