www.propack.pro June 2024 People Technology Business A FOCUS ON: ALSO INSIDE... Jet Technologies and Polly Automatics launch JetIQ range in Australia

& Pack installs Komori GL640 Press at Packaging design trends How brands are embracing new packaging design trends to connect with consumers Sustainability – the ‘megatrend’ Why the time is now for the packaging industry to focus on sustainability Archie Rose’s custom label offering Archie Rose Distilling Co is taking personalisation to new heights

Print

Thanks for doing a great job on the Annual Reports.

They were really pleased with them. I am sure I will have more jobs to print with them soon!!

Nicole - 18/4/24

Wow, thank you!

Your turn-around time on business cards is fantastic.

Thanks again!

Sarah - 9/4/24

The end result of that last foil job you did for us but it came out amazing. The registration was spot on and looked great. Thank you to both yourself and your production team for the great work.

Kris - 28/3/24

I received the job yesterday a day earlier than expected - which was fantastic.

The printing quality is excellent, and overall, I’m very happy with the service.

Thank you!

Jorge - 7/3/24

Just a quicky to let you know both urgent jobs arrived at the Adelaide Expo yesterday.

My client is super happy, so thank you as always

x

Mel - 5/3/24

Thank you for all your invaluable help arranging the printing and delivery of the brochure. It was received extremely well and the printing quality is just superb.

Guy - 8/2/24

OF OUR NEW CLIENTS ARE REFERRALS

YOU CAN SEE WHY...

AUSTRALIA’S BEST TRADE PRINTER

Sustainability and customisation redefining packaging

Sustainability has been a focus for the packaging industry for many years, but it appears to be reaching a critical point. In fact, 2025 is the target year for the many sustainability goals that hundreds of corporations and companies have committed to.

Across all industries, companies are looking for innovations that reduce their environmental footprint. For the packaging sector, the focus is not only on the adoption of biodegradable packaging and recyclable materials, but also sustainable practices and processes, such as minimising waste and energy consumption.

Proving just how important sustainability is for the packaging industry, drupa has made sustainability one of its two ‘megatrends’, along with digitalisation.

According to drupa, “Industry 4.0 is the key to overall sustainable production in the print and packaging industry”. However, sustainability is a huge, multifaceted topic, without easy solutions. Each company needs to identify where they can make the greatest strides forward. In this issue, Bobst’s head of corporate sustainability, Sylvain Lieb, examines how the organisation is leading the sustainability charge across three defined streams – operations, equipment, and packaging use and end-of-life.

Another trend heavily shaping the packaging sector is customised packaging. Customised packaging has gained momentum as brands strive to establish a deeper connection with consumers through personalised experiences. In the era of advancing print technology, the ability to print custom packaging has

opened up exciting possibilities for brands to tailor products to individual preferences. Archie Rose is one such brand that is taking its custom label offering to new heights. In this issue, we take a look at how the success of the Australian distillery’s personalised spirit labels. You can read more about this case study on page 28.

This edition also examines other key packaging design trends to watch. It’s clear that in 2024 brands are not only prioritising eye-catching designs when it comes to packaging design, but are taking into consideration other key components such as inclusivity, creativity, and anti-counterfeiting. Discover how innovation is redefining packaging design to engage with consumers on page 30.

Claire Hibbit | Managing Editor CHibbit@intermedia.com.au

www.propack.pro EDITOR’S LETTER

4 ProPack.pro June 2024 Stay informed… visit www.propack.pro and subscribe to receive the latest packaging industry news and views

ProPack.pro is published by Printer Media Group, registered in Australia ABN 47 628 473 334. This publication may not be reproduced or transmitted in any form in whole or in part without the written permission of the publishers. While every care has been taken in the preparation of this magazine, it is a condition of distribution that the publisher does not assume any responsibility or liability for any loss or damage which may result from any inaccuracy or omission in the publication. Managing Director & Publisher: James Wells Editor: Claire Hibbit News Editor: Melissa Parker Production Manager: Jacqui Cooper Pre-Press Manager: Tony Willson Design: Sarah Vella Printed by: Hero Print, Alexandria, NSW 2015 Mailed by: D&D Mailing Services DISCLAIMER This publication is published by The Intermedia Group Pty Ltd (the “Publisher”). Materials in this publication have been created by a variety of different entities and, to the extent permitted by law, the Publisher accepts no liability for materials created by others. All materials should be considered protected by Australian and international intellectual property laws. Unless you are authorised by law or the copyright owner to do so, you may not copy any of the materials. The mention of a product or service, person or company in this publication does not indicate the Publisher’s endorsement. The views expressed in this publication do not necessarily represent the opinion of the Publisher, its agents, company officers or employees. Any use of the information contained in this publication is at the sole risk of the person using that information. The user should make independent enquiries as to the accuracy of the information before relying on that information. All express or implied terms, conditions, warranties, statements, assurances and representations in relation to the Publisher, its publications and its services are expressly excluded save for those conditions and warranties which must be implied under the laws of any State of Australia or the provisions of Division 2 of Part V of the Trade Practices Act 1974 and any statutory modification or re-enactment thereof. To the extent permitted by law, the Publisher will not be liable for any damages including special, exemplary, punitive or consequential damages (including but not limited to economic loss or loss of profit or revenue or loss of opportunity) or indirect loss or damage of any kind arising in contract, tort or otherwise, even if advised of the possibility of such loss of profits or damages. While we use our best endeavours to ensure accuracy of the materials we create, to the extent permitted by law, the Publisher excludes all liability for loss resulting from any inaccuracies or false or misleading statements that may appear in this publication. Copyright © 2024 — Charted Media Group Pty Ltd ProPack.pro National Sales Manager Carmen Ciappara +61 2 410 582 450 carmen@proprint.com.au Claire Hibbit

ProPack Industry Supporters

IN THIS ISSUE...

Peacock Group acquires insignia P06

Peacock Group acquires insignia to become the most experienced provider in Australia.

TricorBraun acquires two Australian packaging distributors P08

TricorBraun expands footprint across Australia and New Zealand following acquisitions of two packaging distributors.

Durst and OMET to unveil KJet hybrid machine at drupa P08

Durst Group to unveil its latest innovation, the KJet hybrid machine, for the first time at drupa.

Miraclon and Bobst reinforce strategic partnership P10

Miraclon and Bobst reinforce strategic partnership, with Miraclon named as Bobst’s new Competence Center in Atlanta.

Graffica welcomes new supplier launches at drupa P12

Graffica announces new launches from Kolbus, Century Machinery, and Wonder Digital at drupa.

Xeikon unveils 1200 dpi inkjet press for high-end label segment P16

Xeikon reveals details of the next evolution Panther inkjet technology to launch at drupa.

Jet Technologies and Polly Automatics launch JetIQ range in Australia P018

Jet Technologies and Polly Automatics team up to launch the JetIQ range in Australia.

COVER STORY Johnston Packaging continues Komori journey P20

Johnston Packaging is reaping the rewards of its new Komori GL640 Advance 6-colour UV/IR/HA coater press – sold and installed by Print & Pack.

Sustainability – the ‘megatrend’ requiring commitment, collaboration, and continuous innovation P26

Sustainability has been a focus for the packaging industry for many years, but it appears to be reaching a critical point.

OKI’s label printer streamlines a leading Australian distillery’s custom label offering P28

The purchase of OKI Label Printers is elevating Archie Rose Distilling Co. and its Tailored Spirits Experience to new heights

Consumer-focused packaging design trends shaping 2024 P32

How brands are embracing new packaging design trends in 2024 to connect with consumers.

Pack diary P36

A guide to upcoming events globally

CONTENTS

THIS ISSUE SUPPORTED BY

P28

P32

June 2024 ProPack.pro 5

P26

Peacock Group acquires insignia

Australian print packaging and supply chain technology provider Peacock Group acquires insignia to become the most experienced provider in Australia.

The family-owned group established in 1888 has announced it has signed an agreement to acquire the 55-yearold family-owned specialist labelling, coding and data capture company.

The move combines almost 200 years of printing, coding and supply chain technology expertise and merges two of Australia’s reputable family-run businesses within the supply chain solutions industry.

“We are excited to welcome insignia to the Peacock Group. insignia has long been a respected competitor within our industry. Their professional team and expertise, combined with state-of-the-art print manufacturing facilities, allows us to significantly expand our product and service offerings within the region whilst also providing exciting opportunities for our staff, customers, and partners,” said Ryan McGrath, Peacock Group managing director.

For over half a century, insignia has built a reputation as the expert in product identification and traceability. It works with world-leading brands in thermal printing, data capture, and marking and coding solutions, including Domino, Zebra, Honeywell, GS1, and more. insignia is also a leading national label manufacturer, producing custom prime product labels, overprint labels, and blank labels and tags from its production facilities in Brisbane and Melbourne.

insignia operates nationally with over 115 staff members. The company services over 3,500 customers, including multinational businesses across a broad range of industries, including retail, T&L, manufacturing, automotive, food & beverage.

insignia will operate alongside the other key Peacock Group businesses, Peacock Bros. and AMR Hewitts Print Packaging, expanding Group resourcing to over 300

staff and broader geographical depth across Australia and New Zealand. The acquisition combines key skill sets and capabilities to provide world-leading products and solutions to a customer base in excess of 15,000 throughout the region.

“insignia is a proud family-run business with extensive experience solving complex operational challenges for leading brands in Australia. We are pleased to join the Peacock Group, another long-established family-owned business that shares common values and is respected for the quality of its work. Our staff and customers can be reassured that the long history of our company and brand will continue well into the future with the support and backing of the Peacock Group,” said Jack Winson, managing director for insignia.

“The ability to identify and track goods from manufacturing through the supply chain and into retail settings is essential today. insignia leads the way in enhancing the efficiency and accuracy of critical business operations for Australian companies, improving supply chains with advanced technologies. Peacock Group looks forward to supporting insignia’s highly regarded team and growing its business in the future,” said McGrath.

McGrath told ProPack, “I am excited to welcome insignia into the Peacock Group family. Our companies’ shared values and business ethos create a unique opportunity for unparalleled growth and success. By merging our strengths and resources, we are primed to accomplish extraordinary milestones together.”

www.propack.pro 6 ProPack.pro June 2024

Established in 1888 as a printing business, Peacock Group has grown into one of the ANZ region’s largest providers of printing and data capture solutions

NEWS

insignia operates nationally, with more than 115 staff members

VOC FREE HEAV Y METAL FREE REACH COMPLIANT For more information, please contact info@durst-group.com HIGH PRODUCTION FLATBED LED UV PRINTER The Vanguard Digital VK300D-HS is the impressive high speed version of our six-time award winning VK300D series.

TricorBraun acquires two Australian packaging distributors

TricorBraun has acquired spirits packaging distributor UniquePak and industrial packaging distributor Alplas Products (Alplas), further expanding the company’s footprint across Australia and New Zealand.

“These acquisitions broaden our capabilities for spirits and industrial packaging across Australia and New Zealand,” said Andrew Allsop, managing director, TricorBraun ANZ.

“The UniquePak and Alplas teams are highly respected for their expertise, focus on quality, and customer service, and we look forward to investing in their continued growth.”

NSW-based UniquePak is an importer of glass and related packaging products into the wine, spirit, food and pharmaceutical markets of Australia, New Zealand, Europe, and the USA.

Durst and OMET to unveil KJet hybrid machine at drupa

Durst will unveil the next stage of its collaboration with OMET at drupa in Düsseldorf later this month with the release of the KJet digital and flexo hybrid machine.

The KJet hybrid machine is the latest product to be launched under Durst’s partnership with fellow family-owned Italian company OMET, which was first announced in September 2023.

“The KJet is the culmination of the cooperation between Durst and OMET, two business at the top of their game, delivering the solution label converters need, and exclusively supplied and serviced by Durst Oceania,” said Matt Ashman, managing director of Durst Oceania.

According to Durst, the KJet represents the pinnacle of hybrid technology, offering operators a seamless experience with its user-friendly interface and ultra-short web path. This design not only minimises waste but also reduces setup times, showcasing the advantages of digital printing.

Thomas Macina, sales director for labels and flexible packaging at Durst, said the KJet optimises efficiency, while reducing costs.

“The combination of digital with flexo offers an innovative hybrid solution that maximises productivity and flexibility, enabling printers to select between flexo

Alplas Products has operated from Melbourne since 1974 supplying plastic drum taps, valves, and fittings for metal and plastic drums and fittings for all brands of Intermediate Bulk Containers (IBCs).

The companies will continue as standalone businesses, operating as UniquePak, a TricorBraun company, and Alplas Products, a TricorBraun company.

Over time, the companies will transition to the TricorBraun ANZ brand. All UniquePak and Alplas team members will remain with TricorBraun.

TricorBraun established its footprint in the region with the acquisitions of Cormack Packaging in 2021, PB Packaging in 2022, and Plas-Pak Western Australia in 2024.

“For nearly a decade, customers have relied on UniquePak for our wide range of design and sourcing capabilities, and they can continue to do so with the added benefits of TricorBraun’s resources,” said Travis Norman, managing director, UniquePak.

“TricorBraun’s extensive capabilities, along with its dedication to quality and customer service, make it a perfect partner for our next chapter.”

With the acquisition, TricorBraun will leverage UniquePak’s expertise to expand its glass packaging offerings and capabilities to TricorBraun customers in ANZ and globally.

According to TricorBraun, the Alplas acquisition enables TricorBraun to add Alplas’ full scope of industrial packaging products to its existing offering.

TricorBraun, which was established in 1902, operates from more than 100 locations in the Americas, Europe, Asia, and Australia, employing more than 2000 people globally. Since its founding, TricorBraun has partnered with management teams to acquire 44 packaging companies globally.

Financial terms were not disclosed.

or digital printing, thereby optimising efficiency and reducing costs while meeting evolving market demands such as personalisation and just-in-time deliveries in a single-pass,” Macina said.

“We have been leading the inkjet label printing market for many years and we provide solutions for all label converters around the world, starting with entry level solutions up to industrial needs with 100 metres per minute and 510 millimetres wide,” Macina said.

“We have been observing a clear market trend towards end-to-end production and this is why we have reinforced our partnership with OMET. At drupa, you will see we are launching a new machine – the KJet – which is the perfect combination of a dual-servo cylinder based flexo unit combined with the robustness, efficiency, and productivity of the Durst RSCi digital print engine. This provides a new experience to operators in terms of simplicity, minimal set-up time and low waste.”

www.propack.pro 8 ProPack.pro June 2024 NEWS

Travis Norman (UniquePak) and Andrew Allsop (TricorBraun ANZ)

Matt Ashman (Durst Oceania) and Claudio Piretta (OMET)

Jet Press FP790

The Jet Press FP790 digital press could be considered to be three presses in one, able to:

•Print digitally, with all the benefits of digital production

•Print mainstream flexo jobs

•Print rotogravure quality jobs

To discover more, scan below:

FUJIFILM and FUJIFILM Value for Innovation are trademarks of FUJIFILM Corporation. ©2024 FUJIFILM Corporation. All rights reserved.

ABG launches Vectra AutoSet turret rewinder

ABG has announced the launch of the new Vectra AutoSet, the latest addition to its Vectra family of turret rewinders that includes the Vectra ECTR and HDTR models.

The launch marks a significant milestone of 30 years of Vectra production and the successful installation of more than 2500 units.

The Vectra AutoSet, which was initially demonstrated at Labelexpo Europe 2023 features a state-of-the-art AutoSet cutting mechanism, enabling a fully automated set-up that integrates the latest in label applicator technology.

A notable feature is the optional inclusion of the fleyeVision camera system and ABG Connect – offering complete 100 per cent inspection with full automation and connection to an MIS system, all within a non-stop process. This integration is crucial, as it forms a key component of the ABG automation infrastructure, enhancing productivity and reducing the need for extensive operator skill and time.

Additionally, the Vectra AutoSet boasts advanced SKU label printing capabilities and introduces a new glue application method. This method utilises heat exchange technology to extend the open time of the glue, offering greater control and the option to switch between a spiral and glue stripe for narrow cores.

The design of the Vectra AutoSet ensures easy mechanical integration with ABG’s Digicon Series 3 and Converter, as well as third-party presses, providing

Miraclon and Bobst reinforce strategic partnership

Miraclon and Bobst have reinforced their strategic partnership, with Miraclon named as the plate technology partner in Bobst’s new Competence Center in Atlanta.

The center is home to a Flexcel NX System and Flexcel NX Ultra Processing solution to support Bobst’s goal to produce plates that maximise the performance of their presses.

Emma Weston, chief marketing officer, Miraclon, said, “We’ve been collaborating closely with Bobst since our partnership in Europe started more than eight years ago. Visitors to the Bobst Bielefeld Demo Center in Germany have been able to see Flexcel NX plates in action after we installed a Flexcel NX System in 2019. Our strategic

flexibility for different operational needs. Furthermore, it is available with or without a glue option, catering to a wide range of industry requirements.

Mark Norman, technical director at ABG, said the Vectra range has been instrumental in driving efficiencies for customers for many years.

“This new model not only consolidates

Miraclon has been named as the plate technology partner in BOBST’s new Competence Center in Atlanta

relationship underscores both companies’ commitment to enabling our customers and partners to achieve their efficiency,

Vectra’s position as the premier turret rewinder in the market, but also future proofs it with a host of new features and enhanced functionality. The Vectra AutoSet is a testament to our commitment to advancing our customers’ businesses.”

ABG’s entire portfolio is available through Currie Group, the regional distributor of its equipment in Australia and New Zealand.

sustainability, and quality goals with some of the best technology and expertise in the industry.”

The Bobst Competence Center will also be utilised by Miraclon for on-press demonstrations and print trials, giving printers and trade shops in North and South America the opportunity to see firsthand the on-press productivity and savings that Flexcel NX Technology offers. The Miraclon and BOBST partnership will likewise see the companies co-hosting industry events to promote how the technology enables efficient packaging printing.

Emilio Corti, region business director, Americas at Bobst said, “Our longstanding partnership with Miraclon underpins our vision of shaping the future of the packaging world. With sustainability at the forefront of our customers’ and brand owners’ minds, our partnership enables them to see how our collaboration maximises their investment and help to unlock new potential in the press room.”

www.propack.pro 10 ProPack.pro June 2024 NEWS

ABG has announced the launch of the Vectra AutoSet, the latest addition to the Vectra family of turret rewinders

The

Insignia

SERIES DIE CUTTER

magnetic die cutter designed for production-driven operation at an a ordable price point. PRESENTS

SERIES DIE CUTTER

is a sheet-fed, rotar y,

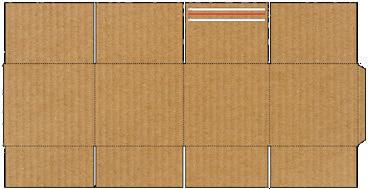

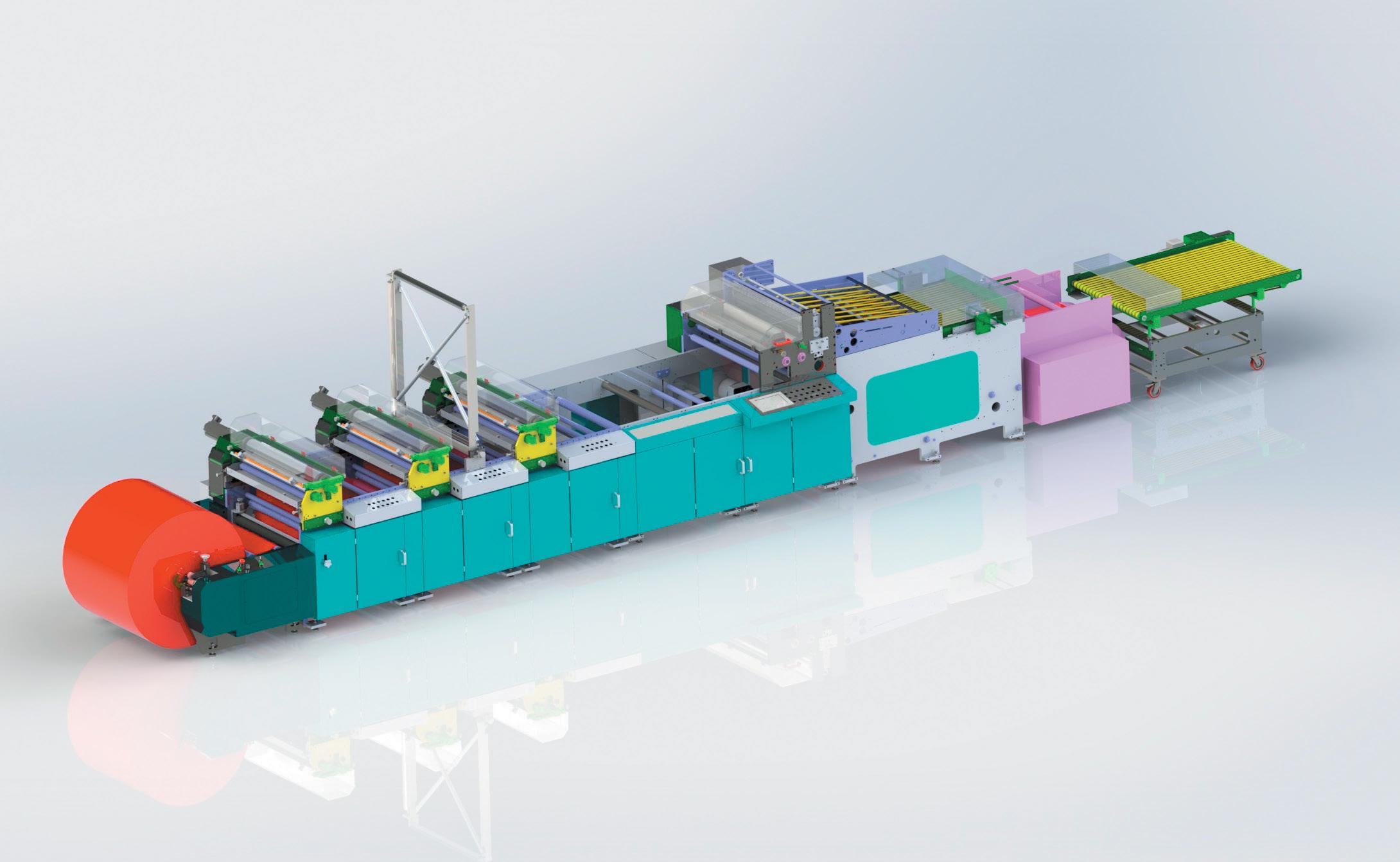

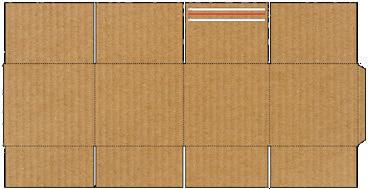

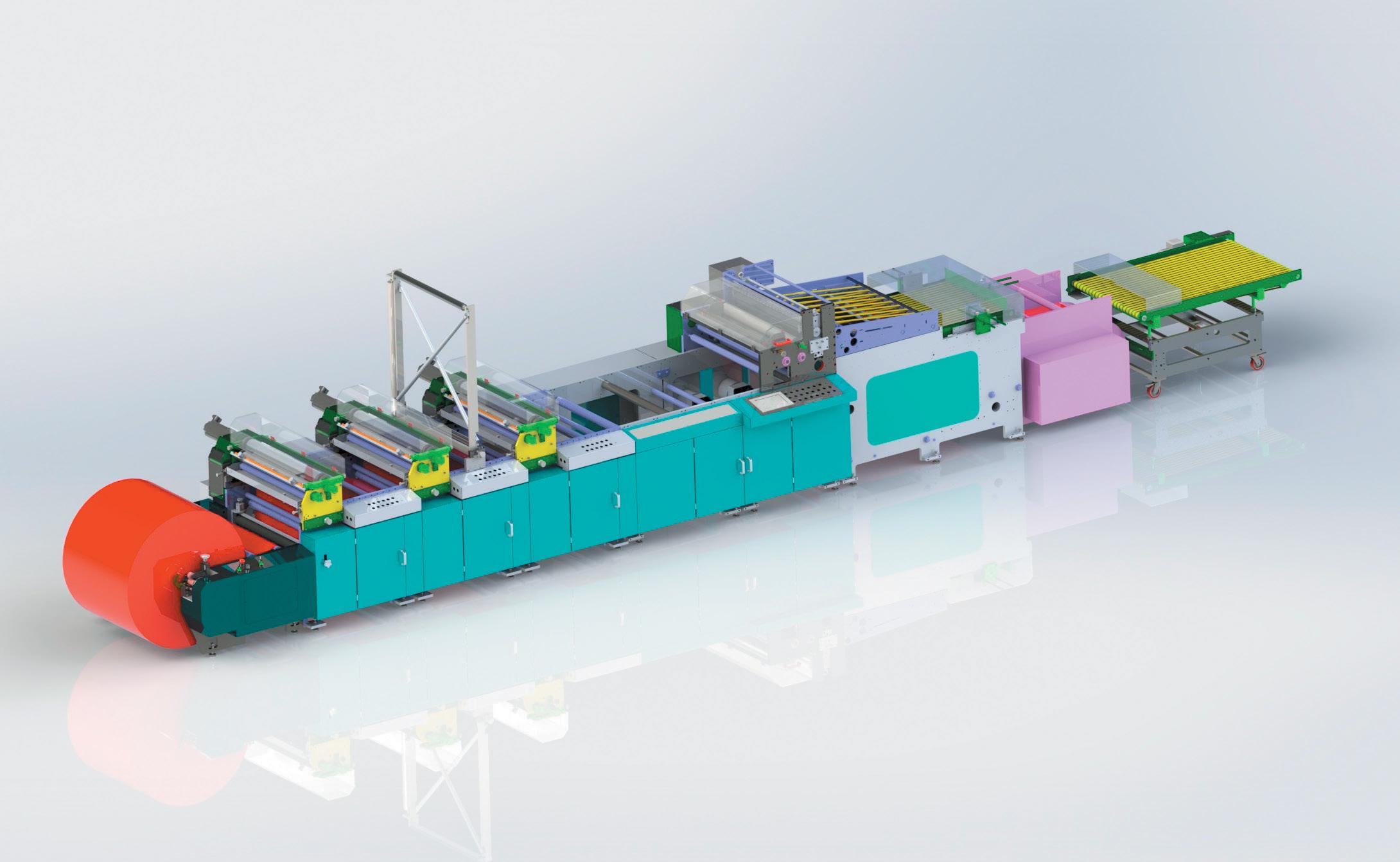

Maxi Box machines for the corrugated market

A TRUE GUIDE & GRIP REGI SYSTEM ENSURE SHEET-TO-SHEET ACCURACY. SIDE PULL GUIDE CAPABLE OF PULLING EITHER LEFT OR RIGHT TO MATCH REGISTER EDGES.

Maxi Box can be offered as a semi automatic or fully automatic machine for applying glue and double-sided adhesive on corrugated also optioned with folding ploughs and various gluing arrangements for a wide range of applications.

TRIPPING UNIT

Features

• Feeder is extendable

• Possibility of double production

• Versatile solution for a wide range

• Media – Cardboard, Corrugated and Forex

• Models 1600 and 2000 wide and by request to 3500 wide

Options

Folding gluing machine with hand feeder and delivery table

• Mobile Pocket

A TRUE GUIDE & GRIP REGI SYSTEM ENSURE SHEET-TO-SHEET ACCURACY. SIDE PULL GUIDE CAPABLE OF PULLING EITHER LEFT OR RIGHT TO MATCH REGISTER EDGES.

Born for eCommerce these machines are built in Europe but aimed at a competitive price tag.

• Double Sided Tape Applicators (RAP 25)

• Silicone Applicators (SIL RAP)

• Tear Strip Applicators (STRIP RAP)

• Magnet Applicators (MAG RAP)

A TRUE GUIDE & GRIP REGISTER SYSTEM ENSURE-SHEET TO-SHEET ACCURACY. SIDE PULL GUIDE CAPABLE OF PULLING EITHER LEFT OR RIGHT TO MATCH PRESS REGISTER EDGES. A TOP SUCTION AIR FEEDER IS POWERED VIA A BUILT IN BLOWER PUMP IN THE MACHINE. AN OPERATOR CAN INDEPENDENTLY ADJUST VOLUMES OF BOTH BLOW & SUCTION TO ADJUST FOR THE WIDEST RANGE OF MATERIALS POSSIBLE. INDEPENDENT SUCKER HEADS CAN BE ADJUSTED TO SHEET SIZE.

Same machine as Box 1 but is upgradable to add the automatic continuous feeder PLUS an automatic delivery table

A TOP SUCTION AIR FEEDER IS POWERED VIA A BUIL T IN BLOWER PUMP IN THE MACHINE. AN OPERATOR INDEPENDENTLY ADJUST VOLUMES OF BOTH BLOW SUCTION TO ADJUST FOR WIDEST RANGE OF MATERIALS POSSIBLE. INDEPENDENT SUCKER HEADS CAN BE ADJUSTED TO SHEET SIZE.

Watch the Maxi Box Gluer and Tape machine in operation

A TRUE GUIDE & GRIP REGI SYSTEM ENSURE SHEET-TO-SHEET ACCURACY. SIDE PULL GUIDE CAPABLE OF PULLING EITHER LEFT OR RIGHT TO MATCH REGISTER EDGES. A TOP SUCTION AIR FEEDER IS POWERED VIA A BUILT IN BLOWER PUMP IN THE MACHINE. AN OPERATOR INDEPENDENTLY ADJUST VOLUMES OF BOTH BLOW SUCTION TO ADJUST FOR WIDEST RANGE OF MATERIALS POSSIBLE. INDEPENDENT SUCKER HEADS CAN BE ADJUSTED TO SHEET SIZE.

Scan to watch

A TOP SUCTION AIR FEEDER IS POWERED VIA A BUIL T IN BLOWER PUMP IN THE MACHINE. AN OPERATOR INDEPENDENTLY ADJUST VOLUMES OF BOTH BLOW SUCTION TO ADJUST FOR WIDEST RANGE OF MATERIALS POSSIBLE. INDEPENDENT SUCKER HEADS CAN BE ADJUSTED TO SHEET SIZE.

A RECESSED SCRIBE LINE ON SINGLE MAGNETIC MACHINES ALLOW FOR FAST, CONSIS DIE MOUNTING & ENSURES TOOLS ARE HUNG PARALLEL CENTERED.

A RECESSED SCRIBE LINE ON SINGLE MAGNETIC MACHINES ALLOW FOR FAST, CONSISTENT DIE MOUNTING & ENSURES OOLS ARE HUNG PARALLEL CENTERED.

A RECESSED SCRIBE LINE ON SINGLE MAGNETIC MACHINES ALLOW FOR FAST, CONSIS DIE MOUNTING & ENSURES TOOLS ARE HUNG PARALLEL CENTERED.

Same machine as Box 1 but is also upgradable by added second folding unit to fold and glue crash lock bottom and machine

PIN MOUNT SYSTEM ON GNETIC MACHINES ENSURE THE ALIGNMENT OF THE P OOLS. CYLINDERS VE BUILT-IN MICR ADJUSTMENT CAPABILITIES ENSURE MATING.

YSTEM ON D ACHINES ENSURE THE ALIGNMENT OF THE PAIRED OOLS. CYLINDERS ALSO HAVE BUILT-IN MICROADJUSTMENT CAPABILITIES ENSURE MATING.

MOUNT S TEM ON DUAL GNETIC MACHINES ENSURE THE ALIGNMENT OF THE P SET OF DIE T OOLS. CYLINDERS ALSO HAVE BUILT-IN MICR ADJUSTMENT CAPABILITIES ENSURE MATING.

A RECESSED SCRIBE LINE ON SINGLE MAGNETIC MACHINES ALLOW FOR FAST, CONSIS DIE MOUNTING & ENSURES TOOLS ARE HUNG PARALLEL PIN MOUNT SYSTEM ON GNETIC MACHINES ENSURE THE ALIGNMENT OF THE P SET OF DIE T OOLS. CYLINDERS ALSO HAVE BUILT-IN MICR ADJUSTMENT CAPABILITIES ENSURE MATING.

These machines have been designed with a manual feeder for various formats of punched and creased materials.

All the materials are positioned by the operator, and at the same time, the machine is set up to add a continuous PLUS FEEDER.

HYDRAULIC PRESSURE ASSEMBLIES ARE ADJUSTED VIA THE BL ACK WHEEL. INFINITE ADJUSTABLE UP TO 3,000 CUTTING PRESSURE IS AVAI GAUGES ENABLE OPERATOR DETERMINE MINIMUM PRESSURES TO EXTEND DIE LIFE.

HYDRAULIC PRESSURE ASSEMBLIES ARE ADJUSTED VIA THE BL ACK WHEEL. INFINITE ADJUSTABLE UP TO 3,000 PSI CUTTING PRESSURE IS AVAIL GAUGES ENABLE OPERATOR DETERMINE MINIMUM PRESSURES TO EXTEND DIE LIFE.

Scan to watch

HYDRAULIC PRESSURE ASSEMBLIES ARE ADJUSTED VIA THE BL ACK WHEEL. INFINITE ADJUSTABLE UP TO 3,000 CUTTING PRESSURE IS AVAI GAUGES ENABLE OPERATOR DETERMINE MINIMUM PRESSURES TO EXTEND DIE LIFE.

HYDRAULIC PRESSURE ASSEMBLIES ARE ADJUSTED VIA THE BL ACK WHEEL. INFINITE ADJUSTABLE UP TO 3,000 CUTTING PRESSURE IS AVAI GAUGES ENABLE OPERATOR DETERMINE MINIMUM PRESSURES TO EXTEND DIE LIFE.

S pe c ia li s i n g i n C a p it a l Equ ip m e n t Sa l es , S e r vi ce , Engineering Solutions and Consumables. Enquiries: info@graph-pak.com.au FOR FURTHER INFORMATION PLEASE CONTACT OUR HEAD OFFICE Unit 1G, 1-3 Endeavour Road, Caringbah NSW 2229, email: info@graph-pak.com.au Toll Free: 1300 885 550 www.gra ph-pak.com.au SERIES DIE CUTTER INSIGNIAS W/ WASTE STRIPPING UNIT

The Insignia is a sheet-fed rotar y flexo magnetic die cutte for production-driven operatio an a ordable price point. SUPPLIER P solutions and services that enable our customers to maximise their business potential. S pe c ia li s i n g i n C a p it a l Equ ip m e n t Sa l es , S e r vi ce , Engineering Solutions and Consumables Enquiries: info@graph-pak.com.au FOR FURTHER INFORMATION PLEASE CONTACT OUR HEAD OFFICE Unit 1G, 1-3 Endeavour Road, Caringbah NSW 2229, email: info@graph-pak.com.au Toll Free: 1300 885 550 www.gra ph-pak.com.au

INSIGNIAS W/ WASTE STRIPPING UNIT TACKER

SERIES DIE CUTTER

The Insignia is a sheet-fed flexo magnetic die cutte for production-driven operatio an a ordable price point. S pe c ia li s i n g i n C a p it a l Equ ip m e n t Sa l es , S e r vi ce , Engineering Solutions and Consumables Enquiries: info@graph-pak.com.au FOR FURTHER INFORMATION PLEASE CONTACT OUR HEAD OFFICE Unit 1G, 1-3 Endeavour Road, Caringbah NSW 2229, email: info@graph-pak.com.au Toll Free: 1300 885 550 www.gra ph-pak.com.au

TACKER

The Insignia is a sheet-fed flexo magnetic die cutte for production-driven operation at an a ordable price point. S pe c ia li s i n g i n C a p it a l Equ ip m e n t Sa l es , S e r vi ce , Engineering Solutions and Consumables Enquiries: info@graph-pak.com.au FOR FURTHER INFORMATION PLEASE CONTACT OUR HEAD OFFICE Unit 1G, 1-3 Endeavour Road, Caringbah NSW 2229, email: info@graph-pak.com.au Toll Free: 1300 885 550 www.gra ph-pak.com.au

INSIGNIAS W/ WASTE STRIPPING UNIT INSIGNIA TACKER

flexo

Scan to watch

72 Grady Crescent, Erskine Park, NSW, 2759 Call us toll free: 1300 885 550 | www.graph-pak.com.au Established in 2006, specialising in capital equipment sales, services, engineering solutions, and consumables.

Graffica welcomes new supplier launches at drupa

Neil Southerington, owner of printing packaging and converting company, Graffica is excited to announce new launches from suppliers Kolbus, Century Machinery, and Wonderjet at drupa.

“My three major suppliers all have a strong presence, with large stands, and multiple exhibits including genuine new releases,” Southerington told ProPack.Pro

“Because of the delay in drupa timing, it seems many things have happened, and advances in technology marches on, with companies chomping at the bit, to get their latest and greatest out there on the world’s biggest stage.”

First Graffica supplier, Kolbus has always been a major presence at drupa and Southerington says it has several new machines, including a wide format Flexo printer slotter / die cutter and the all-new built ground, custom box maker BX Motion 2600.

Southerington said the Kolbus BX Motion will interest the ANZ market, where custom boxes in short runs are the norm.

“The Motion 2600 offers many integrated great features in one relatively small

Registration open for Labelexpo Americas 2024

Registration is now open for Labelexpo Americas 2024, the only dedicated event in the region for the labels and package printing industry.

The show takes place between 10-12 September at the Donald E. Stephens Convention Center in Rosemont, Illinois.

Hundreds of live demonstrations of flexo presses along with digital technology and finishing equipment will be on display. Nilpeter demonstrates a 26-inch FA-26 for the first time in the US along with a US-built FB-17 press. Mark Andy launches a new, wider flexo press, presenting a full line up of flexo and digital technology and HP presents an impressive line of equipment.

Expanded networking opportunities at Labelexpo Americas 2024 will focus on merging educational content and bringing the international package printing community together.

Labelexpo Americas 2024 will also feature a one-day conference program, expanded networking opportunities and two educational workshops and a master class, all aimed at the latest trends impacting the label and package printing industry.

footprint, with one operative. To name but a few features – multiple out in length and width. Built in lead edge feeder, in-line gluing, in-line digital or flexo print, waste removal and shredding, and much more. Kolbus also has an array of machines in the luxury packaging sphere.”

In addition, Graffica supplier, Century Machinery will launch the new model 1060Q high-speed die cutter, 8,500 s.p.h., with a thinplate system and triple-action stripping, at Hall 10 C01. The large-format 1850 semiauto die cutter and the new 1670 fully auto machine will also be demonstrated.

“Century Machinery is a well-known name in ANZ with 13 installations to date, mostly in

the larger formats fully auto and semi-auto 1050 to 2500,” said Southerington.

In Hall 5 D 08, Wonderjet will display the WD 200 Single-pass high-speed water-based printer with UV coater and slotting with Rotary die cutting in line. Southington said this is a first and must see for ANZ packaging companies. The single pass high-res UV printer Printmaster, as well as the multipass WD 250- 32A high res printer ideal for shorter run corrugated and folding cartons will also be displayed.

“Wonderjet has exhibited at many drupa shows in the past, being very early suppliers of corrugated and carton board printers to the world and the first to incorporate slotting and die cutting in-line.”

The show feature areas include a Flex Pack Factory, a focused area for flexible packaging and an RFID Zone and Innovation Stage, focusing on automation, RFID technology application and development.

Tasha Ventimiglia, group director, Labelexpo Americas said: “We’re excited to be back in Rosemont for Labelexpo Americas 2024 when the show returns in September. Attendees can expect to see a range of key innovations that are shaping the future of the label and package printing industry including sustainable material solutions, workflow automation and RFID technology. We can’t wait to connect and network with our international audience at this must

attend event for the industry.”

Linnea Keen, president, TLMI said: “TLMI values the partnership with the Labelexpo organization and what it means to our industry to bring together so many leaders. We can’t wait to see what the TLMI members showcase this year along with the new developments, innovations, and solutions that attendees are seeking. In addition to exhibiting, TLMI will be hosting Eco Stage with the most recent trends and updates related to sustainability. We look forward to supporting current members and meeting new members. Join TLMI and all the industry exhibitors at this year’s Labelexpo Americas 2024!”

www.propack.pro 12 ProPack.pro June 2024 NEWS

Labelexpo Americas 2024 will take place from 10 September until 12 September in Illinois

Century Machinery will launch the new model 1060Q high-speed die cutter

Two Sides global campaign reports increasing greenwashing as organisations focus on sustainability

Two Sides has challenged more than 2650 organisations found to be communicating greenwashing messages to their customers as the not-for-profit ramps up its antigreenwash campaign both globally and in Australia.

According to Two Sides – a global initiative promoting the unique sustainable and attractive attributes of print, paper, and paper packaging – 1180 organisations have, so far, removed misleading anti-paper statements.

Economic pressures remain the driver for much of greenwashing, and many organisations that have relied on paper to communicate with their customers are increasingly transitioning their customers from traditional paper-based services to digital platforms in a bid to reduce costs. The switch to digital is often justified by unsubstantiated environmental marketing messages such as, “Go Green – Go Paperless” or “Choose e-billing and help save a tree”.

Data from the Australian Competition &

Cardboard

manufacturer fined $40,000 after worker’s hand crushed

Lazo Paper Pty Ltd, now in liquidation, has been sentenced in the Dandenong Magistrates’ Court after being found guilty of two charges of failing to provide and maintain a plant that was safe and without risks to health.

The company was also ordered to pay costs of $4941.

In May 2022 the worker, who spoke little English, was tasked with cleaning a large gluing machine that consisted of a flat bench and two powered rollers.

The worker, who had not previously cleaned the machine or seen anyone else do the task, was wiping the bottom roller while it was running when the cloth became caught, dragging his hand between the rollers.

The worker suffered two broken fingers

Consumer Commission (ACCC) report titled, ‘Greenwashing by businesses in Australia 2023’ found that 57 per cent of businesses that were examined raised concerns of using vague or unclear environmental claims, not providing sufficient evidence for their claims, setting environmental goals without clear plans on how these will be achieved, and using third-party certifications and symbols in a confusing way.

Two Sides Australia & New Zealand manager Kellie Northwood said greenwash claims not only violate established environmental marketing regulations, but they are hugely damaging for an industry known for its strong and consistently progressive environmental record.

“Far from ‘saving trees’, a healthy market for forest products such as paper encourages the long-term growth of forests through sustainable forest management. Many of the organisations we challenge are surprised to

and was off work for eight weeks.

A WorkSafe investigation found guarding on the machine, which included the use of

learn that Australia alone has two million hectares of working forests and growing. That equates to over 1,000,000 MCGs in land cover,” said Northwood.

Globally, Two Sides has engaged more than 2650 organisations making misleading statements about paper. In Australia, since 2020, companies have removed unsubstantiated claims about paper, including telcos, schools, councils, retail, and insurance organisations to name a few.

“It remains vital that these misleading messages are challenged to ensure that the industry’s great environmental record is recognised and that the livelihoods of thousands of industry employees are not damaged by the spread of misleading and opportunistic greenwash marketing,” Northwood said.

Two Sides estimates that due to the vast reach of some of these organisations, unsubstantiated claims have a long-lasting damaging effect on consumer perceptions of paper and threatens a sector that employs 229,194 people.

The anti-greenwash campaign continues to be a priority for Two Sides and continues to urge companies not to use unsubstantiated and misleading environmental claims about going paperless in all of their communications.

“We are grateful for the cooperation of the organisations that have changed or eliminated greenwashing claims from their messaging, and we are also thankful for the many industry stakeholders and members of the public who send Two Sides examples of greenwash,” said Northwood.

corrugated cardboard bound together as a makeshift guard on the top of the machine, was unsecured and inadequate.

It was reasonably practicable for the company to ensure the machine had guarding, including an interlock device, that only allowed bodily access to the rollers when there was no risk and prevented bodily access at all other times.

WorkSafe executive director of health and safety Narelle Beer said there were no excuses for employers who failed to manage the risks of working around machinery.

“The installation of guarding is a simple and relatively cost-effective way to reduce the risks of workers making contact with running machines,” Dr Beer said.

“Employers should take proactive steps to ensure the safety of their workers, particularly those who may be more vulnerable due to inexperience or a language barrier.”

According to Lazo Paper’s website, the company first began production in 1994 in a small factory in Huntingdale. Its major products included corrugated, fibreboard, containers, cartons and display, as well as cardboard pallets corrugated cardboard more recently.

www.propack.pro 14 ProPack.pro June 2024 NEWS

Kellie Northwood

Xeikon unveils 1200 dpi inkjet press for high-end label segment

Xeikon has announced details of the next evolution Panther inkjet technology as the manufacturer prepares for the world premiere of the Xeikon PX3300HD, a new 1200 dpi digital press that will be launched at drupa 2024.

Developed for high quality labels, the five-colour machine offers a 330mm printing width and speeds up to 70 m/min, even when printing with high opacity white.

In addition, Xeikon PX3300HD utilises a newly developed ink series, PX-Cure LED HD, to ensure perfect curing, while supporting sustainability targets for converters.

“As inkjet technology continues to mature, there’s a clear need to update Xeikon’s Panther portfolio with a higher resolution option to meet specific customer requests. Consequently, we’re now introducing a 1200 dpi engine to complement the existing 600 dpi product range,” said Jeroen Van Bauwel, director Solution Design.

“The new Xeikon PX3300HD will extend the capabilities for printers by giving them the tools to reach excellent quality at even higher productivity levels in a TCO-friendly way (Total Cost of Ownership).”

A small footprint machine, Xeikon PX3300HD produces high durability, fullcolour labels for diverse markets, covering up to 88 per cent of Pantone colours within Delta E 2 (rising to 94 per cent within Delta E 3). To meet the specific requirements of

Inkjet printing market to lead growth post-drupa 2024, new data finds

Packaging, labels, books, and graphics all provide major growth opportunities for commercial inkjet printing, according to the latest data from Smithers.

A host of the latest inkjet technologies that were on show at Drupa 2024 in Düsseldorf have driven new sales - accelerating te industry transition to digital printing across multiple sectors. Detailed data modelling in the latest Smithers market report – The Future of Inkjet Printing to 2029 – shows that in 2024 global sales from inkjet printing will reach $117.7 billion.

Positive market conditions mean this is

the higher resolution engine, Xeikon has developed new PX-Cure LED HD inks.

The new inks match the sustainability benefits of the recently introduced PantherCure UV LED series for Xeikon 600-dpi inkjet presses, including significant savings in energy consumption, instant warm up for more agile operation, and ten times longer lamp life compared to traditional UV arc lamps, resulting in lower waste.

Combining superior image quality and resolution with remarkable productivity, the new press leverages Xerox W-Series industrial inkjet printheads with dedicated waveforms and screening software developed by Xeikon.

Furthermore, PX3300HD is fully prepared for hybrid printing to increase productivity, with the option to add Xeikon’s modular inline LCUs (Label Converting Units) and a large unwinder for longer uninterrupted production runs.

The highly efficient print workflow presented by Xeikon PX3300HD is driven by the powerful Xeikon X-800 DFE (Digital Front End), supplying faster job turnaround and just-in-time delivery. Colour management is an integral part of the software: every X-800

comes with a Pantone license so customers can easily convert all the latest Pantone colours for their press and substrates.

In addition, the basic press configuration offers efficient operational support with an inline camera for quality inspection included by default. Adjusting registration, stitching and compensation for missing nozzles, all measured and corrected in a fully automated way, this feature also helps to alleviate ongoing issues with finding skilled staff to run the press while extending the lifetime of the printheads and ensuring consistent high-quality.

“This extension of Xeikon’s inkjet capabilities is an incredibly exciting development for customers. It offers them a very cost-effective and highly competitive opportunity to scale their businesses, so they can supply profitable luxury market segments with exceptional productivity and quality. We are currently well underway with customer trials and will start sales at drupa,” said Van Bauwel.

“I’d like to encourage all attendees to make their way to Hall 11, booth A01, to experience the PX3300HD 1200 dpi press running live and discuss their future path in inkjet for labels and packaging with Xeikon.”

forecast to expand at a compound annual growth rate (CAGR) of +6.6 per cent through to 2029. This will push overall market value to $162.1 billion in 2029, at constant pricing.

Across the same period, the volume of publications, graphics media, packaging and labels printed on inkjet will increase from 1.61 trillion A4 print equivalents to 2.29 trillion. These increases contrast with the broader outlook for print, where output will be essentially flat across the remainder of the decade. Smithers expert analysis dissects the business and technology developments that will fuel this inkjet’s expansion across 21 separate end-use segments and six press formats.

Demand for print is changing in an ever more connected world, with consumers able to select their preferred media channels. This is driving run lengths down in multiple applications, where inkjet is much more cost efficient than conventional analogue printing.

As a digital technology, inkjet can interface more rapidly with online resources, such as web-to-print portals. Furthermore, inkjet can be integrated with conversion processes

more readily than competing systems.

As the technology and new applications develop, print manufacturing workflows are increasingly being optimized for inkjet, making the process even more cost competitive. This is happening in book manufacture, for example, where web presses deliver book blocks in a single pass, with flexible finishing allowing formats and paginations to be varied at full press speed. Multiple machine innovations are delivering finished print products, labels, and packaging more efficiently – and inkjet is steadily increasing its share across all print and printed packaging. The process already has good penetration into advertising print, particularly for displays and signage, but this share will diminish as much of this work moves into electronic channels. The fastest growth across 2024-2029 will be in packaging, labels, and books.

As this occurs, the benefits of faster turnarounds, print-on-demand sales, and higher quality mean inkjet’s market share by value will remain well ahead of its volume share in nearly all applications.

www.propack.pro 16 ProPack.pro June 2024

NEWS

The Xeikon PX3300HD will be launched at drupa

www.gd90.de

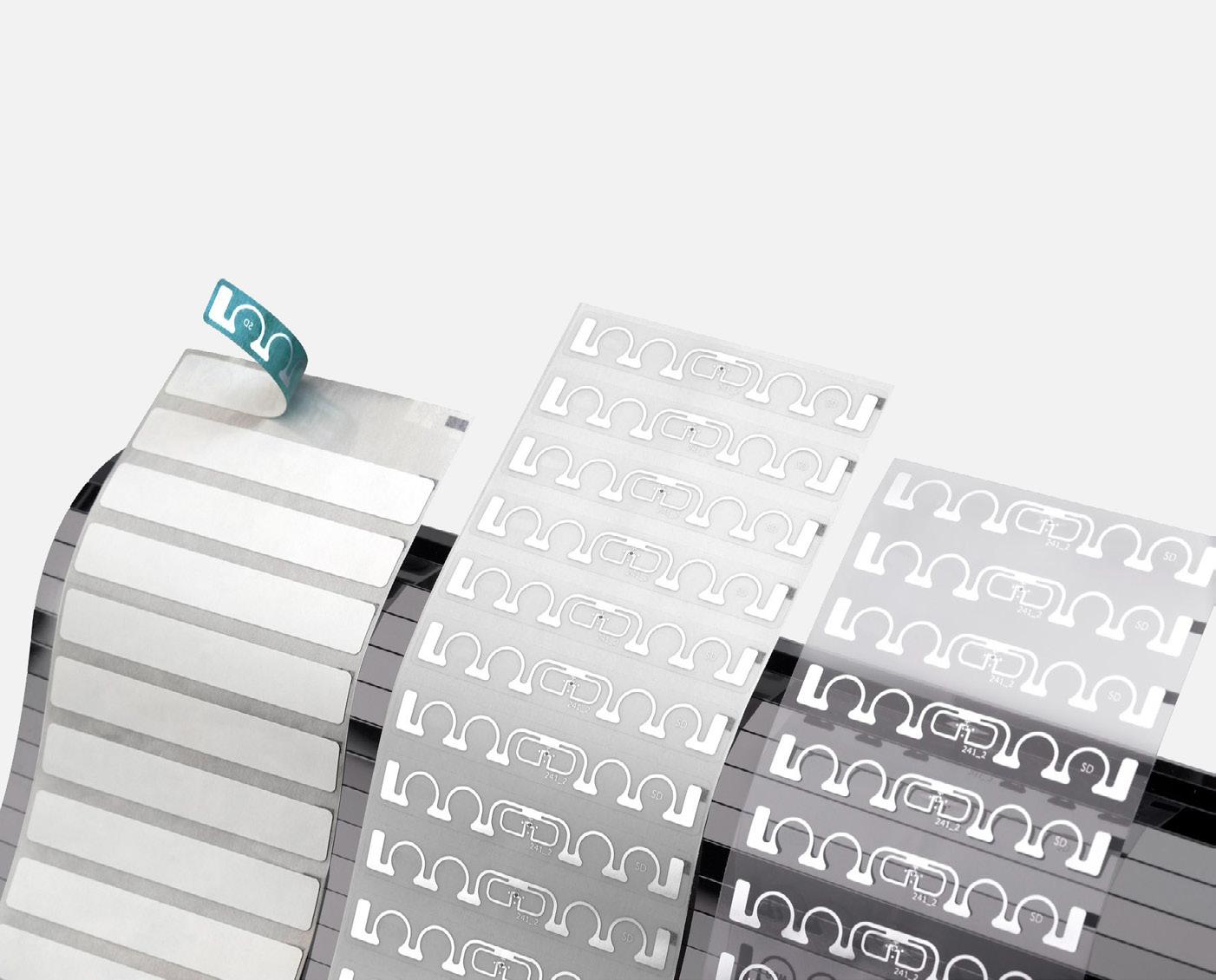

Jet Technologies and Polly Automatics launch JetIQ range in Australia

Jet Technologies and Polly Automatics have teamed up to launch the JetIQ range in Australia.

“The JetIQ range is a cooperation between Jet Technologies and Polly Automatics where we are both bringing our IP and skillset to the table,” Jack Malki, director of Jet Technologies told ProPack.

“At present, Jet Technologies has been able to provide digital print solutions without being able to close the loop with suitable finishing solutions. Therefore, immediately in the digital print space, we can control the solution from end to end,” he said.

“Our range of finishing equipment is extensive, so we will now have a wide range of options from slitting/rewinding/ inspection, to shrink sleeve processing equipment and of course digital finishing.”

According to Malki, one of the key features is the Printbar digital embellishment that is an option on the JetIQ finishing equipment.

“We spent over two years researching and testing the best options, specifically for the uncoated papers that we see in the ANZ wine sector,” said Malki.

“The outcome was a partnership with Xaar

PakTech announces recycling partnership with Endeavour Group

PakTech has announced a new partnership with Endeavour Group and the launch of its local manufacturing in Australia.

Through the partnership, PakTech and Endeavour Group will team up over the coming months to expand Endeavour Group’s closed loop recycling scheme, which seeks to collect recyclable PakTech clips throughout its 270+ Dan Murphy’s outlets. PakTech and its partners have the capacity to manufacture up to 75 million recycled multipack beverage can handles annually within Australia.

Locally, PakTech’s customers include Asahi, Billson’s, Hawkers Beer and a host of craft beer, seltzer, and wine manufacturers. In the US, PakTech’s customers include CPG (Consumer Packaged Goods) companies such as Pepsi, KraftHeinz and Johnson &

that delivers what we think is the best performing print bar for digital embellishment.”

All elements of the range will be available in Australia.

“The market has been crying out for a well-supported alternative and the focus is on support around our very large region,” said Malki.

Jet Technologies will be present across a number of partner spaces at drupa in Düsseldorf, including the Screen Stand where Jet Technologies’ digital print solutions will be on display including a

Johnson as customers, and has seen continued strong growth for sustainable multipack products.

Brandon Rogers, CEO at PakTech said the partnership enables PakTech to “fulfil its vision of made in Australia, recycled in Australia, and repurposed again into new products in Australia”.

“Conscious consumerism is flourishing,

number of new product launches.

“We do have a direct presence booked for Labelexpo SE Asia – in Bangkok next year, so that is exciting as we look to leverage our presence across the region having recently opened in Vietnam, Malaysia, and Singapore in addition to Indonesia where we have been since 2013,” said Malki.

“We are always working on improving our product offering and service to the market. We will be having an open house event in the near future and will invite clients to see this equipment shortly.”

and pressure from consumers around the world is forcing brands and retailers to rethink their approach to sustainable packaging. Sustainability and the circular economy are no longer competitive differentiators, they’re an expectation. We’re thrilled to join forces with an industryleading brand in the Endeavour Group, and to formally commence our on-the-ground manufacturing here in Australia. As we look to promote the circular economy and tackle single use plastics in Australia, there is no better organisation to do it with than the Endeavour Group.”

Sarah McElholum, circular economy sustainability manager at Endeavour Group, said Endeavour is proud to be partnering with PakTech to support the continued recycling and re-use of PakTech products.

“Endeavour supports the development of a circular economy: It’s better for the planet, important to our community and customers. We’re working to understand and improve the way we manage waste and make sure our packaging is sourced sustainably, meets customer expectations of quality and durability, and can be recovered, recycled, and used again.”

www.propack.pro 18 ProPack.pro June 2024 NEWS

One of the key features is the Printbar digital embellishment that is an option on the JetIQ finishing equipment.

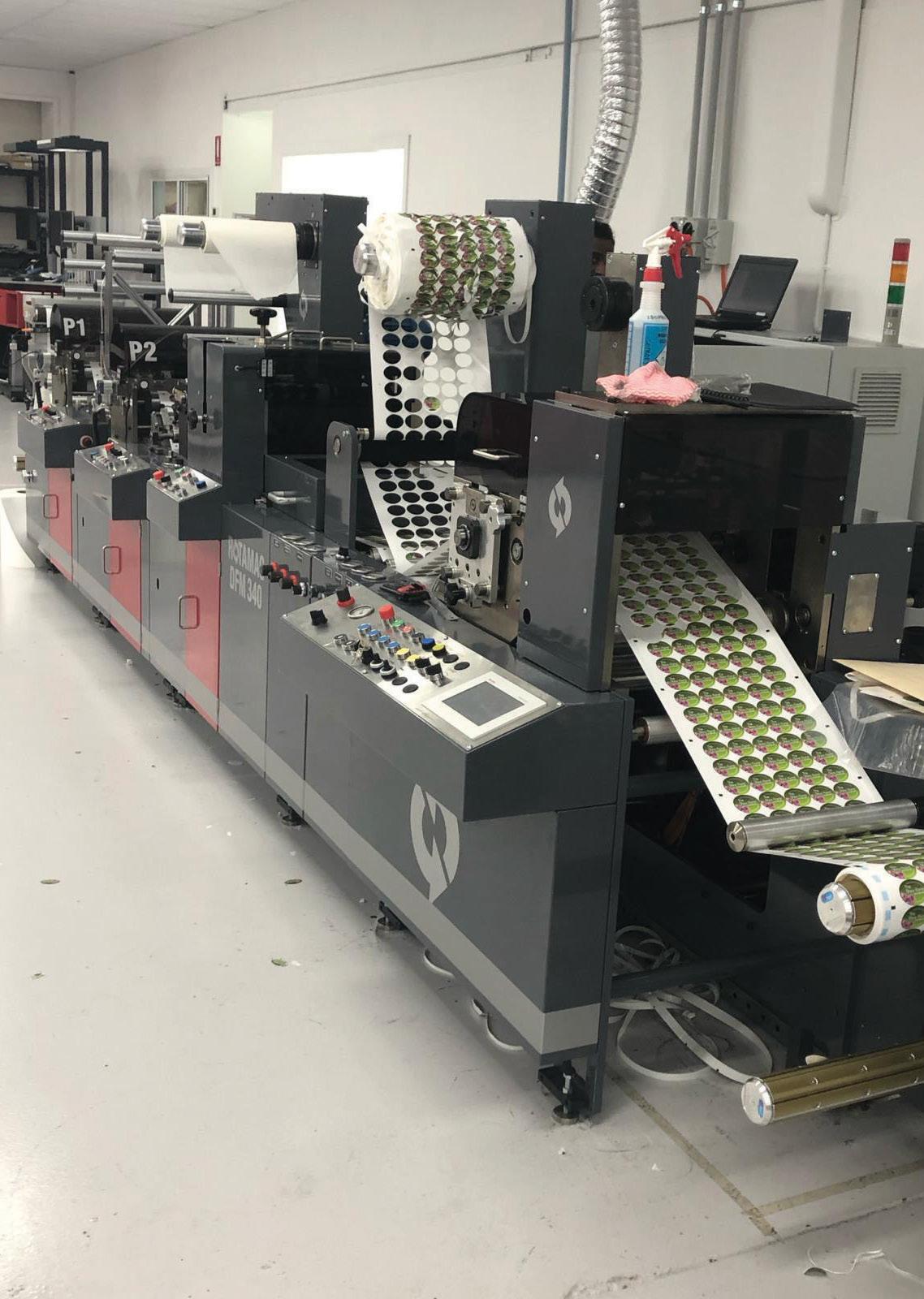

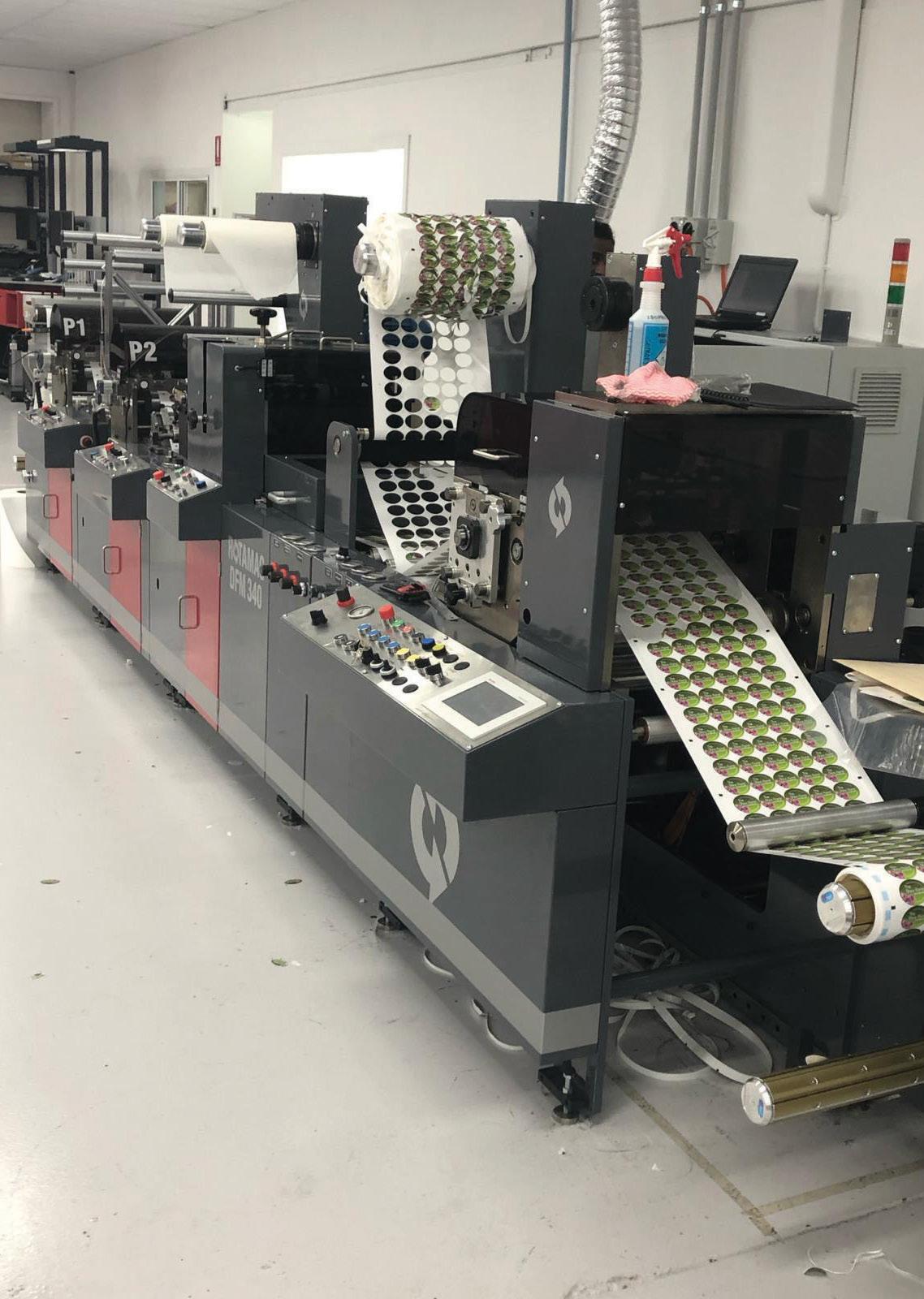

ROTAMAG DIGITAL FINISHER /LABEL CONVERTER/ SLITTER REWINDER

✔ Web width 340mm

✔ Unwind diameter 700mm

✔ Rewind diameter 700mm

✔ Self-wound laminating with waste rewinder

✔ Semi rotary 18” mag cylinder

✔ Powder clutch matrix waste control electric

✔ Crush, scissor and razor

✔ Semi-rotary speeds 20 m/min up to 40 m/min, repeat size pending

✔ Set-up within 500mm material or less – no waste

✔ Full rotary 120 m/min

✔ Compact size, solid build and German servo systems

✔ Rewind spindle 76mm, 38mm, 40mm

2 NEW PRESSES FOR 2024

ROTAMAG 340 – DFM SENIOR DIGITAL FINISHER COMBO

✔ Web width 340mm

✔ Unwind 1000mm corona treater

✔ Rewind diameter 1000mm

✔ Flexo units, UV and hot air dryers, up to 6 flexo units

✔ Standard 1 servo driven flexo unit, varnish, spot varnish

✔ Semi rotary heavy duty 25” mag cylinder

✔ UV optional hot air, cold foil

ROTAMAG 340 JUNIOR

ROTAMAG 340 – DFM SENIOR

✔ Quick and easy plate changes, no waste set-up within 30mm of web

✔ Electric matrix waste control

✔ Crush, scissor and razor

✔ Simplicity at its best

✔ Optional sheeter, delam, relam, coil, foil, multi web, in register, extra print units

Rotary will customize a machine to suit your requirements.

✔ We also offer standard die cutters, Linearless converting equipment solutions, and Down to table top rewinders.

✔ 8 colour servo driven flexo presses with all accessories.

Enquire today for full specifications and pricing: Call 0418 475 045 or email peter@rotaryeng.com.au

21 Bullecourt Avenue, Milperra, NSW 2214 T: 02 9792 4444 W: www.rotaryeng.com.au

Johnston Packaging continues Komori journey with Print & Pack

Johnston Packaging is reaping the rewards of its new Komori GL640 Advance 6-colour UV/IR/HA coater press – sold and installed by Print & Pack.

Johnston Packaging has recently upgraded to a new Komori GL640 Advance 6-colour UV/IR/HA coater press sold and installed by Print & Pack.

Johnston Packaging, located in the western suburbs of Sydney at Condell Park, is a specialist in manufacturing printed and folding cardboard cartons. With more than 50 years of history, the business has now entered its fourth

generation of family members involved in the business.

Over the decades, Johnston Packaging has worked with Komori offset printing machines and enjoyed a long-term relationship with Komori’s local distributor, Print & Pack.

“My grandfather and father started Johnston Packaging almost 50 years ago in a garage and then a small factory

in Kirawee in the southern suburbs of Sydney,” says Rod Johnston – the current managing director of the business.

Johnston started as a lithographic printer and became general manager in 2008 before becoming managing director in 2013.

“The business then moved from Kirawee to the current site at Condell Park and we have been operating Johnston Packaging

Rod Johnston (Johnston Packaging) and Miro Williams (Print & Pack)

COVER STORY www.propack.pro 20 ProPack.pro June 2024

from here for the last 40 years. My grandfather and father worked in the printing industry and my father convinced my grandfather to come out of retirement to start the business. I remember being at home hand-erecting a lot of different types of packaging products when I was growing up – we were the converters,” he recalls fondly.

“These days we have a large number of family members involved in the business and we have clients that we have been consistently working with for over 20 and 30 years – primarily in the FMCG food and beverage categories as well as the hardware, confectionery and animal pharmaceutical areas.”

Johnston Packaging is also well known for inventing KlippaKan – a patented fibre-based packaging innovation for beverage cans.

The new Komori GL640 Advance press

Two years ago, Johnston Packaging started discussions regarding the purchase of a new Komori with Mori Williams and the Print & Pack team shortly after Covid.

“We soon realised that we needed to undertake some renovations to the plant as we have upgraded from a conventional press to a UV press. Once we had made these improvements including increased power availability we committed to the new Komori. This is a long-term decision

for our business, and it will probably be a machine that is replaced not by me, but by the next generation of our family.

“The beauty of Komori is there a broad range of products that are suited to all types of printing and packaging businesses. Whether you are a multisite large organisation, or a small print shop working with small to medium suppliers, Komori has something for you.”

“This replaces an older reconditioned 5-colour Komori that we had for 22 years. We bought the new Komori GL640 Advance press sight-unseen, although we did inspect the model previous to this at the beginning of the research process almost two years ago. Komoris have worked well for us in the past – and we have found that the maintenance side is minimal. We have a second half-size Komori as well that we also use for our packaging work,” Johnston says.

“The new Komori GL640 Advance features a lot more automation that what we have had previously which has been helpful for our production team. It has a great monitoring system that uses cameras to read the sheets and can detect the smallest defects down to 0.5mm. Once it is up and running, our operators and basically monitoring the machine and following up any notifications. It picks up any faults so early there is no damage to any sheets, and this is important with maintaining run times as well as minimising waste.

“We now have over 32 staff working in the business and four staff working specifically on the Komori – a printer and offsider working a day shift and an afternoon shift.

“The Print & Pack team have been terrific to work with. We had numerous meetings beforehand to ensure we had everything in place including working with their engineers on the plinths and marking out the floors. The installation went very smoothly over about four weeks, and we have had an additional five weeks of training. The Komori demonstrator Steve Harper has been very patient with our staff and has been always available if we need to contact him at any time.

“Steve is very well known in the industry with over 30 years of experience and is a very important part of the Print & Pack team,” Williams added.

COVER STORY www.propack.pro June 2024 ProPack.pro 21

Rod Johnston started as a lithographic printer and became managing director of Johnston Packaging in 2013.

The new Komori GL640 Advance will provide Johnston Packaging with the opportunity to offer its customers additional benefits.

“The new machine has allowed us to bring UV finishes, embellishments and coatings back in-house that we couldn’t do on the previous machine that we were outsourcing,” Johnston says.

“It also provides us with opportunities to produce work that we have steered away from in the past as we were unable to compete – we can now win more of that work. It has also eased the pressure and allowed us to have excess capacity to grow our business.”

Packaging industry trends

Johnston has noticed a number of key trends that have been driving the recent growth in the packaging market.

“There has definitely been a trend towards removing plastic from the supply chain – particularly single-use plastic – and replacing this with paper and fibre-based products. We have seen since the beginning of Covid right through to where we are now that there is also the drive towards local manufacturing and relocating work from offshore as a lot of companies were caught out with extended lead times and delays due to unpredictable supply chains and logistics.

“We have noticed that response times are reducing, and this is high on the list when

we are talking to our customers. Clients do not want to see a six-week lead time on a job – they would prefer two to three weeks, and this was another reason why we made this investment so that we can decrease our lead time, increase our capacity as well as improve our offering.

“We have also found that clients are reducing some of their holdings in their own warehouses and this has changed the minimum order quantities. Instead of holding on to their packaging for 8-10 months, they are dropping this down to 3-4 months, and this also allows them to keep their packaging designs fresh.”

Print & Pack success with Komori

According to Williams, Print & Pack continues to see strength in the offset printing category.

“We have had a very successful four-year period with Komori and there have been a lot of installations of our machines in Australia and New Zealand.

“We have installed a couple of Komori GL640 Advance units now and this success reflects the work done by Komori to deliver a return on investment for printers who are also seeking improved efficiencies as they upgrade their equipment. The Advance model features incremental improvements reducing stoppage times, faster makeready as well as improved feeder and delivery system.

“The press offers superb print quality and colour consistency, supported by

Komori’s KHS-AI Production control with Smart Sequence, ensuring HighSpeed Start. Further advancements with PDC-SX Smart Feedback technology provide customers with print quality they can rely on, consistently delivering exceptional results.

“We have seen a larger number of packaging companies investing in Komori offset printing solutions as we can offer everything a packaging printer needs. The growth in fibre-based food packaging has been one of the drivers of this category growth. The market is making the trends, and it has forced printers to diversify into packaging.

“Consumers, particularly younger consumers, are demanding packaging be delivered as an experience. There are more luxury items being packaged and these end customers want a nice high-build UV on the box as part of the experience. Major supermarkets and grocery retailers are also increasingly packaging their fresh produce in fibrebased products and not in soft plastics.”

Williams says the Komori range offers a wide range of options for specialists in the printing and packaging category looking to invest in an offset solution.

“The beauty of Komori is there a broad range of products that are suited to all types of printing and packaging businesses. Whether you are a multi-site large organisation, or a small print shop working with small to medium suppliers, Komori has something for you.”

“For printers that are wanting to growth their business, Komori is a great solution to deliver a return on investment while also offering quick makeready times and stable running capacities. We have 29-inch half-sized presses through to 44-inch packaging presses as well as everything in between – Komori’s range offers something for everyone.

“The Johnston Packaging business is superior to a lot of other packaging manufacturers due to its agility and ability to service clients that little bit quicker for clients. It is great to see a family business thriving and doing well – and it is a true family business with fathers, sons, nieces, and nephews working in the company. The business has been very loyal to Komori and to Print & Pack and they are great to work with. We are proud to have installed a piece of equipment that will directly deliver a return on investment and immediately improve the efficiency of their business. This is an investment that can be further improved and upgraded by the next generation if they want to go to the next level in the years ahead.”

www.propack.pro 22 ProPack.pro June 2024 COVER STORY

* Model in photograph includes optional specifications.

Suite 2.03 / 56 Delhi Road, Macquarie Park, NSW, 2113 Tel: 0402 889 762 Email:miro.williams@printandpack.com.au www.printandpack.com.au

Sustainability – the ‘megatrend’ requiring commitment, collaboration, and innovation

Sustainability has been a focus for the packaging industry for many years, but it appears to be reaching a critical point, writes Bobst’s head of corporate sustainability, Sylvain Lieb.

Sustainability has been a focus for the packaging industry for many years, but we may be reaching a crucial period for the topic.

We are one year away from 2025 – which has been the target year for the many sustainability goals that hundreds of corporations and companies have committed to. This famously includes the Global Commitment, led by the Ellen MacArthur Foundation, in collaboration with the UN Environment Programme, which united more than 500 organisations behind a common vision of a circular economy for plastics.

Although there has been some fantastic progress – a recent assessment concluded that those companies who signed up to the commitment have significantly outperformed their peers in tackling plastic waste – still many of those ambitious 2025 targets will be pushed backwards.

On 24 April 2024, the European Parliament adopted the Packaging and Packaging Waste Regulation (PPWR), which includes packaging reduction targets, restrictions on certain kinds of single-use packaging, certain reuse targets and more. The PPWR, now in the final stage of legal checks and validation, also reiterates that all

packaging placed on the EU market must be recyclable.

drupa 2024 has made sustainability one of its two ‘megatrends’, along with digitalisation. According to drupa, these two megatrends go hand in hand because “Industry 4.0 is the key to overall sustainable production in the print and packaging industry.”

At Bobst, we agree. The four pillars of our industry vision – digitalisation, automation, connectivity, and sustainability – include the two megatrends, and are indeed all mutually

SUSTAINABILITY www.propack.pro 24 ProPack.pro June 2024

SUSTAINABILITY

enabling and together are empowering great progress in our industry.

Sustainability is a huge, multi-faceted topic, without easy solutions. Each company – independently or teaming up with suppliers, customers, or peers – needs to identify where they can make the greatest strides forward.

“Sustainability is a huge, multi-faceted topic, without easy solutions. Each company – independently or teaming up with suppliers, customers, or peers – needs to identify where they can make the greatest strides forward.”

As a leader in the packaging industry, we know we have a responsibility, not only to commit to sustainability, but to truly innovate in this space.

We believe we are doing so, across three defined streams – our operations, our equipment, and packaging use and end-of-life. Innovations across these will help to change the way packaging is produced to help ensure reduction

of waste, increase in efficiencies, compliance with the latest regulations, and the development of environmentally improved packaging solutions.

We joined the Science-Based Targets initiative (SBTi) in 2022, reinforcing our commitment to urgent climate action. We clearly formalised the company’s targets and decarbonisation options, not only for our operational activities, but also for our impact upstream and downstream, to reduce our carbon footprint.

Now, our SBTi targets have been validated and confirmed to be in line with the goal to limit global warming to 1.5°C as decreed in the Paris Agreement.

Optimising operations

Of course, companies have most direct control over their own operations, and this has been a major area of focus for Bobst in recent years.

Our targets in this area are ambitious, including a 42 per cent carbon reduction on our own operations by 2030, but that reflects the speed at which the world needs to decarbonise. We don’t have the luxury of time.

And with ambition, comes greater potential for progress.

In 2021, we had an initial evaluation performed by EcoVadis – the world’s largest and most trusted provider of business sustainability ratings. Following their initial assessment we established

our sustainability program. With our second rating of 49 points, we received a bronze medal.

In 2023, we obtained our third and latest rating of 63 points, receiving a silver medal. This puts Bobst in the top 20 per cent of companies in terms of sustainability. We have not finished, of course, and we still have many improvements to make. But by making great progress with our own operations, we’ve given ourselves a good foundation for sustainable success.

Enhancing equipment

At the core of the Bobst business are its machines. We appreciate that packaging requires large, high-productivity machinery, designed to operate 24 hours a day, seven days a week, which makes the environmental load of machinery in energy and material consumption a significant challenge.

We know that most carbon emissions occur downstream in the value chain – i.e. at our customers’ sites, where we have less leverage. But we believe that we still have a responsibility to help our customers to reduce those emissions. This is why we’ve given our teams a target of reducing energy consumption by 20 per cent for the machines we will sell in 2030 vs our baseline of 2022.

Regarding resources, a key strategy is reduction of ink, waste, and substrate. For example, we have made zero-fault packaging a reality through innovations like ACCUCHECK, which reduces waste by

www.propack.pro June 2024 ProPack.pro 25

Bobst joined the Science-Based Targets initiative (SBTi) in 2022

SUSTAINABILITY

eliminating only boxes which do not correspond to specific quality criteria. oneECG – our extended colour gamut technology, which digitalises and automates colour management – creates no ink waste, uses 30 per cent less ink, and reduces make-ready time and makeready waste by up to 90 per cent.

Meanwhile, our pioneering Start&Go system for optimal print registration enables fast automatic set-up at the start of each job in just a few sheets, enabling considerable savings in sheets used per year. In labels, we have worked with Avery Dennison on a linerless labels solution, which significantly increases material on reel, increasing production efficiency and cutting out the need for backing material.

Another major area of focus is enhancing currently installed machines. We focus on enabling retrofits so that our customers can upgrade previous Bobst machines with more recent developments – for example, adding automatic EcoMode on gravure machines, which can reduce energy consumption by up to 50 per cent during standby.

Another upcoming product for gravure and coating machines is a ventilation efficiency kit, which enables the reuse of waste heat and the optimisation of fan power to save massive amounts of thermal energy needed for drying.

Remanufacturing machines is a highly cost-effective and sustainable way to increase productivity. Bobst offers machine remanufacturing through CM Services, a global supplier of

remanufactured corrugated board and folding carton machinery. In this way, old machines can see their lifetime doubled, while being rejuvenated with new electronics, more efficient motors and the addition of software to enable features such as remote assistance.

Progressing packaging sustainability

Then there’s the actual packaging itself. This is the area where the eyes of the world really are upon us. As an industry, we must lead the world into a new era of recyclable packaging.

“Sustainability has been a focus for the packaging industry for many years, but we may be reaching a crucial period for the topic.”

To support the industry with its goals around recyclable packaging, Bobst together with leading industry partners, has pioneered a range of innovative, environmentally improved packaging solutions. This has been a multi-year journey, which is reaching a critical and very exciting point – when all the hard work, collaboration and R&D is resulting in real, commercialized solutions on our supermarket shelves.

oneBARRIER is a family of industrially viable recycle-ready mono-material ultra-

high and high barrier duplex and triplex substrates for packaging designers as alternatives to non-recyclable metallized polyester film.

The family of Bobst oneBARRIER sustainable solutions to date includes PrimeCycle, comprising EVOH and topcoat-free transparent AlOx-based or opaque AluBond-based full PE monosubstrates, and FibreCycle, a monomaterial high-barrier paper-based structure coated with functional layers that can be recycled in the existing paper stream. Leading third party institutes have confirmed the recyclability of our first two oneBARRIER solutions.

Now, we are expanding into new application types and new packaging models, while also expanding the ecosystem with new partners. We are working on solutions using BOPP as well as biodegradable materials from natural and renewable resources. There is no single ‘silver bullet’ solution, which is why we need a ‘family’ of solutions across all material types.

It’s an example of how sustainability requires commitment, collaboration, and continuous innovation to enable real progress.

Collaboration really is at the heart of it – our work on oneBARRIER has demonstrated just how much can be achieved when multiple experts come together with a shared goal.

Now, we are looking to build on the considerable progress that has been made, achieve our sustainability goals, and help our customers to achieve theirs.

www.propack.pro 26 ProPack.pro June 2024

oneECG is Bobst’s extended colour gamut (ECG) technology

See our range of folding box gluers, board slitters, creasing machines, auto loaders, unloading cutting tables and more.

HARNESS

A ground up redesign is at the heart of this brand new generation modular boxmaker from KOLBUS. It allows custom specification for each module to meet your exact needs, including:

■ Heavy Duty box making

■ In line digital or flexo printing

■ In line gluing

■ Single person operation

■ Waste management system

In short, the BX Motion Pro is your ver y own personalised boxmaking solution. Call your local agent now to arrange a demonstration.

Graffica Pty Ltd Phone +61 477 200 854 I Email grafficapl@bigpond.com I Visit Us www.graffica.com.au

Tel. +49 (0)5771 710 | info@kolbus.com | www.kolbus.com THE HOME OF BOXMAKING

PACKAGING AND DISPLAY EQUIPMENT

THE

NEW BX Motion Pro

THE POWER OF

BRAND

AS

CORRUGATED AND DRUPA 2024

SEEN AT SINO

OKI’s label printers streamlines a leading Australian distillery’s custom label offering

The purchase of OKI label printers has elevated Sydney distillery, Archie Rose Distilling Co. and its Tailored Spirits Experience to new heights.

The Archie Rose Distilling Co. Tailored Spirits Experience was such a hit with customers its external printing provider struggled to keep pace.

The spirits company crunched the numbers and made the savvy business decision to bring its customised label service in-house, and has not looked back.

Archie Rose relied on external printing partner Multi-Color Corporation to create its custom labels. However, as the offering grew in popularity, the outsourcing process needed to meet the distillery’s turnaround times.

This was particularly challenging around key holidays or as a gift for weddings and milestone birthdays when prompt turnaround times were a priority for customers.

After some research and experience with its external provider, Archie Rose purchased its first OKI Pro 10 Label Printer for internal use four years ago.

The OKI Pro 10 Label Printer allows for on-demand printing of different roll media types, including uncoated, glossy, textured, and synthetic papers. Roll media can be printed, cut, and quickly exchanged, while consumables have a high capacity and are also easily changed.

By investing in an OKI Pro 10 Label Printer, Archie Rose significantly accelerated the production of its tailored spirits offering.

Through the in-house process, customers can order via Archie Rose’s website and have their tailored gin, vodka or bottled cocktails delivered to their door within three to five business days – cutting their initial turnaround time in half.

Archie Rose’s head of marketing, Victoria Tulloch, says having the printer in-house has enabled greater design flexibility, allowing for experimentation and trial and error for limited edition runs.

“We’ve been able to robustly test its capabilities, which has led to new ways to include custom prints for customers and corporate clients, including QR codes, printing photos onto labels, and more,” said Tulloch.

The distillery has also noted bringing the process in house has increased customer satisfaction. When customers make a mistake or need to edit a label, quick changes have effectively streamlined this offering.

The OKI printer has enabled Archie Rose to provide multiple test prints for corporate clients who order in bulk, allowing reviews

Archie Rose personalised spirit labels

LABELS www.propack.pro 28 ProPack.pro June 2024

and approval throughout the creation of their labels.

“We can scale, quicken, and streamline the experience for customers ordering Tailored Spirits and other overprint label products, as well as improve sustainability measures related to freight, paper wastage, and test prints,” says Tulloch.

In 2022, Archie Rose purchased a second OKI Label printer, this time the Pro1050 model, adding printing with white to their repertoire. In 2023 it introduced its third.

Last Christmas, Archie Rose brought its tailored spirits process to life at a pop-up service at the Myer Chadstone Melbourne gifting emporium for the first time.

Christmas shoppers interacted with the tailored offering and created personal labels printed on the spot on the OKI Pro10 printer.

The nature of liquor labels required Archie Rose to choose a label printer fit for purpose. Speaking with OKI channel manager Stephen Richards, he said the OKI product delivers on the distillery’s needs.

“They chose the OKI because an inkjet printer wouldn’t have been suitable. They would have had to change too many things,” says Richards.

“They needed software that could communicate with their website to make variable changes,” he added.