DYNO-MITE

EV-Hybrid Disc Brake Pads are AASA Leafmark™ Certified which means they use organic brake friction materials for minimal environmental impact. In addition, low particle emissions deliver cleaner wheels and long disc life. Featuring Bendix’s exclusive Green Titanium Stripe, EV-Hybrid pads provide instant friction (no bedding-in required). Designed for quiet operation and low noise, EV-Hybrid pads are specifically engineered for EV and Hybrid Vehicles.

06 DRIVING CHANGE

A federal election in Australia is looming and VACC has released the automotive industry’s policy priorities

08 YOU BEAUTE

The ute has always been an iconic part of the motoring landscape, now it’s moved far beyond the farm and ‘tradey’ domain

10 APPRENTICE RISE

The latest skills data reveals a 44 per cent increase in apprentice and trainee commencements

12 MILEAGE WOES

Odometer tampering is a tricky business, but should a trader or motorist fall victim there is help out there

14 POLICY MATTERS

VACC’s Industry Policy team is hard at work bringing about meaningful change –read the latest updates

16 LET’S CONNECT

The Tasmanian Automotive Chamber of Commerce briefings were nights of open discussion, industry updates and prizes

18 GOING GREEN

Shane Jacobson looks into the role the automotive industry is taking in environmental and sustainability efforts

20 NEW HOME

VACC’s office relocation signals a move in the right direction for not only the body and its members – but for industry

23 ON SHOW

Cool Cars with Dermott and VACC are hitting the road in Victoria and Tasmania to promote careers in the auto industry

32 BIG CHAIR

AAAA’s Stuart Charity talks automotive service and repair data sharing wins, the revived AAA Expo and his words to live by

36 BUSTING OUT

Building and powering buses will never be the same again, it’s a brave new electric world out there

42 OUTSIDE THE BOX

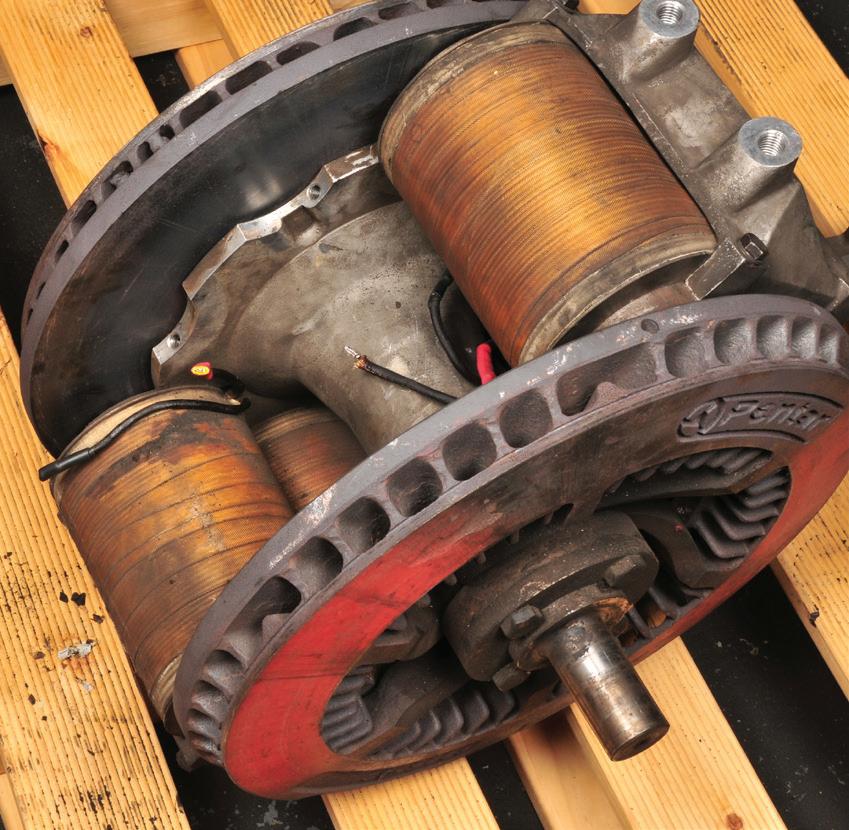

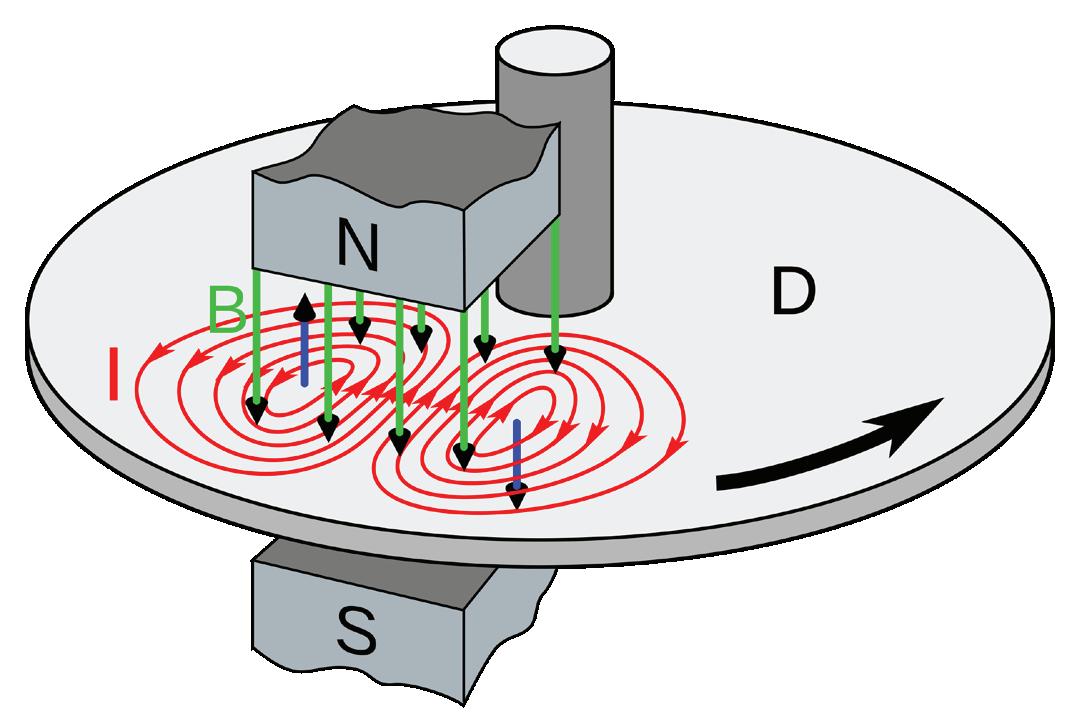

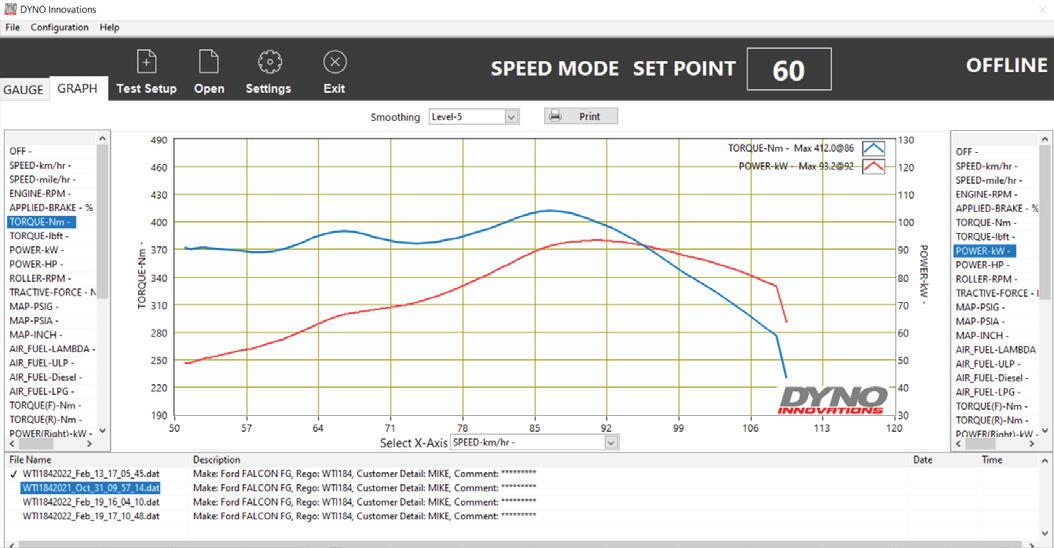

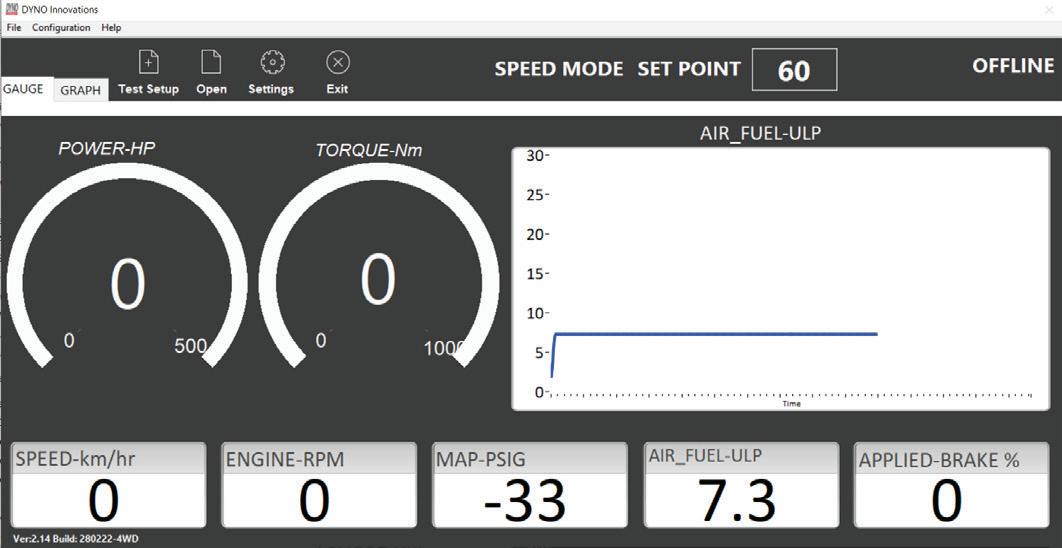

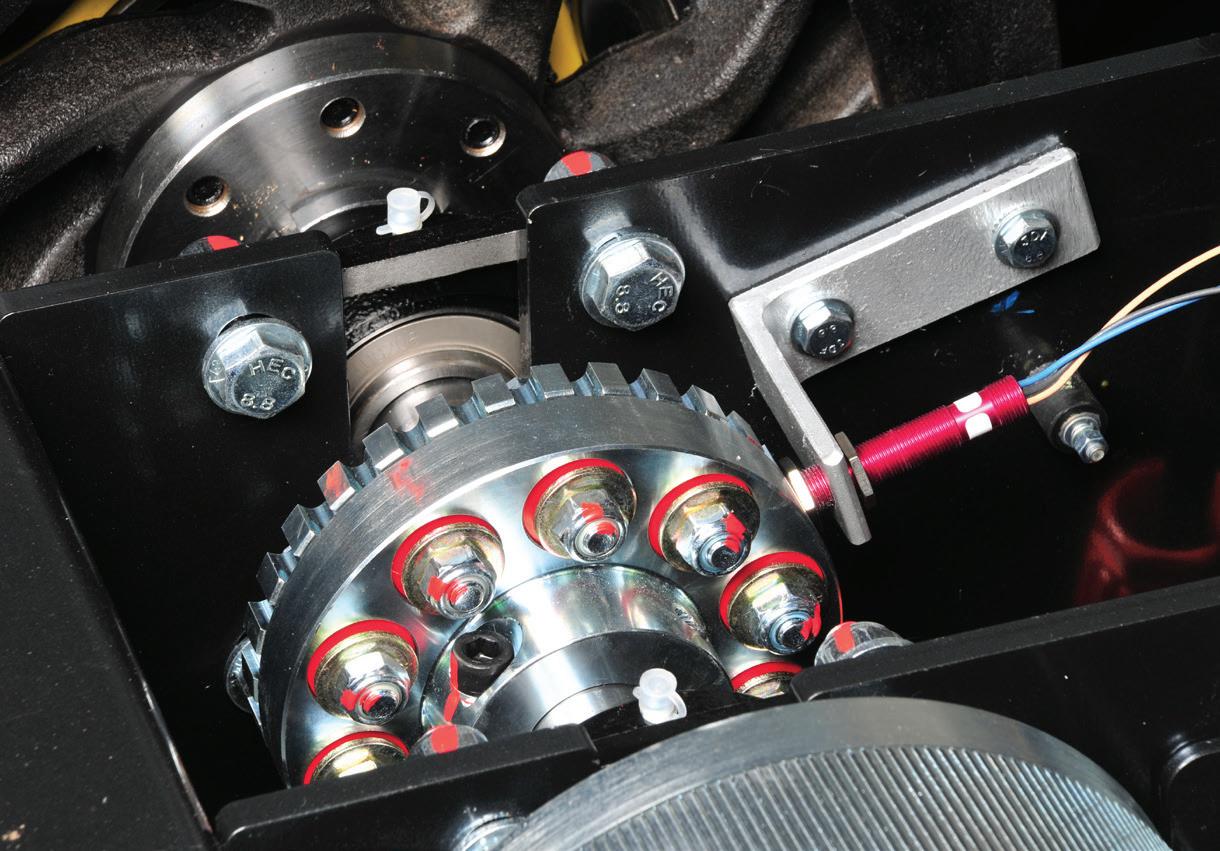

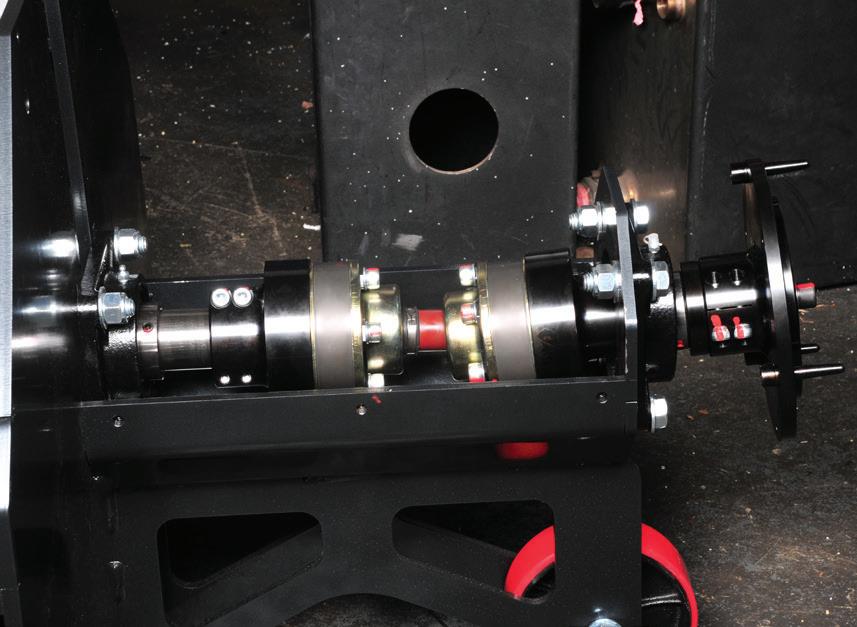

The automtoive industry has always been innovative, but when it comes to dynos –the Aussie industry is dynamite

48 IN THE KNOW

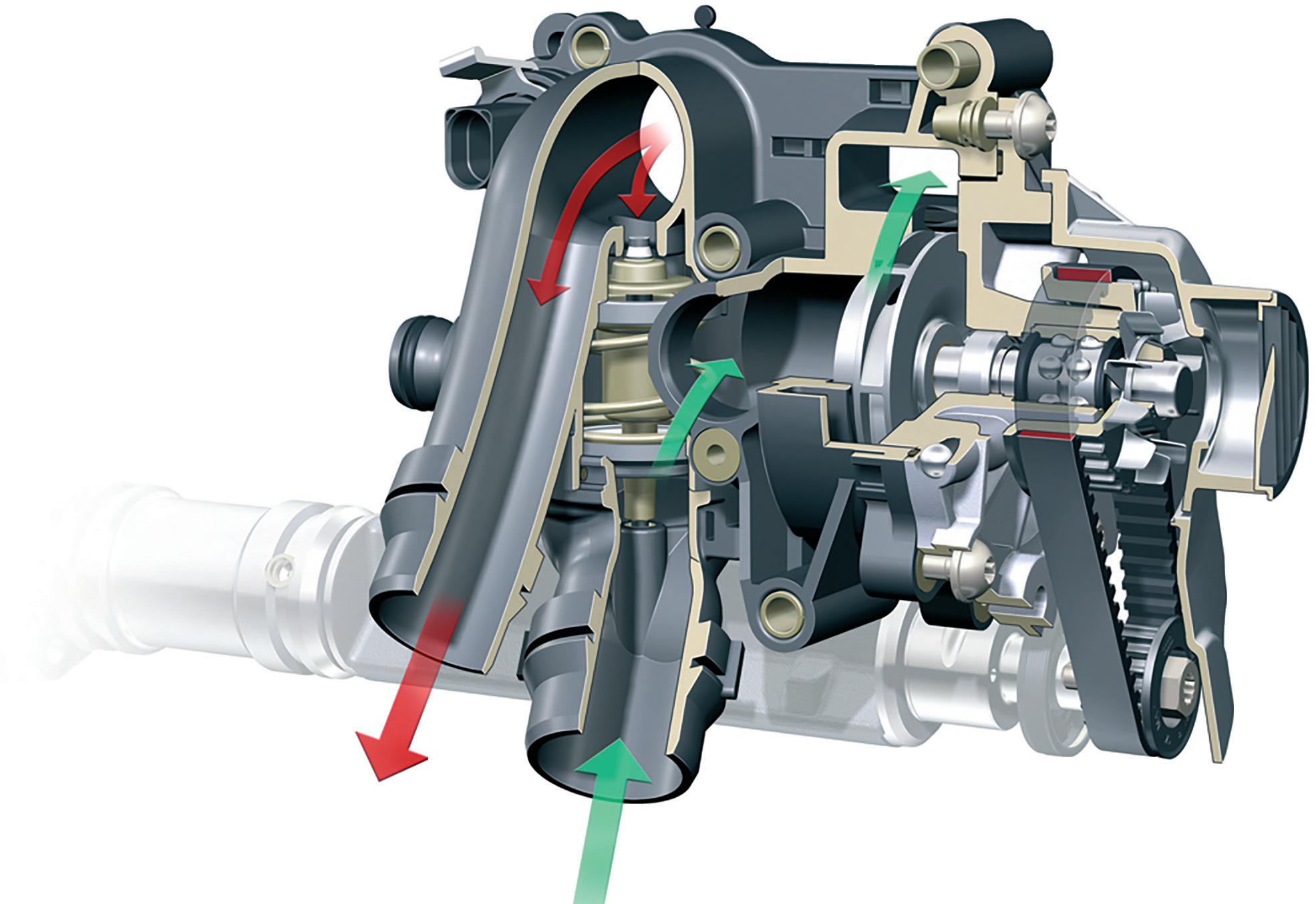

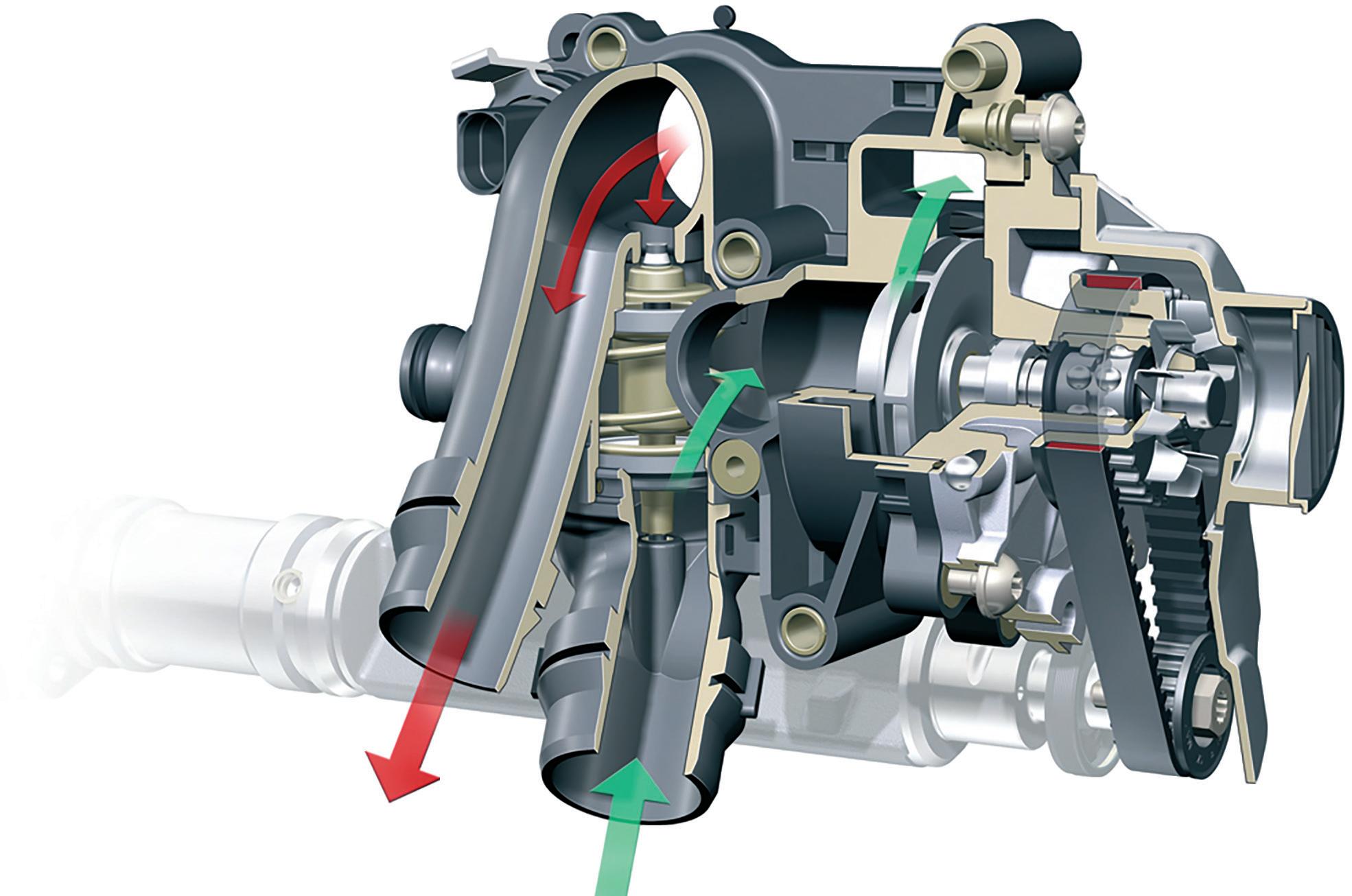

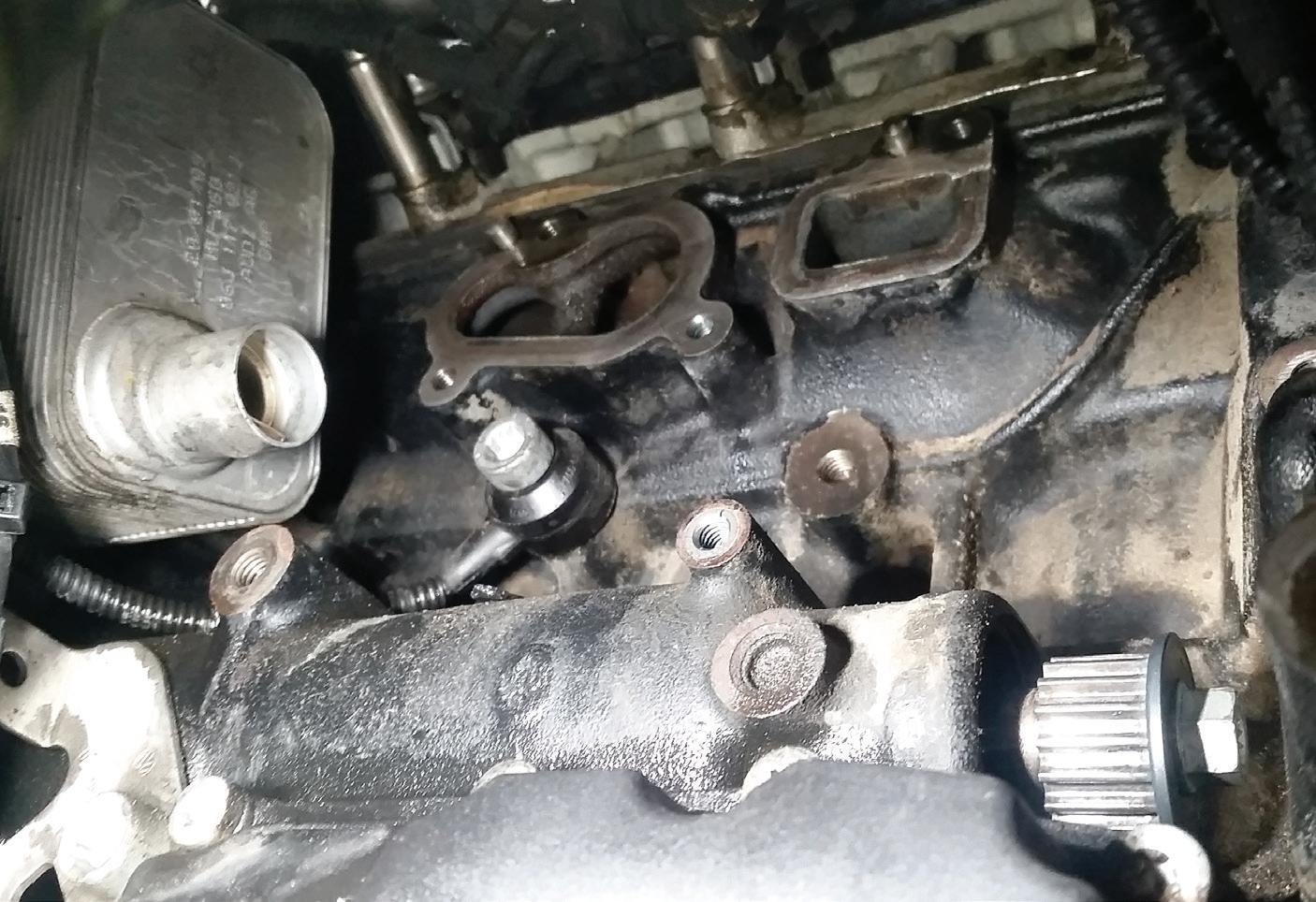

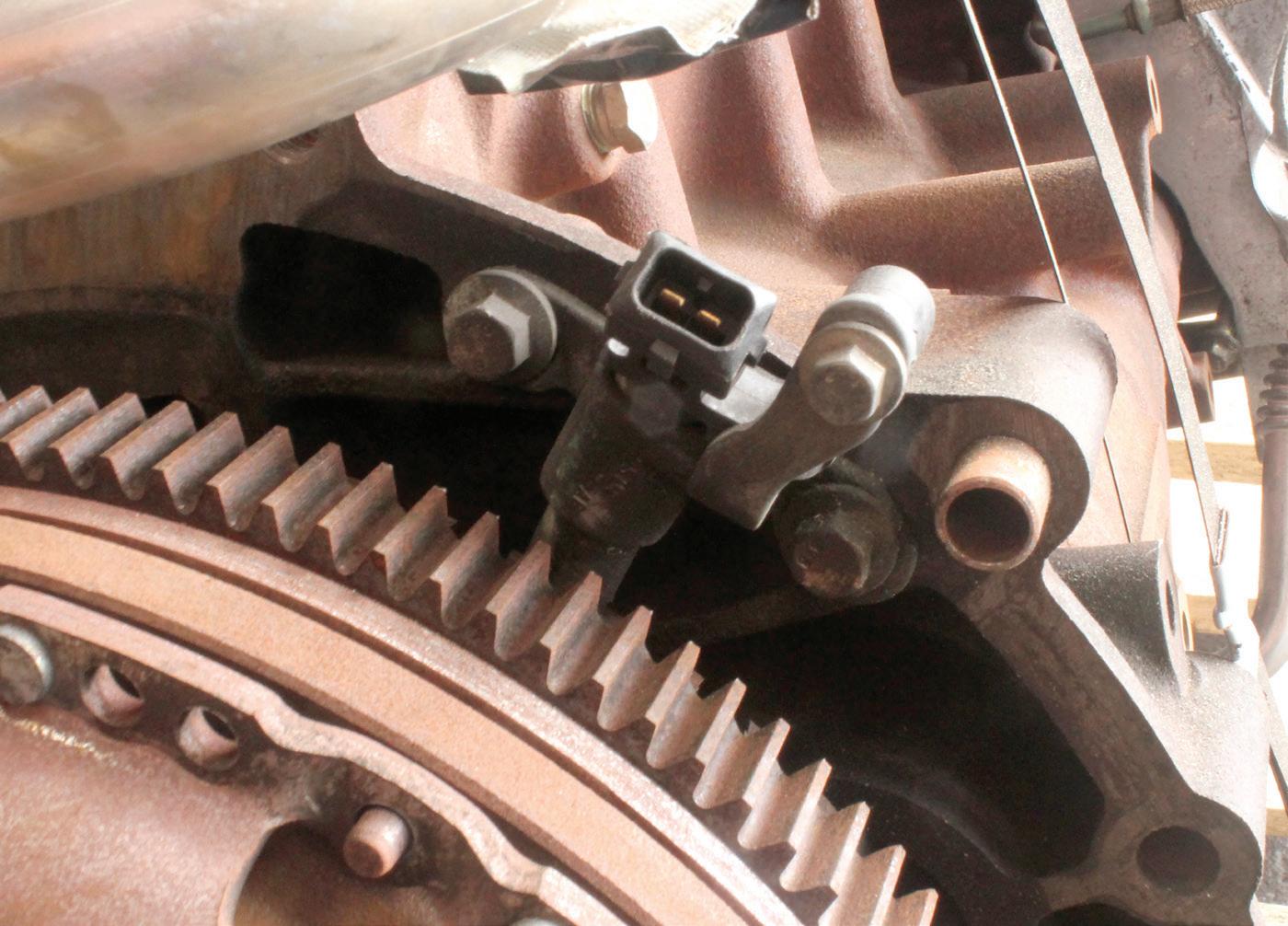

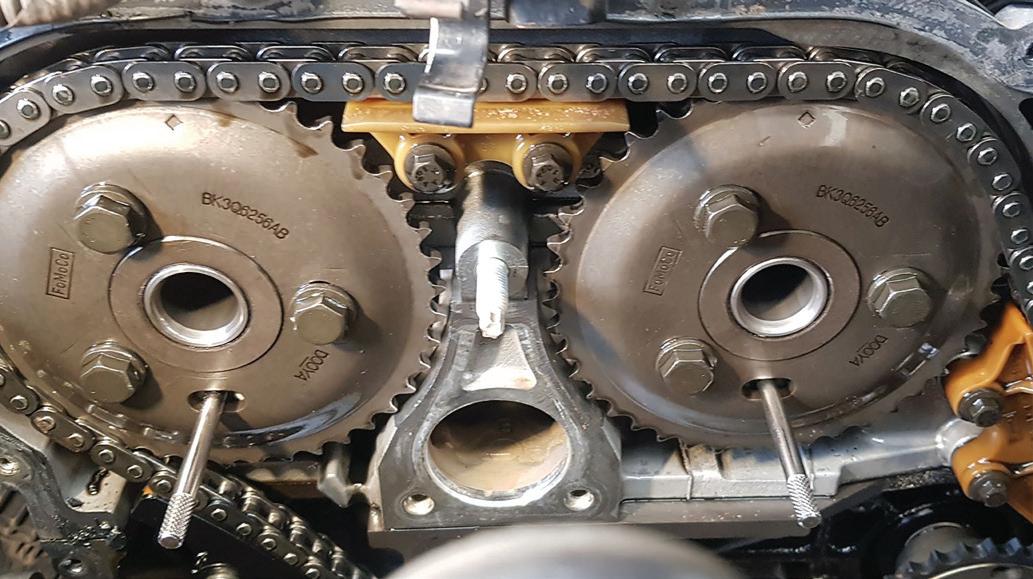

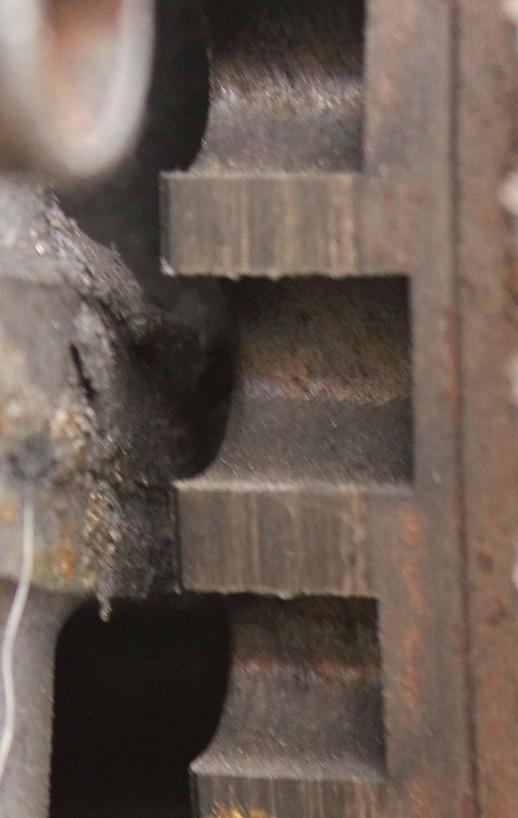

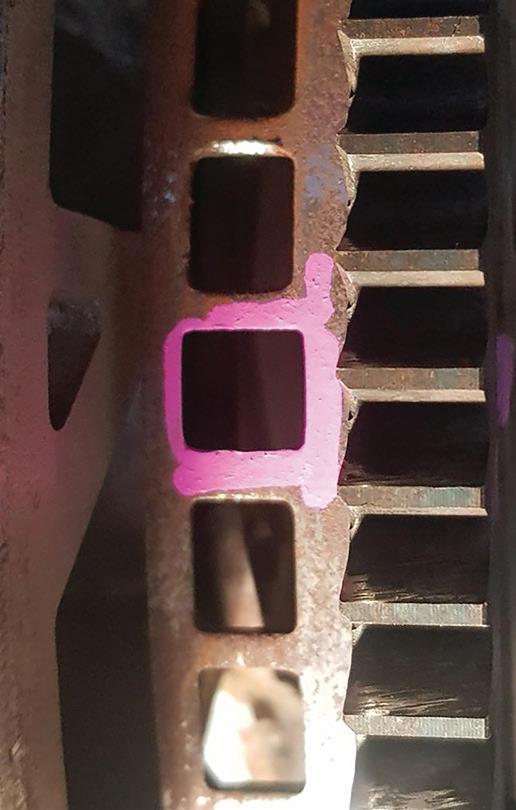

Technical delves into the EA888 engine family and Ford Ranger crankshaft position sensor brackets

54 SERVICE DIRECTORY

Find everything from the latest products to the best business services you need all in one place

BUSINESS INDEX

Drive your business forward by taking advantage of VACC corporate partnerships and services at your fingertips

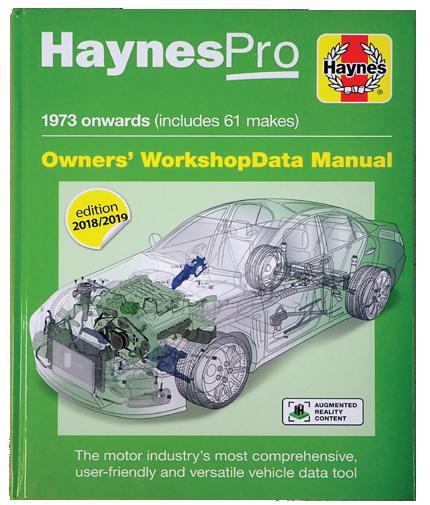

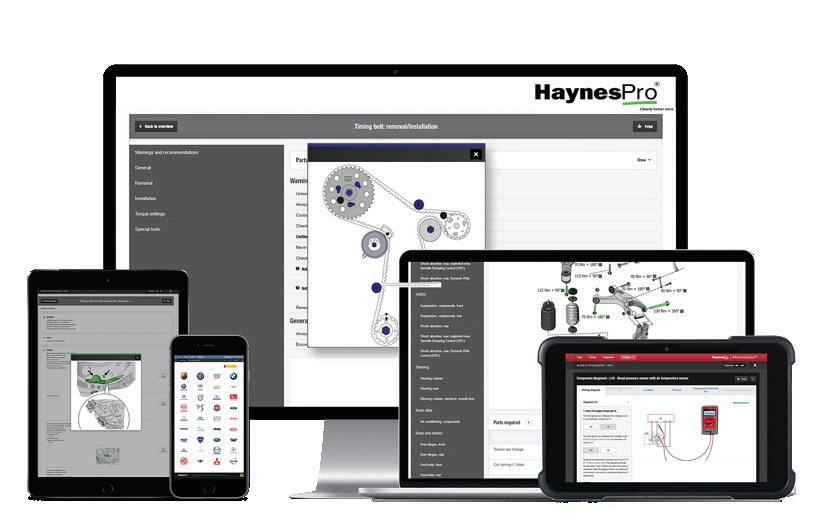

VACC MOTORTECH brings together VACC’s proven suite of technical products with the might of Haynes’ international know-how.

Let us show you how it can drive your business forward...

AUTOMOTIVE CALLS FOR A REVOLUTION

THE next Federal Government must action the key priorities outlined by peak automotive bodies to ensure the industry can continue to employ 380,000 Australians nationally and assist motorists in the transition to a zero and low emission vehicle fleet.

The Victorian Automotive Chamber of Commerce (VACC) has launched its federal election manifesto, REVolution: The automotive industry’s policy priorities for the next Australian Government, which calls on the next Federal Government to implement 35 recommendations that will make a real difference to Australian voters.

The recommendations will see the next Federal Government:

Boost apprentice support

Improve the eligibility for employers to sponsor skilled migrants

Ensure all automotive retailers are eligible for any future Federal Government subsidies related to pandemic or state of emergency relief payments

Take a leadership role in implementing a national Zero and Low Emission Vehicle (ZLEV) policy in collaboration with the automotive retail industry

Increase investment and research in an industry-led and federally funded national program aimed at the proper disposal of End-of-Life Vehicles.

MANAGING EDITOR

David Dowsey

03 9829 1247

editor@australasianautomotive.com

SUB-EDITOR

Pia-Therese Hams

DESIGNERS

Faith Perrett, Gavin van Langenberg 03 9829 1189

creative@australasianautomotive.com

CONTRIBUTORS

Steve Bletsos, John Caine, Geoff Gwilym, John Khoury, Rod Lofts, Imogen Reid, Paul Tuzson

57, 700 READERSHIP

There’s more to do, of course, but if the next Australian Government gets these policies quickly into place it will shore up a $40 billion sector. That’s good for every Australian.

Critically, the election manifesto will inform the government as it considers the implications of a changing automotive landscape – urban infrastructure, skill requirements and government revenue streams, all of which require forward planning and policy debate.

Automotive employs 380,000 people nationally within 72,521 businesses, most of which are small and family owned. The next Federal Government needs to take advantage of industry insight and resources as it lays out its policy intentions.

The automotive industry is a fundamental component of a well-functioning economy, and it is at a critical juncture. With the emergence of ZLEVs and a long-standing skills shortage, industry and government must work together to keep Australia moving.

Read REVolution: The automotive industry’s policy priorities for the next Australian Government on the VACC website. Visit vacc.com.au

David Dowsey – Editor

ADVERTISING REPRESENTATIVE

Andrew Martin, Manager Commercial 03 9829 1169

amartin@ourauto.com.au

PRESIDENT Mark Awramenko CHIEF EXECUTIVE OFFICER Geoff Gwilym

Official publication of the Victorian and Tasmanian Automotive Chambers of Commerce

VACC adheres to its obligations under National Privacy Principles legislation. Information on products and services contained in the editorial and advertising pages of this magazine does not imply the endorsement of any product or service by VACC. Australasian Automotive is copyright and no part may be reproduced without the written permission of VACC. Advertisers and advertising agencies lodging material for publication in Australasian Automotive indemnify the VACC, its directors, Board, employees, members, and its agents against all claims and any other liability whatsoever wholly or partially arising from the publication of the material, and without limiting the generality of the foregoing, indemnify each of them in relation to defamation, libel, slander of title, infringement of copyright, infringement of trademarks or names of publication titles, unfair competition, breach of trade practices or fair trading legislation, violation of rights of privacy or confidential information or licences or royalty rights or other intellectual property rights, and warrant that the material complies with all relevant laws and regulations. This publication is distributed with the understanding that the authors, editors and publishers are not responsible for the results of any actions or works of whatsoever kind based on the information contained in this publication, nor for any errors or omissions contained herein. The publishers, authors and editors expressly disclaim all and any liability to any person whomsoever whether a purchaser of this publication or not in respect of anything and of the consequences of anything done or omitted to be done by any such person in reliance, whether whole or partial upon the whole or any part of the contents of this publication. Advertising accepted for publication in Australasian Automotive is subject to the conditions set out in the Australasian Automotive rate card, available from editor@australasianautomotive.com

Connect with VACC

Australasian

AUSSIE ICON: UTE BOOM

WHEN it comes to classic cars, Australia certainly has the goods. Our beloved Fords and Holdens are more valuable than ever. They’re collectors’ items, but what about the modern vehicles making motorists’ mouths water?

Overall Toyota is the most popular vehicle marque in Australia again – 19 years and counting – taking out 21.3 per cent of the 2021 new vehicle market and outselling its nearest rival Mazda by more than twoto-one. And if I dig even deeper, for the sixth consecutive year the Toyota HiLux was Australia’s best-selling new vehicle with a record 52,801 units sold last year. Yes, the humble ute has always been an iconic part of the Australian motoring landscape but clearly, it has moved above and beyond the farm and ‘tradey’ domain. This is the first time in Australian automotive history that a ute has led the new vehicle market over such a long period. Additionally, last year marked the first time that utes and vans combined outsold passenger cars.

Why? Well, while they may not be cheap, they are flexible and practical. The ute has become the go-to adventure and getaway vehicle, while also having the potential to tick the ‘family-friendly’ box. The appeal extends to younger drivers too – the Commodore and Falcon were once the dream machines. It was almost a cultural statement. Which crew were you? Now the choices are endless but, across the board, the ute is right up there. So, our love affair with the ute continues to go from strength to strength. Yes, the Toyota HiLux has taken the top spot in recent years, but I wonder what changes the electric fleet will bring? Petrol and diesel utes will need to make way for zero and low emission solutions. It’s not an ‘if’ but a ‘when’ scenario. To hear more from industry thought-leader, Geoff Gwilym read the VACC column in Friday's Herald Sun, and subscribe to THE GRILLE podcast.

WHEN VACC President, Mark Awramenko, VACC CEO, Geoff Gwilym and VACC

UTE BOOM

Geo Gwilym VACC CEO

When it comes to classic cars, Australia certainly has the goods. Our beloved Fords and Holdens are more valuable than ever. They’re collectors’ items, but what about the modern vehicles making motorists’ mouths water? Overall Toyota is the most popular vehicle marque in Australia again – 19 years and counting – taking out 21.3 per cent of the 2021 new vehicle market and outselling its nearest rival Mazda by more than two-to-one. And if I dig even deeper, for the sixth consecutive year the Toyota HiLux was Australia’s best-selling new vehicle with a record 52,801 units sold last year.

Yes, the humble ute has always been an iconic part of the Australian motoring landscape but clearly, it has moved above and beyond the farm and ‘tradey’ domain.

This is the first time in Australian automotive history that a ute has led the new vehicle market over such a long period. Additionally, last year marked the first time that utes and vans combined outsold passenger cars.

Why? Well, while they may not be cheap, they are flexible and practical. The ute has become the go-to adventure and getaway vehicle, while also having the potential to tick the ‘family-friendly’ box. The appeal extends to younger drivers too. The Commodore and Falcon were once the dream machines. It was almost a cultural statement. Which crew were you? Now the choices are endless but, across the board, the ute is right up there.

So, our love affair with the ute continues to go from strength to strength. Yes, the Toyota HiLux has taken the top spot in recent years, but I wonder what changes the electric fleet will bring? Petrol and diesel utes will need to make way for zero and low emission solutions. It’s not an ‘if’ but a ‘when’ scenario.

STEVE BLETSOS INCREASE IN APPRENTICES

IT’S not often we see a large rise in the number of businesses putting on apprentices, but the latest data from the National Centre for Vocational Education and Research (NCVER) shows just that. NCVER data for the 2020-21 financial year reveals a 44 per cent increase in apprentices and trainees that commenced within the Automotive Retail, Service and Repair (AUR) Training Package compared to 2019-20. This represents the highest yearly increase since 2011-12 and was driven by strong growth during the January and June quarters of 2021. While this is welcome news, this increase in commencements of automotive apprentices and trainees should be placed into perspective. Over the last decade, there has been a growth of 3.4 million vehicles on road and over 5,000 automotive businesses, yet despite the latest increase in apprentice numbers, there are still over 500 fewer apprentices commencing annually than there were in 2011-12 (Chart 1). Furthermore, given that we have a skills crisis approaching an estimated 39,000 positions across the industry, the recent apprentice increase will barely make a dent in the available workforce for automotive businesses. What the latest data does show, however, is that undoubtedly, the Federal Government’s current package of incentives to employers for taking on new apprentices are working. In particular, the Boosting Apprenticeship Commencements (BAC) wage subsidy and the Completing Apprenticeship Commencements (CAC) wage subsidy programs have provided valuable support to businesses and group training organisations to take on new apprentices and trainees in the current constrained labour market.

Hopefully over time, this will assist towards building a pipeline of skilled workers to support the automotive industry. There is a real risk, however, that these early gains in apprentice numbers may be short-lived. The BAC program is due to cease at the end of March 2022. This may jeopardise any sustained increase in apprentice and trainee commencements moving forward, thus rendering the current increase as a temporary blip. In its pre-budget submission to the Federal Government, the Victorian Automotive Chamber of Commerce (VACC) has recommended that funding of both the BAC and CAC programs should be extended for a further two years. VACC has also recommended for the reinstatement of the Federal Government’s apprentice mentoring program, which in the past has proved

to be enormously successful in raising apprentice retention and completion rates from 50 per cent to around 83 per cent. Other budget recommendations made by VACC include that the Federal Government raise its annual migration levels above the current targets for the next two years, as well as remove the applicability criteria for employer sponsored permanent and temporary migration for the short and medium/long term skill shortage lists. Doing so would enable any migrants holding any skilled occupation to be sponsored by employers. This would also mean all temporary skilled migrants would have a pathway to permanency, thereby adding to the permanent skill base of the economy. As a package, these measures will help address the skills crisis and restore some balance to the depleted labour market.

Chart 1: Apprentice and Trainee Commencements in AUR Training Package, 2011-12 to 2020-21

JOHN CAINE

VEHICLE MILEAGES... TRUE OR FALSE?

ODOMETERS fitted to cars, trucks and motorcycles serve several purposes.

Service intervals are primary and total/ trip distance travelled is secondary. This article will discuss what is known as ‘odometer tampering’ or ‘fraudulent misrepresentation of distance travelled’.

A working definition of this would be when a person causes a vehicle’s indicated total distance travelled to decrease, with the intent to mislead and/or defraud a potential purchaser. This purchaser could be a member of the public or a Licensed Motor Car Trader (LMCT) who is either purchasing the vehicle outright or trading it in.

In colloquial terms or trade slang, it is called ‘whizzing’ or ‘rollback’. Dishonest persons would remove the odometer from the vehicle and manually reset the display to a lesser figure.

Odometers generally work by counting the rotations of the wheel

on a vehicle. A cable or sensor transmits this information either directly to an analogue speedometer or to a computer that calculates the distance travelled and transmits it to an electronic display.

Along with physically altering the numbers, some will disconnect the odometer, continue to drive the vehicle and then hook the odometer back up when it comes time to sell.

An odometer from another vehicle with lower kilometres may also be used to replace the original. It is extremely rare for a LMCT to be involved in odometer tampering these days due to the severe penalties and sanctions which apply. It is more likely to occur in a backyard or unlicensed seller situation. Consumer affairs has successfully prosecuted a number of people in recent years, with large fines being awarded. It is legal to remove and replace

faulty speedometers and dashboard displays, but if this results in lower recorded mileage, then it either needs to be corrected by a suitable person – such as an auto electrician or instrument technician – or a written declaration made to a prospective purchaser noting the time, date and mileage at which the replacement occurred and either the difference or a statement that the vendor believes the display to be incorrect. Should a trader fall victim to an unscrupulous seller, the Victorian Civil and Administrative Tribunal, or other state tribunals, may be able to order rescission and/or compensation. This can also be a valid reason to void a contract of sale for a new or used vehicle should tampering of the tradein’s odometer become evident.

The laws in Victoria relating to odometer tampering can be viewed online via Motor Car Traders Act 1986. Visit legislation.vic.gov.au

Driveline Auto Parts is a division of

DR IMOGEN REID INDUSTRY POLICY MATTERS

WITH 2022 well and truly underway, VACC’s policy team is also full steam ahead. In the lead up the likely May Federal Election, VACC has launched its Federal Election manifesto REVolution, which outlines the automotive industry’s key policy priorities for the next Australian Government. Culminating in 35 recommendations, the manifesto covers nine important areas for reform. It will come as little surprise that skills shortages and access to qualified labour is the biggest issue facing our industry and tops our policy list. While the automotive industry is no stranger to skills shortages, the added pressure of COVID-19 and closed borders has exacerbated an already tenuous situation. VACC’s modelling predicted a labour deficit of approximately 31,000 positions in 2020-21. Updated analysis forecasts this figure to rise to almost 39,000 throughout 2022-23. These are alarming numbers. VACC is demanding urgent government action in three ways: 1) prioritise automotive motor mechanics for visa processing, 2) reinstate permanent and temporary skilled migration at a heightened level; and 3) implement greater training incentives and support for automotive apprentices and employers – including support for

the training of a Zero and Low Emissions Vehicle (ZLEV) workforce. While it’s acknowledged there are no ‘quick fixes’ when it comes to skills shortages, VACC is doing all it can to support members and work towards a workable solution that will allow members to employ and grow. Further to the skills crisis, COVID-19 business recovery is also a priority. VACC argues that any future government COVID-19 relief or stimulus packages should be equitably distributed. Research conducted by VACC found at the height of the pandemic in 2020, approximately 70 per cent of dealers, nationally, did not qualify for three of the Federal Government’s key relief packages. This was based on the criteria of aggregated turnover, insufficient loss of business turnover (70 per cent in some instances) or staff levels being too high. As we move into the third year of the pandemic, it is essential the next Australian Government learns from previous experiences and ensures equitable support is delivered. Rounding out our top three issues is the imperative to future proof the Australian automotive retail industry. The industry has a significant role to play in the sustainably of our environment, which includes the promotion, sale and servicing of ZLEVs. As the phasing out of internal combustion engines (ICEs) draws closer, it is crucial government and industry is prepared for the changes (and

challenges) this will have on supply chains, businesses and the public purse. VACC argues that the next Australian Government must to take a leadership role, in collaboration with the automotive retail industry, in the implementation of a national ZLEV policy. This will provide clarity and harmonisation across jurisdictions as the country moves to upskill technicians, provide adequate infrastructure, align incentives (if any) and bridge tax shortfalls brought about by lost excise.

Other areas covered in the manifesto include: tax reform, red-tape reduction, environmental considerations, workplace relations and the need for fairer competition for some parts of the industry. It is a detailed document that, in our view, covers the many areas requiring urgent attention as we move towards a new post-COVID world. The document has been sent to all state and federal members of parliament and relevant stakeholders. It will also be accompanied by a comprehensive communication campaign, so please stay tuned and feel free to connect with any of the policy team to discuss any of its content. I invite members to download REVolution from the VACC website to read our priorities at your leisure. Once again, I thank those members who were actively engaged in providing feedback. Your input was absolutely essential and has meant our policy manifesto genuinely reflects the voice of our members. As the election draws closer we will ensure the voice of the automotive service, retail and repair industry continues to be heard.

THE Tasmanian Automotive Chamber of Commerce (TACC) hosted its first member briefings for 2022, kick-starting member engagement activities following two years of restricted gathering protocols.

These events were conducted in Launceston and Hobart, for the convenience of both Northern and Southern member-businesses.

Supported by Victorian Automotive Chamber of Commerce (VACC) industry policy advisors John Khoury and Kathy Zdravevski, the briefings were an opportunity

BRUCE MCINTOSH MEMBER RECONNECT

to reconnect with members and provide an update on legislative changes to the Vehicle Manufacturer Information Sharing Scheme and its national rollout later this year.

TACC area managers, Darren Anderson and David Goldstone were the conduits to the local discussion, while VACC technical advisors from the Chamber’s commercial arm, OurAuto and MotorTech – along with sponsors Spirit Super, DENSO and Exedy –presented their latest offerings.

Food and beverages from local suppliers were provided to the

over 35 TACC members in attendance, with Kathy Zdravevski crowning the Hobart venue ‘best finger food’ winner.

I had the honour of running the obligatory business card draw and congratulated the winning members with prizes from MotorTech and TACC.

Both were nights of open discussion, industry updates and prizes, and I encourage TACC chamber representatives to keep an eye out for future invitations and get involved in our informative and engaging member events.

TACC Manager Bruce McIntosh, top right, and VACC Industry Policy Advisor John Khoury, above, update Tasmanian members on the latest news and trends

SHANE JACOBSON AUTOMOTIVE IS MAKING MOVES

OFTEN automotive isn’t front of mind when we talk about sustainability or the environment. But maybe it should be!

The automotive industry is driving important change and helping Australia clean up its act. My mates at the Victorian Automotive Chamber of Commerce (VACC) certainly take their environmental efforts seriously – that goes for the support, tools and advice they provide their member-businesses, as well as head office efforts. What’s that saying? Lead by example…

VACC has a dedicated Occupational Health, Safety and Environment (OHS&E) unit which provides overthe-phone, digital and face-to-face advice and information to help their member-businesses stay on top of OHS responsibilities and environmental law. They also drive a national program called Green Stamp, an initiative rewarding businesses that introduce environmental and sustainability

measures into day-to-day operations. Then there’s Tyre Stewardship Australia (TSA), formed to implement the national Tyre Product Stewardship Scheme. By choosing TSA Accredited participants, $0.25c from your new tyres goes towards finding sustainable markets and a new life for your old ones. Sounds pretty good to me.

VACC has its sights set on Canberra in a bid to up the ante when it comes to industry environmental efforts on a national scale. With a federal election looming this year, the Chamber has released its manifesto, REVolution: The automotive industry’s policy priorities for the next Australian Government – check it out on vacc.com.au – which includes specific environment recommendations. Did you know 750,000 vehicles reach the end of their economic lives every year, creating more than one million tonnes of waste? VACC dismantling and recycling member-businesses have dedicated

substantial resources and are currently collaborating with authorities to identify options for an End-of-Life Vehicle program in Australia. They want to stop this cycle – but the government needs to play ball. Even the Chamber’s new office in North Melbourne reflects the group’s values and environmentally conscious commitment. The building has a five-star green rating – representing Australian excellence in environmentally sustainable building practices. The basement car has electric charging stations. Can’t wait for a tour! Businesses being proactive when it comes to the environment, I love to see it. Just another reason to look for orange sign, I’d say. See ya on the road, folks! What to hear more from Shane? Visit: thegrillepodcast.com.au

New home for VACC

THE Victorian Automotive Chamber of Commerce (VACC) has officially relocated to its purpose-built office in North Melbourne. The three-year project ended with the handing over of the building keys to VACC President Mark Awramenko, the occasion marking the beginning of an exciting new chapter for the Chamber. Representatives from the VACC House builders, Hacer Group; architects, Gray Puksand; and project managers, Case Meallin were in attendance.

While the old office on St Kilda Road had a rich history, the Chamber’s new home at 650 Victoria Street, North Melbourne positions VACC as a forward-thinking and contemporary association for its members.

The building is at the forefront of modern sustainable technology, with its architectural features a subtle nod to the automotive industry, including a facade inspired by the grille of the classic Ford Mustang.

VACC occupies 3,172 square metres of office space on levels one to three, and there is a rooftop balcony providing views across the Melbourne CBD – perfect for member functions. The office also features an inter-tenancy atrium staircase allowing natural light to flood into the building and

providing easy interaction and connectivity between floors. VACC will use the expansive level one lobby area as a function space and exhibition area to showcase new technology and automotive achievements. The property has 91 basement car spaces with five electric charging stations and meets a minimum five-star green rating, representing

Australian excellence in environmentally sustainable building practices.

VACC House 650 Victoria Street, North Melbourne Victoria, Australia 3051 P: 03 9829 1111 | E: vacc@vacc.com.au

All other contact details remain the same.

Driving diversity

ACCELERATING Women into Automotive (AWIA) is calling on women curious about an automotive career, and businesses looking for a new apprentice, to participate in the program’s next intake.

A Victorian Automotive Chamber of Commerce (VACC) initiative, AWIA was developed in order to help boost the number of women commencing apprenticeships in the industry.

The program provides a four-week, intensive and engaging introduction to the sector. Participants receive training at a Registered Training Provider and hands-on experience in a variety of workplaces. Automotive businesses that provide work placement to participants will receive free diversity training for their employees and, at the end of the placement, can offer an apprenticeship to their participant.

Program facilitators provide ongoing support as participants transition into their apprenticeships

To register or for more information, contact the VACC Skills Development Centre on 03 9829 1130 or AWIA@vacc.com.au

AWIA is funded by the Apprenticeship Innovation Fund.

From left: VACC CEO Geoff Gwilym, Hugh Moodie, Steve Emonson, Peter Meallin, Charlotte Ham, and VACC President Mark Awramenko

OurAuto Diagnostic Tool

OurAuto Diagnostic Tool

OEM level access to module programming, resets, relearn, key programming and standard diagnostic functions.

Covering a large range of vehicles worldwide, with capacity to perform vehicle health checks on all systems on late model vehicles, checking all computers on the vehicle.

Alarms can be set for range sensor problems, quick resets of fault codes, along with automatic vehicle model detection on late model vehicles (mostly European).

Dynamic health reports can be generated with the ability to email reports to customers.

The Diagnostic Tool has regular software updates and is available on a convenient monthly subscription plan.

Bright spark

SPARKS Auto Electrical recently celebrated 50 years as a Victorian Automotive Chamber of Commerce (VACC) member-business and VACC CEO, Geoff Gwilym met with owner Gary Marrocco onsite to mark the occasion.

Gary’s father, Luigi and his uncle, Joe, established Sparks Auto Electrical in 1968. The brothers emigrated from Italy and quickly set up shop in what would have been an industrious time for the automotive industry. A dynamic business-minded duo, Joe had training on the tools and taught Luigi the trade on-the-job. A successful venture from the start, in those early days, the business called 596 Sydney Road in Coburg home, before the brothers made the move to 1 Allenby Street in Coburg North where the business continues to operate today.

Luigi has three children, but it seems he only passed down the automotive gene to Gary. “My sisters are not into working on cars.” But, Gary started working at 14 years old, helping around the shop. “Even at this early age I was fascinated with cars and the way they worked. I wanted to be active in the industry and thought being an engineer would be a good start,” he said.

Gary attended St Joseph’s College in North Melbourne and, after finishing high school, started a diploma in electrical engineering at RMIT. However, despite his father’s encouragement, Gary’s time at RMIT was brief, as he was keen to get back in the shop. “I wanted to be hands on.” So, Gary left university to begin his apprenticeship and never looked back.

Gary undertook his automotive electrical training at the Batman Automotive College of TAFE. Coincidently, Geoff taught at the college in the early 90s, and they both fondly remember the teachers there throughout the years. Gary agreed that instructors including David Cox and George Pontikis really knew their trade. “Many of the skills I apply today came out of these great teachers.”

Fast forward a few decades and Luigi retired first from the business at 55 years old. Joe stayed on until he was 65, after which Gary took the reins.

When he first began his apprenticeship, could he have imagined one day calling the shots?

“Yes, that was always the plan. It was always going to stay in the family.”

Now a father himself, with a young daughter and a son at home, Gary is unsure whether he will pass Sparks Auto Electrical onto the third generation of Marroccos.

Gary sees automotive jobs in the future will be very different from what he has experienced in his own career. For example, with electric vehicles gaining popularity – the Federal Government aiming for 1.7 million Zero and Low Emission Vehicles on-road by 2030 – the tasks of an electric vehicle diagnostic technician would be “a lot cleaner work" compared to that of today’s technicians. The rise of the electric fleet is already changing the automotive industry landscape – with ground-breaking legislation to mandate providing motor vehicle service and repair information to Australian automotive repairers passing the Senate.

This world-leading legislation fulfills a government commitment for a mandatory scheme to compel car manufacturers to share technical service and repair information with all qualified Australian

repairers from 1 July 2022. Sparks Auto Electrical is counting down the days. Technical information is crucial when repairing vehicles today, and the new rules will even-up the playing field for independent repairers – a big win for business and for motorists.

On technical matters, Gary reveals Sparks Auto Electrical is already a VACC MotorTech subscriber and an avid user of Tech Online. In terms of VACC services, the Chamber’s technical offering tops the list and – while the team is happy – Gary insists the more technical information, the better...

With more than enough work and a loyal customer-base, Gary is content with current business operations, and, while he is not looking to expand the premises, he is open to employing an apprentice in the future. “I get a lot of phone calls (from young people looking to learn the trade).”

With progress being made at government levels and business full steam ahead on the workshop floor, Gary and the team have positioned Sparks Auto Electrical for many more successful years ahead

VACC MotorTech is a technical solution that combines VACC’s extensive online and physical repair, service and diagnostic resources with the global might of Haynes. For more information, call 03 9829 1268 or visit motortech.com.au

Gary Marrocco, his father Luigi and uncle Joe were presented with their 50-year membership certificate (above). The team has built a loyal customer base which keeps business booming (left and below)

Cool Cars with Dermott hits the road to promote auto careers

VICTORIAN Automotive Chamber of Commerce (VACC) member-businesses will star on the small screen this year with Cool Cars with Dermott, a brand-new television show starring Dermott Brereton and Elise Elliott. Both self-confessed rev heads, the duo will visit eight VACC and Tasmanian Automotive Chamber of Commerce (TACC) member-businesses across Victoria and Tasmania, sitting down with business owners and their apprentices to talk all things automotive, with a particular focus on skills and career pathways.

Eight businesses will be selected from different sectors such as mechanical, tyres, heavy vehicles, motorcycles, restoration, windscreens, body repair and towing to appear on the show. The Chamber has sent a call-out to its membership base, encouraging businesses currently hosting

ADVERTORIAL

an apprentice – and keen to show off their workshop on national TV – to register their interest to appear on the show.

VACC and TACC member-businesses can register their interest via VACC Automotive Apprenticeships. Call 03 9829 1130 or email jmokos@vacc.com.au. Help combat the automotive industry’s national skills shortage and spread the word about the exciting career opportunities within the sector!

With agency focussed sales on the rise, dealers reminded

Words: Pitcher Partners

AS the auto industry begins the move to an agency-focussed sales model, leading auto business advisor Steven Bragg proposes dealers prioritise selling cars to drive revenue while not being overly distracted by pursuing litigation, which is vital to the future of the industry. By focussing on their own business’s financial wellbeing, the dealers are better equipped to support the industry.

Mr Bragg is the Motor Services industry lead at Pitcher Partners Sydney. He suggests that as the OEMs continue to increasingly take over significant elements of dealer revenue channels and profit centres, they should not be surprised to see their dealers move to importing cars from sources other than the OEMs themselves, including parallel importation.

Parallel imports are new or nearly new cars sourced from other right-hand drive markets where those manufacturers and distributors carrying excess stock in those markets export the vehicles to other right-hand drive markets. While parallel imports are largely limited (and in some cases banned) in Australia, if dealers were able to get Canberra to free the grip foreign OEMs have over the import trade, it could place dealers and distributors as direct competitors with the OEMs. “This looks to be one of the unintended consequences the OEMs face by pushing

to hold focus

further and further into the profit centres of the dealers while expecting increasing investments in representation,” Mr Bragg said. This commentary was in response to last week’s article in GoAutoNews Premium which reported that court papers indicated that Mercedes-Benz Australia (MBA) was acting under orders from head office Stuttgart to get the agency sales model in place in Australia and that it was going to adopt the model with or without the agreement of dealers.

The article said that discussions with dealers about the agency model, and suggestions that MBA would listen to their concerns, were just window dressing.

Most Mercedes-Benz dealers in Australia are pursuing MBA in the Federal Court to recover $650 million which they claim is the combined value of their businesses which they say they have effectively been forced to transfer to Mercedes-Benz Australia under their agency sales model agreements.

Mr Bragg said that the position in which Mercedes-Benz dealers in Australia find themselves “is really just a reflection of the position all dealers are going to find themselves in as the world gears up for EVs.

“Dealers deserve their goodwill for building the businesses and basically being asked to hand their customer base over to the OEM. But the problem is occurring at a time

when the OEM financial commitment is fully geared to developing EVs and associated infrastructure, not tidying up the past.

“This will play out with various OEMs, in multiple countries, for years to come. The dealers only bargaining chip is the customer through past service activities or by geographical positioning.

“My concern is that dealers will be so focussed on fighting city hall, they will not focus on their relativity going forward.

“Selling cars to their customers is still the main game and the dealer is now firmly in competition with the OEMs heading into agency.

“Parallel Imports, once the natural enemy of the new car dealer, should now be the preferred partner. Dealers sell cars to their customers, the agency removes that core premise, that’s why they become dealers not agents.

“Dealers can obviously act as agents if that works for them financially, but the main business must remain the dealership business. Giving customers access to various high quality, new or near new imports keeps them delivering for their customers.

“It will also keep the dealer in the ICE end of the business much longer than the OEMs who globally are legislated towards EVs.

“I think the biggest risk dealers face is distraction. Whilst they focus on agency-based litigation, they may potentially take their eye off the prize, parallel imports,” Mr Bragg said.

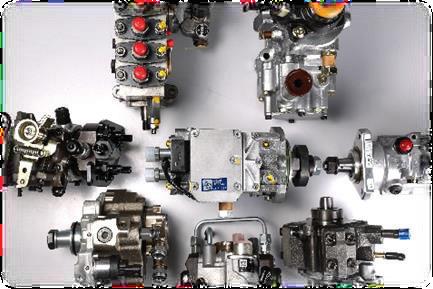

VACC Technical has changed

VACC Technical Services has launched into a new era of product offerings that will change the automotive technical information game in Australia.

VACC has signed a multi-year deal with the famous British-based Haynes Publishing Group, bringing to market a suite of products, unsurpassed in Australia, under the banner of VACC MotorTech.

VACC MotorTech brings together VACC’s proven Tech Online, Times Guide, Tech Estimate, Tech Advisory Service and Tech Talk products with the might of Haynes’ international know-how, to provide an enormous (and evergrowing) amount of technical service and repair information to subscribers. Available now for subscription are four ‘solutions’: Maintenance, Service & Repair, Diagnostics and Commercials. These new products are positioned at an unbeatable price and VACC members receive generous discounts of up to 50 percent. Haynes is best known in Australia for its Haynes manuals that have been in print since 1965 and have sold over 200 million copies worldwide. However, they

also provide automotive service, repair and diagnostic information via different online products, designed for automotive professionals under the HaynesPro brand.

Until the agreement with VACC, HaynesPro products have not been available in the Australian market in such affordable and convenient packages.

The HaynesPro products include:

• HaynesPro Manuals AllAccess Cars allows access to all Haynes manuals online, providing step-by-step repair and service information, along with extra details not published in the hard copy versions. The Haynes OnDemand video tutorials – available for many of the most popular models – are the ultimate aid to getting vehicles correctly serviced and repaired.

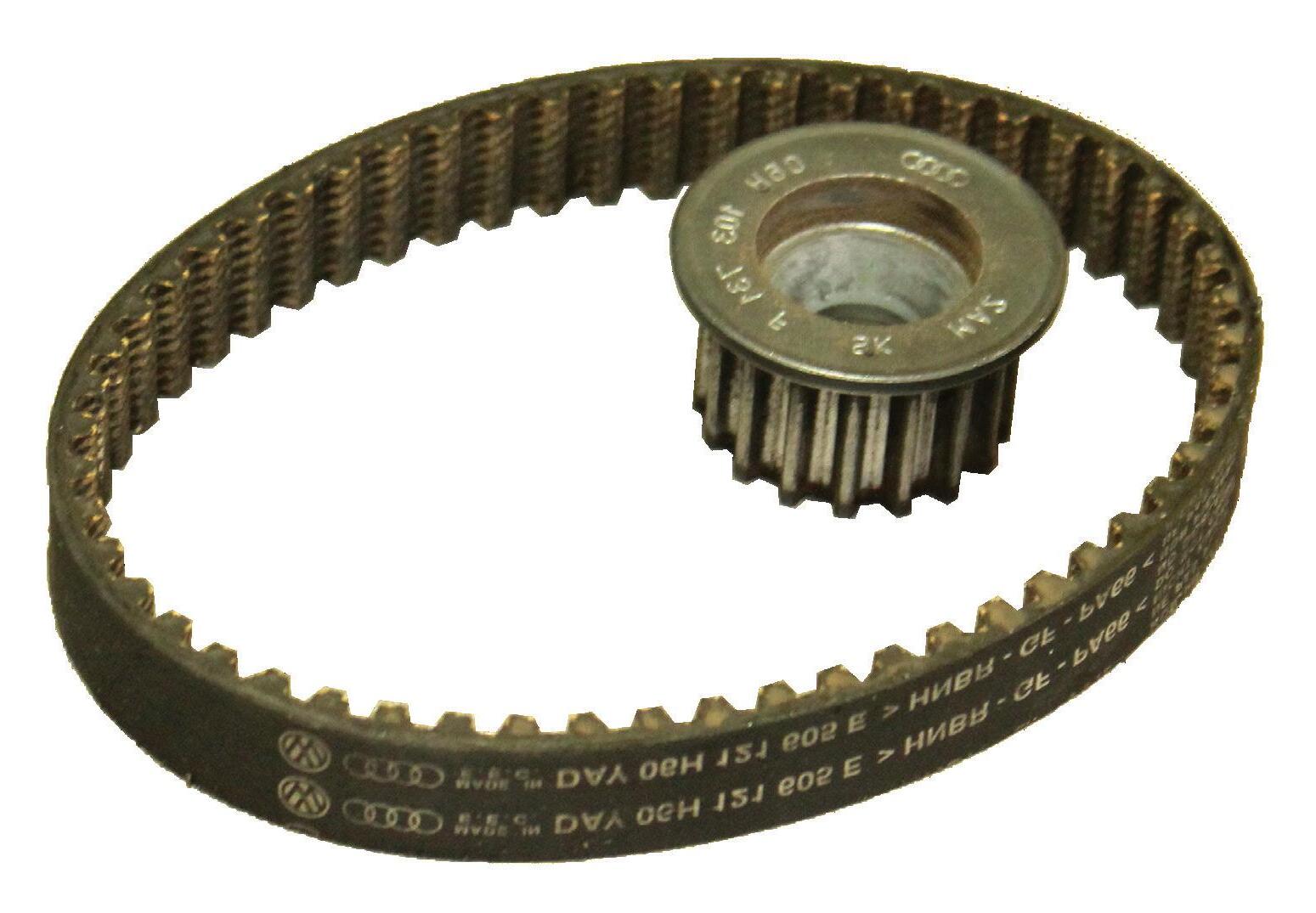

• HaynesPro WorkshopData Tech contains extensive maintenance information like repair times, timing belt

and chain replacement procedures, capacities, wheel alignment, torque specification and over 100,000 high-quality technical drawings.

• HaynesPro WorkshopData Electronics and Smart includes the VESA guided diagnostics system, wiring diagrams for most vehicle systems, fuse and relay locations, earth point and control unit locations, TSBs and known fixes.

• HaynesPro WorkshopData Truck includes WorkshopData Tech, WorkshopData Electronics and WorkshopData Smart. It is the most effective application from fault to fix.

The agreement between VACC and Haynes provides automotive business owners new options and easy access to repair information and vehicle repair times not available previously, in bundles to suit every business’s needs.

Visit: motortech.com.au

Long-awaited reform edges closer

Words: VACC Industry Policy Advisor, John Khoury

THE implementation of the highly anticipated Competition and Consumer Amendment (Motor Vehicle Service and Repair Information Sharing Scheme) Act 2021 (the Act) is gaining momentum as vehicle manufacturers actively develop their information-sharing platforms to comply with the legislative obligations. From 1 July 2022, all service and repair information including diagnostic and reprogramming procedures provided by a vehicle manufacturer to an affiliated dealership or authorised repairer network must be made available to independent repairers and registered training organisations on fair and reasonable terms. Information relating to vehicle safety and security is restricted to persons who can satisfy specified criteria. There are penalties of up to $10 million for a breach of the provisions.

The Act only covers passenger and light commercial vehicles manufactured after 1 January 2002, although certain right to repair advocates are pushing for the inclusion of farm machinery.

Aimed at promoting competition, and establishing a fair and level playing field, this world-leading legislative framework provides small automotive business owners surety in an era of substantial high-tech advancements such as electric, connected, and autonomous vehicles.

The safety of motorists and the wider community is paramount, and this legislation also ensures people's pride and joy will be maintained and repaired in accordance with manufacturer specifications by the repairer of their choice.

In other major developments, the Australian Automotive Service and Repair Authority (AASRA), was established in late 2021 and has formally been granted the role of Scheme Advisor as outlined in section 57FA of the Act. AASRA is a not-for-profit industry body consisting of representatives from the Australian Automotive Aftermarket Association, the Australian Automotive Dealer Association, the Federal Chamber of Automotive Industries, and VACC’s national body, the Motor Trades Association of Australia. AASRA’s main functions will be to oversee and ensure the operational functions of

the legislation, including facilitating dispute resolution and periodically reporting to the relevant minister. The board is working on a major project in collaboration with the National Automotive Service Task Force (NASTF) that will ensure technicians are vetted and certified as vehicle security professionals in line with fit and proper person requirements. This will allow technicians to gain access to key codes and reprogramming information.

Technicians requiring access to safety information relating to hydrogen, high voltage and electric propulsion systems will need to demonstrate they have completed appropriate training such as safely depowering, isolating and re-intialising a high voltage battery. This outcome would not have been possible without the advocacy efforts of industry stakeholders and workshop owners, many of whom have given up their time to ensure a brighter future exists for future generations of automotive technicians. VACC once again thanks the Morrison Government, and in particular the Assistant Treasurer and Housing Minister, the Hon. Michael Sukkar MP for seeing this legislation through.

Whether you re star ting, running or growing your business, CommBank, proud Alliance Par tner of VACC can help you do business your way

D e d i c a

To help you take your business to the next level, VACC members can benefit from direct access to a dedicated CommBank Relationship Manager and team of banking specialists They ’ll work with you through every stage of your business life cycle You’ll also receive 24/7 Australian based phone suppor t for all your business banking needs

B u s i n e s s p

VACC members may be eligible to access the latest innovative business banking products and solutions with preferential pricing applied, making it easier for you to do business These include:

No merchant joining fee

Same day se�lement every day of the year^

Daily IQ - free business insight s tool with CommBiz and NetBank

Business Loans and Asset Finance

Overdra� Facilities and Bank Guarantees

Free business financial health checks

To find out how CommBank can help you do business your way, contact VACC on 03 9829 1152 or email marketing@vacc com au and they’ll put you in touch with a CommBank Relationship Manager.

Facilitators

•

•

•

•

Toyota Australia engineers based in Victoria played a crucial role in the development of the new LandCruiser 300 series

THE publication of automotive ‘spy pics’ in print and online by photographers such as Hans Lehmann, Bernd Rauh, Jim Dunne, and Andreas Mau has made generations of motoring enthusiasts familiar with the idea of camouflaged mules undergoing hot-weather testing in Death Valley, or cold weather testing in some frigid Scandinavian outpost.

But Victoria’s role as vital automotive development testing ground for one of the world’s biggest car makers is less well known, as is the ongoing role of Australian automotive engineers in the development of the iconic Toyota LandCruiser. The arrival of the all-new LandCruiser 300 Series was one of the most widely anticipated new model launches of 2021, with legions of fans still keen to get behind the wheel of the supply-interrupted new model to experience the advances over its long-serving and highly regarded predecessor, the 200 Series. Despite looking like an evolution of the

200 Series, Toyota says the 300 Series is an all-new from the ground up model and sets new benchmarks for the nameplate in areas including performance, fuel efficiency, and the all-important offroad ability. And it’s in the dust, heat, mud, thump, and grind of off-road testing that Australia – and more specifically Toyota Motor Corporation Australia’s (TMCA) Australian development engineering and technical staff – have played a key role in the development of this new global model.

Australasian Automotive spoke with Manager of Research, Evaluation and Training within TMCA’s Vehicle Evaluation Group, Ray Munday, and his engineering colleague Kirstie Beugger from the Advanced Systems Development team, both of whom played significant roles in the development of the new Cruiser. The pair are part of TMCA’s 50-strong engineering and technical staff, based at the Toyota Centre of Excellence, on the site of the company’s former manufacturing plant in Altona.

While the LandCruiser 300 is still new news for Australian consumers, for Ray and Kirstie and the rest of the development team at TMCA, the 300 Series has dominated their working lives since as far back as 2015.

“In terms of this vehicle, we were involved all the way through the (development) process. The first prototypes arrived here in 2015 and we’ve had a vehicle here pretty much the whole time up until the launch,” said Ray.

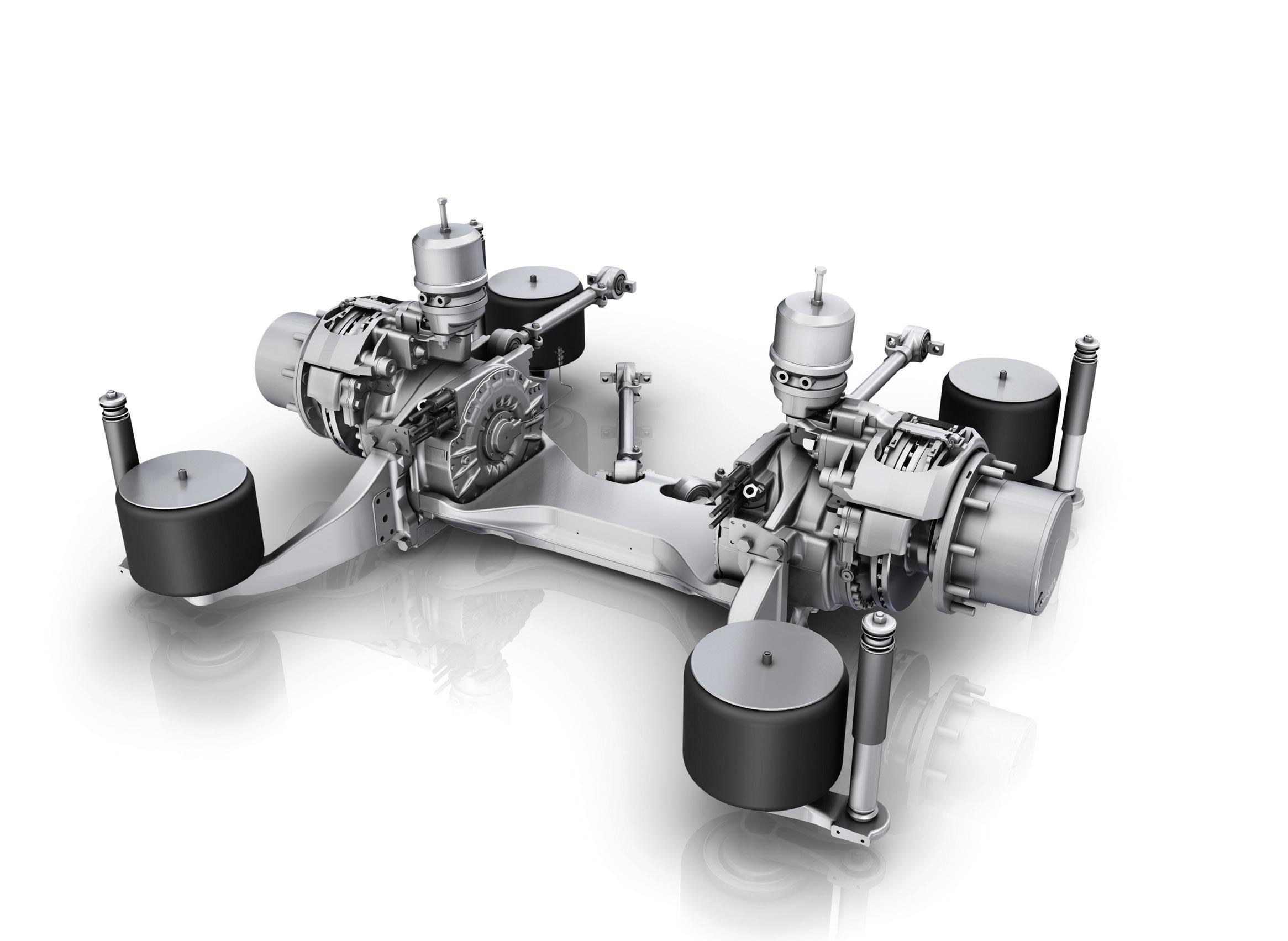

He explains the 300 Series development cycle took seven years, and Australia played a crucial role in developing the vehicle’s sophisticated electronic off-road control system, dubbed Multi-Terrain Select (MTS), as well as its e-KDSS electronic stabiliser bar control system, and its all-terrain tyres.

“Our contribution started all the way back with the early target setting, to help define the basic scope (including) what kind of platform it was even going to be, all the way through to detailed development

of control systems, and then through to the final confirmation of the total vehicle package. And it’s ongoing now into our production vehicles, to check that they meet the (final) prototype spec,” he said.

“In total, we had more than five prototype vehicles going all the way back to 2015. These started with vehicles that were technology evaluation vehicles and then, as the cycle went on, they became more and more the full platform, and then onto the full vehicle for final evaluation.”

Ray explains evaluation of LandCruiser models in Australia has been happening for several generations, but that TMCA’s technical involvement has grown significantly since the mid-2000s.

One of the big shifts driving this deeper integration was Toyota Australia’s designation in 2008 as a Centre of Excellence for four-wheel drive development within the Toyota world. This was due to the recognised skills of the local vehicle development team, and the fact Australia has around 80 percent of the world’s different onroad and off-road conditions.

“We’re the main centre outside of Japan for this role. Toyota Japan has amazing test courses and standards to develop cars to the very high quality they are, but when it comes to off-road vehicles it’s very difficult to replicate all the global conditions that customers drive on in a test course,” said Ray.

TMCA’s role in developing the new LandCruiser 300 Series began with its predecessor, the 200 Series, with Australian engineers providing valuable research, data, and customer feedback on how the product could be improved. Ray explains some of this came from Toyota’s 2014 Five Continents Drive, which saw Australia chosen as the first location for the gruelling 20,000-kilometre collaborative test event, involving local and Japanese engineers.

“The Five Continent Drive was an initiative by Toyota’s global president, Akio Toyoda, and it was for the engineers and technicians from Toyota Japan to understand the global conditions,” he said.

“It happened in 2014, just as LC300 development was about to begin, so it was perfect timing for the TMC members who came from Japan to not only drive (the LC200) around Australia, but also in conjunction with TMCA, interview a lot of customers and get a lot of feedback, which would have been very difficult to achieve otherwise.

“You can imagine for someone based in Toyota City Japan, that you don’t get those big outback roads, the long highways, you don’t get the same UV and temperature, so it was a chance for them to really experience, for days on end, what it’s like to be a LandCruiser driver in Australia.”

Kirstie picks up the story of how her Melbourne-based team helped shape the final tune of the LandCruiser 300’s advanced MTS system, which features six different modes for off-road terrain – five in high range and four in low range.

“We had a lot of input into the development of the MTS system, simply by virtue of the skill set that we have available here, and also the environments we have,” she said.

“The previous generation LC200 did have an MTS system but LandCruiser 300 is an entirely new vehicle, it’s got a new engine, transmission, brake actuator and so on, so all these new systems come with new processing power and new control systems, so all of the MTS from the ground up is completely new.”

Much of the development work was conducted in Victoria, thanks to the state’s wide variety of terrain and its ready access to the Australian Automotive Research Centre in Anglesea, explains Ray.

“We used (Anglesea) extensively for our evaluation. It’s a fantastic proving ground to do off-road evaluation; it’s got real world courses and a range of off-road conditions, so we used that, and we used a lot of the natural sites that also exist in Victoria. Within Victoria we have the High Country, the Toolangi Forest, you’ve got lots of farms, you’ve got the deserts, like the Big Desert around Mildura, and we can go down to Portland for the sand. There’s a massive range of terrain just within Victoria, and then we also utilise other parts of Australia, such as the desert and tropics in the Northern Territory, and the sand of outback South Australia and New South Wales.”

It was this ready access to such a wide variety of different off-road locations, both in Victoria and beyond, that contributed to the final MTS system being a significant advance over the system fitted to the 200 Series.

“One of the great things we were able to contribute to the MTS system was to go around to all our different types of test sites and all our different types of terrain and measure the grip-slip relationship.

“The vehicle that we got out of the box was already great, having incorporated all of that research. The next step in our process

is when we get the prototypes here and we take them out to see if they meet or exceed the targets that we set for them, and then we start the process of tuning that system, making it smoother and more capable. That’s a closed-loop process, (so) we’re in direct communication with TMC during that process, so we’re out at our test site, we find a gap, we’re able to communicate that gap to them and then receive software back straight away that we can plug into the car and make sure that gap is filled,” said Kirstie. In addition to working on MTS, TMCA engineers were also involved in development of the 300 Series’ new electronic stabiliser bar control (e-KDSS), which is available on the new GR Sport variant, and developing its all-terrain tyres. The latter was described by Ray as “a huge challenge” given the competing priorities of efficiency, durability, plus on and off-road performance.

“This vehicle is also about high efficiency, so developing a high efficiency tyre that’s also good and durable off-road, that was a massive challenge, (and) required a lot of new technology from the tyre suppliers. Typical high-efficiency tyres are often very easily damaged off-road with existing technology, so there was a lot of iterations of new compounds, new tread designs, optimising those, and testing them in the real world. Australia was the place that we did all the off-road testing for those tyres. They are specifically developed tyres for the LC300 and with all the testing that was done, we feel that in the end they perform better than the previous model tyre.”

As to the question of whether TMCA will continue to have such deep integration into crucial TMC products in the years to come, given that Australia is no longer a vehicle manufacturing hub, Ray is in no doubt.

“We have a very strong technical skill base in Australia, we’ve got strong and passionate automotive people, we’ve got a fantastic environment, and we’ve had some people come across from manufacturing, retaining that skill. These core skills are already there and with all the new technologies coming out in the world now, and the need to make sure that they work properly in the real world, I don’t see that level of involvement reducing, in fact I see it increasing.”

Victoria tops the list for trial terrains. Vehicle Evaluation Group's Ray Munday (inset)

STUART CHARITY

CEO AUSTRALIAN AUTOMOTIVE AFTERMARKET ASSOCIATION

Stuart Charity has served the automotive industry in a variety of roles and is currently CEO of the Australian Automotive Aftermarket Association (AAAA), which represents 4,100 member businesses across the entire automotive aftermarket, an industry which contributes $25 billion annually to the economy. Under Charity’s leadership, AAAA has championed many initiatives, services and regulatory reforms; improving the sustainability and growth of the industry. The association’s bi-annual AAA Expo is widely attended by professionals from all sectors of the aftermarket.

The relationship between VACC and AAAA is better today than it once was. What do you put that down to?

It is. I think that’s due to a number of factors. VACC CEO, Geoff Gwilym and I meet regularly and that’s good from a leadership perspective. Collectively, our organisations supported the industry through challenging COVID-19 times; there was quite a bit of coordination in regards to messaging, to ensure communication was consistent. Now, with mandatory data sharing and actively working on an industrybased solution, there’s a much closer collaboration too. There are a lot of shared challenges and opportunities. We will be much stronger if we work collectively.

How can VACC and AAAA best work together for the betterment of the industry in future?

We have some big challenges – and when I say ‘we’ I mean across the industry.

Just look at skills issues, that’s not just an aftermarket or dealer issue – it’s across the board. Same with technological challenges. I think the level of information sharing and coordination in the industry has to change, simply because of technology. The future of the industry is very different to the vehicles we have worked on in the past. I think we need a change in thinking because the industry is changing, whether we like it or not.

When mass car manufacturing closed, AAAA and its members went through a transition.

We represent parts, manufacturers, distributors, retailers and so on, and the simple fact is that car manufacturers make very few of the parts that go on the vehicle – build or genuine accessories.

So, many of our members are originally equipment suppliers at an OEM build level and aftermarket level. It was certainly an adjustment for our members to transition away from supplying the local building industry. Many members were direct OE suppliers for Ford, Toyota, Holden and Mitsubishi. We were advocating on behalf of our OEM members, when the car industry was still here, and we certainly did advocate for ongoing government support during the transition. When the car companies made their decision (to leave Australia), we had to support our OEM members to transition to pure aftermarket. We also changed our focus from an advocacy point of view. We always advocated on behalf of our OEM members, supporting the local car industry, but we always made the point that the government support never extended to the independent aftermarket from a parts and accessory point of view. There’s huge potential for growth in that sector, domestically and internationally. Tell us about your auto innovation centres.

There are two centres. The main centre is in Melbourne at the Mulgrave head office, and then we have a satellite centre in Adelaide. Essentially, it’s about providing all the vehicles state of the art equipment and engineering expertise to centres of excellence, to help reduce the time and cost of the product development process and to lift the bar in terms of how we develop and integrate test products for fitment for vehicles. I’ll give an example. We’ve got the LandCruiser 300 series that was released prior to Christmas. Our members need those vehicles in order to develop products for them. You do that with 3D

scanning (and so on). Then you need the vehicle itself to be able to do prototyping and product testing. In the past, we’d probably have 200 to 300 companies that would be wanting to develop products for the vehicle. Independently, they would all have to access a vehicle, scan it, (then there’s) product tests and validation processes. That’s a lot of inefficiencies. Now, (with the centres,) we got the first delivered product, our engineers scanned every bit of it for the data library, and then the vehicle was reassembled. (At the moment) we are (now) doing dynamic testing with it. (So) all those companies can buy near OE level scanned data packages (that suit their needs). Now we have put the vehicle together, we are doing a collaborative project with the majority of suspension suppliers (too), (for a) gross vehicle mass upgrade package which will be federally approved. With the centres, we have a lot of capability to collectively support our industry. An important part of AAAA’s activities is in the event space. COVID-19 must have knocked the organisation around. Yes, it did. I think we were all (wondering) with a fair degree of dread (about) what was going to happen (back in March 2020). From my point of view, because we have got so much industry at a service delivery level –independent repairers that are mostly small, family-owned affairs without a lot of cash reserves – I thought this isn’t going to go well if we are going to have to close down for six months or 12 months. By and large (though), automotive was categorised as an essential service and so, in the most part, able to stay open – albeit with restrictions. (However), from an AAAA perspective, a lot of what we do from a service delivery point of view is bring people together. We had a convention scheduled for June 2020 in Brisbane; we

pushed it back to October before eventually having to cancel it. With our expo – 10,000 trade visitors, 300 exhibitors, a dinner for 900 people, a seminar program – it’s a massive event, and we just couldn’t do it. (So,) essentially we have had two years of not being able to run any major events. Fortunately, we had strong cash reserves, so we were able to ride out the storm and here we are on the other side. We have an amazing event (this month). Now, after two years, you are about to host the AAA Expo. How important is it for AAAA and the auto aftermarket?

It’s important to AAAA financially, but not just financially. I think reputationally, we have got – for the size of the market – one of the highest quality shows in the world. I travel to a lot of trade shows, and we’ve got a show we should be very proud of; it punches well above its weight. Trade shows are important in our industry, for a whole lot of reasons. We have such a diverse set of products across the industry that it’s impossible to get the trade to visit different manufacturers of different products. You physically can’t do it. (Instead) you need to bring all the products and the technical people to one place – and then bring the trade (to them). Trade shows are (also) important from an industry training, education and awareness point of view. Another thing – our industry loves and needs that networking opportunity. Many businesses, particularly at a retail level, are family-owned businesses. It can be quite isolating working on your own and only having your own staff to converse with (day-to-day). So, bringing people in and giving them the opportunity to share experiences is very important. It’s about bringing industry together every two years, under one roof. It’s an important show for the industry, not just AAAA. What’s new at this year’s expo. It will have all the major brands. We are 97 per cent sold out, which is pretty remarkable, given the last two years. I think that signals the importance our members and industry place in the show. We won’t have international pavilions this year. We’ve basically swapped them out for some new features. There is a Workshop of the Future pavilion, a dedicated space at the centre of the show. What we are doing here is creating a workshop environment. When we say ‘Workshop of the Future’, we’re not talking flying cars, we’re talking about what workshops need to do now to be able to prepare for what’s coming down the line. We’re looking at workshop management systems, customer experience, tooling and equipment – including programming. There will be a focus on electric and low emissions vehicles. So, what you need to set up an electric vehicle (EV) bay in your workshop in terms of equipment and training. Additionally, there will be

advanced driver-assistance systems and so on. (However), this isn’t just another pavilion filled with exhibitors and equipment, it’s going to be done in a very educational way. We aren’t pushing a particular product or service; we are trying to educate workshop owners on what’s coming and how to prepare for it. It’s all free of charge, everything at the show is free of charge for trade. We’ll have electric vehicles on the stand, and all the required equipment from a health and safety and standards perspective. We’ll be doing regular presentations over the course of three days, we’ll be bringing in (a variety of) presenters, and attendees can ask questions. It’s going to be a really popular feature and something that really makes a difference in this year’s show. The second new zone is (centred around) four-wheeldrive (FWD) innovation. So, we’re talking about the boom in the FWD sector, it’s about getting the best of the best in terms of FWD parts and accessory manufacturers – but with a trade focus. So, if you’re a workshop out there that’s been thinking about getting involved in either fitting or selling FWD parts, it’s an opportunity to talk to some of the manufacturers. We are going to be bringing in fleet buyers, through an alliance with the Fleet Managers Association, so we will have all the major fleet buyers coming through the show for our members. It really is about educating the industry on where the opportunities are in that growing FWD space, both at a recreational and consumer level, and at a fleet level. The fleet market in Australia is massive, over four million of the 20 million (vehicles) on Australian roads are owned and run by fleets, so there’s a real opportunity there. The other difference this year (and this change was based on past exhibitor feedback) is that we used to have a lot of seminars and other things in rooms away from the show floor. So, what we are doing this year is bringing a lot of activity to the show floor. We’ll have a dedicated stage and on the hour, there will be different activities – seminars, celebrity appearances, competitions and other demonstrations throughout the course of three days.

AAAA has worked hard lobbying government to bring about fair data sharing. As an aftermarket representative, why was that so important for your members?

The way vehicle technology is going, ultimately without full and fair access to repair and service information – and we are talking everything here, all the processes that are required to efficiently, safely and effectively repair and service a vehicle – without access, it was going to be death by a thousand cuts for the independent mechanical repair and service industry. With each new model year, there was more requirement for access to that information. We did a survey in 2016 that showed with one in 10 vehicles repairers were struggling to get access to information, and it was only going to get exponentially worse. (Without this agreement), independent repairers would have only been able to work on older vehicles and as those vehicles got retired from the fleet, the market would just have gotten narrower and narrower. AAAA could see that if something wasn’t done, it would ultimately spell the end of what we know as the independent mechanical repair industry. We’ve got a lot of linkages with international counterparts – so we knew exactly what was happening in Europe, in North America. So, we knew it was going to be a difficult path if we didn’t get (the agreement) in place. How many service and repair businesses does AAAA represent?

Directly, we’ve got about 3,000 independent repairer members. In terms of sites, we’ve got about 6,000 or 7,000. We predominantly have all the major chains. However, this (service and repair data) campaign wasn’t for our members only; it was for the entire industry. Our research shows there are about 26,000 independent repairer facilities out there, mobile and fixed sites. Every one of those is going to need access to information moving forward. Our supply base needs those businesses to be out there too.

The Australian Auto Aftermarket Expo brings in trade, industry and political figures, including Martin Pakula MP; The AASRA board - Stuart Charity, FCAI Director Emerging Technologies Rob Langridge, AAAA Director Government Relations & Advocacy Lesley Yates, MTAA CEO Richard Dudley (on screen), AADA COO Brian Savage, and VACC Industry Policy Advisor John Khoury - missing are AADA CEO James Voortman and FCAI CE Tony Weber; Charity, Rex Patrick and Luke Trsukinger at the satellite Auto Innovation Centre launch in Adelaide

Tell us about the new Australian Automotive Service and Repair Authority (AASRA) and what it will mean for independent repairers.

AASRA is actually a company, another association. Its directors are representatives from the Federal Chamber of Automotive Industries, Australian Automotive Dealer Association, Motor Trades Association of Australia and AAAA. Under the legislation the government has drafted up, this organisation has just been conferred scheme advisor status. That’s bureaucratic-speak for a pretty powerful role for administrating schemes. So, AASRA will provide a portal for all independent repairers, and dealer technicians are covered under the legislation as well. There are certain requirements that need to be met to access the information. AASRA will provide that portal into each of the car company’s data-sharing platforms and in

particular, where there’s security-related information – so if there’s any coding that needs to be done on vehicles – we need to make sure it’s only shared with people who have authorisation. (Additionally) the government has built in a requirement in the legislation to ensure anyone who is working on high voltage vehicles has undertaken basic safety training, a 10-hour training course to be able to de-power, work on and re-initialise vehicles. So, there will be a pre-requirement for basic level training before you get access to the EV high-voltage information. If there is any missing information, so if a repairer contacts an OEM and something they believe should be shared is withheld, or they can’t find it, they can log a missing information report with AASRA – which has all the direct contacts needed to follow it up. (Based on) experience overseas, 90 per cent of these cases are misunderstandings. However, in

the case of a formal dispute, AASRA will run a dispute and mediation service and report to the Australian Competition and Consumer Commission accordingly if required. There is also a role for AASRA to report back to the minister of the day on operations and any improvements required. There is flexibility to be able to make changes to the rules of the scheme as we go, so we can adapt to new technology. In terms of the infrastructure to support the security and safety-related information, AASRA has formed a commercial relationship with an organisation called the National Automotive Service Task Force (NASTF). NASTF US has been running almost the exact same scheme, albeit without the legislation behind them, and its executive director is going to be the interim Executive Officer of NASTF Australia. At the moment AASRA is actively working with 37 car brands – representing 90 per cent of the new car sales in Australia – to effectively onboard them on the platform for a 1 July launch. Exciting times, it’s a complex process but AASRA will be the window into full dealer-level data sharing for all repair and service operators.

What’s the best life advice you have received?

Don’t let anyone tell you that something can’t be done. I think almost anything is possible if you’ve got the will to make it happen. Nothing happens without hard work; you’ve got to have determination and tenacity, and if you believe in something enough it will happen. I live my life by that, and I have applied that to the mandatory data-sharing project. When we initially launched it, people thought I was coming from Mars and to see it now only a few months away from being a reality, you pinch yourself.

Stuart Charity opening the Auto Innovation Centre in Victoria. Below, from left:

Building buses is not what it used to be. Neither is powering them.

WORDS Paul Tuzson

MANY consider the new Victorian distance tax on electric vehicles an outrage that will hinder the adoption of this important technology. On the other hand the government is doing other things to accelerate the adoption of emissions free transport. One example is the $2.3 billion contract awarded to national bus operator Kinetic last year to bring electric buses into service across the Metropolitan Bus Franchise. The contract runs until 2030 and will fund the introduction of hundreds of plugin battery and hybrid buses to routes currently served by diesel powered units. Thirty-six of these will be in service by 2025. Importantly, the bus bodies will be built locally by Volgren at its Dandenong South plant.

Other bus companies are also adopting electric buses and Melbourne operator Ventura is

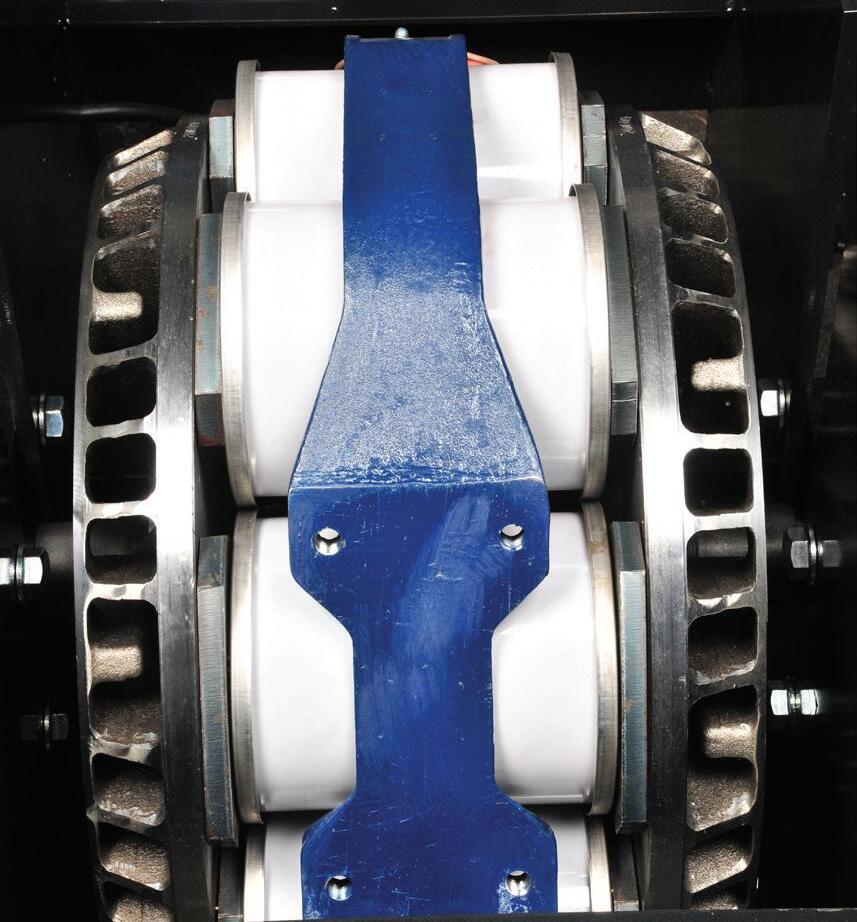

currently trialing a Volgren bodied battery electric bus out of its Ivanhoe depot. This, and other programmes around the country, all constitute the thin end of the wedge. What’s more, the opportunity for expansion in this transport industry segment is so great we’re going to be at the thin end of the wedge for years to come. Buses are subject to stresses similar to those in cars, only more so. Because they’re so long Z-axis bending, lateral bending and torsional twisting are all more pronounced than they are in cars. Monocoque construction isn’t an option for something as long as a bus with flat sides and a long roof line. This means a body built on a steel chassis is necessary, as with virtually all larger commercial vehicles. Volgren, as a bus body builder, works in partnership with the main global chassis OEMs. Volgren imports the chassis used in its electric buses. These are specialised units from BYD designed and built around electric hub motors and support components for them like inverters, controllers and batteries. The batteries in these buses are mounted on the roof, but more on batteries shortly.

Hub motors aren’t really suitable for cars because they contribute to unsprung weight, which is highly detrimental to handling. This is not such an issue in buses because they aren’t subjected to high speed cornering and other demands that require the nimble responses of a car. So, setting the electric motors in the wheels is an excellent choice for a bus. Doing so eliminates the need for mechanical transfer hardware like drive shafts and differentials resulting in less weight and reduced servicing requirements. Weight is an important consideration in any vehicle but particularly so in battery electric vehicles like these buses. Less weight means greater range from each charge. In turn, this means longer runs that can be a greater distance from charging stations at company depots. Given buses make regular stops at predicted locations, there are some quick charge options appearing in Europe that are of interest. At some stops, roof located arms (pantographs) are extended to couple with quick charge outlets that can push a significant charge into battery packs to extend range. The first of these flash charging pantographs

in Australia is being constructed right now as part of the $1.244 billion Brisbane Metro Project. Swiss company, HESS won the contract to deliver 60 biarticualted, 25-metre electric vehicles and work with charging partner Hitachi. HESS also offers a unique technology for bus construction called Co-Bolt. Volgren, who are responsible for two out of every three route bus bodies in Melbourne, has used this technology in the body construction since 1977. It’s a system of aluminium C-formed extrusions joined by cast corner pieces and clamping plates held in place with bolts. Importantly, welding is not required with the Co-Bolt system. Bolts may not seem like the ideal joiners for vehicles due to NVH concerns but the bolts in this system are fitted and held firmly in place using a two-part adhesive that prevents them from coming loose due to the rigours of operating stresses. Despite this, they are readily removable if necessary. No welds also means no cracks.

The exterior panels of buses built using the Co-Bolt system couple with the frame fairly simply. They are made to be easily removable in case of damage. Removing and replacing a plain side panel is said to take only a couple of minutes and hinged access panel replacement takes just five minutes according to HESS. The Co-Bolt system has been extensively tested and used to construct more than 20,000 bus bodies worldwide. As you’d expect, crash, roll-over and stress tests are among those that various authorities have imposed on the system. In fact, aluminium demonstrates very good energy absorption in crash tests and doesn’t suffer from corrosion like steel. Also, in keeping with environmental concerns, aluminium is completely recyclable. These days mention of anything battery electric brings to mind Li-ion batteries. Li-ion is a generic term covering batteries that use a number of different materials.

Volgren uses Lithium Iron Phosphate (LiFePO4 or abbreviated - LFP) types. These are becoming increasingly popular. LFP is a type of Li-ion battery but with its own particular chemistry.

Volgren makes buses for operators right around