FUTURE FUEL

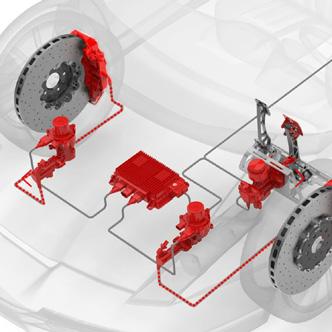

ALL ABOUT OIL TRANSPORT AND BEYOND BRAKE UP WHAT IS BRAKE BY WIRE EXACTLY?

ALL ABOUT OIL TRANSPORT AND BEYOND BRAKE UP WHAT IS BRAKE BY WIRE EXACTLY?

FROM 2021, ALL CASTROL PRODUCTS WE SELL IN AUSTRALIA AND NEW ZEALAND WILL BE COMMITTED TO CARBON NEUTRALITY IN ACCORDANCE WITH PAS 2060 ** A SMALL STEP TOWARDS A MORE SUSTAINABLE FUTURE

VACC President, Mark Awramenko offers hope to his membership and beyond as COVID-19 continues to hit businesses hard

Shane Jacobson is a self-declared car-coraller and truck-tragic. And it’s got him thinking about his insurance policies

Australia’s most comprehensive technical solution combines VACC’s suite of products with the global reach of Haynes

The era of Hydrogen Fuel Cell Electric Vehicles is finally upon us, Oz has 40 on the road already and more to come

The initial findings from the Environment Protection Authority Victoria’s pilot program have been released

VACC heads to the Murray River to mark some important membership milestones, and gather valuable member insight

Accreditation is on the agenda for VACC, the goal being to reform the system in order to stay ahead of the curve

Emma McIndoe – WinA’s member of the month – has taken the reins in the family business and is ready for action

Fostering a positive and productive workplace culture takes a lot of time and effort – it also makes all the difference

ACCC Chair, Rod Sims digs deeper into the new Motor Vehicle Service and Repair Information Sharing Scheme update

Oil – can’t live with it, can’t live without it. One thing is certain though, transportation needs to be weaned off it

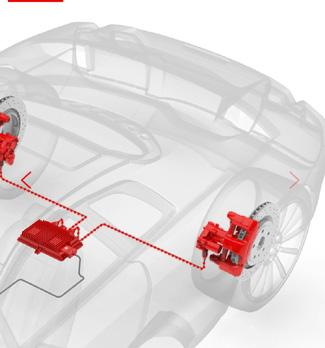

Brake-by-wire can mean different things to different people. It’s time to get some answers

Viable geometry turbochargers and P0420 and P0430 diagnostic trouble codes are the hot tech topics this issue

Find everything from the latest products to the best business services you need all in one place

Drive your business forward by taking

Facilitators

•

•

•

WITH extended COVID lockdowns biting particularly hard in Victoria, VACC President, Mark Awramenko recently wrote to all members offering solidarity during this most difficult of times. But he also offered so much more.

President Awramenko offered hope.

It is a difficult time for many businesses and the staff that work within them, and that can create a heavy toll on how people feel, communicate, and interact.

Constantly worrying about the viability of your business, how your staff are holding up, and how things are going back at home creates enormous stress. Sometimes it might feel like there’s no way out.

To help, VACC has arranged for all members and their staff to have access to free external mental health support available through Psychology Melbourne. VACC will cover the fees and all sessions are confidential. Members can simply provide their VACC membership number to Psychology Melbourne when booking.

Psychology Melbourne is committed to helping people improve their mental health and wellbeing, assisting them through personal, work, and relationship difficulties and introducing them to strategies that can fundamentally change and enrich their lives. It also works with organisations to help them create psychologically healthy workplaces and provide Employee Assistance Programs that improve productivity by helping their staff deal with personal and work-related difficulties.

for? If you could do with some additional support, get in touch with Psychology Melbourne today. And don’t forget to have a word with your staff.

If you are seeing signs of stress, a gentle and private word with them could make all the difference in the world.

And don’t forget that things will get better.

President Awramenko concluded his letter: As I look ahead, I am conscious that we will bear the scars of COVID-19 for many years, but things will eventually return to relative normality. I remain

and the industry will recover and prosper again.

I wish every member and their staff the best possible health in the months ahead and with every effort we will come through this together.

It’s true: better times will come around again. Until then, VACC is here to help.

David Dowsey

Contact Psychology Melbourne: psychologymelbourne.com.au or 03 9629 1001.

MANAGING

David Dowsey 03 9829 1247

editor@australianautomotive.com

SUB-EDITOR

Pia-Therese Hams

DESIGNERS

Faith Perrett, Gavin van Langenberg 03 9829 1159

creative@australianautomotive.com

CONTRIBUTORS

Paul Tuzson, Ged Bulmer, Geoff Gwilym, Rod Lofts, Pia-Therese Hams, John Khoury

and

breach of trade practices or fair trading legislation, violation of rights of privacy or confidential information or licences or royalty rights or other intellectual property rights, and warrant that the material complies with all relevant laws and regulations. This publication is distributed with the understanding that the authors, editors and publishers are not responsible for the results of any actions or works of whatsoever kind based on the information contained in this publication, nor for any errors or omissions contained herein. The publishers, authors and editors expressly disclaim all and any liability to any person whomsoever whether a purchaser of this publication or not in respect of anything and of the consequences of anything done or omitted to be done by any such person in reliance, whether whole or partial upon the whole or any part of the contents of this publication. Advertising accepted for publication in Australian Automotive is subject to the conditions set out in the Australian Automotive rate card, available from editor@australianautomotive.com

No interest. None.

Plans

That’s why you should choose choice of repairer.

Some benefits of choosing your own repairer include:

You can use a specialist repairer. Choice of repairer is important for owners of any car, no matter the make or model, but using a specialist repairer can really give you peace of mind if you’re in love with your vehicles, like I am.

truck-titus, or something like that. My doctor told me once, but I forgot all about it. Thing is, I’m not looking for a cure for my disease. I’m happy being a car-coraller, a bike-belover and a truck-tragic. I just love all things on four wheels, and three… better make that two, too. Probably not one, but I digress. Look, I just love things with wheels. That all right with you?

I’ve got a bunch of stuff in my garage, including my pride and joy EH Holden, the first car I fell in love with. I have some Fords and Holdens, and some bikes, too. I also have an MGB Roadster with whitewall tyres. What? Don’t you start…

All these vehicles are insured, of course but, after speaking to the people at VACC I got to thinking more about what was actually in my insurance policies. What I found out was not everybody can choose who repairs their vehicle in the event of an accident. I was stunned. I thought, ‘It’s my car, my choice, right?’ Wrong.

Insurance companies are increasingly making choice of repairer an optional extra. But it’s an extra you should have. It’s your vehicle and you should be free to choose who repairs it. Having a ‘choice of repairer’ option in your vehicle insurance policy is important if you want more say in who repairs your car. Being able to choose your repairer can have many benefits. With your chosen repairer you’ll have peace of mind knowing they will care for you and your vehicle. And that’s a good thing, right?

I have a trusted bloke that does all the panel repairs and resto bits and pieces on my vehicles. He’s the guy whose advice and skills I believe in the most. So, I wouldn’t want an insurance company to tell me that I can’t use him. Unfortunately, that’s where a lot of motorists find themselves. It doesn’t make any sense.

Your car deserves quality repairs. Your chosen repairer will quote on every damaged component on your vehicle, including the bits you can’t see. You can choose local. Being able to choose a repairer close to home can save you the trouble of whizzing all about town. Having your car repaired locally could also create jobs in your local

corporations that may not see you or your vehicle individually. If you allow your insurer to control who repairs your car, you could wait longer than necessary, and your repairs may not come out the way you expected. If you feel you’re being treated like a number, choose ‘choice of repairer’ and get some control back. So, come on, be in the driver’s seat and choose ‘choice of repairer’. Remember, it’s your car, your choice. VACC is spreading the word amongst motorists, so visit yourcaryourchoice. com.au. You can learn more about your rights and even go in the draw to win one year’s comprehensive car insurance! And don’t forget to catch up with me on the next episode of THE GRILLE podcast. I talk shop with Greg Rust

At DENSO, we bring together everything we know as an air conditioning systems manufacturer to bring you the highest quality line of factory-new compressors available. DENSO compressors are manufactured and tested to the strictest OE standards for unparalleled performance because we know drivers and their passengers expect a comfortable cabin environment

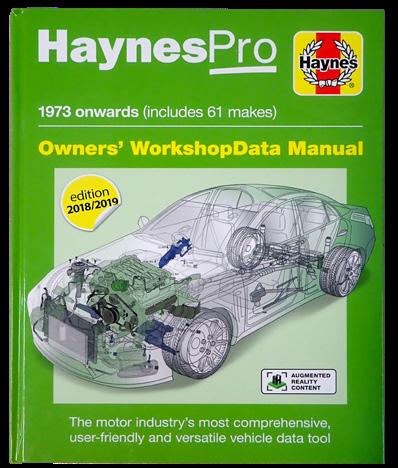

VACC Technical Services has launched into a new era of product offerings that will change the automotive technical information game in Australia.

VACC has signed a multi-year deal with the famous British-based Haynes Publishing Group, bringing to market a suite of products, unsurpassed in Australia, under the banner of VACC MotorTech.

VACC MotorTech brings together VACC’s proven Tech Online, Times Guide, Tech Estimate, Tech Advisory Service and Tech Talk products with the might of Haynes’ international know-how, to provide an enormous (and evergrowing) amount of technical service and repair information to subscribers.

Available now for subscription are four ‘solutions’: Maintenance, Service & Repair, Diagnostics and Commercials. These new products are positioned at an unbeatable price and VACC members receive generous discounts of up to 50 percent.

Haynes is best known in Australia for its Haynes manuals that have been in print since 1965 and have sold over 200 million copies worldwide. However, they

online products, designed for automotive professionals under the HaynesPro brand.

Until the agreement with VACC, HaynesPro products have not been available in the Australian market in such affordable and convenient packages.

The HaynesPro products include:

• HaynesPro Manuals AllAccess Cars allows access to all Haynes manuals online, providing step-by-step repair and service information, along with extra details not published in the hard copy versions. The Haynes OnDemand video tutorials – available for many of the most popular models – are the ultimate aid to getting vehicles correctly serviced and repaired.

• HaynesPro WorkshopData Tech contains extensive maintenance information like repair times, timing belt and chain replacement procedures, capacities, wheel alignment, torque specification and over 100,000 high-quality technical drawings.

• HaynesPro WorkshopData Electronics and Smart includes the VESA guided diagnostics system, wiring diagrams for most vehicle systems, fuse and relay locations, earth point and control unit locations, TSBs and known fixes.

• HaynesPro WorkshopData Truck includes WorkshopData Tech, WorkshopData Electronics and WorkshopData Smart. It is the most effective application from fault to fix.

The agreement between VACC and Haynes provides automotive business owners new options and easy access to repair information and vehicle repair times not available previously, in bundles to suit every business’s needs.

Visit: motortech.com.au to learn more.

The new auto industry

brought to you by the best in the business

Join journalist Greg Rust, motoring enthusiast Shane Jacobson, and industry authority Geoff Gwilym as we dig deep into automotive. There’ll be news and views, industry insights and trends, special guests, and plenty of laughs along the way.

So join us.

Listen and review now

Words Ged Bulmer

Hydrogen-fuelled cars have been like a slow train but suddenly Australia has 40 of the revolutionary vehicles wafting silently along our roads, with more on the way.

AFTER decades of being touted as the ultimate solution to the issue of vehicle tailpipe emissions the era of Hydrogen Fuel Cell Electric Vehicles (FCEVs) is finally upon us, following the recent Australian launch of not one but two of the revolutionary vehicles.

Korean car maker, Hyundai narrowly beat its Japanese rival Toyota to the draw, launching its fleet of 20 zeroemission Nexo FCEVs in Canberra in April as part of a three-year trial with the ACT government, in what is billed as the first use of hydrogen vehicles by any government in Australia.

The launch coincided with the opening of a new 700-bar hydrogen refueling station in Canberra. It manufactures its own hydrogen on-site using harvested rainwater and green electricity, providing filling capability for the Nexo fleet which will be used in a variety of real-world applications across several ACT Government departments.

Three weeks later, Toyota announced its own hydrogen trial, launching a 20-strong fleet trail of its Mirai FCEV in

Melbourne, in what it described as “an extended demonstration program,” with selected Victorian organisations and businesses. The move follows the launch of the second-generation Mirai in Japan late last year, and the development of Victoria’s first permanent hydrogen production and refueling facility at Toyota’s Centre of Excellence in Altona. In both instances the vehicles are being deployed in limited fleet trials, so, while fully ADR-approved, they are not technically available for sale. Hyundai at least is open to leasing more of its Nexo SUVs to other fleets and early adopters, however, through an all-inclusive lease program.

The catch with either vehicle is that hydrogen refueling sites are currently as rare as hen’s teeth in Australia, with those mentioned above being the country’s only publicly available facilities. More are expected to come online in Brisbane and Melbourne by the end of this year, with additional stations also planned for NSW, South Australia, Western Australia and Tasmania.

Complex and expensive to build, such refuelling sites are key to the broader uptake of hydrogen technology, and their relative scarcity has held back the technology in other markets where FCEVs have been available for several years. In the US state of California, one of the world’s most enthusiastic supporters

of FCEVs, there are currently only 43 publicly accessible hydrogen stations, while Germany, with three times the population of Australia, has only around 92 stations. Hyundai’s Senior Manager of Future Mobility and Government Relations, Scott Nargar acknowledges the challenges this presents to the public acceptance of hydrogen, noting that there is a “strong link between consumer adoption of these new technologies and available infrastructure.”

He also concedes that the cost to build refueling stations, such as the Canberra Scott Nargar, Hyundai (above inset). Compressed hydrogen dispenser (below)

Hydrogen Fuel Cell Electric Vehicles (HCEVs) are like Battery Electric Vehicles (BEVs) in that they use an electric motor or motors to power the vehicle, so are considered more efficient and reliable than a conventional combustion engine due to fewer moving parts. However, FCEVs have certain technical advantages over BEVs, including greater range, lower weight and quicker refuelling time. The Hyundai Nexo, for instance, has a claimed electric range of 666km and the ability to refuel its 156.6-litre hydrogen tanks in three to five minutes. Some of

facility, is currently not justified by the low number of FCEVs forecast to be on our roads anytime soon. Despite this, he says that government and industry must continue to collaborate on such projects to help spark the nascent industry here.

This is because hydrogen FCEVs are regarded by many as the ultimate solution to the problem of tailpipe CO2 emissions, since hydrogen is an already abundant element and can be produced using nothing more than water and green electricity. It is for these reasons, plus the fact hydrogen can be made safely from renewable energy sources and is virtually non-polluting, that it is often touted as the fuel of the future.

While both Hyundai and Toyota have conducted small-scale FCEV trials here for the past few years, the move to these larger fleet trials is seen as a significant step towards embracing hydrogen technology in Australia.

Hyundai Motor Company Australia CEO, Mr. Jun Heo, said hydrogen would play a key role in the company’s vision for a low-CO2 motoring future.

“For a long time, hydrogen has been touted as the fuel of the future. However, with the arrival of a fleet of Nexo FCEVs for the Australian Capital Territory Government, we’re pleased to say that it’s now the fuel of today,” Mr. Heo said.

“Nexo is the embodiment of our longterm commitment to introducing hydrogen-powered transport in Australia and around the world,” he said.

Toyota Australia Vice President Sales; Marketing and Franchise Operations, Sean Hanley said Toyota was a firm believer that hydrogen fuel cell technology could play a central role in reducing emissions and it was committed to helping drive towards a cleaner society.

“When we launched the Prius hybrid 20 years ago, we started

the best BEVs, such as the Tesla Model S can almost match the Nexo’s range, but even the most powerful 350kW DC fast chargers take 20 minutes or more to deliver similar range, and most chargers are much slower. Where BEVs use large and heavy lithium-ion batteries that are recharged by plugging into the electricity grid, the FCEV carries its energy source as hydrogen in tanks. The fuel is mixed with oxygen and passed through a fuel cell catalyst to create electricity, which in turn powers the electric motor.

a drive towards helping reduce emissions from our vehicles through a process of electrification.

“With the introduction of the zeroemission Mirai FCEV and its use by pioneering organisations, Toyota is continuing that journey as we aim to achieve zero emissions from our vehicles by 2050 under the global Toyota Environmental Challenge 2050,” he said.

While acknowledging hydrogen technology is still in its infancy in Australia, Nargar believes its day has finally come. He points to what he calls “a perfect storm of rising government and industry action on CO2, the declining cost of renewable energy, which can be used to create green hydrogen cost-effectively, and falling costs of the vehicles and their fuelling stations as capacity and demand grows.

“Australia, with its existing ports and quality infrastructure, plus our abundance of wind and solar power potential, is in a unique position to maximise the opportunity presented by hydrogen. There is no better place in the world to establish a green hydrogen industry,” he said.

The Federal Government seems to agree, having set an objective to be a major global hydrogen player by 2030, including being a top three exporter of hydrogen to Asian markets by that year.

In addition to its clean energy credentials, it’s the versatility of hydrogen to power everything from cars to trucks, buses, and even ships, along with its ability to be transported as a liquid or a gas, and therefore exported, that has people so excited about its potential.

As members of the Hydrogen Council of Australia, car makers like Toyota and Hyundai are working to grow a sustainable hydrogen industry in Australia, even if it seems highly unlikely the technology will overtake

The only by-product of this process is distilled water, which is discharged as vapour from beneath the vehicle. It’s for this reason that FCEVs, using hydrogen manufactured with green electricity, are seen as the ultimate solution to harmful vehicle emissions.

However, just like petrol, diesel, or LPG, the hydrogen in an FCEV’s tank must be replenished when it runs out, and therein lies one of the major barriers to the uptake of the technology, because hydrogen refuelling stations are rare in Australia and expensive to build.

BEVs, let alone internal combustion powered vehicles any time soon.

Nonetheless, as the Chinese philosopher Lao Tzu is claimed to have said: A journey of a thousand miles begins with a single step. Or – as is the case with FCEVs – with the launch of these two technically advanced vehicles to the Australian market.

Toyota’s sleek and stylish Mirai is a five-seat, rear-drive four-door sedan that uses an advanced hydrogen fuel cell powertrain with peak outputs of 134kW/300Nm and generates zero carbon emissions.

At the heart of the Mirai is a fuel cell powertrain that comprises a 128kW 330-cell fuel cell stack, three compressed hydrogen tanks, a lithium-ion battery and integrated electric motor and rear transaxle.

Mounted under the bonnet, the fuel cell stack draws in air that is purified and combined with hydrogen in a chemical reaction to produce electrical energy, with water vapour as the only emission. The hydrogen is stored in three carbon fibre reinforced plastic (CFRP) tanks that have a combined capacity of 5.6kg, giving the Mirai a range of approximately 650km.

Electrical energy generated by the fuel cell stack is fed to either the battery, mounted behind the rear seat, or directly to the electric rear-drive motor, depending on requirements.

The electric motor is housed in a rear transaxle that combines the motor, transmission, and differential.

Words Pia-Therese Hams

THE initial findings from the Environment Protection Authority Victoria (EPA) pilot program conducted with VACC members have been released.

The EPA pilot program was developed to help prepare industry for the new Victorian environmental regulations that came into play this year. Under the new laws, a business that conducts activities posing any risk to human health and the environment must take reasonably practicable steps to minimise them. Participants received free advice, with EPA covering the cost of consultant site visits, as well as a tailored action plan outlining how to improve the management of risks of harm from pollution or waste.

Positive findings:

Almost all businesses have good housekeeping, meaning the sites

85 percent of sites had good or acceptable maintenance of equipment 71 percent of the sites had

For more information about the new Victorian environmental regulations, visit: epa.vic.gov.au

Words John Khoury

RODNEY O’Gorman, owner of long time VACC member-business Kingsbury Auto Electrical, has called time on his automotive career – a journey spanning decades. He took a break from clearing up the workshop to reflect on his experiences and provide some sound advice for auto newcomers.

Rod, a third-year apprentice at the time, and his father Colin, started the auto electrical business in 1978 and joined VACC a year later. By 1982, he had saved enough to buy the business outright from Colin and decided to join the Bosch authorised network of auto electrical repairers. Up until recently, Rod’s business was recognised as the longest Bosch service centre in Australia, not to mention the recipient of many awards along the way.

Rod eventually branched out into other services, including the Victorian interlock program and, at one stage, was the second largest provider in Australia. In more recent times, Rod started repairing Bosch power tools. This move was in response to a lack of parts, access to repair information and

what he describes as 'the throwaway society' that automotive had become. To demonstrate his point, Rod nodded to a pile of near new alternators and starter motors. In the past, people could order parts to repair these components but now they are just a replaceable item. The last 10 years have been particularly challenging. Manufacturer control over repair data played a big role, with technicians – like Rod – restricted

when trying to undertake a repair and see it through to the end. Frequently, a vehicle had to be sent on to an authorised dealer for reinitialisation or a software update. On the other hand, as a Bosch power tool service agent, Rod has access to all the parts and repair information necessary to restore them back to their original state. Put simply, he says the role of the technician is to fix things. There is nothing more satisfying than that.

Rod’s contribution to the broader automotive industry and VACC has been invaluable over the years. He has advocated for right to repair reforms, as well as training and industry standards, throughout his 24 years on the VACC Automotive Electrical Division Executive Committee. He also sat for 10 years on the Boschequivalent body. Rod's advice for anyone starting a new business in automotive is to surround themselves with a good support network. If possible, join a well-known repairer network and belong to an industry association that can provide practical support when it comes to employment, technical and regulatory obligations.

VACC wishes Rod all the best in retirement and thanks him for his long association with the Chamber.

Words Pia-Therese Hams

VACC President, Mark Awramenko, VACC CEO, Geoff Gwilym and VACC Industry Policy Advisor, Michael McKenna hit the road recently to mark the milestones of some of the Chamber’s longest-standing regional members.

First visit was to 50-year memberbusiness, Mustica Motors in Cobram, where they were welcomed by owner, Chris Mustica. The business was founded by Chris’ father, Neville, the son of Italian migrants. Neville had been working as a mechanic for Alan Marxsen Motors, a Leyland dealer, and was given the opportunity to buy the dealership on a ‘handshake deal’ in

to the impact of electric and hybrid vehicles, especially in regional Victoria. The consensus was that it will be a less brand-driven market in future, with the next generation of drivers regarding their vehicle as more of a commodity – rather than a prized asset. Before hitting the road, President Awramenko thanked the team again for their support and contribution to the Chamber and their local community, presenting them with a 50-year certificate.

automotive overseas, Chris stayed on and has been involved in the business 36 years and counting – he and his wife Annette buying it from his parents in 2008. The successful enterprise has faced its fair share of challenges along the way. Mustica Motors was one of the 180 dealers that lost their Holden franchise when the marque made the decision to leave Australian shores in 2020. It disappointed Chris that, due to pandemic restrictions, dealerships were unable to eyeball the management at the time and put a case forward for local dealership presence and retention.

Additionally, it astounds Chris that motor vehicle manufacturing was permitted to up and leave Australia. He put to the table: Should Australia consider manufacturing vehicles again given the continued restrictions with COVID-19 and international delays? A loaded subject, Geoff maintained that only electric vehicles could be considered in that case. However, an even greater challenge would be convincing Australians to buy home-grown vehicles again, especially when the aspirational buyer still dreams of the likes of Audi or BMW.

The Mustica family being Nissan dealers since 1974 and Holden dealers for 29 years, the conversation quickly turned

Koondrook was the next stop for VACC – more than 300 kilometres northwest of VACC House in Melbourne and home to 75-year member, Molin Motorcycle & Marine. Originally Molin’s Garage, the business was founded by Arthur and Thelma Molin in 1936. Nowadays, it is run by their son, Geoff and his son, Paul, who takes care of the day-to-day administrative, sales and repair side of the business.

Like the automotive industry it serves, the business has evolved since it first opened its doors. The original workshop was rebuilt and the team eventually moved into the current premises – down the road – in 2003. The business service offerings have also expanded but the main reason behind the move was space, the team moving from a 2000 square-metre to 5000 square-metre site. “Well we said we’d build a big one so we wouldn’t have to put anything outside. Now, half the stuff is outside,” admitted Geoff Molin.

Sitting down with the team, Geoff Gwilym wanted to learn more about the business’ local clientele and ability to attract staff. Paul explained that originally customers predominantly worked in the rail or timber industry. Today, the business largely relies on tourist traffic, the timber mill, dairy farming, and other farming sectors to support its day-today operations. “And the sawmill is still in the middle of town. One-hundred and thirty-eight years,” added Geoff Molin. The scope of work has changed too. “In the old days, we’d pull cars apart and rebuild the engine,” said Geoff. However, if someone came to him today, wanting a rebuild? “I’d say, throw a new one in”. He maintains that it is simply not viable to repair engines like that anymore. Overall, times are buoyant, but supply chain issues remain a challenge. Echoing reports from across the Australian retail sector, the business’ stock orders are running behind. For new boats and agricultural bikes, the wait can be over a year. The team are feeling it and customers can be impatient, but they maintain that the good reputation of the business locally makes a big difference.

The team has also felt the direct impact of the industry’s skills shortage. Chamber research shows a current skills gap of 31,140 automotive positions nationally. VACC continues to lobby the Morrison Government to expand its Priority Migration Skilled Occupation List but, for the time being at least, it

comes down to taking what labour is available. “You’ve just got to,” says Geoff. “Everyone I speak too, whether it be Echuca, Bendigo, whoever, it’s the same – we can’t get staff.”

Typical of most country families, the bonds are tight and Paul’s son, Ash, helps out. A great asset to the business, Geoff recalls him always “mucking around with (machines)” growing up. Currently a second-year carpentry apprentice, Ash is still weighing up his options and considering his trade aspirations. As apprenticeships and engaging the next generation remain a primary objective of the Chamber, he was able to provide the

group with some insight into the younger generation’s perception of the trade.

“From my point of view, I am quite happy in the current environment but a lot of other people say 'no, get out on site',” said Ash. Another factor is wages, with automotive apprenticeships paying a lower rate compared to other trades.

Thanking the Molin family again for their loyalty to the Chamber and valuable industry insights, Geoff, Mark and Michael headed back to Melbourne with a lot to think about.

In summary, while there is still work to be done, the member-visits proved once again that the energy and drive of VACC’s regional members is alive and well.

THE GRILLE, a new automotive industry podcast hosted by Australian motorsport journalist and commentator, Greg Rust; beloved actor, presenter, and knowledgeable automotive enthusiast, Shane Jacobson and Victorian Automotive Chamber of Commerce (VACC) CEO, Geoff Gwilym has taken off.

The inaugural August episode included an interview with UK motoring personality, Jeremy Clarkson and THE GRILLE has not looked back. With 4000 downloads and counting since launch, the show is fast becoming a favourite among automotive professionals, motoring enthusiasts, and motorsport fans.

In episode two – out now – the crew breaks down the latest new-vehicle

registration numbers from the Federal Chamber of Automotive Industries’ VFACTS. VACC Body Repair Division Committee Chair, Carly Ruggeri is also on board to discuss the Chamber’s Your Car, Your Choice campaign –which aims to engage motorists in Victoria and Tasmania by offering up the chance to win one year’s free comprehensive car insurance, while using the opportunity to educate entrants on the reasons they should choose who repairs their vehicle in the event of an accident.

Mixing business with pleasure, five times MotoGP World Champion, Mick Doohan comes by for a chat, followed by some automotive movie trivia.

Did you know that for the National Lampoon’s Vacation movie, producers had five station wagons waiting in the

wings– to account for the series of bad luck that the Griswold family encountered.

“There’s a good reason for teaming up with Greg Rust and Shane Jacobson for THE GRILLE. VACC completely understands there are two components to a good podcast. One is great content, delivered in an authoritative way. The other essential element is entertainment. THE GRILLE delivers both,” said Geoff. Rate and subscribe to THE GRILLE on Apple Podcasts, Spotify, Google Play, LiSTNR or the VACC website. New episodes released on the tenth of each month.

Visit: thegrillepodcast.com.au

Special thanks to THE GRILLE naming rights sponsor, Bendix and advertising partner, DENSO.

Words Geoff Gwilym

CARS, batteries, and particularly electric vehicle batteries are full of important resources that we need to recover and reuse.

Precious metals such as lithium, copper, cobalt and graphite are all finite – that is, we can’t just create more when we need them. They need to be mined from the earth or urban mined from things we have already used.

With the growth in the uptake of electric vehicles in Australia looking to hit around 26 percent by 2030, it’s clear we need to shift our battery recycling rates from around three percent to big double digits, even up to 80 percent.

That’s all batteries, including those in cars, torches, computers, and almost every household appliance that blips when you turn it on.

Metals recovered from electric vehicle batteries, including lithium, can go back into new batteries, which underpins one of the key purchasing decisions for EV drivers.

For the automotive industry, this is about having a national plan

for end-of-life vehicles that includes the full recovery of EV batteries.

Given we are at a new beginning with electric power trains – we had a good go back in 1910 – it’s an ideal time for government to hatch a master plan that manages the recycling of critical metals

in batteries, which would make buying an EV a truly green pursuit.

How about a battery deposit scheme for all new EVs that helps offset the cost of recovering these precious metals? That’s an idea worth pursuing.

Words Geoff Gwilym

VICTORIAN Automotive Chamber of Commerce (VACC) accreditation, at a divisional level and through A-Grade accreditation, appears it has been around for as long as VACC. But it hasn’t.

VACC A-Grade accreditation was born in 2013. It borrows its name from the original A-Grade Automotive Engineer Certificate that was awarded to members who passed the A-Grade examination, held at VACC from 1926 to 1998.

While the original A-Grade engineers’ certificate focused on technical and academic capability, the modern version of A-Grade bolsters divisional accreditation. It has as much to do with the way a business presents and operates, as it does with tooling and technical capability. While pushing forward into a broader accreditation design, it has struggled to attract over 120 members at its height and membership currently stands at 55.

Divisional accreditation was born in 1991 as pressure built in the Victorian Government to have the local automotive industry regulated, following the many consumer issues government and regulators received. To combat having intervening government oversight in the industry, VACC built an accreditation system that focused on consumer protections, business registration, and a process whereby the association managed consumer complaints.

Today, the role of VACC’s consumer and business advisory service is a function of the original accreditation program.

It would be true to say that in 1991, like many industries, automotive was in a transitional phase between relatively light-handed consumer protections and limited government regulation, to where we are today – an environment peppered with consumer protection laws and recourse mechanisms, and regulators at every corner. Things have certainly changed.

VACC has reviewed – or engaged specialists to review – accreditation programs over the years, with little change in the content or structure of the divisional accreditation programs. Change has been recommended, but it hasn’t happened.

A review of accreditation in 2014, and two studies in 2019, all showed challenges for the current accreditation systems and recommended modernisation to make them more consumer centric.

While workshop tooling still heavily influences the systems design, the studies recommend a consistent program that is more about what consumers look for in an accreditation program. It also calls for more transparency so consumers can see what the accreditation is, and how VACC measures and audits it. This shouldn’t surprise us. These are basic consumer expectations.

A study of VACC accreditations undertaken by the University of Melbourne found consumers are unlikely to distinguish between accredited and non-accredited members.

Consumers also raised brand confusion when looking across a VACC sign, a VACC accredited sign, and a VACC A-Grade sign. What does it all mean?

Another review undertaken by the research group, Lucidity raised questions about the value of divisional accreditation to members and the low level of take-up for the A-Grade program. This study also found that many members had trouble understanding what VACC accreditation was, and consequently valued it poorly.

At an organisational level, it’s easy to see why accreditation – divisional or A-Grade –has lost a bit of its mojo. Having 15 divisions with slightly different accreditation, plus A-Grade, is an administrative task that is time-consuming and heavily duplicated. Currently, it’s like 15 McDonald’s restaurants having the option of designing their own quality standards and hamburgers.

The University of Melbourne study also highlighted cumbersome administrative processes for managing accreditation

at VACC and suggested a range of ways modern electronic accreditation and audit processes could better handle this.

Any study of the current programs is likely to highlight that accreditation programs are not consumer centered, have high levels of inconsistency, and have low value to the public and members.

We can change this.

From a governance perspective, there is also work and change that needs to take place so the VACC Executive Board can get on with its job of providing high-level governance and protections to VACC and its members. The Board’s influence on divisional accreditation is limited, and that’s part of the challenge. Ultimately, it’s the VACC Executive Board that bears the responsibility of all governance in the association and that includes its branding and any promises it makes to the public about members and VACC products, including accreditation programs. After all, it’s a VACC brand if it has a VACC logo on it.

The Constitution, created in 1918 and updated when needed, currently leaves responsibilities and obligations for divisions for their own accreditations. This is problematic, both for the Board and Division Executive Committees.

The Constitution currently allows for divisions to build their own accreditation programs, effectively anything they like. But the Board has the overarching liabilities for anything with a VACC logo on it. Can you see the problem here?

This is a good example of where the rules of the association need to change to reflect the contemporary industry and consumer environment.

There are also opportunities to build a better arrangement whereby the Executive Board develops and endorses membershipwide accreditation systems that engage all members and highlights to the public how an accredited business will protect them. Is a consumer more interested in the tooling you have in your workshop or how you will deal with their personal information, their data security, and their complaints?

Clearly, things have changed.

There is also a great opportunity to protect the VACC brand for members, irrespective of accreditation or not. Workshops that carry the accreditation sign while run down and outdated are bad for all members. It’s no wonder this confuses consumers.

Accreditation is on the agenda for November’s VACC Special General Meeting. This is a great opportunity for members to provide their position on the motion to reform the accreditation system that ensures VACC stays ahead of the curve.

IT is a difficult time for many businesses, therefore Victorian Automotive Chamber of Commerce (VACC) has arranged for its members and their staff to have access to external mental health support. Available through Psychology Melbourne, the Chamber will cover the fee and all sessions are confidential, members can simply provide their membership number to Psychology Melbourne when booking.

Call Psychology Melbourne: 03 9629 1001.

Psychology Melbourne is committed to helping people improve their mental health and wellbeing, assisting them

through personal, work and relationship difficulties and introducing them to strategies that can fundamentally change and enrich their lives. It also works with organisations to help them create psychologically healthy workplaces and provide Employee Assistance Programs that improve productivity by helping their staff deal with personal and work-related difficulties (Psychology Melbourne)

Fine Tuning Automotive Mental Health (FTAMH) is another initiative available to Chamber members. Funded by the WorkSafe WorkWell Mental Health Improvement Fund, VACC developed the FTAMH program to provide

information, resources and practical measures to the automotive industry in order to prevent mental health issues in the workplace.

Psychology Melbourne: psychologymelbourne.com.au

Fine Tuning Automotive Mental Health: finetune.vacc.com.au

Words Pia-Therese Hams

THE introduction of a new automotive section into the Franchising Code of Conduct only applies to new-car dealers. Leaving farm machinery, motorcycle, and commercial vehicle dealers out of franchising reforms could threaten their survival, cause significant local job losses and leave the businesses they service without crucial equipment.

The peak bodies representing farm machinery, motorcycle and truck dealers in Victoria and Australia, the Victorian Automotive Chamber of Commerce (VACC) and its national body, the Motor Trades Association of Australia, seek the inclusion of farm machinery, motorcycle, and commercial vehicle dealers in newcar dealer retailing franchising reforms that became active from 1 July 2021.

The government omission is puzzling, as the infrastructure requirements, capital expenditure, and business model for farm machinery, motorcycle and truck dealers is identical to that of new-car dealers.

The new regulations do not apply to all franchise motor vehicle dealerships, only those that come within the definition of a ‘new vehicle dealership agreement’, which refers to dealerships that predominantly deal in new passenger vehicles or new light goods vehicles – or both. Franchise agreements dealing with farm machinery, motorcycles, and trucks will not be captured under the new provisions. Consequently, these sectors won’t be afforded the same level of protection under the Franchising Code that new-car dealers enjoy.

“VACC does not understand why the Australian Government has made this policy distinction. The word ‘predominantly’ in the definition is likely to be closely scrutinised by overseas-based franchisors who seek to avoid the application of the new regulations in Australia,” said VACC CEO, Geoff Gwilym. “We have historically seen unscrupulous behaviours in these areas from overseasbased franchisors to our farm and motorcycle dealer franchisees. We can’t risk another Holden or Honda scenario for these vital sectors.

“The government has now created two regulatory regimes for dealing with automotive franchise dealerships. One that is comprehensive, the other which is not, and it is the predominantly rural and regional businesses that miss out. VACC wants to know why.”

WOMEN in Automotive (WinA)’s member of the month is Managing Director of AA Recycling & Pick-A-Part, Emma McIndoe. While only recently commencing her first official role in the industry, Emma has been immersed in automotive her entire life. She has now taken over the family business, which has been running for over 35 years. With a passion for the industry ingrained in her since childhood, Emma has over 20 years’ experience in strategic consulting and financial services, preparing her for her current role at AA Recycling & Pick-A-Part. Emma talks fondly of her experiences throughout her career and enjoys educating those around her about gender diversity in the automotive industry.

Tell us a bit about your current role or involvement in the automotive industry.

I am the Managing Director of AA Recycling & Pick-A-Part. We are a family-owned and operated Australian business that has proudly served the community for 35 years.

We have two parts to our business: Auto recycling (Pick-A-Part) and metal recycling (AA Recycling). I am the leader of all parts of the business, and responsible for all strategic and operational decisions. I am also a part-owner. We operate across two locations, Kilsyth and Campbellfield, and have an online store. We pride ourselves on customer service, industry knowledge and making it easy for customers to interact with us. We are industry leaders in the automotive and metal recycling fields, and are continually looking for opportunities to innovate and find new ways to recycle and reduce the amount of material going into landfill.

What was your first professional experience within the automotive industry?

On one hand, my current role is my first official role in the automotive industry and I have been in this role since October 2019. On the other hand, however, I have been immersed in the industry my whole life! My parents, Jan and Peter O’Callaghan, started their first business in the automotive field in 1976, Apollo Gas Products, specialising in the wholesale distribution of LPG equipment – before expanding into auto and metal recycling, starting AA Recycling and Pick-A-Part in 1986. I feel privileged to be the new custodian of our family business, to continue the

legacy while I juggle raising my three children with my husband Paul, but always reflecting on how my parents paved the way for me all those years ago. Prior to joining the automotive industry, I worked in strategic consulting and the financial services industry for 20 years.

Do you think you have experienced challenges within the industry that your male counterparts have not?

This is a really good question. As I have worked in a number of different industries prior to joining the automotive industry, I have a broad perspective on this one. Generally, I have always felt very well supported throughout my career and this stems back to how I was raised. It was always instilled in me from a young age that I could achieve anything I put my mind to.

My key observation since joining the automotive industry, in relation to gender challenges, would be mostly around two areas. Firstly, a question I (get) asked: Why did I take over running our family business and not one of my brothers? Or, the comment that was made that “I don’t look like someone who runs an automotivemetal recycling business”. Given my many years of professional experience, I take these observations as opportunities to educate, lead and create change, particularly for those who are newer to their careers.

Secondly, the open recognition from senior leaders in the automotive industry that there has been an imbalance of diversity, greater than gender, at all levels and it has impacted decision-making over the years. I do think that this is rapidly changing, and it is exciting to be part of this change.

What is your biggest achievement within the automotive industry, personal or professional?

I am very proud of how my team has handled everything that COVID-19 has thrown at them so far. Being relatively new to my role when the pandemic hit meant that it was all hands on deck and something new for us to navigate through together. My team all rose to the challenge, and as a result, we are still here in business today. Do you have a favourite resource as a woman working in the automotive industry? Maybe a book, event, organisation, mentor, or online platform?

I am a member of the VACC Auto Dismantling Recyclers Division Executive Committee, which I joined in 2020. The committee is very inclusive and has allowed me to meet and collaborate with many like-minded leaders and industry members.

There is open recognition of the value of diversity of background and thought leadership, in both automotive and other industries. I feel I can add value from my experience to date in automotive and my prior experience, as there are many overlaps in the skills required to engage and empower teams and to run and grow a business.

I also have a mentor from my time working in financial services, Ken. Ken works in the financial services industry and has been a mentor to me for over seven years now. He also happens to be a big car enthusiast! We have great wide-ranging conversations from key business issues and opportunities, the industry, global economics, and cars. Ken’s experience and points of view have really assisted me over the years, especially as I transitioned from financial services to the automotive industry. Who is your inspiration as a female in automotive?

The answer to this one is simple, my mum. In 1976, with five children under 10 years old and a mortgage, my parents took a leap of faith and took out a loan of $20,000 – which was a lot in those days – to start their first automotive business from our garage. The risk paid off, with the business being a success and expanding into Pick-A-Part and AA Recycling in the 1980s. My parents jointly lead these businesses, all while raising us five kids, with my mum only retiring three years ago! What is the best piece of advice that you have received or that you could give to another woman working in the automotive industry?

Always ask questions and don’t be afraid to approach people who you think have interesting careers and experiences. From my experience, they will appreciate that you have reached out and be more than happy to share their time (and) talk to you about their own career journey and give you advice. I have found this to be so beneficial in my career. To date, I have met many fascinating people along the way, with amazing stories and advice, many of whom I am still in contact with today.

Whether you re star ting, running or growing your business, CommBank, proud Alliance Par tner of VACC can help you do business your way

To help you take your business to the next level, VACC members can benefit from direct access to a dedicated CommBank Relationship Manager and team of banking specialists They ’ll work with you through every stage of your business life cycle You’ll also receive 24/7 Australian based phone suppor t for all your business banking needs.

B u s i n e s s p

VACC members may be eligible to access the latest innovative business banking products and solutions with preferential pricing applied, making it easier for you to do business These include:

No merchant joining fee

Same day se�lement every day of the year^

Daily IQ - free business insight s tool with CommBiz and NetBank

Business Loans and Asset Finance

Overdra� Facilities and Bank Guarantees

Free business financial health checks

To find out how CommBank can help you do business your way, contact VACC on 03 9829 1152 or email marketing@vacc com au and they’ll put you in touch with a CommBank Relationship Manager.

Connecting towing operators with automotive workshops, Tow Me VACC is an easy-to-use booking platform that gives users access to competitive towing rates at the press of a button.

towme.vacc.com.au

Words: Tim O’Brien, ADA Australia

If you were looking for an organisational metaphor for a good business, you would not be alone if the first thing that came to mind was ‘a well-oiled machine’.

Ah, yes Bill, Antonio, Gracie… (insert any name), they’ve got a good thing going there; it all just runs like a well-oiled machine.

Who hasn’t heard words to that effect?

The term, in fact, comes from an American engineer, Frederick Winslow Taylor. From 1908 he worked with Henry Ford, refining and improving Ford’s assemblyline manufacturing process.

Taylor’s The Principles of Scientific Management, published in 1911, proposed that by focussing on systems of work – studying the way things are done by looking for efficiencies and simplifying tasks – it was possible to find ‘the one right way’ of doing things.

While ideas like quality control, production planning, and the study of time and motion, spring from the thoughts of Frederick Taylor,

his top-down, one-dimensional view of people, where the worker became just another tool of management, is now out of step with modern business thinking.

Workplaces are ‘people places’ Sure, any manager knows that the planning has to be right. And while it is tempting to think that driving productivity and competitive advantage – and profits – is just a matter of systems and efficiencies, it doesn’t work like that.

Workplaces are ‘people places’ and people are angular, they don’t neatly mesh like cogs and gears. People can be Taylor’s well-oiled machine some days, and others they can be all elbows and knees. It’s this little matter of our essential humanity – flawed, capable, different, clever, challenging, surprising, unpredictable, predictable – that is missing in Taylor’s thinking.

If we want the workplace to mesh (and we do!), the task is to get all those elbows and knees

working together, sharing the vision, remaining committed and engaged.

Those of us who may have experienced both good and poor workplace cultures in our time will know that the key to creating and maintaining energy and commitment, and driving engagement and productivity – the shared vision for success, lies in getting the human factor right. Which hangs on relationships and culture. It is simply fact that a workplace with a poor workplace culture is an uncomfortable place to work and the best people quickly begin looking for the door.

So, how is this achieved? Well, yes, it has to do with good systems and efficiencies (Taylor was not entirely wrong) but at its core is the quality of relationships, the participation of all, and a sense of belonging, feeling valued, being respected, consulted and engaged.

That means setting standards – talking about relationships, about respect for each other, respect for effort, respect for difference and respectful

Getting this right, the workplace culture, is the foundation for a productive, agile, mentally healthy workplace. Everyone has a role to play to ensure a safe and respectful working environment.

If you’d like to learn more about fostering healthy relationships at work, and access practical advice and tips for making your workplace the best it can be, visit finetune.vacc.com.au or call 03 9829 1130.

Rod Sims was appointed Chair of the Australian Competition and Consumer Commission (ACCC) in August 2011 and is the commission’s longest serving Chair. Immediately prior to this, he was Chairman of the Independent Pricing and Regulatory Tribunal of New South Wales (IPART), Commissioner on the National Competition Council, Chairman of InfraCo Asia, Director of Ingeus Limited, and a member of the Research and Policy Council of the Committee for Economic Development of Australia. Rod was also a Director of Port Jackson Partners Limited, where he was an advisor to some of the top 50 companies in Australia. He is a past Chairman of the NSW Rail Infrastructure Corporation and the State Rail Authority, as well as being a director for a number of private sector companies.

Rod has worked as Deputy Secretary in the Commonwealth Department of the Prime Minister and Cabinet, and the Department of Transport and Communications. He was also the Economic Advisor to the Prime Minister between 1988 and 1990. Rod holds a first-class honours degree in commerce from the University of Melbourne and a Master of Economics from the Australian National University. Australian Automotive spoke to Rod about the ACCC’s crucial role in helping the new Motor Vehicle Service and Repair Information Sharing Scheme to become law and the commission’s responsiblities in policing the new legislation.

How significant is the new Motor Vehicle Service and Repair Information Sharing Scheme law?

It’s extremely significant. We do a lot of advocacy at the ACCC, and we regard this as one of our more important advocacy efforts; we are delighted this has come about. There is such a process around getting any new law done, so this is incredibly significant. We’re extremely pleased with where this has ended up and we should all celebrate that. It is a terrific outcome.

What got this bill over the line?

I think this benefited from a good constituency in favour of change. The independent repairers were very strong in their lobbying and had a very good case – that helped. The fact that there had been a voluntary code that had failed helped; the fact that our market study laid it all out also helped. When you get law change like this, it usually is the result of a series of fortuitous things coming together – I think that’s what you had here. Crucially, you need to get the industry onside, making the case; here they did. I went to conferences of repairers where they overwhelmingly wanted this to happen. I was at a conference where Minister (Michael) Sukkar, who was

then the relevant minister, was talking – there was a lot of groundswell for this, and that mattered a lot. It had momentum in a number of ways. Also, the fourth point, there was a scheme in the United States. It can’t be far-fetched if it’s being done overseas, so that helps as well.

How does the ACCC become involved in such an issue?

Going back in history, there was the voluntary agreement that (former Minister for Small Business), Bruce Billson, put into place, so the issue has been around for a long time. We got involved because we did a study. We had the ability to do market studies off our own bat and this was one we did; it wasn’t directed by government. We were concerned with two issues - one was warranties, where people were not getting their consumer guarantees; there were a lot of statements being made about warranties seeming to override consumer guarantees, so we wanted to have a look at that. We also wanted to look at this issue because we had complaints from a lot of repairers that they couldn’t get the parts. We thought the only way to advance this issue, and the consumer guarantee/warranty issue, was to

do a market study. It was helped by the fact that motor vehicles are a serious purchase for most people and getting them repaired is serious. There are generally two big expenditures in life – buying your house - we’ve done a lot of work in mortgages and things like that because it’s such a big consumer item. The other is motor vehicles; we felt this really mattered to consumers, so we thought we’d have a look at it.

OEMs argue that the information is intellectual property (IP) that should be protected.

We looked at all the arguments and concluded that when you buy a vehicle, you should have rights associated with it. You shouldn’t be required to take it to a dealer to get it repaired. In certain areas, you are restricted to getting your car repaired by a dealer because information is required. Sometimes, particularly in regional areas, there might only be one dealer, so you have no choice as to who repairs your car. This is not only IP, sometimes it can be anything from what oil you put in the car to having some complicated piece of equipment to unlock the electronics. We feel that’s just anti-competitive.

Apart from safety and security issues, if you’re not providing that information then you’re doing it for an anticompetitive purpose or effect. Now, rather than bringing a lot of court cases, we think it’s better to have a law that requires that (information be provided). These issues are always tricky. When someone has huge market power in one part of a market, they want to take that market power and use it in another market in ways that give them an unfair advantage. You can’t be doing things which exclude competition from the market. We take the view that competition which benefits consumers, overrides the motor vehicle manufacturer’s IP. They’ve sold the vehicle – I now own the vehicle, therefore if I want to repair it, they shouldn’t be withholding something crucial that allows me to do so. That’s not protecting IP in our view – that’s inhibiting competition.

It’s no different, for example, to repairing a house.

I think that’s right. With this aftermarket issue, you’ve bought something and then want to do things with it. The person who sold it to you shouldn’t be able to put restrictions on what you can do with something you now own. When you buy a car, you’re paying $30,000, sometimes more, sometimes less, you should have the right to repair it as you wish.

You mentioned warranties and consumer guarantees. OEMs have threatened to dishonour warranties if consumers use independent repairers.

Absolutely, and that’s where the consumer guarantees come in. Obviously if a motor vehicle manufacturer offers a warranty at the point of sale, and I buy the car plus get the warranty, then

I get the warranty the manufacturer wants to give me because I go into that with my eyes open. What you can’t do though is say that you’ve got no rights if you get the thing repaired by somebody else, because you do have consumer guarantee rights.

If within, say, three years - the normal warranty period - the car has got a fault you may well, under consumer guarantees, have a right to get that repaired at no cost. If it’s a major fault you might have a right to a replacement car or a refund. So, they can’t use language that excludes those consumer guarantee outcomes, albeit, I accept, they have the right to set the terms of the warranty in any way they want – provided it was clear to the consumer when they bought the car. They bought the car, and they bought the warranty on the terms that it was sold to them.

Who will police the scheme and set the fair market price for information?

This will be done by the Scheme Advisor, which will involve a range of people from the aftermarket associations through to the Federal Chamber of Automotive Industries - it will be representative. It won’t be difficult because information will have to be shared, provided there isn’t a security or safety reason preventing it. The price should be low, very low. It can’t be prohibitive to independent repairers, and it can’t rake in a massive return over what it would cost to put this thing together, because it already exists. They have certain obligations to provide this information and they must charge a fair market value. If the prices sought are high then we, or the government, will step in. We can take people to court because the manufacturers are

obliged to work under this scheme. Ultimately, we are the people who will enforce this, and we will be working closely with the Scheme Advisor. We’ll be sitting back a bit but if we see the scheme being frustrated, we’ll definitely step in. We’re committed to making this work, we’re committed to making sure the car manufacturers meet their obligations, we’re committed to consumers getting choice of repairer, and to the aftermarket repairers having the ability to perform in this market; I don’t think the fair price will be a problem. I accept there are varying views of ‘fair price’, but it will be very workable. And of course, you do not have a commercial interest – you look at it from a competition point of view. Absolutely. We recommended this in the interests of both the consumers and the independent repairers.

To put it more broadly, we recommended this in the interests of consumers and competition, which is what our mandate is all about. Therefore, we will be enforcing this with an eye to the consumers getting the benefit and the aftermarket repairers having the ability to properly participate in this market.

What penalties will apply for scheme breaches?

We can issue infringement notices if we see concerns, but we can also take people to court and get a penalty of up to $10 million per breach; we’ve got all the enforcement armoury we need. The penalties are much like they are for the rest of our act, so I’ve got no doubt that we have what we need to make sure this works. The penalties are real and substantial.

Can’t live with it, certainly can’t live without it. Will we have enough?

WORDS Paul Tuzson

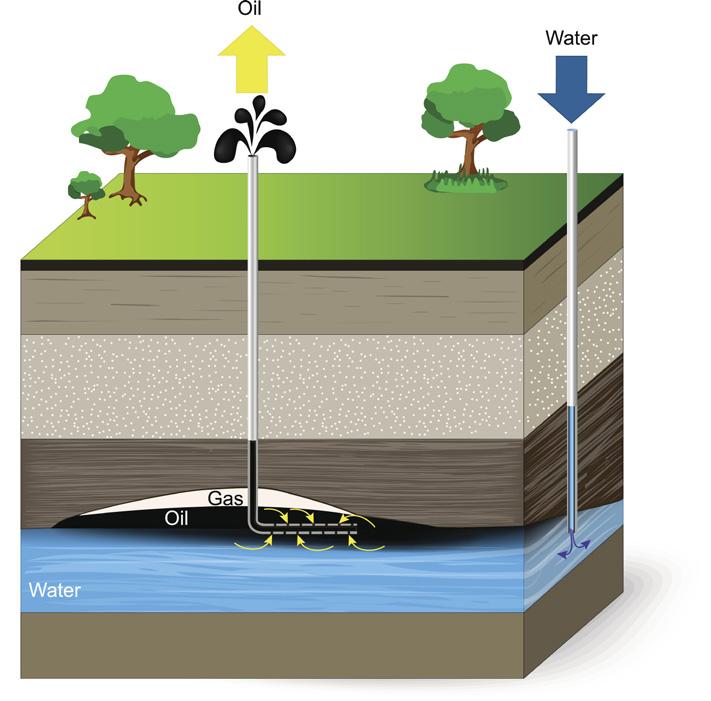

FOSSIL fuels, oil, coal, gas are entirely responsible for everything we enjoy in modern life, absolutely everything. Had they not been discovered, developed and utilised we’d still be burning wood and pollution would be much worse. Also, our quality of life would be diminished enormously. We in the transport industry are most concerned with oil but oil is used for much more than just transport. Oil is used to make plastics, chemicals, medicines (aspirin, for instance) and many other vital products like tyres, roads and paint. Oil is also used to make fertilisers and power the equipment needed for large scale farming. Without such farming, the world would run out of food in short order. So, we can’t afford to run out of oil. This begs the question, will we run out of oil? Has the amount of oil that can be extracted from the world’s oil reserves peaked? Many say it has. The idea of peak oil is that we will get to a point at which the extraction of oil reaches a maximum and then goes into a steady decline and, importantly, fails to meet our needs. The idea was first advanced seriously by Shell Oil man M. King Hubbert in 1956, although there were others before and after him. Popularity of the notion has waxed and waned over the years and decades since Hubbert’s prediction. It’s a reasonable hypothesis based on good science but the dire predictions of socioeconomic catastrophe made by its supporters haven’t proved true.

Australia uses a bit more than 1.1 million barrels of oil per day. Our oil reserves are just shy of 1.2 billion barrels, which is about 0.3 percent of total world reserves. This means that Australia only has enough oil to keep itself going for about three years at current levels of consumption. We should point out that these figures are from 2016 but the issue is clear. It also aids the understanding of why Australian refineries are closing down. Keeping all of our oil and refining it ourselves isn’t a realistic path to fuel security. Our oil is fairly light and although it is good for making fuel, we need a broader range of oils than those available locally. So, we import the oils we need. Also, our light, sweet crude is highly valued overseas so it makes better economic sense to export it. Refining oil is expensive, and the economics of the industry mean that it’s simply cheaper to import the fuel we need directly. That’s why refineries are being, and have been, converted to import terminals. Notions that these changes undermine our fuel and even national security aren’t really valid. If we did find ourselves in conflict with a major power the first thing they’d do would be to block our sea lanes. It wouldn’t matter whether incoming ships were carrying oil or fuel, they wouldn’t get here. It’s also likely our refineries or import terminals would be destroyed to cripple the country. There’s only a handful of them and this is much more easily done with modern weapons than it was with dumb bombs in past wars. Australia certainly has a fine and capable navy and air force, but many other countries have much, much larger forces. Australia is simply energy vulnerable on all vectors and will remain so.

Is the sun setting on our oil-based lifestyles?

We don’t think so (left). Many people think oil reserves will continue to shrink into the future (below). It seems unlikely that oil supplies will dwindle to a drip (above right)

The foregoing is actually a good reason for purchasing and storing fuel overseas, specifically in the US. No country is going to attack our oil reserves on American shores. Of course, it still needs to get here but if it came on US tankers no one would attack them either; not unless they wanted war with America. We’re pretty sure the government knows this. This is not to say Australia doesn’t need more local fuel storage. It does because many things besides armed conflict can threaten our fuel security. Returning to a broader view, the world is currently said to have oil reserves of around 1.65 trillion barrels of oil. It consumes more than 35 billion barrels annually. Dividing those figures gives a figure of about 47 years at current levels of consumption, population and economic development. Of course, countries like India and China and other smaller but significant nations have growing economies and increasing populations that are becoming more affluent. A more rapid consumption of our oil reserves would be inevitable if demand for oil maintained its current profile. It seems, however, that it might not. Ironically, running out of oil is no longer the driving force to cut consumption. Global warming and carbon dioxide emissions are the foremost concerns these days. Calls for the elimination of all fossil fuels have combined into an intense crescendo. Although it still hasn’t reached its climax, we’re rapidly approaching peak intolerance

for oil, gas and coal: the so-called fossil fuels. This is actually a misnomer as far as oil is concerned. Oil is not formed from fossils, although the most widely accepted theory of how it’s formed is that it comes from things that could have become fossils if they hadn’t become oil. The conventional view of the origin of oil is well known; dead biological matter that sank to the bottom of oceans and lakes eons ago. Normally such matter would simply decompose but because deep water is oxygen deficient this didn’t happen as rapidly. Then silt flowed from rivers and settled on top of this matter, not to mention yet more layers of expired biological matter. This continued and layers of this material built up over eons. As the layers built up, pressure increased on the lower layers – forcing them down to deeper levels and forcing water out. This left behind a fairly thick ooze of lipids (fats), sugars and amino acids. Heat and pressure then cooked this ooze and caused chemical reactions, resulting in a substance called kerogen. Britannica defines kerogen as a waxy mixture of paraffin hydrocarbon compounds insoluble in organic solvents like benzene or alcohol. When kerogen is further heated under increased pressure, the large paraffin molecules break down into various hydrocarbon chains in a process called catagenesis. Voila, oil. One of the many, many reasons this explanation has become mainstream is the presence in oil of chemical markers called pristane and phytane, derived from plant chlorophyll. However, molecules derived from bacterial cell walls called hopanoids are also present. Pristane and phytane can also be derived from bacteria. This has led Russian and Ukrainian petrochemical specialists – and a particular US scientist called Thomas Gold – to speculate that there is bacterial life deep in the earth that derives energy from hydrocarbons

and internal heat, rather than sunlight and photosynthesis as with surface life. The hydrogen and hydrocarbons including methane, suggested Gold, were derived from rocks and minerals in Earth’s mantle and interacted with bacterial life as it rose toward the surface over eons. Hence the bacteriological chemical signatures. This sounds a bit out there but it’s interesting to note that hydrogen is the most abundant element in the universe. There’s also a lot of methane in the gas giants and on Pluto and moons like Jupiter’s Titan. The occurrence of these extra-terrestrial gases is obviously not from once living organisms on

the surface or in the oceans of such bodies. So, there’s methane out there. The inference from all of this, and a great many more extremely complex things, is that petroleum is a renewable resource constantly being created in the depths of the earth itself, whence it percolates upward. Many scientists say this doesn’t happen. Among supporters of the general idea, estimates of how long such refilling might take vary greatly. Some suggest geological time scales, while others suggest it might occur over a handful of lifetimes. If the latter is correct, it could have an impact on oil reserves. As we said, there’s a great deal of opposition to these ideas and

Demand for transport fuel will fall as electrification of the vehicle fleet proceeds (above). Predictions of peak oil have been up and down for decades but through it all oil consumption has been go, go, go. We were promised, and still are promised, severe crashes and the end of society as we know it, but we’re still on the ride (below)

some scientists dismiss Gold. While many scientists certainly have the qualifications to disagree with him, none have the qualifications to simply ‘dismiss’ him.

Illustrations of oil-bearing deposits are a bit misleading. They tend to show reservoirs of oil as large subterranean lakes trapped in cavernous voids, most often with a cloud of pressurised gas on top. This is not how oil accumulates in most cases, although it can be sometimes. Generally, oil bearing rocks are porous, and the oil is actually inside the rocks. It occupies micro voids called pores. In addition to being porous some rocks are permeable, which means the micro voids are interconnected to some degree, like a sponge. Oil, gas and water can move through such rocks by traversing these voids.

The layers of rock in which oil is formed tend to be porous but not very permeable. However, they are permeable to a degree, so oil is able to move up through them very slowly. They also have micro fissures through which oil can migrate upward. If the rock layer above the source layer is very porous, the oil can migrate through it and reach the surface – much like it

Horizontal drilling has increased the rate at which oil can be extracted. Increasing reservoir pressure with water or gas allows us to leave less behind (above right). The diagram shows how important vehicle electrification will be in freeing up oil for other uses that contribute as much to our modern lives as oil-based transportation has. With the closure of Kwinana and Altona refineries, the refinery inputs and outputs will dwindle and move to imports (above)

did when Jed Clampett was shootin’ at some food. If, however, there is a layer of impermeable rock above, known as cap rock, it traps the oil in what then becomes known as the reservoir layer. There it sits waiting for liberation by drill bit. Because of plate tectonics these rock layers move and thus oil is found in places other than ocean floors. It’s often found very deep because of the shifting of Earth’s crust. Oil drilling technology has improved a lot over the years and decades. We can now drill for oil in places previously unreachable and to much greater depths than decades ago. New fields have been discovered as deep as 12 kilometres. We’ve found a great deal more oil than we knew about when Hubbert tabled his findings. Still, others say that it’s virtually impossible to find enough to meet future demand. There’s excitement about the Gulf of Mexico and one field eight kilometres down is hoped to have as much as 15 billion barrels. All well and good but in world terms it’s only enough for about six months. Still, it’s believed that

there are many more fields like this, and the US will be keeping it rather than sharing it.

We’ve all seen images of ‘gushers’ coming in. It’s gas pressure in a well that pushes oil out like this. No pumping needed. Over time this pressure is reduced, and the oil has to be recovered by pumping it out or by pumping gas or water into the well to artificially increase pressure. Even so, it’s difficult to extract all of the oil from every well. Sometimes as much as two thirds has been left in the bore because it’s been uneconomical to obtain it. We’re getting better at extracting more of it, but the amounts left behind are still significant. Further technological developments may make the recovery of this oil more economical. Such developments will continue. In fact, rising prices due to shortages would actually help speed innovation and technological development. About 70 percent of all oil is used for transport. Petrol alone accounts for around 46 percent of it. This is a huge amount so the gradual electrification of the vehicle fleet will significantly reduce future demand for oil. Of course, the uptake of

electric vehicles is fairly slow, particularly in Australia, so this will be a very gradual transformation, but it will occur.

There are other sources of oil. Oil shale contains precursors for oil that never reached depths at which there was enough heat and pressure to cause the necessary chemical reactions needed for the process. Still, with enough processing such shale does yield oil. It’s calculated that the US has more oil in shale than Saudi Arabia has in conventional oil. Tar sands in Alberta Canada contain heavy oil. It’s mined and processed but very energy intensive and environmentally challenging. Still, there’s a great deal of it.