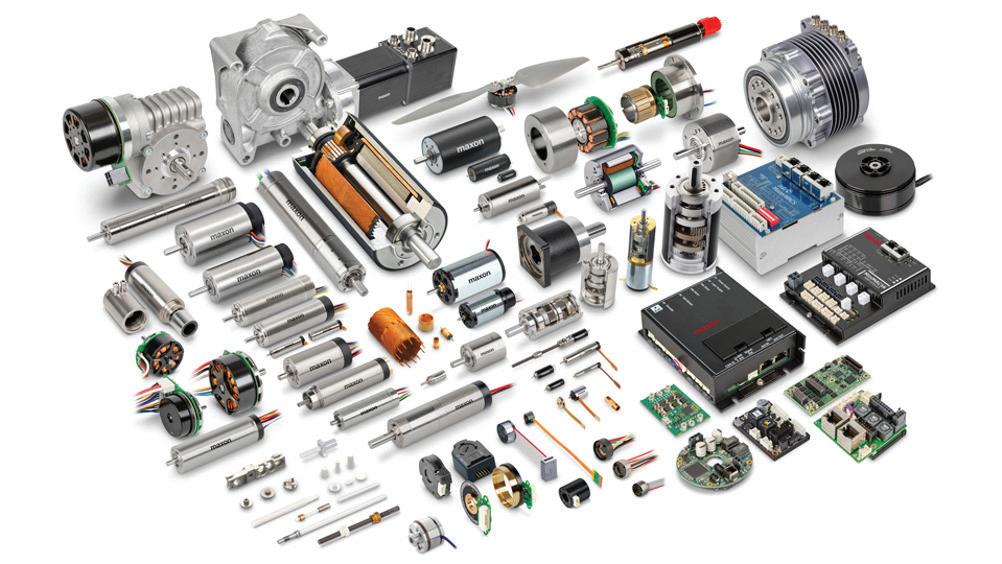

Motion control is an often-overlooked aspect of robotics. While every robotics developer must find their own motion control solution, it's easy to underestimate its potential effects on the final robot. Switzerland based maxon Group is a leader in this area.

The company won a 2025 RBR50 Robotics Innovation Award from The Robot Report for its High Efficiency Joint line. Its core technology is based on more than 60 years of

experience in combining mechanical micro-components and electrical systems.

“Being vertically integrated is one of the key items [to differentiate maxon]. We design our own motors, design our own gearboxes, own controllers, and encoders,” Biren Patel, head of business development in the U.S. at maxon, told The Robot Report. “This flexibility allows us to make more compact actuators.”

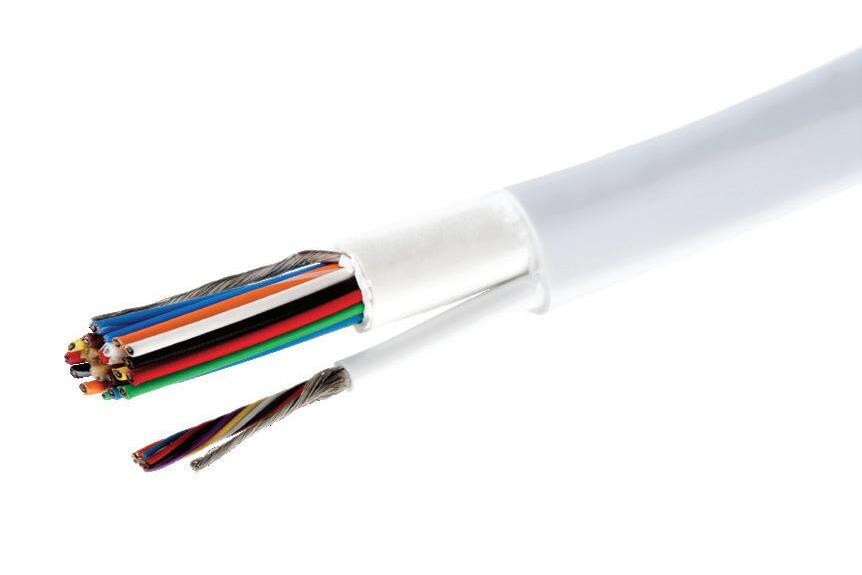

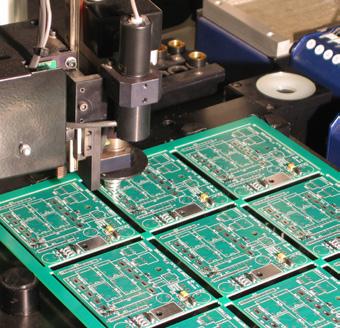

Systems for motion control are becoming ever smaller to fit robot power and space requirements. maxon motor

What’s new with motion control?

While motion control may seem like a field that changes slowly, Patel highlighted some recent developments in the industry. In particular, maxon is looking into MOSFETs, or metal-oxidesemiconductor field-effect transistors, to create smaller motion controllers. The company is continually working toward more miniaturization.

EVERYONE’S LOOKING FOR SHORTER AND SHORTER LEAD TIMES. THAT’S ALWAYS BEEN THE CASE, BUT I THINK WITH THE RECENT HUMANOID HYPE AND WITH THE NUMBER OF COMPANIES THAT ARE GOING TO RELEASE THEM, THERE’S PRESSURE TO BE IN FRONT OF THE MARKET.

“We're taking our position controllers and our speed-torque controllers to a much smaller footprint,” said Patel. “So we've got about 250-watt controllers in the size of a postage stamp now because of the new technologies and in the MOSFET area.”

“Space is a critical thing for anything from surgical suites to automated warehouses; all of that is creating the demand,” he continued.

While customer needs have mostly stayed the same, Patel said expectations have changed, particularly when it comes to lead times.

“I don't think [customer needs] have really shifted,” he said. “I think everyone's looking to get the highest torque density for the lowest price. That's been a commonality.”

“Everyone's looking for shorter and shorter lead times,” observed Patel. “That's always been the case, but I think with the recent humanoid hype and with the number of companies that are going to release them, there’s pressure to be in front of the market.”

When should startups start working motion control providers?

maxon said it works closely with each of its customers to find the right motion control system for its unique robot. However, startups can have difficulty determining the right time to start working with a partner like maxon. So, when should startups reach out?

“The easy answer is, ‘As soon as possible,’” Patel replied. “If you’d asked me, let’s say last year, I would have said, give it six months, nine months, whatever. But with the fact that we now have a product portfolio of actuators that are going to be on stock, I think it’s wise to start engaging somebody like maxon from the beginning so that we can have the conversation.”

He noted that there are many benefits to working with maxon sooner rather than later. If it does have what the customer needs off the shelf, then you can speed up development times, said Patel.

“I think it saves them probably three to six months of aggravation of integrating those components to start with somebody like maxon from the beginning,” he said.

AI has an impact on motion control

Recent advances in artificial intelligence are touching every corner of the robotics industry, including in motion control.

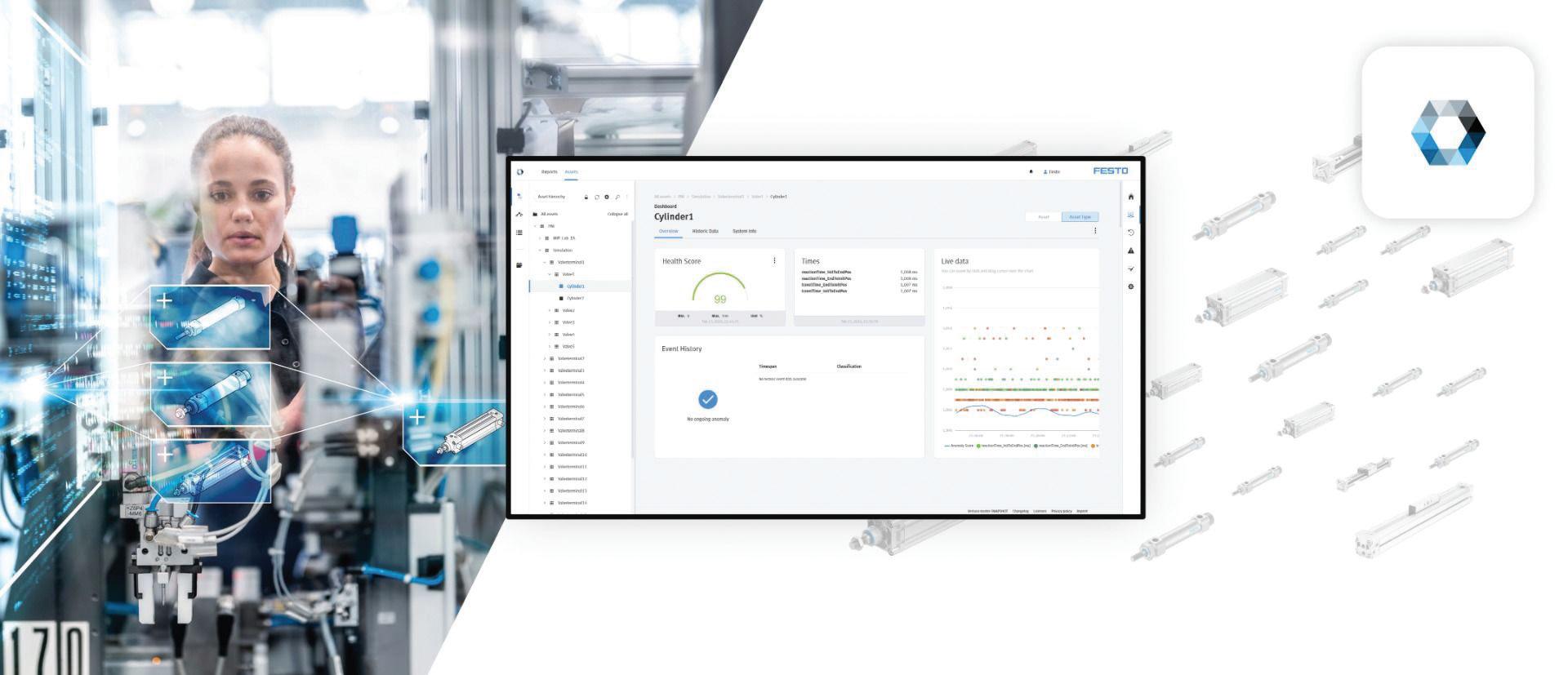

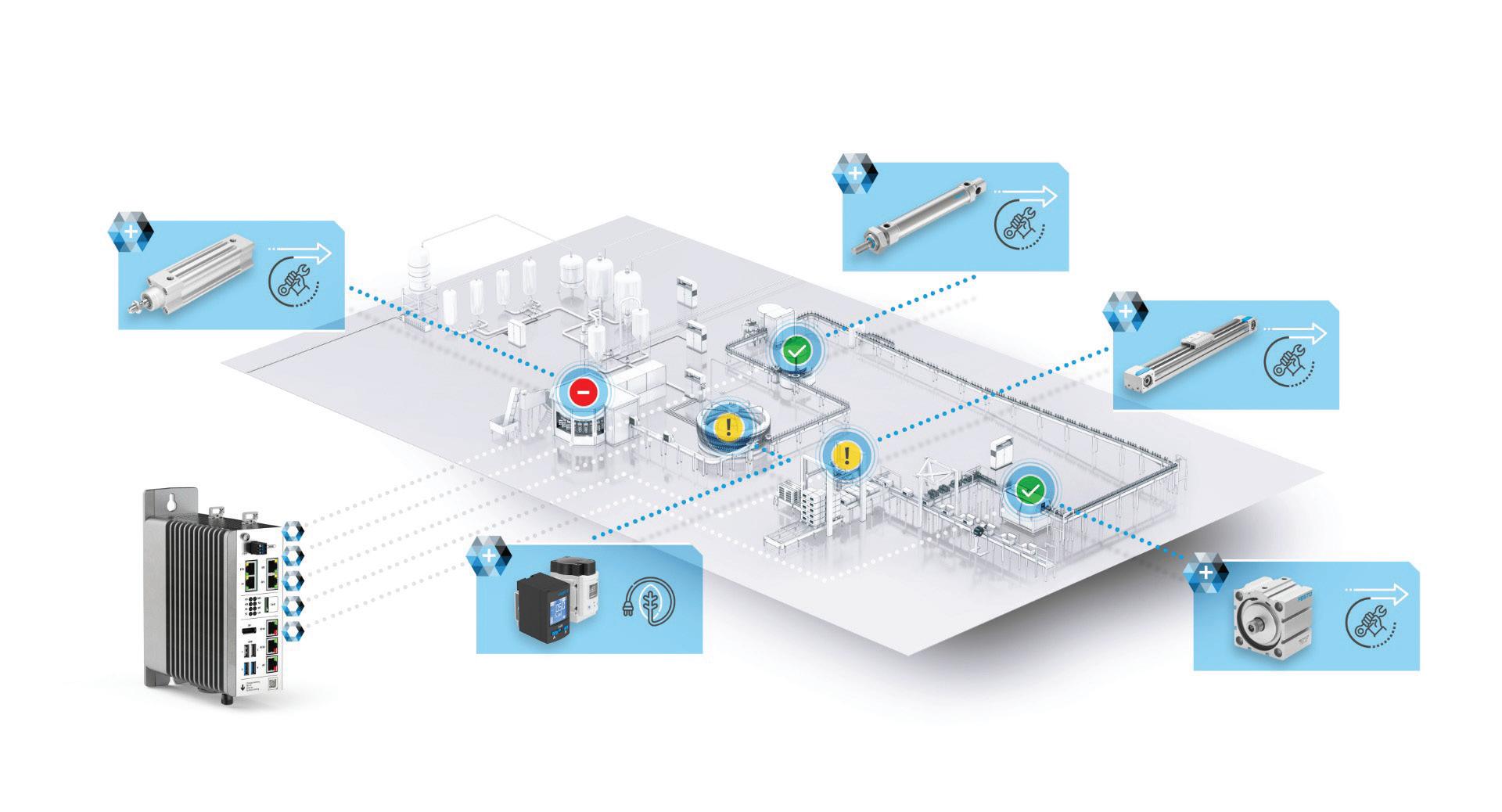

“We’re looking to integrate some of the AI features with anomaly detection, using our motors as sensors monitoring currents to be able to tell our customer, or for them to tell their customer, that a part is about to fail, so they can do preventative maintenance,” explained Patel.

“A lot of the new areas that these robots are going to be put into, you’re not going to have access to them all the time,” he added. “So companies want to try to save on how often they must make trips to fix items. To make it cost-effective, we’re looking to embed that part into our controllers.”

“We can do anomaly detection and see if a motor is about to fail, or further down, if a coupling that’s attached to the motor is looking to fail,” Patel said. “So

not only the motor, but we can go down to the coupling level.”

maxon is also working to integrate AI into the integration side.

“On the simulation side, we’re working on models that are compatible with NVIDIA’s Isaac. A customer can take our joint, put it in, and get some ideas,” Patel said.

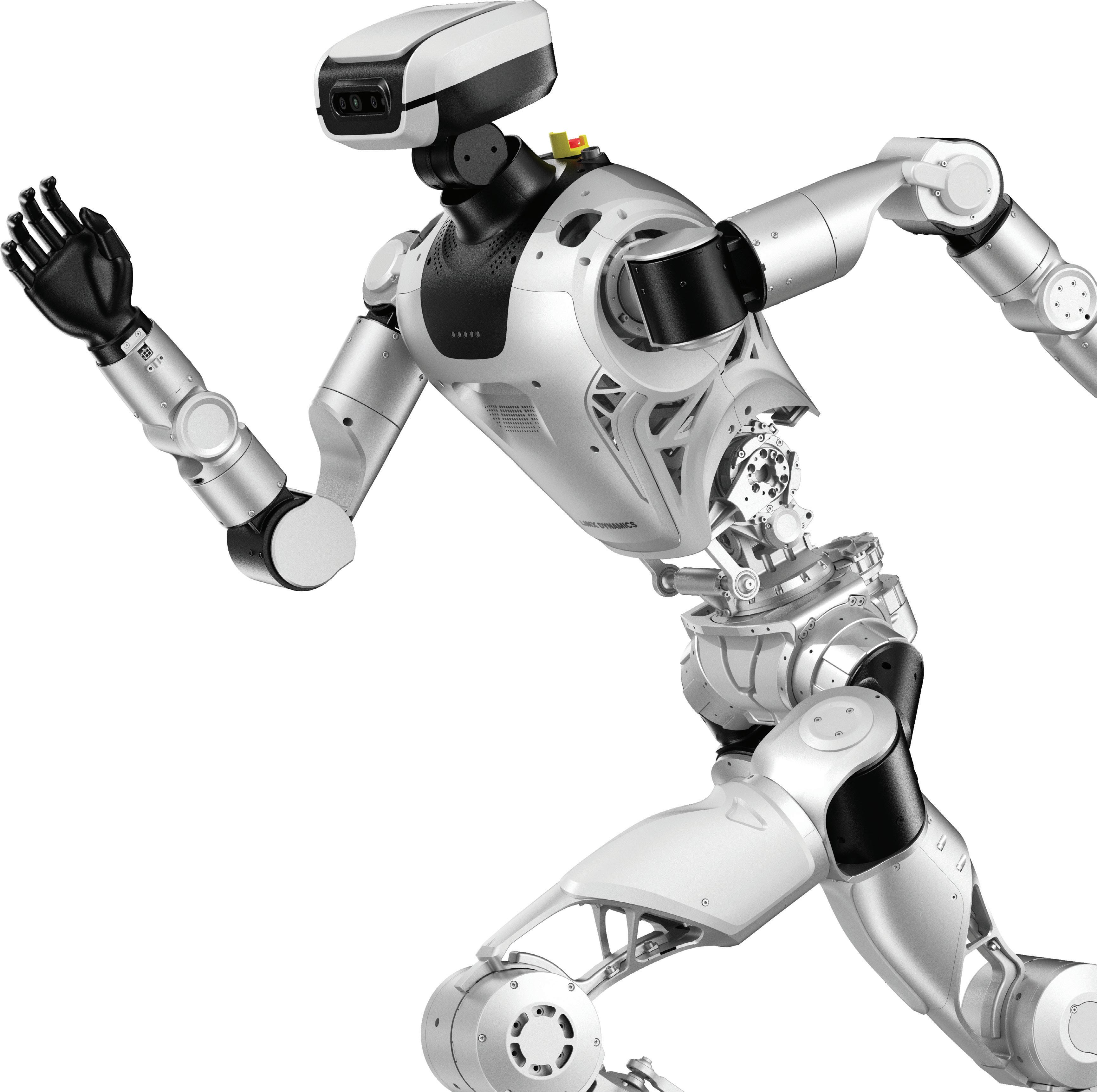

Humanoid hype helps motor demand

Another recent trend in robotics is the attention being paid to humanoid robots. According to Patel, maxon is seeing the effects of the recent humanoid boom.

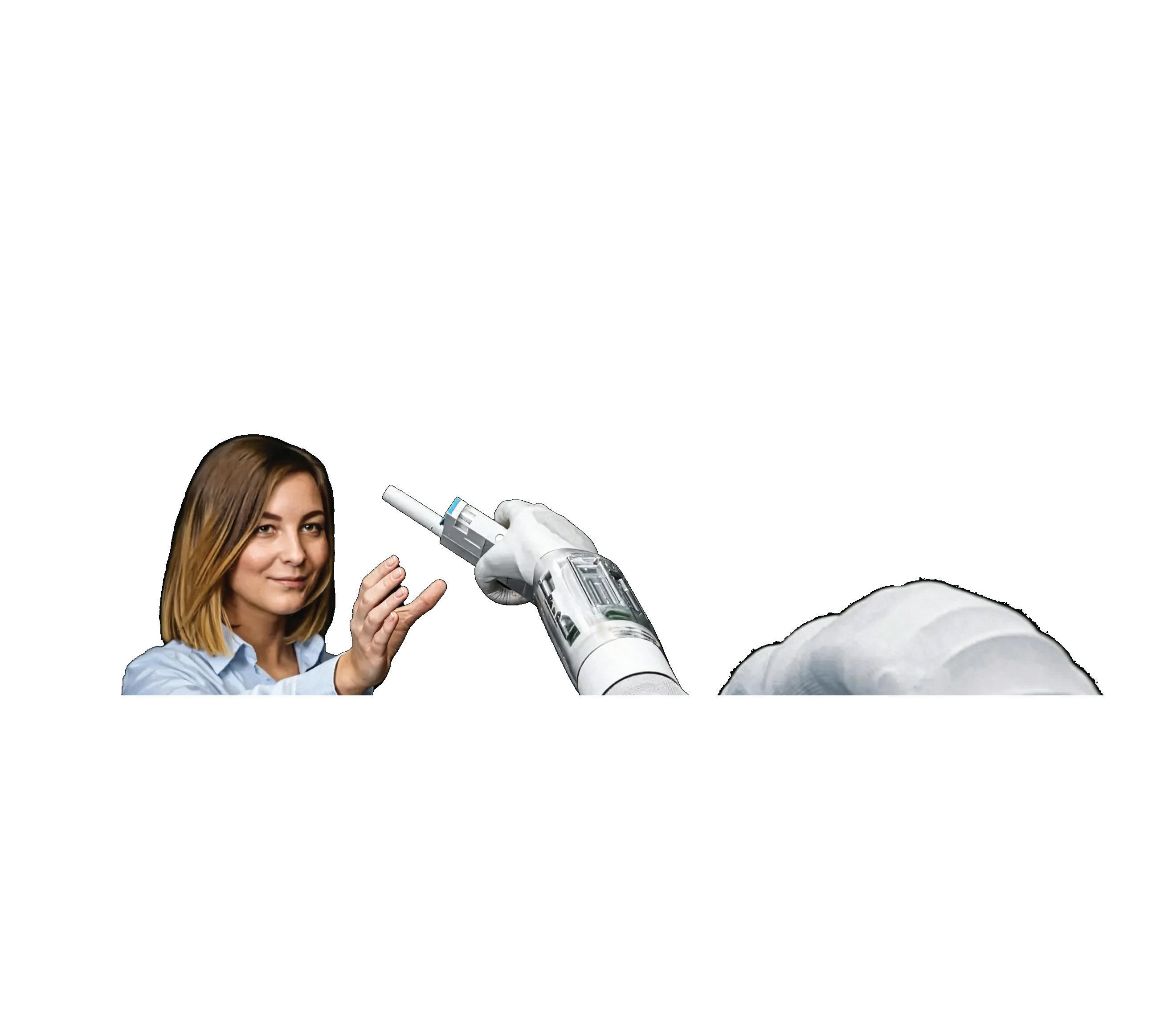

“We are working with different [humanoid] developers, and we’re seeing more and more things for prototyping everything from the larger joints to the smaller motors for the manipulation side,” he said. “So there’s definitely a huge demand there. The biggest challenge we’re seeing, especially with

BIREN PATEL HEAD OF BUSINESS DEVELOPMENT MAXON MOTOR

the end effectors, is high torque density.”

“We have two different sets of drives: one to tackle precision, one to tackle efficiency, because, depending on the type of robot being built, one’s more important than the other,” Patel told The Robot Report. “Precision is more important when we’re looking at industrial applications, where the robots are doing the same task, and they have to precisely place something.

“With the humanoids and things like that, it’s more about efficiency,” he continued. “Even with the fine manipulation, because of the number of cameras and the sensors that are in place, I feel like the precision isn’t as important.”

maxon shares

2026

priorities

Looking forward, maxon is focusing on serving new and emerging developments in robotics.

“We are engaging a lot of our existing customers, as well as new customers that are coming into the space, in terms of what is required,” said Patel. “From there, we’re looking at development. So just like the high-efficiency line or our wheel drive lines, we’re looking at what customers are acquiring.”

maxon is also keeping an eye on how macroeconomic and geopolitical concerns are affecting the motion control market. For instance, motors use rare earth minerals, which have become an increasingly hot topic.

“We’re definitely looking at motors that use the rare-earth magnets,” acknowledged Patel. “How can we use a different grade of material and still get the same performance?”

He said maxon is more interested in these magnets than in adjusting the winding technology to get more out of these rare minerals. RR

Long gone are the days of rigid robotics, where arms jerk and clank in the most unintuitive ways. These movements have hindered production and industry for years, requiring massive spaces to operate and maintain the machinery.

Fluid robot motion has revolutionized the game, enabling machinery to operate in tighter spaces with greater mobility.

Behind these innovations are several crucial components and technologies that are often overlooked.

The importance of fluid robot motion

Conventional robotic locomotion is restrictive, especially in fields that require a more delicate approach. Industries

such as surgical science and emergency response require more flexible tools to support workers in hazardous and fragile environments. Historical machinery would be cumbersome in these applications, hindering efficacy.

Soft robotics more reliably accomplishes complex assignments, enhancing human-robot collaboration with increased dependability and utility.

Additionally, fluid motion makes it easier for tech to move in tight spaces or mimic more biologically intuitive movement. The advantage makes the equipment adaptable and scalable across various industries.

A robot could handle more tasks, especially if they require precision or

finesse. Due to their wider range of programming potential and motion, robots can achieve results in fewer steps, thereby reducing energy consumption. Many mechanisms contribute to these enhancements.

5 essential components in fluid robotics

Although it is a constantly evolving field with numerous innovations on the horizon, the following are several examples of the most influential mechanisms in soft robots to date.

1. Pneumatic artificial muscles

Compared with a structured motor, pneumatic artificial muscles or PAMs offer a softer alternative. The mechanism expands and contracts like a lung, manipulating itself with air based on its needs for movement.

Because the part can constantly adjust its air capacity, its movements are less forceful and more intuitive. PAMs remove a robot’s structural limitations by crafting a body more akin to a human’s.

One example is the E-Trunk robot from Festo, whose innovations have inspired further research in biomimetic models and designs. The arm features many PAMs that use air pressure to bend and twist in a manner that a standard robotic arm could never achieve. Its materials have inherent give, whereas older models would hit literal barriers by rubbing up against their own metal joints.

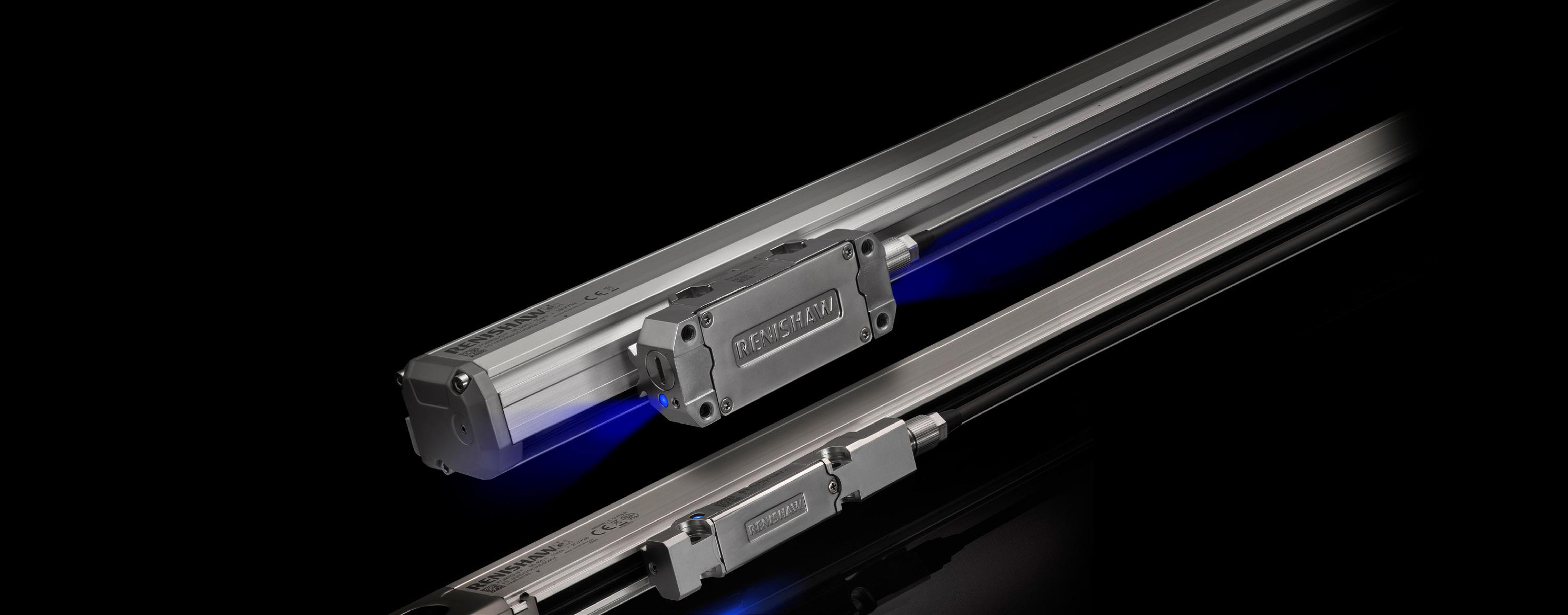

2. Strain wave gears

Strain wave gears are flexible alternatives to traditional motors. They enable robots to move more smoothly by using teeth and a wave generator to enable elliptical mobility.

The mechanism creates a backlashfree design, as the flexspline teeth manipulate the circular spline with a preloaded connection. There is always some tension — without jitter — due to the teeth, but equal mobility is achieved because of its design.

A prominent example of this is the UR5 series from Universal Robots.

Strain wave gears are critical components for boosting joint elasticity, though more research is needed to uncover how to lower the friction that strain wave gears can cause. However, reducers can mitigate some of these concerns.

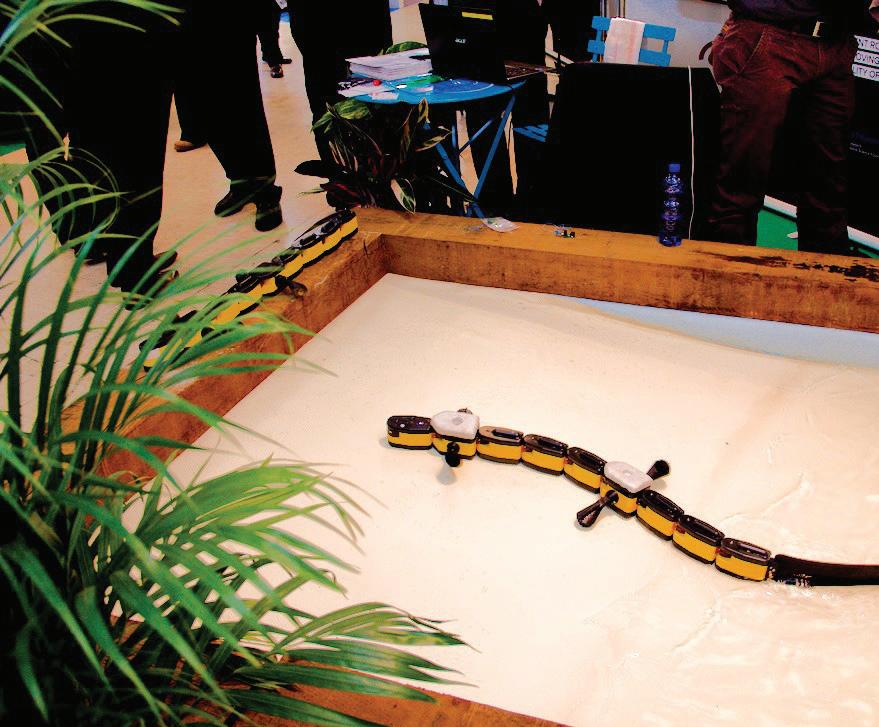

3. Central pattern generators

Central pattern generators (CPGs) are an integral part of the robot’s control hub, manifesting as software or hardware, typically as a neural network in modern applications. They automate movement programming by replicating how a spine works, producing more natural locomotive patterns. Engineers issue wave-based commands to CPGs.

A key example of this is an amphibious creation called the Salamandra Robotica II. EPFL researchers demonstrated how its CPGs allowed it to smoothly switch between swimming and walking.

4. Electroactive polymers

Electroactive polymers (EAPs) are a pivotal material in robot fluid motion, rather than a distinct part. They are considered smart materials because they can replicate muscle movement without mechanical influence, eliminating common pain points such as stilted movement or the need for excessive lubrication.

EAPs react to electrical stimuli instead, altering their shape to fit the use case. NASA developed a robotic gripping machine with fingers made from EAPs as early as 1999.

5. Shape memory alloys

Shape memory alloys (SMAs) are metals that are like phase-change materials in that they can change shape when subjected to heat or electrical triggers.

An artist’s concept of electroactive polymers, nicknamed ‘artificial muscles.’ NASA JPL/Carolina Martinez

Once the stimulus is applied, the material can remain in a specific form until instructed to revert to its original shape. This could reduce the number of parts flexible robots need, as SMAs can adapt to the task in real time.

SMAs make motion smoother by adjusting components on a molecular

level, making the robot the most dynamic version of itself. Harvard researchers are proposing these tools for wearable robotics, assisting humans with elbow and forearm flexion that could help with daily life or industrial applications.

Follow Fluid robot motion

These examples are only a few of the innovations behind this generation’s imagining of robotic movement. Many other technical marvels contribute to these flexible and adaptable machines, which change the way industries operate.

Knowing the hidden players behind these advancements can help robotics developers and integrators discover ways to continue improving the blueprints for the robots of the future, making them even more mobile and capable. RR

ABOUT THE AUTHOR

Lou Farrell, a senior editor at Revolutionized, has written on the topics of robotics, computing, and technology for years.