YOU RELY ON US, BECAUSE SHE RELIES ON YOU.

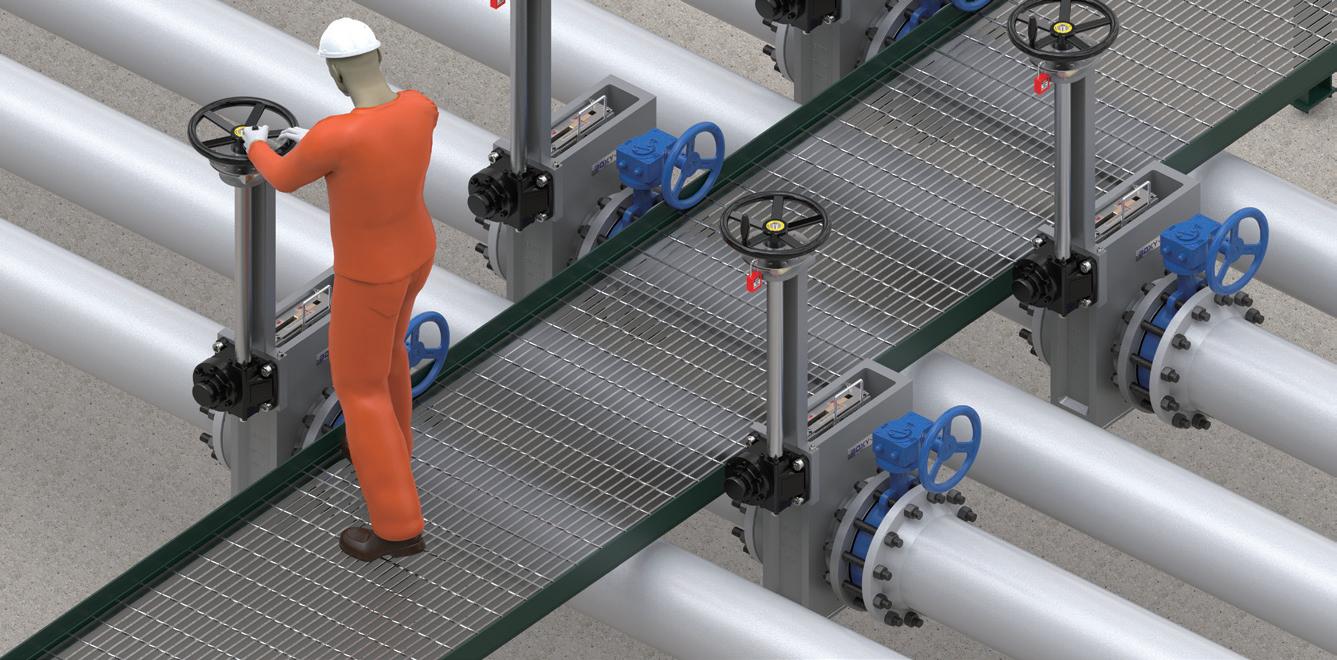

When getting home safely is the only option, you need advanced safety equipment you can trust without having to compromise productivity and throughput.

We know people rely on you. That’s why we do what we do — engineer and install the most innovative facility safety equipment in the world. www.saferack.com +44 (0) 1843 609672 UK +1-866-761-7225 US

UP FRONT

TERMINAL NEWS

INTERVIEWS

forward-thinking

Arabian Chemical Terminals Abu Dhabi’s commercial manager tells Tank Storage Magazine what it means to be the region’s first independent liquid petrochemical

Europe’s ambitious new ammonia

Storage Magazine speaks to ACE Terminal’s project director, Egbert Vrijen, to find out how this cross-company collaboration is facilitating the green

import into

MARKET ANALYSIS

Ravi Bhatiani,

Stanlow Terminals’

how

Stanlow

TECHNICAL FEATURES

32 Technical news

34 Resilience, security and business continuity

Holger Berens, chairman of the Board of the German Association for Critical Infrastructure Protection discusses holistic approaches to business security

36 Designing in security

Safwan Akram, MSS director at Help AG explains how Saudi Arabia is supporting key infrastructure in cybersecurity

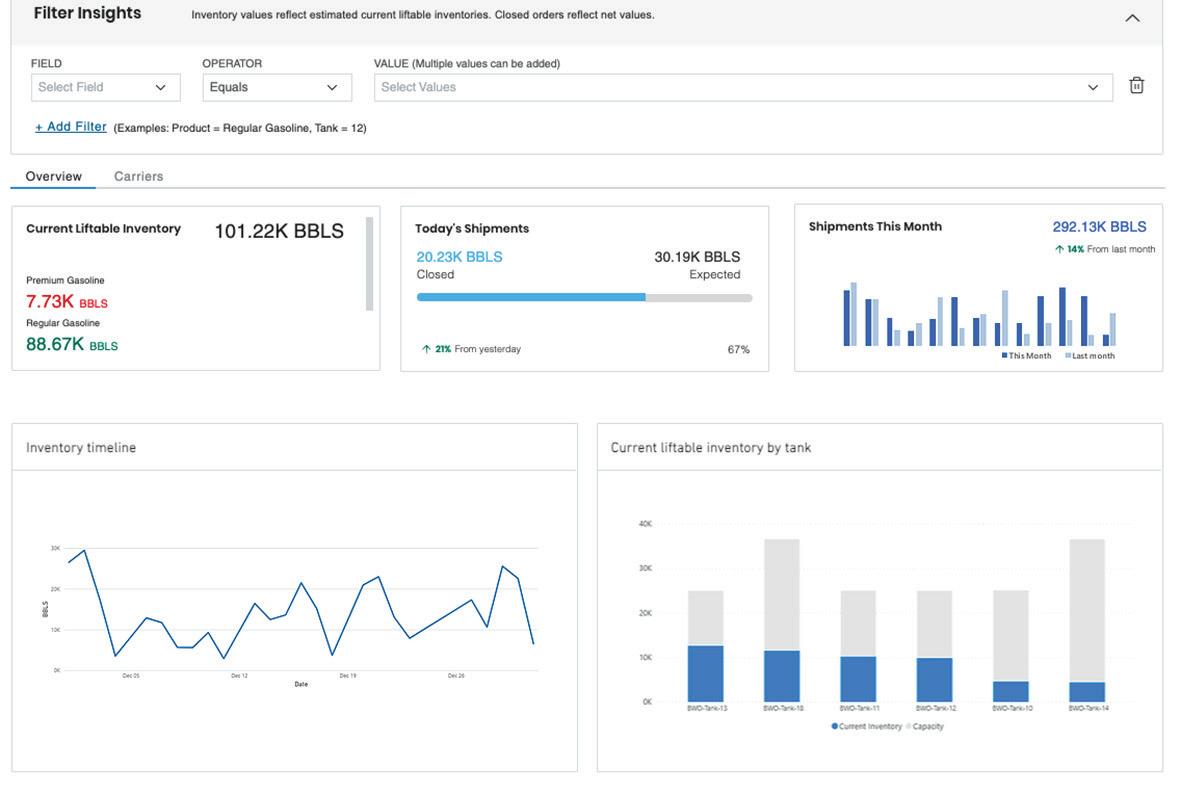

38 Increasing efficiency, improving service and reducing costs with AI

The experts at Supplai tell Tank Storage Magazine how the company is making artificial intelligence accessible to the tank storage industry

40 Fit for the future

Bulk liquid storage provider TanQuid digitalises its Duisburg terminal with technology from downstream IT specialist Implico

42 Digitally connected supply chains & terminal automation

Sam Reid CEO of Dearman Systems, discusses how the digitalisation of terminals and the wider supply chain is impacting operations

44 Establishing a digital marketplace for storage opportunities

The Tank Tiger tells Tank Storage Magazine why digitalisation in the sector is so important and how it can be implemented to make processes seamless

45 Data-driven decisions

Cameron LNG enhances process performance via Hint’s automated information management

46 Marine operations in a digital world

How the UAB-Online SaaS platform is optimising marine operations for liquid bulk handling for sea-going and inland vessels

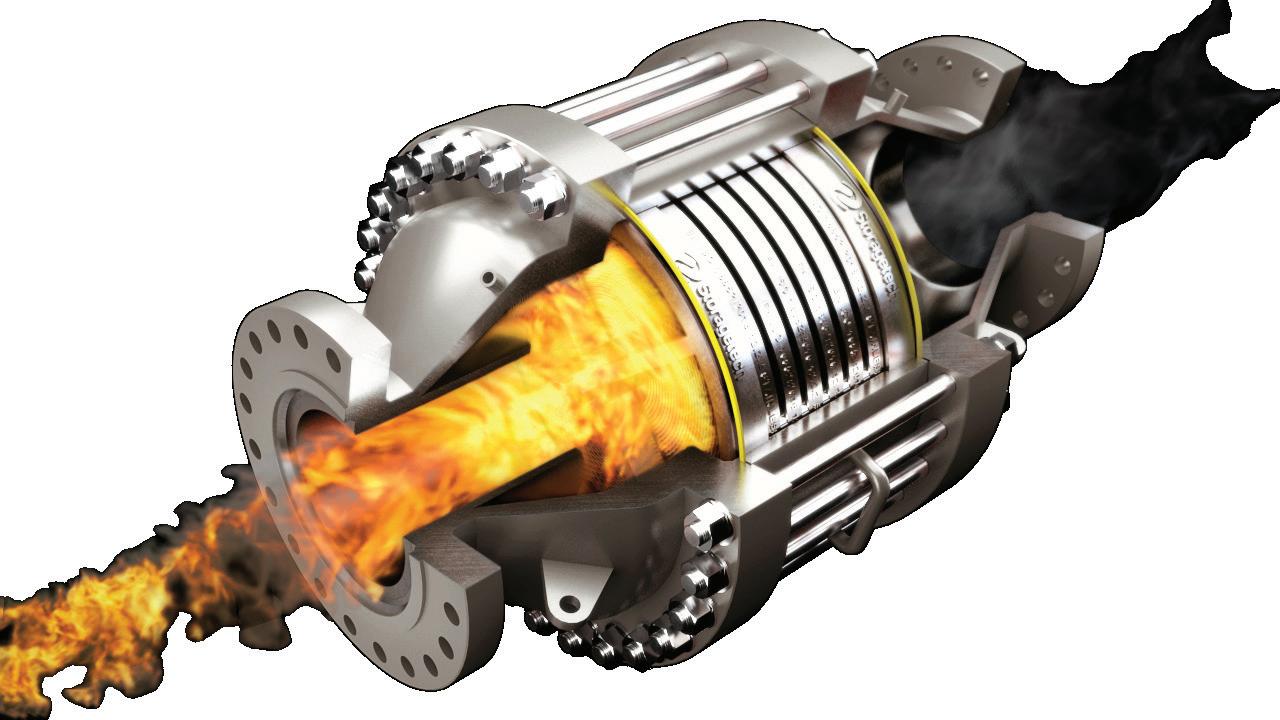

47 Flame arresters from Storagetech

Emission and air pollution control equipment manufacturing and engineering company Äager discuss their fire-fighting products

48 Extinguishing foam transition with a sound plan

The experts at Kenbri Fire Fighting explain how the European Chemicals Agency’s proposed PFAS restriction will impact operations

50 Lessons to be learned

CTS Group’s Gert van Meijeren shares his preliminary observations from the fire at Cuba’s main oil terminal in Matanzas

52 Using LOHC for a sustainable energy supply

Learn the cost and availability advantages of using liquid organic hydrogen carriers (LOHCs), like the one from Hydrogenious, for hydrogen transport

EVENTS

55 Into the unknown Marion Cleveland at Advanced 3D Laser Solutions Group shares her experience of being a woman working in male-dominated spaces

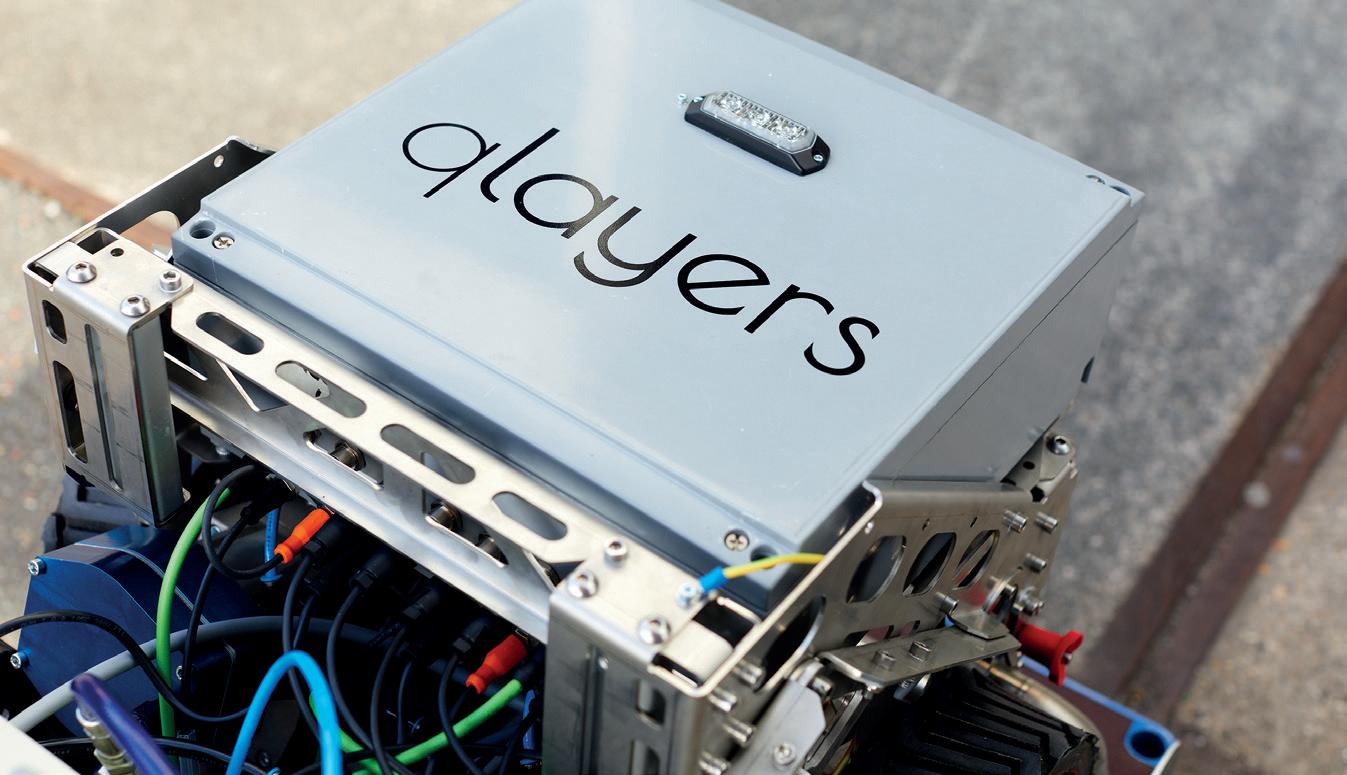

56 Painting tanks of the future

Josefien Groot, co-founder and CEO at Qlayers tells Tank Storage Magazine about the firm’s award-winning 10Q paint robot

58 The future of LNG storage

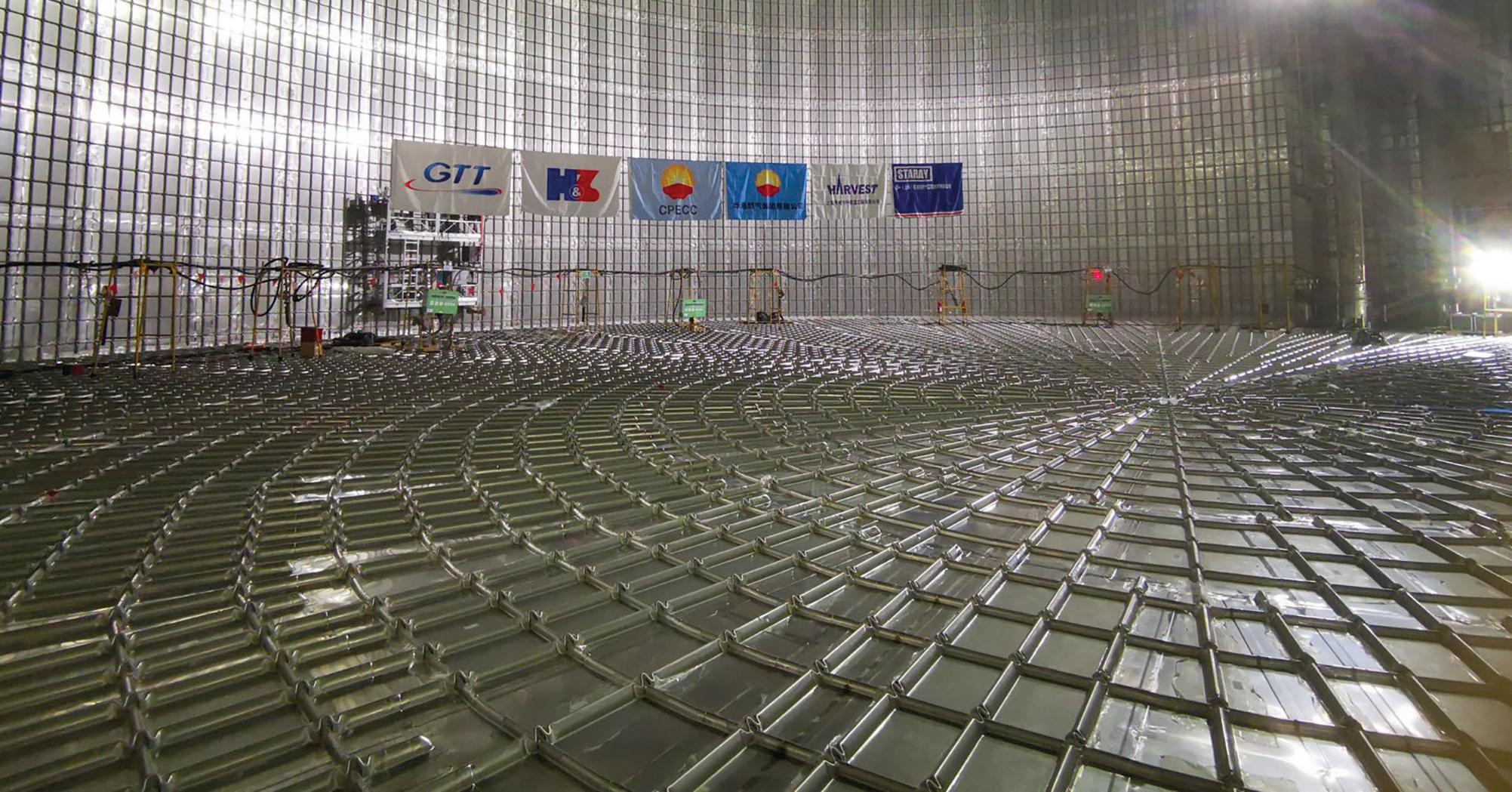

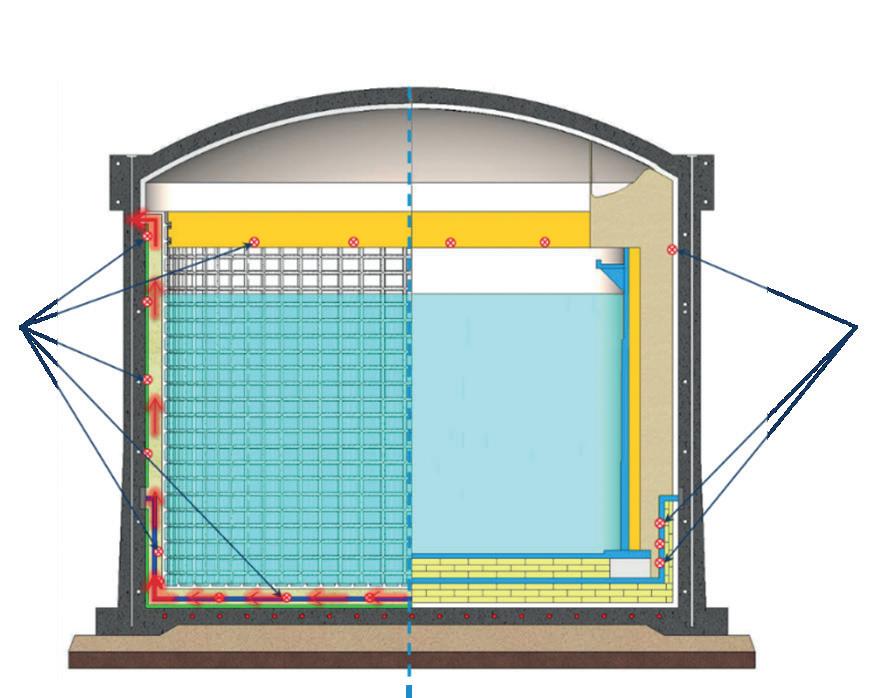

Edward Chen from GTT tells Tank Storage Magazine about the company’s GST LNG tanks and winning the Global Tank Storage Award for Environmental Performance

Breakbulk’s most focused event

Tank Storage Magazine looks at the highlights and key points from the long-awaited AntwerpXL 2022

Collaboration is the name of the game

Tank Storage Magazine checks out the hot topics discussed at last month’s TSA Conference

Inspection and maintenance robotics

A variety of exhibitors and industry leaders got together to showcase the new and exciting developments in robotics

PORTFOLIO DIRECTOR

Margaret Dunn +44 (0)20 3551 5721 margaret@tankstoragemag.com

EDITOR

Anamika Talwaria +44 (0)20 3876 9339 anamika.talwaria@easyfairs.com

JOURNALIST

Cyann Fielding +44 (0)20 3196 4416 cyann.fielding@easyfairs.com

STAFF WRITER

Molly Cooper +44 (0)20 3196 4263 molly.cooper@easyfairs.com

HEAD OF SALES

Sophie McKimm +44 (0)20 3196 4356 sophie.mckimm@easyfairs.com

INTERNATIONAL SALES MANAGER

David Kelly +44 (0)20 3196 4401 david@tankstoragemag.com

SENIOR SALES MANAGER

Matthew Barlow

+44 (0)20 3198 4380 matthew.barlow@easyfairs.com

HEAD OF MARKETING

Rikki Bhachu

+44 (0)20 3196 4282 rikki.bhachu@easyfairs.com

DATABASE MANAGER

Beth Welcomme +44 (0)20 3196 4345 beth.welcomme@easyfairs.com

CEO EASYFAIRS UK & GLOBAL

Matt Benyon matt.benyon@easyfairs.com

Anne Lafère anne.lafere@easyfairs.com

SUBSCRIPTION RATES

A one-year, 7-issue subscription costs €250. Individual back issues can be purchased at a cost of €45 each.

CONNECT WITH US

@tankstorageinfo

Tank Storage Magazine

Tank Storage Magazine

CONTACT

T +44 (0)20 3196 4300

F +44 (0)20 8892 1929 margaret@tankstoragemag.com www.tankstoragemag.com

Easyfairs

2nd Floor, Regal House 70 London Road Twickenham TW1 3QS United Kingdom

ISSN 1750-841X

Tank Storage Magazine, (ISSN 1750-841X) is published seven times a year (in February, March, May, August, September, October and November) by Easyfairs UK Ltd, 2nd Floor, Regal House, 70 London Road, Twickenham, TW1 3QS, UK. The US annual subscription price is $243. Airfreight and mailing in the USA by agent named WN Shipping USA, 156-15, 146th Avenue, 2nd Floor, Jamaica, NY 11434, USA. Periodicals postage paid at Jamaica NY 11431. US Postmaster: Send address changes to Tank Storage Magazine, WN Shipping USA, 156-15, 146th Avenue, 2nd Floor, Jamaica, NY 11434, USA. Subscription records are maintained at Easyfairs UK Ltd, 2nd Floor, Regal House, 70 London Road, Twickenham, TW1 3QS, UK.

LAST ISSUE , you met the new editorial team at Tank Storage Magazine. I’m happy to report that the new team of writers and I have got well and truly stuck in over the last month or so.

I met many of you at the TSA Conference in the UK, and Cyann met even more across the breakbulk event, AntwerpXL. And staff writer, Molly, experienced first-hand the many robotics innovations that the industry has been cooking up at Sprint Robotics’ conference in Amsterdam last month. You can read all about our experiences in the events section at the back of this issue.

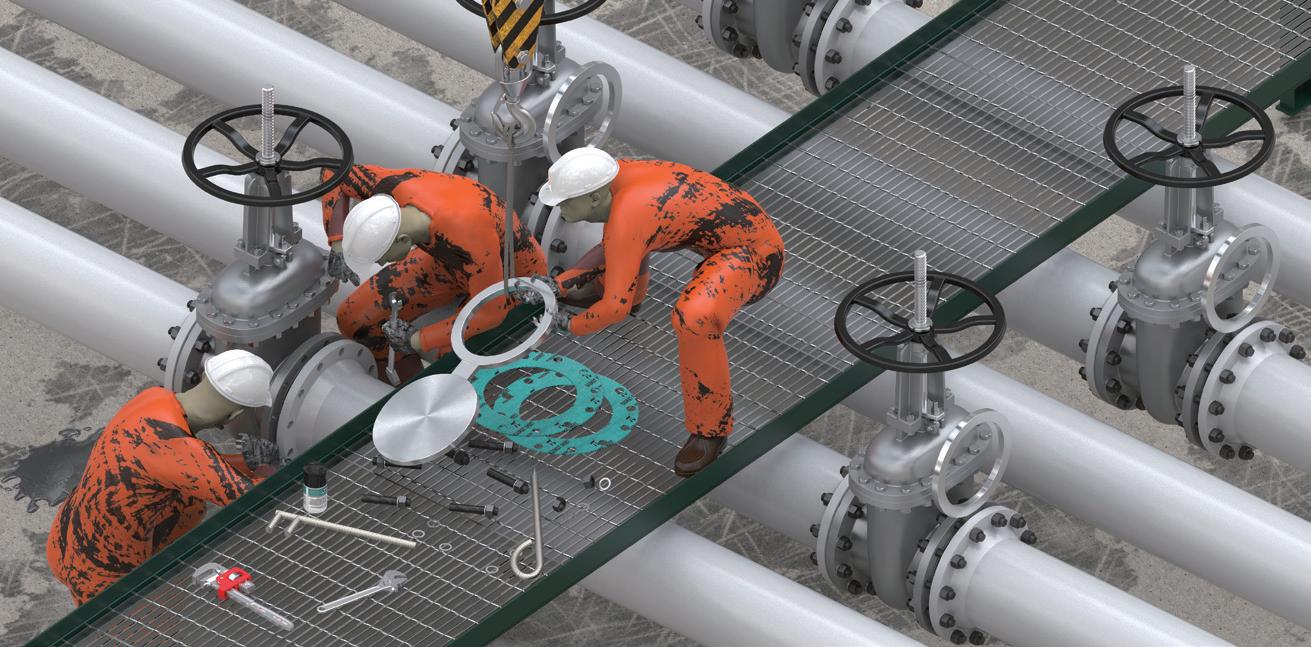

The clear running theme at all the events was a focus on the health and safety of workers. Robotics are part of the equation – with innovative tank cleaners and painters removing humans from unsafe, hazardous environments. I had the opportunity to try out Re-Gen Robotics’ tank cleaner while at the TSA Conference and seeing how easy it was to handle made it clear why these sorts of products are a no-brainer. After all, why endanger people when there’s no need to?

There’s been a slew of incidents at terminals over the last few months, and so safety must be a top priority for the sector. Advances in technology – not just physical robots replacing humans – are going to be key to creating safer, more efficient workspaces.

Tank terminals are becoming more digital by the minute – automation is making processes more efficient and freeing up time for people to focus on their job roles, rather than getting bogged down in admin tasks. But with increased digitalisation comes a higher risk of cyberattacks. Luckily for you tank terminal operators, this issue is packed with ideas for terminal automation, digitalisation and cybersecurity measures to keep your terminal safe and operational.

Before you plough ahead to those articles, though, you’ll find an exclusive interview with Arabian Chemical Terminals (ACT) (page 22) discussing the company’s brand new terminal in Abu Dhabi – the first of its kind. Having secured such a key location, ACTAD is primed to benefit from increased growth in the region particularly in the Khalifa industrial zone.

On page 24, ACE Terminal tells us all about the new venture from the experts at Vopak, Gasunie and HES International.

The plan is to bring ammonia to northwest Europe – with a time-to-market of 2026 (that’s just two years!).

We’ve also got exclusive analysis pieces looking at the growth of LNG imports into Asia (page 27) and how the need for energy security is impacting the EU’s strategy for stockpiles (page 26).

By the time this copy reaches you, I’ll be away in Rotterdam at the World Hydrogen Congress, so expect even more exclusive scoops coming up in the next issue of Tank Storage Magazine!

And as always, if you want to share your thoughts on where the tank terminal sector is headed, you can get in contact with me or one of the team.

Best wishes,

THE FUTURE IS NOW Anamika

TERMINAL NEWS: EUROPE

ECOSPRAY AND RUHE GROUP TO BUILD ADDITIONAL BIO-LNG PLANTS

Italian engineering firm, Ecospray, has announced a new contract with Germany’s Ruhe Group to build two biomethane plants and three CO 2 liquefaction plants.

Each project involves the construction of a complete system for pre-treatment, upgrading, liquefaction of biomethane and the liquefaction of CO 2 , with associated storage and cryogenic tank filling.

The first project is expected to produce eight tons of bio-LNG per day, while the second one is set to produce three tons per day, the same quantity as the one that started the collaboration between Ecospray and Ruhe in 2021. The construction of this plant is ongoing and it will be commissioned according to the schedule.

Ecospray plans to establish and deliver all three plants in Bavaria and Brandenberg in autumn 2023. These are estimated to produce a total of 26.5 tonnes of bio-LNG per day for heavy-duty transport.

Boris Drewes, CTO of Ruhe Biogas Service, says: ‘Our goal is to establish this product together with our partners for the decentralised production of alternative fuels in Germany and Europe.’

‘We share the same vision as Ruhe and the same trust in this technology as a tool for achieving decarbonisation by 2050,’ adds Maurizio Archetti, President of Ecospray.

terminal to create an entry point into the northwest European markets for its growing green ammonia and hydrogen activities. This will additionally be able to support the security of supply in Europe.

Uniper will aim to establish several access points for green energy in Europe and will be pursued in parallel with the ongoing Wilhelmshaven ammonia terminal project – which is not only building the first LNG import terminal in Germany but also planning an import terminal for green ammonia.

As a future hub, Vesta Terminals in Vlissingen will be able to handle an initial throughput capacity of 0.96 mtpa. In the second phase, the throughput capacity of the facility can be extended to 1.92 mtpa and the terminal will be connected to the Dutch hydrogen pipeline network. The planned start date is 2026.

LIWATHON PURCHASES VOPAK’S MUUGA TERMINALS FOR $33M

Liwathon has paid $32.8 million (€33.75 million) for Vopak EOS – the largest independent oil products terminal operator in the Baltic Region.

Vopak has announced the sale of its 50% holding in EOS for €16.3 million. Liwathon EOS owns four oil terminals at Muuga with a combined capacity of 1.05 million cubic metres. It provides sea and rail transportation of oil products from eastern Europe to western Europe, America, and Southeast Asia.

new hydrocarbon storage terminal at Dublin Airport, doubling the plant’s storage capacity.

The new facility has three storage tanks of 5,000 m 3 each, parking, pumping stations, charging systems for the onboard units and modern safety systems.

The project has included the construction of a hydrant system at the airport’s boarding piers with 86 fuel pits from the hydrant to facilitate on-board operations, which is connected to the storage terminal via a double pipeline.

This distribution network allows Jet A1 fuel to be transported underground from the storage terminal to the aircraft supply points. This reduces the presence of fossil fuel tanker trucks on the airport apron, enhancing the efficiency, safety and sustainability of the whole process, as well as significantly reducing the time taken to supply aircraft and cutting CO 2 emissions.

The works have resulted in new refueling unit loading bays, together with two vehicle service maintenance buildings and offices for board agents.

UNIPER AND VESTA TO DEVELOP GREEN AMMONIA TERMINAL IN THE NETHERLANDS

Uniper and Vesta have signed a Memorandum of Understanding (MoU) to investigate the feasibility of refurbishing and expanding an existing storage facility to create northwest Europe’s first green ammonia hub: Greenpoint Valley. Uniper intends to book capacity in the

DAA AND EXOLUM COMPLETE €40M RENOVATION OF FUEL STORAGE FACILITIES

daa and Exolum, Europe’s leading liquid product logistics company, have announced the completion of work to expand and improve the efficiency of the fuel storage facilities at Dublin Airport.

daa and Exolum’s investment of €40 million includes the installation of a

MITECO INITIATES EXPRESSION OF INTEREST FOR GREEN HYDROGEN AND STORAGE PROJECTS IN LÉON

The Ministry for the Ecological Transition and Demographic Challenge has opened an expression of interest to understand green hydrogen and energy storage projects that have the potential to be carried out in the CIUDEN Technology Development Centre in Léon, Spain.

The opening of the expression of interest is to gauge possible projects which promote the development of green hydrogen technologies and energy storage, that are also suitable for the Technological Development Centre of Ciudad de la Energiá foundation.

The expression of interest will allow businesses to submit relevant projects that also suit the facilities in Léon.

Estonia Spain Germany The Netherlands IrelandPORTS OF AMSTERDAM AND CORK AND EIH2 TO ESTABLISH IRELANDEUROPE HYDROGEN SUPPLY CHAIN

Irish green energy company EIH2 has signed a deal with the ports of Cork and Amsterdam to allow Ireland to maximise its use of offshore wind as a source of energy by providing an alternative route to market.

The partnership will provide Ireland with the necessary route to market to become a net exporter of energy over time.

The project aims to increase collaboration on energy transition between Ireland and the Netherlands.

EIH2 claims to be Ireland’s first green hydrogen company, and in pursuing this collaboration, hopes to offer a route to market for Irish green hydrogen, in both the port itself and the rest of Europe.

DUISPORT AND PORT OF ANTWERPBRUGES AGREE TO A PARTNERSHIP

duisport and Port of AntwerpBruges have signed a long-term partnership, with the main objective of the partnership being to expand cooperation in the areas of the energy transition, rail and hinterland connections, and port infrastructure.

The areas set out for expansion, are all of outstanding importance for the reliable supply of industry and the stabilisation of German-Belgium supply chains and within Europe.

The European Energy system will focus on sustainable energy sources, with green hydrogen carriers playing an essential role.

The overall goal is to build an international supply chain for hydrogen in which both partners become central hydrogen hubs for Europe. To achieve this, duisport and Port of Antwerp-Bruges wish to establish a high-frequency rail shuttle in addition to planned pipeline connections and establish rail as a ‘rolling pipeline’.

As both ports aim for climate neutrality by 2050, the development of environmentally friendly port handling equipment is also part of the agreement.

For duisport, this is a step in the right direction for the expansion of its future network.

PORT OF ANTWERP FIRST TO INTRODUCE GDP CERTIFICATE FOR PHARMACEUTICAL DISTRIBUTION

Belgium UK

When distributing pharmaceutical products, specific handling is required. The Good Distribution Practice (GDP) sets out the guidelines for the method by which to do this. The Port of Antwerp has successfully situated itself as the first seaport to transform these rules into the maritime sphere.

Recently, domestic, and foreign stakeholders from the Life Sciences & Healthcare visited Antwerp for a tour of the distribution process for the pharmaceutical products of the port.

Individuals who visited the port were able to see the security checks in the port, the loading processes, and the journey to which the port become the world’s first GDP maritime port.

Operating by the GDP regulations creates a quality assurance system, whereby medicinal products, blood plasma, and medical equipment journey

through the port. At the tour, it was also announced that these GDP rules shave been enshrined into an official certification.

Those who apply for the certification, demonstrate they care about quality in all aspects of their service.

With the increasing demand for medicinal transportation to be moved away from the air, the Port of AntwerpBruges offers a crucial alternative and plays an important role in this process.

in collaboration with other UK gas networks. These are the pipelines that connect the high-pressure National Transmission System (NTS) with the lower pressure tiers. These pipelines are considered to be the backbone of the energy network, currently delivering gas from NTS offtakes to towns and cities across the country.

Angus McIntosh, Director of Energy Futures at SGN comments: ‘Repurposing the UK’s extensive gas networks to transport hydrogen offers an exciting opportunity to deliver deep decarbonisation of the energy system.’

DNV SECURE CONTRACT FOR HYDROGEN PIPELINE CONVERSION

DNV has secured a three-year contract in the UK to provide the evidence required to demonstrate the safe use and conversion of local transmission systems (LTS) high pressure pipelines for transporting 100% hydrogen.

Gas distribution company SGN manages approximately 3,100km of the UK’s LTS pipelines and is leading the project

Throughout the project, DNV will provide key safety and operational evidence through a series of offline tests at a research facility in Cumbria, England. The aim is to demonstrate hot working on hydrogen pipelines, delayed ignition, and overpressure tests, burst and fatigue tests and exploring hydrogen compatibility. DNV will also aid a live network SGN trial by investigating the measurement and monitoring of a hydrogen linepack, (the volume of gas that can be stored in a gas pipeline), on a section of the LTN.

FINCO AND GANE ENERGY TO INTRODUCE GREEN METHANOL BLEND

FinCo Fuel Group and Gane Energy have signed an agreement to introduce a green methanol blend for heavy-duty engines, with an aim of reducing greenhouse gases and exhaust emissions. The liquid fuel will be used in new and retrofitted heavy-duty diesel engines. The partnership hopes to tackle climate challenges by delivering climateneutral fuels to meet both present and future emissions regulations.

The methanol blend will not produce soot during combustion, unlike diesel or heavy fuel oil. The methanol/water-based fuel, instead, performs like diesel, but provides a cleaner solution with no loss in performance and also restricts engines from having to be replaced in their fleets.

FinCo Fuel Group and Gane Energy are currently identifying demonstrations with customers in different market sectors which will be commencing in 2023.

LNG PLANT AND TERMINAL TO BE BUILT IN YAKUTIA, RUSSIA

A five-party agreement on the construction of a petrochemical facility has been announced. The facility will include an LNG plant and terminal, which has been signed off by the Eastern Economic Forum. The document signed by several parties confirms that the facility is to be built in the settlement of Pavlovsk, Yakutia.

Vladimir Kozhokar, Executive Director of Starway Logistics, says: ‘The project will facilitate the delivery of oil products to northern areas of Yakutia and let create a transport and logistics hub.’

The project is set to contribute to the progression of green agenda in the region and develop the internal market of LNG in Yakutia and the neighbouring entities of the Russian Federation.

The project has gained the support of the Far Eastern Arctic Development Cooperation, allowing investors to develop and submit requests for the expansion of the priority development area to obtain the status of Yakutia PDA residents in the future.

When managing real pressure is your job…

MIPC® helps practitioner-level

stay on-site and on top of the latest industry developments and good practice in primary

of

substances.

Using a blend of live, online classes, one-to-one sessions with expert tutors, and e-learning, enhanced by a mentor’s support and guidance, EEMUA’s Mechanical Integrity Practitioner Certificate course delivers in depth training to engineers where they work – to give professionals the flexibility to learn on-site or on-call.

to

schedule

The NetherlandsTERMINAL NEWS: ASIA PACIFIC

has also been equipped with a Very Early Smoke Detection Apparatus system.

V-LOGIS ANNOUNCES SPECIALISED CHEMICAL STORAGE FACILITY

V-Logis, a part of V-Trans India, comprehensive warehousing, 3 PL solutions, and end-to-end integrated logistics provider has announced Chemstore, including the latest technology. Chemstore is a specialised chemical storage solution that complies with international safety standards.

The facility is fully compliant with National Building Code 2016 and National Fire Protection Association. The facility is located away from highways, residential areas, schools, and a river body. To further enhance safety measures, the facility

The new Chemstore facility scores better than other warehouses and is amongst the best in the industry, in meeting all storage requirements and emergency preparedness.

energy, hydrogen and green mobility solutions for commercial, industrial and retail customers.

Gentari aims to stand out, by offering a complete model, which aims to fulfill each customer’s needs.

Malaysia’s targets for the period 20212025 include an aim of 31% of Malaysia’s total installed energy capacity to be renewable by 2025.

PETRONAS LAUNCHES GENTARI – PUSHING MALAYSIA TO A GREEN FUTURE

Petronas has launched a clean energy solutions provider Gentari. Owned by Petronas, Gentari hopes to become an integrated clean energy solutions provider. They will begin by boasting a portfolio of renewable

Focusing on hydrogen, renewable energy, and green mobility, Gentari will be supported by Petronas to establish greener opportunities and a greener future for Malaysia.

Your storage partner

TOTAL EREN AND PROVARIS ENERGY TO CREATE COMPRESSED HYDROGEN STORAGE AND TRANSPORT

Provaris Energy and Total Eren have signed a Memorandum of Understanding (MoU) to cooperate on green hydrogen projects using compressed hydrogen storage and transport solutions in the hope to reach Asian and European markets.

The MoU will provide a framework for working together on the identification and assessment of green hydrogen projects, currently being developed by Total Eren to use Provaris’ GH2 Carriers to transport compressed hydrogen.

Your storage partner

meters, Nordic Storage offers storage for biofuels, renewables and various petroleumbased products. Our terminals are strategically located in Scandinavia and operated by our highly experienced and dedicated team, ensuring the safe and efficient storage and handling of products.

Your storage partner

With a capacity of more than 1 million cubic meters, Nordic Storage offers storage for biofuels, renewables and various petroleumbased products. Our terminals are strategically located in Scandinavia and operated by our highly experienced and dedicated team, ensuring the safe and efficient storage and handling of products.

With a capacity of more than 1 million cubic meters, Nordic Storage offers storage for biofuels, renewables and various petroleumbased products. Our terminals are strategically located in Scandinavia and operated by our highly experienced and dedicated team, ensuring the safe and efficient storage and handling of products.

The two companies will investigate opportunities for the import of hydrogen into Europe and Asia using Provaris’ GH2 Carriers and opportunities for a bulk compressed hydrogen storage solution utilising design concepts developed by Provaris for floating storage.

Contact us for our best storage offer tailored to your specific needs.

Contact us for our best storage offer tailored to your specific needs.

Contact us for our best storage offer tailored to your specific needs.

Nordic Storage AB

Nordic Storage AB

With a capacity of more than 1 million cubic meters, Nordic Storage offers storage for biofuels, renewables and various petroleumbased products. Our terminals are strategically located in Scandinavia and operated by our highly experienced and dedicated team, ensuring the safe and efficient storage and handling of products.

+46 31 53 45 00 info@nordicstorage.se www.nordicstorage.se

+46 31 53 45 00 info@nordicstorage.se www.nordicstorage.se

Contact us for our best storage offer tailored to your specific needs.

Nordic Storage AB

+46 31 53 45 00 info@nordicstorage.se

Total Eren is currently working on several large-scale green hydrogen projects globally, including in South America, Australia, and Africa.

India Asia MalaysiaINPEX EXTENDS MOU ON LNG SUPPLY

INPEX has announced the extension of a Memorandum of Understanding (MoU) with PT PLN, in regard to long-term LNG supply. The MoU has also been expanded to include joint studies in hydrogen and ammonia and in carbon capture and storage (CCS) in relation to the Abadi LNG Project.

INPEX’s new MoU expands on the original, concerning LNG sales and procurement, now with a focus on potential future collaboration.

The scope of the MoU announced today includes conducting joint studies on supplying blue hydrogen and ammonia using natural gas produced from the Abadi LNG Project as co-firing fuel for thermal power plants in Indonesia, as well as on the capture and transport of CO 2 emitted from thermal power plants in Indonesia and the storage of this CO 2 in the Abadi gas field.

This initiative is expected to contribute to achieving PLN’s goal of net zero emissions by 2060.

Customised tank mixing solutions

PETRONAS PARTNERS WITH JAPAN ON CARBON NEUTRALITY

Global energy group, Petronas, has signed a Memorandum of Cooperation (MoC) with Japan’s Ministry of Economy, Trade and Industry (METI) as well as an MoU with Japan Bank for International Cooperation (JBIC), to collaboratively pursue sustainability goals of carbon neutrality by 2050.

The MoC with METI aims to enhance the cooperation between Petronas and Japan in the development and utilisation of energy sources and technologies towards the energy transition.

The MoU with JBIC focuses on expanding and enhancing collaboration between Petronas and Japanese companies in projects undertaken by Petronas globally in a variety of sectors including: hydrogen and ammonia, renewable energy, carbon capture and storage (CCS), and green mobility.

The MoC and MoU are expected to facilitate investment and financing, and also enhance technical collaboration and competencies in low-carbon technologies in the region.

JapanTERMINAL NEWS: THE AMERICAS

of oil per day, process up to 12 million m³ of gas per day, and store more than 1.6 million barrels.

PETROBRAS SIGNS WITH SEMBCORP

Oil, gas and energy company, Petrobras Brazil, has signed a contract with Sembcorp Marine Rigs & Floaters Singapore, an energy and urban development firm, for the construction of a P-82 FPSO (floating system of production) in Búzios field in the Santos Basin, Brazil.

Petrobras has said the unit will incorporate: closed flare technology, which increases gas utilisation; a methane gas detection system capable of acting to prevent or mitigate the risk of leaks and; digital twins, which will create a virtual reproduction of the platform to enable simulations and remote tests before it goes into operation.

The vessel is scheduled to start operating in 2026 and will be one of

ZENITH ENERGY TO REMOVE CRUDE OIL IN FAVOUR OF RENEWABLE FUELS

Over the next five years, Zenith Energy has agreed to transition its Portland, US facility out of crude oil storage and to renewable fuels.

In replacing crude oil with renewable fuels, Zenith’s facility will aid the city of Portland in reaching its Climate Emergency Workplan goals and the 2035 Comprehensive Plan. The Climate Emergency Workplan sets out the actions which Portland needs to take to eliminate carbon emissions by 2050. This includes cutting Portland’s carbon emissions by 50% by 2030, and then by 2050, reducing carbon emissions to net zero.

After initially being denied a land use compatibility statement by the city of Portland, Zenith Energy changed its plan from 50% renewable fuel storage in five years, to 100%.

In a move to ensure a more sustainable future, Zenith Energy wishes to change to renewable fuels as they have 80% fewer carbon emissions, 33% less fine particulates, 30% fewer hydrocarbons and 24% less carbon monoxide.

MEXICO PLANS LNG HUB AT GULF PORT

To help serve European demand, Mexico is planning to build a liquefied natural gas (LNG) hub worth $4-$5 billion, according to President Andres Manuel Lopez Obrador. The President announced the plans at a regular press conference last week.

The hub will be located at the port of Coatzacoalcos in the Gulf of Mexico. The planned port would transport LNG to Europe via boat.

At present, Mexico does not commercially export LNG, though it is a top exporter of crude oil.

US Mexico BrazilTERMINAL NEWS: AFRICA & THE MIDDLE EAST

RAS MARKAZ OIL STORAGE TO BE COMMISSIONED BY END-OF-YEAR

The Ras Markaz oil storage terminal is due to receive the first cargo for the Duqm Refinery in November amid conversations with customers to store their crude.

The planned Ras Markaz facility will initially be able to hold 5.2 million barrels of crude oil for the Duqm Refinery project. The Duqm Refinery project is a joint venture between Oman’s OQ Group and Kuwait Petroleum International.

With sufficient land, Ras Markaz will also provide blending services to develop itself into a regional crude oil hub.

Oman Tank Terminal Company (OTTCO) plans to have some 26 million barrels of oil storage capacity at Ras Markaz in its first phases but hopes to eventually increase storage at the facility to 200 million barrels.

In addition to this new project, HDF Energy is also looking at projects across Africa and other parts of the world.

The move to the green hydrogen sector is also supported by the European Union, which is planning a deal with Namibia to support the country’s emerging green hydrogen sector and boost its own imports of the fuel, as the bloc works

toward reducing its dependence on Russian energy.

Hyphen Hydrogen Energy is also in talks with the country’s governmental bodies to secure an implementation agreement for their $10 billion green hydrogen project, which will produce 350,000 tonnes of green hydrogen each year, before 2030, for both global and regional markets.

AFRICA’S FIRST HYDROGEN POWER PLANT TO PRODUCE ELECTRICITY IN 2024

French independent power producer HDF Energy expects its green hydrogen power plant in Namibia, to start producing by 2024.

The project is estimated to cost approximately $181.25 million (€186.57 million) and will aim to supply clean electricity power constantly. This will boost the electricity supply in the southern African nation, which imports around 40% of its power from South Africa.

Namibia wishes to harness its vast potential for solar and wind energy to produce green hydrogen and position itself as a renewable energy hub in Africa.

The project will see 85 megawatts of solar panels powering electrolysers to produce the hydrogen that will be stored.

Looking for longterm digester efficiency?

60 years of experience in mixing of various

Tailored solutions

SUMA Rührtechnik GmbH Martinszeller Str. 21 | 87477 Sulzberg/Germany E-Mail: info@suma.de | www.suma.de/en SUMA America Inc. (USA) | www.gosuma.com BRASUMA Ltda. (Brasil) | www.brasuma.com

Namibia OmanSUMA, the leading innovator in advancing mixing technology.

RWE AND ADNOC AGREE ON FIRST CARGO TO FLOATING LNG IMPORT TERMINAL

RWE, a German multinational energy company has formed an agreement with Abu Dhabi National Oil Company (ADNOC) on LNG supplies.

ADNOC and RWE have signed a supply agreement on the first delivery of a cargo of liquefied natural gas (LNG) to be supplied to Brunsbüttel in Germany. The cargo is expected to be shipped from Das Island, Abu Dhabi, arriving in Germany in December 2022. ADNOC is set to deliver 137,000 cubic metres of LNG. This will be the first LNG to be supplied to the German gas market via the floating LNG import terminal at Brunsbüttel.

The two companies have also signed a memorandum of understanding (MoU) on multi-year LNG supplies, where cargoes will be delivered to Germany starting from 2023. LNG supplies from ADNOC can be delivered to Germany through either floating or land-based regasification terminals as these become operational.

Select Control Valves, Regulators, & Storage Tank Products

We are a leading manufacturer and worldwide marketer of control valves, regulators, controllers, pressure/vacuum relief vents, and flame and detonation arrestors.

Used for the normal venting requirements.

BROOGE ENERGY ENGAGES THYSSENKRUPP UHDE FOR A TECHNICAL STUDY

Brooge Energy, a Cayman Islandsbased infrastructure provider, announced that it has engaged thyssenkrupp Uhde, a leading German chemical technology and EPC provider, to undertake the technical study of its planned green hydrogen and green ammonia plant.

The study will cover the green hydrogen production facilities, the ammonia plant, and the associated utilities. The study aims to provide cost estimates for capital and operating expenditures, EPC timeline, and selected process and layout documents. They plan to commence the study shortly with the final report expected to be delivered during fourth quarter 2022.

Nicolaas Paardenkooper, Chief Executive Officer of Brooge Energy, said ‘Engaging thyssenkrupp Uhde is another important step in our transition to clean energy.

Global demand for clean energy sources has been strong and is expected to accelerate in the coming years.’

Provide emergency pressure relief beyond that furnished by the normal pressure vent for atmospheric and low pressure tanks, as well as a convenient access for tank cleaning, inspection, and repair.

Allows the flow of gases or vapor of flammable liquids through the enclosure, but prevents the transmission of a flame.

Pilot-operated valve, specifically designed to reduce blanketing gas losses on low pressure storage tanks.

INCIDENT REPORT

A summary of the recent explosions, fires and leaks in the tank storage industry

07 September 2022

KRYVYI RIH, UKRAINE

A large fire erupted at an oil depot in Kryvyi Rih, Ukraine, after Russian forces launched missiles that hit the base. Firefighters attended the scene working to put out the fire.

Governor Vilkul has confirmed that a large stock of fuel has been destroyed. The number of confirmed casualties has yet to be announced.

16 September 2022 PERU

A pipeline transporting crude oil from the Amazon to Peru’s desert coast suffered a spill, affecting indigenous communities in Peru’s northeast region of Loreto. Peru’s environment ministry has estimated that the spill is at least 2,500 barrels.

State-owned oil company Petroperu is yet to release an official estimate of the losses.

22 September 2022

PLAZA HUINCUL, ARGENTINA

An explosion erupted at New American Oil refinery, in the Neuquén town of Huincul Square.

Three workers died at the scene. The Petroleum union declared a strike after the accident.

The mayor of Plaza Huincul, Gustavo Suarez, says efforts were made to control the fire immediately so it did not spread to other adjoining tanks.

17 September 2022

ANZOÁTEGUI, VENEZUELA

A hose used for supplying gasoline to a tanker broke lose causing a fire to erupt at a oil terminal in Venezuela. It occurred at one of Guaraguao terminal’s berths.

While the initial fire was extinguished shortly after, the incident also affected another oil vessel and interrupted terminal operations.

20 September 2022

TOLEDO, OHIO, US

A fire that broke out at a BP oil refinery in Ohio, US, has killed two people. Witnesses saw giant smoke clouds as the fire spread across the refinery. BP said that it shut the facility after the fire.

BP is yet to comment on the cause of the fire. However, it is speculated that leaking fumes from a crude oil unit may have been responsible for the ignition.

30 September 2022

SWEDEN

After two leaks were found in Nord Stream 1, following another leak on Nord Stream 2, near Denmark, a fourth leak was detected in the pipeline that connects Russia to Europe.

Prior to the discovery of the leaks, several underwater explosions along the pipeline were recorded.

NATO has labelled the damage as ‘deliberate sabotage’.

TANK TERMINAL UPDATE: ASIA

OMAN TANK TERMINAL COMPANY

Products: Crude oil pipeline Construction/Expansion/Acquisition:

Oman’s Ministry of Energy and Minerals signed an agreement with Oman Tank Terminal Company (OTTCO) for the development of a new pipeline which will export Oman blend crude oil at the Ras Markaz crude oil terminal in the port town of Duqm, Oman.

Comment:

The first phase of the terminal is currently under construction, with the expectation of its trial operation to be conducted in winter of 2022.

SHANGAHI AND LOCAL DEPARTMENTS

Products: Hydrogen pipeline

Cost: 100 billion yuan (€14.6 billion)

Construction/Expansion/Acquisition:

Shanghai and its local departments have announced extensive plans to build a regional hydrogen pipeline network and a national trading platform.

Comment:

Lin Boqiang says: ‘Hydrogen plays an important part in China’s promotion of new energy development to peak carbon emissions by 2030 and reach carbon neutrality by 2060.’

V-LOGIS

Products: Chemical storage Capacity: 218,350 sq ft

Construction/Expansion/Acquisition: V-Logis, a part of V-Trans India, comprehensive warehousing, 3 PL solutions, and end-to-end integrated logistics provider has announced Chemstore.

Comment:

It will include the latest technology. Chemstore is a specialised chemical storage solution that complies with international safety standards.

GPS GROUP

Products: LPG Storage terminal

Capacity: 1.2 million tpa

Construction/Expansion/Acquisition:

GPS Group has announced the successful completion of its LPG storage terminal in Port Klang, Malaysia. The new infrastructure will enable costadvantaged shipments of fully laden very large gas carriers (VLGC) into Malaysia and the region.

Comment:

The 135,000 m 3 terminal commenced commercial operation in May 2022.

CHINA NATIONAL OFFSHORE OIL COMPANY

Products: LNG storage tanks

Capacity: 270,000 cbm

Construction/Expansion/Acquisition: China National Offshore Oil Company (CNOOC) has finished raising the roofs of three out of its six LNG storage tanks, at the Binhai LNG import terminal in Jiangsu.

Comment:

The three tanks will each have a capacity of 270,000 m 3 and add to the already four existing tanks, that have a capacity of 220,000 m 3 in Yancheng Binhai Port Industrial Park.

HYUNDAI SAMHO

Products: LNG-powdered carriers

Cost: $240 million

Construction/Expansion/Acquisition: South Korean shipbuilder Hyundai Samho has secured an order to build two new LNG-powered pure car and truck carriers.

Comment: Ray Car Carriers had ordered these two LNG-powered PCTCs with a capacity of 7,500 units and scheduled for delivery in 2025.

Duqm, Oman Port Klang, Malaysia Shanghai, China Jiangsu, China Mankoli-Bhiwandi, India South Korea TANKJERA

Products: Carbon capture and storage facility

Construction/Expansion/Acquisition:

ConocoPhillips will provide natural gas and manage a carbon capture and storage facility for a proposed US hydrogen gas project to be jointly developed with Japan’s largest utility JERA.

Comment:

‘JERA and ConocoPhillips will be a low-cost ammonia supplier to domestic and international markets,’ said JERA Americas Chief Executive Steven Winn.

PETRONAS/GENTARI

Products: Clean energy solution provider

Construction/Expansion/Acquisition:

Petronas has launched a clean energy solutions provider Gentari. They will begin by boasting a portfolio of renewable energy, hydrogen and green mobility solutions for commercial, industrial and retail customers.

Comment:

Gentari will be supported by Petronas to establish greener opportunities and a greener future for Malaysia.

SK GAS

Products: LPG, LNG and Hydrogen Construction/Expansion/Acquisition:

SK Gas is expanding its current LNG and hydrogen business in plans to become eco-friendly and carbon neutral within the industry.

Comment: Plans will begin from 2024.

PHILIPPINES, DOE

Products: LNG import terminals

Construction/Expansion/Acquisition:

Three government-approved LNG import terminals are expected to commence commercial operations in the Philippines in the beginning of 2023.

Comment:

The three terminals are the start of six projects approved by the DOE marking the beginning of the country’s liquified gas industry. They are to include a project proposed by Shell.

ABU DHABI’S FORWARD-THINKING PETROCHEMICAL TERMINAL

Arabian Chemical Terminals Abu Dhabi’s commercial manager Mike Cromack tells Tank Storage Magazine what it means to be the region’s first independent liquid petrochemical facility

FOUNDED IN 1985, Arabian Chemical Terminals (ACT) has grown and expanded its expertise to become a key service provider in the breakbulk and general supply chain segments in the GCC region. With no existing commercial tank terminal in Abu Dhabi, ACT is developing a new site there for liquids and gases: the Arabian Chemical Terminal Abu Dhabi (ACTAD). The twostage project at Khalifa Port will primarily serve KIZAD (Khalifa Industrial Zone Abu Dhabi), ZonesCorp and ICAD (Industrial City of Abu Dhabi), and is ideally situated to become a new distribution hub in the United Arab Emirates. Tank Storage Magazine sat down with Mike Cromack, commercial manager at ACTAD to find out what makes the Abu Dhabi facility so forward-thinking.

CHOOSING A NEW LOCATION

The Abu Dhabi terminal location was central to ACTAD’s decision. ‘It is a

massive benefit being here,’ says Cromack. ‘It is a bit of a blank canvas in the area between the cities of Abu Dhabi and Dubai. It is currently devoid of [breakbulk] services. Being first in and providing an excellent range of highquality services is a powerful combination here in Abu Dhabi.’

And whilst Abu Dhabi is a very new site for petrochemical facilities, ACT has deep and rich experience to draw on from elsewhere. ACTAD is the latest in a fleet of terminals owned and operated by the Reza Investment Company, a firm with a proven track record of operational excellence, which enabled it to win the competitive tender to create the Khalifa Port facility. The new site in Abu Dhabi is being completed by experts who have extensive hands-on experience. ‘ACTAD broke ground in Abu Dhabi in May 2021,’ says Cromack. ‘It is the first independent liquid petrochemical facility in Abu Dhabi.’ The facility is adjacent to KIZAD, which is attracting new industrial tenants day-by-

day. Cromack believes this will be key to ACTAD’s success, allowing the terminal to grow in harmony with other activities developing around it.

BREAKDOWN OF OPERATIONS

At present, the terminal is still in the early stages. ‘Tankage is currently being built,’ says Cromack. ‘ACTAD will initially consist of 40 main storage tanks. All tanks will be 2,500 m3 in size and store liquids. Services will include drumming and handling of ISO tankers as well as IBCs [intermediate bulk containers] plus a range of surveying and marine services.’

The first phase of ACTAD will see the company offering breakbulk services equal to any first-rate commercial terminal: storage, logistics, and handling, all vetted to leading international standards. Cromack says: ‘Being first in and doing it right first time is critical, but we have the strong success in Saudi Arabi to build on.’

It is a bold move but we’ll be providing a comprehensive offering and the time is right,’ says Cromack. ACTAD will initially use one-quarter of the total land area that has been reserved for the merchant terminal. The remaining three-quarters of the land will be used in the near future to expand its services and offerings, especially for bespoke tanks and a move to handling a range of gases.

Service and product quality are central to what ACTAD does. ‘We have eliminated the possibility of any on-site material contamination occurring. Each of the 40 tanks will have dedicated lines and pumps from berth-to-tank-to-gantry to create a closed loop system and ensure the integrity of each and every product is guaranteed,’ says Cromack. ‘The second phase is where we can get even more directly involved with industrial partners and build specifically to their needs.’

Cromack also highlights that using local trades and materials was crucial for the project, especially due to its location. By keeping the construction, materials and project management services with local businesses, ACTAD has built a terminal using home-grown talent, boosting the local economy to serve an international customer base.

BESPOKE SOLUTIONS

ACTAD expects the biggest challenge to be project selection. ‘The sheer number of projects coming forward will be a challenge; there’s a lot of inquiries coming in,’ says Cromack. ‘We are filling Phase One well, as a merchant trade terminal. But Phase Two is a different proposition. The development will be driven by our clients’ particular needs which will clearly require specific capital investment and a longer-term commitment. Together

with our clients we will go through a technical and commercial assessment before embarking on the full design. We expect this will involve a different range of materials as the drive to deliver more sustainable, alternative energy sources intensifies.’

However, ACTAD has the drive and capability to be flexible and versatile. Cromack suggests this gives the terminal an edge as it leaves an opportunity for ACTAD to work on such key issues immediately and directly with clients.

THE FUTURE OF STORAGE TERMINALS

The evolution of the sector is constant and ACTAD aims to help deliver new solutions by looking at what is possible and the consequences of the change. This innovative approach helps ACTAD to build deep and trusting relationships with clients based on collective understanding and an appraisal of the feasibility of ideas.

Cromack believes that what makes ACTAD stand out is its connections and ability to simplify processes based on its vast range of expertise. Early engagement

with potential clients, followed by an open and pragmatic exchange on what can be achieved is key. ‘This approach, using decades of experience to identify pinchpoints and to devise potential solutions to perceived problems, generates connected thinking and better results,’ he says.

ESG AND SUSTAINABILITY

ACTAD understands the importance of bringing focus to more sustainable products and services, and this is exactly what they are trying to do with its clients. Cromack says: ‘We work with clients closely to determine what their focus is and their needs may be. We are a service company, so the key thing is not to be a limiting factor or inhibitor, but rather an accelerator. We prefer to be engaged early and get the design and construction phases moving quickly. We bring learnings and extensive experience from our other projects, enabling us to progress more effectively and efficiently.’

The site has just achieved 1 million hours LTI-free (lost time injury). This is great for a new site with a large amount of heavy construction underway. ‘The design, construction and operating teams have a history of no compromise on safety and quality, repeatedly demonstrating a determination to do things right first time,’ says Cromack.

From a social inclusion perspective, the new terminal is looking to recruit a diverse workforce. ‘We are starting right now as we speak. There is an evident drive to diversify gender in the company and bring in skilled people from different backgrounds,’ says Cromack. ‘As we are in the process of growing, it gives us the unique opportunity to be aware and sensitive now, and once again, to get it right first time.’

When complete in 2023, the facility’s capabilities will include strategic storage, industrial terminalling and specialised product handling of liquids and gases. It will perform several breakbulk functions for the import, export, and distribution of a broad range of basic and specialty chemicals including ammonia, hydrogen, LOHCs, hydrocarbons and vegetable products.

more information: www.act-uae.com

By keeping construction, materials and project management services with local businesses, ACTAD has built a terminal using home-grown talent, boosting the local economy to serve an international customer base

EUROPE’S AMBITIOUS NEW AMMONIA TERMINAL

Tank Storage Magazine speaks to ACE Terminal’s project director, Egbert Vrijen, to find out how this cross-company collaboration is facilitating the import of ammonia as a hydrogen carrier into northwest Europe

IN THE PORT of Rotterdam, three strategic partners, Gasunie, HES International and Vopak, have joined forces to develop an import terminal for ammonia as a hydrogen carrier. By working together, the group aims to use existing Gasunie pipeline infrastructure at the port, combined with Vopak’s tank storage expertise and HES International’s terminal experience.

ACE Terminal is planned to be operational in 2026. ‘The planned terminal is strategically located with direct deep water access from the North Sea, including quay capacity and ample land availability, connection to Rotterdam’s industry and Gasunie’s extensive pipeline infrastructure,’ says Egbert Vrijen, project director ACE Terminal. ‘The location offers an excellent starting position for the import, storage and transshipment of the green ammonia, and the further transit of both ammonia and hydrogen to end users within northwest Europe. There is also enough space to expand storage capacity and for the conversion of the ammonia back into green hydrogen.’

EUROPE’S APPETITE FOR GREEN AMMONIA

As Europe moves towards future fuels and zero carbon targets, facilities like ACE terminal will become more necessary. ‘The main reason for ACE terminal is to facilitate the need for green hydrogen in

northwest Europe,’ says Vrijen. ‘Hydrogen will play an important role in the energy transition. The future demand for green hydrogen in the region exceeds the capacity that can be produced locally from sustainable sources.’ So, hydrogen will need to be imported to satisfy the increased demand.

There are several ways to transport hydrogen over sea. It can be cooled to an extremely low temperature so that it becomes liquid. This makes it considerably more dense, taking up less space. Or you can bind the hydrogen to liquid organic hydrogen carriers (LOHC). ‘At the moment, we see that the most attention is currently being paid to the

With our access to the Dutch and European hydrogen pipeline network and waterways, the hydrogen can be fed into the energy system, ready for use

variant where hydrogen and nitrogen are combined to form ammonia. This is a technology and a trade that already exists and is currently the most promising solution in the short term for long distances,’ says Vrijen. ‘At ACE terminal we focus on this technology, in which ammonia is a hydrogen carrier.’

The partners are currently in talks with several parties across the globe that are looking to convert green hydrogen into ammonia enabling higher volumes to be transported. ‘From Chile to Namibia, from Australia to Saudi Arabia, anywhere with a lot of sun and/or wind and plenty of space for energy farms,’ says Vrijen. ACE Terminal will be an open access terminal. Once ACE terminal customers import the ammonia to Rotterdam, it can be stored as feedstock or cracked to hydrogen ready to distribute.

It’s key to note that ACE Terminal will not own the ammonia it receives. ‘We will

facilitate the import towards northwest Europe for our customers,’ says Vrijen. ‘It is expected that the imported green ammonia will initially be of interest in particular to markets that now use grey ammonia made from natural gas. For example the fertilizer industry uses ammonia as feedstock. But there are also opportunities for using ammonia in heavy transport like for example as a shipping fuel.’

On top of facilitating the import of ammonia, ACE terminal could be a facility that extracts even more use from the product. ‘This location might also give opportunities for converting the ammonia into hydrogen again. The hydrogen can be fed into the energy system using the Dutch and European hydrogen pipeline network, or via the excellent waterway connectivities,’ suggests Vrijen.

COLLABORATIVE APPROACH

None of the work happening at ACE Terminal Rotterdam would be possible without the collaboration between Vopak, HES International and Gasunie. Gasunie already has a range of facilities and infrastructure in place at Maasvlakte in the Port of Rotterdam. ‘We are aiming to make the tanks suitable for the storage of ammonia with expected relatively limited adjustments,’ says Vrijen.

‘Access to the adjacent site of HES International gives us quayside capacity for large seagoing vessels and space for future expansion and other developments like ammonia cracking,’ he continues. ‘And our partner Vopak already owns and operates several ammonia terminals located all over the world. Vopak has a great deal of knowledge about the technology to safely store ammonia and the global market. Therefore this partnership is a powerful combination!’

With three well-established, reputable companies coming together for this initiative, it’s no surprise that standards are high. ‘The future company will

embrace and promote the same standards and values as its parent companies which all have a strong focus on diversity and inclusion,’ says Vrijen.

As for sustainability measures, Vrijen explains: ‘The Netherlands is one of the countries with the most stringent laws and regulations of the world. We are currently investigating the technical, economic and financial scope of the project focused on handling and storing ammonia (and green hydrogen). Sustainability, as well as safety, are always part of our scope.’

RAPID TIME-TO-MARKET

While it’s not fully up and running yet, ACE Terminal is planned to be operational in 2026. ‘For a large part we will make use of existing assets, currently used for natural gas storage for peak load capture,’ says Vrijen. That includes two tanks that can currently store 78 million m3 of LNG.

‘HES International has a deep sea quay and ample land available to expand the storage capacity. Gasunie is currently developing the national hydrogen network which means that ACE Terminal will be connected to the pipelines into northwest Europe,’ Vrijen continues. Making use of the existing infrastructure will facilitate the speedy timeline for operations.

This is also what sets ACE Terminal apart from other facilities, according to Vrijen. ‘ACE Terminal differentiates itself from others because of its short timeto-market. The terminal will make use of existing infrastructure and assets to achieve this,’ he says.

EUROPE’S ENERGY SECURITY

‘The current geopolitical situation has made everyone very aware of

dependence and energy security,’ says Vrijen. By repurposing equipment and infrastructure to be able to handle future fuels, ACE terminal Rotterdam is positioning itself as a leader in achieving regional energy security – all in a very short timescale.

Beyond securing ammonia for distribution, the goal is to turn the existing natural gas facility into one that’s equipped for the impending energy transition. ‘By 2026, ACE Terminal will be able to handle and store ammonia and green hydrogen,’ says Vrijen. ‘A cracker facility added to our services would make it possible to convert the ammonia back into hydrogen again.’

‘With our access to the Dutch and European hydrogen pipeline network and waterways, the hydrogen can then be fed into the energy system, ready for use and fulfilling customer demand for green hydrogen,’ Vrijen continues. This could have a huge impact on Europe’s net zero goals and help wean the region off fossil fuels much sooner than perhaps initially thought possible.

For more information: www.aceterminal.nl

01 Access to existing Gasunie infrastructure at the Port of Rotterdam speeds up the time-tomarket and lessens the terminal’s impact on the environment

02 Egbert Vrijen, project director, ACE Terminal

03 ACE Terminal outlines how the facility is expected to store, handle and distribute ammonia and hydrogen once operational in 2026

STOCKPILING, ENERGY SECURITY AND THE SINGLE MARKET

A MORE volatile world leads to greater economic planning for worst case scenarios. In September, the European Commission proposed a Single Market Emergency Instrument. While this was partly triggered by the war in Ukraine, it was mostly prompted by the lack of stockpiles of critical supplies at the start of the pandemic and the semiconductor shortage.

In summary, the Single Market Emergency Instrument establishes a framework of measures to anticipate, prepare for and respond to impacts of crises on the single market. Part of this project is to build up stockpiles of critical raw materials and strategic products across the European Union.

Stockpiles act as a buffer to even out supply and demand in case of market volatility. They also potentially offer a mechanism to stabilise prices, if stockpiles are released during a period of market tightness. A stockpile also reduces other countries’ leverage on Europe, as a stockpile can help to reduce dependency on a third country and reduces the impact of a supply cut off, for example.

HOW MIGHT AN EMERGENCY SYSTEM WORK?

The EU system is still in the early days of development and the precise way in which this will work is still being elaborated.

Our previous experience under the Oil Stocks Directive has been that there is a central authority that determines, on the basis of market monitoring, when a stockpile should be released and this body also determines the quantity of product to be released. In the case of oil stockpiles that exist today, this body is the International Energy Agency.

The UK is unlikely to be included in EU plans due to Brexit and the EU wanting to control stockpiles on EU territory. However, it’s safe to assume that the UK and other countries might also consider this kind of initiative, especially given the consequences of relying on spot markets

for gas security. For example, the lack of strategic gas storage in the UK does not help with energy security in this region.

WHAT IS CONSIDERED CRITICAL?

An open question related to the Single Market Emergency Instrument is precisely what are the products that will be stockpiled and deemed strategic for the EU. Finished products, like chips, have been mentioned, but also gases for critical supply chains like noble gases.

Other potential critical products include future fuels such as hydrogen and raw materials going into renewable and battery technologies such as lithium.

As usual, the extent and composition of stockpiles will probably depend on their costs, locations, criticality of the product in question, etc. Normally, stockpiles are located in a range of regions to ensure

resilience, and proximity to users. They tend to be close to industrial hubs and are situated in places where there are good road, rail and sea links to transport to feed industry and replenish stocks.

Tank storage companies are used to holding stockpiles and have permits for storage of a variety of products. So it makes sense that many will be looking closely at the opportunities that could arise from EU stockpiles of strategic products. Rather than a slew of new terminals, however, operators would be looking at a potential change in product mix if future energy carriers, critical chemicals and critical gases for strategic supply chains were to be listed as needed for stockpiling.

For more information: www.fetsa.eu

FETSA’s executive director, Ravi Bhatiani, tells Tank Storage Magazine about the proposals for a Single Market Emergency Instrument

CRUCIAL & SUSTAINED ROLE FOR LNG IN ASIA’S SUPPLY

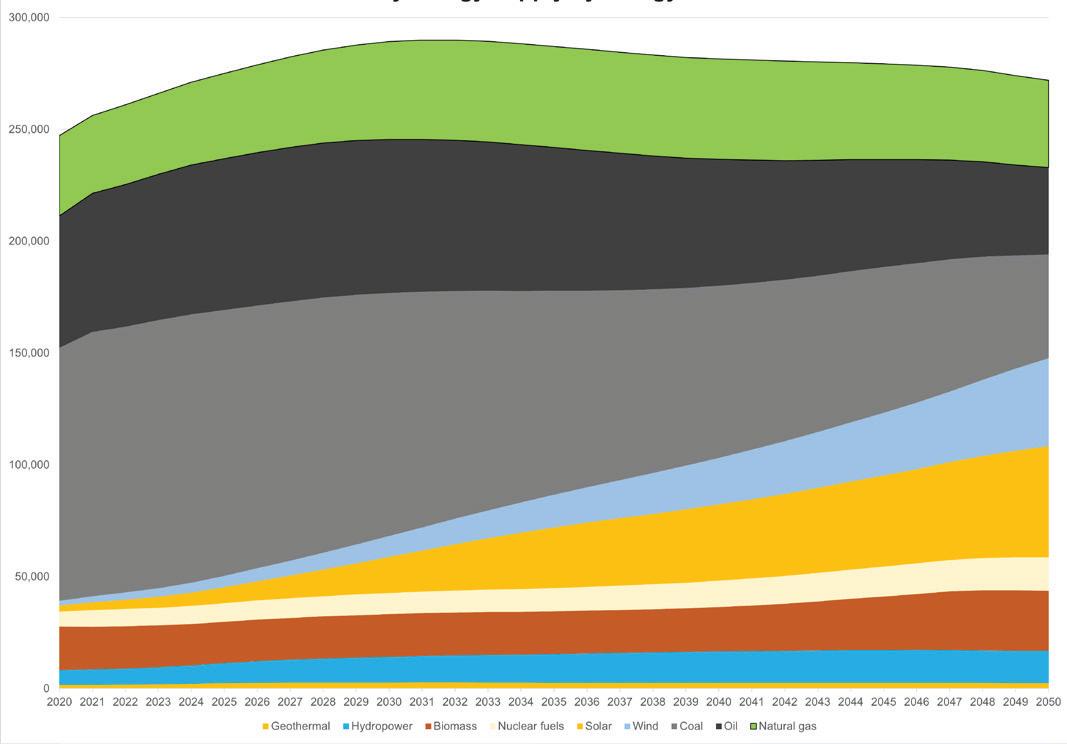

ENERGY DEMAND is expected to continue rising across Asia, with a predicted peak in the early 2030s; approximately 20% higher than 2020 levels, according to DNV’s Energy Transition Outlook.

Renewable sources are expected to meet a majority of the growth forecast. However, the medium-term growth potential of greener options in Asian markets is limited by challenges in integrating them with existing electrical infrastructure, all while ensuring reliable, secure, and dispatchable power.

This means that the requirement for natural gas, the lowest carbon fossil fuel, will also grow in the future, alongside the development of increased renewable capacity. Given the limited availability of domestic natural gas, and the lack of local pipeline infrastructure, LNG imports will have a larger part to play.

RENEWABLES FORECAST

‘We expect that growth in renewables will be the primary support for rising energy demands across Asia over the coming decade, increasing from 13% of primary energy supply in 2020 to over 20% by 2030,’ says James Laybourn, regional sales director for DNV Energy Systems in Singapore.

‘We are actively supporting the rapid development of new renewables sources across Asia, as well as the associated power infrastructure to support them,’

Laybourn continues. ‘However, the growth in overall energy demand combined with challenges scaling renewable infrastructure means that we expect natural gas to play a particularly important and sustained role in Asia’s energy supply through to 2050.’

Asia is expected to maintain a continued dependence on natural gas to fulfil around 15% of its total primary energy supply until mid-century. Much of this supply will be in the form of increased LNG imports to Asia.

CURRENT LNG IMPORTS IN ASIA

Imports of LNG into the region are currently curtailed as Europe scrambles to secure supply ahead of winter. This has been fuelled by Russian supply being largely cut off and the inability of Norway to scale up its own.

This is leading to supplies being diverted from Asia which, in combination with high spot prices, is reducing imports. In some countries, a return to coal has also been precipitated by the urgent need for a readily available, reliable and less costly energy supply.

Sustained high LNG prices have therefore eroded the present economic case for imports of gas into Asia. Two of the largest forecast growth markets in the region –China and India – have reduced their LNG imports by 20% and 10% year-over-year, respectively. Sales in Asia through July 2022 have fallen more than 6%, compared to the same period in 2021.

ASIA’S LNG RESOURCES

For the long term, continued investment is necessary if LNG supply, alongside the development of renewable energy capacity, is to meet Asia’s increased demand. There will need to be a particular focus on LNG import facilities and supporting downstream infrastructure in new markets – and investment needs to be accelerated soon. The maintenance and integrity management of existing infrastructure will also be necessary to retain the system’s efficiency and functionality.

Domestic supplies of natural gas are limited and cannot ramp up to meet the growing demand. Geopolitical fears also lead to a need to diversify supply sources to ensure security in an uncertain world.

Singapore is one example where LNG is now favoured over regionally sourced (and increasingly scarce) pipeline gas.

LNG imports present the most logical candidate for most Asian countries due to limitations on pipeline infrastructure, and an increased focus on energy security.

In the medium term, DNV expects a returned focus on LNG imports into Asia, particularly among developing economies looking to reduce their dependency on highly carbon intensive coal-fired power generation.

Hence, LNG is expected to bounce back after gas prices have normalised. It will enhance its role as the most flexible and secure natural gas source and will see a diversification in its role in downstream markets in the transition to a lower carbon future. Preparations for infrastructure development will have to be made to accommodate this increased market activity.

For more information: www.dnv.com https://eto.dnv.com/2021

ADAPTING TO CHANGING NEEDS

AS THE UK moves to embrace the next steps in its net zero campaign, the use of traditional fuels is set to decline, while sustainable alternatives will play a growing role. The pace of change is accelerating as 2030 comes ever closer and the UK strives to hit emissions targets by 2050.

Information recently published by the Hague Centre for Strategic Studies (HCSS) covering tank storage in global supply chains has noted that in the UK and Europe, reliance on petrol, diesel and crude oil is already depleting.

This reduction is a sign of change across the UK as companies like Stanlow Terminals adapt storage capabilities to open doors to lower carbon fuels and new energies.

BIOFUELS: SUPPLYING TOMORROW’S FUEL SUPPLY

As the UK moves towards more environmentally friendly sources of energy, reliance on biofuels is increasing. Both the government and industry are, for example, investing substantial sums in sustainable aviation fuel (SAF) and we see that in the growing number of production plants being announced, enabling the product to be used on its own or blended into current fuels to help offset fossil fuel usage.

The blending target of biofuels into fossil fuels in the EU is 14% up to 2030 and is expected to become even more ambitious as we move beyond that following the revision of the Renewable Energy Directive (RED). Eventually,

conventional fuels could be fully replaced by low-carbon biofuel alternatives, for applications like aviation where alternatives such as electric power or hydrogen are technologically challenging. For road transport, petrol and diesel sold to consumers at UK pumps already contain up to 10% and 7% of biocomponents respectively. This is set to increase in the years ahead, providing short-term sustainability goals that will work alongside the longer-term drive to electrify road vehicles.

Stanlow recognises this shift in needs on both a national and international level.

At the end of 2021, Stanlow Terminals announced a three-year project to see its facilities expand, with the aim of developing the UK’s largest biofuels

Simon White, Stanlow Terminals’ lead engineer, looks at how the terminals industry is adapting to growing climate pressures and how Stanlow itself is supporting the drive to net zero

storage hub located in the northwest of England. The Stanlow facility is perfectly placed to play this role, offering 300,000 m 3 of storage capacity in an advantageous strategic location.

The new facilities at Stanlow and Tranmere Terminal, located within the Port of Liverpool, will allow customers to store, blend and distribute biofuels suitable for use in the energy transition as drop-in replacement transport fuels for road, aviation, and marine travel.

The customer-led investment will support the growth of SAF and strengthen Stanlow Terminal’s existing ties with Fulcrum’s Northpoint project, which will be creating the fuel from municipal waste for use by airline companies. Stanlow’s expansion doesn’t stop there, as the company invests to become the largest bulk storage and energy infrastructure provider for storage of hydrotreated vegetable oil (HVO), a direct diesel replacement, and a new bioethanol and methanol storage, blending and distribution facility to support the transition towards a renewable energy society.

GETTING SERIOUS ABOUT HYDROGEN ADOPTION

While bio-derived fuels and bioblend components offer effective solutions for some pressing challenges, they still involve burning fuels that release emissions. That’s why, alongside this, development is continuing along with Stanlow Terminal’s sister company, Vertex Hydrogen, into the production of green and blue hydrogen, which provide a completely emissions-free form of energy at the point of use.

One of the main methods to create blue hydrogen fuel is to use an intermediary product rich in hydrogen atoms, such as methane, and strip the carbon from it, leaving behind pure hydrogen for distribution to users. The carbon released during the process can be captured for long-term storage. The result is a useable fuel with low carbon emissions, even when the hydrogen itself is burnt. One of the key pieces of the hydrogen adoption puzzle that Stanlow Terminals is addressing is delivering solutions to support the efficient transport of hydrogen to where the energy is needed.

This can be achieved in many ways, but one such approach is using hydrogen rich carriers such as methanol and green ammonia. While these have their own particular safety requirements when it comes to transport and storage (particularly in the case of ammonia) new tank, pipeline and transport infrastructure will be constructed to support the safe distribution and storage of these products.

It is clear that low-cost, sustainable electricity sources will play a key role in delivering the hydrogen required for the future. Globally, geographies with advantages in the production of electricity from solar, wind, wave and geothermal generation are likely to see significant growth in their hydrogen production capabilities, but these will not always be in the same location as the demand centres for the fuel. Hydrogen carriers are likely to play a critical distribution role in this disparity.

Storage and transportation of hydrogen is set to be a key challenge in the UK and around the world as it becomes an increasingly common means of getting energy from power-generation source to point of use. While hydrogen carriers will help, significant upgrading of the infrastructure will be required to support widespread usage across the country.

Stanlow Terminals is working to support hydrogen adoption by investing in creating infrastructure through which it can be transported and stored. This includes hydrogen-ready pipelines, road, rail and marine terminals.

INDUSTRY HYDROGEN ADOPTION

As a newer energy solution, there are a number of ongoing attempts to integrate hydrogen fuels into industry. Stanlow Terminals parent company, Essar Oil UK, has commissioned a new furnace for its refinery that will be capable of using hydrogen fuel as its main source of power, proving that clean and renewable fuel can already play a role in further efforts for greener fuel storage and usage.

GOING UNDERGROUND: CARBON CAPTURE AND STORAGE

Carbon capture, utilisation, and storage (CCUS) is considered to be a cornerstone of the decarbonisation of Europe’s energy-intensive industries. CCUS is also essential to produce blue hydrogen, with the leftover carbon needing to be stored for the process to be worthwhile to the environment. This is achieved by siphoning the carbon off and pumping it underground into larger natural reservoirs.

As an emerging technology in the fight for net zero transition, CCUS is expected to be deployed at Stanlow on a large scale before 2030. But total global CO 2 capture capacity as of 2021 stands at 40 million tonnes. The international Energy Agency has already said it expects this figure to increase to 840 million tonnes by 2030.

As efforts to move away from traditional fuel sources increase, increased storage capacity will become an integral factor in the viability of hydrogen and other fuel sources.

The continued work is a vote of confidence towards the long-term viability of hydrogen being a serious contender as a zero-emissions fuel source.

THE FUTURE FOR FUEL STORAGE

As the UK and Europe move towards these new types of fuel, it will be the job of storage terminals and connected ports to be the backbone of the move towards a sustainable future.

Stanlow Terminals recognises that its optimal positioning for bulk liquid infrastructure and storage facilities as well as its expertise in handling high hazardous and regulated products will mean the northwest of England will play a pivotal role in supporting the UK’s net zero ambitions long into the future.

As Stanlow continues to adapt its offerings and storage capabilities for traditional and newer fuel sources, there is confidence that Stanlow Terminals will play a pivotal role in supporting a much-needed bulk liquid evolution across the country.

For more information: www.stanlowterminals.co.uk

EVERYTHING YOU NEED TO KNOW ABOUT ESOS PHASE THREE

Dan Ellis, head of sustainability at Adler and Allan, discusses how to ready your operations for the government’s new regulations

THE GOVERNMENT’S Energy Savings Opportunity Scheme (ESOS) aims to boost the energy efficiency of UK businesses. It’s a mandatory programme that applies to large UK companies with a specified turnover and headcount. As part of ESOS, qualifying businesses must track and report energy usage across their buildings, processes, and transport. They’re also encouraged to find costeffective ways to cut consumption.

The scheme runs in four-year phases. Adler and Allan is currently in phase three, and the countdown to compliance has begun.

HOW TO KNOW IF YOUR BUSINESS QUALIFIES

Businesses need to carry out an ESOS assessment if they have:

• More than 250 employees in the UK; or

• A turnover exceeding £44.1m (€49.1m) and a balance sheet exceeding £37.9m (€43.1m)

If your business took part in the two previous ESOS phases, it’s likely you’ll need to participate in phase three.

THE BUSINESS QUALIFIES FOR ESOS: NOW WHAT?

ESOS assessment is a six-stage journey – from measuring energy use to Environment Agency reporting and recordkeeping. If guidance is required, working with a trusted partner can streamline the process, helping businesses to navigate audit requirements and ensure their submission fully complies with ESOS guidance.

1. Calculate your business’s total energy consumption

Businesses are required to measure all energy use across their premises,

Businesses will not be allowed to simply replicate the same historical ESOS energy audits for phase three.

The Environment Agency expects to see different and progressive energy audits rather than tick-box compliance activity

industrial processes, and fleet. Under ESOS, energy is defined as combustible fuels, heat, renewable energy, electricity, and transport fuel. Your assessment should cover a representative sample of your operations and sites, and results should be presented in a common unit, such as pounds sterling or kilowatt hours.

2. Identify and audit areas of significant energy consumption

Pinpoint which assets and activities account for at least 90% of your overall energy usage. Up to 10% of your energy consumption can be classed as de minimis (too small to be meaningful) and can be omitted from your calculations.

Once you have identified your highest consumption areas, you need to audit them against minimum government requirements. Any energy audits conducted between December 2019 and December 2023 count towards ESOS compliance.

3. Create an ESOS compliance plan

Use your audit results to map out energysaving opportunities. Your plans should outline practical ways to minimise waste and improve energy efficiency – and detail their estimated cost benefits.

An experienced sustainability consultant can produce a comprehensive ESOS

compliance plan, including innovative and achievable solutions – from installing EV charge points to embracing renewable energy and alternative fuels.

4. Appoint a lead assessor to review the report

A lead assessor will oversee your business’s energy audits and sign off on your final ESOS assessment. They could be a professionally registered employee. However, working with an external specialist can guarantee compliance and place decades of industry experience on your side.

5. Notify the Environment Agency

When your ESOS assessment is complete, you need to submit your notification of compliance to the Environment Agency.

6. Keep accurate compliance records

Businesses are expected to maintain records of how they’ve complied with ESOS in an evidence pack – and you’re free to choose the format.

ARE THERE PENALTIES FOR NOT COMPLYING WITH ESOS?

Yes, and they’re getting steeper. Failure to notify the Environment Agency can lead to an initial penalty of up to £5,000 and a daily fine of up to £500 for each working day of non-compliance. Making a false or misleading statement could lead to fines of up to £50,000.

WHEN SHOULD MY BUSINESS BEGIN ITS ESOS ASSESSMENT?

As soon as possible. The deadline for ESOS submissions is 5 December 2023, but it pays to get ahead of the curve.