Garvey’s aluminum BiFlo accumulation table, developed in collaboration with Dorner Manufacturing, offers a high-load capacity for non-washdown applications.

Garvey, Columbus McKinnon Corporation

Garvey’s aluminum BiFlo accumulation table, developed in collaboration with Dorner Manufacturing, offers a high-load capacity for non-washdown applications.

Garvey, Columbus McKinnon Corporation

Collaboration within Columbus McKinnon’s conveyance group led to Garvey’s latest accumulation table, designed with energy-efficient features for industrial applications that do not require washdowns.

Garvey, a business unit of Columbus McKinnon Corporation, recently announced the launch of its aluminum Bi-Flo accumulation table. The company provides conveying and automation solutions for a wide range of industries, including food, beverage, and pharmaceuticals.

The aluminum Bi-Flo is designed to work with round, oval, and rectangular products to help manufacturers optimize

product movement, reduce operational bottlenecks, and boost overall throughput.

Bill Reese, general manager of accumulation and senior director of engineering for Columbus McKinnon, spoke with Packaging OEM about the new system, emphasizing that it was made possible through a collaboration within the Columbus McKinnon portfolio of brands.

“We’re constantly trying to expand our product lines and find markets where we might have a solution but not the right product fit,” said Reese. “We teamed up with Dorner Manufacturing to develop the aluminum Bi-Flo to help us touch more markets that might be a bit more of an industrial setting where stainless steel is not required.”

That aluminum design offers high-load capacity for non-washdown applications

such as feeding machine parts or moving household or cleaning products. It also helps to reduce cost, energy use, and space requirements on the plant floor.

Recirculation in a compact footprint

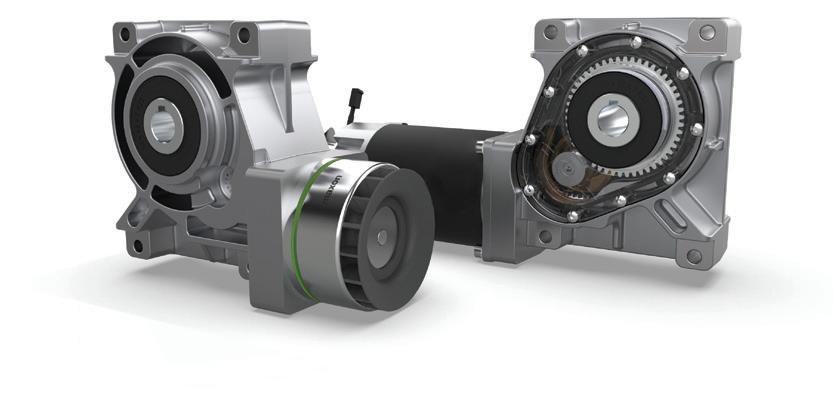

The aluminum Bi-Flo uses a single motor to drive three modular chain sets in different directions, enabling product recirculation in a small footprint.

“Traditionally, you might have two, sometimes three motors on the system. We replace those with one slightly larger motor to be able to take the load of the product and the chain,” said Reese. “It tends to be more energy-efficient because that single motor can run in its most efficient range.”

He added that this setup also eases integration, as it only requires one variable frequency drive (VFD). It also supports multi-line integration to merge or split product flow across lines.

The Bi-Flo can handle products from 1.25 to 10-in. in diameter or length, supports a maximum load of 500 lb, and has a top-of-chain height range of 20 to 60-in. The system includes safety features, including a pinch-free design and controlled flow with optional manual or automatic gates.

Adaptable for different line setups

Garvey says the aluminum Bi-Flo can be configured in three ways to suit different

TRADITIONALLY, YOU MIGHT HAVE TWO, SOMETIMES THREE MOTORS ON THE SYSTEM. WE REPLACE THOSE WITH ONE SLIGHTLY LARGER MOTOR TO BE ABLE TO TAKE THE LOAD OF THE PRODUCT AND THE CHAIN. IT TENDS TO BE MORE ENERGY-EFFICIENT BECAUSE THAT SINGLE MOTOR CAN RUN IN ITS MOST EFFICIENT RANGE.

packaging line needs, including:

• One outfeed lane: Applied in applications where the product needs to be introduced to a line in a single file from a bulk station.

• One infeed lane: Designed for endof-line applications with inconsistent output to prevent backups.

• One infeed and one outfeed: Serves as an accumulation station to balance a production line and maintain throughput.

“It can not only act like an accumulation table, but it can almost act like a machine itself,” said Reese. “If you have a manual process where maybe on a smaller line, they’re manually placing products onto a single-linked conveyor and feeding them onto the line, you could put that infeed table at the beginning. It allows the operators to load the table up with maybe three, five minutes of product.”

With this method, labor is freed up so employees can pay attention to other parts of the line. “It’s not always about just throughput of the line, which you do get the benefit of that, but also making the employees more efficient on the line,” Reese said.

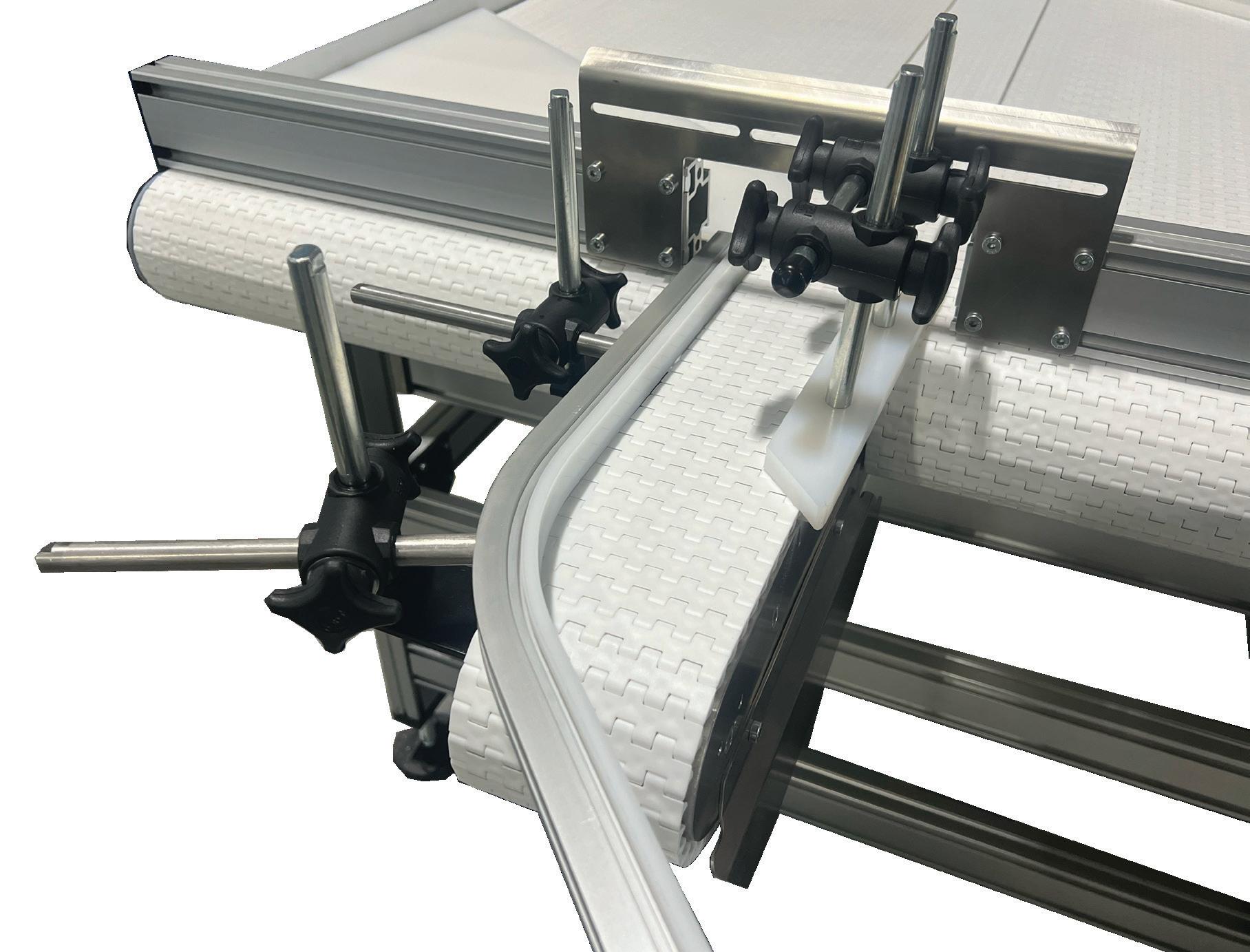

The company adds that the system provides optimized product transfer with flush side in/outfeeds and offers an optional nosebar for tight spaces.

Reese said the collaboration between Dorner and the wider Columbus McKinnon conveyance group allows Garvey to reach new customers in markets that previously required lighter-duty, nonwashdown solutions. OEM

The outfeed of Garvey’s aluminum Bi-Flo accumulation table, which can be applied in applications where the product needs to be introduced to a line in a single file from a bulk station. Garvey, Columbus McKinnon Corporation

Garvey’s aluminum Bi-Flo accumulation table supports flexible product handling in packaging and material handling operations, enabling manufacturers to optimize product flow, improve throughput, and integrate safely with multiline conveyor systems.

Garvey, Columbus McKinnon Corporation

From flexible solutions—like pouches, bags, lids, flow wrap, and high-barrier foils and films—to rigid options including trays, blisters, automation trays, and die cards, we engineer packaging that protects your medical device or pharmaceutical products.

Count on us for complete packaging solutions from concept to point-of-use, including performance packaging, sealers, and lab validation services—all tailored to your unique needs and built to deliver confidence at every stage. For more information, contact us: Email: info@nelipak.com