AUSSIE INGENUITY

SCAN FOR MORE TESTIMONIALS

06 SKILLS AND JOBS

VACC and TACC continue their multi-media marketing campaign to promote an auto labour pipeline

08 BE PREPARED

It ’s summertime and your customers are on the road more than ever. Here’s some advice you can pass on to keep them safe

10 INDUSTRY INSIGHT

Af ter more than a year’s wait, the latest snapshot on Australia’s motor vehicle fleet has been released

14 FULLY CHARGED

The automotive industry reiterates key priorities for policy-makers, and outlines the latest advocacy news from VACC

16 GREY IMPORTS

Industry is ‘all in’ and wants more EVs in Australia, but tapping into the used import market is a regressive solution

18 YOUNG DRIVERS

VACC ambassador Shane Jacobson examines minimum driving ages across the globe and comes up with a few surprises

20 AIA LAUNCHED

VACC and TACC members can now apply for the re-imagined Automotive Industry Awards. Are you the best? Then prove it

21 FRESH LEADERSHIP

VACC and TACC members have a new board and a new president. Who will represent you for the next two years?

FE ATURES

28 FLYING HIGH

Ford Australia’s Melbourne office keeps producing winning designs that fly the flag for local ingenuity

32 BATTERY TECH

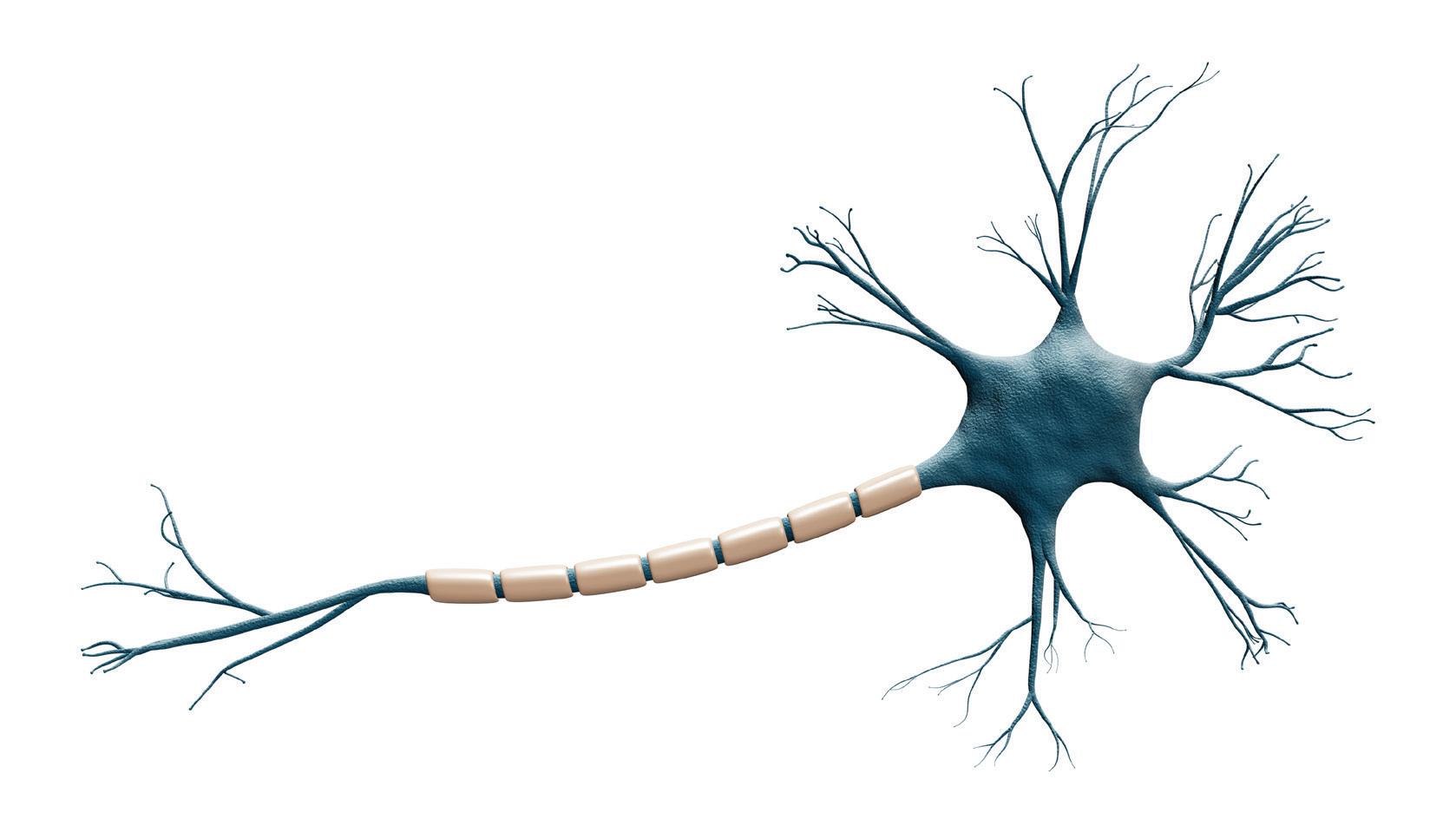

What’s the latest in battery thinking? With EVs now mainstream, find out what you might see next in your workshop

38 NEXT LEVEL

Is artificial intelligence alive? Not really, but it sure looks and sounds like it. AI is already part of your life, so best make sure...

44 IN THE KNOW

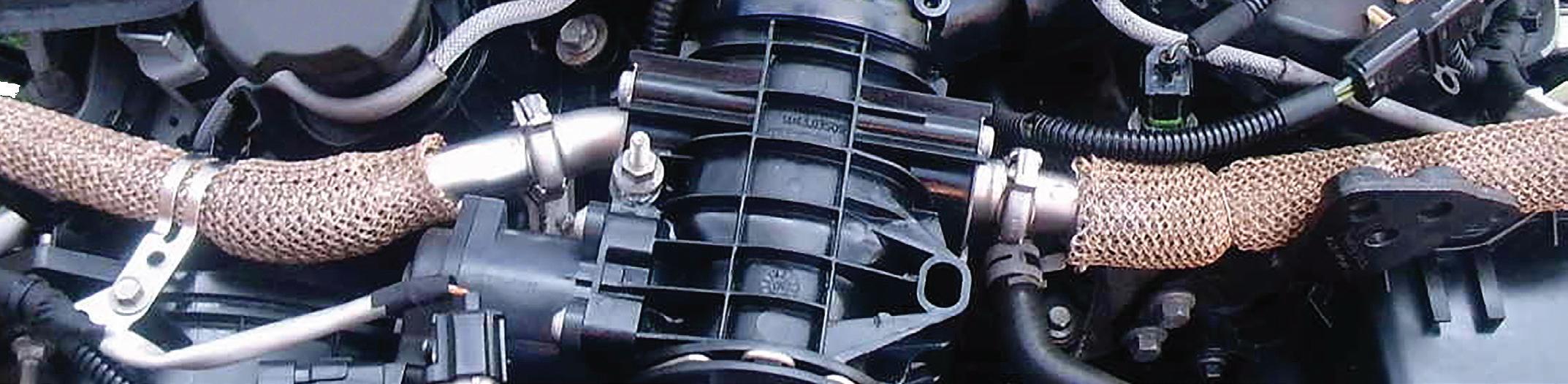

Get the lowdown on Territory and Discovery 2.7-litre diesel valves, plus we answer all your diesel exhaust fluids questions

50 SERVICE DIRECTORY

Find everything from the latest products to the best business services you need all in one place

52 BUSINESS INDEX

Take advantage of VACC corporate partnerships and services, and drive your business forward

WELL , we’ve wrapped filming for the upcoming motoring TV show, Cool Cars with Dermott and Elise

As major sponsors of the program, VACC/TACC features heavily, so we’ve been all over Victoria and Tasmania, visiting member businesses in the name of attracting skills and labour into the automotive industry.

Major industry sectors will be represented including mechanical and auto electrical for light and heavy vehicles, panel repair and spray-painting, restoration including trimming, light and heavy vehicle sales and parts supply, motorcycle sales and service, and farm and industrial machinery sales and service.

Hosts Dermott Brereton and Elise Elliott visited Blackmans Bay Motors in Tasmania, Bendigo Mazda, Dale Paterson Motorsports in Tullamarine, Zagame Auto Body also in Tullamarine, AgPower in Lilydale, Maskells Customs and Classics in Shepparton, and Geelong Harley-Davison and Geelong Isuzu. There were, of course, plenty of cool cars, and trucks and motorcycles, with the duo driving an Austin-Healey 3000 MkIII, Mazda MX-5, Ford GTHO Phase III Tribute, Isuzu three-tonne truck, Harley-Davidson Low Rider, Alfa Romeo 1600GT Junior, Bentley Continental GT, and Ford XT GT.

MANAGING EDITOR

David Dowsey

03 9829 1247

editor@australasianautomotive.com

SUB-EDITOR

Pia-Therese Hams

DESIGNERS

Faith Perrett, Gavin van Langenberg 03 9829 1189

creative@australasianautomotive.com

CONTRIBUTORS

Geoff Gwilym, Steve Bletsos, John Caine, Rod Lofts, Imogen Reid, Bruce McIntosh, Paul Tuzson, Shane Jacobson, Joe Brogno, Harry Quinlan

DAVID DOWSEY

SKILLS AND JOBS

Business owners appeared on camera to discuss their operations, the diversity of their work and the opportunities available, while VACC and TACC Automotive Apprenticeships apprentices had their say about the high-tech work on offer and the possibilities for career advancement.

Cool Cars with Dermott and Elise starts next month on 7Mate. Keep an eye on our social channels for updates on a starting date and be watching at midday Saturdays in March or check out the repeats on Thursday nights at 9pm.

Automotive indemnify VACC, its directors, board, employees, members, and its agents against all claims and any other liability whatsoever wholly or partially arising from the publication of the material, and without limiting the generality of the foregoing, indemnify each of them in relation to defamation, libel, slander of title, infringement of copyright, infringement of trademarks or names of publication titles, unfair competition, breach of trade practices or fair trading legislation, violation of rights of privacy or confidential information or licences or royalty rights or other intellectual property rights, and warrant that the material complies with all relevant laws and regulations. This publication is distributed with the understanding the authors, editors and publishers are not responsible for the results of any actions or works of whatsoever kind based on the information contained in this publication, nor for any errors or omissions contained herein. The publishers, authors and editors expressly disclaim all and any liability to any person whomsoever whether a purchaser of this publication or not in respect of anything and of the consequences of anything done or omitted to be done by any such person in reliance, whether whole or partial upon the whole or any part of the contents of this publication. Advertising accepted for publication is subject to the conditions set out in the Australasian Automotive rate card, available from editor@australasianautomotive.com

IT’S summertime and for many families that may mean the first road trip in a long time.

Driving is an economical and fun way to create a memorable holiday but, whether you’re going off-road or glamping, things won’t always turn out how you planned.

So, here are my tips to get you there safely.

Before heading off, check you have a roadworthy spare tyre and wheel on board, and you know how to change it.

Never change a tyre on the side of the road if there’s traffic close to your vehicle. Call a breakdown service instead.

Inspect all tyres for wear and ensure they’re inflated to the recommended pressure – that goes for trailers and caravans, too.

If towing a caravan, trailer or boat, connect it properly, checking all lights work, and you have correctly positioned the driving mirrors.

GEOFF GWILYM BE PREPARED

Also, make sure you know how to safely manoeuvre your vehicle and the load behind. If your skills need brushing up, practise before you leave home.

Fill up your tank and carry spare fuel in a safe container if you visit remote areas.

Keep a first aid kit in your vehicle and a portable phone charger. Take cash, a torch and spare batteries, blankets and water. Carrying jumper leads is also essential.

Importantly, tell someone where you’re going and when you’ll be back. There will be lots of people on the roads. Be patient, be courteous, and take regular rest breaks. That way we can all have a fun and safe holiday.

Want to hear more from Geoff Gwilym? Read his weekly column in The Herald Sun or join him – along with co-hosts Greg Rust and Shane Jacobson – on THE GRILLE podcast. There’s auto news and views, industry insights and trends, special guests, and plenty of laughs along the way. Visit: thegrillepodcast.com.au

STEVE BLETSOS

FLEET BIGGER AND OLDER

AFTER more than a year’s wait, the latest snapshot on Australia’s motor vehicle fleet has been released.

Historically, this information has been compiled by the Australian Bureau of Statistics (ABS) through its annual Motor Vehicle Census data collection. As from July 2021, however, this collection was taken over by the Bureau of Infrastructure and Transport Research Economics (BITRE), who has recently published its first report on the size, composition, and age of Australia’s motor vehicle fleet.

According to BITRE, there were an estimated 20,680,152 registered motor vehicles in Australia as of 31 January 2022 – an increase of 419,143 vehicles or approximately two per cent compared to January 2021. In addition to this, there are a further 4.5 million trailers, caravans, campers, and plant and equipment (e.g. agricultural tractors, all-terrain vehicles, forklifts, golf buggies) that are not included in the total count of registered motor vehicles.

The number of registered vehicles increased in all jurisdictions, where Tasmania, Queensland and Western Australia reported the largest increases

in vehicle registrations (2.9, 2.7 and 2.5 per cent respectively), followed by South Australia (2.3 per cent), Victoria and ACT (1.8 per cent), NSW (1.6 per cent) and Northern Territory (0.6 per cent).

Toyota remains the largest passenger vehicle make for the seventeenth consecutive year, with three million registrations, followed by Mazda (1.4 million), Holden (1.36 million), Hyundai (1.2 million) and Ford (974,880).

In terms of the average age of the vehicle fleet across Australia, this increased from 10.8 years in 2021 to 11.0 years in 2022. The average vehicle age increased across all jurisdictions between 2021 and 2022, with Tasmania having the oldest vehicle fleet (13 years), and the ACT has the youngest (9.9 years). Campervans and heavy rigid trucks remain the oldest vehicle types on road, with average vehicle ages of 17 years and 16.3 years respectively.

In terms of the break-up of the fleet by fuel type at the end of January 2022:

Petrol powered vehicles comprised 70.1 per cent of the fleet (down from 71.3 per cent in 2021)

Diesel powered vehicles comprised 27.2 percent (up

from 26.4 per cent in 2021)

Hybrid electric vehicles numbered approximately 277,000 (up by 35 per cent over 2021)

Battery electric vehicles on register numbered approximately 40,000 (up by approximately 100 per cent)

Hydrogen fuel cell vehicles on register numbered 46 (up from four vehicles in 2021).

Of the 40,000 battery electric vehicles (BEVs) on register, around 34,000 were passenger cars, of which Tesla had the largest share with approximately 22,260 vehicles on register as of 31 January 2022, up from 10,125 vehicles on 31 January 2021. Hyundai accounted for the second highest number of BEVs on register as at the end of January 2022 with 2,753 vehicles, followed by Nissan (2,508), MG (1,435) and Mercedes-Benz (1,077).

BITRE has also made it known that it will also make available more detailed estimates of the car parc by make/model, registered postcode, year of manufacture and other available vehicle characteristics, for users upon special request.

Gerard Geyle Performance

Sole trader operation with large, loyal customer base built over 35-plus years. Busy and well-located Ballarat workshop with minimal opposition. Long lease and good landlord (annual rental: $32,235.92 plus GST $3,223.59)

Included in sale:

• $80,000 stock on hand (retail)

• Workshop ute (pictured)

• Specialised tools

• Security camera

• Courtesy car

• Rechargeable battery forklift

• 20-foot container full of second-hand hard parts

• Office equipment including desk, office chairs, filing cabinet, lockers, fridge, microwave

Transition period negotiable (six to 12 months)

Ballarat is a large regional historic town. Great schools, hospitals, shopping, Sovereign Hill, Lake Wendouree, gardens, tourist attractions, one hour to Melbourne and Geelong.

A customer concern or complaint can provide a useful opportunity for you to form a better relationship with them.

Even the most dissatisfied customer can become an advocate for your business, winning new customers for you through word of mouth. This can mean dealing with a customer issue, even when you’re not at fault.

You should have a complaint handling procedure which receives complaints, deals with them straight away, and includes some staff training.

Your procedure should include the following:

JOHN CAINE WHEN THE INEVITABLE OCCURS

a one-off situation due to a faulty product or service but it can also be an ongoing systemic problem which can be traced to a flaw in operations or a problem with one of your providers.

Scope of works agreements/ contracts and job cards can often prevent disputes from arising.

Contracts can clarify you and your customers’ responsibilities and expectations and, as a result, reduce the likelihood of disputes arising, as long as everyone works by the contract.

Listening sympathetically to establish the details of the complaint

Recording the details together with relevant material – such as a sales receipt or damaged goods

Offering to fix the problem – by repair, replacement or refund

Handling the complaint courteously and swiftly

An appropriate follow-up action – such as a letter of apology or phone call to ensure you and the customer resolve the problem.

Where practicable, empower staff that deal directly with customers so they can resolve issues when customers make complaints.

Make all staff aware of the ongoing

On some occasions, formal legal advice may save you from carrying out a promotion or particular business practice that could easily result in a dispute or legal complications. Expense incurred as a result of obtaining the advice is worth the avoidance of disputes and bad publicity.

Dispute resolution clauses should be written into all contracts to encourage joint problem solving with your customer before a problem turns into a dispute. Key elements to the clause should include:

Informal discussion of the issue or problem

How you will deal with complaints from the start (who will manage the complaint and how they will do it)

Internal negotiation methods (focusing on joint decision making and practical solutions)

way to resolve a dispute, such as in mediation or at a tribunal.

No business can be successful unless it meets the needs of its customers. One of the essential activities of any business is to discover what customers want or need, and then act on that information.

There are numerous ways businesses can gather relevant information from customers. The methods you use depend on the type of business and industry you are in.

Important ways of collecting customer feedback are:

Employees. Find out what customers complain about, or what kind of service or product they request

Short surveys. Ask simple questions customers can quickly answer. Include open-ended questions about the services or goods they want, and ask their opinion about current goods and services

Conversations. Chat to customers informally to learn about their needs and wants

• Market competitor observation. Observe the actions of main competitors and, if the opportunity arises, question their customers discreetly Market research. Employ a company to ask target audiences about your goods and services

Documenting sales. Keep

TRUST. RESPECT. LOYALTY.

When trust is earned, respect is given, and loyalty is demonstrated, exceptional outcomes follow .

EXEDY has earned the trust and respect of OE clients across the globe, having supplied more than 300,000,000 clutch kits to their exacting standards. The majority of which are manufactured in our own factories to meet the strictest specifications for quality, fitment, longevity, and noise suppression.

OE suppliers, including NSK, Nachi, Koyo, NTN and FTE provide us with bearings and concentric slave cylinders to guarantee the quality of our OEM replacement kits.

All EXEDY OEM replacement kits include high-quality cover assemblies, clutch discs and release bearings. To guarantee correct fit and function, an alignment tool is also included in most high-volume kits.

When you choose to fit an OEM replacement kit from our extensive range, you’ll enjoy the same loyalty that we demonstrate to our OE clients.

AS 2023 gains momentum, VACC is preparing to meet with Victoria’s new Cabinet following the 2022 Victorian State election. The result saw the Andrews Labor Government returned to power by a significant majority. The Victorian Legislative Council (Upper House) will be made up of 15 Labor MPs (six short of a majority), 14 Liberal-National Coalition, four Greens, two Legalise Cannabis MPs and single representatives from the Democratic Labour Party (DLP), One Nation, Liberal Democrats, the Animal Justice Party and the Shooters Fishers and Farmers.

In the Legislative Assembly (Lower House) Labor won 56 seats (an increase of one from 2018) and the LiberalNationals Coalition maintained their overall total of 27 seats. The Greens won four seats. This means the cross-bench in the Upper House, will once again, be as important as ever in the debate of new or existing state legislation.

Part of these discussions with government will include our ongoing advocacy to establish a dedicated ZLEV transition taskforce, with automotive retail at its core. VACC has engaged with the Minister for Climate Action, Energy and Resources and Minister for the State Electricity Commission the Hon. Lily D’Ambrosio MP and her department to take this forward now the government is out of caretaker mode. We will also continue our push to have minimum safety and training standards implemented for electric vehicle technicians by way of a

DR IMOGEN REID INDUSTRY INSIGHTS

licensed repairer’s scheme amongst a range of other policy priorities outlined in our Fully Charged policy document.

Also of note, in January this year, the policy team submitted our State PreBudget submission (available on the VACC website). Acknowledging Victoria – and Australia – is experiencing fiscal austerity and high inflation, VACC maintains its stance on the reduction of outdated or inequitable duties levied at the Victorian automotive aftermarket. This includes the abolition or reduction in state-based payroll tax, the removal of the super-luxury tax and the modernisation of Motor Vehicle Duty In The Duties Act 2000 (Vic).

The issue of accessing talent remains an ongoing industry-wide problem, and one that VACC is acutely aware. While there are no quick fixes, I want to assure members VACC is doing all it can behind the scenes with the Federal Government to find a practical, workable, short and long term solution.

Most recently, VACC provided submissions to the Department of Home Affairs consultation A migration system for Australia’s future, along with input to the Joint Standing Committee on Migration’s Migration, Pathway to Nation Building consultation VACC seeks not only mutual recognition of relevant automotive trade qualifications from relevant countries, but also the acceleration of visa

processing and skills assessments to enable our members to access the talent sooner than the nine to 12-month period currently experienced.

Finally, a reminder that Industry Policy Advisors (IPA) do not just meet with government and regulatory bodies. A key aspect of our jobs is being out in the membership, learning directly from business, and the issues affecting your day-to-day. For example, IPA Michael McKenna has recently concluded extensive dealership briefings regarding Australian Consumer Law and manufacturers’ indemnity. These sessions outlined dealers’ rights and obligations as a supplier. The seminars had a heavy focus on ensuring dealerships are well versed in their legislated responsibilities (keeping them out of trouble!) and are free to members. I encourage you to reach out to the policy team anytime to discuss any industry concerns or have us come and visit – the team is listed on the VACC website.

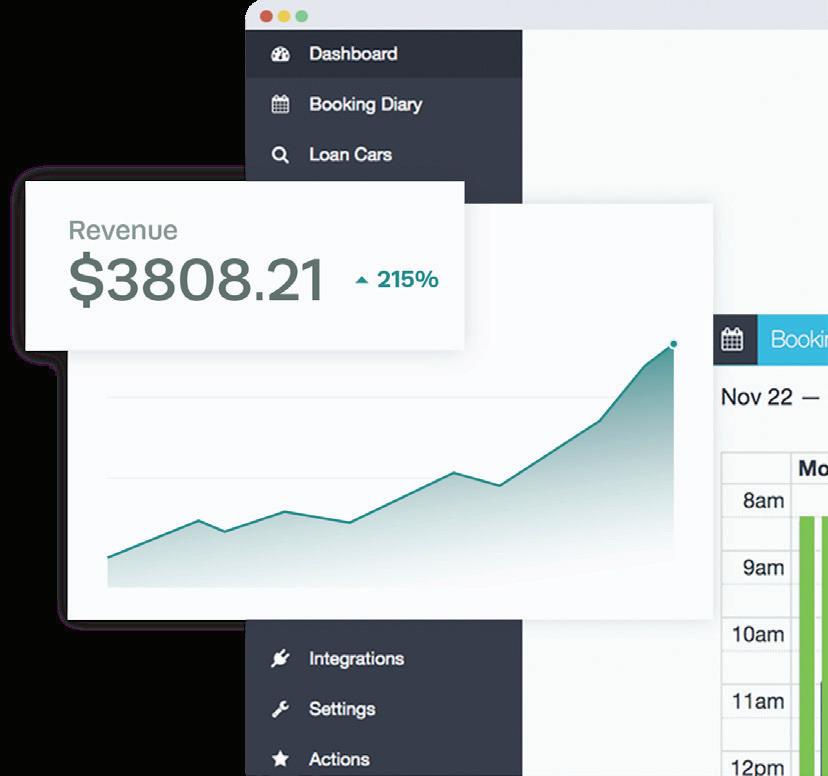

Podium is powering the Australian automotive industry into the future. Australia’s leading text messaging platform is helping over 100,000 businesses communicate with customers, schedule services and collect payments – all through the power of two-way text.

"Podium is so good that we have cancelled our traditional eftpos machines. I’ve never been more impressed with a software provider, and can’t wait to see what features Podium releases next."

Justin

Walker, General Manager, Grant Walker Parts

I’M disappointed ‘grey import’ used vehicles is again on the Federal Government’s agenda.

The issue is part of the government’s consultation on the National Electric Vehicle Strategy (NEVS), questioning if importing used EVs will help boost supply.

Industry is ‘all in’ and wants more EVs in Australia but tapping into the used import market is a regressive solution. The safety and consumer risks do not magically disappear because these vehicles are electric.

Provenance is even more important for EVs. Lithium-ion batteries comprise a major component of EV costs and consumers should have access to factory warranties, national spare parts availability and the security of service capability.

The Albanese Government should consider the risk Australia will become a dumping ground for old batteries. These batteries can be

BRUCE MCINTOSH

OTHER PEOPLE'S JUNK

hazardous and should only be handled by industry trained technicians.

It’s no doubt tempting for other countries to neglect their responsibility to properly recycle and dispose of batteries, but it makes no sense for Australia to adopt a disproportional role on this issue.

Mature EV markets (US and Europe) have not resorted to drastic measures such as used EV imports to boost their EV numbers. Instead, they have worked through the OEM and dealer networks to facilitate a safe and considered transition, affording consumers appropriate protections.

Increasing the importation of old EVs is a lazy policy solution which will be bad for consumers, bad for automotive businesses and could even set back our transition to zero emissions transport.

Want to hear more from Bruce? Read his weekly column in the Mercury.

IF you’re anything like me, you would have got your licence on your eighteenth birthday, am I right? Thought so. Across Australia, it varies from state to state, but in Victoria it’s generally accepted people must be 18 years old to hit the road alone. So, how does Australia compare to those abroad?

In some US states, drivers can be as young as 14, albeit with supervision.

In Central America, you can drive with supervision at 15 in El Salvador, and at 16 with parent approval in Guatemala and Panama.

In Japan, riders can hit the road on a motorcycle at 16 (under 400cc), and motorbikes under 125cc in South Korea.

SHANE JACOBSON YOUNG DRIVERS

Meanwhile, in South America, with parental approval, people can drive a car at 17 in Argentina and Chile. However, a driver cannot get behind the wheel until they’re 23 in the Republic of Niger, West Africa.

Have you got a young driver at home eager to explore the wide-open road? Age limits and vehicle guidelines are important discussion topics.

In Victoria, for example, probationary drivers cannot drive a vehicle that has a power-to-mass ratio of more than 130kW per tonne, or an engine that’s been modified to beef-up performance. V8s? Forget about it. So, it pays to do your homework and get your kids in the right vehicle.

Visit the VicRoads website for all the legal and regulatory stuff, and buy from a trusted Licensed Motor Car Trader when it comes time to get some wheels.

And while I’m at it, buy your children a decent vehicle – one with airbags and all the safety gear that will keep them alive if things go pear-shaped.

See ya on the road, folks!

Want to hear more from Shane? Catch him – along with co-hosts Greg Rust and VACC CEO Geoff Gwilym – on THE GRILLE podcast each month. There’s auto news and views, industry insights and trends, special guests, and plenty of laughs along the way.

Visit: thegrillepodcast.com.au

Exclusive benefits for members of VACC.

THERE'S still time to enter! Applications for the 2023 Automotive Industry Awards (AIA) are open until Friday 10 February. All VACC and TACC members are eligible to apply (accredited and non-accredited).

Entering the AIA is a great way to showcase your and your staff’s achievements, gain recognition for your successes and promote your business to consumers.

Best

Award winners will be revealed at the 2023 President’s Gala Dinner. Hosted by Shane Jacobson, the gala will be a jam-packed evening of entertainment, gourmet food and drinks, magic, music, and dancing. The next generation, VACC and TACC Automotive Apprenticeships’ award winners and graduating apprentices, will also be celebrated on the night. For more information about the awards and to buy tickets to the 2023 President’s Gala Dinner, visit: automotiveindustryawards.com.au

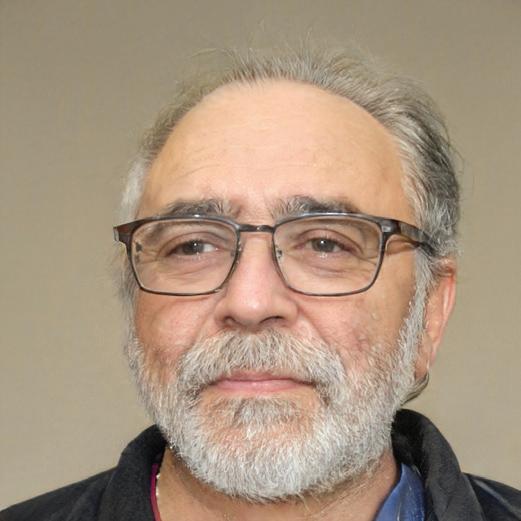

VACC and TACC members welcome new leadership

MEMBERS of the Victorian Automotive Chamber of Commerce (VACC) and its Tasmanian arm, TACC, have a new-look board, headed by a new president.

At the Annual General Meeting held at VACC House in North Melbourne late last year, members elected nine peers to represent them for the next two years.

The VACC Executive Board now comprises the following directors: Chris Hummer, Mark Awramenko, Paul Bertoli, Michael Grubb, Craig Beruldsen, Trevor Parkes, Sid Centindag, Paul Hopper, and Matt Jones.

The new board elected Chris Hummer to be the incoming VACC president.

Paul Bertoli now acts as vice president, Craig Beruldsen has been elected secretary, and Mark Awramenko remains as immediate past-president.

Other returning board members include Michael Grubb and Trevor Parkes.

The outgoing board members are Fury Bortolotto, Tony Sanchez, and John Buskes, all past presidents.

“The members have spoken,” said VACC President Chris Hummer.

“On behalf of the entire membership, I congratulate the VACC Executive Board directors, who will lead the association for the following two years. I look forward to working with them all.

“We have three new directors and their contribution will inject fresh ideas, different

skill-sets, and renewed enthusiasm into the Executive Board,” said Mr Hummer.

While this is an exciting new era, with three past presidents leaving the board, VACC will lose decades of valuable experience.

“I acknowledge the three outgoing board members: Fury Bortolotto, Tony Sanchez, and John Buskes, who have, for many years, represented the interests of all members without fear or favour.

As presidents and board members, they have provided wise counsel, and a steady hand that has seen VACC enter a new period of growth, prosperity, and influence,” said Mr Hummer.

Meet Chris Hummer!

Chris Hummer began his career as an apprentice diesel mechanic before establishing his own automotive repair business in Melbourne. Motorsport interests led him to develop off-road racing tyres and, in 1998, he established tyre and wheel wholesale business, Dynamic Wheel Co.

His service since joining VACC in September 2001 includes VTDA Division Chair (2007–2015), ATDRA President (2012–), Board of Management/Industry Policy Council (2007–), Executive Board (2011–), Finance and Audit Committee (2019–), and Investment Committee Chair (2020–).

VACC President Chris Hummer

Australian-first sustainable hybrid and electric vehicle battery circular economy program

IN an Australian automotive first, Infinitev has shifted the industry’s take-makewaste approach to hybrid and electric vehicle batteries, replacing it with a service that ensures end-of-life batteries are reused, repurposed, and recycled as part of a sustainable circular economy. Currently, electric vehicle (EV) batteries will fault after they lose about 20-30 per cent of their capacity. Often, this is due to a small number of individual cells bringing down the overall total capacity. Instead of the whole battery pack going to waste, Infinitev considers opportunities to reuse, repurpose, and recycle them. Creating a circular economy for hybrid and electric vehicle batteries significantly reduces waste. Infinitev, part of the IM Group, offers three unique service programs to the automotive industry - specifically to original equipment manufacturers and their dealership networks, as well as independent workshops - when it comes to faulty hybrid and electric battery packs.

Hybrid electric vehicle battery remanufacturing (reuse)

To help workshops meet the needs of their hybrid battery customers, Infinitev’s hybrid battery remanufacturing exchange project delivers Australia’s first scalable component reuse and resource recovery program of retired battery packs from hybrid electric vehicles.

Until now, a hybrid battery was seen as a single-use part, but Infinitev’s ability to

identify and repair battery packs that are faulty, slow to charge, or no longer performing at an effective level, provides these batteries with a second life.

Infinitev Battery Energy Storage System (repurpose)

Developed in partnership with Sustainability Victoria, Infinitev’s innovative Battery Energy Storage System (BESS) utilises batteries no longer suited to vehicle applications and repurposes them into an energy storage system.

This plug and play industrial grade energy system provides reliable energy peak shaving, load levelling, and potential off-grid power.

Sustainable end-of-life parts treatment (recycle)

The automotive industry traditionally sources materials from the earth to manufacture hybrid and electric vehicle batteries, eventually disposing of the faulty product as waste.

Infinitev partners with the automotive industry, and other stakeholders, to create a sustainable circular economy for EV batteries. When batteries reach end-of-life, and can’t be reused or repurposed, Infinitev partners with industry recycling programs to recover valuable materials that are used to create new batteries.

“Infinitev is unique in what it offers the automotive industry in the recovery and repair of faulty or endof-life hybrid and electric batteries,” said Infinitev General Manager Dickson Leow. “Infinitev is the only service provider in the industry that offers a three-pronged program that considers battery reuse, repurpose and recycling opportunities, and the circular economy advantages.

“Infinitev can enhance an organisation’s environmental and sustainability (green) credentials and eliminate waste.”

Infinitev General Manager Dickson Leow (below left). Infinitev's sustainable circular economy model could be a game-changer for Australia's automotive industry (below)

Trends in the Australian retail auto industry and their impacts on dealership values

WORDS Steven Bragg, Partner –Motor Services Industry Lead, Pitcher Partners Sydney

As the automotive industry continues to evolve and change, there are a number of trends emerging that impact dealership value. In the last year, we observed some trends that will set the tone for an interesting 2023: Towards the end of 2022 auto dealer groups were still enjoying extraordinary earnings, however, the growth in profits saw a levelling off in Q2/Q3 2022

Average estimated goodwill values for dealerships have doubled since Q4 2019, with the multiples of net profit before tax (NPBT) remaining constant. The uplift in goodwill values attributed to increased profitability Pent-up demand for new cars drove 2022 volumes with tight supply, which will underpin dealer profits for some time – at least another 12 months – despite the significant economic headwinds that are emerging.

Source: Pitcher Partners dealer listing

New Car Sales in Australia

Consolidation continues to be a dominant trend in retail automotive and will be for some time as the industry is still very fragmented as demonstrated by the below breakdown:

The state of the dealer landscape

Pitcher Partners has recently released the first iteration of the Australian Listed Dealer Comparison and it reveals that it is a very interesting time to be a part of the motor industry.

Our analysis covers:

2022 dealers sales results and 2022/23 outlook including impacts from agency, EVs and continued aggregation

Key macroeconomic conditions that will provide headwinds for dealers in the next 12 months

Listed dealer groups consolidated snapshot

Comparisons of the Australian Listed Dealer Groups from several perspectives, including by ranking, financial performance, capital structure, funding ratios, management efficiency ratios and liquidity ratios as well as market share.

Visit the Pitcher Partners website to access the full report today. https://protect-au.mimecast. com/s/kSAbC3Q8WKCpnorysv_je?domain=issuu.com

New Car Sales in Australia

Four-day work week

WORDS Joe Brogno

I’M sure many automotive business owners experienced quite a shock to their business and personal lives during the COVID-19 pandemic. It was an incredible time with so many mixed emotions. The fact we were forced to close or reduce our workload and make no profit was extraordinary, something which none of us would ever have imagined.

At the time, I remember reading so many government and industry publications and information.

inspire you to go and implement all those wonderful ideas which were shown to you. I had so many great ideas and solutions to implement, but because business was doing well and the money was coming in, those ideas always seemed to end up on the backburner; to be dealt with ‘one day.’

One of those curiously cool ideas came from

Rachael Evans, an amazing business coach known as The Workshop Whisperer.

Trying to stay ahead of the latest rules, regulations, protocols and handouts was overwhelming. Organisations like VACC were incredibly supportive. I’m not sure how I would have managed without them. The government payments were a godsend and the fact we were considered an Essential Service certainly took the pressure off and put many of our minds at ease. However, many of us were still terribly concerned about our loved ones and generally dealing with the unknown. It was an awful time.

The years before COVID-19 were incredibly good to me, and the businesses we started way back grew quickly, to a level where we employed around 30 people over three sites. Being busy was normal and I became used to the hectic lifestyle. The momentum of life was fast-paced and there was no time to think about anything other than running a successful business. The world really was spinning too fast and even if I wanted to, I couldn’t jump off. Then along came COVID-19. I could never have imagined the world would stop the way it did.

The pause

Like many other automotive businesses, our workload reduced by around 30 per cent and, so, stand-downs and reduced hours were normal for many weeks. Not hearing that phone ring was daunting, but somehow, we managed to survive, and the money situation was surprisingly good: JobKeeper definitely stopped a lot of potential pain. For me, this pause in my life provided time to think about many things in my business and life. For the first time I could remember, I had time to think about the business and complete those tasks which always seemed to return to the bottom of the pile. One thing I found difficult was improving the business. As a business owner, you often go to trade events and conferences, including many training seminars, which

One of those curiously cool ideas came from Rachael Evans, an amazing business coach known as The Workshop Whisperer. She often spruiked the idea and benefits of a four-day work week (4DWW). I often said that would be a great idea to do one day, but like so many other great ideas, it was simply forgotten about the next day. Little did I realise, and without even thinking, we would actually implement a 4DWW during the pandemic. The idea of a four-day work week

During the COVID-19 months, we created a stand-down roster where the staff would work three or four days a week. This roster seemed to work well and for obvious reasons; the staff really enjoyed the extra time at home. It wasn’t until a meeting with my foreman that he suggested we continue with the 4DWW even after the lockdowns finished. Of course, during the lockdowns, I had a lot of time to think, so I started researching the concept.

I soon discovered there were a small number of other businesses adopting the idea, especially in New Zealand, so I contacted a few of them to get their perspective. I took lots of notes about their experiences and ideas, which were a big help. I thank these businesses for their time and generosity.

I had several meetings with my General Manager, Martin Lemin and my long-time business mentor, Rabi Gunaratnam. Many discussions were had about which 4DWW model would best suit our business requirements, especially for a business the size of ours. In the end, we decided the best way would be to completely close the same day each week, in our case we chose Friday. The bigger the business is, the simpler things need to be, and this is why we chose this model.

and provide quotations. This meant, in the eyes of the customer, we were open every day. Importantly, we did not and do not advertise that we are closed on Fridays. However, I felt it was important to communicate the fact we were going to a 4DWW, and so we did this via a newsletter. The feedback surprised me. The amount of people who congratulated me for implementing such a ground-breaking solution to looking after the wellbeing of our staff was something I never expected. It was a pleasant surprise.

Number crunching

Let’s get one thing straight: all our staff still work and get paid 38 hours per week; they just do it over four days. So, instead of 7.6 hours per day, they work a long 9.5 hours per day. The day starts at 7.45am and work finishes at 6.00pm. On Thursday we finish at 5.30pm. They now get three decent breaks per day: one at 9.45am for 20 minutes; a 35-minute lunch break from 12.30pm; then an afternoon break at 3pm for another 20 minutes. These breaks are essential to give the staff something to look forward to and speed up the day.

Little did I realise, and without even thinking, we would actually implement a 4DWW during the pandemic.

The plan

Our plan was relatively simple, the workshop remains closed on Friday, however the office remains open to take bookings, enquiries

Bookings and labour sales were my biggest concern. Ensuring we still booked the correct amount of cars and sold the correct amount of hours was crucial for this 4DWW plan to work. During a normal five-day week, we would work on an average of 13 cars per day, so over five days we would work on around 65 cars. With a 4DWW plan, over four days, we would have to work on around 16 cars per day to turn over the same amount of work. As you can see, it was quite simple; sell the same amount of work over four days instead of five. How hard can that be? Okay, now you’re probably waiting for me to come up with all the, ‘buts’. Actually, the whole plan went extremely well, with minimal hiccups or changes required. There were certainly no regrets. The important thing about this whole exercise was to have an answer on absolutely every possible scenario. The biggest effort went into the plan to book more cars each day, and this was made possible by utilising our workshop software bookings diary and planner, and booking-in cars based on numbers and not by feeling. This is really important because many businesses seem to book according to how the day looks or how the week is panning out. Going by the numbers and booking in cars until all available hours have been used was paramount in ensuring we filled the days with the extra cars needed for the 4DWW.

Implementation

Once we were satisfied the business model would work, we decided to take a chance and implement the idea, at least as a trial. We held a big after-hours meeting with all the staff in attendance and outlined the proposal in fine detail. Needless to say, all staff were in favour and so the green light was given to begin a threemonth 4DWW trial on 1 November 2020. During the meeting, I sensed a real feeling of contentment and optimism with the staff, something which I’d never experienced before. For the first time in a long while, more staff members were actively participating in the conversation, and you could see the excitement in their faces; it was really refreshing.

Of course, all good plans must come with caveats. The biggest one was to never take advantage of the scheme and always strive to make it work.

One example I mentioned was that they would need to make all personal appointments, like going to their accountant, doctor, bank manager, etc, only on a Friday, because they would be refused otherwise. Okay, I know I can’t really refuse this, however what I could do is revert back to a five-day week. They all got the picture.

with staff members, and they simply love it. Having the Friday off every week gives them something to look forward to and coming to work on Monday, they feel quite refreshed and ready to go.

5. Less personal leave. That’s right, personal days off dropped considerably.

6. Better staff. Now we all know how difficult it is to find skilled staff these days, and maybe we are just lucky, but we currently have a full team with many highly skilled technicians. Let’s face it, if you were looking for a new job and were confronted with two scenarios: one is a five-day week and the other is a four-day week, which one would you choose?

...staff members were actively participating in the conversation, and you could see the excitement in their faces

7. On occasions where customers called to book in and choose a Friday and were told we don't open on Fridays, they would change the appointment to Thursday or Monday and, if on the rare occasion the no-Friday option was inconvenient, we would offer a loan car; we found it really wasn’t an issue. To the best of my knowledge, we have lost one customer, so I can’t complain.

The morning drop-off

I also made a point of saying to them that, if they want to have a long weekend every week, it will come down to every individual to ensure they don’t allow the labour sales to drop off. Whether they are the receptionist, the service adviser, a technician or a car cleaner, everyone plays an important part. I also mentioned that if labour sales dropped off then we would revert back to the normal five-day week. Fortunately, the labour sales remained the same.

Initial observations

1. The first thing we all noticed was how busy the morning drop-offs were. Booking in an extra three-to-four cars a day really stressed the service reception. The afternoon pick-ups weren’t too bad but still a lot busier.

2. I received many congratulations from customers. I expected a backlash, yet I received the opposite. I was quite taken aback by how many customers were thrilled or pleasantly surprised to hear the news, even kind of envious. Many said they wished their employer would do the same.

3. More jobs were finished each day. By extending the working day by 1.5 hours, the technicians completed larger jobs sooner, which meant less carry-overs, which reduced the workload pressures on the next day. This was a big bonus.

4. Happier staff. This is difficult to gauge but I’ve had many one-on-one meetings

Cramming five days into four has its challenges. The biggest issue we found was how busy the morning drop offs, and the afternoon pick-ups became. So much so, we needed to introduce a new role within the organisation, and that was the role of the shop porter.

We chose one of the first-year apprentices to be the porter, and their job was to perform a body check, move the customer’s car, note the service status and mileage and bring in the service books. While this happened, the service adviser would speak with the owner and check-in the car. By giving this

job to the porter for about an hour each morning, the service adviser's time was freed up and allowed for an efficient drop-off. The morning drop-offs are so important for efficiency and productivity because it’s what determines the flow of the day, which in turn determines how many cars we will complete. In a typical large workshop, from the moment a customer arrives, a series of events must occur:

Job card is ready (produced night before). Car arrives and is checked-in – job card updated with customer’s details

Service and/or jobs determined and authorised

Job card delivered to Workshop Control

• Job handed over to technician

Technician checks and reports all items on job card – foreman double-checks report Workshop Control locates parts and allocates hours then carries out a quotation on all reported items

Job card delivered to service adviser who contacts the customer for discussion and approvals

Job card back to Workshop Control where parts are ordered. Job handed back to technician for completion. This series of events must be carried out before our main parts suppliers leave for their first parts delivery, which is usually between 9-10am. This means the parts would normally arrive while the technician is still working on the car, making for a very efficient and productive day. Of course, having the parts on the shelves would be ideal, but these days I find we don’t need to carry much stock due to many suppliers offering multiple daily deliveries.

Another 1.5 hours to complete the car Before we went to the 4DWW, our technicians used to finish at 4.30pm. Many times, if a parts delivery was running late or a job wasn’t going smoothly, they would need to work past

4.30pm and enter into overtime, which of course would increase expenses and, in many cases, see customers waiting around. Sometimes, a car would need to be carried-over to the next day, which of course is usually booked out, putting the workshop under a lot more pressure, not to mention inconveniencing the customer, and if the customer had a loan-car then the problem would escalate further because that loan car was booked to someone else.

Now the technicians finish work at 6pm, late parts deliveries are not a problem anymore, jobs are usually completed before closing time, and without overtime, and customers now don’t need to rush from their workplace to pick up their car.

Stretching out the day by 1.5 hours was one of the biggest benefits to the company. Stretching out jobs

Stretching out jobs is probably one of the biggest disadvantages of a 4DWW. This is an area that we focussed on a lot because we understand that a technician will sub-consciously stretch out a job at the end of the day, especially knowing that there are no more cars to work on before closing time, plus it’s a long day, and so tiredness can also play a factor. The only real way to combat this is to observe, monitor and act. A good workshop foreman and or/controller will set time limits for the technicians and act immediately if the time is running over. Unfortunately, because the stakes are high with the potential to increase expenses and lose income, constant monitoring is extremely important.

One advantage if a technician unfortunately runs out of work is that they can be assigned to assist another technician to complete their job without the need to pay overtime. This works well on those larger type jobs which can take many hours to complete. The afternoon service

To ensure the technicians have plenty of work right up until closing time, we introduced an afternoon service for our customers. This involves the owner dropping off the car before 2pm and picking it up the next day by the same time. This meant the technician would work on the car until closing time and resume working on the same car the next morning when they arrived for work, eliminating any down-time or stretching-out of jobs. We also found customers, especially retirees, found this arrangement convenient, especially because they avoided the morning and afternoon peak-hour traffic.

Conclusion

working the brain is much more tiring and stressful. Years ago, I would’ve said 75 per cent of cars booked-in were for service and repairs, and 25 per cent would be for diagnostic type jobs. However, today, I’d say that figure would be more like 60 per cent service/repairs and 40 per cent diagnostic. Today’s technicians work much harder than they used to, and to maintain a high level of quality combined with the pressures of productivity, is difficult to sustain. The risk of burn-out is real and we are now seeing many technicians leaving the industry. Therefore, we as an industry must make it a priority to think of the well-being of our people.

...we now make good profits with happier staff and happier customers

One thing this pandemic did was made me realise that there is more to life than just work. Lifestyle and happiness are just as important, and a balance is needed. Modern life can be very challenging, and I believe there are simply too many options in life. The life of a car technician is not as simple as it used to be, the pressure to stay in front of technology is daunting. These days technicians need to use their brains more than their muscles, and

If you were to introduce a 4DWW in your workplace, you would only ever do it for your staff. Think about it, the automotive service industry is all about people. It’s about utilising the resources of people who can maintain cars. Your business is only as good as the people who work there. If you have unhappy people working for you, who are stressed and unmotivated, then what kind of business do you have? I made the decision to improve the well-being and lifestyle of the people who work for us, and the bonus for me is we now make good profits with happier staff and happier customers.

Introducing a 4DWW would be one of the best decisions I’ve ever made! Are you ready for the fourday work week?

Compare your merchant service today.

With Commonwealth Bank, VACC members can receive special discounts on EFTPOS solution.

We can also offer a customised comparison^ of your current merchant service to Commonwealth Bank’s merchant solutions, to help you discover which product is right for you. We have flexible terminal and pricing options to suit your needs today and that can change with you in the future.

To find out how much you could save with Commonwealth Bank, contact VACC on 03 9829 1152 or email marketing@vacc.com.au and they’ll put you in touch with a Commonwealth Bank Relationship Manager.

From Falcon to Raptor, Ford Australia is still flying

Ford Australia may no longer be in the car manufacturing business but its Victorian-based designers and engineers ensure the company continues its critical role in developing globally significant vehicles

WORDS Harry Quinlan

AS automotive engineering projects go; they don’t come much bigger than Ford’s third generation T6 body-on-frame global architecture. The T6 platform underpins not just the new generation Ford Ranger ute and Everest SUV, but also the highperformance Ranger Raptor ute, and from next year will also be the basis for Volkswagen’s new Amarok ute range.

With the Ford badged products alone selling into more than 180 markets worldwide and the Ranger now one of the world’s biggest selling models, you might think Ford Motor Company would keep a project of this scale and significance close to its Dearborn HQ or, at least, at some of its other US-based design and engineering hubs. Instead, the company handed the enormous task of developing these globally significant models to the team at Ford Australia, which for the last five years has been buried deep in the detail of creating four distinct model lines and a dizzying array of variants

off the T6-platform. The vehicles will be manufactured at different plants around the world, including Thailand, Vietnam, South Africa, North America and South America, adding further degrees of complexity to this vast, Australian-led project.

FoMoCo has backed its Aussie operations to deliver, providing more than $2.6 billion in research and development investment between 2016-20, $538 million of which was spent on Australian R&D in 2020 alone. This included $30 million on new and upgraded facilities and equipment at the company’s Campbellfield Design Studio, You Yangs Proving Ground, and the Geelong Research and Development Centre.

So, despite being the first of our ‘Big Three’ auto manufacturers to close its car making operations here in 2016, Ford Australia appears to be in rude good health, having deftly repositioned itself to be a key product development hub for Ford globally.

It’s now Australia’s biggest automotive employer and retains the country’s largest

engineering and design footprint, with a team of more than 2,300 engineers, designers, technical, automotive and other specialists working across its four Victorian locations.

We asked Ian Foston, Global Chief Program Engineer for the T6 platform-based vehicles, how Ford Australia has transitioned so successfully from manufacturing primarily for the domestic Australian and New Zealand markets, to this broader and far more integrated design and engineering role with Ford globally.

Ian wears the twin hats of T6 chief platform engineer, as well as global chief for Ranger, Everest and Amarok, which essentially means he oversees all the programs that come off the T6 body-on-frame platform.

“With manufacturing closing, I think Ford Australia handled that very respectfully,” says Ian.

“It’s sad that we’re not making Falcons and Territorys anymore but what we did is, we reskilled a lot of the team coming out of manufacturing into engineering positions to support us during this development.”

Ian also attributes part of the success to the attitude and passion of the people working on the T6-based products, which he says has made a huge difference to the way the company is perceived globally.

“We’ve got such a talented group of engineers, people who are really passionate about the product, and I think that’s been a strength of why the (parent) company has put so much faith in the Australian Product Development team.

“I know it’s a corny phrase but our engineers and designers actually live the life of our customers. We have people here who use these vehicles for overlanding, and others who go out on weekends and use their vehicles to do recreational off-roading. Having this real, visceral understanding of how customers use their vehicles, allows them to make good engineering decisions.

“When we’re going through the development process and needing to make a tough decision on, ‘do we do this or not, and where do we spend the money?’ the

team really has that knowledge and understanding to make those right decisions.

“To me, that’s been where the confidence Ford in Detroit has seen in the team here comes from, and why they’ve said, ‘you’re perfectly placed, with all that knowledge to be developing these vehicles for the globe.’”

Having spent the first decade of his automotive engineering career working with Jaguar Land Rover in the UK, before moving to China with Ford, followed by a stint with Chinese Qoros Auto, Ian has a wellrounded view of how the industry works here and abroad, and believes the aptitude and attitude of his Australian engineering team is a critical element of its success.

“The one thing I say about when I came to Australia is that I’d never met such a resilient, hard-working bunch of people. But they do it with a smile on their face. We work a lot of hours; we work extremely hard and we put a lot of effort into the products – there’s passion that goes into them – but everyone really wants to work on these products. They really want to come to work each day.

“And we’ve got some great skills here as well. Some of the universities around Melbourne are world class in terms of the skills they’re teaching people. We’ve got a very active graduate program bringing people in each year, getting them to understand the business, and for them to give us a different perspective as well.”

Ian believes Australia’s uniquely multicultural society and workforce is another major strength when dealing with global product development.

“One of the other benefits of doing this work in Australia is we have such a diverse group of people here. We’ve got people working in Ford Australia who come from everywhere. I come from the UK originally and we’ve got people in my team from Vietnam, Thailand, South America, Europe, Germany and the UK. We’ve got a really good, diverse group of people here with different backgrounds, experiences, educations, and that melting pot coming together when we’re making global products is invaluable. We need that diversity of thought so that when we’re developing the vehicle we can say, ‘well hang on, that’s not how a customer in Europe, or a customer in South America uses the vehicle.”

Ford made much of its new ‘customercentered’ design approach during the media launch of the new Ranger ute, claiming to have conducted more than 5,000 interviews with owners, resulting in more than 1,800 pages of field notes, which helped guide engineers and designers about the features and capability owners wanted in the final product.

The shift to becoming a global design and engineering hub has also meant a huge shift in the diversity of design and engineering disciplines required to create modern vehicles like the Ranger, Raptor and Everest, says Ian.

From a heavy focus on mechanical engineers back in the Falcon-Territory days the company is now a hub of mechatronics, electrical and electronics engineers, working alongside mechanical engineers, who themselves need to have a high degree of electrical skills due to all the modern electronics throughout these vehicles.

This is reflected in the graduate intake program, with the company planning three to five years ahead and trying to ensure it has the right skill set in place to manage rapidly changing vehicle technologies, says Ian.

“We look at the skill mix, of course, because often you can have people on, say, mechatronics courses, or electronic courses, that we know are going to be more relevant in the future, so we’re really looking out for those up-and-coming engineers to come in and assist us in the business.”

Having arrived here in 2013, in time to witness the development of the last Falcon FG X series, Ian can attest to the fact the T6-based program represents multiples of complexity over Ford’s former domestically focused models. In Australia, the Ranger’s model range alone spans 23 variants, encompassing two and fourwheel drive, three body styles, three engines and two transmissions. And while the Raptor and Everest share the core elements of the T6 platform, they are individual vehicles with their own unique engineering challenges.

There’s also a dizzying array of Ford engineered factory fit options, ranging from tow bar packs to heavy-duty suspension upgrades, off-road packs with additional underbody protection and more, all of which need to be engineered to cover the widely different use cases these vehicles are used for across the globe.

“It’s hugely more complex, with 180 markets, meaning we sell into more markets than any other product in Ford. We’re the most global of all the Ford nameplates, so for us it’s a huge challenge to make sure that not only do we meet with the legislative and market-specific requirements, but actually understand the customers in those markets and the things they hold dear. That’s always the challenge, to make sure you’re tailoring the product to those markets, to make sure it’s exactly what they want.

“At its peak we probably had around 2,000 engineers working on these next generation products all around the globe, with the centre of that being in Melbourne. We’ve got people in the UK helping us with diesel engines, people in the US helping us with gas engines and transmissions, but the vast majority of the work is done here.”

With the Australian launch of the Ranger, Raptor and Everest complete, Ian and his team now turn their attention to other global markets where the new models are yet to launch, while also positioning themselves to be ready for the next big design and engineering project Ford might hand its Antipodean outpost.

Everybody starts somewhere

Partnered with

Start with

This is for general information only and doesn’t take into account your financial position, personal objectives and needs. Consider these and the PDS and TMD available at spiritsuper.com.au/pds before making a decision. Issuer is Motor Trades Association of Australia Superannuation Fund Pty Ltd (AFSL 238 718, ABN 14 008 650 628). Advice is provided by Quadrant First Pty Ltd (AFSL 284 443, ABN 78 102 167 877).

WORDS

Not all ideas are what they seem

Paul Tuzson

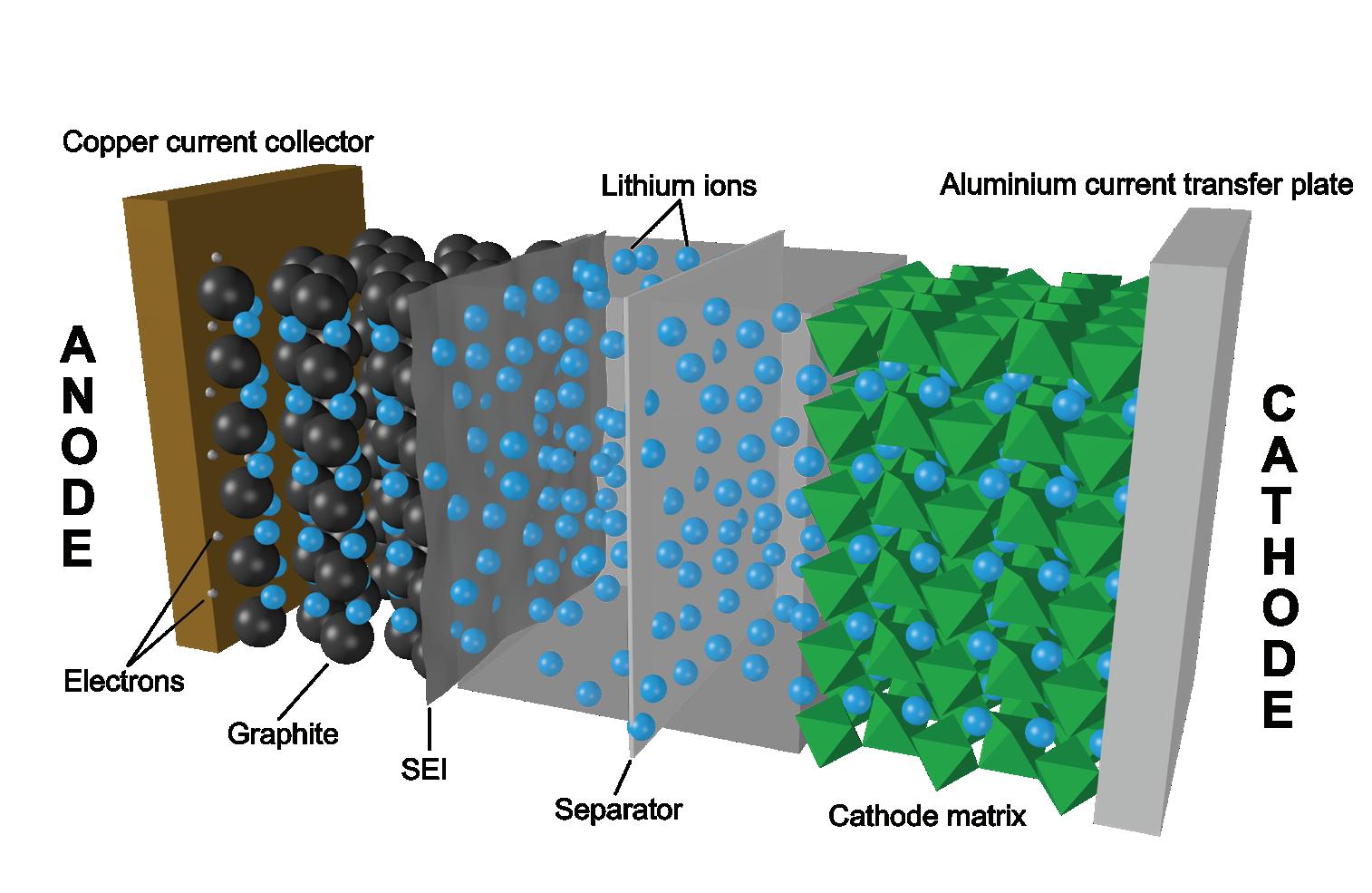

GIVEN batteries are such an important part of our electric future, it’s not surprising attempts to improve their performance are constant. Some of these attempts are valid, some are the work of charlatans, others are sincere but just wrong.

Battery development tends to move in two broad directions - changes to cell chemistry or changes to battery and cell structure, or perhaps both. The new 4680 cell Tesla provides an example of improved structural engineering, quite apart from any changes to cell chemistry.

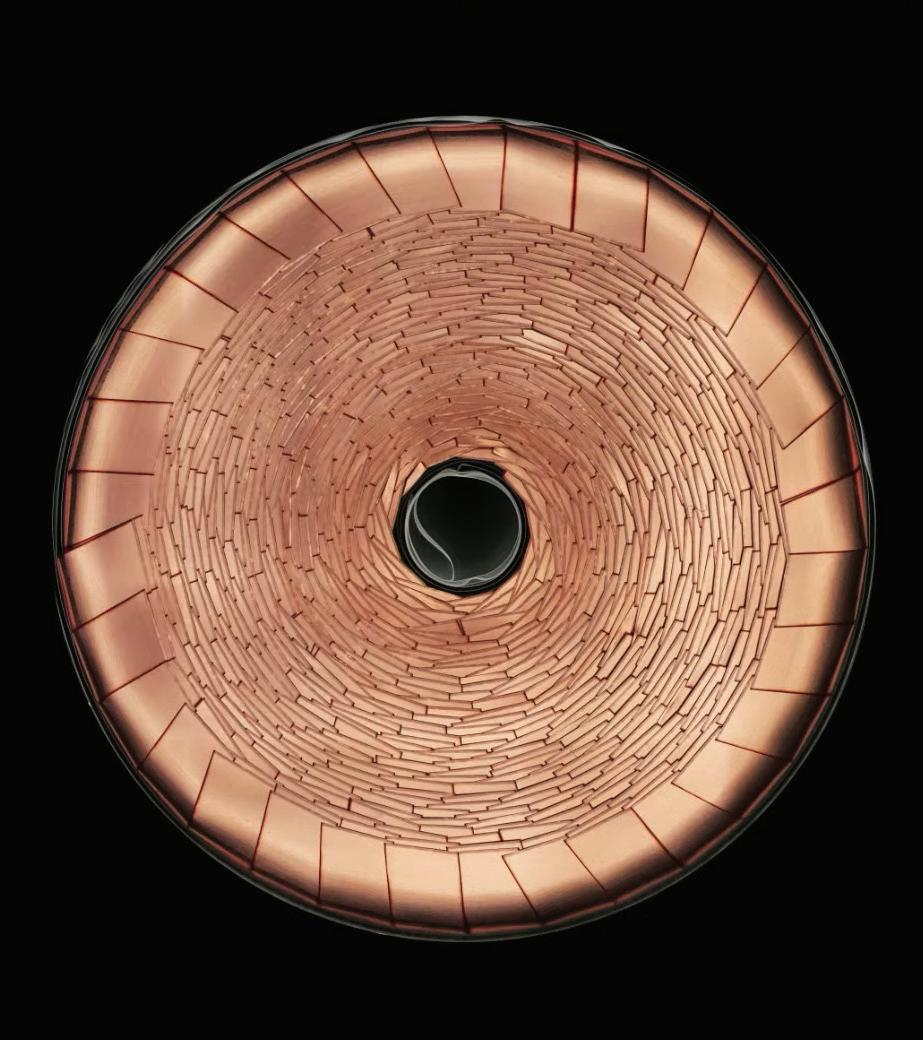

One of the most important things about the 4680 cell is that it’s bigger, which gives greater energy density. However, another of the most innovative changes embodied in the 4680 is the so-called ‘tabless’ design of the electrodes. Rather than having current flow through a single concentrated point as with most battery cells, the 4680 features a continuous fringe of tabs folded into one large composite tab as shown in the photograph. This design simultaneously allows the transfer of increased current while reducing the associated heat through a point contact.

The tabless design reduces the cell’s internal resistance. When the electrodes in a cylindrical cell are unrolled, they’re long. In conventional cell designs, current has to pass along the entire length of each electrode to reach the tab. With the 4680, current only has to travel across the electrode (a much shorter distance) to reach the terminal. Also, in many battery designs, the positive and negative cell tabs are connected to the respective busbars by wires. In the 4680 the wires are omitted and the bus bar is welded directly to the metal cap covering the cell tabs. Finally, the larger diameter of 4680 cells have a reduced surface area compared with smaller cells of the same volume. The outer casing is made of steel so this results in reduced weight. In all, the

new cells are said to have five times the energy and six times the power of the smaller cells Tesla has been using, resulting in a range increase of about 16 per cent. So, applying clever engineering to the design of battery packs can yield verifiable service advantages. Anyone who’s accidentally shorted the terminals of a lead-acid battery with a spanner or the like will forever remember the ensuing fuss. Batteries contain a great deal of stored energy and lithium cells contain the most at the highest voltage. It’s difficult to imagine another chemistry (other than lithium variations) that could perform better in an EV. Importantly, though, lithium cells contain everything needed for a sustained fire that’s almost impossible to extinguish if the electrodes are shorted. Researchers have devoted a good deal of effort to increase the safety of lithium ion battery packs. Many approaches have involved armouring the packs.

Tesla originally fitted a titanium plate to the underside of the Model S to protect against puncture and short circuiting after a number of well publicised fires. However, another company called Enovix has been working on a protective system called BrakeFlow that’s built directly into the cell. Enovix spokesman TJ Rodgers explains one way to limit thermal runaway between shorted electrodes is to protect the system with a resistor that reduces current. However, a resistor that can do this will probably limit current too much and restrict performance. The BrakeFlow solution employs a number of resistors in parallel. Resistors in parallel reduce overall resistance.

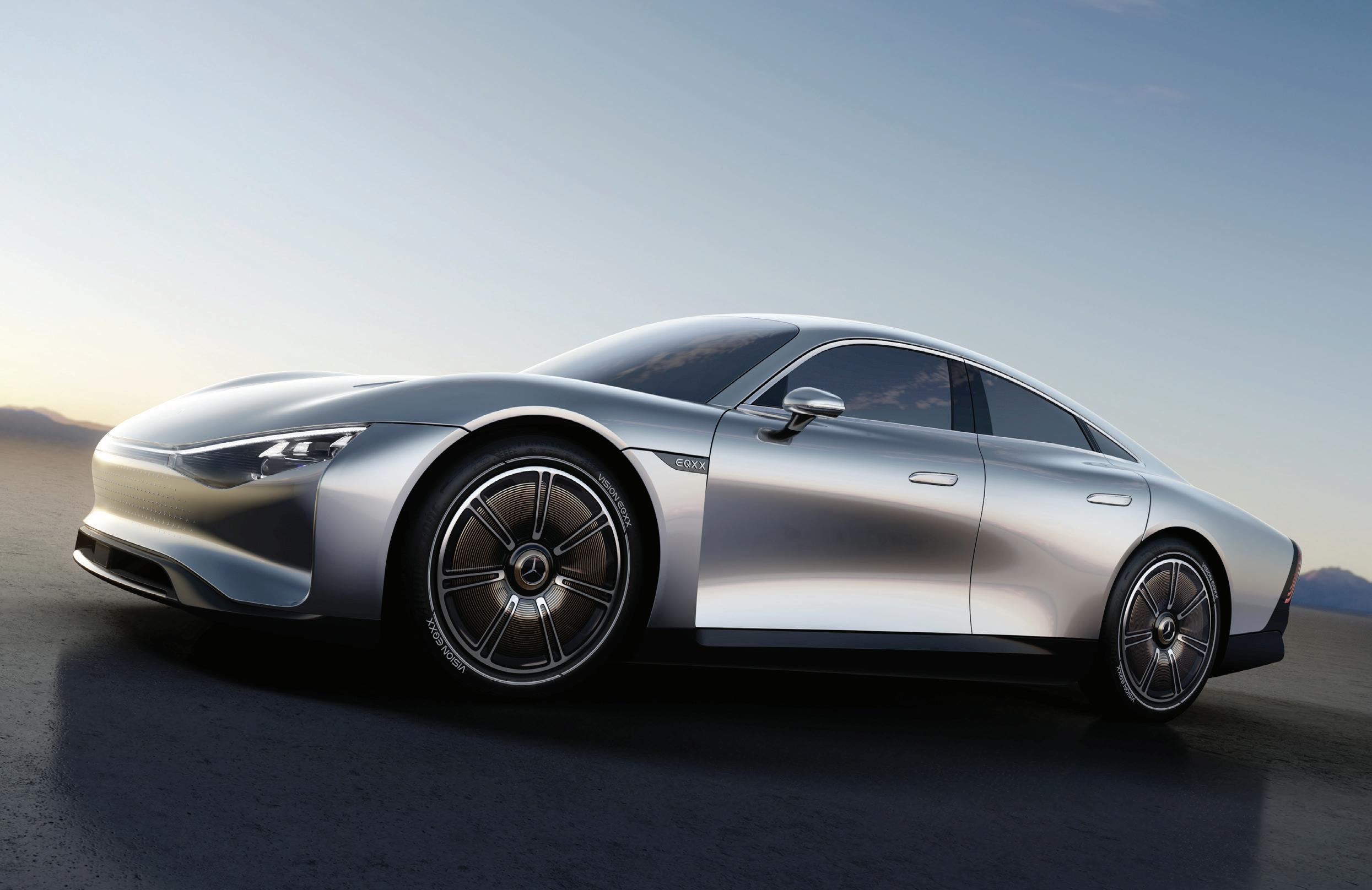

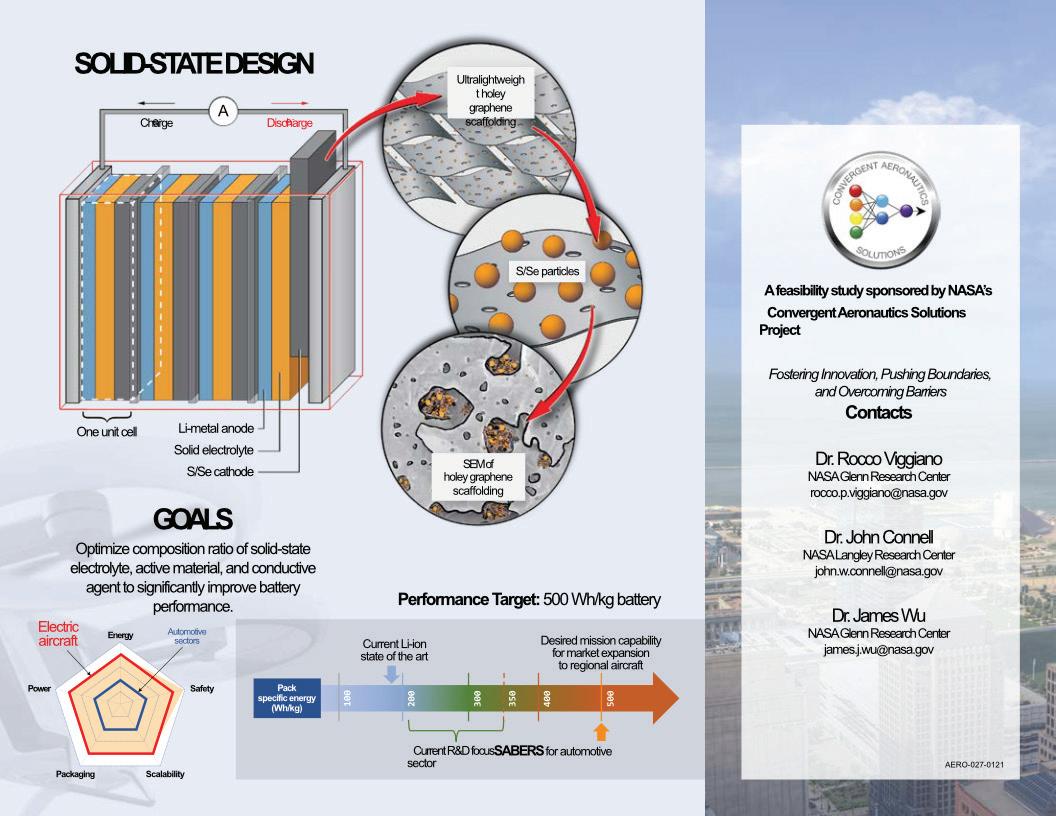

Manufacturing new battery chemistry is challenging (left). Improving battery chemistry matters. The Mercedes-Benz VISION EQXX concept car travelled over 1,000km on one charge. This is what the BMW Battery Cell Competence Center is all about. This was partly due to a new anode material containing silicon (below)

The anode (negative terminal during discharge) of a Li-ion cell contains a carbon matrix that stores lithium ions. However, silicon-based anode material can store many more lithium ions leading to increased energy density. But in such applications silicon expands much more than carbon, which leads to greatly reduced cycle life. Enovix is also active in solving this problem and has developed cells with 100 per cent silicon anodes. How?

It’s difficult to imagine what chemistry might surpass lithium-ion chemistry. If some new chemistry did come along it would be even more dangerous. Certainly, petrol is much more energy dense but if it’s not vaporised and mixed with air it can’t burn. Lithium batteries contain everything needed for a fire inside them (above left). Mechanical developments can offer improvements. This is the anode of the Tesla 4680 cell. It features much lower resistance (above right). As this image from BMW shows, solid-state electrodes are considerably thinner. This offers a number of advantages (below)

Enovix describes its battery technology as 3D, meaning individual strip electrodes are stacked atop each other to form each cell. This construction allows the fitting of stainless steel reinforcing plates that hold the silicon elements tightly in place and prevent expansion. Other battery designs can also do this but require the reinforcing plates to act over a much broader area. Enovix has been quietly developing its battery technology since about 2010 and has only just released its first batteries in form factors suited to mobile devices. This is because battery capacity in this space commands a price premium compared with EV batteries. The company strategy

is to maximise revenue from this market to further fund development of its EV battery technology, which is scheduled for mid-decade availability. A measured approach. The solid-state battery is another oft-mentioned technology in the discussion of revolutionary battery development. Current Li-ion batteries use a liquid or gel electrolyte with a separator to isolate the electrodes from each other. The liquid electrolyte is a point of vulnerability and is what burns so vigorously (along with other components) during thermal runaway. A solid-state electrolyte

alleviates the likelihood of such an event but that’s just part of the story. Solid-state cells/batteries have a reduced volume compared with conventional lithium ion batteries. This can be seen in the illustration from BMW representing the internal structures of conventional and solid-state cells. The reduced volume means either more charge and longer range for the same sized battery pack, or a smaller, lighter, less expensive battery pack. Solid-state batteries can also be charged much more quickly. Further, the greater efficiency of solidstate batteries means they require less cooling, which also reduces weight. Solid-state battery technology is often described as an EV ‘game changer’ and this would be correct if only such batteries were available for electric vehicles, but they’re not - not yet, anyway. All the big names have solid-state technology in development. Toyota is said to be in front but eventually, when all the production difficulties are solved, the technology will be ubiquitous. Even NASA is working on the technology within its SABERS project with a view to developing a realistic power source for electric aircraft. It uses what’s known as sulphur-selenium technology to reduce material costs because there’s so much sulphur available. It’s a by-product of oil refining. This chemistry also has better energy storage potential than conventional lithium. Atomic, or nuclear batteries constitute another technology that’s in development. However, these cells are much further behind solid-state batteries in progress towards general availability, despite some over-excited claims. In short, atomic

Even NASA is working on solid-state battery technology (top). These are BMW solid-state cells. All manufacturers are working on this technology (above). Below L-R: Enovix has a well-developed cell technology along with the techniques and equipment to manufacture them. The elements in an Enovix cell are cut into strips and stacked on top of each other. The company calls this 3D design. The structure of the Enovix 3D cell allows small resistors embedded in a special strip to be connected in parallel to reduce overall resistance. The system is called BrakeFlow and acts to limit runaway current in case of damage. Bottom left: Here’s what happens when an ordinary cell is pierced. Bottom right: Here’s what happens, or rather doesn’t happen, when a BrakeFlow cell is pierced

batteries utilise the beta radiation decay of nuclear waste as a source of electrical energy. This is a scientifically valid concept known as betavoltaics and it’s promoted as a useful utilisation of this otherwise waste material. In fact, the long half-life of such nuclear waste is touted as a strong positive if it’s used as the raw material for a battery.

A diamond battery is an atomic battery named after the artificial diamonds upon which the technology will be built. This is to be derived from radioactive graphite currently stored as waste. Atomic batteries are primary types and can’t be recharged like secondary lithium-ion or lead-acid types. However, it’s suggested they could last for thousands of years. NDB (Nano Diamond Batteries) claims they could remain in service for as long as 28,000 years. More moderate claims still suggest a couple of thousand years is possible.

The important thing to remember, though, is that atomic batteries have very low outputs - just a handful of microwatts. The idea of a radioactive battery in your phone or laptop may seem abhorrent but it’s not as bad as it sounds. Beta radiation is free electrons in motion. These have low penetrating power and pose virtually no risk if they remain outside the body. Further, the NDB system will encase the radioactive diamond in another artificial diamond layer, so the resulting cell will be suitable for use in things like pacemakers. It’s also suggested the technology could be scaled up to run EVs and homes. Despite the hype surrounding atomic, or nuclear batteries, they don’t exist. There have only been lab prototypes produced. That they will ever exist in a form that might support an EV is nothing more than conjecture. People are clever and there are some unique ideas out there. In fact, some of them can best be described as ‘out there’, like Tanktwo. This is an off-beat attempt to solve the ever present problem of long charging times. In a nutshell, the idea is to vacuum the spent cells out of a car and ‘pump’ replacements in. Each Tanktwo cell is an ellipsoid covered with six separate conductive panels that can be made individually active, or not.

The shape of the cells is such that contact between them is limited. These end up in the tank at random orientations and the various contacts are activated to create the required paths between the cells to conduct the current required. Obviously, the walls of the tank have conductors to draw current from the cells. The company calls this a string battery.

Clearly, the current path through the nest of eggs to the car’s electrical system is going to be complex and different each time the tank is filled.

Tanktwo suggests artificial intelligence will be key to calculating such paths. Each cell

is to have on-board computing capability needed to control its function within the tank and within the mesh network.

The system would solve a number of EV problems. Charging time is the most obvious but constantly replacing discharged cells for fresh ones would allow low capacity cells to be removed and replaced with others to achieve a balanced battery with matching cells. Also, the tank doesn’t have to be filled. Drivers could load as many cells as needed and be on their way.

Unfortunately, the Tanktwo system doesn’t yet exist. The idea has been in place since 2015 but there doesn’t seem to be a working model. Given the extreme complexity of the system this is not surprising. One of the potential issues we see is limited point contact between the connectors. Also, Tanktwo would still suffer from infrastructure challenges although there might be unique solutions to this. Regardless, the system is yet to materialise and may never. It’s a shame because it’s so innovative.

The EV battery industry is rife with unique ideas that will probably never progress beyond concept and early stage graphics oriented towards attracting investors.

Every Tanktwo String Cell will contain a smart controller so it can function in the tank of randomly oriented cells (above left). Tanktwo anode and cathode elements are rolled into an ellipsoid form to fit inside the cell case (above). The contact area of Tanktwo cells are oriented to ensure only one contact panel can contact only one other contact panel (right). Tanktwo will use AI to determine the contact paths needed to transmit current when cells are randomly stacked into the tank (below)

It seems the only true path to implementing innovation is by genuine research and hard work. Enovix seems to have the right approach. The product is real and subjected to on-going testing and validation. Manufacturing processes and operations are well developed and ready for large-scale integration with existing manufacturers. The company has avoided the temptation to trumpet its potential before being ready to support its products in a scalable manufacturing environment. It’s more than just hype. Solid-state batteries may have been over-hyped but they do exist. It’s a matter of bringing the technology into mass manufacturing mode. Other technologies may claim similar status but do so with nothing more than concept renderings and animations based on theories. The popular press can be as much to blame for this as the companies. It’s a shame scam videos and sites exist because as people get wise and become rightfully cynical, matters will become difficult for those who have genuine announcements.

Actually, no it’s not

WORDS Paul Tuzson

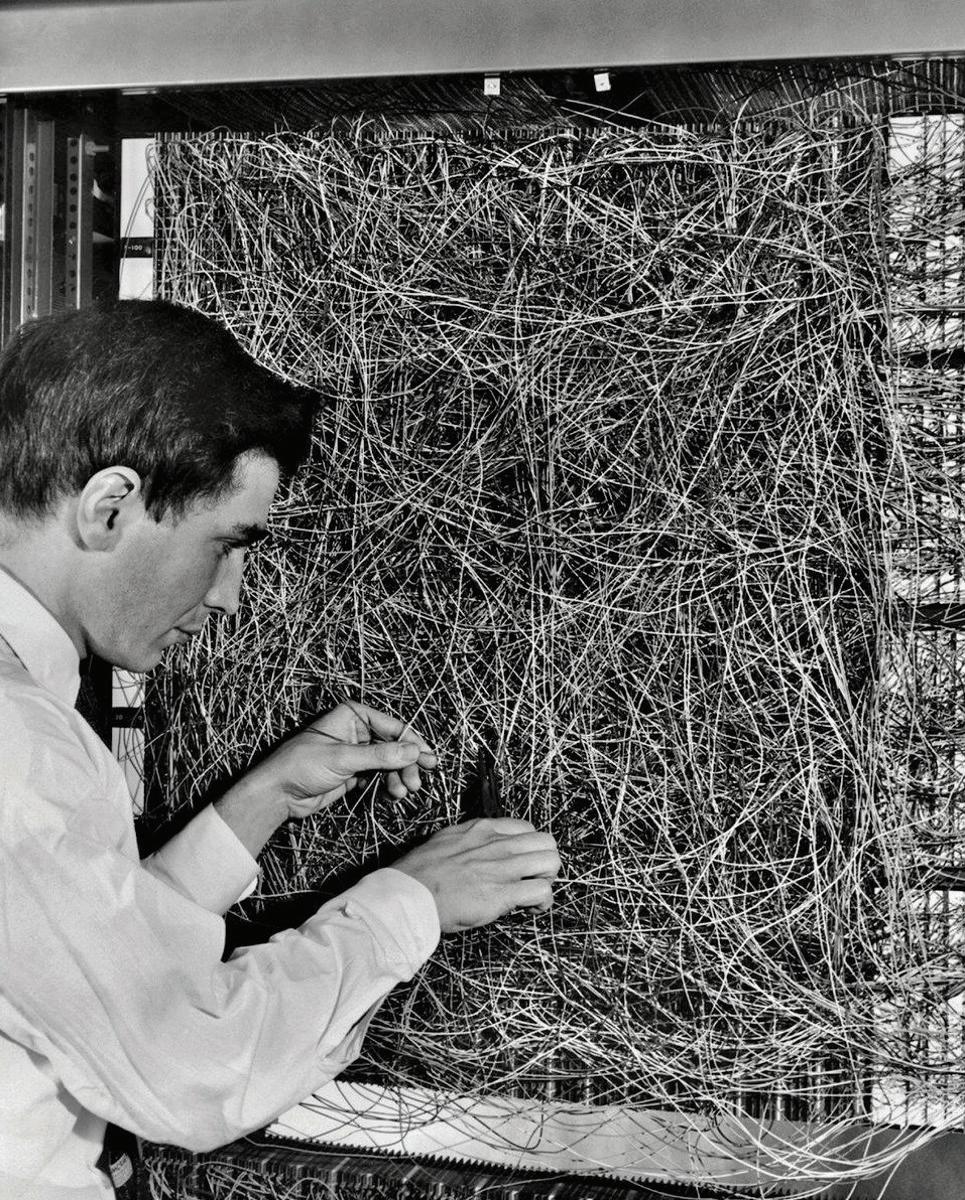

STEAM powered the first Industrial Revolution. The application of electricity and the adoption of assembly line techniques characterised the second. We’re presently in the third, which is all about digitally controlled and augmented production. The thing is, these revolutions overlap and we’re currently moving into the next iteration of manufacturing: Industry 4.0 which is all about interconnection and the IIoT (Industrial Internet of Things).

The preceding is the broadest overview. There’s a great deal of detail that further defines these stages of industrial activity. Probably the most pertinent aspect of Industry 4.0 is data; absolutely massive amounts of data. In fact, we’re going to define this new manufacturing paradigm as production and distribution methods that create data on a scale so vast humans will never be able to analyse the information and certainly never make any sense of it. This brings us to artificial intelligence, or AI, as it’s commonly labelled.

How does AI benefit manufacturing?

It’s easiest to start with a human based example. Back in the 1980s, a friend of ours worked in the Holden Fishermans Bend Plant 6 tool room alongside a guy who was deaf. This very experienced fellow was extremely sensitive to vibration and he could tell when a machine wasn’t

running correctly. His maintenance predictions were always correct. These days, sensors within machines transmit this sort of data all the time. AI interprets it and acts on it in real time with no human intervention. So, instead of having to send one man (with a very rare talent) around to each machine, this sort of information is produced as a continuous flow. We also spoke with an ex-Toyota employee some years ago who said if anything went wrong and the local production line stopped, Japan would be on the phone in minutes wanting to know what was wrong. This seemed impressive at the time, but it’s just so Industry 3.0. These days, AI will analyse data from every production and supply element in real time to provide predictive analysis aimed to prevent production interruptions in the first place. One description of an AI is it’s a system that gathers data, interprets the embodied information, makes decisions and then takes action independent of humans. In order to do these things, AIs are constructed so they can learn independently, without human assistance. AI is everywhere and its capabilities are rightfully lauded. It almost seems as if it’s alive, but it’s not. You don’t have to spend long looking into AI before coming across the terms Machine

Learning and Deep Learning. These are subsets of artificial intelligence and, in turn, also have sub-categories, as does just about everything in AI.

As mentioned above, the IIoT generates a great deal of data. If the data arrives categorised and labelled, its structure informs the methodology of the processing algorithm dealing with it. This is known as supervised learning. An algorithm is a set of rules and instructions constructed to achieve a particular end. However, much data is unstructured. That is, it isn’t separated into neatly labelled categories. Yet it must be categorised and labelled in order to infer meaning. In this case, AI algorithms examine the spread of the data and note clusters based on various parameters. These clusters are then used to categorise the data. This is known as unsupervised learning. So, for structured data, supervised learning is used. For unstructured data, unsupervised learning is the approach. These different approaches form the main divisions of Machine Learning but sometimes both are used when a mix of structured and unstructured data is to be analysed. Doing so illustrates an important point: different AI algorithms are mixed, matched, modified and developed in order to achieve desired results.