The August report from RIBA into the state of the industry shows that while architects remain broadly positive about future workloads, confidence has weakened.

The RIBA Future Workload Index fell to +2, down from +9 in July. Current workloads are on average 13% lower than a year ago.

This softer outlook is driven largely by the sharp decline in the private housing sector, which has moved firmly into negative territory, and by a downturn in sentiment among small practices. In contrast, medium and large practices remain firmly optimistic, with the Commercial sector proving resilient.

Staffing expectations remain positive overall, with both permanent and temporary indices still in positive territory, though the balance has weakened compared with July.

Adrian Malleson, RIBA Head of Economic Research and Analysis, said: “The August RIBA Future Workload Index shows a profession becoming more measured in its outlook, with the headline figure falling to +2, down from +9 in July. While this still indicates overall growth expectations, the fall reflects growing concern, particularly for the private housing sector, and among smaller practices.

“The sector-specific data is the most concerning. While the commercial sector, a significant source of revenue for medium to large practices, is proving resilient, the private housing sector, the largest revenue source for smaller practices, has shown a sharp decline. The public and community sectors have also slipped into negative territory.

“Commentary this month is downbeat, with practices reporting a slowdown in project activity and enquiries. Downward pressure is coming from rising costs, weak client confidence, a stagnant economy, and regulatory burdens, especially the Building Safety Act. Planning delays remain a major barrier.

“Nevertheless, some practices are cautiously optimistic, expecting workloads to improve after the summer. Recruiting to meet demand remains a challenge for some.”

Paul Groves Group Editor paul.groves@tspmedia.co.uk

Now offering an enviable portfolio of four of the UK’s leading appliance brands – Whirlpool, Hotpoint, Beko and Indesit – under one trusted supplier, Beko Appliance Partners delivers solutions tailored to every housing type.

With design-led, energy-efficient and user-friendly appliances, supported by the UK’s largest appliance service network and strong sustainability credentials, it’s a portfolio that ensures performance, compliance, and reliability.

Grosvenor House, Central Park, Telford, TF2 9TW T: 01952 234000 | F: 01952 234003 www.tspmedia.co.uk | E: info@tspmedia.co.uk

One of the UK’s leading organisations for building design professionals has released a new plan to future-proof homes across England through a National Retrofit Programme.

The Chartered Institute of Architectural Technologists (CIAT) has outlined the Programme in a new report, Beyond the Warm Homes Plan: A National Retrofit Programme for people and planet, published today. Under the proposals, which build on the Government’s “Warm Homes Plan”, a combination of grant and low-interest loans would be used to finance design-led, holistic retrofits of the England’s homes, ensuring that they are not simply warm in winter, but healthy all year round, affordable to run, sustainable and resilient to a changing climate.

Key recommendations from the Report include combining the numerous separate funding pots and support schemes for home

energy efficiency improvements into a single, streamlined Programme, removing VAT on retrofit measures, providing “home instruction manuals” to support households to get the best performance from new, energy efficient systems, and implementing a lower rate of stamp duty for the most energy efficient homes.

President, Eddie Weir PCIAT, said: “Everyone deserves a healthy, safe home. But too many homes in this country are poor quality, excessively cold in winter and hot in winter. This poor housing contributes to ill health, costing the NHS around £2.5 billion per year. Housing is also a key contributor to climate change, with residential building responsible for 12% of UK greenhouse gas emissions in 2023. By tackling these challenges in a coordinated way, government has the opportunity to deliver profound benefits to households, boost productivity, and provide high-quality, well-paid jobs right across the country. And,

The UK’s house-building sector is gearing up to address its most urgent challenges, from housing market growth and climate change to the Future Homes Standard and build quality, as the industry works to deliver the government’s target of building 1.5 million new homes this Parliament.

The National House Building Council (NHBC) will host BEYOND ’26 LIVE on 25 February 2026 at the CBS Arena, Coventry.

The event will bring together over 1,200 professionals and more than 40 expert speakers and leaders. It will offer valuable content for all levels, from CEOs and technical directors to site managers, subcontractors and apprentices.

Attendees will gain fresh ideas, practical guidance and new insights from leading voices in house building.

Hosted by broadcaster and journalist Louise Minchin, best known for her 20 years on BBC Breakfast, the event will take on the climate crisis with sessions on sustainable construction and preparing for the UK’s 2050 net-zero commitment.

It will also address future skills needs, the current housing market and what needs to be done to stimulate growth.

BEYOND ’26 LIVE will showcase best practice in modern timber frame construction, including expert guidance and a live demonstration.

A Pride in the Job panel will share insights from this year’s competition and what it takes for site managers to succeed. A dedicated stage will cover roofing quality, highlighting critical external elements and how to avoid common faults, costly rework and claims.

by abolishing VAT on retrofit measures, and lowering Stamp Duty for the best performing homes, government can create a commercial market for healthy, sustainable homes over the long term.”

Chair of the CIAT Climate Society, Chris Halligan MCIAT, said: “The UK Climate Change Committee has made it clear that we need to rapidly decarbonise our homes over the next two decades, in order to achieve Net Zero by 2050, as part of global efforts to limit warming. But more than that, our homes need to be resilient to the climatic changes we are already living through. The good news is, we already have the technology to deliver such a transformation in our homes. Technologies such as air source heat pumps are now tried and tested, including in cold countries such as Norway. This plan provides a blueprint for Government to accelerate the roll-out of these measures, so that everyone can benefit from them.”

An ornate Victorian building has been given a new lease of life after being lovingly restored to provide new homes in the heart of Birmingham’s historic Jewellery Quarter. Mayor Richard Parker toured the finished Great Hampton Street Works for the first time since seeing work begin on the project 15 months ago. At that time, the Grade II* Listed building in Great Hampton Street had been an unheated, bare warehouse and needed a complete overhaul to bring it back to life and protect it for future generations.

The restoration and conversion of the former warehouse has been carried out by Great Hampton Street Button Works Ltd and Hanehouse Developments, with support from an investment by the West Midlands Combined Authority (WMCA), chaired by the Mayor. The building is now home to 29 oneand two-bedroom apartments boasting original features such as exposed beams and brickwork, original cast iron windows, and some of the machinery from its days as a button factory. The new homes, set around landscaped courtyards, are being made available for rent.

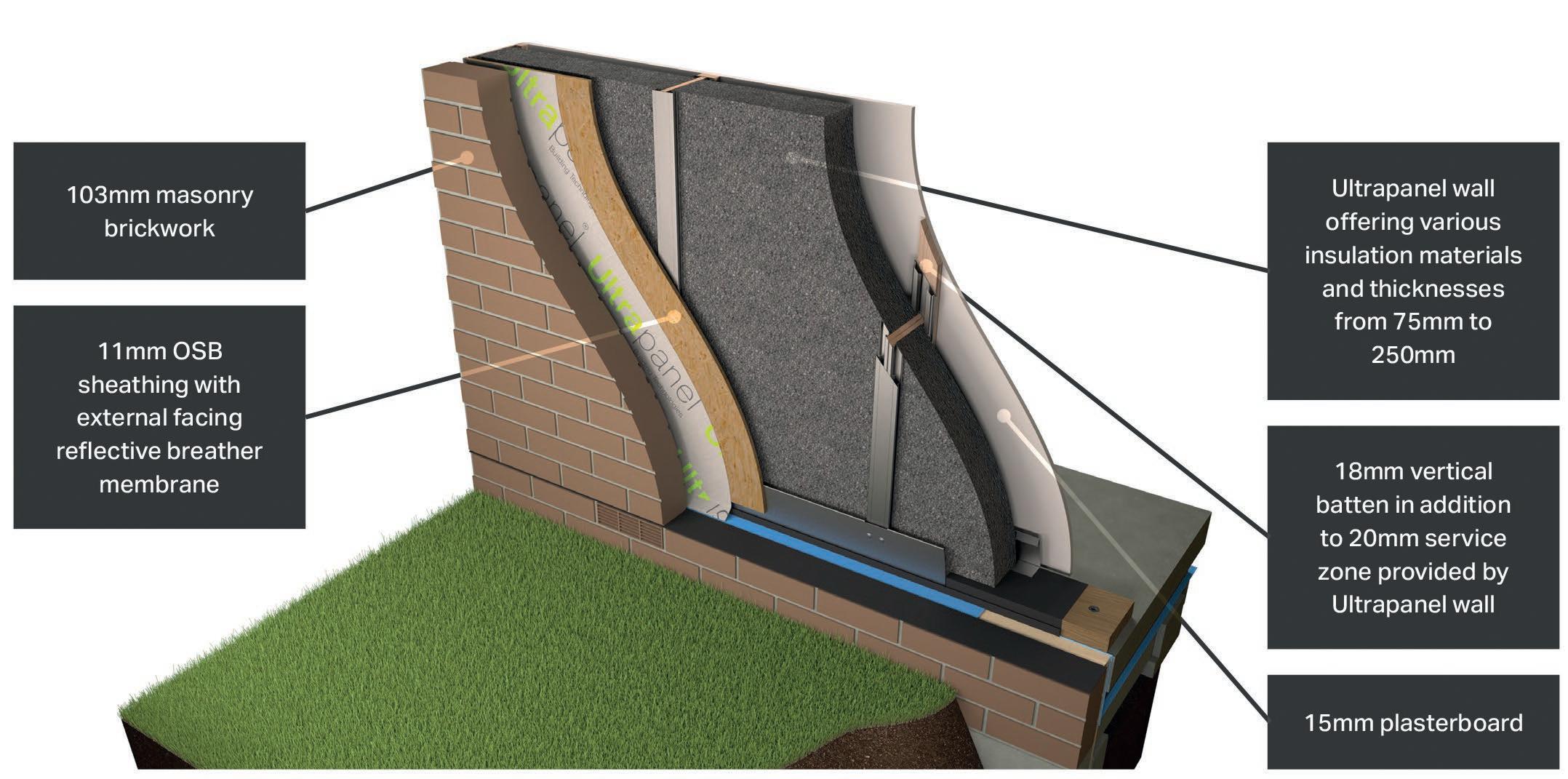

▸ Timber frame construction

▸ Spandrel panels

▸ Modular build

▸ Rainscreen cladding

▸ Render carrier board

▸ High performance dry lining

▸ Tilebacker

▸ Fire resistant floors and ceilings

▸ Passive fire protection

▸ Steel frame construction

As the new academic year gets underway, firms involved in building accommodation to house the growing number of students in the UK are becoming busier.

The value of project starts on student accommodation schemes rose to £849 million in the three months to July, double the value in the same period a year earlier, according to recent Glenigan data. In all, student homes accounted for 7% of total housing projects getting underway.

A series of factors is driving up activity in the sector. Today, student numbers are on the rise, and there is a growing shortage of places in purpose-built student accommodation (PBSA) schemes.

Applicant numbers through the UCAS university admissions agency were up by 1.3% compared with the same point last year, with notably healthy growth

amongst UK 18-year-olds (+2.2%) and overseas students (+2.2%).

Demand for new student accommodation is strongest in cities with highly regarded Russell Group universities. Today, London, Nottingham, and Leeds are expected to see the largest increases in supply, according to a recent report from agents Knight Frank. For now, demand for student accommodation continues to exceed supply. This year, just 1,609 new student beds had been added by the end of July, with 17,802 set to be delivered in time for the start of the 2025/26 academic year in October.

Unite, the largest owner and developer of UK student accommodation, said earlier this year that the new supply of PBSA was down 60% on pre-pandemic levels, as high construction costs, planning backlogs, and building safety approvals take their toll. Meanwhile, private landlords who have traditionally rented homes to

Linear Living has concluded work on phase one of its £34m Trafford Gardens development.

The developer finished the initial phase of the Talbot Road scheme earlier this month, bringing 33 affordable homes to market. The 33 units have all been purchased by not-for-profit Salford-based housing association, Irwell Valley Homes, who will let them on a rent-to-buy basis. Phase two is now underway and will add

116 homes for sale, with prices starting from £220,000.Contractor Linear Design and Construct, an associated company to Linear Living, began work on the ambitious scheme in January 2024. Full completion is expected in late 2025.

Once finished, Trafford Gardens will comprise a mixture of one-, two-, and three-bedroom apartments across a 13-storey block, as well as a rooftop garden and a private courtyard.

students in university cities are retreating from the sector, deterred by high mortgage costs and tighter regulations.

But against a background of supply shortages, investment in the sector is growing. Knight Frank notes that £1.6 billion was invested in UK PBSA in the first half of this year, well above the longrun average of £1.1 billion. Today, Unite has a fully funded pipeline of off-campus accommodation, worth £925 million and concentrated around Russell Group universities.

Unite also has an on-campus pipeline of 4,300 beds for delivery over the next three to five years. In May, the group unveiled a second university joint venture with Manchester Metropolitan University for 2,300 new beds in the city centre. This follows a similar partnership with Newcastle University, and the group is in talks on accommodation JVs with other academic institutions.

VIVID has completed its redevelopment of the historic Brickworks Museum site in Bursledon, with 12 new affordable homes now ready for customers. Working in partnership with Imperial Homes, the 2- and 3-bedroom houses are built using traditional Flemish bond brickwork — a nod to the cottage-style homes once lived in by brickworks employees.

The homes offer a blend of heritage and modern living, designed to meet local housing needs through a mix of social rent and shared ownership. The land was purchased from The Brickworks Museum, allowing the renovation and preservation of two Grade II listed Victorian brick drying sheds. Built in 1897, these historic structures were once part of a bustling site that produced over 20 million bricks a year.

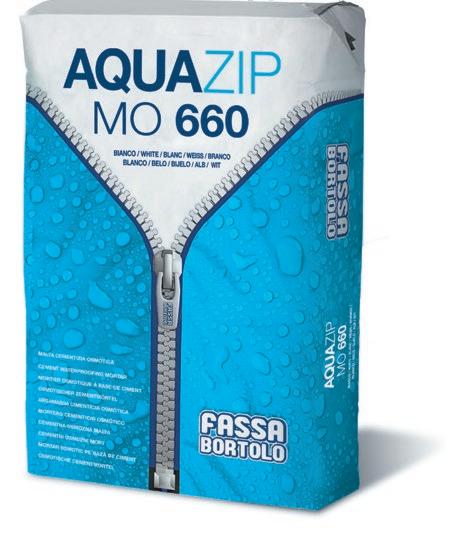

The Fassa Waterproofing System consists of a range of products and accessories for all kinds of application, for the protection and waterproofing of balconies, floors (including old, thin floors), swimming pools, terraces, wellness centres, basins and basements.

DG 74: A water-based primer made using synthetic resins

AQUAZIP FAST: Two-component, fastdrying, cementitious elastic coating with high bonding strength and elasticity

AQUAZIP MO 660: One-component osmotic cement mortar for waterproofing masonry and concrete structures

AQUAZIP RDY: Ready-to-use elastic waterproof coating paste for interiors

TO FIND OUT MORE about Fassa Bortolo and its range of flooring systems and building products. Visit www.fassabortolo.co.uk or call 01684 218 305

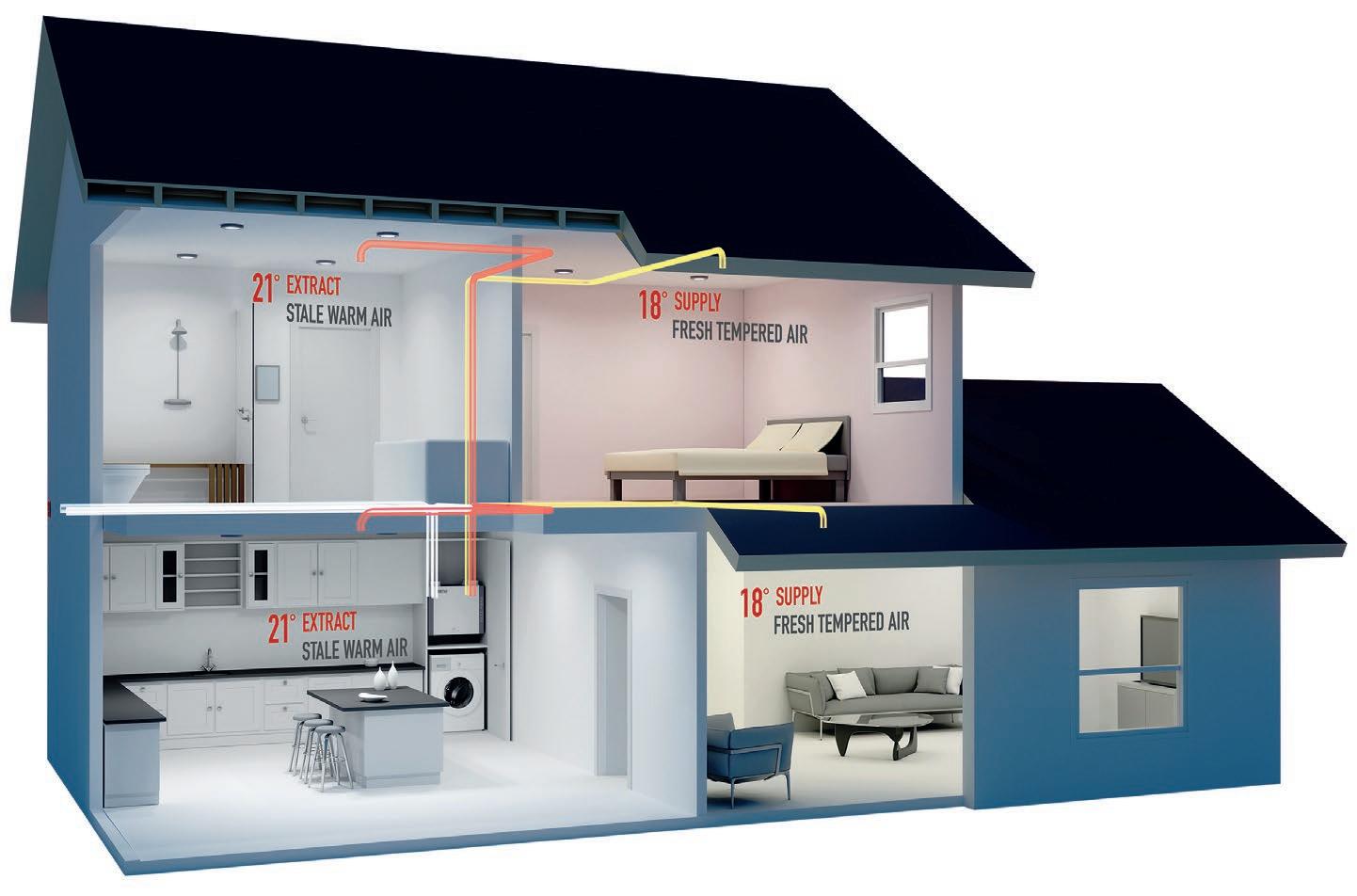

As the UK edges closer to its 2050 Net Zero emissions target, the spotlight on building design has never been more intense - Paul Williams, Domus Ventilation Product Manager, explains.

While much attention has rightly been given to insulation, renewables, and heating systems, ventilation is quietly emerging as one of the most crucial—and complex— elements in creating homes that are both energy-efficient and healthy to live in.

Specifying residential ventilation systems should no longer be just about compliance with current Building Regulations. It’s about anticipating future standards, technological advances, and occupant expectations. In short, it’s about future-proofing.

The Future Homes Standard, set to come into force in Autumn 2025, will raise the bar for energy performance in new homes. Central to this will be reducing heat loss, which inherently leads to more airtight building envelopes. While this is positive from an energy-saving perspective, it brings a major challenge: without adequate ventilation, indoor air quality (IAQ) suffers. Poor IAQ is known to be detrimental to occupants’ health, as well as their comfort.

Approved Document F (Ventilation) was updated to reflect these concerns. The 2021 changes introduced stricter airflow requirements and clearer guidance on mechanical ventilation systems, especially in airtight properties. But if you're only designing to meet today's minimum standards, your developments may fall short of tomorrow’s expectations—and may require costly retrofits later.

Traditionally, ventilation has often been treated as a compliance checkbox. But forward-thinking specifiers are now treating it as a core component of a building’s environmental strategy. Here’s how that shift is playing out:

From Intermittent to Continuous Ventilation: Intermittent extract fans, once common in residential new builds, are increasingly giving way to continuous mechanical extract ventilation (MEV) and mechanical ventilation with heat recovery (MVHR). These systems provide consistent airflow and improved IAQ while reducing energy loss. MVHR, in particular, is ideal for high-performance, airtight homes as it recycles heat from extracted air to warm incoming fresh air—supporting both energy efficiency and comfort. Our HRXE MVHR range recovers heat with up to 95% efficiency.

Retrofitting with Intent: Over 80% of the homes that will exist in 2050 have already been built. Retrofitting them for Net Zero presents one of the UK’s biggest carbon-reduction challenges. Improving energy performance in existing homes often involves enhancing insulation and sealing leaks—actions that can exacerbate ventilation problems if not balanced properly. Retrofitting with whole house ventilation systems - particularly where ducting space is limited - may not be an option here, but the use of more powerful extract fans is. These modern fans not only improve IAQ but also help protect the building fabric by reducing moisturerelated issues.

Looking ahead - what specifiers should do now

To truly future-proof your residential projects, consider the following:

• Design for where the standards are going, not where they are now.

• Design for airtightness and ventilation working in harmony together, not as separate disciplines.

• Engage early with ventilation experts to avoid compromises later.

• Specify systems with durability, low maintenance, and long-term energy performance in mind.

For those in the housing sector, now is the time to rethink how ventilation is specified— not just for compliance, but for carbon, comfort, and the long-term future of our built environment.

Newham Council's James Riley Point retrofit is set to be London's largest EnerPHit project to date. The project, that has just started on site, involves the refurbishment of a 1960s tower block on the Carpenters Estate to the EnerPHit standard to create 136 apartments.

Newham Council is undertaking a 12year estate regeneration scheme of the Carpenters Estate in Stratford. Phase 1 of the regeneration sees the retrofit of the 23-storeyJames Riley Point tower block to the EnerPHit standard. James Riley Point is one of three landmark modernist towers on the Carpenters Estate, which residents were keen to see retained in the Masterplan, resulting in plans for two to be refurbished.

will reduce the building’s operational carbon by limiting the heat and energy demand. This is in line with Newham’s Just Transition Plan, with its focus on reducing emissions and building long-term environmental resilience for the benefit of residents. Right to return residents have the option of moving into the building on intermediate rent, while the remaining homes will be social rent, making the majority of the

improved amenity space. The scheme also creates four additional new properties in the tower, bringing the number of apartments to 136, made up of 1-3 bed homes.

Hot water and heating demand for the apartments will be supplied by ASHP (air source heat pumps) and solar PV panels. External shading will be employed as a summer comfort strategy. An external vertical grid of aluminium fins will provide shading to the glazing while maintaining desired daylight levels in apartments. New high-performance fabric will add acoustic as well as thermal insulation between homes.

Retention of the existing building will significantly reduce embodied carbon in comparison to rebuilding and redevelopment, whilst achieving the Passivhaus EnerPHit Standard

homes genuinely affordable to Newham residents. As part of the plans, the existing balconies will be internalised to increase living space inside homes, improving the building form factor, and helping minimise thermal bridging.

New external policy-compliant balconies will be added, outside the thermal envelope, to provide additional

The project's fabric-first approach means the proposal will far exceed the London Plan’s CO2 saving target of a 35% reduction. An estimated regulated CO2 savings on site of 66.1% for residential use and 64.1% for the non-residential use of the development, against a Part L 2013 compliant ‘gas boiler baseline’ scheme (for new build elements) and a ‘refurbishment baseline’ (for refurbished areas) with SAP10 carbon factors.

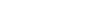

Bricks continue to be a major product area for the housebuilding industry. But for this very traditional product, innovation continues to help shape the future.

Lignacite has become the first concrete block manufacturer to have the recycled content in its products independently verified by sustainability consultancy Blue Marble.

The verification covers over 90% of its range – including the Lignacite ECO, Lignacite GP and Lignacite dense blocks – and confirms the percentage of recycled material used in each.

The milestone comes as required sustainability standards continue to be applied for UK construction projects through regulations such as Section 106 Agreements, alongside localised initiatives like whole life-cycle carbon reduction requirements in the City of London.

Together with Lignacite’s existing Environmental Product Declarations (EPDs) – which confirm embodied carbon levels of its products from source to site – this verification adds an extra level of assurance for architects and specifiers looking to make sustainable choices.

Jacky Whiffen, SHEQ Coordinator at Lignacite’s Nazeing site, said: “Every claim we make about recycled content is now independently verified. It wasn’t a tick-box exercise. It was a detailed, three-and-a-half-month process that covered everything from site visits and materials trials to documentation, procurement and auditing.

“Our partners at Blue Marble went through it all – from how we source recycled sand and manage contamination risks to how much was used, when, and in which blocks.”

The verification process confirmed that the Lignacite ECO 50 and ECO 70 blocks contain 50% and 70% recycled content respectively, while Lignacite GP and dense blocks – including 7.3N and 10.4N units –now meet the 30% verification threshold.

To reach these levels, the team sourced and trialled new recycled materials from local suppliers, undertaking extensive testing to ensure the blocks remained strong, durable and visually consistent. The effort reflects Lignacite’s broader sustainability ambitions. The company aims to reach Net Zero by 2030, and verification of recycled content forms a key part of that journey. Unlike many products on the market, the

Lignacite ECO Range is supported by thirdparty EPDs and independent verification of recycled aggregates, helping customers avoid greenwashing and make credible sustainability claims.

New range of concrete facing bricks Brett Landscaping & Building Products has launched a new range of concrete facing bricks, offering housebuilders, architects, brickwork contractors and Builders Merchants with a UK manufactured product with many desirable qualities. With vast experience in the creation of high-quality concrete landscaping products, the new brick range represents a natural expansion.

The new Stonehurst range has been manufactured with high compressive strength, low porosity and excellent weather resistance to provide a durable façade solution. Suitable for the outer walls of buildings, the bricks are nominally sized at 215mm in length, 100mm in width, and 65mm in height in line with the traditional UK standard. The bricks are crafted in frogged and perforated formats, come with a choice of smooth or textured finishes, and are available in five accessible colours most often used by the UK’s largest house builders.

The Stonehurst range is manufactured and tested to BS EN771-3: 2011+A1 2015, the industry specification for masonry units. Concrete facing bricks have a lower carbon footprint compared to traditional clay bricks, typically producing 60% less carbon during the manufacturing process, offering a low carbon alternative to traditional clay bricks.

“The Stonehurst range has been developed in conjunction with house builders and can be produced at volume in a timely manner from our manufacturing site in central England. This will offer a more resilient and predictable supply chain to builders, especially for volume projects.” Further, with the UK government launching the £39bn Social and Affordable Homes

The bricks are manufactured at Brett Landscaping’s Leicestershire site at Barrow-upon-Soar and offer a short lead time and nationwide delivery.

Mark Barter, Head of Commercial Sales, Brett Landscaping & Building Products said: “The launch of the Stonehurst range represents a natural progression for Brett Landscaping & Building Products. We have decades of experience in the production of concrete landscaping products and have exceptional relationships with merchants, housebuilders and architects across the UK.

Programme to deliver 300,000 new affordable homes in the next decade, and separately, the Scottish Government pledging up to £4.9bn over the next four years as part of its Housing Emergency Action Plan, the construction supply chain has to find ways to meet demand for affordable housing.

Vandersanden, a leading manufacturer of sustainable brick solutions, announces the launch of its new Eco Habitat brick range, designed to integrate nature into the built

environment and support biodiversity across urban and rural developments. This innovative new collection includes bat boxes, swift boxes, and bee bricks, all seamlessly incorporated into traditional brick facades.

Developed in collaboration with ecological specialists, these solutions offer safe nesting spaces for wildlife while maintaining architectural integrity, longevity and aesthetic appeal. Proper placement is key, ensuring these features function effectively by considering factors such as orientation, climate conditions, and available food sources.

“At Vandersanden, we believe that sustainability goes beyond energy efficiency, it’s about creating spaces where nature and people thrive together,” said Wayne Harris, Area Sales Manager Vandersanden.

“Our Eco Habitat bricks allow architects and specifiers to embed biodiversity directly into their projects and show our commitment to nature-inclusive building and climate-adaptive design.”

Each product is engineered for durability, low maintenance, and compatibility with standard masonry. Vandersanden also offers custom specifications and decorative motifs to suit diverse project needs.

By embedding ecological features directly into construction materials, Vandersanden empowers architects, developers, and planners to create greener, healthier communities. This initiative aligns with the company’s broader mission to create sustainably attractive facades and to ensure that biodiversity is a cornerstone of modern construction.

Against a complex backdrop of pressures housebuilders face today, including tighter sustainability standards, the need for long-term reliability, and growing buyer expectations around quality and design, Beko Appliance Partners know choosing the right supplier has never been more important.

That’s why Beko Appliance Partners are excited to announce a major enhancement to their offering with a game changing new portfolio. UK housebuilders now have access to four of the UK’s leading appliance brands - Whirlpool, Hotpoint, Beko, and Indesit - under one roof. The result is a single, dependable partner that gives developers the flexibility to tailor solutions to every type of residential scheme, backed by the service and sustainability credentials needed to deliver with confidence.

Developers are supported at every stage of a project by a dedicated team, from planning through installation and aftercare. Backed by the UK’s largest appliance service network, more than 1,000 engineers covering 99% of the country, developers can be confident that their project will be handled seamlessly, regardless of the size or complexity.

Why brand power matters

Each of Beko Appliance Partners’ four brands brings unique value to developers. Whirlpool is known for sleek design and innovative 6TH SENSE technology to create smarter, more efficient homes from day one. Hotpoint, the UK’s most trusted major domestic appliance brand*, delivers dependable, high-performing appliances designed to offer long-term value. Beko, the UK’s best-selling appliance brand**

and winner of the Which? Best Value Appliance Brand for two consecutive years, offers stylish, energy-efficient and reliable appliances that are rigorously tested, while Indesit provides simple, easy-to-use appliances that make handovers smooth and everyday use straightforward.

Service that scales with your project

Beko Appliance Partners’ dedicated team works closely with architects, specifiers, and developers throughout the project, from planning through to installation and aftercare. As Katie O’Shea, National Specification Manager, explains: “We’re here to make things easier for housebuilders and developers. With four strong brands and a service network to match, we’re ready to support any type of development. Whether it’s high-end private homes demanding premium design, large-scale rental schemes requiring robust service agreements, or affordable housing where efficiency and simplicity are key, we have a solution to fit.”

Meeting the sustainability challenge

Beko has earned global recognition for sustainability, ranking 17th on Time Magazine’s 2025 list of the World’s Most Sustainable Companies and number one in its industry. Each of its brands plays a role in reducing environmental impact:

Whirlpool’s 6TH SENSE technology optimises energy and water use, Beko’s appliances are designed for efficiency and longevity, Hotpoint’s durable products minimise the need for early replacements, and Indesit delivers affordable performance for everyday living.

Why developers can build with confidence

By uniting four trusted brands with a single, expert partner, Beko Appliance Partners delivers a complete proposition: the strength of four, the simplicity of one, the sustainability to meet tomorrow’s challenges, and the service to support developments from start to finish.

Find out more:

appliance-partners.bekoplc.com

*Based on Trustpilot five-star rating among the leading Major Domestic Appliances (MDA) brands with published Trustpilot reviews specific to MDA and to the UK in July 2025. To verify visit www.hotpoint.co.uk/trustpilot

**Beko is the UK’s number one large home appliance brand.

Beko Appliance Partners - Enquiry 9

In modern construction, longevity and performance depend on more than just visible finishes. The unseen preparation stages are just as vital, ensuring that systems perform as intended and surfaces remain protected against environmental stress. At the forefront of these critical preparatory and protective solutions is Fassa Bortolo, whose extensive range of waterproofers and primers deliver both security and performance for a wide variety of applications.

Fassa Bortolo’s primers are specifically formulated to improve adhesion, regulate absorbency, and create the ideal base for subsequent coatings and finishes. Surfaces in construction can vary dramatically in porosity, density, and texture, and without the correct preparation, the performance of renders, plasters, and adhesives can be compromised. Fassa Bortolo primers, such as DG 74 and other specialist products, are engineered to ensure consistent absorption, reducing the risk of uneven finishes, delamination, or cracking. This not only streamlines the installation process but also guarantees that the final finish will meet both aesthetic and performance expectations.

The waterproofing range demonstrates Fassa Bortolo’s technical expertise in protecting structures against one of the most persistent challenges in construction: moisture ingress. Water can compromise buildings in countless ways – from structural weakening and mould growth to aesthetic damage – making robust waterproofing solutions essential. Products such as Aquazip Fast, Aquazip MO 660, and Aquazip RDY provide reliable protection in diverse conditions, offering solutions for everything from bathrooms and wet rooms to terraces, balconies, basements, and even swimming pools.

Each product within the range has been designed with performance and versatility in mind. For example, Aquazip Fast offers rapid-setting waterproofing for projects requiring speed without sacrificing reliability. Aquazip MO 660 is a highly flexible, fibre-reinforced coating that can bridge small cracks and adapt to substrate movements, ensuring longterm durability. Meanwhile, Aquazip RDY provides a ready-to-use waterproofing option, ideal for simplifying installation while delivering proven resistance to water penetration. Together, these systems cover a wide spectrum of needs, ensuring specifiers and contractors can match the right product to each unique project requirement.

A key advantage of Fassa Bortolo’s waterproofers and primers lies in their compatibility with the wider product portfolio. They integrate seamlessly with renders, adhesives, and finishing systems, ensuring that each layer performs as part of a complete, wellengineered solution. This compatibility gives professionals confidence that every stage of application, from preparation to final finish, is supported by Fassa Bortolo’s expertise.

Equally important is the ease of use that defines the range. Contractors benefit from products that are straightforward to mix, apply, and cure, reducing installation times without compromising on reliability. With demand for efficiency on construction sites increasing, Fassa Bortolo’s waterproofing and primer solutions are designed to deliver both speed and certainty, ensuring deadlines are met while quality remains uncompromised.

Sustainability is also a growing consideration in product development. By creating durable, long-lasting waterproofers and primers, Fassa Bortolo supports a more responsible approach to construction, reducing the likelihood of early failure and costly remedial works.

This focus on product longevity not only benefits contractors and building owners but also contributes to reducing waste and resource use across the industry.

From regulating absorption to safeguarding structures against moisture, Fassa Bortolo’s primers and waterproofing systems represent a complete package of reliability and performance.

By addressing both preparation and protection, the range underlines the company’s commitment to delivering innovative, high-quality solutions that underpin successful projects across residential, commercial, and industrial construction.

With Fassa Bortolo, the unseen stages of building are never overlooked – they are given the same level of expertise and innovation as the visible finishes, ensuring every project is built to last.

If you’d like to find out more about Fassa’s primers, waterproofers or flooring systems, please call 01684 218305, or email our team at info.fassauk@fassabortolo.com

Fassa Bortolo - Enquiry 11

With the Regulator of Social Housing reporting in January that social housing providers spent £8.8 billion during the year to March 2024, which included fire remediation, cost effectiveness is a key consideration while ensuring that quality and safety are not compromised. Peterborough based, Encasement, explores the cost benefits of pre-formed sprinkler boxing solutions.

As fire sprinklers need to be located within individual flats and communal areas to suppress fires and aid escape, the process of incorporating them in new builds is comparatively simple, as they can be integrated at the building design stage and pipework can be hidden within wall cavities or ceiling voids.

For retrofitted sprinkler installations, however, it’s not as straightforward, as in most cases the pipework will need to be surface mounted. Once a sprinkler system is installed, the pipework needs to be concealed to cover sprinkler system components and act as a visible barrier to potential tampering. It also provides a more aesthetic finish and can help avoid potential tenant complaints.

Surface mounted pipework, however, does improve the simplicity and speed with which it can be installed by skilled contractors. Clearly, the fitting of pipe boxing also needs to be quick and easy to ensure all associated costs are effectively managed.

Pre-formed and pre-finished boxing solutions, such as Encasement’s Versa pipe & fire sprinkler boxing, are increasingly specified by sprinkler contractors and installers, as they provide a simple and practical solution for sprinkler pipework, usually at high level. Versa ‘L’ shaped boxing is manufactured, from 5mm or 8mm thick UKTR compliant plywood and is available in a range of sizes and profiles to meet various sprinkler pipework configurations.

A range of dedicated accessories is also incorporated as part of the Encasement system, including internal and external corners, as well as stop ends, fixing battens, screws and caps.

These help create an integrated and consistent finish within each flat whilst also simplifying the sprinkler installation project.

Experience of working with contractors across the UK on countless social housing projects where pipework

needs to be concealed, has shown that Versa pipe and fire sprinkler boxing can typically be fitted in less than half the time of site made alternatives. In addition, as it is pre-finished there’s no painting required on site, which further helps to save time and cost.

This time saving provides several advantages. For contractors, local authorities and housing associations, fire safety upgrades can be completed within a shorter timescale and also help minimise disruption for tenants while the work is being carried out.

Potentially the most important benefit is that costs can be reduced, not by ‘cutting corners’, but by cutting the time taken on the project without compromising the quality or integrity of the installation.

The focus, rightfully, is on improving fire safety in high-rise residential buildings and Versa can contribute to that process, in terms of effectiveness, ease of installation and economics.

Encasement - Enquiry 12

The first line of defence in social homes

For social housing environments that demand durability, Beauflor® sheet vinyl flooring is the first line of defence against premature wear and early replacement.

Beauflor sheet vinyl floors are made to fulfil requirements of affordable, durable, easy to look after, comfortable and in a wide range of calming natural designs. For the best in durability, Xtreme and Phoni-Xtreme are two top-tier options for flooring in social homes. Featuring a 0.70mm wear layer, these floors deliver impressive wear performance and can withstand constant use.

Beauflor - Enquiry 13

Mapei UK unveils ‘Seal the Envelope’

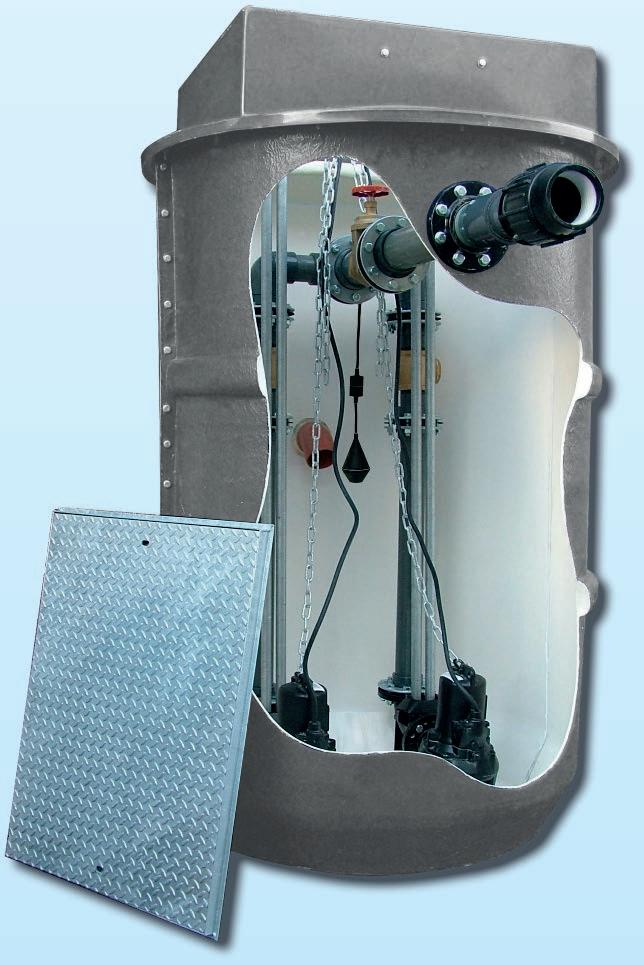

Brett Martin has launched Adopta, a complete portfolio of drain and sewer pipes, fittings and non-entry inspection chambers for where the drains/sewers are required to be adopted by the sewerage or water authority.

All of the products in Adopta’s comprehensive range are manufactured and tested to ensure full compliance with the strict industry guidelines and requirements for adoptable drain and sewer projects in England, Scotland and Wales.

The introduction of a “full package” adoptable system is a seminal moment for the company, which is the UK’s most successful independent building products manufacturer of above- and below-ground drainage systems, including underground, rainwater, soil and waste systems.

Speaking about the introduction of Adopta, Sales Director Chris Dawson said, through its network of merchant stockists, Brett Martin can now offer a greater range of adoptable drain and sewer packages to fulfil the requirements for housebuilders and developers when it comes to water and sewerage management. “In Adopta, we now have the full package of products – along with all the technical back-up and support that merchants will ever need, giving them complete assurance when recommending and stocking high-quality products that meet their contractor customers’ needs and comply with local legal requirements,” he said.

Brett Martin - Enquiry 14

Mapei UK announces the official launch of ‘Seal the Envelope’, a comprehensive initiative designed to transform retrofit and refurbishment projects across the UK. This campaign brings together Mapei’s extensive expertise and product portfolio, offering a fully integrated building envelope solution that spans from the foundation to the roof.

‘Seal the Envelope’ addresses the critical need for structured, compliant refurbishment systems in today’s construction landscape. Mapei’s system-first philosophy eliminates the risks and inefficiencies of fragmented solutions by delivering a coordinated, logical approach to every layer of the building envelope. The campaign empowers professionals to specify and ensure clarity, compliance, and technical excellence.

Mapei UK - Enquiry 15

that helps reduce environmental impact

Beauflor® provides cost-effective and durable sheet vinyl flooring for social and affordable homes that delivers value throughout the life cycle and that can help projects to be more sustainable.

Chris Roberts, sales director UK, says: “Of course, social housing providers must deliver a good standard of home within budget, but that doesn’t necessarily mean that choosing a product that’s more sustainable has to be compromised, particularly in the choice of flooring. Our sheet vinyl not only delivers a floor that’s cost-effective, but one that can help housing to reduce its impact.”

Beauflor - Enquiry 16

Nuaire helps solve damp and mould in property

Indoor air quality and ventilation manufacturing specialist Nuaire has had its Drimaster ECO-HEAT-HC Positive Input Ventilation (PIV) unit and Cyfan extract fans installed into a Grade II listed almshouse in Brixton where it has dramatically reduced humidity levels in this unusual social housing property.

Aico Environmental Sensors installed within the property have shown a sizable difference in humidity levels since the Nuaire Cyfan extract fans and Drimaster PIV have been installed, with the ability to open the bathroom window also making a sizeable contribution. The property has gone from 98% humidity to within the ‘Goldilocks zone’ of 40-60% relative humidity.

Nuaire - Enquiry 17

Constructing wet indoor areas can be a challenge but help is at hand thanks to the Knauf AQUAPANEL® Cement Board Indoor, which is available nationwide via interior building products distributor CCF’s extensive branch network.

As part of the company’s commitment to collaborating with some of the UK’s biggest manufacturers and offering customers a wide choice of specialist solutions, CCF stocks a large selection of Knauf products, including the Knauf AQUAPANEL® Cement Board Indoor.

Developed specifically for use in wet and humid areas, Knauf AQUAPANEL® Cement Board Indoor is manufactured from inorganic materials, offering protection from water damage and resistance to mould.

Whether it’s bathrooms, kitchens, wet rooms, or even steam saunas, this system is engineered to withstand the most challenging conditions, including exposure to chlorine and salt. Knauf AQUAPANEL® Cement Board Indoor meets the requirements of the updated NHBC Technical Guidance 9.2/06, which emphasises the importance of robust substrates for tiling in bath and shower enclosures, wet rooms, and bathroom pods.

The lightweight construction of the Knauf AQUAPANEL® Cement Board Indoor at just 11kg/m2 also supports ease of handling and installation. The boards are pre drilled to reduce preparation time on site and its score-and-snap cutting method eliminates the need for specialist cutting tools.

Design flexibility has also been prioritised, with a variety of finishing options available. For tiled finishes, the

system can support tiles up to 120kg/m2 with specific build-up applying for tile weights above 50kg/m2. For areas where tiles aren’t being applied, housebuilders can choose between Knauf Ready-Mixed Interior Skim, an option that can help reduce water usage and dust creation on site, and Knauf AQUAPANEL Joint Filler and Skim Coating – White, which is a powdered cement-based filling material used in conjunction with AQUAPANEL reinforcing mesh. Both finishing options, alongside a range of accessories designed to work seamlessly with Knauf

AQUAPANEL® Cement Board Indoor including screws, adhesives and tape, are also available from CCF’s branches nationwide.

Full product information is available at www.aquapanel.com and CCF’s technical and local branch teams are also on hand to provide further support.

For more information or to locate your nearest branch, visit www.ccfltd.co.uk

CCF - Enquiry 18

The Great Northern Tower is an impressive 72-metre (236 ft) high-rise tower block home to 287 self-contained apartments in the heart of Manchester. An effective door entry system plays a critical role in convenient, secure and flexible access control as well as the safety and wellbeing of residents.

The building was completed in 2007 and fitted with a door entry system that, 15 years later, was hugely outdated and causing issues for entry into the tower block by residents, visitors and for concierge use too.

Replacing the system with a bespoke solution but retaining the existing access control fob reader aspect, all fitted within a glass wall, was highly complex. Installer Access Ability UK Ltd opted to fit a Videx 4G GSM system that was highly customised, integrated perfectly with the existing fob reader but, crucially, solved the key entry challenges residents and the concierge team were facing.

Barry Kimber, a director at Access Ability UK Ltd, said: “One major issue that we needed to solve was to enable effective, easy but secure door entry for residents to authorise entry in and out of the tower block.

“By installing a GSM intercom system with a VX2200 panel it meant residents could receive notification of someone

at the entrance straight to their phone, whether they were home or not. For example, they could be on holiday or at work but receive a call to say a delivery had arrived, grant entry to the courier driver who can leave the parcel with concierge for safe keeping until the resident returns. In terms of calling each flat, visitors now simply need to enter the number of the flat and it calls that flat directly – there’s no need to look the flat number up on the system to dial a code to then input.

“The GSM powered intercom system also enables the concierge team to authorise entry for visitors to deliver parcels or fix appliances for example, when the resident is away. Conveniently, the intercom is very easy to adapt and modify and the concierge team can programme the system both locally and remotely when flat residence changes as people move into and out of the tower block.”

Alongside the GSM technology, Videx also supplied a highly customised entry

panel that was not only specifically manufactured for The Great Northern Tower, to sit within a very difficult-tonavigate glass wall, and feature the existing third-party access control reader, but also carried bespoke engraving too. For example, the block numbers are clearly identified as well as the concierge service button.

The Videx 4G GSM system is extremely flexible and provides the utmost convenience and security to users. Programming can be done via apps, text messages and PC software both local and remotely.

The digital 4G intercoms can support up to 1000 apartments each with coded access and proximity access as additions to the dial to open access control option.

Up to 10 free access periods can be programmed for any of the outputs on the 4G GSM’s. Great for public access at busy times.

Videx - Enquiry 19

Add the Ei3000MRF for wireless interconnection and data extraction via the Ei1000G Gateway

The latest addition to the technologically advanced 30 0 0 Series, the Ei3030 combines individual Optical, Heat and CO sensors for the ultimate fire and CO response, while maintaining the simplicity that Installers love.

Smart, connected and future-proof.

Scan here to learn more about the Ei3030

The landscape of UK construction has changed dramatically in recent years. There has been a decisive shift toward safer, more resilient construction systems – especially in the residential sector. Here Martin Jamieson and Nik Teagle, Joint Managing Directors of light steel frame specialists, Frameclad – consider the importance of fire testing to meet the rigorous standards of the Building Safety Regulator (BSR).

As regulatory bodies together with developers and residents – demand higher levels of fire safety, the role of fire testing has never been more crucial. Independent, third-party tests and certifications from UKAS accredited fire test centres offer a clear benchmark for performance under fire conditions and help ensure that systems specified, particularly for higherrisk buildings – are fit for purpose.

Frameclad’s systems undergo extensive fire performance testing in accordance with BS EN 1365, BS EN 1364 and BS 476, which assess the loadbearing and non-loadbearing performance of construction elements when exposed to fire. Our light steel frame systems have achieved up to 120 minutes fire resistance, a key requirement for many multi-storey residential buildings and critical in compartmentation strategies.

We have successfully conducted over fifty fire tests to date and are continuously expanding our data with additional fire tests to cover a broader range of products and configurations. Where necessary, we collaborate with product manufacturers and industry partners to conduct joint fire tests – further enhancing the scope of products covered within our dataset.

Accreditation, Assurance and Compliance

Our systems are backed by comprehensive third-party certification and accreditation.

We are members of SSIP (Safety Schemes in Procurement) and Construction Line – Gold Standard. Frameclad was an early adopter of ISO and we are proud to attain ISO 9001 Quality Management System, ISO 14001 Environmental Management Systems and ISO 45001 Occupational Health and Safety.

Our fire-rated systems are fully tested and certified to meet the requirements of:

• NHBC Accepts

• SCI/NHBC Stage 1

• CE Marking

• BOPAS

Building Confidence Through Competence and Innovation

At Frameclad, we believe that fire safety is not an optional add-on – it is a fundamental requirement. By leveraging the natural properties of steel and validating our systems through rigorous testing and certification, we are helping to raise the bar for residential construction across the UK.

From concept through to completion, Frameclad brings together advanced manufacturing, technical expertise, competence and a deep understanding of compliance to provide an optimum

solution for safer, smarter building. With a proven track record in the residential sector, our systems continue to play a key role in delivering future-ready homes – backed by structural integrity, fire resistance, thermal and acoustic performance, and design versatility.

Spearheading a

As the industry embraces modern methods of construction and leans into the challenges of safety and sustainability, Frameclad stands as a trusted partner –delivering high-performance, accredited and innovative solutions that protect people, property and investment.

For more information on our fire-rated systems or to get in touch with our technical team, visit www.frameclad.com and head to the download section to review our Fire Test Data.

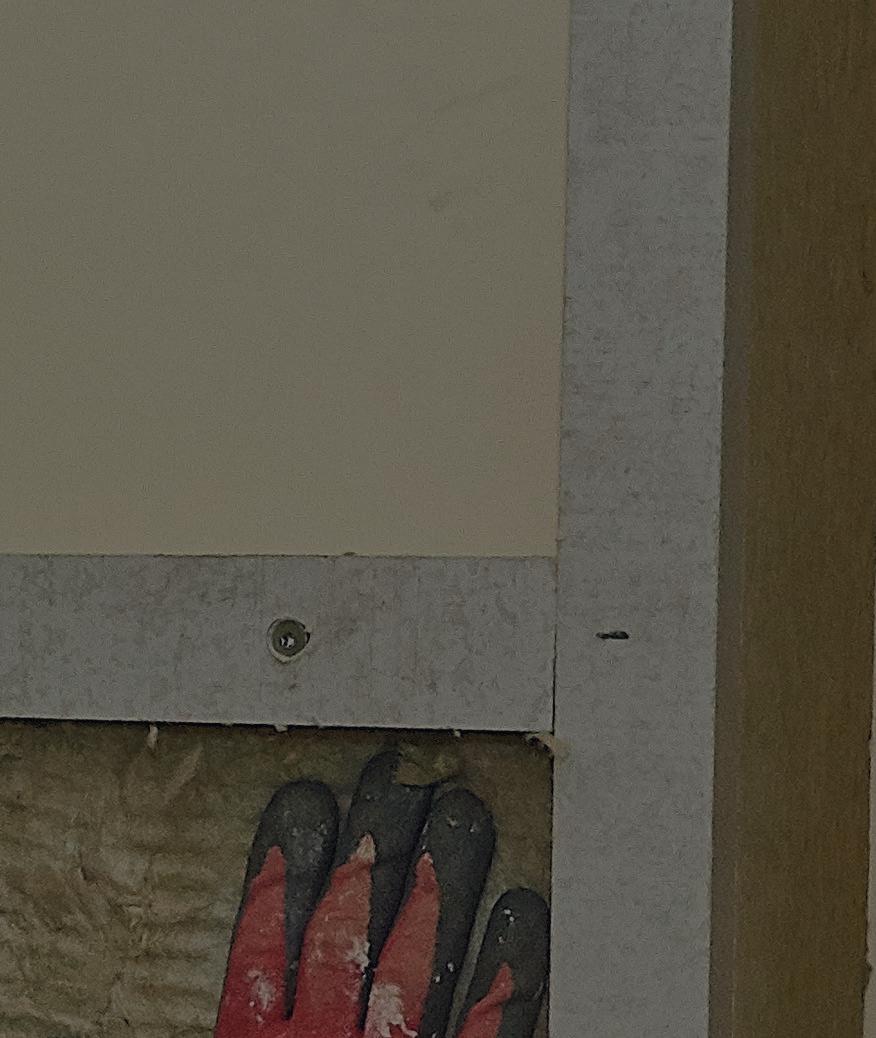

Image 1: Frameclad have conducted over fifty fire tests to date and are continuously expanding test data.

Image 2: Frameclad’s light steel frame systems achieve up to 120 minutes fire resistance.

Frameclad - Enquiry 21

AIM – Acoustic & Insulation Manufacturing has demonstrated that its Wall Cavity Barrier (Red Edition) provides effective fire performance without compression in masonry construction. The new zero compression solution means AIM’s Wall Cavity Barrier (Red Edition) can be installed easily with green brickwork, or other forms of masonry cladding, and avoids the problem of “brick push off” which can be associated with barriers installed under compression.

Acting as a fire and smoke barrier for masonry cavity walls, AIM’s Wall Cavity Barrier (Red Edition) is used to provide a fully closed cavity fire barrier along compartmentation lines in the external cavity wall in a wide variety of construction types, including masonry and SFS.

The different barrier thicknesses of 75mm, 100mm and 125mm provide 30, 60 and 120-minute fire ratings to BS EN 1366-4.

Applicable to masonry construction only, zero compression installation has been tested horizontally and vertically for use within voids up to 400mm. The barrier is installed and then the bricks built up against its edge.

Once the mortar has set, AIM Acrylic Intumescent Mastic should be applied between the barrier and both substrates. A DPC separating layer can be included if required.

“Tests have demonstrated that the AIM Wall Cavity Barrier is effective without compression in masonry voids, a significant product enhancement that offers far greater flexibility during construction,” explains Ian Exall, AIM’s Commercial Director.

The high-density foil faced stone wool barrier also reduces airborne transmission of sound by a minimum of 21dB RW.

AIM will sell slab versions of the Wall Cavity Barrier (Red Edition) for zero compression applications – not cut barrier.

This is so that the installer has total flexibility in sizing of the barrier to exactly suit the cavity void size as required.

Installation details, with a step by step guide, can be found in AIM’s Wall Cavity Barrier (Red edition) Technical Guide, which can be downloaded at: https://www.aimlimited.co.uk/ solutions/wall-cavity-barrier/

Part of the Performance Technology Group, UK-based AIM - Acoustic & Insulation Manufacturing has over 30 years of experience in the design, testing and manufacturing of highquality fire, thermal and acoustic barriers. The company produces a wide

variety of bespoke insulation products to customer specification and a range of standard products.

Find out more at www.aimlimited.co.uk

AIM - Enquiry 22

Ultrapanel Building Technologies is celebrating two major victories after its next generation SIP system picked-up two coveted awards for new build and retrofit – on the same day!

BOS Innovation Hub Challenge

First-up, the team took centre stage at the BUILDOFFSITE Innovation Hub Challenge taking place during the inaugural day of Offsite Expo. Finalists pitched to judges and the assembled audience innovative offsite solutions, vying for a £5,000 marketing package and BOS membership.

Ultrapanel EWI wowed the crowd – with the system’s proven ability to efficiently retrofit outdated housing stock, improving lives, vastly reducing energy costs and carbon.

Andrew Thomson, Technical Director at Ultrapanel Building Technologies, said: “The challenge of decarbonising our existing housing stock is one of the most pressing issues of our time, and we are proud that our Ultrapanel EWI system has been recognised as a meaningful step toward delivering retrofit at pace and scale.”

Redefining the Future of Retrofit

Combining patented technology, prefabricated design and engineering excellence, Ultrapanel EWI goes beyond traditional retrofit methods, enabling registered housing providers and local authorities to upgrade outdated housing stock with minimal disruption to tenants. The system delivers robust, highperformance external wall insulation and roof upgrades across a wide range of housing types.

In the evening the Ultrapanel Building Technologies team had another cause for celebration, when Ultrapanel picked up the prestigious Product Innovation trophy at the Offsite Awards.

The win shines a spotlight on the company’s pioneering approach and confirms its patented Ultrapanel building system as a breakthrough in modern housebuilding – setting new benchmarks for speed, sustainability and scalability across the industry.

Innovation With Impact

Cutting construction timelines by up to 40% – weather-tight structures are delivered in days, not weeks.

Arriving onsite pre-fabricated and ready for rapid assembly by trained installers, the panels are up to 70% lighter than blockwork and 50% lighter than timber frame – reducing transport emissions, onsite plant requirements and overall embodied carbon.

Ultrapanel also delivers exceptional thermal performance, achieving average U-values of 0.16 W/m2K and the capability to meet Passivhaus standards.

Designed for disassembly, the system supports circular construction principles, enabling reuse, recycling and long-term sustainability.

Certified by both the BBA and NHBC Accepts, Ultrapanel meets the Future Homes Standard and exceeds the most rigorous safety, fire and energy performance requirements. With interchangeable wall depths and insulation types, the system offers true mass customisation opportunities.

Industry Recognition

By winning an Offsite Award and the BUILDOFFSITE Innovation Hub Challenge – Ultrapanel next generation SIP systems has cemented its

reputation as one of the most exciting innovations in the offsite construction sector today. Speaking of the award wins, Tristin Willis, Managing Director of Ultrapanel Building Technologies, said: “We are thrilled that Ultrapanel has been recognised as the Offsite Award winner for Product Innovation, and triumphed at the BUILDOFFSITE Innovation Hub challenge.

“These accolades are a testament to our team’s dedication to pushing the boundaries of what’s possible in modern construction. Ultrapanel is not just about faster build or retrofit times – it is about delivering homes to meet the toughest performance standards while driving down costs and carbon. At a time when the housing sector faces unprecedented challenges, this innovation is about delivering real, tangible benefits.”

Ultrapanel Building Technologies as part of the Ultraframe Group, was established to develop future-ready building solutions designed to deliver high-quality homes at speed and scale.

To find out more about retrofit applications and to watch the ‘live build’ video where a complete Ultrapanel super-structure for a detached new three bedroom home was installed in less than a day, head to: www.ultrapanel.co.uk

- Enquiry 23

Wetherby Wall Systems, part of the ROCKWOOL Group, has launched InteriA, a next-generation Internal Wall Insulation (IWI) system developed in response to increasing demand for enhanced fire safety and compliant retrofit solutions in line with today’s best- practice.

Internal Wall Insulation has long been recognised as a vital measure for improving the thermal performance of solid wall properties, particularly where external wall insulation is restricted by planning requirements, heritage considerations, or site access. Yet, the market has lacked a fully developed solution that can combine high fire resistance with the moisture management now identified as best practice by government guidance.

InteriA has been designed to meet both challenges head on. Constructed from A-rated components, the system offers strong fire performance, aligning with today’s more stringent safety expectations. In parallel, its moisture-open design reflects advice from the Department for Business, Energy & Industrial Strategy (BEIS), which highlights that the lowestrisk IWI solutions are those that allow walls to dry to both sides, minimising the risk of condensation and safeguarding long-term building health.

“InteriA has been developed in direct response to what the industry was asking for: an A-rated, moisture-open internal wall solution,” said Joe Ragdale, Technical Director at Wetherby Wall Systems. “By combining robust fire performance with safe moisture management, it provides

confidence for specifiers and housing providers that compliance, resident safety, and building durability are all addressed within one system.”

The InteriA build-up has been engineered with retrofit practicality in mind. A slim profile ensures compliance with UK refurbishment U-value targets using just 100mm of insulation, maximising internal space while delivering a step change in thermal efficiency. For residents, the result is warmer homes, reduced energy bills, and improved comfort levels.

Installation has been designed to be quick and minimally disruptive, making it particularly suited to occupied dwellings and phased upgrade programmes. This ensures that Housing Associations, Utility Companies, and Managing Agents can roll out retrofit schemes efficiently while keeping inconvenience to tenants to a minimum.

Now part of the ROCKWOOL Group, Wetherby Wall Systems combines its UK expertise with the group’s global innovation in stone wool insulation. The InteriA system benefits from this partnership by offering:

• Fire Safety – Built from A-rated, noncombustible stone wool components. Moisture Management – Breathable

design reduces risks of damp and mould.

• Thermal Efficiency – 0.034 W/(m·K) thermal conductivity provided by the main insulant.

• Sustainability – 60-year design life, fully recyclable materials, and RockCycle waste recovery.

• Compliance – Supports the requirements and recommendations of the BEIS best practice guide and PAS 2035.

For Housing Associations, InteriA provides a reliable way to improve building stock while ensuring resident safety. For Energy Providers, it offers a route to delivering energy efficiency targets and supporting government-backed retrofit initiatives. For Managing Agents and Certification Bodies, the system represents a tested, compliant option that reduces programme risk while simplifying quality assurance.

InteriA has been carefully developed from A-rated components to give specifiers confidence today. It marks a significant step forward for IWI solutions, offering a balance of fire performance, moisture safety, and sustainability in one system.

For technical support or project enquiries, contact Wetherby Wall Systems on 01942 717 100 or info@wall-systems.co.uk, or visit www.wall-systems.co.uk.

Wetherby Wall Systems - Enquiry 24

The construction of two apartment buildings within the ground-breaking Climate Innovation District in Leeds demonstrates how the EJOT CROSSFIX® substructure system enables rainscreen facades to be incorporated into highly sustainable buildings, without the need to vastly increase insulation depth.

Developed by Citu, this new sustainable neighbourhood provides over 500 low energy homes with a PHPP (Passive House Planning Package) assessed design.

The rear ventilated facade (RVF) of the development’s latest apartment buildings, District Lofts, was created wholly using EJOT CROSSFIX® after its successful deployment on the ground and first floor levels of neighbouring building, Aire Lofts.

CROSSFIX was chosen for the RVF substructure because it enabled the construction of a highly insulated envelope in line with the EWS1 fire safety rating without compromising aesthetics, and enabling installation to be streamlined. A mix of Swisspearl secret fix and through fix fibre cement panels were used, all installed by Hansen Facades working in conjunction with main contractor Artium Construction.

The innovative design and stainless steel composition of CROSSFIX, which minimises the risk of thermal bridging, enabled the thermal requirements to be achieved, creating a highly insulated facade accommodating a 250mm layer of Rockwool insulation with the required ventilation.

EJOT - Enquiry 25

CUPA PIZARRAS Heavy 3 roof slate has been installed on a new self-build home in Cawthorne, South Yorkshire.

Specified to echo the traditional style of neighbouring properties, the slate also provides a clean striking finish that complements the home’s extensive glazing.

Contractor Martyn Taylor from Taylor Development Service LTD commented: “The CUPA PIZARRAS Heavy 3 slate was recommended to me by Burton Roofing Merchants. I would highly recommend it as it was really nice to work with, so installation was easy.

“The natural slate complemented the tones of the Yorkshire stone property and those surrounding it, and we eventually installed 400 metres square of the slate. The finish is fantastic.”

CUPA PIZARRAS Heavy 3 slate comes in blue/black with a gritty texture, replicating traditional Scottish highland slate from Ballachulish, which is no longer available to purchase. It is heavier and thicker than standard slates - 7 to 8mm thick – which means it has the strength to withstand high-speed winds and driving rain.

As a natural slate product, Heavy 3 is also chemical, UV and pollutant resistant as well as noncombustible. As such it comes with a 100-year warranty as standard.

CUPA PIZARRAS -

From design to delivery –introducing BuildEase with Nudura

UK housing developers face mounting pressure: rising demand, labour shortages, compliance hurdles, and tight delivery schedules are straining traditional build methods.

Fragmented supply chains and inefficiencies are no longer sustainable. That’s why Nudura, backed by Tremco CPG UK, has launched BuildEase—a streamlined ICF delivery enablement service designed to simplify housing construction.

BuildEase offers a single partner from design to completion, aligning buildability, supplying tailored Nudura ICF systems, ensuring compliance, and supporting on-site execution.

Our factory-prepared ICF components reduce waste, speed up installation, and create cleaner, more controlled build environments. Everything arrives ready to install, based on your approved site layout.

Compliance is built in. Our systems are NHBC-ready from day one, with documentation prepared to support technical submissions and smooth approvals. We engage early to reduce risk and avoid last-minute surprises.

On-site, we provide supervision, crew training, and regular visits—ensuring correct installation and minimising errors. BuildEase also supports ESG goals by reducing material waste and transport emissions.

In a market demanding faster, smarter housing delivery, BuildEase delivers clarity, speed, and confidence. Whether building 10 homes or 100, our scalable system and integrated support make us the reliable partner for repeatable success.

Nudura - Enquiry 27

Daikin launches podcast series to navigate industry transformation

Daikin has announced the launch of ‘On Air With Daikin’, a new podcast series designed to keep HVAC professionals informed and ahead of rapid industry changes.

Hosted by Matteo Dall'Ombra, National Specification Manager at Daikin UK, the series features conversations with industry leaders, policy makers, technical experts and installers about the evolving HVAC landscape – with a key focus on decarbonisation, legislation changes and best practice.

"The HVAC world is moving quickly. New rules, new tech, and bigger sustainability goals are changing the game for all of us," said Dall'Ombra. "At Daikin, we've been leading that change for years, but we know technology alone isn't enough. Staying ahead means staying informed."

Bringing together diverse perspectives from across the industry, the podcast addresses the need for accessible, expert-driven content as the industry faces unprecedented transformation. Each episode delivers practical insights that professionals can implement immediately, from understanding complex regulations to identifying new business opportunities.

The podcast series directly tackles two critical needs in today's HVAC market: maintaining compliance with evolving regulations and remaining competitive in a rapidly changing landscape. By providing real-world advice from leading industry figures, ‘On Air With Daikin’ is as an essential resource for professionals at all levels.

Daikin - Enquiry 28

Viessmann offers 10-year warranty on the Vitodens 200-W boiler

Viessmann Climate Solutions UK has introduced a 10-year warranty on Vitodens 200-W boilers registered between September 1st and December 31st 2025.

The promotion is open to all installers who register any combi or system (11-32 kW) Vitodens 200-W gas-condensing wallhung boilers within 30 days of installation via the VPlus platform. Viessmann Climate Solutions is a part of Carrier Global Corporation (NYSE: CARR), global leader in intelligent climate and energy solutions.

Chris Leech, Marketing Manager, UK & Ireland, at Viessmann Climate Solutions UK, said, “For the 2025 heating season, we’re launching an attractive promotion that underlines Viessmann Climate Solution UK’s continued commitment to product quality, reliability, and customer confidence. The Vitodens 200-W is recognised as a premium product by the market, offering features such as a MatriX Plus burner and modulation range of 1:17, as well as Lambda Pro Plus automatic combustion control.”

The boiler is rated as energy efficiency class A with up to 98% efficiency under the EU Energyrelated Products (ErP) Directive. The new 10-year warranty extends the previous standard 7-year warranty on the Vitodens 200-W and indeed the Vitodens boiler range from the 050-W model upwards. Installers may still upgrade the new standard 10-year warranty to 12 years on the Vitodens 200-W at an additional cost.

Viessmann - Enquiry 29

A Banbury based gas heating specialist has successfully completed his first ever installation of an air-source heat pump (ASHP) using one of ESBE’s renowned 4-Way valves, as part of a significant energy upgrade to his own home which, being off-gas grid, had formerly been reliant on an oilfired boiler.

SMH Gas Specialist Ltd. was originally set up by Mark Hall’s father back in the eighties and has built up a strong reputation serving customers across Oxfordshire and beyond, mainly being involved with high end domestic houses and renovations.

With the main part of the property comprising a 300-year-old brick structure, with much later extensions in both solid wall and cavity wall construction, the heat loss calculation generated a worrying figure of 20kW across the 250m2 home.

Significant fabric improvements were therefore required across the building envelope before even a high-performance heat pump could be considered.

However, having recently completed a course at the renowned Northampton Heating Academy and Heat Geek training, Mark also sought to find efficiencies by employing the ESBE valve to help address the costly ‘defrost cycle’ which affects most ASHP setups in colder weather.

The ESBE range of advanced hydronic products is available UK wide through its distributor partners.

range of

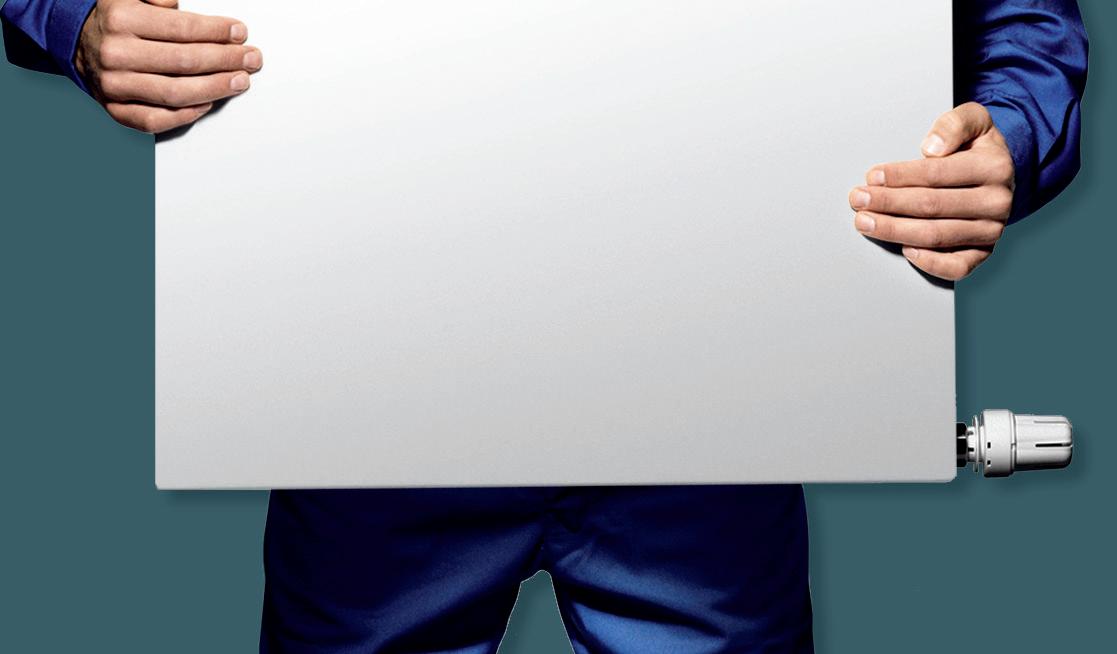

Heating systems are increasingly being designed with lower flow temperatures to help decarbonise buildings. To maximize impact, it‘s crucial to choose the right heat emitters and user-friendly controls for precise temperature management.

As a total solutions provider, Myson has carefully created a complete range that caters to all needs. Ranging from hydronic and electric radiators to underfloor heating, heating valves and electronic controls, all products are designed to offer the highest levels of comfort and efficiency.

Low Temperature Heating Solutions, it has to be MYSON

Explore our solutions