1987-2022 years in print New Zealand Printer November 2022 Making better decisions Women In Print returns Printing United review Innovative packaging WIDE FORMAT +Plus with Pro C9210 delivers quality and productivity for Blue Star

Offset Printing | Digital Printing | Wide Format | High Speed Inkjet Chat with us today 0800 289 774, or order online www.wholesaleprint.co.nz TRADE ONLY Wholesale Print will be closed for the holiday break from the 23 rd December and will re-open on the 9 th January 2023 We all know this holiday season will be uber busy. Place your Christmas print orders with us now to ensure that you and your customers will have them in time for Christmas. Order your Christmas Cards, 2023 Calendars & so much more online at wholesaleprint.co.nz.

Cover Story p14-15

Ricoh New Zealand has partnered with Blue Star Group for digital printing excellence. Amongst its Ricoh solutions, the country’s largest integrated print and marketing company has installed four of Ricoh’s flagship Pro C9210 presses

PrintNZ p10-12

10-11 Helping Hand: Printing is art. Iain MacIntyre explains how award winning display manufacturer APC Innovate has evolved with the industry

12 Comment: Ruth Cobb reports from the welcome return of Women In Print with celebrations in Christchurch and Auckland

Printing United p31-41

We visited the giant American show in Las Vegas, seeing the latest technology and innovations from: 32 Agfa 33 Durst 34 EFI 35 Heidelberg 36 Epson 37 HP Indigo 38 HP 39 Kornit 40 Ricoh 41 RMGT

Wide Format Plus p21-30

22 Aarque: The Canon Colorado 1650 printer offers an impressive application range

24 Fujifilm: deSotogi Fine Art is achieving excellent results with a new Epson P9650 printer supplied through Fujifilm

26 NZSDA Update/Secretary: Melissa Coutts has the dates we need to mark on our calendars for next year

27 NZSDA President: Andy Lowe discusses how we can find a better work life balance

Features p6-27

6 Flint Group: Recognising ongoing industry growth in the region, Flint Group makes key appointments across Australia and New Zealand

8 Jet Technologies: Supporting the industry for over 40 years, Jet Technologies is a leading supplier for local companies 16 Konica Minolta: A new AccurioPress C12000 at Banner express is bringing high print quality, accuracy and productivity gains 18 Currie Group: Benefitz has taken B2 digital printing to a whole new level with the HP Indigo 10000 Digital Press 20 Think Laterally: Knowing how your brain works helps when you have to make significant purchasing decisions, says Mick Rowan 27 Printerverse: Deb Corn explains how helping professional print customers do their jobs could one day help save yours

3 newzealandprinter.co.nz November 2022

November 2022

CONTENTS

021 631 559

Editor

Ruth

Deborah Corn, Melissa Coutts, Andy

DISPLAY ADVERTISING SALES & SERVICE: Brian Moore - brian@newzealandprinter.co.nz +61 410 578 876 CLASSIFIED ADVERTISING: Brian Moore - brian@newzealandprinter.co.nz DESIGN & PRODUCTION: Sarah Vella - sarahvelladesigns@gmail.com New Zealand Printer is mailed to members of the printing, packaging and graphic communications industry in New Zealand 11 times a year, February-December. New Zealand Printer is a member of the Printer Media Group New Zealand:

©

2022

Contents of this magazine are subject to copyright and cannot be reproduced without written permission of the publisher. ISSN 1171 7912 DISCLAIMER This publication is published by The Intermedia Group Pty Ltd (the “Publisher”). Materials in this publication have been created by a variety of different entities and, to the extent permitted by law, the Publisher accepts no liability for materials created by others. All materials should be considered protected by Australian and international intellectual property laws. Unless you are authorised by law or the copyright owner to do so, you may not copy any of the materials. The mention of a product or service, person or company in this publication does not indicate the Publisher’s endorsement. The views expressed in this publication do not necessarily represent the

of the Publisher, its agents, company officers or employees.

the information

this publication

the sole

the

The user should make independent enquiries as to the accuracy of the information before relying on that information. All express or implied terms, conditions, warranties, statements, assurances and representations in relation to the Publisher, its publications and its services are expressly excluded save for those conditions and warranties which must be implied under the laws of any State of Australia or the provisions of Division 2 of Part V of the Trade Practices Act 1974 and any statutory modification or re-enactment thereof. To the extent permitted by law, the Publisher will not be liable for any damages including special, exemplary, punitive or consequential damages (including but not limited to economic loss or loss of profit or revenue or loss of opportunity) or indirect loss or damage of any kind arising in contract, tort or otherwise, even if advised of the possibility of such loss of profits or damages. While we use our best endeavours to ensure accuracy of the materials we create, to the extent permitted by law, the Publisher excludes all liability for loss resulting from any inaccuracies or false or misleading statements that may appear in this publication. Copyright © 2022 — Charted Media Group Pty Ltd Official Media Sponsor 2021 NEW ZEALAND PRINTER PO Box 32-395, Devonport, Auckland 0744 An Epson P9560 printer, supplied through Fujifilm, is giving deSotogi Fine Art high quality prints, p24

Advertiser’s Index Aarque Group 23 APM 7 Contact Labels 7 Currie Group 7,19 Cyber 44 Eamar Plastics 42 Fujifilm 25 GLC 5 Jet Technologies 9 Konica Minolta 17 NZSDA 29 Pride In Print 43 Print NZ 13 Ricoh 1 Think Laterally 42 VPR 42 Wholesale Print 2

EDITORIAL:

Bruce Craig,

- bruce@newzealandprinter.co.nz CONTRIBUTORS:

Cobb,

Lowe, Iain MacIntyre, Mick Rowan CIRCULATION: brian@newzealandprinter.co.nz

New Zealand Printer Asia Pacific: ProPack.pro Australia: Australian Printer, ProPrint MANAGING DIRECTOR: James Wells - james@intermedia.com.au GROUP PUBLISHER: Brian Moore - brian@newzealandprinter.co.nz

Copyright

:

opinion

Any use of

contained in

is at

risk of

person using that information.

IN BRIEF

EPSON has re-equipped and reopened the Fujimi Inkjet Innovation Lab at its Fujimi Plant in Nagan Japan as part of Epson’s strategy to expand applications for printhead-based solutions in new markets and to accelerate innovation in its customers’ printing and production processes. The Lab has been newly outfitted with direct to surface colour inkjet printers and facilities for performing tests using Epson’s inkjet printheads, as well as a battery of other machines, instruments, and tools for running trial production and evaluations.

UPM RAFLATAC has released a digital label material swatch book for wine, sprits and beverage. The new tool allows designers to download high definition images and use the selected label material in their preferred design software.

Stefano Pistoni, senior manager business development for Wine, Spirits and Beverages at UPM Raflatac, says, “There are plenty of label materials available, but the challenge is to find the right match to the packaging, easy and fast. This efficient, user friendly digital tool can change the landscape of label and packaging design.”

KOENIG & BAUER has announced that it will roll out an energy management system on a subscription basis as a software as a service solution globally in 2023. Certified in accordance with DIN ISO 50001, the system is the first product developed and brought to the market by Koenig & Bauer’s new digital unit. The company says sustainability and digitalisation are two of three key goals that it has placed at the focus of corporate activities under the group-wide ‘Exceeding Print’ strategy.

The Revoria Press PC1120 has earned the Keypoint Intelligence ‘Buyers Lab 2022 Pro Award’ in the ‘Outstanding High-Volume CMYK+ Production Device’ category.

David Sweetnam, director of Keypoint Intelligence EMEA/Asia Research and Lab Services, says, “The extra imaging stations before and after the standard CMYK units, along with the diverse range of toner options, make the device stand out amongst others in this digital arena.

“The Revoria Flow PC1120 Print Server provides a high level of media management, with seamless integration aided by an excellent user friendly interface.”

Revoria takes out Buyers Lab Award Packaging growth spurs board conversion

Stora Enso will invest €1bn ($1.68bn) to convert an idle paper machine in Finland into a high volume consumer board production line. The investment supports its growth strategy in renewable packaging by providing new volume for growing packaging segments.

The conversion will create a flexible consumer board line for folding box board and coated unbleached kraft with an annual capacity of 750,000

Keypoint Intelligence noted several features on the Revoria Press PC1102 including its six colour stations with before, and after, CMYK capabilities that allow for a wider range of inline creative options than some competitors and its outstanding halftone image reproduction with the largest CMYK colour gamut tested to date and a range of speciality colours that help create a broad colour palette.

The press also has a customisable and intuitive print server platform, which enables efficient device/ remote management capabilities; and outstanding

mixed-media workflow performance, with no productivity slowdown, which translates to more work being handled inline in a single job submission.

Fujifilm Business Innovation says the Revoria Press PC1120 achieves production speeds of 120 pages per minute with superb, high definition quality and a combination of feeding and finishing options to provide flexibility for whatever job comes next. The press uses a one-pass, six-colour print engine enabling up to two special toners such as gold, silver, clear, white or pink to be used in addition to CMYK.

can build on existing assets for quick and cost-effective time to market compared to other investment alternatives.”

tonnes of consumer board. It will supply food and beverage packaging, especially frozen and chilled, and dry and fast food.

Annica Bresky, president and chief executive at Stora Enso, says, “Renewable packaging continues to be our largest strategic growth area. It’s also a market that is now, for the first time, growing faster than plastic based alternatives. Through this conversion, we

The company expects annual sales of around €800m. Hannu Kasurinen, head of Stora Enso’s packaging materials division, says, “This investment represents a step change in the market and will improve profitability and competitiveness for both our consumer board and containerboard offerings. The converted line will enable us to optimise production at other sites to unlock further growth.”

4 newzealandprinter.co.nz November 2022 NEWS for New Zealand – all the latest print industry news from home and overseas, delivered to your inbox Go to the news website newzealandprinter.co.nz Join the rest of the local print industry and sign up for your free newsletter NEWS

The Revoria Press

PC1120

Expat Kiwi wins major industry award

Across the Tasman, Cactus Imaging co-founder and general manager – operations, Keith Ferrel, has taken out the top gong at the 2022 ProPrint Awards in the Printer 50 category, formerly known as the Power 50.

Three decades ago, Keith and his then New Zealand newspaper industry colleague, Warwick Spicer, threw all caution to the wind and decided to move to Sydney and start Cactus Imaging. The pair could see a big future in digital billboard printing and they were spot on.

Today, and after many twists and turns including forays into India, a private equity takeover and the eventual purchase by ASXlisted giant oOh!media,

Cactus Imaging is going strong with Keith still very much involved as general manager operations, working side by side with Warwick’s son - Cactus Imaging general manager, Nigel Spicer.

He is certainly not showing any signs of slowing down with a litany of overseas trips to various trade shows and events on his calendar, most recently Printing United in Las Vegas. He currently sits on HP’s Asia Pacific Japan Dscoop board as well as the Fespa Australia board. He has also been a member of the HP

Epson campaign raises Arctic greening issues

To boost its efforts to increase awareness of global warming, Epson has launched a campaign focused on Arctic greening, and showing how businesses and consumers can take more action to reduce their environmental impact. Last year, the company won a Webby award for its campaign produced by National Geographic CreativeWorks.

Yasunori Ogawa, Epson global president, says, “We are delighted to work with National Geographic CreativeWorks for a second year to raise awareness about the issue of Arctic greening. Sustainability is at the heart of everything we do, and we are committed to lowering our own environmental footprint and helping our customers to do so too.”

In this year’s campaign, National Geographic Explorer and ecologist Professor Isla Myers-Smith of University of Edinburgh details her

research on how rising temperatures and warming seasons are leading to a phenomenon called ‘the greening of the Arctic’. For almost 20 years, she has studied the impact of climate change on the Arctic tundra. In recent years, she and her colleagues have noticed a distinct trend, with trees and shrubs growing more readily in the Arctic where permafrost is thawing.

She believes it is critical that people understand the implications of Arctic greening and how making small changes in our daily lives can have a positive effect on the environment. She says, “From saving energy at home to biking to work and eating local, we can each make a difference. It is important for all of us to be aware of how our choices impact the environment, in our own backyards and around the planet.”

Customer Advisory Board and the Dscoop Global Board.

Keith is highly respected in the industry, both domestically and globally. He is always prepared to help out other printers with advice and acts as an advisor to many printing equipment manufacturers to help ensure the products they are making deliver the results printers need.

Durst Oceania is platinum sponsor of the ProPrint Awards, which are organised annually by NZP sister magazine across the ditch, ProPrint.

IN BRIEF

COLOR-LOGIC has announced a new layout format that simplifies the selection of metallic colours for graphic designers, enabling them to choose metallic colours that are complementary to and harmonious with their designs. Mark Geeves, director of sales and marketing at Color-Logic, says, “The Color-Logic metallic colour system utilises only five colours, whether the designer uses one or as many as 924 metallic colours. In addition, Color-Logic embellishments are economical to implement and control in production.”

KODAK has increased its Magnus Q800 platesetter speed, which can now output a plate every 42.9 seconds. This translates to a throughput of up to 84 B1 or eight-up plates per hour, a 40 per cent increase in output. The Magnus Q800 platesetter can also image Kodak Sonora Xtra process free plates at its new top speed. All automation options available for the Magnus Q800 platesetter support the new speed. These are the singlepallet loader, multi-pallet loader and multi-cassette unit.

5 newzealandprinter.co.nz November 2022 THERMAL LAMINATING • MATT & GLOSS • SPECIALTY FILMS • ADHESIVE LAMINATING • HOT FOIL STAMPING & EMBOSSING • ENCAPSULATION & WIDE FORMAT • METALLISED FILMS • SCRATCH OFF INKS SPOT & OVERALL UV FINISHES • SPECIALISED COATINGS • INDEX TABBING • NEW LAMINATES • SCRATCH RESISTANT MATT • VELVET FEEL • SLURPEX SOFT CLOTH & CHAMOIS PRODUCTS Unit 3, 343 Church St, PO BOX 12797, Penrose Auckland 1642, New Zealand, +64 9 636 8354 reception@glc.co.nz www.glc.co.nz ALBANY • PENROSE • PETONE NEWS

Matt Ashman (l), Durst Oceania managing director with ProPrint Awards Printer 50 winner Keith Ferrel

Flint Group A/NZ targets growth with key appointments

One of the largest suppliers to the printing, packaging and labelling industries worldwide, Flint Group, has put A/NZ on its radar with the appointment of key personnel, taking the number of its local team to about 120 people.

The company recently promoted Paul Lamberti to the role of A/NZ general manager earlier this year following the retirement of Thorsten Schauer, who headed that role previously.

Prior to taking up this role, Lamberti was the A/NZ director of commercial, publication and sheetfed (CPS) inks at Flint Group, where he oversaw the business producing web and sheetfed inks to the local printing industry and the manufacture of coldset, heatset and sheetfed inks.

“I’ve been with Flint Group for over 20 years. I have a science and business background and started with the company as a technical manager in 2002. I then progressed through several commercial roles with the business and ran various business units within Flint Group before being appointed to this role,” he said.

The company also recently named David Mitchell as its new key account manager of narrow web in Australia and appointed Grant Tychsen to a newly-created role –New Zealand narrow web sales manager – in September.

Tychsen had many years of experience working in South Africa before he moved to New Zealand five years ago. Some of the companies he has worked for include Liquid Colours, Huber Group, Damar Industries and Cambridge Steel Fabricators and Engineers.

As for Mitchell, he has had several years’ experience in print having worked for Maxcess International as its sales director and customer service manager.

“Grant’s sales and technical experience lends itself very well to his new role. He is a good fit for our New Zealand market as it bolsters the commercial component of New Zealand,” Lamberti said.

“David has a lot of sales experience within the narrow web print market. His understanding of the narrow web market,

and his sales experience will assist Flint Group in providing growth for our business.

“Our plan is to execute our strategy, which is to grow our business in the Australian and New Zealand market, especially within our packaging business. So, the recent hires and appointments are key to the development of this strategy.”

Lamberti added that the company hires people with diverse experience, talent, and ideas to achieve business objectives.

“At Flint Group, we invest in people, and we look for long-term employees that understand and work with the Flint strategy. This is to deliver premium products and services to the to the print markets in Australia and New Zealand,” he mentioned.

“We encourage continuous learning and creative thinking, we promote team-based problem-solving, and we recognise and share successes. Continuous improvement drives performance and supports our aspiration to achieve excellence.”

With compliance and sustainability high on the company’s agenda, Lamberti said this will be central to Flint Group’s longterm engagement.

“A continuous improvement culture helps to reduce our current and future environmental footprint. Making progress on our sustainability journey would not be possible without the dedication of our employees,” he said.

“We strive to stay ahead of evolving regulations on chemicals, packaging and labelling. Over the years, we have maintained a strong focus on building and consolidating our sustainability culture. We have taken some important steps to reduce our environmental footprint, and we only partner with trusted suppliers who adhere to our high standards and uphold rigorous human rights and environmental standards.

“We’ve also globally launched a lot of sustainable products recently. Our customers are looking for innovation to offset inflationary costs, as well as solid partnerships. This will result in the needed stability in the market, especially with the ongoing disruptions to supply chains.”

According to Lamberti, Flint Group A/NZ will also focus on new product development, which includes the digitisation of the business.

“This means providing our customers with digital service solutions. We recently launched Flint Link, which is an app for our customers to do business using this program,” he said.

“We also have our global Colour Centre, based at Flint Group Poland, which we work with to support our customers through various digital packages like our Vivo Colour Solutions.

“We are here to partner with our customers and provide them with value-added solutions. The industry can expect stability with Flint Group and our dedication to our customers is and will remain unparalleled.”

6 newzealandprinter.co.nz November 2022 FLINT

GROUP HIRES

Hires David Mitchell and Grant Tychsen, and promotes Paul Lamberti in A/NZ as the company continues to support further growth in the region

Grant Tychsen, Flint Group’s New Zealand sales

manager

David Mitchell, key account manager of Flint Group narrow web in Australia

Paul Lamberti, Flint Group A/NZ general manager

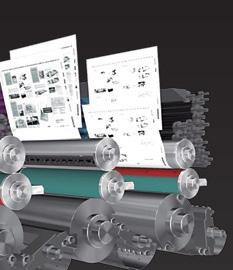

Jet Technologies: supporting the industry for over 40 years

Encore film

With the launch of its Encore range of films, Jet Technologies is bringing the latest in environmental innovation to the Australian and NZ markets.

Service, innovation, and expertise in the local and global industrial printing and packaging industries has seen family-owned and operated Jet Technologies position itself as a leading supplier.

Jack Malki, director at Jet Technologies, says: “Jet Technologies is proud to be a leader in the industry. Our expert staff continue to deliver our customers the knowledge and expertise they need to provide premium quality products and outstanding service.”

The story of Jet Technologies began when managing director Albert Malki and his family made their journey from Italy to Australia in 1980. When Albert and his family immigrated to Australia, hardly able to speak English, the landscape was vastly different, with difficulties faced in assimilating into the Australian culture. With this very obstacle in mind, Albert decided to start a company called Jet Overseas Trade to facilitate trade of a varied range of products between Australia and Europe.

Industrial products were added over the years including surfactants and aluminium. By the late 1980s, Amcor requested the assistance of Jet Overseas Trade in working with the Cerutti Group, an Italian manufacturer of gravure printing presses, and from there grew the print division of the company.

Albert says, “We pride ourselves on our strong family-based values, which we translate to our staff and our culture; investing in our staff to build long-lasting relationships with our customers, and

striving to deliver genuine and expert service always.”

Working originally from offices in Sydney’s Bondi Junction, the team quickly expanded and in 2001, moved to a larger location in Alexandria and became Jet Technologies. With further growth, including the addition of new team members in South Australia, Victoria and New Zealand, Jet Technologies moved to even larger locations with warehouses in Mascot and then its current headquarters in Rosebery. The Rosebery site features a state of the-art demonstration centre and a purpose-built ink management facility. Jet Technologies now also has a state of the art office-warehouse in Melbourne.

Daniel Malki, general manager Jet Technologies, says, “Today, we have grown and diversified significantly into the divisions of industrial, packaging, and printing, now employing over 70 staff and operating from locations across Australia, New Zealand, Indonesia, and Singapore, alongside a range of leading supplier partners including Screen GP, Kocher + Beck, ESKO, Flexo Wash, Crown, Goglio, ILPRA, and LG.”

Albert continues to lead Jet Technologies and is supported by the second generation of the family business, with director Jack Malki and general manager Daniel Malki. They say that the company’s core focus on family, expertise, partnership, reliability, and trust has really been the key for its success, alongside the company’s collective and constant push to find and materialise the latest industry innovations to offer its customers.

This new film solution is manufactured with 30 per cent recycled material and is suitable for a wide range of applications including packaging, labels and books. Jack says, “With organisations like the Australian Packaging. Covenant Organisation (APCO) setting 2025 targets of having 70 per cent of plastic packaging being recycled or composted and 50 per cent of average recycled content (recently revised from 30 per cent) included in packaging, Australian product manufacturers are having to quickly focus on, and take steps towards increased sustainability.

“Encore is a strong step in the right direction for using plastics within the circular economy and provide a sorely needed path forward for brand owners who are ready to work towards these recyclability and sustainability goals. It is a sensible option for businesses looking to transition from using virgin plastics and from either PLA (corn starch) or wood-based alternatives in their printing and packaging.

“As well as being produced from 30 per cent recycled content, the films are also fully recyclable, offering product manufacturers the functional benefits of plastic films, whilst ensuring that they work fully within a sustainable circular economy.”

“We have a responsibility and a commitment to provide the local market with the very best sustainable options in order to improve the environment. Introducing new film ranges can be challenging, but we are seeing a strong and constant demand from brand owners for better solutions in order to meet their environmental pledges.

“We see this demand as a strong sign that films like Encore will quickly replace less sustainable traditional films. We also expect the percentage of recycled content in these new films to be increased over time as the technology permits it.”

8 newzealandprinter.co.nz November 2022 DIGITAL

Leading supplier is still family-owned and operated

Jet Technologies’ first and second generation leaders, from left: Jack, Albert and Daniel Malki

C M Y CM MY CY CMY K

Jet Technologies Brings Latest Innovation in Print and Packaging Sustainability to the Australian Market

Sydney - 18 August, 2022 - Jet Technologies brings the latest in environmental innovation to the Australian and NZ markets with the launch of their Encore range of Films. Encore is a new film solution that is manufactured with 30% recycled material and is suitable for a wide range of applications including packaging, labels, books and more.

“With organisations like the Australian Packaging Covenant Organisation (APCO) setting 2025 targets of having 70% of plastic packaging being recycled or composted and 50% of average recycled content included in packaging, Australian product manufacturers are having to quickly focus on and takes steps towards increased sustainability,” explained Jack Malki, Director at Jet Technologies.

“Encore is a strong step in the right direction for using plastics within the circular economy and provide a sorely needed path forward for brand owners who are ready to work towards these recyclability and sustainability goals. Encore is a leading option for businesses looking to make the shi away from using virgin plastics and from either PLA (corn starch) or wood-based alternatives in their printing and packaging. There is little to no industrial composting in the ANZ region, meaning that biofilm solutions are o en having to be put into landfill. At the same time as being produced from 30% recycled content,

the films are also fully recyclable, ensuring that product manufacturers can enjoy the functional benefits of plastic films, whilst ensuring that they work fully within a sustainable circular economy.”

“Jet Technologies acknowledges that it is our responsibility to provide the local market with the very best sustainable options in order to improve the environment,” continued Jack. “Introducing new film ranges can be challenging, but we are seeing a strong and constant demand from brand owners for better solutions in order to meet their environmental pledges.

“We see this demand as a strong sign that films like Encore will quickly replace less sustainable traditional films. We also expect the percentage of recycled content in these new films to be increased over time as the technology permits it,” said Jack.

The Encore films are currently BOPP based, with PET options also in development. They look and feel like regular films and run on various machinery in a normal way, ensuring that businesses do not have to make any adjustments from existing films. Costs are also comparable to existing films, with a small premium of approximately 15-20% being very well received by brand owners looking for solutions to meet recyclability targets. “

Please scan the QR Code to request a trial run

APC Innovate evolves with the industry’s direction and growth

Established in 1978 as a purely cardboard box manufacturer, APC Innovate’s offering has undergone a massive transformation in the subsequent 44 years.

Based in East Tamaki, Auckland, APC Innovate employs 110 staff, the business’ single-site facilities entail a 900 square metre office and showroom, supported by a 6000 square metre factory that delivers a myriad of capabilities.

APC Innovate chief executive Tim Houlden has manned the helm at the

company for 19 years. He says, “When I started, about 80 per cent of our turnover was brown boxes and nowadays it is about 20 per cent. We are now New Zealand’s largest designer and manufacturer of point of sale displays.

“In 2017 we purchased Display Group which took us into the permanent display and shop fit out market. We have full steel, plastic and wood services workshops on site. Then in December last year, we purchased Jazz Print, which gave us entry into the real estate market and automotive industry.

“The acquisition of Jazz, and bringing them onto our site, meant we added further capability to our overall offering; digital offset HP Indigo printing and signage install probably being the key ones.

“Today we probably don’t have any one, singular competitor as we compete across a number of product areas.”

One of the company’s catchphrases is: ‘We live and breathe innovation’. He says, “We can print, laser cut, mould and fabricate just about anything with absolute precision, from corrugated board to steel and plastics.

“We take a client’s vision or idea from concept stage and production through to completion and market distribution. There is no part of the process we can’t handle.

“Given we have the largest structural design team of any business of this type in New Zealand, our philosophy from a sales perspective is ‘If you can imagine it, we can create it’.”

While emphasising the role that employees directly play in the ongoing evolution and success of the business, He also describes APC Innovate as arguably being an “industry-leading investor in new technology”.

10 newzealandprinter.co.nz November 2022

helping hand

Award winning display manufacturer lives up to its name

IAIN MACINTYRE

Investing in people: APC Innovate constantly upskills its team members

He says, “Our robotic large-format printing system was the first such install in the world six years ago. We make significant technology investments probably every two years.”

He says APC Innovate is driven by a strong community and ‘New Zealand Inc.’ philosophy. He continues, “We were purchased in 1999 by 100 per cent New Zealand-owned Rangatira Ltd, a Wellington-based investment company. Profits go back to the local community through principal shareholder, JR McKenzie Trust, which provides about $6m in grants every year.

“We also have a very strong policy around supporting New Zealand made. We try our best not to import any finished or semi-finished goods. For example, following our acquisition of Jazz, which had been importing a range of products, we have now started in house manufacturing and sourcing locally.”

The firm’s pursuit of excellence has received recognition as one of only four New Zealand companies to have won in excess of 100 Pride In Print Gold Medals.

Having established an export market over the past decade-plus, APC Innovate has more recently proactively seized on opportunities presented by the pandemic. Tim says, “The Covid-19 times and lack of product coming out of China, for example, have opened up some markets that traditionally have been difficult to get into.

“Today we export to Australia, the Pacific Islands, North America and Europe.

It is towards five per cent of our turnover and is an important, and growing, part of our business.”

In regard to thoughts on the overall New Zealand print sector, he particularly enjoys the professional pride evident throughout the industry. He says, “We do unique things and we do them really well. We are actually worldwide leaders in some of the processes and equipment that we use in New Zealand.

“We should be rightfully proud and we should be standing up and saying ‘the New Zealand print industry is in good nick and we do a good job’.”

However, he notes one issue continuing to plague the industry is simply being able to “access qualified staff”. He says, “I think the government has made it incredibly difficult for us to bring in overseas labour; it is almost impossible. Historically, that has been a strong source of qualified and quality labour, but that’s very, very difficult to do at the moment.

“I think PrintNZ and Competenz (now Te Pūkenga) do a really good job to promote our industry and apprenticeships. But the difficulty we have right now is simply access to staff.”

Although, he is quick to emphasise that APC Innovate also has a strong culture of both investing in training its workforce and “promoting from within”. He adds, “Currently we have four apprentices. Most

of our production management team have come from starting on the floor.”

In regard to the future, he says APC Innovate is “always looking ahead”. He says, “We take great pride in our environmental policy, as we focus on circular manufacturing and new energyefficient ways to work smarter and more sustainably.

“We are constantly seeking to upskill our team as well as invest in new technology which will both expand our offering and increase our delivery and speed to market.”

•

•

•

•

•

•

•

•

•

•

•

•

•

11 newzealandprinter.co.nz November 2022

APC Innovate is one of only four companies to have won in excess of 100 Pride In Print Gold Medals

helping hand APC Innovate services

itself as “New Zealand’s leading manufacturer of retail display solutions, specialised printing and creative packaging”, APC Innovate boasts these capabilities:

Describing

Design and concept development

3D rendering and prototyping

High quality digital printing

Screen printing

Intricate flatbed cutting

Die-cutting

Large-format printing

Assembly

Campaign management

Inventory warehousing

Stock reporting

and distribution

Packing

Export

Innovate is New Zealand’s largest designer and manufacturer of point of sale displays

APC

Women In Print & Sign – a thrill to be back, and with a twist

Popular event returns with a twist

Women In Print returned in November to two sell-out crowds of 190 attendees in Auckland and 70 in Christchurch.

After a three-year hiatus, courtesy of Covid-19, the event has returned with a new twist: PrintNZ’s first collaboration with the NZSDA saw the inclusion of women from the sign industry and it was a pleasure to welcome them along.

The women at both events were thrilled to be back and if the noise in both the rooms was anything to go by, substantial networking took place. In the spirit of the event, everyone was challenged to make at least one new contact before they left for the evening and I am sure they did.

Guest speaker at both events, well known media personality Kerre Woodham gave a delightful no holds barred account of not just her career, but her life to date, imparting some of the valuable lessons she has learned along the way. The audiences were certainly kept entertained.

These events provide a great opportunity for networking and also recognised the women that are leading companies in our industry, and those that have been in the industry for over 20 years.

The nights would not have been possible without the generous support of our sponsors: B&F Papers, Torque Digital, BJ Ball Papers, Computaleta, Heidelberg, DIC and Spicers/Total Supply, with support from Finely Finished, Office Max and Tuapeka Gold.

12 newzealandprinter.co.nz November 2022 PRINTNZ COMMENT

RUTH COBB

The B&F papers team with Kerre Woodham, from left: Paula Vasquez, Sandra Robinson, Carmen Tough, Penelope Savidan, Kerre Woodham and Angie Johnson-Heremia

Women In Print from BJ Ball Papers

Women In Print from Blue Star Group

Women in Print from Easy 2C

Keeping it local, let the world know

455 PNZORG 0000 WORKING FOR OUR INDUSTRY AND OUR MEMBERS EVERY DAY

Keeping print in New Zealand is more important than ever. Use this logo so both you and your customers can demonstrate the part you are playing. Apply to PrintNZ on info@printnz.co.nz or phone 0800 654

Blue Star Group’s partnership with Ricoh continues for digital print excellence

Country’s largest printer operates Ricoh flagship presses

Operating multiple printing sites across the country, Blue Star Group employs over 600 people, producing the full range of printed products.

Craig Loveridge, head of commercial for Blue Star Group New Zealand, says, “As New Zealand’s largest integrated print and marketing company, we cover web printing, commercial work, publications, design, retail display and packaging; the last two being real areas of strategic growth for us.

“With a diverse range of sites around the country, we have to consider the geography as we focus on cohesion through integrated units. With this in mind, we made a decision to use Ricoh technology and solutions for all our digital toner production.

“We have partnered with Ricoh New Zealand for over five years so the

relationship is a mature one, and strong strategically. We share some good alignments with Ricoh in regard to business attitudes, perspectives, and the crossover of customers.

“Ricoh has supplied us with competitive and impressive technology to help keep Blue Star ahead of the game. For example, we have installed five Ricoh Pro C9210 presses across our sites. These machines deliver close to offset quality and are a significant update to the Pro C9100 Series, running higher volumes.

“The Ricoh Pro C9210 is a tough and reliable machine. Last month, our Wellington Jackson site did 420,000 A3 impressions with the Ricoh Pro C9210 and it is consistently running that kind of volume.

“The banner capability on the Pro C9210 is also impressive. We get a fast turnaround on the banners for point of sale work. We complete inline finishing

for work like saddle stitching, booklet finishing and stapling and square edge trimming. The machines give us industrial grade finishing.

“Ricoh’s nationwide service and support capability means we have access to technical expertise, which complements Ricoh’s Trained Customer Replacement Units (TCRU) programme.

“Blue Star Group also runs three Ricoh mono machines, which are solid workhorses; bullet proof and reliable.”

Can do attitude

He continues: “Ricoh’s service and support is excellent. It goes beyond the standard preventative maintenance. Essentially, Ricoh is proactive around service and support; the team makes sure that things get done. Ricoh has a can do attitude. The relationship we have with the Ricoh team is really solid. Mike

14 newzealandprinter.co.nz November 2022 COVER STORY

Delmar Mebius (l), manager ADC Blue Star and Mark Burgess, national print specialist for Ricoh Graphic Communications, with the Ricoh Pro C9210

Laursen and Mark Burgess have gone the extra mile to get the job done.

“Blue Star Group’s philosophy also aligns with Ricoh’s approach to sustainability, which is something both companies embrace. We have taken a logical and systematic approach to our environmental management systems and we are proud to have 100 per cent of our sites now Toitū Enviromark Gold Certified and more recently Carbon Reduce Certified.

“Other important certifications are Forest Stewardship Council (FSC) Chain of Custody Certification, the Program for Endorsement of Forest Certification (PEFC), and for Blue Star Wellington, HACCP and GMP Food Safety Management, which allows us to manufacture paper and board based packaging solutions for use in the food industry.

“All our key suppliers are ISO14001 certified. Ricoh has not only received ISO14001 certification but is also Toitū net carbonzero organisation certified. Blue Star Group actively recycles toner

bottles. So far, over 3,500 bottles have been diverted from going to landfill.

“Sustainability also involves our customers and our partners so we need to have that as we attempt to balance sustainability as an economically viable strategy.”

Like Ricoh, Blue Star Group sponsors and supports numerous local charities and organisations. Craig says, “On a nationwide scale, we have long-term community projects running with organisations like Paralympics New Zealand. However, we see the value of our individual sites being involved with more local projects and we encourage them to get across local organisations and charities.”

Ricoh Pro C9210

With its flagship Pro C9210 press, Ricoh says it has tailored a solution to meet the needs of even the most demanding production environments. Mike Laursen, national manager for Ricoh Graphic Communications, says, “The Ricoh Pro C9210 delivers a number of benefits to our customers. Firstly, the print quality

is comparable to Offset. Second, it has proved to be highly reliable for long runs with generous paper capacity and expansive media support. Lastly, it is easy to operate.

“Commercial printers like Blue Star Group are maximising their profitability and return on investment with this machine. Its benefits include:

• Consistent, repeatable, superb colour and image quality.

• Long runs achieved efficiently and cost-effectively.

• Capability for high-margin applications using diverse sizes and types of media.

• Higher uptime and asset utilisation with advanced automation and usability.

• Flexibility to handle changing market conditions and customer requirements.

With the partnership being so successful in New Zealand, IVE Group Australia, one of Australia’s largest printers has recently installed a similar platform of Ricoh engines.

Ricoh Pro C9210 delivers high quality print and high volumes

Enabling print companies to achieve their digital objectives using the innovative features of the RicohPro C9210. Ricoh lists its benefits and advantages:

• Saddle stitch booklet finishing and 100-sheet stapling using the SR5060 Booklet Finisher. Additional commercial finishing options are also available.

• High Capacity Stacker SK5040 allows you to keep jobs running continually. Up to 5,000 sheets can to be stacked and moved with the Roll Away Cart. Up to two stackers can be configured in one system.

• In line sensor ensures real-time colour analysis with automatic adjustment and correction during printing.

• Automatic front to back image registration with an inline sensor provides the data used by the system to adjust image position and shape.

• Oversize sheet printing capabilities allow you to print up to 1,260mm simplex and 1,030mm duplex.

• Operator productivity increases as each operator can customise the new 43cm Smart Operation Panel, which displays the entire device configuration.

• Image Calibration System scans image density to make any necessary corrections prior to maintain image gradation quality.

• Enhanced Graphical Media Library lets you easily create paper settings and select desired papers.

• Vertical cavity Surface Emitting Laser VCSEL beam technology and 2400dpi x 4800dpi print laser resolution provide output that compares favourably with Offset.

• Vacuum Feed Trays ensure the paper feeding ability of Coated Media up to 470gsm maximum. Up to three units can be added to increase the feeding capacity to 18,100 sheets.

• Media Management Tool enables operators to share the media catalogue among multiple Pro C9200/C9210 digital presses

• Variable data processing (VDP) capabilities enable personalised, versioned and customised printing.

• Colour management capabilities offer industry standards, calibration methods and G7 certification.

• TotalFlow Suite of software automates and streamlines tasks related to makeready, ticketing, scheduling, creating workflows, reporting and more.

15 newzealandprinter.co.nz November 2022

COVER STORY

Craig Loveridge, head of commercial for Blue Star Group New Zealand

Mike Laursen, national manager for Ricoh Graphic Communications

AccurioPress accelerates production for Banner Express

business cards. We can duplex with that as well. A lot of other machines can only do simplex on the heavier stock.

“Another important point I want to raise is the technical support we get from the Konica Minolta team. We have never had a Konica Minolta machine before and they have responded really well with any issues, reducing downtime. I think the Konica Minolta support is fantastic and their communication is very good.

“Right now we are really busy but we are keen to explore new products with the improved production capabilities and finishing options of the AccurioPress C12000; that is the next step, sometime next year.”

Web to print

Recently, Auckland-based web to print specialist Banner Express installed a Konica Minolta AccurioPress C12000.

Raymond Kho, owner and director at Banner Express, says, “We had another machine and the lease had expired, so it was time to upgrade. I had been talking to Rob Whiting from Konica Minolta New Zealand about the AccurioPress.

“I told Rob about the issues we were having with our old machine, and then we started to engage with their ideas. Rob was quite helpful and when he showed me the machine, it ran really well. I liked the colour quality and after discussing pricing, we got a great deal from Konica Minolta. Now, the AccurioPress C12000 is delivering high quality print for us.”

Konica Minolta’s IQ-501 is a fully automated, closed-loop quality management tool that performs automatic density correction and front-to-back registration prior to printing. This unit inspects colour density and registration accuracy on a sheet-by-sheet basis throughout the print run taking remedial action if it detects any deviation. It does all of this, and more at the full rated speed of 120 pages per minute.

Raymond says, “I would like to mention a few key points about how the IQ is helping

us. Firstly, we have long term customers with repeat jobs and we used to spend a fair amount of time adjusting colours. Second, we used to have to do a lot of printing to get the alignment right. The AccurioPress has put an end to those issues.

“Most of our work is booklets, flyers, brochures and business cards. Not having to worry about manual colour adjustment and registration is a major benefit to our business. I would say production has improved 25 per cent; we are simply doing more work in the same amount of time and that is not just because the AccurioPress is printing much faster than our previous machine.

“It is interesting because I try not to have to do overtime. Previously, the team would have to stay at work to get the long run jobs done but now, we can finish the jobs on time.

“Also, having the alignment basically spot on is also vital for print finishing. For example, folding and die-cutting require accurate registration and we have that with the AccurioPress C12000. It is a seriously good machine and we are running it pretty much constantly.

“One really cool feature of the AccurioPress is its ability to handle media up to 450gsm at the rated speed, enabling us to do thick cards and premium

Immigrating to New Zealand in 2014, Raymond Kho saw an opportunity for web to print.

He explains, “I had owned and run a print company in Singapore, although I am originally from Malaysia. I started Banner Express in 2013 because I saw the possibilities for web to print as a niche print business. We initially focused on designs but later we moved to digital printing.

“We have been able to go nationwide because we have such a strong web presence, and that goes back to when I started Banner Express.

“While we lost 40 per cent of business during Covid-19, we also had long term customers who stayed with us. We are actually busier now than pre-Covid and our Customer base has grown. We did not lose any staff. In fact, after Covid we have employed more staff.

“I am appreciative of the 10 staff members here at Banner Express. For me, the people around me are important. Any company can come up with the same pricing and product but it is the service level that we provide that makes the difference.

“It is a fact that our staff are a significant factor in the success of this business and its survival through the worst part of the pandemic. Their support certainly helped us get through a difficult time.”

16 newzealandprinter.co.nz November 2022 DIGITAL

Konica Minolta AccurioPress C12000 delivers quality, accuracy and productivity gains

Lily Bong, digital print supervisor at Banner Express and Rob Whiting, production print specialist for Konica Minolta with the AccurioPress C12000

RETHINK EFFICIENCY

WITH THE ALL NEW ACCURIOPRESS C14000 SERIES

The digital revolution continues with the highly evolved, all NEW AccurioPress C14000 series designed to ensure you never stop printing. These high speed digital colour presses offer next level automation for ultra-efficient, high volume colour printing. Packed with an array of impressive features, powerful inline finishing options for high productivity and with in-built technology, they offer unparalleled quality and consistency print after print.

To rethink efficiency, simply visit konicaminolta.co.nz/AccurioPressC14000series

HP Indigo 10000 Digital Press raises B2 quality at Benefitz

New press delivers impressive quality, consistency and speed

Support and success

Currie Group provides comprehensive service and support for all its solutions. Kent says, “The inner workings of the machine are pretty sophisticated and can be intimidating, but the software and the technical backup is solid.

“We have had a long relationship with Currie Group and Craig Paul, the country manager. They have supplied us with various bits of Horizon kit over the years and so now, with the HP Indigo 10000 Digital Press, we just see them all quite a bit more. Currie Group’s team members are always happy to help and go that extra mile; we just keep them supplied with coffee and cakes.

Based on Auckland’s North Shore, diverse media company Benefitz offers a comprehensive range of services and products including commercial print, sign and display, as well as design and web.

Last year, Benefitz installed an HP Indigo 10000 Digital Press, supplied through Currie Group. Kent Bowyer-Sidwell, from Benefitz, says, “Having had a B2 digital press for nearly 10 years, this was a natural step for us. For the installation, Chris Bennett, senior HP Indigo engineer, and the team at Currie Group did a great job. We were up and running in no time at all. There was plenty for us to learn, despite being familiar with B2 digital. The HP Indigo 10000 Digital Press is a very different beast.

“The press is very flexible but we use it predominantly for collated book blocks. This has been a large growth area for the business and is complemented with our Horizon PUR binder, case maker and three knife trimmer. This saves on a lot of folding and keeps our binding in house.

“The HP Indigo gives us speed and enormous production capacity. We are printing jobs in hours on the large sheet, which took us literally days on the SRA3 toner machines, and the results are much closer to offset quality.

“Our book and brochure covers are much easier to produce multiple up on a large sheet with the correct grain direction, and much less curl. We can also use normal OPP lamination, not digital lamination. This further reduces costs while increasing efficiencies and speed.

“The quality is superb. We are staggered at how easily it can print some very difficult work. The results are more often than not as good or better than offset. So everyone is happy; most importantly, our clients.

“We also love the Enhance Productivity Mode (EPM), where we can really push up production efficiencies and reduce costs. We wish we could run EPM on the offset or the toner presses.

“Another notable benefit is our paper usage has dropped dramatically per job. With most jobs on the new press, the first print sheet off the press is good to go, so we are using up to 95 per cent less makeready paper per colour lay than our offset presses, which over a year is really significant in dollar value and results in far less waste paper.

“The machine is very much at home at Benefitz. It complements our existing B2 Litho presses and our two toner presses. So we can mix it up to get larger multi element jobs through, while maintaining consistency across a client’s branding.”

“Currie Group understands what we want from the press and that is important. In the end, it’s a partnership; the more the machine is a success for Benefitz, the more it’s a success for Currie Group.”

Currie Group and HP Indigo also provide ongoing training support. He says, “We had three operators train up immediately for the new press. Two ex–litho operators and one prepress/toner operator, who also had some experience of an early SRA3 HP Indigo Digital Press. They all took to it like ducks to water.

“Benefitz has great staff who are flexible in many areas of the business, so they can move into areas where they are needed. We offer a diverse range of printed products with the variety of what we do here and what we can deliver to our clients. The HP Indigo 10000 Digital Press is a very important addition to that offering.

“While Benefitz has had a B2 digital press for over 10 years, the HP Indigo 10000 Digital Press is a massive step up in quality and productivity.

“We know we can pretty much take on larger digital run jobs without clogging up production. Seriously, the quality, consistency and the speed of what it can chomp through at B2 and SRA2 sheet size is impressive.”

He concludes, “It’s been a good first year and we are looking forward to pressing on this year with the knowledge, and tricks, we have acquired.”

18 newzealandprinter.co.nz November 2022 DIGITAL

The HP Indigo 10000 Digital Press at Benefitz, from left: Rob Gunston, general manager Benefitz with operators Rob Moore and Leighton Hill

www.curriegroup.co.nz

See which part of your brain drives your decision making

goal. SMART is an acronym for Specific, Measurable, Achievable, Relevant, and Time-bound. In the case of equipment purchase, your plan would be based on the specific purpose of buying the press. It would have measurable benchmarks such as return on investment, increased throughput, reduced overtime and so on. And it would be achievable in your financial position and relevant to your business operations. Lastly, it would have to take place in a reasonable timeline.

For the next step, a form of Cartesian Logic is an excellent way to work through the situation. This method uses four lenses rather than one to view the problem. You achieve this by asking yourself a question posed in four different ways:

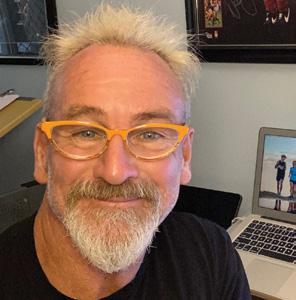

MICK ROWAN

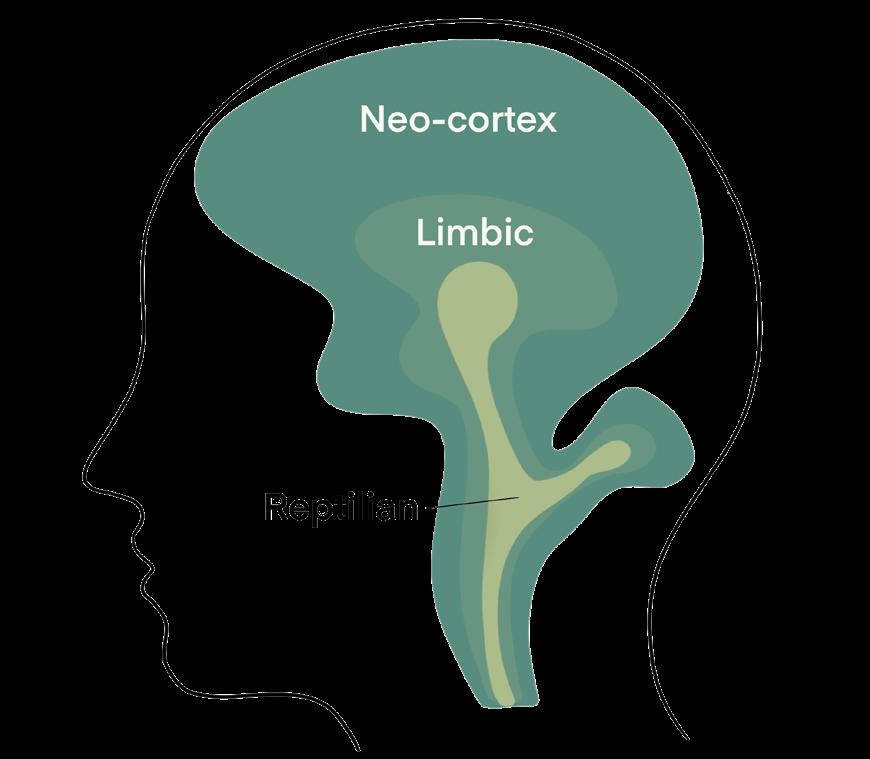

Ever wonder how CEOs and other business leaders make decisions? It’s not all based on logic, despite what you may think. In fact, a lot of it has to do with the way our brains are wired.

Let’s create a scenario to put this in perspective. The world has been effectively shut down for a couple of years after governments worldwide have massively overreacted to a situation. The world finally awakens, and it’s obvious that we all need to be more adaptable in how we do things, because rapid change has become a permanent reality of life on earth!

After a couple of years of inactivity, there’s a lot of new equipment on the market. You pop over for Labelexpo and, after walking the halls and talking to everyone, you’ve set your sights on the new HP Indigo V12, delivering 120 linear metres per minute with 1600dpi image resolution!

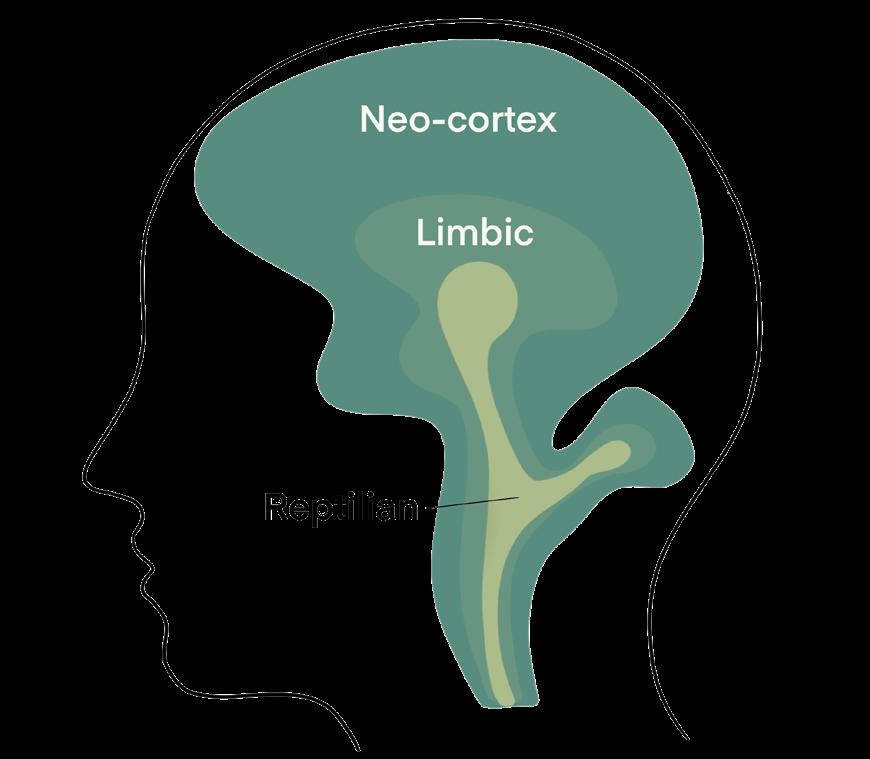

To get that goal to the next stage, you’ll need to light up all three regions of your brainstem, with the hind-brain, midbrain, and fore-brain all playing a role in your decision making process.

The hind-brain, or reptilian complex, is

responsible for our basic instincts, such as fight or flight. This part of the brain is often associated with risk aversion because it helps us to avoid dangerous situations. In business, the reptilian brain might lead us to play it safe and avoid risks that could lead to loss.

The mid-brain, or limbic system, is associated with emotion, which is the part of the brain that gives us feelings of pleasure and happiness. The mid-brain is often influencing our decision-making without us even realising it. When you make a purchase simply because it makes you feel good, that’s your limbic system at work! In business, the limbic system can be a powerful tool for marketing products and services. If we can tap into positive emotions like happiness and pleasure, we’re more likely to get people to buy what we’re selling. But for significant purchasing decisions, acting on feelings and emotions alone can be disastrous.

The fore-brain, or neo-cortex, is responsible for higher level thinking, such as language and abstract thought. This brain part helps us see the bigger picture and make long term plans. In business, the neo-cortex is often used for strategic planning and deciding where to allocate resources. However, because this part of the brain is so analytical, it can sometimes lead us to overthink things or get bogged down in the details.

Knowing how the brain works can help you plan a strategy to cover all bases. And one of the best ways to get a project underway is to start with a SMART

What will happen if I get the HP Indigo V12? I’ll be able to produce more high-quality work in less time. What won’t happen if I get the HP Indigo V12? I won’t miss deadlines or worry about the quality of my work. What will happen if I don’t get the HP Indigo V12? I’ll continue to be stressed and miss the opportunity to win higher-value jobs. What won’t happen if I don’t get the HP Indigo V12? My business won’t grow, and I’ll stay in the same position I’m in now, underresourced and working hard to keep up.

Using a SMART framework and Cartesian Logic will remove the fear from the reptilian brain because it no longer seems so risky. The limbic system still influences our decision making, but we are fully aware of it and have planned our decision on more than just emotion. And finally, the neo-cortex has the details it needs without being bogged down.

So, the next time you’re faced with a business decision, take a moment to consider which part of your brain is driving that decision. Is it based on logic or emotion? Are you playing it safe or taking risks? Decision making varies depending on what’s best for your situation. But by understanding how your brain works, you can make more informed choices that will help you achieve your desired results.

Mick has spent the past decade building printIQ into one of the most recognised software brands in the printing industry, and with over four decades of experience, Mick truly has ink in his veins.

20 newzealandprinter.co.nz November 2022 THINK LATERALLY

Understanding your decision making.

Knowing how your brain works can help you devise an effective strategy.

: Epson’s fine art l CCG offers DTG l NZSDA has dates for 2023 Stickr goes to Colorado for wallpaper Aarque supplies Canon Colorado 1650 roll to roll printer

Stickr goes to Colorado for wallpaper and decals

Aarque Group helps Stickr bring a new print concept to New Zealand

From its Henderson base, Stickr offers around 120 designs for its self-adhesive wallpaper, which customers can order online. The e-commerce operation despatches orders within three to five working days, printing everything on the Colorado 1650.

Jaimee says, “The Colorado 1650 is the ideal solution for Stickr, allowing us to print in-house and keep our customers happy. Having the Colorado 1650 means we can pump out high quality wallpaper. The colours the Colorado produces are vibrant and dynamic with no dull patches. It delivers high print quality.

“For ease of operation, the Colorado 1650 is intuitive and very user friendly. I don’t have a background in printing but I find it easy to use. We provide a library of 120 designs, which gives our customers plenty of variations and the Colorado 1650 gives them the wallpaper they want. In addition, we roll and fold our samples and that doesn’t damage the print finish.”

“The prospects for Stickr in the New Year and beyond are quite exciting. As a Kiwi company, we are looking to work with some New Zealand artists and designers.

“The Colorado 1650 allows us to be bold when we choose new designs because we know we will never have to compromise on the colour quality.”

She adds, “The Colorado 1650 is doing a great job. To learn more about Stickr, jump online to www.stickrshop.com.”

Independent analysis

When independent testing agency Keypoint Intelligences analysed the Colorado 1650 roll to roll printer, it obtained “exceptional results”. The assessment, across three categories of image quality, usability and speed, concluded that “as an all-round impressive performer, the Colorado 1650 is a standout choice for virtually all wide format printing applications”.

Stickr began in 2020, when two friends went in search of simple, affordable and beautiful wallpaper decals to liven up their little ones’ nurseries. When they came up emptyhanded, they saw the chance to launch their own.

Using their 15+ years of experience in commercial interior graphics, the friends created Stickr, a collection of affordable, premium, high quality, and on-trend decals that are produced on a PVC Free peel-and-stick wallcovering product, making it easier than ever to bring any room to life.

Subsequently, Stickr installed a Canon Colorado 1650 roll to roll printer through Aarque Group. Jaimee Aislabie, brand marketing specialist for Stickr, says the Colorado 1650 fits perfectly with the startup’s business model.

She says, “The understanding that you can have your own self-adhesive wallpaper is new to New Zealand, but Kiwis have been quick to pick up on the concept. Our customers are amazed that we can produce these wallpapers here in New Zealand and they love the quality we deliver.”

Steve Wilton-Jones, national equipment sales consultant at Aarque Group, says, “The Colorado 1650 offers a truly impressive application range, thanks to two additional technologies: the more flexible and stretchable formulation of the UVgel 460 inks and the FLXfinish+ technology. The UVgel 460 inks provide perfect image stability even when folded, bent and wrapped. And with the FLXfinish+ technology, you can print your applications both with a flawless glossy and a luxurious matte finish, independent of media finish.”

Recently, Stickr expanded its offering to include decals. Jaimee says, “The decals are peel and stick wall coverings but on a smaller scale. We offer many designs for families that don’t want to do an entire wall. The decals have a range of applications, for example emergency vehicles such as fire and police. Also, with the right preparation and a good quality surface, the wallpaper and decals are removable. Recently, I removed a wall covering, that had been up for 18 months, with no issues.

“Right now, we are busy with a number of jobs going on as we move into Christmas, and the Colorado 1650 has no difficulty in keeping up with our production schedule.

Steve says, “The Colorado 1650 was found to be three times faster than the competitive average across each quality mode tested. In addition to its speed, the printer’s automatic maintenance, user replaceable components and on the fly ink replacement features were all recognised as contributing factors for increased uptime and faster turnarounds.

“The technicians highlighted how the Colorado 1650 can produce both gloss and matte finishes without the need to change inks or media. In switching output finish, there was no impact on image quality, even at the most productive speeds.

“The machine’s FLXfinish curing technology enhances the printer’s handling of porous materials such as soft signage and uncoated media because its UVgel technology ensures that each ink droplet is immediately fixed on the media, allowing for highly controlled dot gain and more precise image quality.”

“Given its highly accurate dimensional stability, modular design and matte finishing capabilities, the Colorado 1650 roll to roll printer is the perfect solution for producing digital wallpaper.”

22 newzealandprinter.co.nz November 2022 WIDE FORMAT

Kris Hassett, co-owner of Stickr, with the Canon Colorado 1650 roll to roll printer

The Colorado 1650 www aarque.co.nz focus@aarque co.nz Freephone 0508 22 77 83 THE UVGEL ADVANTAGE The Colorado 1650 maximises the UVgel advantage with certified flexible inks and FLXfinish+. It has been designed for Print Service Providers for whom ‘no’ is not an option, enabling them to explore new business horizons with its astonishing range of applications. Explore new business horizons with an astounding application range. FLXfinish+ empowers to print with a flawless glossy or a luxurious matte finish independent of media.

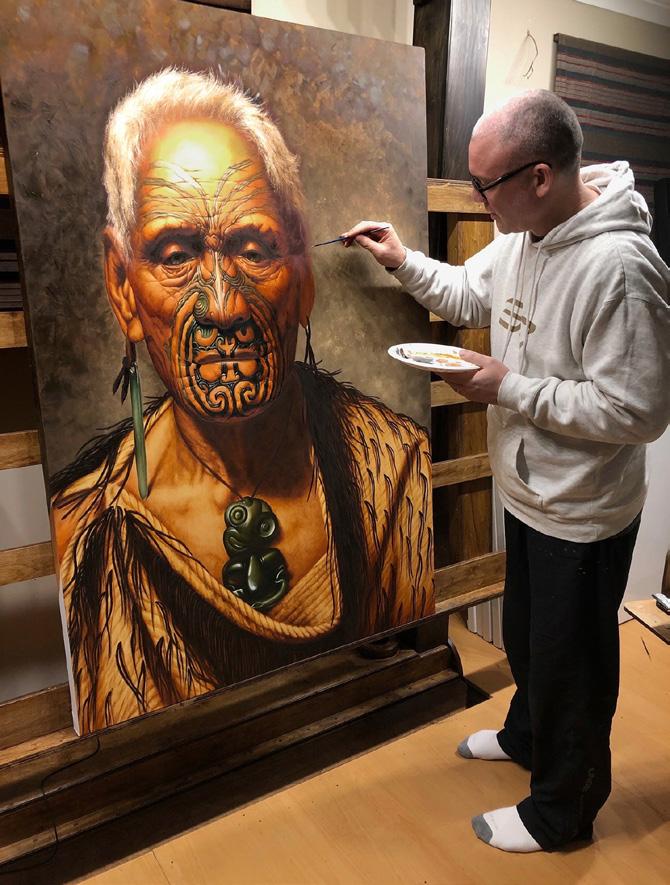

Epson achieves excellence for deSotogi fine art reproduction

deSotogi Fine Art gains quality and speed partnering with Fujifilm Business Innovation

get someone to do the colour profiles but I find the Epson software is excellent.

“This is my first involvement with Fujifilm and the team there is great. Firstly, Patrick Crosby steered me in the right direction. Also, when the Fujifilm technician Ryan set it up, we talked the whole time. I was able to learn it quickly. One time I texted him at 9pm to ask him if it necessary that the printer was self-cleaning. He replied straight away.”

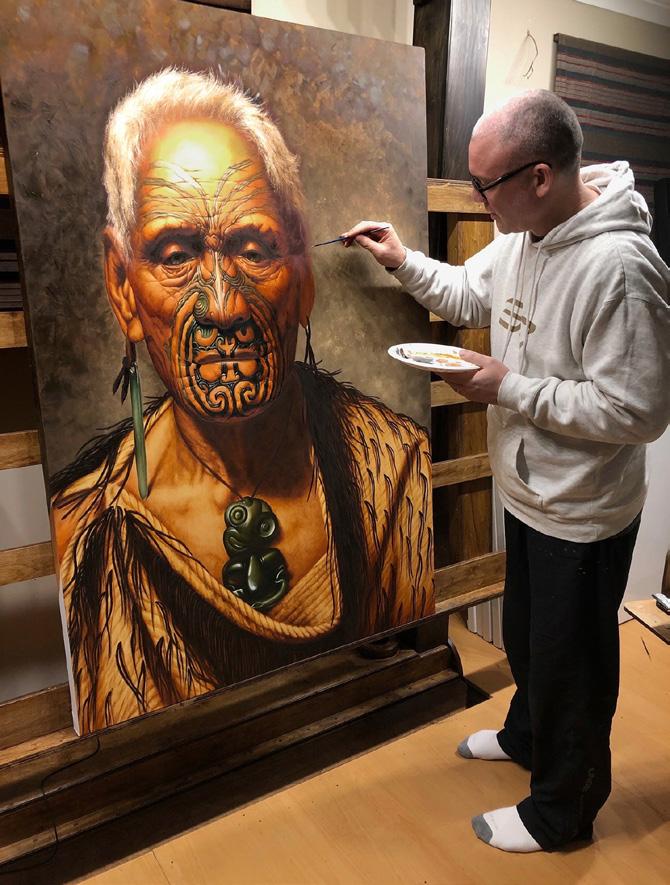

Founding deSotogi Fine Art in 2005, artist Dave Sotogi had an intention to make prints from his original paintings and sell them.

He explains, “I was painting a lot and wanted find a way to reproduce the artwork that would do it justice. It took off and we began wholesaling them nationwide. I hired staff to do the canvas stretching and other jobs. At one stage, we had nine in the company but in the last six years we have re thought the business. Now it is just my wife Valerie and me.

“We roll the canvas up now; it is easier to send that way. Looking at our analytics for this year, we have sent about 30 per cent to Australia, five per cent to other overseas countries and the rest across New Zealand, and interestingly to places I have never heard of.”

Recently, deSotogi Fine Art installed an Epson SC-P9560 printer, supplied through Fujifilm. Dave says, “This is our fourth Epson; we bought our first Epson printer in 2005. Previously, I had run a 64 inch Epson printer for nearly 10 years, which I had bought from the US. It was time to upgrade.”

Fujifilm says that, designed for the world’s greatest artists and photographers, the

UltraChrome Pro12 all-pigment aqueous inks add Violet to produce a wider colour gamut, up to 99 per cent coverage of the Pantone Formula Guide solid-coated standard. The Epson SC-P9560 is ideal for premium photo, fine art, proofing and packaging design, delivering vibrant, long lasting prints that captivate and inspire.

Dave says, “It is unbelievable how good the Epson SC-P9560 is. It is fast and the printheads are great. It has features that I always thought printers should have like the LED lighting inside that enables me to look inside the printer to see how it is going Also, the way the paper roll cover seals to stop dust getting in and the big LED touchscreen is easy to use.

“But the main thing is its speed, which is important. I had not previously thought about it but it is mind blowing the difference between this and the last one. When it arrived, I was backlogged on orders. As soon as it came, I was able to print all the backlog in one weekend.

“The print quality is beautiful. I am used to printing at 1440dpi but I had to change the settings because it was laying down too much ink. I don’t need to run it at the highest setting. It delivers museum quality prints. I am using the Epson profiles for colour management. I used to

Dave’s paintings can sell for between for $8,000 to $40,000. He paints in oils and the artwork predominantly has a New Zealand flavour. He says, “I get a lot of expats who want the prints. I am not doing so much painting now, just commissioned work. The printer is really the bread and butter for the business. I don’t print anyone else’s art but my own. That is the model we have stayed with and it has worked for 20 years. I enjoy printing. This year marks 17 years of printing and the process still blows me away. The technology is incredible when you see it in action.

“The biggest challenge I am facing in the business right now is trying to keep up. Right now, the supply chain is an issue. Trying to get canvas is difficult.

“What is great is that the new Epson SC-P9560 printer frees up my time with its speed and efficiency; it’s just cranking them out. The customers are happy getting quality.”

24 newzealandprinter.co.nz November 2022 WIDE FORMAT

Dave Sotogi with the Epson SC-P9560 printer

deSotogi Fine Art has a predominantly New Zealand flavour

The Art of Performance Featuring all-new UltraChrome® PRO12 Violet Ink, discover astounding colour with 99% PANTONE® coverage, the SureColor P9560 captures every detail with unparalleled colour brilliance and accuracy. Delivering A1 prints in speeds of just 94 seconds, transform your artistic vision into a truly unforgettable experience. Find out more: https://www.fujifilm.com/fbnz/

Updated unit standards focus on new processes

that, and top of mind for many, was Installation, which has become its own specialised part of this industry. It numbers among many sign making processes that have developed over the past few years.

As a result, a new strand for Installation of 400 hours (40 credits) was developed. Traditional remains but has been reduced to 100 hours (10 credits). It has also been absorbed into other standards throughout the sign qualification.

Another change involved correcting the context around the questions asked in the unit standards, ensuring that they are fit for purpose for the scenario, the learner and the outcomes.

Together with a small working group of passionate sign makers, the NZSDA has revised and reshaped the sign making unit standards for apprenticeships. And, working with the Hanga-Aro-Rau Manufacturing, Engineering and Logistics Workforce Development Group, a new sign making qualification that focuses on new processes and practices has been developed.

One major change is in the Traditional specialisation strand, which has not

received any enrolments over the past three to five years. The time had come to rethink how to incorporate this strand of 400 hours (40 credits) into the qualifications without losing its significance. For sign makers, this is where they have come from.

Many sign shops find traditional sign writing hard to teach. There is little opportunity to practice this work, especially for apprentices –certainly not 400 hours. Alongside

Changes to the qualification have been published on the NZQA website, www. nzqa.govt.nz as well as the specialisation units, with the addition of the Installation strand. The changes have been approved, and now the programmes for the learners must be developed with Hanga-AroRau Manufacturing, Engineering and Logistics Workforce Development Group and Competenz.

The timeframe for the new standards to be made available to new apprentices is yet to be confirmed, but looking like early 2024. The current unit standards will remain until 2025.

Secretary Update – taking action on mental health and well-being

COUTTS Secretary NZSDA

COUTTS Secretary NZSDA

However, those struggles, plus a host of other pandemic-related issues like inflation and cost of living are still here; they are real and not going away anytime soon.

Stress levels are high. Businesses that don’t take this seriously risk the knock-on effects of loss in productivity, recurring mistakes and increased absenteeism.

To find out more about what the association can offer with this pathway, go to the members’ section on our website. You will see the Safety Charter Health, Safety and Well-being workshops, toolbox resources and peer-to peer advice groups. There is an insurance group discount for staff and their families with the nib Health Insurance Association Scheme, plus discounted EWP courses with Goleman Training.

Last month, we featured NZSDA’s efforts to address mental health and well-being, which can lead to burn out for employees and employers alike.

The Covid-19 pandemic has brought these issues into focus as we have seen its heavy effect on economic activity, employment and the way we work. Many employees managed to struggle through the prolonged uncertainty of the future, job security, lockdowns and isolations.

NZSDA has engaged with new partnerships that offer valuable knowledge in health, wellbeing and safety. We are encouraging employers to look at their workplace culture to address how to support mental health and protect people. Offering benefits, advice and support to staff members helps them feel valued. They can learn to adopt behaviours that will improve their wellbeing which will assist in maintaining a happier, healthier and more productive workplace environment.

Our newest partnership is with Business Advantage, which is helping with workshops and advice on creating good cultures, looking after your people, succession planning and other business practices Workshops will begin in our regional meetings and be made available online. We have the tools to help you, as a business owner, to get started on helping your staff with their health and well-being.

26 newzealandprinter.co.nz November 2022

MELISSA

The new sign making qualification incorporates new processes and practices

NZSDA UPDATE

TALES FROM THE PRINTERVERSE

Help your print customers to buy more of your products

to help professional print customers, the infiltration of print management services is imminent.

The situation for printers when print management services (PMS) take over is more complicated. Some printers benefit and can get more work from the network if they can print at the price required. In many cases, they can’t afford to print at the required pricing for PMS companies to profit and they lose work they may have had for years. Work that they counted on to keep the lights on.

Making print sales isn’t easy these days. Supply chain issues are disrupting the process, as is the ability to promise everything will be okay with 100 per cent certainty. This situation can make even the most seasoned print customers nervous especially if they work as a print producer at advertising agencies, brands, or corporations that plan their print marketing and media placement strategy well in advance.

I recently reached out to a friend who is the director of production of a specialised, full-service production agency with a roster of clients that includes other ad agencies in this space. When he didn’t answer, I followed up and this was his reply:

“Sorry Deborah. My department is haemorrhaging. Three rounds of layoffs and now three more people resigned. I went from 17 people down to three, and I’m working 65 hours a week. I’m literally just trying to survive.”

He is one of three overworked and overwhelmed print producers responsible

for every job from every client at this agency. Think about that. Professional print producers can be pains in the ass, but we cannot let them go extinct. Our world without them is only about price. Craft transforms to commodity and then game over in so many ways.

What you can do right now is stop bothering these clients unless you have something specific to discuss. If they need your help, they will find you. You can send a ‘checking in’ email, text, or social media messages to remain top of mind without any expectation of a reply.

Review their past work. If they always do a mailing in June, don’t wait on them to contact you. Figure out how to get the paper and when it can arrive, share that information and a quote with the customer now. Repeat that process or everything you can think of to pre-empt a quote request and be super attentive to being super proactive, especially with paper and postage.