6 minute read

Increasing efficiency, improving service and reducing costs with AI

The experts at Supplai tell Tank Storage Magazine how the company is making artificial intelligence accessible to the tank storage industry

SUPPLAI is an artificial intelligence (AI) software developer. The company was founded in May 2020 by CEO, Koen de Jong and CTO, Casper van Lit. Supplai implements AI algorithms that make processes more efficient and effective. It is forging ahead with tailor-made AI solutions, and de Jong’s background means he understands the particular challenges of the tank storage market.

Advertisement

AI THAT DELIVERS VALUE

‘Supplai’s approach is to get to know the customer and how they work, understand their problems and find the right solution for each challenge,’ says de Jong. ‘This process adds value, targeting AI where the client needs it. In this market where AI can be over-hyped, people forget to talk about the actual value it can deliver. Our tailored approach is why we’ve been able to grow to where we are today without any venture capital.’ Companies need tailored solutions, not generalist tech, and brainstorming sessions with a client can lead to a long-term relationship and an AI solution that covers several problems. ‘We can grow and create value – and that is a win-win,’ he says.

AI IN THE TANK STORAGE INDUSTRY

Tank storage companies struggle with three main issues for which AI can provide the perfect solution: • Document automation • Real-time video analytics • Data predictions

DOCUMENT AUTOMATION

In a dynamic market with a huge variety of customers, tank storage terminals receive many semi-structured documents. Call offs and order instructions can waste a lot of valuable time for customer service employees. With Supplai’s document automation solution based on deep-learning AI, such documents can be automatically analysed and the most important information extracted. The output is then automatically sent in real-time to any terminal operating system (TOS). Due to the transparency the system offers, it can even be used as a document management system (DMS). On entering a terminal, drivers have to go to a service desk to show ADR certificates or other documents. Some terminals may use an app to pre-notify staff, but the process still requires human checks. When using Supplai, a scanner will make a scan of an ADR certificate at the self-service desk, and the AI model will extract the right information and perform the checks. This automation saves time and allows the AI to start building a database to make the process even smoother.

REAL-TIME INTELLIGENT VIDEO ANALYTICS

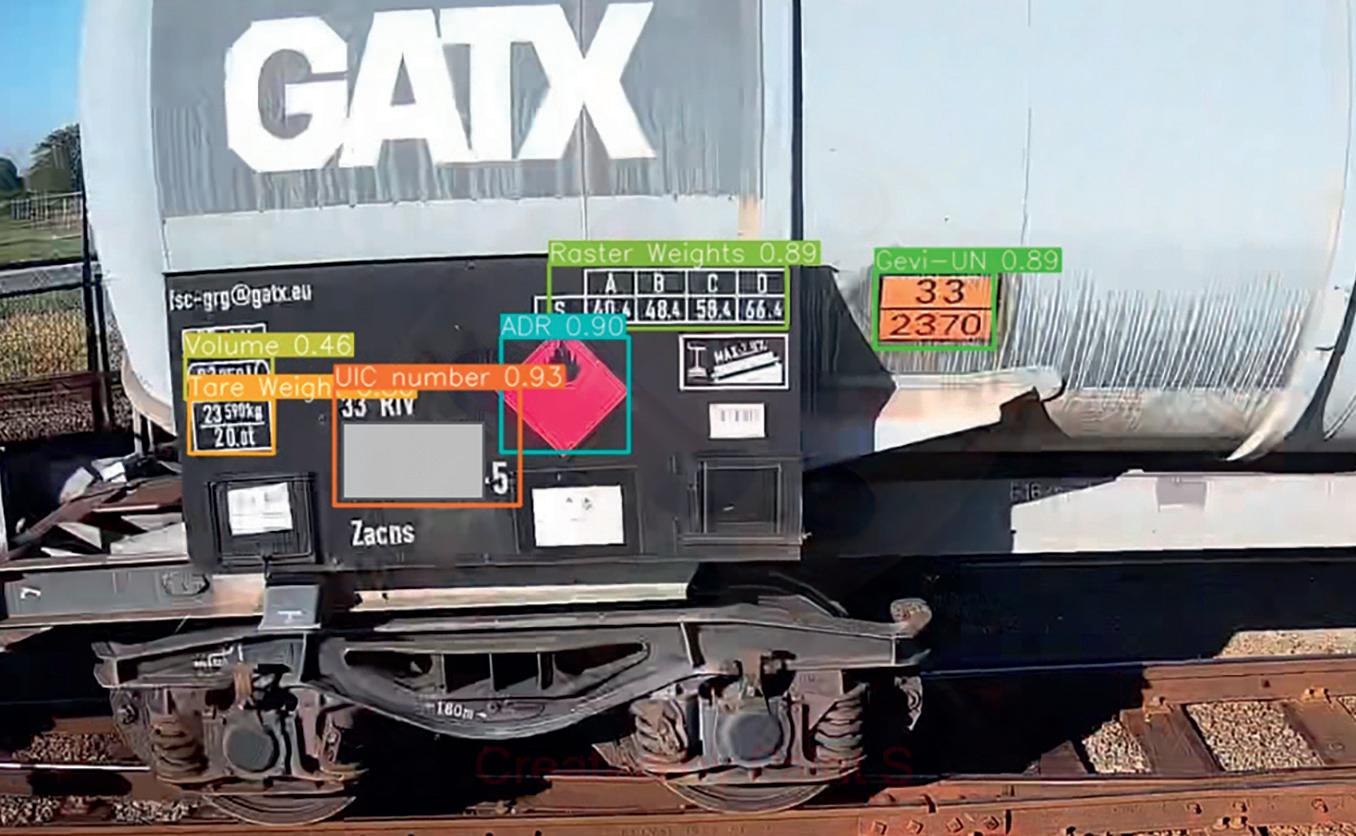

De Jong says: ‘The biggest breakthrough that deep-learning AI can offer is the processing of video streams. We see massive opportunities for this type of technology, and our customers also clearly see the low-hanging fruit in this application of AI.’ Supplai’s motto in this area is: ‘Anything a human can see on a video or image, we can turn into an AI model and make your camera smart.’ Supplai has made gate and rail entry OCR (Optical Character Recognition) accessible to the tank storage market with the use of deep-learning AI. Usually, only big container terminals have the throughput to invest in this expensive solution. They require a large hardware investment and often work with a relatively old technology stack of photostitching and basic OCR. Using AI, Supplai has created gate and rail OCR systems that can technically work with just a single IP security camera. Now, for any terminal receiving trains or trucks, an entry-level OCR

01

The biggest breakthrough that deep-learning AI can offer is the processing of video streams...Anything a human can see on a video or image, we can turn into an AI model

solution is available. Advantages of automation with rail OCR are: • It saves sending employees out with paper or tables to check the numbers • It allows a data-driven approach.

Every video is available in Supplai’s online platform and can be checked at any time • Data is sent directly to the TOS, meaning immediate workflow management can be performed once equipment enters the facility • Increase compliance to automatically control all ADR labels

OCR SOLUTION IN PLACE

Supplai implemented this solution at Advario Stolthaven Antwerp. Thomas Beyers from Advario Stolthaven Antwerp says: ‘To increase our terminal automation, we had been looking to implement this solution for quite some time. Too much time was being lost walking along the trains and manually taking note of the data and transferring it into our terminal management system. We chose Supplai for their expertise in this specific domain, their ability to roll out quickly and the limited hardware changes that were needed.’ The algorithm detects a full range of classes. On containers, it recognises the container number, ISO code, ADR labels and GEVI/UN stickers. It knows what ADR labels are attached to the truck and verifies if they match the GEVI number. On trains, it recognises the UIC number, ADR labels, GEVI/UN stickers, revision date of the tank, revision date of the chassis, volume, raster weights and tare weights.

SPILLAGE DETECTION

For Koole Terminals, Supplai developed a thermal spillage detection model. At the terminal, Koole already had a thermal camera that recorded potential leaking trucks. But, when a leakage occurred, it was hard to spot due to the large number of trucks passing through every day. Supplai added its computing solution and AI model to the existing networking and was able to create an automated way of detecting leakages.

DATA PREDICTIONS

Before the energy crisis, data predictions were not a key topic among tank storage customers. But now insight into the heating of tanks is a big consideration. In a typical tank farm, tanks are heated in a non-optimal way. However, this can actually be done in a much smarter way with a dynamic system that uses AI. With the combination of different data sources, an AI model can predict times when it’s most economical to heat up the product and to what temperature. This ensures the product remains within a predetermined temperature range.

OTHER AI APPLICATIONS

Other projects that Supplai is working on include automation of the jetty procedure, closed valve detection on bottom loadings, PPE (personal protective equipment) detection and many more. For the jetty procedure, Supplai’s model can detect the vessel name, arrival times are registered, pilot on board detection, hose connected detection, surveyor on board detection and more. This can all be registered by simple IP cameras combined with a powerful AI model. The PPE detection algorithm can detect if a person has a helmet and safety vest on. This can be useful in places such as the rack where drivers climb on their truck or entry locations. Supplai was recently awarded with a MIT R&D AI subsidy to develop and deploy its real-time video analytics solution on drones. It means the edge computing is directly mounted on the drone and analytics are performed directly while flying. This gives chances for inspections into time-critical situations, such as leakages.

02

For more information:

www.supplai.nl

01 AI can recognise a train’s UIC number, ADR labels, GEVI/UN stickers, etc 02 L-R: Casper van Lit (Supplai), Thomas Beyers (Advario) and Koen de Jong (Supplai) at the deployment of Supplai’s Rail OCR at Advario

Stolthaven Antwerp