Energy solutions | Material handling | Wear & corrosion protection Teknikum® CERAMIC hoses provide 3-10 longer working life for boiler sand transfer page 12 rubber lining solution brings new era to efficient material handling page 30 teknikum.com TEKNIKUM® CERAMIC TEKNIKUM® CERAMIC NUCLEAR: Know-how to supply documentation and certifications for the most demanding use environments

Dear customer,

Teknikum’s high-quality abrasive material handling hoses, hose bends and smart ceramic hoses are popular solutions due to their long service life and sustainability. We use the best raw materials, both renewable and recycled, and offer excellent service along with our engineering experience and knowhow.

Teknikum differs from the competition with agile services, offering of the most durable hoses as well as through our wide range of lining rubbers, rubber lined pipes and customer-specific solutions. This is how we ensure the best possible customer experience for our customers, representing various demanding industries.

Timo Kokkonen Director Hoses Business Unit Teknikum Group

Offer requests:

sales@teknikum.com

+358 3 51911

Switch

2

Contents Operational values .................................................................................................... 4 Selected references .................................................................................................. 6 District heating/cooling 8 Thermal power ........................................................................................................... 8 Electricity network ................................................................................................... 8 SUCCESS STORY: Tampere Energy 10 Teknikum TITAN™ CERAMIC Antistatic Hose 12 Teknikum GRANIT® CERAMIC Antistatic Hose 14 Teknikum® abrasive working hoses - easy to handle, durable in use. 16 How to select a hose? 18 Teknikum® Rubber lining for steel scrubbers 20 Teknikum® Bird guard 22 Offshore wind farms (subsea) ............................................................................ 24 Teknikum® PUCAST Customized polyurethane cast products 26 Customized plastic products 28 Teknikum WEAR SAFE™ Black 40 rubber lining compound 29 Nuclear 30 Rubber lined valves DN 1000 – DN 3600 32 Teknikum TITAN™ Large compensator 33 Teknikum TITAN™ Rubber lined steel pipes 34 Teknikum CLEAN SAFE™ FDA rubber lining compound 35 Contacts (back cover) 36 Energy Electricity Heating 3

As European polymer technology expert,

Operational values – Safety, Sustainability and Sincerity

Our aim is to produce safe products and solutions to environment and our customers while offering a safe working environment to our employees. Based on this core value, we consider the environmental effects in everything we do – by setting goals that make our operations even more environmentally friendly. As a company with Nordics roots, sincerity is important operational cornerstone for us.

To maintain a high level of operations, we plan with Sustainability Roadmap and measure the safety related observations and actions closely. The mission of Teknikum Group is to drive sustainability in polymer technology. Therefore, our brand promise to customers is that they can reach sustainability while using Teknikum® products and services.

We are committed to the Science Based Targets initiative (SBTi) to reduce emissions according to Paris Agreement and to the Chemical Industry Federation of Finland’s Responsible Care –environmental program that is the most long-running and renowned voluntary program supporting sustainable development.

We consider the environmental effects in everything we do – by setting goals that make our operations even more environmentally friendly. Safety is our top priority.

4

we are on a sustainable mission – for you

Our values

SAFETY of our products, solutions and working environment

SUSTAINABILITY in our operations

SINCERITY in our actions

Our mission is to drive sustainability in polymer technology.

When using Teknikum® products, our customers can reach sustainability.

5

Selected references

Norway

Switzherland

Germany

Spain

Harbours globally

Finland

Sweden

Scrubbers and rubber lined pipes for marine industry

See page 16

6

Poland

Finland

Hungary

Poland

Finland

Hungary

7

Czech Republic

District heating/cooling

Thermal power

Electricity network

Material handling hoses for very abrasive materials, such as boiler sand, coal and and granulates.

Rubber lining of scrubbers.

Teknikum GRANIT® CERAMIC Antistatic

Teknikum TITAN™ CERAMIC Antistatic

Rubber lining of scrubbers

8

"Long lasting hoses for different abrasive materials make an economical and sustainable choice."

Pia Hanski Sales Manager, Hoses BU

Green thinking and long life-cycle benefits

Teknikum’s high-quality industrial hoses, bends and connector systems provide advanced solutions for demanding abrasive environment. Our hoses are known from their innovative, extremely durable and flexible structure.

You can get straight, curved and flexible CERAMIC hoses from us. As the innovator of Smart Hose system and recycled wear resistant rubber qualities, we bring additional sustainability, GREEN & SMART ideology, to Energy Industry and to the reach of our demanding customers.

Contact me pia.hanski@teknikum.com +358 50 411 9654 9

SUCCESS STORY: Tampere Energy

Teknikum’s Ceramic hose enables maintenance-free process in the power plant’s boiler sand transfer

Heat production at Tampere’s Naistenlahti power plant is intensified by boiler sand, which is consumed in boilers by tons every week. The sand is transferred to the power plant’s silo with the help of Teknikum’s hose innovation, along a ceramic material transfer hose developed and manufactured in Sastamala Finland.

A tank truck reverses at the power plant’s yard and the driver attaches a hose that transfers huge masses of sand to the power plant’s silo via a connector. Soon 16 tons of boiler sand erupt from the tank truck as strong impulses to the power plant’s furnace. The rubber hose must withstand relentless wear as the sand shakes with force in the bends of the hose. The transfer of boiler sand is made possible by the result of hundreds of hours and several years of product development: a rubber hose with a ceramic-coated inner surface.

Mr. Jari Perälä, a maintenance engineer of Tampereen Energia’s Naistenlahti power plant, follows the transfer of sand from the tank truck with confidence.

Nordic top product also for export

Teknikum’s Product Manager Mr. Jarkko Kalliomäki is pleased that long-term development work has opened up new business opportunities and strengthened Teknikum’s future.

– We have supplied hoses to the energy industry, the forest and paper industry and especially to the mining industry, but also to the steel industry. The latest customer segment is waste treatment and recycling plants, Kalliomäki describes the expanded customer base.

Teknikum has been manufacturing material transfer hoses for the demanding industries for decades and has customers in the Nordics and around Europe.

– The ceramic hose combines the great features of a rubber hose, such as easy installation, flexibility, easy adaptability of transmission lines and damping properties, Mr. Kalliomäki multiplies the great features of the product.

– We are able to manufacture almost all of our hose products with a ceramic inner surface. From small material transfer hoses to large heavy hoses up to a meter in diameter.

10

"The ceramic inner lining lasts up to years where the previous metal pipe was worn out in a few months.

The puncture-proof rubber-ceramic hose increases occupational safety, protects the environment and reduces the risk of production delays. We manufacture industrial hoses in all size classes, for demanding applications from the transfer of soil materials to acids and oils.

– Markku Haaranen, Teknikum

The hose is suitable for the transfer of highly abrasive materials, such as mining slurry, lime powder, coal, quartz sand and granules, in areas where it is desired to reduce and avoid continuous service interruptions caused by hose replacement. The market is global.

Sustainable development and continuous improvement

Teknikum’s sales manager Mr. Markku Haaranen remembers well how the cooperation with the Naistenlahti power plant, owned by Tampereen Energia, started few years ago.

– Our local dealer was able to advise the power plant’s maintenance manager to contact us with the need for a customer-specific solution. Together with the dealer and customer, we got to the site and learned the challenges of the plant’s material transfer. When the original metal pipe was upgraded to a extremely durable Teknikum GRANIT Ceramic hose, the reliabil-

ity and efficiency of the customer’s production process improved significantly. The ceramic inner lining lasts for years where the previous metal was worn out in a few months, Haaranen recalls.

Haaranen is rightly satisfied with the solution.

– Many have tried to copy the structure of our innovative hose, but so far only Teknikum knows how to produce a high-quality ceramic lining on a curved surface. As a Nordic manufacturer, we want to spread the useful good news of our solution to European industry.

The puncture-proof rubber-ceramic hose increases occupational safety, protects the environment and reduces the risk of production delays. We manufacture industrial hoses in all size classes, for demanding applications from the transfer of soil materials to acids and oils.

– – –

Watch the video

Teknikum also offers couplings and special hose solutions with fast delivery from factory stock.

11

The ceramic lining on the inner surface of the rubber hose withstands the transfer of abrasive materials such as sand and sharp stones while remaining flexible and easy-to-use.

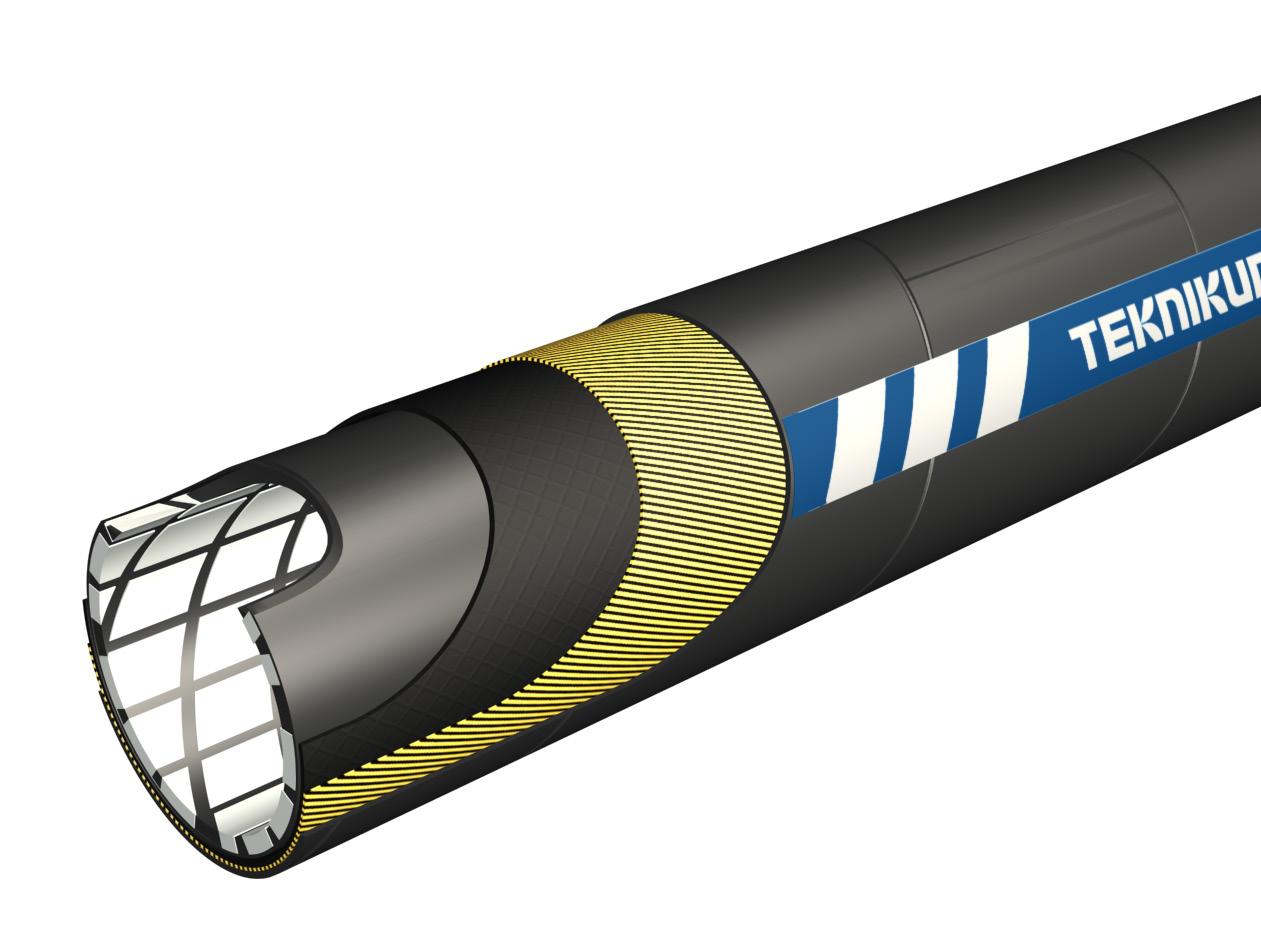

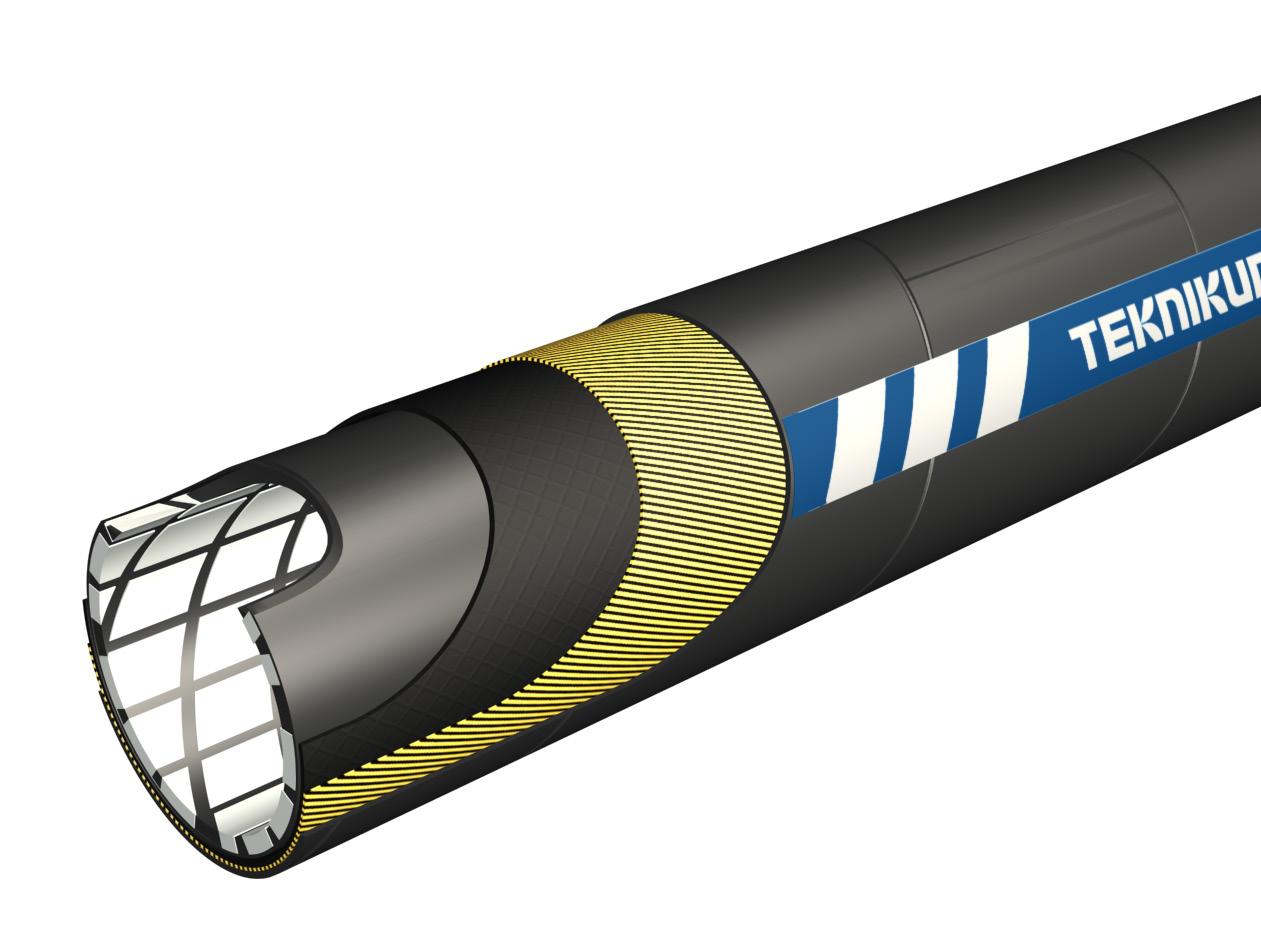

Teknikum TITAN™

CERAMIC Antistatic Hose

Complete with TITAN™ Select couplings

ISO 28017:2011

- 40°C

SBR

+80°C

DESCRIPTION AND ADVANTAGES

• Abrasive material handling hose with smooth SBR cover and CERAMIC lining

• Up to 3-10 times the life of a rubber hose or metal tube, depending on the material being transferred

• Excellent resistance to abrasion and weather

Eliminates vibrations and noise

• Low bending radius due to special rubber-ceramic structure

• Antistatic, ESD protection

Customization options: hose dimensions and working pressure according to need. Ask more from Teknikum sales.

Quick and easy installation

Complete with TITAN™ Select couplings or Teknikum PLUS™ flange system

Teknikum® CERAMIC hoses provide 3-10 longer working life for boiler sand transfer

12

TITAN™ CERAMIC GREEN & SMART

CERAMIC LINING

TEXTILE STEEL SPIRAL

TEKNIKUM® CERAMIC

12

13 Product code Ø i.d. mm Ø o.d. mm Working press. MPa Vacuum max. MPa Bending radius mm Weight kg/m Length m Teknikum TITAN™ CERAMIC Antistatic H4920040 40 64 1 0,09 170 3,1 10 H4920050 50 72 1 0,09 220 3,6 10 H4920063 63 82 1 0,09 320 4 10 H4920076 76 100 1 0,09 420 5,5 10 H4920080 80 104 1 0,09 440 6 10 H4920090 90 113 1 0,09 500 6,8 10 H4920102 102 125 1 0,09 520 7,4 10 H4920115 115 141 1 0,09 560 9 10 H4920127 127 154 1 0,09 620 9,8 10 H4920152 152 178 1 0,09 820 12,5 10 H4920180 180 212 1 0,09 1200 18,1 10 H4920203 203 238 1 0,09 1800 21,3 10 H4920253 253 291 1 0,05 2500 26,4 10 H4920300 300 341 1 0,05 3000 32,7 10 H4920305 305 341 1 0,05 3000 32,7 10 H4920350 350 403 1 0,05 3600 48,5 10 H4920405 405 456 0,5 0,05 4200 53,4 10 H4920450 450 508 0,5 0,05 4700 63 10 H4920508 508 558 0,5 0,05 5200 76,5 10 H4920600 600 664 0,5 0,05 6500 96,7 10

TEKNIKUM® CERAMIC Abrasive PRODUCT INFORMATION

dimensions available on request. 13

https://teknikum.com/product/teknikum-titan-ceramic-antistatic/

Other

Teknikum GRANIT® CERAMIC Antistatic Hose

ISO 28017:2011

Complete with GRANIT Select™ couplings

-

DESCRIPTION

• Robust, but flexible material handling hose with corrugated SBR cover and CERAMIC inner lining

• Up to 3-10 times the life of a rubber hose or metal tube, depending on the material being transferred

For slurry and very abrasive substances

Excellent resistance to abrasion and weather

• Eliminates vibrations and noise

High burst pressure ≥ 3,2 MPa

Antistatic, ESD protection

• Customization options: hose dimensions according to need. Ask more from Teknikum sales.

Flexible and low bending radius due to corrugated cover and rubber-ceramic lining structure

Quick and easy installation

Recommened connection with Teknikum GRANIT Select™ couplings or Teknikum PLUS™ flange system

Teknikum®

CERAMIC hoses provide 3-10 longer working life for boiler sand transfer

14

GRANIT® CERAMIC GREEN & SMART

AND ADVANTAGES

TEKNIKUM® CERAMIC

40°C +80°C

SBR

CERAMIC LINING

TEXTILE STEEL SPIRAL

14

15 Product code Ø i.d. mm Ø o.d. mm Working press. MPa Vacuum max. MPa Bending radius mm Weight kg/m Length m Teknikum GRANIT® CERAMIC 4910025 25 53 1 0,09 130 2,7 10 4910032 32 60 1 0,09 140 3,2 10 4910040 40 73 1 0,09 150 4,6 10 4910050 50 83 1 0,09 200 4,7 10 4910065 65 98 1 0,09 300 6 10 4910080 80 113 1 0,09 400 8,2 10 4910102 102 133 1 0,09 500 9,7 10 4910127 127 164 1 0,09 600 12,6 10 4910152 152 189 1 0,09 800 14,7 10 4910203 203 246 1 0,09 1800 21,5 10 4910253 253 293 1 0,09 2200 25 10 4910305 305 352 1 0,09 3000 42 10 4910350 350 407 1 0,09 3600 54 10 4910350 350 407 1 0,09 3600 54 10

TEKNIKUM® CERAMIC Abrasive PRODUCT INFORMATION

dimensions available on request. 15

https://teknikum.com/product/teknikum-granit-sd-material-handling-hose/

Other

Teknikum® abrasive working hoses - easy to handle, durable in use.

TEKNIKUM® multi-purpose industrial working hoses can be utilized in transferring dry or wet, finegrained and irregular, or sharp and hard objects and substances. In addition to high resistance to wear, the hoses are designed to withstand various demanding processes, such as industrial vacuuming and suction applications.

Typical targets for industrial vacuuming and blowing are the emptying and filling of tanks, silos and warehouses in, for example, power plants, the food industry and the process industry. As a common denominator, the suction and blow hoses of the applications have high wear resistance and easy handling.

Teknikum® CARBON hoses

Teknikum CARBON™ working hose family with corrugated or smooth cover are extremely flexible and durable abrasive material handling hoses. The hoses are designed for industrial vacuum systems and are also suitable for a wide range of industrial suction applications.

The lightness of the best work hose on the market does not come at the expense of wear resistance: with a new inner surface, we significantly improve the tear strength – and offer even slightly less abrasion wear. According to our tests, the tear strength of the new inner surface increased by 40 »90 N / mm!

One of the basic features of Teknikum’s CARBON hose range is that we offer an antistatic version. This means that the hose has a black natural rubber inner surface, which guarantees excellent durability combined with electrical conductivity and better safety. The hoses are available also with spiral-free cuffs.

Our products are manufactured with special Finnish expertise and have been awarded with the “Made in Finland” Key Flag symbol.

Teknikum® BLAST-TEK hoses

This hose series offer multi-functional blasting hoses for both dry and wet materials. A great choice for work applications such as sand and grit blasting, concrete pumping or transferring granulates.

Teknikum® BLAST-TEK hose’s CERAMIC version enables very long life due its ceramic inner lining. The life cycle of the hose is significantly longer and thus work interruptions and continuous hose purchases can be avoided. Teknikum BLAST-TEK® exceeds EN ISO 3861:2008 (Rubber hoses for sand and grit blasting) technical requirements as well as fits to commonly used sand blasting hose couplings.

16

Get Teknikum hoses directly from our factory warehouse in Europe!

How to select a hose?

In most situations it is easy choose the right industrial hose because a use application or some other feature (e.g. transferred material) defines the hose and a standard guides to the right solution.

In addition to standard hose products, Teknikum manufactures industrial hoses according to customer-specific dimensions and requirements. When designing a suitable material handling solution, customers can choose the hose structure, rubber grade, diameter, length and connectors.

Our specialty is wear and chemical resistance in extreme conditions.

When no suitable hose is available in standard product range or the use application is special, several hose properties must be considered.

Please go through following check list. Our sales will help you to select the right, safe and durable hose solution: sales@teknikum.com

1. Transferred substance?

• state of the substance?

• concentration?

• temperature?

2. Working pressure and/or vacuum?

Select hose type S, SD, or D accordingly.

3. Dimensions?

• inner diameter?

• outer diameter?

• length?

4. Physical properties?

• weight?

• bending radius?

• bending force?

5. Electrical conductivity requirements?

€

Features are listed on the product datasheets.

To be sure, please send us the chemical’s safety data sheet for review and possible lab testing. You can send it via our website’s suitability inquiry.

S = Suction hose

SD = Suction delivery hose

D = Delivery hose

18

6. Other requirements from operation environment?

For example, dynamic stress from machines or outer wear and tear due pulling the hose along the ground.

7. Hose couplings and clamps to be used?

• type?

• material?

• in case of flanges, the connecting dimensions

8. Legislation, regulations, standards or other official requirements?

We have know-how to supply documentation and certifications for the most demanding use environments.

9. Required hose or hose assembly testing and needed documentation?

For example, pressure proof test, burst pressure test, electrical conductivity, etc.

10. Packing and shipment requirements?

See our standard packaging at the end of this catalog. Teknikum® industrial hoses and services

About storage conditions

When keeping rubber hose products in storage or for maintenance operations, we highly recommend to view standard EN ISO 8331: Rubber and plastics hoses and hose assemblies – guidelines for selection, storage, use and maintenance.

rights reserved. ©Teknikum Group Ltd 2021 Burst Pressure Nominal Weight Vacuum Length Inside Diameter Outside Diameter Code Working Pressure Bending Radius

All

Teknikum® Rubber lining for steel scrubbers

ISO 9001

ISO 14001

ISO 45001

NR/BIIR

Hardness 40 or 60 ShA

APPLICATIONS

All Teknikum Rubber linings are tailor made for the customer’s scrubbers and processes, such as controlling gaseous emissions, especially acid gases. The scrubbers can also be used for heat recovery from hot gases by flue-gas condensation.

The compound and the thickness of the lining can be chosen for every purpose differently from Teknikum’s portfolio of lining rubbers.

Teknikum provides rubber lining services for industrial customers in Europe – on-site of at our factory. The largest autoclave we use is 3.8 m in diameter and 12 m in length. The object’s size imposes no limitations to the rubber lining work we do at customers’ site.

ADVANTAGES

Longer life for scrubbers in corrosive environments

• Gain high resistance to acids

Thickness of rubber can be modified according to specific scrubber and process values

Multiple lining rubber options available from NR to BIIR

Proven quality

COMPLIANCY

Suitable for:

Nuclear power plants

Wastewater treatment plants

Marine vessels

A CUSTOMIZED SOLUTION

Customized configurations to scrubbers as well as complex technical solution are made by order.

TECHNICAL PROPERTIES

Standard configuration includes:

Rubber lining elastomer:

Natural rubber and bromobutyl rubber (NR/BIIR)

Hardness 40 or 60 ShA

• Color black (or red or white)

Thickness of rubber lining:

5 mm – 10 mm

Any other standards can be applied in the manufacturing according to customers' requirements

LINING RUBBER

Teknikum ACID SAFE™ Hard

Compound is based on natural rubber (NR)

This black hard rubber is highly resistant to various saline solutions, alkalis, acids, damp chlorine gas and salt solutions containing chlorine.

It is great for environments with highly corrosive chemicals and can be vulcanized in autoclave.

Teknikum ACID SAFE™ Soft

Compound is based on bromobutyl (BIIR)

This black, soft rubber has high resistance to concentrated saline solutions, strong alkalis and acids. Teknikum ACID SAFE™ Soft is great for environments with highly corrosive chemicals.

• This compound can be vulcanized in multiple ways and pre-vulcanized sheets are also available.

More compound options available. More information on compound datasheets.

20

Rubber lining for steel scrubbers 20

21

Teknikum® Bird guard

ISO 9001

ISO 14001

ISO 45001

- 40°C +100°C

APPLICATION

The Teknikum® Bird guard is used to protect the pole transformer's overvoltage connector from short circuits caused by birds and other forest animals.

The Bird guard is made from durable, weather-resistant polypropylene (thermoplastic). The Bird guard comes in set of three (3) in a box, including cable ties and installation instructions.

ADVANTAGES

Prevents short circuits caused by birds and other forest animals.

Increases environmental safety

Easy to attach

• Light weight and durable

Weather-resistant

TECHNICAL PROPERTIES

Structure

Polypropylene (thermoplastic)

ENVIRONMENTAL RESISTANCE

Weather- and ozone-resistant

Wear-resistant

• UV-resistant

INSTALLATION

For the overvoltage terminal of the transformer:

The guard is attached to the upper flange of the overvoltage penetration of the transformer and is tightened firmly with the included cable tie. The excess part of the bundle is cut off.

For surge protector (ABB MWK):

The protector can also be attached to ABB MWK type surge protectors.

In this case, two opposite overhanging parts are cut from the bird guard above the fastening groove. The cut parts are turned inwards on the flange of the surge protector. The protection is tightened with the help of the four protrusions on the edge of the flange and the bundle tie, and the cut parts ensure that blows from above do not detach the bird protection from the surge protector.

Note: Do not cut the projections with the fastening loops for the cable tie.

PACKING

One carton box includes set of three (3) products including cable ties. One FIN pallet includes 125 boxes.

RECYCLING

Recycle unused or damaged products according to PP code.

https://teknikum.com/product/teknikum-bird-guard/

22

PP

Rubber lining for steel scrubbers Bird guard

22

23

Offshore wind farms (subsea)

Customized polyurethane cast products size range up to 1900 kg with metal frame.

Customized plastic products and rubber lining compounds.

Cable protection Customized plastic products Sea water resistant rubber compounds 24

"Polyurethane enables easy processability and excellent durability in harsh enviroments. We supply cast products with all size classes, as large production series or small runs."

Satu Hyökki-Siltanen Sales Manager, Moulded products BU

CONTACT ME

satu.hyokki-siltanen@teknikum.com

+358 50 468 1181

Customized polyurethane cast products

Teknikum manufactures customized polyurethane cast products for demanding environments. Our customers operate in the Mining, Energy, Marine, Infrastructure and Logistics industries.

Teknikum is a specialist in combining metal and polyurethane in a longlasting, sustainable way. We are safe European subcontractor offering certified production with various polymer materials and production technology know-how.

25

Teknikum® PUCAST Customized polyurethane cast products

Teknikum® PUCAST material and manufacturing technology is particularly suitable for subsea cable protectors

and marine products.

You can get customized polyurethane cast products for demanding environments from us - in a size range up to 1900 kg with metal frame!

Teknikum is a specialist in combining metal and polymers, such as polyurethane, rubber and plastic, in a long-lasting way. We are safe and sustainable European subcontractor with more than 30 years of expertise.

Our offering includes certified contract manufacturing services, materials, R&D and production technology know-how. Our typical customers operate in various demanding environments, such as the Marine, Mining, Energy, Infrastructure and Logistics industries.

Polyurethane – for extra wear-resistance

Products made of Teknikum Pucast® polyurethane are used all over the world, for instance in the processing and mining applications, mechanical wood processing equipment, and demanding special applications, where resistance to wear, load-bearing capacity or soundproofing is needed.

As material, Teknikum Pucast® polyurethane provides easy processability. The products can be made completely of polyurethane or equipped with metal frames.

Our manufacturing technique is suitable for both small and large production series, and we offer vast product development experience and technical support. We have modern, computer-aided design and simulation systems. Our products are designed in collaboration with our customers.

Why to select Teknikum® PUCAST?

> All size classes: large production series or small runs

> Easy processability with various PU raw materials

> The products can be made completely of polyurethane or equipped with metal frames

26

Generated with AI 27

Customized plastic products

Plastic products from 3D prototypes to injection molding mass production and assemblies

Agile partner with know-how

Along with foam converting and moulded product, Teknikum manufactures industrial hoses in Hungary and Finland, has sales office in Germany and wide reseller network in Europe.

The versatile manufacturing experience gives several benefits to demanding customers. The company differentiates from competition by combining plastic parts with foam and rubber and being able to deliver finished assembled products.

“Teknikum’s product development department serves with latest technologies: agile 3D modeling is available with CAD and 3D-printing. Also, both FEM and Moldflow analysis are used for evaluating functionality and durability of the product, ensuring quality finish”, tells Mr. Ilkka Nieminen, Director, Plastics Business Unit of Teknikum Group.

Production capability from small products up to 2,000 cubic centimeters in volume with a maximum weight of 4 kg.

Simple or complex quality products

Sales Manager Mr. Ádám Boldizsár helps customers with the team to find suitable solution, from early engineering stage to mold deliveries and eventually to a product delivery.

“By using the injection molding, extrusion and 2D/3D cutting techniques, our plastic department manufactures customer-specific special products. Our raw material selection covers all the main grades of thermoplastics, and certain engineering plastics such as POM, PA, and PA-fiberglass compounds. Additionally, our hightech mold shop manufactures and maintains molds for customer’s projects”, Mr. Boldizsár tells.

“Some of our products may be very small in size, but here in Jászladány our equipment also enables making very large plastic products with up to 2,000 cubic centimeters in volume with a maximum weight of 4 kg”, Mr. Boldizsár tells.

“With technical foam, we offer wide range of materials, such as light PU, waterproof PE, chemical resistant EPDM, recycled rebound foams and special materials and tapes”, Mr. Boldizsár explains.

Typical volume foam products are done by using kiss-cut or full-cut technologies.

28

Teknikum WEAR SAFE™ Black 40 rubber lining compound

APPLICATIONS

Natural rubber and butadiene rubber based soft black rubber, which is highly resistant to various abrasive slurries. This proven compound is used in mining environment, seawater applications and other process industry applications.

The hardness 40 ShA is great for abrasion resistance supported by excellent resilience to stand flexible surface for material flow.

Developed for the mining industry, e.g. material transfer at concentration plants and tailings pipelines.

Autoclave vulcanization.

Available on roll. Standard width is 1100 mm rolls, which is convenient for transportation in wooden boxes.

Widths between 600-1500 mm are available upon request.

ADVANTAGES

Great wear resistance

Very strong adhesion to steel

• Good strength values

TECHNICAL PROPERTIES

Elastomer

Natural rubber and butadiene rubber (NR/BR)

Environmental resistance

Moderate resistance to chemicals

1Note: The above values are typical mean values of the production compounds and should not be used as specification limit or as a basis of design.

"This compund is suitable for sea water contact."

- Mira Juutilainen, R&D Manager

29

Property Standard Unit Value Teknikum CLEAN SAFE™ FDA Hardness ISO 48-4 Shore A 40 ± 5 Tensile strength ISO 37 MPa 11 Elongation at break ISO 37 % 520 Tear strength ISO 34 Crescent N/mm 30 Abrasion resistance (5 N weight) ISO 4649 Method A mm3 55 Rebound resilience ISO 4662 % 65 Temperature range - °C - 40 - + 70

WEAR SAFE™ Black 40 29

Nuclear

Wear-resistant, flexible and easy to handle industrial hoses for abrasive environment.

Rubber bearing pads for plant construction.

30

"We have the right rubber lining materials for different types of abrasive wear and tear."

Matti Pohjala Sales Manager, Linings BU

CONTACT ME

matti.pohjala@teknikum.com

+358 50 329 9948

Long-lasting steel pipes with rubber lining

Teknikum® Rubber Lining is a long-lasting, wear and chemical resistant solution for pipelines where the need of inflexibility and permanent load bearing capacity is critical. We have the experience and know-how to supply documentation and certifications for the most demanding use environments.

Our offering includes premium rubber lining compounds for steel pipes, curves, Y-branches, T- and X-branches as well as for multi-pipe manifolds and steel reducers. Teknikum rubber lining provides long life and wear protection for the pipes, while ensuring maximum capacity of material handling.

The long-lasting Teknikum® rubber bearing pad is suitable for plant construction, damping structure-borne noise in buildings and low-frequency vibrations from machines.

31

31

Rubber lined valves

DN 1000 – DN 3600

ISO 9001

ISO 14001

ISO 45001

APPLICATIONS

NR/BIIR Hardness 40 or 60 ShA

Teknikum specializes in rubber lining of large size valves, such as butterfly valves, check valves or non-return valves in the waste water treatment plants, nuclear power plants and other type of power plants managing sea water in their cooling systems.

We have the capacity to vulcanize valve sizes DN1000 –DN3600 and know-how to supply documentation and certifications for the most demanding use environments.

The compound and the thickness of the lining can be chosen for every purpose differently from Teknikum’s portfolio of lining rubbers.

Teknikum provides rubber lining services for industrial customers in Europe – on-site of at our factory. The largest autoclave we use is 3.8 m in diameter and 12 m in length. The object’s size imposes no limitations to the rubber lining work we do at customers’ site.

ADVANTAGES

Longer life for scrubbers in corrosive environments

Gain high resistance to acids

Thickness of rubber can be modified according to specific scrubber and process values

• Multiple lining rubber options available from NR to BIIR Proven quality

COMPLIANCY

Suitable for:

• Nuclear power plants

Wastewater treatment plants

Marine vessels

A CUSTOMIZED SOLUTION

Customized configurations to scrubbers as well as complex technical solution are made by order.

TECHNICAL PROPERTIES

Standard configuration includes:

Rubber lining elastomer:

• Natural rubber and bromobutyl rubber (NR/BIIR)

Hardness 40 or 60 ShA

Color black (or red or white)

Thickness of rubber lining:

• 5 mm – 10 mm

Any other standards can be applied in the manufacturing according to customers' requirements

LINING RUBBER

Teknikum ACID SAFE™ Hard

Compound is based on natural rubber (NR)

• This black hard rubber is highly resistant to various saline solutions, alkalis, acids, damp chlorine gas and salt solutions containing chlorine.

It is great for environments with highly corrosive chemicals and can be vulcanized in autoclave.

Teknikum ACID SAFE™ Soft

Compound is based on bromobutyl (BIIR)

This black, soft rubber has high resistance to concentrated saline solutions, strong alkalis and acids.

• Teknikum ACID SAFE™ Soft is great for environments with highly corrosive chemicals.

This compound can be vulcanized in multiple ways and pre-vulcanized sheets are also available.

More compound options available.

More information on compound datasheets.

https://teknikum.com/custom-solutions/rubber-lined-large-valves-dn-1400-dn-3600/

32

Rubber Lined VALVES

32

Teknikum TITAN™

NR/SBR: +70°C

NBR: +90°

For compensating heat expansion and movement, to absorb noise and vibration as well as for eliminating pipeline tension.

Suitable for power plants and other process industries as well as for civil engineering applications.

• Highly customizable with alternative rubber materials. Customized steel flanges available according of required material and connection dimensions.

https://teknikum.com/product/teknikum-large-compensators/

33 TITAN™ Large compensator

AND ADVANTAGES

Large compensator DESCRIPTION

NR (or NBR or EPDM) Ø D 780-2113 mm

EPDM: +100°C

Ø i.d. mm Ø D mm h mm Lenght (min-max) mm Max. working pressure MPa Max. Vacuum MPa Max. axial flexibity mm Lateral flexibility mm Max. angular deviation Approximate weight with min. length kg Teknikum TITAN™ Large compensator 600 780 16 300 - 500 0,6 0,07 ± 30 15 4,0° 45 700 892 16 300 - 500 0,6 0,07 ± 30 18 4,0° 65 800 1015 16 300 - 500 0,6 0,07 ± 30 21 4,0° 90 900 1117 22 300 - 500 0,6 0,07 ± 30 24 3,0° 120 1000 1222 16 300 - 500 0,6 0,07 ± 30 27 3,0° 130 1200 1455 20 300 - 500 0,6 0,07 ± 30 30 3,0° 150 1400 1675 15 300 0,6 0,07 ± 15 33 2,0° 170 1600 1915 15 300 0,6 0,07 ± 15 39 2,0° 200 1800 2113 25 300 0,6 0,07 ± 15 45 1,5° 250 PRODUCT INFORMATION Other dimensions available on request. 33

Teknikum TITAN™ Rubber lined steel pipes

DESCRIPTION AND ADVANTAGES

• Rubber lined steel pipes are the best choice for pipelines where a need of inflexibility and permanent load bearing capacity of a pipe is critical.

• Great wear resistance of lining Very strong adhesion to steel Good strength values

Low flow resistance

• Listed standard sizes and forms are available with quick delivery

Retains the free flow area without turbulence at the couplings

Pipe ends are vulcanized by rubber to eliminate leakages without the need of extra gaskets

Delivery reliability – the used rubber compounds are developed and manufactured in-house by Teknikum

NR/BR Hardness 40 or 60 ShA Steel: P235 JRG2

Flat flanges according to EN1092-1. Typical flange connection PN10.

Rubber lining with Teknikum CLEAN SAFE™ FDA

The red color allows use as visual wear indicator in case of two (2) layers of rubber lining is placed (black soft rubber lining on top).

TECHNICAL PROPERTIES. Standard configuration includes:

Flat flanges according to EN1092-1

Steel: P235 JRG2

Typical flange connection PN10

Thickness of rubber lining:

5 mm for pipes DN50-DN300, flanges 5mm 10 mm from DN350 mm, flanges 5mm

Body steel in accordance with P235TR1

Surface treatment:

preparation grade Sa 2.5

painting system EP180/1

default color gray

Mounting kit for flanges can be included into a scope

• Any other standards can be applied in the manufacturing according to customers' requirements

Select lining rubber page 11

34 TITAN™ Rubber Lined STEEL PIPES

34

Teknikum CLEAN SAFE™

FDA rubber lining compound

Applications

Natural rubber based white soft rubber, which is resistant to various cleaning agents and aqueous solutions. This rubber compound is specially developed for rubber lining applications where low migration of any chemicals from the lining is critical, such as nuclear power plants, clean water lines of ships or food contact applications.

Autoclave vulcanization.

This compound is FDA 21 CFR 177.2600 (e) approved material.

Advantages

Suitable for food contact applications

Extremely low migration of chemicals from inner lining

For critical clear water applications

TECHNICAL PROPERTIES

Elastomer

Compound is based on natural rubber (NR) and styrene butadiene rubber (SBR) mix.

Environmental resistance

Moderate resistance to chemicals

1Note: The above values are typical mean values of the production compounds and should not be used as specification limit or as a basis of design.

https://teknikum.com/product/teknikum-rubber-lined-steel-pipes/

35 35

Check all current product details and specification on product datasheet (QR code):

Property Standard Unit Value Teknikum CLEAN SAFE™ FDA Hardness ISO 48-4 Shore A 40 ± 5 Tensile strength ISO 37 MPa 12 Elongation at break ISO 37 % 700 Tear strength ISO 34 Crescent N/mm 20 Abrasion resistance (5 N weight) ISO 4649 Method A mm3 80 Temperature range - °C - 40 - + 70

35

Contact us

In Finland

Teknikum Group Ltd

Switch +358 3 51911 sales@teknikum.com

In Germany

Teknikum GmbH

+49 208 444 2303 sales.de@teknikum.com

In Hungary

Teknikum Kft.

+36 30/ 681-6000 sales.hu@teknikum.com

In Poland

PIOMET

Piotr Świeźawski

(+48) 502 260 460 sales@piomet-cnc.pl

In Sweden

Lars Åström

+46 70 44 88 147 lars.astrom@teknikum.com

Contacts (back cover)

3 / 2024

Poland

Finland

Hungary

Poland

Finland

Hungary