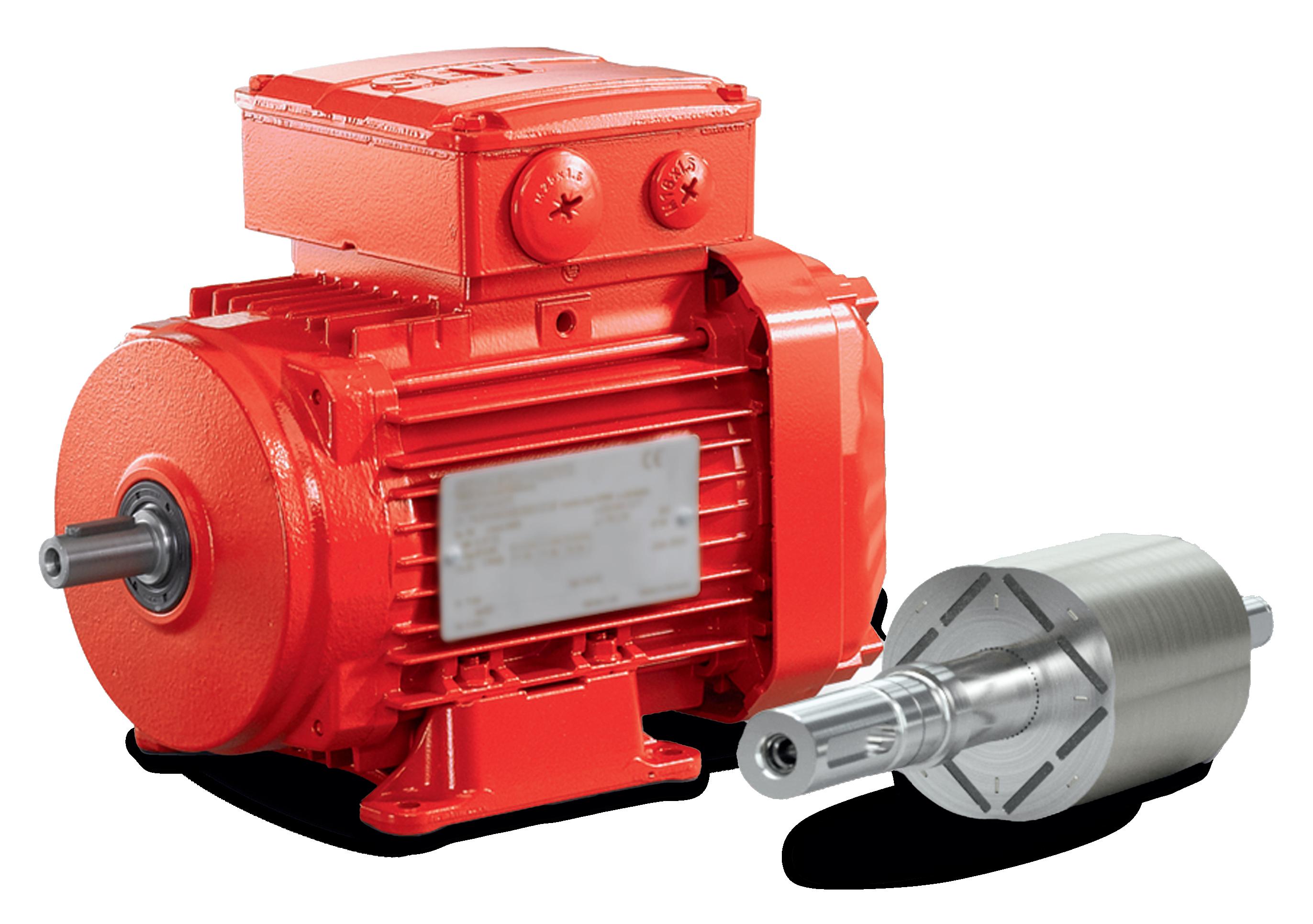

AutomationDirect has thousands of high-quality, cost-effective motor control products that can easily start, control, and protect your motors.

NEW! WEG Electric Motor Controls

Starting at $47.50 (CWBN00-11-30D15)

New additions to our WEG Electric motor control components support a wider range of motor sizes, environments, and control requirements, including NEMA-rated IEC-style contactors, general-purpose and washdown manual motor starters, IEC contactors, safety contactors, and overload relays. The full selection includes:

• General purpose manual motor starters up to 50hp

• Washdown manual motor starters up to 20hp

• Manual motor protectors up to 65A

• IEC contactors up to 125A

• NEMA-rated IEC-style contactors up to 95A

• IEC safety contactors up to 125A

• Overload relays up to 140A

Starting at $89.00 (SC1DD2315)

Eltwin solid state contactors provide fast load switching with no moving parts, which extends service life and reduces maintenance costs. They can be used for motors, heaters, transformers, and more, thanks to their UL/CUL rating as motor controllers.

• Precise/fast motor control

• No wear, tear, friction, or mechanical fatigue

• No contact bounce or arcing

• Cost savings

• Improved safety

IronHorse Motor Controls

Starting at $23.00 (HMC-9B30-11-BS)

IronHorse series IEC contactors, overload relays, and manual motor protectors are available in ratings up to 300 hp at 480 VAC and offer reliable, cost-effective motor control solutions for a wide variety of industrial applications.

• Manual motor protectors up to 100A

• IEC contactors up to 400A

• Overload relays up to 400A

Material selection is of utmost importance not only for product viability and performance, but also for long-term impacts that can create new problems later. Our global plastic usage has been causing significant issues in our water supplies for decades, yet the problem, or at least its severity, is still not common knowledge, nor is there a socially embedded sense of urgency to address the concern. Research on how plastics navigate the Earth through environmental and biological systems reveals that we’re too late to reverse contamination, but we can certainly manage the flow and mitigate impacts.

In a recent study, scientists recorded and measured in real time how fast microplastics move through the gut passages of copepods (a zooplankton species) to estimate how fast they may transport plastics up and down the water column. Typically, plastic pollution is viewed as a surface problem, with visuals of crumpled water bottles and grocery bags riding currents and cluttering beaches. But now we have evidence that innocent copepods may be a major microplastic transport mechanism, embedding plastics into the seafloor and marine food web. Land animals and humans are not removed from marine systems, as researchers have detected microplastics in our food and bodies, expanding environmental concerns to potential global public health problems.

This is not a hippie-dippie way of thinking. It’s practical, data-driven, and essential, which is why we have worldwide initiatives for ecosystem restoration and environmental responsibility. But what does all this mean for the design engineer who knows that plastic is

likely the cheapest, most durable, and easiest material to source reliably for their products to be manufactured at scale?

As engineers, every design decision needs to meet certain criteria to achieve performance, durability, and other factors, but when you start thinking more broadly, considering the end-of-life of a product is critical.

Though most visible and measured plastic pollution is attributed to consumer products, industrial sources play an underappreciated role, especially upstream and at smaller particle sizes. Industry has a unique advantage to more efficiently recapture scrap and used materials still of good quality to recycle and repurpose for further industrial applications. Dozens of companies we cover in Design World have recapturing programs in place so that industries can leverage the benefits of plastics and other materials while recovering them responsibly. Such programs help engineers make design decisions that meet functional and business requirements without escalating broader concerns. Plus, they align with design for manufacturability (DFM) principles aimed to reduce costs, improve quality, optimize processes, and eliminate waste.

There’s no perfect solution here, but I challenge you to think on it. If you’d like to think on it together, message me and let’s have a discussion. Also, stay tuned for more ponderings like this as we cover DFM principles and applications in an upcoming special report and webinar series. DW

Rachael Pasini

rpasini@wtwhmedia.com

linkedin.com/in/rachaelpasini

Sources:

• Biological pumps: how zooplankton are transporting microplastics to the ocean depths, wtwh.me/pml

Layers of performance and specifications in motion control: Part 2

Here, the focus is on motors as key elements of motion control systems, and the way in which they help achieve true precision in motion control applications.

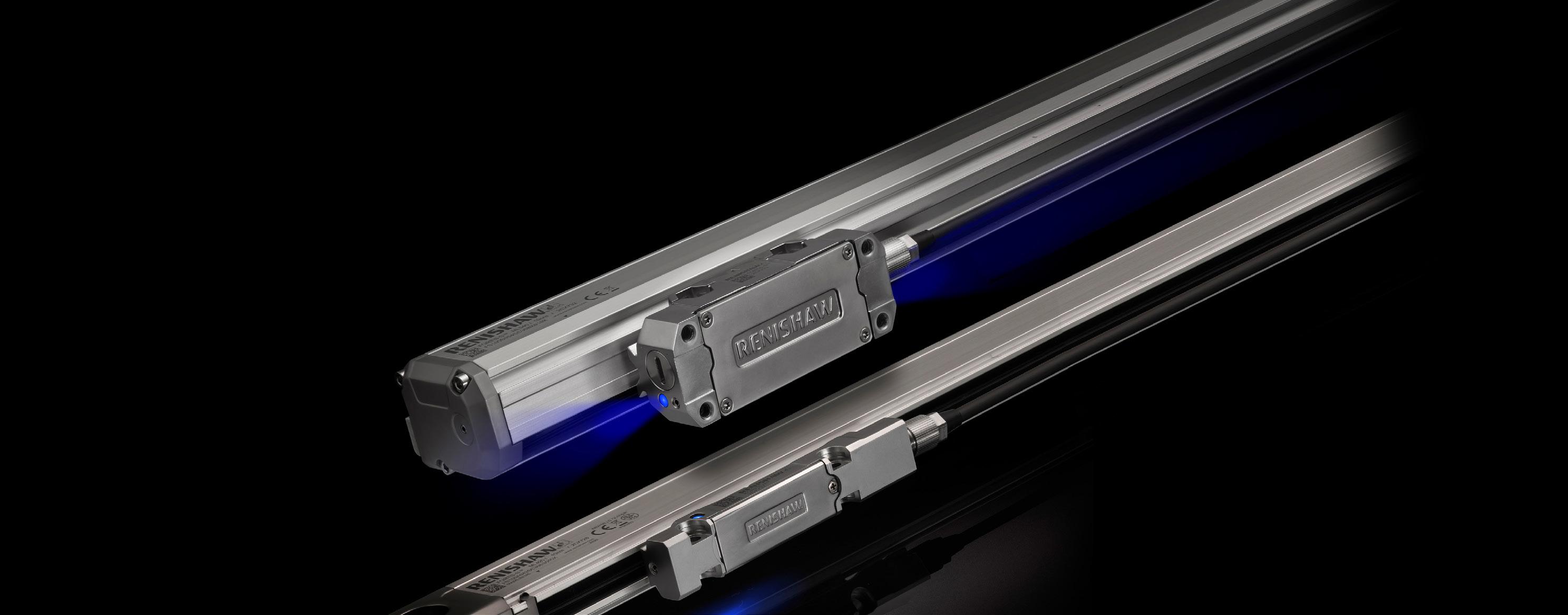

Linear sensors give it straight

Linear encoders are often essential. Even where they’re not, their benefits can justify the additional cost they incur.

Why we’re still fighting for perfect

It’s not just laggy assemblies. Here are six reasons fasteners continue to frustrate CAD users — and how engineers can fight back.

High-current, low-impedance systems need advanced current sensing technology

The global demand for power supplies is expected to exceed USD 46.5 billion by 2031. This growth is fueled by the proliferation of EVs, renewable energy systems, and industrial automation, particularly for AC-DC power supplies.

Poor electromagnetic compatibility can disrupt variable speed drive performance and lead to compliance issues. Technidrive’s David Strain explains how to tackle EMC challenges in modern VSD installations.

Design World reports on the vast world of design engineering and machine building with technical, indepth content. We cover semiconductor, medical, factory automation, packaging, off-highway, material handling, simulation, rapid prototyping, and more. By signing up for the Engineer’s Edge, you’ll stay on top of the news and trends happening in the engineering space. Fill out the form below to access three weekly newsletters plus new product announcements!

EDITORIAL

VP, Editorial Director

Paul J. Heney pheney@wtwhmedia.com

Editor-in-Chief

Rachael Pasini rpasini@wtwhmedia.com

Managing Editor Mike Santora msantora@wtwhmedia.com

Executive Editor Lisa Eitel leitel@wtwhmedia.com

Senior Editor Miles Budimir mbudimir@wtwhmedia.com

Senior Editor Mary Gannon mgannon@wtwhmedia.com

DIGITAL MARKETING

VP, Marketing Annie Wissner awissner@wtwhmedia.com

Digital Marketing Manager

Taylor Meade tmeade@wtwhmedia.com

PRODUCTION SERVICES

Customer Service Manager

Stephanie Hulett shulett@wtwhmedia.com

Customer Service Rep Tracy Powers tpowers@wtwhmedia.com

Customer Service Rep JoAnn Martin jmartin@wtwhmedia.com

Customer Service Rep

DIGITAL PRODUCTION

Digital Production Manager Reggie Hall rhall@wtwhmedia.com

Digital Production Specialist Nicole Johnson njohnson@wtwhmedia.com

Digital Design Manager Samantha Goodrich sgoodrich@wtwhmedia.com

Marketing Graphic Designer Hannah Bragg hbragg@wtwhmedia.com

Digital Production Specialist Elise Ondak eondak@wtwhmedia.com

WEB DEVELOPMENT

Web Development Manager

www.linkedin.com/company/design-world-online

The AM Conference Where Users Lead the Conversation

JOIN US

March 15 - 19, 2026 | Reno, NV

REAL CONNECTIONS

Camaraderie, conversations, and meaningful relationships —without the agenda.

REAL EXPERTISE

Hands-on learning, real-world solutions, and a community of problem-solvers.

REAL VALUE

All-inclusive access: 4 days of sessions, workshops, expo, competitions, meals, and entertainment.

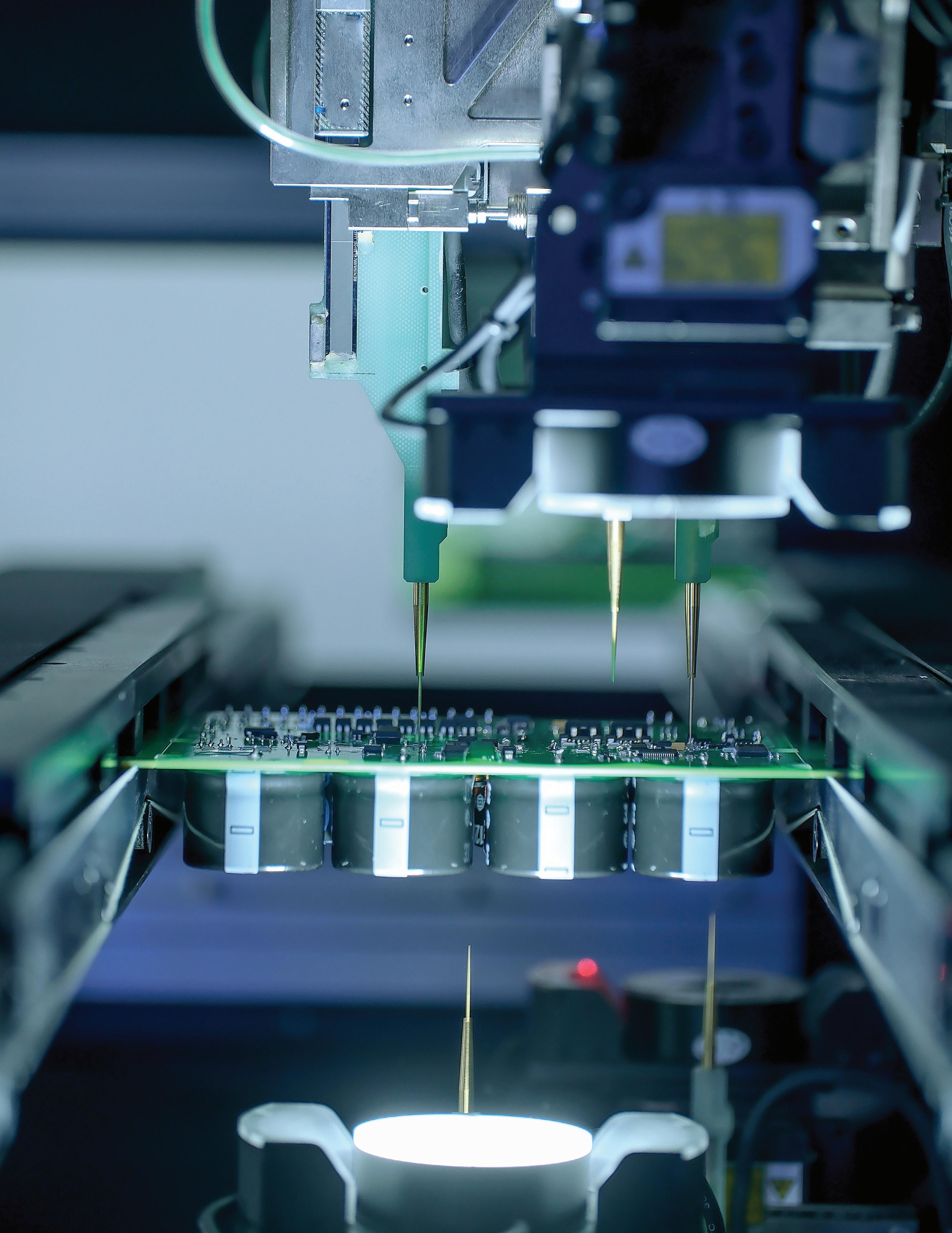

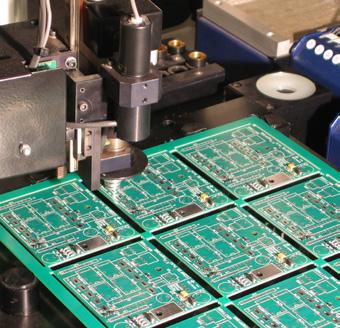

Laser micromachining is a noncontact thermal material-removal process that uses focused laser beams to ablate, cut, drill, or mark materials at the microscale with extreme precision. The process is widely used in semiconductor manufacturing, electronics assembly, and medical device fabrication for applications including wafer dicing, via drilling in advanced packaging, and precision cutting of thin films.

Key challenges in laser micromachining include maintaining submicron positioning accuracy across large work areas, controlling heat-affected zones to prevent material damage, ensuring consistent energy delivery at high speeds, and minimizing thermal drift during extended production runs. A precision laser scan head addresses these challenges by providing high-resolution beam positioning through digital encoders, rapid scanning dynamics for increased throughput, integrated thermal management to maintain process stability, and synchronized laser firing based on real-time position feedback. All this ensures that the laser energy is delivered exactly where and when it’s needed for repeatable, high-quality results in demanding micromachining applications.

The AGV-CPO CORE Performance 2-Axis Laser Scan Head is Areotech’s latest precision motion control product designed for laser processing applications across multiple industries. The new scan head delivers performance characteristics similar to Aerotech’s established AGV scanner

line while offering compatibility with existing control infrastructure, allowing users to expand their systems without additional controller investments.

According to Bryan Germann, optomechatronics lead at Aerotech, the AGV-CPO combines high-resolution positioning and advanced control capabilities with scalability to support a broader range of laser processing applications.

The scan head features Aerotech’s Automation1 control platform, which supports up to 32 servo and galvo axes from a single controller. The system includes RS-274-compliant G-code programming, motion lookahead, and C-transformations for complex motion coordination.

Technical capabilities include digital optical encoders and advanced materials for positioning resolution and dynamic performance. The AGV-CPO incorporates Infinite Field of View (IFOV) technology, which integrates scanner motion with servo stages to expand the working area and reduce repositioning requirements during processing.

Position Synchronized Output (PSO) functionality provides laser firing control based on real-time feedback from both scanner mirror position and coordinated

stage positions, supporting applications requiring precise energy delivery, such as cutting, welding, and additive manufacturing.

Additionally, thermal management features include integrated motor water cooling and scanner mirror air cooling to minimize thermal drift during extended processing operations.

Aside from TGV drilling and wafer dicing in semiconductor manufacturing, the laser scanner head is suitable for novel ultrafast laser process development; flat cutting and drilling in medical device micromachining; electronics display cutting and PCB drilling; and additive manufacturing support processes such as two-photon polymerization. DW

Aerotech aerotech.com

The machine tool industry faces the same challenges as other industries: skilled labor shortages, rising cost pressures, and geopolitical shifts. Traditional customer groups such as automotive manufacturers and suppliers are undergoing restructuring and reducing their investments, while other export-oriented sectors are postponing investments due to tariff disputes and potential trade restrictions.

For suppliers such as Fanuc, a key focus is on making products easier to operate and gradually evolving existing systems. For example, according to Robert Koopmann, CTO at Fanuc Europe, the company’s latest CNC Design Studio is an

integrated development environment that consolidates CNC settings data, provides efficient debugging capabilities, and facilitates conversion to its latest CNC generation, 500i-A.

Advanced AI-driven features, including the Smart Digital Twin, help machine tool builders and end-users optimize performance by reducing cycle time and improving surface quality. Automation with robots also enables the existing workers to focus on highervalue tasks. Connecting a robot to a CNC-controlled machine tool has been further simplified and now requires only minimal configuration effort.

Energy efficiency and cost competitiveness are also top priorities

in the factory automation business. Fanuc’s latest servo drive series, the αi-D, delivers a 10 to 15% reduction in power loss and up to 30% space savings compared to previous models, while boosting speed and precision. Standardized solutions further accelerate automation deployment.

Additionally, as manufacturers reassess the geographic distribution of their production networks, IoT solutions enable remote monitoring and maintenance — capabilities that proved essential during border closures and supply chain disruptions.

Plus, as Koopmann emphasizes, as production becomes more global and interconnected, cybersecurity is

paramount. Fanuc’s latest CNC generation 500i-A and the R-50iA robot controller meet a high level of cybersecurity standards. The IoT platform Field System Basic Package also features robust cybersecurity at its core.

As Eric Potter, general manager of the Robot Application Engineering Segment at Fanuc America, put it, manufacturers of all sizes face increasing demands for flexibility and efficiency in their production processes. Hence, the company focuses on developing automation solutions that are smart, scalable, and easy to use. DW

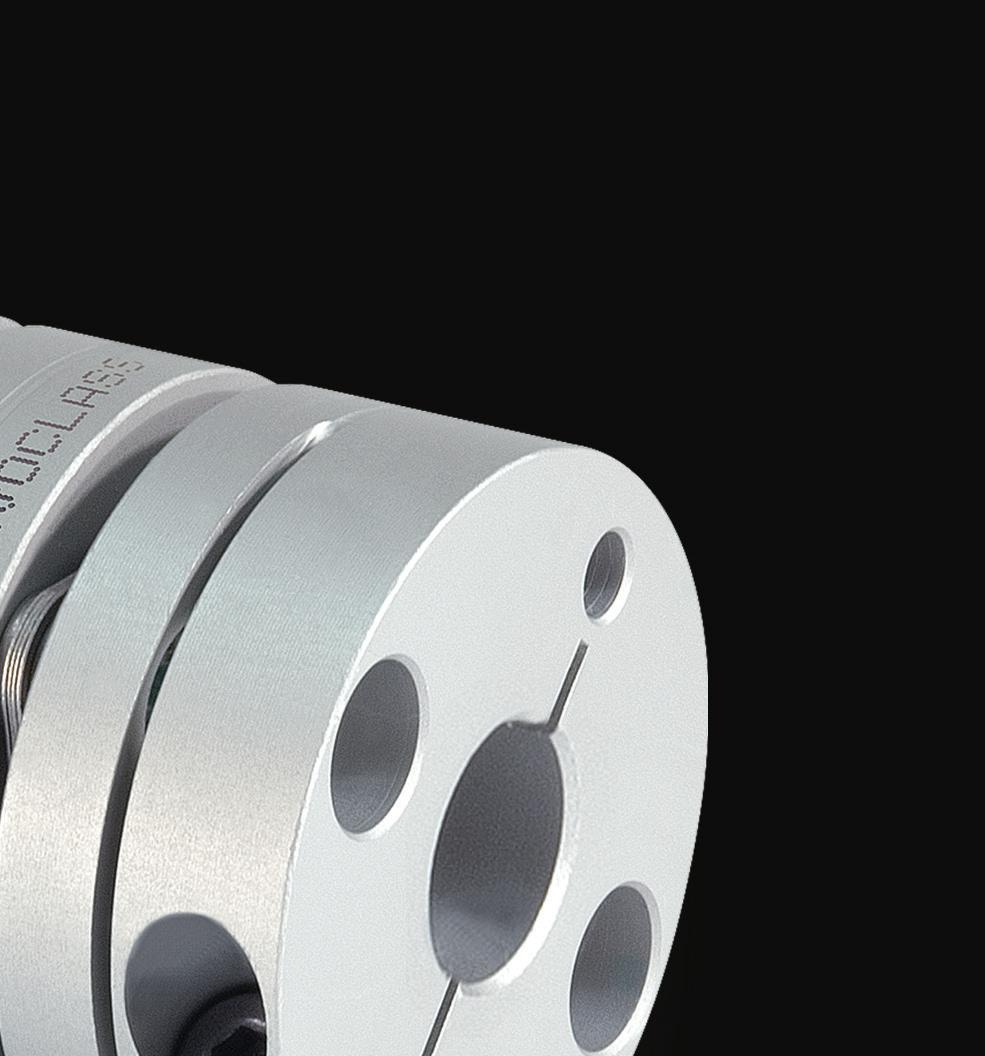

Materials

Materials of: ALLUMINUM and CORROSION RESISTANT STEEL

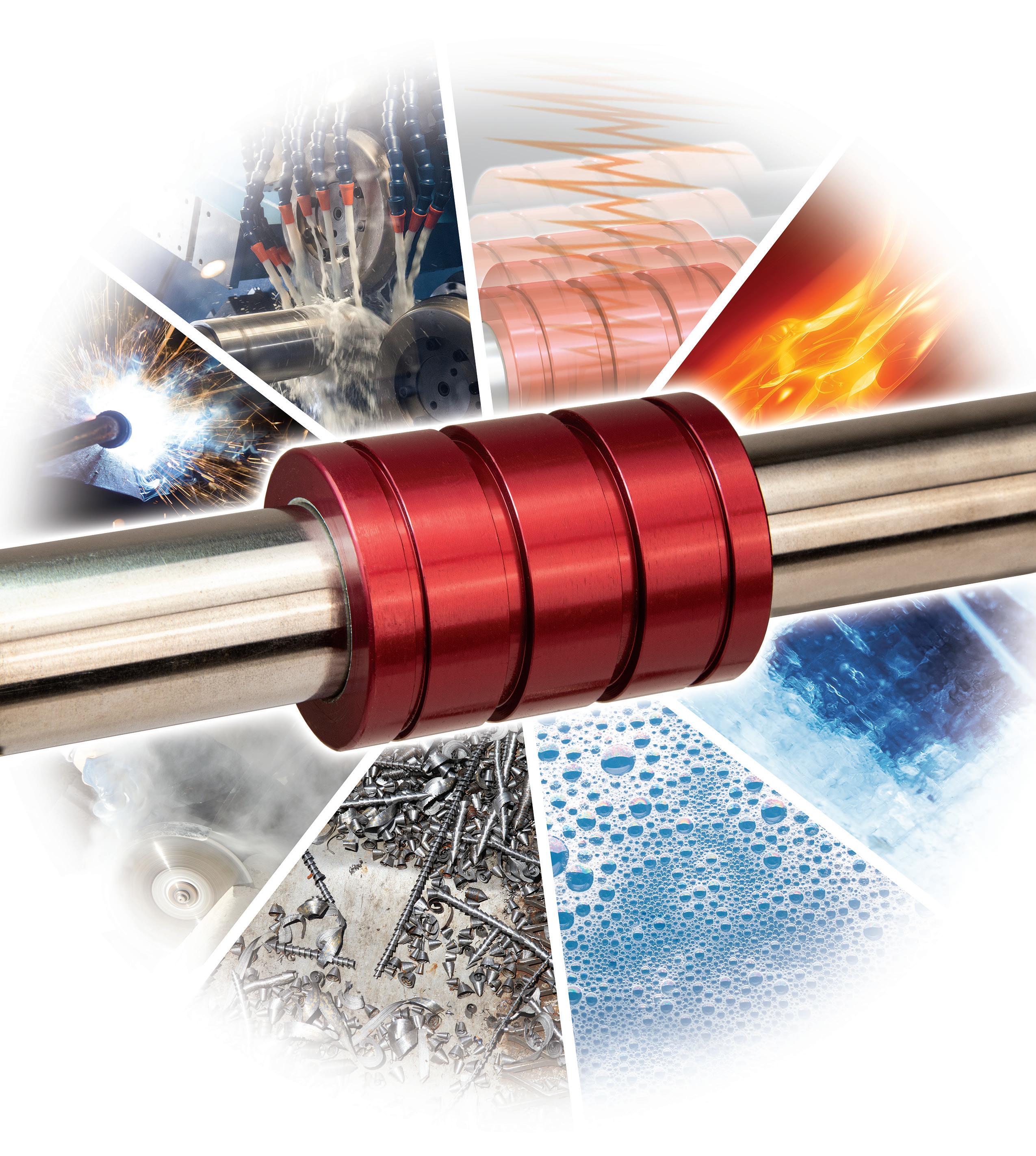

WHITTET-HIGGINS manufactures quality oriented, stocks abundantly and delivers quickly the best quality and largest array of adjustable, heavy thrust bearing, and torque load carrying retaining devices for bearing, power transmission and other industrial assemblies; and specialized tools for their careful assembly.

Visit our website–whittet-higgins.com–to peruse the many possibilities to improve your assemblies. Much technical detail delineated as well as 2D and 3D CAD models for engineering assistance. Call your local or a good distributor.

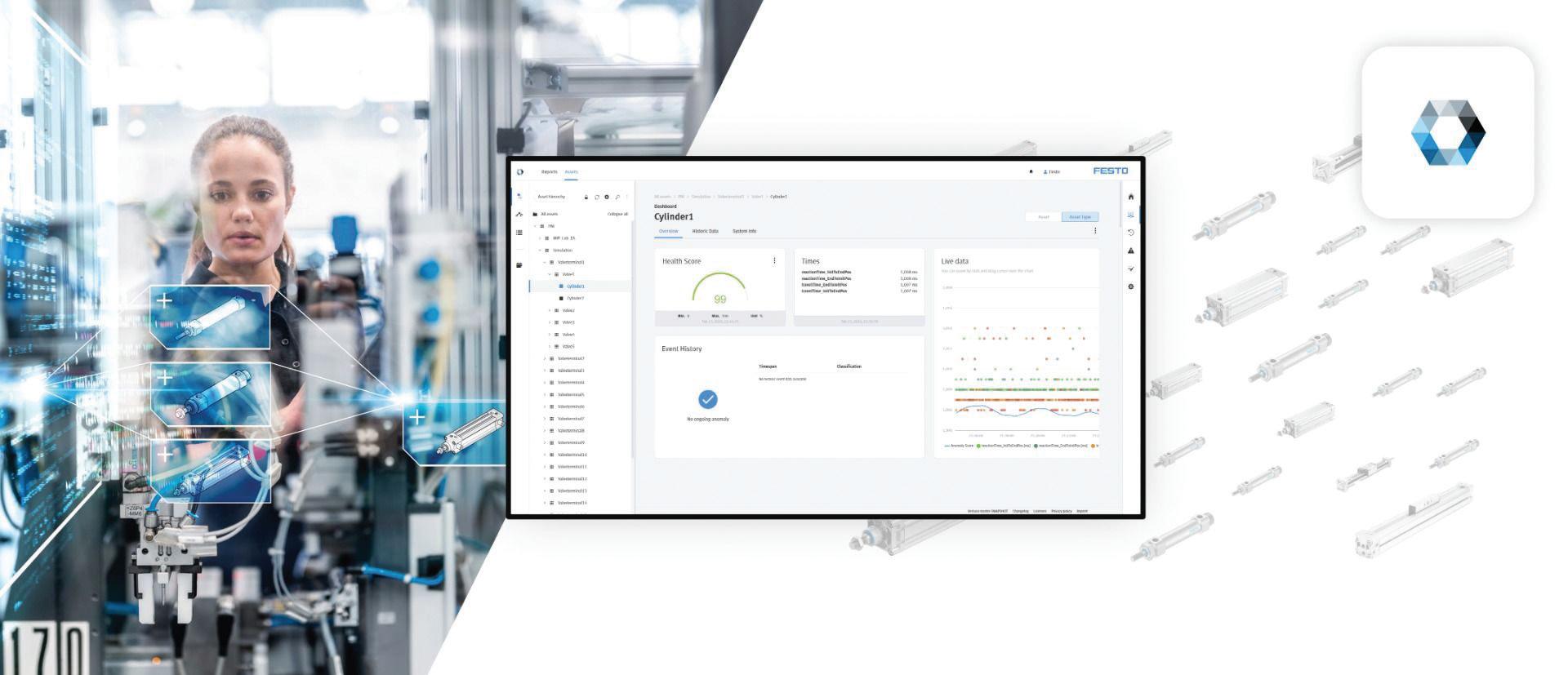

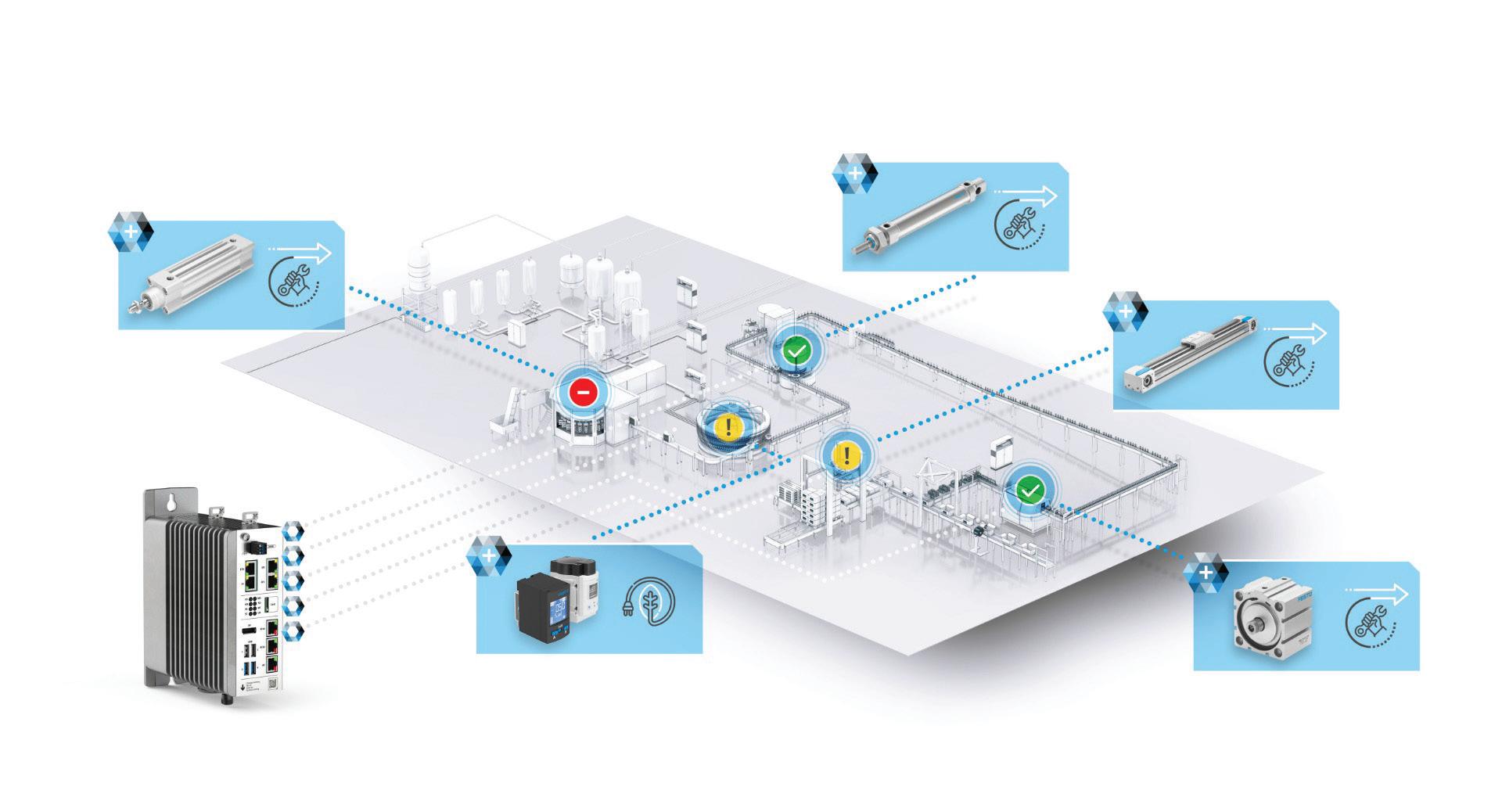

Extensive cooling systems drive much of the growing energy demand of data centers, as high-density computer equipment — including servers, networking gear, and storage systems — generates enormous amounts of heat as a byproduct of electrical consumption. Jeff Hemphill, CTO of Schaeffler Americas, noted that one of the most critical challenges of our time is meeting exponential energy demand while maximizing efficiency and reliability. With data centers critical to the digital economy and supporting vital applications such as cloud computing, data analytics, and AI, operators face intense pressure to maximize energy efficiency while ensuring 99.9% uptime.

Schaeffler aims to help data centers curb and reliably meet the growing electrical demand of cooling systems by boosting efficiency, uptime, and maintainability across fans, pumps, compressors, and motors with an array of products and systems. By enabling critical data for AI and predictive maintenance, the company’s sensorequipped components and digital condition-monitoring technologies aim to help maximize the performance of conventional and renewable energy generation, as well as data centers that power the digital economy.

For example, variable-frequency drives (VFDs) used in data center HVAC systems can cause electrical erosion, leading to premature bearing failure and costly unplanned downtime. Schaeffler’s current-insulating bearings — including hybrid ceramic or ceramic-coated versions featuring proprietary coatings — can help protect HVAC motors from electrical erosion caused by VFDs.

Looking further upstream, the exponential growth in electricity

demand from data centers and AI infrastructure is driving significant responses from the traditional energy sector, leading to greater near-term reliance on fossil fuels. This increased demand for natural gas-fired power plants and diesel-powered generator sets is placing extreme stress on oil and gas infrastructure, where equipment failures can halt production and cost operators millions in lost revenue. Delivering reliability and performance under unprecedented utilization rates and demanding conditions is more important than ever.

Beyond data centers and traditional energy generation, the company emphasizes the need for advanced solutions for renewable energy equipment, particularly wind turbines.

Wind turbines operate in harsh, variable environments where bearing failures can result in months of downtime and costly crane operations for repairs. With features such as bainitic or casecarburized components, optimized geometries, and proprietary coatings, the company offers a lineup of highperformance rolling bearings that are engineered for a variety of positions within wind turbine gearboxes:

• Deep-groove ball bearings for lightduty support in small envelopes and high radial capacity are widely used in generator positions, where extremely high speeds convert mechanical energy into electrical energy. Schaeffler’s Generation C designs, with optimized internal geometries and increased cage

rigidity, enable even higher speeds and greater load capacities.

• Double-row tapered roller bearings serve as the main “workhorse” bearing for most wind turbine transmissions as main locating bearings within high-speed, intermediate, and low-speed shafts. High axial and radial rigidity ensure outstanding load-carrying capacity; optimized internal geometry reduces friction and wear; proprietary Durotect B coating offers superior run-in properties while reducing corrosion, wear from sliding and friction, and the risk of white etching cracks (WECs).

• Cylindrical roller bearings function as floating bearings in transmissions, enabling the system to expand, move, and deflect to compensate for demanding loads and harsh conditions. High-speed capability improves gearbox efficiency, while the Durotect B coating can improve run-in properties, reduce corrosion and wear from sliding and friction, and decrease the risk of white etching cracks (WEC).

Additionally, to maximize the efficiency of solar farms, Schaeffler now has a custom-designed solar tracker actuator that adjusts the solar panel position to track the sun throughout the day. The weather-resistant inline design houses a single-unit motor, gearbox, pulse-count functionality, and limit switches. At the same time, the anodized aluminum housing eliminates multiple ingress points for moisture and contamination without requiring additional covers or seals, reducing UV stress on components. DW

Schaeffler schaeffler.us

In a conventional axial piston pump, each piston has a slipper to maintain sliding contact with the swash plate. This slipper, also called a shoe, helps support the load from the piston, creates a high-pressure seal to prevent leakage, and lubricates the sliding surface. Although critical to the pump’s operation, the slipper experiences wear, cavitation damage, and contamination from fine particles, and its lubrication requirements often pose a complex engineering challenge.

Moog introduced a patented slipperless axial piston pump, the AXP Series, with a 15-piston floating configuration that combines the strengths of internal gear and piston pump technologies. The new pump is compact, high-speed, and operates with low noise and resistance to cavitation and contamination. It supports pressure holding at zero speed and dynamic performance at high speed, enabling energy savings, motor downsizing, and broader application flexibility.

The new pump has a simplified architecture with fewer components. It includes a sound-optimized case that reduces pulsation and noise, enhancing workplace comfort and motion precision. Again, the design is slipperless, which significantly reduces sensitivity to low suction pressures and works together with an

external drain to improve overall system reliability. Additionally, the pump has high power density and 100% throughdrive capability, allowing for smaller system footprints and flow scalability.

Currently, the AXP Series is available in sizes 33, 63, and 100 with fixed displacement, but the company plans to expand the product family to include size 145, variable displacement pumps, and versions for fourquadrant operation. The pump is suitable for a wide range

of applications, including construction machinery, material handling, injection molding, die casting, metal forming, marine systems, and general industrial machinery. DW

moog.com

As the inventor of the edgewound wave spring with 100+ years of innovation, here’s why Smalley is The Engineer’s Choice®:

ᘩ 11,000+ standard parts in stock

ᘩ Customizable with No-Tooling-Charges™

ᘩ Trusted performance in 25,000+ applications

ᘩ Award-winning quality backed by leading industry certification

Smalley Wave Springs

ᘩ Same Force, Same Travel as a coil spring

ᘩ Lightweight and compact

ᘩ Diameters from .118" to 120" in 40+ materials

EDITED BY MIKE SANTORA

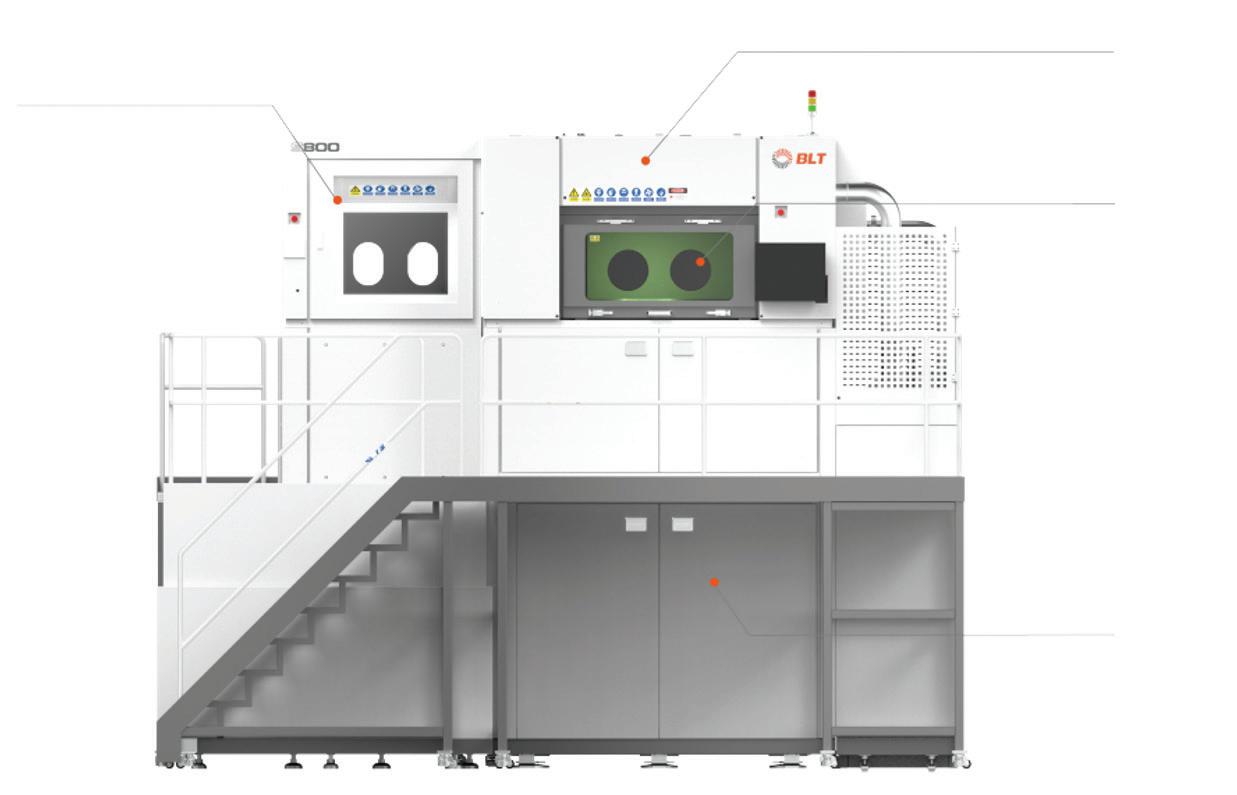

Space Circling Aerospace Technology Co., Ltd. recently completed a successful 50-second engine test of its independently developed 85-ton-class rocket engine, QL-1 (QiaoLong-1). The engine demonstrated smooth ignition, rapid shutdown, and stable, high-efficiency operation throughout the test, marking another milestone in the development of China’s commercial space propulsion capabilities. This achievement was made possible not only by Space Circling’s dedicated engineering efforts, but also by Bright Laser Technologies’ (BLT) critical support in metal 3D printing technology.

In the QL-1 engine project, BLT provided customized 3D printing services for more than 20 critical components, including thrust chambers, turbopumps, valves, and other key structures. As a core supplier of the engine’s essential metal additive manufactured parts, BLT played a crucial role in supporting the successful

A thrust chamber (shown here) is the primary power source of a rocket engine. It converts the thermal energy of high-temperature, highpressure combustion gases into kinetic energy to provide propulsion.

engine test firing. Thrust chambers and turbopumps are vital components that ensure the stable operation of rocket engine systems. From the initial design phase, BLT was deeply involved, leveraging integrated 3D printing technology to efficiently and precisely manufacture these key structures. This approach significantly enhanced the engine’s overall performance and reliability.

complex flow channel fabrication beyond traditional limits

The thrust chamber, as the primary power source of a rocket engine, converts the thermal energy of hightemperature, high-pressure combustion gases into kinetic energy to provide propulsion. For the QL-1 engine, BLT used its BLT-S800, BLT-S515, BLT-S1000, and BLT-S450 printing systems to achieve integrated manufacturing of key components, including the thrust chamber nozzle extension, gas

generator, thrust chamber body, and oxygen inlet.

Traditional manufacturing methods face challenges in fabricating complex internal flow channels and require multiple processes such as welding and assembly, which may introduce structural weaknesses and affect part performance. Additive manufacturing enables the production of complex internal flow channels in a single build, allowing precise optimization of propellant pathways. This leads to higher combustion efficiency and lower energy losses, resulting in improved engine thrust and overall performance.

Turbopump components: Reducing cost and enabling rapid iteration

The turbopump serves as the “heart” of the rocket engine, driving the pump to pressurize and deliver propellant to the combustion chamber, ensuring continuous fuel supply. For the QL-1 engine development, BLT 3D printed multiple critical components — including

dual-stage impellers, turbine guide vanes, fuel and oxidizer housings — significantly reducing manufacturing costs and accelerating production efficiency.

Traditional manufacturing involves multiple time-consuming and costly steps such as machining, electrode design, and electrical discharge machining (EDM), which hinder rapid design iterations. In contrast, additive manufacturing consolidates these processes into a single, integrated build, streamlining production and significantly accelerating part development.

Taking the two-stage impeller as an example, with dimensions of 340 × 340 × 55mm, it was fabricated using the BLT-S450 in a single, integrated 3D printing process. Under traditional manufacturing methods, the production cycle — from material procurement to final machining — typically exceeds three months. By leveraging 3D printing technology, the manufacturing time was reduced to 45 days, while

the cost was cut by approximately 75%. This advance not only improves production efficiency and enables rapid part fabrication but also supports faster iterative design cycles.

The collaboration between BLT and Space Circling Aerospace has enabled efficient, cost-effective production of key rocket engine components, contributing directly to the successful engine hot-fire test. This partnership highlights how advanced metal 3D printing can be seamlessly integrated into aerospace manufacturing, broadening its applications within the sector. BLT’s expertise in additive manufacturing supports the evolving needs of commercial space by providing flexible, high-quality solutions that help accelerate innovation and manufacturing agility. DW

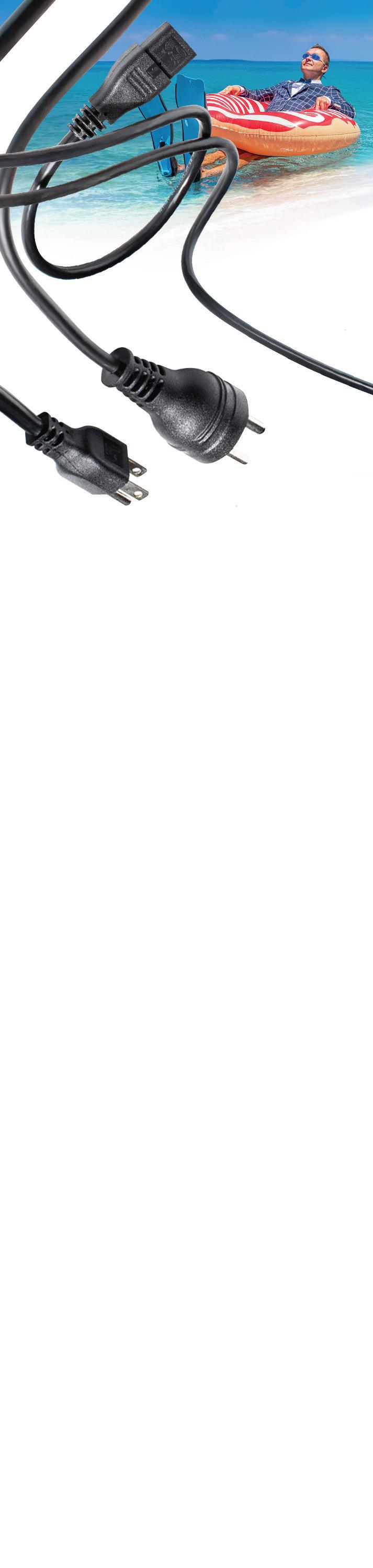

All molded Interpower cords and cord sets are made in the U.S.A., including the raw materials that go into their production. So, what does that mean besides best-inclass power cords and reliability? No tariffs! While many cord manufacturers produce cords in Asia and Europe (thus tacking on tariffs to consumers), you won’t find the additional costs of tariffs on molded Interpower cords and cord sets. And there’s no minimum or maximum order limit! Blanket and scheduled orders also available. 1-week U.S. lead times, and same-day shipping on stocked products.

EDITED BY MIKE SANTORA

Technology company Siemens and machine tools and laser manufacturer TRUMPF recently announced a partnership that seeks to elevate industrial production by harnessing advanced digital manufacturing solutions. The collaboration joins Siemens' Xcelerator portfolio with TRUMPF's machine-building and software expertise. The goal?

Tackle a critical challenge in modern manufacturing head on: fix the

disconnect between information technology (IT) and operational technology (OT) systems.

The challenge has historically hindered production efficiency and innovation at multiple steps in production processes. By leveraging Siemens' Xcelerator portfolio and TRUMPF's manufacturing excellence, the collaboration aims to deliver comprehensive solutions that bridge this gap. Both companies are working

on open and interoperable IT interfaces that will help to advance artificial intelligence (AI) readiness for motion control applications.

“Real transformation in a factory begins when machines on the shop floor are connected through a shared digital backbone — so that data flows seamlessly, decisions happen faster, and production responds to changing conditions,” said Cedrik Neike, Member of the Managing Board at Siemens AG

and CEO of Siemens Digital Industries.

“By working with TRUMPF, we’re making that connection effortless. We’re bridging the gap between IT and OT so that manufacturers can move faster, adapt in real time and prepare for the AI era. I’m proud to see two European champions leading the way.”

Overcoming complexity with seamless system integration In today’s rapidly evolving industrial landscape, software is no longer just an addon to hardware, it’s becoming the key differentiator in manufacturing. From intelligent control systems to data-driven optimization, a seamless integration of hardware and software enables entirely new levels of flexibility, efficiency, and value creation. For Siemens and TRUMPF, this shift has created significant opportunities, but also new complexities. Therefore, collaboration is essential and will enable faster innovation cycles, better integration of hardware and software, and a more scalable approach to delivering solutions and value through standardized interfaces.

The collaboration will also deliver tangible user benefits through modular system architecture and unified system solutions. Standardized interfaces will allow for seamless connectivity between shop floor equipment and enterprise-level systems. Siemens also said users will benefit from increased operational efficiency, reduced engineering costs, and future-proof scalability by using open, modular automation solutions.

These are critical to ensure futureproof AI readiness, that will permit users to achieve faster time-to-market, improved production flexibility, and competitive manufacturing operations.

“TRUMPF is a leading company for smart factory solutions in the sheet

metal industry. The cooperation with Siemens underpins our position as a solution provider. Thanks to the open standards, our customers will benefit even more from the digital networking of the production — from our machines to robots, grippers, and part recognition with the help of AI. We’re taking industrial manufacturing to a whole new level with Siemens," said Stephan Mayer, CEO of Machine Tools at TRUMPF.

The partnership builds on regular exchanges among development teams at Siemens and TRUMPF, which underscores the importance of vibrant ecosystems for solving industry’s most pressing challenges. DW

Siemens/TRUMPF siemens.com | trumpf.com

Interpower molded power cords and cord sets are made in the U.S.A., which includes the finest raw materials that go into their production. Since our cords are made right here in Iowa, there are no tariffs and no minimum orders—order 1 cord or 5,000 cords. If what you need is in stock, those stocked items ship the same day as ordered. Currently Interpower has nearly 2 million cords and components in stock. Interpower—cords made your way. Why wait?

E-mail: info@interpower.com

Business Hours: 7 a.m.–5 p.m. CST Order

COREY FOSTER • DIRECTOR OF AUTOMATION SALES & APPLICATION ENGINEERING • VALIN CORPORATION

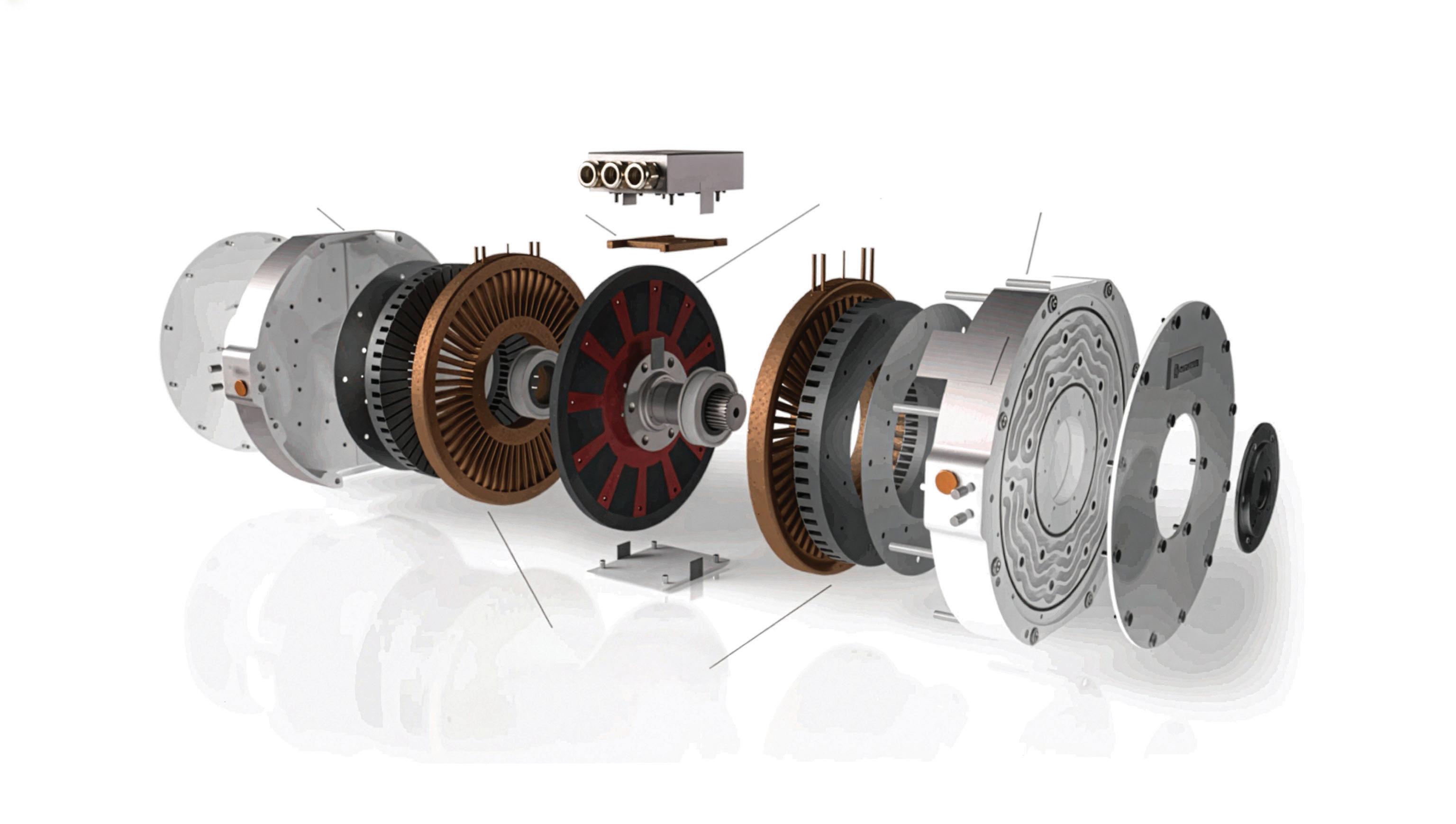

HERE, THE FOCUS IS ON MOTORS AS KEY ELEMENTS OF MOTION CONTROL SYSTEMS, AND THE WAY IN WHICH THEY HELP ACHIEVE TRUE PRECISION IN MOTION CONTROL APPLICATIONS.

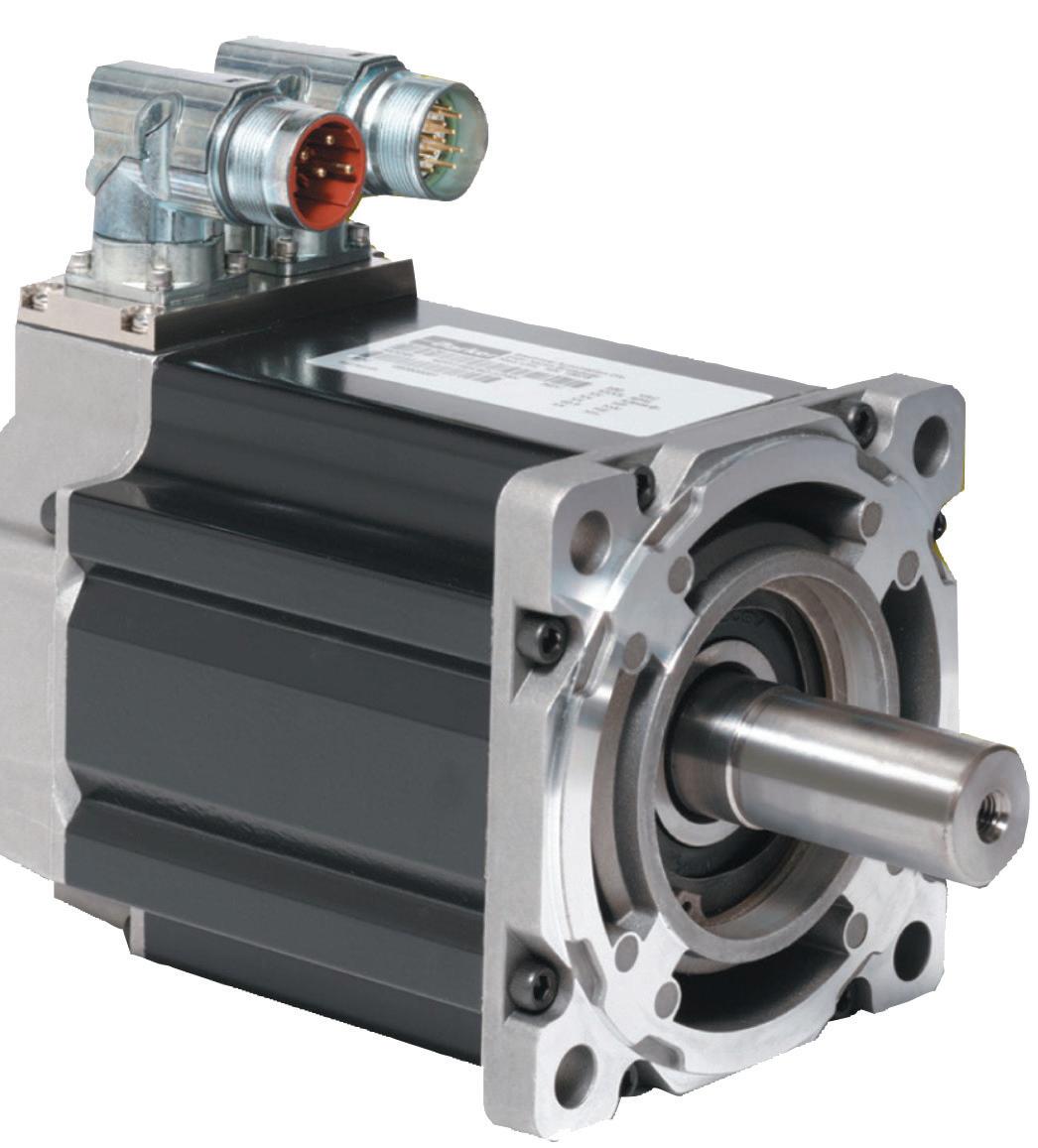

TThe MPP Series from Parker is a high-performance servo motor using eightpole segmented lamination technology, along with high-grade neodymium magnets. The MPP produces more torque in a shorter package to save space, weight, and lower overall costs.

he central focus of this series of articles is how achieving true precision requires a deeper understanding of the full motion control system, from the mechanics to the motors, drives, and controls. The fact is that there are details that do not show up on data sheets but can make or break the high-performance expectations of an entire system. As motion systems push beyond micron-level accuracy, traditional specifications start to lose their typical meaning and relevance, making nuanced engineering decisions essential.

This series continues to explore how each layer of technology contributes to the overall systems performance. The first article in the series looked at the mechanics, examining critical factors that are often overlooked such as bearing deflection, body stiffness, and structural smoothness. In this second part of the

series, we’re discussing how motor design and construction can cause torque ripple which affects everything else. In the third article, the discussion will center on the importance of the designs and features of drives and controls for the system, and lastly, the series will end with the critical elements of the system integration itself.

In the previous article, we discussed three general tiers of performance to consider in a motion control system: basic, specification-level, and pushingbeyond-the-specifications performance. This applies to motors as well.

Many applications call for simply grabbing a motor out of a catalog. In most cases, practically any motor will do. People will often ask for motors about “yea big” holding their hands up like they are holding a ball of some kind as if size defines what they need. Those are typically ac motors where the size generally does tell a person how much power it puts out. Alternatively, it is simply based upon the size of the mechanics the motor is expected to be mounted to. This is because motors are physically limited by those mechanics. Neither shafts nor mounting flanges can be too large or too small for many actuators. This approach is great for getting a conversation started and putting things together when the situation calls for it. In these situations, people don’t care about the motor being over-sized because that gives them a large torque margin. Then, they don’t have much expectation for speed or positioning as they will “get by” with whatever they do achieve. This also allows them to look only at cost and find the least expensive option they can. There is a reason, though, why there are plenty of articles, resources, classes and software programs dedicated to sizing motors. I’ve even written and taught them myself while having used probably 30 different tools over the years. These are all important when a

process requires something more than a motor about “yea big” or even a motor defined simply by power such as a 200 W or 1 hp motor. The exercise of “sizing” a motor is more about selecting the optimal size of motor for the application’s torque and speed requirements without breaking the bank.

The motor sizing calculations always include hidden assumptions, such as the ambient temperature, the airflow for cooling, and the heatsink where the motor is mounted. Those assumptions will even include the orientation of the motor, the size of the drive powering it, and whether the power input is clean.

Factors that are usually not included in the motor sizing process are the motor design, the feedback options, and the cable installation. That is why we actually refer to this as the sizing and “selection” process, with “selection” being a key part.

which are out of the manufacturer’s control. It starts with the torque ripple (the variance in torque from phase to phase as the motor turns). However, tuning, loading, and application factors all come into play.

Issues to watch for when the selection portion isn’t done well are torque ripple (causing velocity ripple and degrading smoothness), jumpy motion (caused by low-resolution feedback or electrical noise), and lowerthan-expected torque output (caused by poor thermal management).

A common question during this process for some applications concerns what the expected velocity ripple is for a given motor. This is important for applications that need smooth velocity, such as scanning and inspection applications. I have yet to find a manufacturer that will give this as a specification, though. They may provide a guideline, but ones that usually sound like a politician trying not to answer the question. This is because velocity ripple

Motor designers aim to minimize the attraction forces between motors’ magnets and coils. Those forces provide the torque and motion control, but they also cause torque ripple and other problems. The goal, therefore, is to cause a tension between them that is both useful and minimizes the problems. As always when designing a product, there are other give-and-takes to the various design options. In the case of rotary motors, torque versus smoothness, torque versus high inertia, speed versus cost, speed versus torque, cost versus thermal management, and smoothness versus low inertia are all battlegrounds of contention. Motor manufacturers typically have two or three different lines of motors that, to the untrained mind, seem redundant to

Frameless kit motors, such as these from Parker, are ideal for machine designs that require high performance in small spaces. Kit motors allow for direct integration with a mechanical transmission device, eliminating parts that add size and complexity.

each other. However, to the trained one, they have different application niches.

For applications with the highest performance demands, motor quality should also be considered. One may think that all motors are created equal within a given class, but the old axiom of “you get what you pay for” usually rings true. Here are some factors that will have an impact on motors in high-performance applications:

• Poor winding consistency will cause motor torque ripple

• Great rotor balance can allow for higher motor velocities

• Bearings will affect efficiency and smoothness

• Encoder alignment will affect efficiency and smoothness

• Housings will affect heat dissipation and resonance points

• Magnets affect the torque output and can limit peak velocities

For example, there is one standard motor that typically peaked out around 7,000 rpm. However, when special care was taken to balance the rotor precisely, filter the bearing grease so it was extra smooth, and use different feedback to allow for higher frequency output, the motor was able to hit 12,000 rpm. Clearly, this motor would cost significantly more than its standard brethren.

When the motor isn’t sized and selected properly, especially for high-performance applications, a motor mismatched to the actuator means the control loop can become unstable, the specifications of the mechanics are not achieved, and the overall investment in the high-performance actuator is wasted. DW

Diagnostic imaging should be seen and not heard

MedTech equipment manufacturers demand that their motors not only run fl awlessly, but also silently. That’s why you’ll find quiet Bodine Electric motors in CT scanners, mammography systems, blood collection centrifuges, and x-ray patient beds. If a patient’s peace of mind while using your equipment is important, then you need a Bodine.

Learn how a quiet-running Bodine motor made mammography a little less stressful.

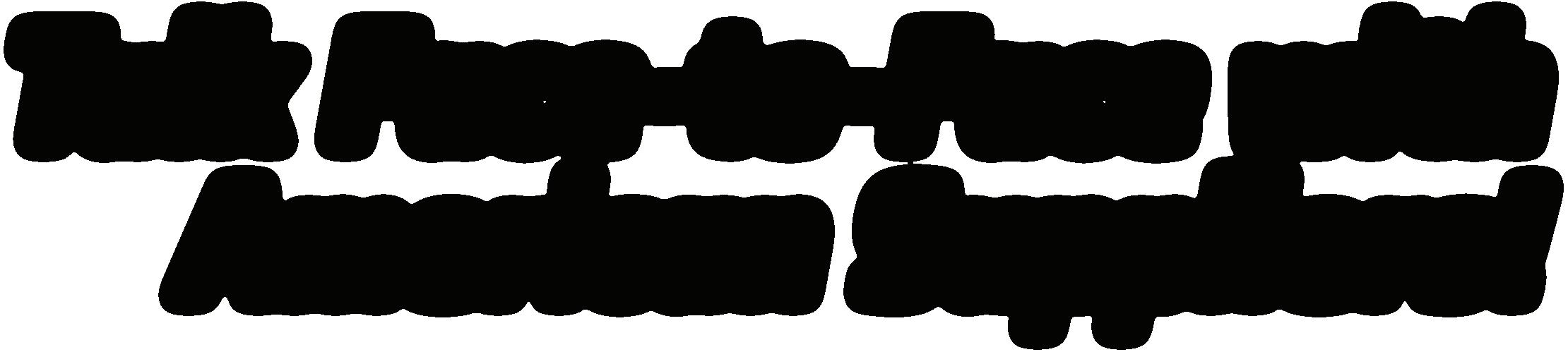

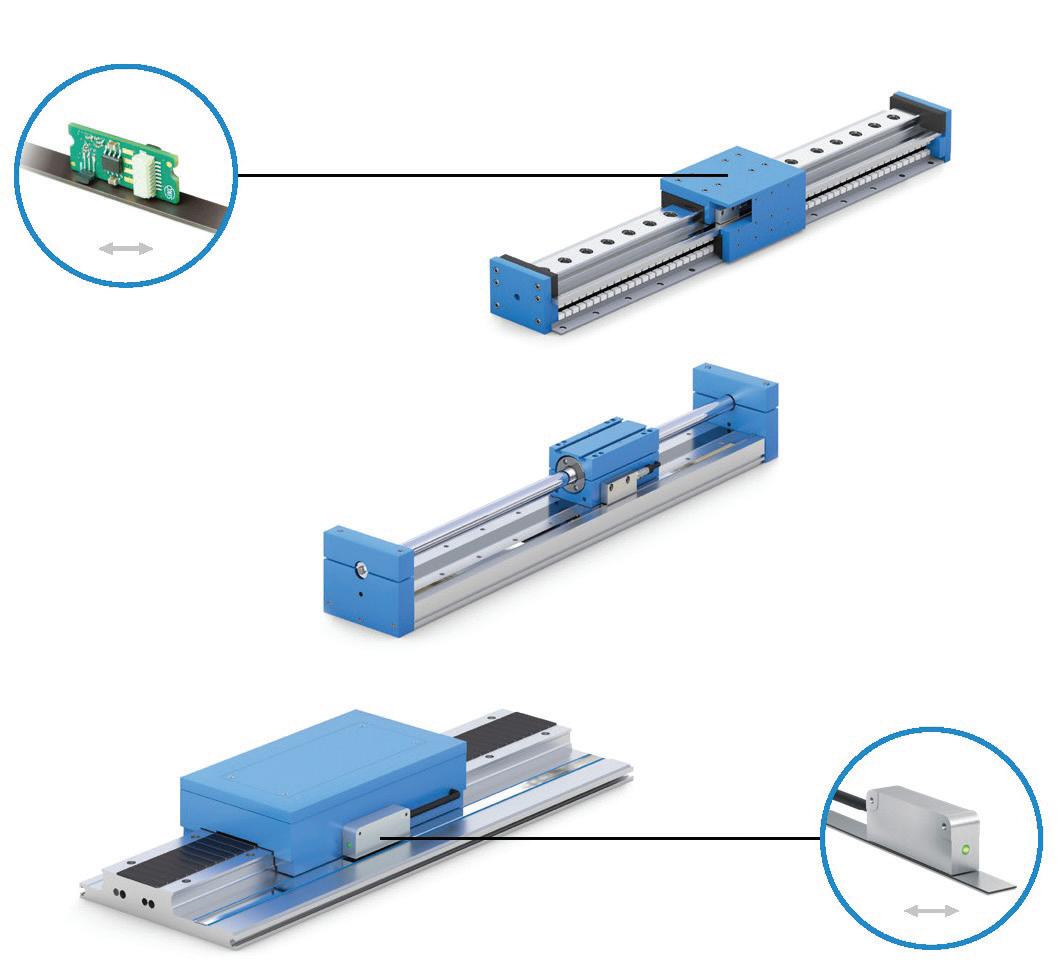

Linear encoders are often essential. Even where they’re not, their benefits can justify the additional cost they incur.

Lisa Eitel • Executive Editor

Linear encoders bypass the mechanical linkages of rotary-to-linear motion axes to directly measure positions of loads. That avoids the effect of backlash, pitch errors, vibration problems, and the way in which heat causes expansion and geometrical distortion … which is helpful in precision designs as well as a broadening array of automated machinery.

In the past, linear encoders were reserved mostly for advanced motion-system axes sporting linear motors, as linear encoders to get high enough resolution (to 5 µm or better) were costly glass-scale optical types.

encoder variations that use magnetic operation include a linear scale that has permanent magnets or variable-reluctance strips. The read head travels with the guideway carriage with has sensors to track magnetic-field during strokes — to track position with resolutions of 25 to just a few µm in some cases.

Still more cost-effective are linear-encoder variations that use magnetic induction through a steel strip covered in grooves and raised lines that a read head tracks. Elsewhere, very simple linear encoders use a read head to track the presence and absence of ball bearings within a guideway carriage.

Whether a linear system uses servo or stepper motors, adding a linear encoder can improve the performance of the machine and the quality of the process. In servo applications, the motor’s rotary encoder monitors its speed and direction, but a linear encoder monitors the load’s actual position. When stepper motors are HOW DO I PICK

But now new technologies employing magnetic operation or (in setups that are optical but designed to be more affordable) tape-scale sensor technologies are making linear encoders increasingly common on axes driven by rotary electric motors and ballscrews. Linear encoders with tape scales excel on long-stroke axes and applications needing easy installation. Linear-

In this semiconductorassembly application, a miniature vertical axis features a tiny linear drive complete with

“In ballscrew-driven applications, a lower accuracy screw can be chosen if a linear encoder is used, because the encoder feedback lets the controller compensate for positioning errors introduced by the screw.”

The most commonly used encoder technologies generally fall into three categories — optical, magnetic, and capacitive. Optical and magnetic encoders make up the bulk of the industrial automation encoder market. Not long ago, only optical technologies delivered high resolution. Now however, magnetic technologies (thanks to improvements in manufacturing and signal-processing electronics) let magnetic linear encoders operate at high resolutions as well.

MAGNETIZED ARRAY

RELATED

WHAT TYPES OF LINEAR ENCODERS ARE THERE AND HOW DO I CHOOSE?

used, position monitoring is especially important, as steppers typically run in open-loop configuration … making it difficult to unequivocally verify that the system moved to the correct position.

The first consideration when choosing a linear encoder is whether the application requires incremental or absolute feedback. Here, design engineers should consider whether they need to know the actuator’s position after a power loss. If so, an absolute encoder is necessary — because an incremental encoder will lose its reference when the power supply is interrupted … requiring a rehoming sequence to determine the load’s actual position.

Another way to decide whether an application requires an incremental or an absolute encoder is to consider whether rehoming is feasible after a power loss. Knowing the actuator’s exact position may be noncritical, but if the travel distance is long relative to the machine’s speed (as is common with machine tools) an absolute encoder can help avoid downtime and productivity due to lengthy rehoming sequences.

Whether incremental or absolute, the next factor to consider is what technology the application requires.

The two most common types of linear encoders are optical and magnetic. Traditionally, optical scales were the sole option for feedback resolutions below 5 µm. Today, improvements in magnetic-scale technology now allow their use on axes requiring feedback resolutions down to 1 µm as well.

Optical linear encoders for position tracking: Just as their rotary counterparts, optical linear encoders use a light source that shines through a linear scale and photodetectors on the scale’s other side to determine position. Optical linear

LIGHT SOURCE

Regardless of encoder type, maintaining the correct gap between the sensor and scale is key to maintaining read accuracy. Encoders employing magnetic modes of operation can allow gaps to several millimeters; in contrast, optical encoders can necessitate airgaps to within a fraction of a millimeter. Many manufacturers publish encoder accuracy at a minimum or maximum gap value. Using the latter value ensures that even with gapdistance variability, keeping the gap below the maximum allowable value essentially guarantees the encoder will deliver its published accuracy. In most cases, actual accuracy will exceed published values.

Here’s one version of distance-coded encoder reference marks, where the even-numbered reference marks shift by one grating period, and any two consecutive reference marks that are detected let machine controls calculate where the reader head is along the encoder scale upon startup. To provide absolute position measurement, magnetic encoders typically employ two magnetic tracks on the same scale — an incremental track and an absolute track.

HOW DO MAGNETIC ENCODERS WORK?

encoders excel on motion axes requiring sub-µm resolution. Their use of light reflection or refraction does make them unforgiving of contaminants. Plus shock loads can knock this sensor gap out of specification and even damage the encoder — especially those with glass scales or delicate sensor ASICs.

Magnetic linear encoders for position tracking: Just as their rotary counterparts, magnetic linear encoders use a magnetic reader head and a magnetic scale to determine position. Consider the most common variation of magnetic linear encoders. These have a read-head sensing element that rides along a magnetically coded scale. The scale coding consists of regions of alternating polarity. These alternating north and south magnetic poles are spaced at a precise distance called the pole pitch. The read head of a magnetic linear encoder contains either Hall or magnetoresistive sensors. These two technologies offer similar strengths and drawbacks, and in fact both quantify magnetic fields as well. However:

• Magnetoresistive linear-encoder read heads track magnetic-field direction

• Hall effect linear-encoder read heads track magnetic-field strength

As the read head moves over the tape, it detects the magnetic poles on the scale through either a change in voltage or a change in magnetic resistance.

The linear scales of magnetic linear encoders are flexible multi-layered strips having an adhesive backing and the magnetic scale — topped off (in some cases) with a plastic or stainless-steel cover

strip to protect the magnetic scale. Because it’s flexible and has an adhesive backing, the scale assembly is sometimes called a magnetic tape.

One advantage of magnetic linear encoders is the way in which magnetic tape can be supplied in very long lengths. In fact, real-world application examples include magnetic scales upwards of 50 meters long. But for incremental encoding, this means the homing sequence to a single reference mark could require traversing the entire

Shown here are three SIKO sensors to get incremental or absolute position feedback on axes driven by linear motors. The sensor read head can mount within or flank the carriage. Completely contactless operation imparts ruggedness even when subject to shock and vibration. SIKO

length of the encoder. Therefore, magnetic linear encoders often include distance-coded reference marks. These extra marks are magnetic poles on the scale in addition to the standard magnetic poles. The reference marks are individually spaced — in other words, in a distinctive irregular pattern along the length of the tape that’s independent of the standard magnetic poles.

After traversing two reference marks, linear encoders with such scales can report absolute position as well as the distance between the two marks and the direction of travel as well as the length of each magnetic pole and the basic increment — the distance between odd reference marks. DW

Linear-measurement solutions come in a variety of packages not covered in this article. Wheel options suit a range of running surfaces. Shown here are Tru-Trac Models TR3 and TR1 — all-in-one linearmeasurement solutions from Encoder

PETER BRINKHUIS OWNER • CAD BOOSTER

It’s not just laggy assemblies. Here are six reasons fasteners continue to frustrate CAD users — and how engineers can fight back.

If there’s one thing that CAD software should have solved by now, it’s fasteners. And yet, these simple, ubiquitous parts remain a frustration for many engineers.

Why don’t we have a single library of amazing fastener models? After eight years of building a fastener library from scratch, I think I know the answer.

My name is Peter Brinkhuis. After five years of working as a mechanical engineer, I noticed that my work could use some more automation. So I quit my job and founded CAD Booster, where we create user-friendly software (and other tools) for Solidworks. I’ve

created a drawing automation addin, an incredibly consistent fastener library, and a tool to make working with fasteners fun again.

So what’s the problem with fasteners? The problem is there’s not just one problem. Fasteners are being held back by CAD performance, business models, withdrawn standards, and more. But by understanding what we’re fighting, engineers can fight back — and win the battle for better fasteners.

We’re fighting performance

A mechanical model is by definition an

approximation of reality. How accurate that model should be is up to you and your employer.

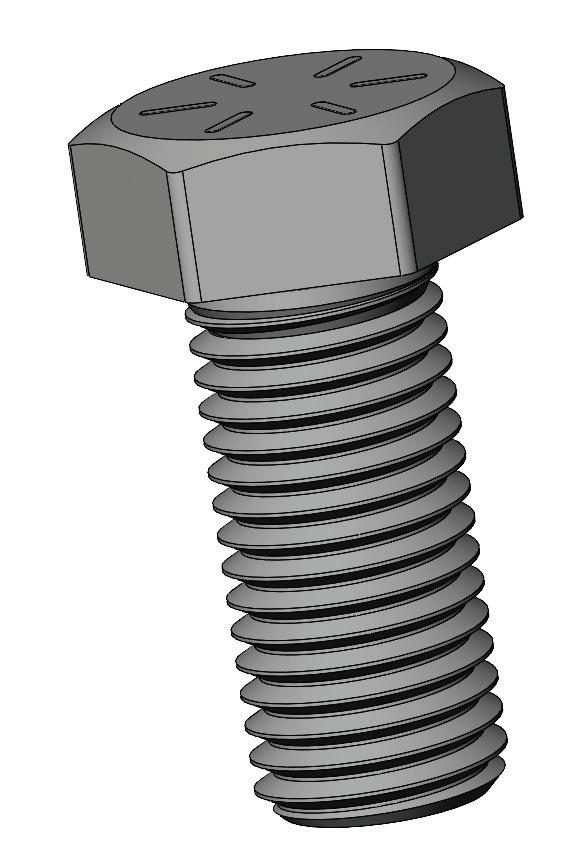

Do you want geometrically accurate helical threads modeled on all your bolts? Go ahead, but you’ll kill performance and make your colleagues want to pull their hair out. The supplier McMaster-Carr still includes helical threads in most of its models, unfortunately, and with a rebuild time to match: 0.25 seconds. Simplified models are 25 times faster.

I once debugged a large, slow assembly in Solidworks and found it was lagging due to four leveling feet with

fully modeled threads. Once the threads were gone, the assembly got snappy.

But how far do you go? I stop at bolts that still look like bolts but that have no modeled threads or radii. I’ve also talked with a company that designs slaughterhouses, and they’ve resorted to only adding an attribute to a hole. Zero geometry, lots of speed, accurate BOMs — but not very lifelike.

We’re fighting entropy

Every engineering company has a fastener library. They may start out using the Solidworks Toolbox, but at some point, they’ll quit using that and start

“FASTENERS ARE BEING HELD BACK BY CAD PERFORMANCE, BUSINESS MODELS, WITHDRAWN STANDARDS, AND MORE.”

creating their own fastener models. How hard could it be, right? It’s just a sketch, a few dimensions, a revolve, and a cut-extrude.

But then comes the request for consistency across all thousands of files or configurations. It would be great if bolt types were interchangeable without breaking mates. How about metadata? And how do the files appear in your BOMs? Does every material get its own file, its own configuration? Can you buy every size in every material? No task is trivial if you have to perform it 50,000 times.

And who’s managing all those fastener files? Is someone in charge (great for large companies), or can any engineer add a size (the reality of SMBs)? I’ve seen libraries with fastener sizes such as M7x22; sizes that you cannot (and should not) buy anywhere.

I have worked my way through the PDFs of more than 60 DIN and ISO standards, and one thing I learned from reading between the lines is that these standards are not written for the engineer. They are written for the

“…ONE THING I LEARNED FROM READING BETWEEN THE LINES IS THAT THESE STANDARDS ARE NOT WRITTEN FOR THE ENGINEER. THEY ARE WRITTEN FOR THE MANUFACTURER.”

manufacturer. Things have gotten better with the ISO standards, but the old DIN standards were bad.

For most fastener standards, the shape is not fully defined. Manufacturers get lots of leeway, especially with the under-head shape of bolts. Drawing those bolts in CAD is impossible because the shape is undefined.

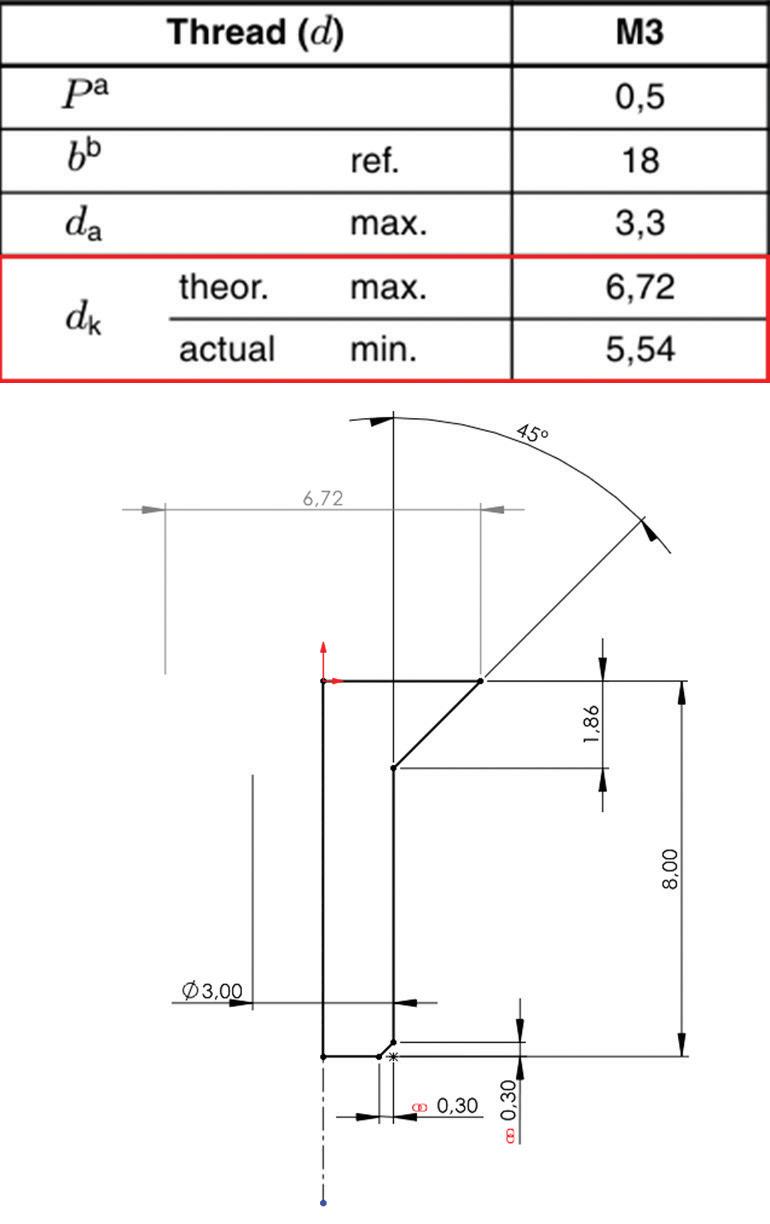

Countersunk ISO 10642 bolts only have a theoretical max head diameter and a minimum value, not a target value with a tolerance.

Standards are also written to fit on an A4 piece of paper, which is terrible if you want to copy the data from a long table that spans multiple pages (but that’s a whole different story).

Most DIN standards for fasteners, such as DIN 933 for hexagon head bolts and DIN 912 for hexagon socket head cap screws, were withdrawn 20 to 30 years ago. But engineers keep adding them to their designs, and shops keep stocking them, because purchasing doesn’t care what the current ISO standard is. So we’re stuck.

The only way out is to move forward. Stop using standards that were withdrawn decades ago and start using the ISO replacements. There are tiny differences, such as the width across flats for hexagon head bolts size M10, M12, M14, and M22, so keep your eyes open. Lead engineers should take charge, and the rest will follow. If you don’t know who the fastener police are at your company, it should be you.

And please stop using spring lock washers such as DIN 127 and serrated washers. They are the 1950s idea of locking devices, but they just don’t work. Junker vibration tests show this, and DIN withdrew these standards without a replacement. Your fasteners will still come loose, so switch to NordLock washers or a properly preloaded set of fasteners.

If engineers don’t stop ordering withdrawn fastener standards, shops will keep selling them, and manufacturers will keep making them. There’s no incentive for a shop to tell a purchaser “no” when the company is ready to buy a pallet of DIN 931 bolts. And a purchaser will never ask the engineering department to update their assembly just to comply with the latest standards.

So engineers need to take the lead. Ask for the latest standard and don’t budge at the first sign of resistance. Tell them Peter sent you.

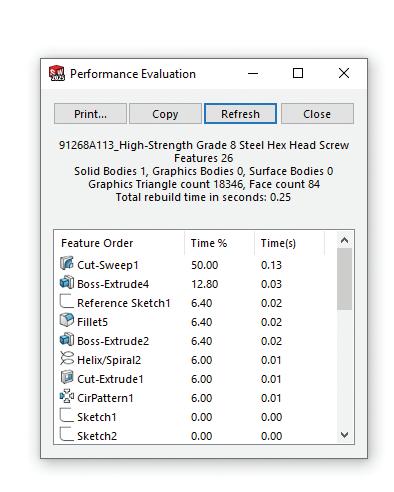

This is the goal: a perfectly consistent fastener library.

Consistency is valuable, so most CAD suppliers are happy to put fasteners behind a paywall. Solidworks has its Toolbox, which requires a Professional or Premium license, and it’s great until it’s not. Onshape does it better with their Standard Content, which is available to all users.

But how about sharing our fasteners? Send your Toolbox fasteners to a supplier without the proper license, and your assembly breaks. I’ve seen situations where the supplier or contractor had to have the same exact Toolbox setup, or the fasteners would break. How are we supposed to collaborate?

The end result is that CAD companies are holding our fastener libraries hostage. Skip a bill or downgrade your license, and you lose

access to a fundamental part of your engineering business. I think you should own your fastener library.

I’m honestly amazed that fasteners are so consistent all around the world. That means standards work, even though they are theoretical and they are written for manufacturers, not engineers.

But 3D models are implementations of those theoretical documents, and implementations are even harder. You can’t draw a bolt shape that isn’t fully defined, but you can buy a length that is not in the standard. I think that ISO should include fully defined fastener shapes in its standards from now on.

Every engineering company is different, so every fastener library will be built on different assumptions. You

and your team should choose your path: build your own fastener library, buy one, or improve the existing one. Fight for your fasteners. Take the lead, put in some effort, and the rest of the company will follow. Kick out the fasteners that don’t work, replace withdrawn standards, fight for consistency. And prepare to do it again in a decade. DW

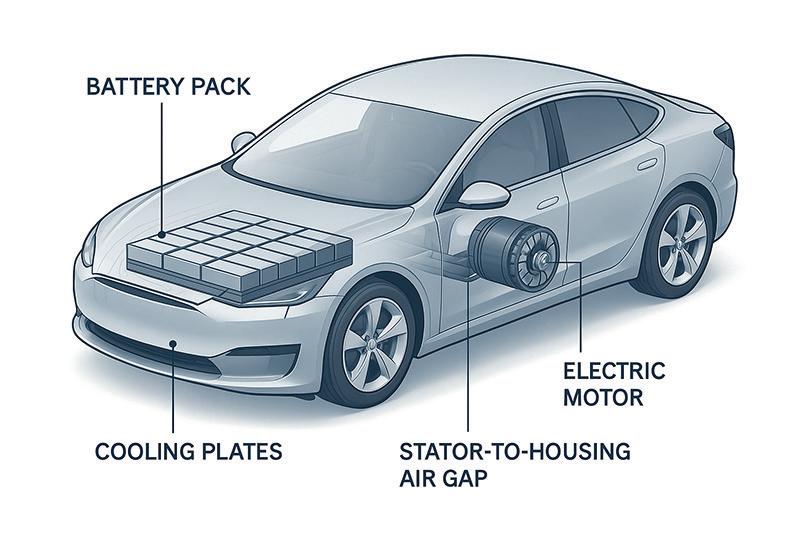

The global demand for power supplies is expected to exceed USD 46.5 billion by 2031. This growth is fueled by the proliferation of EVs, renewable energy systems, and industrial automation, particularly for AC-DC power supplies.

hese applications require current sensors with high accuracy, low noise, and fast response times. As the demand for higher power densities increases, so does the need for advanced current sensing technologies. These technologies enable real-time control and monitoring.

In this article, we explore the advantages of current monitoring. We also examine the drawbacks of traditional open-loop current sensors and the evolution of sensor technologies that address these challenges.

Accurate current monitoring and control in power supply systems help optimize performance. This ensures the longevity of energy storage systems, converters, and other system-critical components. In applications like UPS systems and energy storage, maintaining the correct balance of current flow prevents overheating, overcurrent conditions, and unexpected system shutdowns. Additionally, in renewable energy systems where power generation may be intermittent, real-time current

measurement enables the dynamic adjustment of power flow, resulting in greater efficiency. In EV charging stations, precise current measurement helps maintain optimal charging rates without an overload. In data centers, precise current monitoring helps ensure that power is distributed evenly across all devices, preventing hotspots and extending the lifespan of the equipment. However, achieving accurate current measurement in high-current, low-impedance systems is not always straightforward. These systems often operate at very high power levels, and

inaccuracies in current sensing can lead to inefficiencies, operational instability, and even safety hazards such as fire or electrical failure. This is why finding the ideal current sensing solution is so important.

Traditionally, open-loop current sensors have been used in power supply applications. These sensors measure current by indirectly detecting the magnetic field generated by the current flowing through a conductor. While this method is useful in some cases, it has significant drawbacks, particularly for high-current applications.

One of the primary issues is size. Open-loop sensor modules require large magnetic cores or external components to function effectively, leading to bulky designs that are why difficult to integrate into spaceconstrained applications.

Cost is another limiting factor, especially when high precision is required. The need for external components, such as compensation circuits, increases both the complexity and the total bill of materials (BOM) for the system.

Finally, the accuracy of open-loop current sensors is often insufficient for applications that require precise realtime monitoring.

An alternative approach is to use a closed-loop transducer. These include a compensation circuit that improves performance and accuracy compared to their open-loop predecessors, but they require additional components such as signal conditioning circuitry. Therefore, like open-loop current sensors, this makes them a more expensive and bulky option.

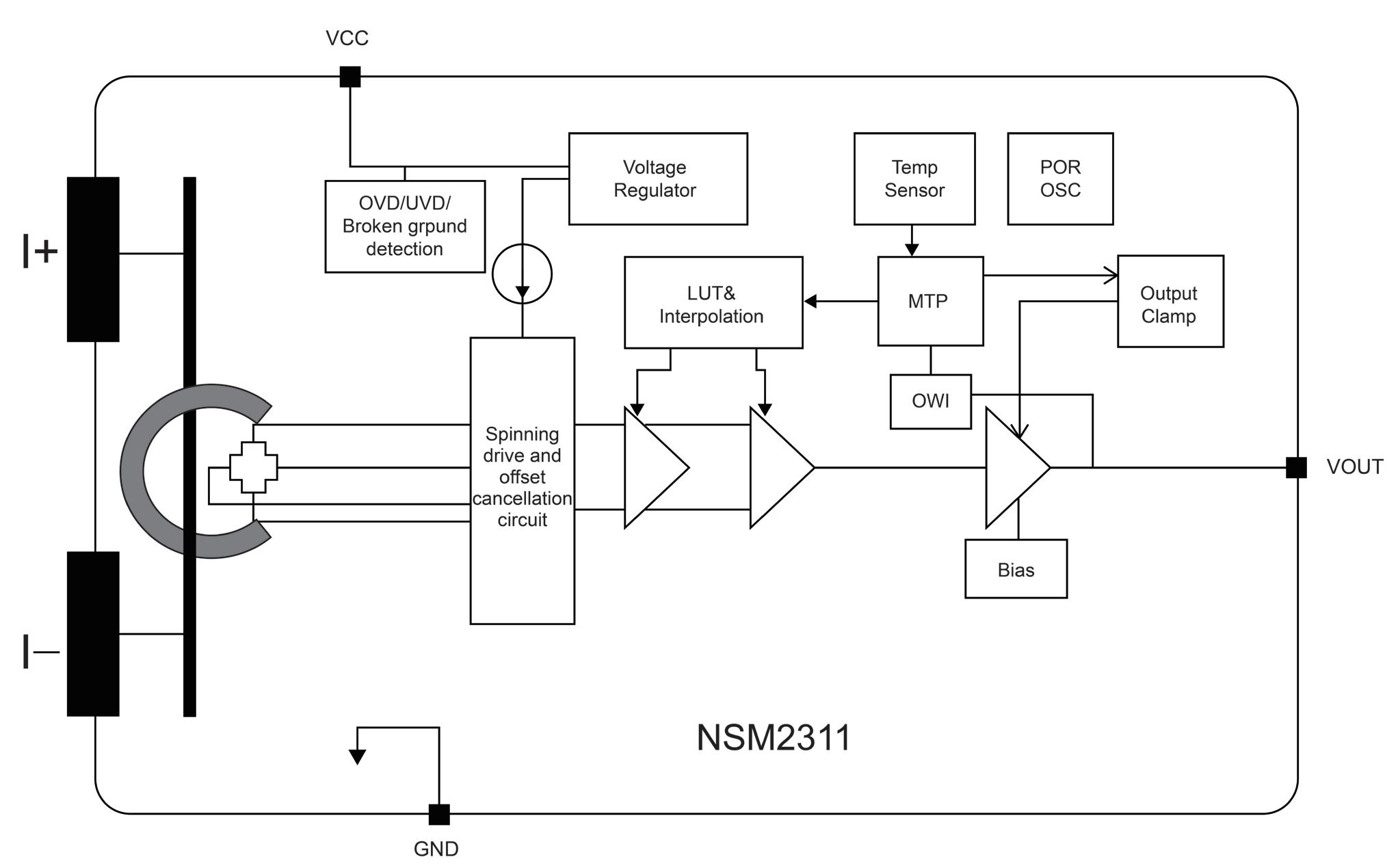

Addressing these shortcomings, the integrated current sensor (ICS) has an enhanced performance through advanced integration technology. ICSs, such as those shown in Figure 1, combine analog sensing elements and signal conditioning circuitry into a single, compact package, thereby reducing size, cost, and complexity.

One key advantage of ICSs is their small footprint. By eliminating the need for large magnetic cores and external components, these sensors can fit into space-constrained systems. This makes them ideal for high-density power supplies, UPS systems, and energy storage applications. This compactness also simplifies the overall system design, reducing the number of components required and, therefore, the overall system cost.

ICSs also use advanced algorithms for temperature compensation and drift reduction, ensuring high-precision current measurements across a wide temperature range.

Additionally, these sensors offer higher bandwidth and faster response times than their traditional counterparts, allowing for real-time current monitoring and control in high-frequency switching applications. The improved system stability and more efficient power management make them a valuable component for energy-efficient designs. By integrating multiple functions into a single package, as shown in

Figure 2, these sensors reduce the need for additional compensation or signal processing circuits. This lowers the overall BOM and cost, as well as simplifying the manufacturing process.

When choosing an integrated current sensor for low-impedance, highcurrent-capacity power supplies, the priorities go beyond basic measurement accuracy. Primary conductor resistance should be kept well below a milliohm to minimize power loss and heating in high-current systems. Values around 100 µΩ or lower are preferable. Continuous current ratings need to comfortably exceed the expected load. For many high-power designs, this means sensors that can sustain in the region of 200 A without derating.

In applications involving high voltages, the insulation system must be

robust. Creepage distances should be in the range of 6.5 mm — ideally, a little more — and a tested isolation rating should be approximately 5 kVrms. This ensures long-term reliability and safety compliance. The output stage should deliver a stable and predictable signal that remains unaffected by moderate supply fluctuations. This reduces the need for complex external voltage regulation and eases the analogue front-end design.

Precision over temperature is equally important. For demanding environments, sensors should have a total sensitivity error within ±1% across a broad temperature range, from at least −40°C up to 120°C, ideally 150°C. This ensures that readings remain consistent in both outdoor installations and highdensity enclosures.

When these characteristics are combined with a compact package and the integration of necessary signalconditioning functions, the result is a current sensing solution that supports accurate, real-time monitoring without excessive footprint or bill-of-materials cost. DW Novosense novosns.com/en

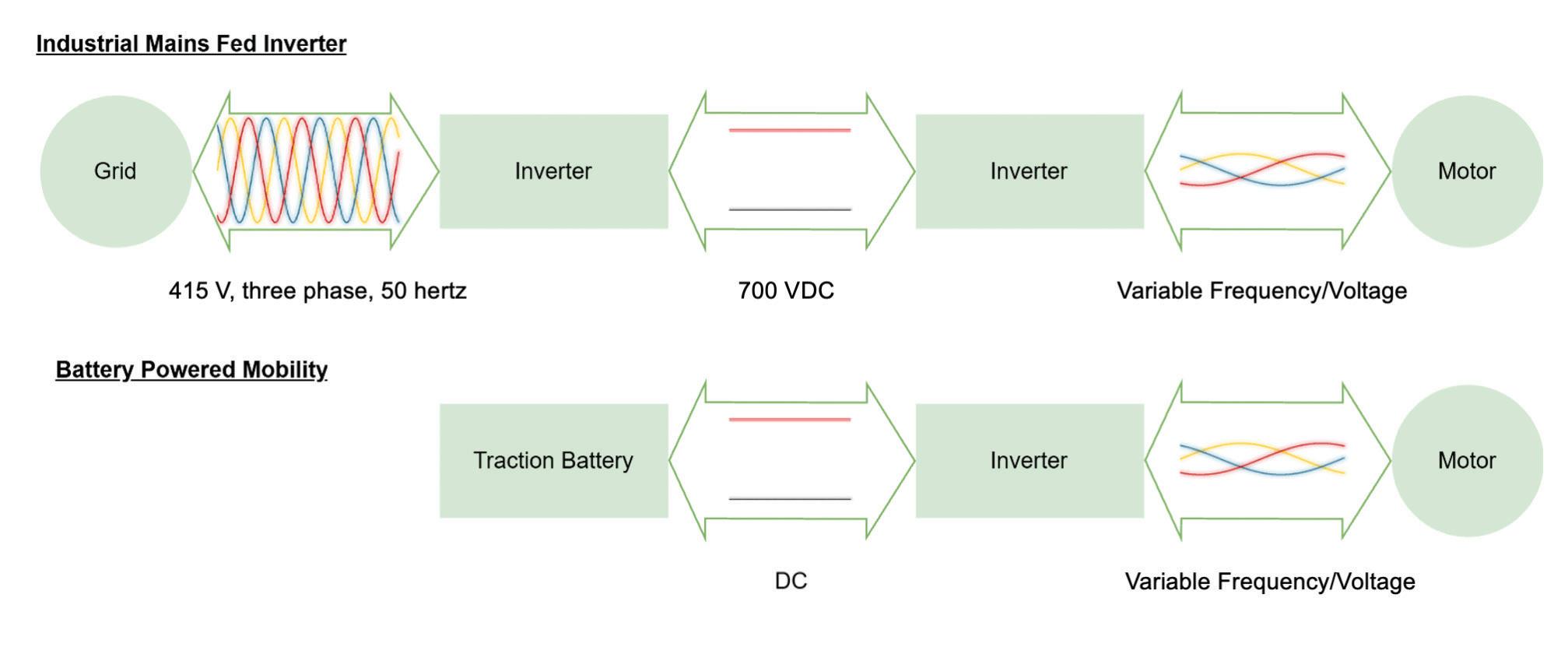

Electromagnetic compatibility (EMC) is a crucial consideration in modern electrical engineering, particularly in the design and implementation of variable speed drive (VSD) systems. When EMC is not properly addressed, systems can suffer from operational disturbances, interference with nearby equipment and non-compliance with legal directives. Here, David Strain, technical director at integrated drive system specialist, Technidrive provides a comprehensive guide to managing EMC challenges in VSD installations.

DAVID STRAIN • TECHNICAL DIRECTOR • TECHNIDRIVE

At its core, EMC refers to a system's ability to operate effectively in its electromagnetic environment without emitting levels of electromagnetic interference (EMI) that would disrupt other equipment. The term encompasses both emissions from the device and its immunity to external electromagnetic disturbances. EMI, on the other hand, refers specifically to the unwanted disturbances — either conducted through cables or radiated through space — that can cause systems to malfunction.

A detailed EMC checklist should be used to verify key aspects of an installation, including the make and model of the VSD, the necessity and category of EMC filters, the length of the motorside power cables, the grounding and bonding of enclosures, the termination method of cable shields, and the carrier frequency setting of the inverter.

The distinction between conducted and radiated EMI is especially important in VSD systems, where the highfrequency switching of inverter outputs can generate both forms of interference.

Compliance with the European EMC Directive (2014/30/EU) is not optional. The harmonized EMC product standard for VSDs defines categories from C1 to C4 that set specific emission limits and application conditions, helping ensure products are suitable for their intended environments. Selecting a VSD and associated EMC filters that meet the appropriate category requirements is a key first step towards a compliant and reliable system.

However, ensuring EMC compliance goes beyond product selection — the entire installation must also meet EMC standards. Correct installation practices are essential, including proper grounding, shielded cabling and adherence to manufacturer guidelines. Inadequate installation could degrade EMC performance and result in non-compliance at the system level, regardless of the product’s CE marking. Finally, clear documentation and traceability must be maintained, as failure to demonstrate compliance can expose projects to legal and operational risks.

The physical installation of VSD systems plays a pivotal role in controlling EMC performance. Drives should always be mounted inside a well-grounded metal enclosure. The quality of the grounding connection is paramount, and the enclosure door must be earth bonded using a short, thick braided cable to maintain shielding integrity.

Additionally, the enclosure should include an EMI conductive seal to prevent radiated emissions from leaking through door seams.

If a gland plate is used for cable entry, it should be correctly fitted and

either incorporate an EMI conductive seal or ensure bare metal contact at all mating surfaces by removing any paint or coatings that could act as insulators. It's also essential to note that the grounding system must be tested to ensure low resistance values, as high resistance can degrade the effectiveness of the shielding and compromise EMC compliance.

Another critical area of EMC control lies in the cabling. Both the mains power cables and the motor output cables should be shielded to limit conducted and radiated EMI. In particular, motor cables are notorious for acting as antennas that radiate high-frequency noise. Shield terminations must use 360°bonding techniques, such as EMI-compliant glands or properly grounded clips and must be connected to unpainted metal surfaces to maintain continuity.

While pigtail terminations (often used for grounding purposes) are a common installation practice, they can introduce unwanted impedance into the shielding system, potentially reducing the effectiveness of the EMI shielding. This can compromise the overall EMC performance by allowing higherfrequency interference to radiate.

To avoid this issue, it is crucial to ensure that any grounding or shielding terminations maintain a low-impedance connection. Ideally, grounding should be done using a solid, continuous connection to a suitable grounding point, without the need for pigtails. If pigtail connections are necessary, they should be kept as short and direct as possible to minimise impedance and maintain the integrity of the shielded system.

Control cables must also be screened according to the VSD manufacturer's specifications, with care taken not to connect the screen to control common or 0V lines. While many installers hesitate to ground cable screens at both ends due to concerns over circulating currents, following the equipment manufacturer’s guidance is critical for achieving EMC compliance.

Even when best installation practices are followed, EMC problems can still arise, particularly in complex or highperformance systems. In such cases, using a structured troubleshooting approach is essential. A detailed EMC checklist should be used to verify key aspects of the installation, including the make and model of the VSD, the necessity and category of EMC filters, the length of the motor-side power cables, the grounding and bonding of enclosures, the termination method of cable shields and the carrier frequency setting of the inverter.

Correct installation practices are essential, including proper grounding, shielded cabling and adherence to manufacturer guidelines. Inadequate installation could degrade EMC performance and result in non-compliance at the system level, regardless of the product’s CE marking.

Each of these elements can have a significant impact on the EMC profile of the installation. For example, exceeding the cable length limits recommended by the filter manufacturer can lead to diminished filter performance. Likewise, incorrect termination of shields or inadequate grounding can result in elevated emissions or reduced immunity.

When standard measures are insufficient, additional EMC mitigation components may be required. One effective solution is the use of line chokes, which are inductive devices installed in series at the input of the drive. These chokes help reduce highfrequency disturbances by increasing the impedance to transients and also assist in reducing harmonic distortion,

improving the overall power quality. Line filters are another vital tool. These are installed on the mains supply side and are designed to suppress conducted EMI generated by the inverter’s switching operation, particularly in the 150 kHz to 30 MHz frequency range. They also offer a degree of protection from disturbances originating from the grid.

On the output side of the inverter, output chokes serve to dampen highfrequency leakage currents that can occur due to the pulsed operation of the VSD. These components are especially useful when the use of motor cable shielding is limited or when long motor leads are necessary.

In more demanding applications, output filters can be employed to convert the square wave output of the inverter into a waveform that closely approximates a sinusoidal signal. These low-pass LC filters allow the fundamental motor frequency to pass while attenuating the high-frequency switching components. Although they are generally larger due to the current requirements of the motor, they are highly effective at minimising EMI and protecting both the drive and motor from voltage spikes.

At Technidrive, we understand the importance of a robust and EMC-compliant VSD installation. Our expertise lies not only in supplying the right components, but also in offering engineering support tailored to each application. We work closely with our customers and with leading VSD manufacturers to ensure that systems are properly designed, installed and compliant with all relevant standards. By assisting with equipment selection, installation best practices and troubleshooting techniques, we help prevent costly EMC-related failures and ensure long-term system reliability. DW

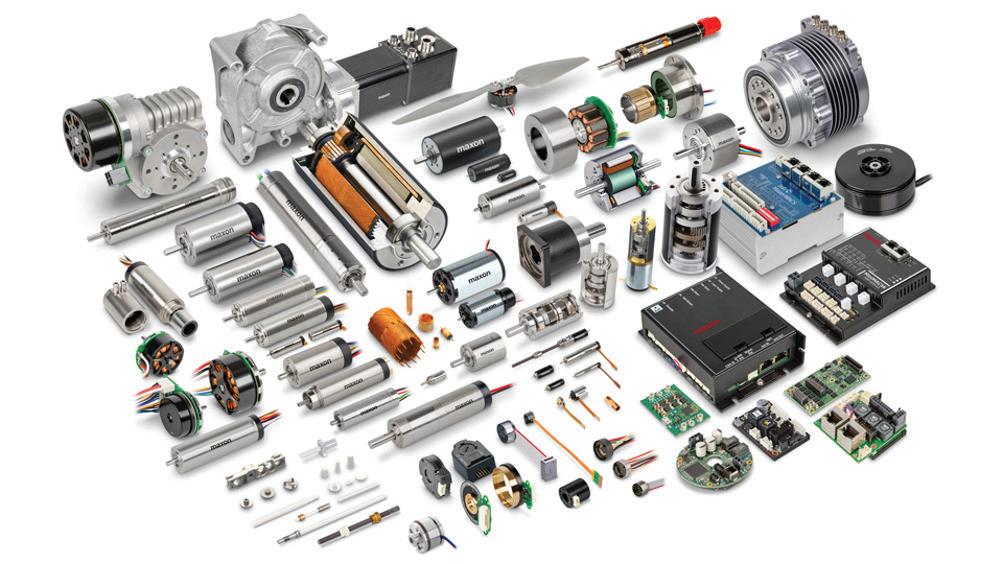

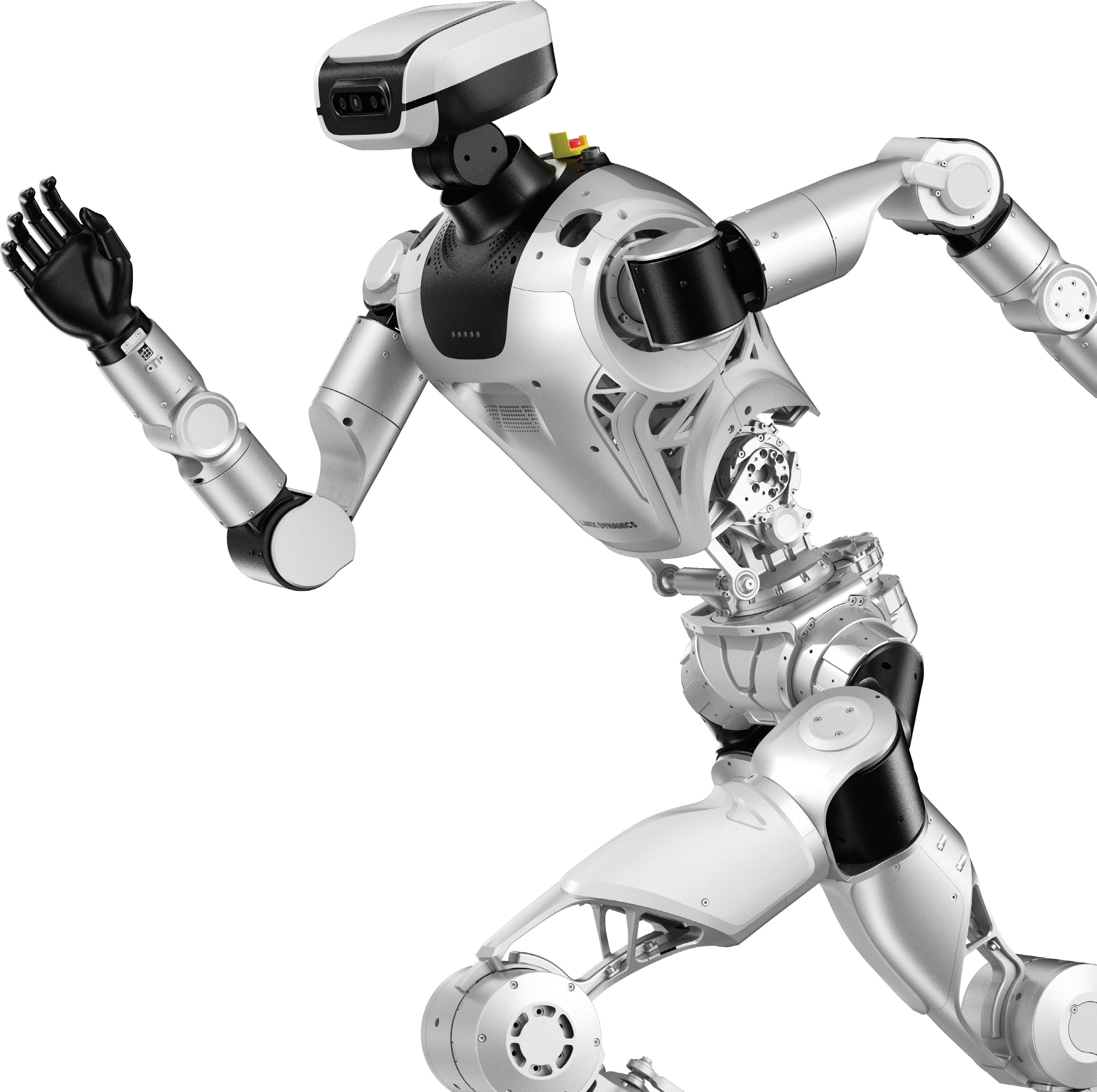

Motion control is an often-overlooked aspect of robotics. While every robotics developer must find their own motion control solution, it's easy to underestimate its potential effects on the final robot. Switzerland based maxon Group is a leader in this area.

The company won a 2025 RBR50 Robotics Innovation Award from The Robot Report for its High Efficiency Joint line. Its core technology is based on more than 60 years of

experience in combining mechanical micro-components and electrical systems.

“Being vertically integrated is one of the key items [to differentiate maxon]. We design our own motors, design our own gearboxes, own controllers, and encoders,” Biren Patel, head of business development in the U.S. at maxon, told The Robot Report. “This flexibility allows us to make more compact actuators.”

Systems for motion control are becoming ever smaller to fit robot power and space requirements. maxon motor

What’s new with motion control?

While motion control may seem like a field that changes slowly, Patel highlighted some recent developments in the industry. In particular, maxon is looking into MOSFETs, or metal-oxidesemiconductor field-effect transistors, to create smaller motion controllers. The company is continually working toward more miniaturization.

EVERYONE’S LOOKING FOR SHORTER AND SHORTER LEAD TIMES. THAT’S ALWAYS BEEN THE CASE, BUT I THINK WITH THE RECENT HUMANOID HYPE AND WITH THE NUMBER OF COMPANIES THAT ARE GOING TO RELEASE THEM, THERE’S PRESSURE TO BE IN FRONT OF THE MARKET.

“We're taking our position controllers and our speed-torque controllers to a much smaller footprint,” said Patel. “So we've got about 250-watt controllers in the size of a postage stamp now because of the new technologies and in the MOSFET area.”

“Space is a critical thing for anything from surgical suites to automated warehouses; all of that is creating the demand,” he continued.

While customer needs have mostly stayed the same, Patel said expectations have changed, particularly when it comes to lead times.

“I don't think [customer needs] have really shifted,” he said. “I think everyone's looking to get the highest torque density for the lowest price. That's been a commonality.”

“Everyone's looking for shorter and shorter lead times,” observed Patel. “That's always been the case, but I think with the recent humanoid hype and with the number of companies that are going to release them, there’s pressure to be in front of the market.”

When should startups start working motion control providers?

maxon said it works closely with each of its customers to find the right motion control system for its unique robot. However, startups can have difficulty determining the right time to start working with a partner like maxon. So, when should startups reach out?

“The easy answer is, ‘As soon as possible,’” Patel replied. “If you’d asked me, let’s say last year, I would have said, give it six months, nine months, whatever. But with the fact that we now have a product portfolio of actuators that are going to be on stock, I think it’s wise to start engaging somebody like maxon from the beginning so that we can have the conversation.”

He noted that there are many benefits to working with maxon sooner rather than later. If it does have what the customer needs off the shelf, then you can speed up development times, said Patel.

“I think it saves them probably three to six months of aggravation of integrating those components to start with somebody like maxon from the beginning,” he said.

Recent advances in artificial intelligence are touching every corner of the robotics industry, including in motion control.

“We’re looking to integrate some of the AI features with anomaly detection, using our motors as sensors monitoring currents to be able to tell our customer, or for them to tell their customer, that a part is about to fail, so they can do preventative maintenance,” explained Patel.

“A lot of the new areas that these robots are going to be put into, you’re not going to have access to them all the time,” he added. “So companies want to try to save on how often they must make trips to fix items. To make it cost-effective, we’re looking to embed that part into our controllers.”

“We can do anomaly detection and see if a motor is about to fail, or further down, if a coupling that’s attached to the motor is looking to fail,” Patel said. “So

not only the motor, but we can go down to the coupling level.”

maxon is also working to integrate AI into the integration side.

“On the simulation side, we’re working on models that are compatible with NVIDIA’s Isaac. A customer can take our joint, put it in, and get some ideas,” Patel said.

Another recent trend in robotics is the attention being paid to humanoid robots. According to Patel, maxon is seeing the effects of the recent humanoid boom.

“We are working with different [humanoid] developers, and we’re seeing more and more things for prototyping everything from the larger joints to the smaller motors for the manipulation side,” he said. “So there’s definitely a huge demand there. The biggest challenge we’re seeing, especially with

BIREN PATEL HEAD OF BUSINESS DEVELOPMENT MAXON MOTOR

the end effectors, is high torque density.”

“We have two different sets of drives: one to tackle precision, one to tackle efficiency, because, depending on the type of robot being built, one’s more important than the other,” Patel told The Robot Report. “Precision is more important when we’re looking at industrial applications, where the robots are doing the same task, and they have to precisely place something.

“With the humanoids and things like that, it’s more about efficiency,” he continued. “Even with the fine manipulation, because of the number of cameras and the sensors that are in place, I feel like the precision isn’t as important.”

2026

Looking forward, maxon is focusing on serving new and emerging developments in robotics.

“We are engaging a lot of our existing customers, as well as new customers that are coming into the space, in terms of what is required,” said Patel. “From there, we’re looking at development. So just like the high-efficiency line or our wheel drive lines, we’re looking at what customers are acquiring.”

maxon is also keeping an eye on how macroeconomic and geopolitical concerns are affecting the motion control market. For instance, motors use rare earth minerals, which have become an increasingly hot topic.

“We’re definitely looking at motors that use the rare-earth magnets,” acknowledged Patel. “How can we use a different grade of material and still get the same performance?”

He said maxon is more interested in these magnets than in adjusting the winding technology to get more out of these rare minerals. RR

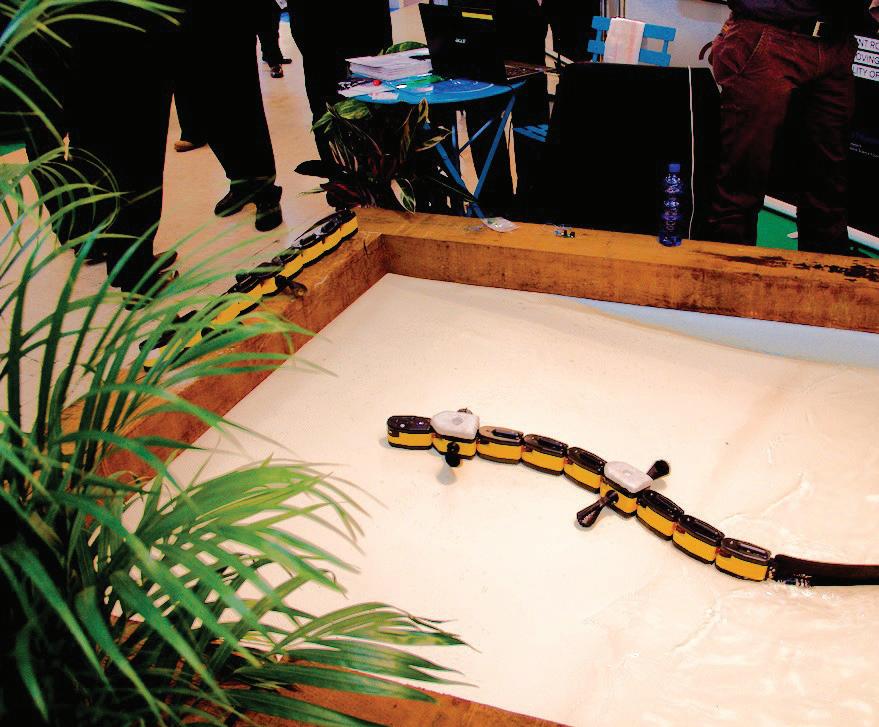

Long gone are the days of rigid robotics, where arms jerk and clank in the most unintuitive ways. These movements have hindered production and industry for years, requiring massive spaces to operate and maintain the machinery.

Fluid robot motion has revolutionized the game, enabling machinery to operate in tighter spaces with greater mobility.

Behind these innovations are several crucial components and technologies that are often overlooked.

Conventional robotic locomotion is restrictive, especially in fields that require a more delicate approach. Industries

such as surgical science and emergency response require more flexible tools to support workers in hazardous and fragile environments. Historical machinery would be cumbersome in these applications, hindering efficacy.

Soft robotics more reliably accomplishes complex assignments, enhancing human-robot collaboration with increased dependability and utility.

Additionally, fluid motion makes it easier for tech to move in tight spaces or mimic more biologically intuitive movement. The advantage makes the equipment adaptable and scalable across various industries.

A robot could handle more tasks, especially if they require precision or

finesse. Due to their wider range of programming potential and motion, robots can achieve results in fewer steps, thereby reducing energy consumption. Many mechanisms contribute to these enhancements.

Although it is a constantly evolving field with numerous innovations on the horizon, the following are several examples of the most influential mechanisms in soft robots to date.

Compared with a structured motor, pneumatic artificial muscles or PAMs offer a softer alternative. The mechanism expands and contracts like a lung, manipulating itself with air based on its needs for movement.