LET’S TALK INSULATION

In association with

To find out why, scan the QR code:

In association with

To find out why, scan the QR code:

In this issue of Let’s Talk Insulation and Acoustics we focus on some of the practicalities of working within a new regulation landscape and the industry’s move towards net zero and future proofing the built environment.

The findings from the Phase Two report of the Grenfell Tower Inquiry revealed truly shocking details.

Dame Judith Hackitt, known for her Independent Review of Building Regulations and Fire Safety commissioned by the Government following the Grenfell Tower Fire, has spearheaded campaigns to bring about culture change.

She has focused on areas such as competence and accountability, wider lessons for the Industry, professional standards and accreditation and enhanced fire safety regulations and accountability.

As a leader in the built industry, Dame Judith urges professionals to make and stand by their expert decisions. In a recent interview with SFG20 she said: “You can delegate the work, but you can never delegate the accountability” and urges professionals to make and stand by their expert decisions.

She continued: “I think one of the key issues here is ensuring the competence of the people you engage. That's not a completely unfamiliar concept. In many areas of our broader health and safety regime, anyone performing high-risk tasks in industry, particularly the duty holder or accountable person, is required to ensure they employ someone competent to do the job.

“For me, that’s where this all begins: making sure you're using people who know what they're doing, ask them to demonstrate and prove their competence.

“What's also linked to this is the need to ensure that the products used in both maintaining and constructing buildings are properly assured as well.

“One of the significant gaps we still need to address, and which the government has

committed to resolving in its response to the inquiry, is the issue of construction products and how they are tested. I believe this is critically important.”

As regards the principle of the golden thread, which means that building information management should be structured, traceable, accurate, and held digitally, Dame Judith is adamant this needs to be adopted more widely.

“I find it quite extraordinary, the extent to which this sector, which we call the built environment (though whether that's the best definition is debatable), lacks proper record-keeping and stored information,” she added.

“Not just about what was built, but how it was built, what its limitations are, what the fire strategy is, what the design philosophy behind the building was, and so on. I just

find it remarkable that this information often doesn’t exist. In any other sector, whether it's chemicals, which is where I came from, or manufacturing in general, they can trace everything. They know the limitations of their products, how things perform, and what they’re capable of. ”

“So it’s absolutely a case of catching up with what we all assumed was happening, but in fact, wasn’t. And if we’re going to do that in the 21st century, for goodness’ sake, let’s not do it on paper. Let’s do it digitally.”

Paul Groves || Group Editor

The government-backed Net Zero Week was a timely opportunity to reflect on the current status with regard to improving the energy efficiency of buildings. The message from IMA remains clear - we must get the basics right first if we want to remain on track towards the UK’s 2050 carbon neutral target.

The pledge to build 1.5 million ‘safe and decent homes’ during this parliament and recent relaunch of the Net Zero Council has seen a renewed focus on housing delivery.

Whilst there is little confidence this housing target will be achieved, every ambition must be balanced with an emphasis on quality. We cannot afford to add properties to the future retrofit challenge by building homes that will require substantial retrofitting and refurbishment in the coming decades.

We have long advocated the need for a fabric first approach on the way to meet the binding net zero 2050 targets but too often there are conflicting views that mistakenly believe fabric first can be bypassed in favour of heat pumps and renewables. This top-down, technologyfirst approach will result in homes that will

underperform and use more energy than necessary. If we are serious about achieving net zero, new builds must be built to the highest possible standard and that starts with getting the insulation right.

Proprietary work must be done to ensure a property is geared up to receive these heating systems, so they are able to operate efficiently. There is no point installing heat pumps and solar panels in buildings that leak and underperform.

By reducing the total energy demand of a building, the heat pump performance will be maximised, which in turn will reduce capital and running costs. Only when energy demands are reduced to a low level, is it possible to service those demands in the most efficient way. It is important not to add undue burdens through

the running costs of renewables such as heat pumps.

Fabric first is a low-tech, ‘fit and forget’ solution that homeowners or occupiers will appreciate without even realising it, as the thermal performance is an inherent part of the building fabric throughout the life of the building. By concentrating initially on delivering a high standard fabric-first solution, heat pumps and other renewables can then be introduced successfully.

The net zero challenge does not stop with new homes. We must also deal with the multitude of existing buildings with poor energy-efficiency, including nearly 30 million existing homes across the social, owner occupier and private rented sectors, many of which require substantial improvements to enhance their energy performance.

Tackling these buildings is not just about applying superficial changes, but about undertaking deep and comprehensive retrofits that address insulation, heating systems, and overall energy efficiency.

Time is not on our side and so we must address the first line of defence with an improved and thermally efficient building fabric to ensure homes are resilient to the changing climate and ensuring the promised benefits of other energy saving measures are achieved. As Net Zero Week reminds us, the road to 2050 starts with the choices we make today and that route begins with getting the building fabric right.

The relaunch of the Net Zero Council and the housing minister’s renewed commitment to large-scale housing delivery is an encouraging sign for the construction sector.

In parallel with the Net Zero Council’s efforts, the Housing Minister’s recent focus on large-scale housing development is another step forward. While Matthew Pennycook’s announcement of the government’s support for the New Towns Taskforce and the New Homes Accelerator is a promising sign, it is imperative that this ambition is balanced with an emphasis on quality, not just quantity.

The push for more homes is undoubtedly important but we cannot afford to add properties to the future retrofit challenge by building homes that will require substantial retrofitting and refurbishment in the coming decades. This is like buying a brand new car with a 20 year old engine and is completely unacceptable. New housing must not cut corners on performance — it should be built to high standards from the start, otherwise we will end up revisiting these same homes for another round of upgrades.

More importantly, we need robust inspection processes in place to guarantee compliance with net zero regulations. Holding housebuilders accountable is essential. Builders should no longer be allowed to cut corners or deliver homes that will need to be refurbished before 2050. We need stricter regulations, and we need to make sure they are followed.

As we look to the future, it’s critical that we close the performance gap by tightening regulations and ensuring that all new developments meet the highest standards of energy efficiency from day one.

Furthermore, regulators must have the tools and the authority to enforce these standards, even dening the ability to sell these homes if they are not compliant. Creating high-performance homes and reducing energy demand now will

save us from expensive problems later and propel us towards our net-zero goals.

A clear, consistent, and enforceable policy framework is necessary for the housing sector to have the confidence to invest and innovate. We are at a critical juncture, and if we are to meet our climate goals and deliver on the promises made to future generations, we must act with urgency, transparency, and resolve.

The industry is ready to rise to the challenge. Now it’s time for government to show that it is, too. Only by closing the performance gap and ensuring that the homes we build today are the energyefficient, sustainable homes of tomorrow will we achieve the net zero future we all strive for.

Let’s make sure we’re not just talking about progress, but delivering it.

With the goal of developing high-quality housing, developers and specifiers have been rightly focused on acquiring materials that meet rigorous standards of design, quality, safety and, above all, sustainability. But what if one of the biggest threats to a building’s performance was hiding in a hidden space of the dwelling?

That often over-looked detail is the eaves junction; the triangular joint found between the pitched roof and cavity wall. Historically, the eaves has been a challenge for installers to insulate due to the nature of its inaccessible shape, often resulting in cold spots.

Traditional methods of insulating the eaves have often led to the space being blindly stuffed with product, leading to either over or under compression. Inadequate insulation can cause thermal bridging and cold spots, creating the perfect environment for damp and mould growth. Whereas excessive insulation can compromise the necessary ventilation, once again resulting in the formation of damp, followed by mould.

But damp and mould growth in buildings typically leads to a significant number of issues, from costly remediation work to negative impacts on the health and wellbeing of occupants. To prevent this, it’s vital the precise requirements are met when insulating the eaves. Current regulations state new-build homes are required to meet a roof and loft U-value of 0.16 W/m²K and existing homes

must meet 0.18 W/m²K. But when using traditional loft roll insulation, it can be difficult to achieve a continuous layer across the building’s fabric.

Recognising the seriousness of this issue, ARC Building Solutions has developed the awardwinning* Eaves Insulator, a simple yet highly effective product that addresses both insulation and ventilation in one product.

ARC Eaves Insulator consists of a specifically shaped insulation layer for the eaves and an integrated ventilation tray with an opening of 10,000 mm²/m. Together, both features directly tackle heat loss through the wall plate junction by up to 49% when compared to traditional loft insulation, improving the thermal efficiency of a home while maintaining an open pathway for airflow.

The Eaves Insulator is designed to be installed much like a standard eaves tray: fast and tool-free, removing any guesswork from a traditionally fiddly job. And its effective design ensures a precise, consistent fit that removes any performance risks associated with human error. There is also a retrofit variant available.

And now with Part L Building Regulations requiring on-site audits and photographic evidence of insulation, which includes the eaves, getting this detail right isn’t optional; it’s mandatory. The Eaves Insulator’s distinctive design makes evidence that the eaves area is filled easy to see, while printed guidance on the product itself helps ensure correct installation, even by less experienced installers. This is particularly valuable in the context of a growing construction skills shortage, where ease of use and efficiency is essential.

Already trusted by major housebuilders, the ARC Eaves Insulator’s ease of installation, robust compliance credentials, and proven performance has made it the first choice for specifiers looking to improve build quality, reduce future build-quality issues, and meet the growing demand for more sustainable, energyefficient homes. Sometimes it’s the smallest details that make the biggest difference.

*Best Site Product and Product of the Year, 2019 Housebuilder Awards

Speak to one of ARC's technical experts today. Email: technical@arcbuildingsolutions.co.uk Phone: 0113 252 9428

ARC Building Solutions – Enquiry 3

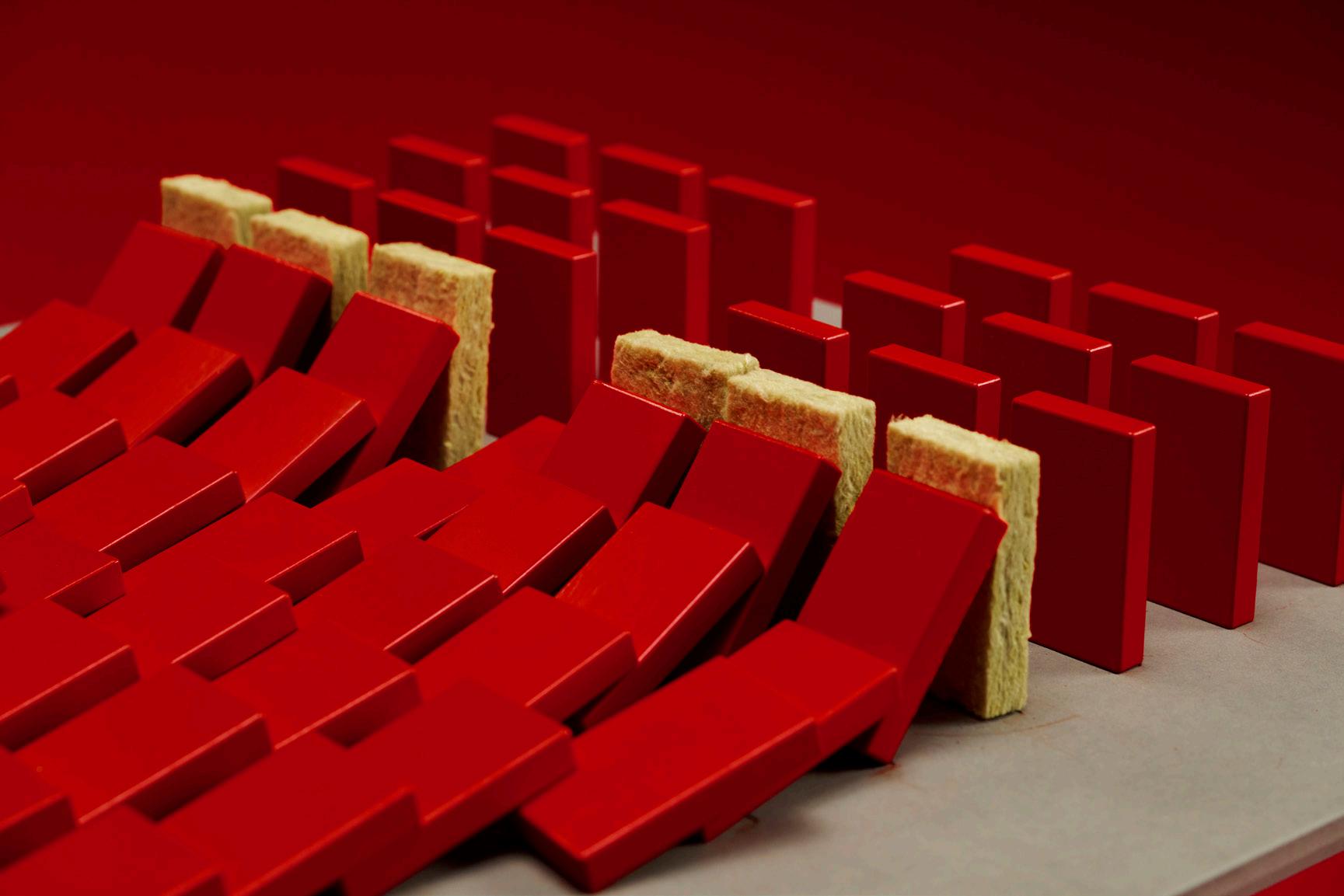

When it comes to designing buildings, your choice of materials matters. It goes beyond simply meeting regulatory requirements –it’s about selecting solutions that improve health and safety, support long-term building performance, and increase occupant comfort. ROCKWOOL stone wool insulation can help in achieving these objectives. Here’s how:

Thermal performance for year-round comfort

Meet and exceed your thermal targets with an insulation specification that supports year-round comfort. By specifying thermally-efficient ROCKWOOL® stone wool insulation, your selection slows the transfer of heat between the inside and outside of a building, helping to create more comfortable and healthier indoor spaces which can help reduce heating and cooling costs.

Improved acoustics for a quieter, healthier environment

Think further than thermal comfort – use your specification to improve acoustics and enhance wellbeing.¹ Evidence shows that reducing unwanted noise can support patient recovery in healthcare environments, improve concentration in schools, and improve people’s overall health and wellbeing.

You can harness this benefit by specifying ROCKWOOL stone wool insulation, which comprises thousands of tiny air pockets to trap and absorb sound waves – reducing noise levels within rooms or minimising sound transfer through walls and floors.

Built-in fire resilience

You play an essential role in designing buildings that inspire confidence and feel safe. One way you can build fire resilience in at design level, and clearly communicate these safety benefits to clients and

occupants, is to select non-combustible construction materials throughout the fabric of the building. When it comes to insulation, ROCKWOOL stone wool offers clear performance benefits towards fire resilience.

Non-combustible by nature, ROCKWOOL stone wool provides built-in fire resilience that is not dependent on chemical flame retardants. It can withstand temperatures in excess of 1000°C and, if exposed to flames, will not fuel or spread a fire nor contribute significant amounts of toxic smoke.

Moisture control for healthier spaces

Moisture is another serious specification consideration. In the wake of Awaab’s Law and the renewed scrutiny of damp and mould in residential settings, you may consider taking a fabric-first approach to improve moisture management for health and wellbeing.²

ROCKWOOL stone wool is non-hygroscopic and moisture-repellent, meaning it doesn't attract or absorb moisture from the surrounding environment. It’s also vapour-resistant, which helps prevent the build-up of mould, mildew and rot – contributing to a healthier indoor environment over time.

Performance that lasts

You're designing for the future - schools, homes, and workplaces that must perform for generations. To give you the

long-lasting capabilities you need,

ROCKWOOL stone wool is highly durable and long-lasting. Tests of our stone wool recovered from old buildings have shown that it retains its performance characteristics – thermal, mechanical, fire resistance – for at least 50 years, and probably longer. A test of a 65-year-old stone wool sample found in 2023 during a renovation of Copenhagen airport showed that these characteristics had not diminished after 65 years.³

Show your sustainability credentials

Finally, you can be confident you’re working with a manufacturer that is helping to overcome complex global sustainability challenges with products that are inspired by nature. ROCKWOOL stone wool is made primarily from volcanic stone, one of the world’s most abundant raw materials. It’s also endlessly recyclable with no loss in its performance properties, contributing to a circular construction economy.

ROCKWOOL stone wool insulation helps you enrich modern living by harnessing the natural power of stone. It’s why your specification is about more than just materials – it’s about creating safe and enjoyable environments that meet today’s needs, and tomorrow’s goals.

It’s a serious commitment we’ll help you to achieve. To learn more about the capabilities of our stone wool insulation, visit:

rockwool.link/specification-aug25

External wall insulation systems are widely used throughout the UK construction industry both in the highly effective thermal upgrade of existing buildings (especially solid wall, hard to treat and non-traditional buildings) and as a method of constructing thermally efficient new buildings across all sectors of the market.

INCA, the recognised trade association for the external wall insulation (EWI) industry in the UK, have published findings of their industry survey which reveals the size and split of the market for the calendar year 2024.

The industry commissioned survey was undertaken by NEMS Market Research on behalf of INCA and targeted all main system manufacturers with a near 100% participation rate reported. It follows on from a similar survey in 2024, the first for many years, and confirmed the over-all size in monetary terms and corrected a discrepancy in terms of total volume by square metres.

Considering significant variations in the cost of the different systems and finishes along with different types and thicknesses of insulation incorporated within the systems, the findings revealed a total of 4,396,661 square metres of EWI was installed in the UK during 2024 on projects across all sectors of the market.

The refurbishment (retrofit) sector (often supported by government funding measures) accounted for 2,912,216 square meters (66.2%) of this total. The forecast sector growth for 2024 didn’t materialise with most contributors reporting funding delays and labour capacity being the main causes. However, 88% of

participants forecast solid growth in 2025 with the majority expecting this growth to lie within the 10% to 20% range but stress that this is entirely dependent on Government initiatives and funding streams.

Perhaps unsurprisingly mineral fibre remained the most popular choice of insulant in 2024 – regulations mandate its use on high rise buildings and in the installation of fire breaks / fire barriers. Some 2,268,659 square metres was installed in 2024 representing 51.6% of the EWI market. Contributors are predicting the split to widen significantly in 2025 with mineral fibre becoming the choice

of insulant of key industry players and as BSR delayed high rise works (mandating the use of mineral fibre) start to filter through – particularly across the new build and cladding remediation sectors.

Other insulations (extruded polystyrene, PIR, wood fibre etc) lost share marginally and accounted for the remaining 210,481 square metres, 4.8% of the over-all market.

Specialist renders remain the main decorative finish of choice, being incorporated within 81.2% of systems and representing a total of 3,568,325 square metres in 2024.

These come in a wide variety of different materials, thicknesses, colours and textures and the number includes those which incorporate an additional dash aggregate within the overall finish and those projects where render is used to create the effect of stone / brickwork. Brick slips (clay or lightweight brick effect

systems), stonework and tiles accounted for the remaining 18.8% of the market –some 828,336 square metres.

John Sparrow, Executive Director at INCA said: “Coming at a time when we have such a clear focus on competence, training and the development of a new industry apprenticeship scheme we regard the results to be of particular importance to better evidence the need to attract new blood into the EWI industry and support our efforts to facilitate this.

“We would like to thank all our system designer membership and close industry partners for their input, support and contribution.”

Mark Weaver, Chair of INCA said: “Whilst the numbers demonstrate that the industry is delivering well at current levels, they also highlight the scale of the opportunity on the horizon as the Government looks to ramp up its retrofit program to deliver on net zero targets. The data also

highlights the significant potential within the new-build sector and the cladding remediation sector – we have a real opportunity to grow our share of the market through innovation and greater awareness of the commercial and environmental benefits of EWI.

“In turn this justifies the efforts INCA are making to address any skills shortage, not just by way of promoting the industry, but directly in relation to training and upskilling.

“We currently spearhead the steering group tasked with defining and mapping out a route to EWI competence (now at implementation stage), we are also finalising the agreement for a new Specialist Applied Skills Program (SAP) in EWI for Wales, supporting on the employer group commissioned to deliver the EWI pathway of a new apprenticeship by the end of 2025 and collaborating with colleges and training facilities across the UK in support of multiple regional and national training and upskilling initiatives.”

Key findings:

• 4.4 million square metres of EWI was installed onto buildings across the UK in 2024

• 66% of this went into the refurbishment of homes and buildings

• 22% into new build construction

• 12% into the cladding remediation market

• Mineral fibre insulation was, at 52%, the main insulant used with expanded polystyrene (EPS) making up 43% of the market (low rise only) and other insulants accounting for the remaining 5%

• Various types of specialist render proved by far the most popular finish and were incorporated within 81% of systems. Brick slips (and similar) decorative finishes accounted for the remaining 19%

INCA – Enquiry 19

When we talk about improving thermal performance and insulation, the conversation usually starts – and often ends – with façades.

Architects and specifiers are now wellversed in selecting non-combustible external wall systems to meet the latest Building Regulations on properties over 11 metres in height, but there’s a critical zone that has long been overlooked: what happens below the damp proof course (DPC) and at the base of the system on balconies and walkways.

Updated UK Building Regulations require that materials used on buildings over 11 metres achieve a minimum A2-s1,d0 fire classification. While this has driven innovation in façade insulation, the treatments used at ground level – around plant rooms, walkways, balconies and below the DPC – have typically remained disconnected, untested, and in many cases reliant on combustible coatings such as bitumen.

This creates a gap in performance and compliance. A building envelope is only as strong as its weakest point, and if the base of the system is not fire-tested to the same standards as façades, can we really say the full building envelope is safe?

That’s the challenge addressed by SOQEL A2, the UK’s first fully fire-tested external wall insulation (EWI) system designed specifically for use below the DPC. Developed by Wetherby Wall Systems, part of the ROCKWOOL Group, in collaboration with HECK in Germany, SOQEL A2 brings continuity to insulation design –extending fire-safe performance all the way down to the ground.

The system uses Coverrock X2 insulation with a durable factory-applied coating that protects its A1-rated stone wool core during installation and improves adhesion for finishing layers. Reinforced with Heck K+A SL basecoat and Heck CER Mesh, SOQEL A2 is engineered for lasting durability, resisting moisture and weather extremes at the most exposed part of the building envelope.

The SOQEL A2 system also provides increased impact resistance, achieving up to 60 joules in comparison with the 10 joules required by standard façade system testing. In areas likely to suffer impact damage from foot traffic, bins, or heavy objects, this represents a significant improvement to the system in a zone that needs robust protection.

One of the barriers to specifying robust below-DPC solutions has been aesthetics.

Traditional treatments can compromise the visual continuity at the base of the system, breaking the clean lines of a façade. SOQEL A2 solves this by integrating Heck 4S Silicone Render, which can be colour-matched to the upper façade finish. The result is a seamless, unified appearance that doesn’t compromise fire performance.

By extending tested fire performance to ground level, SOQEL A2 addresses a blind spot in current practice. As Joe Ragdale, Technical Director at Wetherby Wall Systems, explains:

“SOQEL A2 is the first system of its kind to undergo full fire testing for below DPC use. It’s a major step forward in ensuring fire safety compliance across the entire building envelope.”

For specifiers, this marks an important shift. Building safety isn’t just about façades – it’s about continuity, durability, and integrity from the ground up. With SOQEL A2, that safety gap has finally been closed.

Wetherby Wall Systems – Enquiry 5

When it comes to cavity width, size really does

matter.

Building with a 150mm cavity wall gives you the freedom to choose from a broader range of insulation and find the right product for your build.

Why limit yourself?

Enquiry 6

Go bigger, with 150mm cavities and DriTherm® Cavity Slab 32.

Thermal breaks in external wall systems play a pivotal role in meeting the revised Building Safety Act 2022. Professional design input is a vital part of this process.

Following the Grenfell tragedy and the subsequent Hackett Review, The Building (Amendment) Regulations were introduced in December 2018. These set out restrictions on the combustibility criteria of ‘specified attachments’ forming part of the external wall.

For example, balconies, solar panels or solar shading, attached to the external wall of a ‘relevant building’ in England (over 18m above ground level, or seven storeys). Now, the Building Safety Act 2022 further reforms building safety regulation and has also introduced a Building Safety Regulator; whose primary goal is to improve the design, construction and management of higher-risk ‘relevant’ buildings.

Designers play a critical role in this new regime

At Schöck, we understand the increasingly critical role designers now have. Ensuring the safety and compliance of building projects is of course a given, but the avoidance of unecessary delays by resolving possible issues early on and minimising the need for late-stage changes is also pivotal. That is why we are delighted to offer complimentary design support services, allowing specifiers to create seamless, compliant, and efficient thermal break solutions with confidence. Whether you're working on connecting balconies, canopies, or solar shading, our thermal breaks provide exemplary loadbearing insulation solutions.

How does the Isokorb range comply with the Amended Regulations?

In part 7(3) of Approved Document B in the Amended Regulations there is a list of materials exempt from the restrictions, which includes thermal breaks. Because Schöck Isokorb thermal breaks form part of the external wall, it is critical that they comply with the Amended Regulations. The Isokorb uses thermal insulation material to improve thermal performance (verified to meet the requirement of Part L by independent thermal testing from Oxford Brooks University) and consequently they are exempt according to the amended regulations.

What makes Schöck thermal breaks so effective in meeting Part L?

The quality of the components used in their construction guarantee superior thermal performance. Stainless steel (in the thermal zone) is used for its greatly reduced thermal conductivity when compared with carbon steel. The HTE (High-performance Thermal Element) module used is a concrete thrust bearing designed to both transmit compressive forces and optimise thermal

conductivity. When Neopor®, an expanded polystyrene (EPS) insulation with superior thermal performance, is used together with the HTE module, thermal bridging is almost entirely eradicated.

Design of the Isokorb range addresses key safety requirements

The Building Safety Act emphasises the importance of using tested and certified components in safety-critical systems. Substituting specified products, such as thermal breaks, without ensuring compliance and suitability, could breach the regulations, leading to significant liability risks. The Isokorb range exceeds the demands of the Building Safety Act by addressing key issues such as: BBA Agrément Certified to exceed fire resistance standards

(REI120); helps mitigate fire spread risk as required by the Act for use in high-risk residential buildings – and provides critical documentation (including design calculations) to support the ‘golden thread’ of safety information.

We would be delighted to partner with you and ensure your BSA projects not only meet, but exceed, safety and thermal performance standards.

To leverage our expertise and create a robust engineering solution for your next project connect with us at bsa@schoeck.com or visit our website for more details –www.schoeck.com/en-gb/isokorb

Schöck – Enquiry 7

Fassa complete work on £6.2M specialist residence in Ullenwood

Fassa Bortolo lend rendering expertise to introduce a new accommodation block for a specialist residence for young people with complex needs.

Leading Italian render manufacturer, Fassa Bortolo, has recently completed work on ‘National Star’ a £6.2M specialist residence in Ullenwood, for young people with complex needs and learning disabilities.

Specified in collaboration with Fassa’s National Specification Manager and Richard Moores from Coombes Everitt Architects, this high specification project demanded precision to ensure flawless facilities, to further support the brilliance of students and residents. Alongside this, the requirements of Speller Metcalfe and Coombes Everritt, meant a cost-effective design solution with a warranty and third party certification was required.

Fassatherm Wood® system certified by the ETA

Utilises A 96 adhesive along with mineral wool insulation

RSR 421 silicone resin top coat

Spanning an area of 430 square metres, this project was executed utilising our esteemed Fassatherm system, renowned for its efficiency in External Wall Insulation (EWI) applications onto timber frames. The process commenced with the application of our proprietary A 96 adhesive, facilitating the affixation of the mineral wool insulation panels. The sequential procedure culminated with the application of FS 412 as a primer, before our final embellishment of RSR 421 silicone resin top coat, imparting both protective and decorative attributes to the system.

Our client, Speller Metcalfe commented, “We had a number of design issues with the External Render System on the project. By engaging with Fassa at an early stage and having on site meetings to review the spec and drawings, Fassa were able to come up with a design solution which was practical, saved time and money”.

TO FIND OUT MORE about Fassa Bortolo and its range of render systems and building products. Visit www.fassabortolo.co.uk or call 01684 218 305

MIMA has published a detailed discussion paper making seven recommendations for UK policy and industry standards, geared towards building strong consumer trust and confidence in home retrofit as we transition to Net Zero.

The MIMA paper also discusses insulation’s important role within our framework and within the context of the electrification of home heating.

To ‘take people with us’ on this transition, the insulation, energy efficiency, and clean heat sectors need to work closely together to ensure we achieve reliably good, proven outcomes for customers when retrofitting their homes.

If we, as an industry, can commit to checking, verifying, and increasingly guaranteeing aspects of building performance as the housing stock is decarbonised, we take many of the real or perceived risks of the transition off the shoulders of householders and onto ourselves. We can better assure customers of a positive retrofit experience and a great outcome, ensuring the energy savings and emissions reductions aimed for are realised, and people’s homes are comfortable, healthy, and safe to live in.

To achieve these goals, MIMA is calling for policy and standards to evolve so that by 2030:

• Measuring key aspects of home energy performance has become the norm. Underpinned by three ‘Ms’: measurement, metering, and monitoring of home energy performance, all UK households getting a home fabric and/or clean heat upgrade should be able to opt for a service from their Retrofit Provider which includes checks of the actual performance of the fabric and clean heating system, pre- and/ or post retrofit as appropriate, using accredited methods, technologies, and forms of monitoring.

• An ever-growing number of households can benefit from ‘Outcomes-Based Guarantees’. Fabric upgrades and clean heating systems working together in homes, alongside widespread and routine checks of their in-use performance, will enable and encourage more Retrofit Providers to innovate with market offerings we are calling Outcomes-Based Guarantees. These are optional contracts with customers whose terms assure or guarantee certain outcomes from a home upgrade, such as a specified, minimum heating system efficiency or agreed energy saving in kWh.

Sarah Kostense-Winterton, MIMA’s Executive Director comments, “MIMA’s vision is for every household getting their home’s fabric or heating system upgraded to be offered a form of Outcomes-Based Guarantee from their Retrofit Provider. An assurance and proof the retrofit work "does what it says on the tin." Fortunately, we are now in an era where an increasing number of relatively

low-cost, low disruption technologies and methods exist to measure how homes perform in terms of their heat demand, energy use, and emissions.

“Making such testing routine not only drives the development of new Outcomes-Based Guarantees, but means Retrofit Providers and their customers no longer need to rely solely on modelled performance estimates which can differ significantly to measured results.

“MIMA is calling for such outcomes-focused targets and policies to be woven into the very fabric of the Warm Homes Plan, helping to de-risk the journey to low energy, low emissions homes, for the consumer and for the Government.”

Fresh approach required

A new literature review from the National Retrofit Hub, supported by The MCS Foundation, calls for a broader, more realistic understanding of how resident demand for home energy upgrades is formed and why it often fails to take hold.

The Driving Uptake Literature Review brings together existing insight into what influences resident decision-making, highlighting the emotional, financial and practical barriers that prevent people from taking action.

It challenges the idea that demand is just about making a choice in the moment. Instead, it shows that a series of conditions must be in place before someone is ready to act. Despite the clear benefits of retrofit, including improved comfort, better health and lower energy bills, uptake remains low.

In 2024, fewer than 60,000 heat pumps were installed according to MCS data, well short of the Government’s 600,000-a-year target. And while many households could benefit, only two in five homeowners are considering improvements.

“We need to stop thinking of demand as something that appears at the point of sale,” said Rachael Owens, Co-director at the National Retrofit Hub. “It builds slowly and often invisibly. If we want to support people to take that step, we need to pay more attention to everything that leads up to it.”

Garry Felgate, Chief Executive of The MCS Foundation, said, “The transition to carbon-free and energy-efficient homes must be one that has people at its heart.

“We know that the technology to provide warm, low-carbon and affordable homes already exists, the challenge now is generating public understanding and trust so that households are prepared to make the transition.”

Mineral Wool Insulation Manufacturers Association – Enquiry 20

The new £33m National Quantum Computing Centre (NQCC) in Harwell, Oxfordshire, is a landmark laboratory created to drive quantum technologies for the future. Not only is the facility state-of-the-art in terms of technology but also in design.

Rated BREEAM Excellent, architects Hawkins\Brown has conceived a dynamic and versatile work environment designed to deliver transformative results.

At the building’s heart are non-laboratory spaces full of open-plan areas for collaborative working, interaction and innovation.

To control sound reverberation from the open areas and hard surfaces, Troldtekt’s wood

wool acoustic panels were specified as floating clouds above the open break-out spaces and within the meeting rooms. These effectively maintain acoustic levels, leading to a more productive environment and promoting a healthy indoor climate.

Troldtekt’s wood wool acoustic panels are Cradle to Cradle Certified® at Gold level and manufactured using wood from certified forests (PEFC/09-31-030 and FSC®C115450), positively contributing to a building’s BREEAM, WELL or LEED points. Panels can also be manufactured with FUTURECEM® which achieves an approx. 30 per cent lower carbon footprint than that of Troldtekt based on white cement. Depending on the panel specified, reaction to fire is classed in accordance with EN 13501 as B-s1,d0 or A2s1,d0 respectively.

Available in a wide variety of different structures and colours, they combine optimal sound absorption with an award-winning

design. The Troldtekt range has a minimum expected life cycle of 50 years coupled with excellent resistance to humidity and tested to meet ball impact standards.

Troldtekt – Enquiry 9

SOPREMA Tecsound Tecsound SY Tecsound FT

accoustic membranes deliver proven sound insulation without sacrificing space.

Maximum efficiency with minimal space requirements

Versatile – Suitable for multiple applications

Easy to install

Proven quality and reliability

WWW.SOPREMA.CO.UK E: techsupport@soprema.co.uk

Installers are often faced with the challenge of maintaining fire barrier integrity when passing services through raised access floors. AIM – Acoustic & Insulation Manufacturing’s new technical solution combines its Raised Access Floor Barrier (RAFB) with Rockwool Ablative Batts to provide a tested, cost-effective solution.

RAFBs prevent the passage of flame and smoke through underfloor cavities for at least the period of fire rating specified. The AIM RAFB is used to subdivide large uninterrupted cavities, maintain partition fire ratings when aligned under a partition, reduce flanking transmission of sound through underfloor voids and create plenum chambers.

However, passing services, including cable trays and pipes, through the RAFB can compromise the barrier’s vital primary function if not completed in line with the manufacturer’s standard tested details.

Now, AIM provides installers, specifiers, fire consultants and RAF system holders with a solution. When penetration is required to pass services through the AIM RAFB, two Rockwool FirePro® Coated Batts, the same height as the AIM RAFB, are placed on either side of the barrier.

The services are passed through both the RAFB and ablative batts with any small gaps around the penetrating component filled with Rockwool FirePro® Acoustic Sealant, pipe sleeves and pipe closers. The AIM RAFB is tested to BS EN 1366-4 and the principles of TR31 and can provide up to 120 minutes integrity and

insulation. The addition of Rockwool Ablative Batts, to allow services to penetrate the barrier, does not denigrate or reduce the overall fire resistance of the AIM RAFB.

Without this assessment, the installer would need to seek approval from a competent person, such as a fire engineer, to run services through the RAFB or, which is most common, they replace the whole barrier with a full run of Ablative Batt, which is an expensive response.

“The many services required in modern offices are usually run through raised access floors, so must pass through dedicated fire barriers,” explains Ian Exall, AIM’s commercial director. “AIM’s improved technical solution for accommodating services combines our RAFB with Rockwool Ablative Batts. It is tested and cost effective compared with building the whole fire barrier from an Ablative Batt.”

An additional advantage of AIM’s new solution is that the services do not need to be installed as the barrier is installed.

The Ablative Batt and services can be installed at a later date providing a retrofit solution. AIM sells the Rockwool Ablative Batt along with the

AIM RAFB, but installers can also source the batt from their usual sources.

AIM’s RAFB also reduces airborne transmission of sound by up to 51dB Rw when tested with an access floor system. Made from high density Rockwool stone wool slab faced with impervious foil facing on both sides, it is available cut to size or in slabs for cutting on site.

The AIM RAFB datasheet is available at: https://www.aimlimited.co.uk/solutions/ raised-access-floor-barrier/

Part of the Performance Technology Group, UK-based AIM - Acoustic & Insulation Manufacturing has over 30 years of experience in the design, testing and manufacturing of high-quality fire, thermal and acoustic barriers.

The company produces a wide variety of bespoke insulation products to customer specification and a range of standard products.

www.aimlimited.co.uk

AIM – Enquiry 12

In today's fast-paced construction industry, the demand for highly efficient and durable building solutions is at an all-time high. Fassa Bortolo is meeting this demand head-on by offering a complete solution for External Wall Insulation (EWI) and render systems, which extends far beyond the products themselves.

The company’s integrated approach, combining top-tier technical support, a steadfast commitment to thermal performance, and comprehensive training, positions them as a true partner in building excellence.

At the heart of Fassa Bortolo's expertise is a deep understanding of thermal performance and the importance of U-Values. A low U-Value is the foundation of an energy-efficient building envelope, signifying minimal heat loss and substantial energy savings.

The FassaTherm EWI systems are meticulously designed and rigorously tested to help projects not only meet but exceed current national

Building Regulations. With BBA certification as a testament to their quality, these systems offer architects, specifiers, and contractors a proven method for improving a building's thermal properties. Fassa's versatile range of insulation options, from traditional EPS to advanced mineral wool and eco-friendly cork, ensures that a precise, project-specific solution can always be found to address thermal bridging and optimize a building's energy footprint.

A crucial differentiator is Fassa Bortolo’s highly responsive technical support department. In a trade where technical queries are common

and timely advice is essential, Fassa's team provides invaluable guidance. Their experts are on hand to assist with U-Value calculations, system selection, and on-site troubleshooting. This proactive and collaborative support mitigates project risks and ensures that every step of the installation process, from initial specification to the final finish, is executed correctly. This hands-on assistance, coupled with a comprehensive library of documentation, instils confidence in professionals, knowing they have a reliable partner throughout the project lifecycle.

Furthermore, Fassa Bortolo is deeply invested in the professional development of the trade. The company’s training programs, conducted at their dedicated school and a mobile training centre, provide applicators with the practical skills and product knowledge necessary for impeccable work.

These sessions go beyond simple product demonstrations, focusing on best practices and fostering a community of "Fassa approved" applicators who are certified to uphold the highest standards. By empowering applicators, Fassa Bortolo ensures the longevity and performance of their systems, reinforcing their reputation for quality and reliability across the UK.

If you’d like to find out more about Fassa’s EWI render products and systems or our technical support, please call 01684 218305, or email our team at info.fassauk@fassabortolo.com

Fassa Bortolo – Enquiry 13

Euroform’s Versapanel® cement bonded particle board has played a role in meeting the acoustic performance criteria of the roof system for London’s largest new film and television campus, Eastbrook Studios in Dagenham.

Commissioned to provide the roof system covering an area of over 23,000m², roof and façade specialist Kalzip’s objective was to design a project specific acoustic roof construction to achieve a significant sound reduction performance.

As part of the tested system, Kalzip specified Versapanel® along with other elements, including rockfibre slab, glass wool insulation, an anti-drumming membrane and green roof, to the more noise exposed areas, including beside a train line, along with Kalzip structural components.

Kalzip’s Chris Goldie explains, “Versapanel® was selected as a component in order to provide significant mass to the construction, contributing to the test criteria being meet.”

Euroform supplied 40,000m² of Versapanel® The product’s principal attributes are durability and excellent sound attenuation. Its density increases substantially the mass of systems, providing superior acoustic performance when used in various elements of construction, such as roofs, ceilings and walls.

Versapanel® is specified extensively in constructions where acoustic control is important, such as in high-risk noise areas including airports and motorways. It can also be used in acoustic baffles in theatres, concert halls and recording studios where true sound reverberation is required.

The Kalzip roof system was installed at Eastbrook Studios by sub-contractor FK Group.

Eastbrook Studios is now open for action. A technologically advanced, film and television production centre, it offers a variety of purpose-built spaces, with 12 state-of-theart soundstages ranging from 16,000 to 31,000 sqft, office and support space and 17 workshops, plus a 1.7-acre backlot. Located at Dagenham, it is on London’s underground network. Eastbrook Studios is operated by The MBS Group and owned by Hackman Capital Partners.

One of the leading suppliers of aluminium building envelopes, Kalzip has been producing

roof and façade systems since 1968 and has installed more than 100 million square metres of Kalzip profiled sheets worldwide.

Euroform has been developing, fabricating and supplying materials for the construction industry since 1995. It is part of the Performance Technology Group, a group of companies supporting the construction industry to meet acoustic, fire, thermal and vibration challenges.

www.euroform.co.uk www.kalzip.com www.eastbrookstudios.com

Euroform – Enquiry 14

“Getting

the right products to the right place at the right time is more than logistics,

it’s about delivering on our promises”.

John, Logistics Team

Nothing’s more important to our team than confidence in the products we make. From the boardroom to the production line, our team brings care and expertise to ensure our products meet and exceed expectations. This means maintaining robust internal controls through initiatives like our Change Management Excellence Program and Standards and Compliance Committees. It also means meeting and exceeding our obligations by using external test centres to verify performance, including fire safety through our suite of BS8414 tested systems or AVCP1 certification. Together, these efforts reflect our commitment to our aim of delivering best-in-class products that our team are proud to stand behind.

Kingspaninsulation.co.uk/kingspantoday

Rainscreen systems are designed to protect buildings whilst also offering design flexibility through a wide range of cladding options. But at URSA, we’re focused on what’s on the inside. So much so, we’ve spent 70 years committed to developing insulation that generates a positive impact.

Now we have taken that commitment further, taking a more considered, ethical and responsible approach to everything we do – which includes the way we talk about our products, using CCPI assessment.

Code for Construction Product Information (CCPI) – was established by the Construction Product Association (CPA) following the Grenfell tragedy, to raise the standard of product information across the sector and making sure any claims are evidence-based and substantiated. According to their website, the CCPI’s aim is to make product information ‘clear, accurate, accessible, up-to-date and unambiguous’.

Although voluntary, we became early adopters of the Code, signing up earlier this year as a demonstration of our commitment to being a trusted and reliable provider of glass mineral wool insulation for use in rainscreen applications.

We are proud to announce that URSA WALLTEC BLACK 32, URSAPAN BLACK and URSAPAN, have now been assessed by CCPI – which means specifiers, system designers and specialist installers, can rely on the information provided in our marketing and literature, knowing it conforms to CCPI’s strict standards.

In addition, URSA WALLTEC BLACK 32 and URSAPAN BLACK are the ONLY glass mineral wool insulation products approved by the British Board of Agrément (BBA) for use as a sheathing insulation in rainscreen cladding façade and are deemed non-combustible with a fire classification of Euroclass A1 when tested to EN 13501-1:2018

Find out more at www.ursainside.co.uk

URSA – Enquiry 16

1.

Specifiers Guide to Render Solutions

A general introduction into specifying and using rendered finishes

2. 3.

Specifiers Guide to External Wall Insulation (EWI)

Reviewing the process of specifying the right EWI solution

A general introduction into the benefits of using lime render and plaster