What new domestic solar energy subsidies could be announced prior to the federal election next year

The current economic landscape has created a perfect storm for increased disputes in the automotive industry

There is a lot of misinformation out there about EVs, and it’s critical that the ACCC steps in to manage consumer expectations

Employers do have the right to manage absences. This article provides an overview of how to manage absenteeism

The automotive industry must now grapple with balancing technological advancements and data protection

VACC launched a comprehensive series of industry engagement and networking events that spanned the entire state

Update on the latest submissions and recommendations VACC has submitted to Government

A unique collaboration between VACC and the ADF is more than just a one-off event; it’s a bridge between two worlds

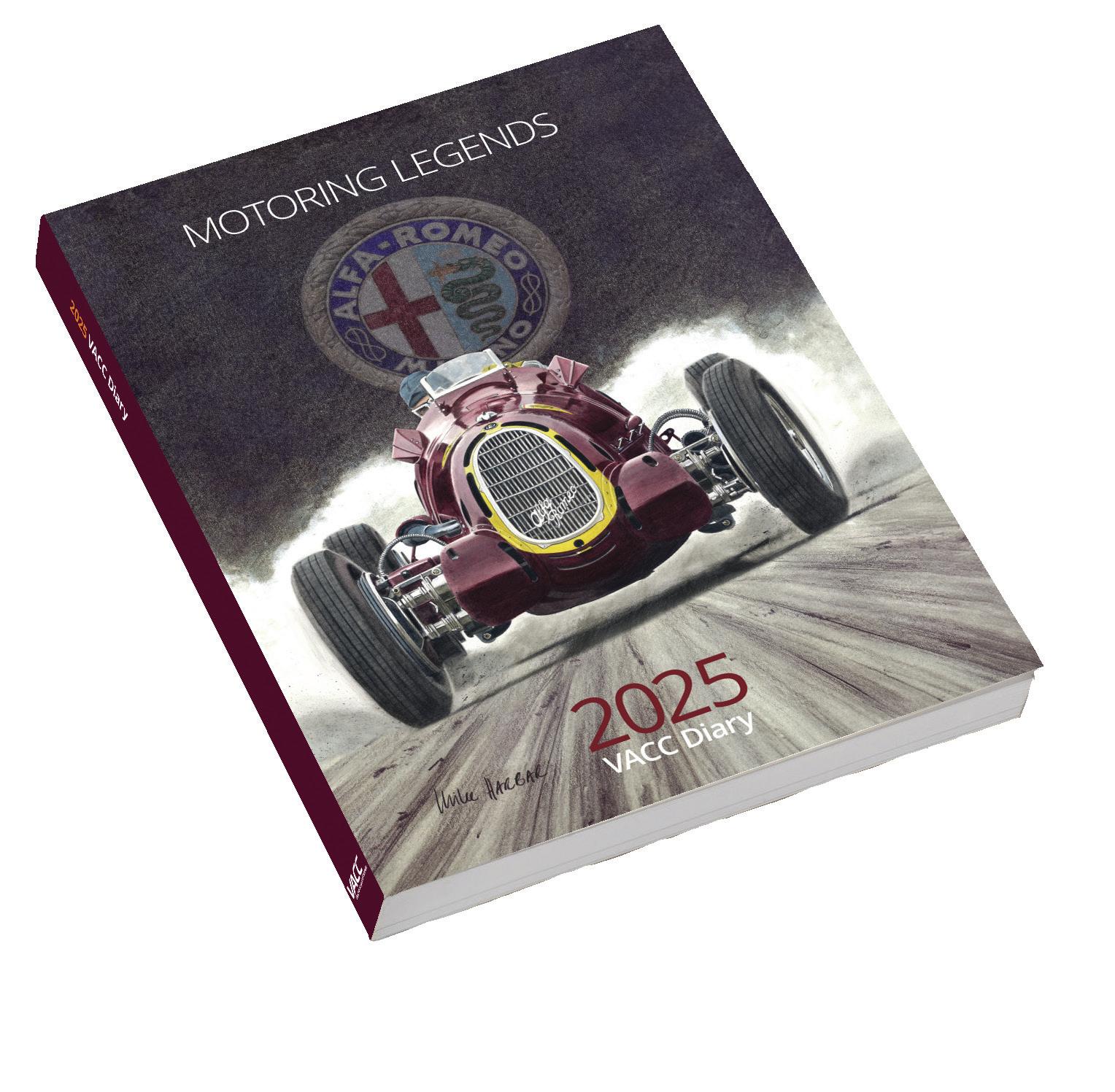

From workshop floor to industry leadership, VACC’s Geoff Gwilym reflects on a lifetime in the automotive industry

Will Porsche’s latest patent ever move from the drawing board to reality?

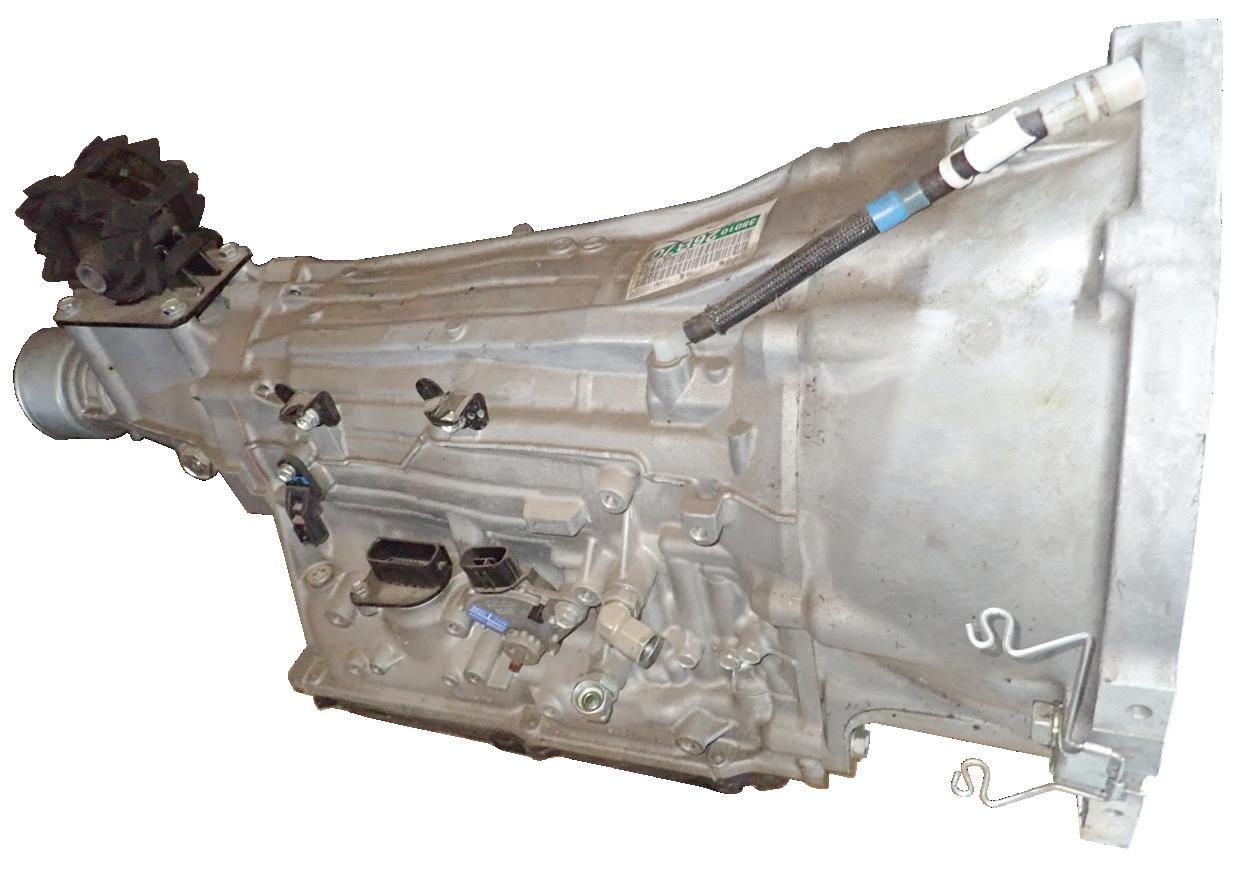

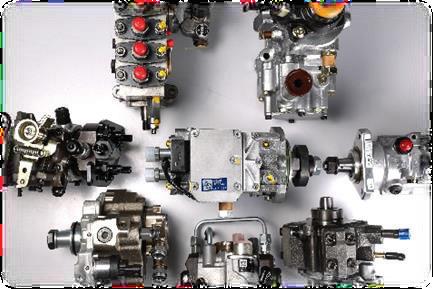

This issue addresses the 5th Generation 200 series HiAce which has received a new six speed automatic transmission

Find everything from the latest products to the best business services you need all in one place

Take advantage of VACC and TACC corporate partnerships and services, and drive your business forward

From our archives, a page from The Australian Automobile Trade Journal published 100 years ago in December 1924

AS we transition into the Australian summer, there’s a sense of change in the air - and I’m not just talking about the weather. This month’s issue captures a pivotal moment in our automotive landscape, where tradition meets transformation, and challenges converge with opportunities. Our cover story this month feels particularly poignant as we bid farewell to one of the industry’s most influential figures. Geoff Gwilym’s journey from a young apprentice in a small English village to becoming VACC’s CEO is more than just a career trajectory - it’s a testament to the evolving nature of our industry. His story, spanning nearly five decades, mirrors the very transformation our sector continues to undergo. As Geoff prepares to step down in February 2025, his reflections offer valuable insights into both where we’ve been and where we’re headed. Speaking of where we’re headed, the buzz around potential new domestic solar energy subsidies ahead of next year’s federal election has caught our attention. As our feature on home charging highlights, the timing couldn’t be better for those considering the switch to electric vehicles. However, the reality of evening charging needs versus daytime solar generation presents a puzzle that needs solving - particularly as we head into these longer summer days.

This month, we’re also proud to showcase an inspiring collaboration between VACC and the Australian Defence Force, where twelve apprentices stepped beyond their familiar workshop environments to experience something truly extraordinary. Their day at the Williamstown base reminds us that automotive skills open doors far beyond the traditional workshop floor. Speaking of innovation, our deep dive into Porsche’s intriguing six-stroke engine patent demonstrates that even in our increasingly electric world, the potential for internal combustion innovation remains alive and well - even if some designs might never leave the drawing board. But with progress comes complexity. Our investigation into the challenges of vehicle data collection and privacy raises important questions about the price of connectivity. As our cars become increasingly sophisticated - capable of everything from autonomous driving to instant crash reporting - we’re forced to grapple with the balance between convenience and privacy. It’s a discussion that’s particularly relevant as more Chinese manufacturers enter our market, bringing both innovation and scrutiny.

The VACC’s recent submission to the ACCC’s 2024 Strategic Review underscores these industry-wide challenges. From warranty repairs to EV servicing realities, the submission highlights the critical need for clear communication and fair practices as we navigate this technological transition. As we wrap up another year, it’s worth noting that change isn’t just about new technology – it’s also about how we manage and protect our workforce. Our piece on managing absenteeism reminds us that as our industry evolves, so too must our approach to managing absenteeism, and the disruptions to our businesses. Summer in Australia has always been a time of renewal and preparation for the year ahead. As you flick through these pages, perhaps beside the pool or at your local beach, I hope you’ll find not just information, but inspiration.

Whether you’re a seasoned industry veteran or just starting your automotive journey, these stories remind us that our industry’s greatest strength has always been its ability to adapt and evolve. From all of us here at the magazine, we wish you a safe and enjoyable summer season. Here’s to embracing the changes ahead while keeping our wheels firmly on the ground. Drive safe.

MANAGING

Imogen Garcia Reid

03 9829 1247

editor@australasianautomotive.com

SUB-EDITOR

Andrew Molloy

DESIGNERS

Faith Perrett

Gavin van Langenberg 03 9829 1189

creative@australasianautomotive.com

CONTRIBUTORS

John Caine, Geoff Gwilym, Rod Lofts, Bruce McIntosh, Imogen Garcia

Daniel Hodges, Paul Tuzson

names of publication titles, unfair competition, breach of trade practices or fair trading legislation, violation of rights of privacy or confidential information or licences or royalty rights or other intellectual property rights, and warrant that the material complies with all relevant laws and regulations. This publication is distributed with the understanding the authors, editors and publishers are not responsible for the results of any actions or works of whatsoever kind based on the information contained in this publication, nor for any errors or omissions contained herein. The publishers, authors and editors expressly disclaim all and any liability to any person whomsoever whether a purchaser of this publication or not in respect of anything and of the consequences of anything done or omitted to be done by any such person in reliance, whether whole or partial upon the whole or any part of the contents of this publication. Advertising accepted for publication is subject to the conditions set out in the Australasian Automotive rate card, available from editor@australasianautomotive.com

THERE is a lot of chatter around regarding the potential for new domestic solar energy subsidies being announced prior to the federal election, which must be held before mid-May next year. If the government is indeed considering new solar panels or battery subsidies, the timing could be ideal for encouraging more drivers to seriously consider switching to an EV or some form of hybrid vehicle. It would be particularly beneficial if domestic batteries were a key part of this initiative, given that feed-in tariffs have generally been declining for quite some time. For instance, the original premium feed-in tariff (PFiT) scheme in Victoria is set to conclude this November. This is especially troubling news for early solar adopters who were fortunate enough to secure a 60 cents per kilowatt hour feed-in benefit under PFiT - a luxury by today’s standards. A quick glance at current feedin tariffs reveals rates that appear utterly paltry in comparison.

However, there’s hope if the government recognises that merely having solar panels on the roof, while families are at work, limits the capacity to charge EVs in the evenings without a battery storing the energy. This limitation becomes particularly apparent during winter months when solar generation is naturally reduced, yet domestic energy consumption typically increases. Feed-in tariffs are essentially a consolation prize if you can secure a reasonable deal, but there’s still likely to be a substantial gap between what you’re paid to feed in and what you’re charged to fill up. This disparity has become increasingly evident as energy prices continue to fluctuate in our uncertain economic climate. Surely, using your own energy to charge your EV is the direction we should be heading.

Want to hear more from VACC CEO Geoff Gwilym? Read his weekly column in The Herald Sun.

IN an increasingly pressured economic climate, the automotive sector is witnessing a surge in business disputes, creating new challenges for industry players across the supply chain. From quality concerns to pricing disagreements, these conflicts can drain valuable resources and potentially damage long-standing business relationships at a time when industry solidarity is most needed. The current economic landscape has created a perfect storm for increased disputes. With tighter margins and heightened customer expectations, even minor disagreements can quickly escalate into significant business challenges, impacting both operations and bottom lines. This trend is particularly concerning as businesses struggle to maintain profitability in an increasingly competitive market.

Common Areas of Dispute

The most common disputes in the sector typically fall into several distinct categories. Contract disputes relating to new and used vehicle sales continue to dominate, followed closely by warranty obligation disagreements. Service and repair conflicts, along with disputes over new and used parts, round out the top concerns facing industry professionals today.

Best Practice Approach

Many of these disputes can be resolved efficiently through a structured approach, often without resorting to costly legal proceedings.

Early intervention and systematic documentation are crucial elements in preventing escalation. Indeed, many disputes that end up in civil tribunals could have been resolved through direct negotiation if properly managed from the outset.

1. Documentation and record keeping

Maintain comprehensive files of all relevant details, including dates, times, and specific product information.

Keep all contracts, warranties, invoices, and photographic evidence. Record verbal agreements and promises made during discussions

2. Break down complex issues

A strategic approach to dispute resolution often involves breaking down complex issues into manageable components. Separating multiple points of contention can lead to quicker resolutions, with smaller issues often creating momentum toward resolving larger disagreements.

3. Understand desired outcomes Solutions might include various combinations of: Compensation Refunds

Repairs

• Replacements

Formal apologies

Behavioural changes

4. Maintain professional communication

The most successful resolutions often come from maintaining professional dialogue and showing respect for all viewpoints. In today’s interconnected automotive industry, maintaining positive business relationships is almost as important as the immediate resolution itself.

Alternative Resolution Paths

While formal processes through Small Business Commissions or Civil Tribunals remain available options, direct negotiation often proves more efficient and less damaging to business relationships. For businesses facing disputes, focusing on swift, fair, and cost-effective solutions is paramount. Looking Forward The key to successful dispute resolution ultimately comes down to preparation and a willingness to find a middle ground. In today’s challenging automotive landscape, the ability to resolve disputes efficiently isn’t just good practice – it’s becoming a crucial business skill that can make the difference between thriving and merely surviving in an increasingly competitive market.

A balanced approach to dispute resolution, combining professional conduct with practical problem-solving, will become increasingly important as economic pressures continue to impact the automotive sector. Those businesses that master these skills now will be better positioned to navigate future challenges while maintaining valuable industry relationships.

AS the automotive industry in Australia undergoes a pivotal transition, the Victorian Automotive Chamber of Commerce (VACC) is calling on the Australian Competition and Consumer Commission (ACCC) to take decisive action on critical issues impacting both consumers and businesses.

"The landscape is rapidly evolving, and we need the ACCC to be a proactive partner in addressing the challenges ahead," says Michael McKenna, Industry Policy Advisor at VACC. With the impending introduction of new vehicle emissions standards in 2025 and the influx of electric vehicles (EVs) from both domestic and international manufacturers, the need for clear consumer protections and fair industry practices has never been more paramount.

One area of grave concern is the lack of accountability among car manufacturers regarding their obligations under the Australian Consumer Law (ACL). VACC has repeatedly raised this issue with the ACCC, urging stronger governance and enforcement to ensure consumers are not misled about the capabilities and maintenance requirements of EVs.

"There is a lot of misinformation out there about EVs, and it's critical that the ACCC steps in to manage consumer expectations and counter false narratives," says Dr. Adiba Fattah, Policy and Research

Analyst at VACC. "Consumers need to understand the real-world limitations of these vehicles, such as range constraints, faster tire degradation, and the complexity of servicing and repair."

VACC's concerns extend beyond just EV education. The association has also highlighted the persistent challenges faced by dealers in securing rightful compensation for warranty-related repairs and recalls from manufacturers. "Research indicates prevalent problematic practices, such as warranty extrapolation and substantial delays in sourcing parts," Fattah explains. "This climate of apprehension regarding reimbursement pursuits is not only detrimental to consumers, but also threatens the financial sustainability of franchisees."

The ACCC's role, VACC argues, should not be limited to consumer representation; it must also advocate for businesses under competition law and ensure that they have access to justice. This is particularly crucial in the context of the Motor Vehicle Service and Repair Information Scheme (MVIS), a worldleading legislative framework that enables independent automotive repairers to access the same repair, maintenance, and diagnostic information provided to franchised and authorised networks.

"The ACCC must strictly enforce the 'fair and reasonable' standard that

underpins the MVIS, ensuring equitable access to essential data for independent businesses," McKenna stresses. "We're also concerned about the protection of privacy data and the compliance of thirdparty data aggregators. These issues must be addressed to maintain a level playing field and allow for the continued safe and effective repair of vehicles across Australia."

Beyond the technical aspects of the industry, VACC is also calling on the ACCC to address the issue of unfair contract terms, particularly those related to operations manuals. "Franchise agreements often require dealerships to adhere to the guidelines outlined in these manuals, which can be unilaterally amended by the franchisor, leading to significant impacts on profitability," Fattah explains. "The ACCC should oversee provisions to prevent essential requirements from being shifted from the contract to the operations manual, where they can be more easily manipulated."

As the automotive industry navigates the road ahead, the VACC is urging the ACCC to take a proactive and comprehensive approach to addressing these critical concerns. "Consumers and businesses alike deserve a fair and transparent marketplace," McKenna concludes. "With the ACCC's leadership and commitment to effective governance, we can ensure that the industry's transition benefits everyone."

ABSENTEEISM can disrupt a business, effecting productivity and morale. It can be difficult to manage because an employer might not want to have a difficult conversation with an employee or may not know whether they can challenge a medical certificate. Employers do have the right to manage absences. This article provides an overview of how to manage absenteeism in the workplace lawfully. What is absenteeism?

Absenteeism refers to frequent absences from work due to sickness or other personal reasons, such as carer responsibilities. It includes all unscheduled absences which are unusual or excessive, such as large or increasing number of sick days per year, systematic pattern of absence; and frequently leaving work early or arriving late. Members seeking a better understanding of what is considered excessive, are encouraged to contact VACC’s IR Department. Employer is entitled to question reasons for absence or evidence provided Where an employer observes a pattern of recurring absences, or suspects dishonesty or misuse of personal leave, is important to address the situation promptly and proactively. Examples of misuse of personal leave include undertaking a secondary employment when allegedly unfit for their usual work or attending a sporting event while reportedly sick. Members should ensure that any queries regarding such absences are conducted in accordance with the requirements of the Fair Work Act 2009 (FW Act) – including in relation to reasonable evidence requirements where an employee’s absence relates to personal or carers leave (see ‘What evidence can an employer require in relation to sick days?’ article for further information).

What to do if there is a pattern of absenteeism?

If there is a pattern of absenteeism (e.g. recurring absences on the same weekday or immediately before or after a public holiday), an employer should seek to resolve the matter informally in the first instance, by asking the employee if there is anything the employer can do to support or help the employee. Scheduling an informal discussion helps

to demonstrate an employer’s concern for the employee’s wellbeing and provides an opportunity to understand the reasons behind their absences. It is important to emphasise that this initial meeting is not a disciplinary meeting. It is important to openly discuss the frequency of absences, explore potential underlying causes and find solutions to improve attendance. Following the conclusion of those discussions, any agreed actions should be documented in writing with a copy provided to the employee and a copy kept on file.

How to manage an employee who frequently comes into work late or is absent from work

Steps an employer should take if an employee is continuously late and/or absent include:

Check what start and finish times were agreed in pre-employment discussions or in the written employment agreement or contract Monitor and retain accurate records of an employee’s late starts and/or absence using timesheets or leave forms

Check whether the employee’s circumstances has changed – e.g. whether they still reside at the same address that was recorded at the commencement of their employment; whether they have changed how they travel to work (e.g. from car to public transport); and whether their personal responsibilities have changed (e.g. school drop off/pick up)

Schedule a time to meet to discuss with the employee to get an understanding of the issue from the employee’s perspective

Ensure that a fair process, consistent with any applicable company policy is followed

Obtain a medical certificate (or other reasonable evidence) and/or as much information regarding the absence.

How to manage an employee who is absent from work without explanation

If an employee is absent from work without explanation it is important for the employee’s manager to ascertain whether the employee has made any contact with another supervisor, manager or other employee.

If there has been no contact which provides an explanation for their absence, the relevant manager should attempt to contact the employee. If contact is made, then the manager should request details about the absence including the reasons for their absence and the possible duration as well as reasons for their failure to notify.

Counselling or disciplining an employee may be appropriate if there has been a failure to notify is in breach of the leave policy. Where an employee is not able to be contacted, a detailed file note should be kept on what was done to contact the employee. Preventing disputes

It is important that employees are given a clear understanding of when, how and to whom they are to notify an absence from work, including what documentation (e.g. medical certificate or statutory declaration) is required to be submitted when taking personal leave. Accordingly, it is highly recommended that employers have clear written policies in place and ensure that these policies are discussed with new employees at or before commencement of employment. Compliance with the leave policy where disciplinary action required If during a formal scheduled meeting, the employee’s explanation for their absence/s are unsatisfactory, you may need to issue a formal warning that outlines the potential consequences for continued attendance issues. Where formal disciplinary action is required, it is essential that it is done in accordance with your employee contract and policies to ensure procedural fairness. Members are also strongly advised to contact the VACC Workplace Relations team for assistance prior to taking any action. Where disciplinary action is not applicable due to the absence from work being a result of a genuine illness or (non-workrelated) injury, it may be appropriate to investigate reasonable short to medium term adjustments for the employee if they have some capacity to work. Again, members are encouraged to advised to contact the VACC Workplace Relations team for assistance.

Members are strongly encouraged to contact VACC Workplace Relations team to discuss each individual case to avoid any future claims at ir@vacc.com.au or 03 98291123.

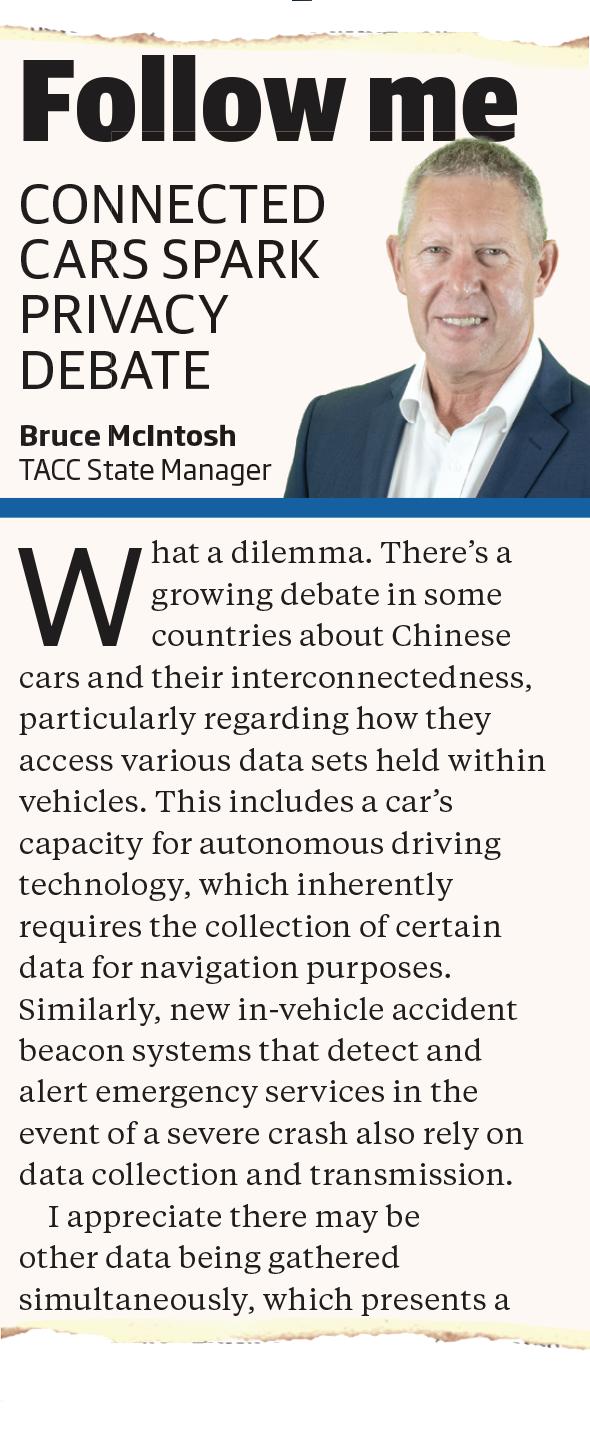

WHAT a dilemma. There’s a growing debate in some countries about Chinese cars and their interconnectedness, particularly regarding how they access various data sets held within vehicles. This includes a car’s capacity for autonomous driving technology, which inherently requires the collection of certain data for navigation purposes. Similarly, new in-vehicle accident beacon systems that detect and alert emergency services in the event of a severe crash also rely on data collection and transmission.

I appreciate there may be other data being gathered simultaneously, which presents a real challenge. It raises questions about what people expect modern cars to do and the extent to which they’re comfortable having their information uploaded to offshore locations or even stored locally.

We want stolen vehicles found swiftly, immediate rectification of

technological faults, and the ability for these machines to seamlessly connect with devices like phones and personal computers. Many also appreciate the convenience of remote diagnostics, where technicians in another country can log into our cars to address running faults, even as we drive. This interconnectedness, however, comes at a potential cost to privacy. The automotive industry must now grapple with balancing technological advancements and data protection. Maybe this is the new frontier for car makers as they strive to leverage technology to provide improved and safer vehicles without infringing on private or personal data. It’s a hard tightrope to walk, requiring careful consideration of both innovation and individual rights in our increasingly connected world. Tricky.

Want to hear more from Bruce? Read his weekly column in the Mercury.

IN 2024 VACC saw the successful launch of a comprehensive series of industry engagement and networking events that spanned the entire state. From inner city Melbourne to the regions of Victoria, these events brought together automotive professionals, fostering meaningful connections, and delivering crucial industry insights. Under the leadership of AVCC Industry Policy Advisor John Khoury, these events marked a significant evolution in how VACC engages with its membership base. The series of carefully curated sessions demonstrated VACC’s commitment to maintaining direct dialogue with industry stakeholders while providing them with actionable insights and updates.

“The response from our members has been fantastic,” reflects Khoury. “We’ve seen packed venues across Victoria, from Geelong to Bendigo, Ballarat to the Latrobe Valley, and throughout metropolitan Melbourne. This enthusiastic participation confirms the industry’s appetite for face-to-face engagement and practical business support.”

The events covered a comprehensive range of topics crucial to today’s automotive landscape. Attendees gained valuable insights into emerging industry trends, including the rapid advancement of electric vehicle technology, the growing importance of digital transformation, and the evolution of driving technology systems. Regulatory updates formed another crucial component, with detailed discussions on upcoming changes to state and

Neway Wheel Repairs is a family owned-and-operated company spanning three generations of knowledge and class-leading experience, servicing the automotive industry with trusted craftsmanship since 1950. We use state of the art equipment to remanufacture your wheels back to OM standard.

national automotive legislation, workplace safety requirements, and environmental regulations.

What set these sessions apart was their practical focus on business issues. Industry experts shared strategies for workforce development, customer service excellence, and business efficiency improvements. The interactive format allowed members to raise concerns, share experiences, and collaborate on solutions to common challenges facing the automotive sector.

One of the most valuable aspects of these events was the networking opportunities they provided.

In an increasingly digital world, the importance of face-to-face connections cannot be understated. Members appreciated the chance to build relationships with peers, share best practices, and establish potential business partnerships. These connections have already led to several collaborative initiatives among members, demonstrating the tangible benefits of VACC’s community-building efforts.

Regional sessions proved particularly successful, with strong attendance numbers highlighting the importance of bringing industry support directly to businesses outside metropolitan areas. These events addressed regionspecific challenges and opportunities, ensuring that VACC’s support remains relevant and accessible to all members, regardless of their location.

The success of these events wouldn’t have been possible without the generous support of our sponsors

and guest speakers, whose commitment to the automotive industry enabled VACC to deliver high-quality, informative sessions throughout the year. Their support allowed for the inclusion of industryleading speakers, comprehensive resource materials, and professional

networking opportunities that added significant value for attendees.

Looking ahead, VACC is already planning to build on this year’s success with an expanded program for the future. The overwhelmingly positive feedback from members has confirmed the value of these face-to-face engagements, and the organisation remains committed to evolving the format to meet the changing needs of its membership.

As we reflect on the success of this year’s events, it’s clear that VACC’s commitment to supporting its members through direct engagement and practical assistance remains stronger than ever. These sessions have not only provided valuable information and networking opportunities but also strengthened the fabric of Victoria’s automotive community, setting the stage for continued growth and collaboration in the years to come.

THE Victorian Automotive Chamber of Commerce (VACC) has submitted a robust response to Consumer Affairs Victoria’s (CAV) inquiry into the sale of used motor vehicles, calling for essential reforms to protect consumers and support Victoria’s automotive retail industry. VACC, which represents over 4,500 businesses across Victoria’s automotive retail sector, is advocating for clearer consumer expectations and strengthened protections, especially in transactions involving Licensed Motor Car Traders (LMCTs).

“Buying a used vehicle is inherently different from purchasing a new one,” said Geoff Gwilym, VACC CEO. “Consumers need to have realistic expectations about the nature of used vehicles, which often come with some level of wear and tear due to age and previous use. However, it’s clear the current laws have room to be refined to balance consumer expectations with industry standards.”

VACC’s submission outlines key recommendations, such as:

1. Distinctive Consumer Guidelines for Used Vehicles: VACC is urging regulators to establish clear definitions around acceptable quality for used vehicles, recognising that these vehicles are not new and should not be expected to perform as such.

2. Enhanced Consumer Awareness: Proposed reforms include a mandatory warning on online platforms and auction houses, informing consumers of the limited protections when purchasing vehicles from private sellers, as opposed to LMCTs who offer statutory protections and warranties.

3. Accountability in Private Sales: To tackle prevalent odometer fraud and the misrepresentation of vehicle quality in private sales, VACC recommends the creation of a crossagency task force. The task force would focus on unlicensed trading, odometer tampering, and fraudulent sales practices, protecting both consumers and legitimate traders.

4. Proposed Legislative Changes: VACC is also calling on the Victorian Government to streamline remedies available under the Australian Consumer Law (ACL), particularly by ensuring that private vehicle sales meet transparent standards that licensed dealers are already upholding.

“We want to ensure a fair playing field,” Mr Gwilym added. “With stronger, clear-cut consumer protection guidelines, consumers will have realistic expectations, and the industry’s reputation will be upheld.”

As the automotive industry continues to evolve with technological advancements and an increasingly digital marketplace, VACC remains committed to collaborating with CAV, other regulatory bodies, and consumer groups to ensure that the industry operates fairly and transparently. This collaboration is essential to addressing the complexities of the used vehicle market, particularly given the potential for consumer detriment in unregulated private sales.

THE Victorian Automotive Chamber of Commerce (VACC) has today submitted its response to the Australian Competition and Consumer Commission's (ACCC) 2024 Strategic Review, highlighting critical issues facing the automotive industry and calling for increased regulatory attention.

Key points from VACC's submission include:

1. Electric Vehicle (EV) education: VACC emphasises the need for better consumer education regarding EVs, particularly concerning servicing requirements and associated costs. The organisation urges the ACCC to play a crucial role in managing consumer expectations and countering misinformation about EV maintenance.

2. Warranty and recall processes: VACC highlights ongoing issues with car manufacturers rejecting or delaying warranty reimbursements to dealers. The submission calls for stricter enforcement of fair compensation for warranty, product defect, and recall reimbursements.

3. Motor Vehicle Service and Repair Information Scheme: Whilst acknowledging progress, VACC identifies several areas requiring immediate ACCC attention, including enforcing the "fair and reasonable" standard for data access and ensuring compliance of third-party data aggregators with safety requirements.

4. Environmental claims and sustainability: VACC stresses the importance of ACCC oversight in mitigating unrealistic consumer expectations about EVs and protecting automotive businesses from potential vexatious claims.

5. Unfair contract terms: The submission highlights concerns about unilateral changes to operations manuals in franchising agreements, which can significantly impact dealership profitability.

6. New market entrants: With the anticipated influx of new EV manufacturers, particularly from China,

VACC calls for proactive ACCC measures to ensure accountability regarding Australian Consumer Law obligations.

VACC CEO, Geoff Gwilym, stated, "As the automotive industry undergoes significant transformation, it's crucial that the ACCC focuses on these key issues to ensure fair competition and protect both consumers and businesses in our sector."

VACC also emphasises the need for balanced regulation that considers the rights and responsibilities of dealers, manufacturers, and consumers alike.

Any individuals employed by Australian repairers or Registered Training Organisations.

What information can be accessed?

Service schedules, service manuals, service bulletins, repair procedures, wiring diagrams, diagnostic hardware, software etc. Key, immobiliser and radio codes require VSP* status.

The legislation covers vehicles (cars, SUVs, light commercial) from 1 January 2002 onwards.

Technician

Technician, Collision repairers, locksmiths* RTO trainers (service manuals, repair procedures, TSBs, diagnostics etc.)

• EV-hybrid high voltage (certificate required)

Hydrogen (certificate required)

Vehicle Security Professional* VSP (key, immobiliser codes etc.) Police certificate, business insurance required

EARLIER this month, 12 automotive apprentices from the Victorian Automotive Chamber of Commerce (VACC) found themselves stepping out of their comfort zones and into the world of the Australian Defence Force (ADF). The Williamstown base, usually bustling with military activity, welcomed these young mechanics for a day that would challenge their skills, broaden their perspectives, and enrich their automotive expertise in ways they never expected.

This unique collaboration between VACC and the ADF is more than just a one-off event; it’s a bridge between two worlds that share more common ground than one might think. At the heart of this connection stands Bruce Parker OAM, a 50-year VACC member from HM Gem Engines, whose own journey

spans both the automotive industry and military service, including multiple military campaigns throughout his career.

As the day began, the apprentices traded their familiar workshop environments for the structured atmosphere of the military base. The commanding officer’s briefing set the tone, outlining protocols and expectations that were a far cry from their usual routines. At that moment, as they stood in the main hall, a mix of excitement, nervousness, and anticipation filled the air. With their orders received, the young mechanics set out to tackle their assigned tasks. This wasn’t just another day in the shop; it was an opportunity to apply their skills to vehicles that have seen

more than just city streets. Older models, often found in military zones and training exercises, presented unique challenges that pushed the apprentices to think creatively and adapt their knowledge to unfamiliar territory. Throughout the day, these apprentices discovered how the fundamental skills they’ve been honing in their daily working lives could be applied in diverse and unexpected ways. As they worked alongside defence personnel, they gained insights into different maintenance approaches, problem-solving techniques, and the importance of precision and reliability in high-stakes environments.

The pinnacle of the day came with a special demonstration for invited guests. As the apprentices stood shoulder to shoulder with Defence

Force members, they showcased not just their automotive prowess, but also their ability to work under pressure, follow precise instructions, and collaborate effectively in a team setting. These skills, often overlooked in traditional training, were brought to the forefront in this unique scenario.

As the day wound down, the group gathered for a well-earned BBQ.

VACC CEO Geoff Gwilym took this moment to address the apprentices, highlighting the significance of the day’s experiences. “What you’ve learned today,” he said, “are skills that will serve you well throughout your careers, no matter where your journey takes you. Adaptability, precision, teamwork – these are invaluable in any workplace.”

Geoff’s words underscored the true value of the day’s activities. While the setting was military, the skills and experiences gained were universally applicable. From enhanced problemsolving abilities to improved communication skills, from learning to work under strict protocols to understanding the importance of maintenance in critical operations, the apprentices had acquired a wealth of knowledge to take back to their everyday work environments.

Bruce Parker OAM also spoke to the assembled group, emphasising the longstanding connections between VACC and the ADF. He highlighted how the automotive skills these apprentices are developing are foundational and transferable, opening doors to various opportunities within and beyond the traditional automotive sector.

As the apprentices prepared to leave the base, the impact of the day was evident in their animated discussions and thoughtful expressions. They had arrived as automotive apprentices but were leaving with a broader perspective.

This day at the Williamstown was more than just an interesting diversion from routine. It was a powerful demonstration of how core automotive skills can be adapted and applied in diverse settings. For these twelve VACC apprentices, their chosen trade suddenly seemed more versatile

and valuable than ever before.

In the years to come, whether they find themselves in local workshops, or large automotive dealerships, the lessons learned on this day will continue to influence their approach to problem-solving, teamwork, and professional growth.

This collaboration between VACC and the Defence Force has not only enriched the apprentices’ skill sets but has also reinforced the idea that in the ever-evolving world of automotive technology, the ability to adapt, learn, and apply knowledge in diverse settings is perhaps the most valuable skill of all.

Cleanaway is Australia’s largest waste management provider and proud new VACC partner. With convenient locations across Victoria and Tasmania, we can build customised, competitive waste solutions for your automotive business, including:

General waste

Commingled recyclables

• Paper and cardboard

• Steel/aluminium cans and plastic

Liquid and hazardous waste

• Used mineral oil and oil filters

• Oily water, oily rags and other hydrocarbons

• Grease trap

• Pit and sump cleaning

Workshop and parts waste

Parts washer services

Industrial service capabilities

Call us today on 13 13 39 and mention VACC or visit our website.

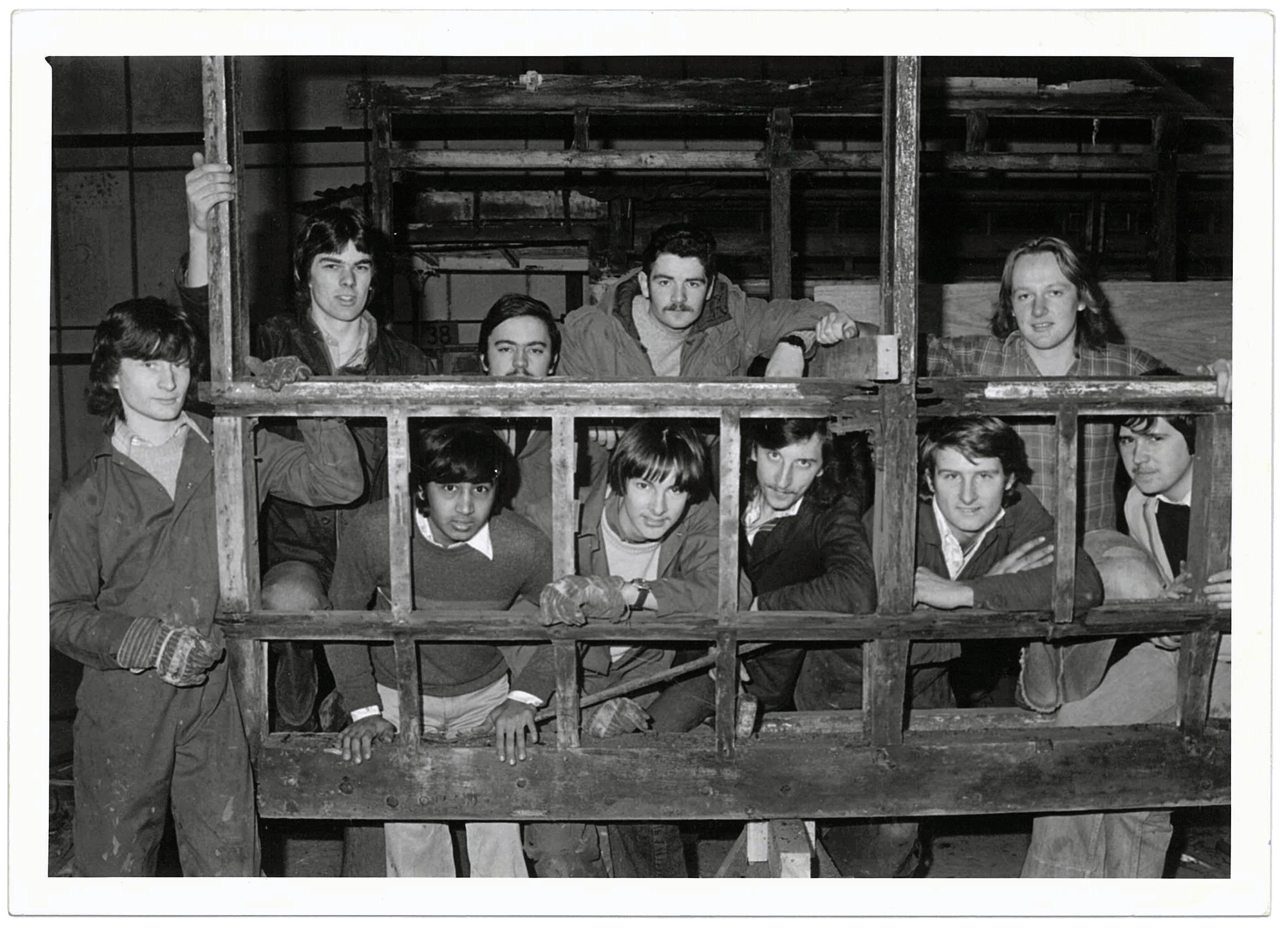

VACC’s Geoff Gwilym reflects on a life in automotive

It doesn’t really matter to me whether it is the Board, senior managers or staff, I have always taken the view that everyone in the team has something useful to contribute. “ ”

Geoff Gwilym (back row centre).

Refurbishing the last tram that ran through the Bargate, Southampton 1978

IN a small village called Titchfield, Hampshire, a young apprentice’s journey in the automotive industry began – one that would span nearly five decades and two continents, ultimately leading to the helm of one of Australia’s most influential automotive industry bodies.

As Geoff Gwilym prepares to step down as CEO of the Victorian Automotive Chamber of Commerce (VACC) in February 2025, we sat down with him as he reflects on a career that has shaped both his life and the industry he serves.

“If you had asked me at the age of 15, starting a Body Making apprenticeship in the UK, it would never have even crossed my mind where I would end up nearly 50 years later,” Geoff recalls with a smile. His early career was shaped by a mentor named Royston Cooper, a village mechanic who would leave an indelible mark on his approach to life’s challenges. “Much of what he taught me has shaped how I have approached challenges in my own life,” he says. The smell of oil in a workshop still brings back memories of those formative years, where Geoff’s mother couldn’t understand why his t-shirts

kept developing mysterious holes – until she discovered him moving batteries around in Cooper’s workshop. These early experiences, combined with his unexpected talent for English alongside his metalworking skills, would lay the foundation for a diverse career path.

Working weekends at Cooper’s workshop wasn’t just about earning pocket money; it was an introduction to a world that would become his life’s passion. “Royston fixed cars, engines and bodywork, and he was a great mentor,” Geoff remembers. “He also had lots of motorbikes which provided great fun hacking around the fields on them, but also helping to fix them. I had an old Greeves Villiers 197, Royston was a Bultaco man.”

The automotive industry of Geoff’s apprenticeship days bears little resemblance to today’s technologydriven sector. From the early introduction of electronic fuel injection and ABS braking systems to today’s hybrid and electric vehicles, the industry has undergone continuous evolution. Geoff’s career has paralleled these transformations, giving him a unique perspective on both the technical and human aspects of industry change.

purely mechanical systems to today’s sophisticated computer-controlled vehicles, it’s remarkable how the industry has adapted,” he observes. “But what’s even more impressive is how automotive technicians have evolved their skills alongside these changes.”

This observation would later influence his approach to professional development and training throughout his career, particularly in his roles in vocational education and at VACC. “We knew we had to secure this ground quickly,” he says, referring to VACC’s leading role in developing electric vehicle training programmes. “The industry’s future depends on our ability to stay ahead of technological changes.”

After working in commercial vehicle body shops and refurbishing trains in the UK, including specialist containers at Southampton Docks and carriage building at the British Rail sheds in Eastleigh, economic conditions in the 1980s prompted a bold move. At age 25, Geoff decided to make Australia his home, a decision that would shape the rest of his career. His first role in Australia was working on coaches for Australian Pacific Tours in Sandringham, but it was

a fortuitous phone call to Batman Automotive College in Coburg that would change everything. “I had no idea where Coburg was or what a job in teaching even looked like,” he admits. “What I didn’t know was this was the only college delivering body-making training in Victoria and they hadn’t put a new teacher on for years.”

Geoff’s transition from workshop floor to education marked a pivotal moment in his career. At Batman Automotive College, he discovered a natural talent for teaching that would inform his future leadership style. “Teaching isn’t just about transferring knowledge,” he reflects. “It’s about understanding how people learn and adapt to change. These insights have been invaluable in every leadership role I’ve held.”

His experience in education also highlighted the crucial relationship between industry and training providers. “There was often a gap between what was being taught and what industry needed,” he notes. “Bridging that gap became a driving force in my career.”

This understanding would later influence VACC’s approach to professional development under his leadership. The organisation has become known for its practical, industry-led training programmes that respond directly to member needs. “We’ve always believed that training should be led by industry requirements, not the other way around,” he explains.

What started as a part-time teaching position evolved into a comprehensive 10-year career in TAFE, where Geoff’s natural writing abilities became increasingly valuable. “During my time at TAFE I undertook just about every course that was available to me and ended up with a teaching qualification and a Masters in Educational Leadership,” he explains. This academic achievement holds special significance for Geoff. “One of the best achievements in my career was gaining a Master of Education while I was working in TAFE,” he shares proudly. “I left school at 15 and really had little idea I could achieve anything academically. I was the first one in the family to gain a post-graduate qualification and I think the copy of the certificate I gave mum would still be folded up behind the radio. She was always afraid that an education would give me too much mobility....and it did.”

The Path to Leadership

Geoff’s journey to VACC wasn’t direct. After his first stint as Training Manager at VACC in the early 2000s, he went on to lead several industry organisations, including the Transport and Logistics Industry Skills Council and Auto Skills Australia. These roles proved to be crucial building blocks for his future leadership of VACC.

“Creating policy papers, writing submissions, building national vocational standards and engaging with industry and government key stakeholders was what I had amassed over 40 years in the industry,” he reflects. “These attributes were very valuable assets to bring into my current role.”

Transforming VACC

During his ten-year tenure as VACC CEO, Geoff has overseen significant transformations, most visibly the organisation’s move to a new state-ofthe-art headquarters in North Melbourne. However, he emphasises that the physical move represented something much more profound: “The real achievement was a dedicated focus on refacing VACC to both be, and look like a forward-looking, contemporary industry association.”

The transformation went far beyond the physical move. “Along with this change came a complete restructuring of the association and a rebuild of VACCs commercial arm, OurAuto,” he explains. “All of these changes, along with selling the old building, were designed to prepare VACC for the next 100 years.”

One of his most challenging achievements was modernising VACC’s governance structure, reducing the Board of Management from 34 members to a streamlined Executive Board of nine

members. “I would have had over 100 separate meetings with existing Board members and other members to discuss the rationale and purpose behind this big structural change,” he reflects. The success of this transition highlighted his collaborative leadership style and ability to navigate complex organisational change.

Navigating

The shift towards electric and hybrid vehicles has been one of the most significant changes during Geoff’s tenure at VACC. He has been instrumental in helping members prepare for this transition, drawing on his experience from observing similar changes internationally. “In Norway, workshops that quickly transitioned to EV workshops looked as though they were doing well. In the UK, workshops that repair EVs and also sell used EVs appear to have a niche in the market,” he shares. “What we’ve learned is that early adoption and adaptability are crucial for business success.”

Under his leadership, VACC has developed comprehensive programmes to support members through this transition. “We’ve seen workshops that embrace new technology consistently outperform those that resist change,” he notes. “But it’s not just about having the right equipment – it’s about having the right mindset and training.”

Throughout his career, Geoff has maintained a deeply personal approach to leadership, one that values individual stories and experiences. “I’ve met some great people and the greatest of all were the most humble,” he reflects. This philosophy has shaped how VACC approaches member services and support.

His leadership style has been particularly evident in how VACC handles industry challenges. “When you’re representing over 5,000 businesses, you need to remember that each one has its own story, its own challenges, and its own aspirations,” he explains. “Our role is to support each of them while advancing the industry as a whole.”

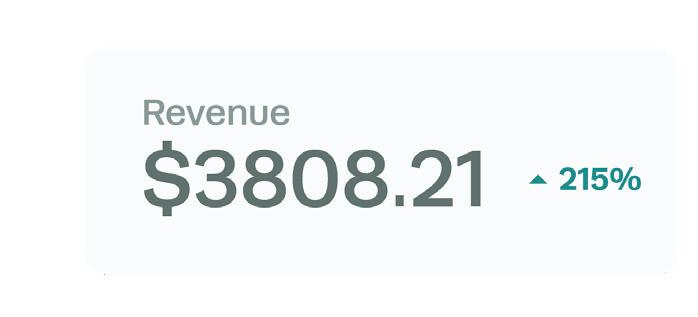

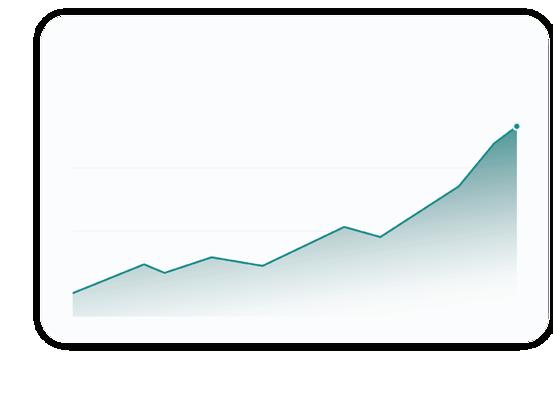

One of Geoff’s most significant achievements has been strengthening VACC’s financial position while maintaining its member-focused ethos. “Running an association should be no different to running any other business,” he argues, “but you need to balance commercial success with member service.”

This philosophy led to significant changes in VACC’s commercial operations. The organisation has developed new revenue streams and modernised its services while maintaining its core focus on member advocacy and support. “Financial strength gives us the ability to fight for our members when they need us most,” he explains.

Geoff’s career has given him a global perspective on the automotive industry, something he has used to benefit VACC members. “What happens in European markets today often reaches Australia within a few years,” he notes. “This gives us the opportunity to learn from overseas experiences and help our members prepare for change.”

He has been particularly active in building international relationships for VACC, establishing connections with similar organisations worldwide. “The automotive industry is increasingly global,” he explains. “Having strong

international networks helps us anticipate changes and advocate more effectively for our members.”

Looking at the industry’s future, Geoff emphasises the importance of embracing technological change. “It is no secret that the automotive industry is in a process of huge technological and structural change,” he notes. His advice to business owners is clear: “Start to plan where you will be in ten years... I really believe any business needs to have their foot in both camps, traditional petrol and diesel sales and/or repairs but with new technology in the workshop as well.”

For those just starting in the industry, his advice is equally forthright: “Make every post a winner. Take every opportunity that the industry throws up and never hesitate to take on something new. This industry really can take you around the world and back again, if you are open to hard work and maximising every opportunity.”

As Geoff prepares for the next chapter, he remains optimistic about the industry’s future. “The automotive sector has always been dynamic, but the pace of change today is unprecedented,” he observes. “The businesses that will thrive are those that see change as an opportunity rather than a threat.”

He is particularly excited about the opportunities for young people entering the industry. “Today’s automotive technicians need to be part mechanic, part computer specialist, and part problem-solver,” he notes. “It’s a fascinating time to be starting in the industry.”

As he prepares to hand over the reins, Geoff’s pride in VACC’s achievements is evident. “VACC has the resources and the human capital to really make a difference in the industry,” he states. “It’s been around for 106 years and is well respected politically at a state and national level.”

His legacy extends far beyond the new building or organisational structures. It lies in the strengthened commercial business, the growing Group Scheme, improved policy outputs, and perhaps most importantly, the culture of innovation and adaptation he has fostered.

When asked what he’ll miss most, his answer reveals the human-centred approach that has defined his leadership: “Going out to see members; to listen to their stories and their challenges. This is still the most valuable part of

my job as CEO, getting into member workshops and understanding what it is VACC can do to improve the industry.”

“It feels weird that I am leaving the best job in the world,” he reflects, “but I really believe that change is a good thing and this means making room for others to bring their expertise to the association. I have had a great journey in automotive, no regrets.”

As Geoff prepares for his next chapter, he leaves behind an organisation well-positioned for the future, having successfully balanced the preservation of VACC’s rich heritage with the necessary evolution to meet the challenges of a rapidly changing automotive landscape. His journey from a young apprentice in Titchfield to industry leader in Australia serves as a testament to the opportunities that exist within the automotive industry for those willing to embrace change and never stop learning.

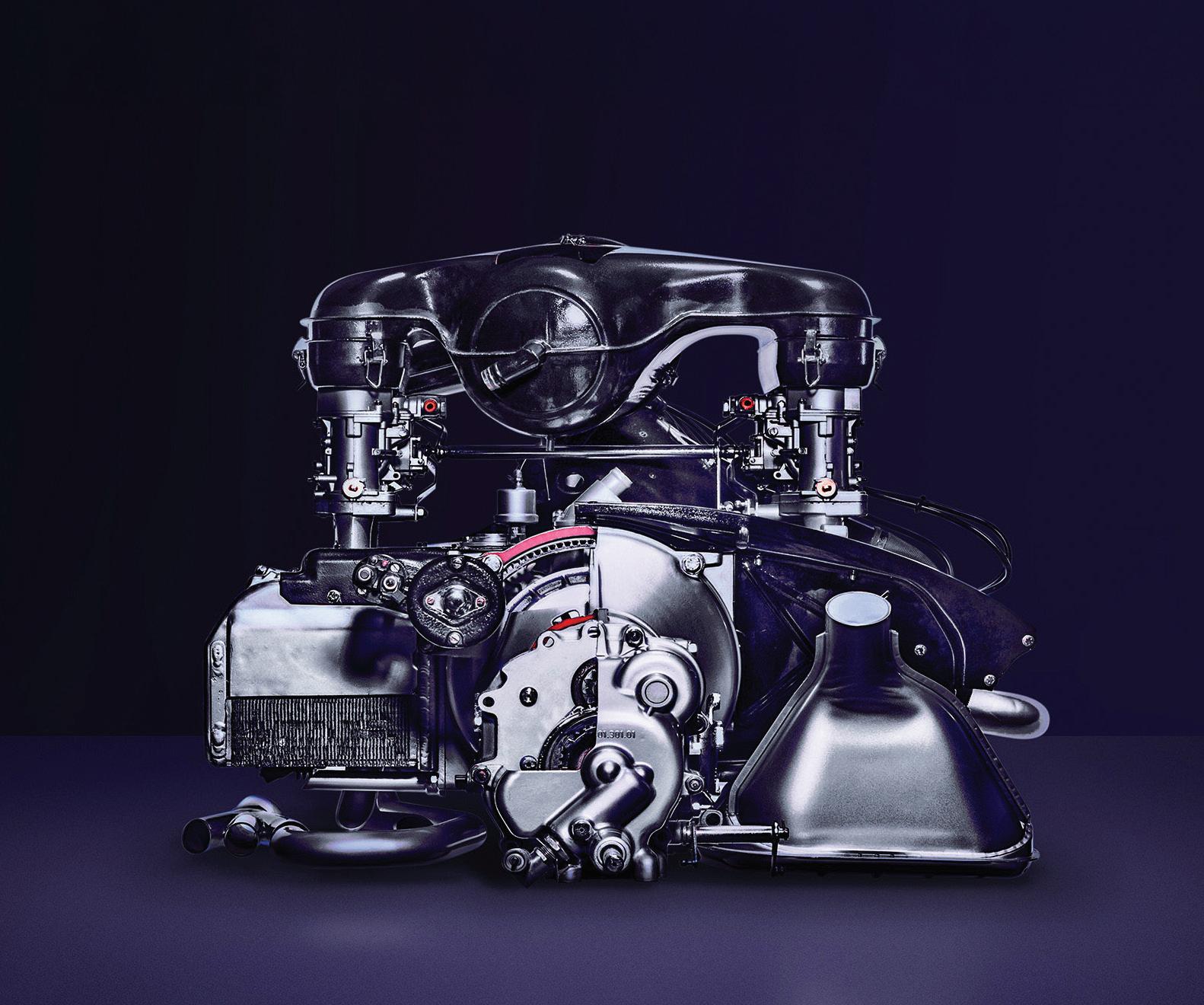

Will Porsche’s latest patent ever move from the drawing board to reality?

OVER the years, we’ve seen many technological innovations in engine design. Some have come out of research establishments and universities, while others were devised and built by selffunded amateurs in humble suburban garages. Indeed, one of the most impressive camshaft designs we ever saw was devised in a home garage in Newcastle. It was truly superb and ran beautifully and reliably in two different engines.

A good number of the other innovations we met had also been constructed and tested in engines and vehicles, some very successfully. Others remained on the drawing board; concepts under investigation. Common to all of them, however, was the idea that they’d revolutionise the internal combustion engine. None of them did.

and all the associated documentation needed to support a new design.

If these factors (and many others unmentioned) aren’t enough, there’s the matter of recalls and lawsuits. Even the simplest recall is very expensive and the dollar cost only increases with more complex designs. And, of course, brand damage is an important consideration. Most inventors don’t consider any of these things in adequate depth.

One of the most common complaints from inventors was that car companies were narrow minded and just wouldn’t listen, but it’s actually this view that’s narrow minded. Why? A new design from a clever amateur or even a skilled engineer will be nowhere near ready for production. The amount of development and testing required is unbelievable. It’s also extremely expensive and time consuming. Engineers at car companies are already busy people. Bringing an innovative new design to maturity and integrating it into production calls for enormous inputs from engineers and technicians. Then there’s the training required for workers on the production line to say nothing of the training required for mechanics at dealerships

Well, what about innovative designs from tier-one automotive suppliers? Delphi was about as tier-one as it gets. Delphi’s antecedent was acquired by GM around the beginning of the First World War (1914). The company knew what it was doing and knew how to work within the GM ecosystem. Still, convincing GM and other OE manufacturers to adopt its revolutionary new braking system in the early 2000’s was an enormous undertaking. Even after proving that the system offered substantial advantages and worked effectively and reliably (it has long been used on commercial jetliners) final stage testing still involved twenty vehicles covering 1.5 million test kilometres. After all of this, the system was never adopted. Car companies have invested hundreds of millions, even billions of dollars in production facilities to bring proven technology to market, and to make money doing it. Effectively, they’ve invested a great deal of money and effort in doing things the same way. So, where does that leave innovation within car companies? Well, it certainly occurs but it’s more iteration than innovation in order to alleviate the risks mentioned above. Small, progressive changes are the main means

of OE development. Evidence suggests that this approach is not without merit because innovation doesn’t have to be a revolution. The internal combustion engine was invented just one hundred and sixty years ago and has been steadily improved ever since. In comparison, modern engines are amazing. Still, sometimes car companies can be radically innovative. Recently, Porsche obtained a patent for a radical new engine design that features a six-stroke operating cycle. It’s been creating quite a stir so we decided to examine it for ourselves. Now, it has to be said that just about every configuration imaginable has been dreamed up over the years and a sixstroke operating cycle is no different. However, the Porsche design is unique enough to qualify for patent protection.

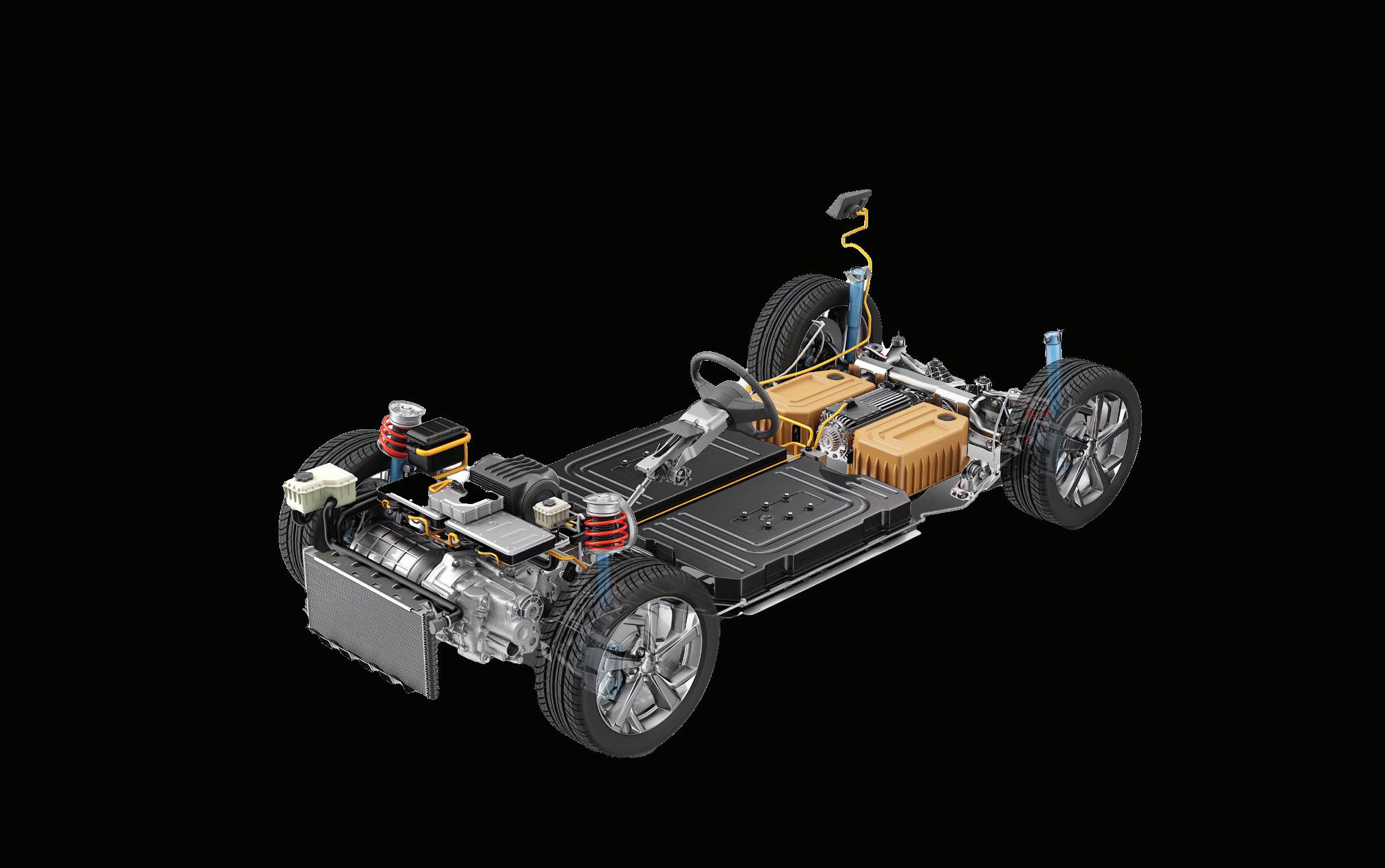

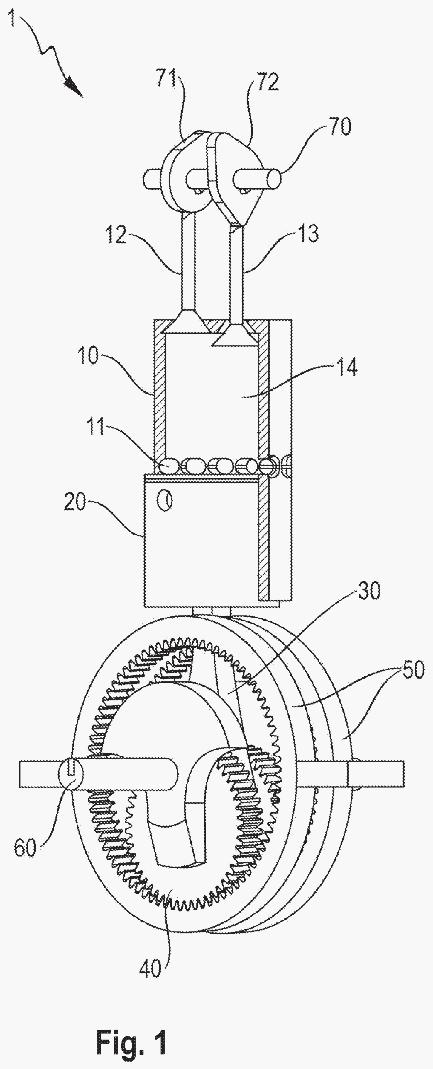

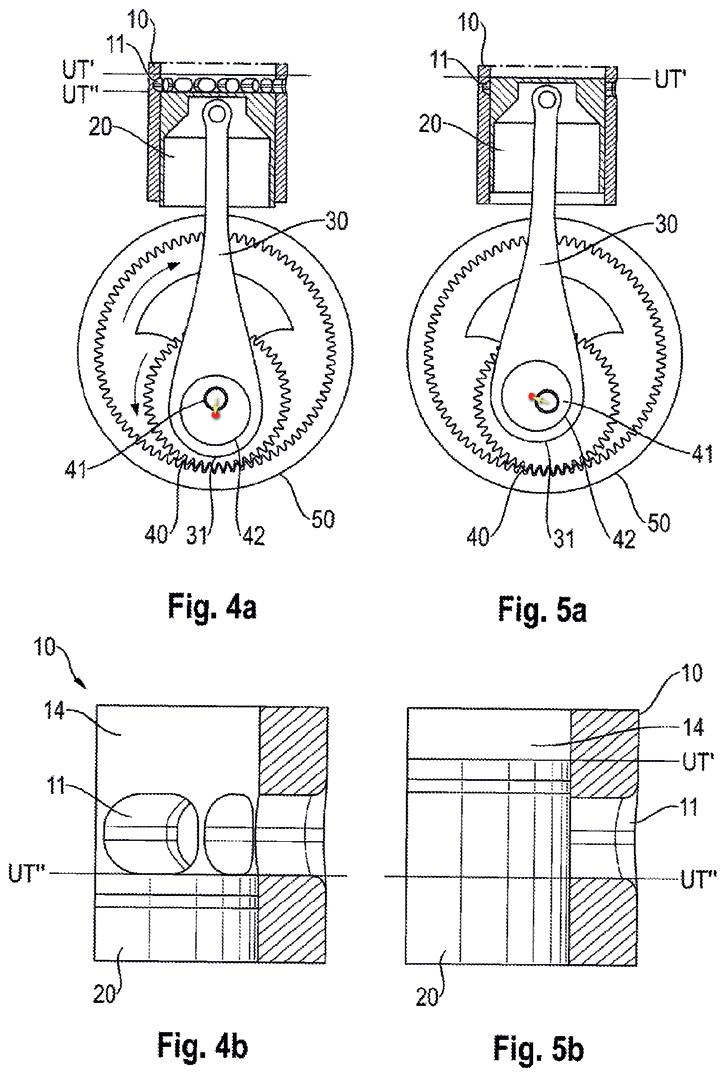

Most descriptions we’ve seen for this design begin with a tedious review of the four-stroke process. Given that this magazine is intended for the automotive trades, we’ll spare you from that. Also, it’s unlikely anyone needing such a review will understand the following details anyway. So . . . In addition to the normal four strokes, the Porsche engine described adds an extra compression and an extra power stroke during each operating cycle. The design that makes this possible is relatively complex and involves extra components interposed between the big-end of the conrod (30 in the illustrations) and the crankshaft (60). These components work on the same basic principle as an epicyclic gearset from an automatic transmission, or from a Lenco if you prefer a manual example.

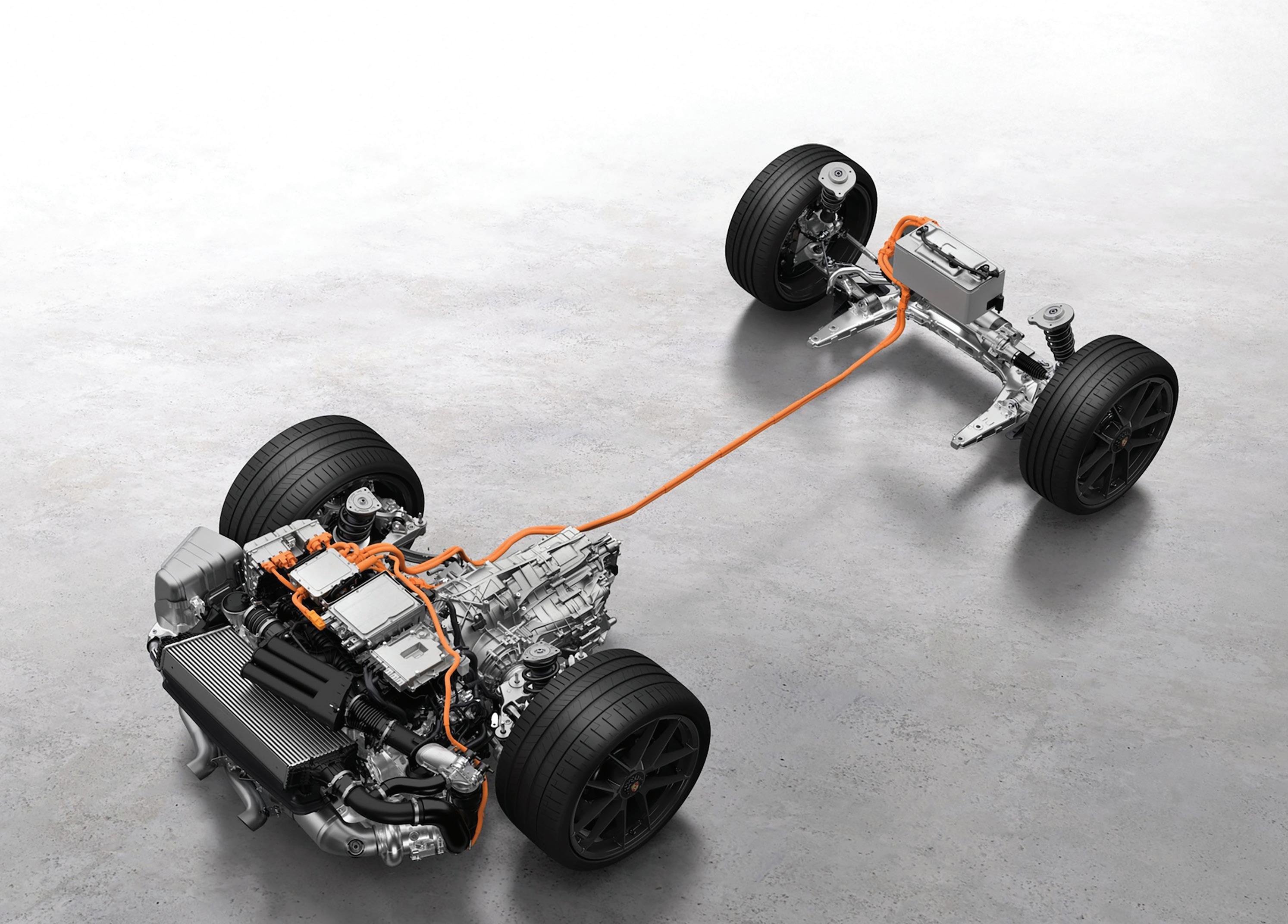

This superb engine is the latest for the 911. Beautiful, isn’t it? It’s a hybrid design and the cutaway section shows that there isn’t much internal space for accommodating the extra components detailed in this patent application, let alone the extra ducting that would be needed to feed the annular ports. We think it unlikely that Porsche would radically alter this iteratively perfected, iconic design for a radically new engine.

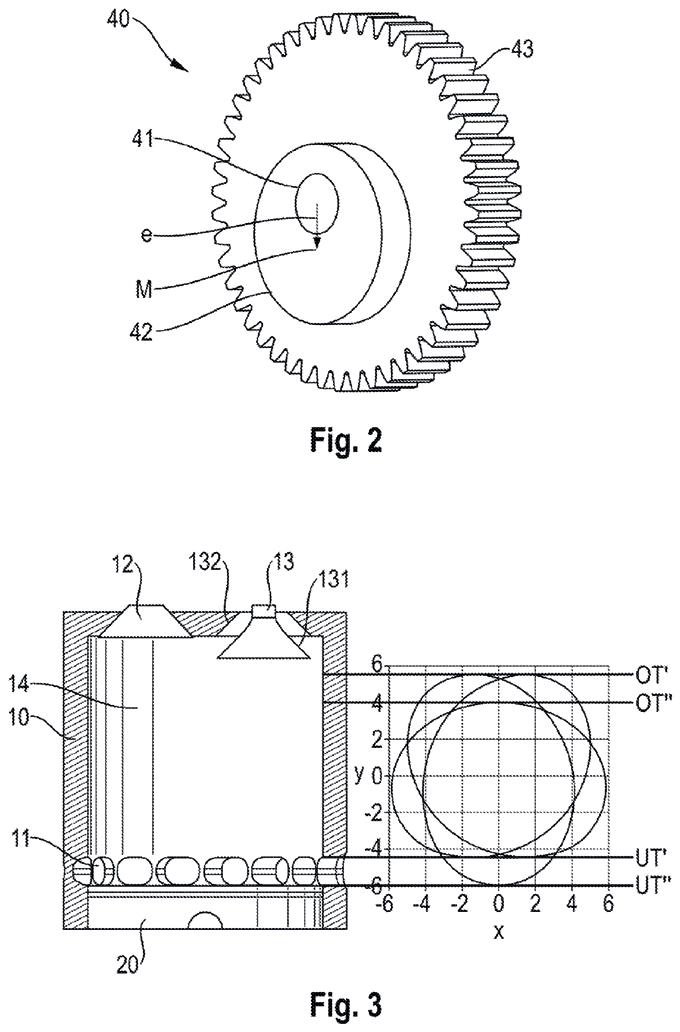

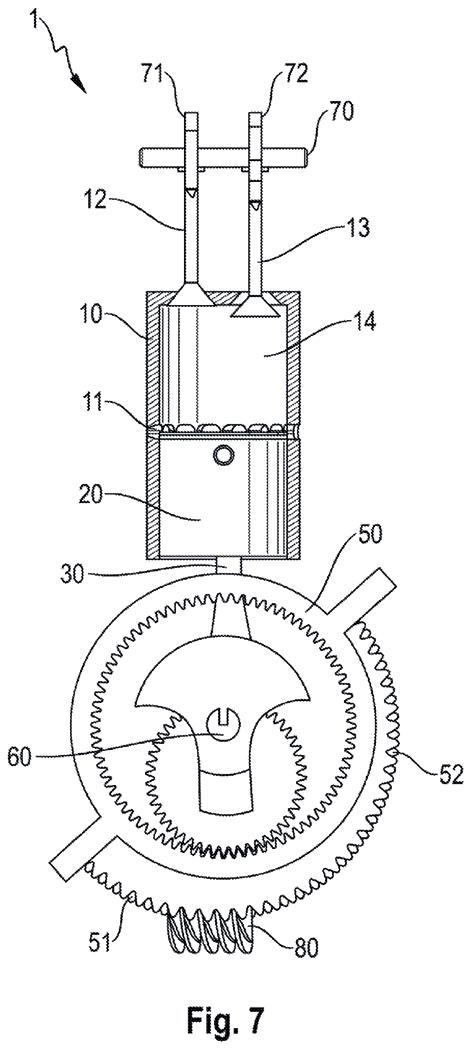

The patent only describes a single cylinder and we’ll do the same, although multiple cylinders would help alleviate some of the balance issues that would occur with a single cylinder. In the patent, the big-end as described doesn’t bear on the rod journal of the crankshaft as in a conventional reciprocating engine. Instead, it operates on a journal (42) fixed to, or perhaps part of, the side of a planet gear (40) interposed between the big-end, annulus gear (50), and then the crankshaft. The journal for the big-end is described as simply a ‘cylindrical connecting element’ (42) and carries a driving/driven element for the crankshaft described as a ‘socket’ (41). The socket is located centrally on 40. At first glance, it may be thought that if the socket is placed centrally on the planet gear, how does it interact with the offset journal (the equivalent of the rod-journal on a traditional crankshaft) of the crankshaft here described?

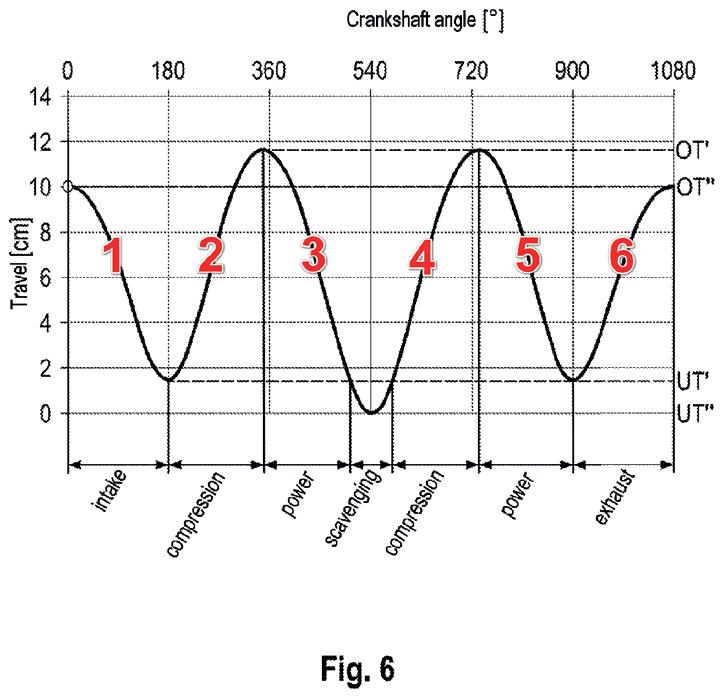

As the conrod interacts with 42, the planet gear 40 ‘walks’ around the inner teeth of the annulus. As it does so, the crank socket 41 traces out a circular path that’s in accordance with the movement requirements of the crank throw. Importantly, the centres of 41 and 42 are not coincident. There is an offset (e) between them. This offset is crucial for the unique operation of the engine. Specifically, the centre of 42 (M) traces out a hypocycloidal path as the planet gear 40 moves around the annulus. This path is plotted graphically in Fig. 3 at lower right. The path plot for (M) in Fig. 3 shows that TDC and BDC each occur in two different positions. That’s to say, there are two TDCs and two BDCs labelled OTI & OTII and UTI & UTII respectively. Here is where the cleverness of this six-stroke design begins to emerge.

As can be seen in Fig. 3 the cylinder (10) is equipped with standard poppet valves

like any other engine. However, around the bottom of the cylinder, there is also an annular ring of ports (11) reminiscent of a two-stroke diesel. Crucially, the height of these ports is equal to the difference in distance between UTI & UTII (the two BDCs). This means that when the piston crown is at UTI the ports are covered by

the piston skirt. However, when the piston is at UTII the ports are uncovered. This is at the heart of the six-stroke process. So, at the beginning of the cycle, when the piston is at OTI the normal inlet valve opens to begin induction on the downstroke. Then, compression begins followed by, of course, ignition and the power stroke; three strokes. So far, so good.

After the power stroke finishes, with the piston at BDC, the conventional exhaust valve opens and spent, pressurised gas begins to exit, just as with conventional four-stroke systems. However, at the beginning of this stroke, the piston has descended further, to the second BDC (UTII) and uncovered the ring of ports through which the cylinder is recharged.

Now, on what would normally be a pure exhaust stroke, the exhaust valve in this design closes early and the mixture of residual exhaust gas and fresh charge (which entered via the ring of ports) is compressed and then reignited for a second power stroke. This second power stroke is the fifth stroke. (Note that a turbocharger probably would be used to help force fresh mixture in through the annular ports.)

Then comes the second exhaust stroke, which is actually the sixth stroke. During this stroke, the piston rises to OTI and the cylinder is fully exhausted as in a conventional four-stroke. It’s also important to note that because there are two exhaust strokes, the exhaust cam lobe has two noses, or points of maximum lift. Further, the camshaft in this engine rotates at one-third of crank speed rather than at half speed. Well, there you have it. In summary, after the first three conventional strokes, the first exhaust stroke performs double duty as a second induction stroke (via the ports in the bottom of the cylinder) and another compression stroke (the fourth stroke). Then, after the subsequent second power stroke (the fifth stroke) a second exhaust stroke becomes the sixth stroke and the cycle is complete. Of course, each stroke is still 180º so that adds up to 1080º or

three full revolutions of the crankshaft for the full operating cycle of this engine. There is also another interesting feature of this design. Fig. 7 shows the annulus carrying an outer gear (51) with a varying root diameter. A worm gear (80) engages this gear and can alter the height of the annulus in relation to crankshaft motion. This arrangement allows variable compression and control of valve timing. These are extremely desirable characteristics.

Reference to Fig. 1 will show that there are actually two annulus gears along with two planet gears for each conrod. One of each is located on either side of the conrod to prevent bending loads on the rotating components. As is plain from the patent drawings, and in the text, Porsche takes this simplified approach for easier comprehension. The patent text also delineates a number of operational variations that are possible within the overall design. We’ve kept the description here as basic as possible. If we were to include all the possible variations mentioned we might just as well publish the entire document. You wouldn’t want that. However, we have included a QR link that leads to the full patent, if you’re a glutton for punishment. One of the advantages of this design is that it makes more power for fewer revolutions. In a four-stroke it takes 1440º of crankshaft rotation to get two power strokes. In this design, it takes only 1080º. It’s also suggested that this design is more fuel efficient because the second combustion stroke makes better use of the fuel entering the cylinder. This is also said to potentially reduce emissions because of more complete combustion. Of course, this is all speculation. The important thing to remember in all of this is that it’s only a patent. As far as we’re aware no working example has been constructed. So, obviously it hasn’t been tested and

there seem to be some significant hurdles to bringing such a design into production. The main drawbacks seem to be the complexity of the design, the extra rotating components needed and the additional mass and volume such an engine would have. Porsches aren’t big cars and there are many other issues that would have to be overcome. For instance, a long piston is required to perform the port sealing function of the design. Fitting a modern, short, light piston would mean that the ports would have to be controlled by, probably, a sleeve valve design. This was used in the many aero engines throughout WWII and was seen as a superior system by none other than Sir Harry Ricardo (look him up if you haven’t heard of him). Still, sleeve valves would mean even more complexity and of course, aero engines and car engines have different operational requirements. There are further issues we could mention but if any company could solve them, it would be Porsche. It’s unlikely the company will ever abandon its tried and true flat six engine layout. Examining the accompanying cutaway rendering of the latest, superb 911 hybrid engine raises the question, where could all of the components detailed in this patent be fitted? Things are already pretty tight. Matching the performance, efficiency and reliability that Porsche engines already have would be difficult. Bringing a new, untested radical design like this into the fold is extremely unlikely. We can’t be sure of why Porsche has taken the trouble to patent this idea but it seems like actual production is unlikely. Further, there’s no information about this idea from within Porsche. No press release, no renderings, no hints. Never say never, but don’t hold your breath.

EXEDY offers a comprehensive range of automotive components, spanning clutches, steering components and Aisin auto parts. Our clutch line boasts high-performance products, catering to various vehicle types and driving needs, ensuring smooth engagement and durability. In steering components, EXEDY provides a diverse selection of parts manufactured by the famous Japanese brand 555 designed for optimal handling and responsiveness. Additionally, our partnership with Aisin enables access to a wide array of auto parts ranging from hydraulic components to engine cooling systems, renowned for their quality and reliability. Overall, EXEDY delivers top-tier solutions across these crucial automotive systems ensuring efficient and reliable performance.

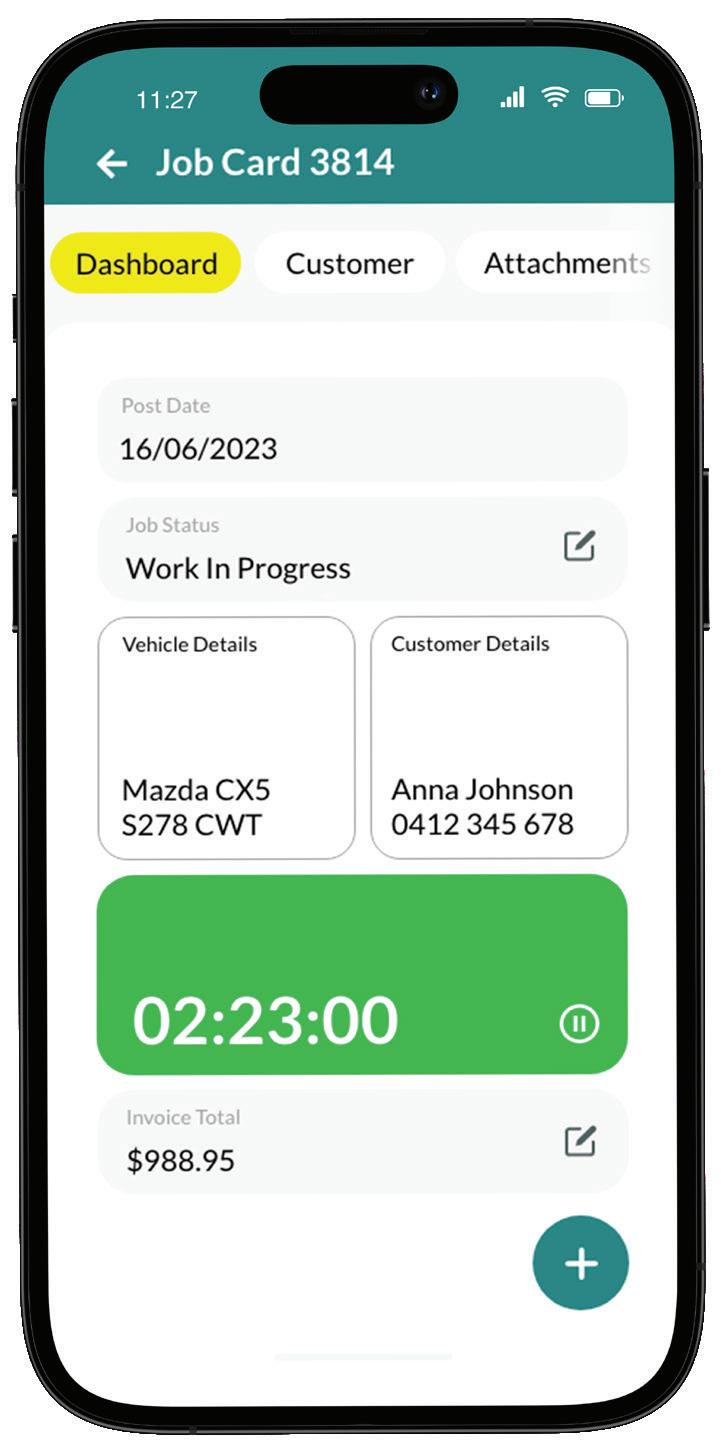

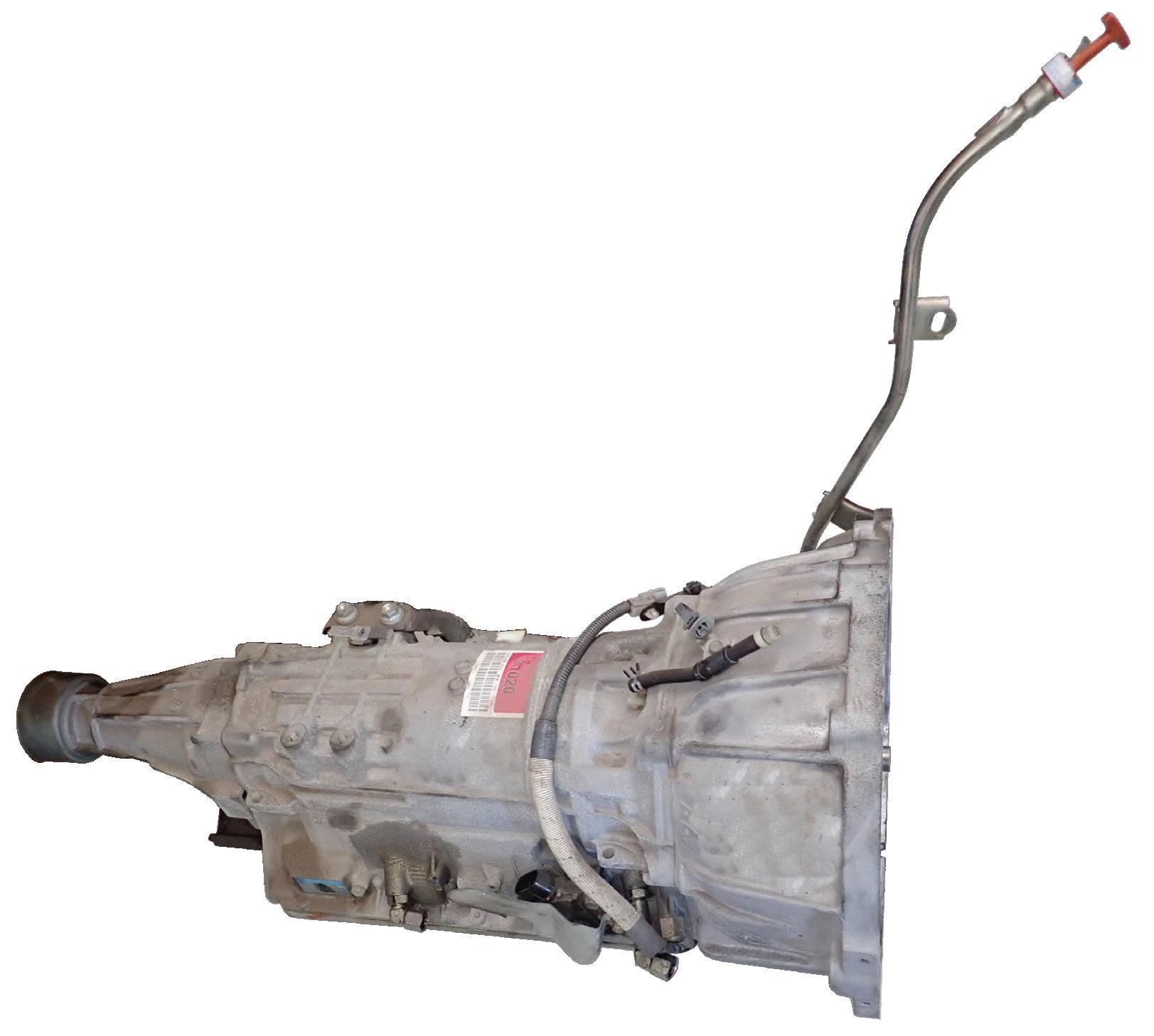

The Toyota HiAce has seen many updates over its long production run. The 5th Generation 200 series HiAce received a new six speed automatic transmission mounted to the petrol 2TR-FE engine from 2015. This new transmission has a different refill and level checking procedure which this article will cover.

The Toyota Group is the overarching entity which owns Toyota Motors among many other companies. One of which is Aisin Seiki Co., Ltd, also known as Aisin. In 1969 Aisin started a joint venture with BorgWarner Inc. of the United States to establish Aisin-Warner then Aisin AW Co., Ltd. Which has gone on to produce many automatic transmissions for Toyota and other manufacturers.

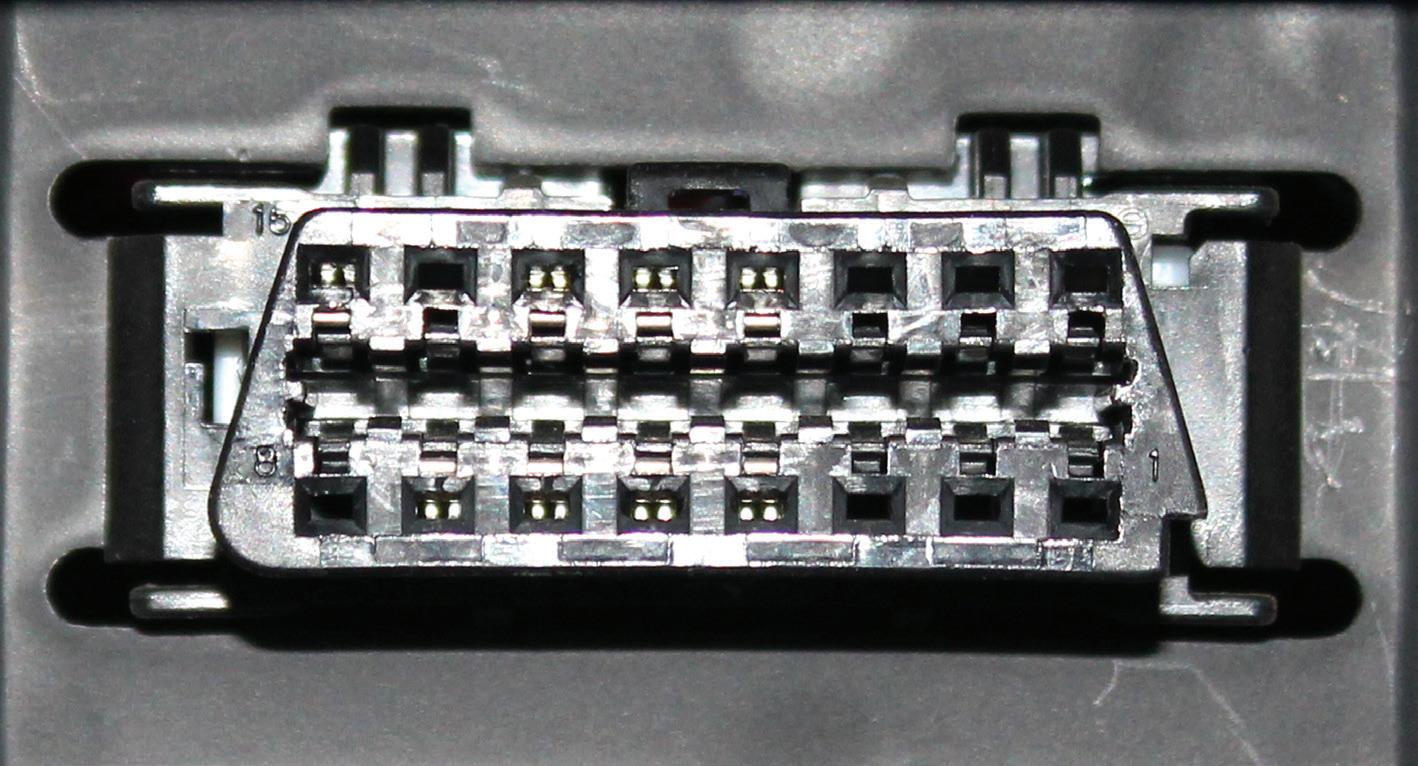

Aisin AW developed this new six-speed automatic transmission to be used in rear-wheel drive vehicles around the world. It has a production code of AWR6B45. This may be different to what the vehicle manufacturers might call it. See Diagram 7

In Australia, this transmission is fitted to the Toyota HiAce, Hilux, Prado and Fortuna and has an identification code of AC60. Which means the following;

A = Aisin-Warner Automatic.

C = The second digit or letter represents the generation, e.g. C means that it is the 3rd generation of this transmission type.

Refill Plug is in the extension housing. Tighten to 36 Nm

60 = The next digits represent the number of gears. e.g. 60 means six-speed, 50 means five-speed

The last digit or letters indicate the application.

E = Electronic control or 2WD

F = Four-wheel drive

This article is based on the draining, refilling and level checking for the 200 series HiAce.

NOTE: The fluid temperatures and capacities for the diesel variants have been included as a guide, but have not been confirmed.

This transmission as fitted in the HiAce does not have ATF replacement as a part of the normal service schedule, However, under the severe service schedule, it shows a fluid inspection every 40,000 km and then a change every 80,000 km.

ATF Thermal Degradation Estimate and Reset

There is an easy way to inspect the condition of the ATF by checking to see what the ECM has calculated. Many manufacturers used various methods of estimating the service life of the ATF and other fluids around the vehicle

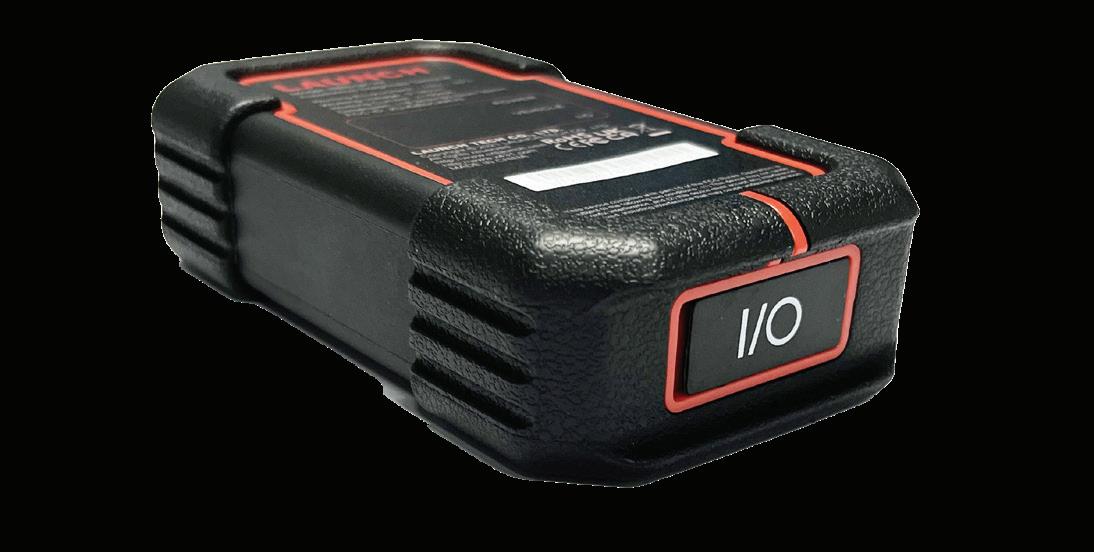

by monitoring the driving conditions and the loads placed on the vehicle. Without the need of a dedicated sensor, the ECM can have an educated guess about the ATF condition based on the distance travelled, temperature ranges and number of gear shifts that have occurred. This is then compared to information the ECM has in its memory that the engineers have programmed it with from their testing about the rate of ATF oxidation and degradation. They have come up with a limit at which they believe that the ATF may start to impact the transmission’s performance and possibly begin to shudder or have rough gear changes, but not cause a catastrophic transmission failure just yet. You can check what the ECM thinks of the ATF, with a compatible diagnostic tool and navigating to the live data for “ATF Thermal Degradation Estimate”. If it displays a figure higher than 50,000, you should replace the ATF. Why 50,000 I hear you asking? This is due to the characteristics of the 16-bit processor in the ECM and its 64 KB memory. This gives the system 65,536 distinct values and an operational range from 0 to 65,535. So, 50,000 is getting to the upper end of this range and is probably a nice round number, close to where the engineers think is

a good time to change the ATF based on their testing. You should still visually check the condition of the ATF.

If during your servicing and repairs, you have replaced 50 per cent or more of the ATF you will have to update the ECM of this fact with a compatible scan tool. Otherwise, the ECM will think it still has the same old ATF it started with.

Transmission Draining

1. Raise the vehicle safely.

2. Remove the drain plug from the pan. See Diagram 2

3. Allow the ATF to drain.

ATF Capacity

Depending on the engine and type of repair, there are different possible refill capacities. The table below gives the official capacities, which seem like an under estimation. Use this table as a guide only. See Diagram 3

Total Dry Refill: Approximately 7.9L

Transmission Refilling

1. Ensure that the vehicle is level within +/- 1˚.

2. Remove the refill plug from the extension housing. See Diagram 1

3. Remove the overflow plug from the transmission pan with a 5 mm Allen key.

NOTE: There is a reinforcement plate on the transmission pan, place a rag between this plate and the pan to prevent ATF getting in between them and making a mess. See Diagram 2

4. Pump correct amount of ATF into the refill hole until fluid flows out of the overflow plug hole.

NOTE: Pump slowly, otherwise fluid may come back out of the refill hole.

5. Wait until the fluid coming out of the overflow plug hole reduces to a slow drip. See Diagram 6

6. Temporarily refit the overflow plug. Use the old gasket at this stage.

7. Temporarily refit the refill plug.

8. Lower the vehicle

9. Start the engine and let it idle with no electrical loads.

There are two plugs in the transmission pan. The one at the rear is the drain plug. The one in the middle and to the LH side is the overflow.

10. With your foot on the brake and park brake engaged.

11. Move the gear selector slowly through all the positions then return it to Park.

12. Allow the engine to idle for about 30 seconds.

13. Turn the ignition off.

14. Raise the vehicle and add approximately the correct amount of fluid depending on the requirements in the table. See Diagram 3

15. Temporarily refit the refill plug. Transmission Fluid Temperature Check

The temperature of the transmission is critical to setting the correct ATF level. It can be checked with, and without a diagnostic tool.

With a scan tool

The following is the navigation path for the genuine diagnostic tool, after market tools may be different.

1. Connect the diagnostic tool to the vehicle and turn the ignition on.

2. Navigate via the following menus. Powertrain/Engine and ECT/Active Test/Connect the TC and TE1.

3. Select the Active Test option. Connect the TC and TE1/ON.

Drain plug. No tension stated

Overflow plug has a 5 mm Hex. Tighten to 20 Nm.

4. Select from the Data List: A/T Oil Temperature 3.

5. The ATF temperature should now be displayed. If the temperature is below 42˚C, proceed to the next step. If the temperature is above 42˚C, turn the ignition off and wait for the temperature to drop to 42˚C.

6. Depress and hold the brake pedal down.

7. Start the engine and let it idle with no additional electrical loads.

8. Move the gear selector slowly through all the positions then return it to Park.

9. While monitoring the D shift indicator on the dashboard, move the shift lever between N to D for six seconds with no pauses longer than 1.5 seconds.

10. The D shift indicator on the dashboard should come on for 2 seconds. This causes the vehicle to enter ATF temperature detection mode. See Diagram 5

4 – Diagnostic Link

5 – “D” Indicator and ATF Temperature

“D” Indicator and ATF Temperature With the vehicle in ATF Temperature Detection Mode, the “D” indicator can show when the ATF is in the correct temperature range. 1 4 13 14

11. If not, repeat the previous two steps.

I2. If the D shift indicator came on for two seconds. Move the shift lever into Park.

13. Release the brake pedal.

14. On the diagnostic tool, select the Active Test option, Connect the TC and TE1/OFF.

Without a scan tool

1. Using an appropriate jumper wire, bridge terminals 4 (CG) and 13 (TC) of the diagnostic connector. See Diagram 4

2. Depress the brake pedal and hold it down.

3. Start the engine and let it idle with no additional electrical loads.

4. Lights on the dashboard should be blinking, indicating terminals 4 and 13 are bridged.

5. Move the shift lever from Park to S, slowly. Then move it back to Park.

6. While monitoring the D shift indicator on the dashboard, move the shift lever from N to D for six seconds with no pauses longer than 1.5 seconds. See Diagram 5

7. The D shift indicator on the dashboard should come on for two seconds. This causes the vehicle to enter “ATF temperature

detection mode”. If not, repeat the previous two steps.

8. If the D shift indicator came on for two seconds. Move the shift lever into Park.

9. Release the brake pedal.

10. Remove the bridging wire from the diagnostic connector. This will activate the “Engine idle speed control mode”. The ATF temperature detection mode will still be active until the ignition is turned off.

Allow the engine to idle until the ATF is between 35˚C and 42˚C on the scan tool. See Diagram 6

The D indicator on the dashboard will be:

OFF - when the ATF temp is below 35˚C. Don’t check or adjust the ATF level.

ON - when the ATF is between 35˚C and 42˚C. Now check or adjust the ATF level.

FLASHING - when the ATF is over 42˚C. Don’t check or adjust the ATF level. See Diagram 5

Diesel Engine

Allow the engine to idle until the ATF is between 51˚C and 57˚C on the scan tool. See Diagram 6

The D indicator on the dashboard will be:

OFF - when the ATF temp is below 51˚C. Don’t check or adjust the ATF level.

• ON - when the ATF is between 51˚C and 57˚C. Now check or adjust the ATF level.

FLASHING - when the ATF is over 57˚C. Don’t check or adjust the ATF level. See Diagram 5

ATF Level Checking and Adjustment

1. With the engine running and the transmission within the correct temperature range for the engine type, raise the vehicle.

2. Remove the overflow plug from the transmission pan with a 5 mm Allen key.

NOTE: There is a reinforcement plate on the transmission pan, fit a rag between this plate and the pan to prevent ATF getting in between them and making a mess. See Diagram 2

3. Allow the overflow drain hole to drain (about 5 cc). If any more comes out, allow it to drain until it becomes a slow drip.

4. If none comes out, remove the refill plug and slowly add ATF until it flows from the overflow drain hole. See Diagram 1

Diagram 6 – ATF Temperature Range for Level Checking

5. Allow the ATF to drain until it becomes a slow drip. See Diagram 6

6. Check that the temperature is still with the appropriate range. If so, fit a new gasket to the overflow plug and refit it to the

7. Fit a new O-ring to the refill plug and refit it to the transmission and tighten it to 39 Nm. See Diagram 1

8. Lower the vehicle.

9. Turn the ignition off.

There seem to be different refilling capacities and level checking procedures across the makes and models with this transmission.

The Hilux and other models seem to use a dipstick. This transmission has been carried over to the new 300 series HiAce, however, we have not confirm if it is the same procedure.

This transmission is also used in the Isuzu D-Max from 2016 and is called the Rev-Tronic six-speed automatic with an identification code of AW TB60-LS. It may also be re-branded and coded differently in other vehicles, but these are the ones that we know of.

Automatic Transmission

Initialisation

If the whole transmission or any of the main components of the transmission have been replaced, you will need to reset the memory of the ECM so it can relearn the new parameters. This can only be done with a compatible diagnostic tool.

1. Connect the diagnostic tool.

2. Turn the ignition ON.

3. Navigate the following menus; Powertrain/Engine and ECT/ Utility/Reset Memory

4. Road test the vehicle and the system will relearn the new parameters.

For more information on the Toyota HiAce, log on to VACC’s MotorTech or call VACC’s Technical Advisory Service.