theming.

theming.

The exhibition is the first project that we as the Radical Empathy studio got. It is the start of the theming process, where we as group was divided into 4 subgroups. I got group A where we were assigned 4 characters, which are:

1. An international business person with connections to the Port and the emerging industry and visits in that capacity.

2. Local resident, 45 years old, attends the local heritage group at the library. Has a passion for Blyth's heritage.

3. Jack Carter, a character from Get Carter who, ran along the staithes in the film

4. Non-human protagonist: Cockle, lives in the marine environment.

These character will be used for making a graphical novel. In addition, we also have to make a sub group model and for the whole group project I was tasked to help make the model for the group exhibition, which is a timber frame covered with fishnets from Blyth. On the right is the process images of making the sub-group model and

was tasked to compile the graphic novel used for the exibition. I divided the task to my sub-group teamates (Liz Mironova, Stella Jianing Guo, Emily-Kate Hobson, and Dora Dildorakhon). I was tasked to compile the images together. In order to have a cohesion and same style of drawing for the graphic novel, I use the help of AI to turn the illustration from my cohesion into 1 cohesion style.

8 Adapted from a hand drawing of " Harvey open big boxes and tells his employees to dump stuff to sea" by Liz Mironova. Stylised using ChatGPT with prompt assintance [https://chatgpt.com/share/682e49ec-d5e8-8006-a507-a8bcad69172e].

Final version developed by the author.

9 Adapted from a hand drawing of " Harvey open big boxes and tells his employees to dump stuff to sea" by Liz Mironova. Stylised using ChatGPT with prompt assintance [https://chatgpt.com/share/682e4e23-505c-8006-829a6cddea8c2bcd]. Final version developed by the author.

Fig 11 - Adapted from a hand drawing of "Steve and Jack see harvey dumping stuff and takes photo" by Liz Mironova. Stylised using ChatGPT with prompt assintance [https://chatgpt.com/ share/682e4e23-505c-8006-829a-6cddea8c2bcd]. Final version developed by the author.

13 Adapted from a hand drawing of Jack

pub" by

using ChatGPT with prompt assintance [https://chatgpt.com/share/682e4e23505c-8006-829a-6cddea8c2bcd]. Final version developed by the author.

in

Fig 15 Adapted from a hand drawing of " Police rush to catch Harvey." by Emily Kate Hobson. Stylised using ChatGPT with prompt assintance [https://chatgpt.com/share/682e4e23505c-8006-829a-6cddea8c2bcd]. Final version developed by the author.

Steve and Jack see

dumping stuff,

Fig 17 Adapted from a hand drawing of " Steve and Jack see harvey dumping stuff." by Emily Kate Hobson. Stylised using ChatGPT with prompt assintance [https://chatgpt. com/share/682e4e23-505c-8006-829a-6cddea8c2bcd]. Final version developed by the author.

18 Steve and Jack run to police station, created by Liz Mironova during theming phase.

Fig 19 - Adapted from a hand drawing of "Steve and Jack run to police station." by Liz Mironova. Stylised using ChatGPT with prompt assintance [https://chatgpt.com/ share/682e4e23-505c-8006-829a-6cddea8c2bcd]. Final version developed by the author.

Fig 21 - Image generated and stylised by the author using ChatGPT (OpenAI) with prompt assistance. Prompt available at: https://chatgpt.com/share/682e49ec-d5e88006-a507-a8bcad69172e

22 Steve testing water and result comeback with high chemicals, created by

theming phase.

Using AI toos, such as ChatGPT played a useful role in my graphic novel making phase, as was the one who was tasked to combine the images together by the sub-group, especially when its time to make the different style of the drawings into 1 cohesion style. However, I was miondful that AI does lack empathy and human judgement, which are qualities essential in architecture. In addition, with our studio name "Radical Empathy", it is important to note that AI lacks the emotion, reasoning, and experience that are central in designing with empathy. Overall, this experience has taught me to reinforce the value of empathy in design and the importance of critical thinking when using new technologies.

reflection on the exhibition.

The exhibition was a wonderful experience for me, especially when it is the first time after a while not doing any architecture work after the summer break. In addition, the model that was displayed has captured the site story by integrating fish nets into the overall structure. Overall, the exhibition was a great experience to begin the work together as a group.

4.

5.

6.

8.

The field trip to Glasgow on the Radical Empathy trip really shifted how I think about architecture. Seeing places like Civic House and New Olympia House made me appreciate how powerful material honesty can be exposed brick, weathered timber, and metal finishes were not just aesthetic choices; they told stories about time, use, and change. For instance, at Our Lady of Good Counsel, was completely surprised by how something that looked so heavy and brutal from the outside could feel so warm and atmospheric inside. The way coloured light filtered through small openings transformed the space entirely. It made me realise how subtle design decisions can have a huge emotional impact. Visiting the Burrell Collection was another moment that stuck with me not just for its collection, but for how the building brought together old and new, inside and out, in such a calm, balanced way.

One of the place the place that captivated me is during the visit to the Burrel Collection. The integration between the timber, concrete, glass create a calm environment where art collection can be displayed. Elements, such as the glulam joint and stained glass windows show that structure and atmosphere of the place has been carefully thought off. The visit has made me realize how materiality and light can be played to create a wonderful environment for my future project.

The project is a two floor building of sustainable food and energy hub in Blyth that integrate biogas production, restaurant, laboratory, and education based on Blyth's marine ecosystem. The ground floor of the main building includes a reception, two office spaces, a meeting room, waiting area, changing room, and a classroom designed for educational engagement. The first floor contains a laboratory with a co-working space, water pH testing room, and cockle testing room, as well as a cooking school to explore sustainable cuisine. A bridge connects the lab to the first floor of the factory, which houses machinery and production systems on its ground level. The second floor features a riverfacing restaurant with two private dining rooms, where guests are welcomed by a bar and receptionist. The main building is topped with a flat roof, while the factory features a green roof that contributes to stormwater management and biodiversity.

What are the benefits of integrating marine byproducts into agricultural practices in coastal communities like Blyth?

How can Blyth's fishing industry integrate marine life to support sustainable food systems?

What opportunities exist in Blyth for turning cockle shells into valuable products like fertilizers or construction materials?

How can bioenergy initiatives in Blyth integrate with marine conservation efforts?

How can Blyth adopt aquaponics or similar methods to combine marine life and farming for food production?

photograph collection.

After careful deliberation, have decided to choose site D for my project. The reason is due to the access to the coastal water that allowed the project to have a unique view. In addition, the site is surrounded by marram grass and sand dunes that not only enhance the natural beauty of the landscape, but also provide shield for strong wind. The site closeness with the shorelines means that it opens up the possibility to integrate local marine ecocystem into my project easier.

In order to understand Blyth and the proposed site context, an analysis that highlight the circular systems sustainable food infrastructure, and inclusive educational spaces in coastal communities have to be done. Based on my analysis, there is a lack of integration between marine resources food production, and public engagement within Blyth's current development trajectory.

To address these missing parts, the project will be a new take on existing innitiatives while bringing new ecological innovation and community participation.

chosen site location: harbour master office area.

The chosen site main purpose is for Blyth Harbour Master's Office that manages the safe and efficient movement of vessels, enforces port regulations, coordinates emergency responses, and oversees berthing and environmental protection within the harbour. The site mainly have a presence of wooden jetty.

analysis.

The chart illustrates the median age of Blyth's population compared to the national average in England across the 2011 and 2021 census periods. It shows that Blyth's median age increased slightly from 40 to 41, remaining consistently higher than the England average, which rose from 38 to 39. This highlights an aging population trend in both Blyth and England over the decade.

This chart compares the age distribution of populations in Blyth, Northumberland, the North East region, and the England average as of mid-2021, highlighting proportions across three age groups: 15 and under, 16-64, and 65 over.

This chart shows deprivation levels across LSOAs in Blyth, categorized by domains like crime, employment, and living environment, and compares the most and least deprived percentages.

maritime heritage.

• Blyth has a long history as a port town, contributing to its strong connection with the sea.

• Shipbuilding and coal exports were central to its economy in the 19th and early 20th centuries, influencing its local culture and architecture.

coal mining heritage.

• The coal industry shaped Blyth's workingclass ethos, creating a culture of resilience and solidarity among its residents.

• Remnants of coal-loading staithes and industrial infrastructure reflect this history.

renewable energy.

• Blyth is a hub for renewable energy, particularly offshore wind farms, symbolizing its role in the transition to a greener future.

• These projects create opportunities for cultural narratives around innovation and sustainability.

marine conservation.

• Blyth's estuary and coastal waters are crucial for biodiversity, supporting species like seals, common eiders, and cockles.

• Conservation projects focus on protecting marine life and promoting eco-tourism.

Local markets and fairs, such as Christmas events and summer food festivals, bring the community together and showcase local crafts, food, and traditions. seasonal market and fairs.

Blyth lies on top of carboniferous sedimentary rocks with sandstones, mudstones, and coal seams lying under the glacier deposits and shales.

bedrock geology. superficial deposits.

• Quaternary deposits from the last glacial period, including glacial till, sands, and gravels.

• These materials shaped the landscape and influenced soil development.

Loamy and clayey texture good for farming.

soil compositions. hydrogeology.

• The Permian Sandstone aquifer underlies parts of Northumberland, including areas near Blyth. This aquifer is a significant groundwater resource, influencing local water supply and management practices.

blyth wind statistic explanation.

The data shows that in November 2024, the area of Blyth recorded an average wind speed of 2.9 mph, with the strongest wind reaching 15.7 mph on November 1st, coming from the west. The wind rose diagram indicates that 36.06% of the wind direction during this period was from the west-southwest (WSW). These patterns align with the annual 5-year average wind distribution, where the majority of winds in the region are calm to moderate, with a predominant direction from the WSW quadrant.

blyth topography explanation.

The topographic map of Blyth shows that the town is predominantly low-lying, with elevations ranging from 0 to 10 meters above sea level. Coastal areas, including Blyth Pier Lighthouse and the surrounding water bodies, are at the lowest elevations (0.1 meter), marked in blue. Inland areas gradually rise, with urban zones like Ridley Park and Crofton Park situated at approximately 5.8 meters above sea level, represented in green. The overall terrain is flat, with gentle elevation changes, characteristic of coastal towns. This highlights the importance of considering flood management and resilience against sealevel rise in any development or planning projects.

blyth tidal analysis explanation.

Blyth experiences semi-diurnal tides, meaning there are two high tides and two low tides each day. The tidal range, or the difference between high and low tides, can vary depending on the lunar cycle, with larger tidal ranges occurring during spring tides and smaller ones during neap tides. It highlights tidal ranges, with larger variations during spring tides and smaller ones during neap tides. This information is crucial for planning coastal developments, flood defenses, and maritime activities. Understanding peak tidal events and seasonal variations ensures safer infrastructure and better environmental management for Blyth.

flood management overview explanation.

The graph provides an overview of flood risks in the Blyth area as part of the Wansbeck and Blyth Catchment Flood Management Plan. It identifies areas most vulnerable to flooding based on factors such as tidal patterns, storm surges, and river flow levels. This data is critical for understanding the extent and frequency of flood risks, which aids in planning flood defenses, enhancing infrastructure resilience, and mitigating potential impacts on the community and environment.

After looking into what marine species that Blyth's offer, common cockle (Cerastoderma edule) was chosen as the focus of this project. The reason behind the decison is due to is that it is one of the character that was given to my sub-group during the exhibition. In addition, Cockle as a native species in Blyth connect with the site that I chose (site D), which is the harbour master area with its direct access to coastal water.

The theming phase was the start of our journey on 3rd year that shaped my understanding of my current project. Working closely with my groupmates, we were encourgaed to developed a shared language around our studio theme of "Radical Empathy" , which was done by exercises like making graphic novels, exhibition, model making, and gigamapping. Through all that journey, I discoverred how emotion, narrative and enviromental awareness could tell an architecture response. Overall, the theming phase has laid the foundation for my personal enquiry into marine species.

A sustainable aquaculture initiative producing high-quality fish and shellfish for local consumption. Focuses on eco-friendly farming techniques that maintain water quality and support biodiversity.

Educational tours exploring Blyth's estuary and marine biodiversity. Participants learn about conservation efforts, such as artificial habitats, and engage in hands-on activities like water quality testing.

A research centre that will do experiment on cockle testing their quality and water pH level in order to contribute to the marine environment.

Biogas factory utilizing waste and crushed cockle shells for catalyst.

Workshops led by chefs and farmers, teaching participants how to prepare meals using fresh, sustainable ingredients from local farms and fisheries. Promotes ethical and eco-friendly dining.

A dining initiative featuring local restaurants that create menus with sustainably sourced seafood and produce. Encourages ethical food practices and reduces waste through innovative cuisine.

34 year old marine biologist that is passionate about restoring Blyth's estuary. With her seashell pendant and curious nature, she works on sustainable fishing and marine conservation, inspiring the community to protect the ocean's biodiversity.

45 year old farmer that is a hands-on sustainable farmer blending traditional methods with modern innovations like aquaponics. He enriches soil with cockle shells and supplies fresh produce to local restaurants, driving Blyth's eco-friendly farming movement.

38-year-old chef, runs a sustainable seafood restaurant in Blyth. Using local produce and seafood, she connects people through eco-friendly dining and workshops, promoting ethical food practices.

a wise common cockle, symbolizes Blyth's marine ecosystem. She filters water, restores soil, and advocates for marine biodiversity.

crushed cockle shells.

Around 10 millions waste from shellfish were disposed every years, which are mainly being dumped into the sea or being repurposed for modifying elements in soil. Incorporating crushed cockle shells into soil can help to balance the pH and neutralizing the acidity inside the soil, which are good for crops that are sensitive to acidic conditions. In addition, the coarse nature of cockle shells help the soil aeration and drainage to help with heavy waterlogging. When the cockle shells start to decompose, nutrients, such as calcium penetrate into the soil, which support plants growth and improving the strength of their cell walls.1

cockle farm.

Cockle farm require shallow tanks with soft, fine grained sediment, which typically use mud or silt with a depth of 40-50 cm.2 The optimal water depth range between 0,5-1 meter in depth, which will ensure the cockles remain submerged during high tide and not exposed to for more 2-3 hours during low tide.3

cockle shells as catalyst. Cockle shells contain high amount of calcium carbonate that can repurposed for bioenergy appliactions, which famously used for catalyst in biodiesel production and wastewater treatment. By using cockles shells, it offers a more sustainable alternative to the usual conventional method. Furthermore, the modified version of cockle based catalyst enhance organic pollutant in wastewater when tested under UV light aquaponics. Sustainable method combining aquaculture and hydroponics. Nutrient-rich fish tank water is filtered and pumped to nourish plants in the hydroponic tank, with clean water recirculated back to the fish tank in a resource-efficient closed-loop system.

aquaponic's efficiency.

• Fish-to-Plant Ratio:

Typical ratio: 1 kg of fish per 2-4 m2 of plants.

• Water Use:

Saves up to 90% water compared to traditional farming.

• Plant Yield:

Produces 2-3 times more yield per m2 than soil farming.

• Feed Conversion Ratio (FCR):

Efficient feed maximizes fish waste as nutrients for plants.

cockle shells catalyst calculation.

• amount of CaO produced.

Mass of CaO = Mass of Shells x Purity of CaCO3 x 0.56

• biodiesel catalyzed.

Biodiesel Catalyzed = Mass of CaO x Catalytic Efficiency

Purity of CaCO3 = Fraction of calcium carbonate in shells (for instance, 0.95g).

Catalytic Efficiency = Oil catalyzed per gram of CaO (for insance, 10 g oil/g CaO).

• example (1kg shells).

CaO produced : 1000g x 0.95 x 0.56 = 532g

biodiesel : 532g x 10g = 5320g (5.32kg)

Calculation made estimating that the farm can produce 1kg of cockle shells.

food waste management (anaerobic digester).

An anaerobic digester is a technology that uses microorganisms to break down organic materials, such as food waste, in the absence of oxygen. This process produces biogas and nutrient-rich product.4

The "Metric Handbook: Planning and Design Data" was used as a key reference to inform the spatial planning, dimensions, and technical requirements of the building. It provides strandardilised guidance on room sizes, circulation spaces, accessibility standarts, and service areas, which help to ensure that the design is both functional and compliant with architectural conventions. application.

The image illustrates the space needed for clear spacing guidelines between chairs and tables to ensure comfort without wasting any space. The arrangement supports an intimate dining atmosphere, which will be ideal for the private dining space in the project. This configuration has been referenced in the restaurant design to optimise space usage while maintaining high-quality dining standards.

AND

The "Metric Handbook: Planning and Design Data" image illustrates the recommended spacing between square dining tables to ensure a comfortable movement and access. The layout provides clear dimensions for seating zones with minimum width of 900 mm between tables and walls. The standart will be used as a reference for the dining layout of the restaurant in the project.

The image illustrates a standard layout for a small commercial kitchen, showing the typical arrangement of preparation, cooking, storage, and wash-up zones. It highlights functional circulation paths and space allocation for both equipment and staff movement. In my project, this reference was used to inform the design of the restaurant kitchen on the ground floor, ensuring a logical flow between food preparation and service areas.

The image illustrates the reach range of a person sealed at a desk area. It explain the comfortable working radius, which help the placement of used items within access without requiring the user to stand or overstretch. This principle will be used for the ground floor office ensuring comfort, accessibility, and efficiency.

146 - Space and circulation requirement of office equipment.

The image illustrates the recommended clearance between desks, tables. and filing unit with focus on circulation and workspace efficiency. It ensures that the users can move freely within shared office environments without obstruction. The standarts will be used to determine the design of the office helping to maintain proper circulation paths and support inclusive, accessible workspace planning.

The image illustrates the space and circulation requirements for various office activities and equipment, as outlined in the Metric Handbook: Planning and Design Data. It shows the minimum dimensions needed for seated and standing tasks, movement between desks, and access to equipment like printers and filing cabinets. These standards were used to inform the layout of the staff office in the project, ensuring comfortable working conditions and clear circulation routes that comply with ergonomic and accessibility guidelines.

Fig 148- Limit of workzone in a laboratory.

Fig 149 Types of worktops for laboratory.

Fig 147 - Access for power and other services through perimeter cable ducts, and cable management.

The image illustrates how power and data services can be integrated through perimeter cable ducts and cable-managed furniture. This approach was considered in the project's office areas to support flexible workstation setups and maintain a tidy, efficient working environment.

The image illustrates the standart vertical reach zones and ergonomic heights for laboratory work. It defines optimal heights for worktops (700-950 mm), service controls, and stools. These standards were used to inform the design of the first-floor laboratory in the project, ensuring comfortable, accessible workspaces that accommodate a range of user postures and tasks.

The image illustrates a variety of lab worktop configurations, including options for integrated service routes from below or overhead. It supports flexible laboratory layouts by allowing services like power, gas, and drainage to be delivered efficiently to each station. These configurations influenced the lab furniture and service planning in the project, supporting adaptability and future-proofing the workspace.

thinking through drawing.

FROM COAST TO PLATE: A JOURNEY OF SUSTAINABILE FOOD AND MARINE CONSERVATION

Sustainable integration of marine life, renewable energy, farming, and dining in Blyth, a coastal town. By utilizing innovative systems such as aquaponics, anaerobic digesters, and renewable energy solutions, it aims to create a circular economy that links food production, waste management, and marine conservation. Public engagement is fostered through interactive workshops, farm-totable dining, and conservation tours, promoting awareness of sustainable practices. It envisions a harmonious relationship between land and sea, where resources are utilized efficiently, and biodiversity is preserved.

During this phase, I focus more on researching ways to utilize cockles as the focal point of my project. My research looked into the biology and role of cockles within the local marine ecosystem, and how they could be integrated into a speculative food and energy system.

This led me to investigate anaerobic digestion, and how waste organic material can be turned to energy and by implementing crushed cockle shells, it will act as a catalyst to speed up the process.

Furthermore, character that will inhabit the building, such as the marine biologist, the chef, the farmer, the cockle itself help me understand the user experience, programme that was needed, and spatial requirements for my project.

Overall, the framing phase was essential in positioning my project as a low-carbon building that connect ecology, community, and architecture. It gave me the tools to define my line of enquiry, test relationships between programme and purpose, and ground my design in both theory and application.

152-

Stereo-Kinetic wall facade in H&M store in Edinburgh was designed by Kappie Design Architecture Firm. Thousands small metal tiles move little by little because of the wind, which create an animation effect and depending on the sunlight creates shines on some metal tiles.

One of the part that was assigned to do for the group model is to make the double-glazed window, specifically the frame and the acrylic (represent glass in real life).

The diagram shows the tiles on different angles and the bracing to communicate with group member of how it will look when the pieces are disassebled.

Fig 155- isometric of kinetic group model. materialthicknessfinish

Digital model made in sketchup is used to visualize how the design would translate in 3D view. In addition, it helped us to have precise measurement of the model.

PlatesingleNormal

Holes

During the time of testing different materials as part of the Kinetic sub-group, I have learned how inclusive focused designed have a powerful impact on future architecture project that I will be working on. The finishes on the panels will help communicate to people on how texture, form, and materiality can affect the movement and sound of the facade.

Charred timber creates protective carbon layer that improves resistance to weather and pests.

Wood dye enhance the timber grain, provides darker color tones but need additional surface protection.

French polish creates glossy, amber surface that feels warm and the grain become more defined.

Varnish creates glossy finish that protet against moisture and wear. It also creates a harder protective layer than oil but less breathable.

Wood oil creates a rich tone and provide natural and breathable protection. It also enhance grain without being shiny.

Beeswax gives a soft, matte finish that offers water resistance and highlight timber grain a

thinking through making. personal material testing.

Based from testing a range of timber finishes, have explored many type of timber finishes together with their benefits and disadvatages. After comparing, all the finishes that have tested, chose the varnished timber as the most appropirate for my project based on looks and the durable protective layer that resist moisture and wear, while also maintaining the clean refined appearance.

reflection.

The model represents a double-glazed window assembly, using timber as the primary structural frame and a combination of metal, timber, and plaster-covered tiles for the facade elements. The tiles vary in finish and geometry, allowing me to test how different materials respond to environmental exposure, particularly corrosion, texture, and patina on metal surfaces.

Through this process, investigated how material transformation can be used as an expressive architectural strategy. The experimentation directly informed my approach to the reused metal facade in my project, where weathered finishes are used not only for sustainability but also to tell a story of ageing, resilience, and adaptation within the coastal context of Blyth. I also wished had the opportunity to experiment with burning or heat-treating the metal to produce blue oxidation effects, adding further depth and dynamic colour to the material palette.

The green area symbolize the farming space that will be added into the project (aquaponics, and ground farm). The reason it was layed out there is due to maximising the amount of sunlight that the plants should be getting.

This diagram is to illustrate the spatial layout and functional relationships within a multipurpose sustainable food facility. It maps out key areas such as the restaurant, laboratory, cooking class, and cockle farm, alongside supporting spaces like the staff area, energy production unit, storage, and public amenities. The diagram helps visualize how different programs including public, educational, operational, and environmental are interconnected through a central lobby and reception hub.

farming. dining. grinding and deboning/deshelling. bioenergy. marine farm.

The yellow area is the space for the dining area and it is situated where the diner can get a view of the surrounding waters that is around the site, and connected with the place where marine life will be processed sustainably for the diners. This image combined both the red and cream colored area, deshelling/deboning area and grinding, and bioenergy area respectively. The reason it is combined is due to the interaction that both area are utilized with each other due to its fuction that complement one another.

The blue area is the marine farm for mainly fishes and cockles that will be needed for making food and specifically cockle shells to be grinded and spread through the soil area to neutralize the pH, catalytst for bioenergy. It is placed near the river for a maximum output of fish and cokcles to be as natural as possible.

This the first iterations that investigates how aquaponics, anaerobic digestion, and hospitality can coexist on a coastal site of Blyth. The sketches focused on program relationships and public engagement, while later placing technical areas like the digester and aquaponics on the ground floor, and coastal-facing spaces like the restaurant and offices above. However, issues such as, circulation between public and operational areas is unclear and the separation between clean and dirty functions needs improvement.

Fig 183 Iteration 2 first floor sketch.

Fig 184 - Massing iteration 2 diagram.

The second iteration is similar to the first iteration but adding the minor details, such as the outdoor space and various amenities for the restaurant like the kitchen and the storage. Overall the cohesion of the building remain the same with the previous iteration.

The third iteration explore on the basis of curves. The curves goes inwards to redirect wind coming into the building and in this iteration, the focus is on the main function of the building with the restaurant as the main function. In addition, one of the key change that has to be made to the project is to make it bigger to fit the brief and adding more function that correspond to the cockle farm.

Fig 191 Iteration 4 second floor sketch. Fig 189 Iteration 4 ground floor sketch.

The fourth iteration point is making the building bigger in size (making it longer). In addition, the fifth iteration explore a more sharp angle rather than curve, the reason is that want to make the building more industrial looking based on the functions that decided. One of the main point is to add cooking school on the ground floor to connect people with cockle farm and the restaurant.

iterations. Fig 192 - Massing iteration 4 diagram.

The fifth iteration is similar to the fift iteration. The difference is that there are no more 2 floor restaurant (first and second orgininally), now the first floor will be for cooking class and laboratory and on the ground floor is going to be classroom (cooking school originally) for adding another education aspect other than cooking school for teaching people about the cockles farm in the project.

The sixth iteration focus on refining and expanding the laboratory space. Compared to what have been done to the sixth iteration, this version (7th iteration) introduce a more structured layout for the co-working and private testing room. There is also addition of a bridge on the first floor that connect the main building with the factory offices (recently added). In addition, the second floor restaurant layout has been optimised for more capacity and flow with the addition of private dining area that introdouce the concept of private dining, which reinforce the initial building's program hierarchy.

Fig 200 Iteration 7 ground floor sketch.

Fig 201 - Iteration 7 first floor sketch.

The seventh iteration overall hierarchy almost remain the same with seventh iteration. The difference between them is on the biogas factory the appliances/machine has been rearanged, a changing room and washroom has been added. In addition, on the first floor of the bio gas factory, the office has been rearranged as well to have it close with each other with the bridge that connect them to the main building, which create a connection between the main building with the biogas factory.

Fig 202 Iteration 7 second floor sketch.

using harness for cleaning the window.

Fig 203 roof iteration changes.

On the seventh iteration, overall all the programme is already sorted, except that the roof have to be changed. The reason that the roof has to be changed is because with the shape of my design, It is impossible to have a pitched roof, thus designing a flat roof is more ideal. In addition, the flatroof will have solar panels as another source of renewable energy.

Fig 204 Iteration 8 first floor ammendement.

Ammendment for the first floor laboratory space collaborative table need to be moved in order to clear the path for access towards or away from the bridge that connect the main building with the biogas factory office. Furthermore, the size of the corridor of the biogas factory 1st floor need to be reduced and create a bigger space for 2 offices. Another change is to remove the extra wall on the emergency corridor (use to be for wheelchair placement) to create a continuous space for the biogas factory fire escape for quicker escape.

205 Iteration 8 second floor ammendement.

Ammendment for the second floor only consist of the furniture placement due to previously only having a standart shape (square). The current bar will have a more dynamic movement that correspond with the sharp angled shape of the building. In addition, the receptionist table is moved sideways to give more flow area for the staff to access both the bar and the receptionist table.

This are the synthesis review page rendered floor plans that I made. The overall hierarchy between floors is already good enough and the space compliment each other according to the programme corectly. However, the rendering of the floor plan still need to be worked on, because it is still hard to distinguish which one is the highest ground level, and which one is the lower ground level of the site. In addition, there are no textures on the floor making it hard to understand the material of each room and the texture of the landscaping part. Finaly, the floor plan lack context of the surrounding building and environment (need names).

The tenth iteration fixes the problem of pitched roof on the building with solar panel going to be added on the main building roof. In adddition, on the biogas factory, the roof will be truned into a green roof in order for the staff to have a berak space. Finally, the problem that remain is the facade, which will be changed.

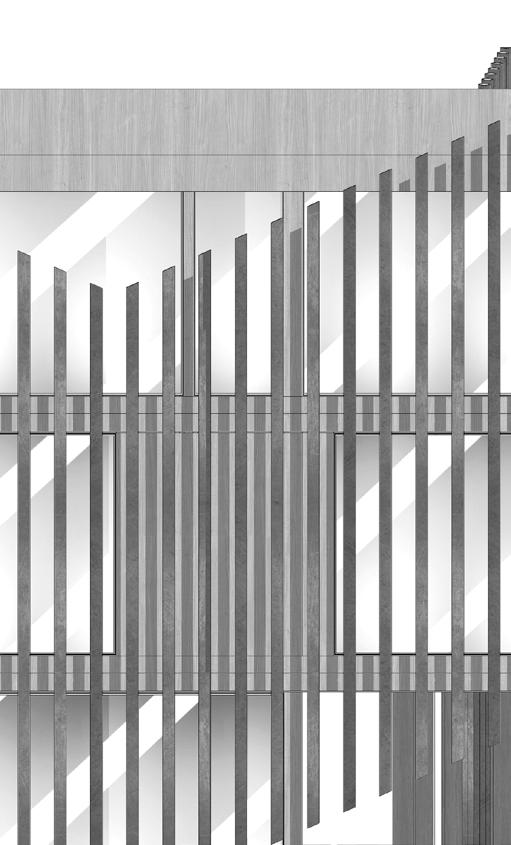

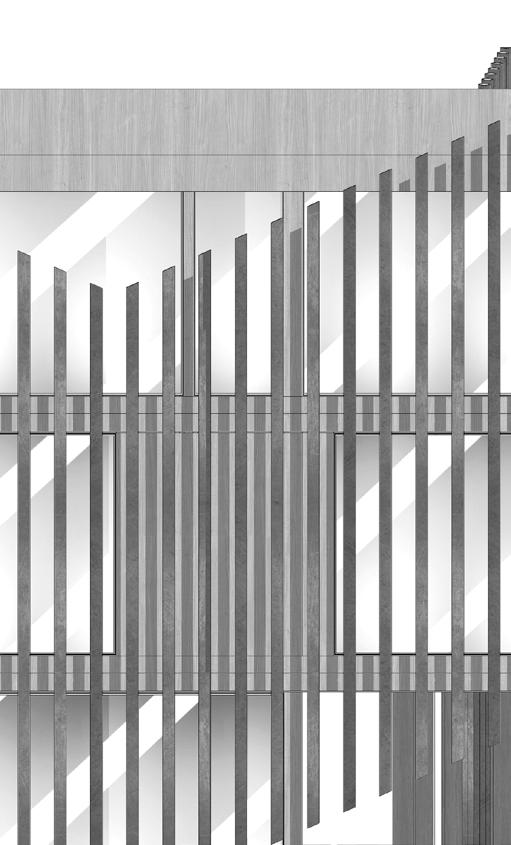

The initial facade concept introduce vertical reused metal pipes as the main shading and aesthetic element. The pipes were arranged to create transparency while connecting with Blyth's industrial character. The wave pattern begins to emerge subtly across the middle portion, which hint at the marine influences but but still have sharp, rigid alignment.

The second iteration developed further the wave concept by introducing more pronounced curves across the pipe arrangement. The overall form became less linear that is aiming for movement and rhytm inspired by the sea. The material remain the same (reused metal pipes), but the arrangement and cuts were refined to enhance the facade fluidity.

The facade design have been changed to cover the building with waves design. Unlike other previous iteration, the facade has bigger waves all over it creating a design that cover the overall area and have a harmonous feeling.

Changes to be made from the previous facade design is to have the facade connecting to the factory creating a sense of connection between one building to another. In addition, experimenting with cutting the top and bottom (matching the flat roof height and ground floor door height). Finally, adding the same style of reused metal pipes facade on the jetti should make the building whole and have the same design element throughout.

After a lot of thought regarding the reused metal facade design, the one that will be finalized is a more big-waves design due to the coverage of the facade gives to certain part of the building. For example, adding more cover for the restaurant to give more private dining experience away from the public view. In addition, semi-opening the office space but give more cover toward the meeting area to ensure privacy.

This syage is where my idea is put on a test, through many feedback, iteration, and slowly but surely the building is complete. began testing how different programs (such as the anaerobic digester, restaurant, laboratory, and public education space) could coexist on my site. Plans, sections, and diagrams were developped to understand the building programme and by researching opportunities that can be help develop my building better. For instance, initially the restaurant was 2 floor and now it has been condensed to a single floor (2nd floor) and the space below was occupied for laboratory. Overall, testing and refining section has helped me to understand further about integrating different idea and eventually the result will always be found.

Most of the selected materials supplier has been evaluated for their embodied carbon but also for their proximity to the site. Most of them is located 6-15 minutes of car ride. This approach reinforces low-carbon material strategy and supports a circular local economy.

Openable window on the classroom (G floor), biogas factory (G floor) and cooking school (1st floor) allow fresh air to be directed into the building, the restaurant (2nd floor) will be a floor-to-ceiling window due to its height. In addition, shading from metal pipes facade to reduce solar gain. The floor heating will also be turned off and MVHR system will support background ventilation.

Openable window on the classroom (G floor), biogas factory (G floor) and cooking school (1st floor) allow passive cooling during the night, the restaurant (2nd floor) will be a floor-to-ceiling window due to its height. In addition, the floor heating will also be turned off, except if its needed it will be turned on at a minimum to reduce operational cost and MVHR system will support background ventilation.

Low winter sun increase the solar gains, which mean it allow air to be heated and maintain warm temperature indoor. The MVHR system will help in ventilating spaces while also recover some wasted heat especially for kitchen, and restaurant (public space). Furthermore, underfloor heating from the biogas will be turned on to warm up the space. The factory does not need underfloor heating due to heat generated from machines.

During evening, window opening kept minimum from the classroom (G floor), biogas factory (G floor) and cooking school (1st floor) to reduce heatloss. In addition, underfloor heating will be used as well to reduce operational cost and MVHR system will ensure the space are well ventilated while also recover wasted heat. The factory does not need underfloor heating due to heat generated from machines.

The MVHR unit is positioned behind the restaurant within the plant room and in the biogas factory. Fresh air is drawn in and distributed through a network of ducts, while stale air is extracted and passed through the MVHR unit for heat recovery before being expelled. This system ensures efficient year-round ventilation while minimising heat loss, supporting both indoor air quality and energy conservation in airtight spaces.

The project is located near the coastal water of Blyth that combine and redirect water to the river. The key strategy is the reused pipe facade, where some vertical pipes are connected to ground and repurposed as rainwater pipes. The rainwater is then redirected out through lines of pipes in the jetti gap, specifically in the cockle farm area.

On the first floor balcony connected to the laboratory, it is an exposed part of the building, while it is semi-covered with the reused metal facade some rainwater can still pass through. In this case, drawing inspiration from Bauder Gulley system should help with the rainwater. Furthermore, using marram grass on the landscaping part of the building help with reducing erosion, slow surface runoff, and promote water absorbtion.

Marram grass helps reduce erosion, slow surface runoff, and promote water absorbtion through its dense, and complex root system. The roots anchor the soil, which makes it more stable and increase the ground's ability to absorb water overtime.

Due to my building's varied functions that consist of public, educational, research, and industrial spaces, the design must comply with multiple purpose groups in accordance with table 2.1 of The Building Regualtions Approved Document B.

The ground floor consist of lobby/reception, offices, meeting space, changing areas, and classroom with lobby/reception and classroom open to public and others are staff only. The ground floor must comply with Purpose group 5 "Assembly and Recreation" with maximum travel distance of X=1 (15M) X>1 (32M). This is due to the occupancy of this floor may reach over 60 but still remain under 600 people, which required a minimum of two escape routes.

The first floor consists of laboratory with water pH testing and cockle testing area, as well as co-working space, and cooking school. This area is categorized under purpose group 3 "Other Non-Residential" due to its educational and experimental aspect. It has been designed with X=1 (18M) X>1(45M) travel distances with occupancy under 60. However, having two fire escape in each space that are connected to ground floor s better.

The second floor house the restaurant and private dining room falls under purpose group 4 "Shop and Commercial" with the occupancy expected to be over 60 people, thus requiring at least two seperate escape routes and travel distance of X=1 (18M) X>1(45M). This problem is tackled by having two fire escape stairs that is connected until ground floor nad later toward to the assembly area. In addition, the open layou of the restaurant allows for efficient, and easier access to the fire escape stairs in case of emergency.

Finaly, the cockle's processing factory that is connected by a bridge on the first floor falls under purpose group "Industrial" The ground floor houses machinery and is restricted to trained staff only, complying with X=1 (25M) X>1 (45M) limits for normal risk for industrial use.

= Number of escape directions. (_M) = Maximum travel distance.

To ensure fire safety compliance, the project height is under 10M, which mean according to table B2 in falls under category and height range of 60 minutes of fire resistance.

On the other hand, according to table C1 self-closing fire doors within compartment walls and escape routes must also meet 30 minutes fire resistance.

Approved Document B, pp. 31-32 outlines the requirements for evacuation and minimum stair widths, which will be determined by the building capacity, number of storeys, and purpose group classification. According to table 3.1 and table 3.2 of the Approved Document B, the second floor houses the restaurant and private dining areas are expected to serve occupancy under 220 people. As illustrated on the project travel distance page (Figure ), two escape stairs are provided.

The escape stairs include clear widths of 1200mmx2600 mm, both are exceeding the minimum width requirement of 1100 stated in Table 3.1 for building occupancy exceeding 60 persons. This facilitates efficient evacuation and the potential for assisted egress. An enclosed stair core is designed to meet a minimum REI 60 fire resistance rating, connecting directly to an external ground-level exit. A wheelchair refuge space has been integrated near the stairwell and exceeds the 900x1400mm minimum clearance as specified in section 3.6, alongside an emergency voice communication (EVC) system in accordance with BS 5839-9 (section 3.7).

While no ramp is included on the second floor due to the height and external escape configuration, step-free level access is available at ground floor level through two separate exits with flush thresholds. These ensure compliance with accessible egress requirements and provide a direct means of external evacuation for mobility-impaired occupants.

In order to meet the structural fire safety of Approved Document B and BS EN 13501-2, all exposed glulam and CLT structure will use a fire resistantresistant finish, specifically Fireshield Timberclear 1FR, which provide protectuon while maintaining the glossy look that is going for.

The varnish coating provides 30-60 minutes of fire resistance depending on where it is going to be needed.

Access for fire fighting appliances has been designed in compliance with Approved Document B (Vol 2). Section 13. The layout ensures that fire vehicles can approach the building quickly and safely with appropriate distances and clear access to the main entrances.

A dedicated vehicle access route runs along the front of the site, providing direct access to both the main entrance and the factory. The furthest point on any elevation is within 45M maximum distance set out in section 13.1-13.4, while ensuring that hoses and fire fighter personnel can rach all areas of the building efficiently.

The building is under 18M in height, so the requirement for high-reach appliances access (ladders or platforms) is not needed. However, fire crews are provided with direct access points at ground level and protected stair cores that serves from ground to 2nd floor. All final exits leads into the assembly point on ground level and the site layout ensures the fire truck's parking position is within range of the main escape stair core.

Escape routes across all floors are designed to comply with Approved Document B, with travel distances and stair placements ensuring occupants can exit the building quickly and safely. All protected stair cores lead to final exits at ground level with level thresholds. Refuge areas and EVC systems are provided at key locations. External escape routes guide occupants to a designated assembly point located safely away from the building footprint. The plan and axonometric diagrams demonstrate vertical and horizontal evacuation strategy for all user groups.

Fig 281 Window tucked behind the reused metal facade.

Window and facade cleaning will be done using a MEWP to ensure safety during the maintance process. There will be enough space for people to deploy the MEWP as the facade is placed further back.

Access for maintance, such as electrical, heating, ventilation will be placed on the second floor behind the kitchen for easy access when need to be fixed (highlighted in blue is MHVR and grey area is the plant room).

The elevated platform presents multiple hazards, such as fall risk, manual handling strain, and potential chemical exposure.

Access to solar panel maintance will be done by climbing up the ladder onto the flat roof of the building. As you can see from the 2nd floor plan, the maintance area has a double-door compartment, which mean only authorised personel will be able to enter the mainance area (ladder going up to solar panel and plant room), which has been designed to keep it hidden from the public area by seperating the space between staff and visitor (dining area).

biogas factory.

Risk: Exposure to bacteria, mold and contaminants.

Mitigation: proper hygiene protocols, protective gear, and controlled waste management.

safety helmet, gas mask, gloves, and safety headphones for worker on the bio digester factory.

laboratory.

Risk: Exposure to bacteria, mold and contaminants.

Mitigation: proper hygiene protocols, protective gear, and controlled waste management.

gloves, safety glasses, closedtoes shoes/boots, and lab gown for lab worker.

Under CDM 2015 regulations, I have a duty to identify and reduce foreseeable risks throughout the building lifetime. This section highlights the key decisions in order to make sure the safety during maintanance, and building day-to-day. It consider access strategies, maintance of machines, and safe operations during its activity. For example, maintaining soalr panels that can be accessed through secure ladder access and physical separation from public zones. In addition, in the anaerobic digester located inside the biogas factory has been designed with safety requirements for manual handling, fall risks, and chemical exposure.

The factiory worker is positioned above the open inlet, indicating a need for improved safety infrastructure such as, guard rails, secure harness points, and splash protection.

fire & explosion risk.

Risk: methane buildup in the digester, and fire hazards in the kitchen.

Mitigation: proper ventilation, gas leak detection, and fire suppressions system.

Mitigation: structural integrity check, nonslip flooring, and training manual.

rubber non-slip flooring for the kitchen to prevent people slipping.

For the kitchen, training the staff with proper words in the kitchen. For example, passing through behind someone and saying "behind" to mitigate the risk of people colliding with each other with hot stuff.

The image illustrate how different type of loads are trasnfered throughout the building's structure. Vertical loads are carried by glulam columns down to the foundation. Wind loads are filtered and absorbedby external facade and braced structural walls, which trasfered laterally through the CLT slabs acting as diaphragm. Horizontal loads are resolved through rigid connections and diaphragm action of the CLT slabs. All loads are then distributed to the foundation to ensure overall stability and integrity of the building.

The stability strategy for the building respond to lateral forces, such as wind loads acting on the facade and roof. Bracing is primarily achieved through a combination of CLT floor, rigid glulam frame, and the intergration of shear walls in selected zones.

The CLT slabs (150mm) act as support for horizontal loads that transfer wind loads across the floor plate to vertical stabilizing elements. The CLT slab help distribute loads to the glulam frame and help limit racking.

Vertical stability can be achieved through a mix between glulam frames and CLT wall panels at stair cores and facade ends that function as shear walls. This approach allow the building to be open and flexible space while also providing sufficient bracing against wind loads from all direction.

Using cross bracing as an extra layer of structure help with structure lateral stability by efficiently distributing winds loads across the frame while reducing sway and structural size. In addition, it increase the stiffness and provides alternate load paths, which improve the overall safety and stability during high winds. Furthermore, it is cost effective and easy to install while not adding too much extra weight.

The structure of the building is mainly chosen to balance sustainibility, flexibility, and buildability. The main structure that I select is glulam post and beam frame because it allows long and open spans that are ideal for spaces like the restaurant, laboratory, and classroom, while also reducing the need for internal walls and bulky supports. Glulam offers a strong visual character that aligns with the project's enviromental narrative, whcih is using a renewable material with low carbon emmision than steel and concrete.

For the floors, integrating CLT (cross laminated timber) panels to provide structural rigidity and contribute to the lateral stability of the building. CLT slabs are efficient to install and can tie the structure together during high wind while maintaining the overall timber aesthetic.

Reused steel pipes will be used for the facade or the secondary frame. The metal pipes facade is not the primary load bearing components, but they reflect the project's interest in material reuse. Structurally, the reused metal pipes facade provide shading and lightweight screening for privacy.

Glulam and CLT are selected as the primary structural system for their low embodied carbon, fast prefabrication construction, and strong performance in both tension and compression. Compared to steel and conrete, glulam and CLT offer a more sustainable, reusable, and naturally insualting solution that align with the project's environmental goals.

The structural grid in my project follows 4 to 6 meter spacing, which provide a flexible and efficient framework for both open-plan and subdivided spaces. This 4-6 meter range suits the open space of the restaurant, laboratory, classroom and others without compromising structural integrity and material efficiency.

The primary glulam structure are sized 300 x 300 mm for both columns and beams giving the structure a clear visual identity and strong presence. Some of the sizing is longer than the 4-6 meter range to accomodate rooms inside the building. The beams spanning across the columns at regular intervals that carry 150 mm thick CLT floor slabs. These slabs provide structural rigidity and also act as horizontal diaphragms that helps to distribute loads and contribute to lateral stability.

All the structural sizes and span are developed based on the design of the building and checked from VS EN 1995-1-1 (Eurocode 5).

The synthesis review has brought together all my project into one, from the narrative and spatial strategy to technical works. have changed the way I render my floor plan since the synthesis review and now it captured the site context, and the texture of material on the building. Overall, synthesis review has helped me refine my ideas, curating all the final drawings, including celebratory drawing.

all figures are by the author, except:

Fig 6 - Harvey open big boxes and tells his employees to dump stuff to sea. Created by Liz Mironova during theming phase.

Fig 8 - Adapted from a hand drawing of "Harvey open big boxes and tells his employees to dump stuff to sea" by Liz Mironova. Stylised using ChatGPT (OpenAI) with prompt assistance. Prompt: https://chatgpt.com/ share/682e49ec-d5e8-8006-a507-a8bcad69172e. Final version developed by the author.

Fig 9 - Adapted from a hand drawing of "Harvey open big boxes" by Liz Mironova. Stylised using ChatGPT with prompt assistance. Prompt: https://chatgpt.com/share/682e49ec-d5e8-8006-a507-a8bcad69172e. Final version developed by the author.

Fig 10 Steve and Jack see Harvey dumping stuff. Created by Liz Mironova during theming phase.

Fig 11- Adapted from a hand drawing of "Steve and Jack see Harvey dumping stuff and takes photo" by Liz Mironova. Stylised using ChatGPT with prompt assistance. Prompt: https://chatgpt.com/share/682e49ec-d5e8-8006-a507a8bcad69172e. Final version developed by the author.

Fig 12 Jack waiting in the pub. Created by Emily Kate Hobson during theming phase.

Fig 13 Adapted from a hand drawing of "Jack waiting in the pub" by Emily Kate Hobson. Stylised using ChatGPT with prompt assistance. Prompt: https://chatgpt.com/share/682e49ec-d5e8-8006-a507-a8bcad69172e. Final version developed by the author.

Fig 14 Police rush to catch Harvey. Created by Emily Kate Hobson during theming phase.

Fig 15 Adapted from a hand drawing of "Police rush to catch Harvey"by Emily Kate Hobson. Stylised using ChatGPT with prompt assistance. Prompt: https://chatgpt.com/share/682e49ec-d5e8-8006-a507-a8bcad69172e. Final version developed by the author.

Fig 16 Steve and Jack see Harvey dumping stuff. Created by Emily Kate Hobson during theming phase.

Fig 17 Adapted from a hand drawing of "Steve and Jack see Harvey dumping stuff" by Emily Kate Hobson. Stylised using ChatGPT with prompt assistance. Prompt: https://chatgpt.com/share/682e49ec-d5e8-8006-a507a8bcad69172e. Final version developed by the author.

Fig 18 Steve and Jack run to police station. Created by Liz Mironova during theming phase.

Fig 19 Adapted from a hand drawing of "Steve and Jack run to police station" by Liz Mironova. Stylised using ChatGPT with prompt assistance. Prompt: https://chatgpt.com/share/682e49ec-d5e8-8006-a507-a8bcad69172e. Final version developed by the author.

Fig 20 Jack informing Steve about Harvey dealings. Created by Stella Jianing Guo during theming phase.

Fig 21 Image generated and stylised by the author using ChatGPT (OpenAI) with prompt assistance. Prompt available at: https://chatgpt.com/share/682e49ec-d5e8-8006-a507-a8bcad69172e.

Fig 22 Steve testing water and result comeback with high chemicals. Created by Stella Jianing Guo during theming phase.

Fig 23 Steve noticing less cockles when tide went out. Created by Stella Jianing Guo during theming phase.

Fig 24 Sub-group model. Photograph taken by Liz Mironova, 2024.

Fig 25 Sub-group poster illustrating a crime-related narrative. Developed during group theming phase (group work).

Fig 26 Gigamap showing how paper can be reused or recycled. Created during group work in Theming phase.

Fig 68 Blyth site map indicating zones. Sourced from studio material provided via Canvas by the ARC3001 teaching team, 2024.

Fig 83 Median age of population in Blyth. Source: ONS Census, 2021. Accessed via Department for Levelling Up, Housing & Communities (Accessed 2024).

Fig 84 Age profile in Blyth. Source: ONS Census, 2021. Accessed via Department for Levelling Up, Housing & Communities Accessed 2024).

Fig 85 Deprivation level in Blyth. Source: ONS Census, 2021. Accessed via Department for Levelling Up, Housing & Communities (Accessed 2024).

Fig 86 Aerial view of Blyth, showing the Bates Clean Energy Terminal. Image sourced from the Port of Blyth official website https://portofblyth.co.uk/facilities/bates-clean-energy-terminal/ (accessed 2025).

Fig 87 Blyth old coal mines. Image sourced from the North East Heritage Library official website: https://www.northeastheritagelibrary.co.uk/coalsarchive/bly01/cowpen-colliery (accessed 2024).

Fig 88- Offshore wind turbines off the coast of Blyth. Image sourced from BBC News, 2021. https://www.bbc.co.uk/news/uk-england-tyne-55842657 (accessed 2024).

Fig 89 Blyth cockle art. Image sourced from Northumerland Gazette. https://www.northumberlandgazette.co.uk/news/environment/artificial-shelter-shells-installed-at-commissioners-quay-in-blyth-to-improve-marinebiodiversity-4121984 (accessed 2024).

Fig 90 Blyth seasonal market. Image sourced from Blyth Market Gallery. Available at: https://www.blythmarket.co.uk/gallery.php (accessed 2024).

Fig 94 Blyth topography. Image sourced from topographic-map. Available at: https://en-us.topographic-map.com/map-82w59m/Blyth/ (accessed 2024).

Fig 95 Blyth wind chart. Image sourced from WillyweatherUK. Available at: https://wind.willyweather.co.uk/ne/northumberland/blyth.html (accessed 2024).

Fig 96 Tidal chart. Image sourced from tide-forecast. Available at: https://www.tide-forecast.com/locations/Blyth/tides/latest? (accessed 2024).

Fig 97- Flood management overview. Image sourced from Wansbeck and Blyth Catchment Flood Management Plan. Available at: https://assets.publishing.service.gov.uk/media/5a7c9493ed915d6969f45e35/Rivers_Wansbeck_ and_Blyth_Catchment_Flood_Management_Plan.pdf (Accessed 2024).

Fig 110 - Cockle farm. Image sourced from Adobe stock. Available at: https://stock.adobe.com/uk/search?k=cockle+farm&search_type=usertyped&asset_id=35066230 (18 accessed 2025).

Fig 111- Laboratory. Image sourced from MR Lab. Available at: https://www.mrclab.com/types-of-science-laboratory (18 accessed 2025).

Fig 112 - Biogas factory. Image sourced from HoSt Bioenergy. Available at: https://www.host-bioenergy.com/solutions/biogas-plants/organic-waste-biogas-plants/ (18 accessed 2025).

Fig 113 - Classroom. Image sourced from AdobeStock. Available at: https://stock.adobe.com/uk/search?k=classroom&asset_id=93969672 18 accessed 2025).

Fig 114 - Cooking school. Image sourced from AdobeStock. Available at: https://stock.adobe.com/uk/search?k=culinary+school&asset_id=1369135009 18 accessed 2025).

Fig 115 - Restaurant. Image sourced from AdobeStock. Available at: https://stock.adobe.com/uk/search?k=restaurant&asset_id=327777097 18 accessed 2025).

Fig 135 - Cockle farm. Image sourced from Adobe stock. Available at: https://stock.adobe.com/uk/search?k=cockle+farm&search_type=usertyped&asset_id=35066230 (18 accessed 2025).

Fig 136 - crushed cockle shells for catalyst. Image sourced from ResearchGate. Available at: https://www.researchgate.net/figure/Preparation-of-CaO-catalyst-derived-from-waste-shell-1-000C_fig4_259878789 (accessed 2024).

Fig 137 - Aquaponics. Image sourced from Earth.org. Available at: https://earth.org/data_visualization/aquaponics-a-solution-to-food-insecurity/ (accessed 2024).

Fig 139 - Anaerobic digester. Image sourced from Nexus PMG. Availabe at: https://www.nexuspmg.com/insights/anaerobic-digestion (accessed 2024).

Fig 140 - Metric handbook cover. Source: Metric Handbook (Adler 1999, p.1).

Fig 141 - Space between square dining tables in mm. Source: Metric Handbook (Adler, 1999, p.289).

Fig 142 - Space between formal dining in mm. Source: Metric Handbook (Adler, 1999, p.289).

Fig 143 - Kitchen layout examples. Source: Metric Handbook (Adler, 1999, p.300).

Fig 144 - Average range of people sitting at a desk to reach outer area. Source: Metric Handbook (Adler, 1999, p.195).

Fig 145 - Desk, table, and file spacing. Source: Metric Handbook (Adler, 1999, p.197).

Fig 146 - Space and circulation requirement of office equipment Source: Metric Handbook (Adler, 1999, p.196).

Fig 147 - Access for power and other services through perimeter cable ducts, and cable management. Source: Metric Handbook (Adler, 1999, p.200).

Fig 148 - Limit of workzone in a laboratory. Source: Metric Handbook (Adler, 1999, p.476).

Fig 149 - Types of worktops for laboratory. Source: Metric Handbook (Adler, 1999, p.478).

Fig 151 - H&M kinetic wall, sourced from Stereo Kinetic walls (https://stereo-kinetic.com/gallery/), accessed (13 May 2025).

Fig 153 - Section of kinetic group model. Created by the group during thinking through making phase.

Fig 154 - Elevation of kinetic group model. Created by the group during thinking through making phase.

Fig 155 - Isometric of kinetic group model. Created by the group during thinking through making phase.

Fig 159 - Dry fitting the tiles into the metal rod. Taken by Sutan Bintang Ramadhan during thinking through making phase.

Fig 160 - Making the hanger for metal tiles. Taken by Sutan Bintang Ramadhan during thinking through making phase.

Fig 161 - Timber floor and wall part of the model. Taken by Sutan Bintang Ramadhan during thinking through making phase.

Fig 232 - Approved document B page 24, sourced from GOVUK (https://www.gov.uk/government/publications/fire-safety-approved-document-b), (accessed 13 May 2025).

Fig 247 - MVHR diagram, sourced from solihul (https://www.solihullheatingandbathrooms.co.uk/mechanical-ventilation-with-heat-recovery-mvhr/), (accessed 13 May 2025).

Fig 251 - Bauder Gulley details, sourced from Bauder (https://www.google.com/imgres?q=bauder%20gullet%20detail&imgurl=x-raw-image%3A%2F%2F%2F8aebb625fc52a2a5bd32de23e0a1c6cc7e4bff87083c225255c60b2a d1f7d35f&imgrefurl=https%3A%2F%2Fwww.bauder.co.uk%2Fassets%2Fmedia%2FBauderMedia%2FProducts%2FAncillary-Items%2FOutlets%2FGeneral-outlets%2FBitumen-outlets%2FCompact-Vertical-DN100%2FBauder-Bitumen-Compact-Vertical-Outlet-DN-100-Technical-Data-Sheet.pdf&docid=CtYHnGbE82aZ6M&tbnid=paJS_CW264o4YM&vet=12ahUKEwiTmL-k06SNAxXvVkEAHc8xLlcQM3oECBEQAA..i&w=1516&h=883&hcb=2&ved=2ahU KEwiTmL-k06SNAxXvVkEAHc8xLlcQM3oECBEQAA), (accessed 13 May 2025).

Fig 254 - Approved document B page 14, sourced from GOVUK (https://www.gov.uk/government/publications/fire-safety-approved-document-b), (accessed 13 May 2025).

Fig 255 - Approved document B page 15, sourced from GOVUK (https://www.gov.uk/government/publications/fire-safety-approved-document-b), (accessed 13 May 2025).

Fig 259 - Approved document B page 149, sourced from GOVUK (https://www.gov.uk/government/publications/fire-safety-approved-document-b), (accessed 13 May 2025).

Fig 260 - Approved document B page 142, sourced from GOVUK (https://www.gov.uk/government/publications/fire-safety-approved-document-b), (accessed 13 May 2025).

Fig 266 - Fireshield varnish, sourced from Logicoat (https://logicoat.com.au/fireshield/) (accessed 13 May 2025).

Fig 268 - Approved document B page 174, sourced from GOVUK (https://www.gov.uk/government/publications/fire-safety-approved-document-b), (accessed 13 May 2025).

Fig 272 - Sprinkler, soruced from Utrasafe Fire Suppression (https://www.ultrasafe.org.uk/what-triggers-fire-sprinklers-and-can-they-go-off-accidentally/) (accessed 21 May 2025).

Fig 282 - MEWP for cleaning window, sourced from Central Training Services (https://central-training.co.uk/mobile-elevating-work-platform-mewp/) (accessed 13 MAy 2025).

Fig 286 - Fire estinguisher, sourced from CheckFire (https://www.checkfire.co.uk/fire-safety/fire-extinguishers/gas-fires/), [accessed 13 May 2025].

Fig 287 - Illustration of factory worker tools, sourced from VMEDO (https://vmedo.com/blog/list-of-safety-equipment-for-industries-factories-and-workplaces/), [accessed 13 May 2025].

Fig 288 - Illustration of a lab technician, sourced from iStock (https://www.istockphoto.com/search/2/image?mediatype=illustration&phrase=lab+technician), (accessed 13 May 2025).

Fig 289 - Kitchen anti slip mat, sourced from Watco (https://www.watco.co.uk/products/watco-kitchen-mat), (accessed 13 May 2025).

1. Topic Popovic, N. et al. (2023) "Shell Waste Management and utilization: Mitigating organic pollution and enhancing sustainability", Applied Sciences, 13(1), p. 623. doi:10.3390/ app13010623.

2. Spencer, B. and Laing, I. (2006) Bivalve cultivation: Criteria for selecting a site, Bivalve cultivation: criteria for selecting a site Available at: https://www.cefas.co.uk/publications/ techrep/techrep136.pdf (Accessed: 23 November 2024).

3. Tookwinas, S. (no date) Commercial Cockle Farming in Southern Thailand, Commercial Cockle Farming in Southern Thailand . Edited by E.W. McCoy and E.W. McCoy Available at: https://patricklepetit.jalbum.net/SAMUT%20SONGKHRAM/LIBRARY/Sea%20Cockle%20farming.pdf (Accessed: 23 November 2024).

4. What is anaerobic digestion (no date) Biogen. Available at: https://www.biogen.co.uk/anaerobic-digestion/what-is-anaerobic-digestion/ (Accessed: 23 November 2024).