CLOSING THE GAPS:

Precision measurement for safer, more reliable EVs

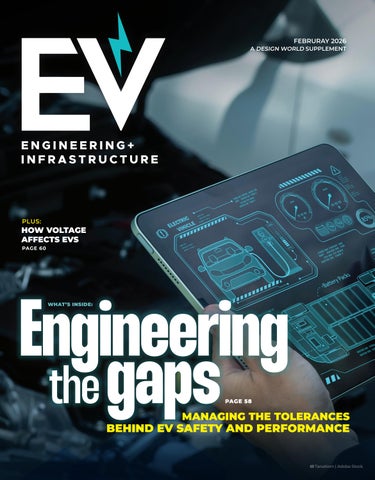

Electric vehicle (EV) engineering is defined as much by what cannot be seen as by what can. The “gaps” or unseen spaces between battery cells, slot die coating of electrode layers, cooling plates, electric motor housings, and composite joints have a significant influence on performance, safety, and durability.

Managing these dimensions with high accuracy has become critical to achieving the reliability and efficiency demanded of today’s EVs. The good news is that advances in sensor technology now make it possible to measure and control these gaps with the kind of precision and repeatability modern EV design demands.

Why gap measurement matters In EV manufacturing, gap measurement is an essential step in safety and function. For example, a deviation of only 100 microns in battery cell spacing can affect cooling pathways and insulation integrity, raising the risk of hotspots or electrical faults.

Thermal management systems also rely on carefully controlled gaps in cooling plates and laminations to regulate fluid flow and maintain uniform heat transfer. Even slight irregularities can result in uneven cooling and lower overall efficiency.

Electric motors and drive units are equally sensitive. Misaligned stator-tohousing air gaps introduce vibration, reduce electromagnetic efficiency,

and accelerate wear on bearings and windings. What begins as a minor deviation in assembly can lower battery capacity, lead to inconsistent torque delivery, and cause premature component failure.

Errors in gap measurement are more than simple deviations from design specifications. They change how systems behave under load, heat, and vibration, and those changes can compound over time. The result is a shortened service life and a higher risk of failures in the field.

How sensors are addressing the gap

Historically, many industries relied on

In EVs, even microscopic deviations in battery cell spacing, cooling plate gaps, or motor air gaps can impact safety, efficiency, and durability. Precision gap measurement ensures consistent performance and reliability across critical systems.

SCOTT ARNOLD • CAPACITEC

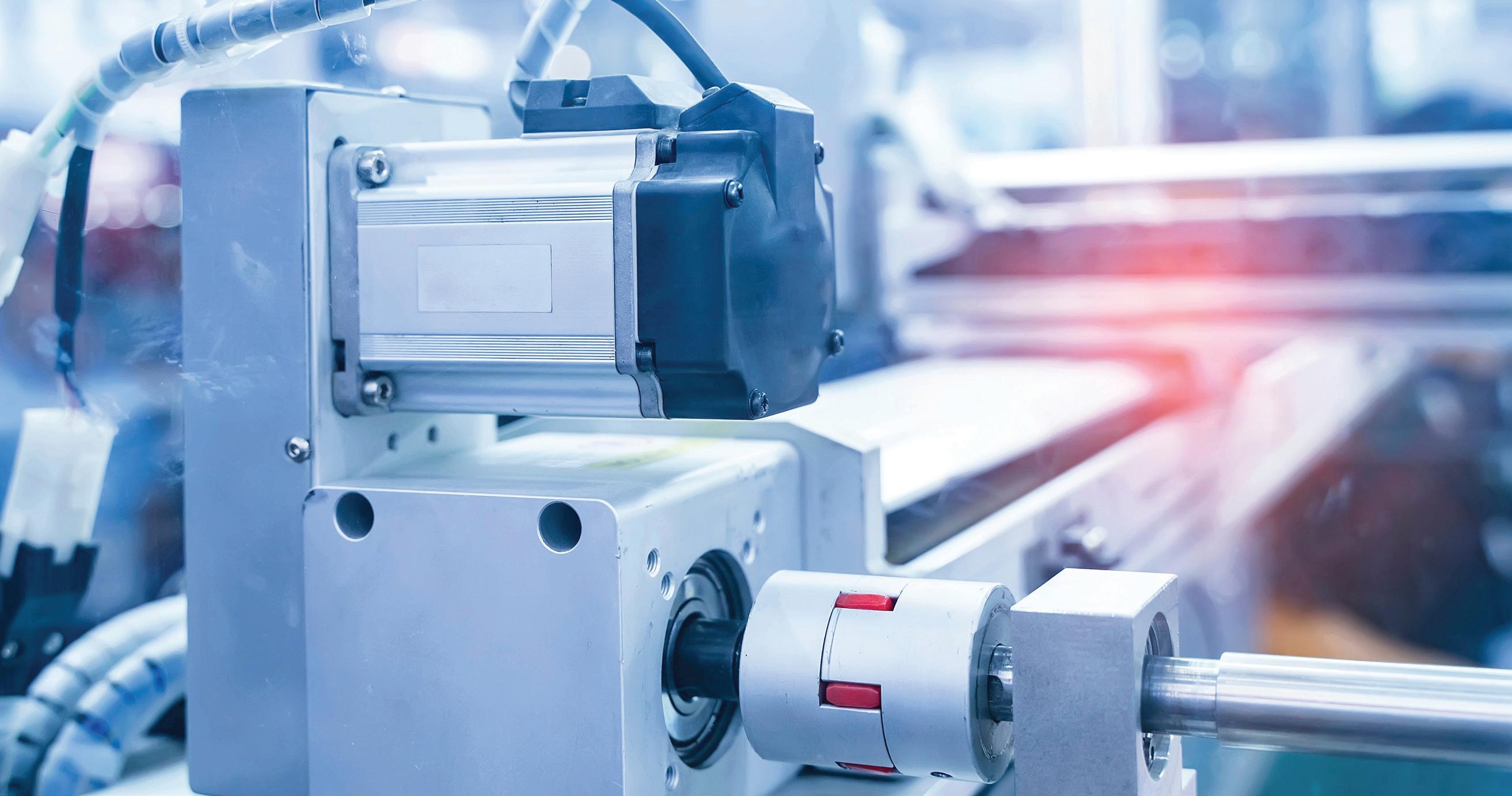

Non-contact capacitive gap sensors are used to set coating thickness in the EV battery manufacturing process.

feeler gauges or mechanical shims to measure gaps. While simple, these methods lack the precision and repeatability required for EV systems. Mechanical tools can introduce operator error, wear over time, or even damage delicate composite and coated surfaces.

More significantly, they cannot capture digital data needed for statistical process control or long-term traceability. That’s where sensors are making a difference, ensuring better accuracy and providing the data EV engineers require.

Capacitive non-contact sensors address traditional limitations by measuring distance through the interaction of an electric field with conductive surfaces.

Unlike mechanical gauges, they do not rely on physical contact, which

eliminates wear and avoids damage to delicate or coated materials. This makes them particularly effective for measuring mixed materials, such as composite-tometal or composite-to-composite joints, which are commonly found in lightweight EV structures. Non-conductive surfaces routinely use capacitive spring contact sensors.

Unlike optical systems, such as laser or vision-based measurement, these sensors are unaffected by reflectivity or geometry. They can achieve sub-micron resolution, providing consistent, repeatable results across operators.

They’re also designed to maintain accuracy in harsh manufacturing environments, where vibration and temperature variation can compromise

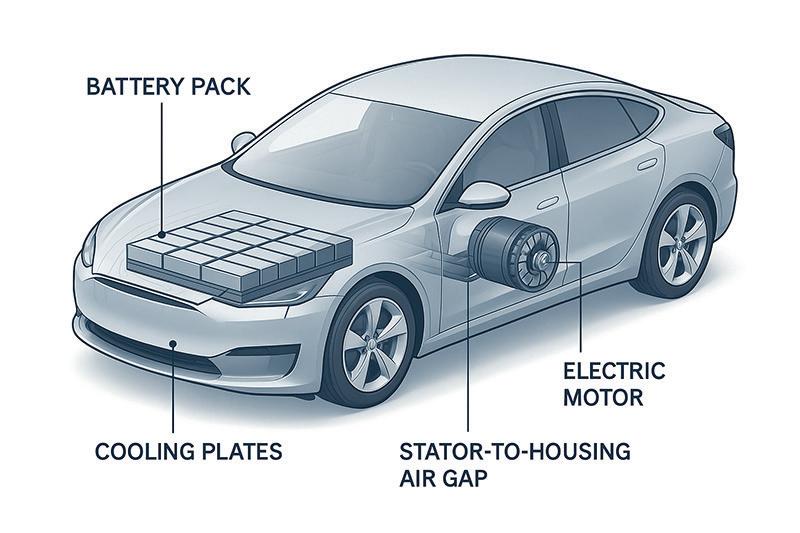

This high-precision, non-contact, portable thin-gap electronic feeler gage offers enhanced measurement capabilities for an expanded range of mission-critical gap measurement applications.

measurements. This consistency is valuable in EV applications where aluminum housings, copper busbars, and carbon-fiber reinforced polymers are combined in tight assemblies.

Additionally, these sensors integrate digital datalogging and wireless transfer, letting engineers track trends, validate process stability, and feed measurements directly into automated quality control systems, effectively closing the loop between design tolerances and production reality while enabling integration into closed-loop manufacturing.

Final thoughts

The integration of high-voltage systems, dense battery packs, and lightweight structural materials leaves little tolerance for error in EV design.

Capacitive sensing technologies allow manufacturers to confirm that battery assemblies maintain consistent spacing, thermal systems function as designed, and electric motor housings align with exacting precision.

In practice, this means that engineers can verify tolerances at scale, track variations across different manufacturing sites, and ensure compliance with the quality standards expected of automotivegrade components and assemblies. The result is a higher degree of confidence in safety and performance, which is essential for the safety and quality standards of EV manufacturing. EV

IMPACTS EV EFFICIENCY, PERFORMANCE, AND COST HOW

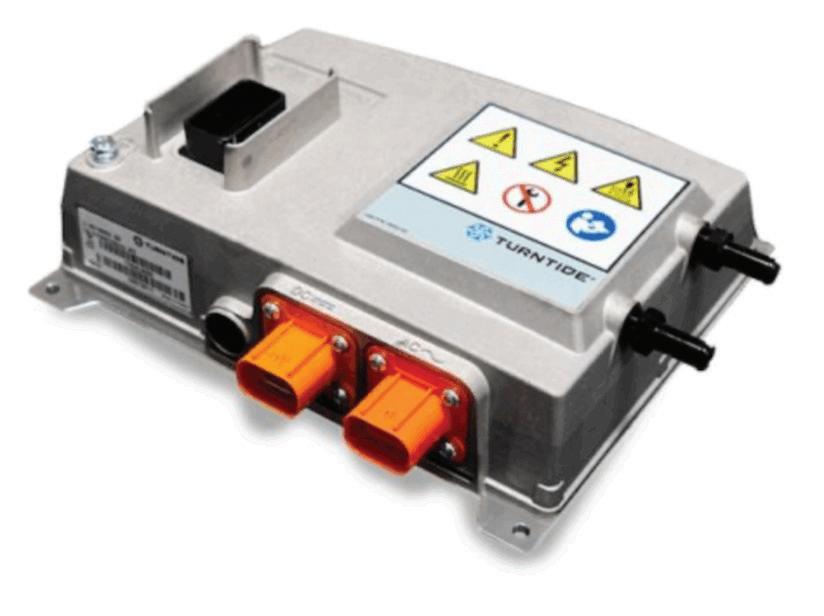

As electric vehicle (EV) platforms evolve toward longer ranges, faster charging, and higher performance, the voltage strategy has become a defining factor in powertrain architecture. Inverter systems are no longer just electrical components; they’re strategic assets shaping efficiency, packaging, and overall system cost.

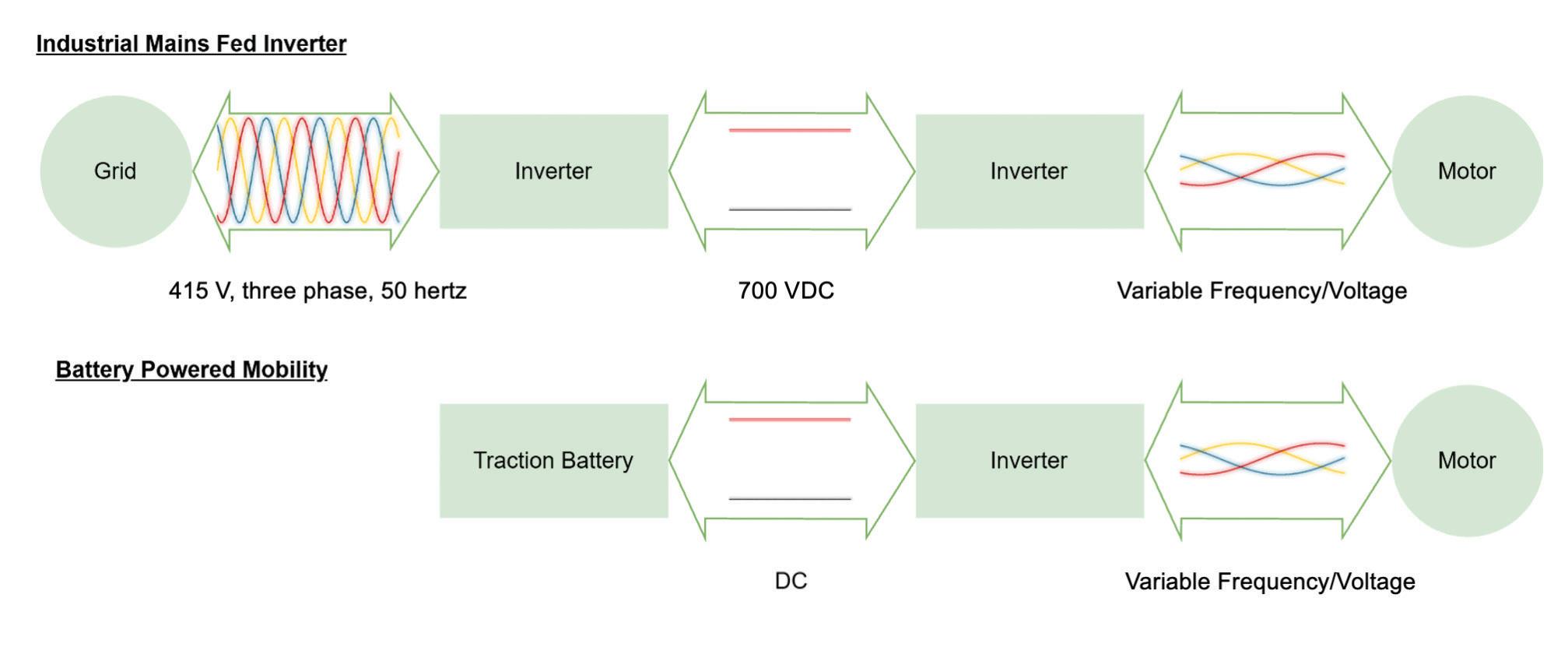

This article explores how voltage selection impacts power conversion systems and why high-voltage inverters are key to unlocking the next generation of mobility (Figure 1).

The role of voltage in inverters In electrified systems, inverters convert direct-current (dc) voltage into alternating-current (ac) voltage and back again, enabling the use of stored or generated energy in a wide range of applications.

The magnitude of this ac output is limited to the system’s dc voltage, making voltage a foundational element of powertrain design.

Fixed dc voltage dictates an inverter system’s power delivery capability and impacts efficiency, thermal management, system size, and reliability.

The basic relationship between voltage (V), current (I), and power (P) is shown in this equation:

P = V x I

Increasing the voltage reduces the current required to deliver the same power (Figure 2). Lower current means lower resistive losses (I²R), enabling more efficient, compact, and cooler-running systems.

High-voltage systems in electrified platforms

Increasing system voltage reduces current, which lowers I²R losses and the resistive heating that can limit efficiency and thermal performance.

The key benefits of high-voltage EV architectures include:

• Reduced size and weight. Lower current requirements enable the use of smaller power conductors, reducing vehicle weight and freeing up space for thermal components and additional features. This gives system designers greater flexibility in layout and packaging.

• Higher efficiency and extended range. Lower I²R losses directly translate to increased vehicle range per kilowatt-hour of battery capacity. This supports OEM efficiency targets and regulatory compliance.

• Lower thermal load. Reduced current generation equates to lower heat production in inverters, motors, and cabling. This simplifies thermal management systems and decreases the components’ thermal stress. It

enables efficient voltage conversion, reduced losses, and scalable power delivery for electric mobility applications.

also improves inverter efficiency, reduces cooling requirements, and enhances long-term system reliability. (Figure 3)

• Access to advanced power electronics. High voltage systems allow designers to capitalize on breakthrough technologies, such as wide bandgap power electronics. These materials enable higher switching frequencies and significantly reduce energy losses, leading to more compact, efficient, and thermally manageable power systems.

Total cost of ownership

The comparison of lifetime electric system costs with their combustion power alternatives is the primary metric affecting the shift toward electrification.

Subsidies related to carbon emissions can skew total cost of ownership (TCO) comparisons and should be considered separately. The choice of voltage has a significant impact on TCO and is, in any commercial mobility electrification project, the primary measure of success.

FIGURE 1. Modern inverter technology

MOTOR HOUSING WITH CONVENTIONAL WATERGLYCOL

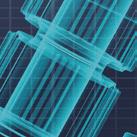

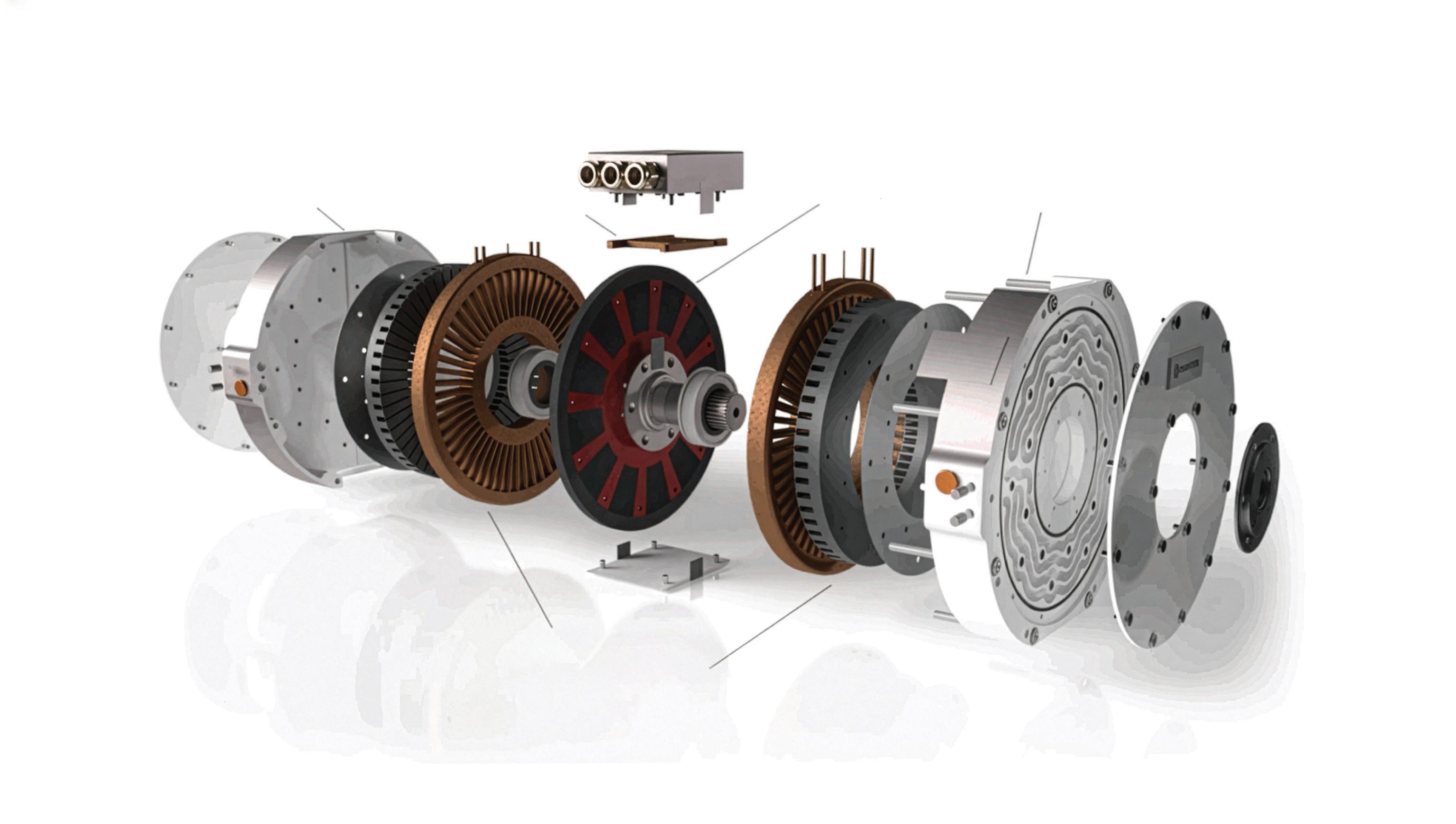

FIGURE 3. Exploded view of an axial flux motor: scalable stators, advanced cooling, and composite rotors all benefit from highvoltage EV architectures that reduce current and thermal stress.

Some measures include:

• Improved system efficiency increases range and runtime for a given capacity, enhancing the return on investment.

• Reduced battery capacity (affecting cost) for a given range helps offset some overall costs for the exact specification at a lower voltage.

• Reduced charging times increase equipment availability.

Design trade-offs and challenges

Transitioning to higher voltage presents several engineering challenges, including:

• Safety: Higher voltages require more rigorous insulation and protection standards, particularly in rugged environments, such as construction and agriculture.

• Training and servicing: Higher voltage systems may require specialized training programs and handling equipment.

• Electromagnetic compatibility: Higher voltage power electronics are more likely to require significant electromagnetic interference mitigation strategies.

• Bearing wear: With increased voltage comes greater influence from parasitic currents in isolated elements, which can lead to premature bearing failure when compared to lower voltage equivalent systems.

• Component cost: High-voltage-rated semiconductors, connectors, and insulation materials may be more expensive.

COMPOSITE ROTOR WITH EMBEDED PERMANENT MAGENTS HELD IN PLACE WITH CARBON FIBER TAPE

MOTOR HOUSING WITH CONVENTIONAL WATER-GLYCOL COOLING JACKET

HIGH EFFICIENCY, SCALABLE, STATORS MANUFACTURED FROM A SINGLE THIN LAMINATION

• Charging infrastructure compatibility: The choice of battery voltage impacts the design of the charging infrastructure since chargers must match the voltage requirements of the system.

A voltage strategy

While automotive OEMs are increasingly adopting 800-volt systems, similar voltage considerations apply in the off-highway, marine, and industrial sectors.

These environments benefit from the same principles: lower current, improved thermal management, and higher system efficiency. In high-demand applications like electric rail, construction equipment, and material handling, voltage choice influences everything from component reliability to infrastructure compatibility.

Choosing the ideal voltage architecture depends on factors such as duty cycle,

operating environment, load profile, and system scalability. Whether it’s reducing fuel use in hybrid agricultural vehicles or improving cycle time in electric construction equipment, voltage is a foundational design factor.

Conclusion

For electrification engineers, voltage is more than just a number on a spec sheet. It is a strategic enabler. As the demand for electrification continues to grow across mobility, energy, and industry, voltage strategy is central to achieving performance, efficiency, and sustainability.

Understanding the trade-offs and opportunities of voltage choice is essential for engineering the future of electrified mobility, on and off the road. EV

COOLING JACKET

BUSBAR TERMINAL BLOCK

FIGURE 2. How inverters manage voltage conversion in grid-fed and battery-powered EV systems.