A simple PID loop tuning technique: Part 1 of 2

The EV grid challenge with bidirectional charging

A simple PID loop tuning technique: Part 1 of 2

The EV grid challenge with bidirectional charging

A simple PID loop tuning technique: Part 1 of 2

The EV grid challenge with bidirectional charging

A simple PID loop tuning technique: Part 1 of 2

The EV grid challenge with bidirectional charging

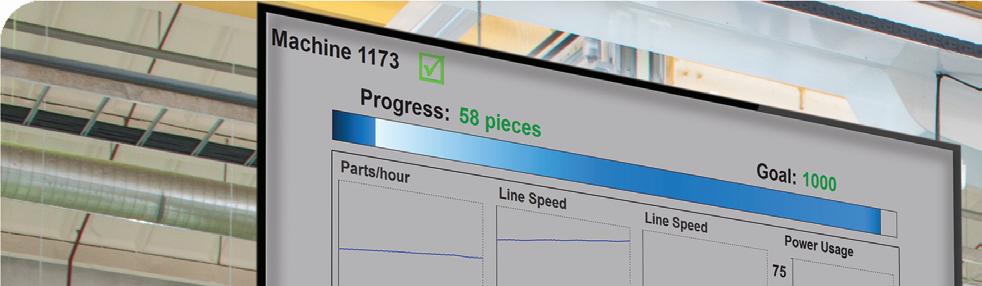

With the C-more headless HMI, you can display your factory floor data how and where you choose. The new CM5-RHMI has all the powerful functionality of the C-more Touch Panel HMIs, but without display size restrictions. This HDMI-enabled device works with televisions, monitors, projectors, and most any other HDMI display device or use the C-more Remote HMI mobile app and/or the embedded Web Server if you prefer no local display at all. The choice is yours!

Features include:

C-more Headless HMI priced at: $599.00 (CM5-RHMI)

• HDMI video/audio output with multiple resolutions

• Video: VGA 640x480, SD 720x480, XGA 1024x768, HD 1280x720, FHD 1920x1080

• Audio: use USB audio adapter (not included)

• Works with most HID-compatible resistive and pCap touch screen monitors

• The USB A port allows support for most industrial touch screen monitors in the market

• Multiple connections

• Ports: (2) Ethernet, (1) 3-pin RS485, (1) RS232 / RS422 / RS485 (serial), these ports support programming and device connections

• USB-B port for programming, monitoring, and configuration

• (4) USB-A ports for USB HID devices such as USB hub, pen drives, touch screen displays, keyboard, mouse, and bar-code scanners

• SD card slot for log files, project memory, or graphic media

• 90MB of user memory

The easy-to-use C-more HMI design software can be downloaded free of charge from our webstore. Get started on your project today or take it for a test drive. Download as often as you need, no license or key required.

Get your copy now at: www.go2adc.com/cmoreswcm5

As the calendar turns toward the final weeks of 2025, it’s a perfect moment to reflect on what has stood out this year at Design World, and to preview the direction we’ll be heading as we enter 2026. It’s been a busy, vibrant year for design engineering content, and the pace of change is only accelerating.

What stands out most in hindsight is an age-old theme: successful engineering teams do not work in silos. The designs of tomorrow — complex mechanical systems embedded with smart sensors, actuated with precision, connected to real-time data flows, and optimized for energy efficiency — increasingly require integrated thinking. Our content has mirrored that shift, providing the component fundamentals you expect and important context within systems and applications.

For engineers and product designers, all of this prompts change. Not a makeover or complete overhaul, but strategic adaptation and evolution. The common theme is that the boundaries between disciplines are blurring and require more knowledge overlap, whether you’re designing a linear motion system for a packaging machine, choosing the right connectivity devices for an industrial robot, or integrating AI-driven analytics into a mechanical product. Though designers and engineers must continuously refine their expertise in their domains, they also need to expand their understanding to ensure applicability, integration with emerging applications, and adaptability to future needs.

At Design World, our editors are committed to helping design engineers,

machine builders, and engineering managers elevate themselves and evolve through awareness, education, and community. In 2026, we have more videos, webinars, reports, columns, and industry coverage already in the works to give you the edge you need. You may have noticed that we redesigned our e-newsletter as the Engineer’s Edge to align with this purpose. We’d also like to connect with you more to ensure we provide the content you need while growing and strengthening our inclusive community. We truly believe our job as editors is to serve as an intersection and curate the most important information on the topics that matter most to you. You have some of the most important jobs in the world, and we’re proud to support you.

Thank you for your continued readership and for engaging with our content online! We wish you a wonderful end-of-the-year season and look forward to evolving alongside you in 2026! DW

Rachael Pasini

rpasini@wtwhmedia.com

linkedin.com/in/rachaelpasini

As a global leader in pump technology, we specialize in providing customized solutions to meet your unique needs. From design and production to distribution, we deliver high-performance diaphragm pumps and systems for handling both gases and liquids. Find your perfect pump solution – contact us today!

Proportional, integral, derivative (PID) position servo-loop tuning can be daunting. However, one simple technique works well for most systems.

IO-Link, the sensor-level network, is charging ahead with more suppliers offering the network connectivity and new application areas including a new wireless standard.

Telecommunications electronics materials protected from emanating spurious transmissions (TEMPEST) testing, also called emission security (EMSEC) by the National Security Agency (NSA), is an NSA specification and is defined in the NATO SDIP-27 standard.

EDITORIAL

VP, Editorial Director

Paul J. Heney pheney@wtwhmedia.com

Editor-in-Chief Rachael Pasini rpasini@wtwhmedia.com

Managing Editor Mike Santora msantora@wtwhmedia.com

Executive Editor Lisa Eitel leitel@wtwhmedia.com

Senior Editor Miles Budimir mbudimir@wtwhmedia.com

Senior Editor Mary Gannon mgannon@wtwhmedia.com

VP, Marketing Annie Wissner awissner@wtwhmedia.com

Digital Marketing Manager Taylor Meade tmeade@wtwhmedia.com

Customer Service Manager Stephanie Hulett shulett@wtwhmedia.com

Customer Service Rep Tracy Powers tpowers@wtwhmedia.com

Customer Service Rep JoAnn Martin jmartin@wtwhmedia.com

Customer Service Rep Renee Massey-Linston renee@wtwhmedia.com

Digital Production Manager Reggie Hall rhall@wtwhmedia.com

Digital Production Specialist Nicole Johnson njohnson@wtwhmedia.com

Digital Design Manager Samantha King sking@wtwhmedia.com

Marketing Graphic Designer Hannah Bragg hbragg@wtwhmedia.com

Digital Production Specialist Elise Ondak eondak@wtwhmedia.com

WEB DEVELOPMENT

Web Development Manager B. David Miyares dmiyares@wtwhmedia.com

For more than a decade, Design World magazine has brought its newsletter Design World Direct straight to your inbox — twice per week. We know that you have counted on DWD to get you up to speed on all the significant happenings within the engineering industry. But we heard that you wanted more. You wanted better. So we listened, and we decided that it was time to level up.

That’s why we are thrilled to announce that Design World Direct is now Engineer’s Edge — a refreshed newsletter format designed to bring you the engineering insights, industry news, and commentary you’ve come to expect from us, in a clearer, more engaging way.

Just as the industry evolves, so does the expectations for how our readers receive information. Do you want newsletters that are easier to scan and more thoughtfully curated? Done. Do you want a newsletter that better aligns with the fast-moving nature of today’s engineering landscape? Of course. And how about frequency? Would an extra newsletter per week be helpful? Yeah, we thought so too. We’ve leaned in and listened closely, and the newsletters you now see are the result of that feedback.

The new Engineer’s Edge format offers a cleaner, more structured layout that highlights the content you value most. At the top of each issue, you’ll now find a concise editorial spotlight that sets up the rest

of the newsletter. You’ll also notice improved visual segmentation, design aesthetics, and technical resources.

Editorially, we’ve increased video interview content, added new columns on ethical engineering and engineering disasters, and are more committed than ever to delivering you the ideal mix of deep-dive articles, short insights, and everything in between. By expanding the mix of media we share, we hope to spark more engineering conversations than ever before.

We hope this new format enhances your experience. As we continue to refine this newsletter, your feedback will be invaluable. Any thoughts on the new layout, editorial focus, or future improvements — please let us know. We’d love to hear from you.

Thank you for being part of the Design World community. We’re excited to share this new chapter with you — and we hope you enjoy the updated newsletter as much as we enjoyed creating it. DW

Design World reports on the vast world of design engineering and machine building with technical, indepth content. We cover semiconductor, medical, factory automation, packaging, off-highway, material handling, simulation, rapid prototyping, and more. By signing up for the Engineer’s Edge, you’ll stay on top of the news and trends happening in the engineering space. Fill out the form below to access three weekly newsletters plus new product announcements!

Mike Santora • Managing Editor msantora@wtwhmedia.com

Electronics in tomorrow’s products

Watch this webinar to learn how electromagnetic simulation can help engineers design better products, meet regulatory requirements, and accelerate time-to-market. An expert from Dassault Systèmes discusses common applications, including antenna design and placement, electric motor design, EMC compliance, and PCB analysis.

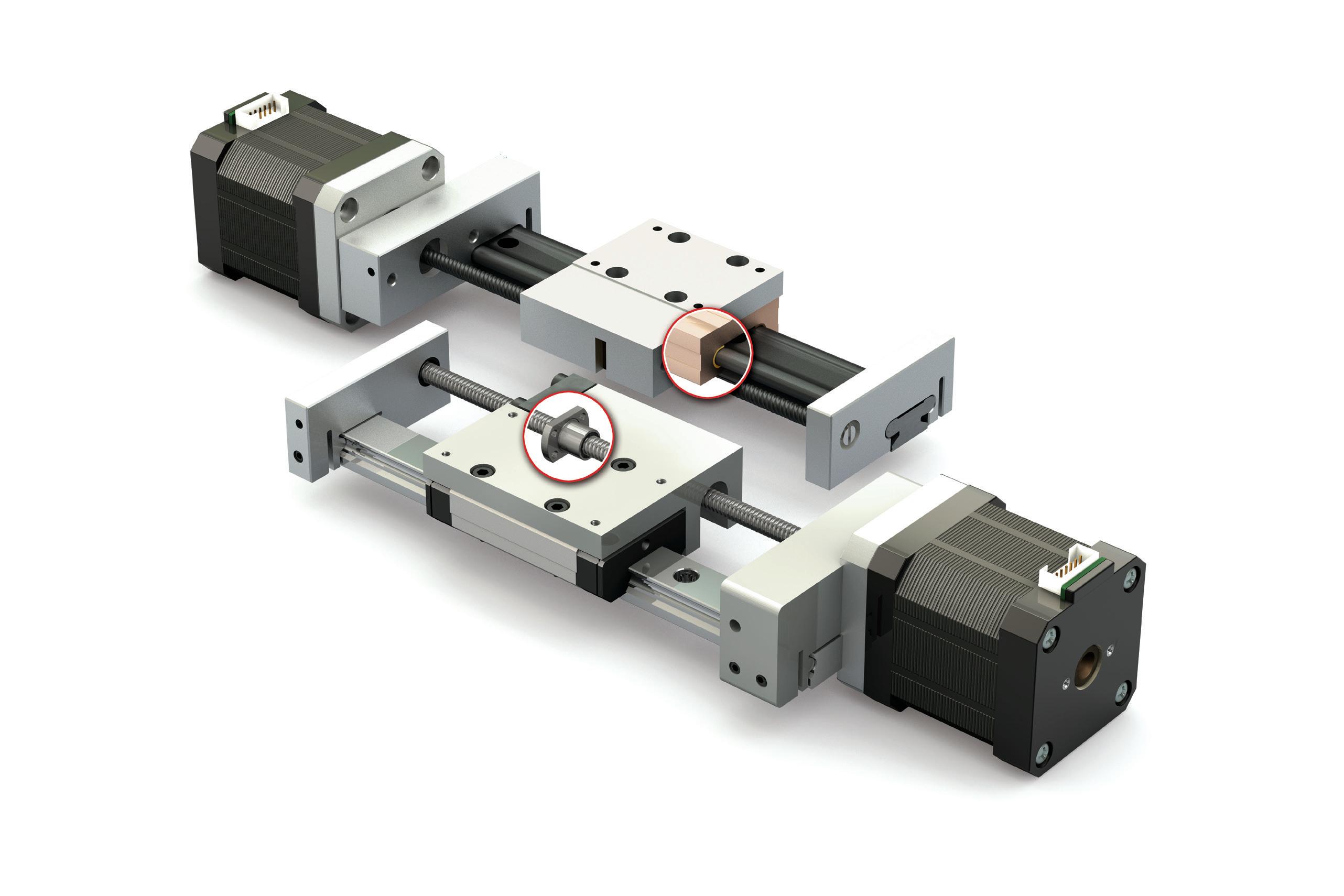

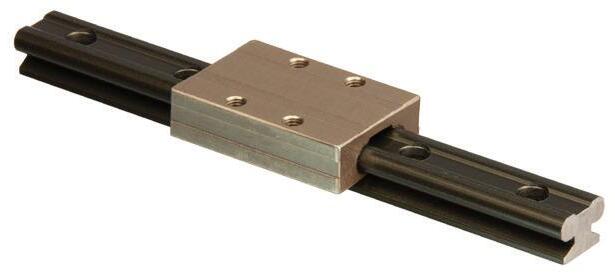

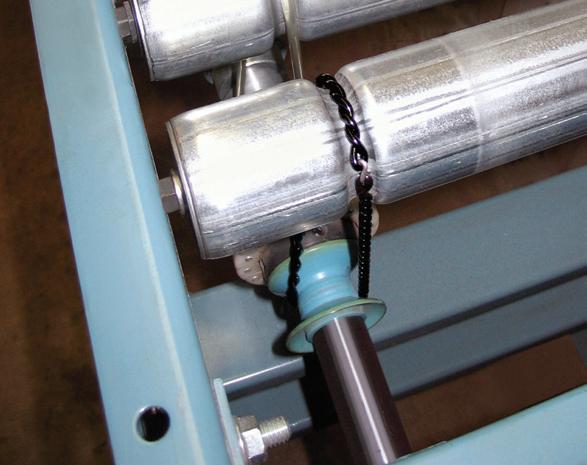

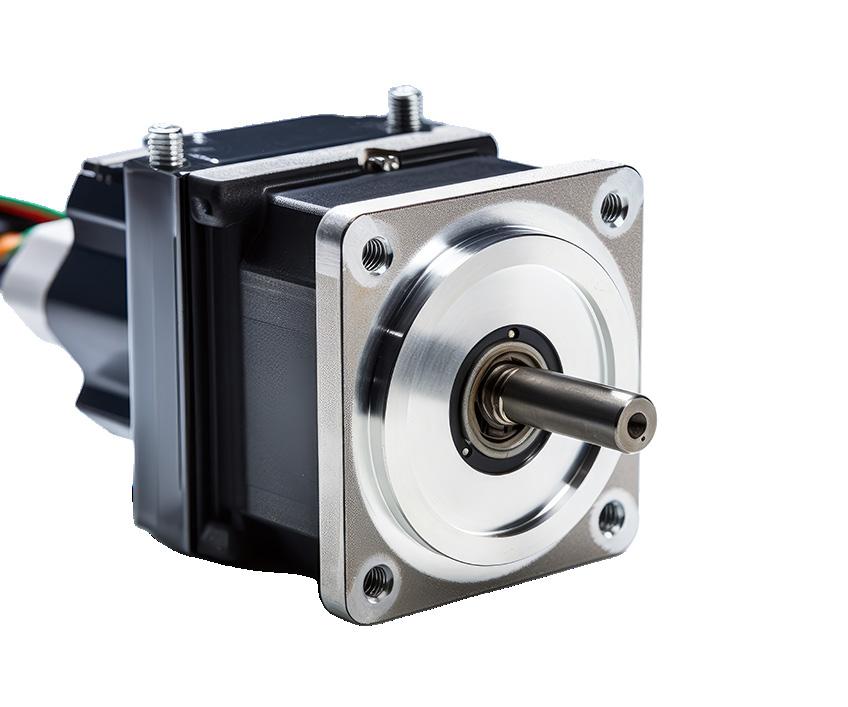

Update on NEMA stepper linear actuator designs and applications

This webinar covers basic concepts and cutting-edge developments in NEMA stepper linear actuators. It also details recent developments in the motors, couplings, and screws integrated into NEMA stepper actuators.

Precision motion control roundtable

Led by six editors from Design World and Fluid Power World, this panel

In 2025, Design World produced 30 editorial webinars designed to educate machine builders on established, new, and emerging components and systems and their integration. Many of them remain available for ondemand viewing. Here is a sampling for the best on design engineering and warehouse automation topics. See a few that relate to your work? Scan the QR codes, expand your expertise, and tune in today.

discusses the evolution of precision electric motors, couplings, servo pneumatics, and encoders. The webinar concludes with a detailing of trends in various industries.

for successful product innovation

In this webinar, leading experts in product development from Prodigy and intellectual property lawyers from Frost Brown Todd discuss the critical intersection of innovation and IP protection — and offer insights into how product developers and attorneys can work together to turn groundbreaking ideas into market-ready products.

Trends and insights for North American manufacturers

Representatives unveil insights from the State of Industrial Automation study and the State of Manufacturing Operations

study as well as findings from the most recent Manufacturing Outlook 2025 Survey. Topics include workforce skill gaps, legacy system integration, cybersecurity, AI-driven predictive maintenance, robotics, and digital twins.

Miniature motion systems: Designs and applications

In this webinar, Design World’s own Lisa Eitel covers miniature motion designs for two application classes: equipment used in the testing, manufacture, or packaging of end products as well as end products that integrate miniaturized components for specialty functions.

Electric vs. pneumatic actuators

This webinar details the long-term value of electric and pneumatic actuators, providing insights into how to choose the best option for your specific needs. Experts cover

energy efficiency, sustainability, cost, performance, precision, and maintenance with real-world examples from robotics, packaging, automotive, and manufacturing.

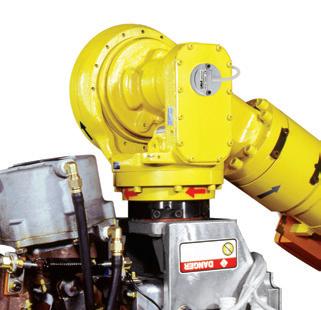

Motion in robotics roundtable

Six editors from Design World and Fluid Power World explore the critical role of automation components in robotics and how these advancements are transforming diverse industries.

Editorial Deep Dive: Electrification

This Design World webinar highlights how transitioning linear axes to electric solutions using ballscrews and roller screws can boost energy efficiency, reduce maintenance, and maximize performance in all kinds of applications.

Material-handling roundtable

The best material-handling systems ensure seamless operations in manufacturing to take products from raw materials to finished products. This Motion Training Days webinar details innovations that boost throughput and cost-effectiveness in material handling.

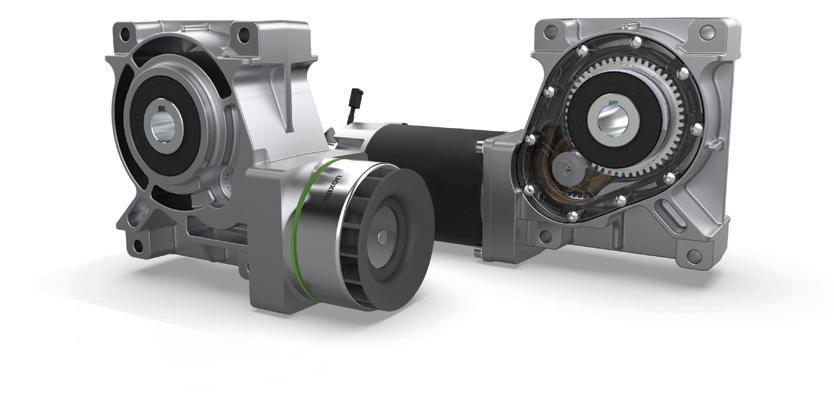

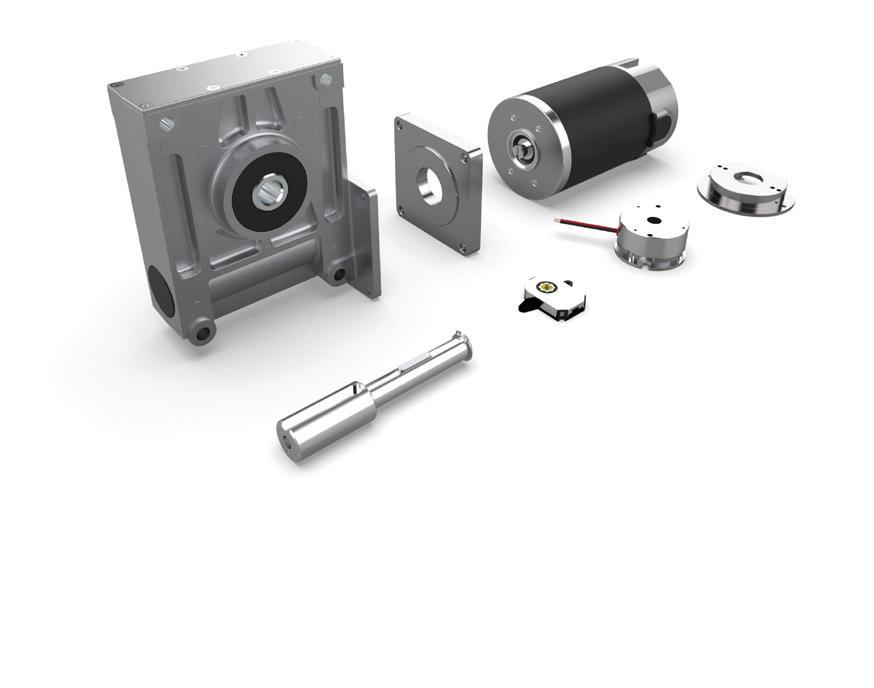

Driving packaging automation

This webinar showcases how gearmotor and drive solutions are transforming void-filling systems, shrink-wrapping machines, on-demand packaging, and case-sealing equipment.

Topics in zinc die casting

This webinar highlights how advances in metallurgy, automation, and process control have reshaped what’s possible in modern manufacturing. The presenters trace how material innovation has kept pace with the increasing demands for strength, precision, and sustainability.

Sealing for sustainable eVTOLs, hybrids, and hydrogen aviation

Hear from Omniseal Solutions’ experts for practical insights into how sealing solutions aid in creating safer, lighter,

and more efficient eco-friendly aircraft. This webinar details sealing and material solutions for urban air mobility (UAM), advanced air mobility (AAM), hybrid propulsion, and hydrogen aviation.

Cleanroom considerations

Join Lisa Eitel to consider the unique challenges of designing systems for cleanroom environments. This webinar covers industry-specific requirements in the semiconductor, pharmaceutical, and aerospace sectors and how cleanliness, particle control, and contamination standards impact equipment design.

Precision gearboxes in ground-based satellite communications

This webinar details high-precision gearboxes for satellite antenna tracking systems and multi-axis positioners for antenna testing … and how to specify gearboxes to ensure long service life, maximal precision, and reliable performance in extreme conditions.

Sensor solutions for space missions

FUTEK’s technical director Richard Walker details three aerospace programs in which custom sensor design played a mission-critical role. Examples include those from lunar landers, orbital platforms, and robotic arms needing force/torque measurement, fault detection, and ruggedness for extreme environments. Ehsan Mokhberi (also of FUTEK) then outlines the company’s process for initiating and executing custom sensor programs to ensure compliance with NASA and private-sector aerospace requirements.

Adopting and integrating automated storage and retrieval systems

In this webinar, warehouse operators adding automation can learn about ASRS flexibility, how much infrastructure and process change they need, and whether such systems can handle items specific to a given supply chain.

Picking systems with AI

This webinar details how robotics, vision, AI, and human-machine collaboration are changing all types of warehouse functions. Beyond gripper hardware and object-recognition software, robot dexterity and perception are raising operations’ precision and throughput.

Robotics, motion, and gearboxes for warehouse automation

Persistent labor shortages, economic uncertainty, and rising fulfillment demands (especially from e-commerce and 3PLs) are driving warehouse operators to adopt more fixed automation and mobile robotics. This webinar details how motion-control technologies (including robotics) are key to automating order picking, palletizing, and goods-to-person handling.

How to invest in automation

Experts from Zebra Robotics Automation detail the best ways to invest in mobile robots and automation for throughput.

Collaborative robots in machine tending, welding, and palletizing

This webinar gives manufacturing and production professionals information on a new line of collaborative robots and advanced software.

Expert roundtable on the future of warehouse automation

This webinar covers robotics trends, the growing interest in AI and humanoid robots, and the promise of “lights-out” facilities. Panelists include Lior Elazary, inVia Robotics co-founder and chief executive officer; Rob Wright, DHL Supply Chain VP OE of automation, engineering, and accelerated digitalization; Rueben Scriven, industry analyst with Interact Analysis; and Eugene Demaitre, editorial director of Design World’s sister brands in robotics.

As artificial intelligence (AI), robotics, quantum computing, and edge workloads grow in complexity, traditional silicon-based architectures may be hitting physical and architectural limits. Rising energy costs, slower data transfer, and fragmented chiplet packaging are constraining progress across industries. CDimension aims to solve these challenges, starting with new materials and progressing toward a monolithic 3D architecture based on atomically thin chiplets.

“The world’s demand for computational power is accelerating faster than traditional hardware can evolve,” said Jiadi Zhu, founder and CEO of CDimension, and an MIT Ph.D. in electrical engineering with deep expertise in 2D materials and monolithic 3D integration. “We’re no longer limited by chip architecture alone — we’re constrained by the physical materials themselves. To move forward, we must rebuild the foundation.”

At the core of the company’s commercial debut is a proprietary lowtemperature process that enables the direct growth of ultra-thin 2D materials, such as molybdenum disulfide (MoS₂), onto finished silicon wafers without damaging underlying circuitry. The resulting layers are atomically thin, low-leakage, and energy efficient, supporting dense vertical stacking and enabling new levels of integration. While 2D materials have long held promise for next-generation chips, manufacturing and integration hurdles can slow adoption. CDimension claims its process overcomes these challenges with an Si back-end-of-line (BEOL) compatible approach that supports uniform, wafer-scale monolayer film growth across full silicon wafers, a key step in moving 2D materials from lab

experiments to scalable commercial use. In internal testing, CDimension says its materials have demonstrated up to 1,000 times improvement in transistor-level energy efficiency compared to silicon.

“2D materials have enormous potential in many areas, especially for the semiconductor industry and future computing, and the development of successful wafer-scale synthesis is the key to unlock many of these possibilities for the future,” said Jing Kong, faculty member at MIT.

In addition to MoS₂, CDimension provides a full suite of 2D materials, including n-type, p-type, metallic, and insulating films, via a wafer-scale deposition process compatible with silicon manufacture. This allows integration with existing manufacturing workflows and forms the materials backbone of CDimension’s broader vision to unify compute, memory, and power in a single chip architecture. DW

Sustainability has become a strong driver of business value as pharmaceutical companies scale and localize operations. Digitalization works in tandem to enable sustainability-related business outcomes, especially in energy and power management, thereby driving efficiency and operational resilience.

1. Cost control. Digitally enabled energy management not only cuts carbon emissions, but it also significantly reduces energy costs. For example, with demand/response capabilities, new facilities can adjust power use in real time based on grid needs or price signals.

2. Business continuity. Power disruptions cost pharmaceutical firms millions in lost productivity and delayed customer commitments. A digitalized energy infrastructure strengthens operational resilience by improving power reliability and quality, thereby minimizing the risk of downtime. Technologies such as combined heat and power (CHP), solar, wind, and battery storage bolster energy security, and microgrid systems provide islanding capabilities that maintain production during local grid outages or fluctuations.

3. Time-to-market. Engaging partners early in the planning phase can significantly accelerate time-to-market. For example, with tools such as Digital Twin, experts can simulate and optimize the plant’s power systems before construction begins, ensuring energy-efficient design from day one.

With rising cost pressures and renewed focus on U.S. manufacturing, leaders can also account for global export market expectations. Designing a future-ready, sustainable facility positions firms to adapt to evolving demands locally and globally. DW

siemens.com

WHITTET-HIGGINS manufactures quality oriented, stocks abundantly and delivers quickly the best quality and largest array of adjustable, heavy thrust bearing, and torque load carrying retaining devices for bearing, power transmission and other industrial assemblies; and specialized tools for their careful assembly.

Visit our website–whittet-higgins.com–to peruse the many possibilities to improve your assemblies. Much technical detail delineated as well as 2D and 3D CAD models for engineering assistance. Call your local or a good distributor.

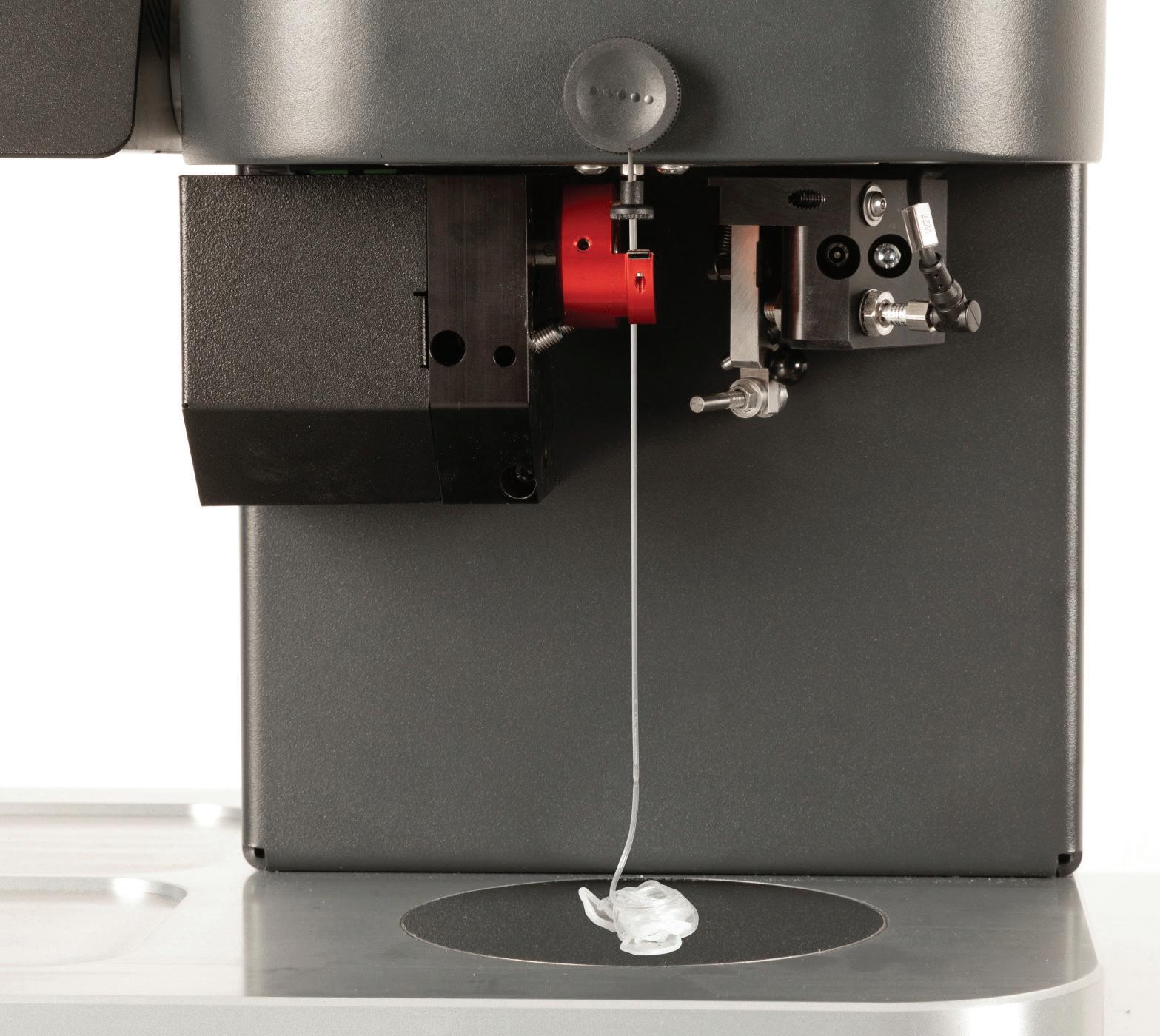

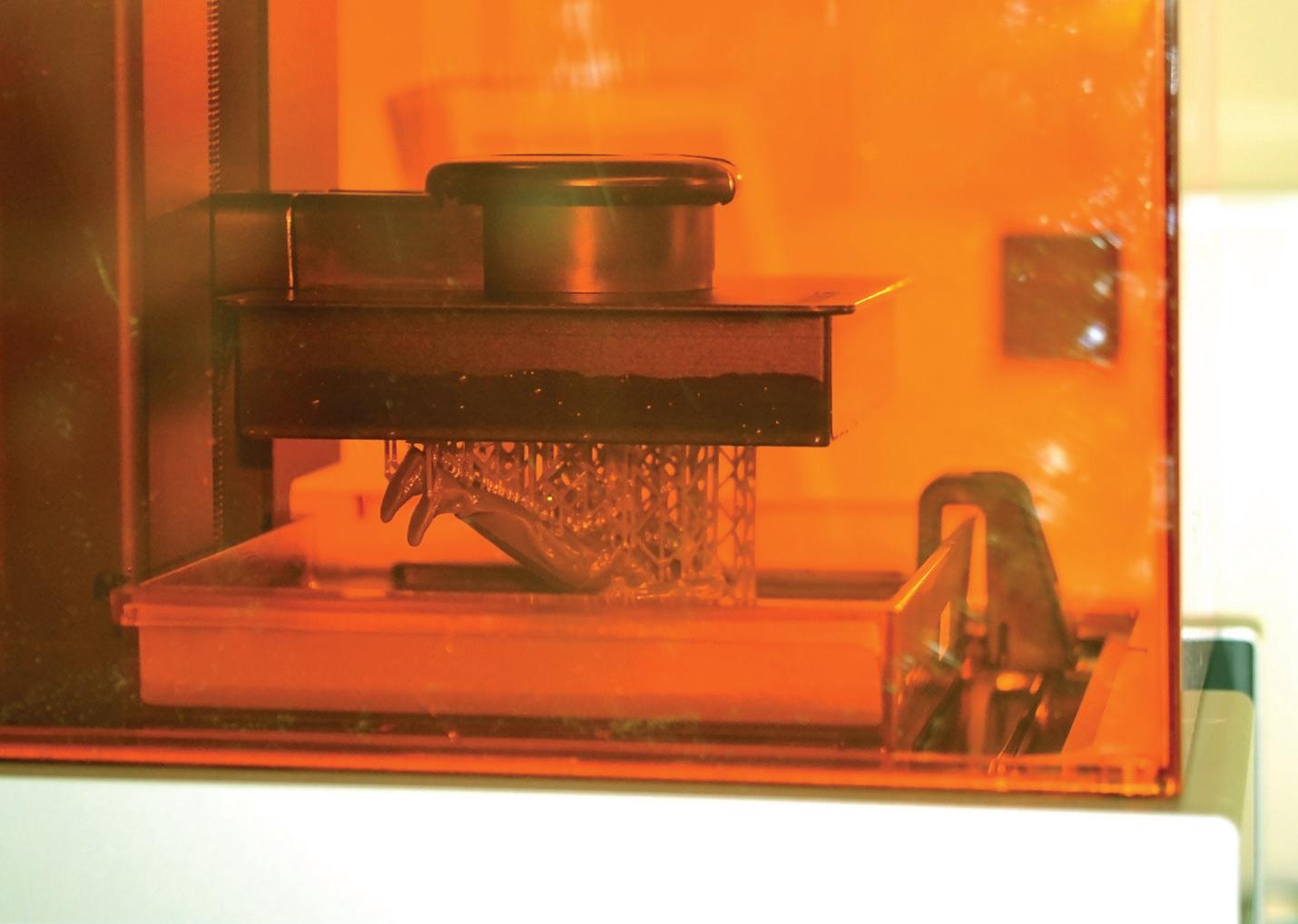

With global plastic production soaring to almost 450 million tonnes annually, slight variations in polymer quality can quickly cascade, leading to scrap, downtime, or even recalls. Stephanie Williams, senior product specialist at Instron, states that melt flow testing (MFT), a precise “flow speed” test, helps ensure consistency and efficiency in polymer processing for medical device manufacturing.

During MFT, molten polymer is forced through a die under standardized conditions, yielding a melt flow rate (MFR) in grams per 10 min (g/10 min).

While high MFRs can ease mold filling and cycle times, they can also signal thermal degradation, especially in engineering materials such as polycarbonates or acrylonitrile butadiene styrene (ABS), risking weaker, crackprone parts. Conversely, low MFRs usually indicate stronger molecular chains but complicate processing due to higher viscosity and greater energy demand. For quality assurance, however, MFR can also reveal inferior or incorrect products. MFT also aids production-floor quality control. For example, a medical device maker faced complaints about

hairline cracks in prefilled syringes after shipment. MFT confirmed the pellets used for the syringes met viscosity specifications and, therefore, the manufacturer had received the correct batch.

This knowledge enabled the company to shift focus to its production processes. Upon investigation, an unevenly heated cavity in an injection press caused poor flow and weak walls. Without MFT, blame might have fallen on suppliers, leading to wasted material and regulatory issues. Instead, fast, consistent MFR results enabled targeted fixes and prevented costly disruptions.

Additionally, with sustainability goals now mainstream, compounders are increasingly using recycled or mixed-source polymers, with forecasts predicting the global recycled plastic market will reach $107 billion by 2032. With this shift comes variability in composition and degradation, and makes ensuring consistent processing and performance more important than ever.

MFT offers a quick check. If a recycled HDPE batch shows an MFR of 25 g/10 min instead of the expected eight, it may indicate degradation or contamination. While MFT cannot identify exact chemistry, it can flag nonconforming batches before they reach production. For compounders, tracking MFR helps determine whether a batch meets specs, needs blending, or should be rejected.

With millions of tonnes of plastic produced each year, ensuring consistent polymer quality through melt flow testing is vital to reducing waste and preventing defects. DW

Instron • instron.com

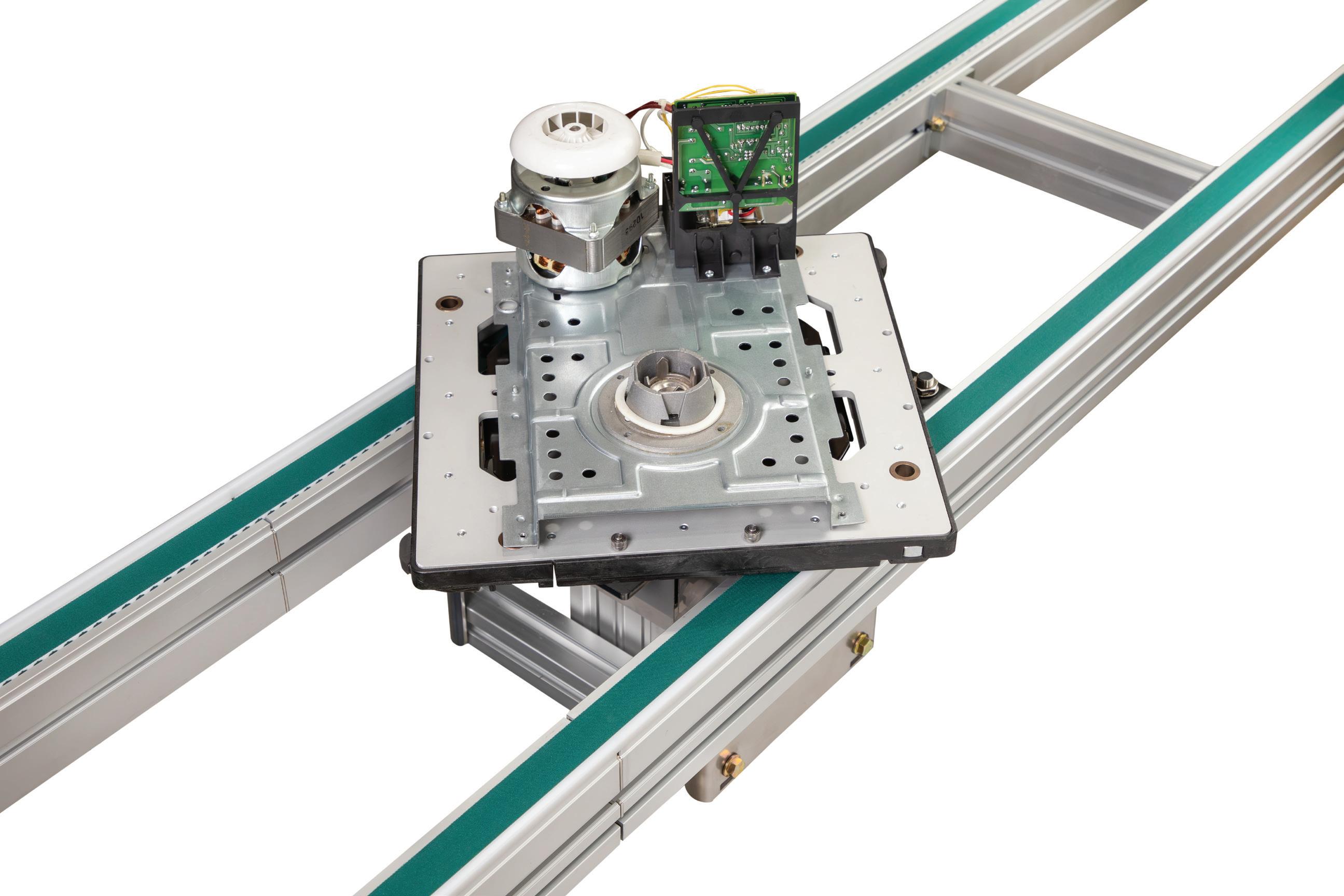

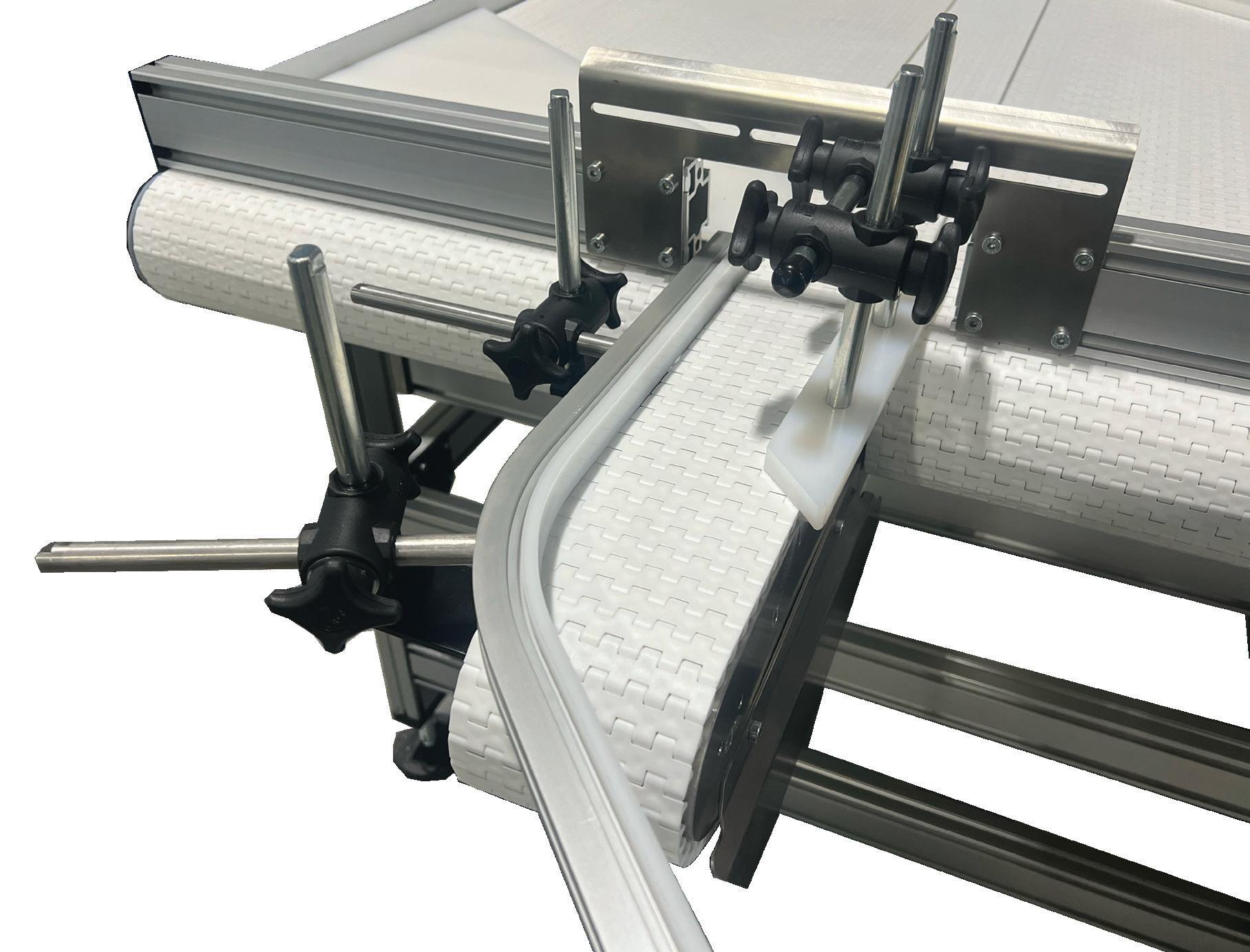

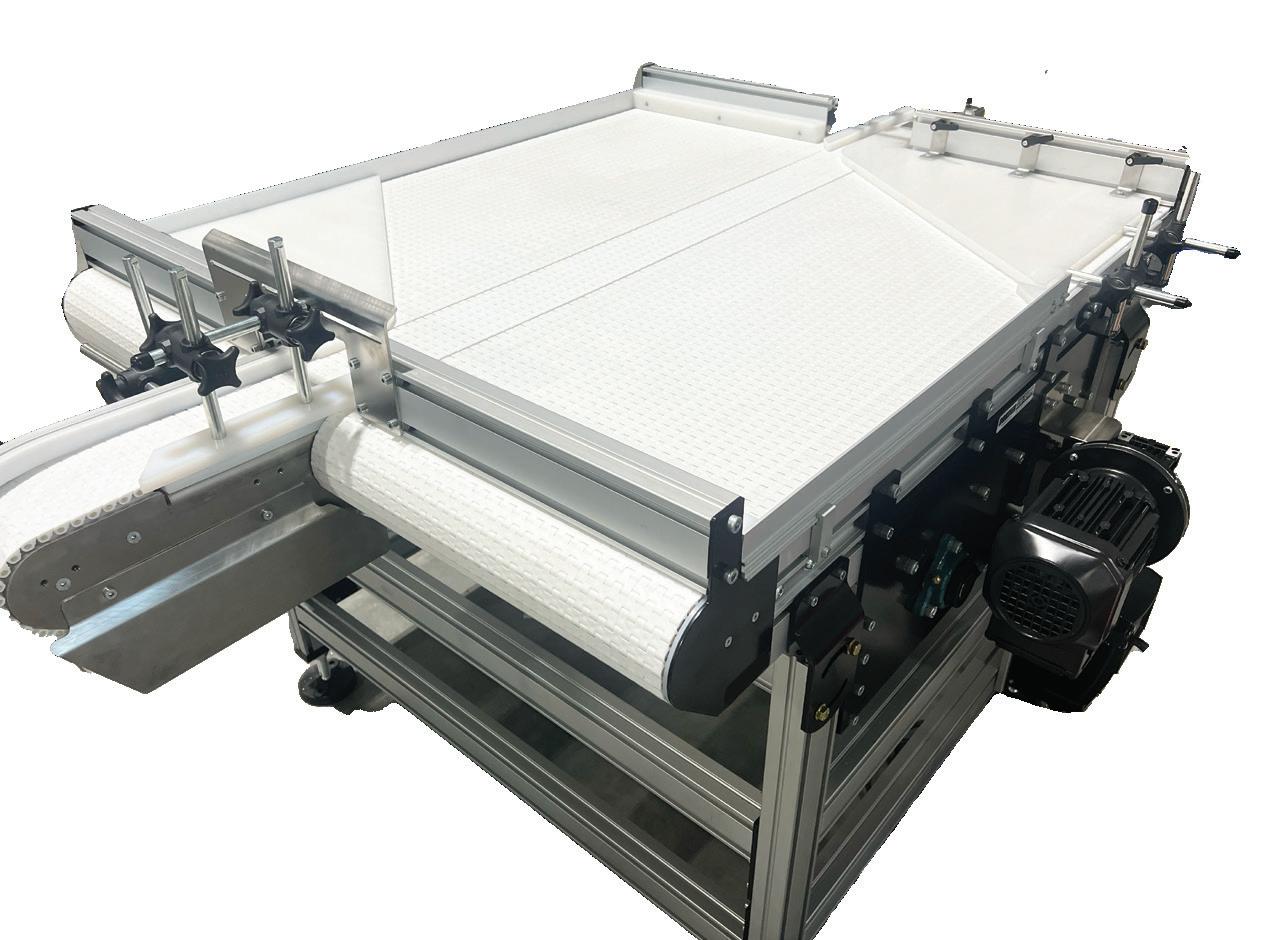

Speed is of the essence for packaging machines: Products must be filled, reliably sealed, and prepared for shipping in the shortest possible cycles. Ideally, maintenance and unplanned downtime are rare to keep the total cost of ownership low. The list of requirements is long and applies to the packaging machine itself and its components, such as the drive technology.

The Belgian company Scaldopack develops, produces, and services advanced spout-inserting machines and pouch-filling and sealing machines. The manufactured packages must be of very high quality, with a low error rate, stable production speeds, and high machine availability. At the same time, flexibility is also important, as their systems are converted from one batch to the next in a short time. Depending on the system and application, changeover times range from a few hours to less than 30 minutes.

Scaldopack uses Faulhaber BLDC motors in their machines, which operate around the clock, seven days a week. The direct linear drives with built-in Hall sensors enable a position accuracy of up to 0.1 mm with an acceleration of up to 4 g. This allows the machine to move pouches quickly and precisely to the proper filling position. There, they are filled and sealed with the correct quantity, then stacked in displays for shipment or sale.

Because floorspace in production facilities is often expensive and limited, the systems need to occupy as little space as possible. In the compact machine, the drive unit has a volume of 22 x 22 x 74 mm, achieves a peak force of 27 N, and can operate continuously for nearly three years without maintenance.

In addition to the drive’s reliability, system integration and machine operability are also

decisive factors. The MC 3603 motion controllers perform the position control in the machines. Using standardized communication interfaces, such as RS232, EtherCAT, or CAN, control setpoints can be easily set, or the drive can be integrated into the automation system. In Scaldopack’s application, the motion controller’s CiA402 compatibility enables integration with the filling system's EtherCAT control system, simplifying integration

and required tests. This allows the company to optimally match drive systems and machines to achieve peak performance. The application makes clear what a decisive role dynamic, precise, compact, lowmaintenance, and easy-to-integrate drive technology plays in the automated packaging industry. DW

Faulhaber • faulhaber.com

The energy industry has long considered hydrogen a promising, sustainable, renewable energy source. However, the technical complexity of liquid hydrogen refueling challenges infrastructure designers seeking to match the operational speed and reliability of diesel systems. Bosch Rexroth’s CryoPump stations, unveiled at Hannover Messe 2025, introduce an electro-hydraulic solution that

addresses these constraints by departing from conventional crankshaftbased pump designs.

Developed in partnership with FirstElement Fuel, a California-based operator of commercial hydrogen stations, the system has two hydraulic stages, each with two hydraulic cylinders powered by electric motors. The CryoPump employs an extended stroke length design that minimizes

load changes and reduces mechanical wear. This approach achieves efficiency levels exceeding 95% while extending maintenance intervals beyond 4,000 hours.

This two-stage pump design allows direct refueling of liquid and gaseous hydrogen without intermediate storage tanks at filling stations, simplifying site infrastructure and reducing the number of pressure vessels required for

operation. This direct-fill architecture streamlines the overall system design while minimizing potential leak points in the hydrogen pathway. With a delivery rate of 600 kg/h, the CryoPump system can fill a Class 8 truck in less than 10 minutes.

Additionally, the system’s compact footprint of less than 11 m3 and noise level below 65 dB(A) enable integration into new and existing fuel station layouts, including residential areas. The design also incorporates AI-supported condition monitoring for predictive maintenance scheduling. Plus, Bosch Rexroth claims that investment costs can be reduced by up to 50% by dispensing with highpressure accumulators and cooling power units.

“Everybody thinks it’s the cost of the molecule, that the hydrogen cost is high. That’s not really the case,” said Dave Hull, regional VP at Bosch Rexroth. “The equipment around the delivery of hydrogen is really immature, it breaks all the time, and it drives the operational expenses of your station really high.”

The CryoPump stations aim to address a fundamental infrastructure gap in hydrogen mobility by accelerating refueling, increasing profitability for operators, and improving the usability of hydrogenpowered commercial vehicles.

Bosch Rexroth boschrexroth.com

• EDITED BY MIKE SANTORA

Why use two bags when you can use one? Too often, we take more steps than necessary to accomplish a task. It sometimes demands an outside perspective to gently point out a more efficient solution that makes life easier — which is what Cortec distributor Lake Engineering Solutions did for an aerospace company by streamlining its packaging process down to one bag instead of two.

Packaging protection for precision machined parts

The client demanded strict quality control to ensure the integrity of precision machined metal parts used in the internal build of aircraft wings and doors. That meant both corrosion and mechanical protection were needed during the unpredictable shipping and handling stage. Lake Engineering Solutions had already met

the first need with VpCI-126 Top-Seal bags that protected the components via a molecular layer of Vapor phase Corrosion Inhibitors which left the parts dry and ready to install. The second layer of protection came from standard bubble bags that provided cushioning on the way to the assembly plant.

Strict quality control was necessary to ensure the integrity of precision machined metal parts used in the internal build of aircraft wings and doors.

A streamlined solution for packaging sensitive aerospace components

One day when visiting the client, Lake Engineering noticed the doublebagging process and suggested a customized solution: replace two bags with one Cortec Cor-Pak VpCI-126 Bubble Bag (also known as VpCI126 Bubble Bag with sealable lips) that provided dual cushioning and corrosion protection. The manufacturer adopted the solution and immediately began saving time by eliminating an extra packaging step while achieving a high level of protection up to company specifications.

One day when visiting the client, Lake Engineering noticed the double-bagging process and suggested a customized solution: replace two bags with one Cortec Cor-Pak VpCI-126 Bubble Bag (also known as VpCI-126 Bubble Bag with sealable lips) that provided dual cushioning and corrosion protection.

and color-coded stickers for easy identification and traceability. These measures guaranteed consistent, robust protection and aligned with the company's commitment to quality and operational excellence in the aerospace sector.

Similar measures can be taken in any industry that requires multifunctional packaging protection such as corrosion + cushioning protection or corrosion + ESD protection.

To further reinforce the integrity of their packaging process, the company introduced a comprehensive tracking system. This included a strict non-reuse policy, date monitoring, Coretec • cortecvci.com

Lead Times!

® ® Interpower® manufactures North American and international cords, cord sets, and IEC 60320 components with over 2 million products in stock. Need cord clips molded onto your cords to prevent tripping? Need your cords hanked, coiled or tied? Bagged and boxed? Want barcodes to place your cords in the exact aisle and bin for storage? Need filters, ferrites or ferrules? Ring or spade terminals? Heat-shrink tubing? NO minimum order requirements? Try Blanket or Scheduled orders for one calendar year—Blanket ordering: lock in your price, and order cords throughout the year when you need them. Scheduled orders: set predetermined dates year-round to receive your cords.

Toll-Free Phone: (800) 662-2290

E-mail: info@interpower.com

Business Hours: 7 a.m.–5 p.m. CST Order Online! www.interpower.com

• EDITED BY MIKE SANTORA

The P60 combines electro-mechanical actuators with integrated pneumatic support to deliver highfidelity motion with significantly reduced energy consumption.

Moog Inc. a worldwide designer, manufacturer, and systems integrator of precision motion and fluid controls and control systems, has upgraded its motion systems: the all-electric E60 Series and the electro-pneumatic P60 Series, both are now globally available. Designed for Level D flight training as well as vehicle and maritime simulation, both platforms support up to 14,000 kilograms of load capacity and deliver precise motion fidelity for professional training environments.

“Our redesigned motion systems improve reliability, simplify maintenance, and enable operators the flexibility to adapt to evolving technologies,” said Noud van Bavel, Global Marketing Manager, Simulation & Test at Moog.

With multiple actuator stroke length selections up to 62.5-in., the E60 is Moog’s largest standard electric motion system. Its electro-mechanical platform delivers precise motion control, while integrated diagnostics reduce maintenance and operating costs. The E60 Series is a fully electric 6-DOF motion system tailored for aviation training centers and other

high-precision applications ranging from vehicle simulation to entertainment.

Key Benefits

• Reliability: Improves Mean Time Between Failures (MTBF) by 15% and eliminates traditional battery systems, ensuring longterm consistent performance.

• Design: A 50% smaller power cabinet saves valuable floor space.

• Performance: Achieves 99.8% uptime and meets Level D certification requirements with industry-leading motion fidelity.

• Operation: Modernized electronics and removal of battery systems reduce energy use and environmental impact.

The P60 combines electro-mechanical actuators with integrated pneumatic support to deliver high-fidelity motion with significantly reduced energy consumption. Optimized for Full Flight Simulator applications, it offers up to 75% lower energy usage compared to fully electric systems.

Key Benefits:

• Efficiency: Pneumatic support reduces energy consumption by up to 75% compared to fully electric systems, significantly lowering operational costs and environmental impact.

• Reliability: Achieves 99% uptime with field-replaceable shocks and a maintenance-free lock spring system that replaces the mechanical brakes of Moog’s prior electropneumatic motion systems.

• Motion Dynamics: State-of-the-art actuators with pneumatic support deliver exceptionally accurate and high-fidelity motion cueing, essential for both fixed-wing and rotary-wing flight training.

• Design: Reduced actuator peak forces by using bi-directional reusable end-of-stroke buffer result in smaller joints. Smaller and thus lighter moving joints increase payload capacity while reducing system footprint. DW

Moog • moog.com

In applications that continually push technology to its limits, using high fidelity and reliable simulation systems is critical for your success.

Advanced simulation motion systems enhance realism and immersion in various industries. MOOG caters primarily to flight simulation solutions, entertainment simulation platforms, and driving simulators, creating motion solutions that replicate real-world dynamics. Its systems use cutting-edge technologies to generate smooth and realistic movements with 6DOF systems, thereby improving training effectiveness, user feedback, and overall training value. Beyond standard applications, the company develops customized solutions including virtual reality flight demonstrators, sophisticated control loading mechanisms, G-seats that provide force feedback, and vibration platforms that simulate environmental cues, all tailored to meet users’ exact specification needs.

Moog is focused on engineering the latest technologies into its systems for long-term reliability, efficiency, and integration flexibility. The offerings are designed to seamlessly blend hardware and software components, ensuring scalable and adaptable solutions for complex simulation setups. By focusing on user-cues and a technology agnostic approach, these systems use hydraulic, electric, and hybrid powered configurations.

While Interpower may not manufacture 50 million NEMA and international power cords each year, they do offer at least 50 different cord set customizations, value-added components, and services no one else in the industry can do inside a 1-week U.S. lead time. From customized cord lengths and colors to cord clips, to multiple packaging and labeling options, specialized barcoding, and shipping options—these components and services help customers stay on schedule. Our cord sets provide correct amperages and voltages for every country-specific mains power.

Phone: (800) 662-2290

info@interpower.com

Hours: 7 a.m.–5 p.m.

CHUCK LEWIN FOUNDER & CEO PERFORMANCE MOTION DEVICES INC.

T here are two types of servomotors commonly used for positioning motion control applications — the dc brush motor (which uses mechanical brushes to commutate the motor) and the brushless dc motor. The latter is also known as the BLDC motor or ac synchronous motor and is electronically commutated by external circuitry.

Unlike stepper motors that move in discrete position steps, servomotors

don’t have a built-in sense of where they are so need feedback (as from an encoder) to control position. A position servo loop drives the motor to a given position. It does this by comparing the target position from the trajectory generator at any given moment with the actual motor position and applying a continuous correcting motor command.

Consider the control-flow diagram for a general-purpose positioning

PROPORTIONAL, INTEGRAL, DERIVATIVE (PID) POSITION SERVOLOOP TUNING CAN BE DAUNTING. HOWEVER, ONE SIMPLE TECHNIQUE WORKS WELL FOR MOST SYSTEMS.

servomotor controller. A host specifies high-level commands such as move from point A to point B using this set of trajectory parameters … then the motion controller’s profile generator continuously generates a commanded position input to the position control loop, followed by a current control loop and amplifier.

Theorists and engineers have developed various servo-position

This is a general-purpose servomotor-positioning control diagram.

control schemes, but the most common for motor positioning is the PID loop. Digital PID loop variations abound but are based on the simplified PID position loop.

A PID position loop is tuned by setting values for the proportional gain Kp, integral gain Ki, and derivative gain Kd which in turn determine their relative influence on the controller’s final output. In its basic form, the PID position loop only requires settings for these three parameters. That said, other commonly used settings are the integral limit, the derivative sample time, and feedforward gains.

PID filter essentials

In the PID position loop diagram the ‘loop’ part of the controller is the summing junction at which actual position is subtracted from commanded position to generate a position-error value. The PID part of the controller is actually a type of filter known (not surprisingly) as a PID filter. The PID filter takes as input a stream of position error values and generates as output a stream of commands to a current loop, or for some systems a velocity loop.

Tuning a position PID loop doesn’t require knowledge of how a PID filter is calculated, but the basic equation is shown below. This PID filter value (as well as its inputs) are updated and calculated at each servo loop update. Modern motion controllers operate with servo loop update rates anywhere from 1 to 80 kHz with 10 to 20 kHz typical for general-purpose small-motor controllers sized NEMA 17 through NEMA 34.

Where En = Current position error value; En-1 = Previous position error value; and Sum(En) is the sum of En values past and present.

A key reason that the PID position control loop is so widespread is that the effect of its constituent P, I, and D can be easily described and understood.

The P term is called the proportional term because it provides a proportional restoring correction to the amplifier output command. When presented with the position error the P term functions such as a spring. The larger the servo’s position error, the larger the corrective restoring motor command.

The I term is the integral (or integration) term because it integrates (over time) the servo position error. This is useful as a proportional term alone can’t arrive at the exact commanded position when subject to forces or mechanical issues such as gravity, stiction, and motor detents. The I term

crescendos over time and can get the servo surmount to the final target position.

The contribution of the D term is calculated by subtracting the previous position error from the current position error. It provides a feedforward boost whenever the profile velocity increases or decreases, and it provides a general purpose drag term to damp oscillations.

Industry staple: Step-response tuning

The most common manual-tuning method to determine PID gain values is the step-response method or step response tuning. This approach leverages the reaction of the motor to an instantaneous (step) change in commanded position.

Manual tuning is relevant because many motion control vendors, in addition to auto-tuning tools, supply tools that help with manual tuning. After all, auto-tuners don’t always devise the best tuning values, and many autotuners don’t determine all the settings offered by a position loop. Of course, manually tuning a motor-driven axis is also a great way to get an intuitive feel

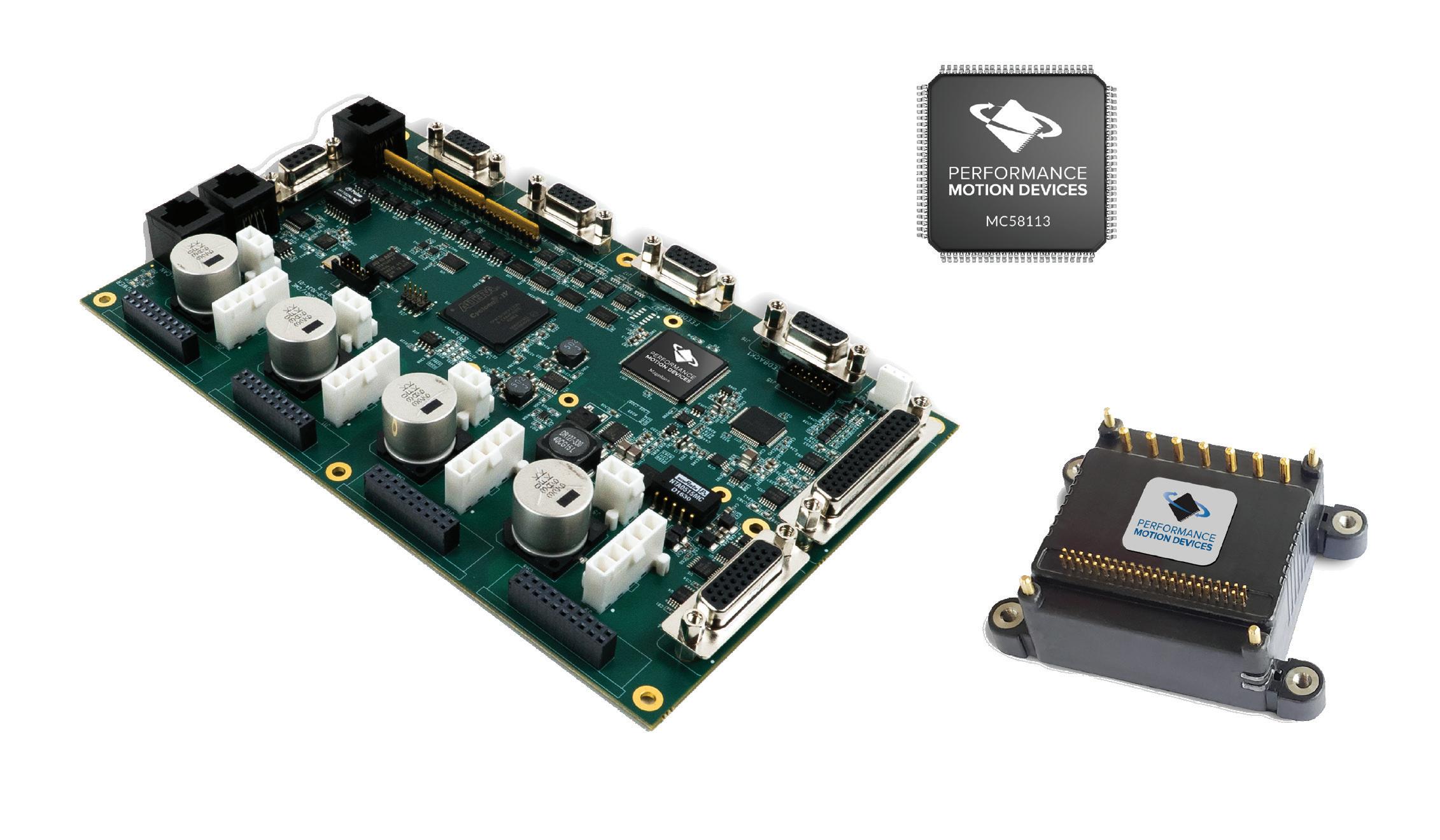

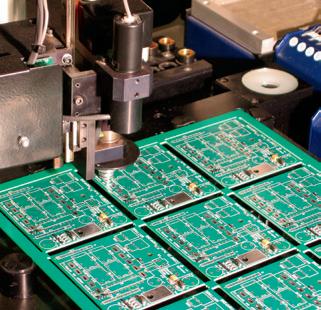

Performance Motion Devices’ Prodigy/CME machine controller boards provide high-performance motion control for medical, scientific, automation, industrial, and robotic applications. Available in one, two, three, and four-axis configurations, these boards support dc brush, brushless dc, and stepper motors … plus accept and run user-written C code. Atlas amplifiers onboard the Prodigy/CME eliminate the need for external amplifiers.

•

Solid or hollow shaft, high performance, housed and frameless, brushless motors and matching drives for demanding applications.

Hall or sensorless motors and drives for surgical tools, aerospace, military, and scientific instrument applications. Custom drive programing and designs available.

Motors up to 95% efficient, power up to 1,500 watts. Highest power density in the industry.

Operating temperatures from -73C to 150C

Slotless and slotted designs. Available with encoders and gearheads and separate or integral electronics. Quantities 1 to 5,000.

for how changes to the P, I, and D gain values affect axis behavior.

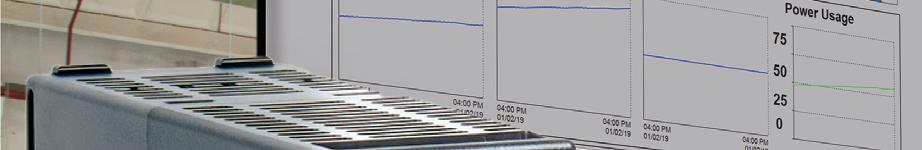

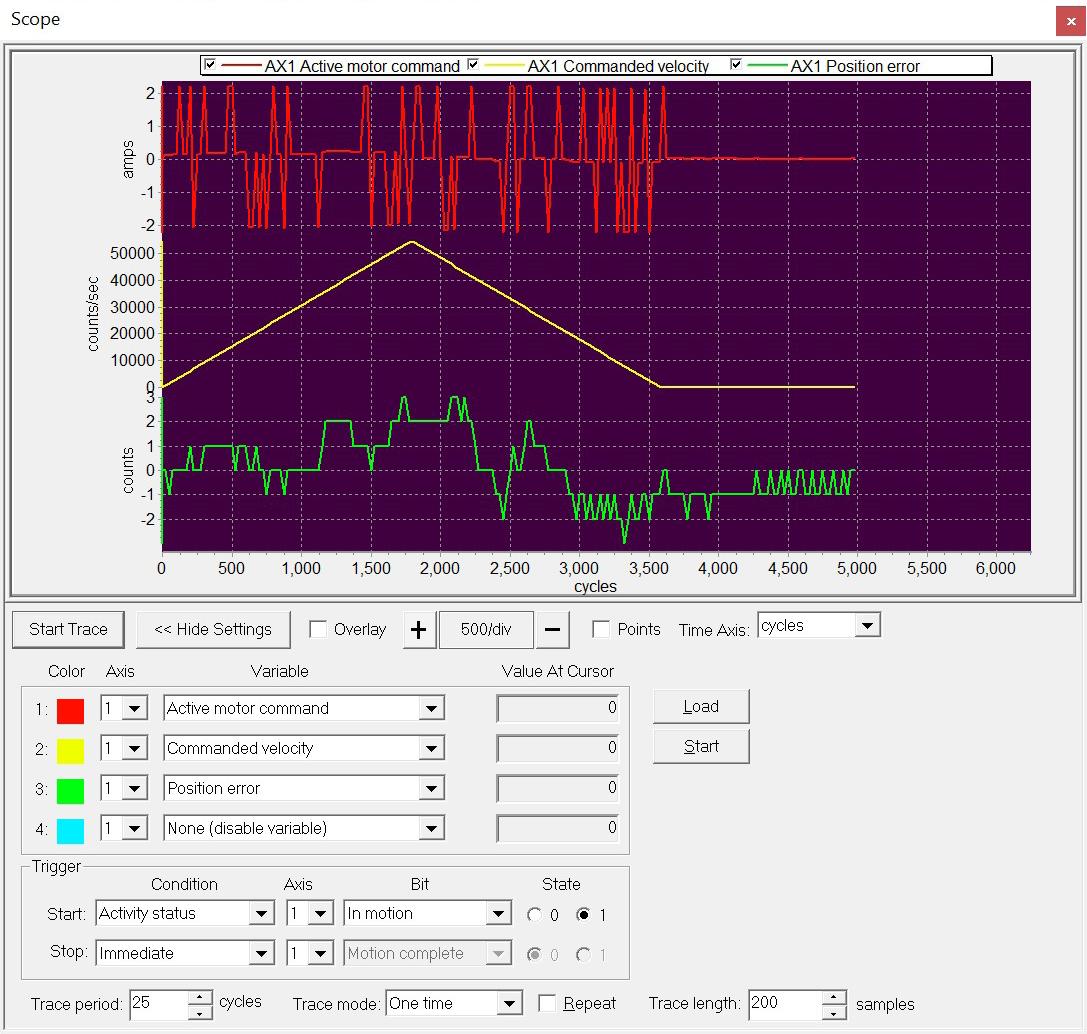

To make step response tuning work, or for that matter any manual tuning method, we need a position trace facility to display the results of the moves. At a minimum we need to display a stream of captured values of the target position (commanded by the trajectory generator) and the actual position (as the motor’s measured location).

Consider the screencapture of such a facility — motion scope and trace software from one motion supplier. In fact, design engineers can use this software, similar products from other motion-control vendors, or even systems developed in-house.

Once the motion controller as well as the motion trace and display software tools are in place, the actual mechanical system that will be tuned should be added. For most engineers the goal is to determine PID gain parameters that will smoothly and accurately operate the machine with significant stability margin.

In fact, this can be more complicated than it sounds because the axis and attached mechanisms being tuned may involve variable loads and operating modes.

So engineers should consider the specific operating condition of for which the controlled mechanism will be tuned. Often servomotor-system tuning starts sans load www.koford.com Contact us at mail@koford.com

or load mechanism. Tuning just the motor is a good first approach because from that baseline one can progressively add more realistic conditions. For example, after tuning just the motor one can connect the mechanism with no load, then one can add the minimum expected load to the mechanism, followed by the maximum expected load.

Having multiple PID settings for various mechanism configurations can also be useful in its own right. Many control systems apply different gain settings depending on the load or performance goal for a given operating mode. As we’ll explore, the PID gain settings that reach the highest end point positioning accuracy may be different than for those used to rapidly slew from one machine operating area to another.

With capture and display software in place with the mechanism to be optimized, tuning can happen in five steps.

Step 1 is to setup the motion-trace capture facility. Different terminology may apply according to the vendor but in PMD’s

PMD has been producing ICs that provide advanced motion control of dc brush and brushless motors for more than 25 years. The supplier has also embedded these ICs into plug-and-play modules and motioncontrol boards. While different in packaging, all these products are controlled by C-Motion — PMD’s motion control language.

system one will set the trace capture system to trace Active Motor Command as the first variable, Commanded Position as the second variable, and actual position as the third variable. An optional fourth variable is position error, but defining this isn’t necessary for the procedure described here.

Step 2 is to setup the motion controller to make an ‘instantaneous’ step move from the current to a programmed destination position. Motion controllers from certain suppliers have a direct step-response mode that lets engineers simply enter the step distance. One caveat: The engineer may need to select a profiling mode (such as trapezoidal point-to-point) and program it with extremely large velocity and acceleration values, so the effective profile move time is close to zero.

One note when setting the step distance: During the step response move, the amplifier command shouldn’t go to 100%. Say the current limit for a given motor is 5.0 A and the controller is properly set so it doesn’t exceed that amplifier command value. Well, if the traced motor-current command reaches 5.0 A, the step distance should be lowered to prevent the servo output from being saturated.

Step 3 (for controllers with certain PID control settings) is to set the integral gain Ki, integral limit Ilim, acceleration feedforward gain Kaff, and velocity feedforward gain Kvff to zero. Proportional gain Kp is then set to a small value — perhaps 10 to 50 for motors

is an example of a system capture made with PMD’s Pro-

LEFT: Pro-Motion software is PMD’s Windowsbased exerciser and motion-analysis program. Capabilities including a step-by- step motor setup axis wizard, auto-tuning, configuration storage, and sophisticated motion data trace and display. Advanced users can access a complete motion-analysis package with Bode plot generation.

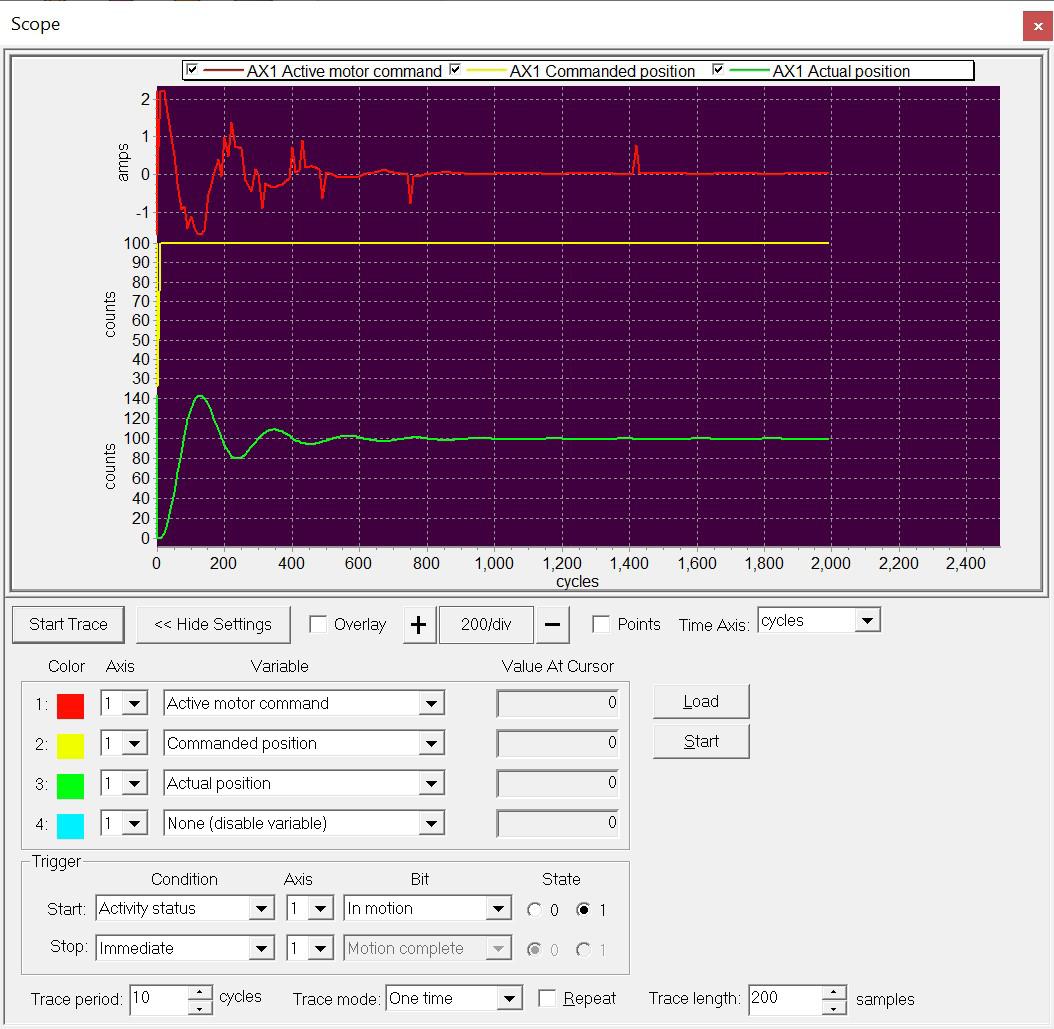

This is a screencapture showing a typical underdamped response. The yellow trace shows that the commanded position instantly changes from 0 to 100. Here, this jump will equal whatever one entered into the step response dialog box. The green trace shows the actual motor location that results.

with quadrature encoders. Then Kd (derivative gain) is set to a value fivefold the specified Kp value. Finally, for small motors such as NEMA-17 motors, set the initial derivative time to 0.25 mSec; for NEMA-23 motors, set to 1.0 mSec; and for NEMA 34 or larger set to 2.5 mSec.

Note that initial gain settings are controller-specific, engineers new to the controller will need to experiment. When in doubt, use lower values of Kp.

Step 4 is to execute the step move. This should quickly spur the trajectory generator (in a single instantaneous step) to command a move having the programmed step distance. Assuming the trace function has been synched to the move start, a trace scope window will then display data. Adjustments to the data capture and scope display may be needed to get the full trace of interest on a single screen.

Uncontrolled motor oscillations mean Kp should be set to a lower value and

Step 4 repeated. If at any point there’s concern that the motor or power supply is over-stressed, the controller should be disabled. If the motor produces a highpitched chatter or whine, KD derivative gain can be lowered or derivative time increased.

Step 5 is next once the position loop is at least somewhat stable. Then comes this repeating sequence:

• View the scope display to determine whether the response is underdamped, critically damped, or overdamped (as described below).

• Adjust the gain settings accordingly.

• Make another step move (as in Step 4).

The next three sections will show one how to characterize the step move response and how gain settings should be adjusted.

Underdamped servo response curve: Refer to the screencapture showing a

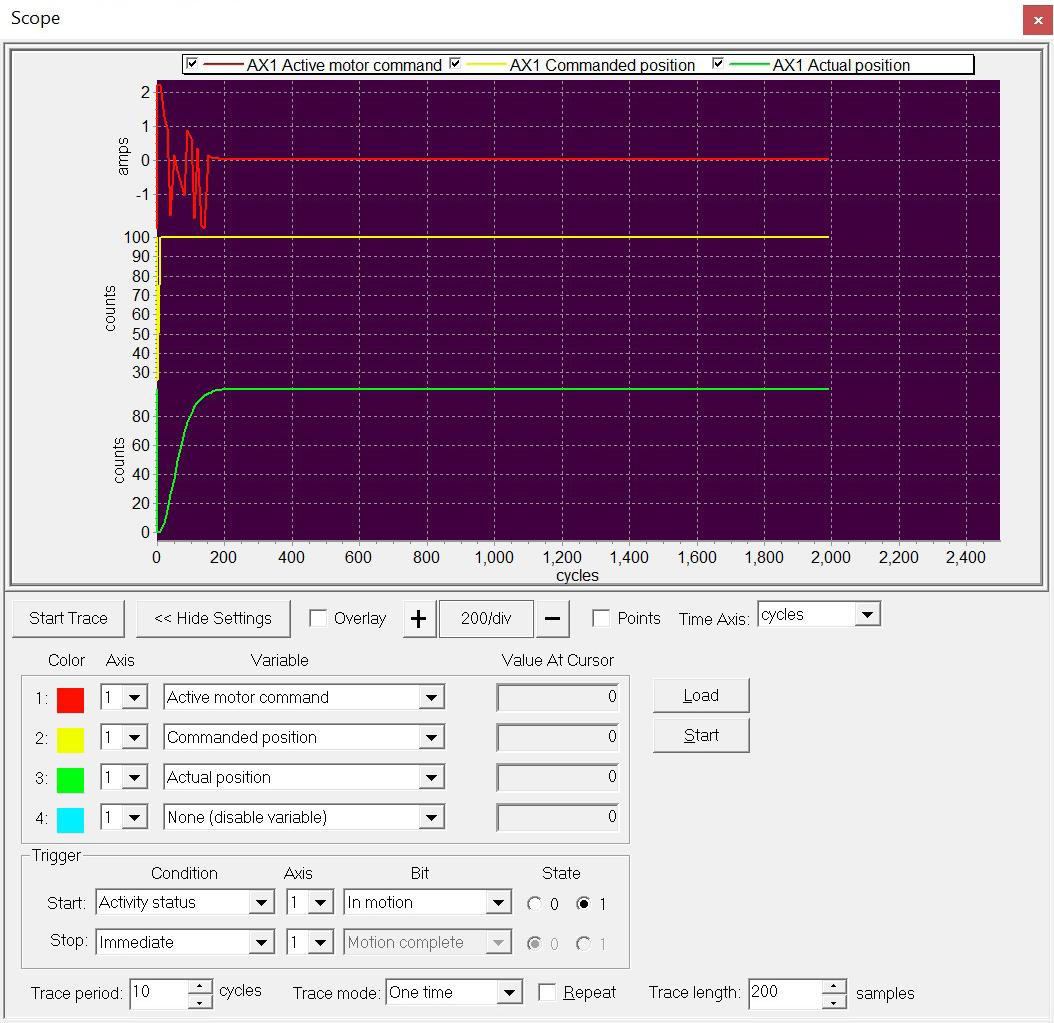

LEFT: This is an example screen from PMD’s Pro-Motion Windows-based motion scope and trace software — more specifically, the plotted response of a critically damped system. This sample capture and display software can help design engineers in their servotuning work.

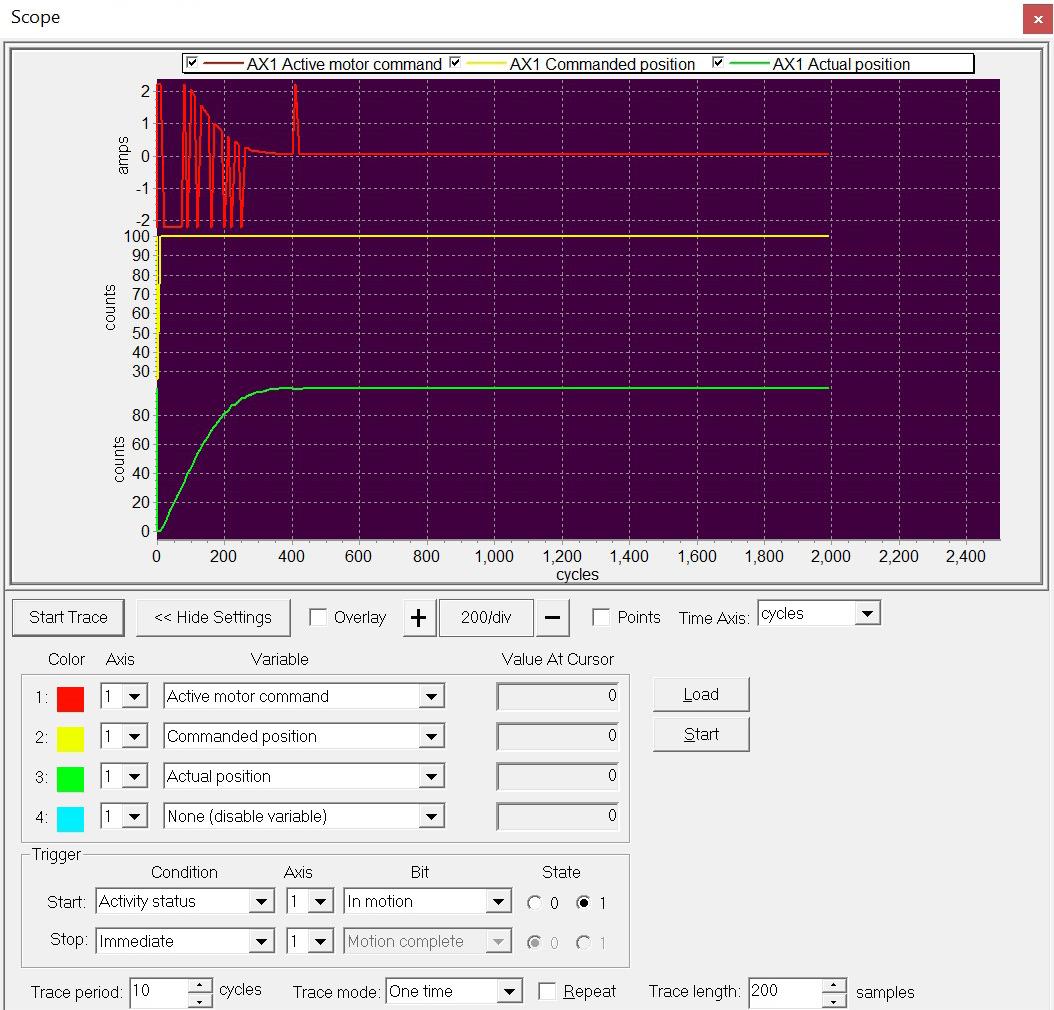

RIGHT: This is the plotted response of an overdamped system.

typical underdamped response. The yellow trace shows that the commanded position instantly changes from a position of 0 to 100. With the software being used in this situation, this jump equals whatever the engineer entered into the step-response dialog box. The green trace shows the resultant motor location.

Though actual position does eventually settle to the commanded 100, it overshoots and oscillates several times. A system behaving this way is underdamped. To correct it, the design engineer should increase the derivative gain Kd.

Lifetime Warranty Against Manufacturing Defects

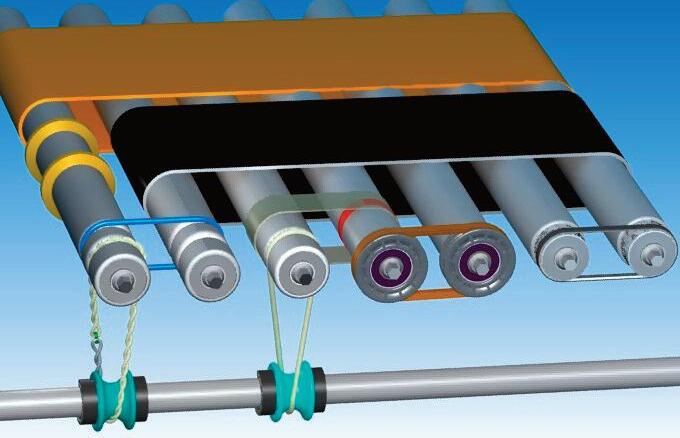

LINE SHAFT CONVEYOR BELTS - Original Equipment and Connectable CUSTOM MADE IN INCH, METRIC and O-RING SIZES

• Round, Flat and Connectable Polyurethane Belts

• Very Clean Operation

A servomotor can deliver the motion commanded by PID control. Tuning just the motor is a good first approach because

Critically damped servo response curve: Now consider the screencapture of a plot of a critically damped response. In this trace the actual position doesn’t overshoot the commanded position, and it settles quickly (in 10 msec) to the commanded position of 100. Note that in these given trace displays, the unit of time is set to servo cycles. For the controller used in this setup, that’s 50 µsec per servo cycle.

It’s worth noting that many Kp and Kd combinations may spur a response that appears critically damped. In this manual tuning process, the distinction between critically damped and overdamped is somewhat subjective.

Overdamped servo response curve: Lastly consider a screencapture showing an overdamped response and compare it with the critically damped response. An overdamped system is stable but needlessly slow in its response to changes in the position command.

If the response is overdamped one should reduce Kd to the smallest value that still yields a critically damped response.

• Eliminates Tensioning Devices

• Exceptional Abrasion Resistance

The derivative time setting is powerful. Derivative time is the period over which the PID loop derivative contribution is calculated in units of servo cycles or in milliseconds depending on how the controller is programmed. Increasing the derivative time can be useful for reducing axis ‘chatter’ by effectively introducing a low-pass filter on the PID loop’s control response. This in turn allows the effective Kd damping contribution to be increased. Again, depending on how the controller functions the impact of the Kd on the PID loop command output is a direct multiple of the derivative time. For example, if the derivative time is set to 10 and the Kd value is 100 this would be an

equivalent derivative term impact as a derivative time of 5 and a Kd of 200.

Larger motors with larger loads will generally use higher derivative time settings and vice versa for smaller motors with smaller loads. Experimentation is the best way to determine what values of derivative time and Kd gain give the quietest critically damped response.

The main position-loop tuning goal is to set Kp as high as possible while still finding an associated Kd value capable of yielding a critically damped response. Higher Kp values will spur more accurate tracking and faster responses to command position changes.

Trying higher and higher Kp values makes it clear at a certain point there’s no value of Kd and derivative sample

time that yields a stable and critically damped response. At this point one should reduce Kp by 35 to 50%, determine the associated Kd for critically damping, and use those settings as the final values for Kp, Kd, and derivative sampling time. Backing down from the ‘borderline’ Kp is key to stability, accommodating small controller and motor differences, allowing for attached hardware behavior, and handling system changes over time.

Once Kp, Kd, and derivative time have been set, one can enter a value of Ki (integral gain) to improve tracking accuracy. It depends on the controller scaling but typically Ki settings are a tenth to half the Kp value. Smaller motors typically use relatively larger ratios, and larger motors with larger loads typically use smaller Ki ratios.

Higher Ki settings increase tracking accuracy during and after the motor move is complete but can also reduce system stability. So, one should set Ki to the smallest value that can reach goals for tracking accuracy while not distorting the critically damped response the Kp and Kd settings created.

For most controllers the integral limit Ilim setting can be left at a very large value to effectively disable it as an integration-value limit. Most controllers including many position and velocity motion controllers have built-in anti-windup logic so it’s unlikely this integration limit will ever be reached. DW

Performance Motion Devices pmdcorp.com

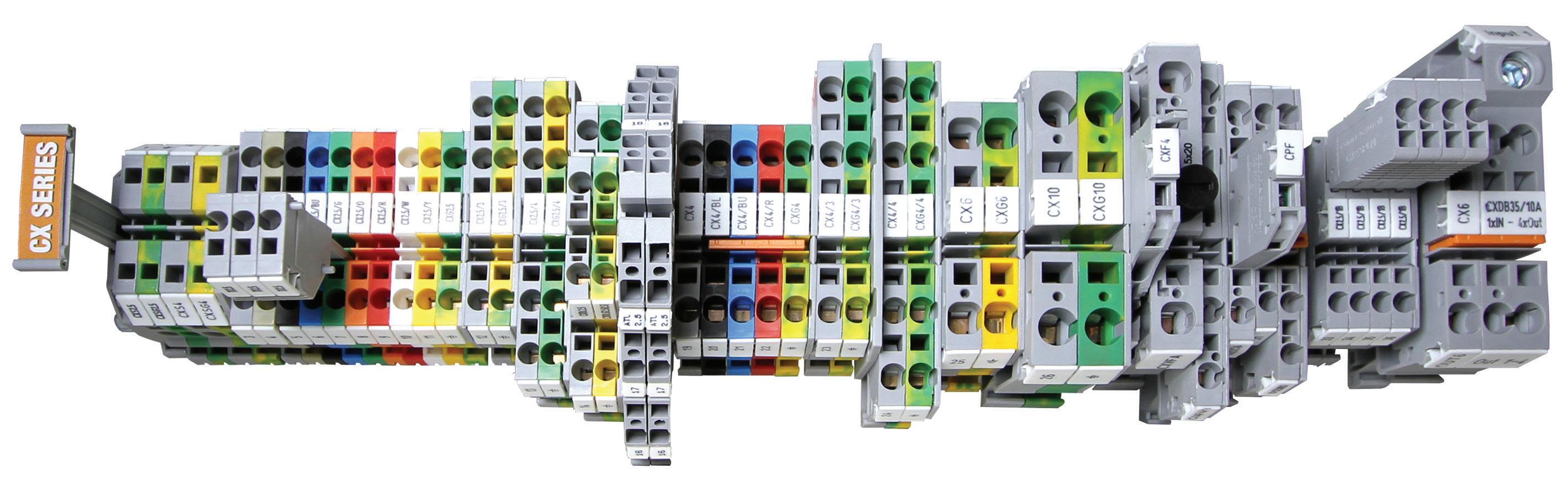

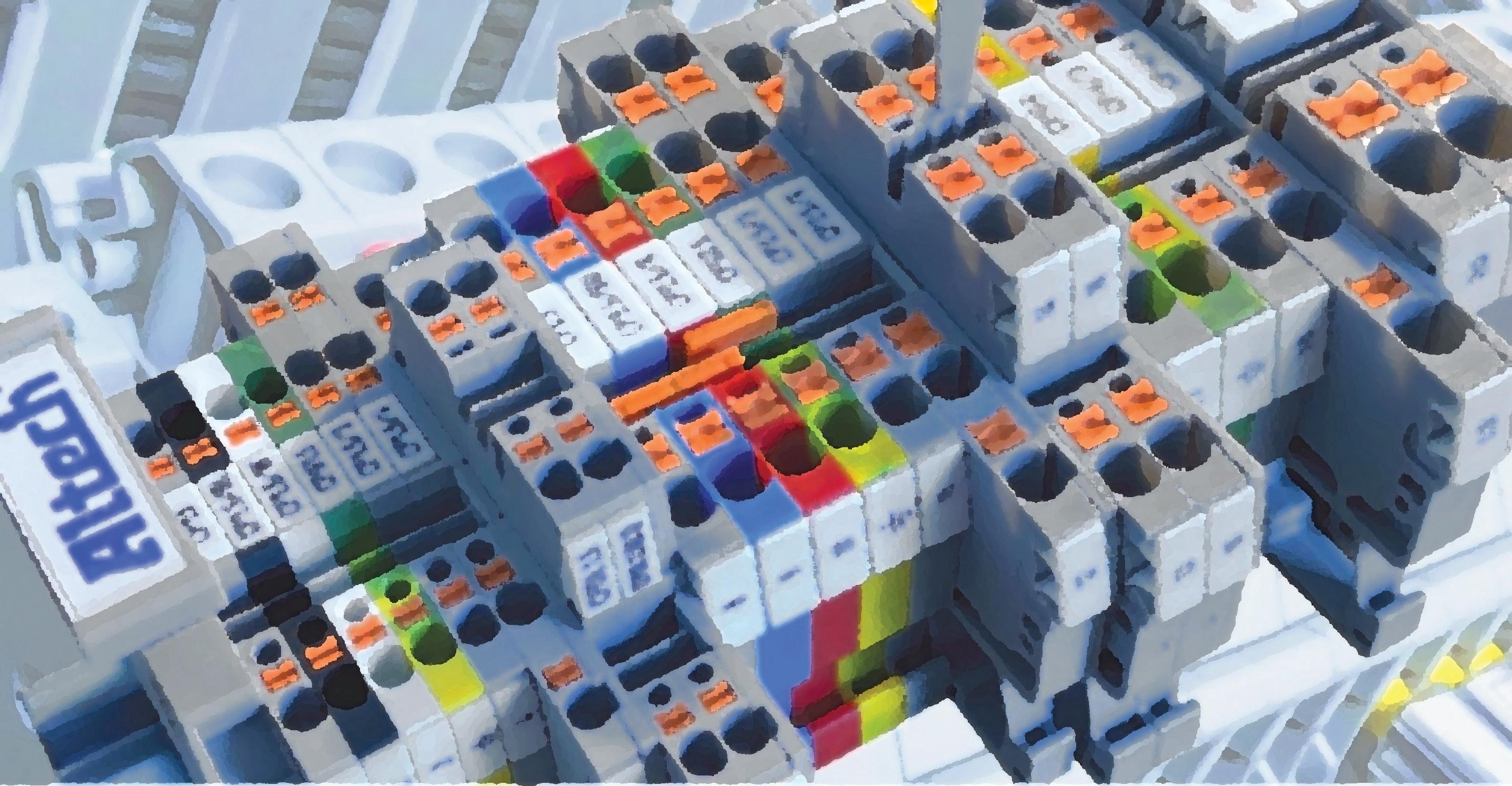

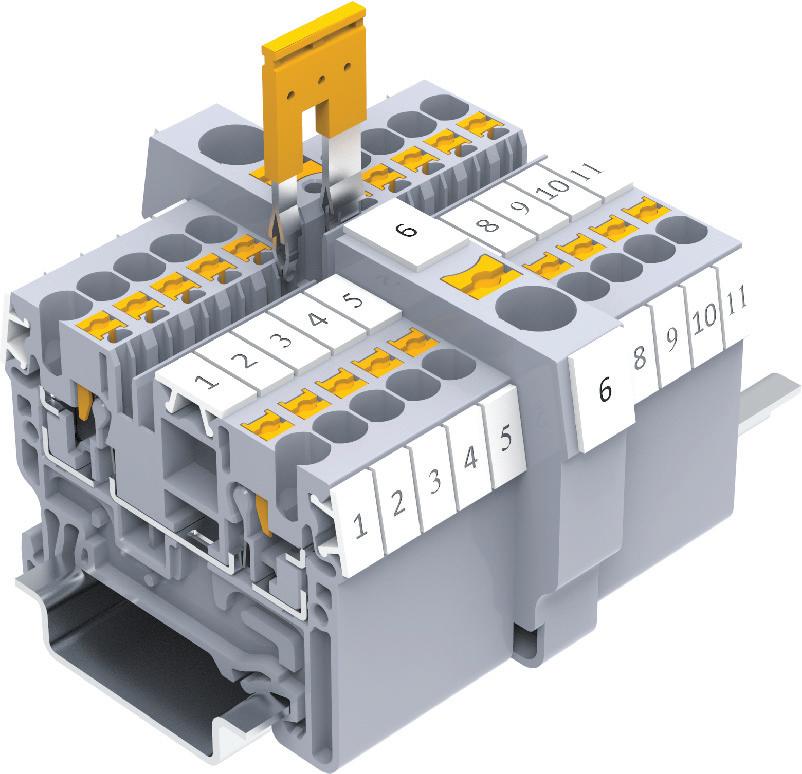

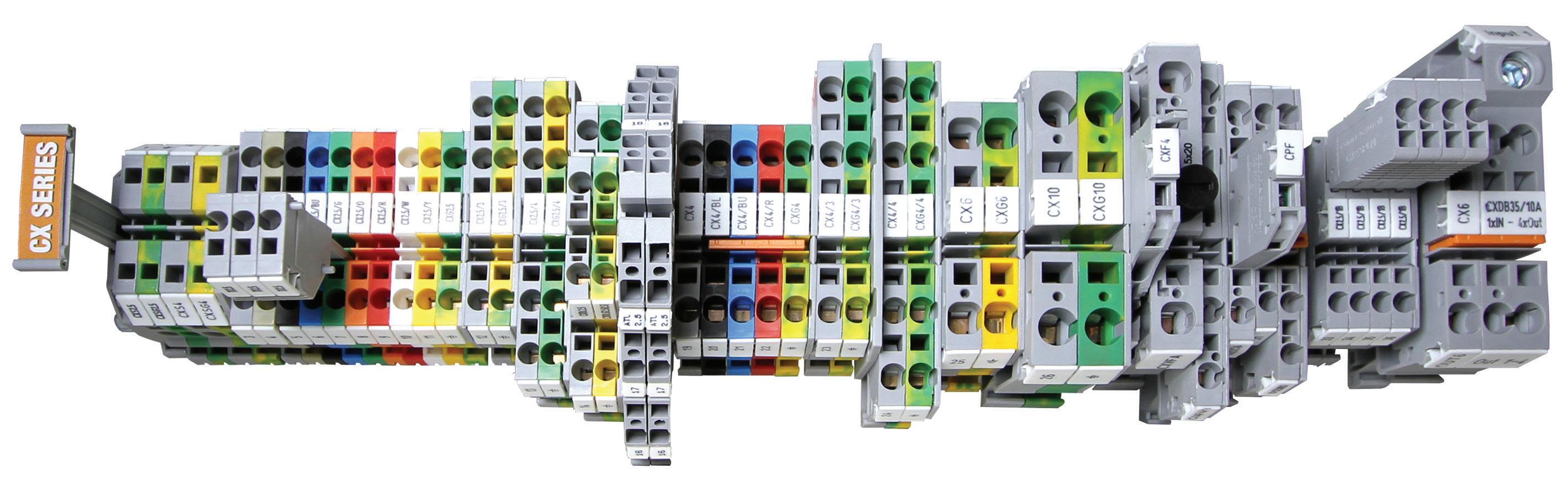

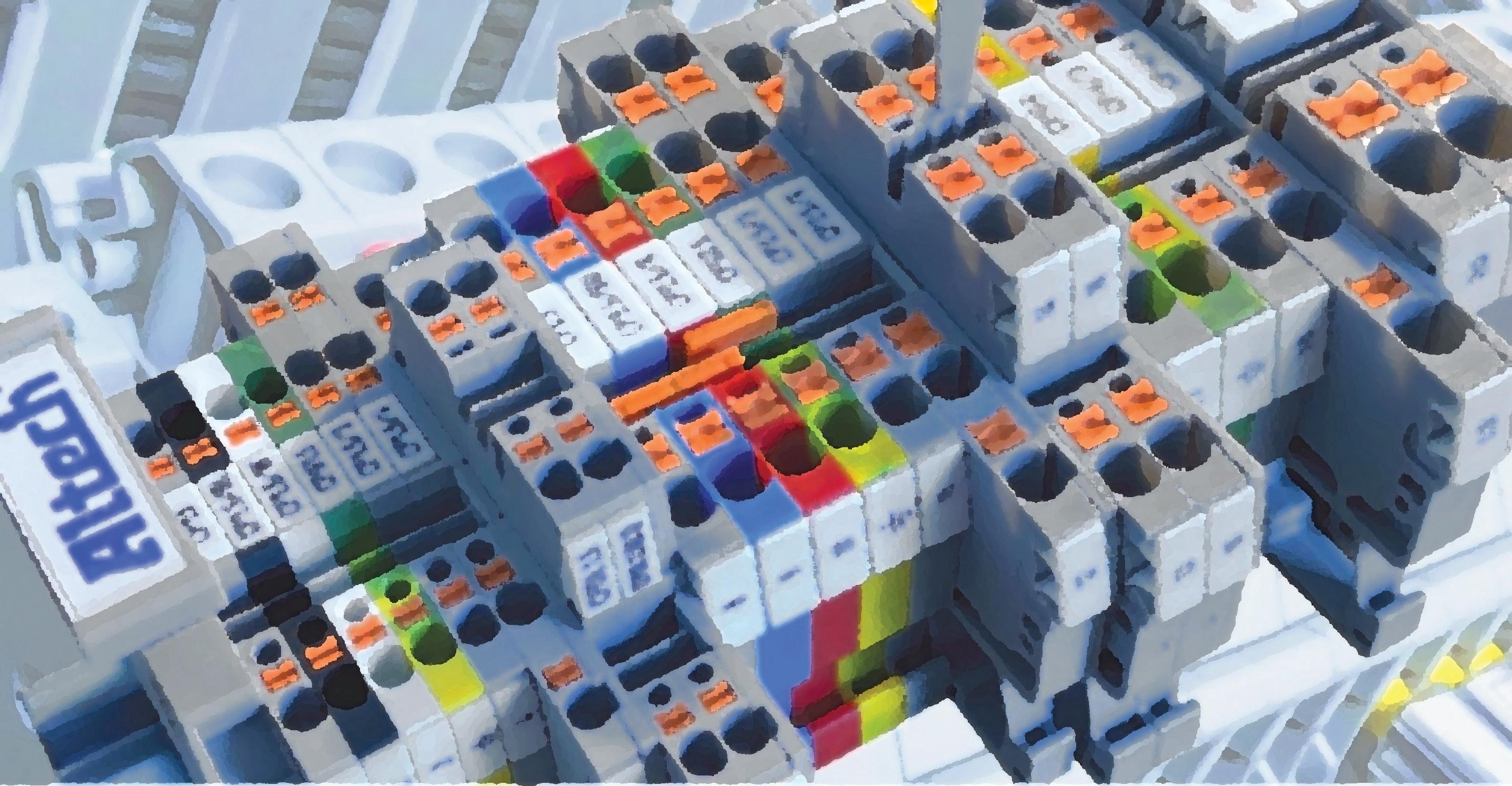

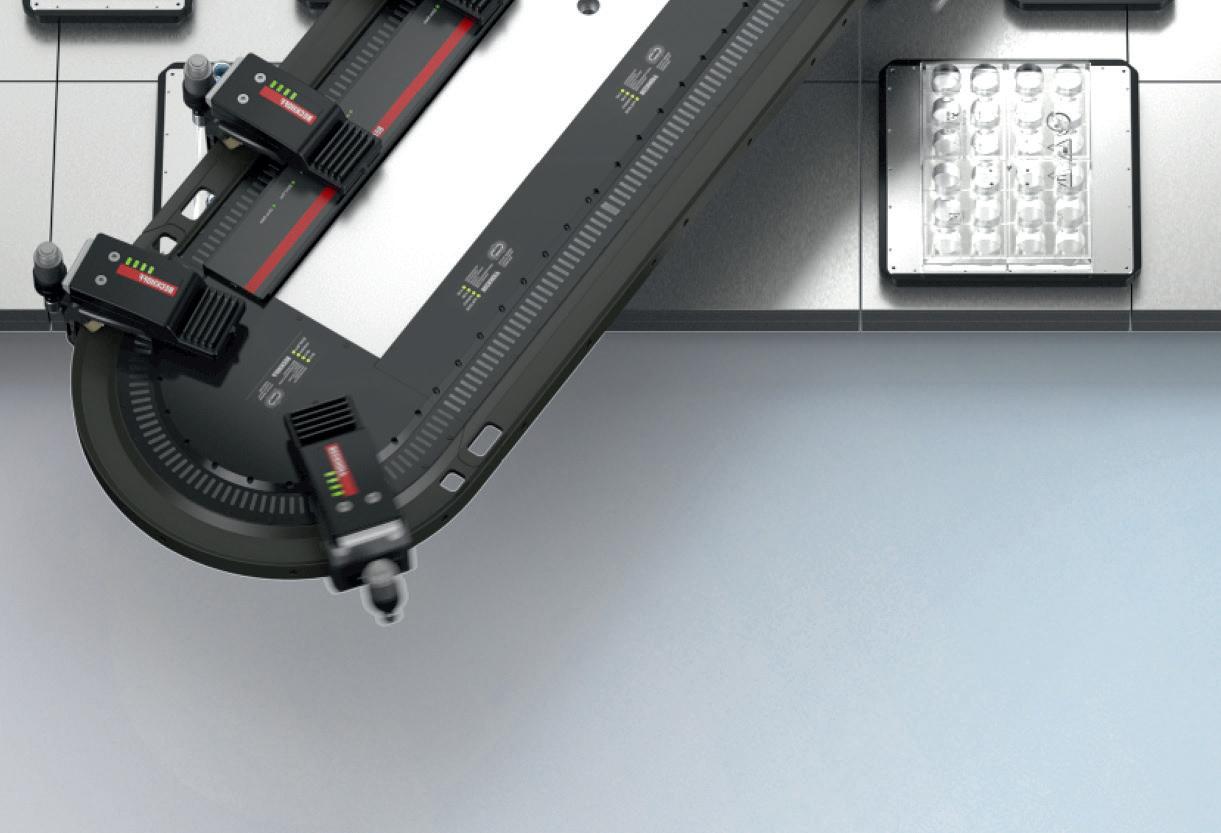

IO-LINK, THE SENSOR-LEVEL NETWORK, IS CHARGING AHEAD WITH MORE SUPPLIERS OFFERING NETWORK CONNECTIVITY AND NEW APPLICATION AREAS INCLUDING A NEW WIRELESS STANDARD.

As industrial automation continues to grow, IO-Link is helping machine builders implement predictive maintenance and support larger Industry 4.0 initiatives. The network protocol connects individual device data from sensors and actuators back to a controller. Because data from those sensors and other machine devices is key to automation, the data link is crucial to any successful automation strategy.

IO-Link basics

IO-Link is an open standard, point-topoint communication link for sensors and actuators. It’s defined by the IEC 61131-9 international standard which specifies a single-drop digital communication interface technology (SDCI, commonly referred to as IO-Link) for sensors and actuators.

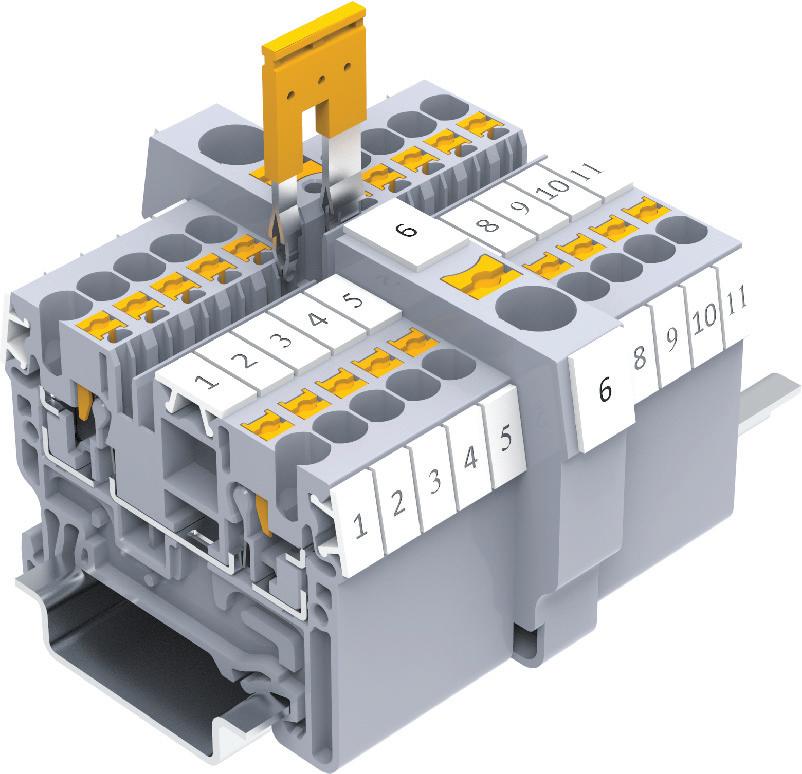

A typical IO-Link configuration includes an IO-Link master, which is the interface between the devices and a controller, such as a PLC. Devices can include sensors or actuators but can also be other devices such as hubs or robotic grippers or even power supplies with IO-Link connections. The master can be connected to virtually any fieldbus, and information flow between the master and devices is bi-directional. A key differentiator between IO-Link and standard IO is that with IO-Link, three types of data can be transmitted between the master and devices: process data, service data, and events.

What’s more, IO-Link is not a fieldbus itself. Being fieldbus-independent, it can be integrated with and applied over various networks, fieldbuses, and backplane buses. IO-Link is a part of PROFIBUS & PROFINET International (PI), one of the world’s largest industrial automation organizations, where continued development includes IO-Link Safety and IO-Link Wireless.

IO-Link has a number of benefits that make it a viable alternative to other types of more traditional I/O setups, including reduced cost and complexity and improved efficiency. One such benefit is that it’s based on standard, unshielded, three-wire cables, so it eliminates custom cabling and connectors and simplifies wiring overall, particularly for analog devices. Plus, IO-Link relies on standards such as M12, M8 or M5 connectors, simplifying connections even further. And in case a device requires a power

connection, a standard 5-wire cable can be used.

IO-Link compares favorably with several types of networking setups, including analog and Ethernet-based methods. While many factories still use analog systems, these can suffer from data and accuracy losses during analog to digital conversion. IO-Link being entirely digital eliminates these losses.

With simple analog connections, there’s an advantage for IO-Link in that it can offer much more. While both are not complex to integrate with standard connections, analog connections lack the digital advantages of real-time diagnostics that IO-Link offers.

With IO-Link, real-time data can be collected directly from devices on the factory floor, providing data about pressure, temperature, and other parameters as well as diagnostic data about individual devices.

IO-Link also supports IIoT and Industry 4.0 initiatives by providing more data about devices and machines, which lets users perform real-time monitoring and diagnostics and make better, faster decisions. In particular, the bidirectional communication feature allows for extended diagnostics of sensors and actuators, and simple and fast parameter setup.

With the added data from factory-floor devices that IO-Link enables, manufacturers can more easily monitor machine performance to predict potential failures. They can also proactively schedule machine maintenance and reduce unplanned downtime to extend equipment and machine life.

There are at present IO-Link-enabled devices on machines and industrial automation systems all over the world, with an installed base estimated at over 50 million. And it continues to grow, with manufacturers continuing to add IO-Link connectivity to product offerings.

Case in point: AutomationDirect now offers Contrinex IO-Link smart proximity and photoelectric sensors that provide functions such as real-time diagnostics, predictive maintenance, high-speed internal decision-making, configurable outputs, and scaled measurement data, without relying on a PLC.

Smart inductive proximity sensors offer up to a 10-mm sensing distance, flush or semi-flush

mounting, one PNP output, and one configurable discrete/IO-Link output.

Smart photoelectric sensors deliver reliable object detection in diffuse, diffuse with background suppression, and polarized retroreflective styles. They offer sensing distances up to 7 m (275 in.), selectable light-on/ dark-on operation, and tubular or rectangular stainless steel bodies. One PNP output and one configurable discrete/IO-Link output provide flexible interfacing, and protection ratings up to IP69K ensure dependable performance in demanding conditions.

Also available is the PocketCodr IO-Link Tool, a compact, handheld master for configuring and monitoring any IO-Link device. It enables precise parameter setup, calibration, and real-time data monitoring without programming, helping prevent errors and reduce downtime. Action Widgets (subscription required) provide stepby-step workflows for Contrinex sensor configuration, including teaching setpoints, defining outputs, and setting alarms. The PocketCodr communicates via Bluetooth to a smartphone or tablet, supporting on-site setup, diagnostics, and troubleshooting, even before the sensors are installed.

Photoelectric sensors aren’t the only ones benefiting from IO-Link.

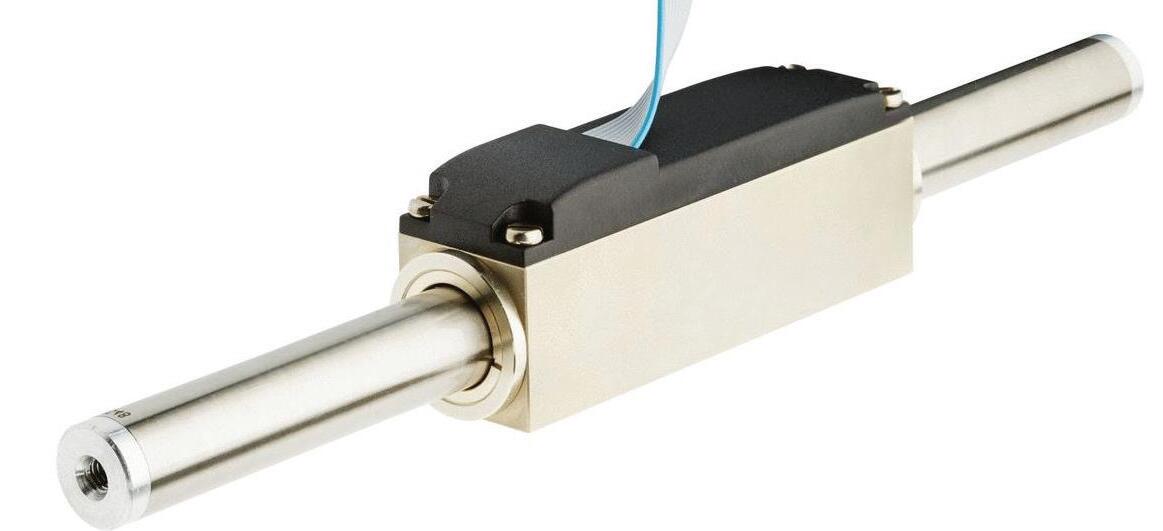

For instance, Hottinger Brüel & Kjær (HBK) has added IO-Link functionality to its T210 torque sensor to help engineers perform R&D and end-ofline torque testing more efficiently while streamlining their processes.

The T210 provides precise torque, rotational speed, angle, and power measurements in a compact, easy-tointegrate format. Each unit is delivered with an individual test report and is suited to a wide range of industries, including automotive, machinery manufacturing, pharmaceutical production, and high-end appliance and commercial goods sectors.

The new IO-Link interface enables the digital transmission of not only measurement data but also extensive process, diagnostic, and statistical information, making it easier to optimize processes and analyze performance in different applications. Compact and

Smart inductive proximity sensors offer up to a 10-mm sensing distance, flush or semi-flush mounting, one PNP output, and one configurable discrete/IO-Link output.

strain-gauge based, the shaft-style T210 is designed for integration into test benches, automation systems, or direct connection to the device under test. Its non-contact energy and signal transmission system ensures long-term reliability and high measurement precision.

Along with the new IO-Link interface, the torque sensor also includes voltage and frequency outputs for torque, speed, and angle, giving engineers flexibility across a wide range of applications, from development testing to automated end-of-line testing.

As the IO-Link organization reports, the long-term IO-Link strategy is based on further development of its range of technologies for opening up new application areas to both manufacturers and endusers. By enhancing transmission technology, IO-Link can also penetrate and open up new markets.

Enhancing data with precise time information is one such improvement. Using so-called time stamps, sensor signals can be synchronized with actuator responses independently of cycle times in a highly precise way, for example. It will also be possible

to correlate measurement data from different sources for time-accurate evaluations. An example of this would be the multi-channel vibration analysis of machines. The goal is time accuracy of under 50 μsec, which represents a significant improvement over the cyclical transmission of 2 msec. Time stamps with an absolute time can be used for the time-accurate logging of events in the devices, for example.

Another building block for future growth is the ease of device use in the applications of machine and system producers. Thanks to profiles for different device classes, data models are being standardized and can also be used in a standardized way. Profiles for the smart lights, identification, smart actuators and smart power device classes are currently in the works.

Another key element of the IOLink strategy is the IIoT connection

of the IO-Link level to the world of IT. Successful JSON connection via the REST API will continue to advance MQTT support in an upcoming release, offering a streamlined, highly functional connection, such as to cloud-based monitoring services or asset management.

Lastly, there is the promise of IOLink Wireless. Wireless connectivity in general is revolutionizing industrial automation. It reduces cabling effort, lowers maintenance costs, and creates new freedom in system design.

The IO-Link wireless standard features a reliable, real-time capable and deterministic protocol that was specially developed for the requirements of factory automation. It enables the wireless transmission of signals from switching and measuring sensors as well as simple actuators. This is particularly advantageous for rotating

or moving systems where conventional cabling is impractical. Retrofits can also be implemented quickly and efficiently thanks to simple integration without point-to-point cabling. DW

Hottinger Brüel & Kjær (HBK) hbkworld.com

Telecommunications electronics materials protected from emanating spurious transmissions (TEMPEST) testing, also called emission security (EMSEC) by the National Security Agency (NSA), is an NSA specification and is defined in the NATO SDIP-27 standard.

TEMPEST is designed to deny unauthorized access to information derived from intercepting and analyzing unintended electrical signals, sounds, and vibrations emanating from electronic equipment, including computers, servers, telecommunications systems, cryptographic equipment, and similar devices.

The specific requirements of TEMPEST testing are classified. This article reviews Van Eck’s phreaking, called Van Eck radiation, which forms the basis of the threat that TEMPEST testing addresses. It also presents an overview of the three levels of TEMPEST testing.

Initially, phreaking was specifically referred to as hacking into a telecommunication system. Today, its definition has expanded to include hacking into any electronic system.

Van Eck’s phreaking uses specialized equipment to attack the electromagnetic emissions of electronic devices’ side channels. While the U.S. government and Bell Labs knew about the possibility of phreaking as early as the Second World War, it was classified.

In 1985, Wim van Eck published the first unclassified paper on the security risks of unintended electromagnetic emissions. The paper described how to remotely reproduce the screen of a cathode-ray tube (CRT) display. The emissions were captured with a specialized antenna to recreate the displayed images (Figure 1). The technique is not limited to CRT displays.

TEMPEST testing measures and analyzes the unintentional

electromagnetic emissions from electronic devices. It uses specialized antennas and receivers to capture the emissions and software to analyze the data and determine whether it can reconstruct sensitive information.

Most of the specifics related to TEMPEST testing are classified. The three general factors include:

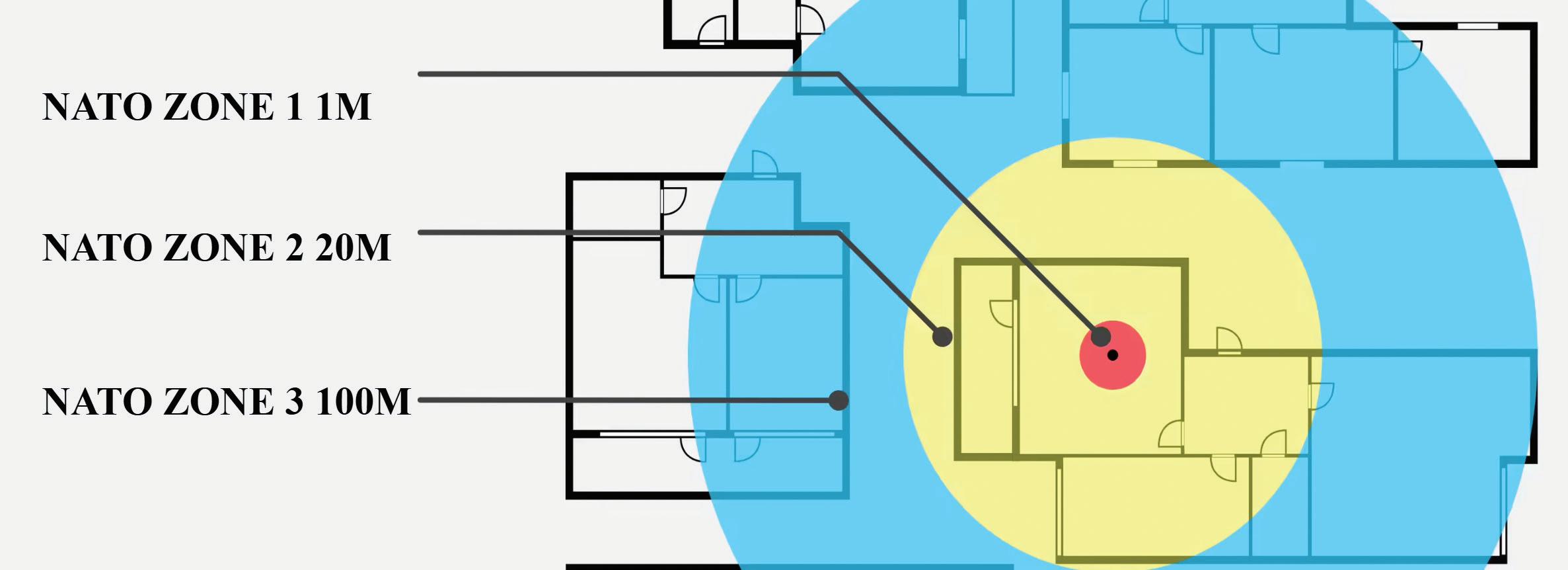

• Distance is a critical factor determining signal attenuation, and TEMPEST testing is defined for 1, 20, and 100 m.

• Frequency range is important, and testing is conducted across various frequencies.

• Orientation is also considered, and devices are tested from various angles to identify potential emission locations.

NSTISSAM TEMPEST/1-92 from the

NSA details the TEMPEST laboratory test requirements for electromagnetic emissions. It defines three security levels and provides a certification framework for equipment and systems that meet the document’s standards.

NATO SDIP-27 also defines three security levels for electronic devices, which limit the electromagnetic radiation they emit to prevent eavesdropping. It also includes three NATO zoning levels.

Zones, levels, and ratings

TEMPEST performance is defined by a series of zones and levels that lead to equipment ratings. The three basic zones and levels are (Figure 2):

• Full is the strictest level of performance, which is called Level A by NATO and Level I by

the NSA. It applies to Zone 0. It assumed that an attacker has almost immediate access to the equipment from 1 m or from a neighboring room.

• Intermediate is called Level B by NATO and Level II by the NSA. It applies to Zone 1 and is designed to protect equipment from 20 meters of unobstructed distance and a comparable distance through walls and obstacles.

• Tactical is the least strict performance and is called Level C by NASA and Level III by the NSA. It applies to Zone 2. This level protects equipment from 100 meters of unobstructed distance or a comparable distance through walls and obstacles.

FIGURE 1. Unintended electromagnetic radiation, called Van Eck radiation, can be used to eavesdrop on electronic devices remotely. LinkedIn

Longer lasting Belts, HEHT Split Spools -- no regrind wide_Layout 1 8/22/2023 6:05 PM

Round, Flat, Vee and Poly-V belts and pulleys

Better than Lifetime Warranty

We use 100% virgin urethane (no regrind waste). Makes stronger, longer lasting belts.

« Abuse Resistant Belts work where others fail.

« Super Strong Joints are virtually unbreakable.

« High Tension Belts move heavier loads.

« HEHT black belts double capacity.

« Low cost, highly efficient, elastic flat belts.

Split Line-shaft

l High precision. Reasonable price.

l Easy to install. Zero downtime.

Round, Flat, Vee and Poly-V Belts and Pulleys

In addition to TEMPEST zones and levels, the NSA includes three equipment type ratings:

1. Type 1 is the highest level for classified cryptographic equipment used for national security purposes.

2. Type 2 is for unclassified cryptographic equipment to protect unclassified but sensitive information.

3. Type 3 is for unclassified commercial cryptographic equipment used in applications like corporate networks. TEMPEST requirements are designed to prevent attackers from using Van Eck radiation to eavesdrop on sensitive and classified data. The specifics are classified and include requirements for distance to the device, frequencies, and orientations for testing. They are based on three levels or zones defined in NSA and NATO standards. DW

• 5 Things Everyone Should Know About TEMPEST and Information Security, FiberPlex

• Electromagnetic Information Extortion from Electronic Devices Using Interceptor and Its Countermeasure, National Institute of Technology

• National Security Agency TEMPEST Certification Program, UNCLASSIFIED

• TEMPEST Electronics Testing: Keeping Your Secrets Secret, GRiD Defense Systems

• TEMPEST Introduction, Spectrum Control

• TEMPEST shielding, NordVPN

• TEMPEST Shielding Standards, Interelectronix

• Van Eck phreaking, Wikipedia

• What is TEMPEST?, Astrodyne TDI

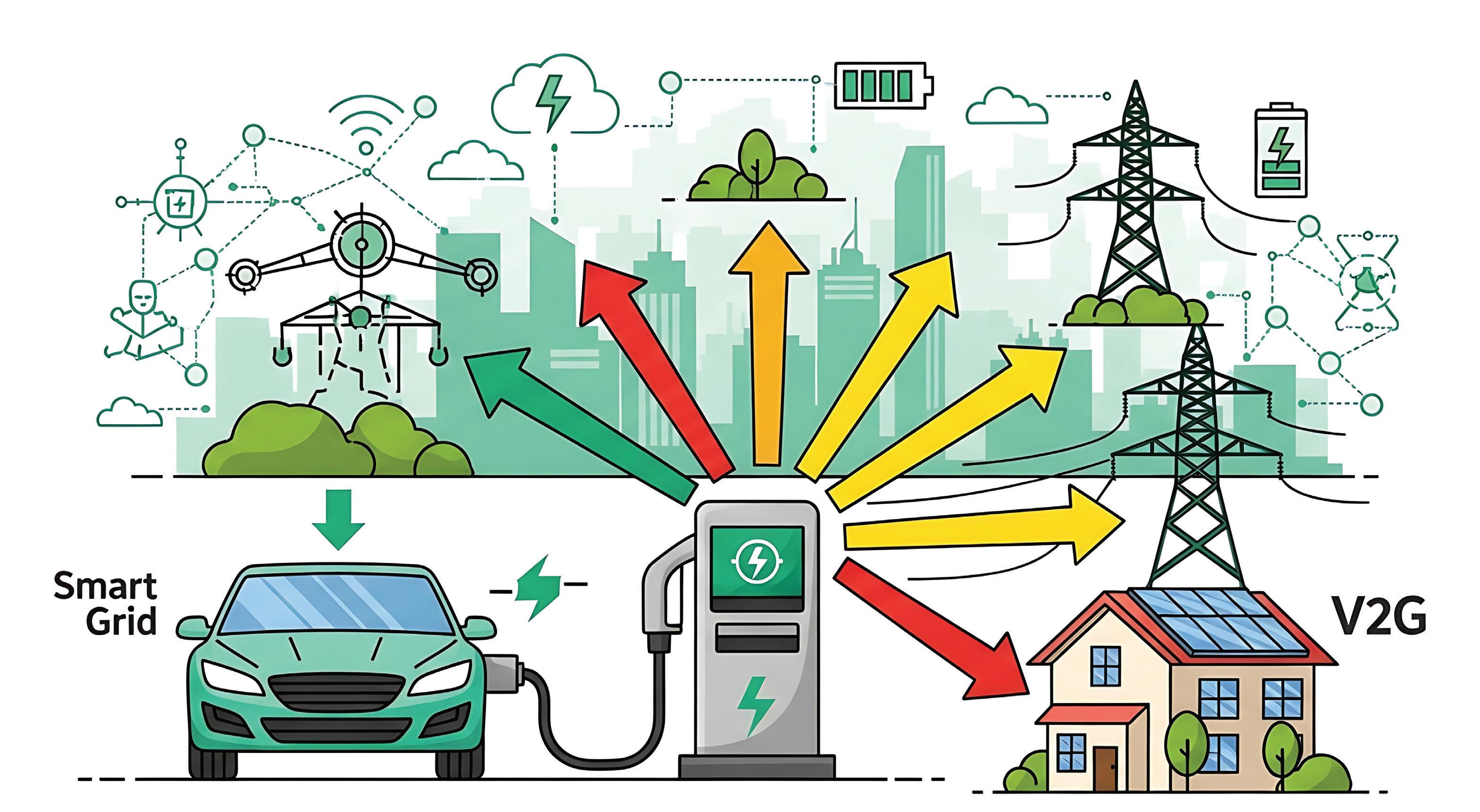

Electric vehicles (EVs) are becoming mobile power stations capable of energizing everything from camping equipment to entire buildings. Vehicle-to-Everything (V2X) technologies, including Vehicle-to-Equipment (V2E) applications, are changing how engineers design EV power architectures.

Bidirectional charging is the core concept behind these systems. This article examines the progress of bidirectional charging systems, including converter types and semiconductor advancements.

What is V2X, and how does V2E fit?

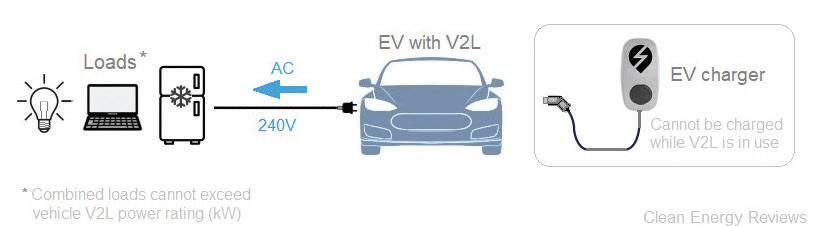

V2X consists of five primary applications, including Vehicle-to-Grid (V2G), Vehicleto-Home (V2H), Vehicle-to-Building (V2B), Vehicle-to-Load (V2L), and Vehicle-to-Vehicle (V2V). Each places unique demands on the vehicle’s power architecture (Figure 1).

However, V2E/V2L stands out for its simplicity and practicality.

Unlike V2G, which requires complex grid synchronization and external bidirectional chargers, V2E operates independently through the vehicle’s

integrated power conversion systems. V2X applications show multiple ways EVs can connect, building a complete ecosystem where EVs serve purposes beyond transportation.

The simplest entry into this ecosystem is V2E/V2L, which needs minimal external infrastructure and can power equipment or applications immediately (Figure 2).

V2E technology lets EVs power external devices and equipment with standard ac power through built-in inverters and outlets. EVs can now act as mobile power stations providing 2.4 to

V2G: Vehicle-to-Grid

V2H: Vehicle-to-Home

V2B: Vehicle-to-Building

V2L: Vehicle-to-Load

V2V: Vehicle-to-Vehicle

9.6 kW of continuous power. The system draws on the EV’s large battery, typically 65 kWh or more, capable of powering camping gear or backup systems during emergencies.

How have EV power architectures evolved to support V2X?

EV power architectures have changed significantly with the addition of V2X and V2E capabilities.

Earlier EVs had power flow systems that were only unidirectional and designed solely for propulsion. Bidirectional applications, however, require more complex power

management. To be safe and efficient, these systems must handle energy flow in both directions.

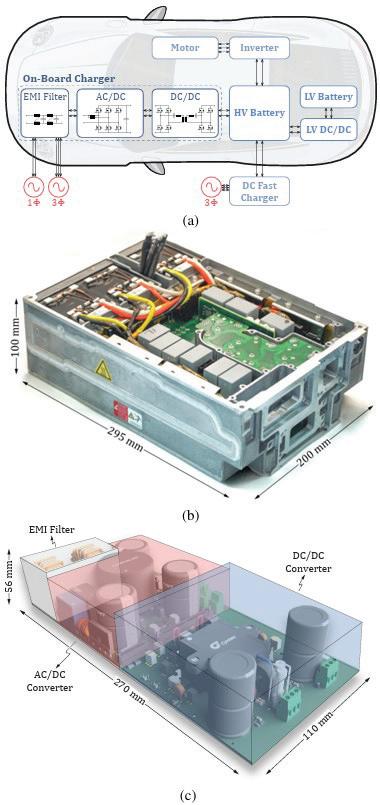

Modern EV power architectures use multi-stage conversion, with each stage optimized for specific functions. As shown in Figure 3, the first stage typically uses an ac/dc converter that corrects power factor so EVs can charge from the grid. Dc/dc converters in the second stage manage the battery and stabilize voltage.

For V2E uses, an extra dc/ac inverter changes the dc voltage from the battery to a normal ac output. In this configuration, the vehicle can work as a power source on its own.

From an engineering point of view, this is where things get interesting. Because of how complex the architecture is, converter topology design has come a long way.

Two-stage bidirectional onboard chargers (OBCs) are now common among manufacturers. These systems separate grid-interface and batterymanagement functions, allowing performance optimization in each mode. Totem-pole power-factor-correction circuits and isolated dc-dc converters are typical, while dual active bridge (DAB) and CLLC resonant converters are the most common designs.

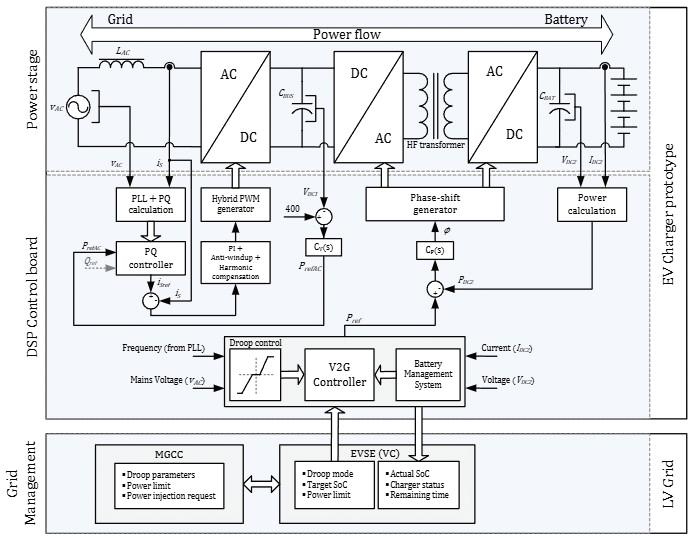

The detailed architecture of the bidirectional charger in Figure 4 illustrates its complex control systems that regulate power-flow direction, battery-charging profiles, and grid synchronization.

How do dc-dc converter technologies support V2E?

As V2X and V2E capabilities have grown, they have sped up development in dc-dc converter technologies. Hybrid energy storage systems in EVs need complex power management. They must work together with different energy sources, like supercapacitors, main traction batteries, and other systems.

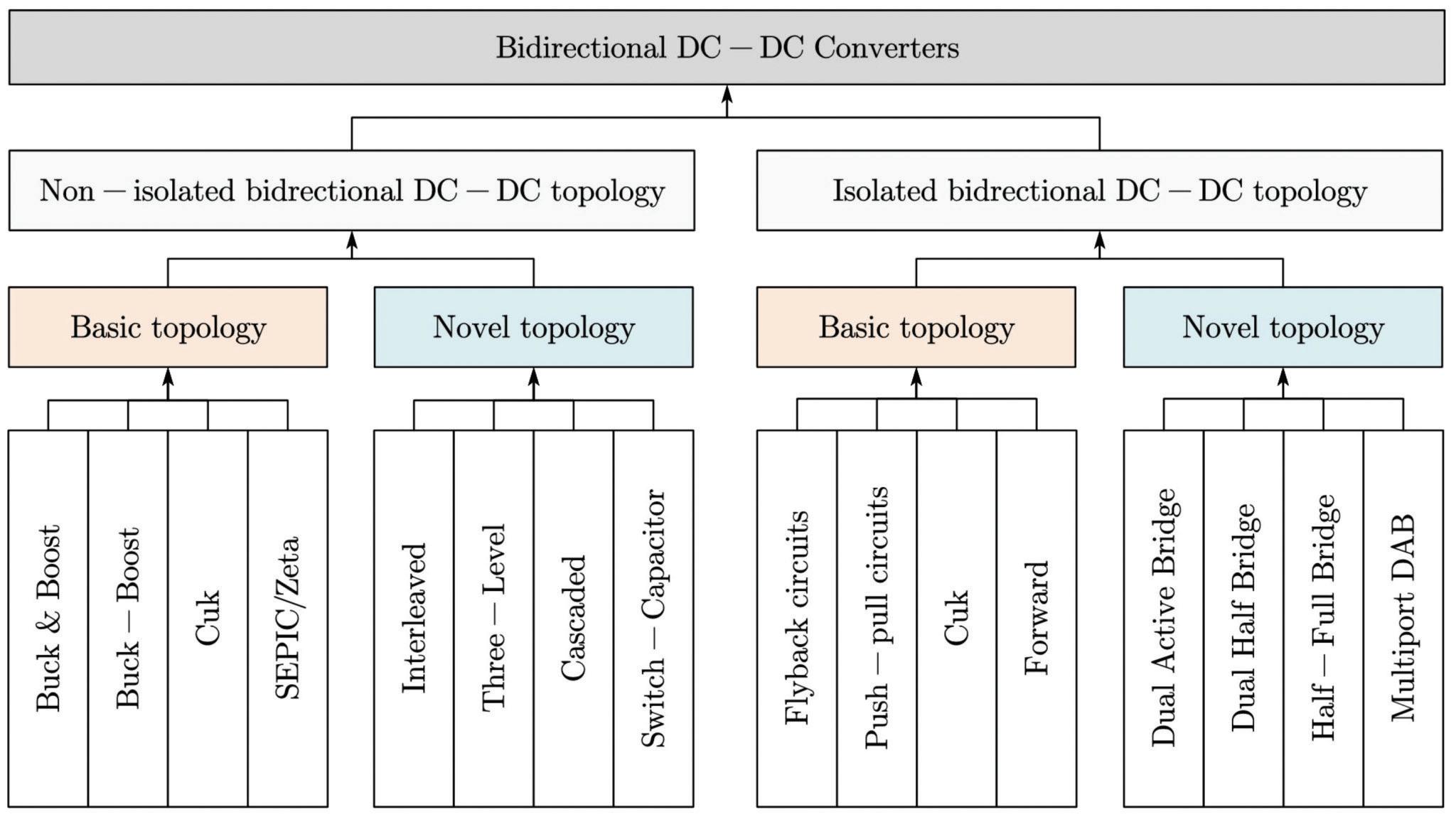

What does this mean for system designers? Because of this need, more advanced bidirectional dc-dc converter topologies have been used. These topologies make it easy for power to flow between different types of energy storage elements.

This level of integration is an improvement over older charging systems that only worked unidirectionally. It’s enabled safety protocols and power management algorithms required for V2X to work reliably.

A detailed classification of topologies shows the wide range of converter architectures used in EVs. It has become more popular to use non-isolated topologies like interleaved buck-boost

and three-level converters. They’re compact and efficient.

These converters lower the voltage stress on power switches and make the whole system more reliable. When galvanic isolation is required, isolated topologies offer higher safety and better voltage conversion. Dual active bridge and bidirectional forward converters are two examples.

Coupled inductors and soft-switching technologies have been added to make converters even better. They cut down on switching losses and current ripple.

These changes are especially important for V2E applications, where power quality and efficiency have a direct effect on the user experience and battery life in V2E systems.

Why have SiC and GaN become essential for V2X architectures?

Wide bandgap (WBG) semiconductors such as silicon carbide (SiC) and gallium nitride (GaN) have transformed EV power architectures. Compared to traditional silicon, they deliver higher breakdown voltages, superior thermal performance, and faster switching speeds, enabling compact and efficient bidirectional converters.

Over the last decade, these materials have rapidly replaced silicon in advanced two-way charger designs, establishing the foundation for next-generation V2X systems. As EVs evolve into integral parts of the broader energy network, these semiconductor advances will define the efficiency, reliability, and scalability of future electric mobility. EV

Figure 1. As electric vehicles become smarter, more connected, and software-driven, their susceptibilities expand, giving cybercriminals a wider attack surface. Cybersecurity is essential.

MARIE HATTAR SENIOR VICE PRESIDENT KEYSIGHT TECHNOLOGIES

Electric vehicles (EVs) have rapidly digitized over the last decade, morphing into a complex web of software and hardware. Technology under the hood now spans lidar sensors, radars, driver assistance systems, and in-vehicle networks. The average EV runs 150 embedded electrical control units and 100 million lines of code.

These innovations are being integrated to improve vehicle performance and increase driver safety. However, while physical safety has benefited, connected cars present many emerging securityrelated threats.

As a result, cybersecurity is one of the top concerns of automotive manufacturers. Security impacts their bottom line in the form of cyberattacks, resulting in billions (yes, billions) of system downtime costs annually.

Software introduces new threat vectors

As EVs become more intelligent and additional software is embedded, their vulnerabilities increase as cybercriminals gain a larger attack surface to exploit (Figure 1).

A couple of years ago, researchers identified several security weak spots that impacted 16 automakers. The flaws affected 20 different API endpoints, and if hackers had exploited them, they could have taken control of the vehicles, tracked locations, and accessed systems containing personally identifiable information (PII) of employees and customers.

Here are five critical areas of vulnerability that cybercriminals may target, as EVs become increasingly connected and autonomous.

1. Over-the-air (OTA) updates and malware-infected apps can introduce vulnerabilities through wireless code updates delivered over Wi-Fi or cellular networks. This lets hackers inject malicious code, modify vehicle firmware, or alter system functionality unless the OTA process is protected with end-to-end encryption, authentication, and verification protocols (Figure 2).